Patents

Literature

464results about How to "Improve pouring efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

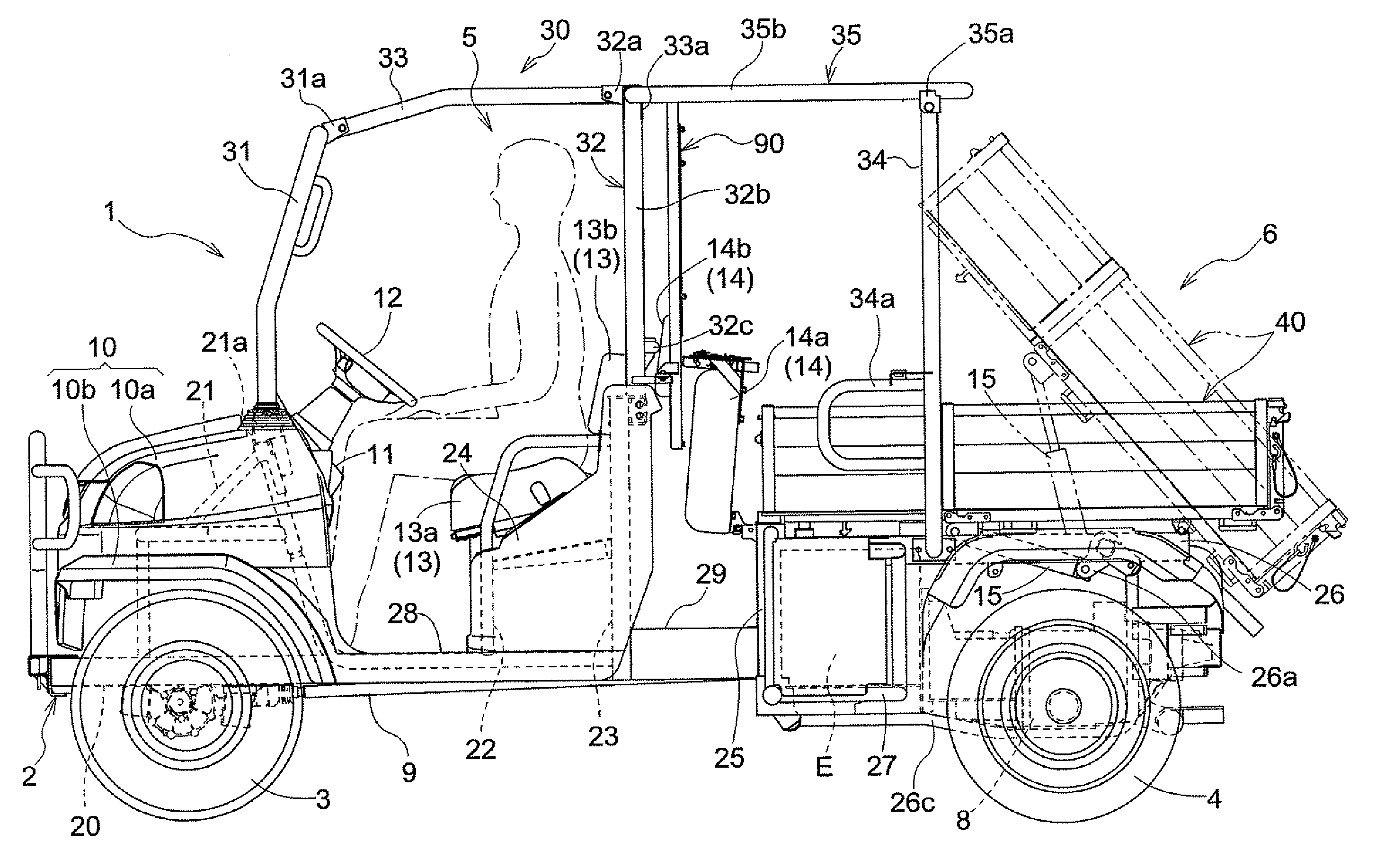

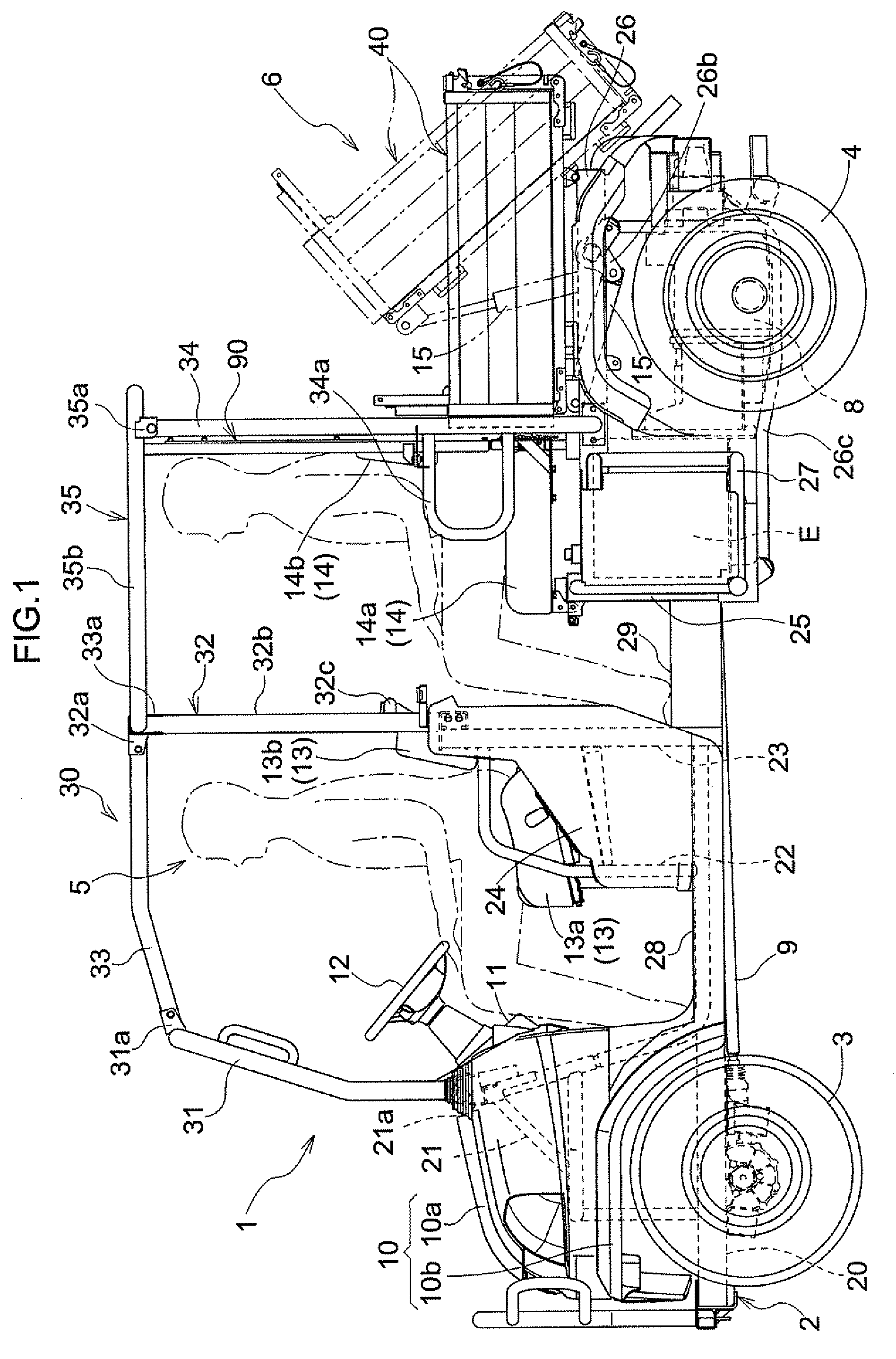

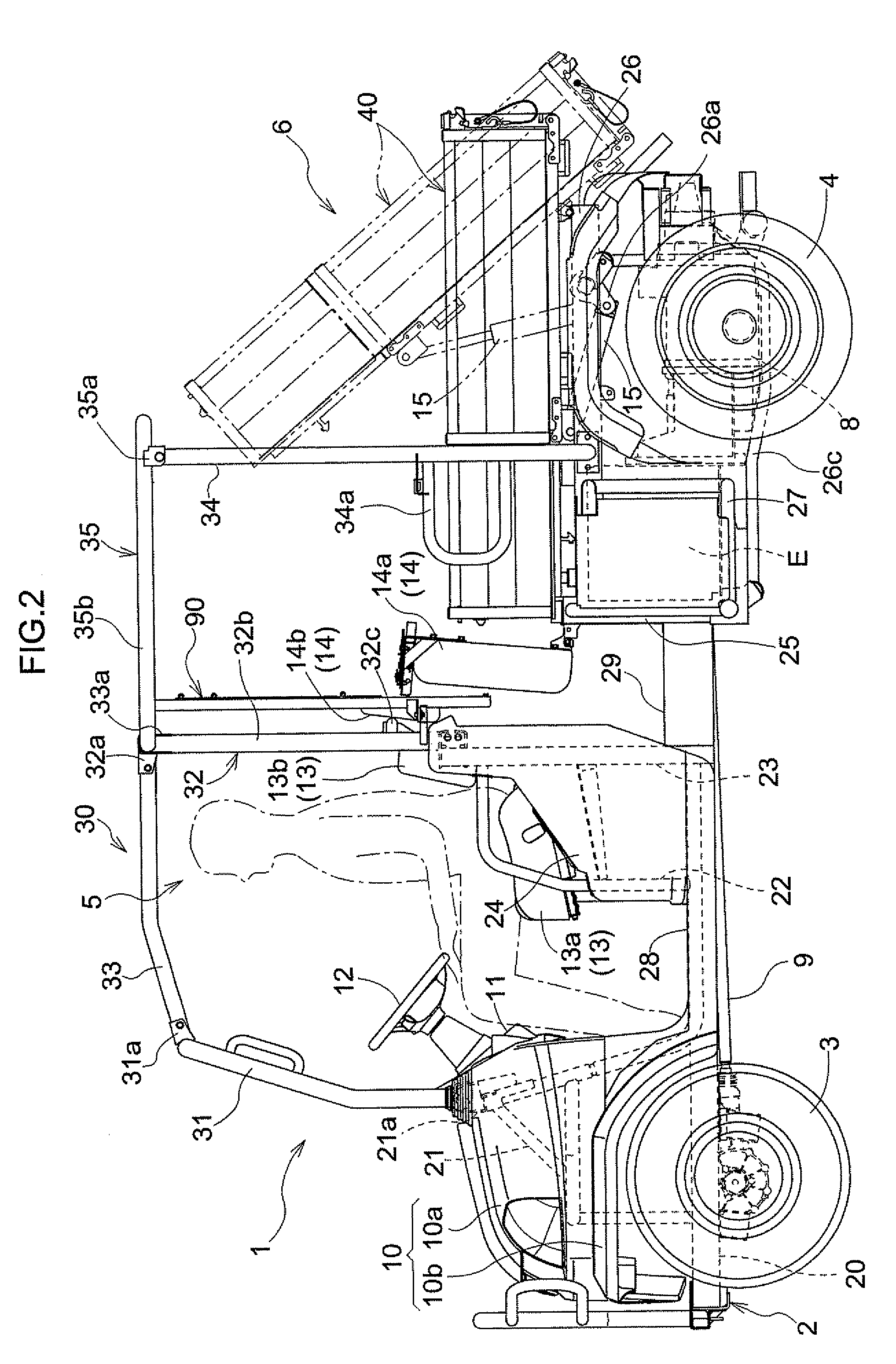

Pickup-style work vehicle

ActiveUS7578544B1Improve pouring efficiencyEasy to operateVehicle with living accommodationSuperstructure subunitsDriver/operatorEngineering

A pickup-style work vehicle comprises a front driver's seat, a backseat, a loading floor that is located rearwardly of the backseat and that can be moved to a dumping position, a loading floor size changeover mechanism, and a backseat posture change mechanism. The loading floor size changeover mechanism changes the size of the loading floor between a first state in which a front wall portion and a front bottom portion of the loading floor are moved forwardly in a fore-and-aft direction and a second state in which the front wall portion and the front bottom portion of the loading floor are moved rearwardly in a fore-and-aft direction. The backseat posture change mechanism changes a posture of the backseat between a first posture which is a non-use state and a second posture which is a use state. The fore-and-aft dimension of the backseat in the first posture is less than a fore-and-aft dimension of the backseat in the second posture. the backseat in the first posture is located immediately forwardly of the loading floor in the first state and the backseat in the second posture is located immediately forwardly of the loading floor in the second state.

Owner:KUBOTA LTD

Casting-curing insensitive high-explosion-heat explosive and preparation method thereof

ActiveCN103073369AImprove pouring qualityHigh Explosive Calorific ValueNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsWorking capacityAluminium

The invention discloses a casting-curing insensitive high-explosion-heat explosive which comprises the following components in parts by weight: 65 parts of hexogen, 21.5 parts of aluminum powder, 6-8 parts of binder, 2-3 parts of insensitive agent, 2.5-3.2 parts of plasticizer and 0.5-0.7 parts of curing agent. The hexogen is subjected to grain composition to improve explosive energy. The invention further discloses a preparation method of the explosive, which comprises the steps of batching, mixing, vacuum treatment and vacuum casting, and heating curing. The explosive has a higher explosion heat value, has good viability in hazardous environments such as shock, high temperature, bullets and detonation waves, and has the characteristics of high work capacity and high safety; and compared with PBXN-109 (plastic-bonded explosive-109), the solid content is higher, and the overall properties are equivalent.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

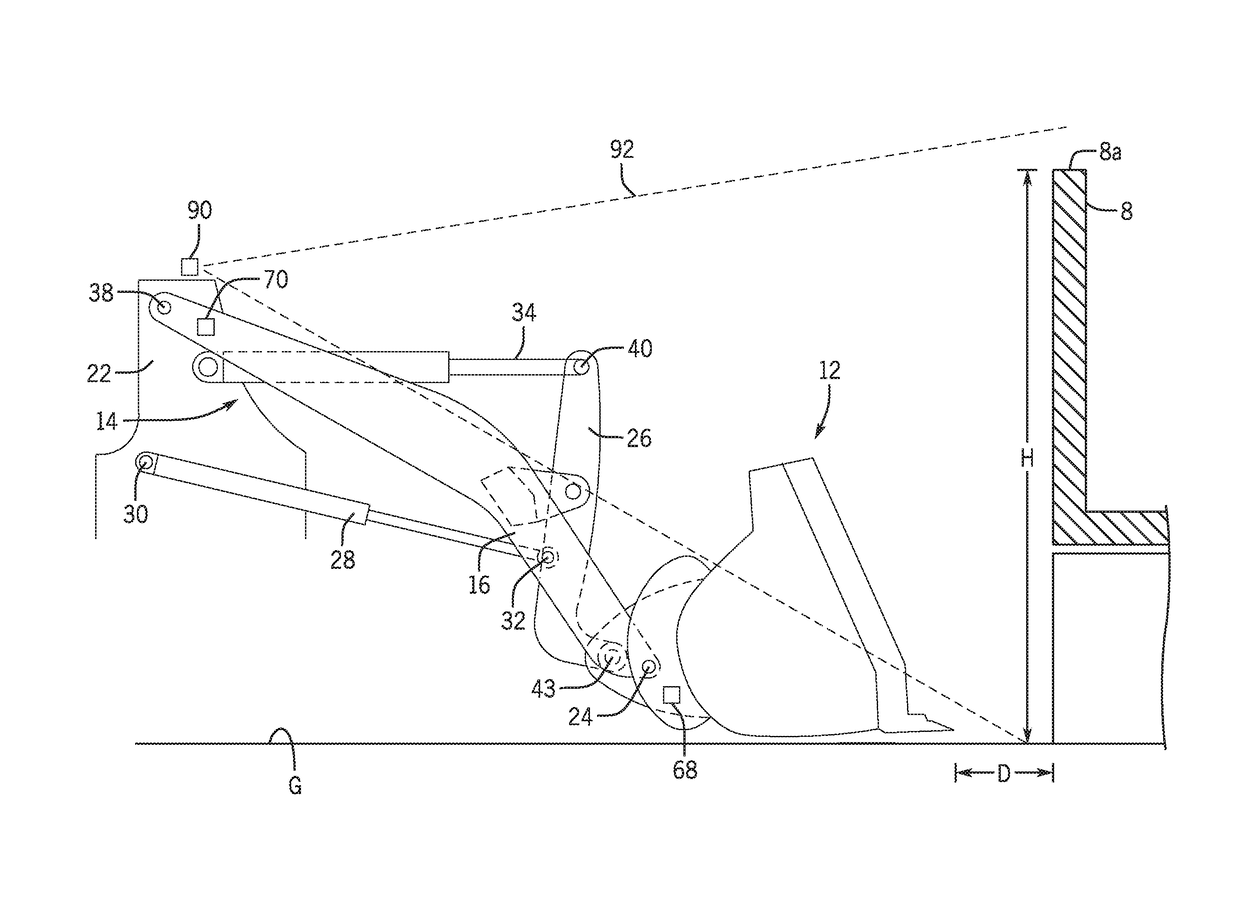

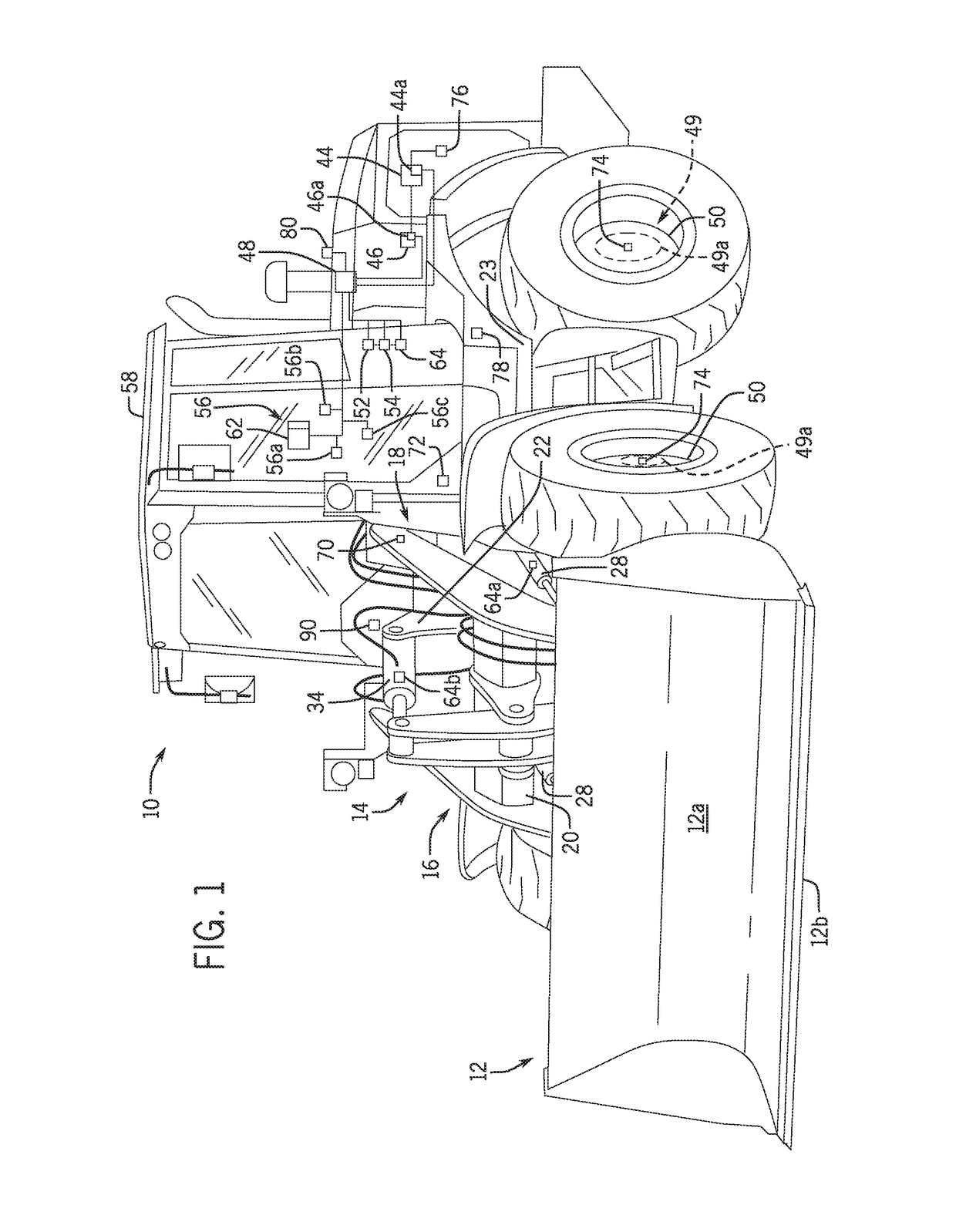

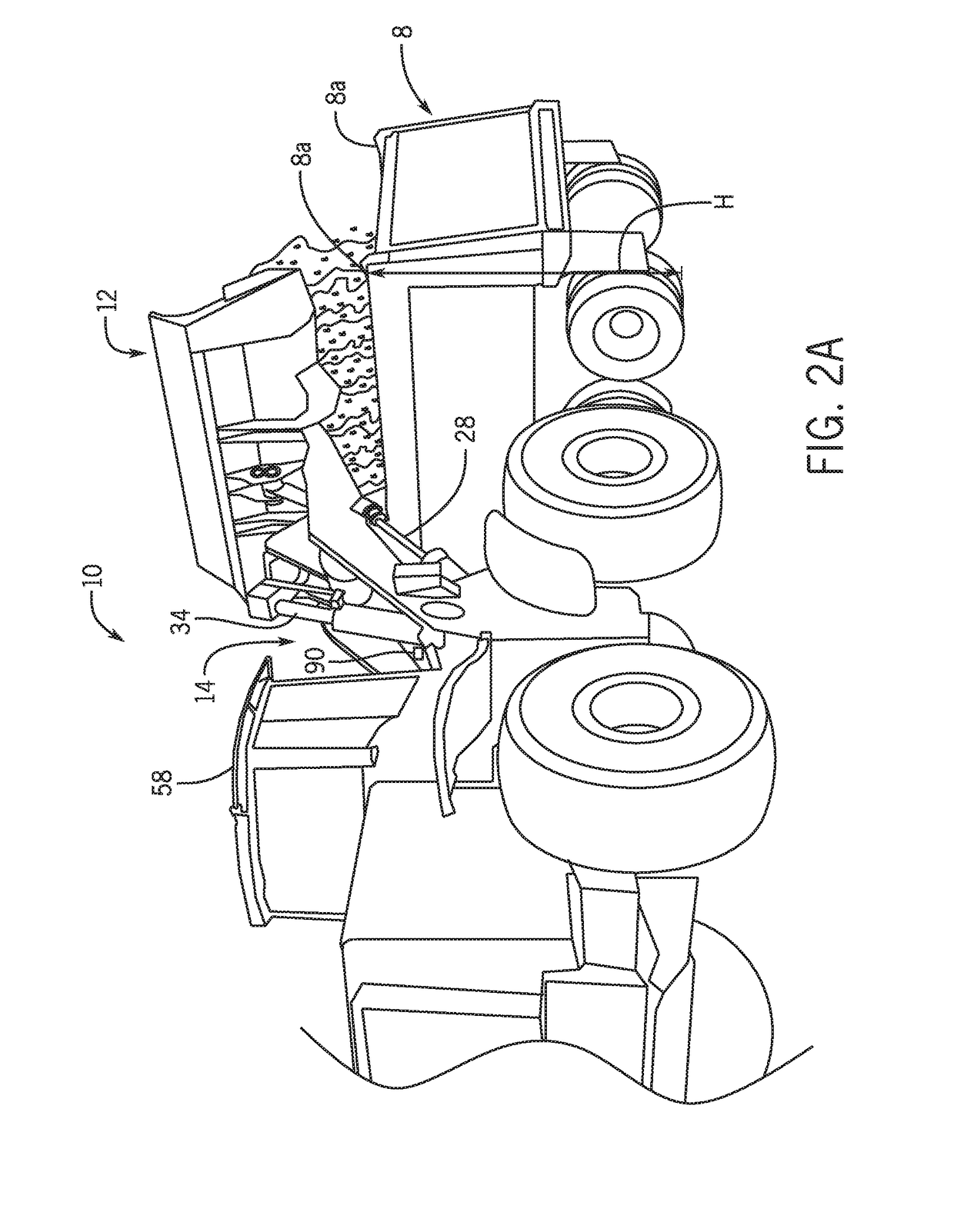

System and method for automatic dump control

ActiveUS20180080193A1Improve efficiencyImprove pouring efficiencyMechanical machines/dredgersHydraulic cylinderControl system

An automatic dump control system and method are disclosed for a loader having a boom and a bucket each positionable by hydraulic cylinders actuated by a hydraulic circuit. The control system includes a source of image data of a receptacle and a source of position data for the boom and the bucket. The control system includes a controller that: determines a height of the receptacle based on the image data; determines a difference between the height of the receptacle and a height of the bucket based on the position data; outputs one or more control signals to the hydraulic circuit to position at least one of the boom and the bucket at a target height above the receptacle; determines that the bucket is positioned over the receptacle; and outputs one or more control signals to the hydraulic circuit to dump a load in the bucket into the receptacle.

