Patents

Literature

62results about How to "Fast pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

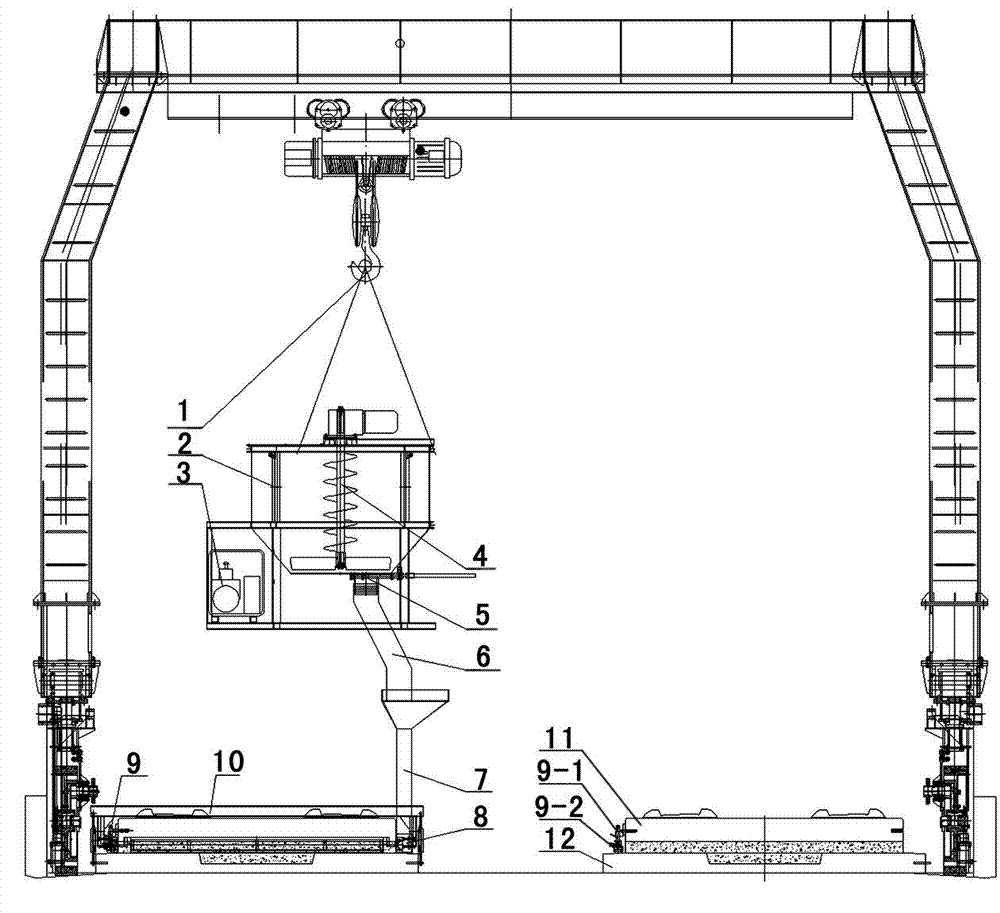

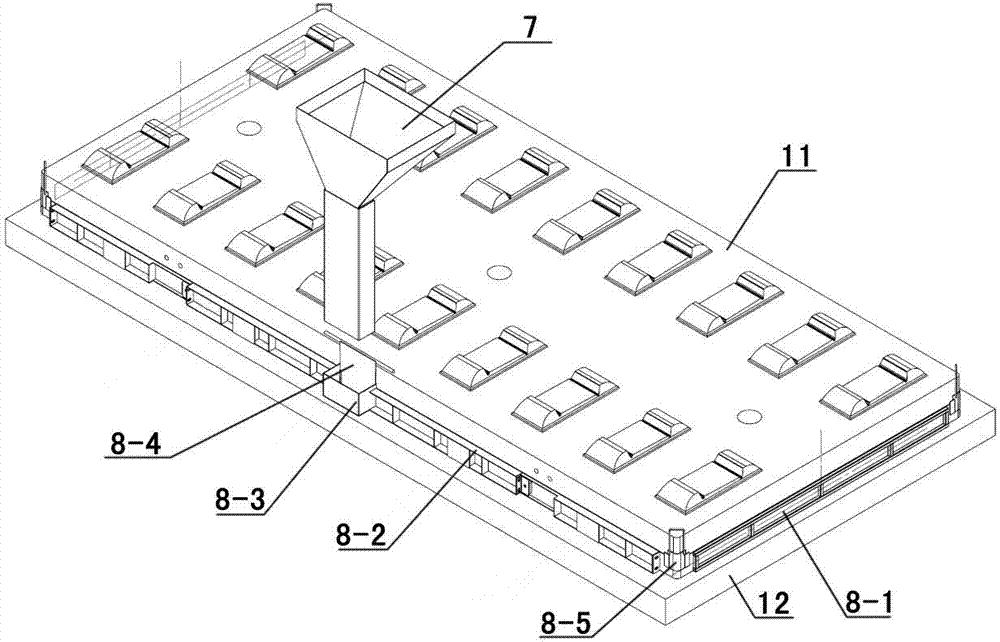

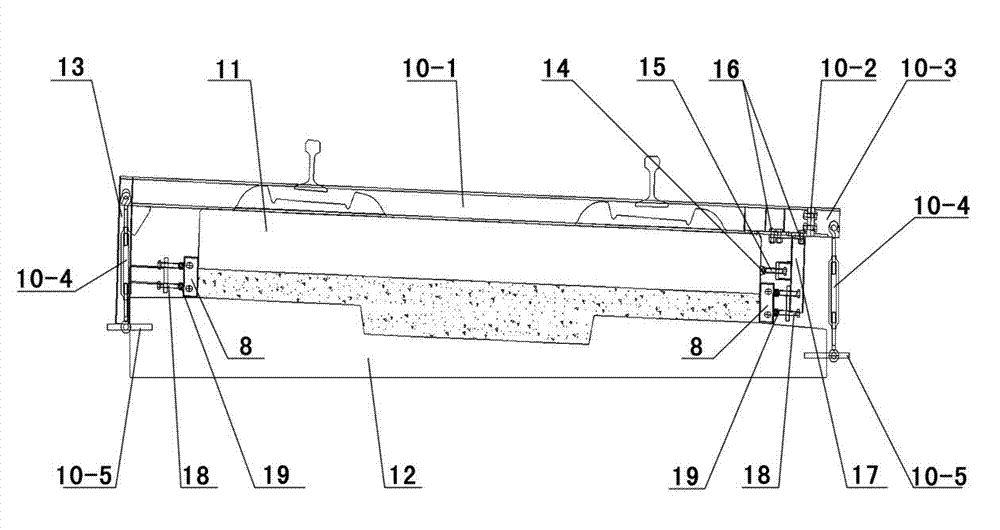

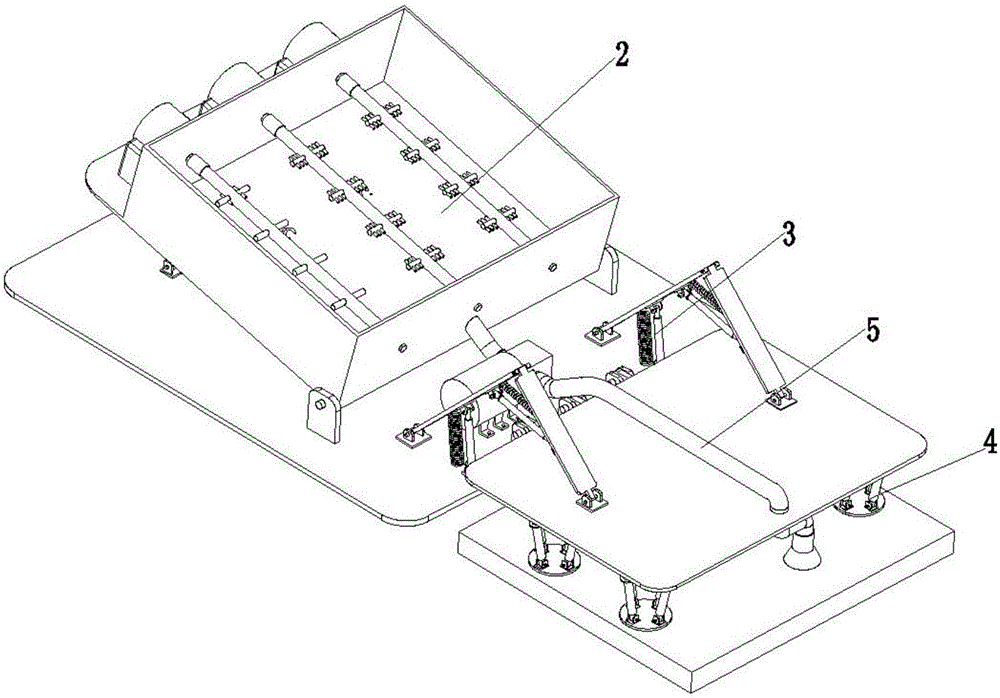

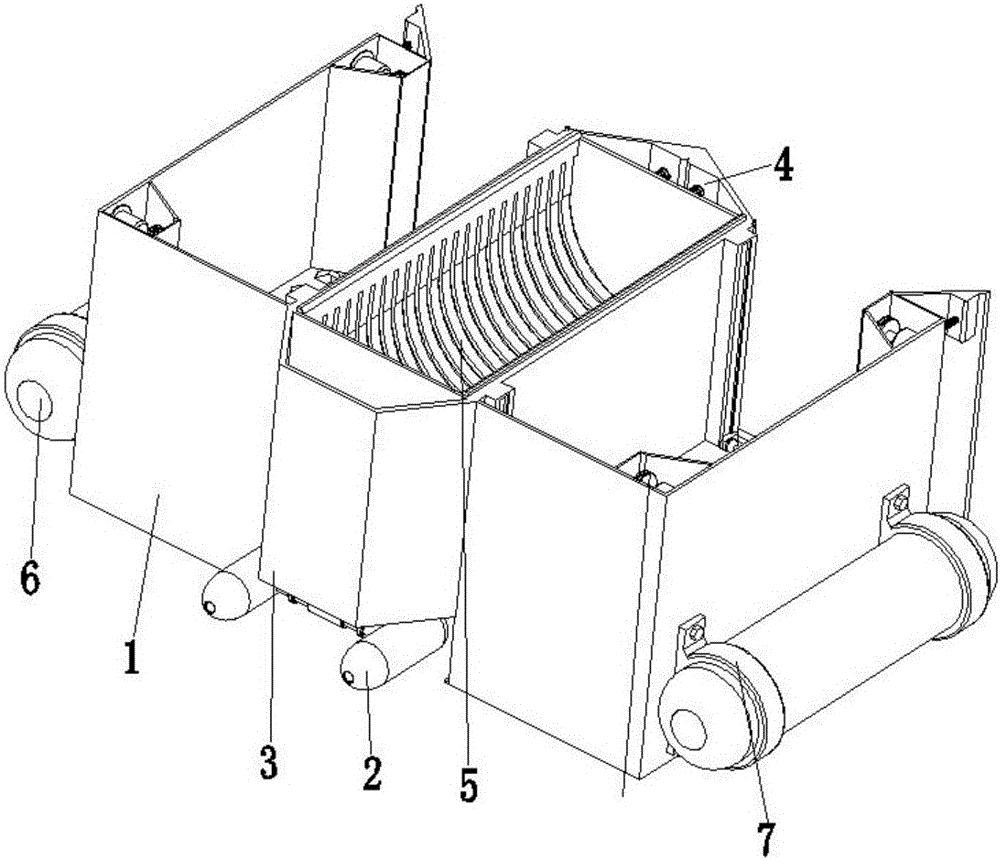

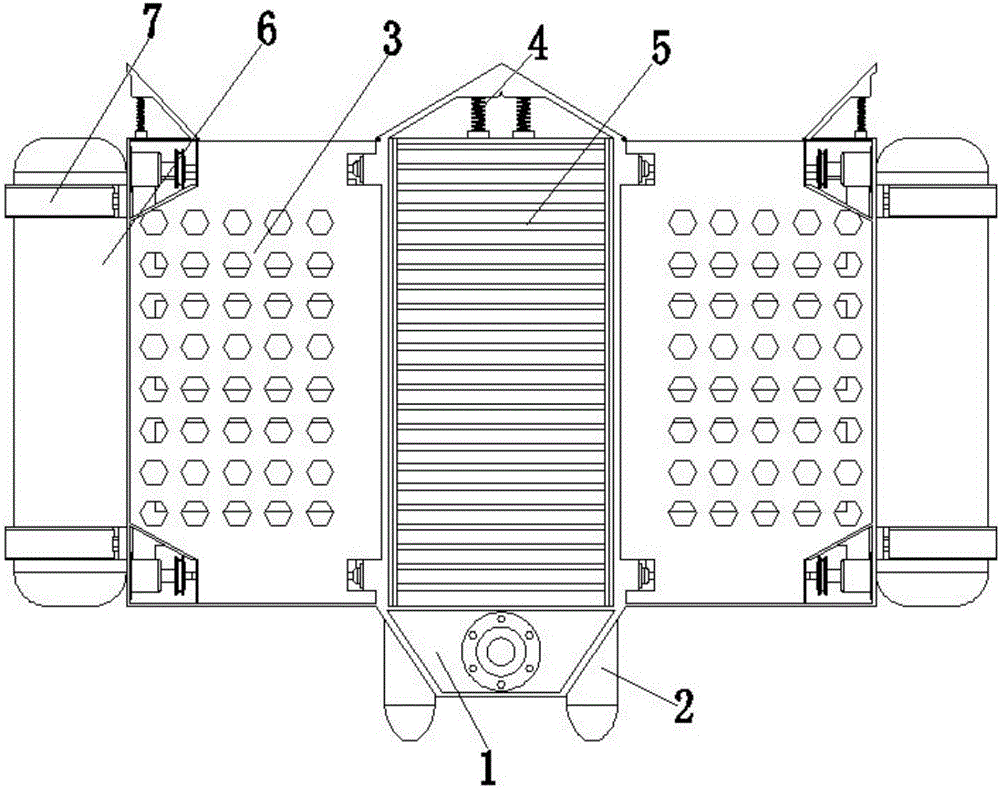

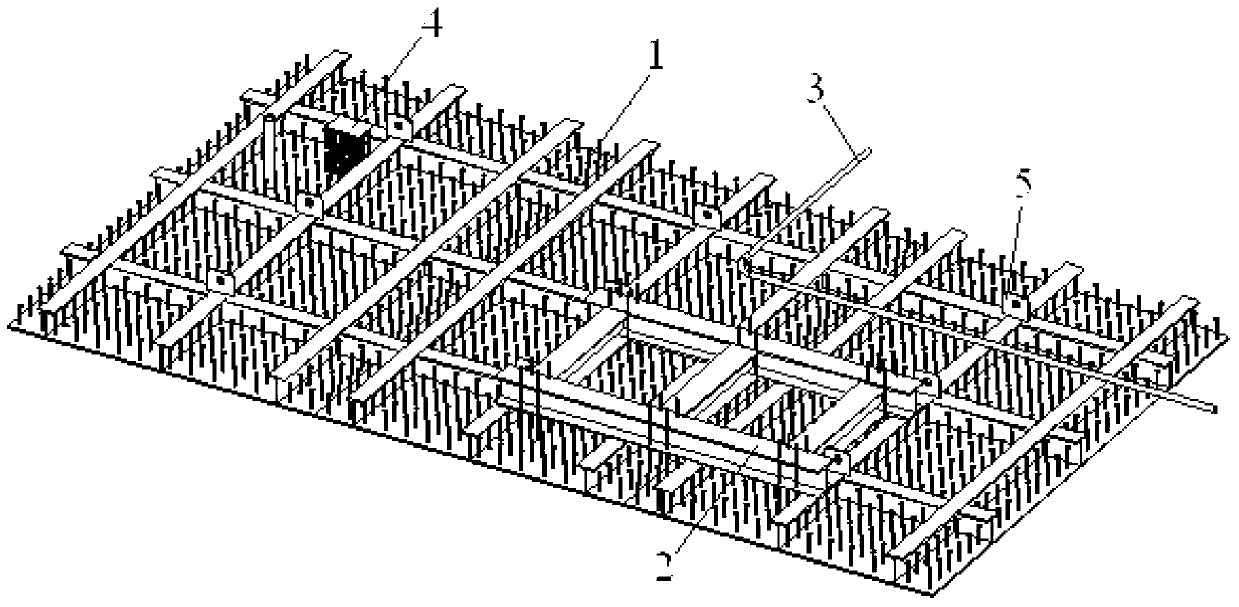

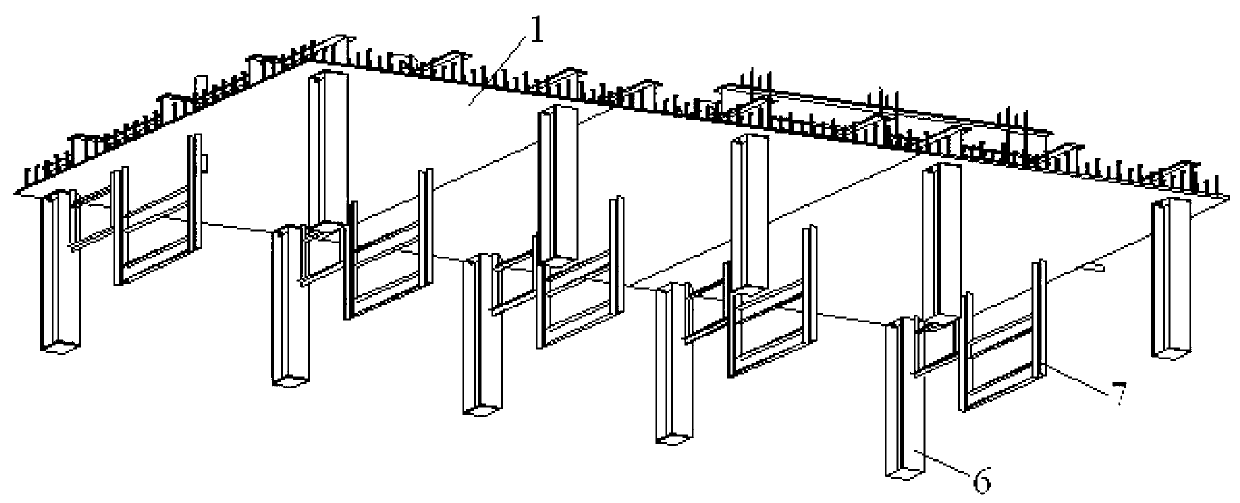

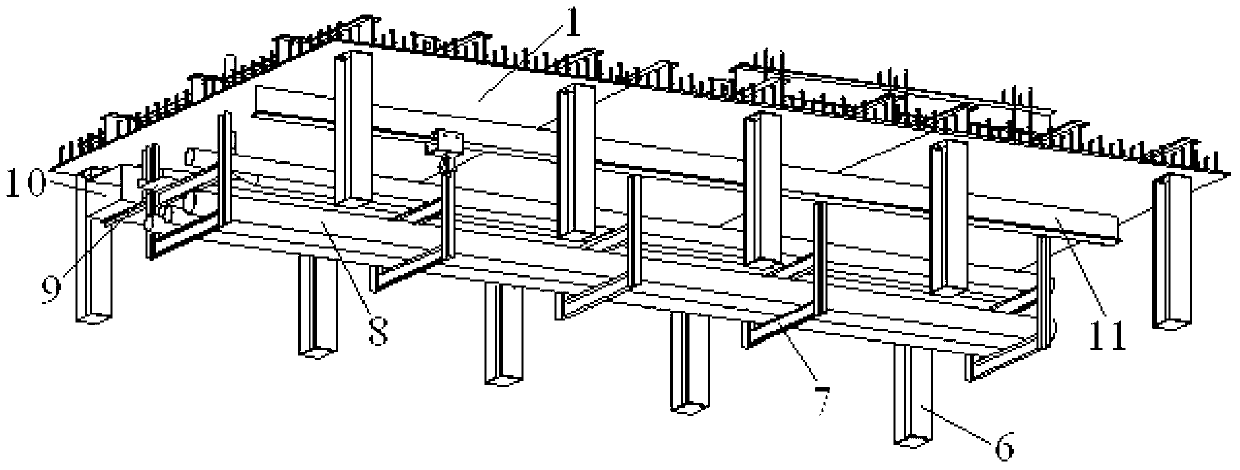

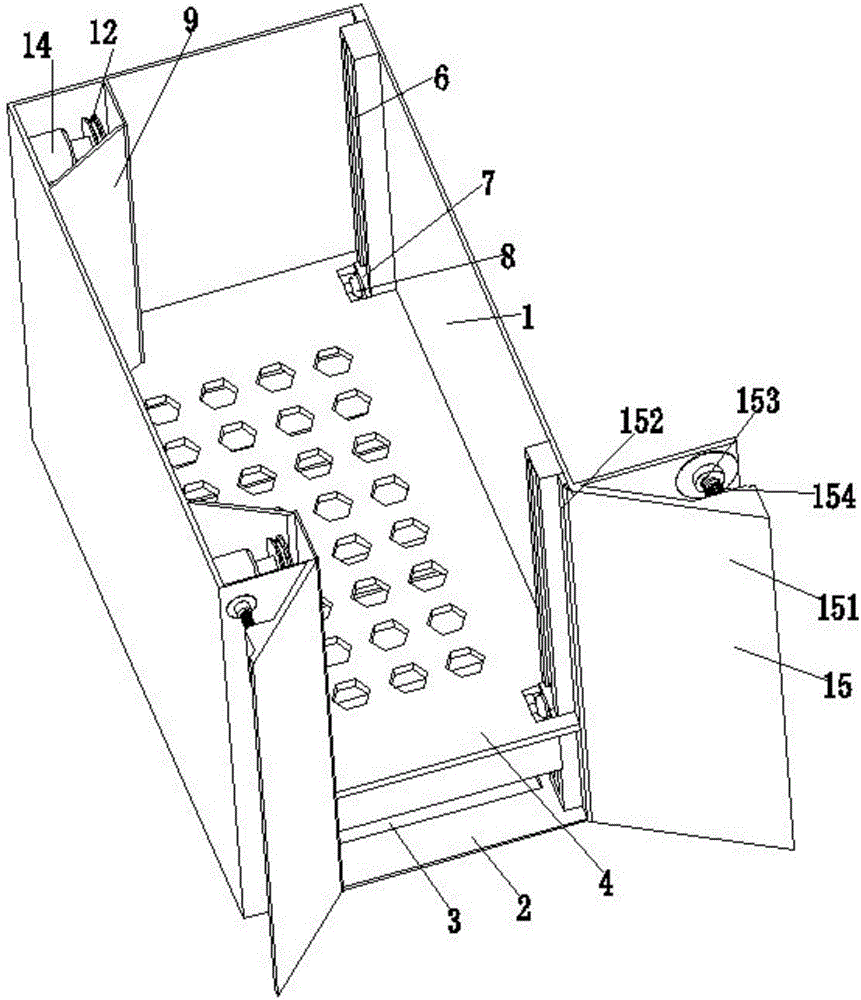

