Patents

Literature

447results about How to "Improve shipping speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

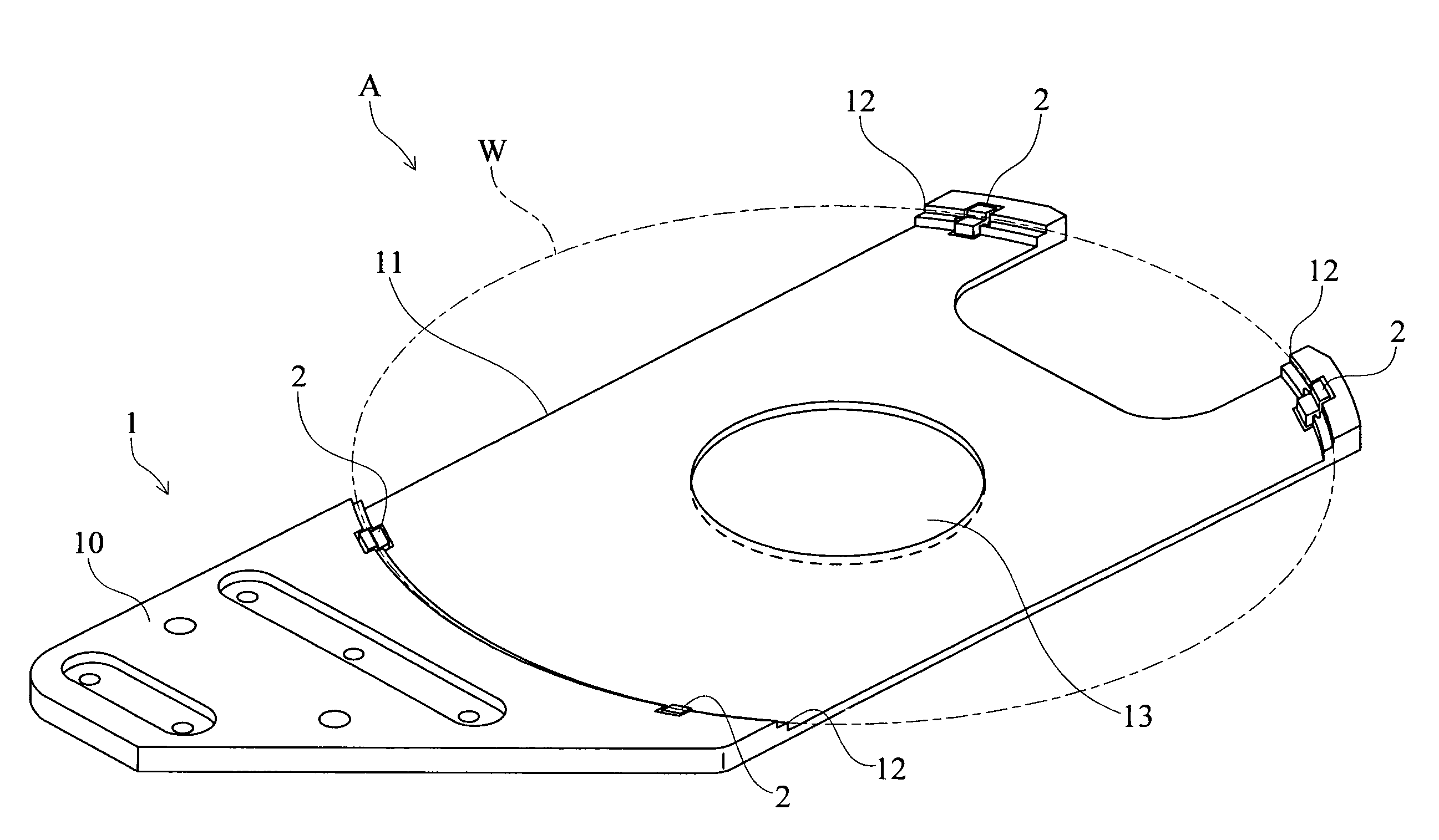

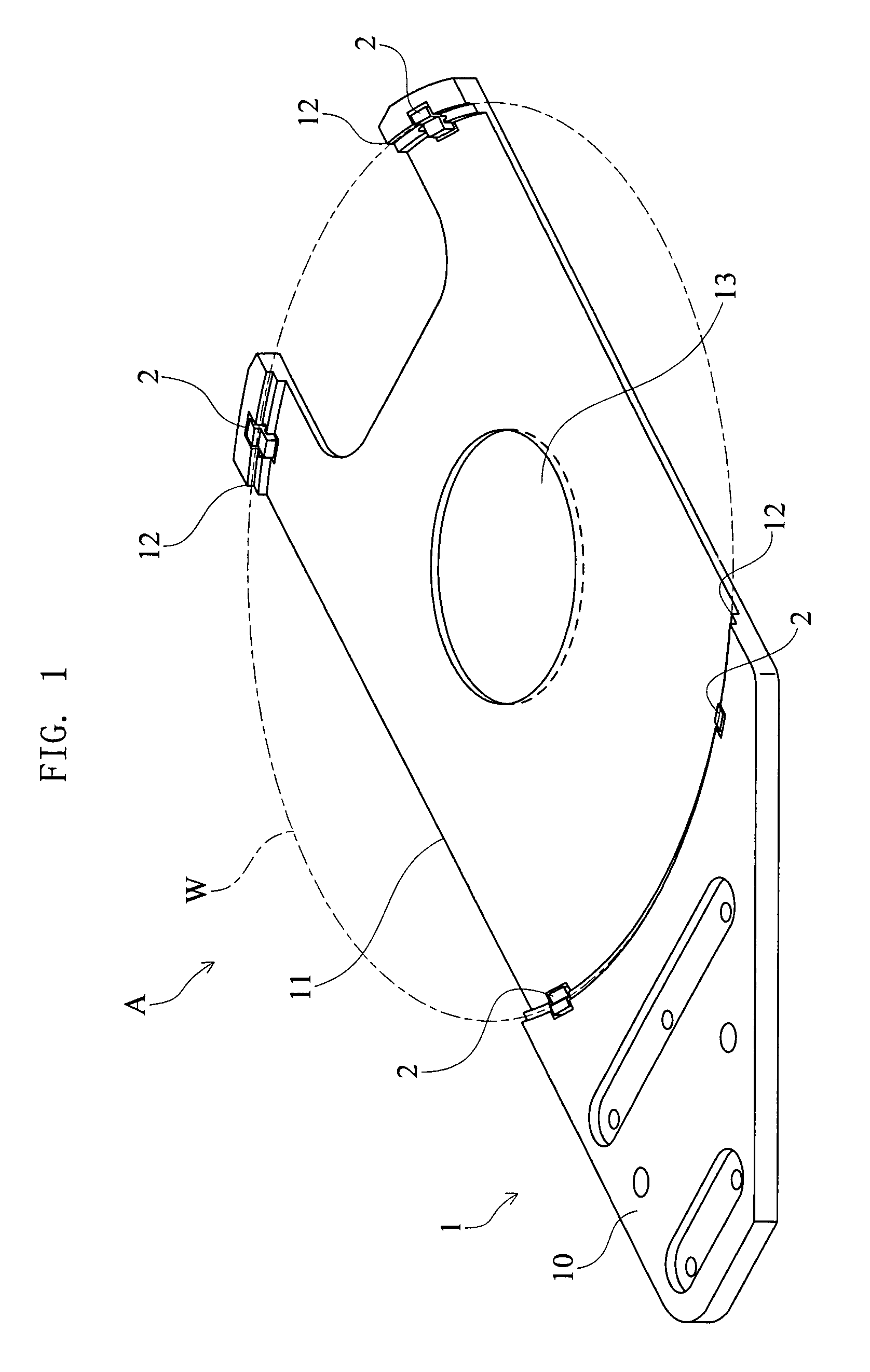

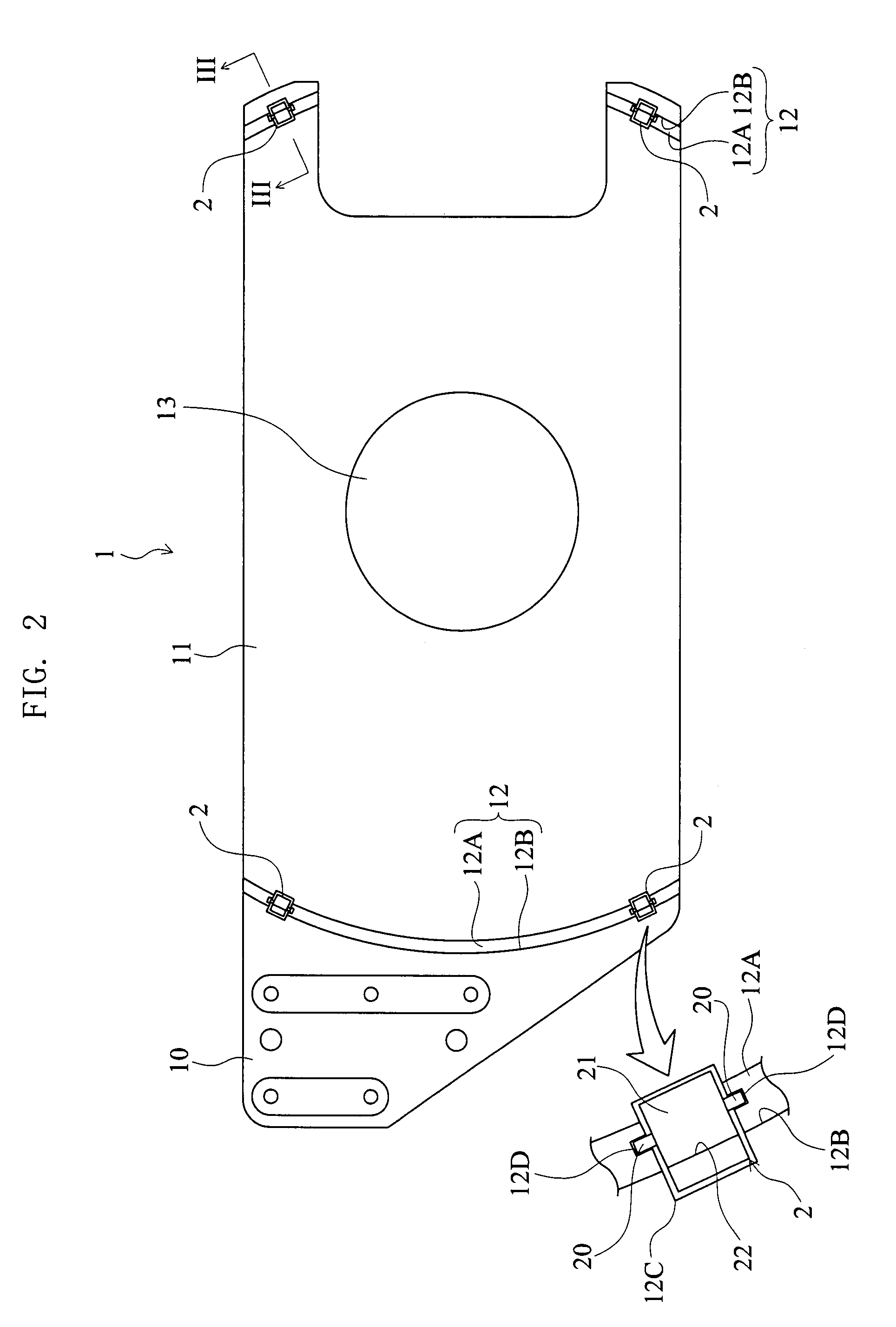

Work holding mechanism

ActiveUS7748760B2Improve shipping speedVacuum operationGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DAIHEN CORP

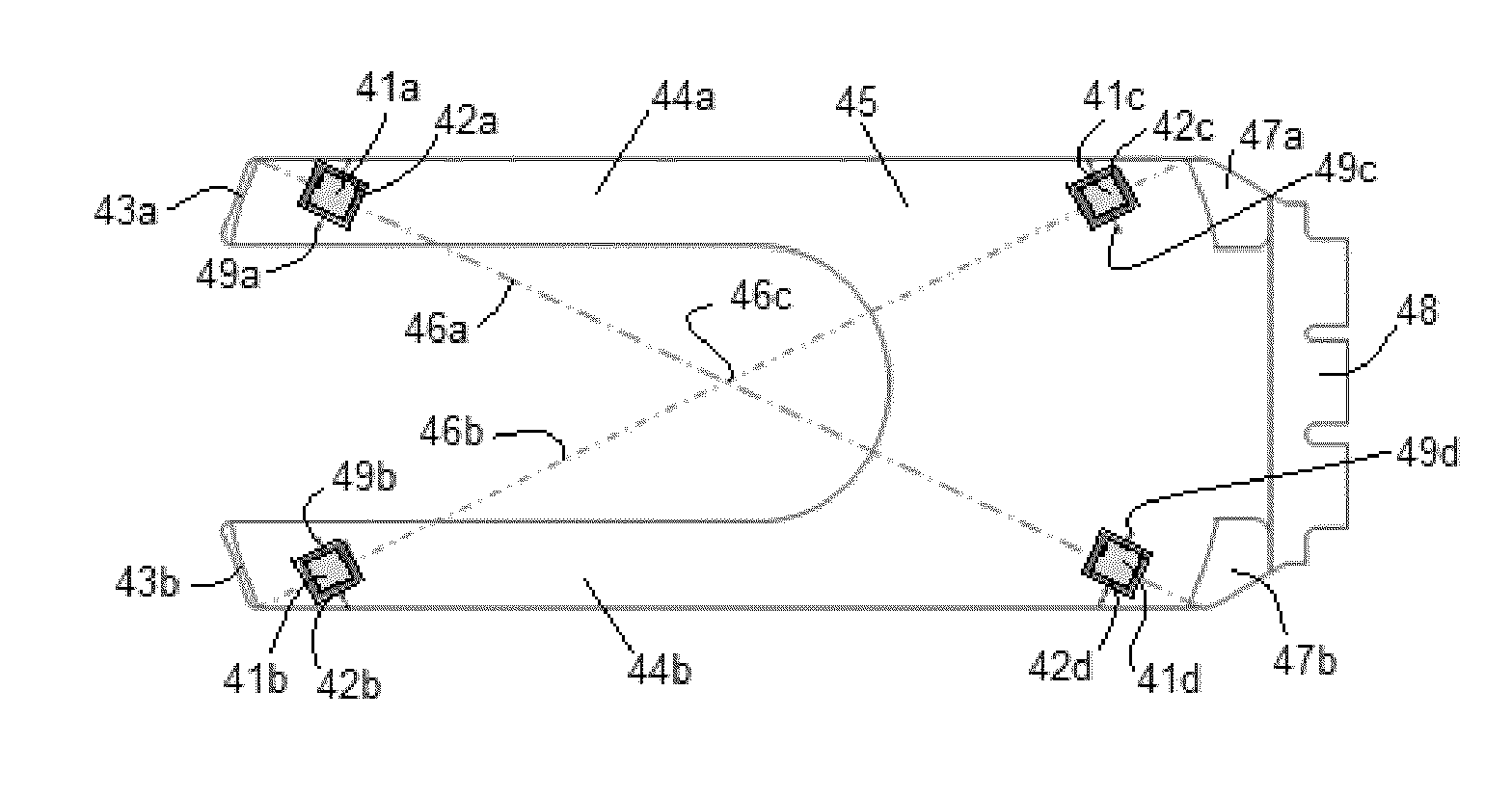

Anti-Slip End Effector For Transporting Workpiece Using Van Der Waals Force

ActiveUS20150287626A1Prevent slippingImprove shipping speedSemiconductor/solid-state device manufacturingLifting devicesRobotic armEngineering

An anti-slip end effector for transporting a workpiece, configured to be attached to a robotic arm, includes: a workpiece-supporting area for placing a workpiece thereon for transportation; and at least one anti-slip protrusion disposed in the workpiece-supporting area for supporting a backside of the workpiece, said anti-slip protrusion having a top face capable of contacting and adhering to the backside of the workpiece by van der Waals force and capable of pivoting on a pivot axis, said pivot axis being disposed away from a center of the top face as viewed from above.

Owner:ASM IP HLDG BV

Anti-slip end effector for transporting workpiece using van der waals force

ActiveUS9343350B2Prevent slippingImprove shipping speedSemiconductor/solid-state device manufacturingConveyor partsRobotic armEngineering

An anti-slip end effector for transporting a workpiece, configured to be attached to a robotic arm, includes: a workpiece-supporting area for placing a workpiece thereon for transportation; and at least one anti-slip protrusion disposed in the workpiece-supporting area for supporting a backside of the workpiece, said anti-slip protrusion having a top face capable of contacting and adhering to the backside of the workpiece by van der Waals force and capable of pivoting on a pivot axis, said pivot axis being disposed away from a center of the top face as viewed from above.

Owner:ASM IP HLDG BV

Apparatus and method of automatically adjusting a document deceleration rate

InactiveUS6065746AEnhance simple reliable selective decelerationQuickly and reliably selectively stopFunction indicatorsArticle feedersEngineeringPaper document

Apparatus and method for automatically adjusting a rate at which a document decelerates when entering a sort pocket of a document processing machine. The apparatus includes a track adapted for transporting the document, a guide wall, and a stacker flag spaced away from the guide wall to define the sort pocket therebetween. The sort pocket communicates with the track so that the document exits the track to enter the sort pocket. A wave spring is disposed proximate the guide wall so that the document engages the wave spring and is decelerated by the wave spring when the document enters the sort pocket. The weight of the document is calculated, and a signal is produced that represents the weight of the document. The wave spring is distorted according to this signal to vary a configuration of the wave spring depending on the weight of the document to decelerate the document at an optimal rate.