Owner:DEERE & CO

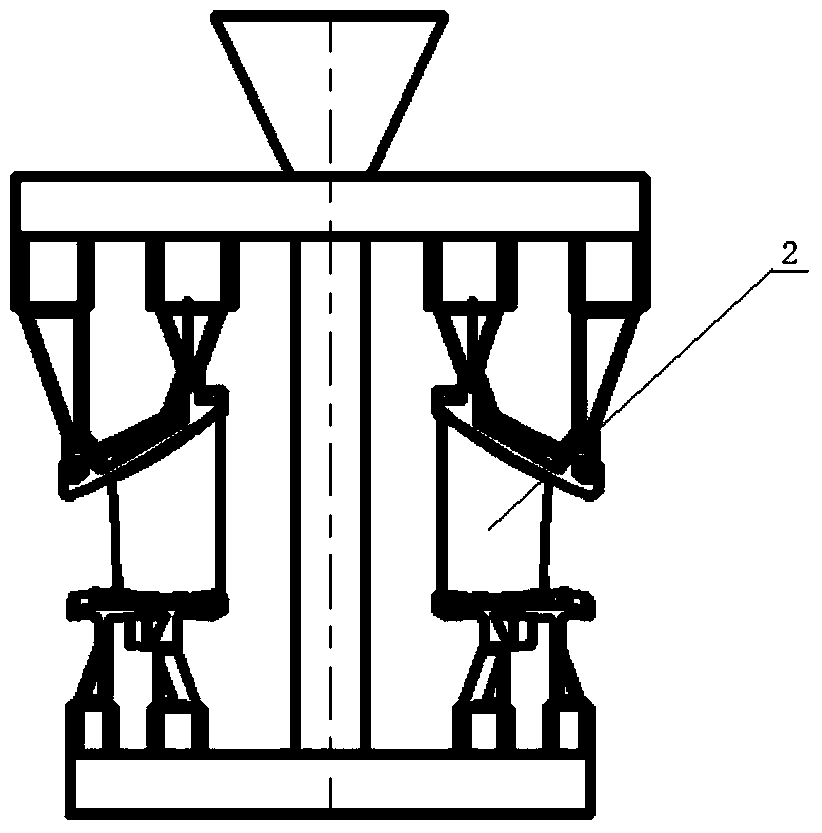

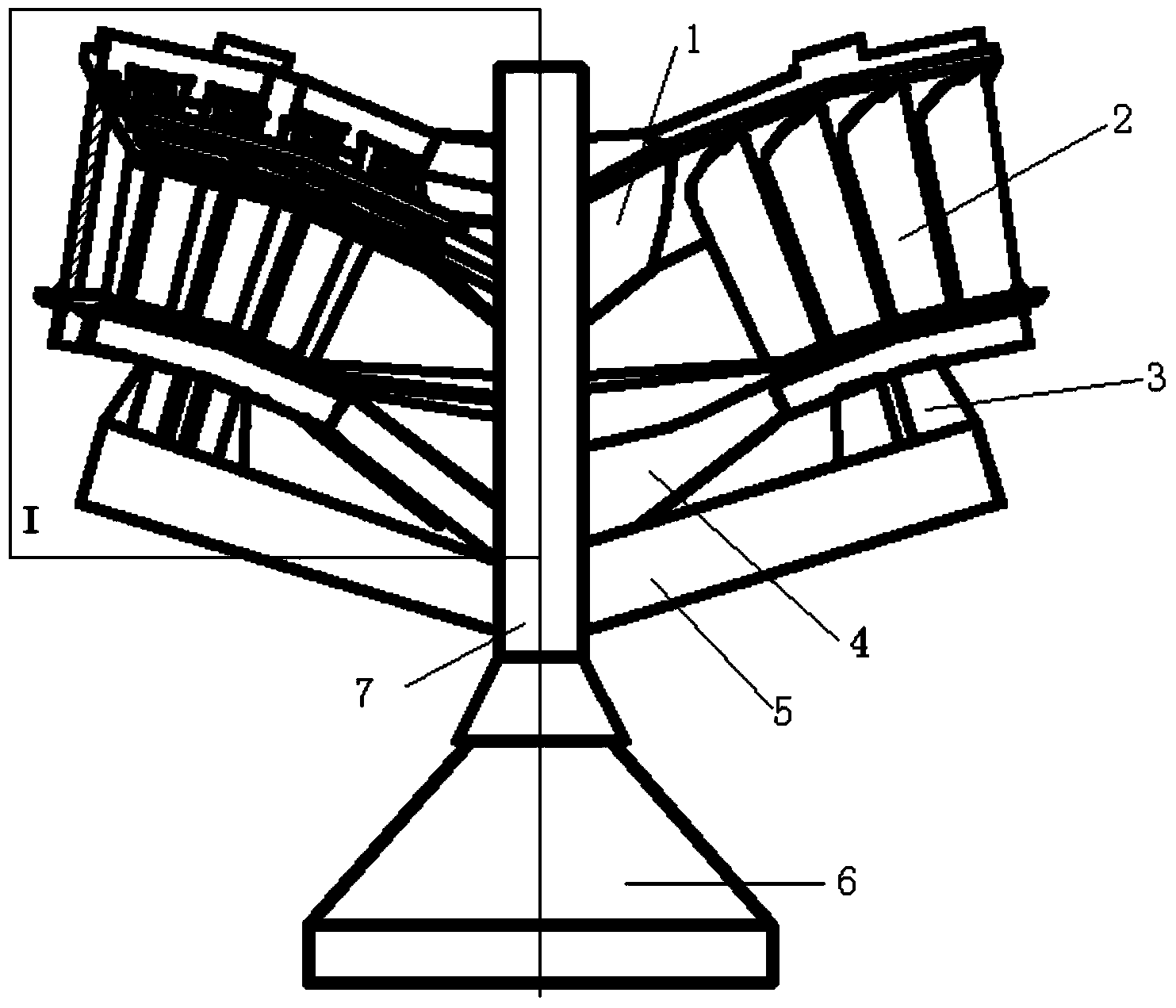

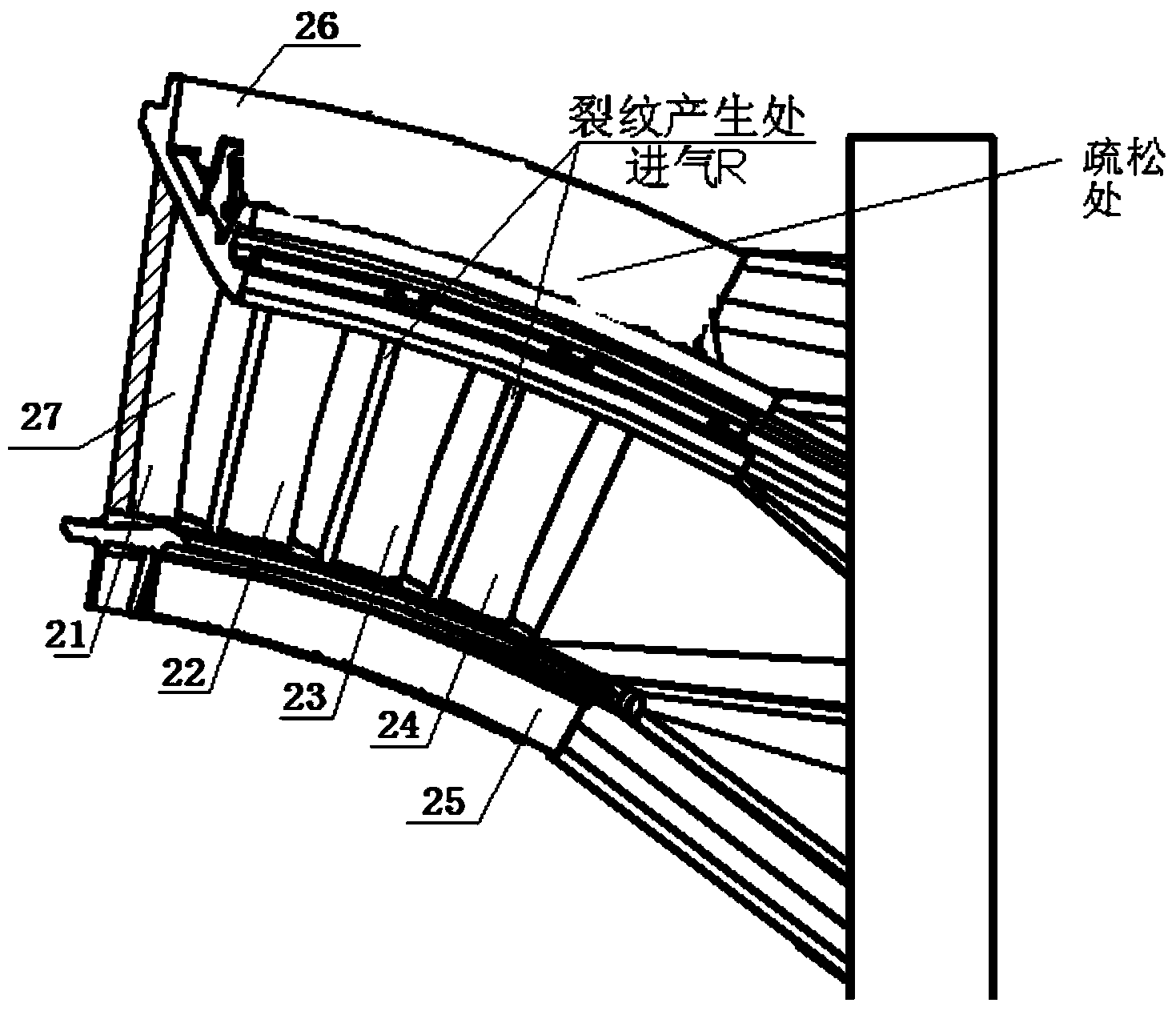

Wax mold combination of four-connection hollow turbine guide vane and precision casting method of wax mold combination

The invention provides a wax mold combination of a four-connection hollow turbine guide vane, which has high product quality and can completely solve the problems that a rotary connection R part of an edge plate and a vane body is hotly cracked and loosened, and a precision casting method of the wax mold combination. The wax mold combination comprises a sprue cup and a straight pouring gate which is communicated with an outlet end of the sprue cup, wherein inner sprue assemblies are arranged on the side wall of the straight pouring gate; each inner sprue assembly comprises a lower edge inner sprue communicated with one side of a vane lower edge plate cavity, and an upper edge inner sprue communicated with one side of a vane upper edge plate cavity; and each lower edge inner sprue and each upper edge inner sprue are sequentially arranged along the flow direction of the straight pouring gate. The precision casting method comprises the following steps: (1) manufacturing the wax mold combination; (2) carrying out shell making on the wax mold combination prepared in the step (1) to obtain a four-connection hollow turbine guide vane shell; and (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part and covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace for carrying out casting.

Owner:AECC AVIATION POWER CO LTD

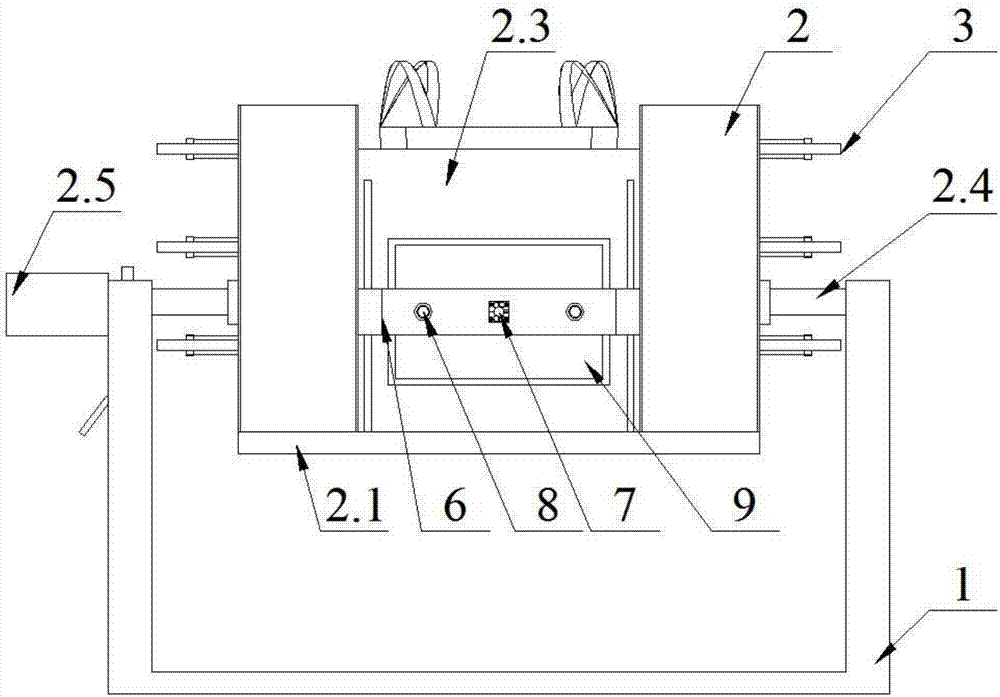

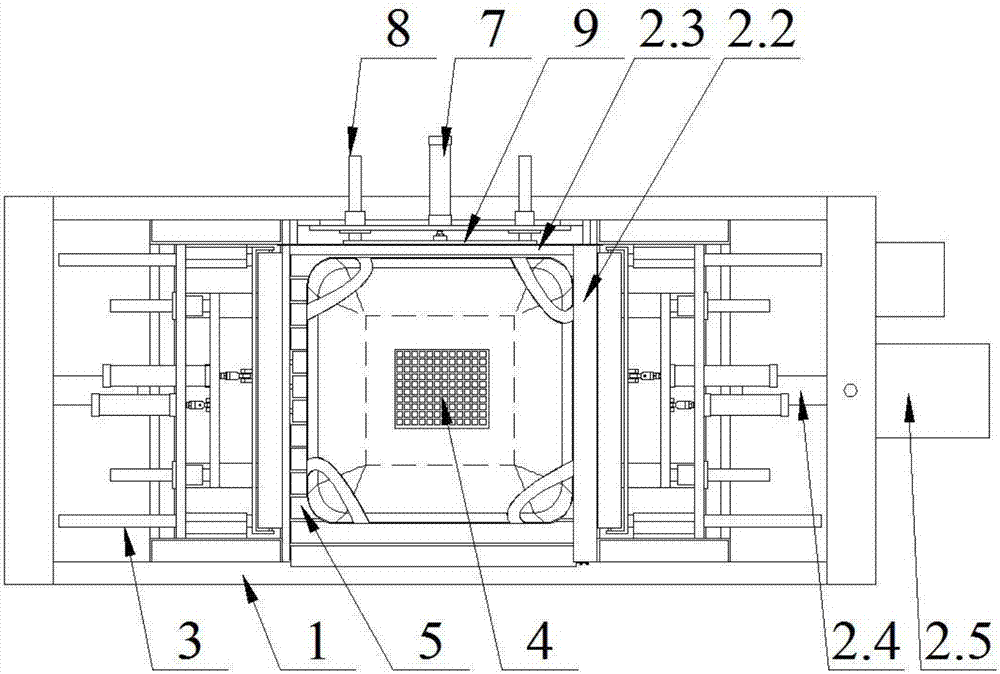

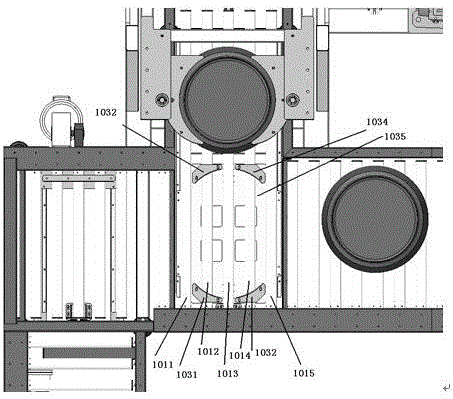

Solid-liquid composite cast rolling machine for dual-metal-layer composite pipe

The invention provides a solid-liquid composite cast rolling machine for a dual-metal-layer composite pipe. The machine comprises a machine frame, a pouring unit used for aluminum liquid pouring, a pressing-down and balance adjusting device and a cast roller unit, and further comprises an annular flow distribution device and a guide support. The annular flow distribution device is covered with a heating device used for keeping metal liquid in a molten state. The cast roller unit comprises a first cast roller and a second cast roller which jointly form a circular hole, and a pipe base material to be composited enters the circular hole. The solid-liquid cast rolling forming technology is adopted for producing the dual-metal-layer composite pipe, and metallurgical bonding of dual metal interfaces can be achieved by combining the rapid solidification technology with the rolling technology. Compared with the prior art, cladding metal is poured in a liquid state, the problem that the requirements of traditional solid-solid composite technologies such as drawing composite, expanded connection composite and spinning composite for blank size and shape precision are high is solved, and the solid-liquid composite cast rolling machine has the beneficial effects of remarkably saving energy, being high in efficiency and short in process, and the like.

Owner:YANSHAN UNIV

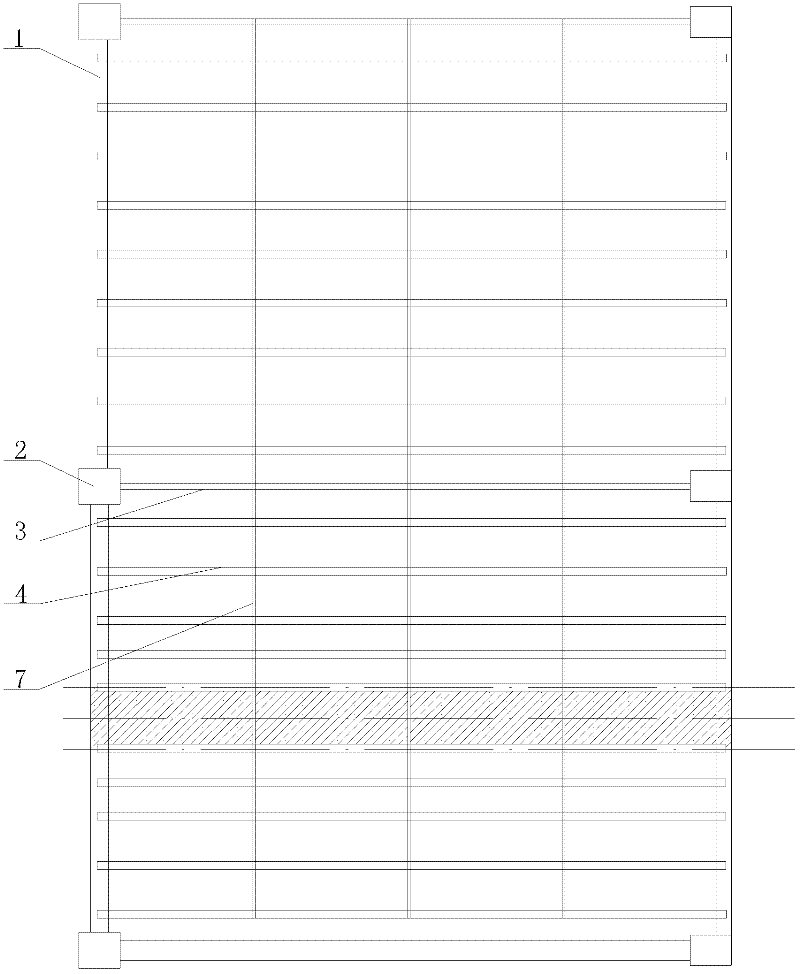

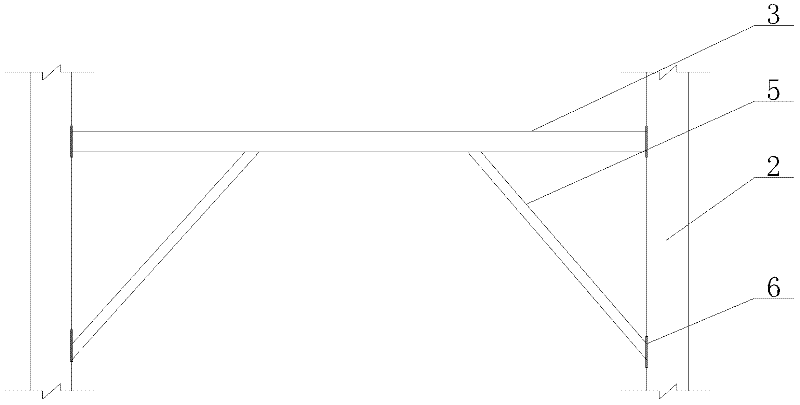

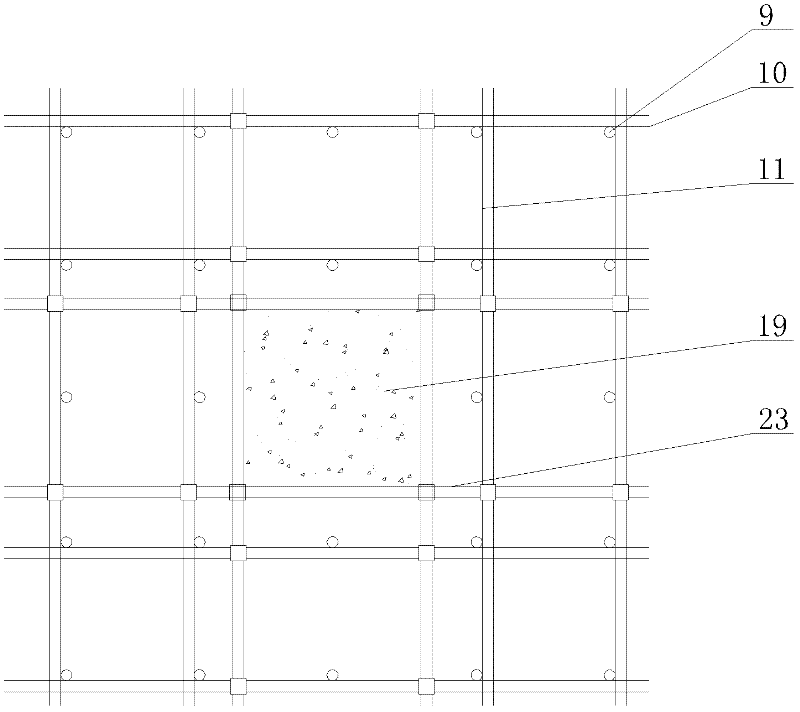

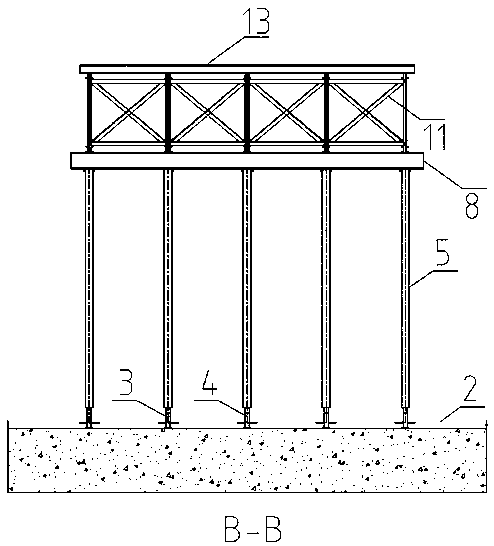

Construction method for long-span hanging vestibule type template support system

InactiveCN102392536AShorten the construction periodImprove pouring efficiencyForms/shuttering/falseworksBuilding material handlingSupporting systemRebar

The invention belongs to the technical field of construction engineering and in particular relates to a construction method for a long-span hanging vestibule type template support system. The construction method comprises the following steps: (1) selecting the position of a hanging steel beam; (2) paying off the hanging steel beam in a positioning mode; (3) installing the hanging steel beam, and welding with a connecting rod; (4) laying a construction operating platform; (5) paying off an upright rod in a positioning mode and installing; (6) erecting longitudinal and horizontal cross rods; (7) unloading inclined rods and erecting inclined rods on a beam bottom; (8) installing an adjustable support; (9) installing templates on the beam bottom; (10) binding beam reinforcing steel bars; (11)installing templates on the beam side; (12) installing templates on the template on a plate bottom; (13) binding plate reinforcing steel bars; and (14) pouring concrete. The construction method has the beneficial effect that a three-dimensional cross operation space is provided for each construction working procedure, the construction period can be greatly shortened, a channel is provided for concrete in-site conveying, the pouring efficiency of concrete is improved, adopted materials can be reused, and the construction method conforms to the environmentally-friendly construction requirementsof high efficacy and energy conservation.

Owner:SHANDONG WANXIN CONSTR

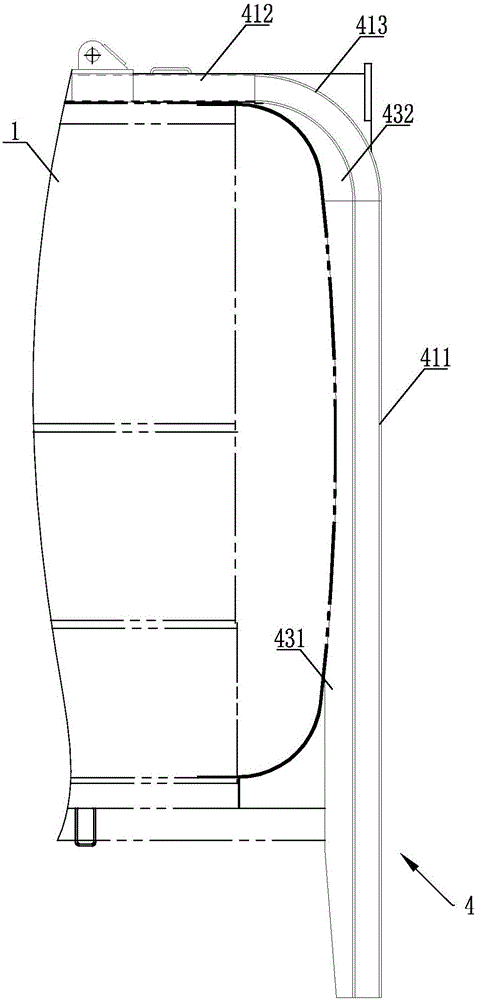

Medical rubbish bin dumping device

The invention relates to a medical rubbish bin dumping device which is characterized in that the medical rubbish bin dumping device comprises a fixing frame, a support shaft supported at the upper end of the fixing frame, and a slowdown motor which is installed at one lateral end of the fixing frame and is in transmission connection with the support shaft. An overturning box consisting of a bottom support part, a left support part, a right support part and a back support part is arranged inside the fixing frame; clamping devices are arranged at the upper ends of the left and right support parts; and the part of the back support part, which is close to the upper end, is fixedly connected with the support shaft. The medical rubbish bin dumping device realizes automatic dumping of the medical rubbish, and an operator only needs to mount a medical rubbish bin on the medical rubbish bin dumping device and then demount the emptied medical rubbish bin from the dumping device. Compared with the conventional manual dumping manner, the medical rubbish bin dumping device has the advantages of lightening the work intensity, and improving the dumping efficiency. Moreover, in the dumping process, the operator can be far away from the medical rubbish bin, so direct contact between the operator and the medical rubbish is avoided. Therefore, the medical rubbish bin dumping device is safe and hygienic, and reduces the probability of iatrogenic infection of the operator.

Owner:天津百利阳光环保设备有限公司

Pouring method of hollow turbine guide vane

ActiveCN104308082AUniform temperature fieldEliminate casting stressFoundry mouldsFoundry coresWaxTurbine

The invention provides a pouring method of a hollow turbine guide vane. The pouring method comprises the following steps: (1) manufacturing a wax mold combination; (2) carrying out shell making on the wax mold combination to obtain a hollow turbine guide vane shell; (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part; covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace and carrying out casting, wherein in a casting process, the temperature of casting the shell is 1065-1085 DEG C and the pouring temperature is 1460-1480 DEG C. According to the pouring method of the hollow turbine guide vane, a pouring system of the hollow turbine guide vane is not changed and the shell temperature and the pouring temperature are adjusted so that the casting temperature field is changed; the two layers of ceramic cotton on the whole body and one layer of the ceramic heat-preservation cotton on the vane body part are matched so that after the temperature of the whole shell is improved, the temperature field is uniform, the casting stress is eliminated and the casting temperature is reduced; and furthermore, the temperature field on a casting vane body and an edge plate keeps uniform, the shell is effectively insulated and the casting stress is eliminated.