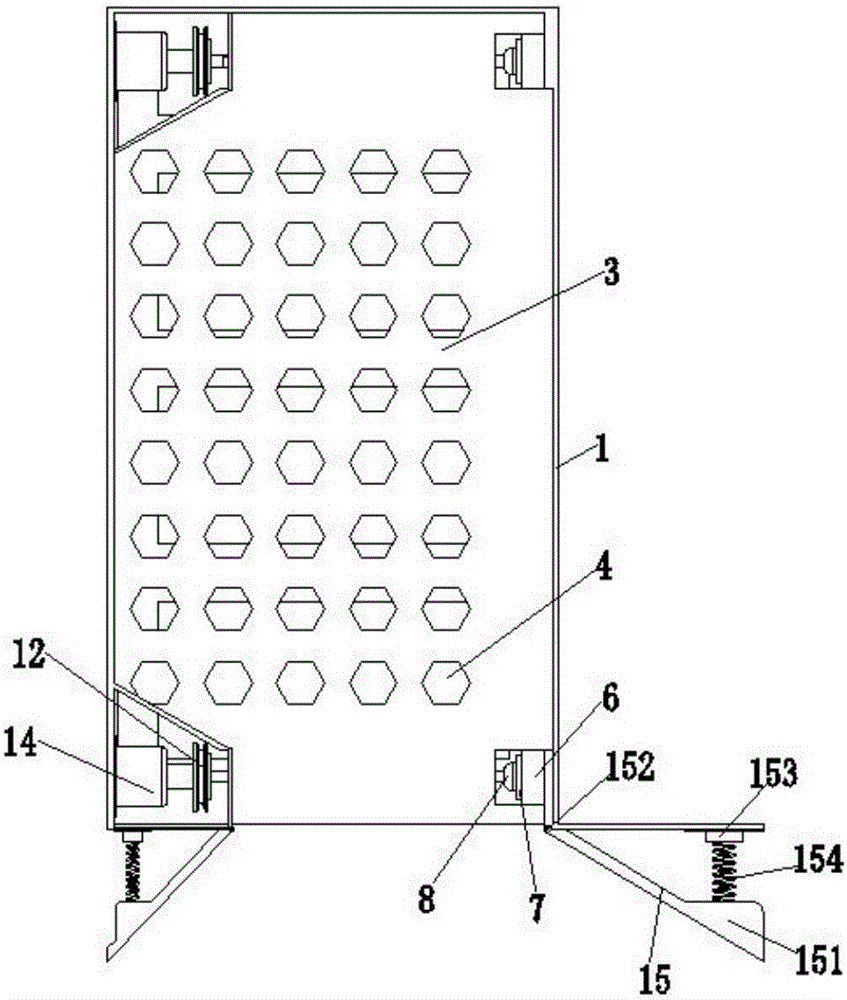

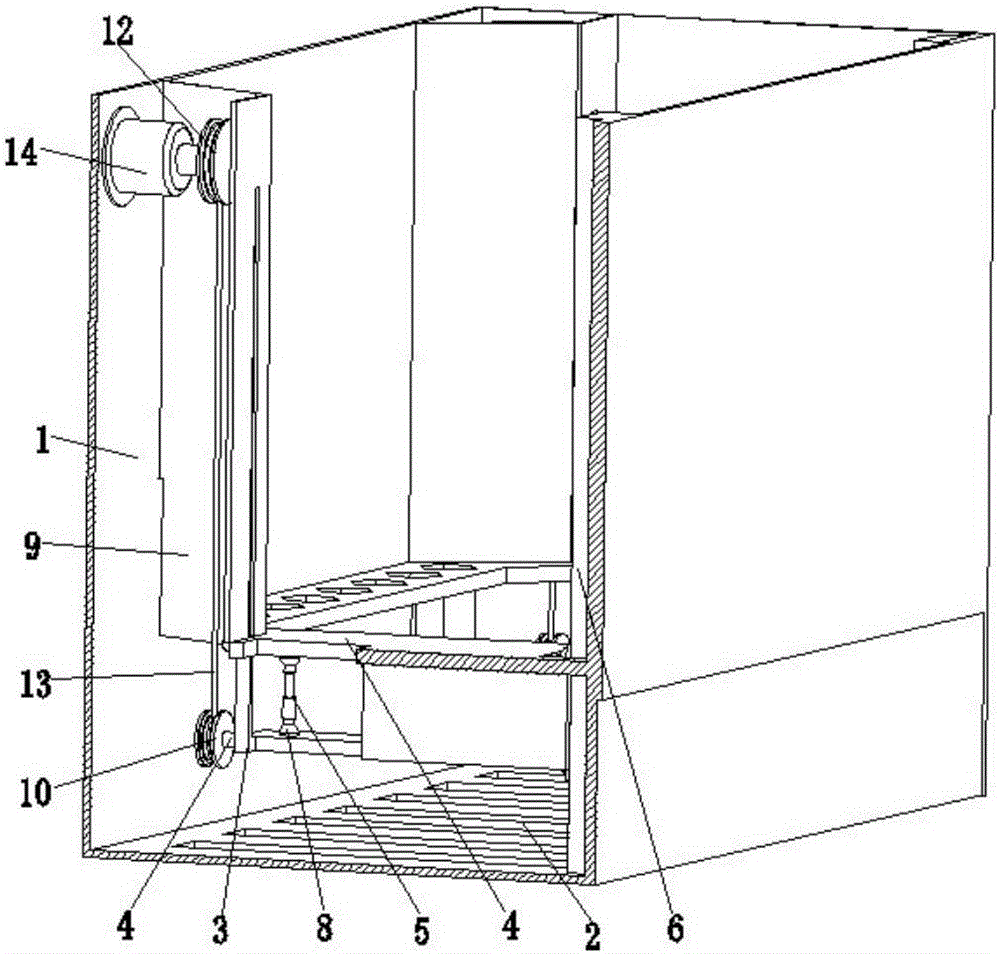

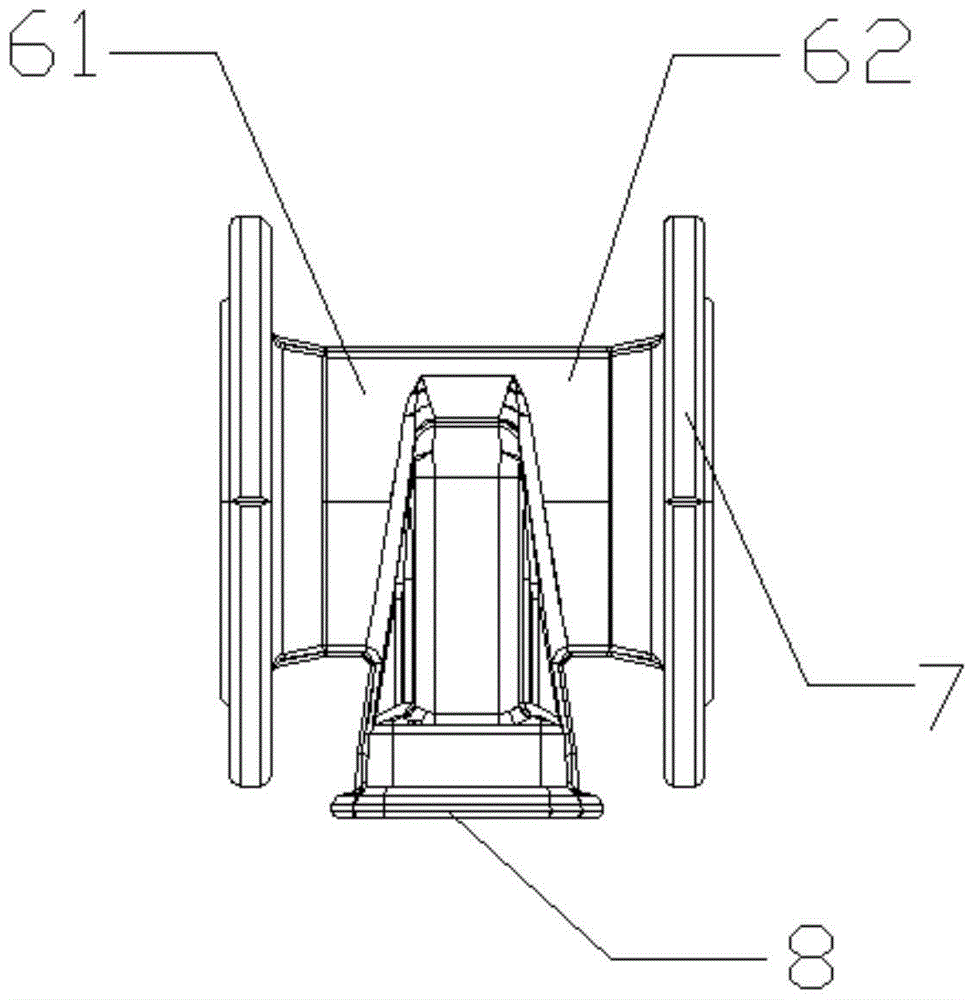

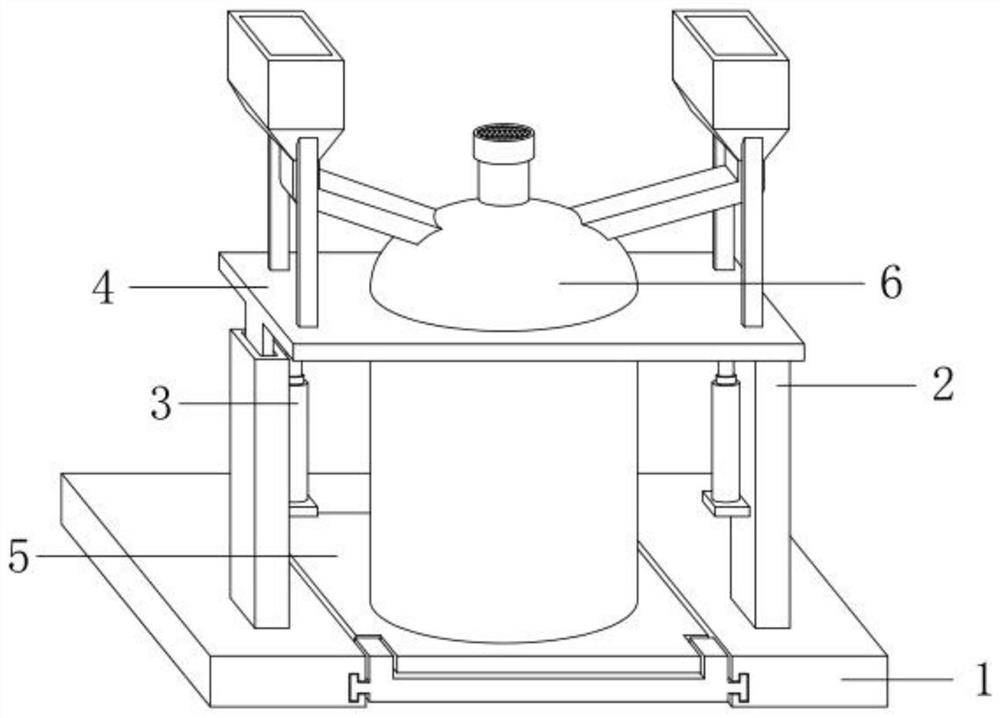

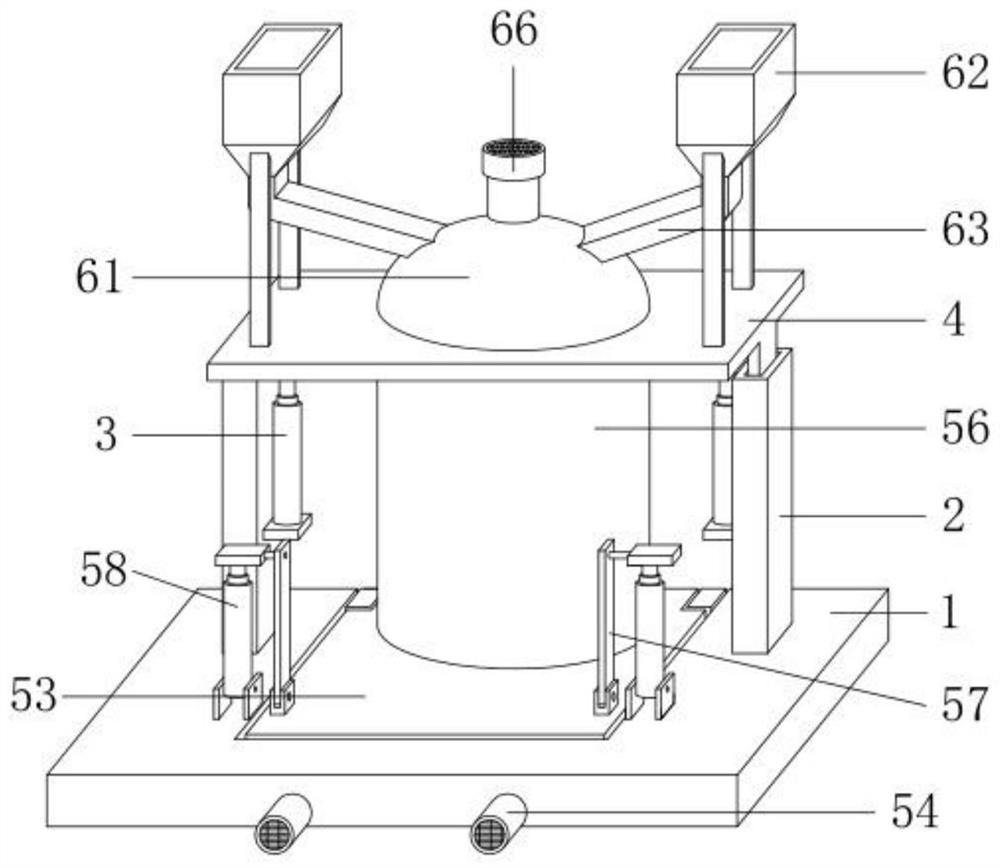

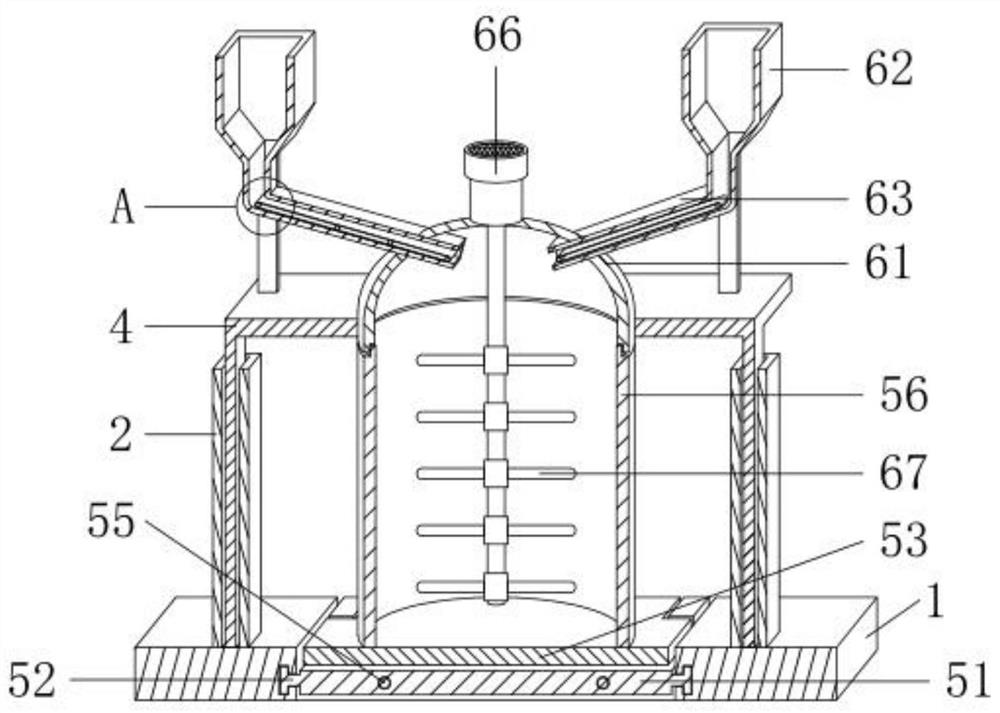

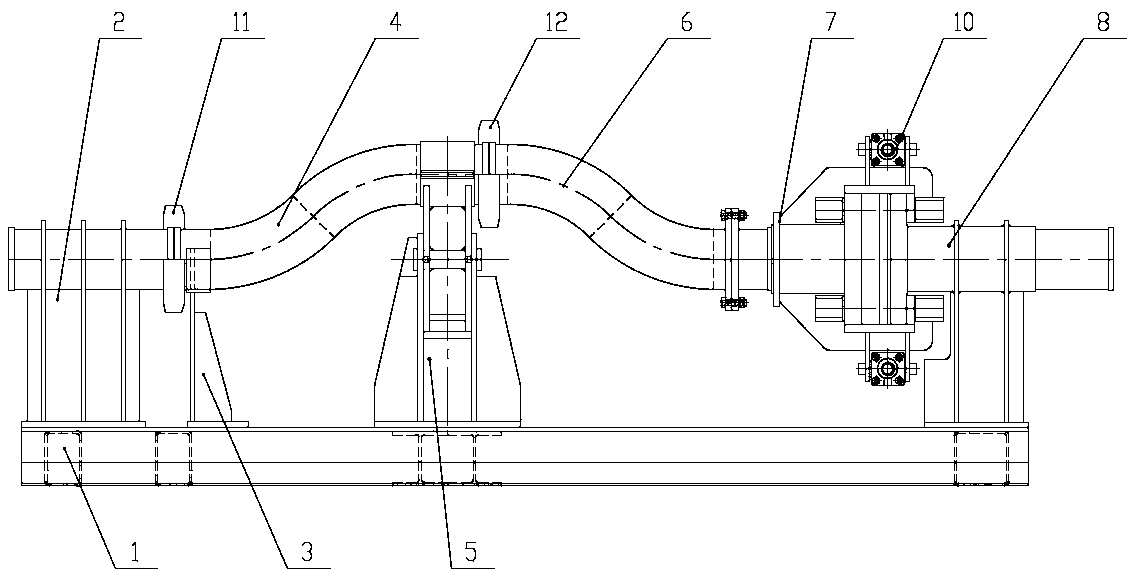

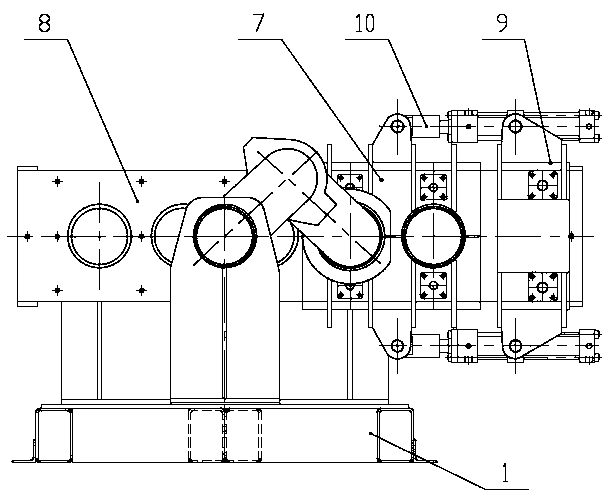

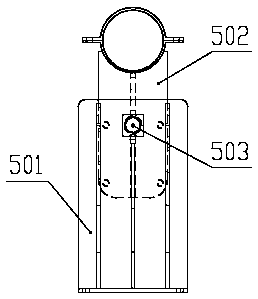

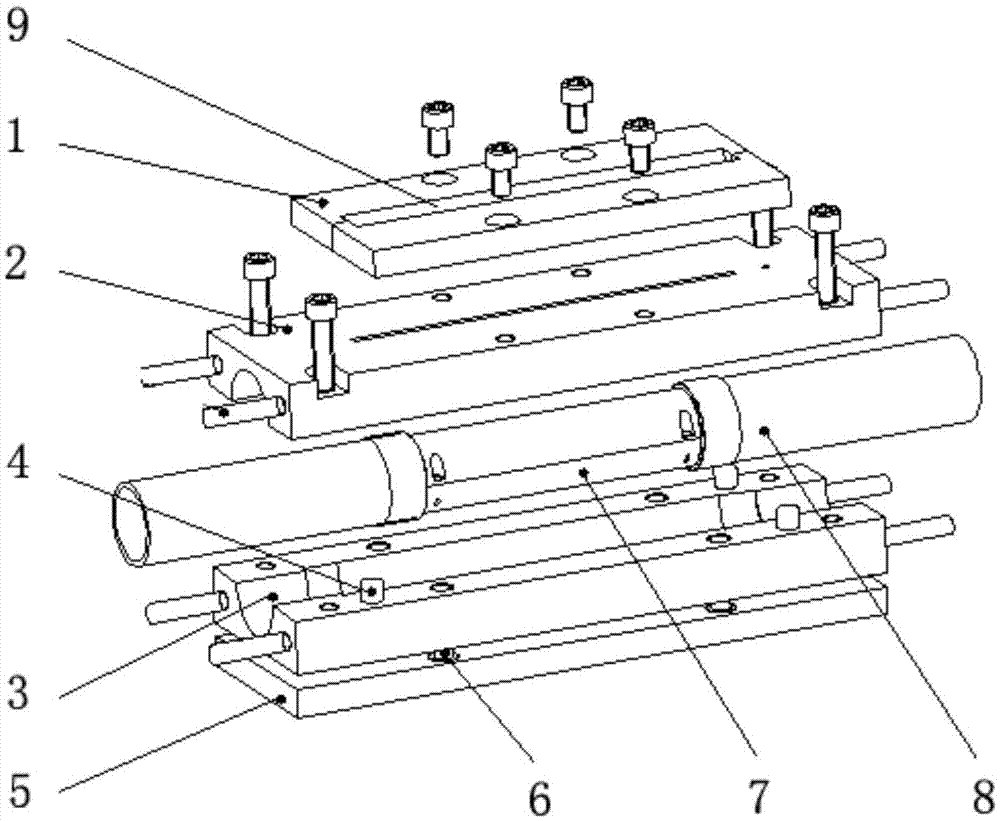

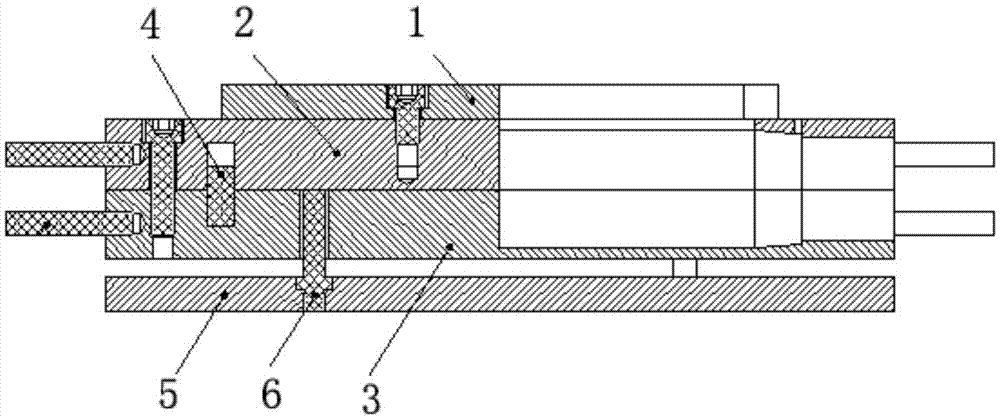

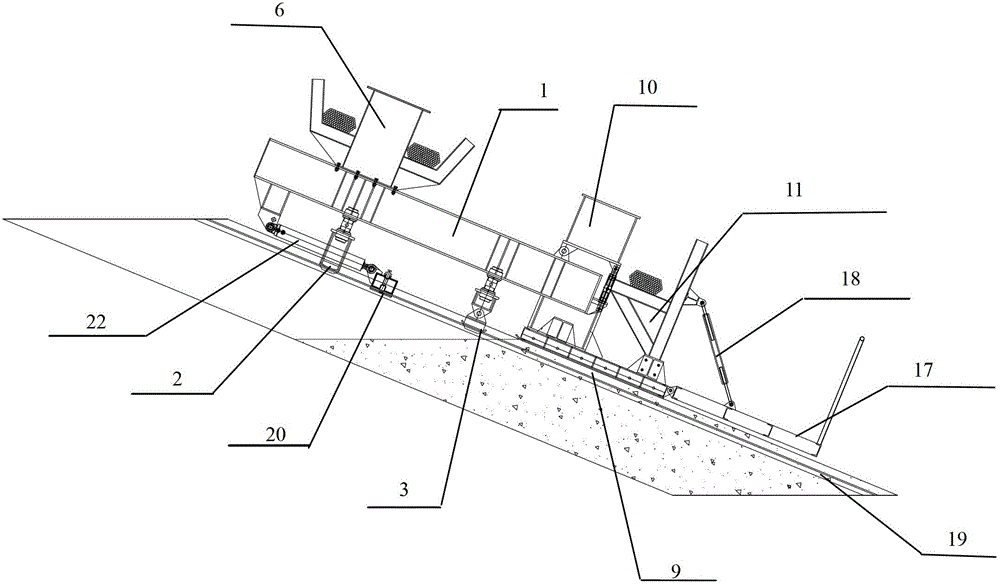

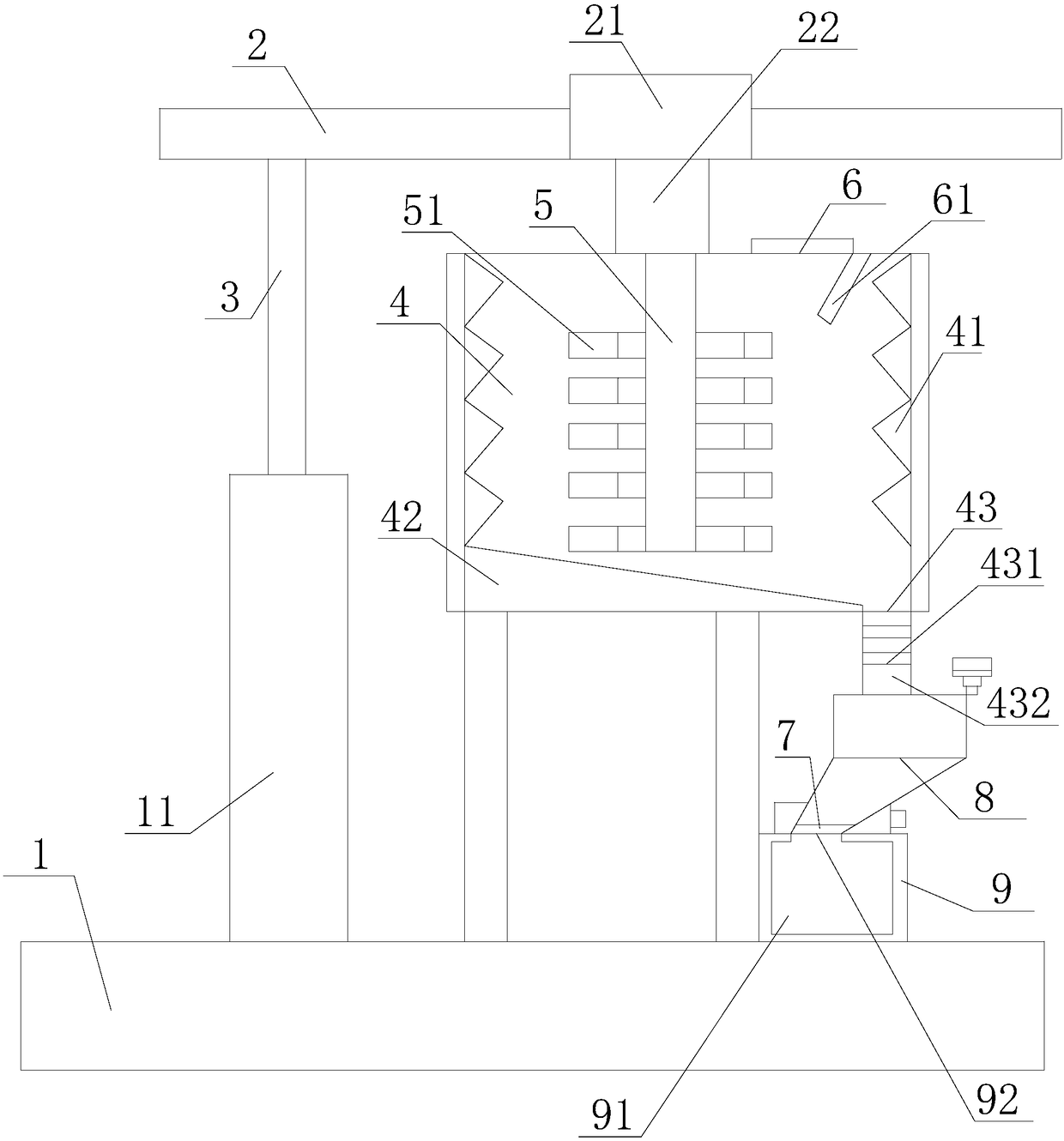