Owner:BURROUGHS CORP

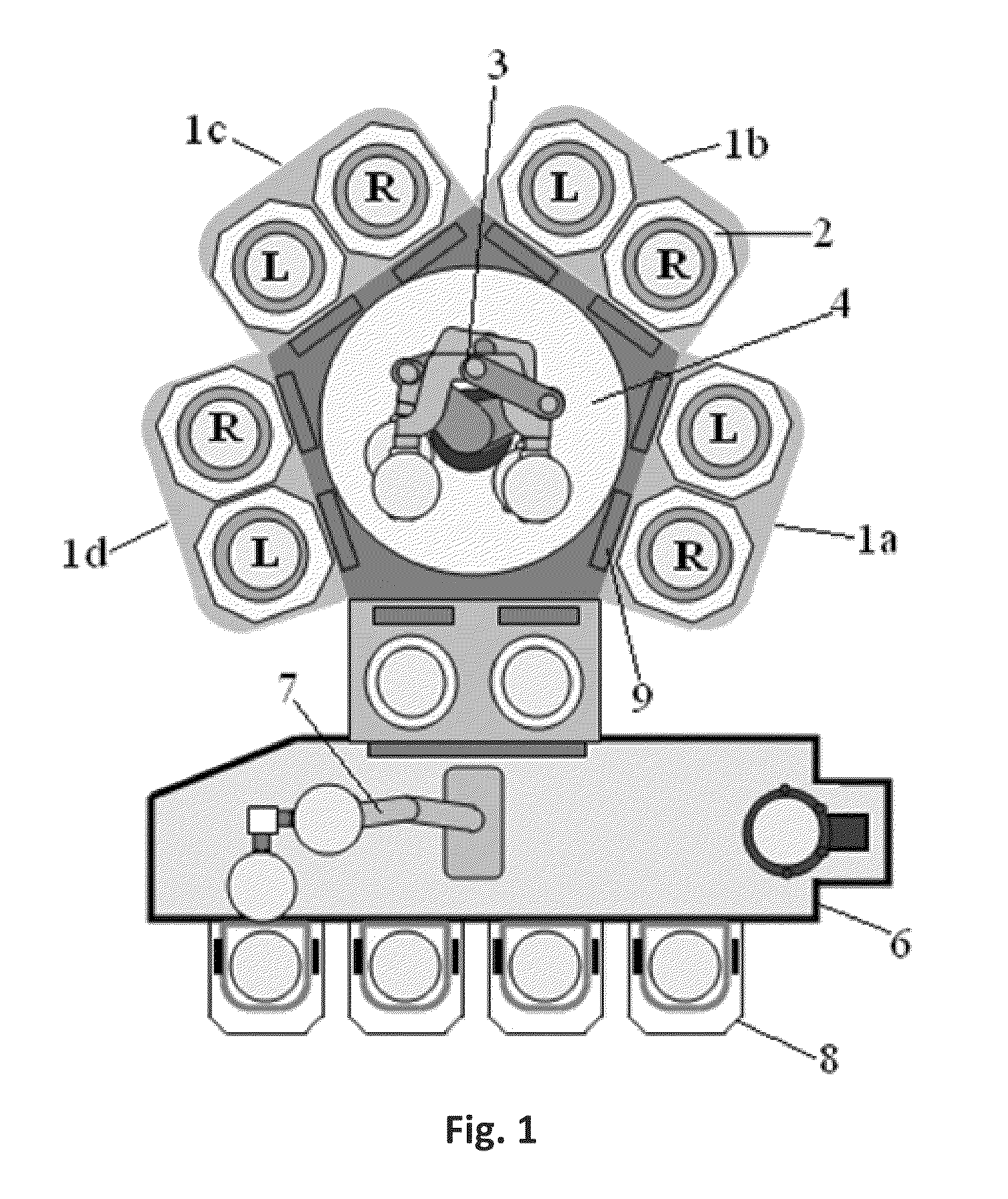

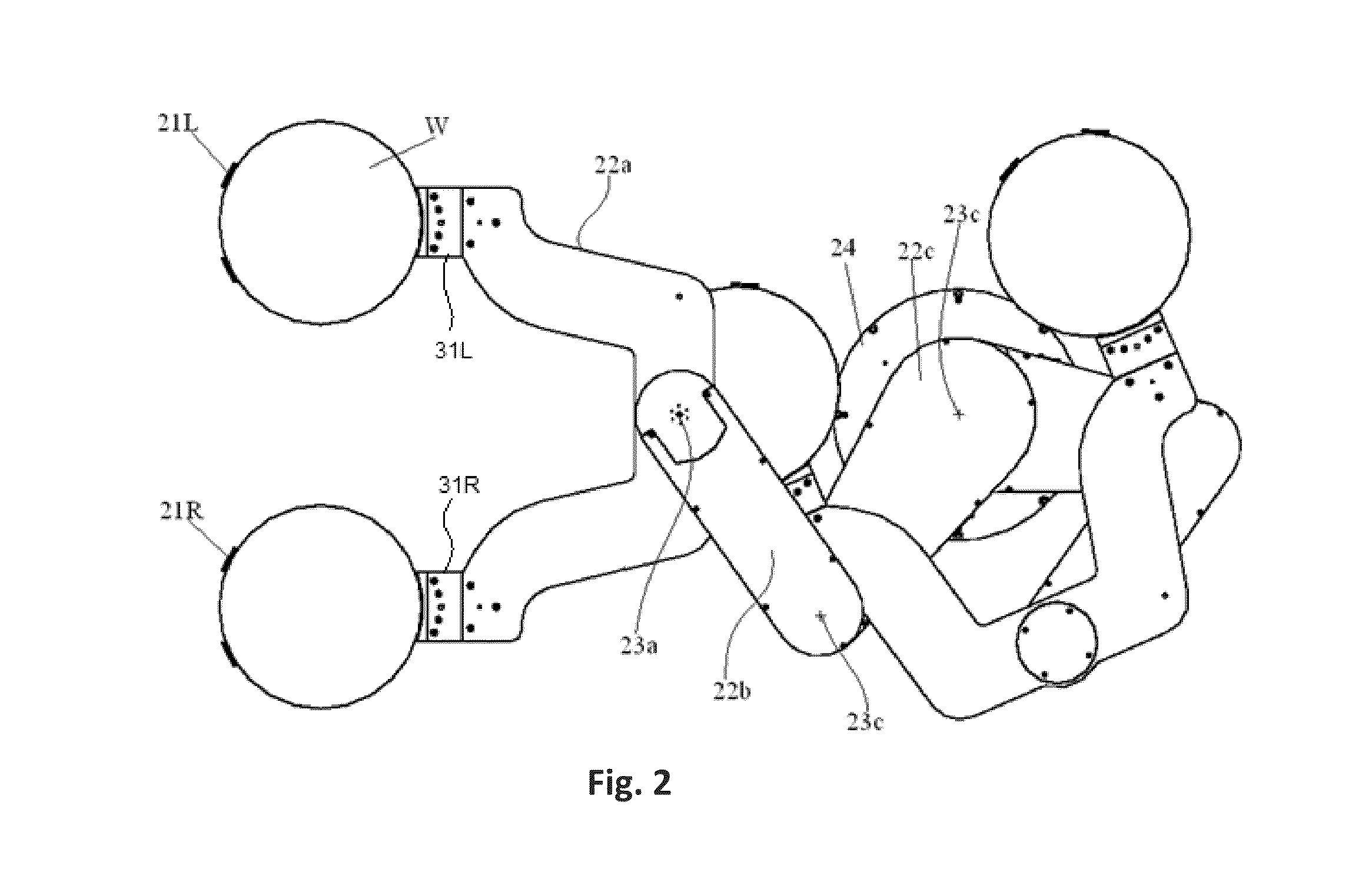

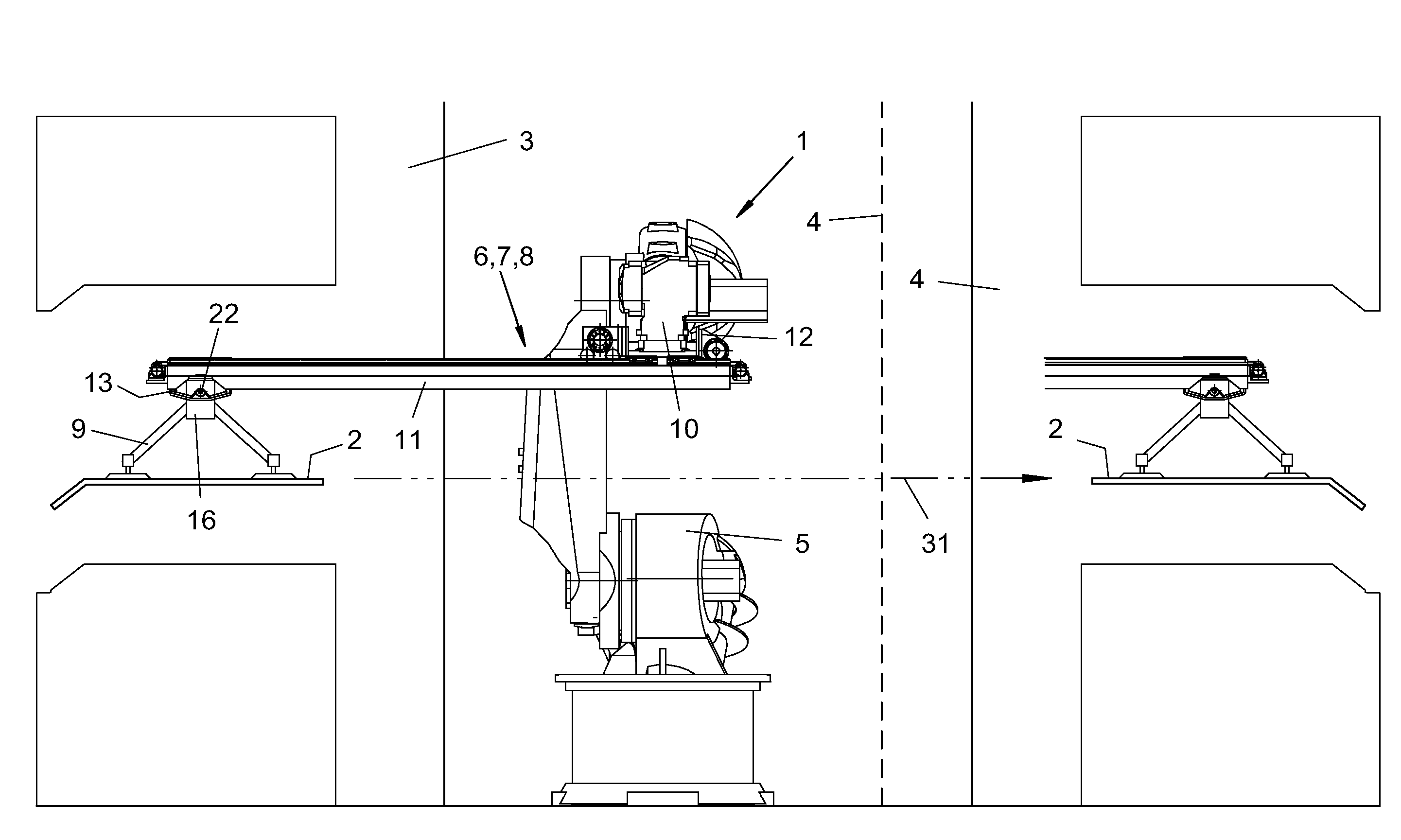

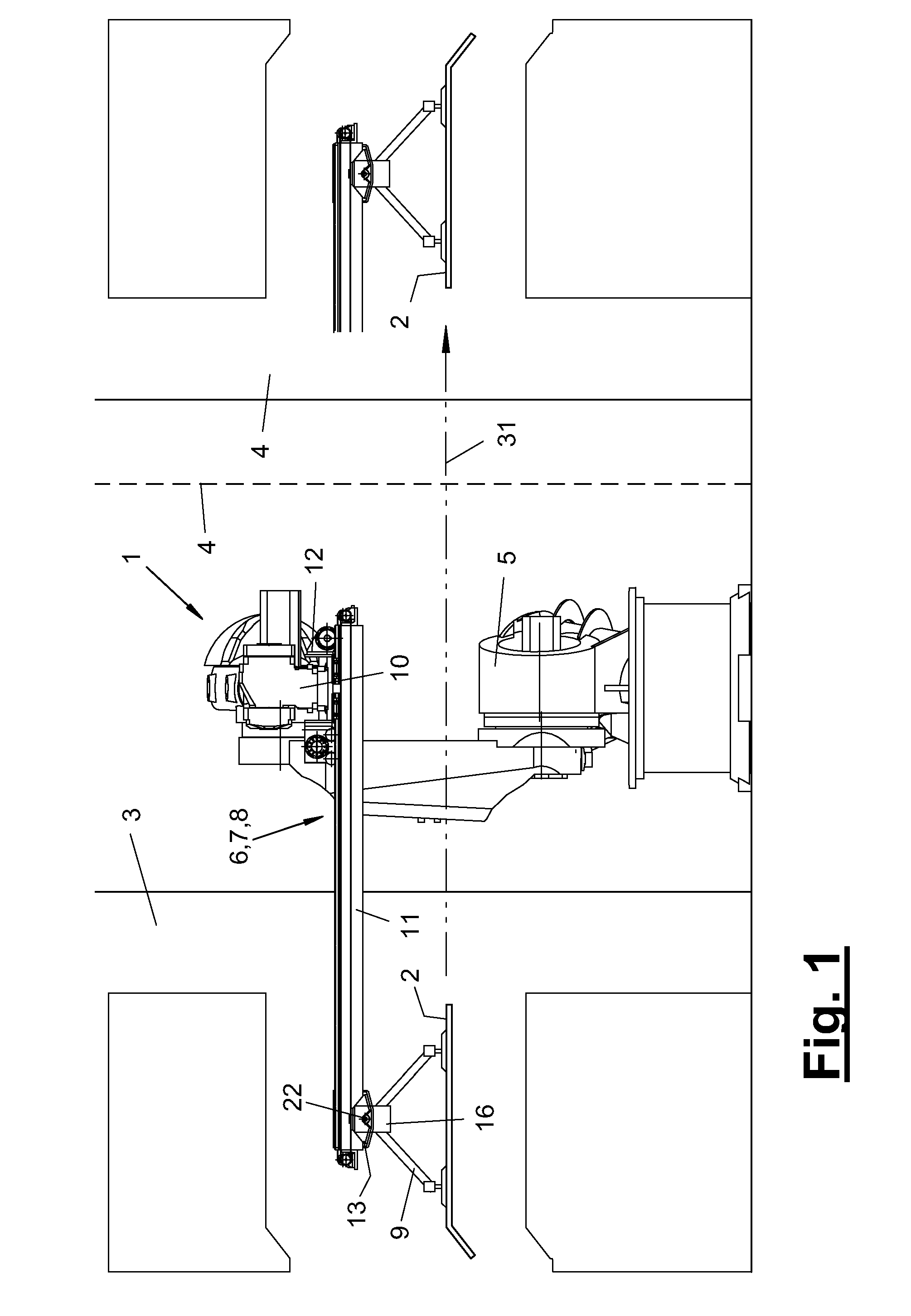

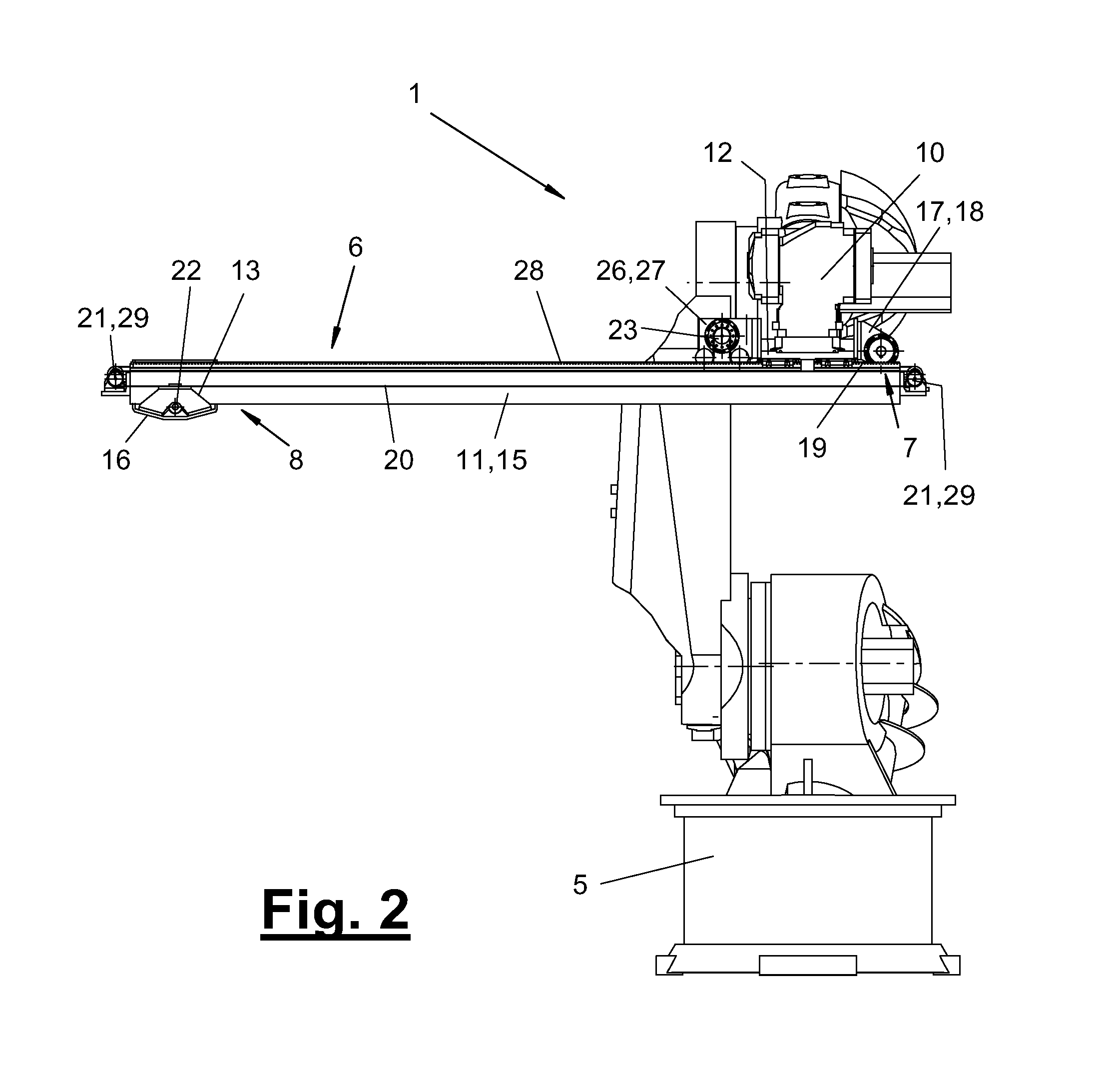

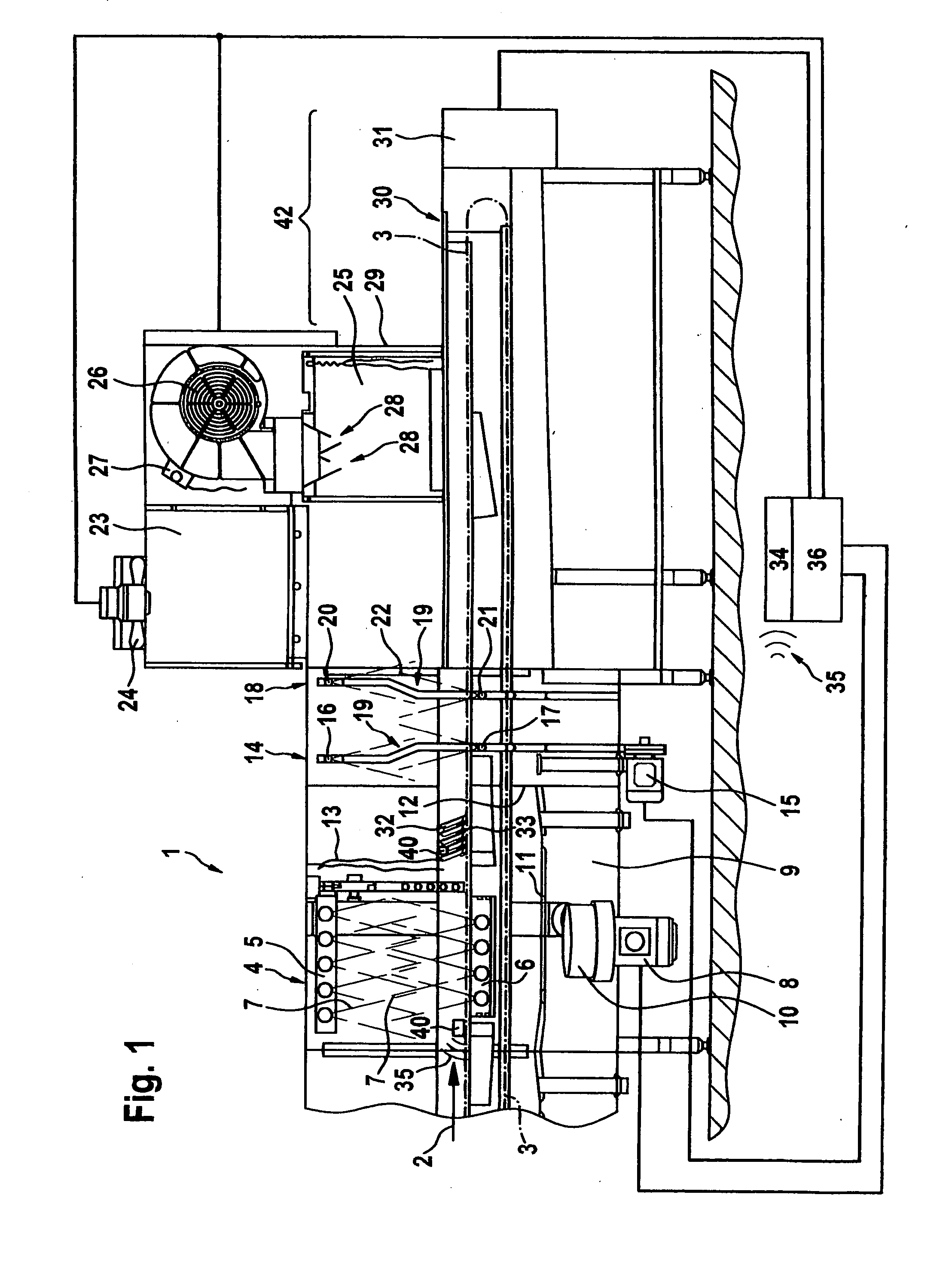

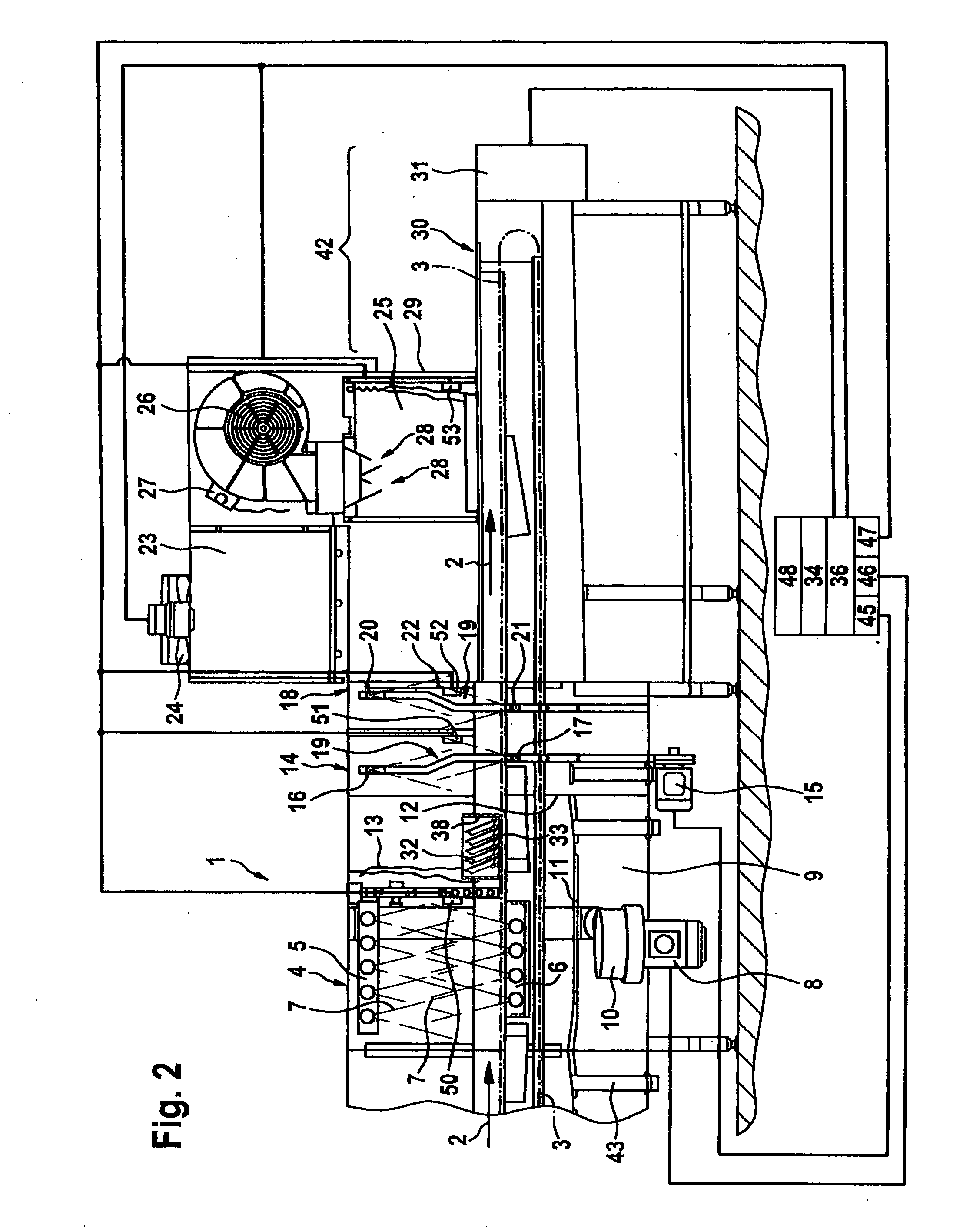

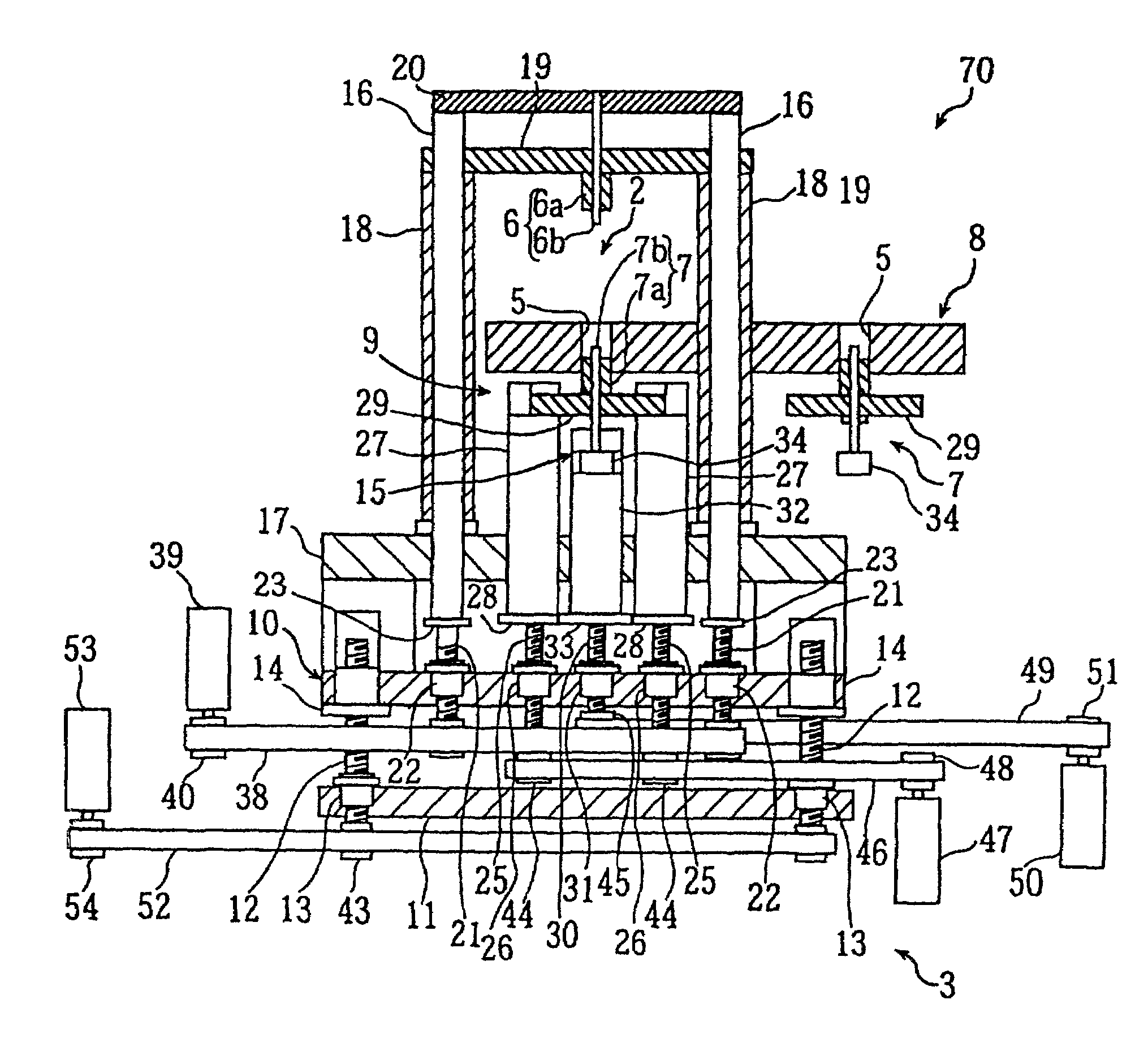

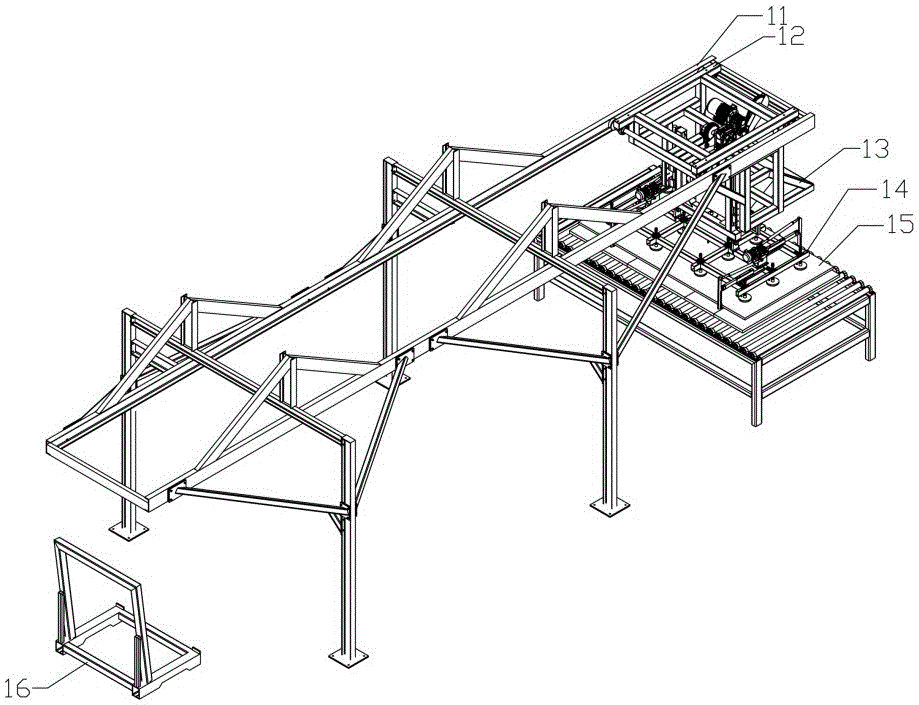

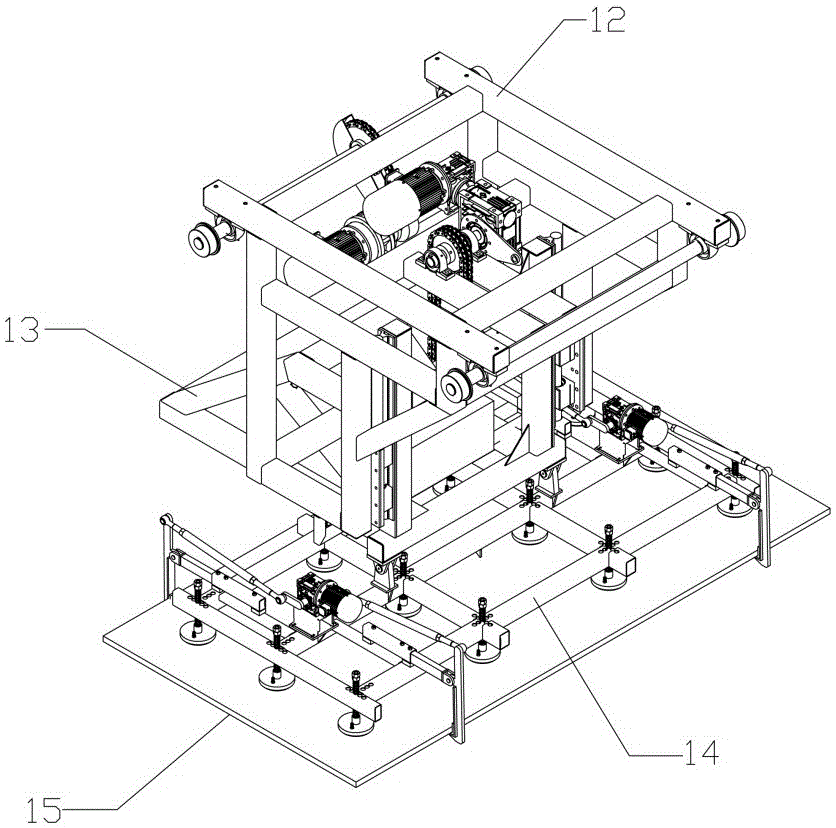

Transport unit

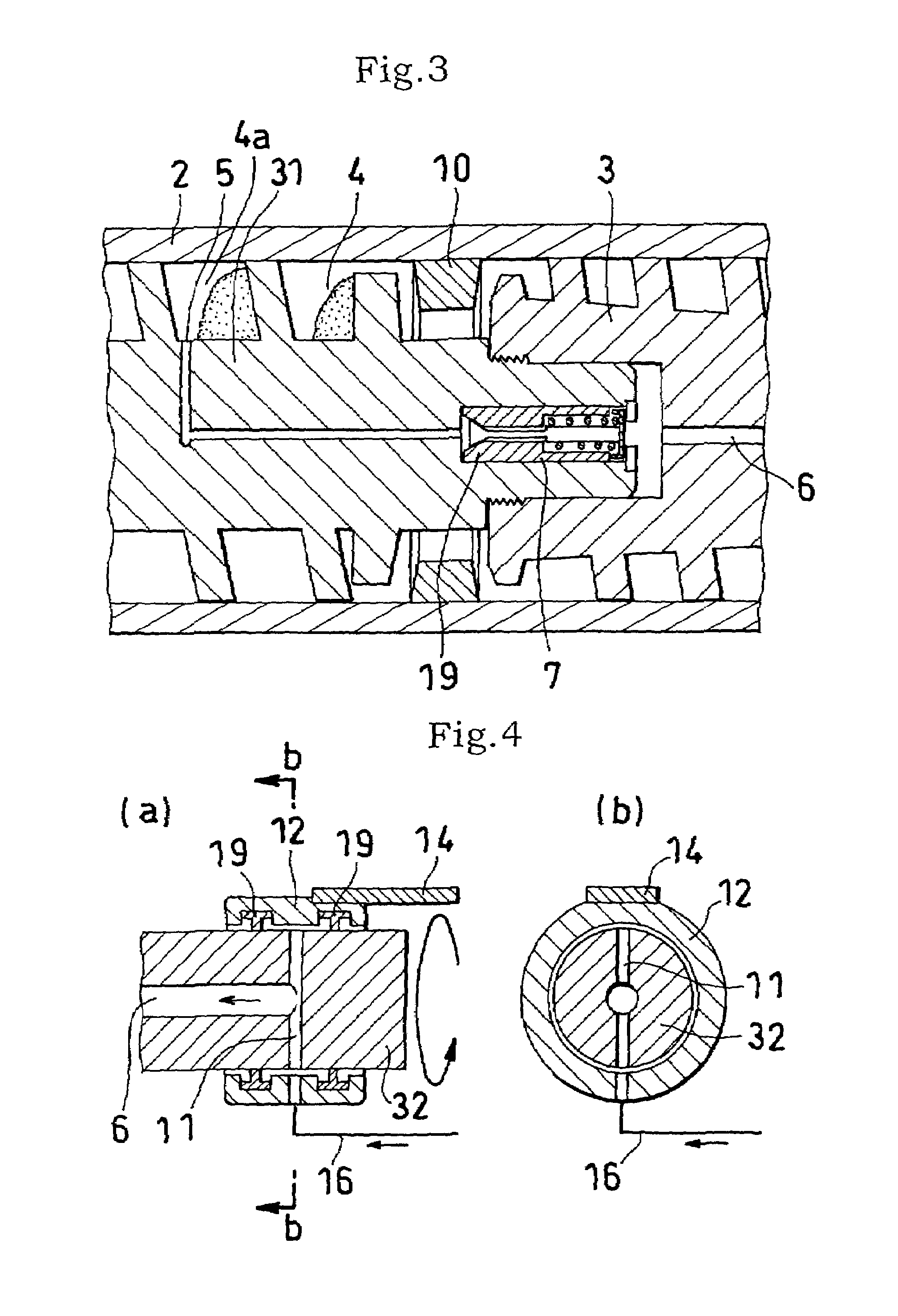

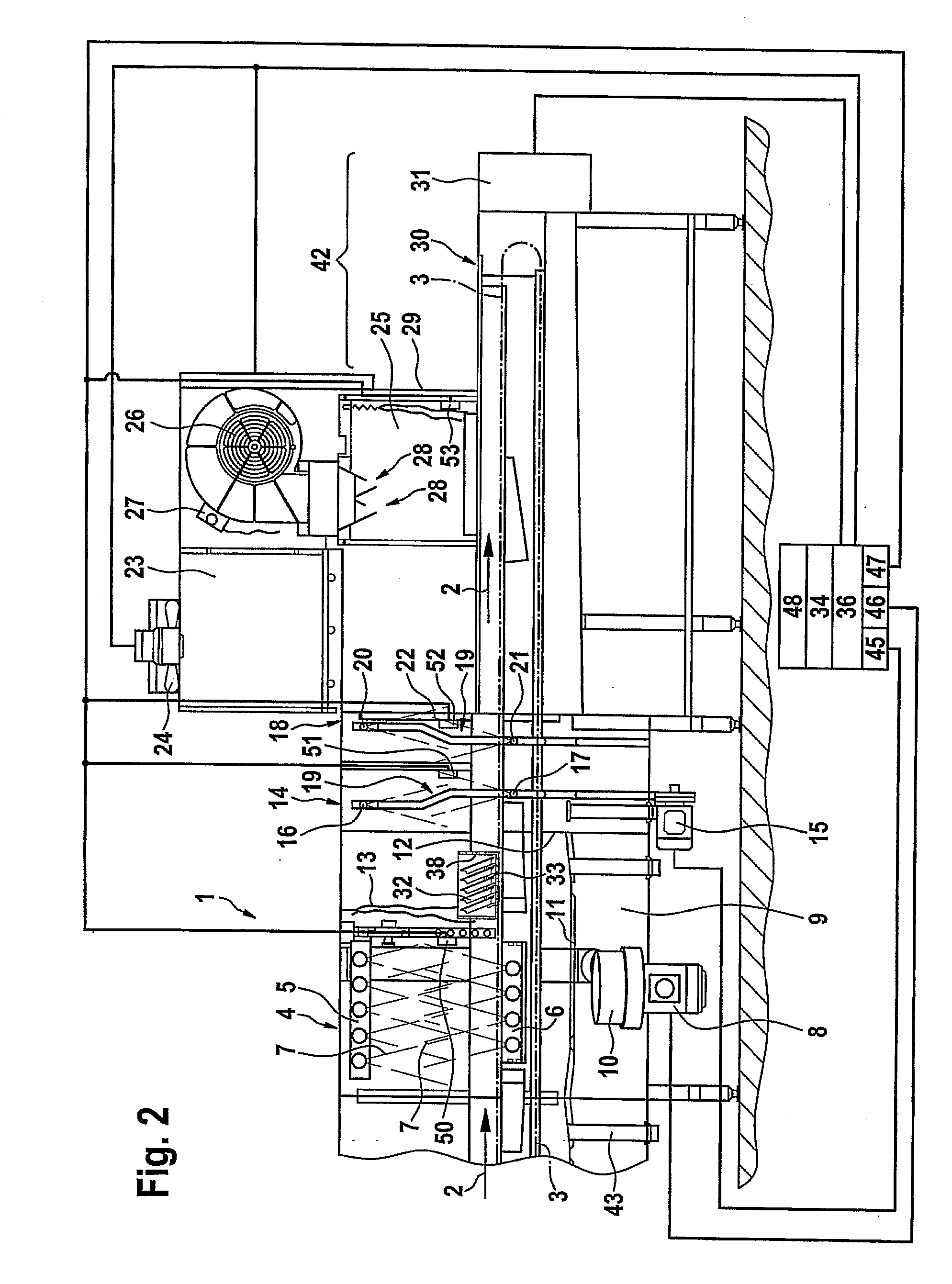

ActiveUS20120239184A1Reduce the overall heightReduced opening width requirementProgramme-controlled manipulatorMetal-working feeding devicesEngineeringMulti axis

A transport unit (1) is provided for workpieces (2), in particular sheet metal parts, between neighboring placement areas or machining devices (3, 4), in particular presses. The transport unit (1) includes a multi-axis robot (5) having a gripper tool (9). A controllable transfer unit (6) is also provided that is guided by the robot (5). The unit includes an advancement unit (7) and a pivot unit (8) for the gripper tool (9).