Owner:AECC AVIATION POWER CO LTD

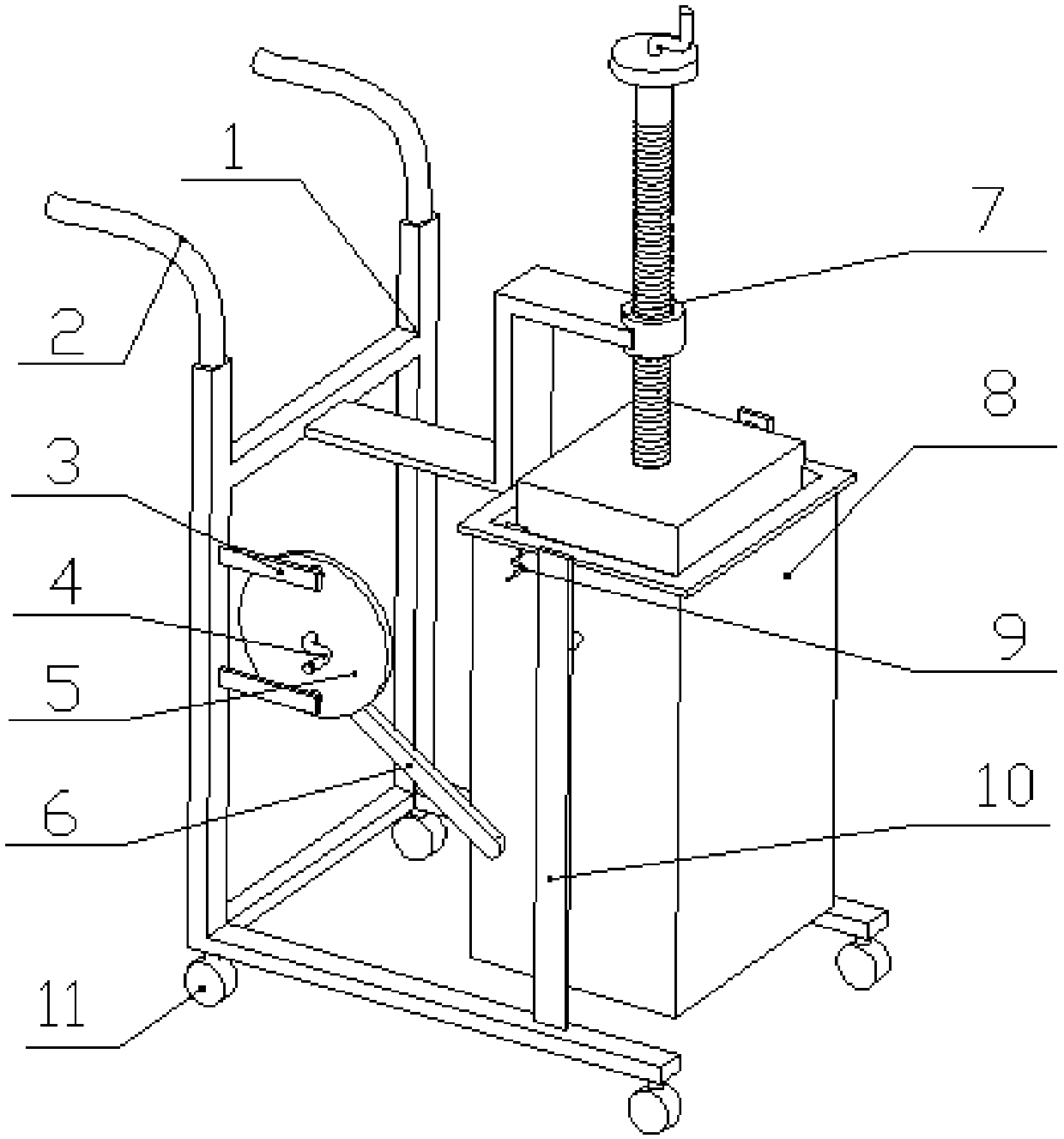

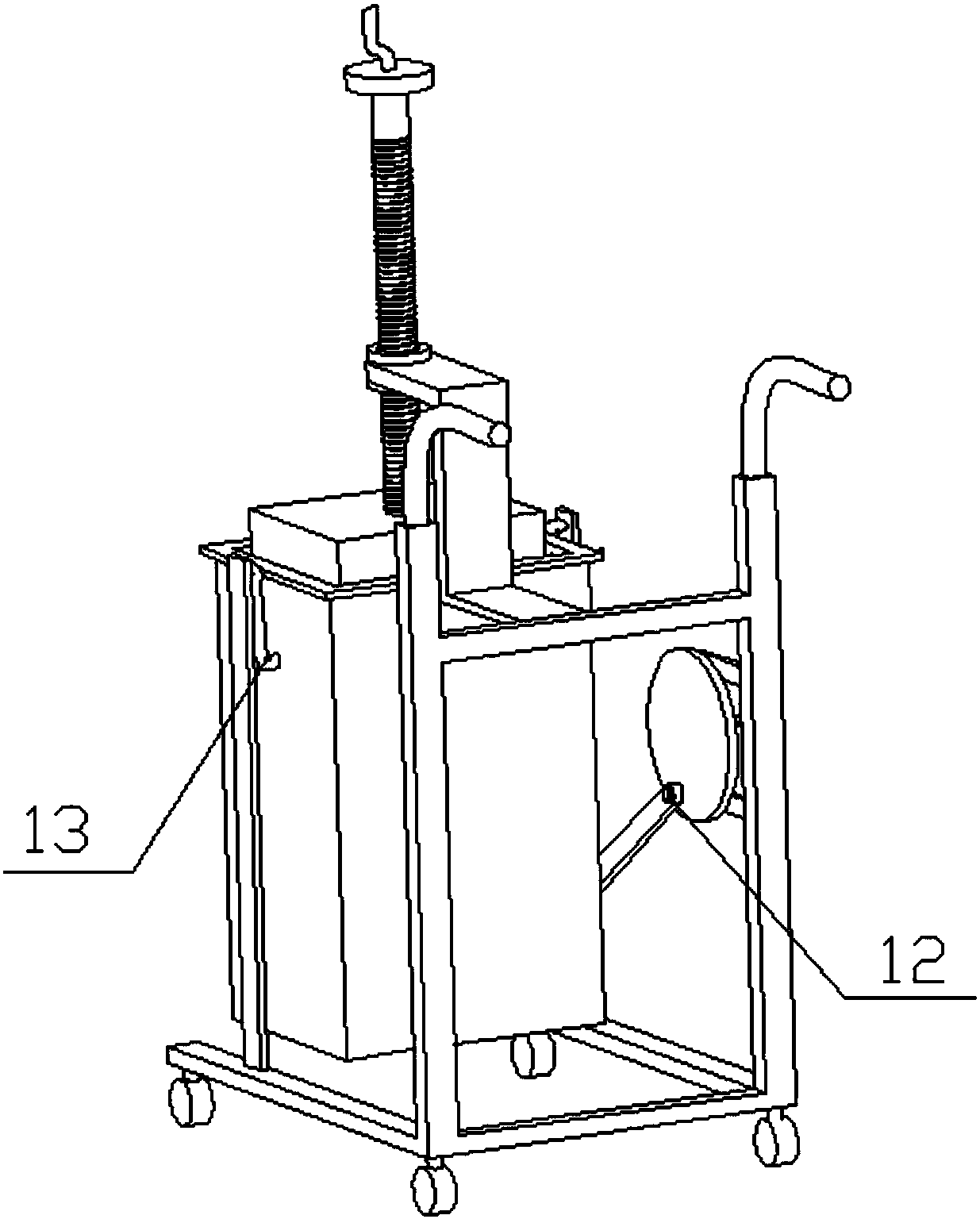

Automatic dumping type medical dustbin

InactiveCN107840043AGuaranteed Stability and ReliabilityProtect healthRefuse receptaclesPressesHandrailVehicle frame

An automatic dumping type medical dustbin is composed of a frame, handrails, crank fixing plates, a dumping hand crank, a crank disc, a connecting rod, a compressing and crushing mechanism, a dustbin,a garbage pushing mechanism, a dustbin fixing plate, wheels, a crank boss and a rotating connecting pipe. The dustbin and the dustbin fixing plate are connected together through the rotating connecting pipe, and the dustbin can freely rotate around the rotating connecting pipe. The crank disc is fixed to the two crank fixing plates. The dumping hand crank is fixedly mounted on the front portionsof the crank fixing plates. The crank boss is fixedly mounted on the rear portions of the crank fixing plates. One end of the connecting rod and the crank boss are connected together, and the other end of the connecting rod is connected with a connecting column on the side face of the dustbin. The compressing and crushing mechanism is mounted above the dustbin. The garbage pushing mechanism is mounted in the dustbin. The automatic dumping type medical dustbin has the beneficial effects that the whole device structure is simple, and operation is convenient; direct contact with medical garbage is avoided; the number of times of garbage dumping is reduced; and the work efficiency is improved.

Owner:鲍兆伟

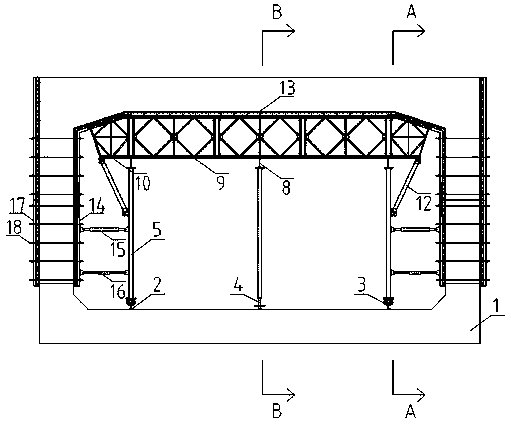

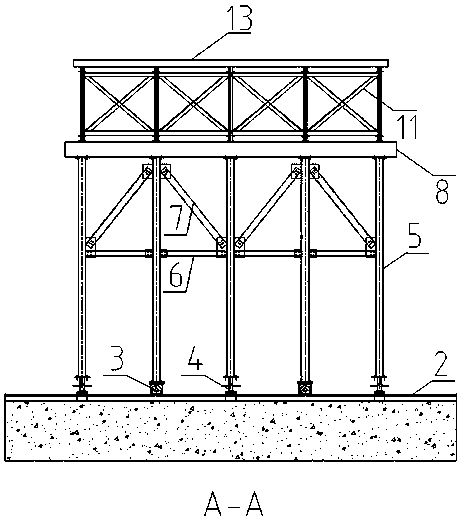

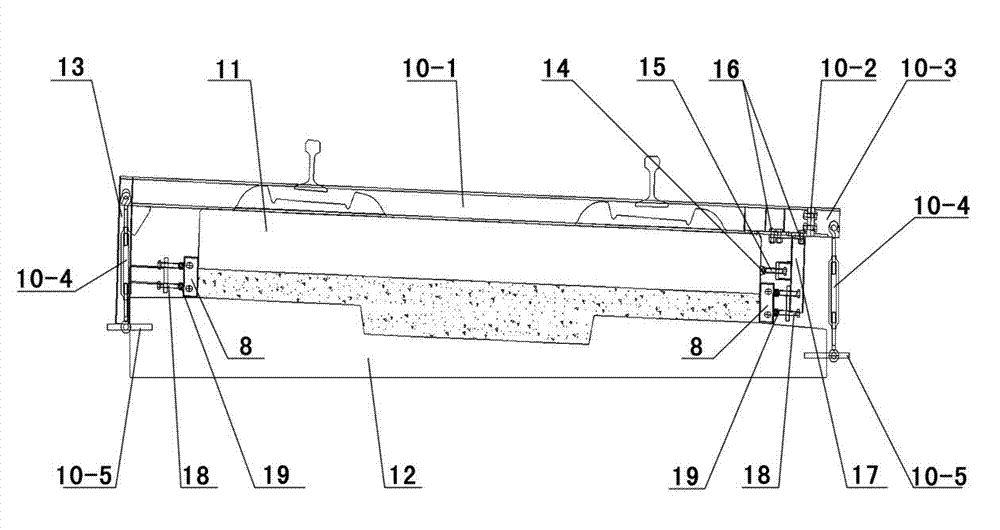

Fabricated trolley for box culvert construction and construction method thereof

PendingCN111424570AImprove pouring efficiencyRigid and stable supportArtificial islandsGround-workArchitectural engineeringStringer

A fabricated trolley for box culvert construction is provided. Rails are longitudinally laid on a poured box culvert bottom plate, stand columns with walking wheels and stand columns with adjustable bottom supports A are arranged above the rails in a staggered mode, longitudinal beams are supported above the stand columns, a plurality of sets of bailey beams are erected above the longitudinal beams, and a top formwork is supported above the bailey beams; left and right ends of each bailey beam are connected with end trusses; the side faces of the stand columns are connected with side formworksthrough adjusting screws and jacks. The fabricated trolley is used for pouring a box culvert wall body and top plate concrete at the same time, the box culvert concrete pouring efficiency can be greatly improved, the inner surface and the outer surface of a poured box culvert are smooth, constructors can use the trolley conveniently, and all components of the trolley can be disassembled and installed quickly and are convenient to maintain.

Owner:GUANGXI ROAD CONSTR ENG GRP CO LTD +1

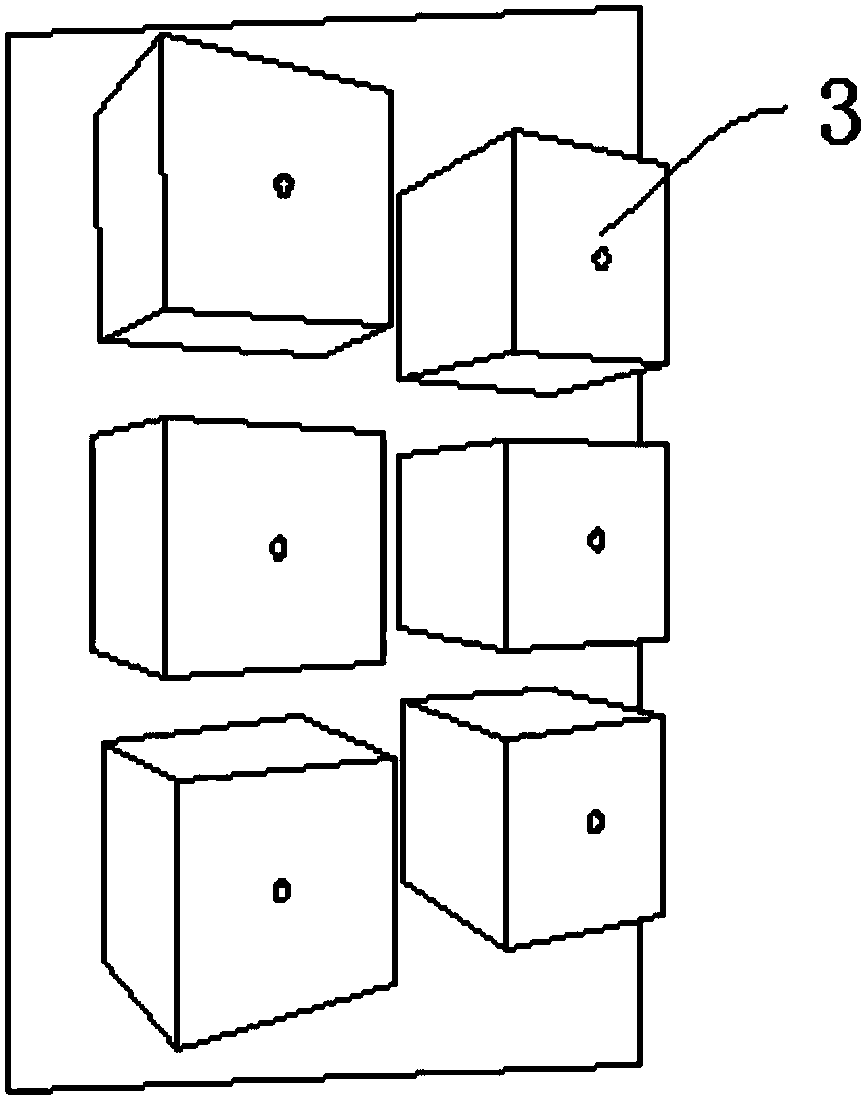

Full-automatic crushed material unloading device and method

ActiveCN107324072AImprove unloading efficiencyEasy to collect and process manuallyBottle emptyingGrain treatmentsEngineeringHanging basket

The invention relates to the technical field of ton bag unloading device structures, in particular to a full-automatic crushed material unloading device and method. The device comprises a rack and an overturn hanging basket. The overturn hanging basket is of a frame structure rotatably connected to the rack through a rotary shaft and is provided with at least one opening used for enabling ton bags to enter, and a gaseous disk used for adsorbing and fixing the ton bags is arranged at the bottom of the overturn hanging basket; a plurality of extruding units arranged on the peripheries of the ton bags correspondingly and capable of applying transverse extruding and pushing acting force to the ton bags are arranged on the inner side of the overturn hanging basket; and the multiple extruding units are vertically arranged at intervals along the ton bags. According to the full-automatic crushed material unloading device and method, the structure is simple, operation is convenient, ton bag materials can be quickly poured through grading unloading and extruding crushing, the ton bags can be conveniently and quickly collected by using a movable plate and a purging structure, damage to the ton bags cannot be caused, working procedures for manual operation are reduced, and the device and method have extremely large popularization value.

Owner:HUBEI UNIV OF TECH

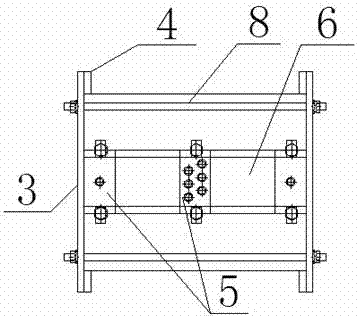

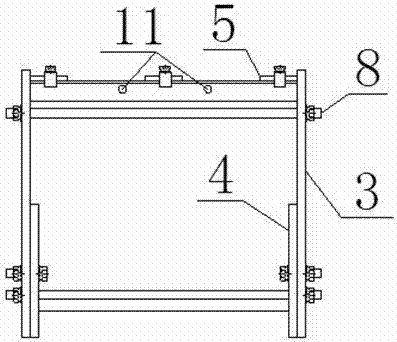

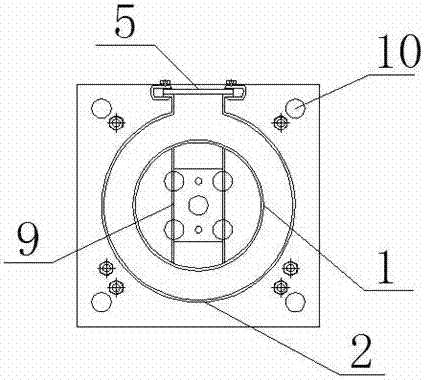

Horizontal casting mold and casting method for high-voltage coil of dry transformer

ActiveCN106935394AIncrease contact areaEnhanced effect of diffusing gasCoils manufacturePartial dischargeAir bubble

The invention discloses a horizontal casting mold and a casting method for a high-voltage coil of a dry transformer. The horizontal casting mold comprises a coil casting inner mold, a coil casting outer mold, an end positioning and fixing support plate, an outer mold lining plate and a connection terminal fixing plate, wherein the coil casting inner mold and the coil casting outer mold are transversely arranged. The horizontal casting mold is good in air dispersity, so that casting is faster, air bubbles are not easily generated, the local discharge amount of the dry transformer is reduced and the operation reliability of the dry transformer is improved. A coil does not need to be erected, so that the possibility of collapse of the coil is reduced and a product is more reliable in quality and safer; the height of the cast coil can reach the height required by the drawings, and the end part is smooth and does not need to be cut, so that the horizontal casting mold is free of dust pollution and environment-friendly. Due to the small height, capital input of a casting tank can be reduced and the cost is lowered.

Owner:山东泰开箱变有限公司

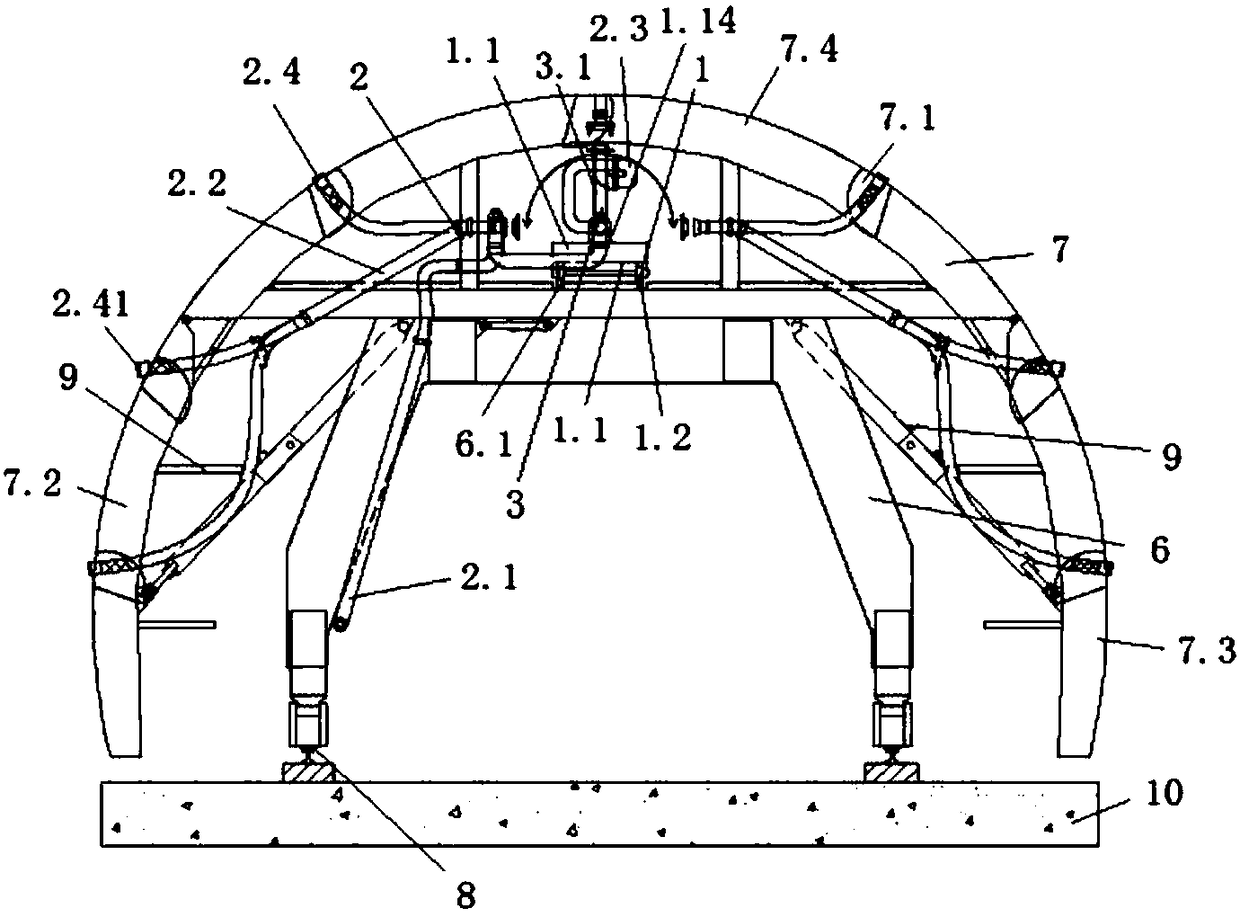

Layered pouring and distributing machine and lining trolley comprising same

PendingCN108798709AEasy grouting operationAvoid cloggingUnderground chambersTunnel liningEngineeringMechanical engineering

The invention provides a layered pouring and distributing machine. The layered pouring and distributing machine comprises a trolley, a pipeline system and a telescopic rotating device. The trolley includes a car body and a walking part. The pipeline system includes a feed pipe group, a discharge pipe group, a connecting pipe group and a grouting opening fixing sleeve. The connecting pipe group isarranged on the car body through the telescopic rotating device. According to the technical scheme, the layered pouring and distributing machine has the effects that the whole structure is tidy; the combined design of the telescopic rotating device and the connecting pipe group can arbitrarily change the position of the outlet end of the connecting pipe group, and concrete grouting operation is facilitated; and grouting opening fixing pipes are arranged in layers to realize the layered grouting of a tunnel, the interruption time of pumping concrete is short, the pipe blockage is avoided, and the grouting quality is improved. The invention further discloses a lining trolley comprising the layered pouring and distributing machine. The lining trolley is applied to enable the distributing machine to distribute the concrete pumped by a conveying pump to pipelines, layered pouring at different longitudinal positions is realized, and the pouring efficiency is greatly improved.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