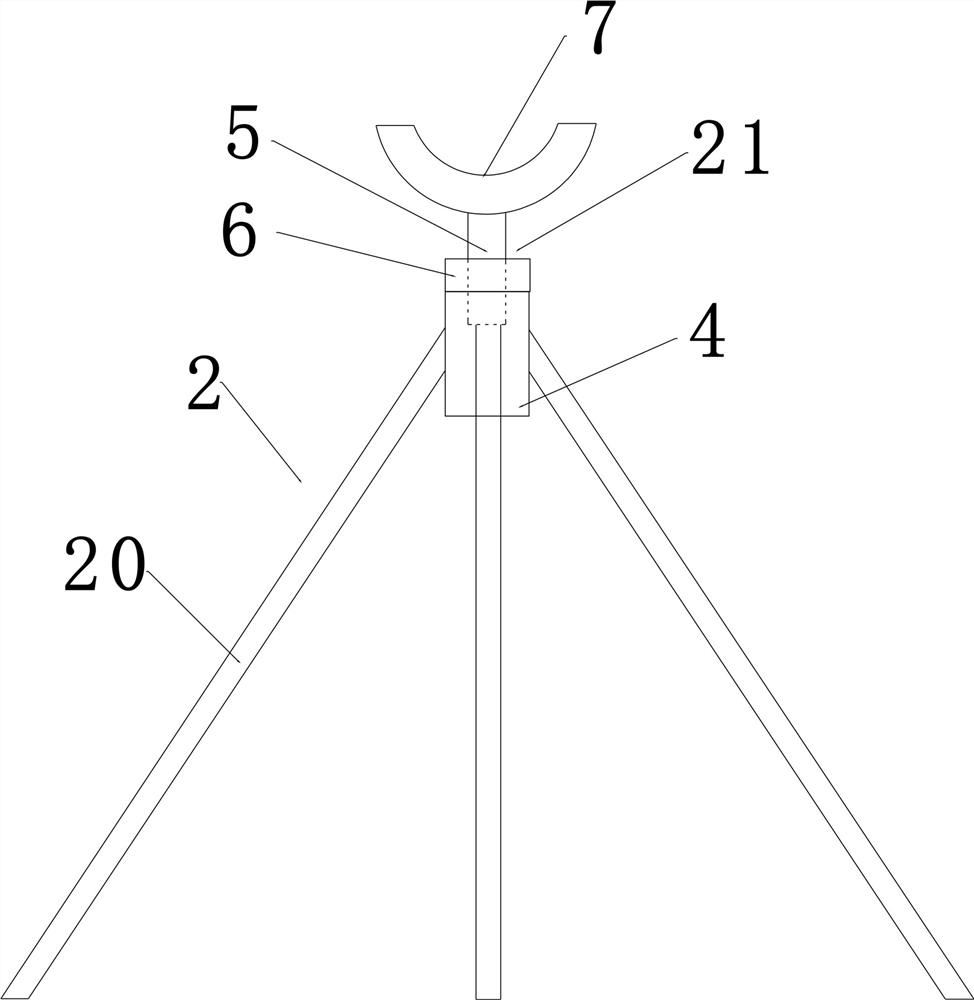

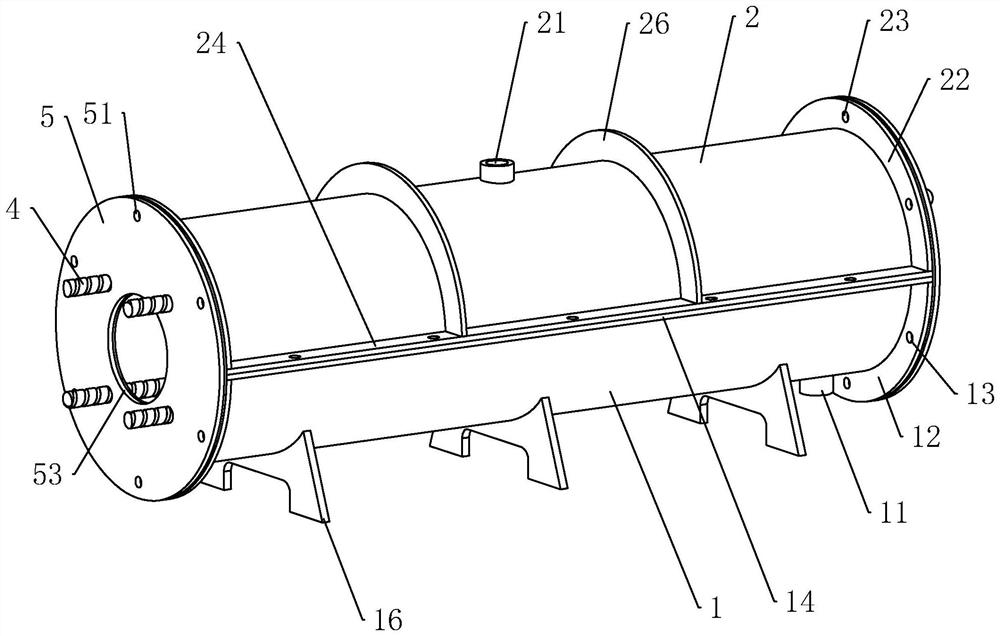

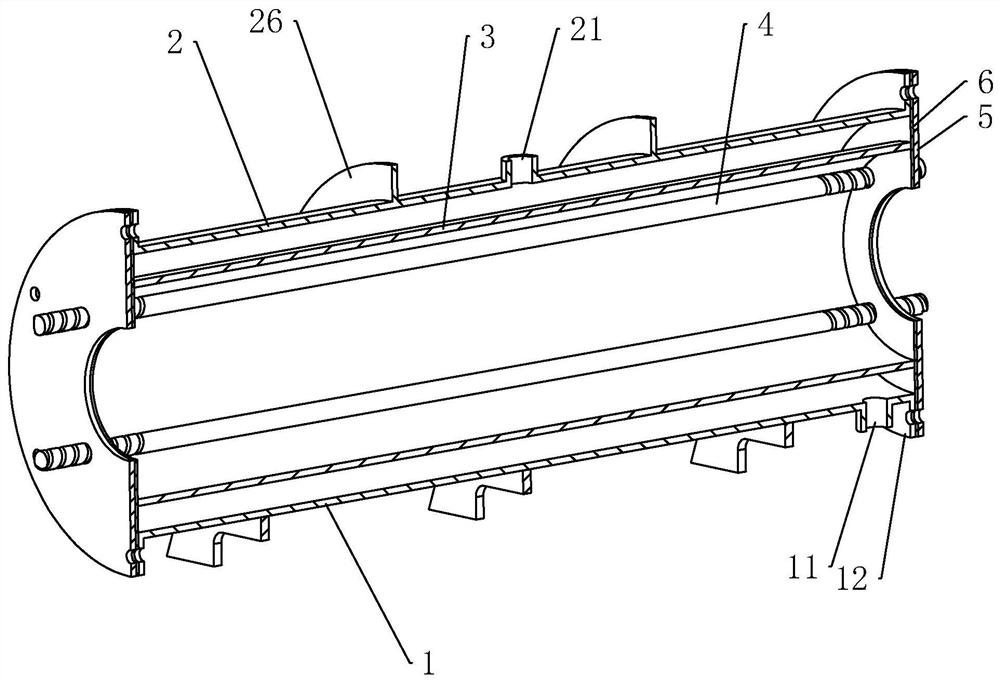

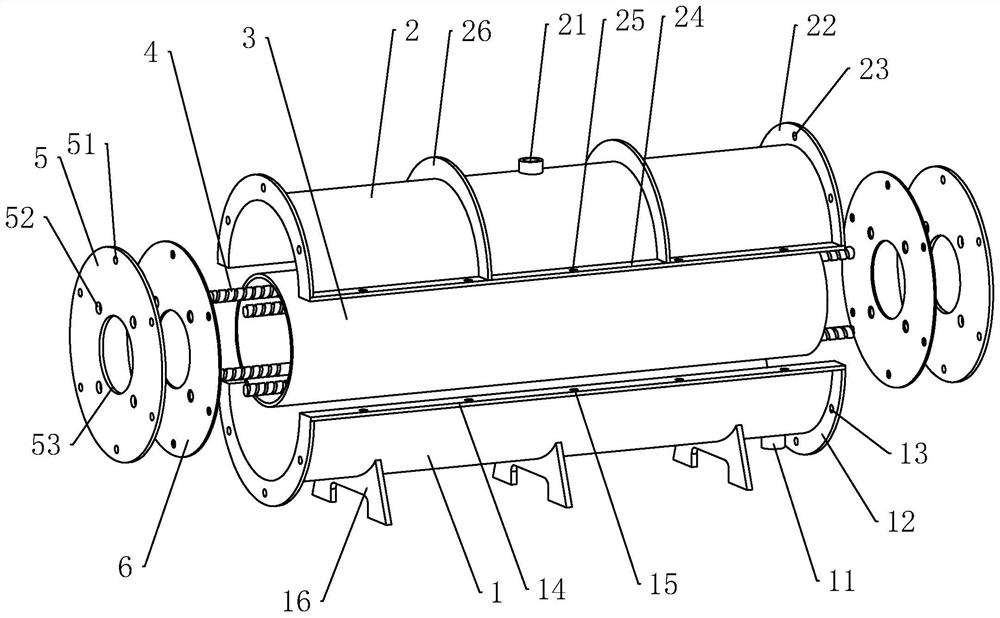

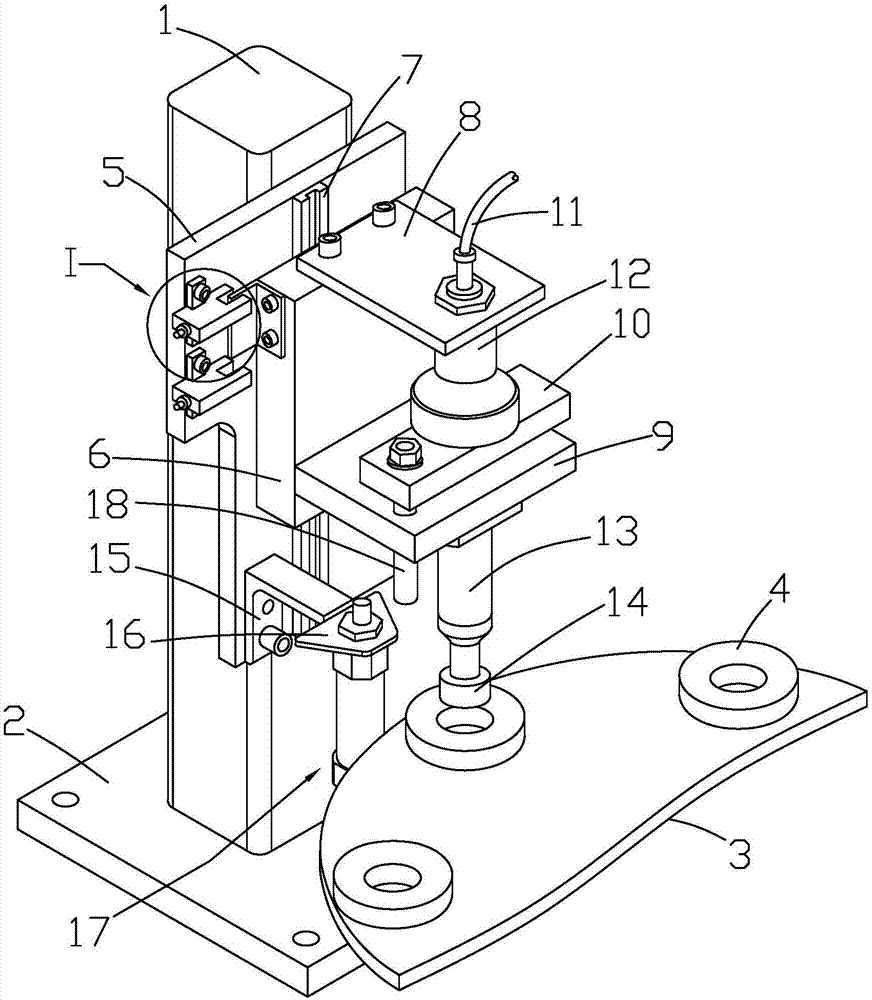

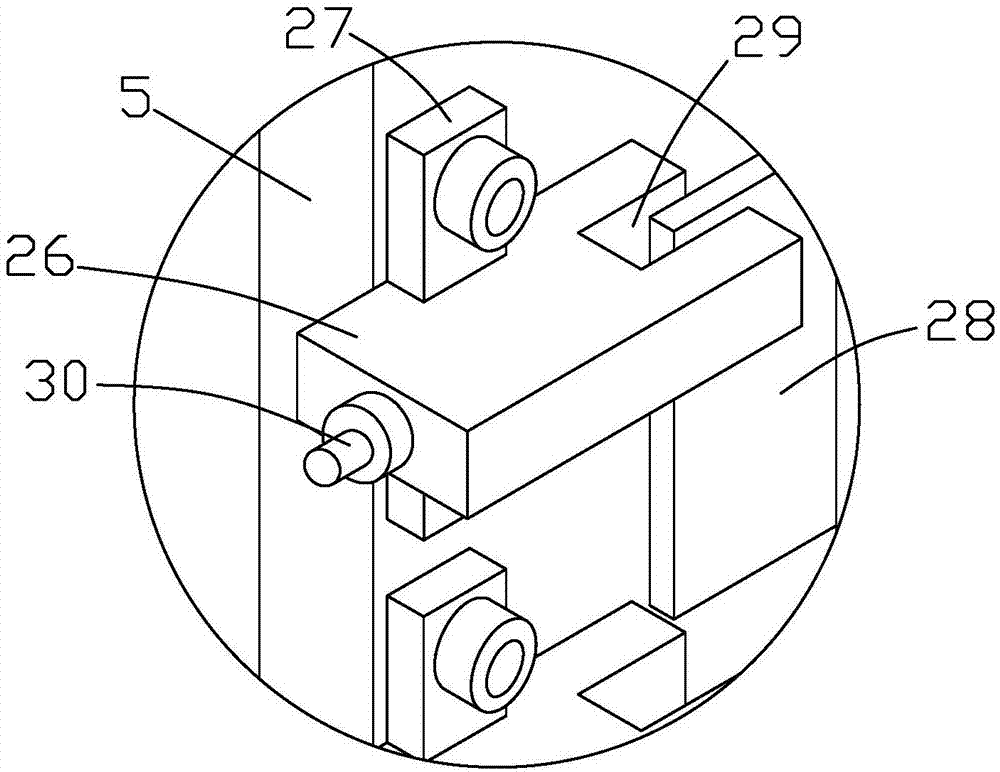

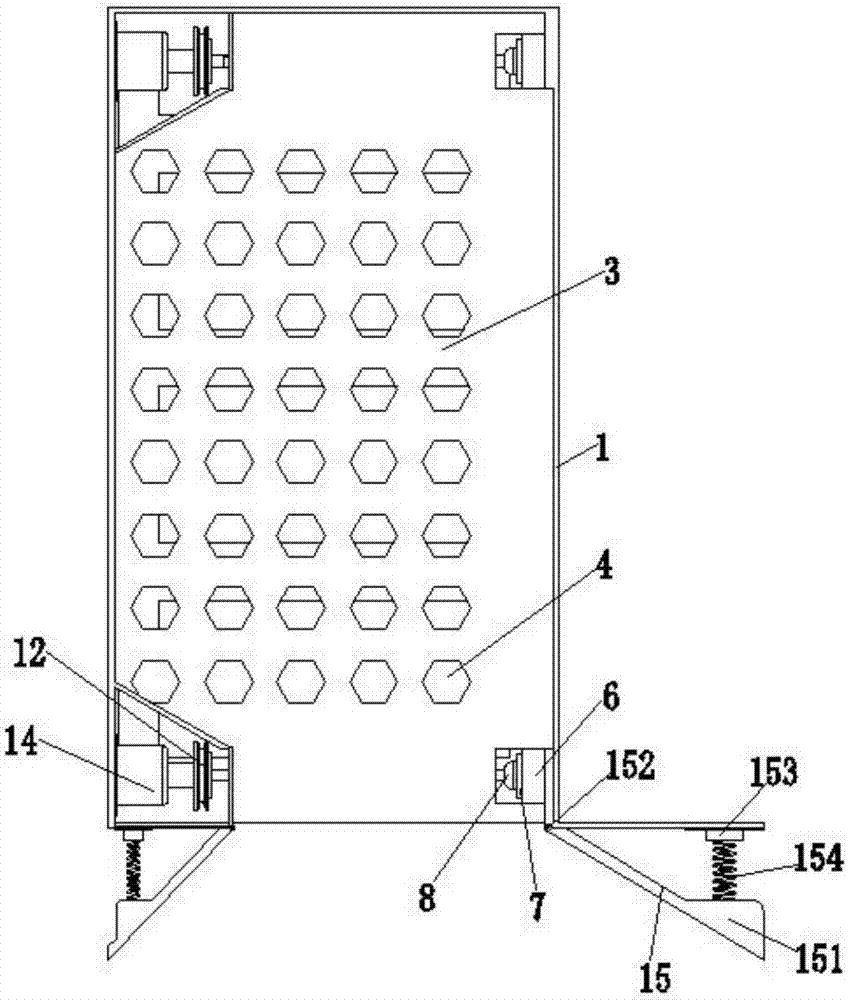

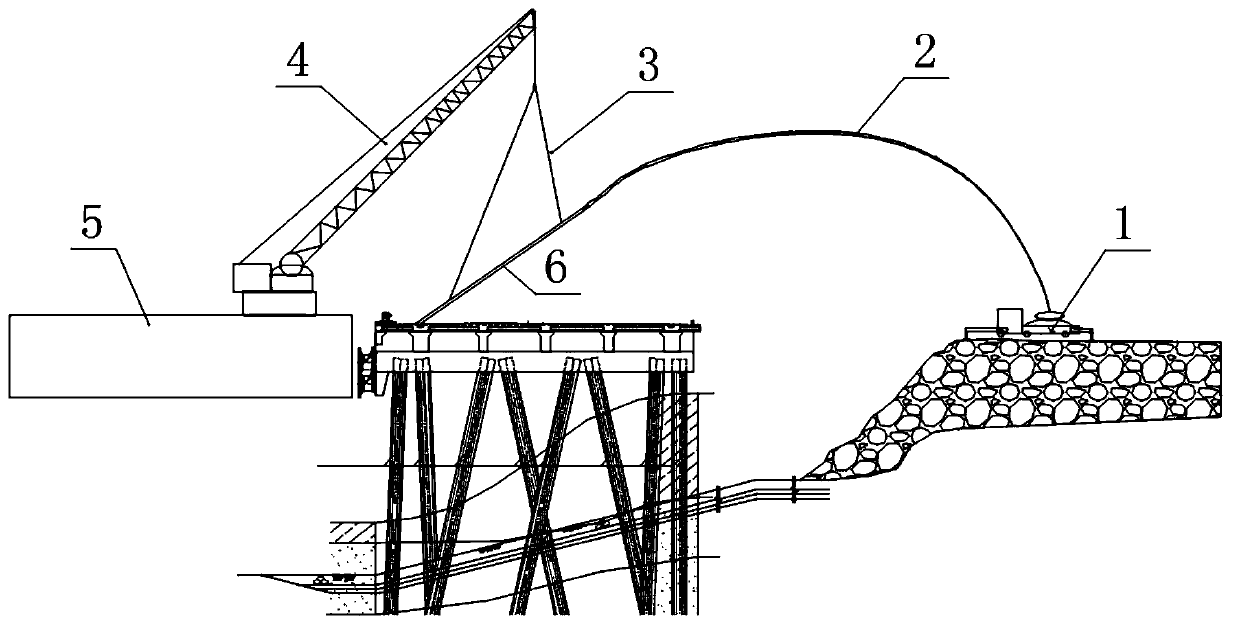

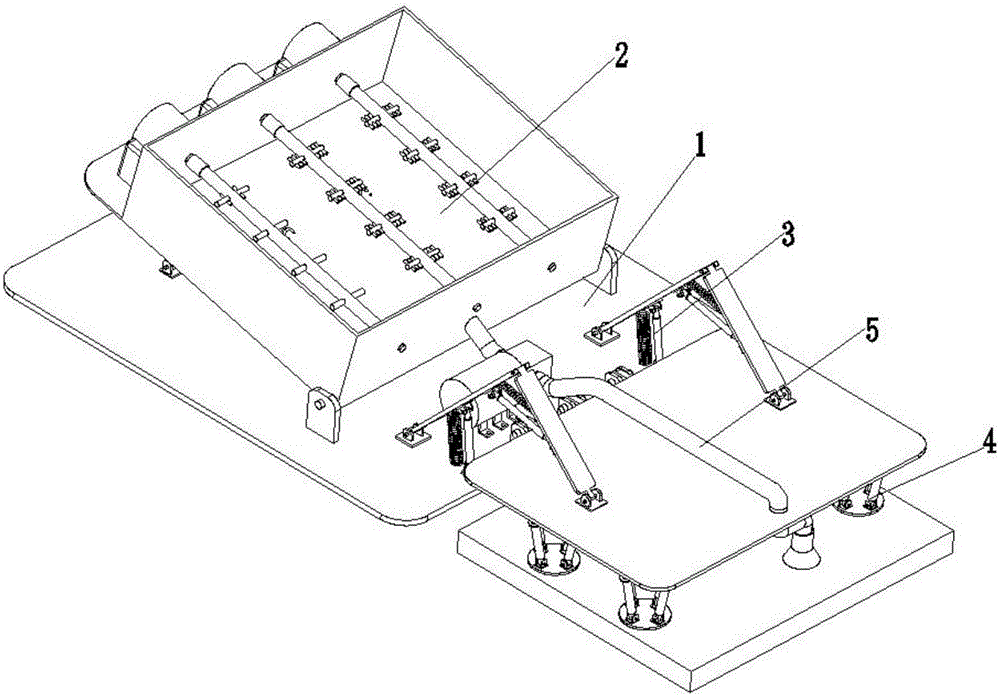

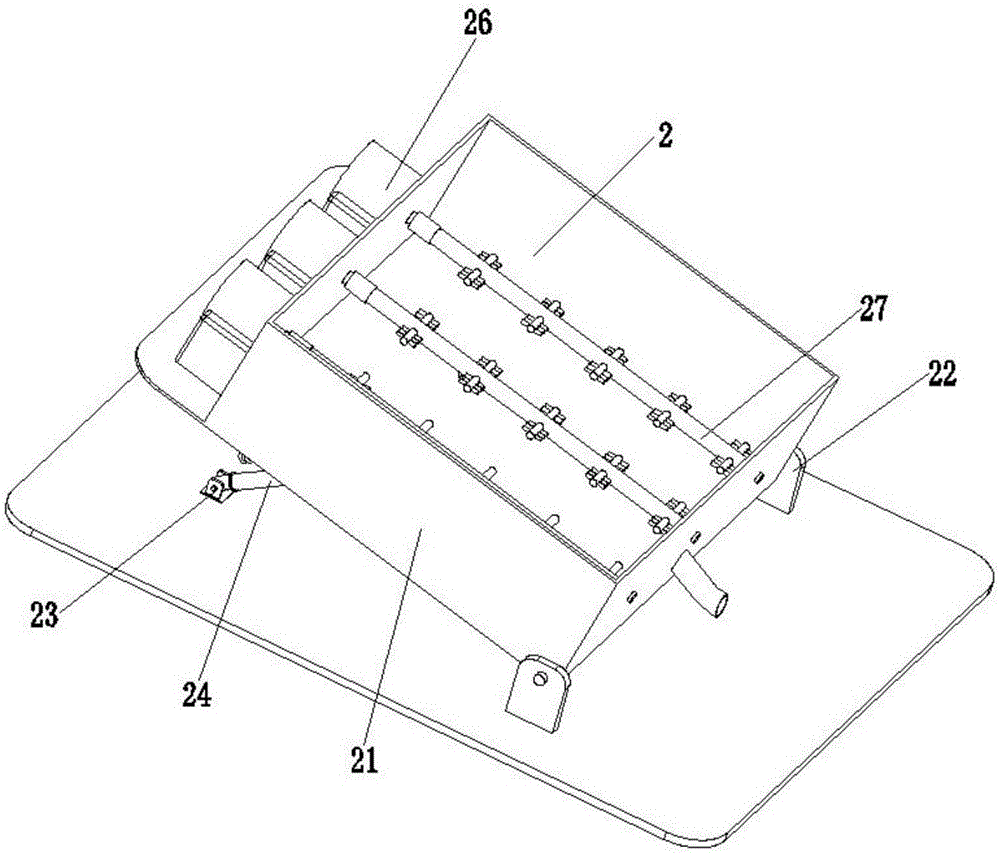

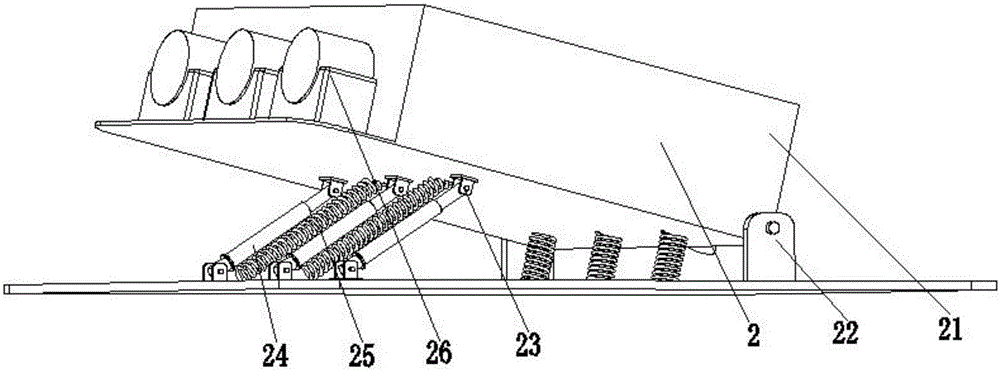

CRTS III type slab ballastless track self-compacting concrete casting tooling and method

