CRTS III type slab ballastless track self-compacting concrete casting tooling and method

A technology of self-compacting concrete and slab ballastless track, which is applied in track, track laying, track maintenance, etc. It can solve the problems of easy formation of foam layer, etc., and achieve the effect of improving quality, avoiding air bubbles, and quickly unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

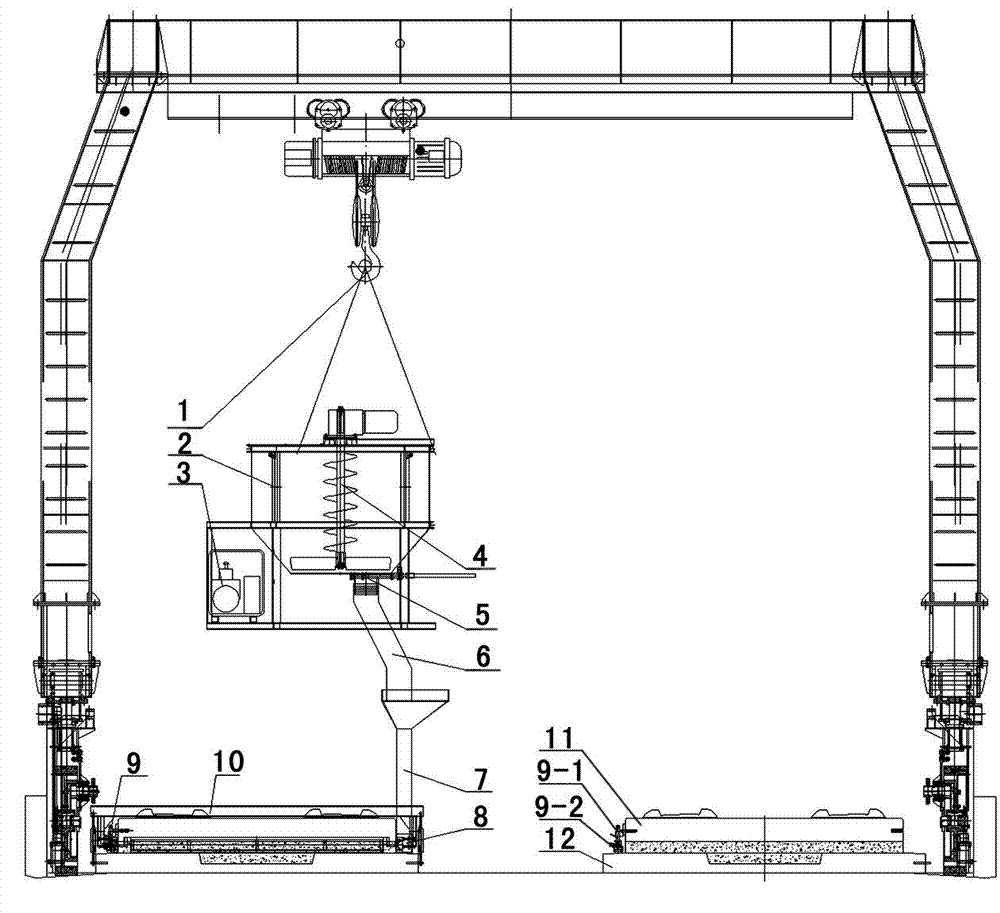

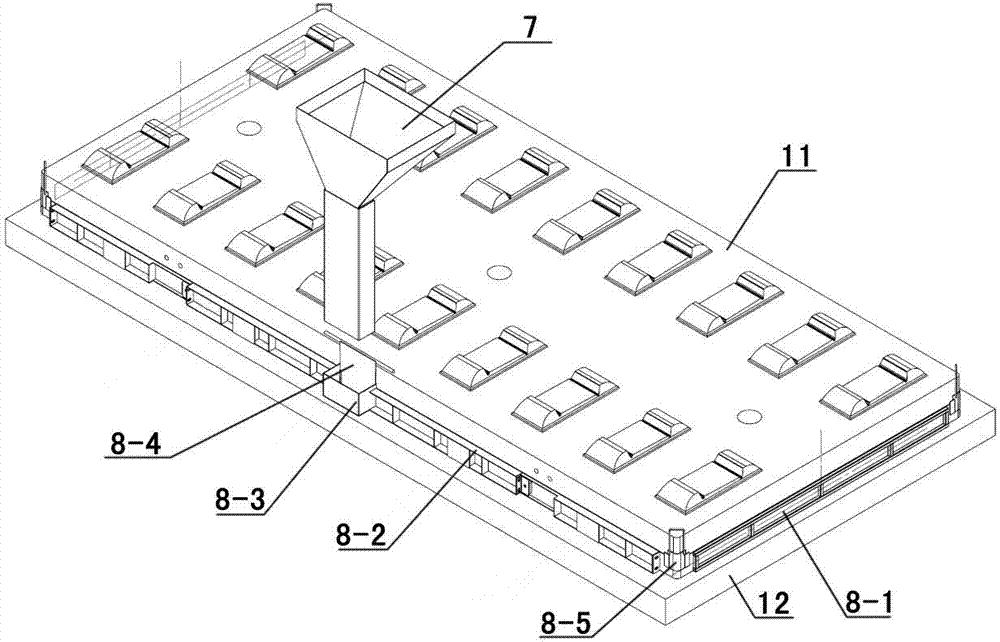

[0042] Example 1, a CRTS III type slab ballastless track self-compacting concrete pouring tool.

[0043] Such as figure 1 As shown, the CRTSⅢ plate type ballastless track self-compacting concrete pouring tool provided by the present invention includes a track plate 11, a base plate 12, a transfer bucket 2, a pouring funnel 7, a slurry retaining formwork 8, a three-dimensional fine adjuster 9, and a track plate press. Tightening device 10, track slab anti-skid device and slurry retaining formwork compacting device.

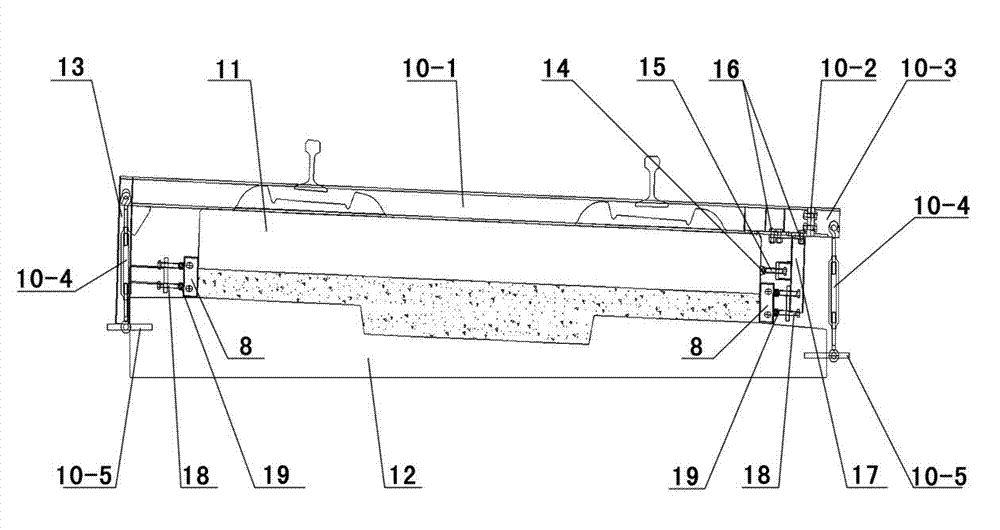

[0044] The base plate 12 is positioned at the lowermost floor, and it is reserved with two steel bars 10-5 (see image 3 ), and the two reserved steel bars 10-5 protrude from the two opposite outer sides of the base plate 12 respectively. The track plate 11 is laid on the top of the base plate 12 with a certain distance therebetween.

[0045] The transfer bucket 2 is a hollow cavity with upper and lower openings and a large top and a small bottom. The top of the...

Embodiment 2

[0056] Embodiment 2, a method for pouring self-compacting concrete for CRTS III slab ballastless track.

[0057] refer to Figure 1~Figure 3 , the method specifically includes the following steps:

[0058] Step a. Install the three-dimensional fine adjuster 9 on both sides of the track plate 11, and adjust the height, center line and front and rear position of the track plate 11 through the three-dimensional fine adjuster 9 to meet the preset requirements.

[0059] Before this step, the manufacture of the base plate 12 and the laying of the track plate 11 have been completed. When the base plate 12 is manufactured, two steel bars 10-5 are reserved inside, and the reserved two steel bars 10-5 protrude from the two opposite outer surfaces of the base plate 12 respectively. The track plate 11 is laid on the base plate 12 with a predetermined distance between them.

[0060] In this step, the three-dimensional fine adjuster 9 includes an elevation adjustment screw 9-1 and a hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com