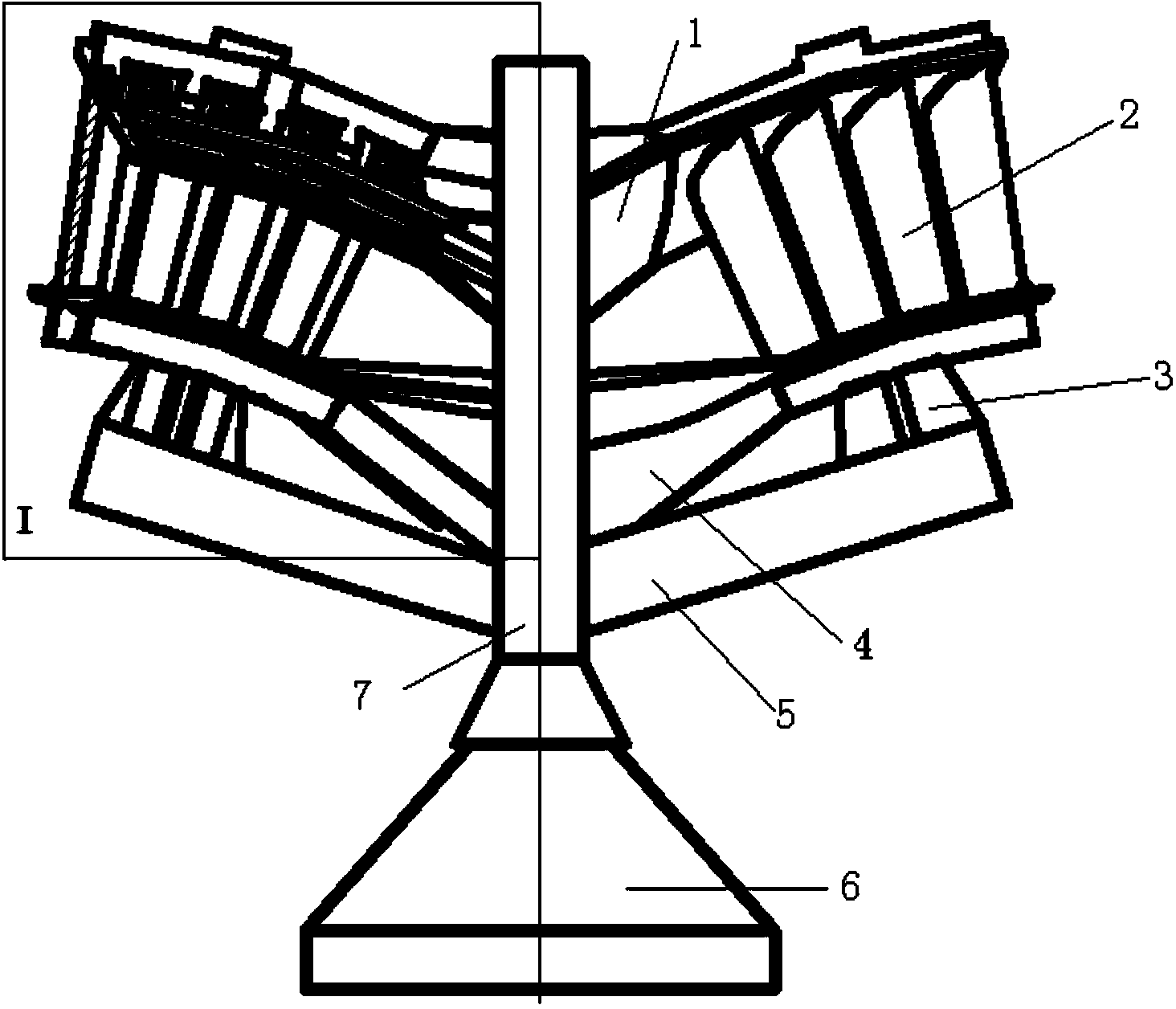

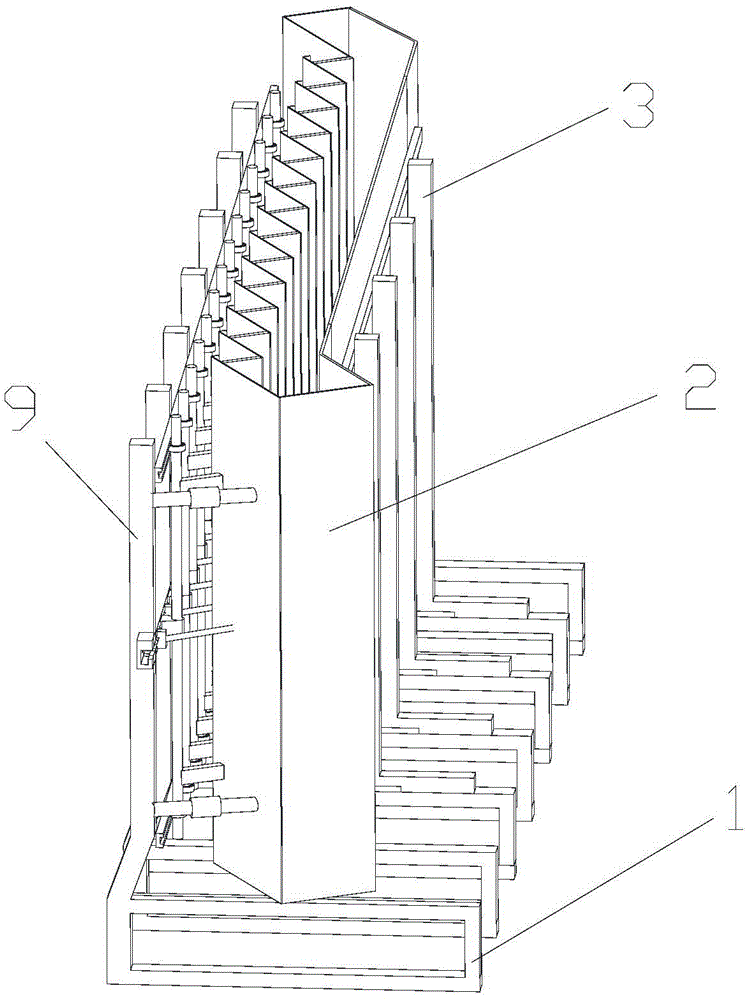

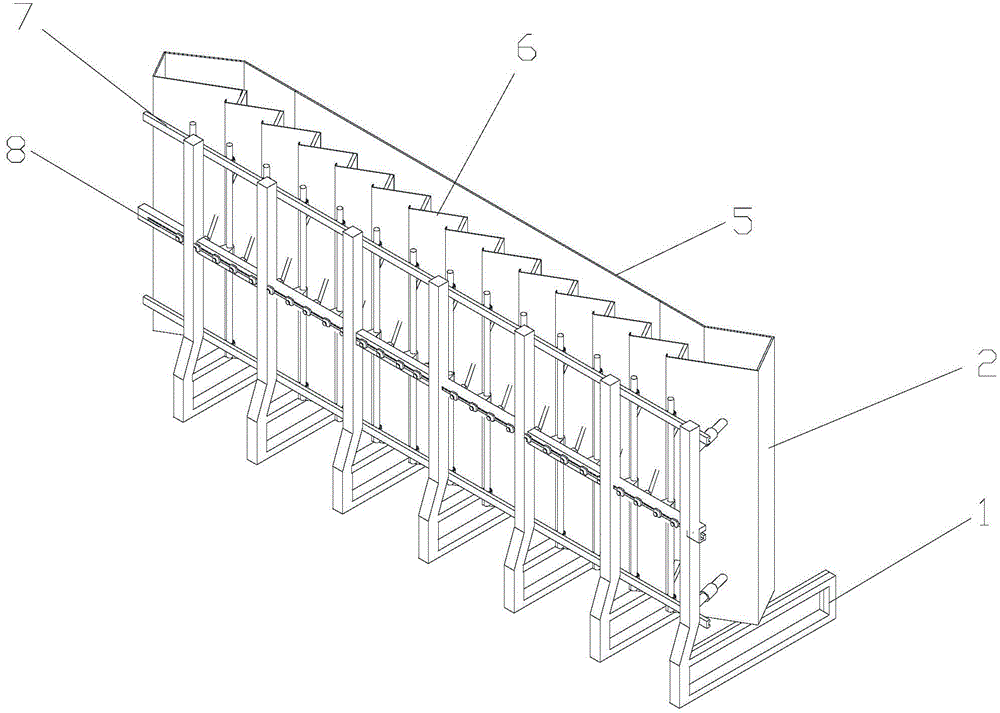

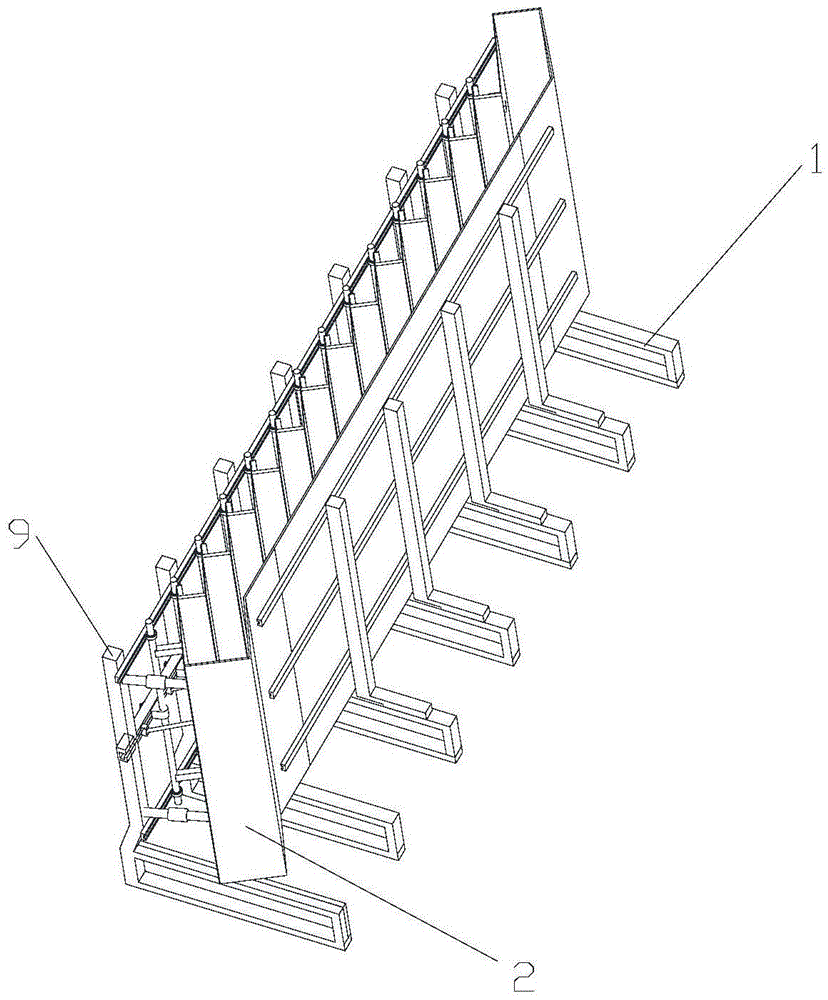

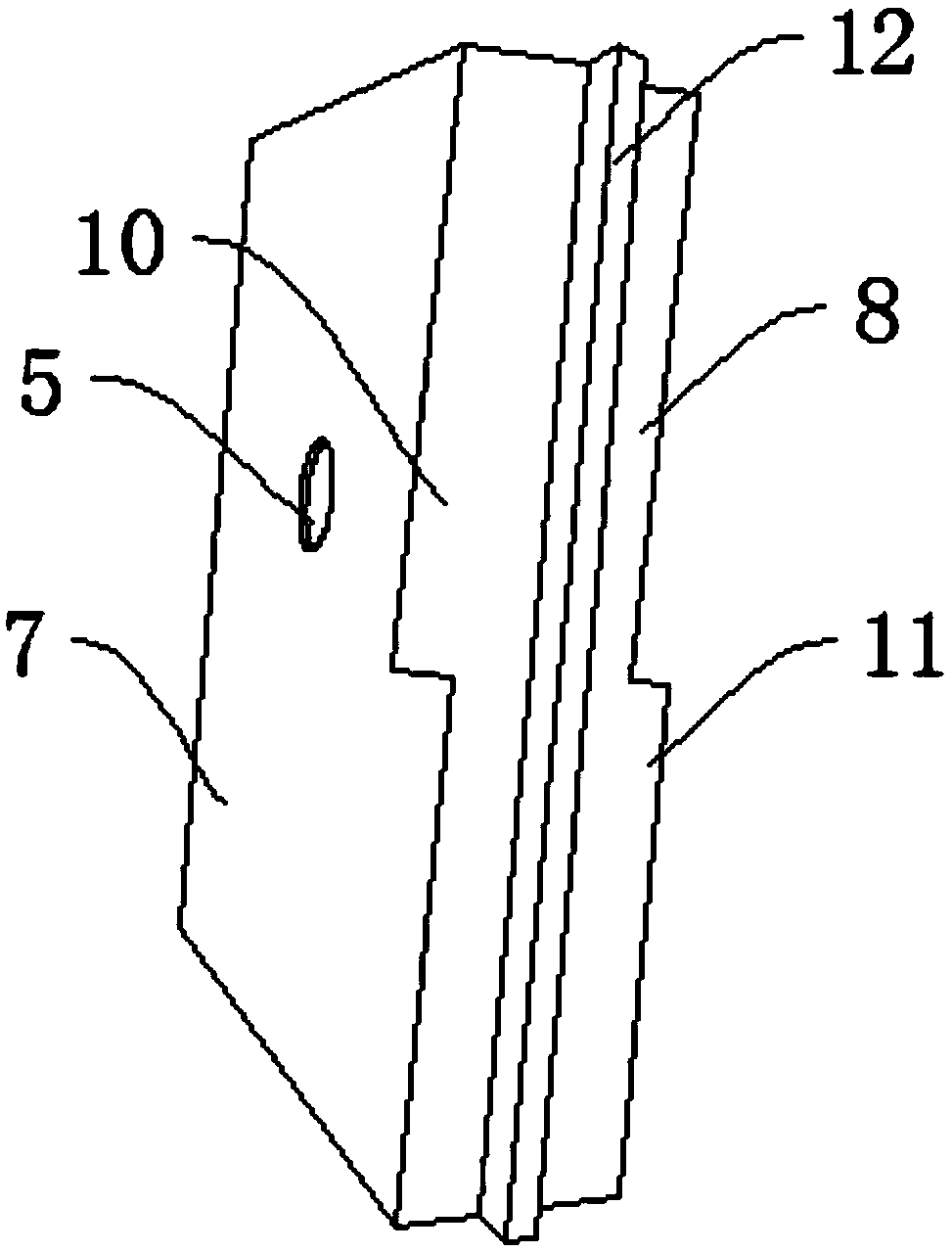

Vertical type stairway mould

InactiveCN104924423AImprove efficiencyImprove pouring efficiencyMouldsMould auxillary partsAgricultural engineeringStairs

The invention provides a vertical type stairway mould. The vertical type stairway mould comprises bases, bottom mould bodies arranged on the bases and a stepping assembly and a side blocking mould body which are vertically arranged on the bottom mould bodies; the two ends of the stepping assembly and the side blocking mould body are each provided with an end mould body, the stepping assembly and the side blocking mould body are relatively arranged at intervals, and the side blocking mould body can move in the direction perpendicular to the plate face of the side blocking mould body; the stepping assembly comprises multiple stepping units, and each stepping unit and each end mould body are rotatably and / or movably arranged on the corresponding bases through adjusting mechanisms. According to the vertical type stairway mould by adopting the structure, the distance between the side blocking mould body and the stepping assembly can be adjusted; meanwhile, due to the fact that the stepping units and the end mould bodies can rotate and / or move relative to the bases, the stair step width can be adjusted; therefore, the vertical type stairway mould can be used for pouring stairways of different specifications. Accordingly, the vertical type stairway mould is not only simple in structure, but also multifunctional, the usage efficiency of the mould is improved, and the production and usage cost can be reduced.

Owner:CHINA MINSHENG ZHUYOU

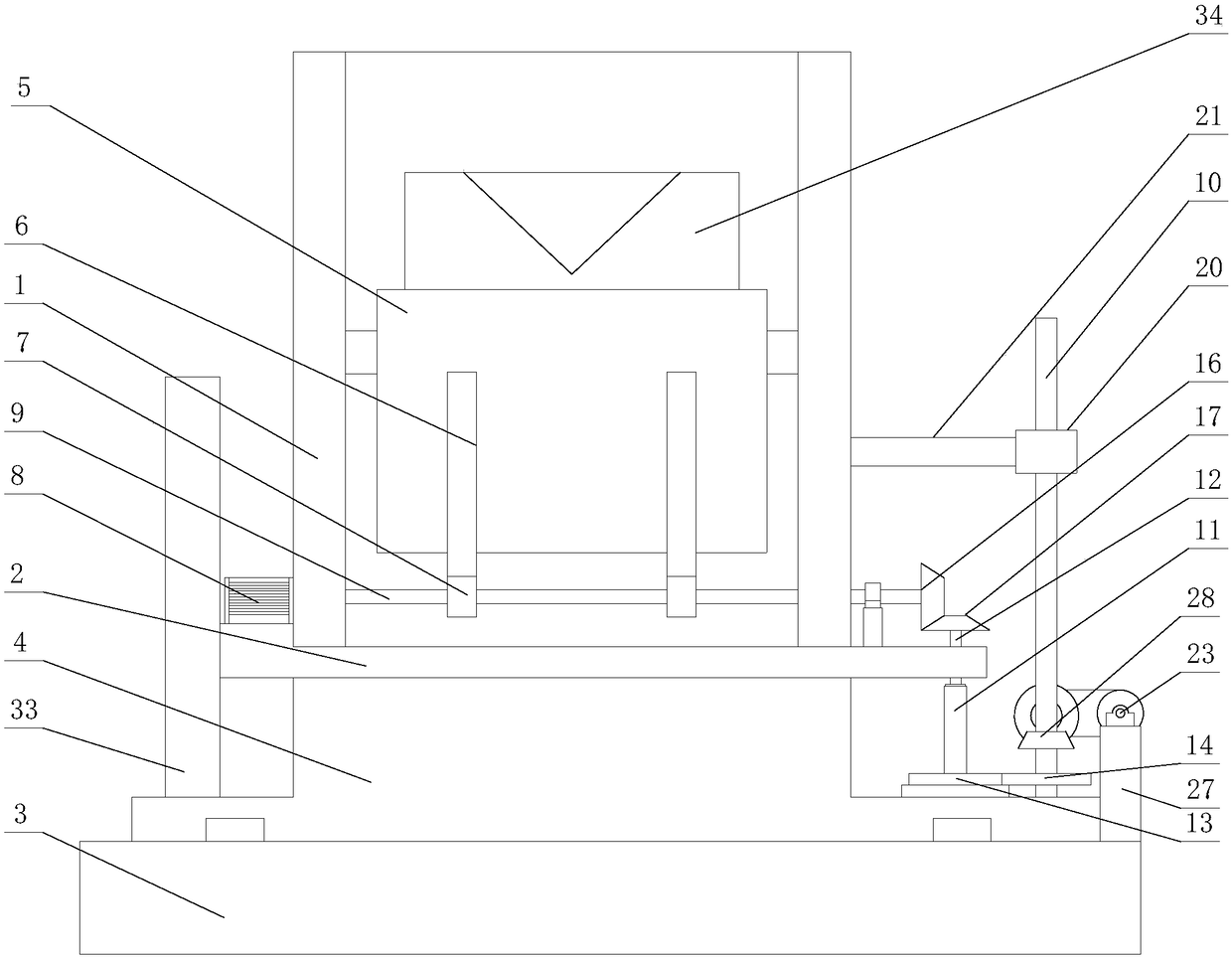

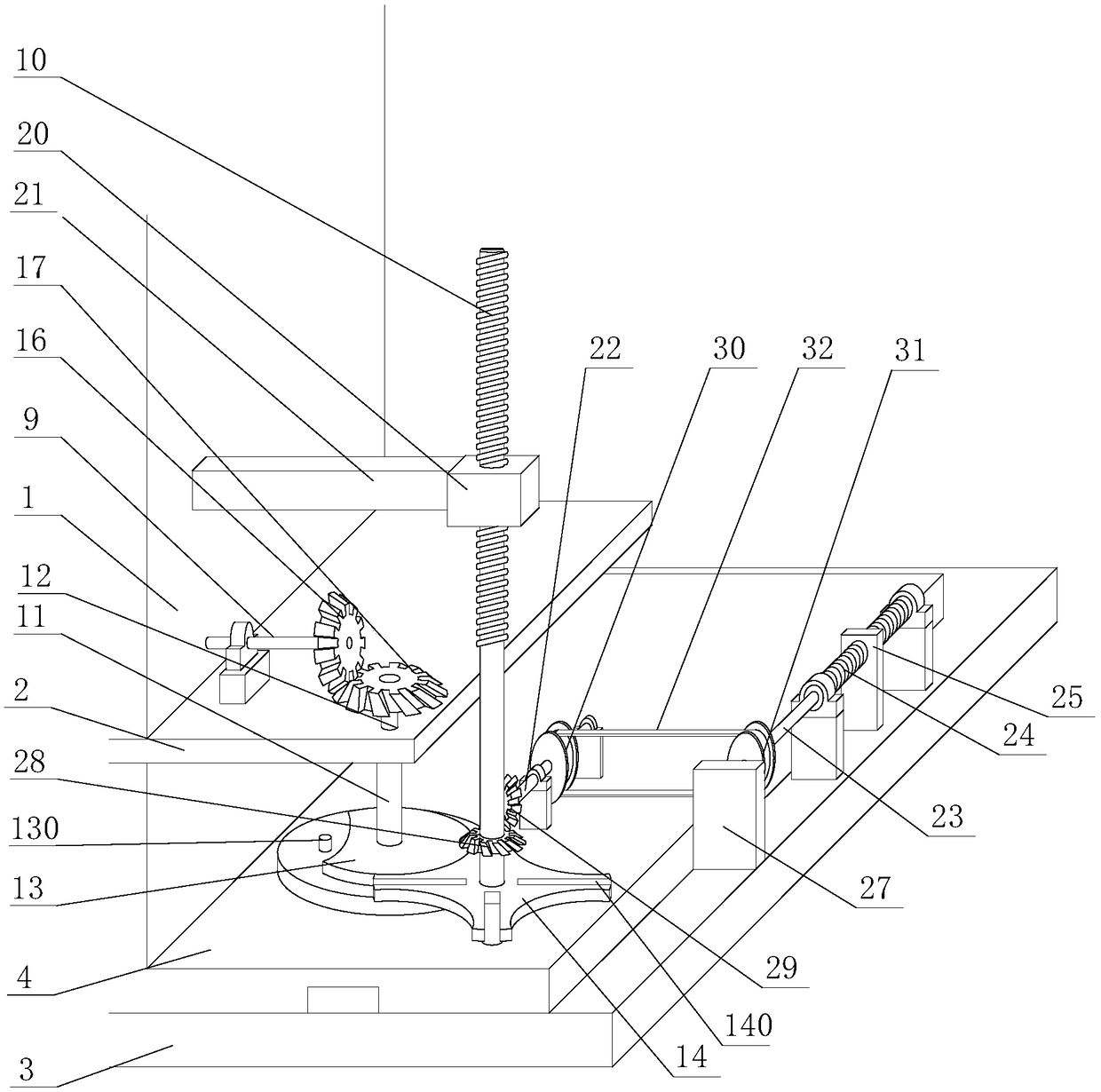

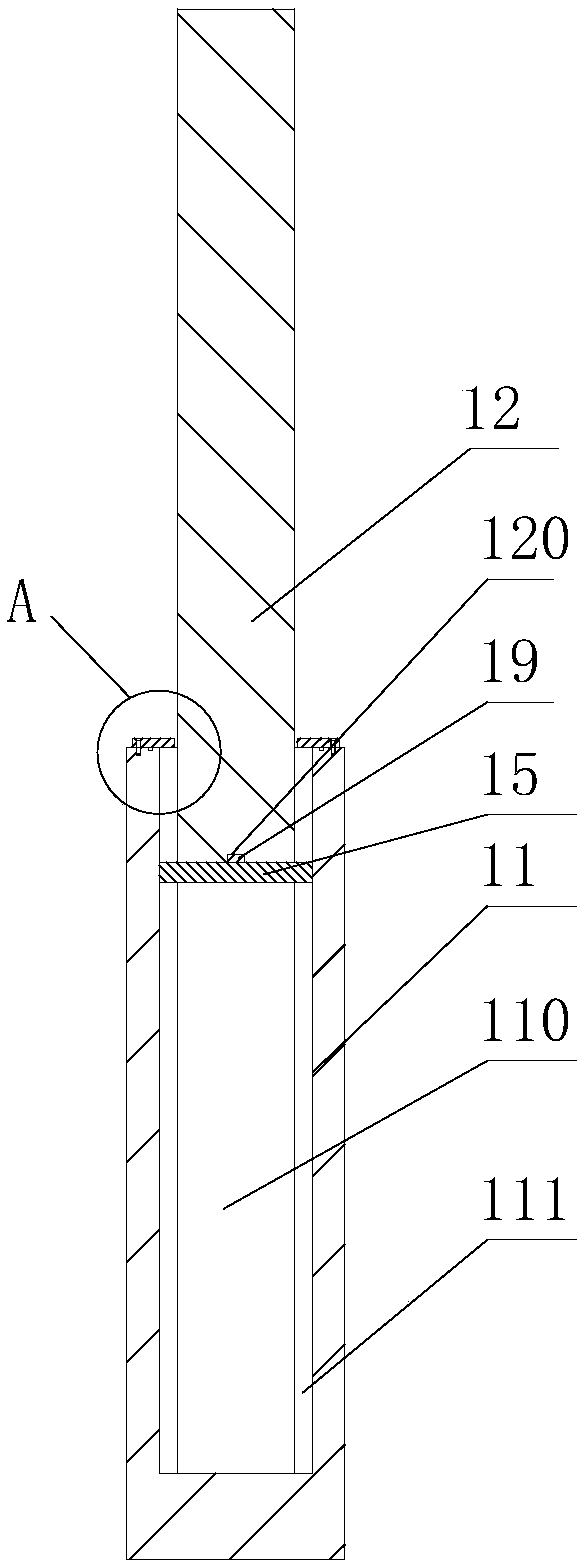

Clearing device and method for concrete conveying pump pipe of super high-rise building

ActiveCN111054708AImprove pouring efficiencyClean up thoroughlyHollow article cleaningVertical vibrationElectric machine

The invention discloses a clearing device and method for a concrete conveying pump pipe of super high-rise building. The problems that concrete bonded to the inner wall of the concrete conveying pumppipe cannot be difficultly and thoroughly cleaned up through an existing water clearing mode, and the construction progress is influenced are solved. The device comprises a vertical vibration mechanism, a lateral supporting and positioning mechanism and a pump pipe dredging and clearing mechanism which are coaxially and sequentially connected, wherein a coarse grinding wheel support and a fine grinding wheel support of the pump pipe dredging and clearing mechanism are driven by a rotating motor to do circular motion along the inner wall of a pipeline, and the concrete on the inner wall of thepipeline is removed through rotating grinding of the coarse grinding wheel and vertical vibration impact of the fine grinding wheel; two installing bases of the vertical vibration mechanism are flexibly connected through a spring type connecting piece arranged between the two installing bases, and a vibration motor set drives the pump pipe dredging and clearing mechanism to vibrate back and forthalong the axis of the pipeline; and a plurality of support positioning springs and guide rolling wheels are uniformly distributed on a guiding rod of the lateral supporting and positioning mechanism in the radial direction, and the guide rolling wheels are driven to prop against the inner wall of the pipeline by reverse acting force generated by pressing the support positioning springs.

Owner:SHANGHAI CONSTRUCTION GROUP

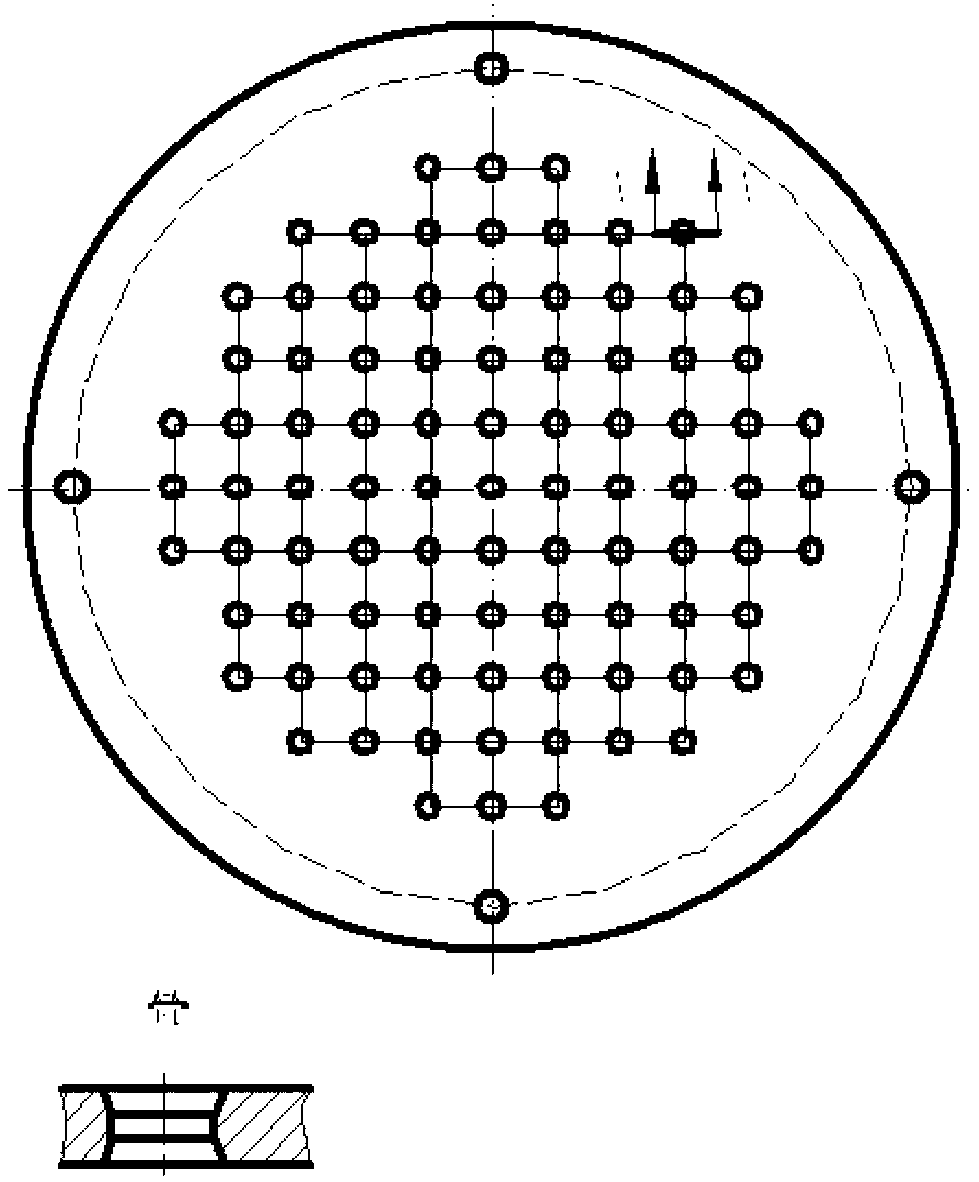

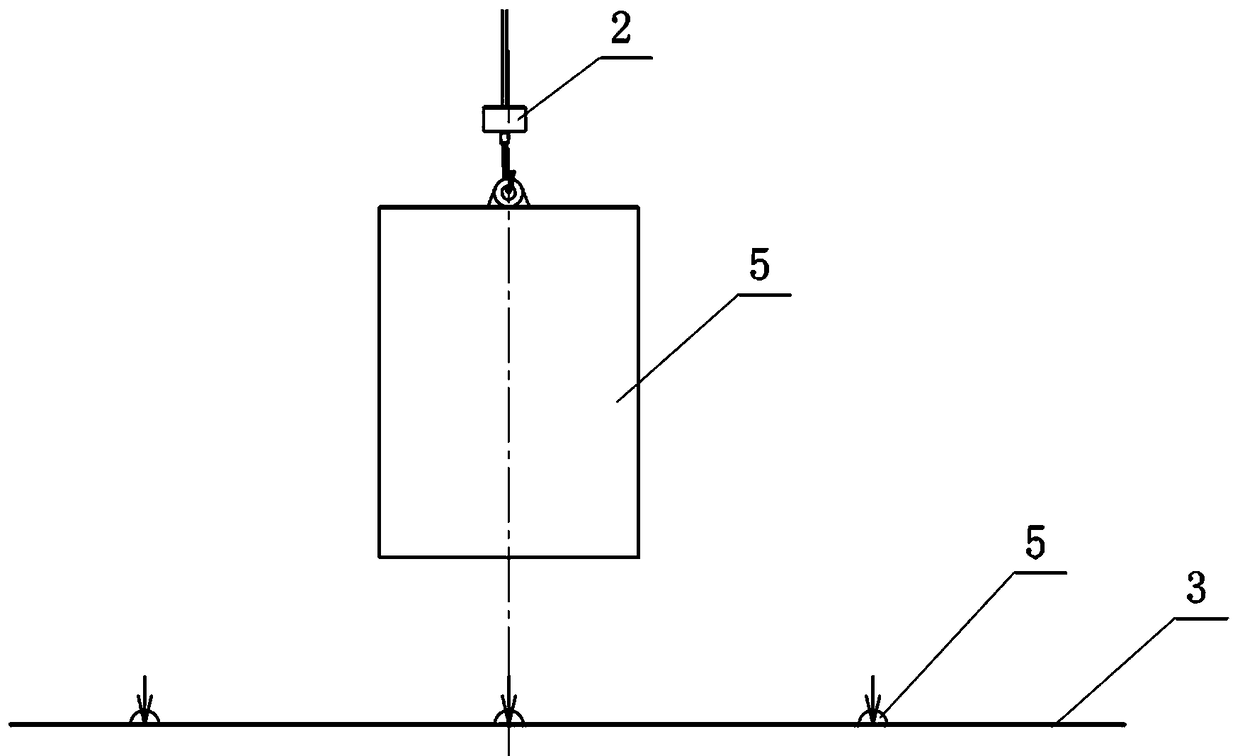

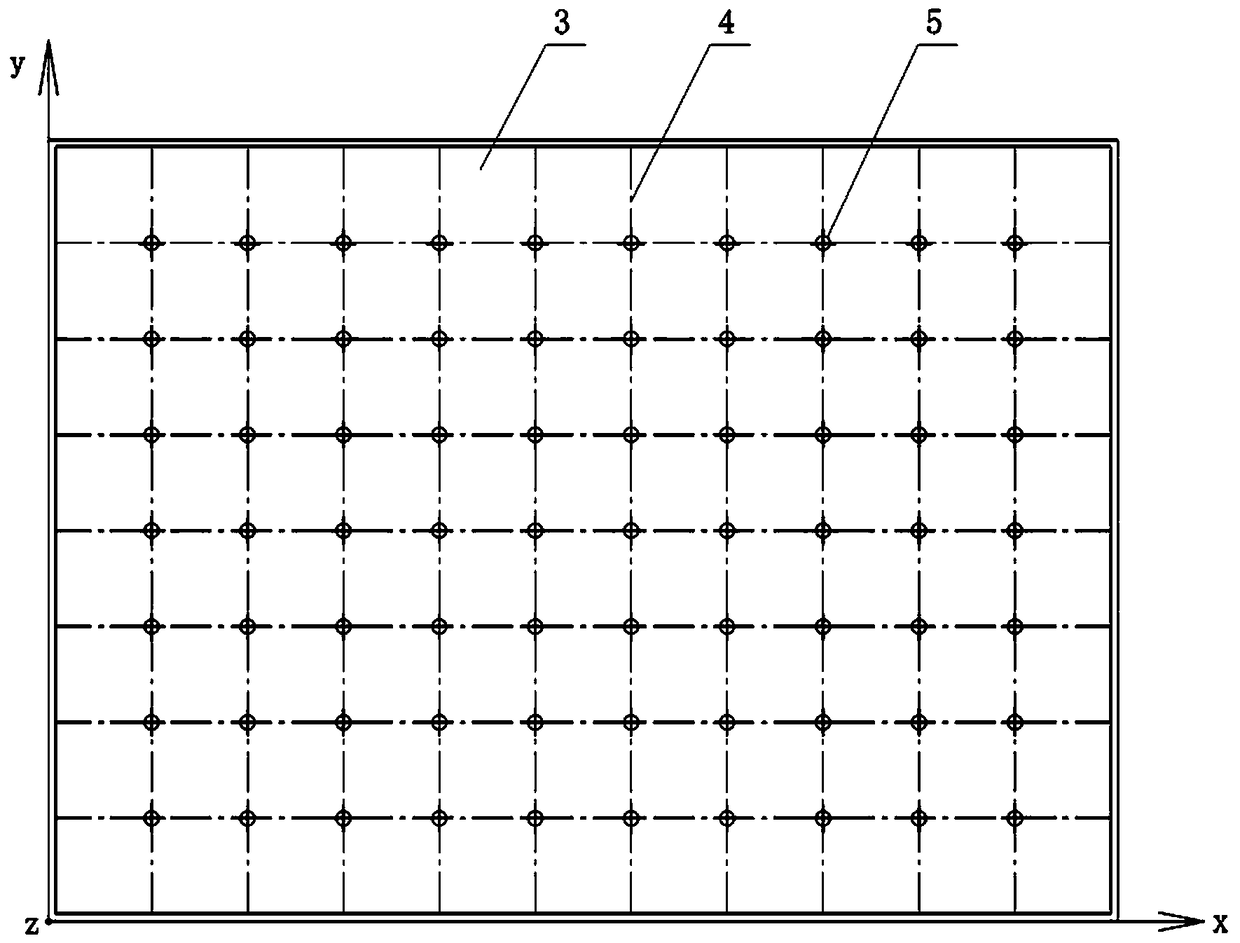

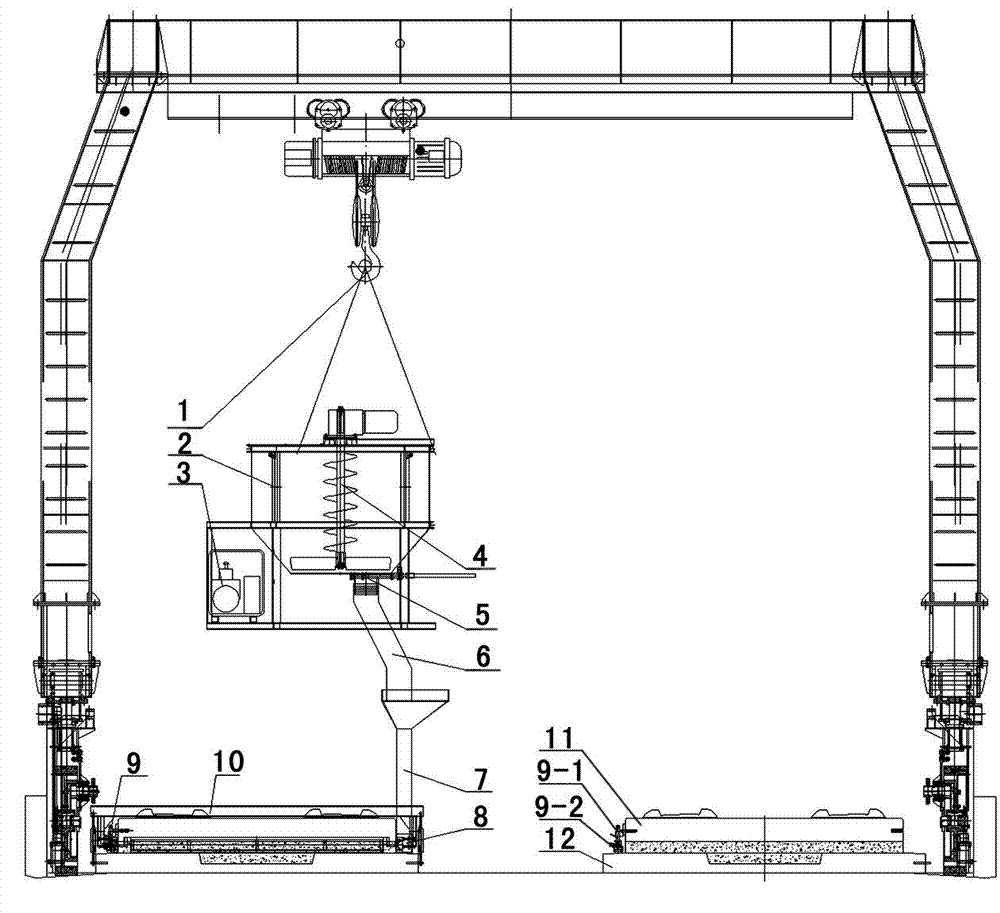

Portal crane and GPS positioning technology combined concrete pouring method

PendingCN108487641AWith automatic positioning functionSave human effortBuilding material handlingControl roomPositioning technology