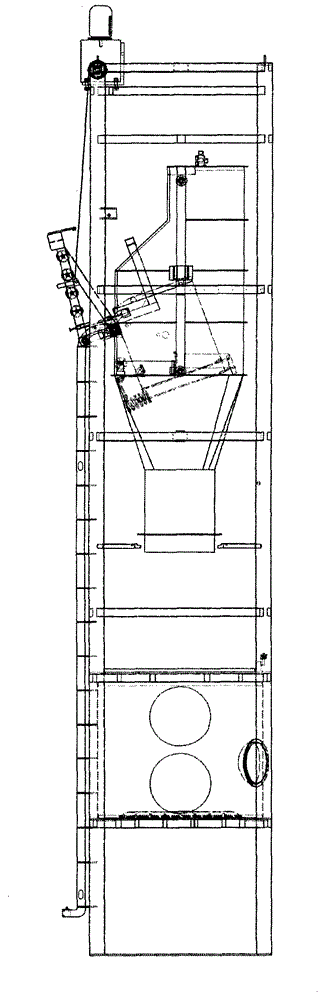

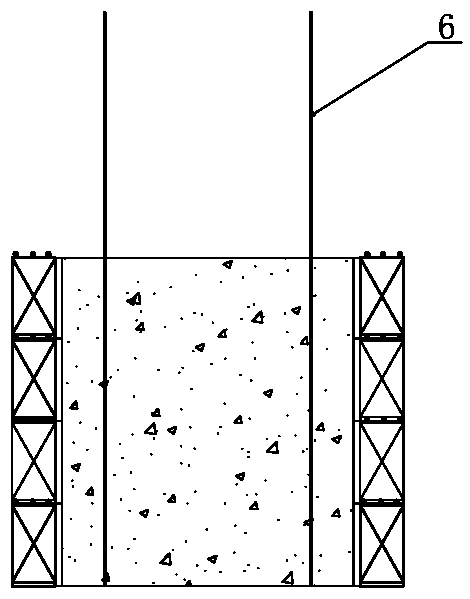

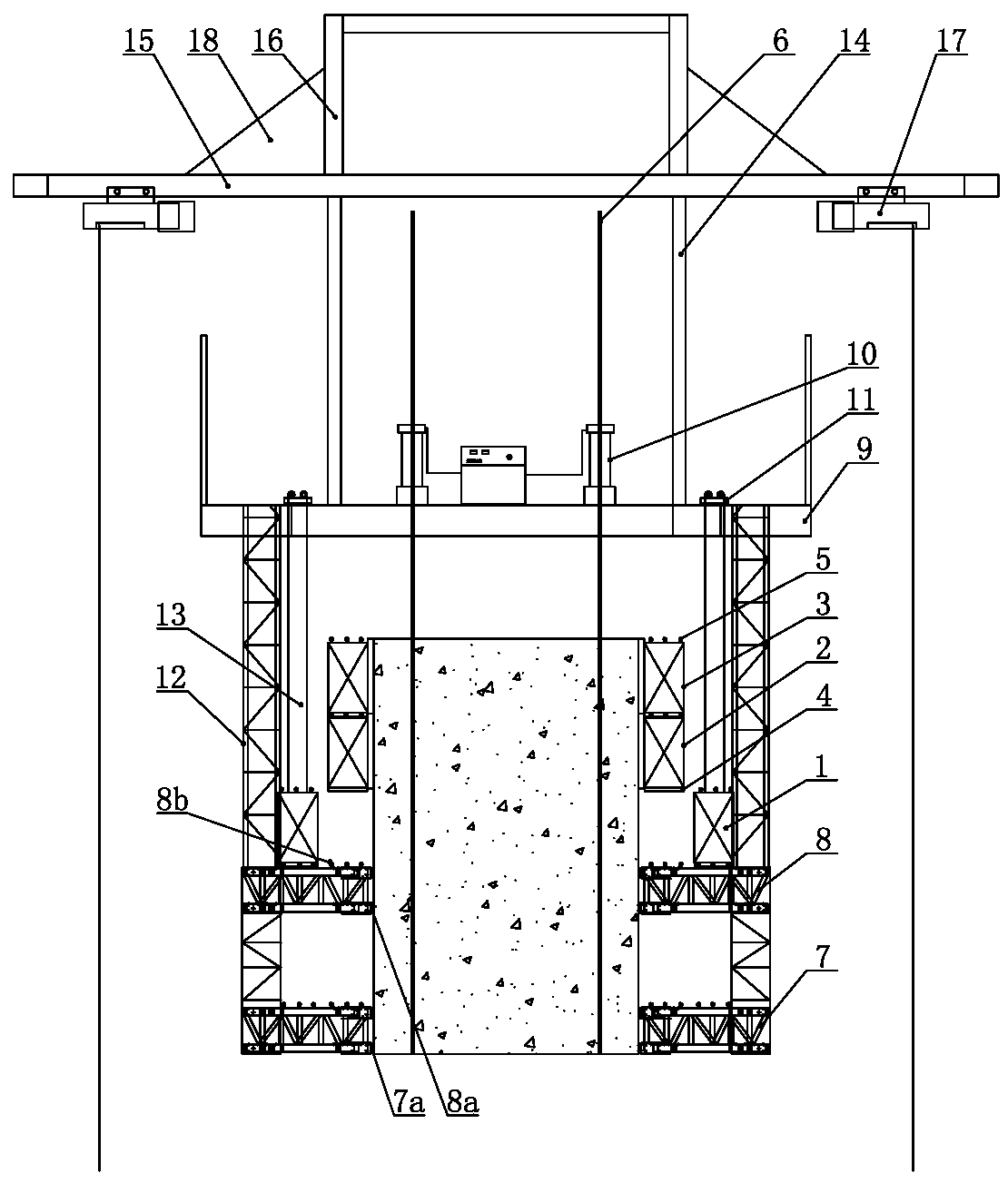

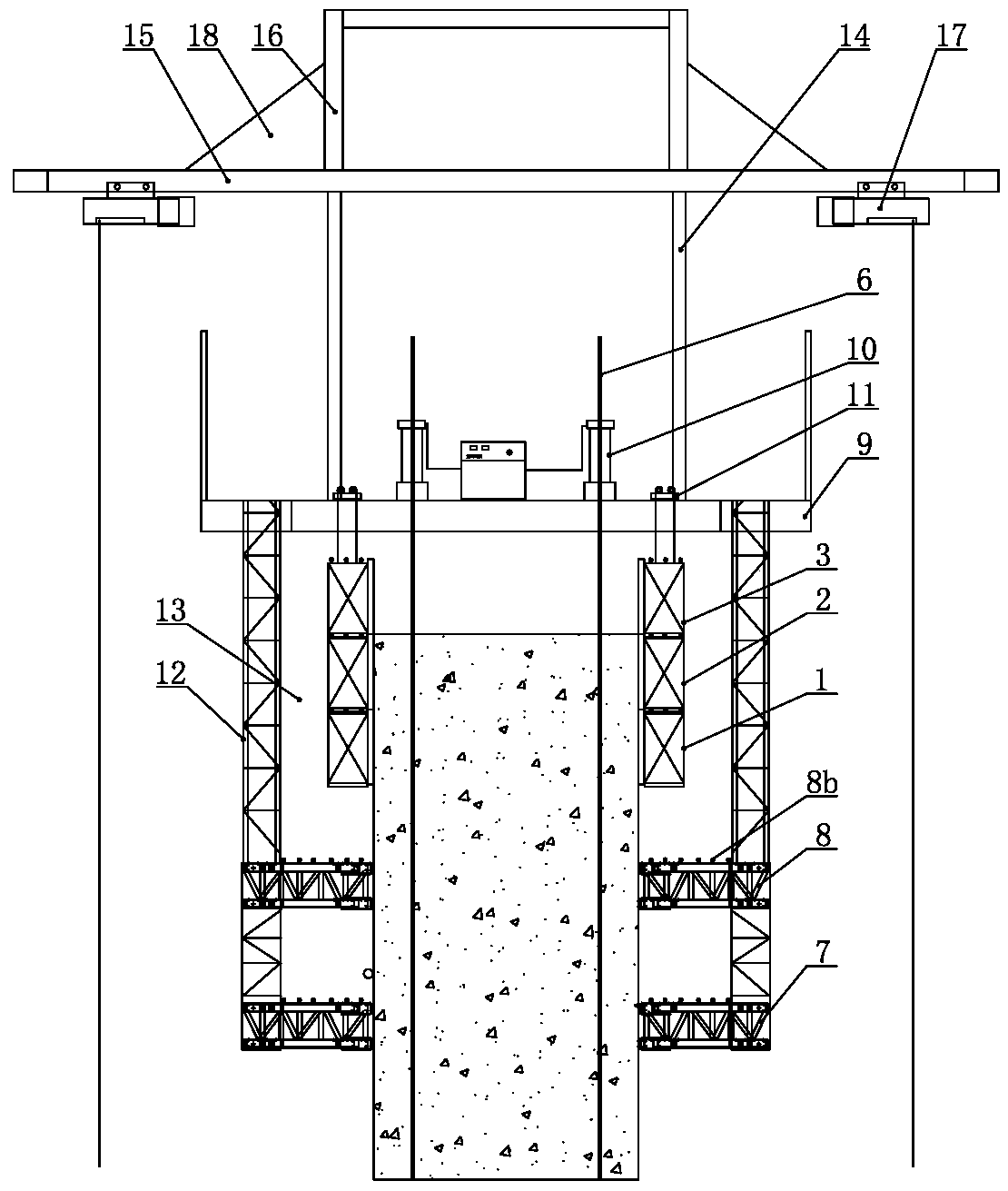

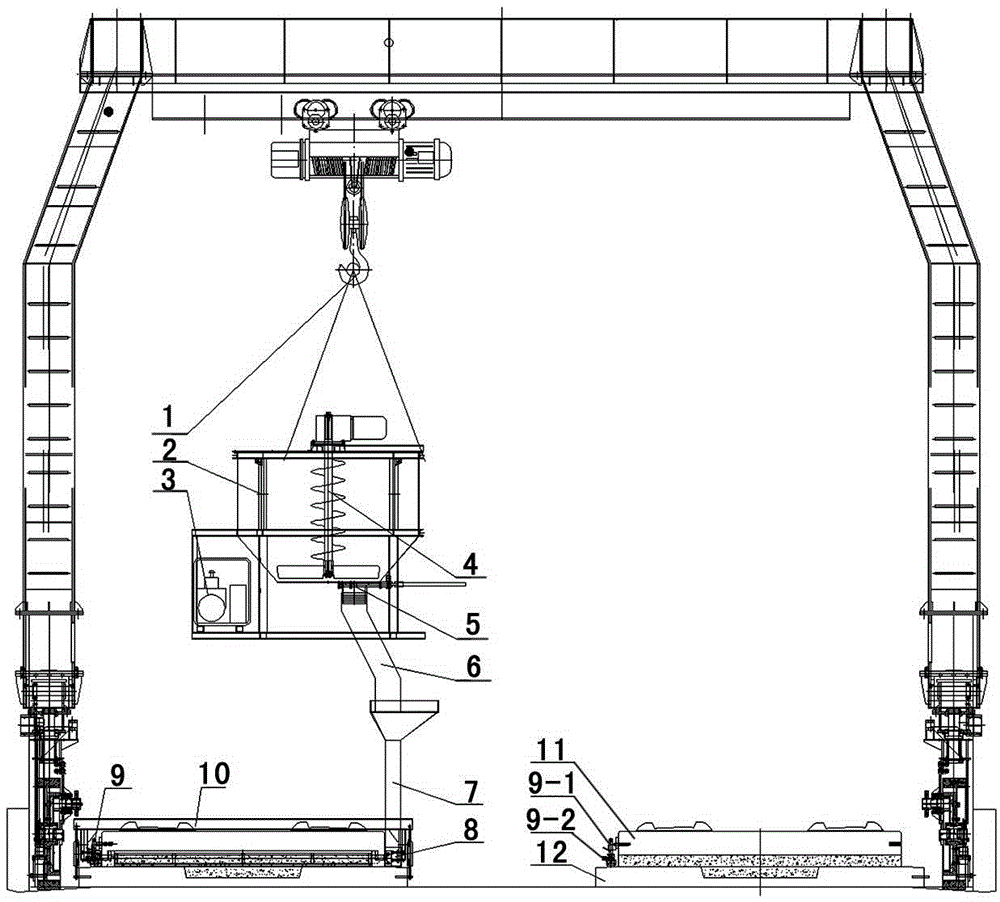

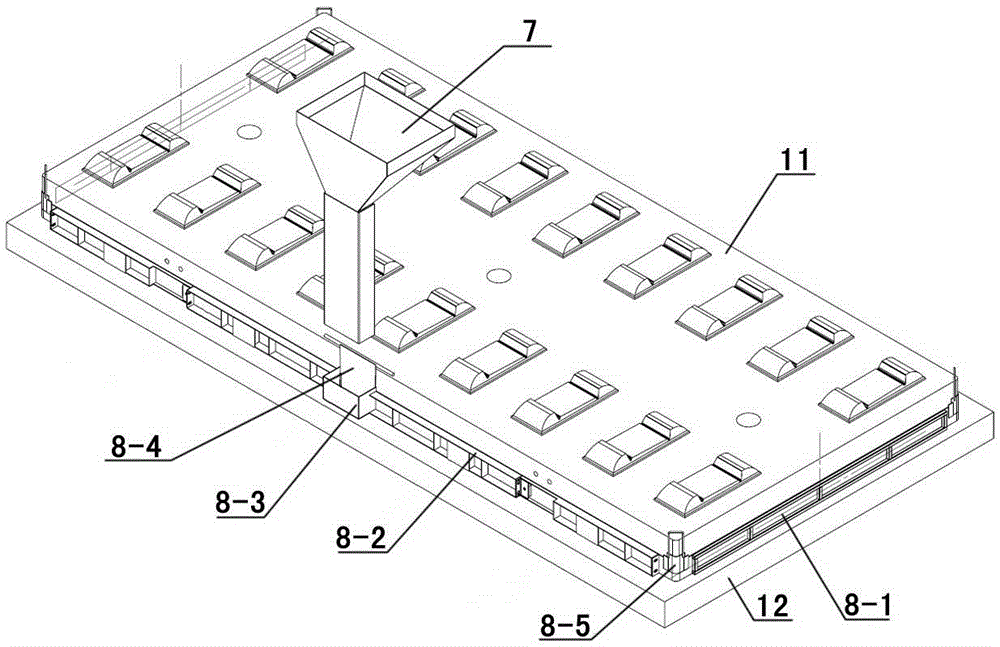

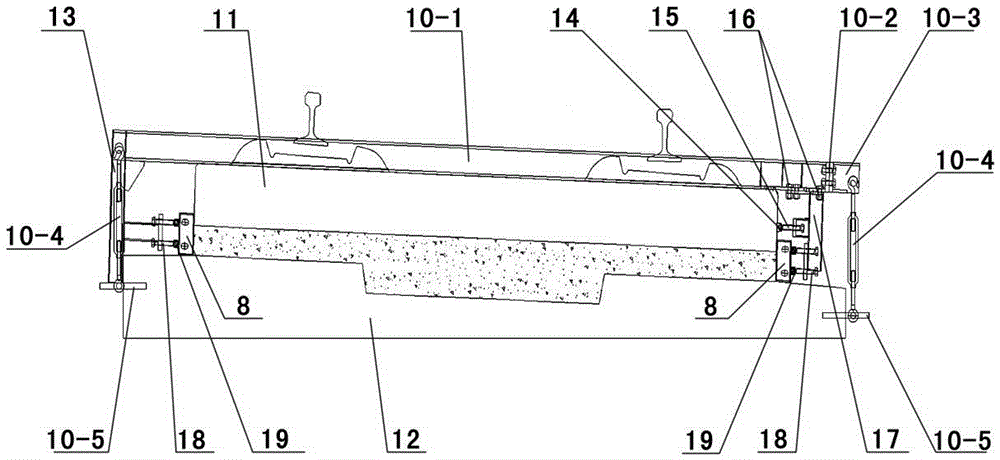

The invention provides a CRTS III type slab ballastless track self-compacting concrete casting tooling and method. The casting tooling comprises a base slab, a track slab, a transferring hopper, a casting funnel, a slurry blocking template, a three-dimensional fine regulator, a track slab pressing device, a track slab lateral sliding preventing device and a slurry blocking template pressing device. The middle casting mode is changed into the lateral surface casting, and the problems of casting efficiency and air exhaust in the CRTS III type slab ballastless track construction are solved. The track slab lateral sliding preventing device, the track slab pressing device and the slurry blocking template pressing device effectively solve the problems of upward floating, lateral sliding and slurry leakage of the track slab in the casting process, so the fine regulation and the casting construction of the CRTS III type slab ballastless track are more convenient and fast, and the casting quality is better. The construction process has the advantages that in the use process, the weight is light, the rigidity is high, the efficiency is high, the operation is simple and convenient, the work intensity is low, and the construction process can adapt to the construction of road segments such as bridges, tunnels and roadbeds.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

Lost foam casting process of high-manganese steel sieve plate

InactiveCN104353782AReduce defectsShorten the timeFoundry mouldsFoundry coresHigh volume manufacturingPilot scale

The invention relates to a lost foam casting process, in particular to a lost foam casting process of a high-manganese steel sieve plate. The lost foam casting process comprises the following steps: 1, performing blank moulding; 2, preparing paint; 3, serially connecting moulds and blank moulds; 4, painting; 5, performing sand moulding; 6, smelting; 7, casting, performing shakeout and performing water toughing treatment. By the lost foam casting process, the top pouring time is shortest and the pouring speed is high, so that sand crushing can be easily prevented; the temperature fall is small, so that defects caused by insufficient pouring and a cold shut can be easily prevented; the product yield is high, and the sequential solidification and feeding effect is good; carbon defects of a cast product can be eliminated; small-batch pilot scale tests and mass production practices show that the one-time pass rate of the cast product reaches about 95%.

Owner:WUXI LEHUA AUTOMATION TECH

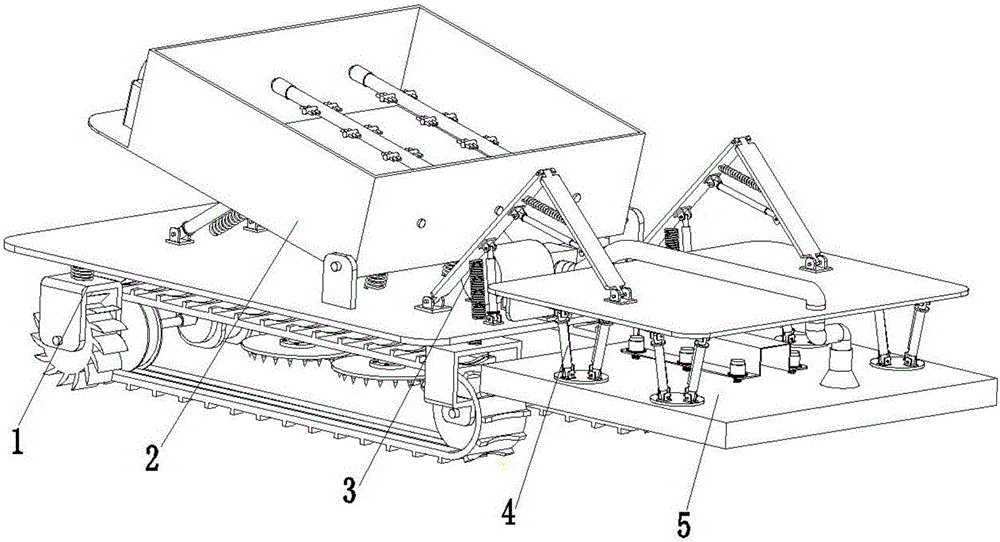

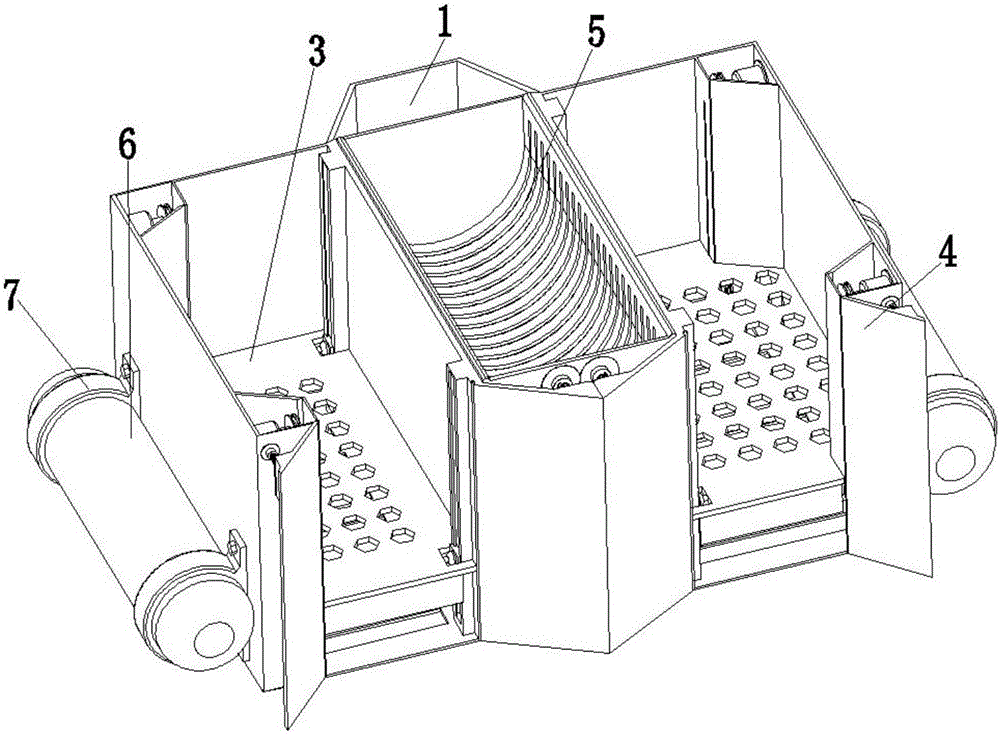

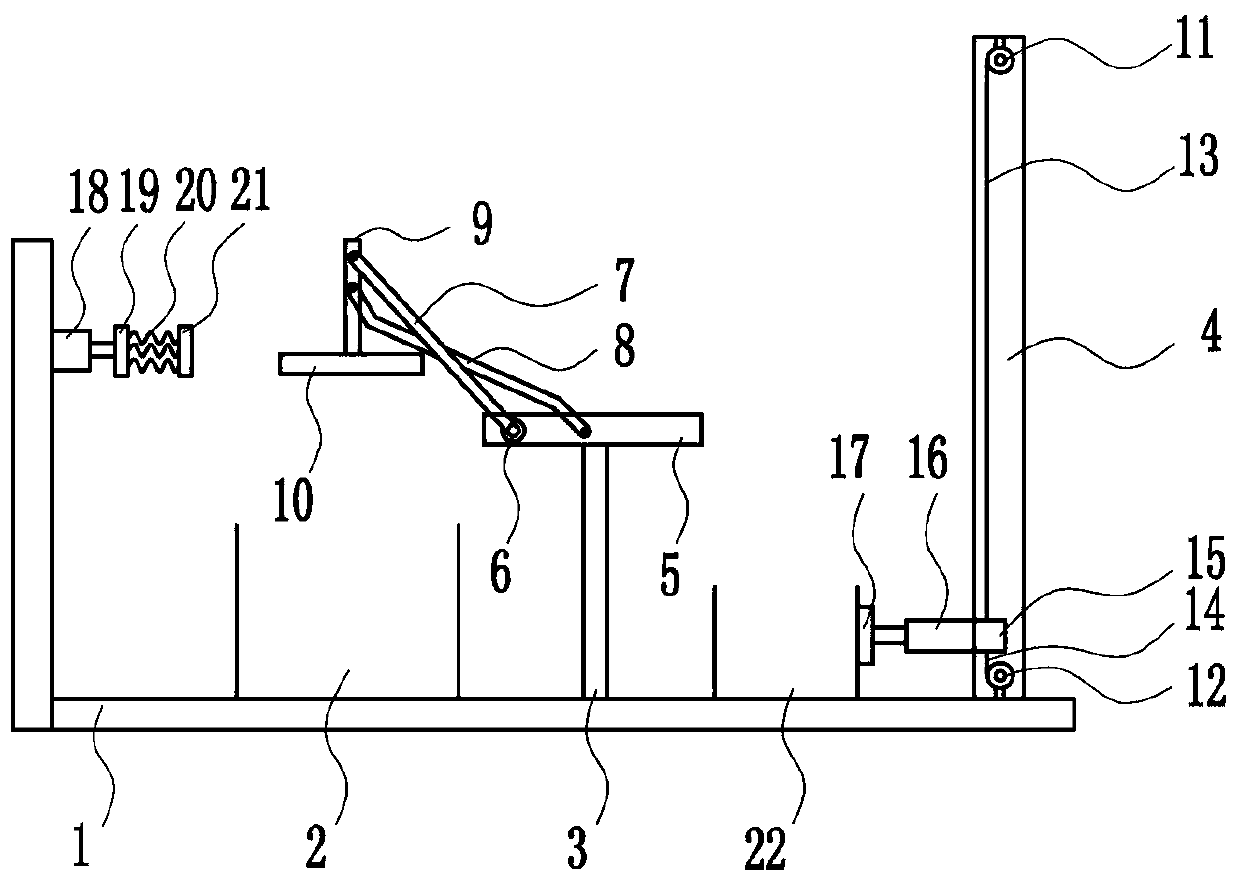

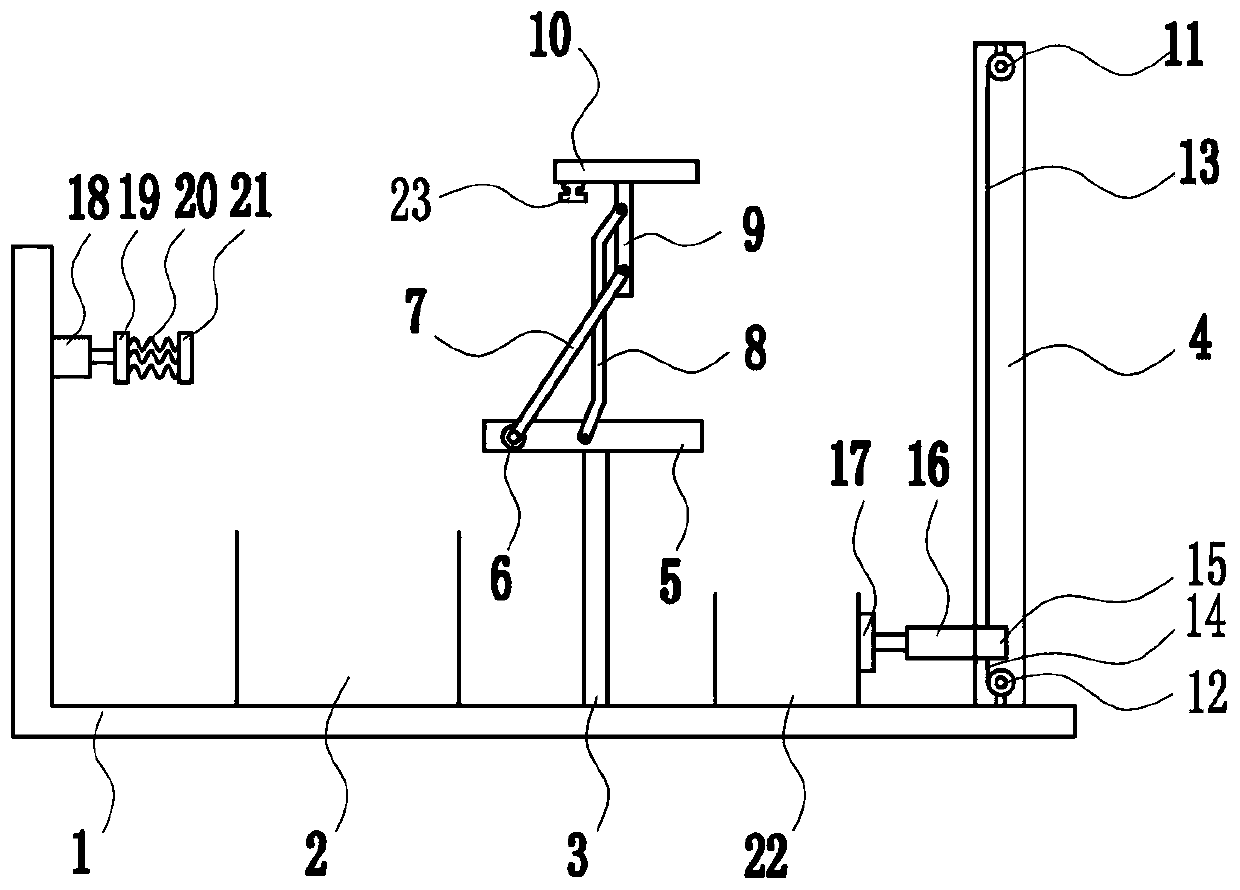

Slope protection building machinery for gardens, roads and river channels

The invention relates to slope protection building machinery for gardens, roads and river channels. The machinery comprises a traveling device, a stirring device, an adjusting device, four vibrating supports and a pouring device; the stirring device is located above the traveling device; the adjusting device is located in front of the stirring device and is connected with the traveling device; the vibrating supports are located between the adjusting device and the pouring device; the upper ends of the vibrating supports are connected with the adjusting device; and the lower ends of the vibrating supports are connected with the pouring device. The machinery integrates functions of moving, slurry stirring, slurry conveying and vibrating pouring, slope protection building can be performed on occasions such as the gardens, the roads, the river channels and the like, the functions are complete and diversified, the slope protection pouring speed is high, a lot of manpower is saved, and the convenience is provided for slope protection building on the occasions such as the gardens, the roads, the river channels and the like.

