Fast installation method of ten-million-ton scale fully mechanized caving face equipment

A technology of fully mechanized caving face and installation method, applied in mining equipment, bolt installation, earthwork drilling, etc., can solve problems such as hidden dangers of transportation safety, long construction period, damage to roadway floor, etc., so as to reduce construction labor intensity and reduce costs. The effect of reducing maintenance costs and speeding up the installation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

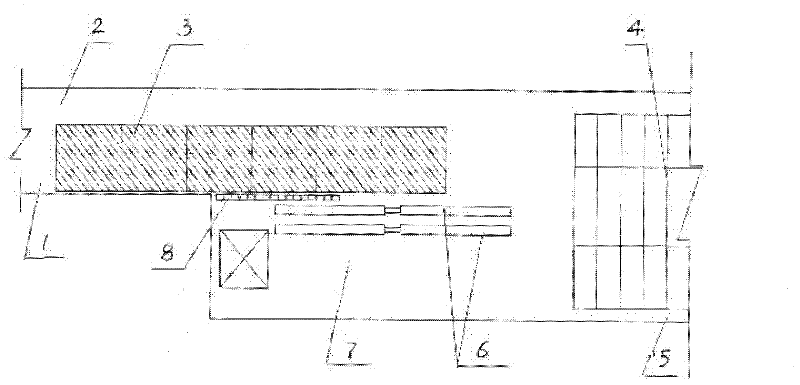

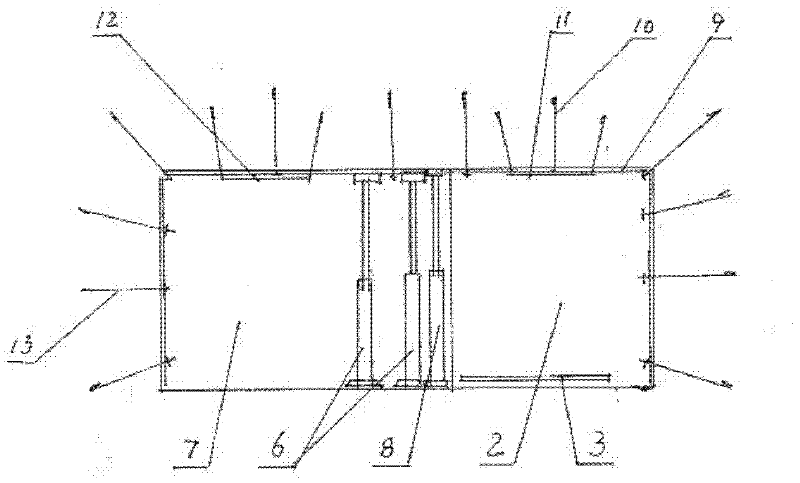

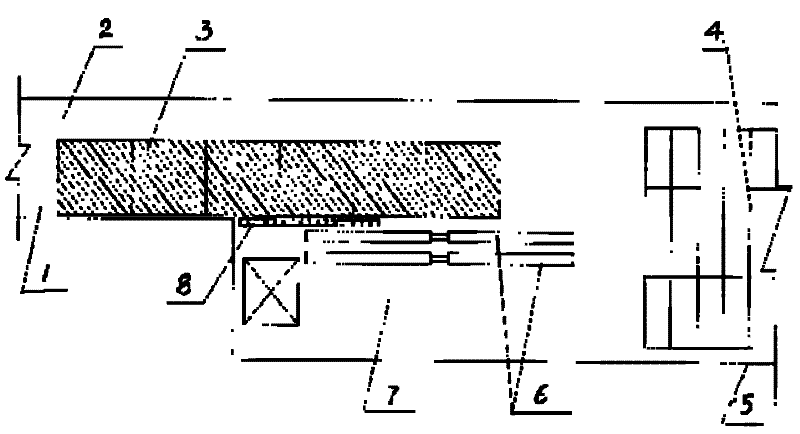

[0027] Such as figure 1 with figure 2 As shown, after the development of the upper and lower level roads in the mining area, a common cut hole 2 with a width of 4.5 meters and a height of 3.7 meters is developed in the pre-mining working face to form a ventilation circulation system; where:

[0028] (1) The transportation method of the hydraulic support is:

[0029] (1) Disassemble the hydraulic support 4 on the well, reassemble it at the bottom of the well, and transport it to the replacement point. After loading the hydraulic support 4 with the support truck, directly transport the hydraulic support 4 to the upper end 1 of the cutting hole, and transport the support with the support truck Three vehicles are used as a group to ensure safety during uphill and downhill transportation.

[0030] (2) When the support truck is transporting, the hinged dry bridge is laid on the upper level lane. The surface increases the friction surface to improve the climbing ability of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com