Owner:KUKA SYSTEMS

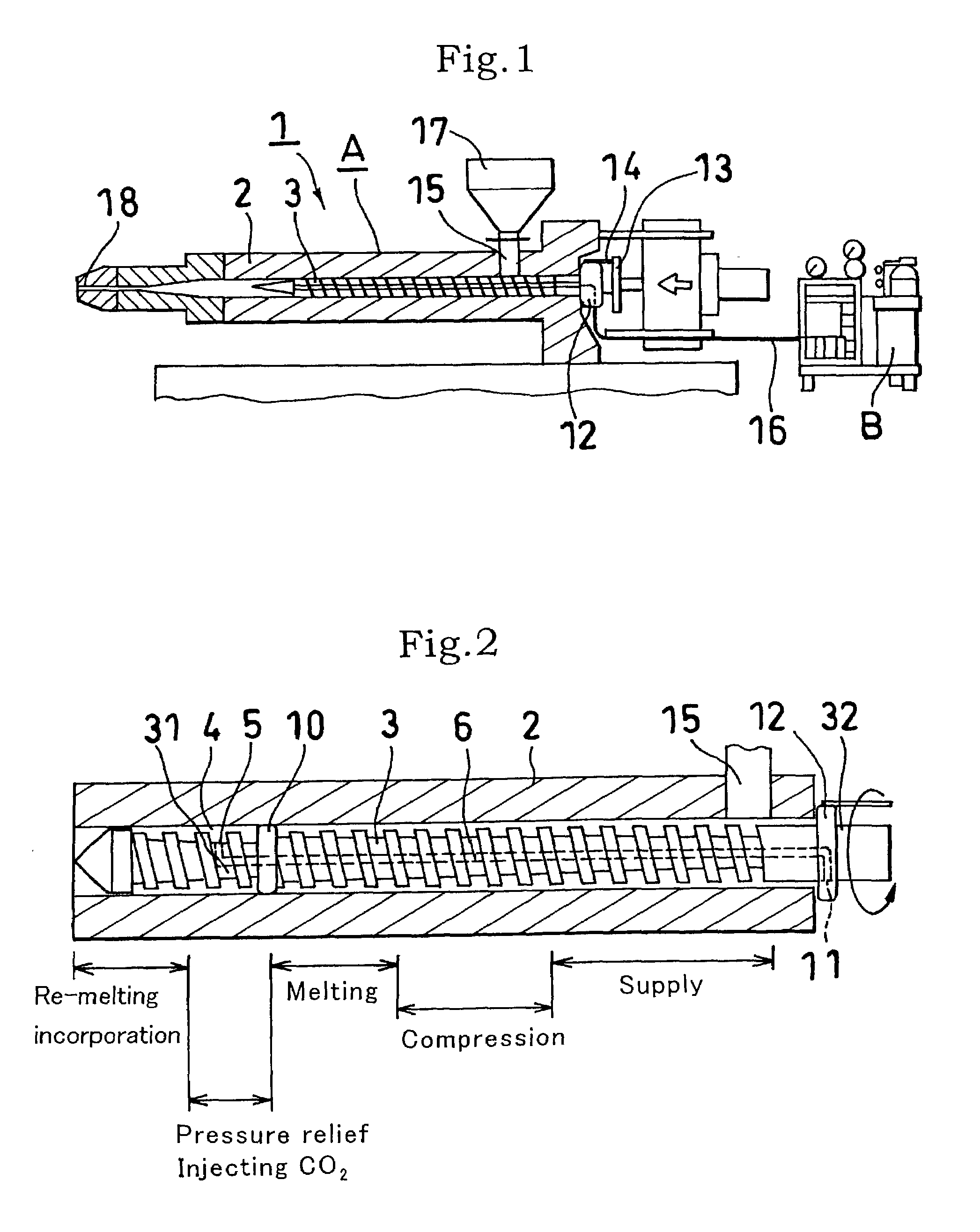

Injection molding process and injection molding apparatus for thermoplastic resin molded articles

InactiveUS6949208B1Efficient meltingIncrease pitchRotary stirring mixersFrozen sweetsFoaming agentReactive gas

Owner:SEKISUI CHEM CO LTD

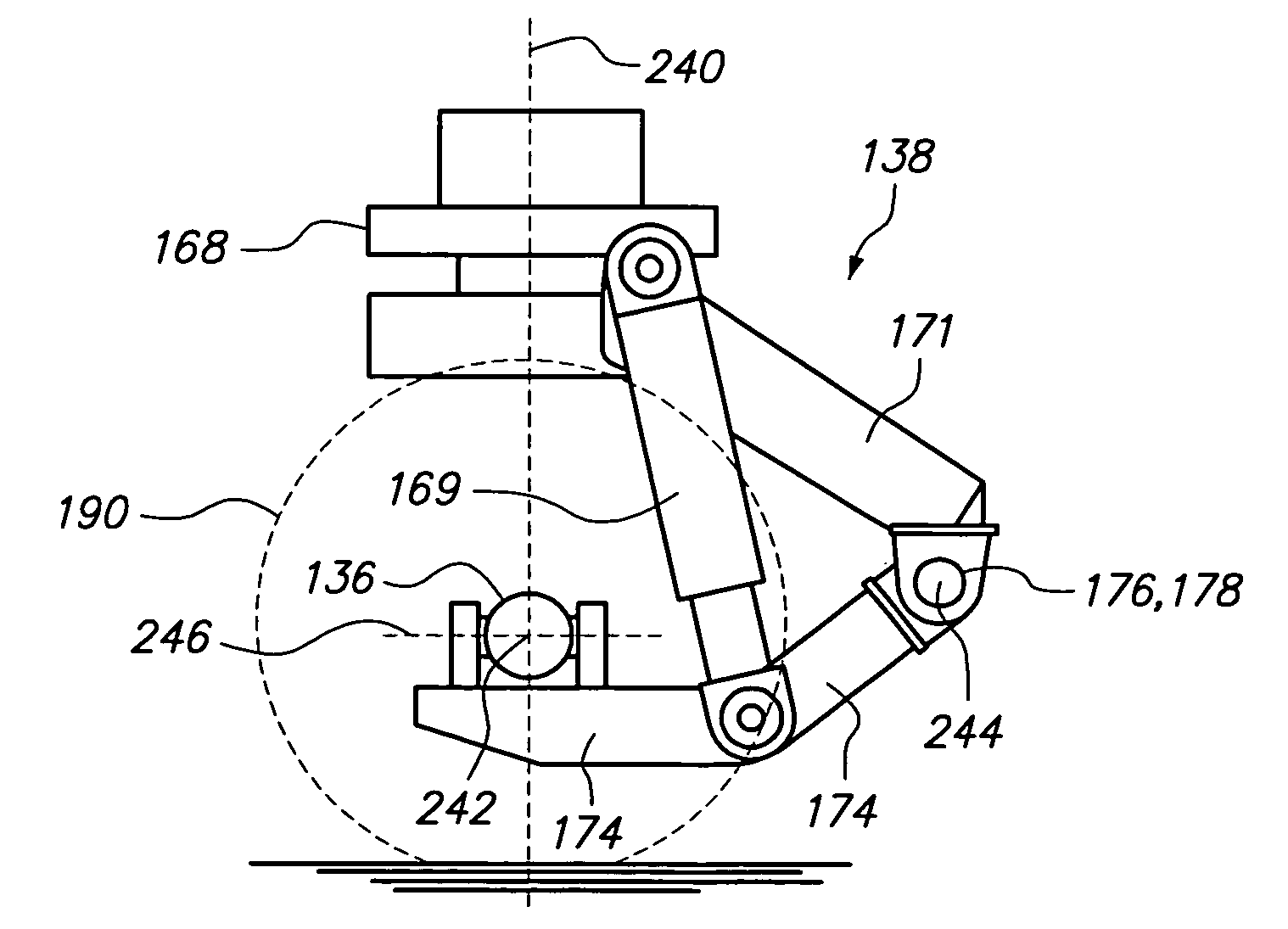

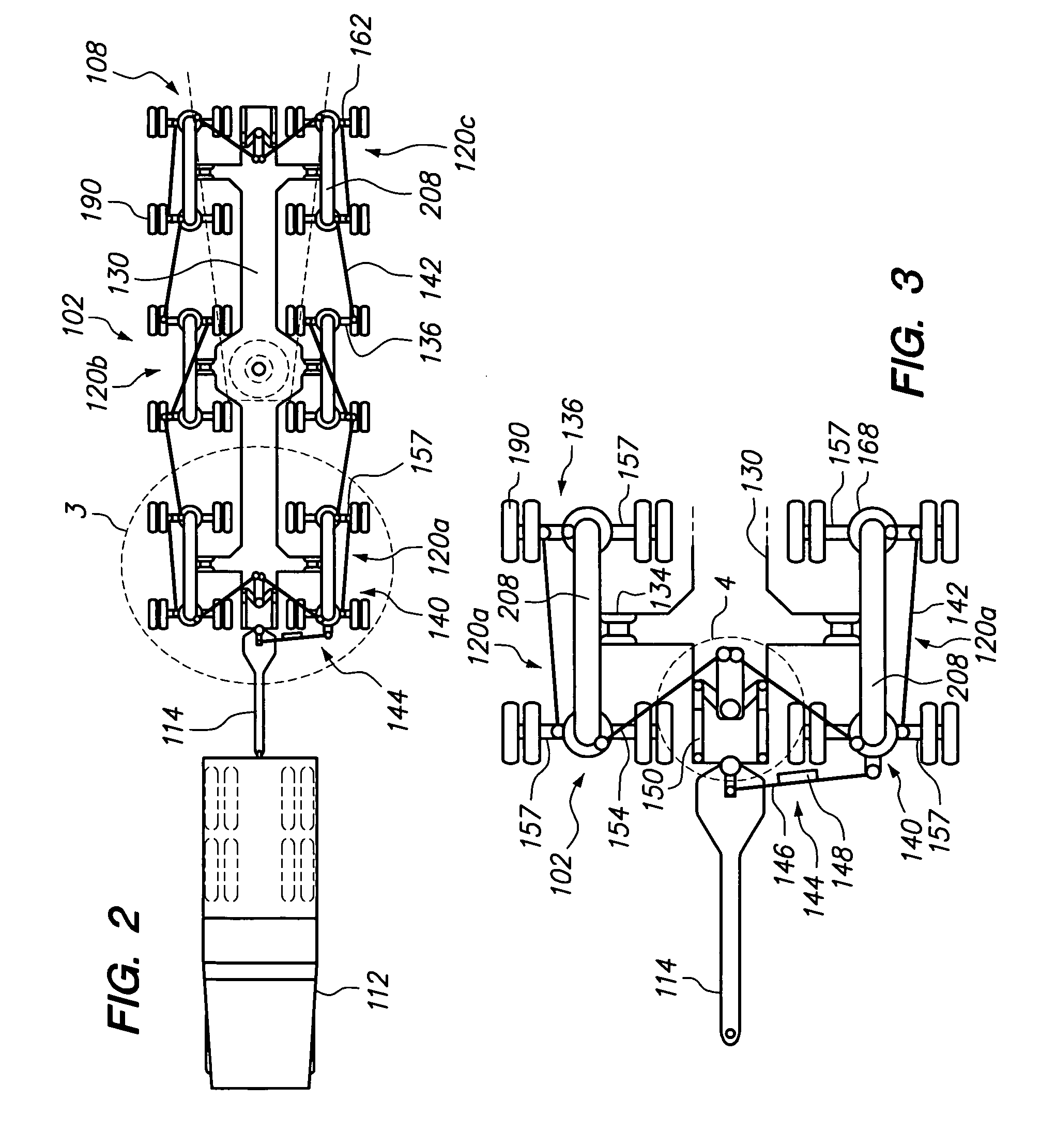

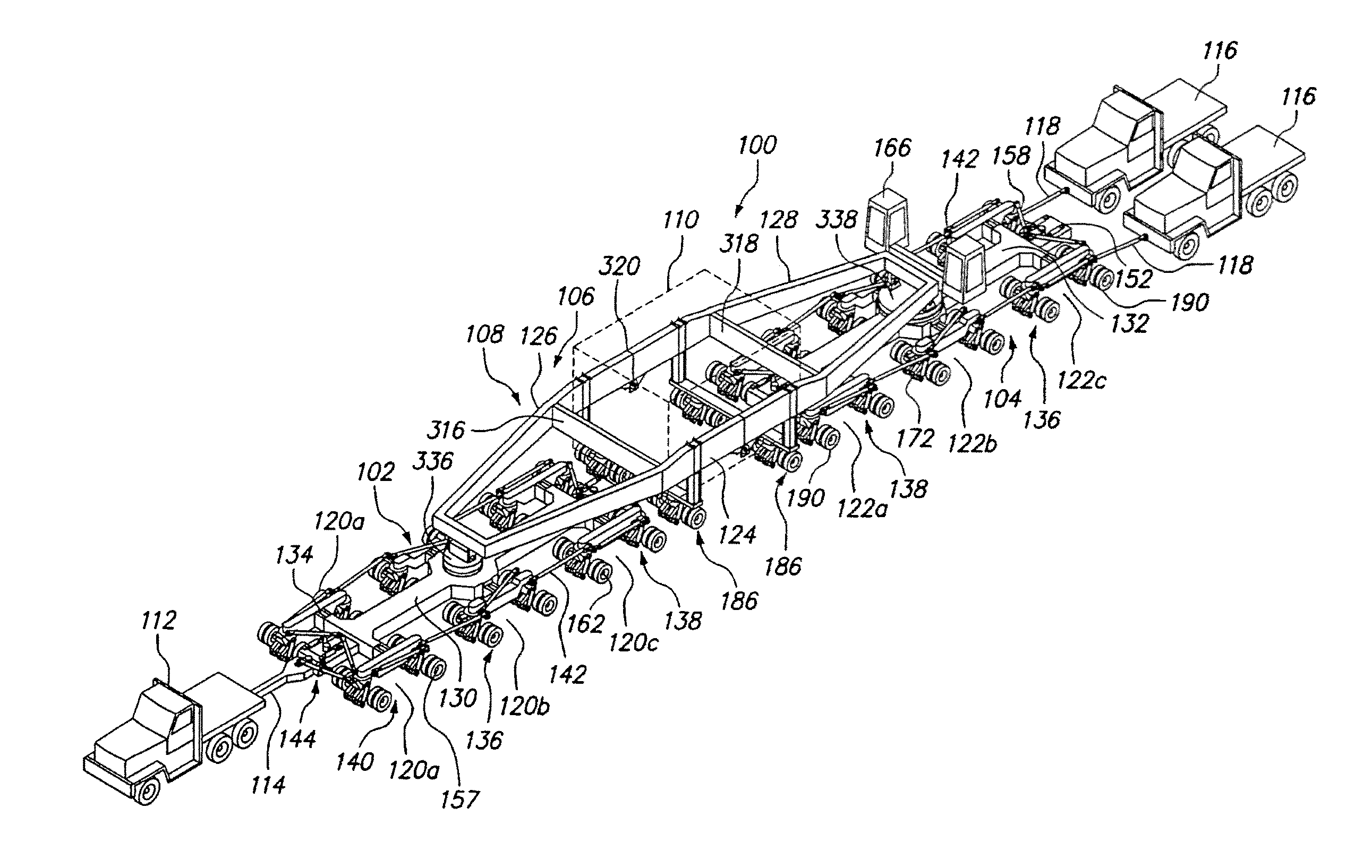

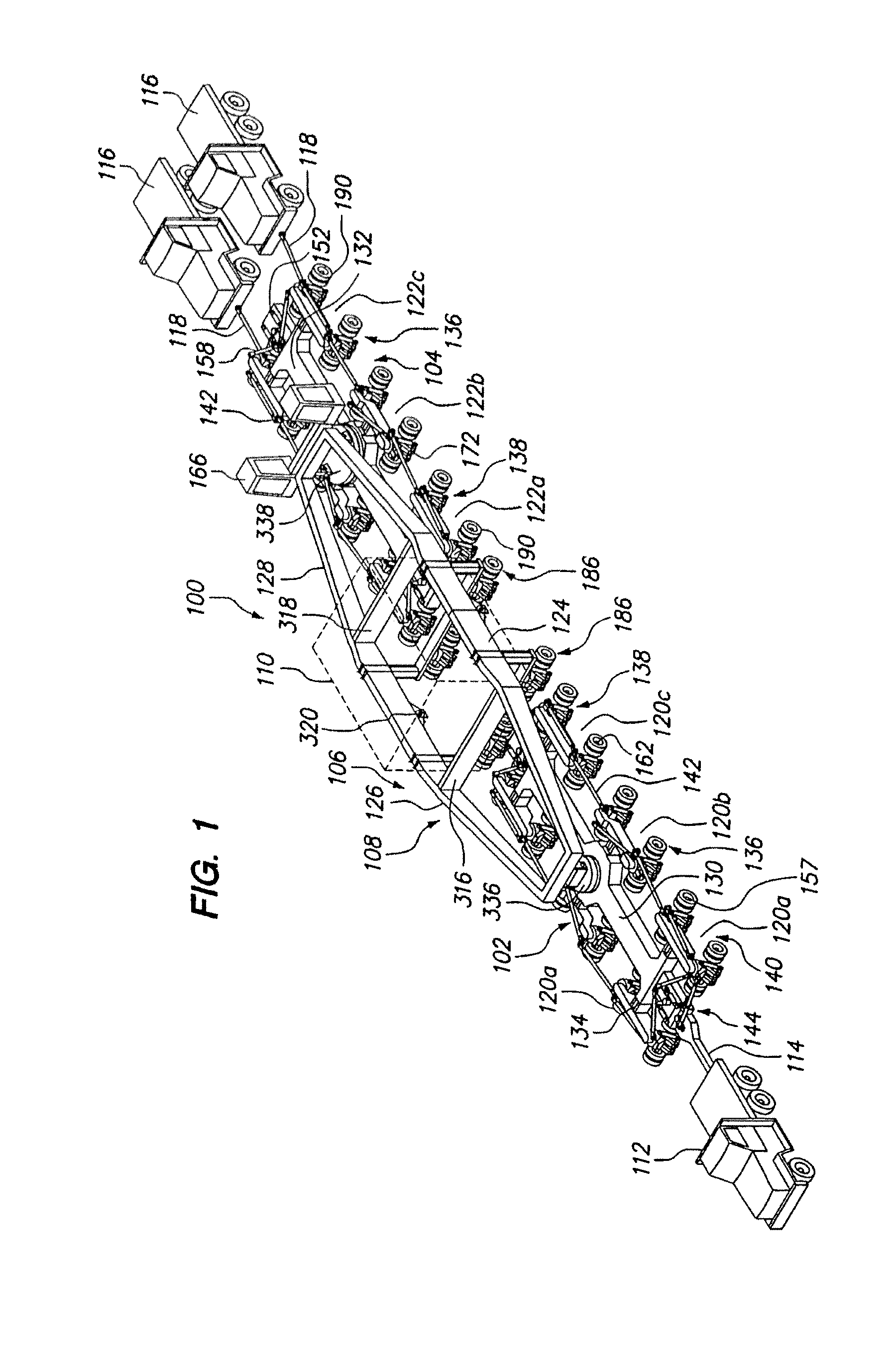

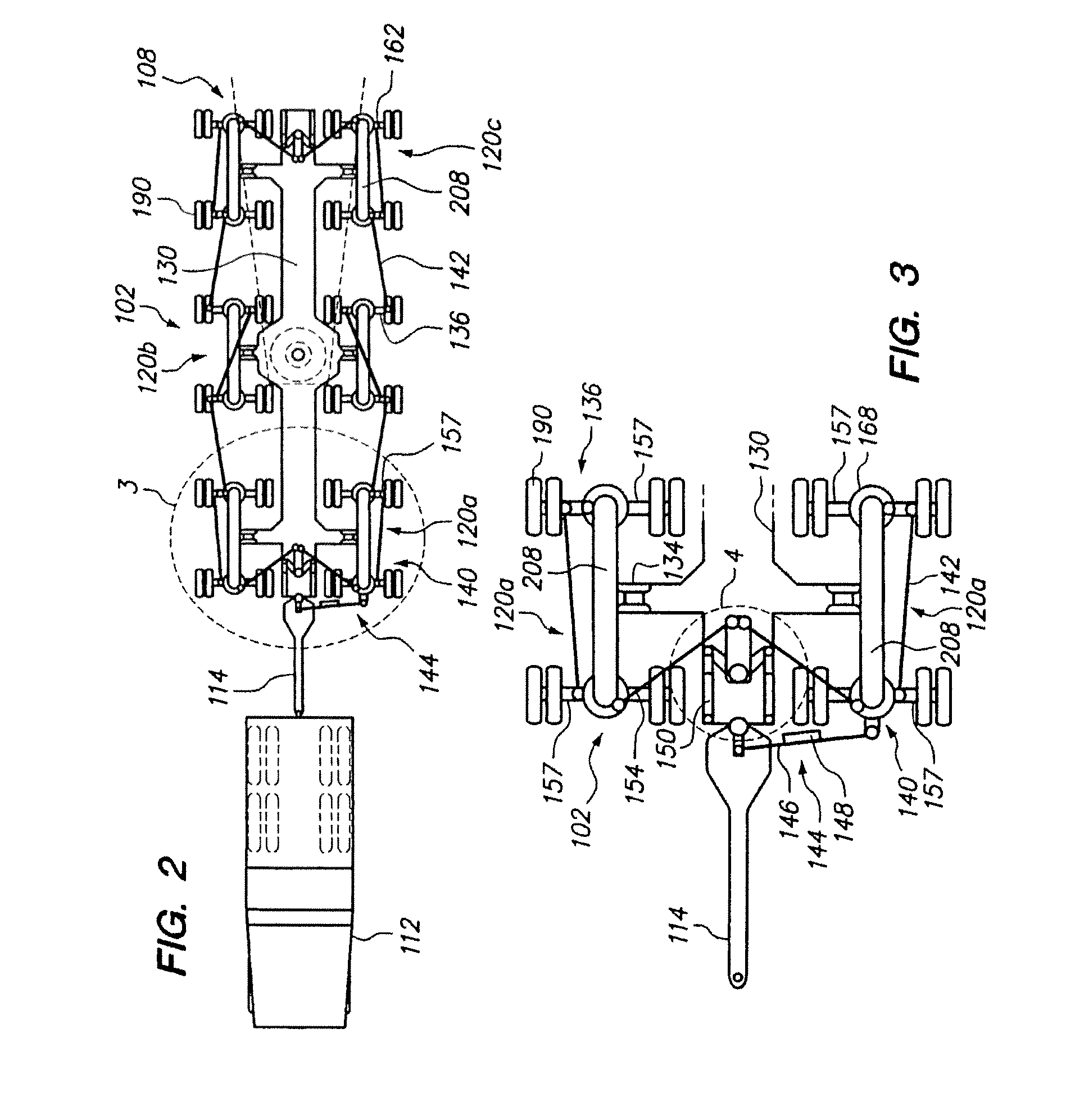

Dual lane multi-axle transport vehicle

InactiveUS20090273159A1Increase profitReducing axle yawVehicle body-frame connectionsUnderstructuresHeavy loadSteering system

A dual lane, multi-axle transport vehicle for moving heavy loads includes a forward module mounted on a plurality of axles and a rearward module mounted on a plurality of axles. The forward module is mechanically connected to the rearward module for providing a dual lane transport body. The forward module and the rearward module of the transport body each have a single central spine wherein the axles of both the forward module and the rearward module are each attached to the corresponding single central spine. The axles of both the forward module and the rearward module have an axle spacing of at least six feet. A hydraulic suspension is provided for dynamically stabilizing the axles for reducing axle yaw. An axle steering system having a plurality of steering rods controls the position of the axles of both the forward module and the rearward module.