Owner:重庆九禾工程设计集团有限公司

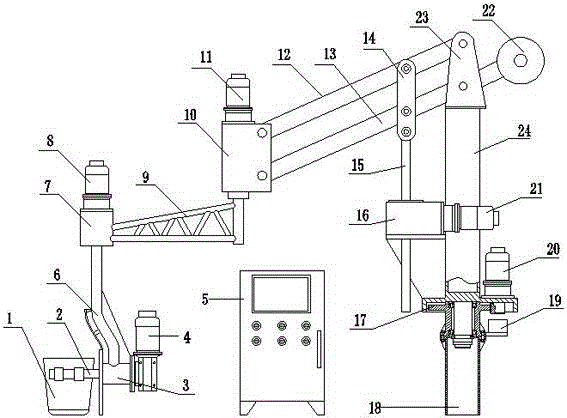

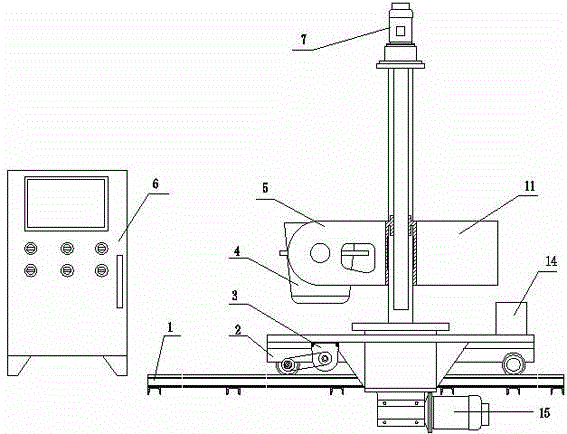

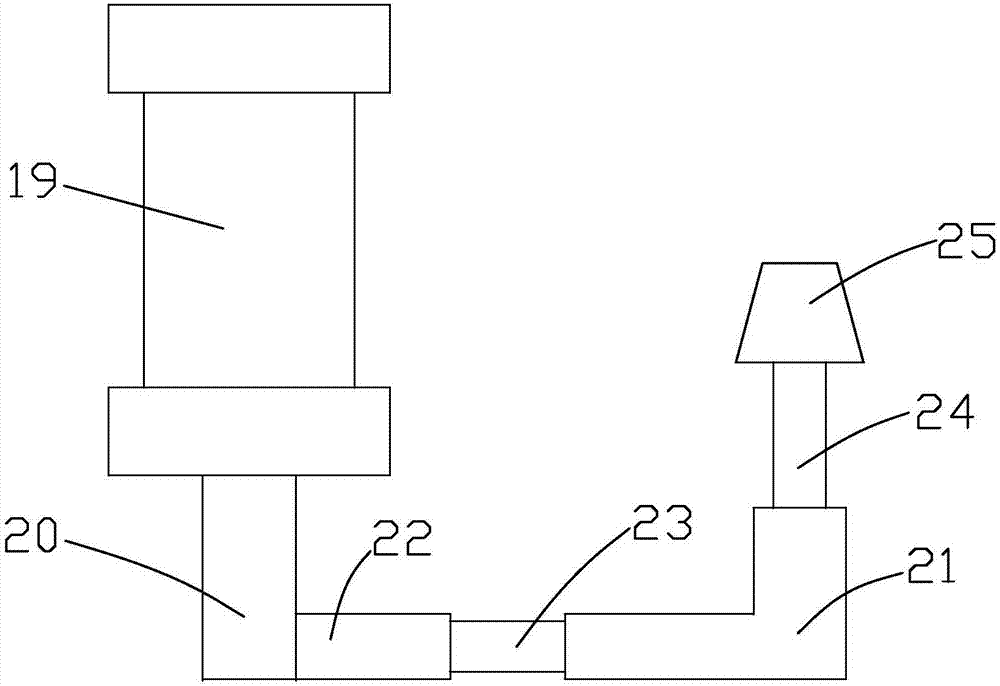

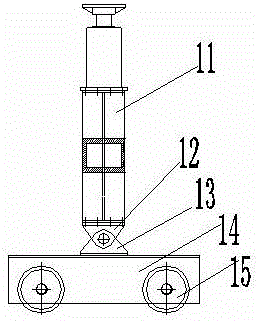

Furnace-front mechanical hand

ActiveCN102717056AImprove shipping speedFast pouringProgramme-controlled manipulatorMolten metal pouring equipmentsComputer control systemEngineering

The invention relates to the field of valve casting, in particular to a furnace-front mechanical hand for molten iron casing. The furnace-front mechanical hand comprises a whole machine rotating support mechanism, a vertical lifting mechanism, a material conveying mechanism and an extending mechanism, wherein the whole machine rotating support mechanism is connected with the vertical lifting mechanism, the vertical lifting mechanism is connected with the extending mechanism, the extending mechanism is connected with the material conveying mechanism, the lower end of the whole machine rotating support mechanism is fixedly arranged on the ground through a base, the furnace-front mechanical hand also comprises a computer control system and a balance mechanism, the computer control system is electrically connected with each mechanism, one end of the balance mechanism is connected with the whole machine rotating support mechanism through a support rod, the other end of the balance mechanism is connected with the extension mechanism, and the balance mechanism is connected with the vertical lifting mechanism through a support plate. The furnace-front mechanical hand has the advantages that the intelligent control is realized, the personnel safety of workers is ensured, and the work efficiency is improved.

Owner:浙江福瑞科流控机械有限公司

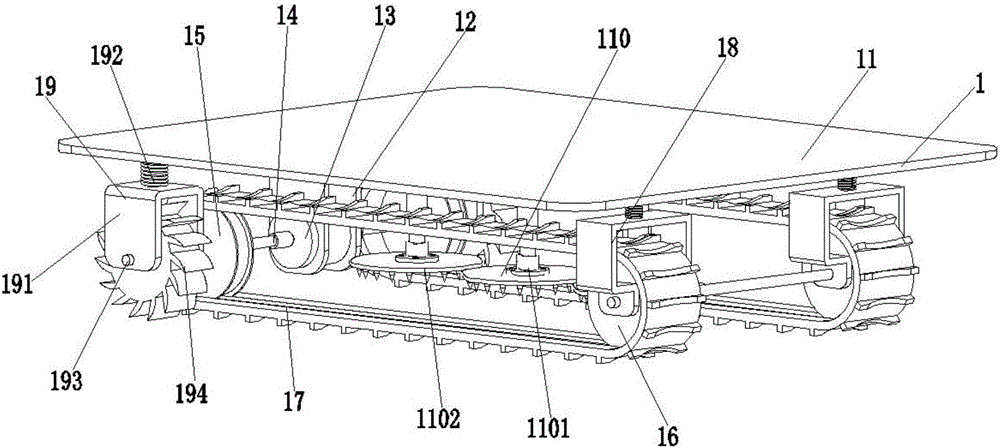

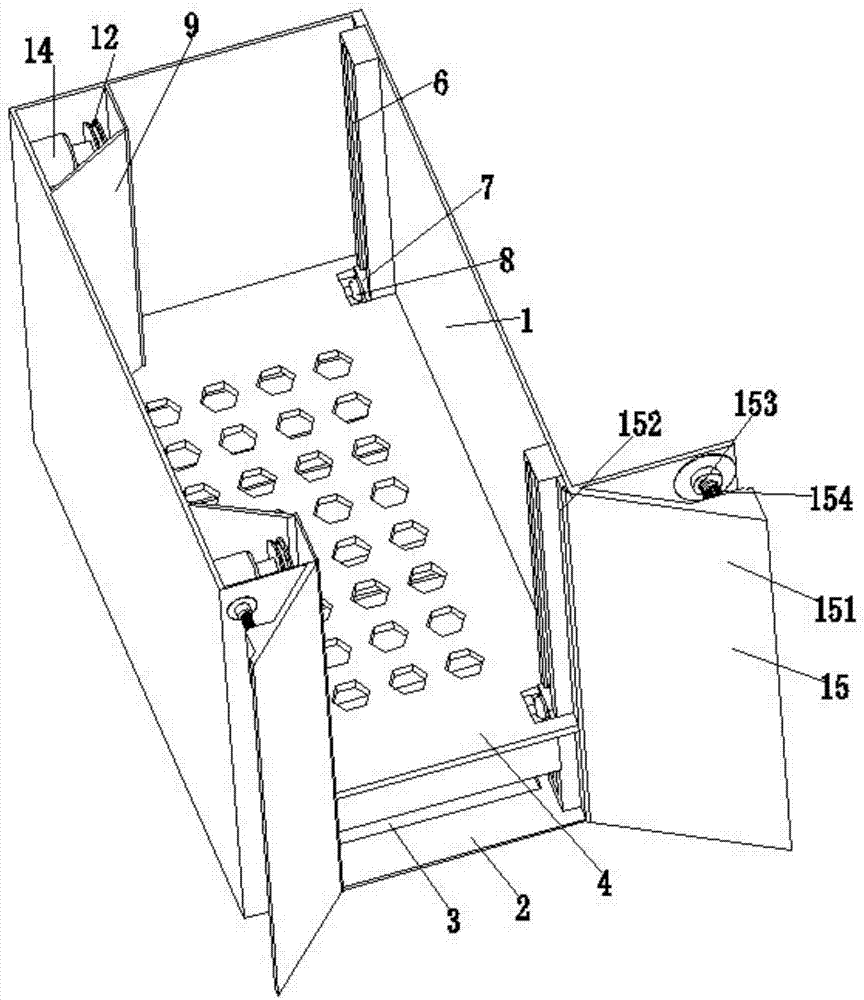

Full-automatic robot for cleaning garbage on water

ActiveCN106013023ARealize multifunctionality of one machineHigh degree of intelligenceWater cleaningWaterborne vesselsRefuse collectionFixed frame

The invention relates to a full-automatic robot for cleaning garbage on water. The full-automatic robot for cleaning the garbage on water comprises a rack, a pneumatic reversing device, charging dumping devices, garbage stopping doors, a filtering net, air barrels and fixing buckles, wherein rectangular fixing frames are symmetrically arranged at the left side and the right side of the rack; the middle part of the rack consists of an upper layer and a lower layer; the upper layer of the rack is of a semi-cylindrical housing structure of which the upper end is opened; the pneumatic reversing device is positioned at the lower rear end of the middle part of the rack; the charging dumping devices are correspondingly positioned in rectangular frame bodies at the left side and the right side of the rack; the garbage stopping doors are correspondingly positioned in front of the rectangular frame bodies at the left side and the right side of the rack; the filtering net is mounted in the upper layer of the semi-cylindrical housing structure of the rack; the air barrels are symmetrically positioned at the left side and the right side of the rack and are connected to the rack through the corresponding fixing buckles. The full-automatic robot for cleaning the garbage on water integrates the garbage collecting performance, the garbage dumping performance and the garbage storing performance, so that the robot is multifunctional; in addition, the full-automatic robot is high in intelligence degree, can fully automatically clean the garbage floating on water, and is high in working efficiency and good in cleaning effect.

Owner:江苏弘汉生物科技有限公司

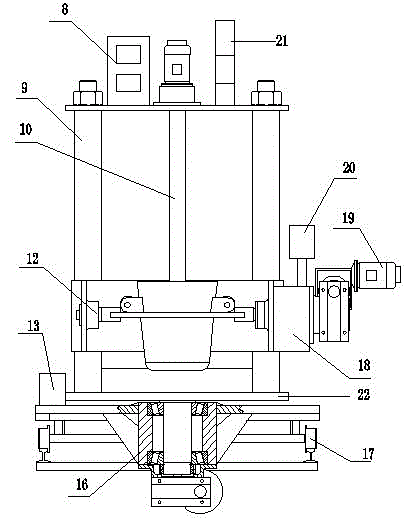

Stokehole auxiliary robot

ActiveCN102717055AImprove shipping speedIncrease alertnessMolten metal pouring equipmentsMetallurgyWater bottle

The invention relates to the valve pouring field, in particular relates to a stokehole auxiliary robot used for pouring molten iron. The stokehole auxiliary robot comprises a molten iron kettle, wherein the molten iron kettle is fixed on a molten iron kettle support by virtue of a molten iron kettle support base, the molten iron kettle support is connected with a lifting screw rod, the other end of the lifting screw rod is provided with a lifting sensor, the molten iron kettle is connected with a lifting servo motor, the molten iron kettle is connected with a molten iron kettle inclining servo motor, and a molten iron kettle inclining sensor is arranged between the molten iron kettle and the molten iron kettle inclining servo motor, so as to control an inclination angle of the molten iron kettle. The stokehole auxiliary robot disclosed by the invention solves the problems that working efficiency is low and potential safety hazard exists in operation; moreover, the stokehole auxiliary robot has the advantages that intelligent control is realized, personal safety of working personnel is guaranteed, and working efficiency is improved.

Owner:浙江福瑞科流控机械有限公司

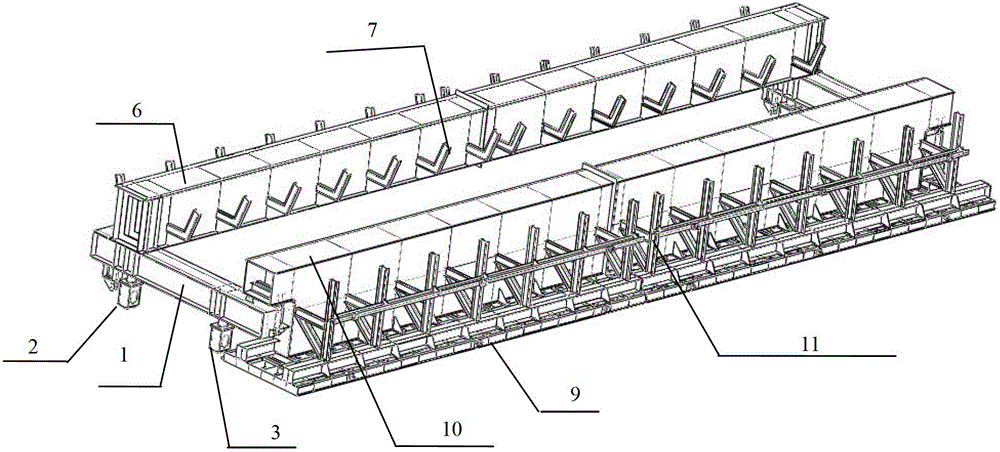

Nuclear power plant composite floor slab module and construction method thereof

The invention discloses a nuclear power plant composite floor slab module and a construction method of the nuclear power plant composite floor slab module. The construction method comprises the following steps that (1) steel structure floor slab parts are prefabricated; (2) professional items are installed on the steel structure floor slab parts, and then the composite floor slab module is acquired; (3) bracket parts for placing the composite floor slab module in position are installed on the side wall where site construction is finished; (4) the composite floor slab module is transported to a site and hoisted in position; (5) the composite floor slab module is connected with a surrounding civil engineering structure to construct, and the professional items are connected with a system. Compared with the prior art, according to the construction method of the nuclear power plant composite floor slab module, a region on a construction site where originally civil engineering is conducted and then installing construction is conducted is changed into the composite floor slab module, therefore, the effects that prefabrication of the composite floor slab module and the composite floor slab module is wholly introduced, located and then poured quickly on the site are achieved.

Owner:中广核工程有限公司 +1

Performing device of full-automatic water surface garbage cleaning robot

ActiveCN105887782ARealize multifunctionality of one machineHigh degree of intelligenceWater cleaningElectric machineryWaste collection

The invention relates to a performing device of a full-automatic water surface garbage cleaning robot. The device comprises a housing, a bottom plate, a lifting plate, a dumping plate, electric pushing rods, linear guide rails, slide blocks, ball hinges, separating plates, movable pulleys, rotating shafts, fixed pulleys, steel wire ropes, lifting motors and garbage stopping mechanisms, wherein the dumping plate is positioned right above the lifting plate; the electric pushing rods are positioned between the lifting plate and the dumping plate; one end of each ball hinge is connected with the lifting plate and the inner side end of the dumping plate, and the other end of each ball hinge is connected to the corresponding slide block; the slide blocks are mounted on the linear guide rails; the separating plates are fixed to corners of the outer side end of the housing; each steel wire rope sleeves between each fixed pulley and each movable pulley in a coiling manner; the fixed pulleys are mounted on main shafts of the lifting motors, and the lifting motors are fixed to the housing; the garbage stopping mechanisms are positioned in front of the housing. The device integrates the garbage collecting function and the garbage dumping function and achieves that a plurality of functions are integrated in one machine, so that the device is high in intelligence, can fully automatically finish the work of cleaning garbage floating in water, and is high in working efficiency and good in cleaning effect.

Owner:骆伟民

Ultralight building material and its producing method

The invention relates to an ultra-light building material which consists of driers, extravasation materials, foaming agents and water and is characterized in that the driers consist of cement which is 10 to 15 percent of the total weight of the driers and semi-hydrated gypsum which is 85 to 90 percent of the total weight of the driers; the extravasation materials consist of an efficient water reducing agent which is 1 to 3 thousandth of the total weight of the driers, a retarder for plaster which is 2 to 4 thousandth of the total weight of the driers, polyvinyl propyl ethernamine which is 0.5 to 1.0 thousandth of the total weight of the driers and anti-cracking fiber which is 1.0 to 1.5 thousandth of the total weight of the driers; the foaming agents is 5 to 6 percent of the total weight of the driers; the weight ratio of the driers to water is 1:0.6 to 1:0.65. The invention also discloses a manufacturing method of the material. The building material is characterized by good mixture workability, easy foam adding and stabilizing and high foaming efficiency.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

Valve body lost mould and using method thereof

ActiveCN105215287AHigh precisionProlong clotting timeFoundry mouldsFoundry coresAfter treatmentMaterials science

The invention discloses a valve body lost mould and a using method thereof. The valve body lost mould comprises a lost mould, a sprue cup and an ingate, wherein the lost mould comprises a sealing surface and a valve seat; the ingate is divided into a straight pouring gate, a transverse pouring gate, a vertical pouring gate and a flow gate; the flow gate is arranged on a joint of the transverse pouring gate and the vertical pouring gate; the sprue cup is connected with the straight pouring gate; the straight pouring gate is connected with a second transverse pouring gate; a sealing surface is arranged on the upper part of the flow gate; and the valve body is parallel to the transverse pouring gate. The using method of the valve body lost mould comprises eleven operation steps. A method for inversely casting a valve body is adopted, and the sealing surface in the valve body is connected with the ingate, so that pouring liquor coagulation time of a sealing surface part can be delayed, the precision of the sealing surface is improved, the principle that the important surface faces downwards in foundry practice is satisfied, the yield can be increased by 7-10%, and the after-treatment cost can be reduced by 10-30%; and meanwhile, the bottom is free of a quality problem, and materials and labor power can be saved.

Owner:埃维柯精密铸造(安徽)有限公司

Cosmetic raw material mixing and stirring device

InactiveCN111939791AEasy to pourAvoid incomplete mixingTransportation and packagingRotary stirring mixersEngineeringProduction quality

A cosmetic raw material mixing and stirring device is disclosed. The device comprises a base, sliding ways, two first telescopic rods, and a lifting table, wherein a groove is formed in the middle ofthe front side of the base in the front-back direction; sliding grooves are formed in the left side and the right side of the inner wall of the groove in the base in the front-back direction correspondingly; the two sliding ways are connected with the left side and the right side of the upper surface of the base through screws in the up-down direction correspondingly; the two first telescopic rodsare arranged on the inner sides of the two sliding ways in the vertical direction correspondingly; the bottom ends of the first telescopic rods are connected with the outer walls of the sliding waysthrough bolts; sliding rails are arranged on the left side and the right side of the bottom end of the lifting table in the vertical direction. According to the cosmetic raw material mixing and stirring device, adaptability is enhanced, incomplete mixing of raw materials is avoided, the quality and the using effect of cosmetics are guaranteed, the stirred cosmetic raw materials can be taken out conveniently, raw material residues in a tank are prevented through pouring, people can clean the interior of the tank easily, and a situation that the raw materials deposit at the bottom of the tank and deteriorate to affect the production quality is avoided.

Owner:陈希凯

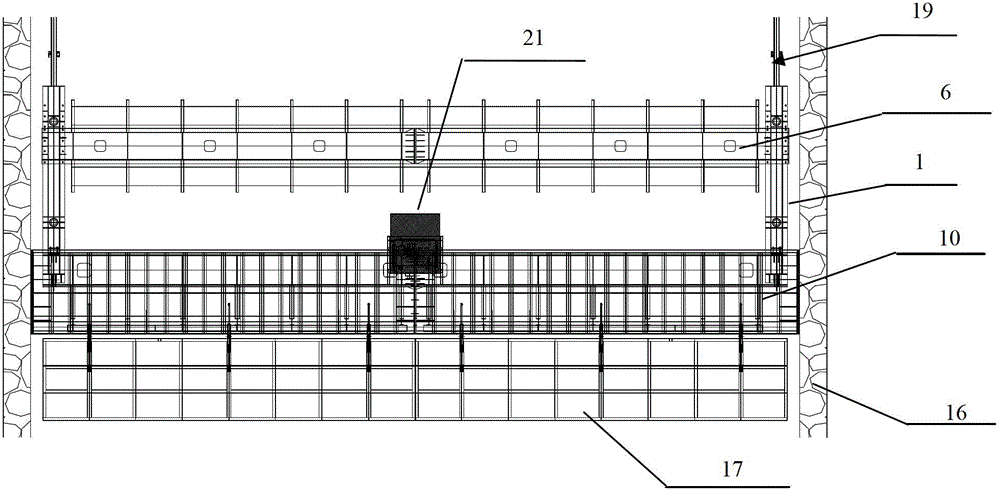

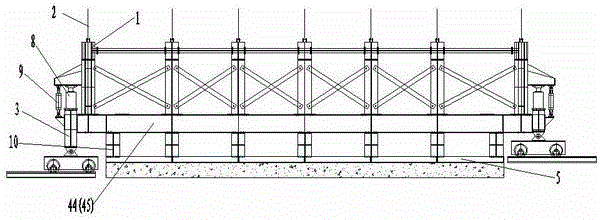

Concrete distributor for tunnel formwork trolley

PendingCN108222973AQuality assuranceEasy to controlUnderground chambersTunnel liningEngineeringDistributor

The invention provides a concrete distributor for a tunnel formwork trolley. The concrete distributor comprises a distributor base, wherein a main pipeline support, an S pipe front bracket, an S piperotary bracket and a sub-pipe sliding seat assembly are arranged on the distributor base; a main pipeline is arranged on the main pipeline support; S1 pipelines are arranged on the S pipe front bracket and the S pipe rotary bracket; a sliding distribution slider assembly and a sliding oil cylinder rear seat are arranged on the sub-pipe sliding seat assembly; a sliding oil cylinder is arranged between the distribution slider assembly and the sliding oil cylinder rear seat; the main pipeline is connected with the S1 pipeline; the S1 pipeline is connected with an S2 pipeline; and the S2 pipelineis connected with the distribution slider assembly. The concrete distributor provided by the invention has the following advantages: the structure is reasonable, and the operation is convenient; a pipeline is adopted for pumping during concrete pouring, and thus the pouring is fast; since the concrete is placed in a closed pipeline, the time of contact with air is reduced, the concrete quality isguaranteed, the control for the concrete pouring process is facilitated in tunnel secondary lining construction, and the construction efficiency and the lining quality are improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