The invention discloses a portal crane and GPS positioning technology combined concrete pouring method. Based on a portal crane and a main control machine, a concrete pouring area is planed through asurveying and mapping system according to the area and elevation of a concrete pre-pouring area to form a pouring area net, and meanwhile a pouring line plan is calculated; the pouring coordinate of each grid of the pouring area net is set to be A (X, Y and Z); a GPS module is mounted on an automatic door bin located at the portal crane hanger end; the position coordinate A1 (X1, Y1 and Z1) of theautomatic door bin is obtained in real time; and a control room host displays the operation direction of the position coordinate A1 (X1, Y1 and Z1) of the automatic door bin and the distance betweenthe position coordinate A1 (X1, Y1 and Z1) of the automatic door bin and a next pouring area target. The automatic positioning function is achieved, thus a large amount of manpower can be saved, the cost is reduced, moreover, the moving precision can be improved, the pouring efficiency is remarkably improved, safety and reliability are achieved, the construction effect is very good, and the portalcrane and GPS positioning technology combined concrete pouring method is suitable for being applied and popularized.

Owner:HUANENG CLEAN ENERGY RES INST +3

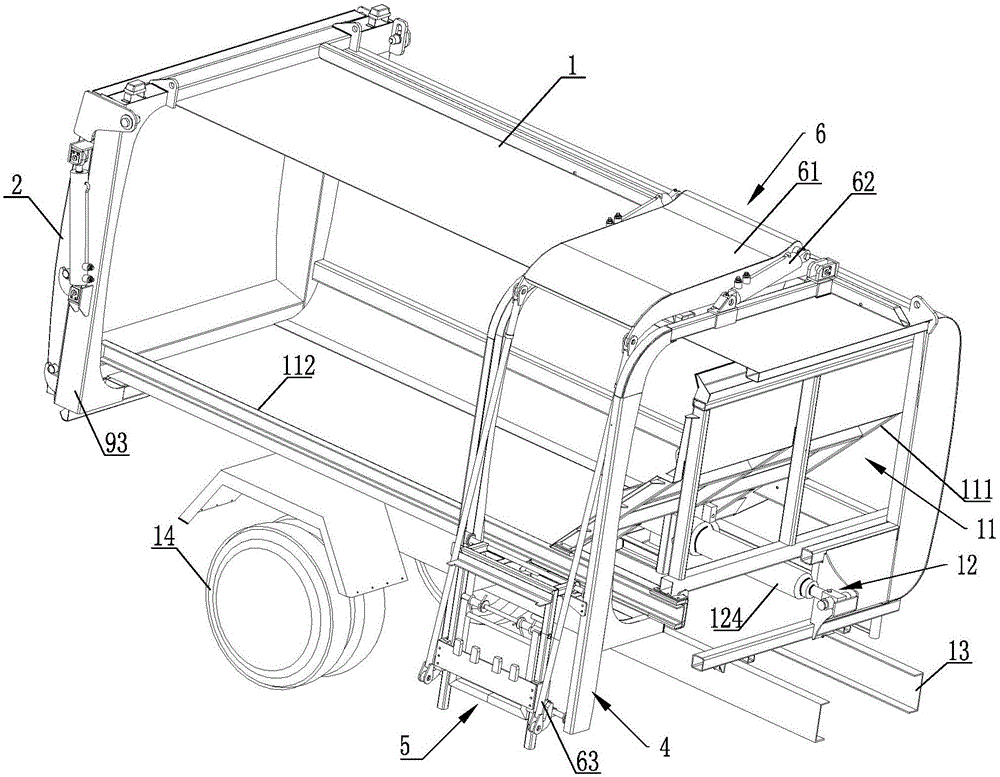

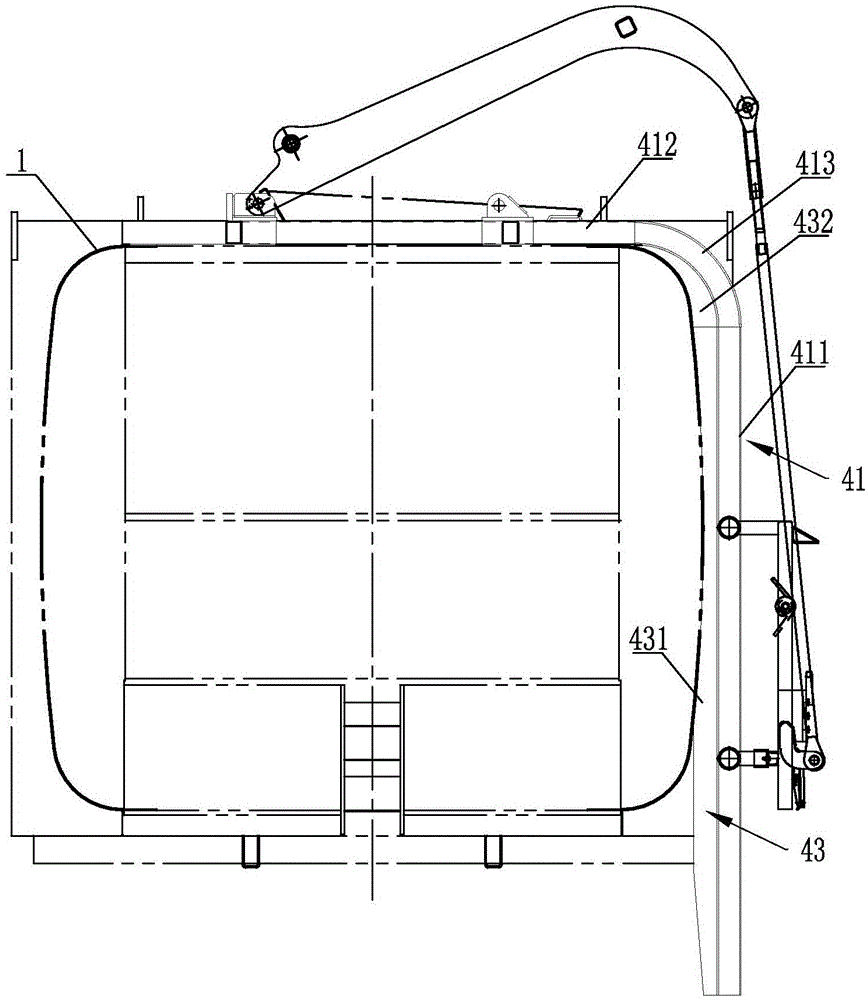

Push plate type side loading and unloading sanitation vehicle

The invention discloses a push plate type side loading and unloading sanitation vehicle. The push plate type side loading and unloading sanitation vehicle comprises a tank with a rear-end tank opening, wherein a garbage dumping opening is formed in the top of the tank; a tank rear baffle plate is hinged to the rear-end tank opening of the tank; a garbage can elevating guiding device is fixedly arranged on the side wall of the tank; a can lifting device is arranged on the top of the tank and is connected to a can hanging device; the can hanging device is arranged in the garbage can elevating guiding device in a rolling manner; a garbage pushing device is arranged in the tank in a sliding manner and is connected to a pushing control device extending to the outer side of the tank; the pushing control device is arranged on a vehicle body of the sanitation vehicle; wheels are arranged at the bottom of the vehicle body; and the front end of the vehicle body is connected to a cab. The friction between the garbage can and the tank is avoided, the realization of protection of the garbage can and the tank is facilitated, the garbage pushing device and the pushing control device can also avoid secondary pollution and prevent a driver from getting off the vehicle to perform operation, and therefore, the push plate type side loading and unloading sanitation vehicle is labor-saving in use and convenient to operate.

Owner:WUZHENG

Low-cement refractory castable for pumping construction

InactiveCN113149675APumping achievedSolve the problem of vertical conveyingFiberMechanical engineering

The invention relates to a low-cement refractory castable for pumping construction, which comprises a dry material and an additive, the dry material comprises the following components in parts by weight: 55-68 parts of refractory aggregate, 12-27 parts of refractory powder, 3-10 parts of superfine powder and 1-9 parts of binding agent, the additive comprises fibers and a composite additive, the weight of the fibers is 0.01-3% of the weight of the dry material, the weight of the composite additive is 0.1-0.5% of the weight of the dry material, and the weight of the water is 5-12% of the weight of the dry material. The invention provides the low-cement refractory castable with the volume density of 2.2-2.8 g / cm3, the castable makes up the defect that the traditional low-cement refractory castable cannot be pumped, realizes the pumping of the low-cement refractory castable, is convenient for on-site pouring construction, solves the difficult problem of vertical conveying of the refractory castable of a high and large furnace body, reduces the workload of workers, and improves the pouring efficiency; and the stirred material reaches the working surface within a short time, so that the working surface can be prevented from being added with water again, and the performance of the refractory lining is effectively ensured.

Owner:HENAN YU & NEW ENERGY SAVING BUILDING MATERIALSCO

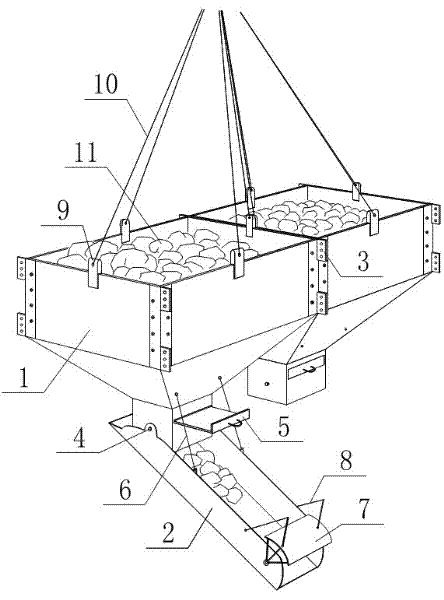

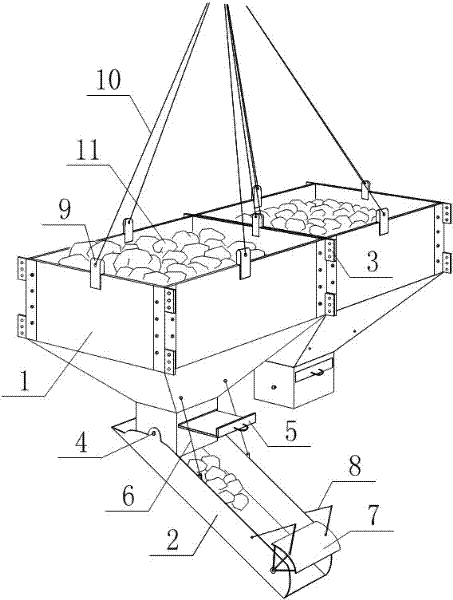

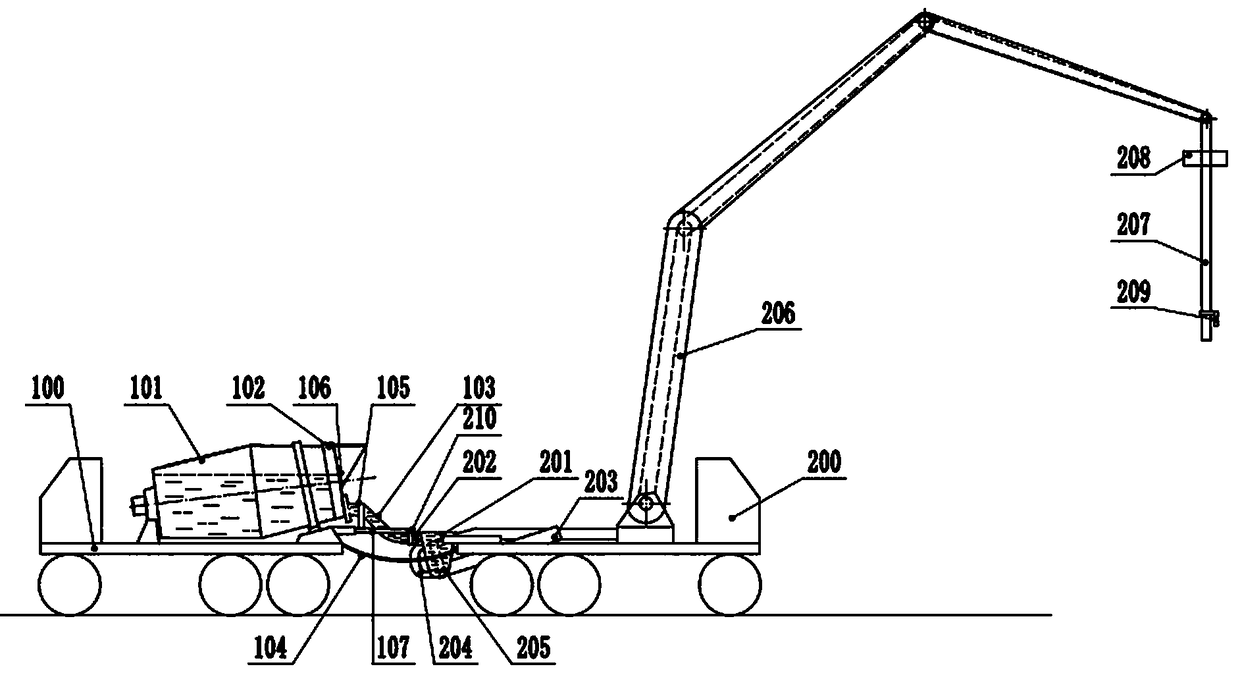

Construction device capable of blanking mixed materials of block-shaped waste concrete

ActiveCN102383604AImprove pouring efficiencySave shipping timeBuilding material handlingLifting capacityMixed materials

The invention discloses a construction device capable of blanking mixed materials of block-shaped waste concrete, which comprises a row type hopper, a chute and ear plates. Hoppers are connected through the ear plates to form the row type hopper, lugs are arranged at the upper portion of the row type hopper and connected with steel wire ropes of a lifting device, and a drawer type baffle is arranged at the lower portion of the row type hopper. The chute is connected with the bottom of the row type hopper in hanging mode through round hinges, the inclined angle of the chute can be changed through stretching out and drawing back of adjusting ropes, and the lower end of the chute is provided with a lifting type baffle to control the blanking. The block-shaped waste concrete or mixed materials formed by cast-in-place concrete and the block-shaped waste concrete are filled in the row type hopper, the number of the hoppers can be determined accordingly to casting requirements and lifting capacity, and casting materials are accurately conveyed to casting operation places through the construction device. The construction device capable of blanking the mixed materials of the block-shaped waste concrete is simple in structure, flexible in use, convenient in installation and dismounting, safe in operation, low in cost and capable of playing a positive role on operation of the project forpromoting the block-shaped waste concrete in large area.