Owner:ALPHA ONE TRANSPORTER

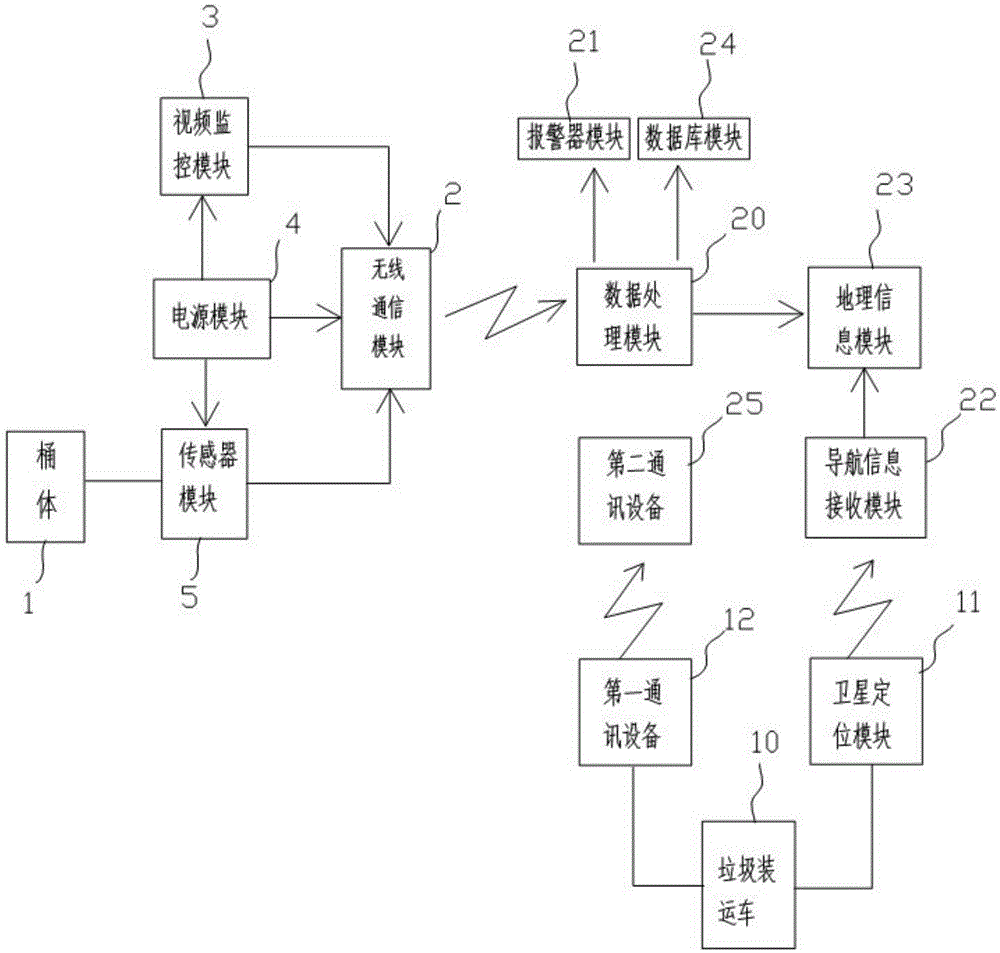

Garbage disposal system based on internet of things

InactiveCN105425751ALow costIncrease the number of collectionsInstruments for road network navigationSatellite radio beaconingVideo monitoringRefuse collection

The invention discloses a garbage disposal system based on internet of things. The garbage disposal system comprises a dustbin terminal device, a garbage truck terminal device and a monitoring center terminal device, wherein the dustbin terminal device comprises a smart dustbin, a wireless communication module, a video monitoring module and a power module; the garbage truck terminal device comprises a garbage truck, a satellite positioning module and a first communication device; and the monitoring center terminal device comprises a data processing module, an alarm module, a navigation information receiving module, a geographic information module, a database module and a second communication device. The garbage disposal system remotely monitors the quantity of garbage and remotely schedules the garbage truck, thus realizing centralized supervision and centralized scheduling, reasonably allocating human resources and realizing optimal garbage collecting efficiency.

Owner:广西昊华科技股份有限公司

Graphene three-dimensional hierarchical porous carbon material and preparation method thereof

The invention provides method for preparation of a graphene three-dimensional hierarchical porous carbon material from biomass raw materials of coconut shell, palm shell and apricot shell. The method fully and reasonably utilizes rich resources of biowaste, and avoids the usage of chemical raw materials. The prepared graphene three-dimensional hierarchical porous carbon material has special laminated structure with wrinkles and hierarchical porous structure containing mesopore, micropore and macropore, so that the conductive performance of the material is better than similar materials in the prior art.

Owner:HAINAN UNIVERSITY

Meal Replacement and Appetite Control/ Diet System

InactiveUS20100278981A1Great tasteIncrease satietyConfectioneryFatty substance preservation using additivesFiberAdditive ingredient

The present invention provides a composition of nutritive based ingredients that together provide a source of balanced and provides the ability to control food cravings, increase satiety, promote a feeling of fullness and provide a user a method to maintain a healthy weight and or achieve weight loss. This composition of ingredients includes a chocolate or caramel flavored confection component, a high protein component, a fiber blend component, an edible oil component, an antioxidant component from natural occurring sources, a supplement component that can provide specific health benefits as well as a balanced group of vitamins and minerals. The composition of ingredients can be delivered in a variety of food platforms. A functional food confectionery is a preferred platform for our invention delivery system. Portion control bars and / or bars that have pre-determined break points that control portion size and portioned squares or other shapes would be the preferred product structure. A complete weight loss and weight maintenance methodology, including use instructions for incorporating the products within the daily diet is identified. Methods of manufacturing and compositions are also included.

Owner:ERVIN GARY

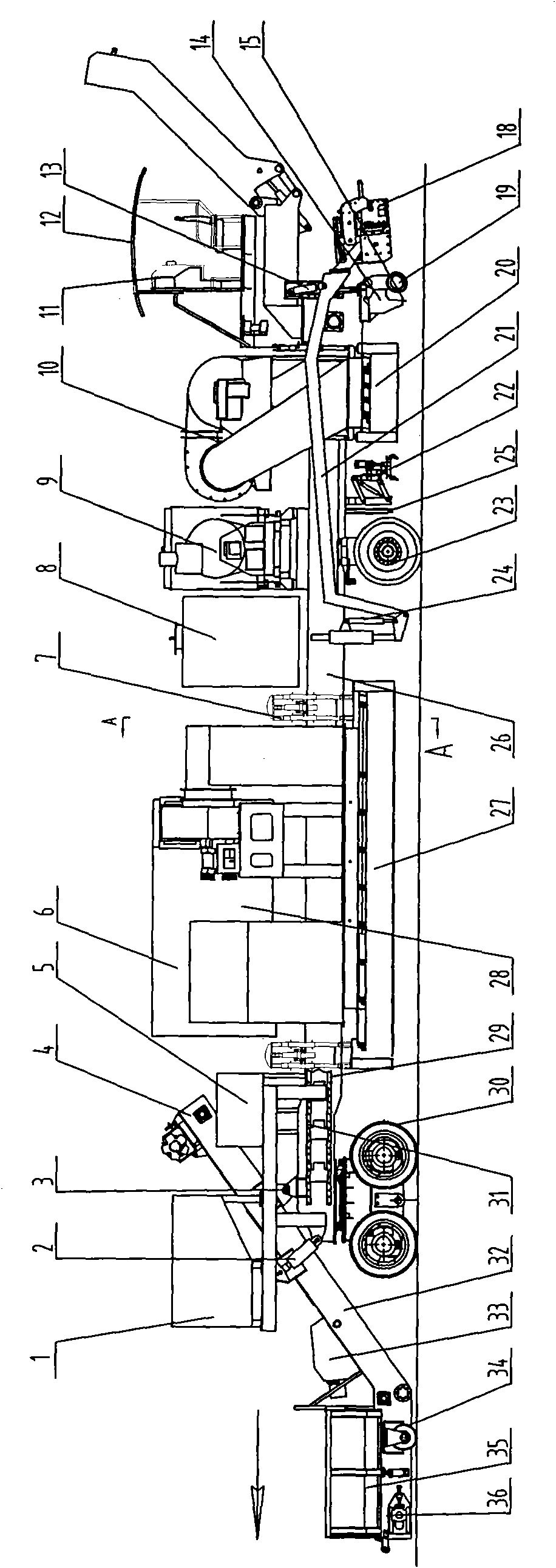

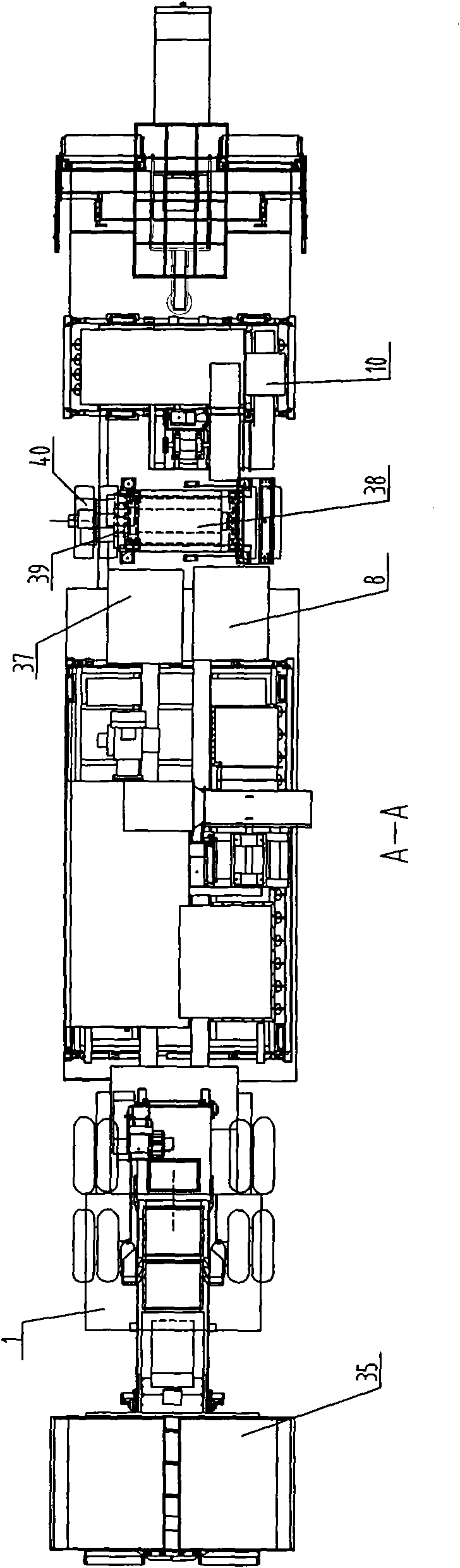

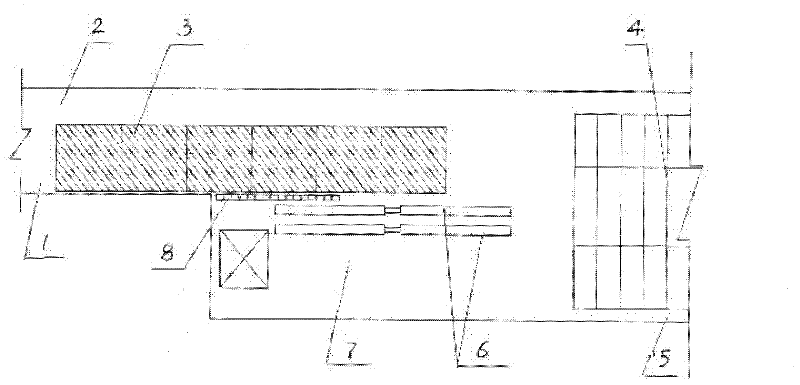

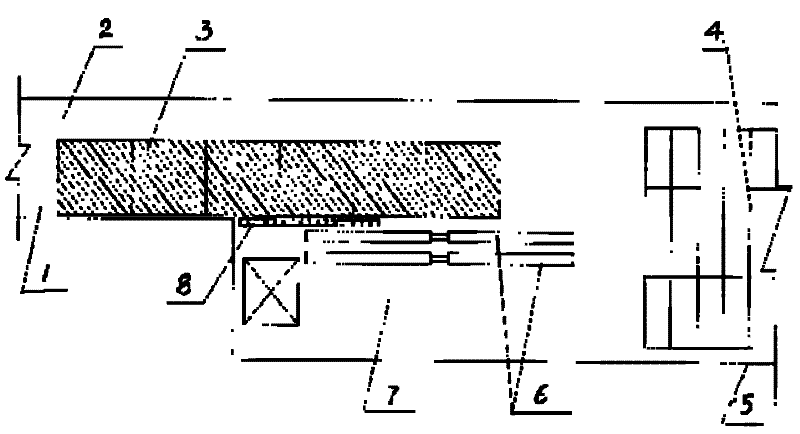

Hot in-place recycling ultrathin overlaying machine of bituminous pavement and construction method thereof

InactiveCN102011362ARestoration of slip resistanceGood lookingIn situ pavingsRoads maintainenceTraffic noiseScreed

The invention provides a hot in-place recycling ultrathin overlaying machine of a bituminous pavement and a construction method thereof. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement comprises an automobile chassis, an integral power device, an electric control system, a diesel tank, a receiving and transporting device, a material transfer hopper, a horizontal transporting device, a heating device, a hydraulic system, a recycling agent spraying system, a harrowing device, a distributing spiral device, a paving screed device, a cab, and an electric control operating floor, wherein the automobile chassis is a special automobile chassis. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement finishes the continuous overlay repair work of the pavement through a series of processes such as receiving the materials, feeding the materials quantitatively, transporting the materials horizontally, spraying the recycling agent, harrowing, heating, distributing and paving the materials, ironing, and grinding and the like, and has the advantage of carrying out one-time maintenance on the defects such as loose, shallow vertical and horizontal cracks, track, slight crack, bituminous aging, pavement seepage and the like of a functional layer of the pavement. By adopting the invention, the antiskid resistance of the pavement is restored, the profile of the pavement is corrected, the appearance and the evenness of the pavement are improved, the pavement strength of the pavement is increased, the traffic noise is reduced, and the service life of the pavement is prolonged.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

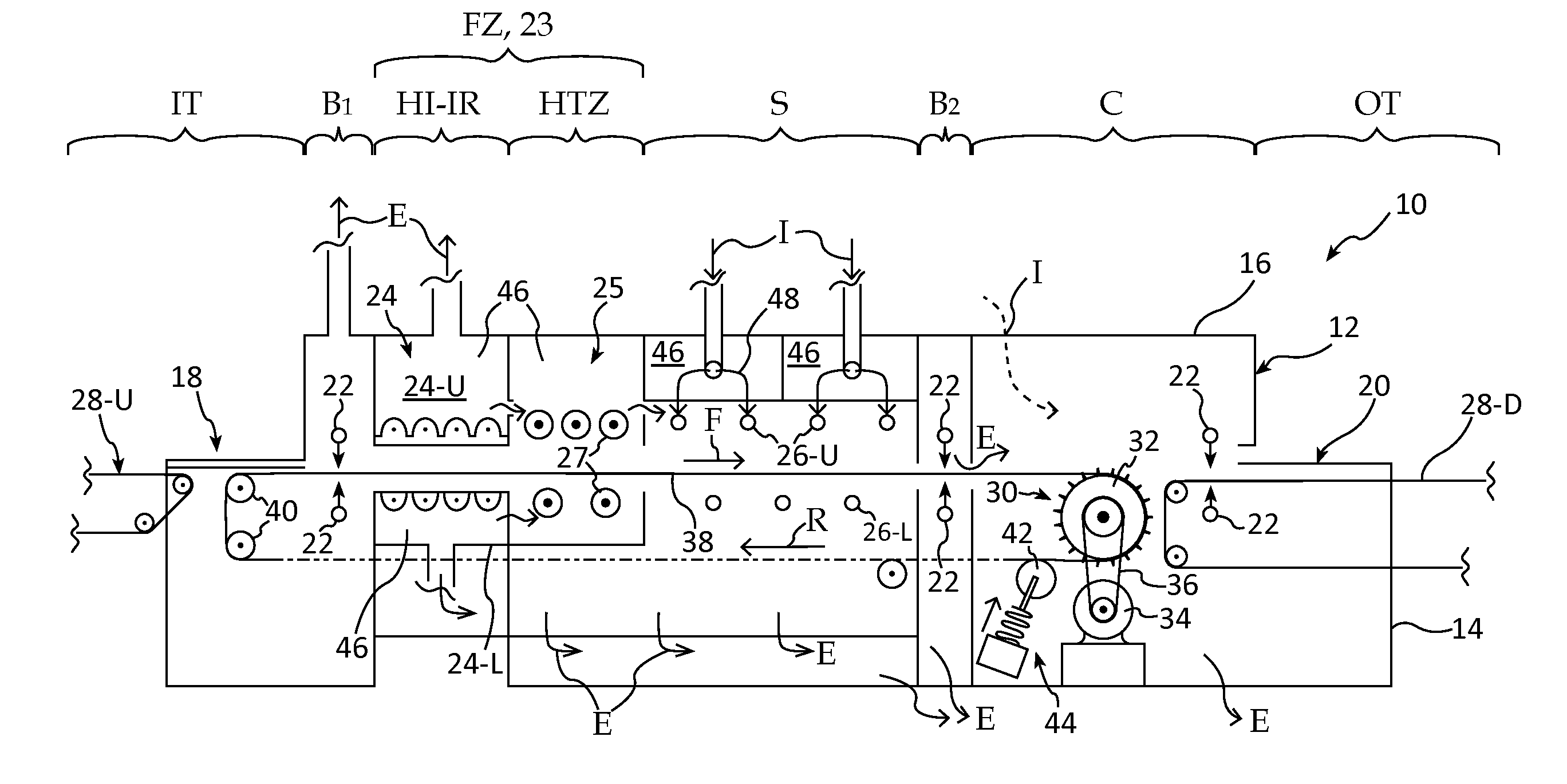

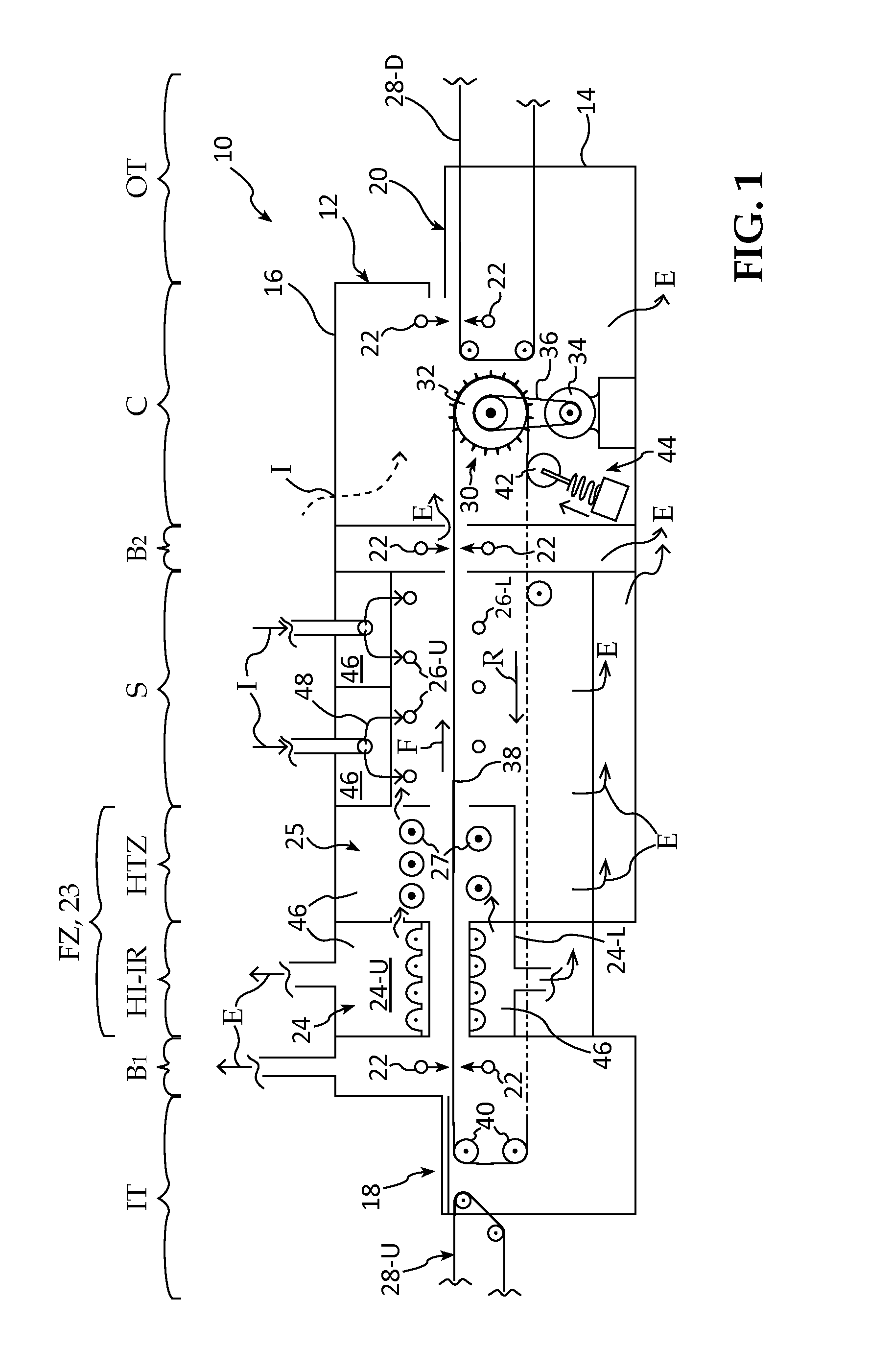

Diffusion Furnaces Employing Ultra Low Mass Transport Systems and Methods of Wafer Rapid Diffusion Processing

InactiveUS20120269226A1Increase heatAccurate temperatureCharge supportsSemiconductor/solid-state device manufacturingTransport systemEngineering

Multi-zone, solar cell diffusion furnaces having a plurality of radiant element (SiC) or / and high intensity IR lamp heated process zones, including baffle, ramp-up, firing, soaking and cooling zone(s). The transport of solar cell wafers, e.g., silicon, selenium, germanium or gallium-based solar cell wafers, through the furnace is implemented by use of an ultra low-mass, wafer transport system comprising laterally spaced shielded, synchronously driven, metal bands or chains carrying non-rotating alumina tubes suspended on wires between them. The wafers rest on raised circumferential standoffs spaced laterally along the alumina tubes, which reduces contamination. The high intensity IR flux rapidly photo-radiation conditions the wafers so that diffusion occurs>3× faster than conventional high-mass thermal furnaces. Longitudinal side wall heaters comprising coil heaters in Inconel sheaths inserted in carrier tubes are employed to insure even heating of wafer edges adjacent the side walls.