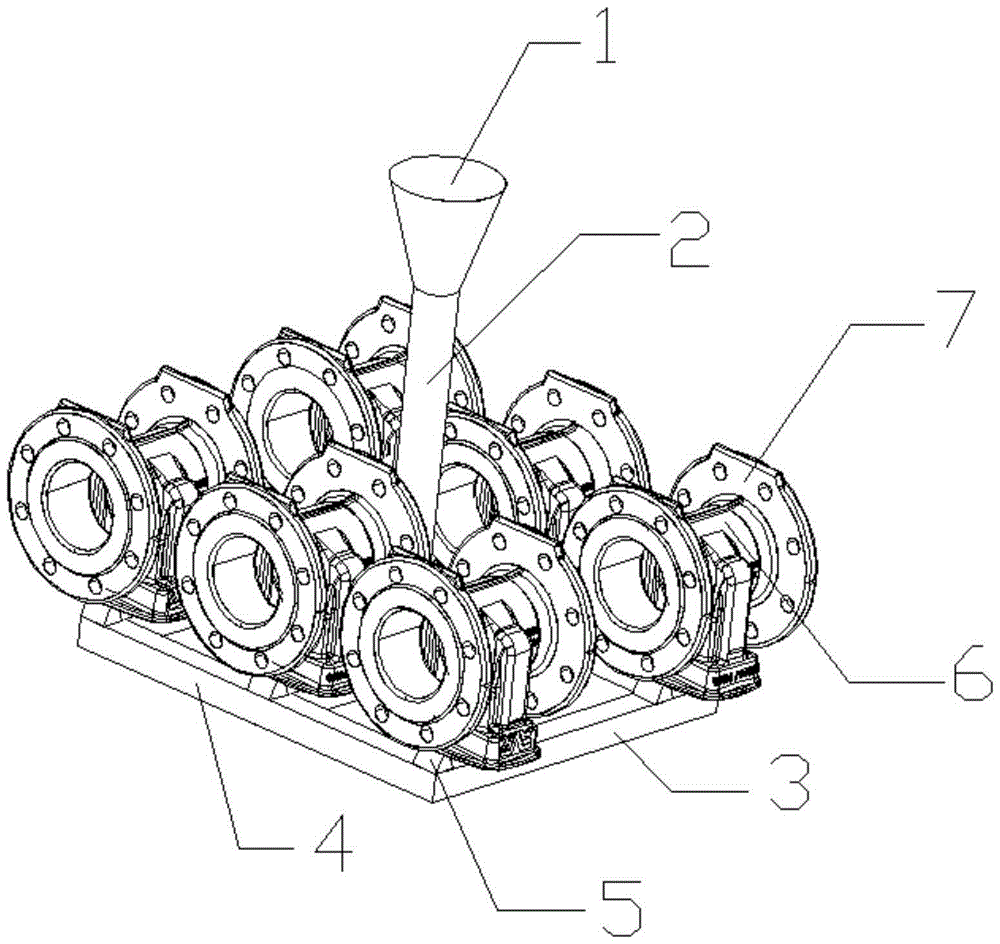

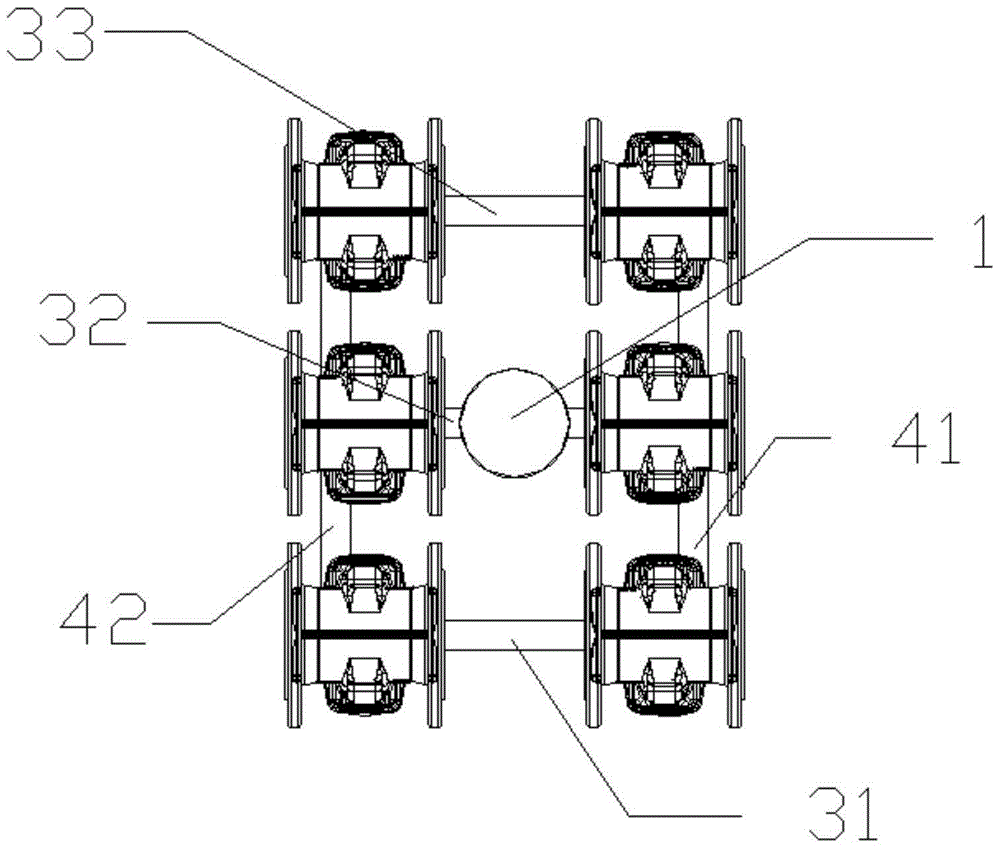

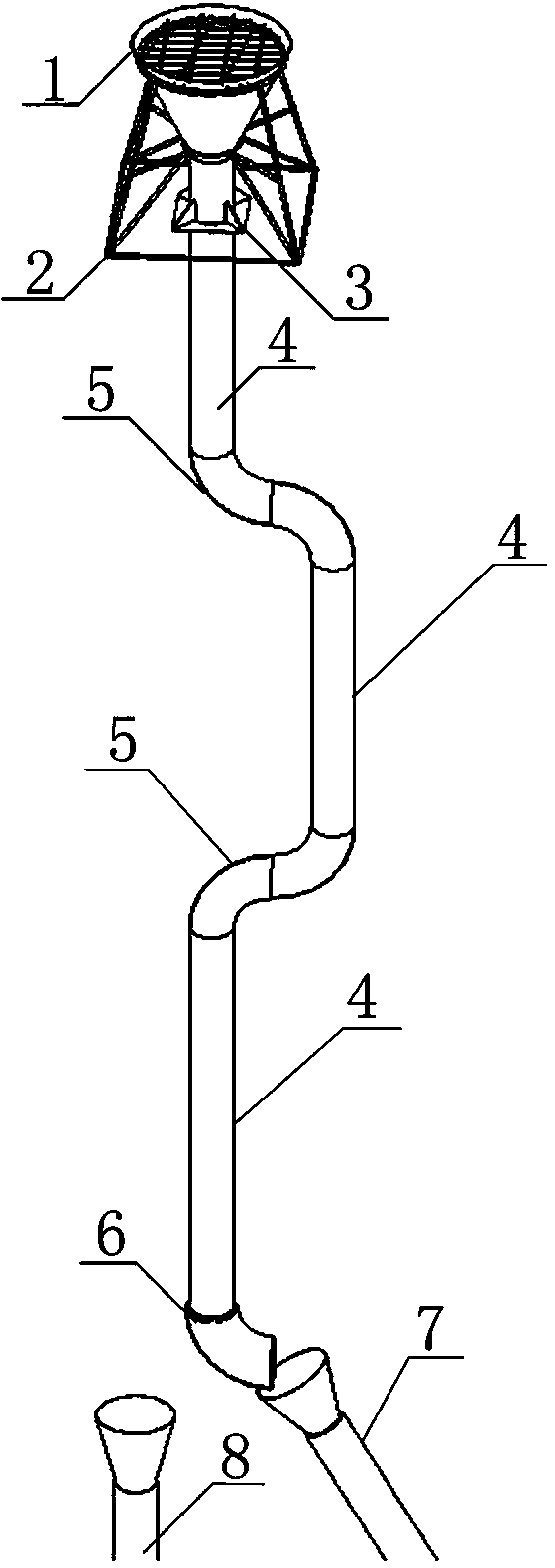

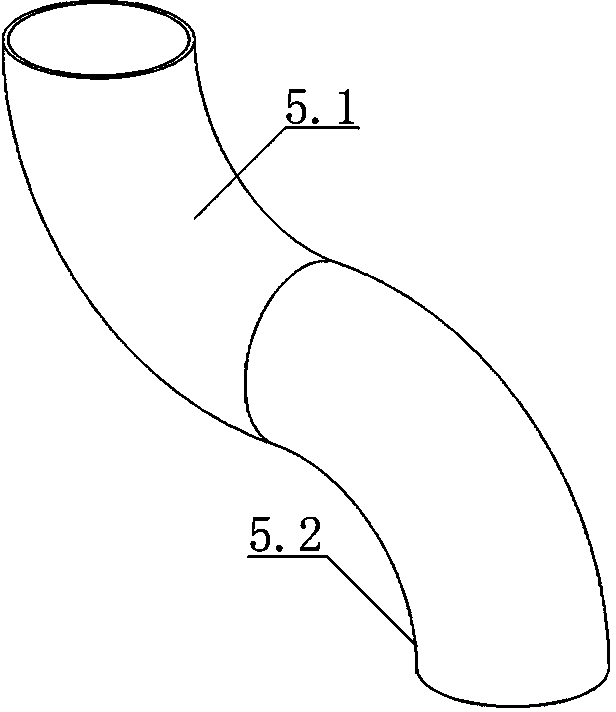

Ultra fast buffer forked type concrete pouring string pipe and construction method thereof

The invention relates to an ultra fast buffer forked type concrete pouring string pipe and a construction method thereof. The concrete pouring string pipe comprises a concrete inlet hopper, a steel bracket, straight pipes, buffer elbows, a rotary elbow and sub-string pipes. The concrete inlet hopper is placed on the steel bracket on a primary concrete inner support. The straight pipes penetrate through holes in the primary concrete inner support and lower concrete inner supports downwards in a segmented mode and are fixed, and each upper straight pipe and the corresponding lower straight pipe are staggered in position and connected through the corresponding buffer elbow. The upper opening of the uppermost straight pipe is connected with the lower opening of the concrete inlet hopper, the lower opening of the lowermost straight pipe is connected with the rotary elbow capable of rotating in the horizontal direction, and the sub-string pipes arranged according to in-situ pouring position requirements are arranged below the rotary elbow. The ultra fast buffer forked type concrete pouring string pipe is capable of being repeatedly used, firm, durable, flexible in layout, simple to install, low in manufacturing cost and suitable for mass concrete pouring construction of deep foundation pit bottom plates used in a concrete inner support protecting mode in soft soil areas.

Owner:CSCEC CITY CONSTR DEV

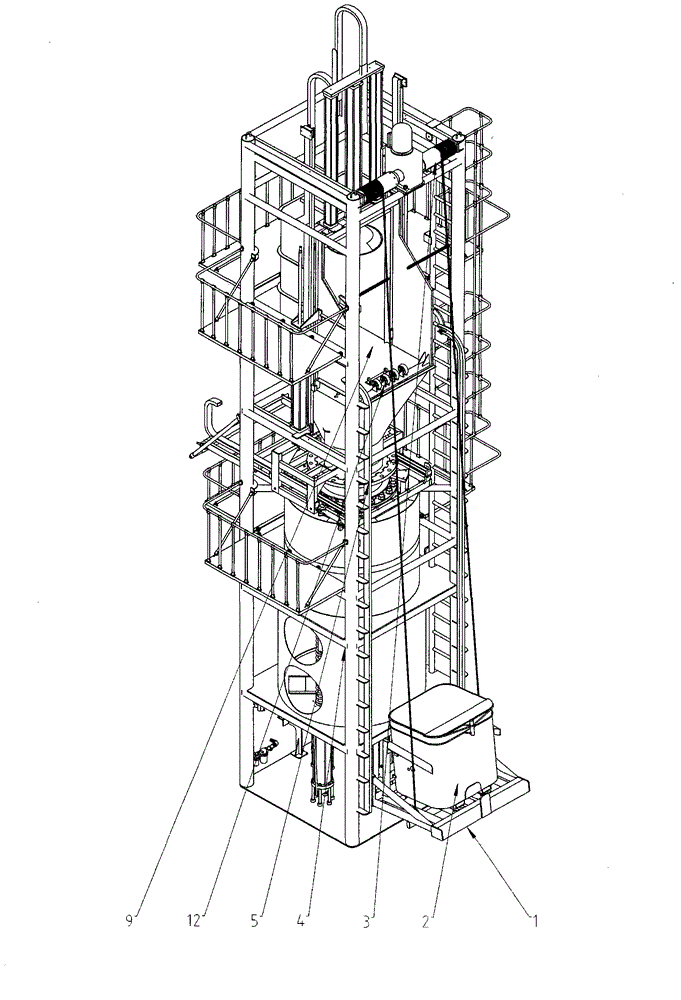

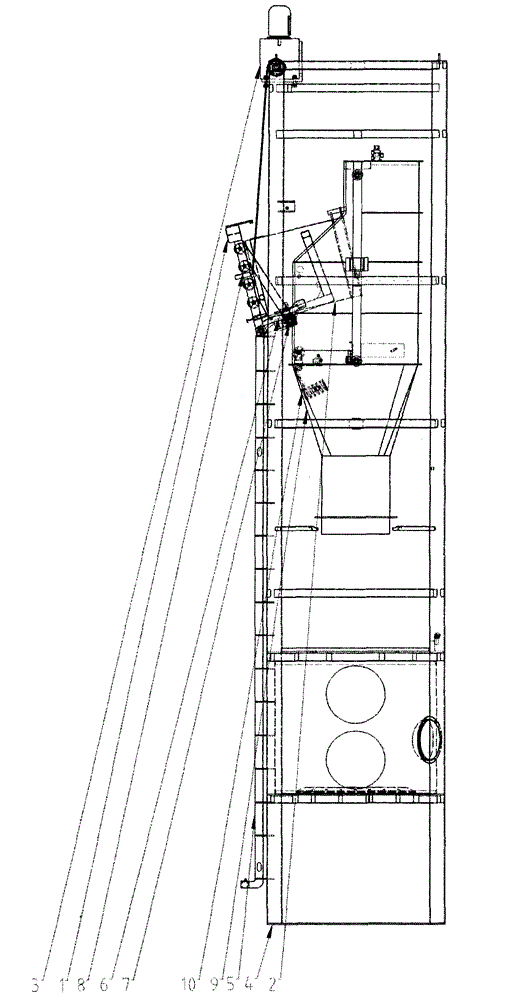

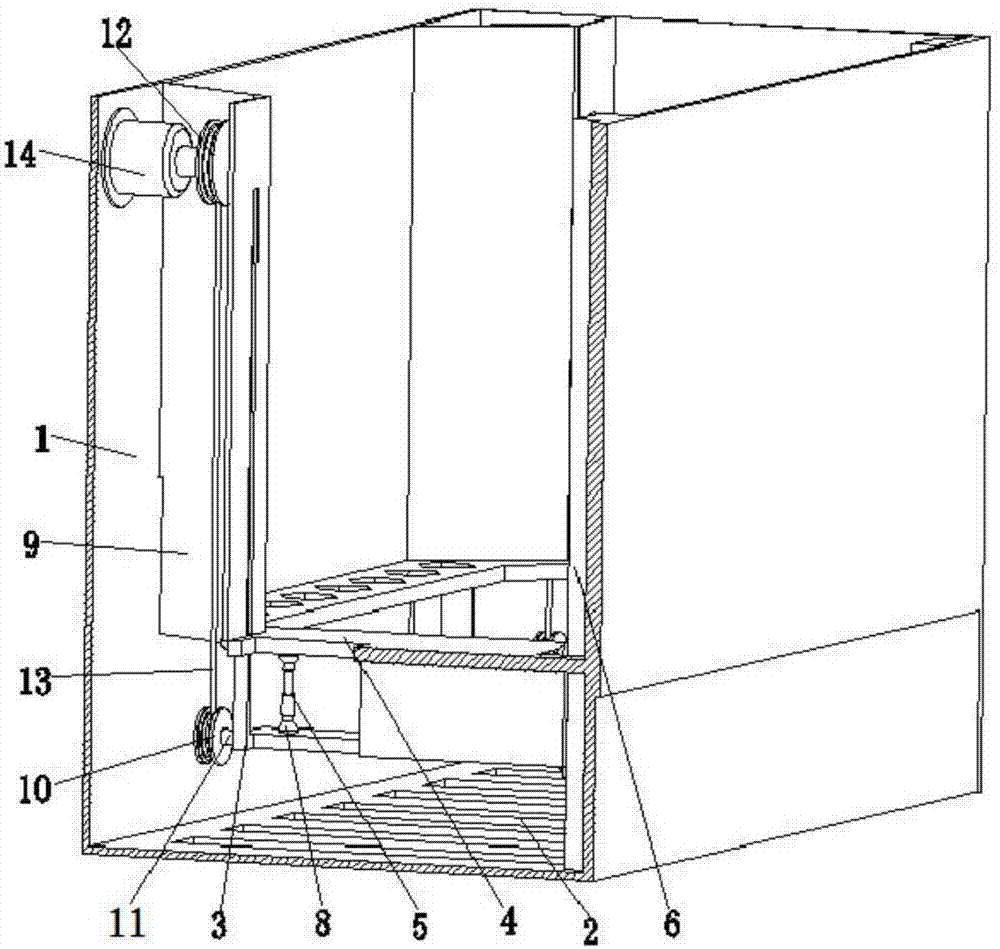

Elevator matched with steam blasting machines

The invention relates to a material elevator matched with steam blasting machines, and belongs to material conveying devices. The elevator matched with the steam blasting machine provided by the invention only adopts a steel wire rope roller as a driving component to lift and drag a bracket to move up and down in a vertical track, and can permit a large-size circulating hopper to be dumped for angles of more than 150-170 degrees and reset. Since the dumping angle is more than 150 degrees, dumping speed is rapid, and thereby light biomass can be dumped completely. A steel wire rope is directly used for vertically hoisting materials without any moving accessories, so that additional energy consumption is avoided. The elevator is attached to the vertical frame of the steam blasting machine, thus being capable of saving occupied space as much as possible. In addition, the machine is simple in structure, few in moving parts, and being capable of fully adapting to various kinds of biomass materials and hostile working environments, and stable and reliable in operation. The circulating hopper can be rapidly assembled and disassembled by forklifts, and the plurality of circulating hoppers can be configured, thus being capable f greatly improving whole logistics efficiency.

Owner:于政道 +1

Construction device of high building and concrete pouring construction method

PendingCN108560992AGuaranteed not to shakeReduce intensityForms/shuttering/falseworksTowersSteel columnsUltimate tensile strength

The invention relates to a construction device of a high building and a concrete pouring construction method. Three layers of formworks are arranged, a middle platform is arranged on the lower side ofthe lower formwork, a bottom platform is arranged a distance away from the lower side of the middle platform, the middle platform and the bottom platform abut against a concrete wall through wall attaching wheels respectively, the outer end of the bottom platform and the outer end of the middle platform are connected with each other through an outer lifting frame, the upper end of the outer lifting frame extends upwards to be fixedly connected with a top platform, the lower end face of the top platform is spaced from the top of the upper formwork, a plurality of hydraulic jacks are arranged on the upper end face of the top platform, each hydraulic jack embraces a supporting steel column, the lower end of each supporting steel column extends to the bottom of poured concrete, a formwork turning channel is arranged between the opposite end faces of the outer lifting frame and the formworks, and a formwork turning trolley supported on a guide rail is arranged on the top platform. When theconcrete intensity of the lower sides of the formworks reaches 0.2 MPa, the lower formwork is detached and turned to the upper layer, and all platforms synchronous rise. The construction device is high in concrete pouring speed, smooth in surface, even in color and luster, high in perpendicularity and high in safety coefficient.

Owner:扬州市中润模板有限公司

Die for vulcanization of watertight connector

The invention discloses a die for vulcanization of a watertight connector. The die comprises an upper die, a lower die, locating pins, a flow guide plate, a die release plate, ejector rods and a die opening rod. A whole set of vulcanization device is made of light metal materials. The upper die and the lower die are assembled for accurately positioning the watertight connector, an inner vulcanization cavity is formed, and it is ensured that the vulcanization thickness of the outer surface of the watertight connector is kept consistent. The flow guide plate is designed to be of a movable structure and is formed by combining two plates, a V-shaped flow guide groove can be formed by the flow guide plate, the flow guide plate is also demounted conveniently, and feeder removal is achieved. The locating pins are asymmetrically distributed, and cooperation accuracy can be improved. The die opening rod and the die release plate are combined to form a die release mechanism, so that the upper die and the lower die can be conveniently disengaged perpendicularly, and a vulcanization surface cannot be torn. The vulcanization device has the beneficial effects of being high in casting speed, even in vulcanization layer thickness, good in vulcanization surface quality, capable of facilitating die release and being used repeatedly, easy to operate and the like.

Owner:HUNAN HAIDUN OPTICAL FIBER SENSING TECH ENG LAB

Slope hydraulic self-propelled concealed-rail drag mold

ActiveCN102720162ASolve problems limited by slope slopeFast constructionCoastlines protectionHydraulic pumpEngineering

The invention provides a slope hydraulic self-propelled concealed-rail drag mold, which comprises travel beams, a balance beam, a template system, a working platform, a hydraulic system and the like, wherein each travel beam consists of a crossbeam, a front sliding seat, a back sliding seat, adjusting screws and a cylinder block; the front sliding seat is in rigid connection with the crossbeam, and the back sliding seat is hinged with the crossbeam; the template system consists of a template, a bearing beam and a template system support frame; the bearing beam is parallel to the balance beam; two ends below the bearing beam and the balance beam are respectively provided with a travel beam in the vertical direction; the rear end of the template is provided with the template system support frame; the working platform is parallel to a rail, and is obliquely tensioned on the template system support frame through a spiral lock button; the hydraulic system mainly comprises a hydraulic pump station, advancing cylinders, a hydraulic pipeline and the like; the hydraulic pump station is arranged in the middle of the bearing beam; and an advancing cylinder is arranged below each of two travel beams. The drag mold is not limited to the slope gradient, can ensure that concrete can be continuously poured in large cube amount and large area, and ensures high pouring speed and good quality.

Owner:SINOHYDRO BUREAU 7 CO LTD

Integrated molding powder stirring and storing device capable of facilitating blanking

The invention provides an integrated molding powder stirring and storing device capable of facilitating blanking. The device comprises a base, a roof cover, a lifting mechanism, a cylinder, a stirringshaft, a feeding door, a discharging door and a storing cylinder, wherein a support seat is arranged above the base; the lifting mechanism is arranged above the support seat; a plurality of telescopic stirring blades are arranged on the stirring shaft; a material guiding plate is fixedly arranged at the bottom of the cylinder; the storing cylinder comprises a first storing cylinder and a second storing cylinder; a scraping ring is arranged on the inner wall of the first storing cylinder in a surrounding manner; a scraping plate is arranged on the inner wall of the second storing cylinder; thedischarging door is arranged below the second storing cylinder; and a support table is arranged below the discharging door. According to the integrated molding powder stirring and storing device, theraw material is fully stirred, the blanking speed of the stirred raw material is high, the mixed raw material is unlikely to be adhered to the inner walls of the storing cylinders when poured out, the pouring speed is high and the cooled material is simple to take out.