Owner:SOUTH CHINA UNIV OF TECH

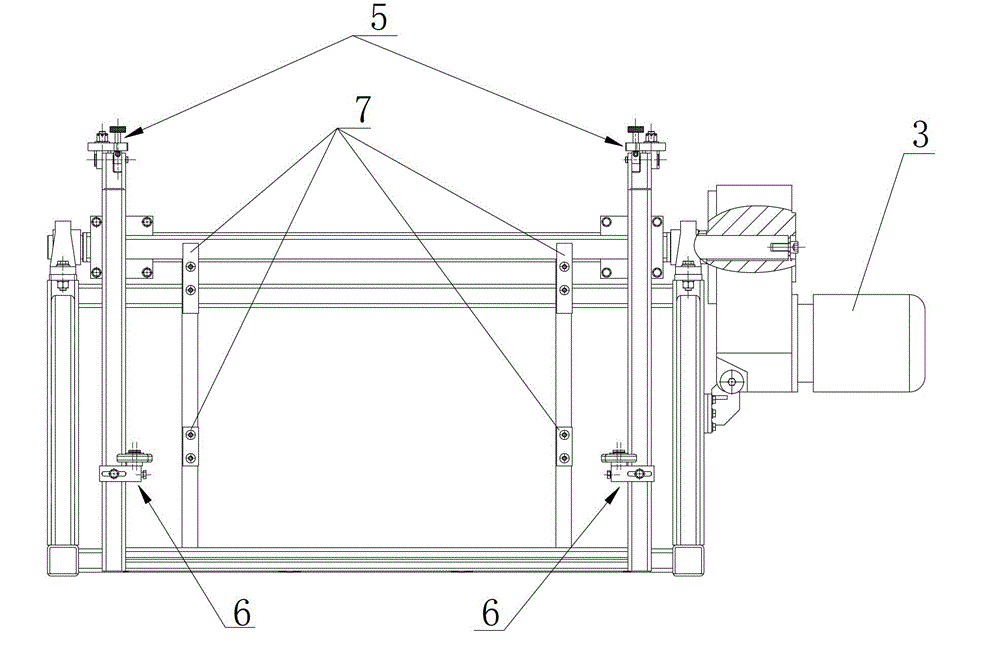

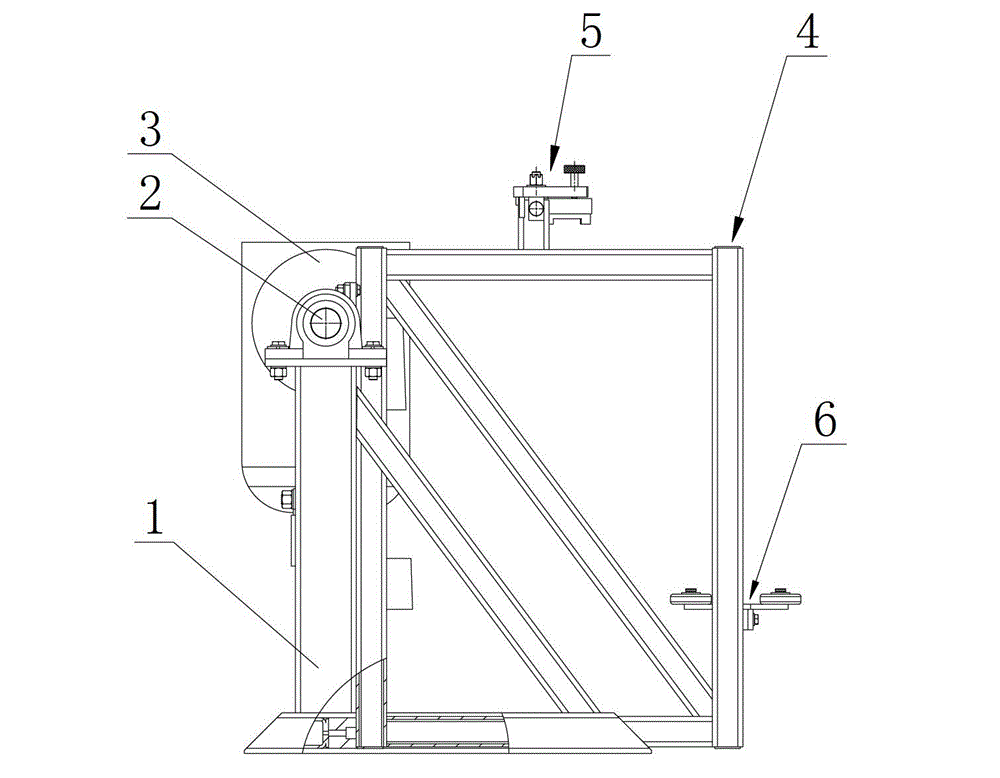

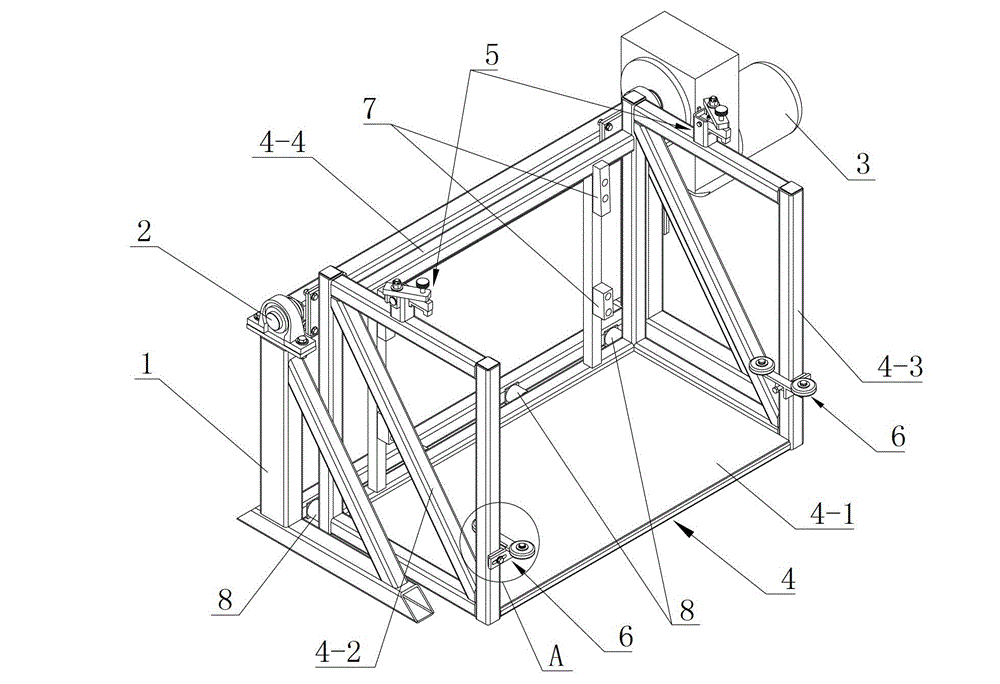

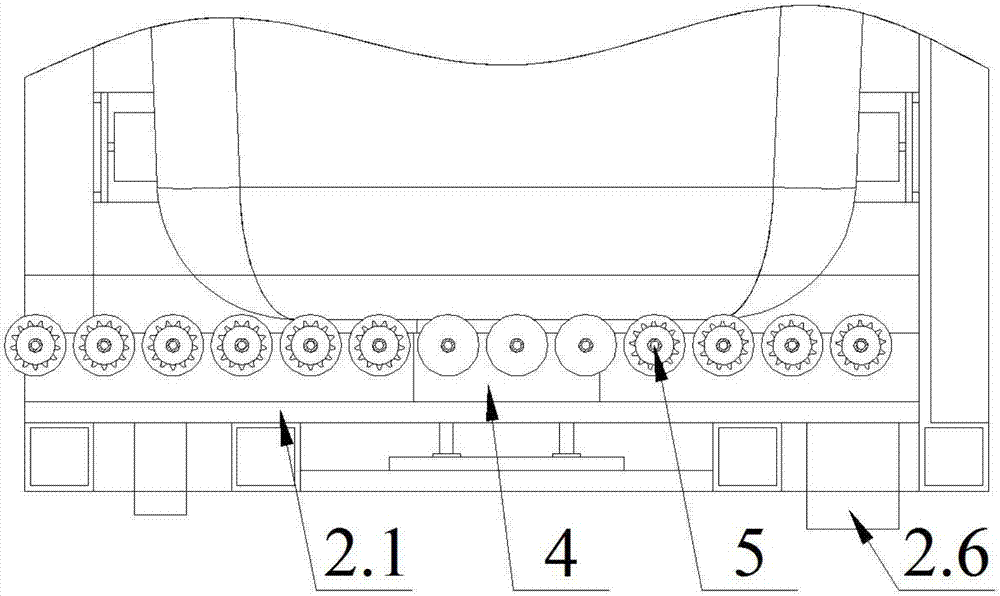

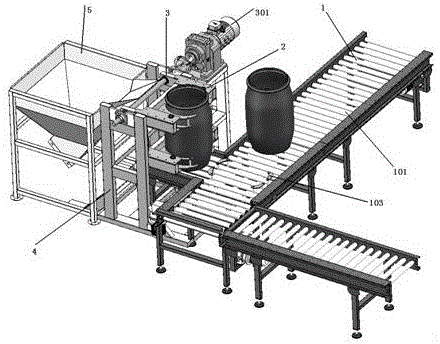

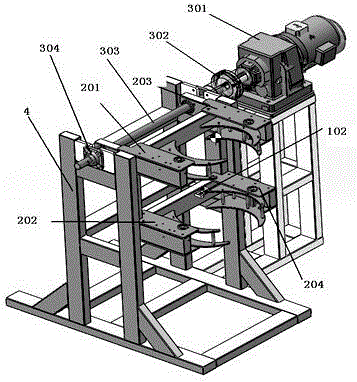

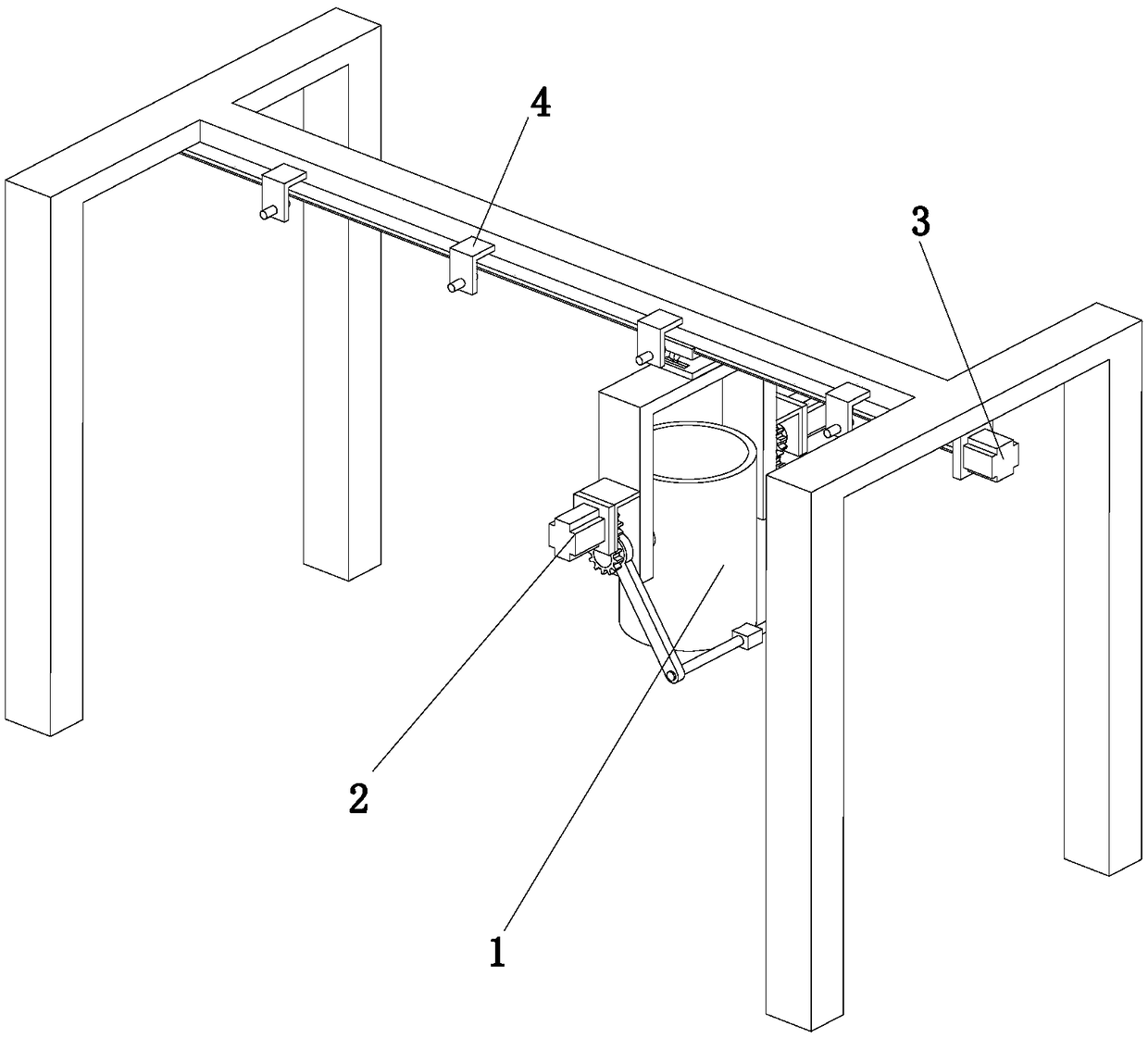

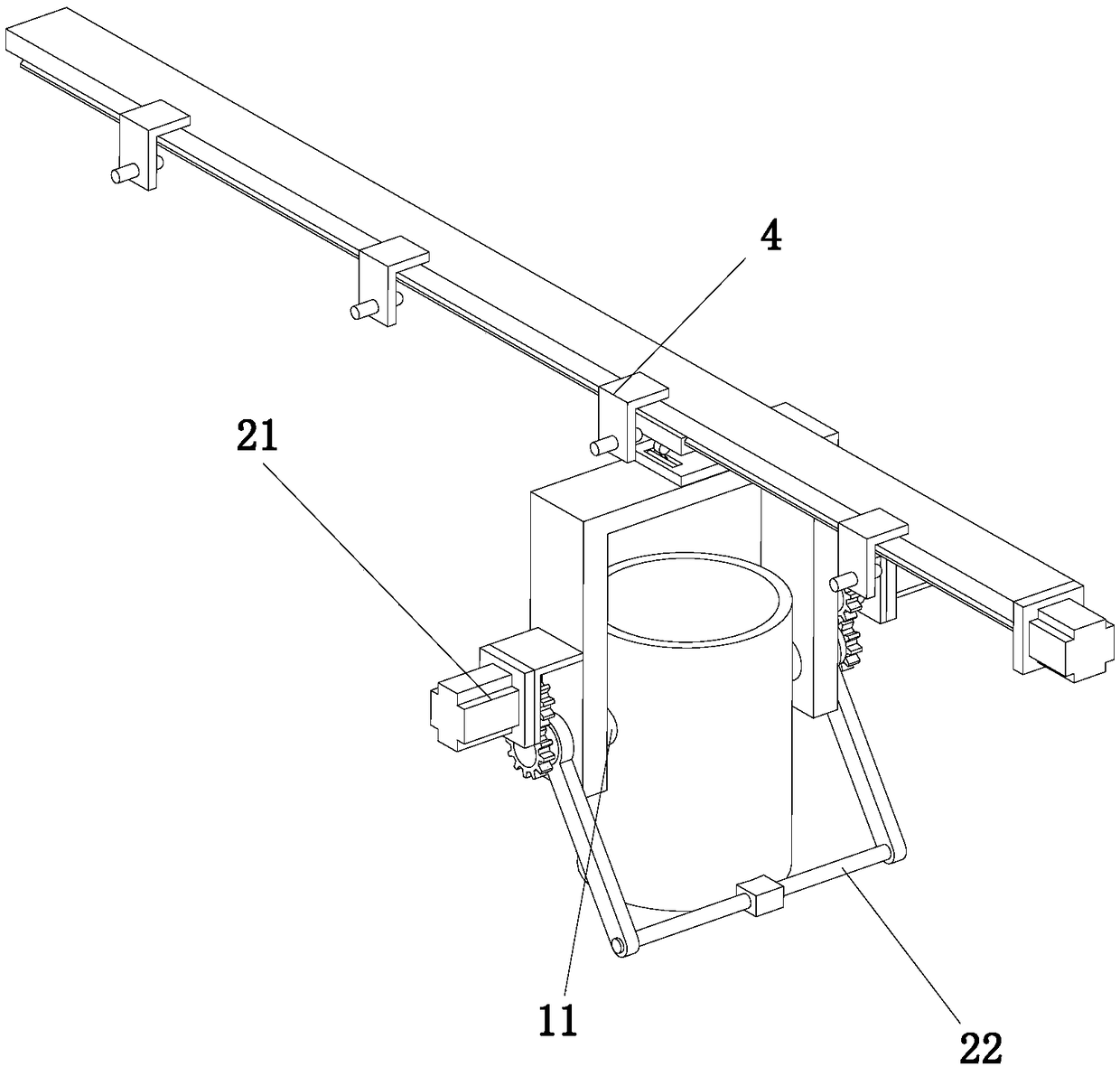

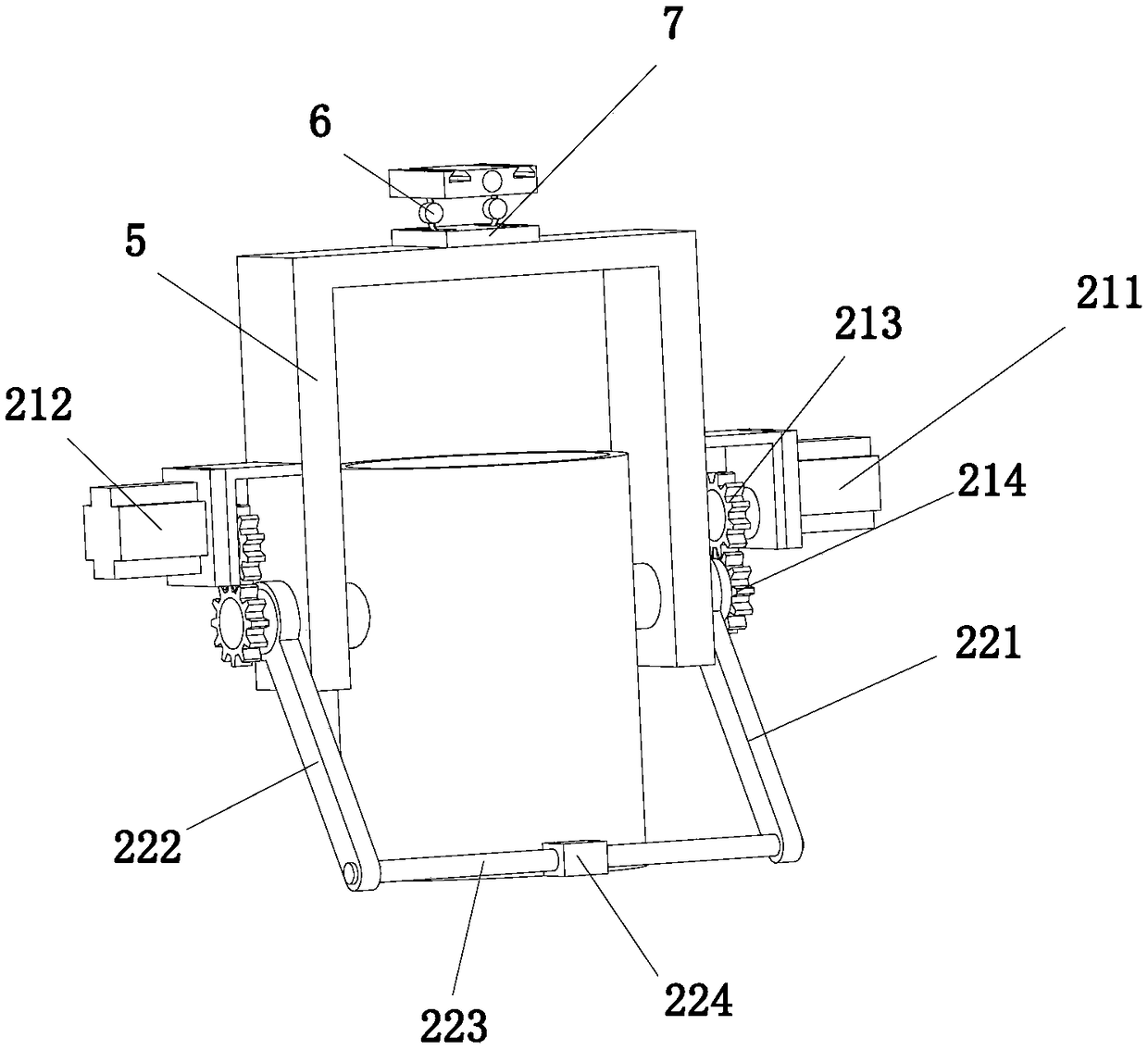

Full-automatic bucket turnover machine

ActiveCN106185358AImprove pouring efficiencySimple and fast operationBottle emptyingLoading/unloadingEngineeringElectric control

A full-automatic bucket turnover machine comprises an automatic bucket feeding device, a clamping and loosening device, a rotating device, a supporting device, a bearing device and an electric control device. The automatic bucket feeding device is connected with the clamping and loosening device. The clamping and loosening device is connected with the rotating device. The clamping and loosening device and the rotating device are mounted on the supporting device. The supporting device is connected with the bearing device. When a bucket containing materials is placed on rollers of the automatic bucket feeding device, the bucket is driven by the rollers to reach clamping jaw portions of the clamping and loosening device; after the bucket is clamped by clamping jaws, the clamping and loosening device clamping the bucket is driven by the rotating device to rotate; the clamping and loosening device rotates by a certain angle to dump the materials into a hopper of the bearing device; and after dumping is finished, the clamping and loosening device rotates reversely, the clamping jaws loosen the bucket, the empty bucket falls on a conveying roller, and the roller conveys the empty bucket to an empty bucket storage position. According to the full-automatic bucket turnover machine, the process can be completely and automatically completed in the discharging process, the material dumping efficiency is improved, and labor force output is saved; and operation is stable, and safety and high efficiency are achieved.

Owner:潍坊星美生物科技股份有限公司

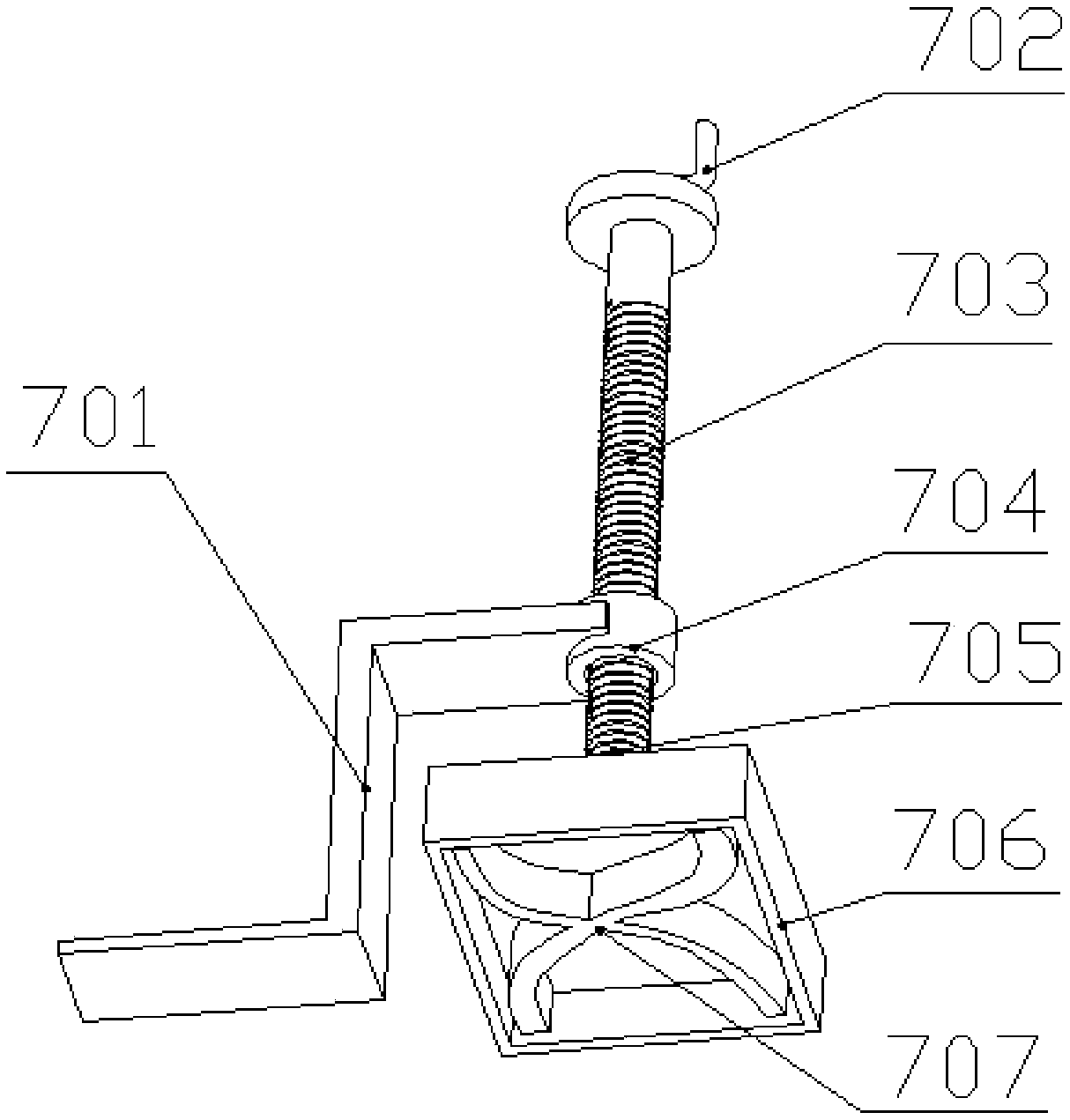

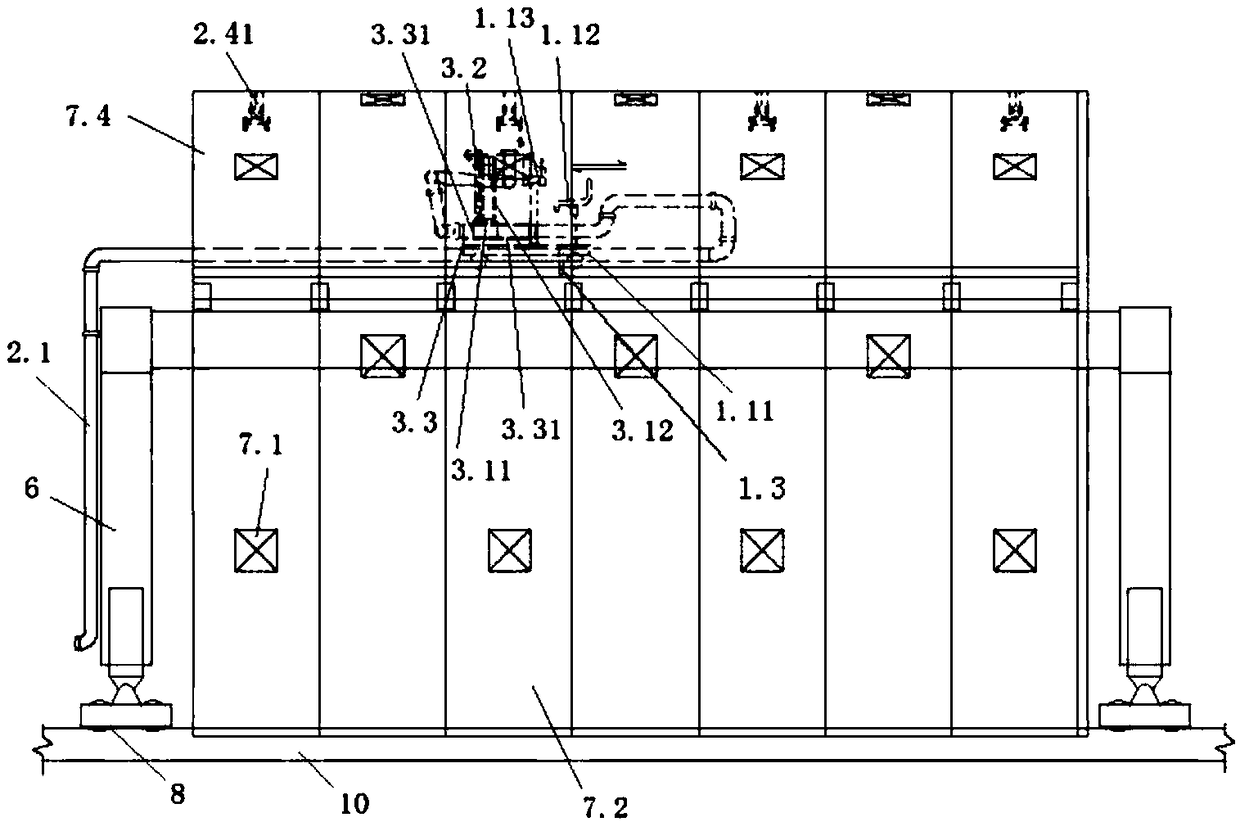

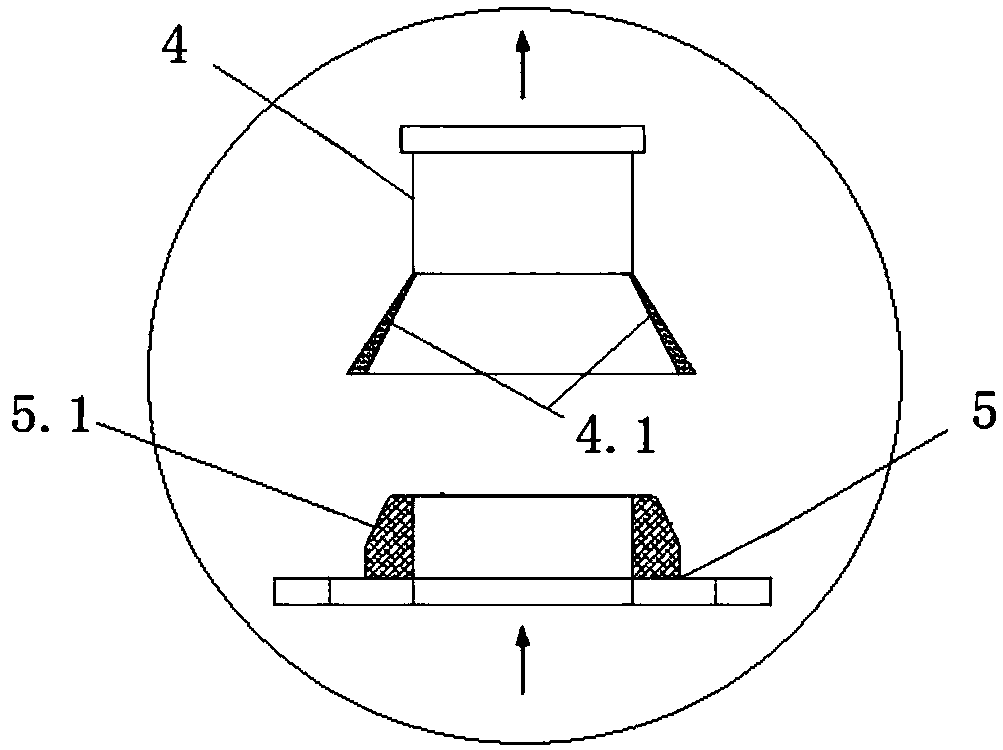

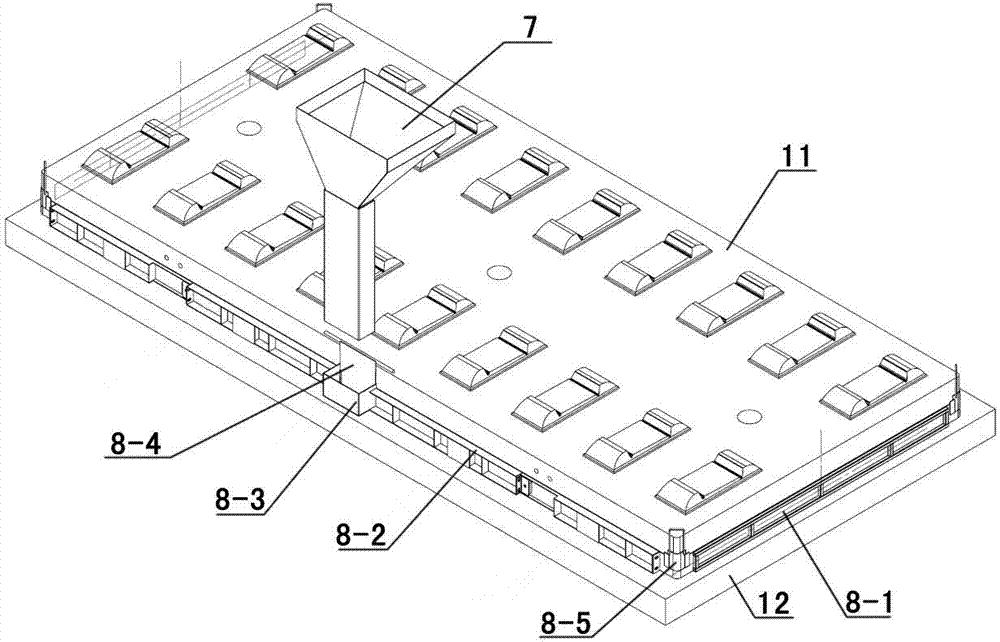

CRTS III type slab ballastless track self-compacting concrete casting tooling and method

The invention provides a CRTS III type slab ballastless track self-compacting concrete casting tooling and method. The casting tooling comprises a base slab, a track slab, a transferring hopper, a casting funnel, a slurry blocking template, a three-dimensional fine regulator, a track slab pressing device, a track slab lateral sliding preventing device and a slurry blocking template pressing device. The middle casting mode is changed into the lateral surface casting, and the problems of casting efficiency and air exhaust in the CRTS III type slab ballastless track construction are solved. The track slab lateral sliding preventing device, the track slab pressing device and the slurry blocking template pressing device effectively solve the problems of upward floating, lateral sliding and slurry leakage of the track slab in the casting process, so the fine regulation and the casting construction of the CRTS III type slab ballastless track are more convenient and fast, and the casting quality is better. The construction process has the advantages that in the use process, the weight is light, the rigidity is high, the efficiency is high, the operation is simple and convenient, the work intensity is low, and the construction process can adapt to the construction of road segments such as bridges, tunnels and roadbeds.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

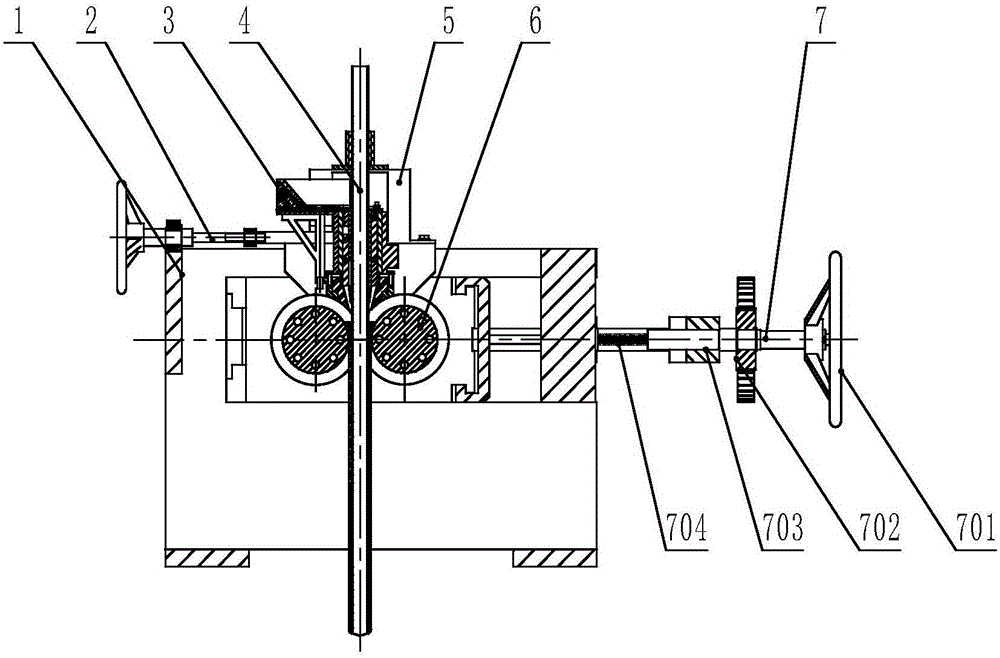

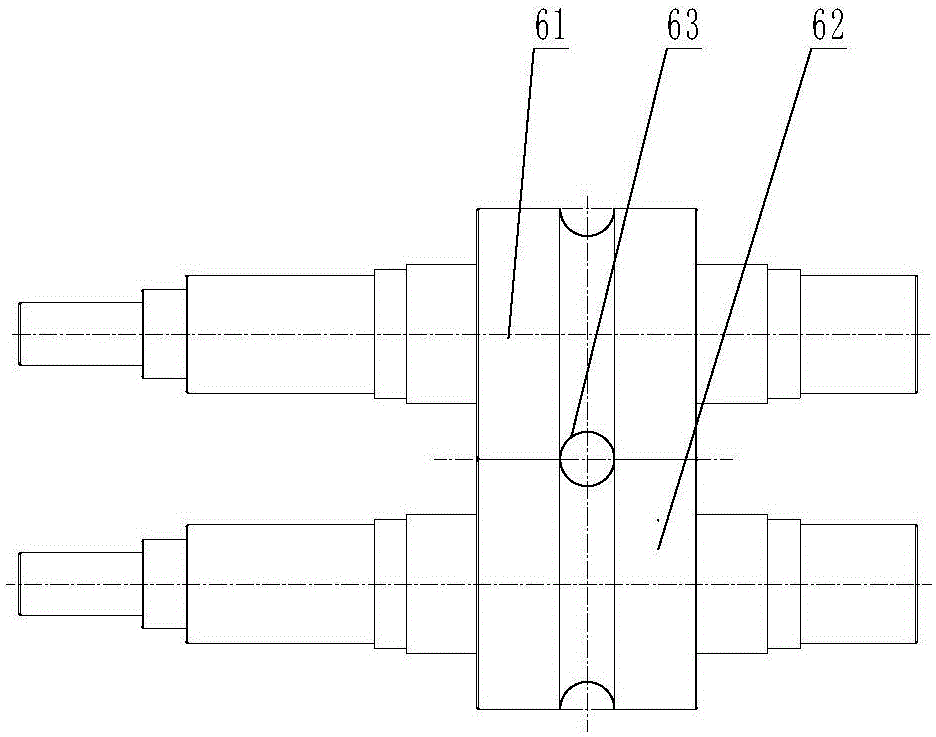

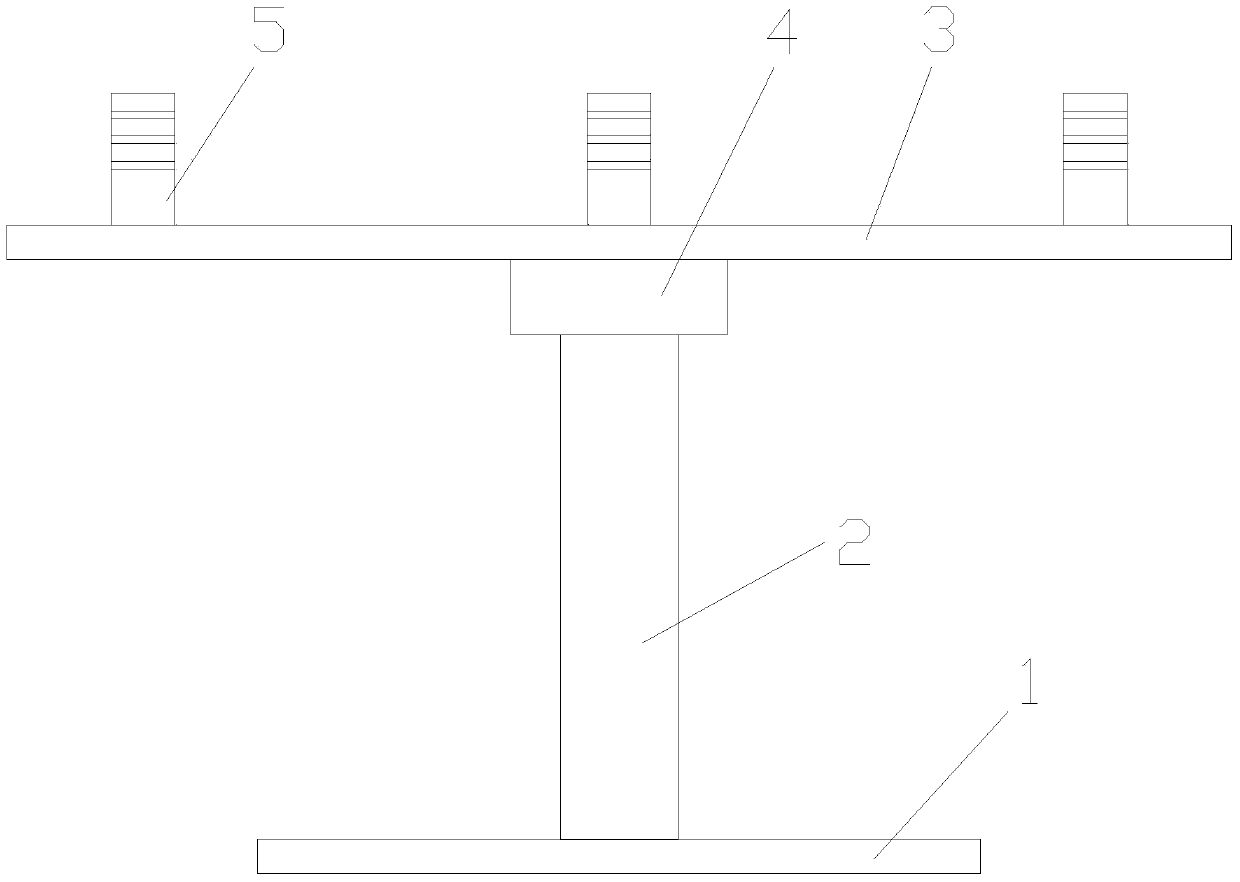

Automatic movement type ladle pouring device

ActiveCN109332674AImprove consistencyImprove pouring efficiencyMelt-holding vesselsDrive shaftFixed frame