Owner:TP SOLAR OF USA

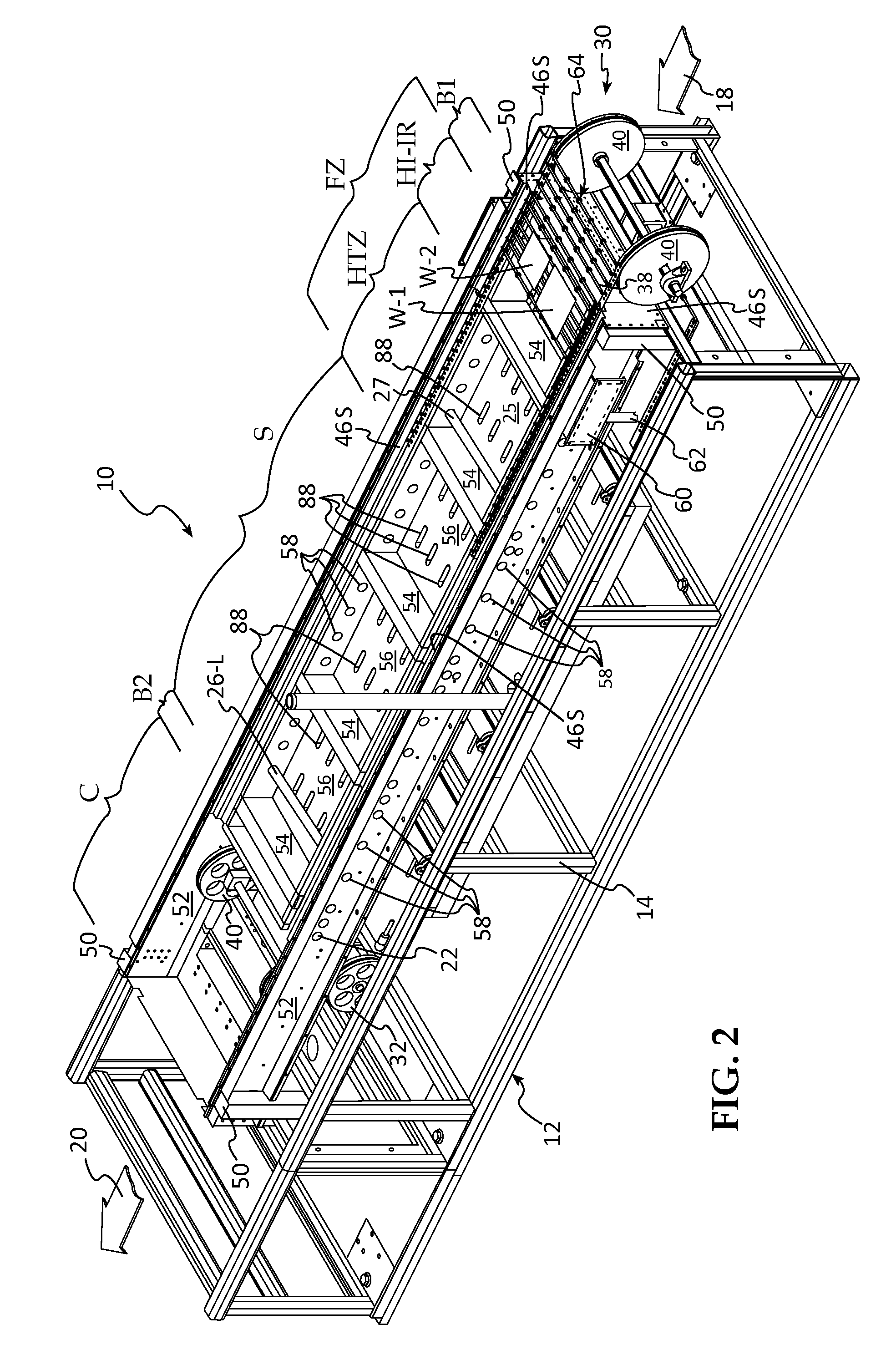

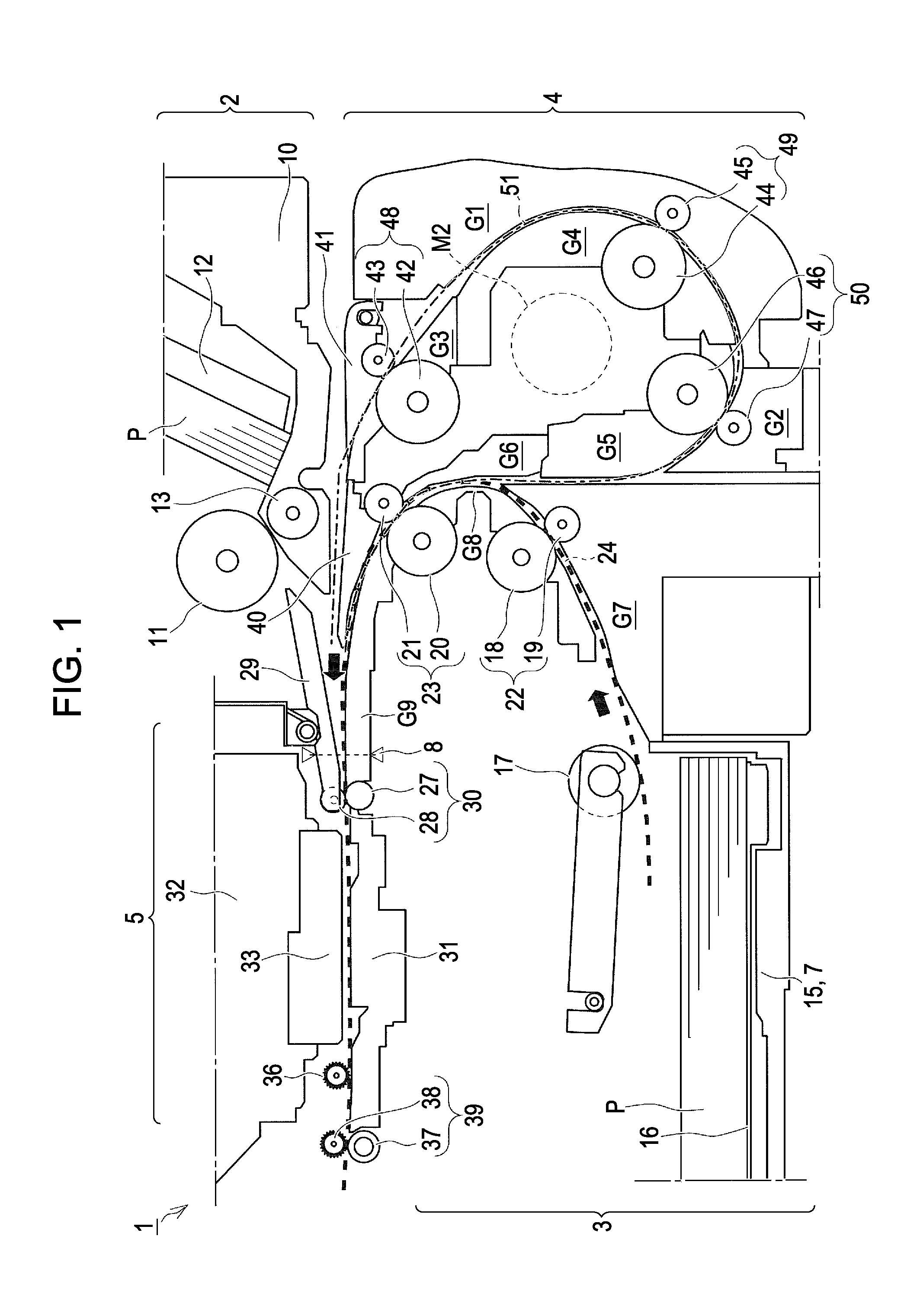

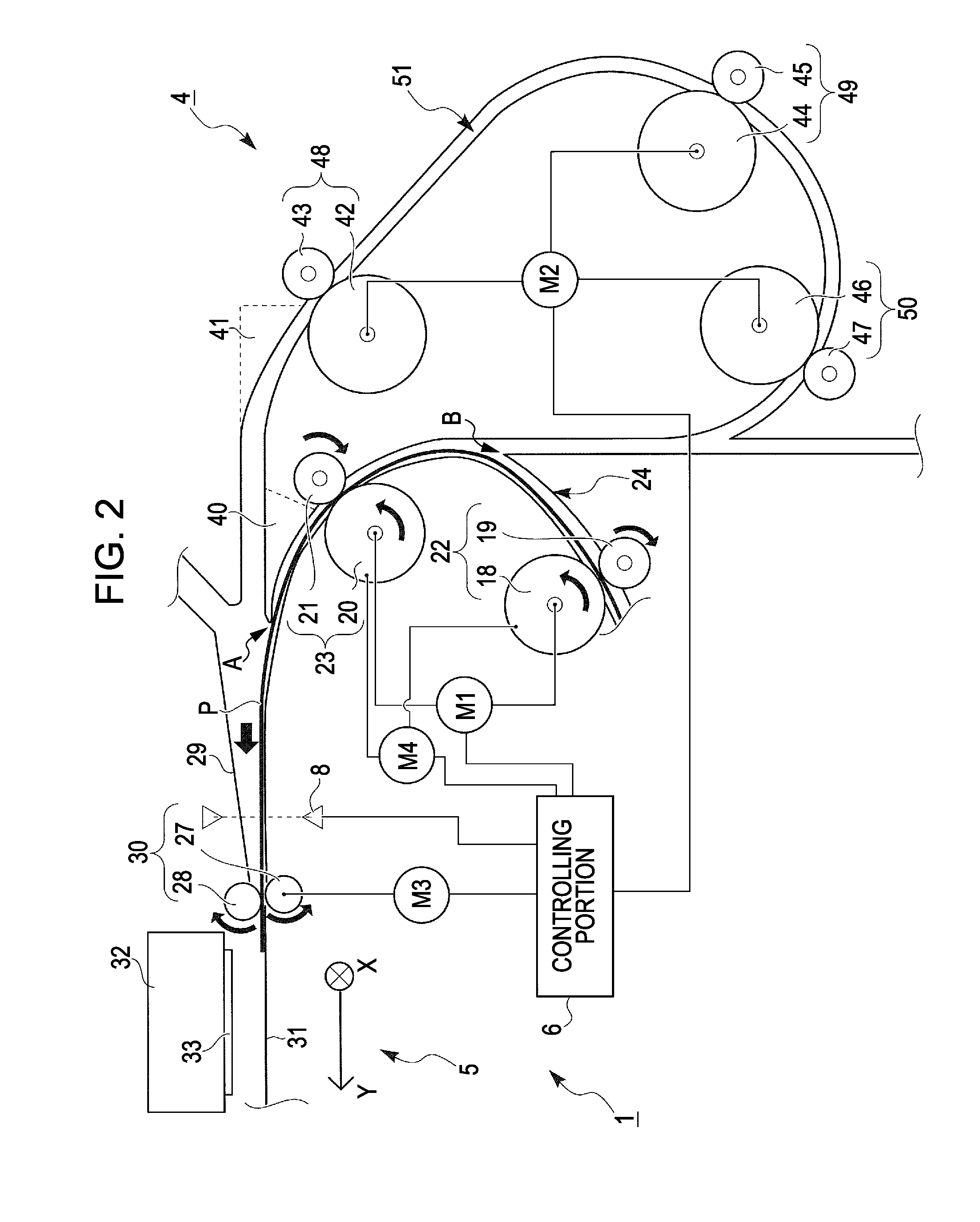

Recording apparatus

ActiveUS20100296856A1Shorten the timeLong movementRegistering devicesFunction indicatorsTransport engineering