Owner:新昌县中邦塑粉科技有限公司

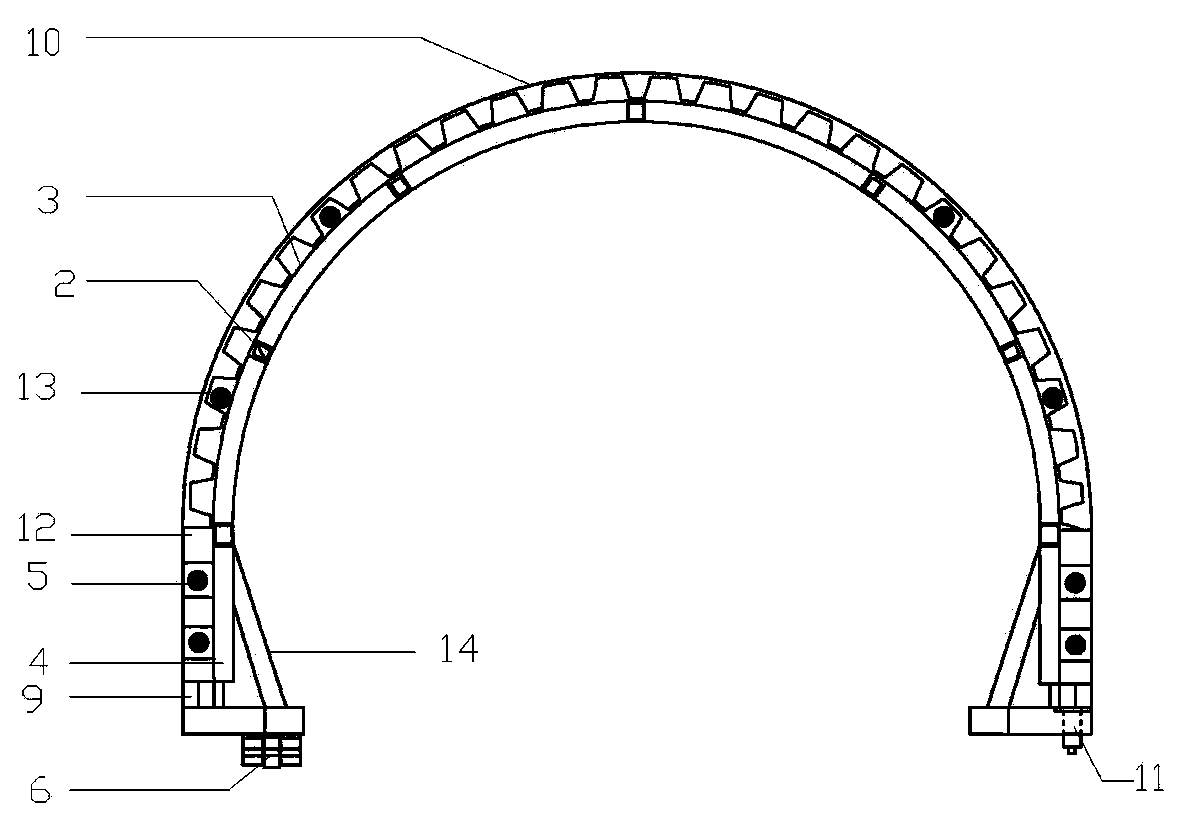

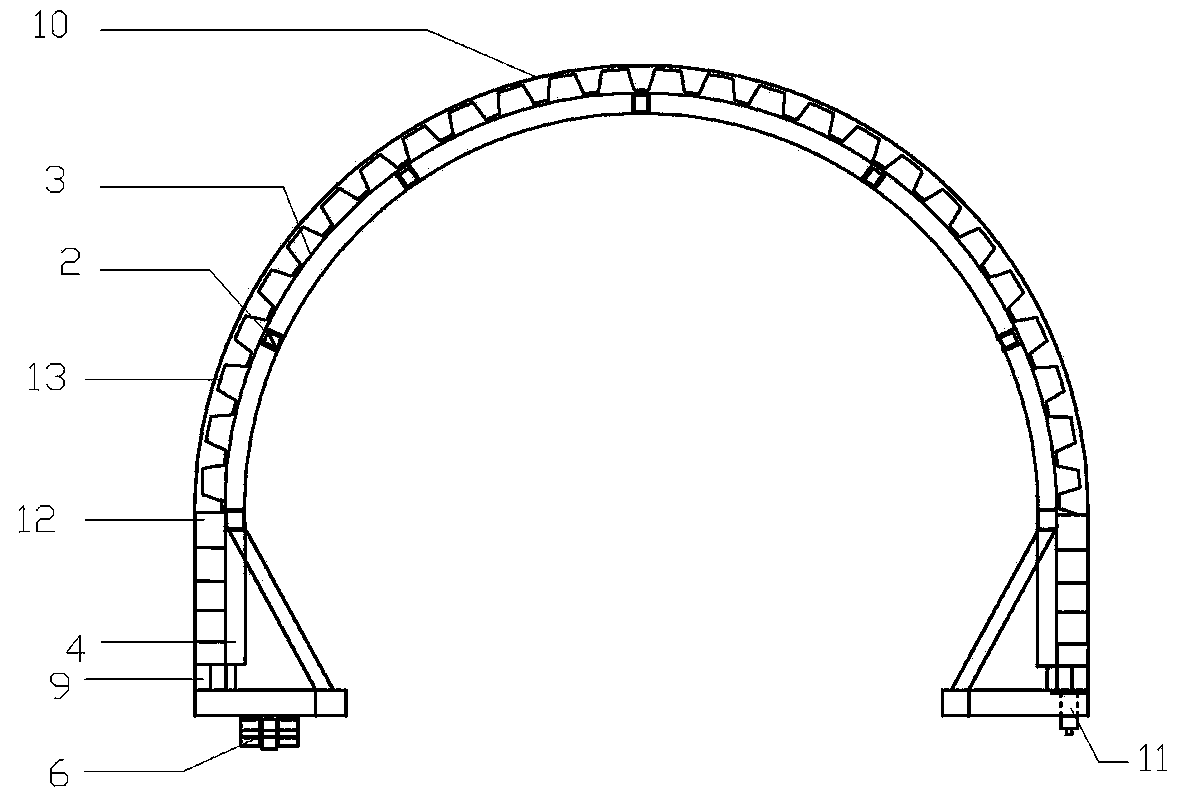

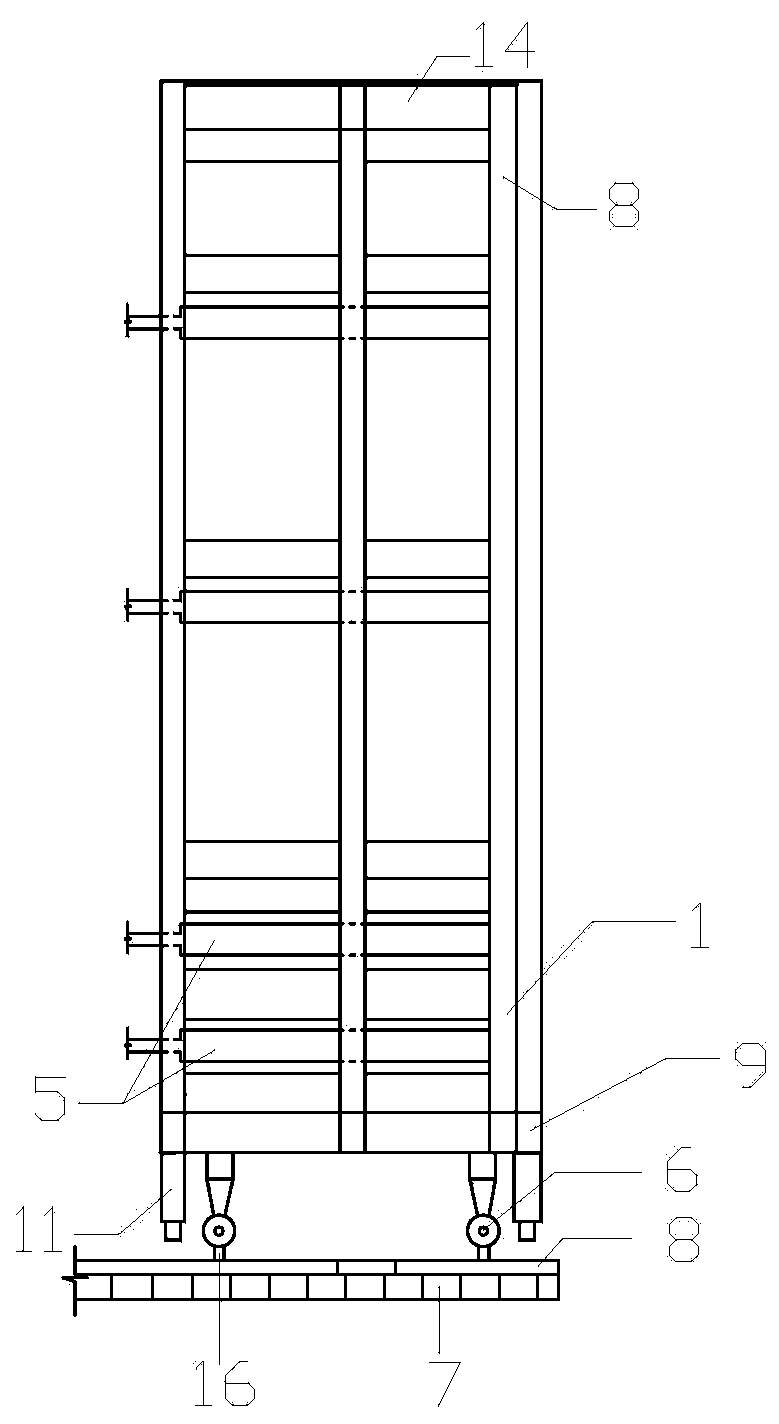

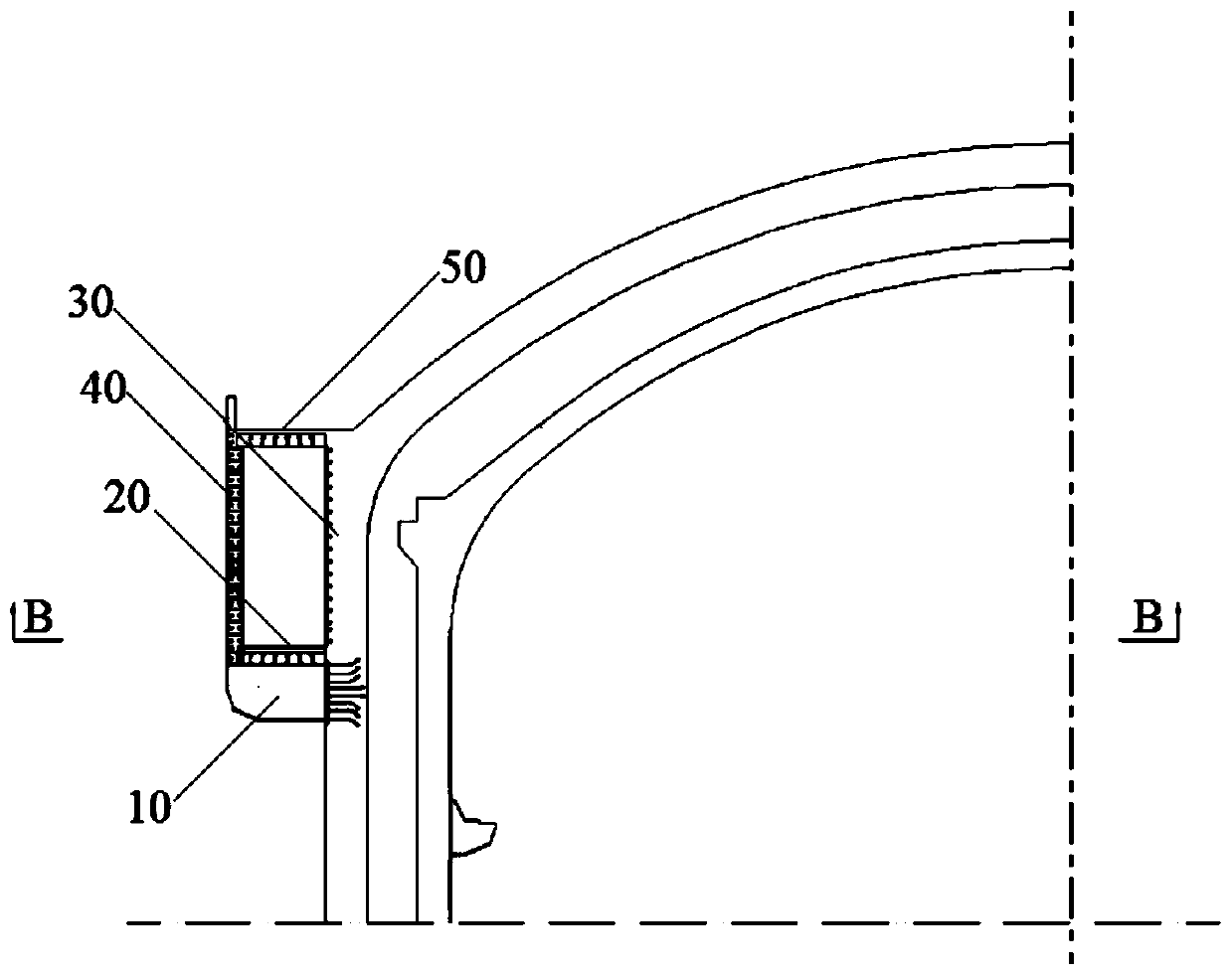

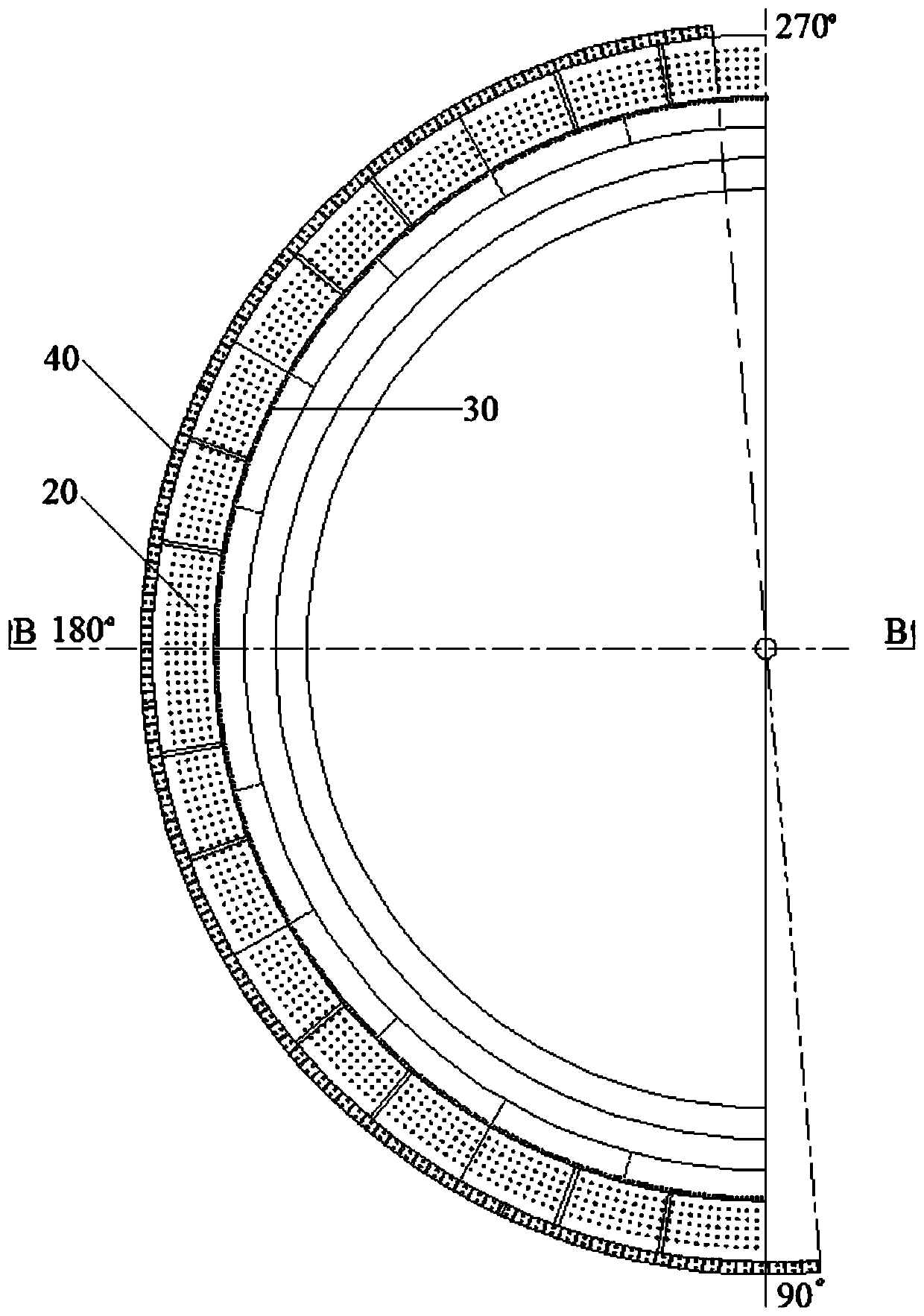

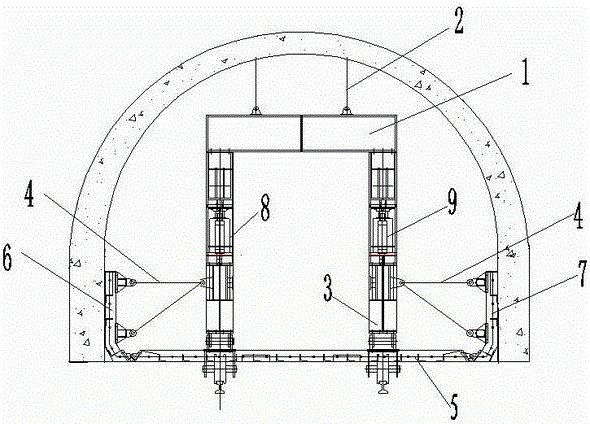

Deviated well bore site cast concrete well wall self-moving type sliding mould

InactiveCN103711490ASolve continuous pouring problemsQuality assuranceShaft liningPush pullMaterials science

The invention relates to a deviated well bore site cast concrete well wall self-moving type sliding mould which can effectively solve the problems that a mould board trolley adopted in the prior art can not slide, and concrete can not be cast continuously. According to the technical scheme, the deviated well bore site cast concrete well wall self-moving type sliding mould comprises two identical steel barrels, and the two steel barrels are connected together through walking push-pull jacks. Each steel barrel comprises an arched support, wherein evenly distributed longitudinal connection rods are installed on the lateral face of the arched support, an inner layer steel plate is installed on the outer wall of the arched support in a sleeved mode, an outer layer steel layer is fixedly arranged on the inner layer steel plate in a sleeved mode through connection bolts, U-shaped cold bending cap structural steel and cold bending channel steel under the U-shaped cold bending cap structural steel are installed in a cavity between the inner layer steel plate and the outer layer steel plate to form the arched steel barrel, the arched support and the arched steel barrel are connected into a whole and are welded to floor beams, a base wheel and a lifting jack are installed under each floor beam, each base wheel is fixed to a rail through a wheel clamp, and the rail is installed on sleepers. The deviated well bore site cast concrete well wall self-moving type sliding mould is simple in structure, high in casting speed, high in efficiency, and creative for existing deviated well bore site cast concrete well wall casting devices.

Owner:李明

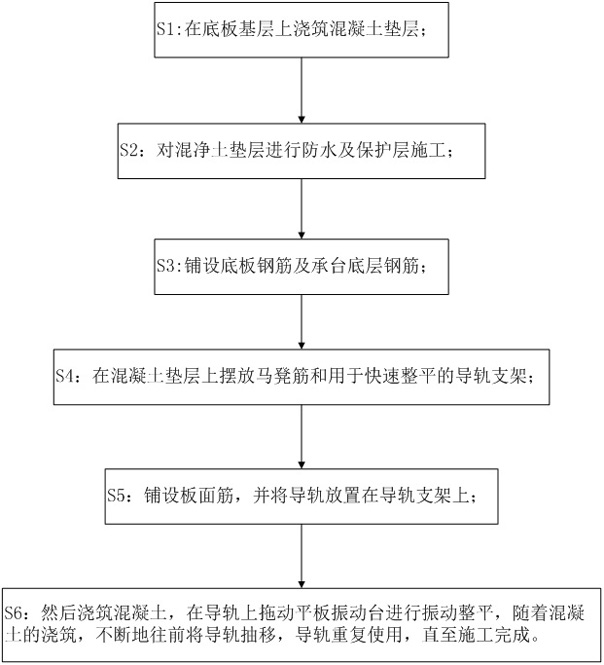

Concrete rapid leveling construction method of basement bottom plate

InactiveCN111851726AFast pouringEfficient pavingFloorsFoundation testingArchitectural engineeringRebar

The invention discloses a concrete rapid leveling construction method of a basement bottom plate. The method comprises the following steps that S1, a concrete cushion is poured on a bottom plate baselayer; S2, waterproof and protection layer construction is carried out on the concrete cushion; S3, bottom plate steel bars and bearing table bottom layer steel bars are paved; S4, stirrups and a guide rail support used for rapid leveling are placed on the concrete cushion; S5, plate face bars are paved, and a guide rail is placed on the guide rail support; and S6, concrete is poured, a flat platevibration table is dragged on the guide rail to carry out vibration leveling, the guide rail is constantly drawn to move forwards along with concrete pouring, and the guide rail is repeatedly used till construction is completed. After the above construction method is adopted, concrete leveling construction of the basement bottom plate is simple, the pouring speed is high, bottom plate leveling height limiting is achieved through the guide rail support and the guide rail, then the flat plate vibration table is used in cooperation to achieve rapid leveling, the labor intensity of workers is reduced, the leveling effect is ideal, and the ultra-level quality effect can be achieved.

Owner:广东电白二建集团有限公司

Municipal drainage pipeline machining die and method

InactiveCN112372822AAchieve moldingRealize the combinationMouldsSurface layering apparatusStructural engineeringRapid tooling

The invention relates to a a municipal drainage pipeline machining die and method. The die comprises a lower die, first flanges, an upper die, second flanges, a lining pipe, positioning rods and sealing plates. A grouting hole is formed in the side wall of the lower die. The first flanges are fixed to the two ends of the lower die, and first bolt holes are formed in the first flanges. An exhaust hole is formed in the side wall of the upper die. The second flanges are fixed to the two ends of the upper die, and second bolt holes are formed in the second flanges. The lining pipe is used for being installed between the lower die and the upper die. The multiple positioning rods are all located in the lining pipe. The two sets of sealing plates are located at the two ends of the lower die and the two ends of the lower die correspondingly, multiple mounting holes are formed in the sealing plates, and when the lower die and the upper die are buckled, the axes of the first bolt holes and the axes of the second bolt holes coincide with the axes of the mounting holes. Multiple positioning holes are formed in the sealing plates, and the two ends of the positioning rods can penetrate through the positioning holes correspondingly. According to the municipal drainage pipeline machining die and method, rapid machining and forming of a composite pipeline can be achieved, and the effect high forming quality is achieved.

Owner:宁波汇洲生态建设有限公司

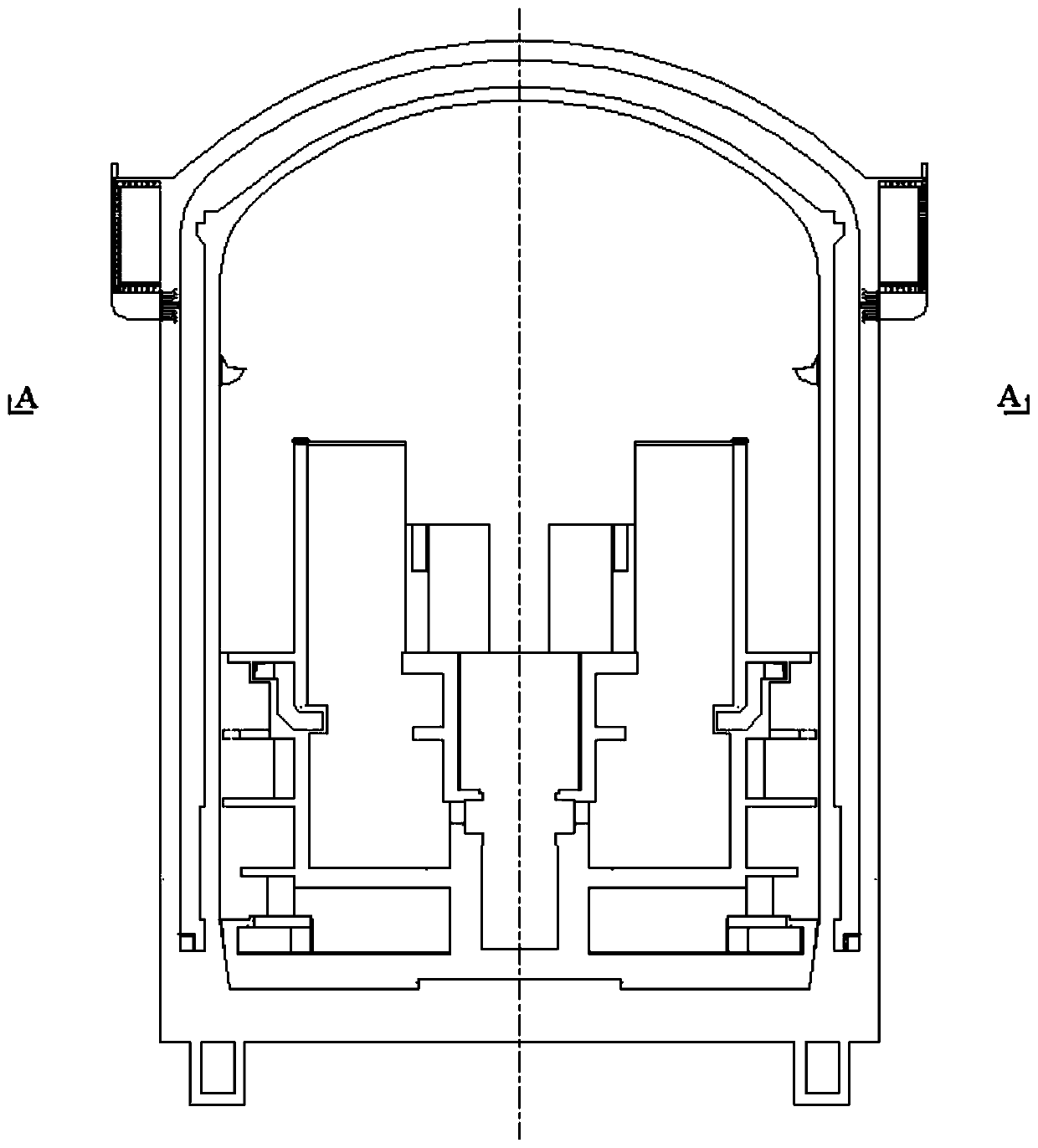

Construction method for passive water tank of nuclear power plant

ActiveCN111075235AFast pouringShorten the construction periodBuilding material handlingBulk storage containerNuclear plantFloor slab

The invention discloses a construction method for a passive water tank of a nuclear power plant. The construction method comprises the following steps that a steel structure supporting module, a bottom floor slab semi-steel plate concrete structure module, a stainless steel plate covered semi-steel plate concrete structure module, a barrel body steel plate concrete structure module and top floor slab semi-steel plate concrete structure modules required by the construction of the passive water tank are precast according to construction requirements and are transported to a containment shell construction site; the steel structure supporting module, the bottom floor slab semi-steel plate concrete structure module, the stainless steel plate covered semi-steel plate concrete structure module and the barrel body steel plate concrete structure module are sequentially hoisted, positioned, but jointed, welded and supported, and concrete is poured in time; after heat exchanger equipment is introduced, the top floor slab semi-steel plate concrete structure modules are hoisted in sequence, and upper concrete is poured to the semi-steel plate concrete structure module; the passive water tank bottom stainless steel covered surface is laid and welded; and the passive water tank and a heat exchanger are transferred.

Owner:中广核工程有限公司 +3

Preparation method of gel forming ultra-high-purity alumina ceramic lining disk trimming ring

ActiveCN107512866AImprove connection strength and stabilityImprove pouring accuracyDischarging arrangementCeramic shaping plantsHigh intensityGel forming

The invention discloses a preparation method of a gel forming ultra-high-purity alumina ceramic lining disk trimming ring, wherein the preparation method comprises the following steps: 1) firstly, preparing a premixed liquid; 2) then adding a ceramic powder to the premixed liquid, carrying out ball milling, and forming a suspension slurry; 3) after the suspension slurry is stable, respectively adding an initiator and a catalyst, discharging from the ball mill, then adding a defoaming agent, and stirring evenly; 4) followed by pouring the treated slurry into a mold by an extrusion molding device; and 5) after a blank body reach the demoulding strength, soaking the demoulded blank body, cooling to room temperature, then taking out the blank body, grinding with sandpaper with the particle size of 600, and thus forming the alumina ceramic lining disk trimming ring. The manufacturing technological process of the alumina ceramic lining disk trimming ring is simplified, a traditional way of mechanical processing under high strength is changed, the assembly line production can be achieved, the manufacturing cost of the alumina ceramic lining disk trimming ring is reduced, and at the same time, the quality and performance of the alumina ceramic lining disk trimming ring are improved.

Owner:衢州飞瑞特种陶瓷有限公司

An executive device for a fully automatic water surface garbage cleaning robot

ActiveCN105887782BRealize multifunctionality of one machineHigh degree of intelligenceWater cleaningWaste collectionEngineering

The invention relates to a performing device of a full-automatic water surface garbage cleaning robot. The device comprises a housing, a bottom plate, a lifting plate, a dumping plate, electric pushing rods, linear guide rails, slide blocks, ball hinges, separating plates, movable pulleys, rotating shafts, fixed pulleys, steel wire ropes, lifting motors and garbage stopping mechanisms, wherein the dumping plate is positioned right above the lifting plate; the electric pushing rods are positioned between the lifting plate and the dumping plate; one end of each ball hinge is connected with the lifting plate and the inner side end of the dumping plate, and the other end of each ball hinge is connected to the corresponding slide block; the slide blocks are mounted on the linear guide rails; the separating plates are fixed to corners of the outer side end of the housing; each steel wire rope sleeves between each fixed pulley and each movable pulley in a coiling manner; the fixed pulleys are mounted on main shafts of the lifting motors, and the lifting motors are fixed to the housing; the garbage stopping mechanisms are positioned in front of the housing. The device integrates the garbage collecting function and the garbage dumping function and achieves that a plurality of functions are integrated in one machine, so that the device is high in intelligence, can fully automatically finish the work of cleaning garbage floating in water, and is high in working efficiency and good in cleaning effect.

Owner:骆伟民

Formwork device for constructing inclined shaft working surface in coal mine

InactiveCN106437771AImprove construction progressRealize parallel operationUnderground chambersTunnel liningCoalMechanization

The invention discloses a formwork device for constructing an inclined shaft working surface in a coal mine. The formwork device mainly comprises portals, fixing oil cylinders, walking mechanisms, framework withdrawing cylinders, a bottom framework, a left side framework, a right side framework, main lifting oil cylinders, main declining oil cylinders, framework fixing bases, a portal bottom longitudinal beam I and a portal bottom longitudinal beam II, wherein square holes are formed in the two ends of the portal bottom longitudinal beam I and the portal bottom longitudinal beam II respectively; the portal bottom longitudinal beam I and the portal bottom longitudinal beam II are arranged side by side; the four walking mechanisms are arranged on the lower parts of the two ends of the portal bottom longitudinal beam I and the portal bottom longitudinal beam II; lifting oil cylinder columns on the walking mechanisms are inserted into the square holes in the two ends of the portal bottom longitudinal beam I and the portal bottom longitudinal beam II respectively; the lifting oil cylinder columns on the walking mechanisms are connected with corresponding ends of the main lifting oil cylinders; the other ends of the main lifting oil cylinders are connected to the bottoms of triangular ribs on one sides of the portals. The formwork device is high in mechanization, low in labor intensity and less in manpower investment, can effectively reduce the cost, and achieves parallel digging, waste rock-removing and pouring operations.