The invention discloses an automatic movement type ladle pouring device comprising a support, a base, an installation plate, a foundation seat, a fixing frame, a ladle, a transmission mechanism, a driving piece, a transverse transmission shaft, a third vertical transmission shaft, an intermittent transmission assembly, a vertical movement sliding block, a front-back movement mechanism, a third longitudinal transmission shaft and a front-back movement sliding block. The installation plate is installed on the foundation seat in a sliding manner and connected with the foundation seat in a slidingmanner. The base is installed on the installation plate. The support is vertically installed on the base. The transverse transmission shaft drives the fixing frame to rotate relative to the support through the transmission mechanism. The vertical movement sliding block drives the support and the base to move up and down relative to the installation plate. The front-back movement mechanism drivesthe installation plate to move front and back relative to the foundation seat. According to the automatic movement type ladle pouring device, in the ladle pouring process, adjustment of the height andthe front-back position of the ladle is achieved, time and effort are saved, and the pouring efficiency is improved.

Owner:广德亚太汽车智能制动系统有限公司

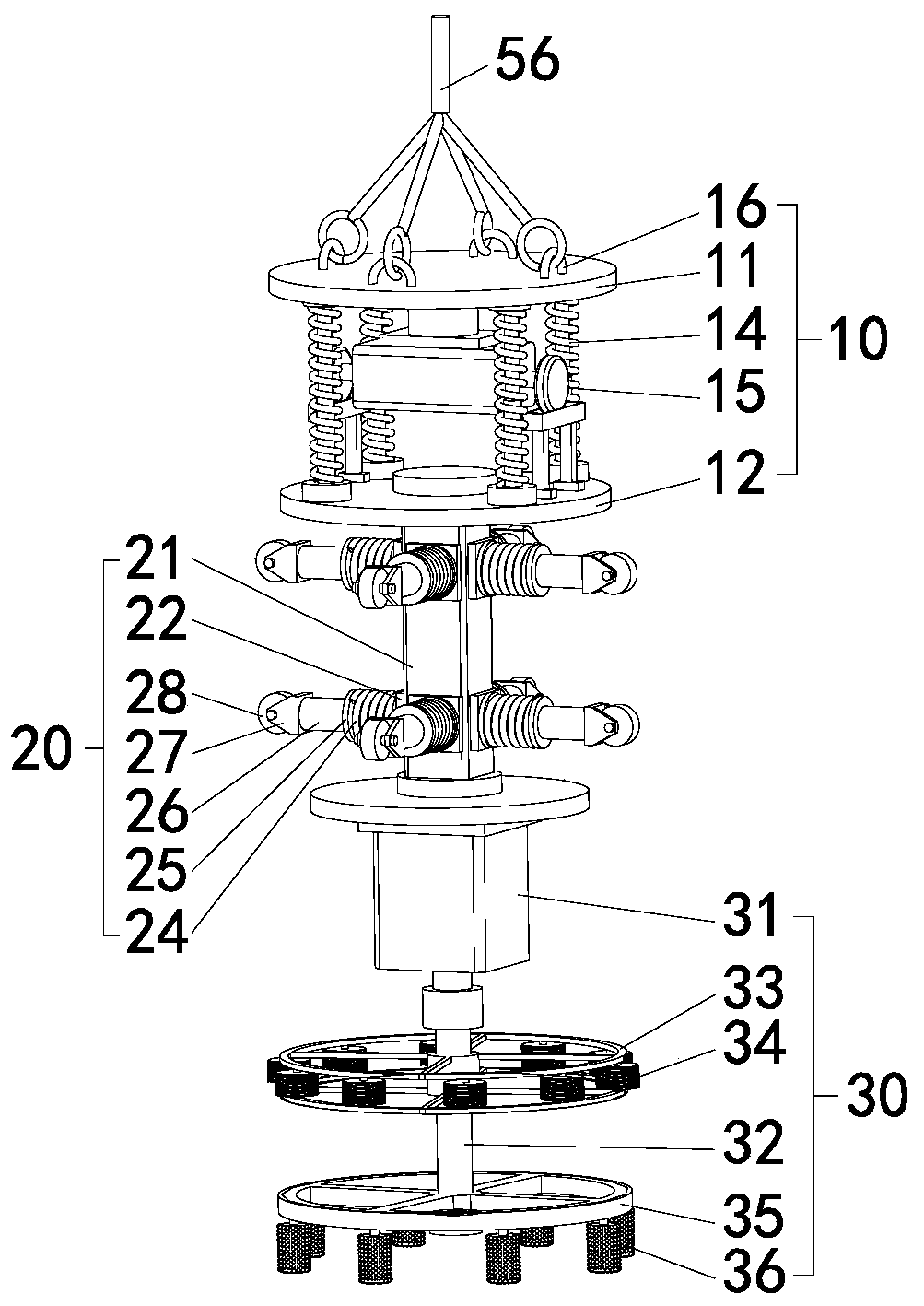

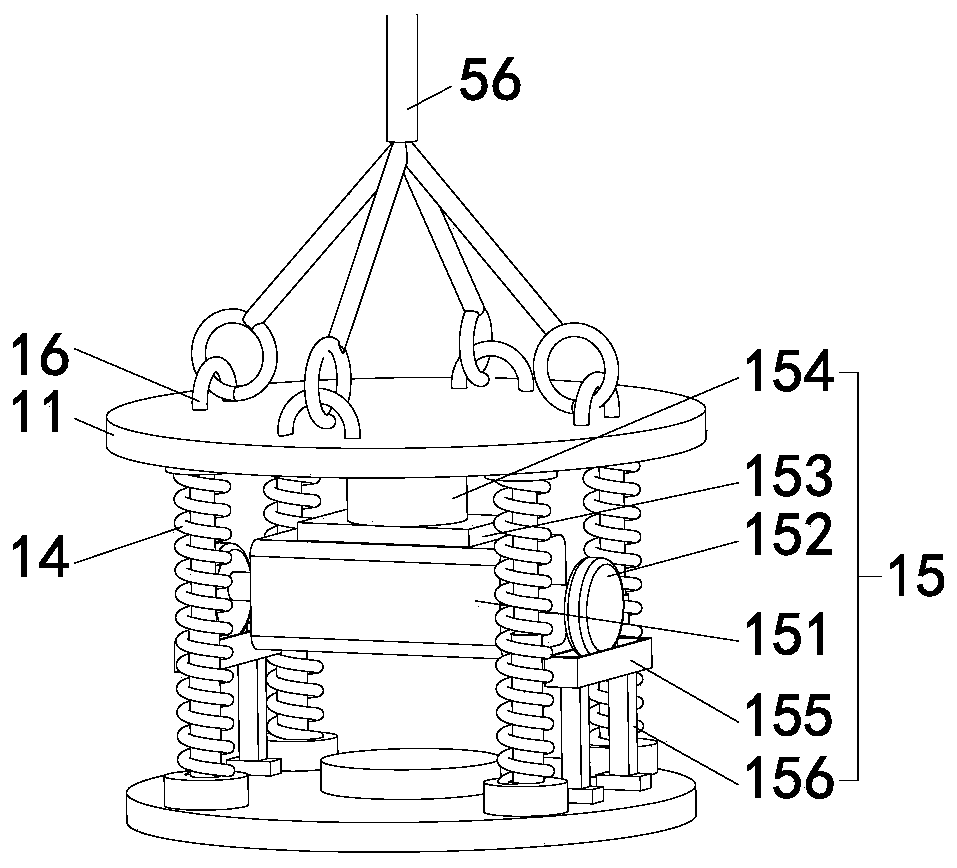

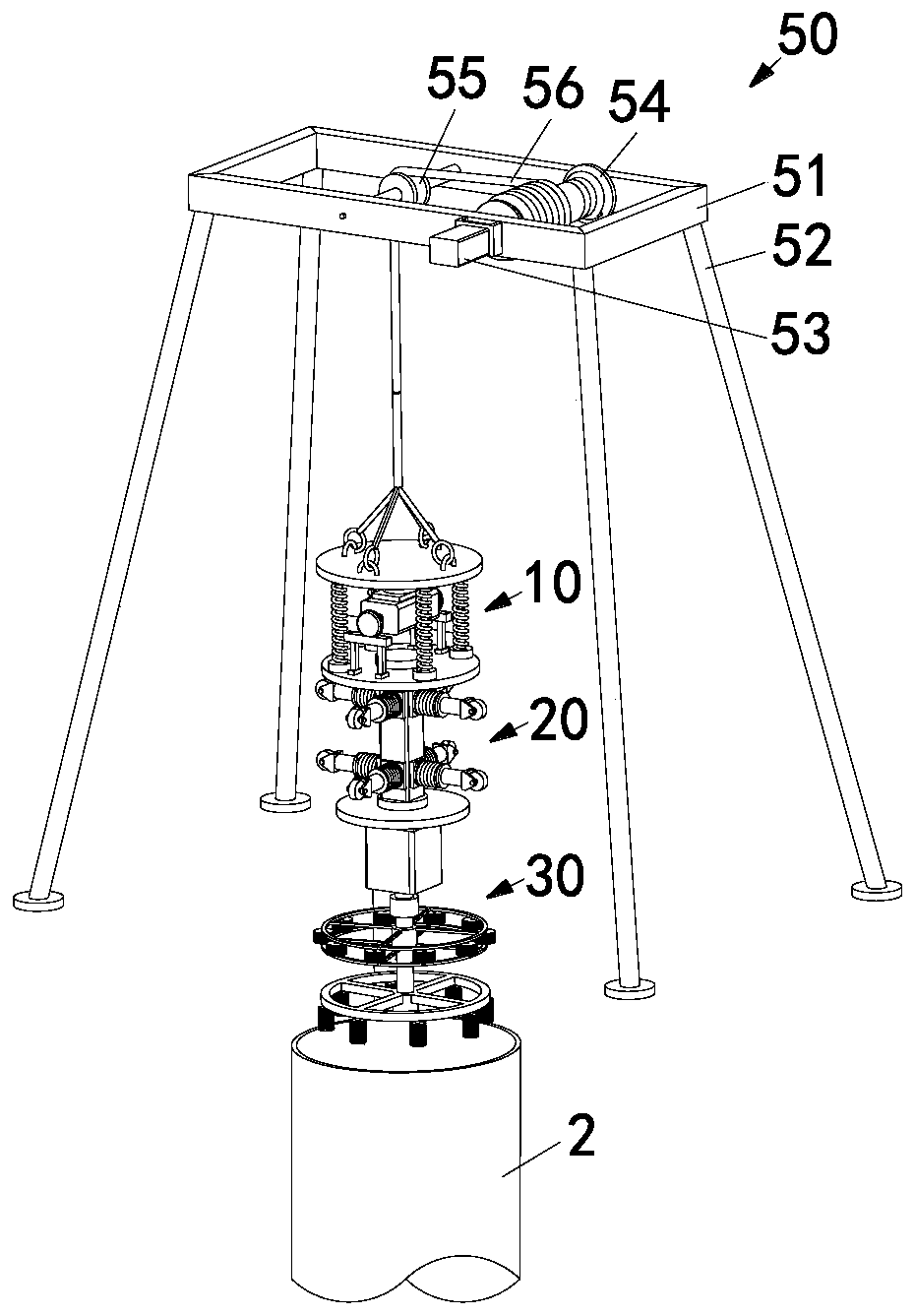

Automatic molten iron casting equipment for sand mould casting

ActiveCN108907164AAvoid wastingReduce security risksMolten metal supplying equipmentsProximity sensorCasting

The invention belongs to the technical field of production casting, and particularly relates to automatic molten iron casting equipment for sand mould casting. The automatic molten iron casting equipment for the sand mould casting comprises an accommodating barrel, a rotating device, a driving mechanism and a control device; the accommodating barrel is in transmission connection with the driving mechanism through a connecting frame; the rotating device comprises a connecting rod assembly and a rotating assembly; the driving mechanism comprises a driving electric cylinder; the control device comprises a controller, a sensor assembly and a weighing assembly; the sensor assembly comprises an angle sensor and a plurality of proximity sensors; the weighing assembly comprises a gravity sensor and a connecting plate; and the connecting plate is fixedly mounted on the connecting frame. According to the automatic molten iron casting equipment for the sand mould casting, the pouring efficiency is improved; the potential safety hazard of working personnel is reduced; and the weight of molten iron which is poured into a mould can be controlled, so that excessive waste of the molten iron is avoided.

Owner:繁昌县长城铸造厂(普通合伙)

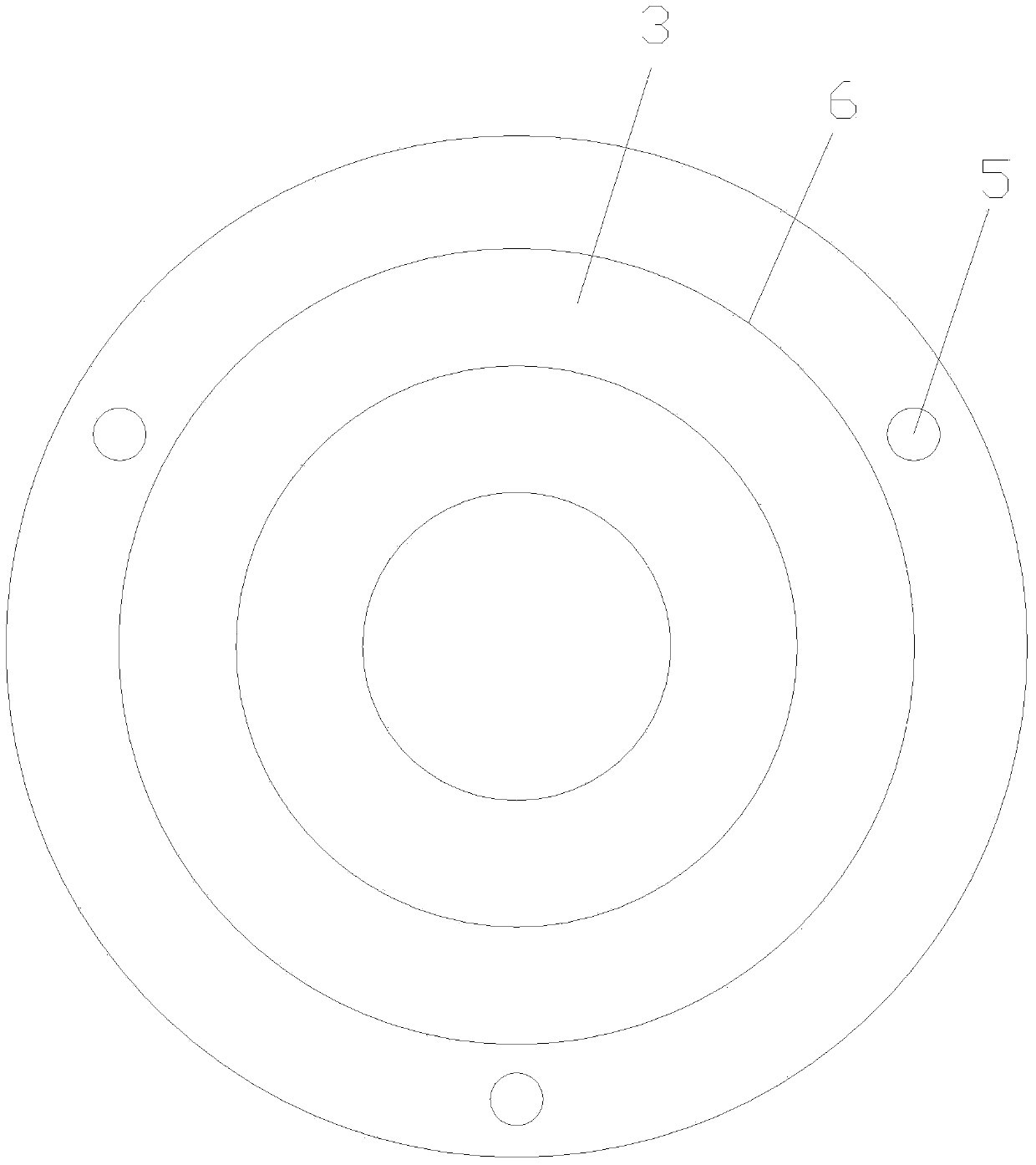

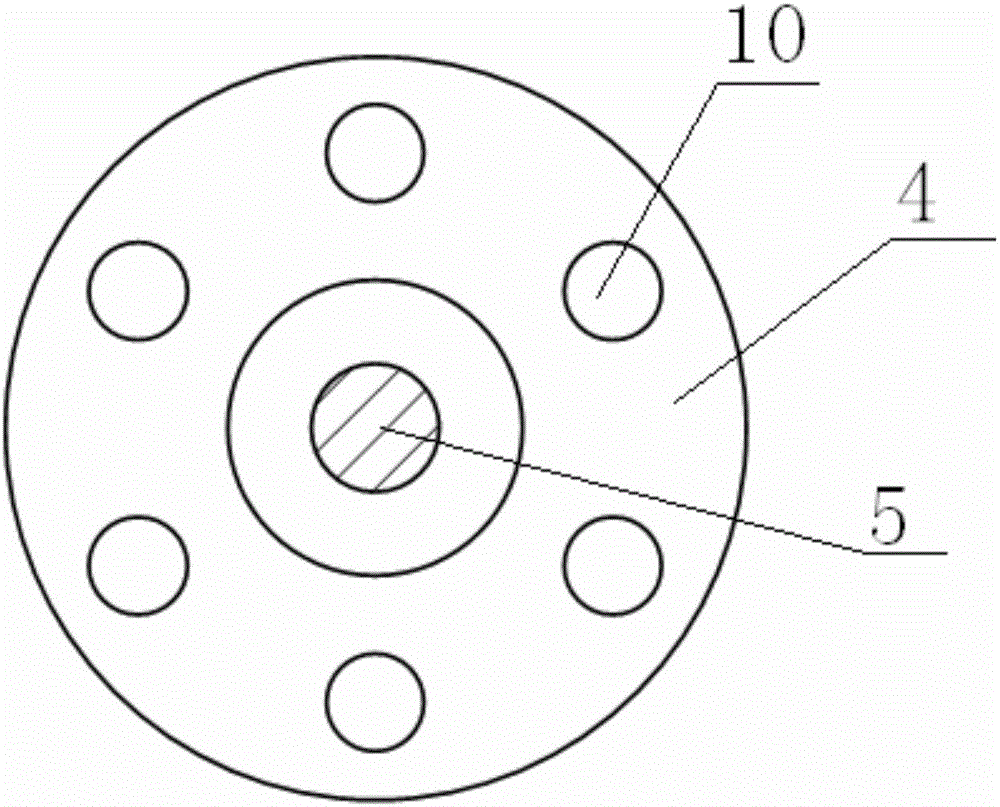

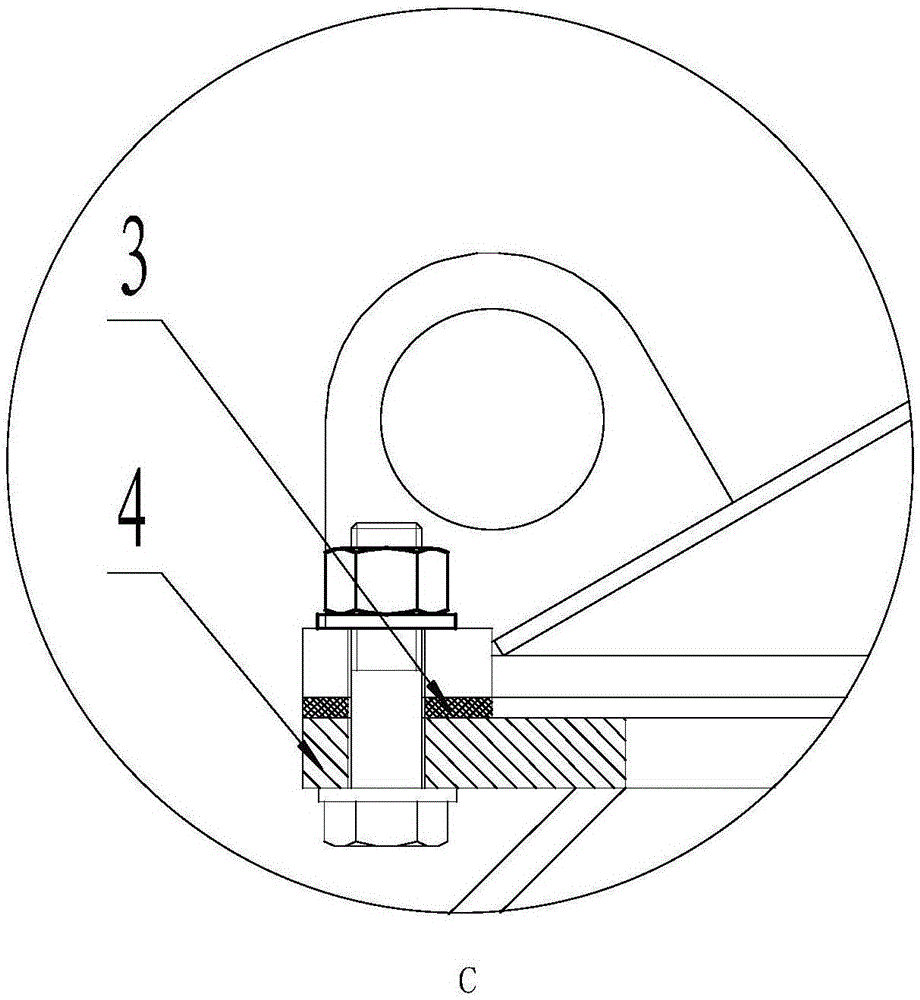

Rubber injection turntable

InactiveCN103464346APouring evenlySimple structureLiquid surface applicatorsCoatingsControl theoryMechanical engineering

A rubber injection turntable relates to the field of filter production equipment and comprises a round base plate and a round turntable, wherein the base plate and the turntable are connected through a vertically arranged support shaft, the upper end of the support shaft is connected with the turntable through a bearing, the lower end of the support shaft is fixedly connected with the base plate, and three cylindrical limit blocks are arranged at the upper end of the turntable. The rubber injection turntable is simple in structure, low in manufacturing cost and simple and convenient to use, a filter element end cover is limited through a movable magnetic block, the rubber injection turntable is applicable to different specifications of the filter element end covers, a scale mark is arranged on the turntable, so that the position of the limit block is arranged according to the size of the filter element end cover, the rubber can be uniformly poured in the rotating process of the filter element end cover, and the pouring efficiency is improved.