Owner:SEIKO EPSON CORP

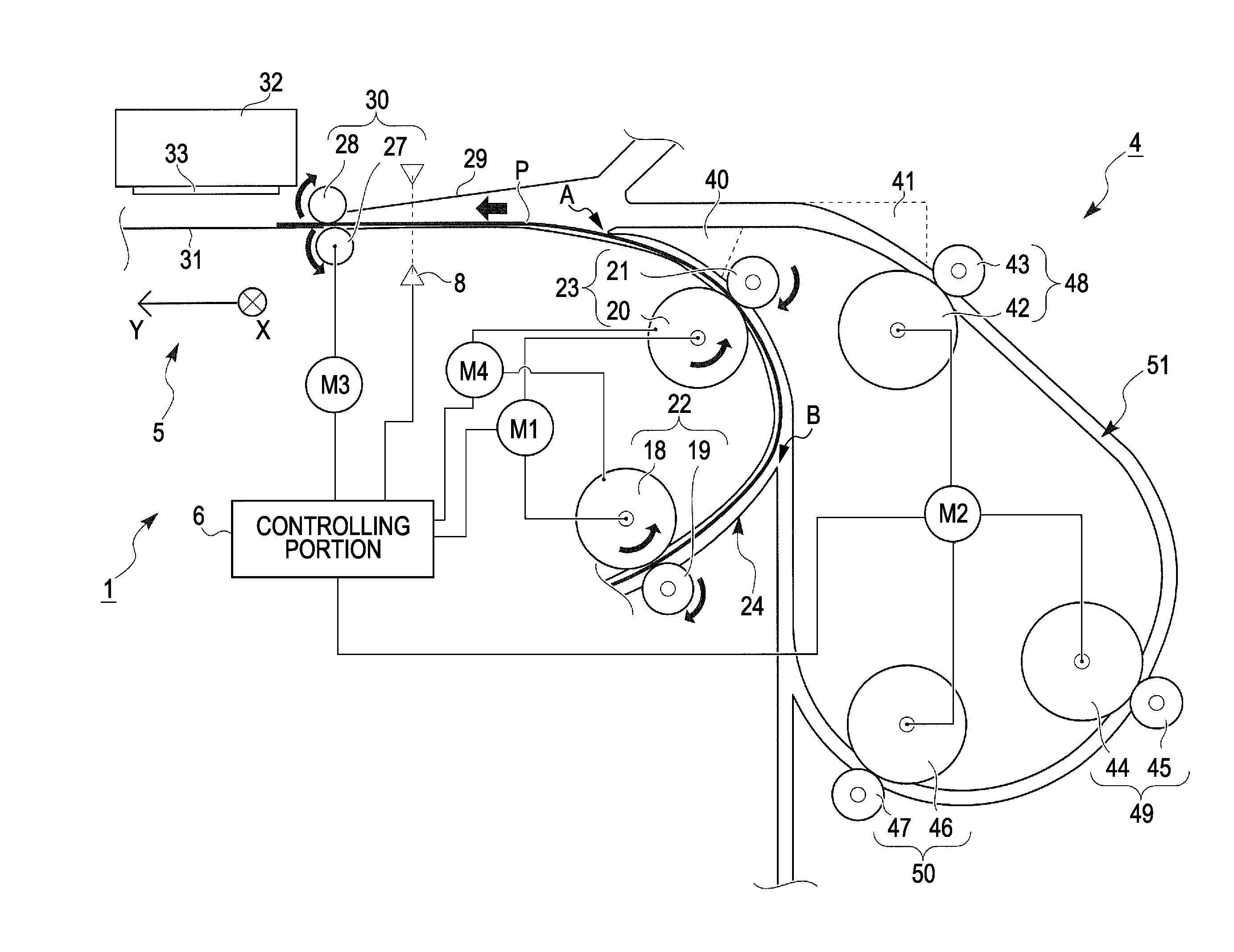

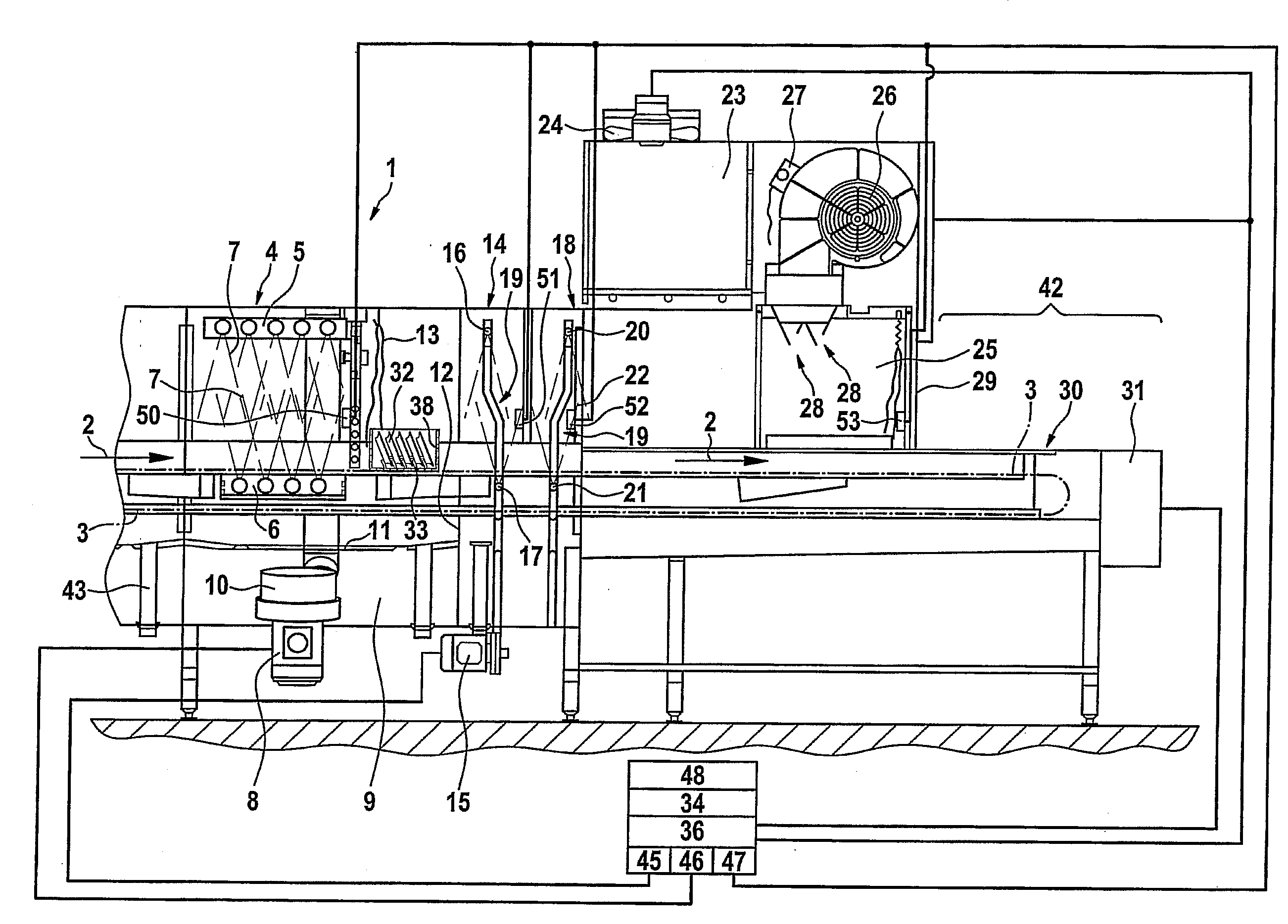

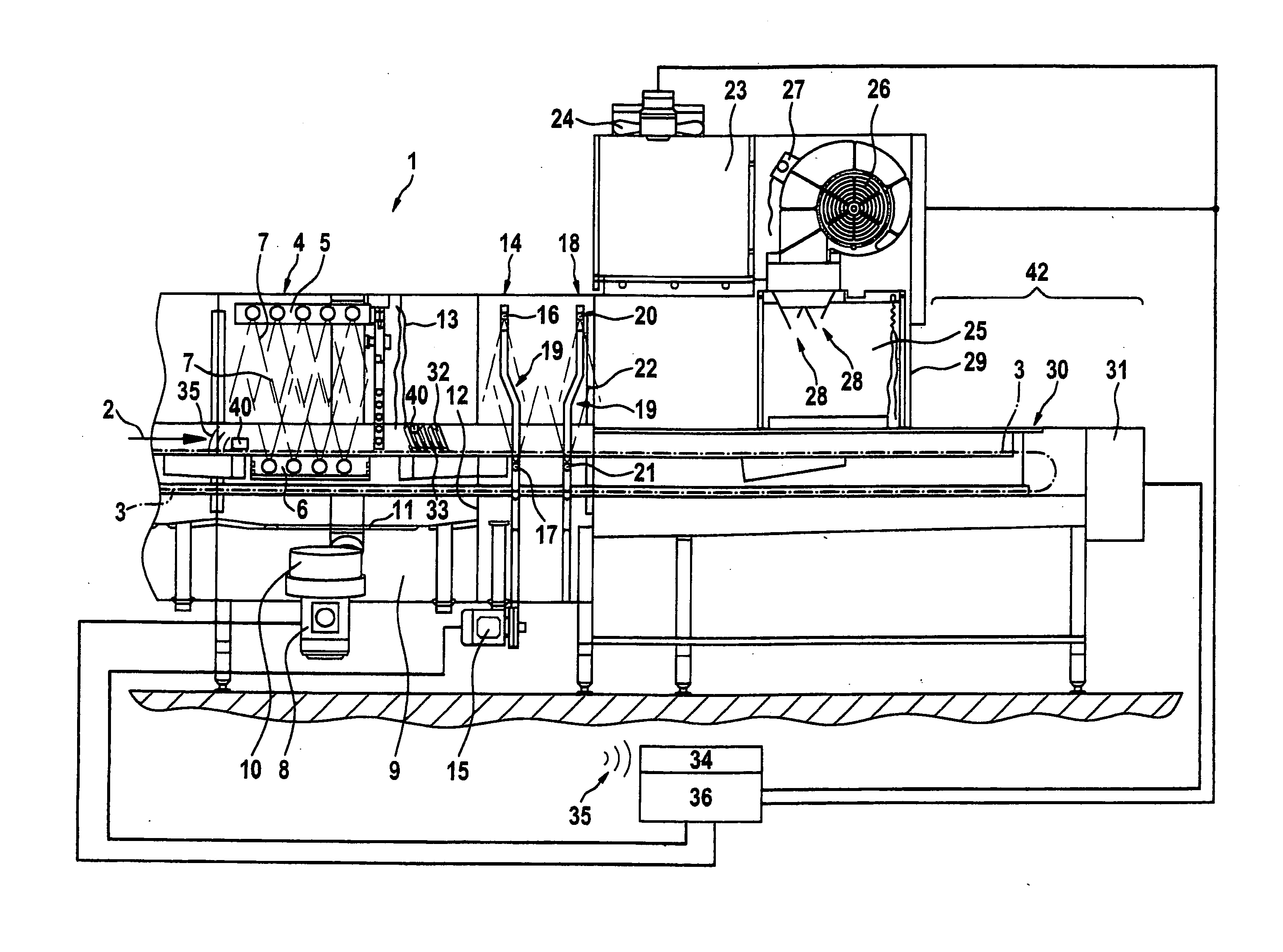

Method for evaluating and guaranteeing the thermal hygienic effect in a multitank dishwasher

InactiveUS20080115807A1Improve reliabilityShorter in buildAutomatic washing/rinsing machine detectionHollow article cleaningMachine controlProcess region

A method for evaluating and guaranteeing a thermal hygienic effect in a conveying dishwashing machine preferably a multi-chamber dishwasher, is provided. The inventive dishwasher is provided with one or several sensors which are fixed therein and transmit a temperature inside each treatment areas to a machine controller, preferably a controller for the conveying dishwashing machine. The machine controller determines the thermal hygienic effect by means of heat equivalent-based temperature and time acting on a cleanable object. A washing process is controlled in such a way that predetermined quantity of heat equivalents is transmitted to the cleanable object.

Owner:MEIKO MASCHENBAU

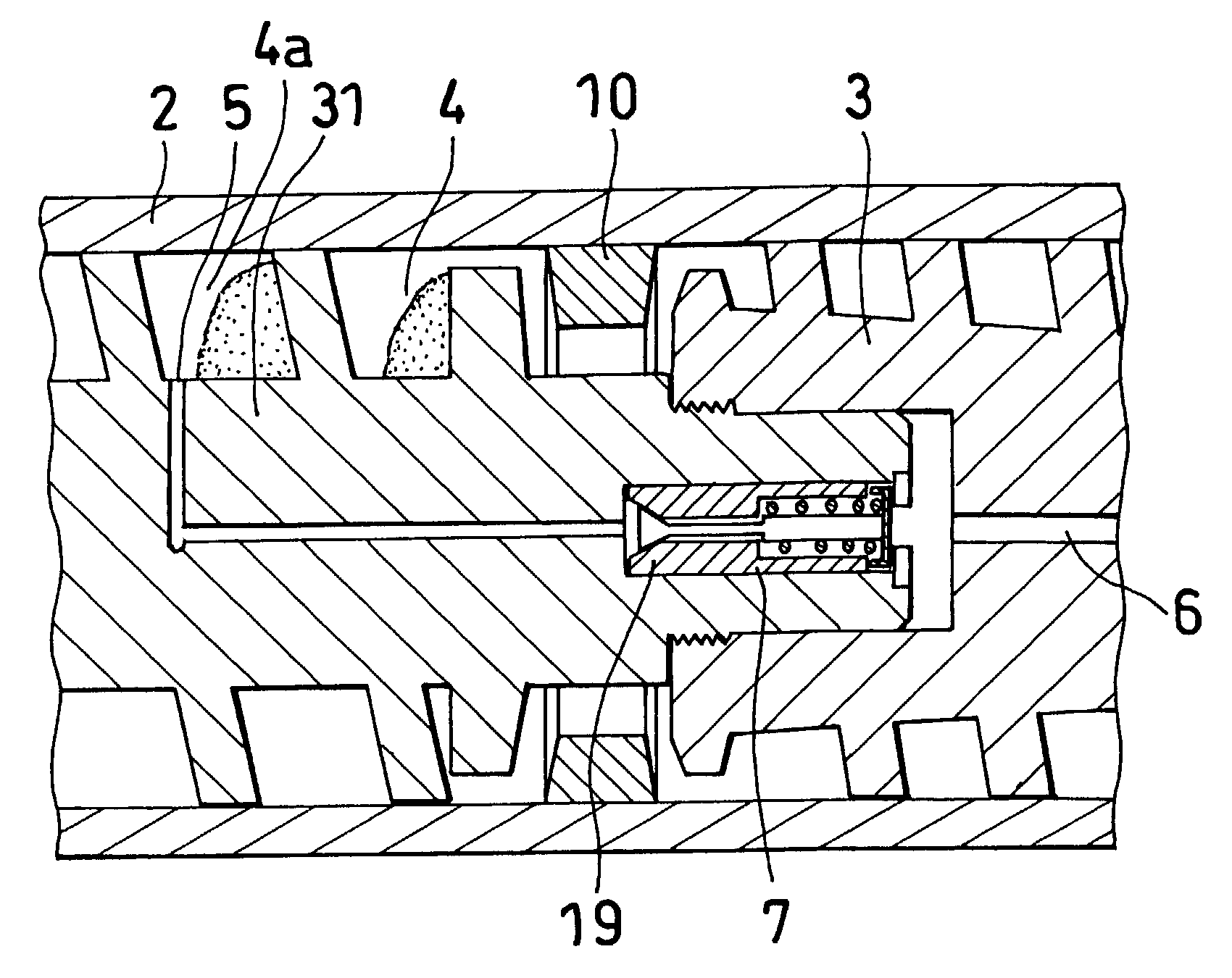

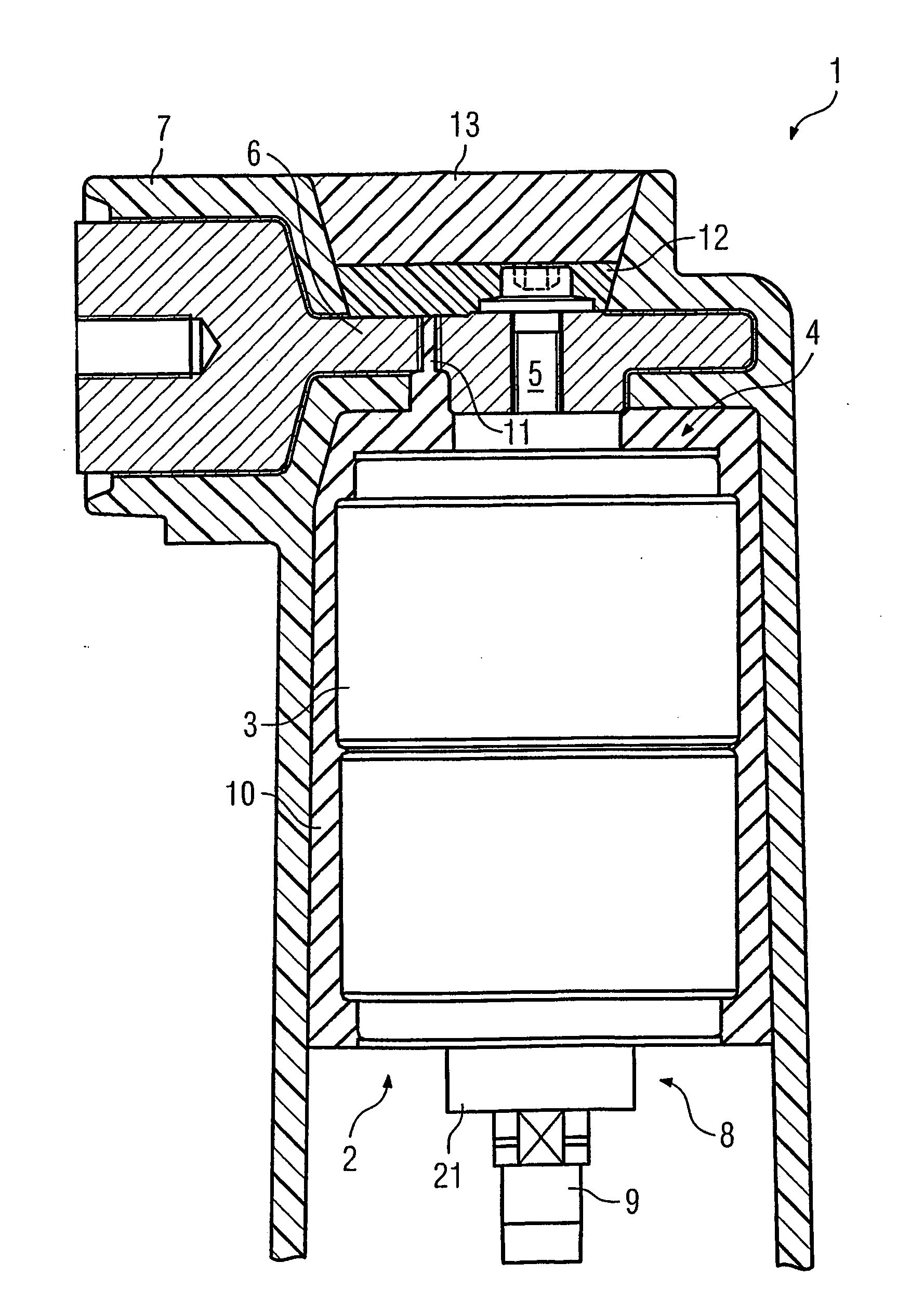

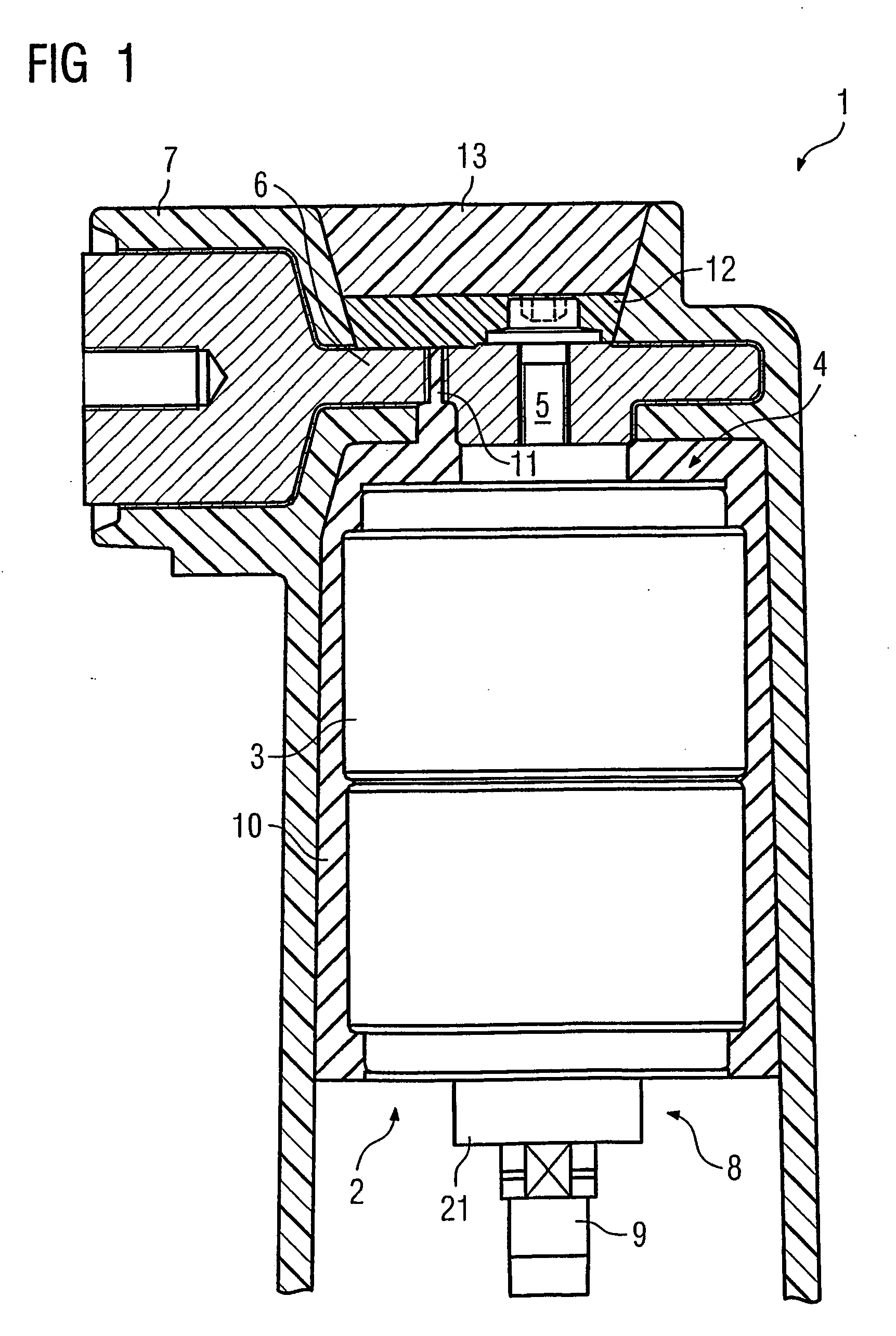

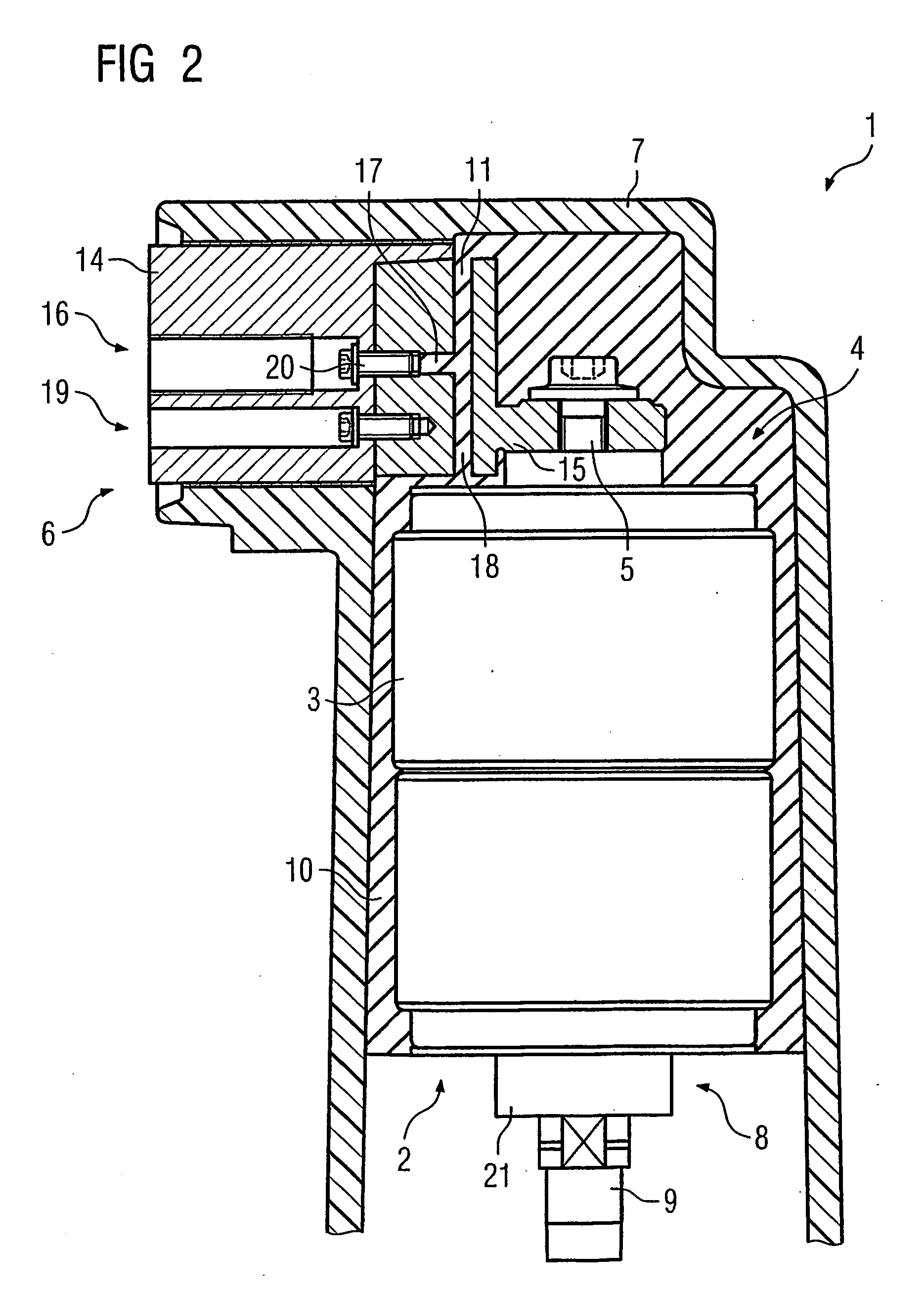

Production of a circuit-breaker pole, insulated by a solid material

InactiveUS20060011589A1Avoid transportResistance to currentHigh-tension/heavy-dress switchesDomestic articlesEngineeringActuator

The invention relates to a method for producing a circuit-breaker pole (1), insulated by a solid material, said pole comprising an actuator opening that is configured to introduce an actuation displacement. According to said method: a switch (2) comprising a switch housing (3), which has an actuation face (8), through which a drive rod (9) is guided and a dimensionally stable jacket (7) consisting of insulation material and provided with a connection part (6) are produced independently of one another; the switch (2) is fixed in the jacket (7) in such a way that the switch housing (3) excluding the actuation face (8) and the jacket (7) that is provided with the connecting part (6) delimit a gap which opens towards the actuation opening; the gap is subsequently filled with a fluidic compensating mass (10) and finally said mass (10) is cured. The invention also relates to a circuit-breaker pole (1) comprising a potting channel, for interrupting an electric current.

