Stokehole auxiliary robot

A robot and sensor technology, which is used in the control of molten metal pouring from the ladle, metal processing equipment, casting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

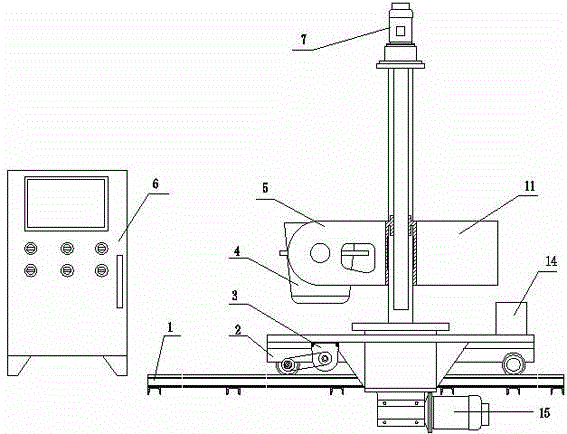

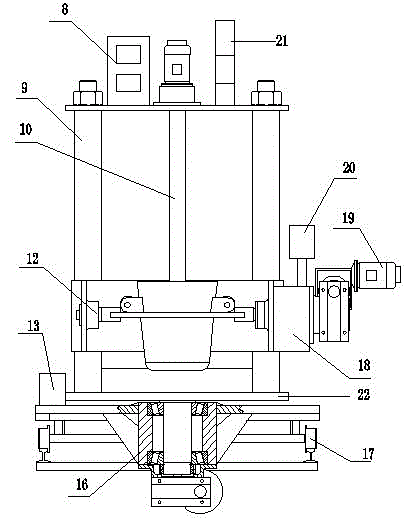

[0020] Embodiment 1, an auxiliary robot in front of a furnace includes a guide rail 1, a moving table 2, a motor 3, an iron kettle 4, an iron kettle bracket 5, a computer control box 6, a lifting servo motor 7, a speaker 8, a guide rod 9, and a lifting screw 10. Counterweight 11, iron kettle support base 12, rotation sensor 13, moving table surface sensor 14, rotation servo motor 15, rotation support 16, walking wheel 17, iron kettle tilt sensor 18, iron kettle tilt servo motor 19. Lifting sensor 20, warning light 21, receiving plate 22.

[0021] combine figure 1 , figure 2 , the iron kettle 4 is fixed on the iron kettle support 5 by the iron kettle support seat 12, and can rotate around the iron kettle support seat 12, the iron kettle support 5 can slide up and down on the guide rod 9 through the lifting screw 10, and the iron kettle support 5 is another One side is equipped with a counterweight 11 to balance the force on the lifting screw 10, the other end of the iron ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com