Owner:BENGBU HONGWEI FILTER

Multi-shot feed divider for charging of tactic engine

InactiveCN106401794AIncrease productivityAvoid the problem of poor levelingRocket engine plantsCombustion chamberEngineering

The invention provides a multi-shot feed divider for charging of a tactic engine. The multi-shot feed divider comprises a feed dividing sprayer, pressing plates, a feed dividing cone, feed dividing pipes and six discharging pipes. The edge of the feed dividing sprayer is fixed to the upper surfaces of the pressing plates. The lower end of the feed dividing cone is put in the feed dividing sprayer and corresponds to center holes of the pressing plates. The six discharging pipes are evenly distributed on the lower surfaces of the pressing plates. The upper ends of the discharging pipes are fixedly connected with the feed dividing pipes, and the lower ends of the discharging pipes are fixedly connected with all single-shot pouring sprayers. When an engine combustion chamber is poured, propellant medicine slurry enters all the feed dividing pipes through the feed dividing sprayer via discharging sleeves and then enters an engine shell, and it is achieved that the propellant medicine slurry can be divided into charging processes of multi-shot engines at a time. Pouring efficiency is improved by six times. The problems that during single-shot multi-pouring operation, the pouring total time is long, and the leveling property of the medicine slurry becomes poorer are avoided, multiple times of cleaning are reduced, and the production efficiency of the combustion chamber is improved.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

Green and environment-friendly explosive simulant material and preparation method therefor

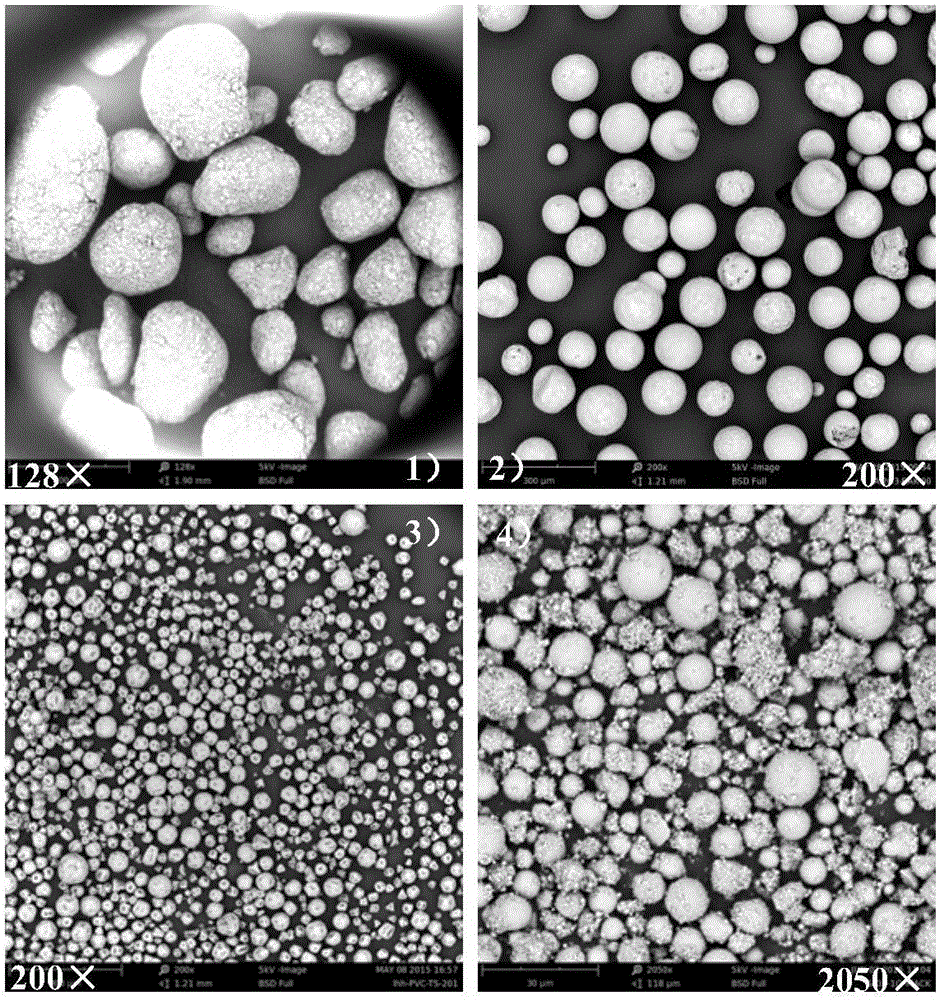

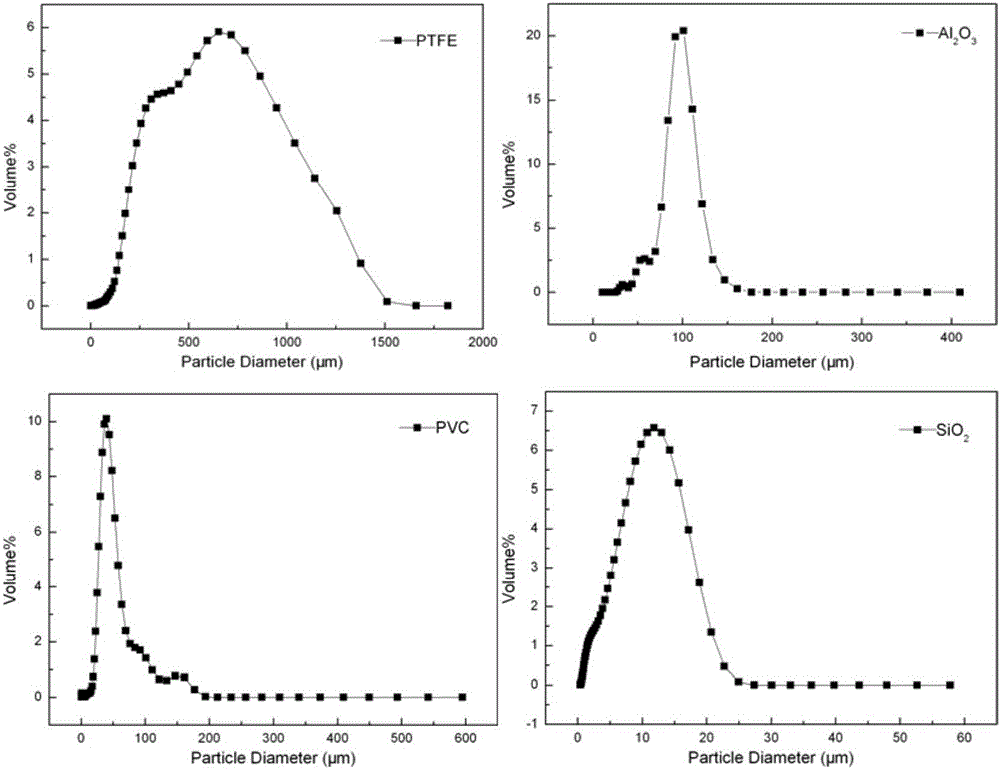

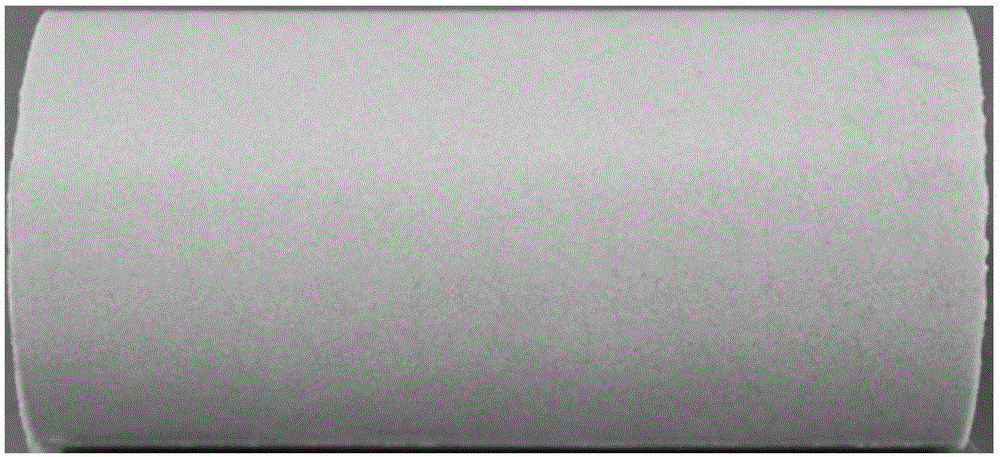

ActiveCN106083501AImprove pouring effectImprove pouring qualityExplosivesPolytetrafluoroethyleneMechanical properties of carbon nanotubes

The invention discloses a green and environment-friendly explosive simulant material. The green and environment-friendly explosive simulant material contains the following ingredients in parts by weight: 0-30 parts of polytetrafluoroethylene, 0-35 parts of aluminum oxide, 0-14 parts of polyvinyl chloride, 19-30 parts of silicon dioxide, 30-40 parts of binder, 0.4-0.8 part of curing agent, 0.01-0.1 part of colorant, 0.02-0.08 part of surfactant and 0.25-2 parts of diluent. The invention further discloses a preparation method for the green and environment-friendly explosive simulant material. According to the preparation method, through adding green and environment-friendly simulant materials into a binder system, the explosive simulant material prepared through curing is not only good in formability, good in machined dimensional stability and uniform in product interior filling, but also can be used for accurately simulating the density and mechanical properties of real explosives.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

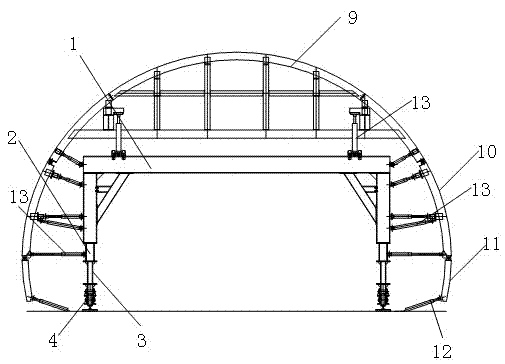

Steel form jumbo with main structure capable of passing conventional sections, and implementation method thereof

ActiveCN103615262ASave human effortReduce labor intensityUnderground chambersTunnel liningMaterials scienceSafety risk

The invention discloses a steel form jumbo with main structure capable of passing conventional sections, and an implementation method thereof and mainly solves the problems such as low production efficiency, high labor intensity and high safety risk caused by the fact that the existing steel form jumbo needs removal of a form mechanism and narrowing of gantry span before passing a conventional section. The steel form jumbo comprises a jumbo main structure and an operating travelling device. The jumbo main structure is composed of a gantry, a sill disposed on the lower portion of the gantry, and a form mechanism disposed outside the gantry. The operating travelling device is mounted below the sill through height adjusting posts which are demountable height adjustment posts. The gantry is further provided with a rotating transport mechanism, and the rotating transport mechanism connected with the gantry is used for lifting, rotating and transporting the jumbo. The steel form jumbo can pass the conventional section just by removing the height adjustment posts, the operating travelling device and a lower bottom form, reserving the main structure and using the main structure as a body. The application of the steel form jumbo ensures safety, convenience and high construction efficiency. Therefore, the steel form jumbo is suitable for popularization and application.

Owner:GUODIAN DADU RIVER SHAPING HYDROPOWER CONSTR

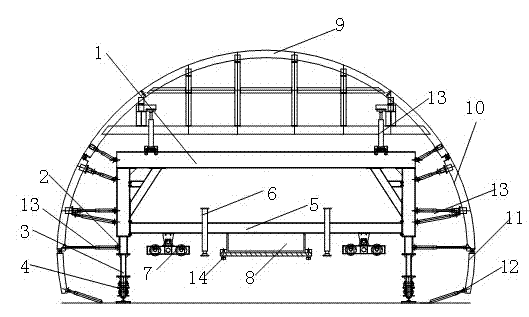

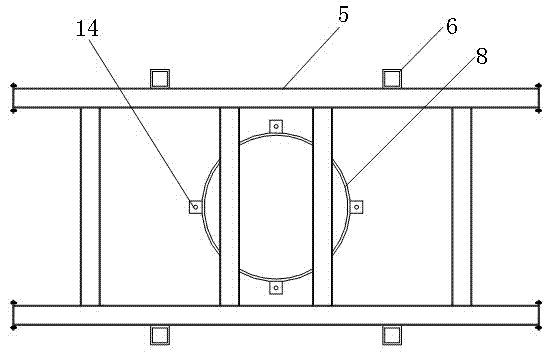

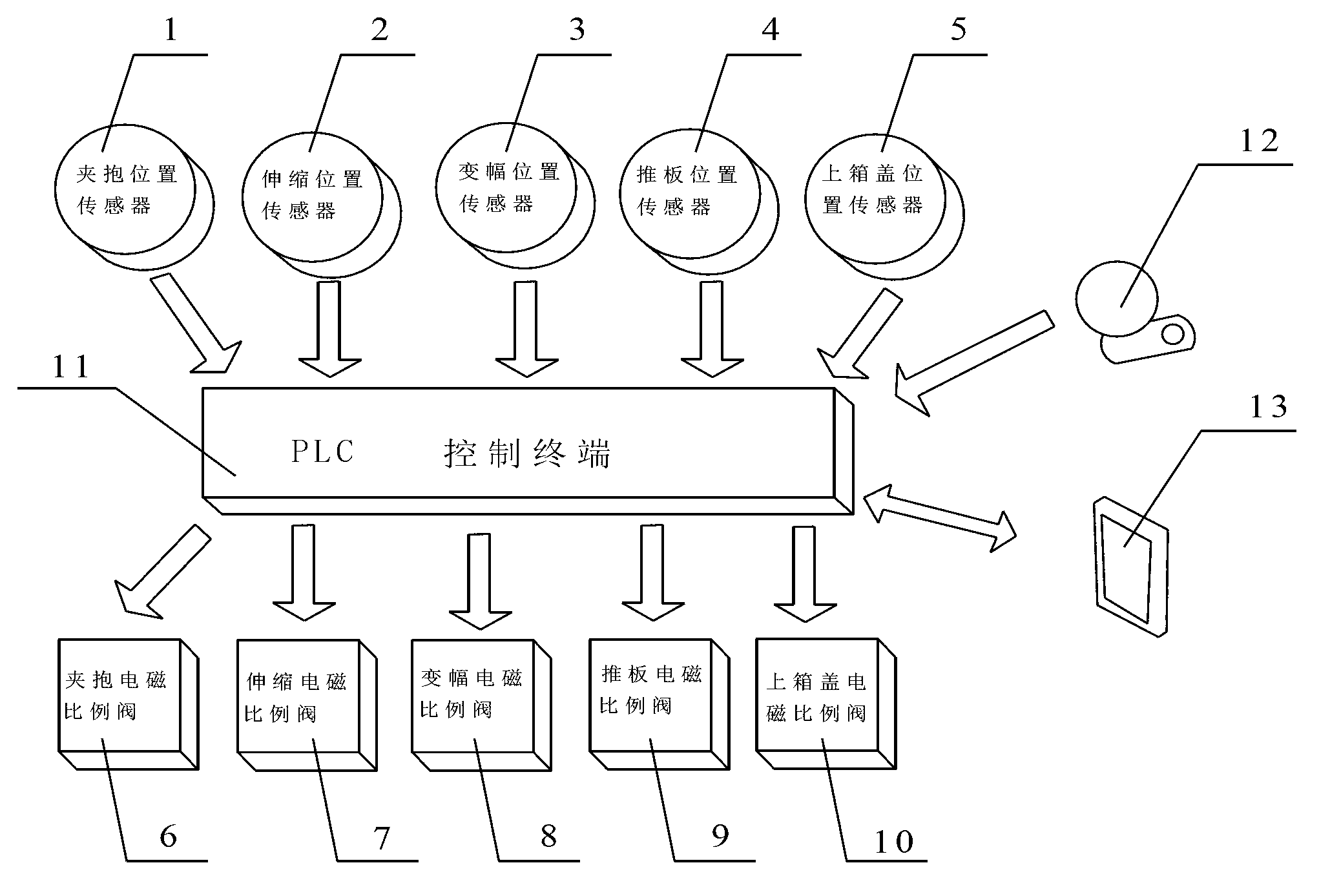

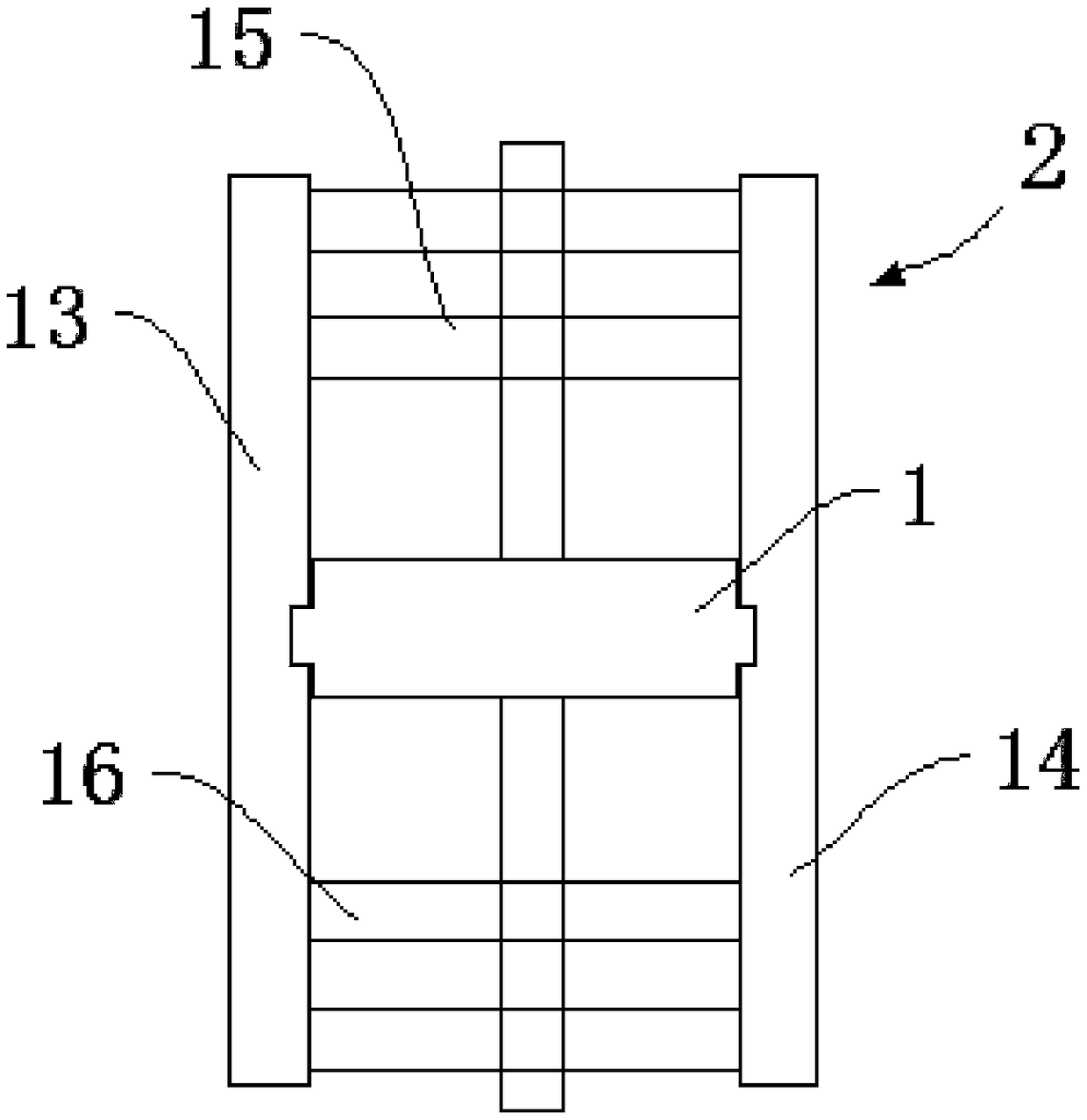

Electric control system of rubbish dumping transport car

InactiveCN102837923AImprove pouring efficiencyImprove working environmentProgramme control in sequence/logic controllersRefuse vehiclesEngineeringProportional valve

The invention belongs to the field of a rubbish transport car. Particularly, the invention relates to an electric control system of the rubbish dumping transport car. The electric control system comprises a control terminal, an operation mechanism, a telescopic executing mechanism, a holding clamp executing mechanism, a dumping executing mechanism and a compression executing mechanism. The holding clamp executing mechanism arranged on the telescopic executing mechanism is used for holding a trash can and mainly consists of a holding position sensor, a holding electromagnetic proportional valve; specific to various square trash cans, circular trash cans and irregular trash cans, the holding position sensor can detect the relative position of the trash can, then the holding trash can of the holding electromagnetic proportional valve is controlled; the dumping efficiency is high, and workers can finish the dumping work without contacting the trash can with various bacteria; the working environment of sanitation workers is improved and praised by everyone. The compression executing mechanism is arranged and used for compressing rubbish, thereby improving the transferring efficiency.

Owner:上海派恩科技有限公司

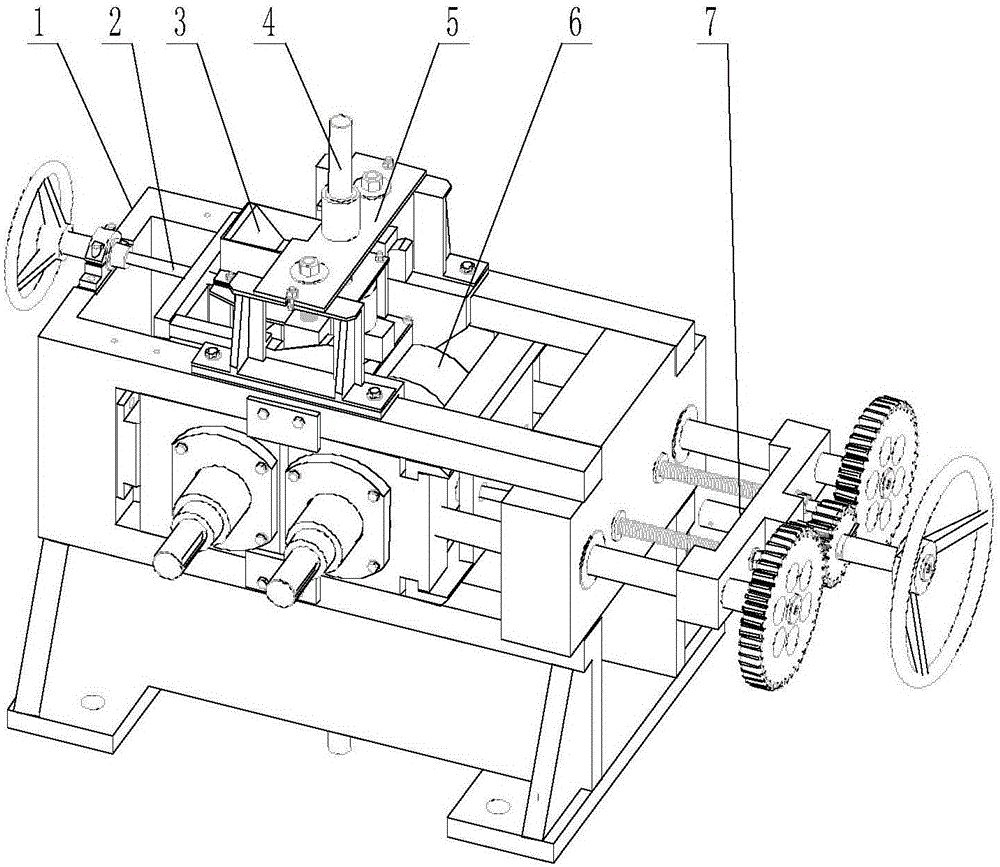

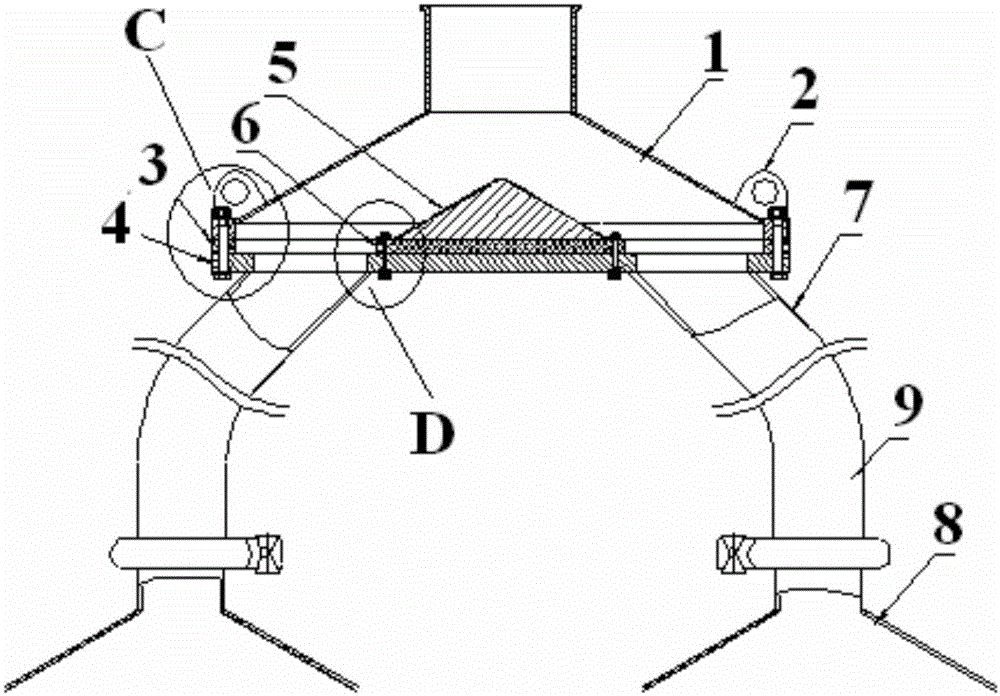

Accurate sample production method for inclined anchored jointed rock mass, and anchored jointed rock mass

ActiveCN108663244AEasy to makeEasy to operatePreparing sample for investigationPetrologyGeomechanics

The invention discloses an accurate sample production method for an inclined anchored jointed rock mass, and the anchored jointed rock mass, and relates to the technical fields of geomechanics and geotechnical engineering. The method includes the following steps: S1, processing a sample production mold according to the anchoring scheme of the inclined and anchored rock mass; S2, mounting the sample production mold in a sample pouring mold; S3, pouring a pouring sample with an anchor pole mounting hole into the sample pouring mold according to an assigned material proportioning ratio; and S4, mounting an anchor rod in the anchor rod mounting hole. The arbitrary inclined anchored jointed rock mass can be obtained through the method.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

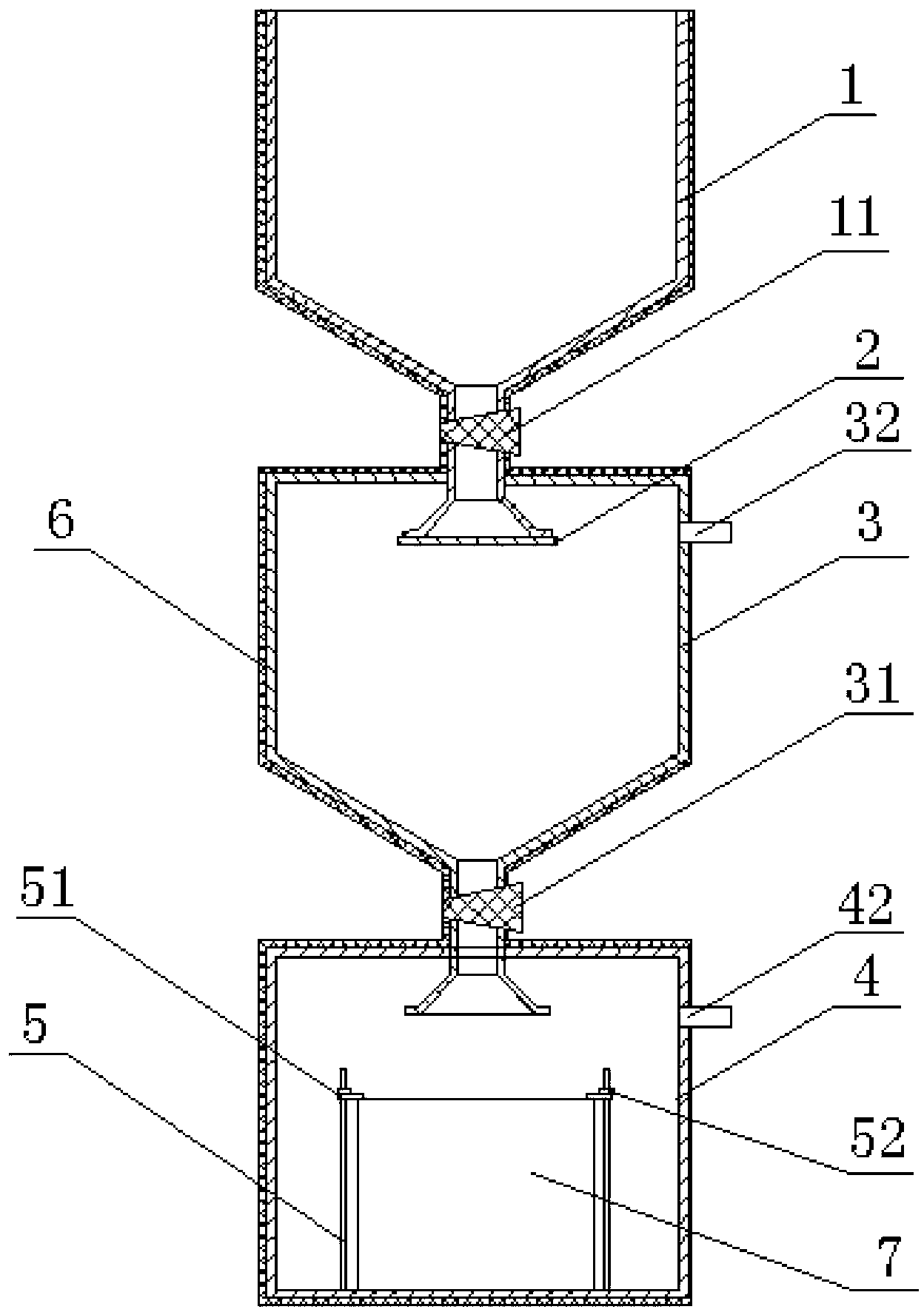

Integrated double concrete supplying and pouring system and supplying method

ActiveCN108331351AReduce volumeAvoid spillingBuilding material handlingThermal insulationEvaporation

The invention discloses an integrated double concrete supplying and pouring system and supplying method. The supplying system comprises a stirring truck and a pump truck, wherein the stirring truck isprovided with a stirring barrel and a sealing end cover, the pump vehicle comprises a closed supplying system, the stirring truck and the pump truck are communicated through a closed supplying pipe and a feeding pipe, so that a communicated concrete fluid with pressure difference is formed, and concrete in a receiving hopper of the pump truck is endowed with lasting supplying pressure. Integratedand concentrated control of the stirring truck and the pump truck is realized by connecting operating systems of the stirring truck and the pump truck. Integrated and automatic operation of the stirring truck and the pump truck is convenient to realize, the concrete pouring construction efficiency is improved, water adding in the pumping position due to concrete water evaporation and slump loss is also avoided, the concrete quality is ensured, overflow leakage of the concrete at the receiving hopper is eradicated, the thermal insulation effect is improved, and the purpose of continuous concrete supply to the pump truck under certain pressure conditions is achieved.

Owner:盛富春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com