Owner:中煤第一建设有限公司第三十一工程处

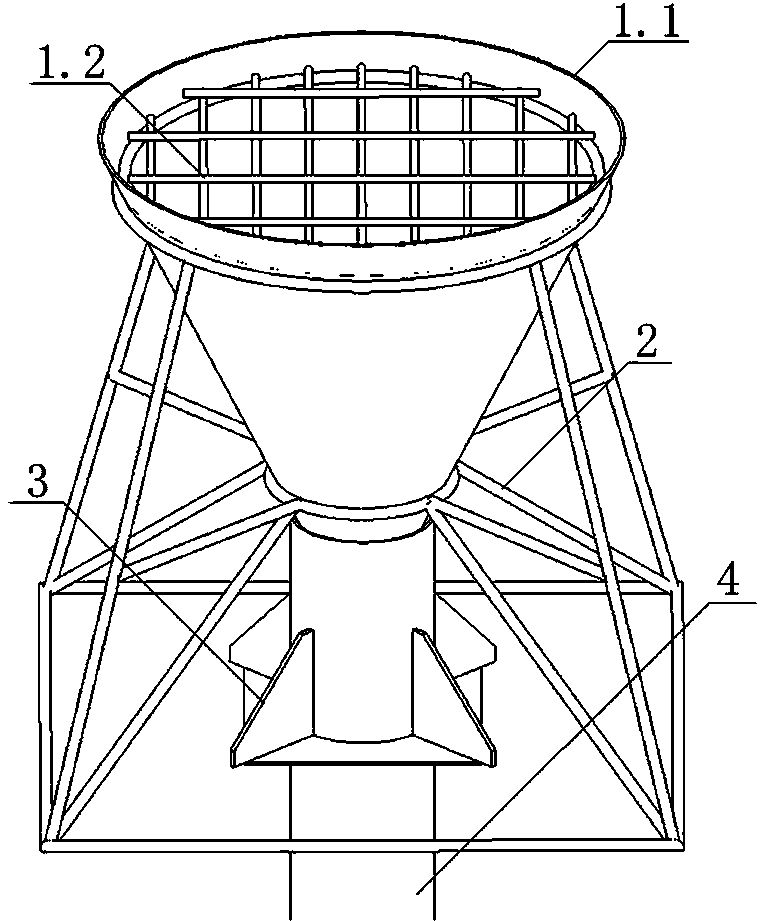

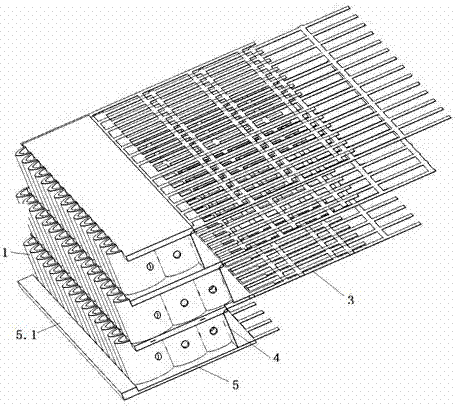

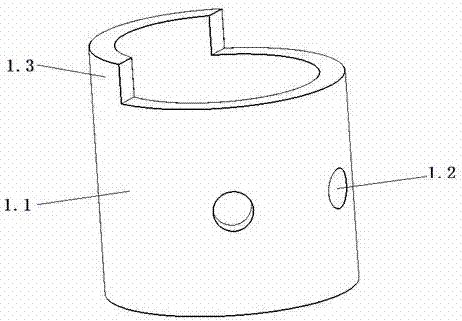

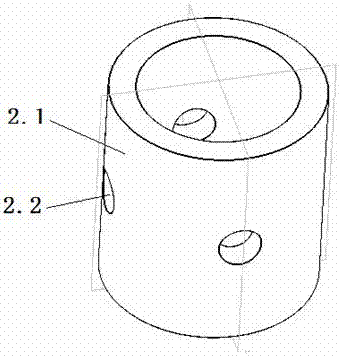

Prefabricated concrete tubular block ecological retaining wall

The invention relates to an assembly concrete tubular block ecological retaining wall. The assembly concrete tubular block ecological retaining wall is characterized by comprising a base plate (5), wherein a plurality of concrete tubular block layers are arranged on the base plate (5) from bottom to top, the outer edge surfaces of the plurality of concrete tubular block layers are gradually retracted backwards, each concrete tubular block layer comprises a front first tubular block row and at least one back second tubular block row, and a first tubular block body (1.1) of a first tubular block (1) of each concrete tubular block layer, a second tubular block body (2.1) of a second tubular block (2) and gaps formed by adjacent tubular block rows are filled with planting soil. The assembly concrete tubular block ecological retaining wall has the advantages of good ecological benefit, simplicity in construction, reliable quality and controllable cost and is a novel high-quality ecological retaining wall.

Owner:过杰 +1

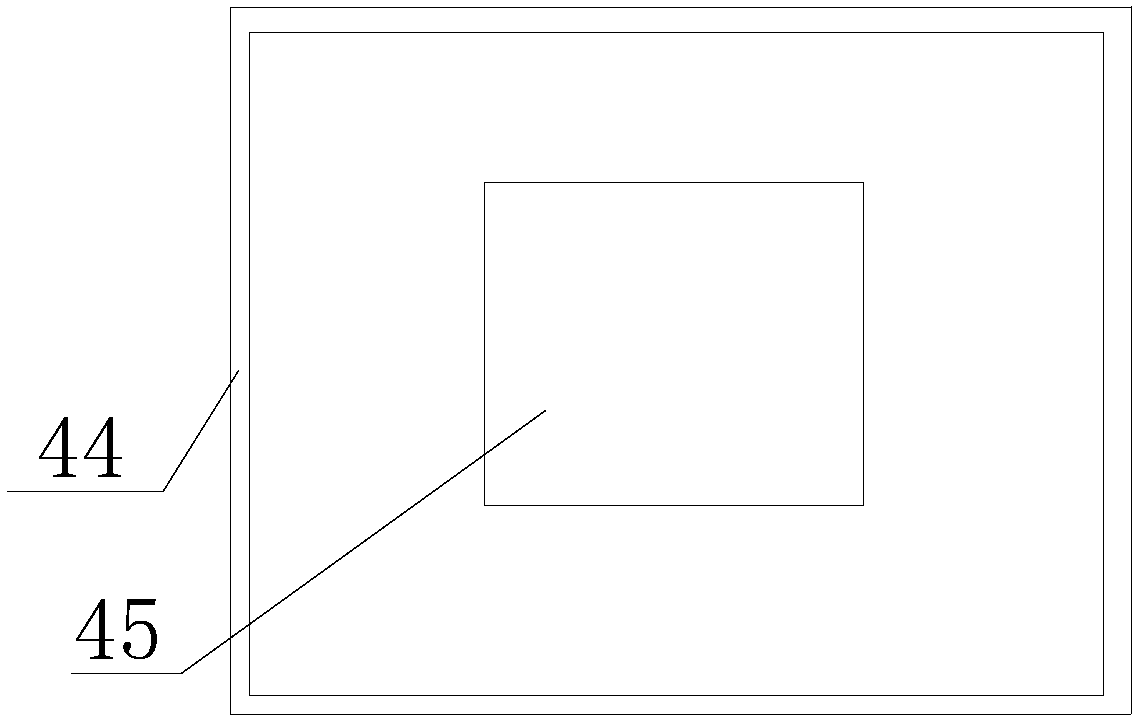

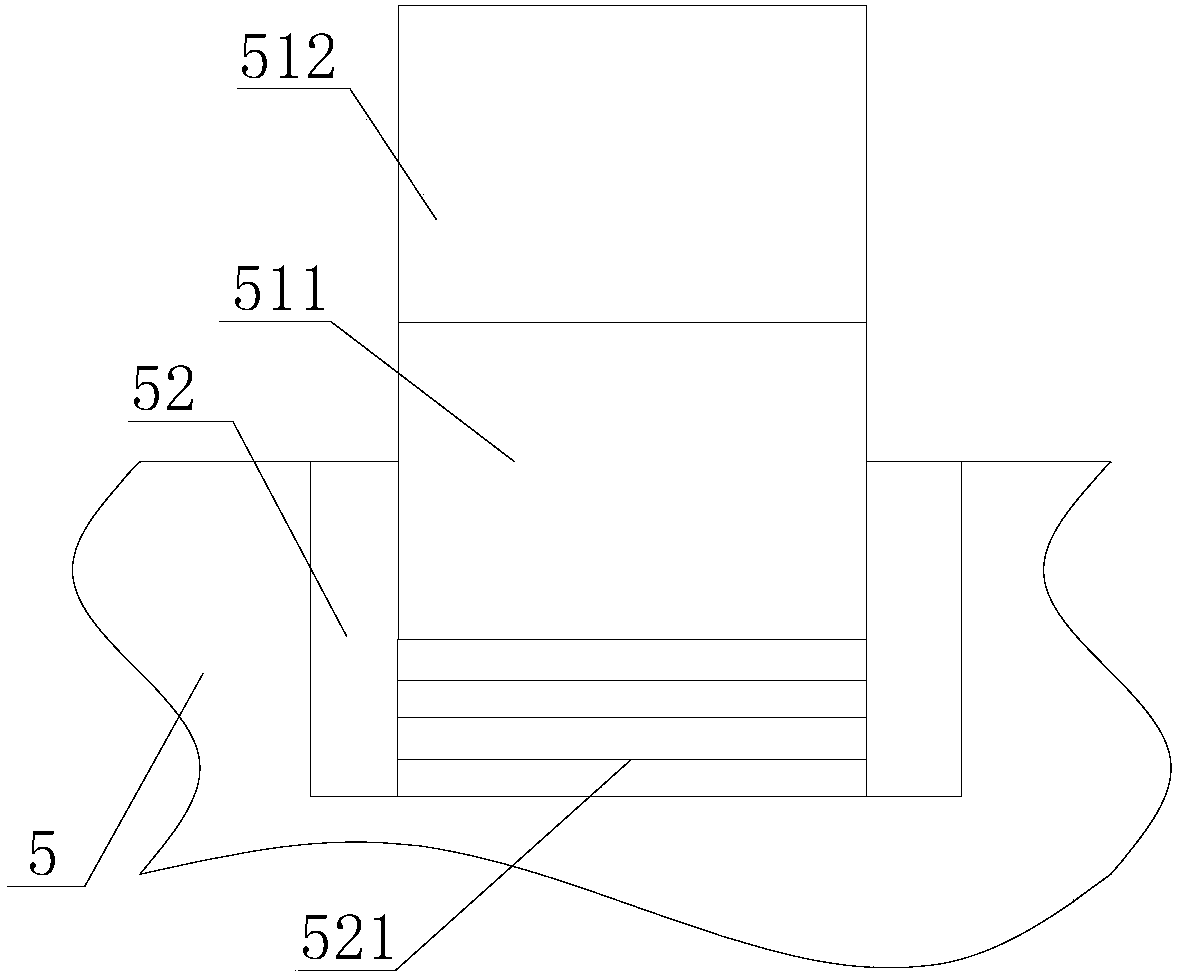

CrtsⅢ type slab ballastless track self-compacting concrete pouring tool and method

InactiveCN104328717BPrecise position adjustmentPrevent movementRailway track constructionSlurryUltimate tensile strength

The invention provides a CRTS III type slab ballastless track self-compacting concrete casting tooling and method. The casting tooling comprises a base slab, a track slab, a transferring hopper, a casting funnel, a slurry blocking template, a three-dimensional fine regulator, a track slab pressing device, a track slab lateral sliding preventing device and a slurry blocking template pressing device. The middle casting mode is changed into the lateral surface casting, and the problems of casting efficiency and air exhaust in the CRTS III type slab ballastless track construction are solved. The track slab lateral sliding preventing device, the track slab pressing device and the slurry blocking template pressing device effectively solve the problems of upward floating, lateral sliding and slurry leakage of the track slab in the casting process, so the fine regulation and the casting construction of the CRTS III type slab ballastless track are more convenient and fast, and the casting quality is better. The construction process has the advantages that in the use process, the weight is light, the rigidity is high, the efficiency is high, the operation is simple and convenient, the work intensity is low, and the construction process can adapt to the construction of road segments such as bridges, tunnels and roadbeds.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

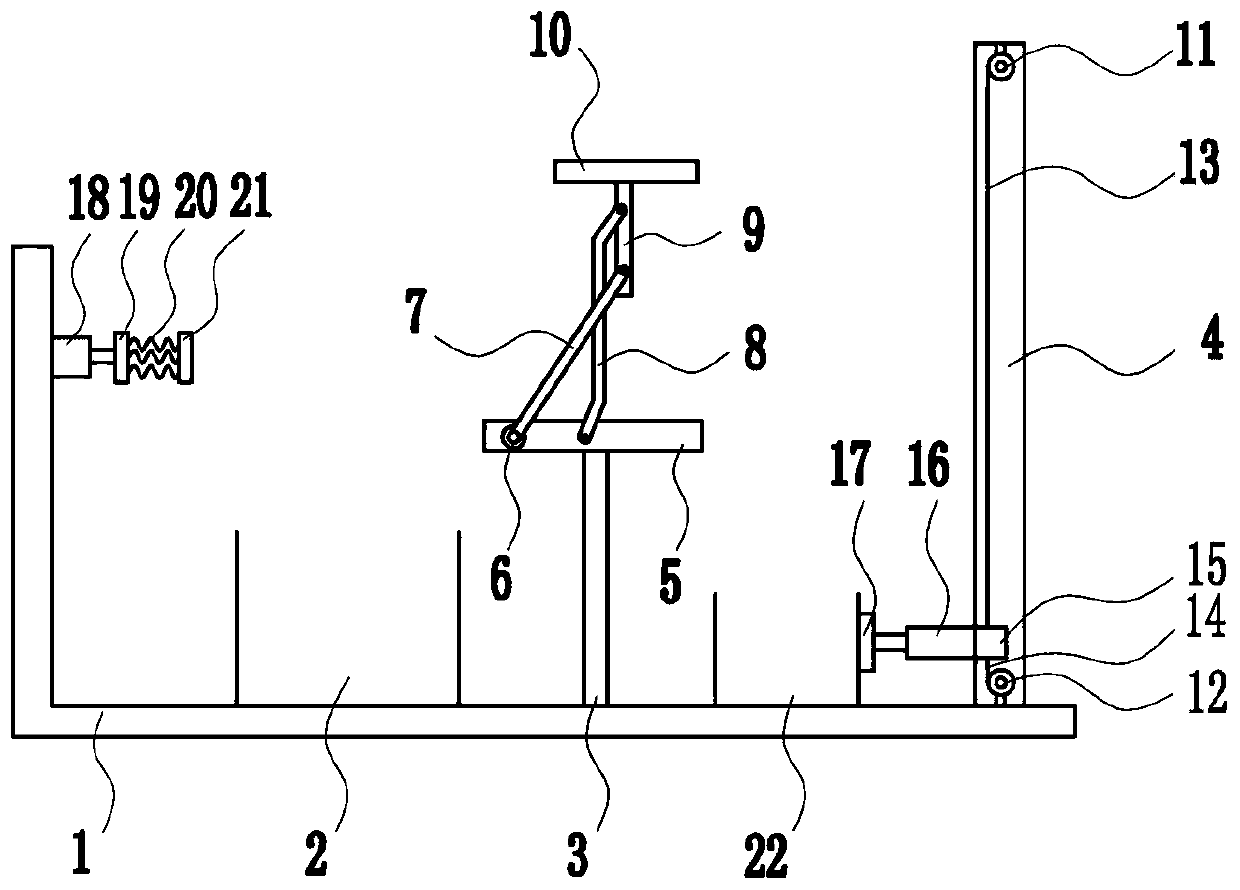

Special pouring device for powder coating

InactiveCN110342273AFast pouringDump completelyBottle emptyingLoading/unloadingPowder coatingMaterials science

The invention relates to a pouring device, in particular to a special pouring device for a powder coating. The invention aims to provide the special pouring device for the powder coating with fast pouring speed, complete pouring, time saving and labor saving effects. According to the purpose of the invention, the invention provides the special pouring device for the powder coating. The special pouring device comprises a support, a collecting barrel, a supporting rod, a sliding rail, a base, a motor, a connecting rod I, a connecting rod II, a rotating rod, an electromagnet I, an electric wheelI, an electric wheel II, a pulling rope I, a pulling rope II, a sliding block, an air cylinder, an electromagnet II, an electric push rod, an electromagnet III, an elastic part and an electromagnet IV; and the collecting barrel, the supporting rod and the sliding rail are sequentially arranged on the support from left to right, the base is arranged above the supporting rod, the motor is installedon the base, the connecting rod I is arranged on the motor, and the connecting rod II is hinged to the right side of the base. According to the special pouring device for the powder coating, the effects of fast pouring speed, complete pouring and time-saving and labor-saving are achieved.

Owner:LICHANG TECH GANZHOU

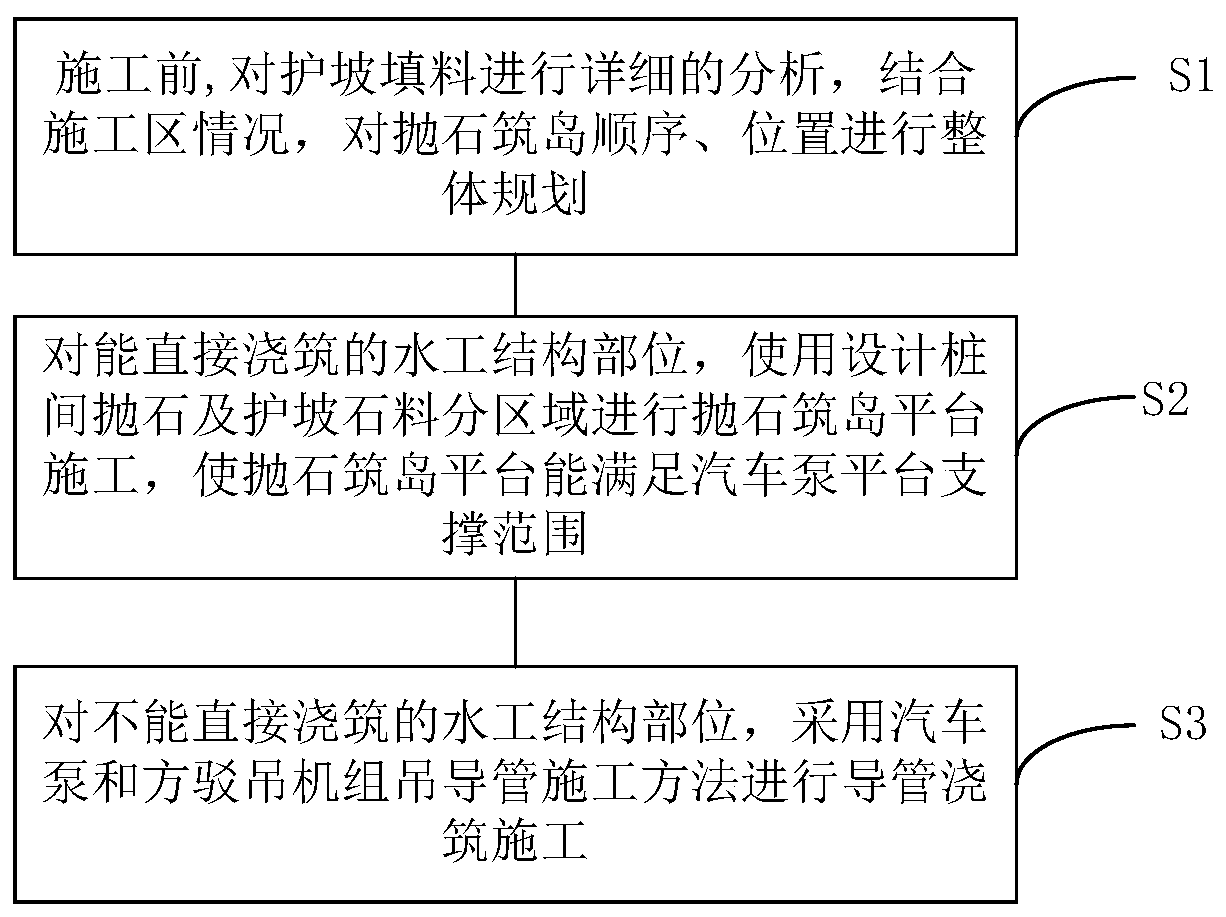

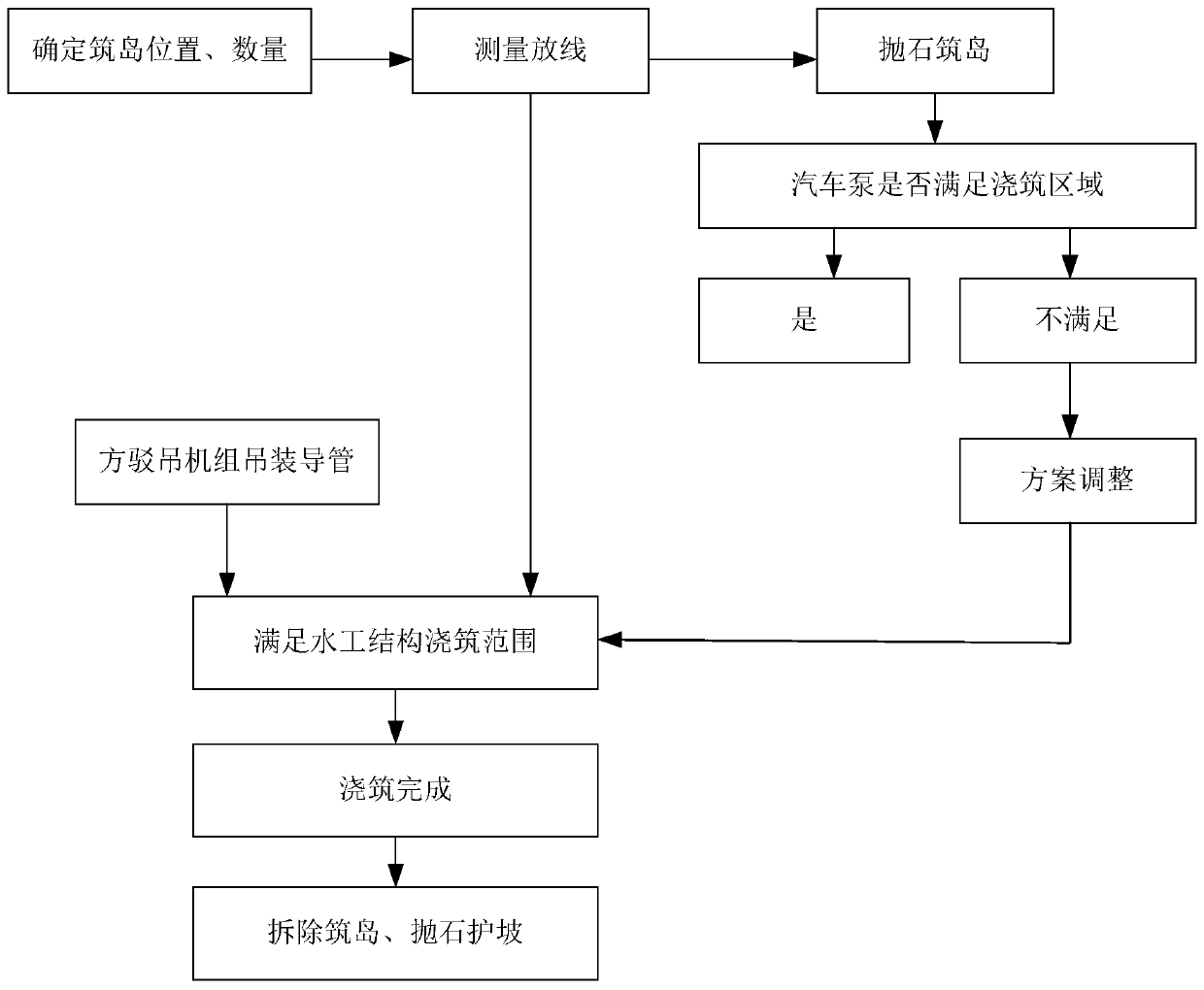

High-pile wharf long-distance concrete casting construction method

ActiveCN110714438AHigh speedThe structural effect is obviousBreakwatersQuaysArchitectural engineeringHydraulic structure

The invention provides a high-pile wharf long-distance concrete casting construction method which comprises the steps of S1, before construction, analyzing a slope protection filler in details, combining the situations of a construction area, and integrally planning a sequence and a position of a riprap building island; S2, for a hydraulic structure part capable of being directly casted, constructing a riprap building island platform in a partitioned way by using riprap and slope protection stones between designed piles, and enabling the riprap building island platform to satisfy an automobilepump platform support range; and S3, for a hydraulic structure part incapable of being directly casted, casting and constructing a guide pipe by adopting a construction method for hanging the guide pipe by an automobile pump and a barge crane unit. According to the high-pile wharf long-distance concrete casting construction method provided by the invention, through integrating current resources of a construction site and fully utilizing a ship machine working gap for hanging the pipe, the concrete casting construction is accomplished, the ship machine cost cannot be increased, and the ship machine use efficiency is higher.

Owner:CCCC TDC ENVIRONMENTAL PROTECTION DREDGING

Garden, highway and river channel slope automatic construction equipment

The invention relates to garden, highway and river channel slope automatic construction equipment. The equipment comprises a walking platform, a stirring device, an adjusting device, vibration brackets and a casting device; the stirring device is positioned above the walking device; the adjusting device is positioned in front of the stirring device, and is connected with the walking device; four vibration brackets are provided; the vibration brackets are positioned between the adjusting device and the casting device; the upper ends of the vibration brackets are connected with the adjusting device; and the lower ends of the vibration brackets are connected with the casting device. The garden, highway and river channel slope automatic construction equipment has such functions as slurry stirring, slurry conveying and vibration casting, can realize the slope construction in such places as gardens, highways and river channels, is complete and various in function, is fast in slope casting sped, saves a lot of labors, and provides convenience for the slope construction in such places as gardens, highways and river channels.

Owner:广州怡境规划设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com