Owner:SIEMENS AG

Preparation method of superhydrophobic surface of metal zirconium

ActiveCN101941000AExcellent superhydrophobic propertiesMeet actual needsSurface reaction electrolytic coatingPretreated surfacesAnodizingEtching

The invention provides a preparation method of a superhydrophobic surface of a metal zirconium. The method is as follows: firstly, in site building a nano / micro coarse structure on the surface of the metal zirconium through chemical etching, anodizing and ultraphonic strip membranes; and subsequently, carrying out hydrophobic treatment on the surface through low surface energy substances such as self-assembling siloxane and the like, thereby obtaining the superhydrophobic metal zirconium surface. The metal zirconium surface treated by using the method of the invention has good superhydrophobic property, a contact angle with water-drop reaches 157-163 degrees, and a roll angle is less than 3 degrees, thereby meeting the demand of industry fields on the superhydrophobic surface of the metal zirconium. The method of the invention has the characteristics of simple process, convenient operation, low production cost, easy large-scale preparation, industrial production and the like.

Owner:苏州盛泽科技创业园发展有限公司

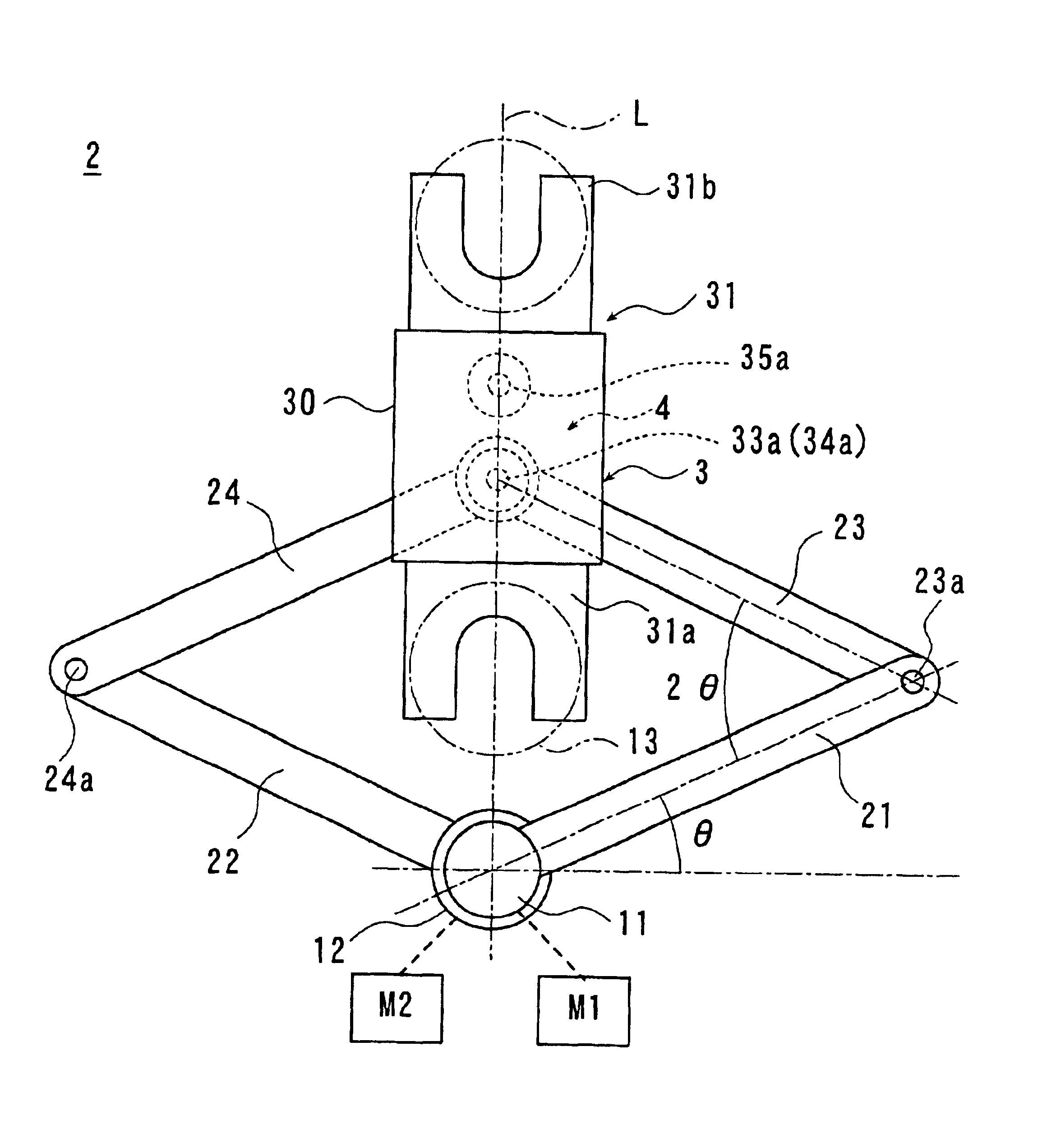

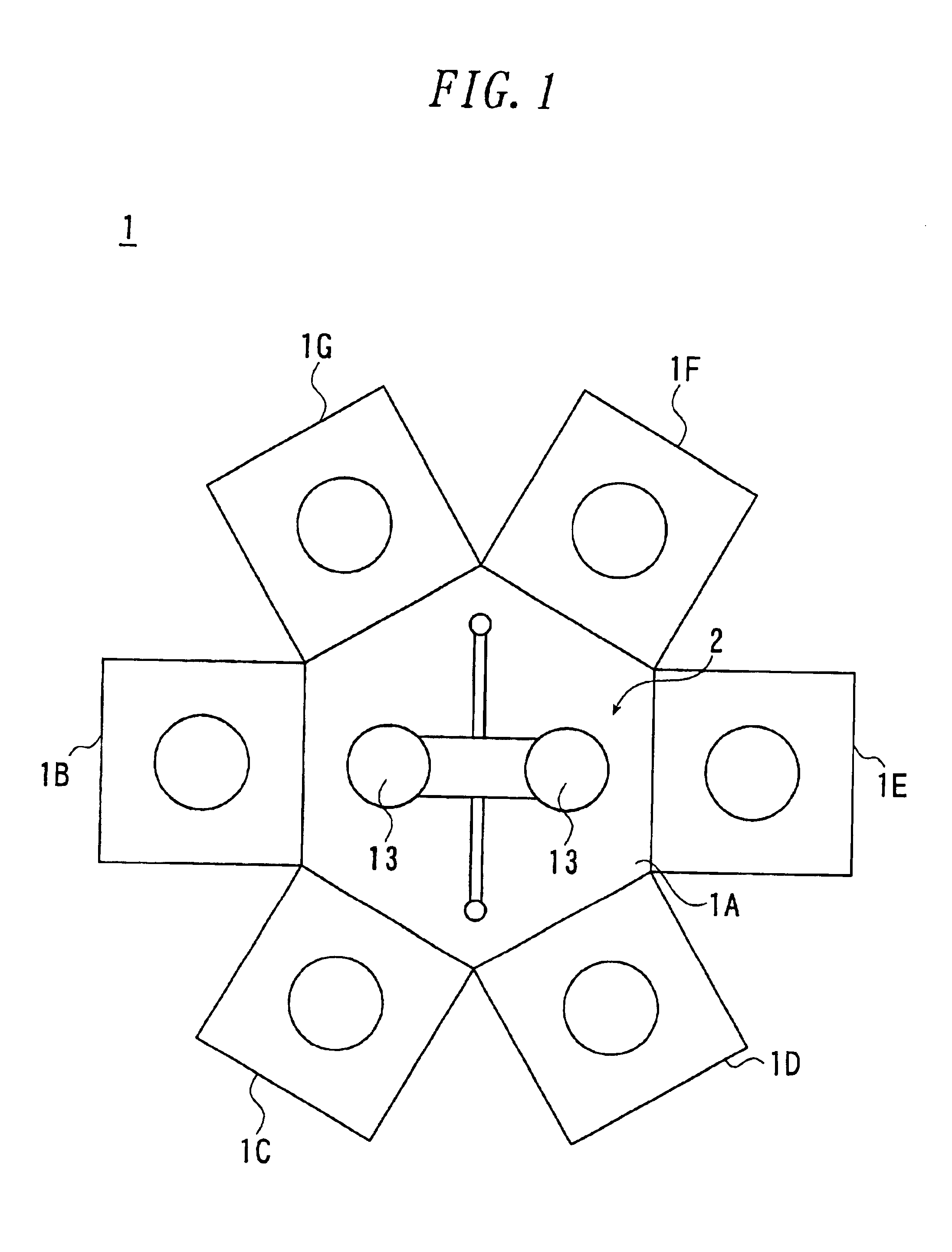

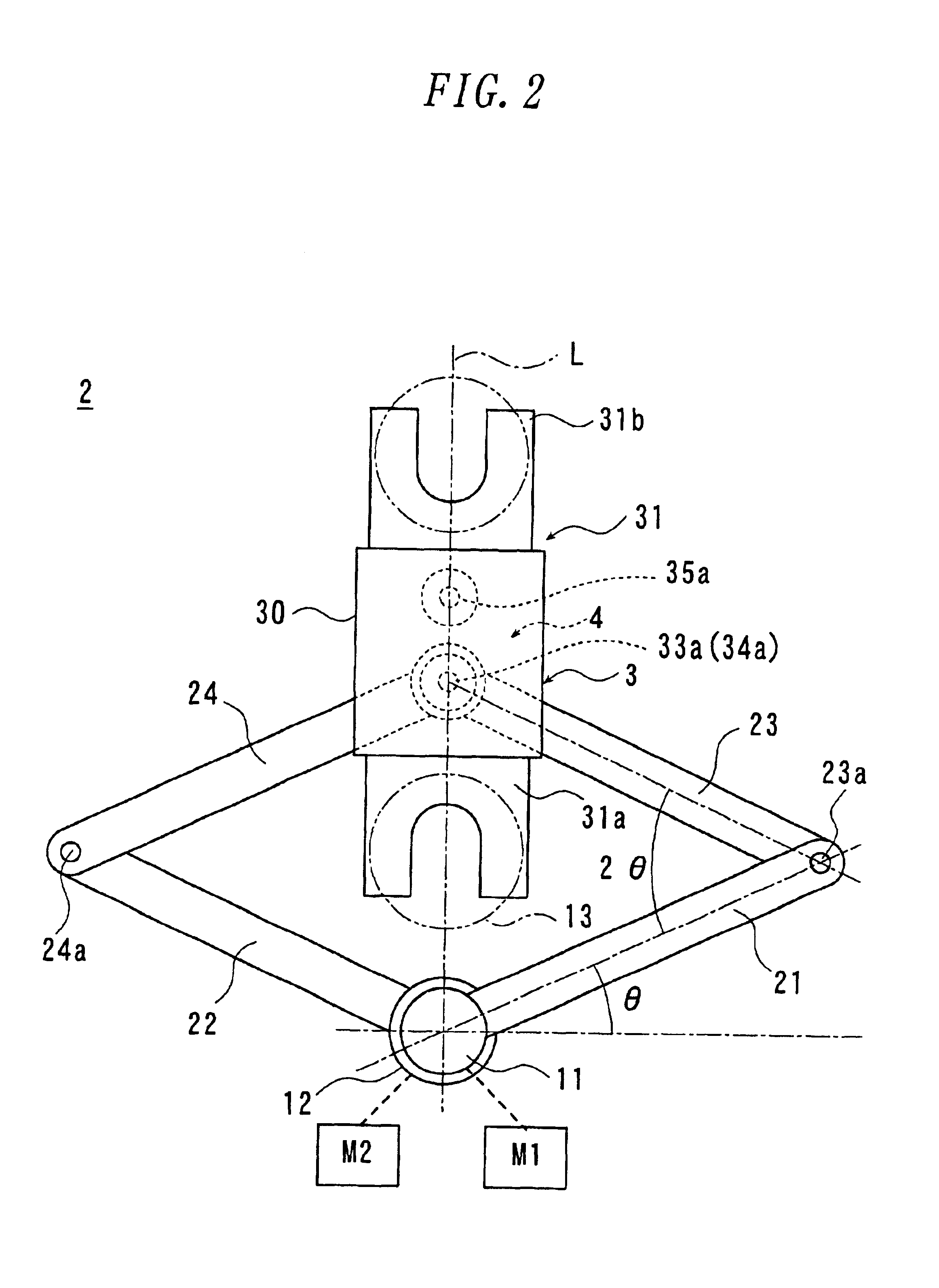

Transport apparatus and vacuum processing system using the same

InactiveUS6840732B2Eliminate effectStable linear movementSemiconductor/solid-state device manufacturingCharge manipulationAttitude controlSemiconductor

This invention provides a transport apparatus having a simple configuration that can reduce its turning radius and transport semiconductor devices at high speed. The transport apparatus comprising the first and second arms having at a first end of each thereof a rotary drive shaft being arranged coaxially, and third and fourth arms rotatably linked at respective the first ends thereof to the respective second ends of the first and second arms. The second ends of the third and fourth arms are supported around centers of coaxially arranged spindles, respectively. The transport apparatus further comprises an articulating mechanism having an attitude control mechanism adapted to apply rotary forces with opposite phases to the respective spindles arranged at the third and fourth arms.

Owner:ULVAC INC

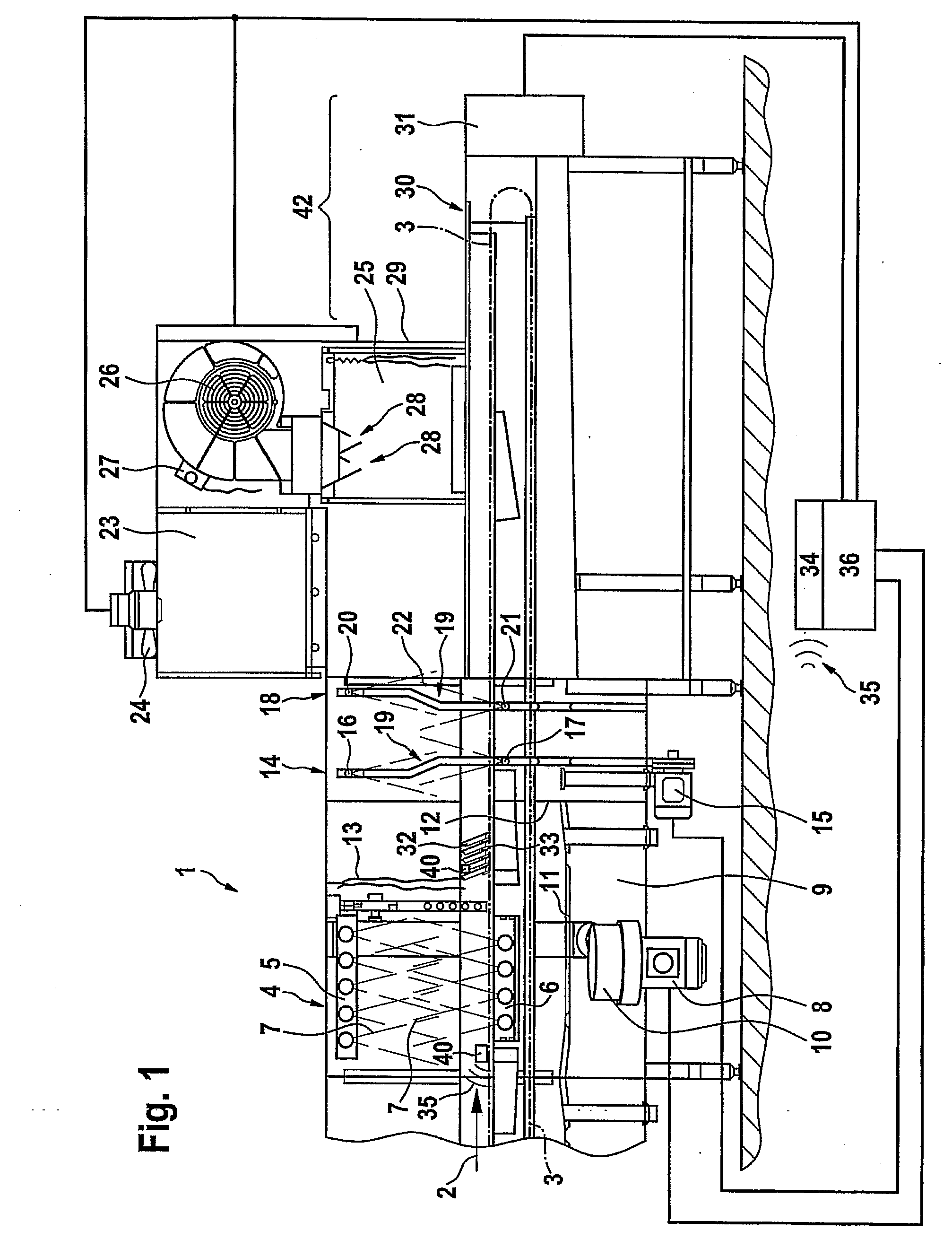

Method for assessing and guaranteeing the thermal hygiene efficiency in a multi-tank dishwasher

ActiveUS20080077281A1Improve securityEliminate disadvantagesTemperatue controlAutomatic washing/rinsing machine detectionMachine controlControl system

A method for assessing and guaranteeing the thermal hygiene efficiency in a multi-tank dishwasher in which there is at least one sensor that transmits a temperature inside at least one treatment zone to a machine control system, in particular to the control system of the multi-tank dishwasher, the method includes: detecting the temperature inside at least one of the treatment zones by the sensor; determining the heat input applied to the items to be cleaned in at least one of the treatment zones on the basis of the temperature determined; comparing the heat input in the at least one treatment zone with a predefined heat input; and, as a function of the result of the comparison of the heat input values, varying the transport speed of the items to be cleaned through the multi-tank dishwasher, or varying the temperature of at least one of the process parameters acting on the heat input values as a control variable in a control loop for at least one of the treatment zones.

Owner:MEIKO MASCHENBAU

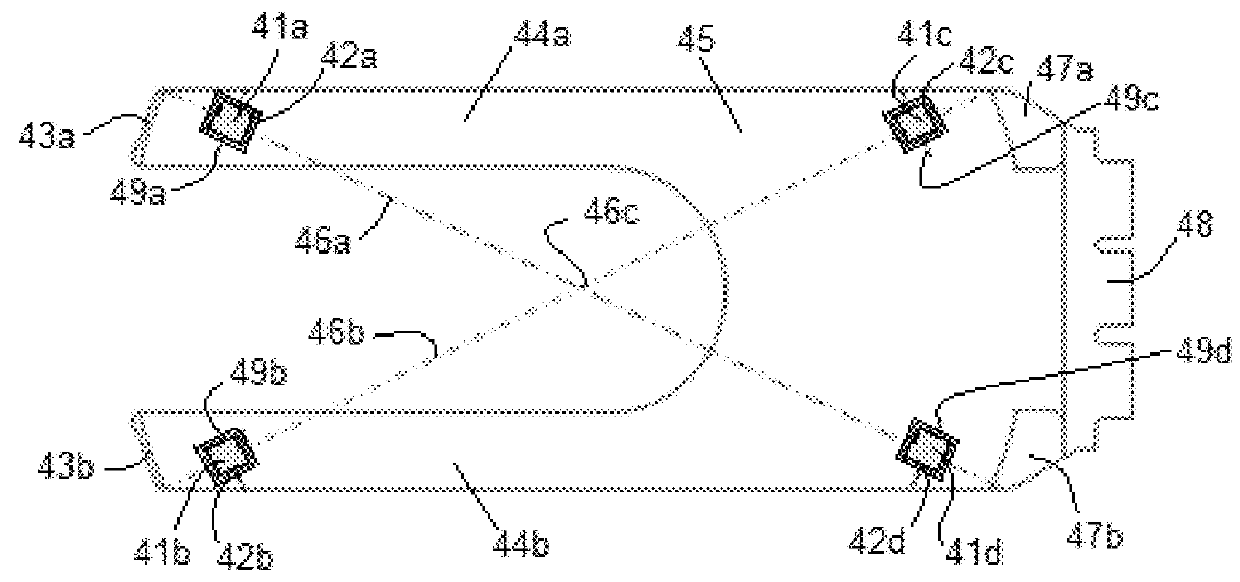

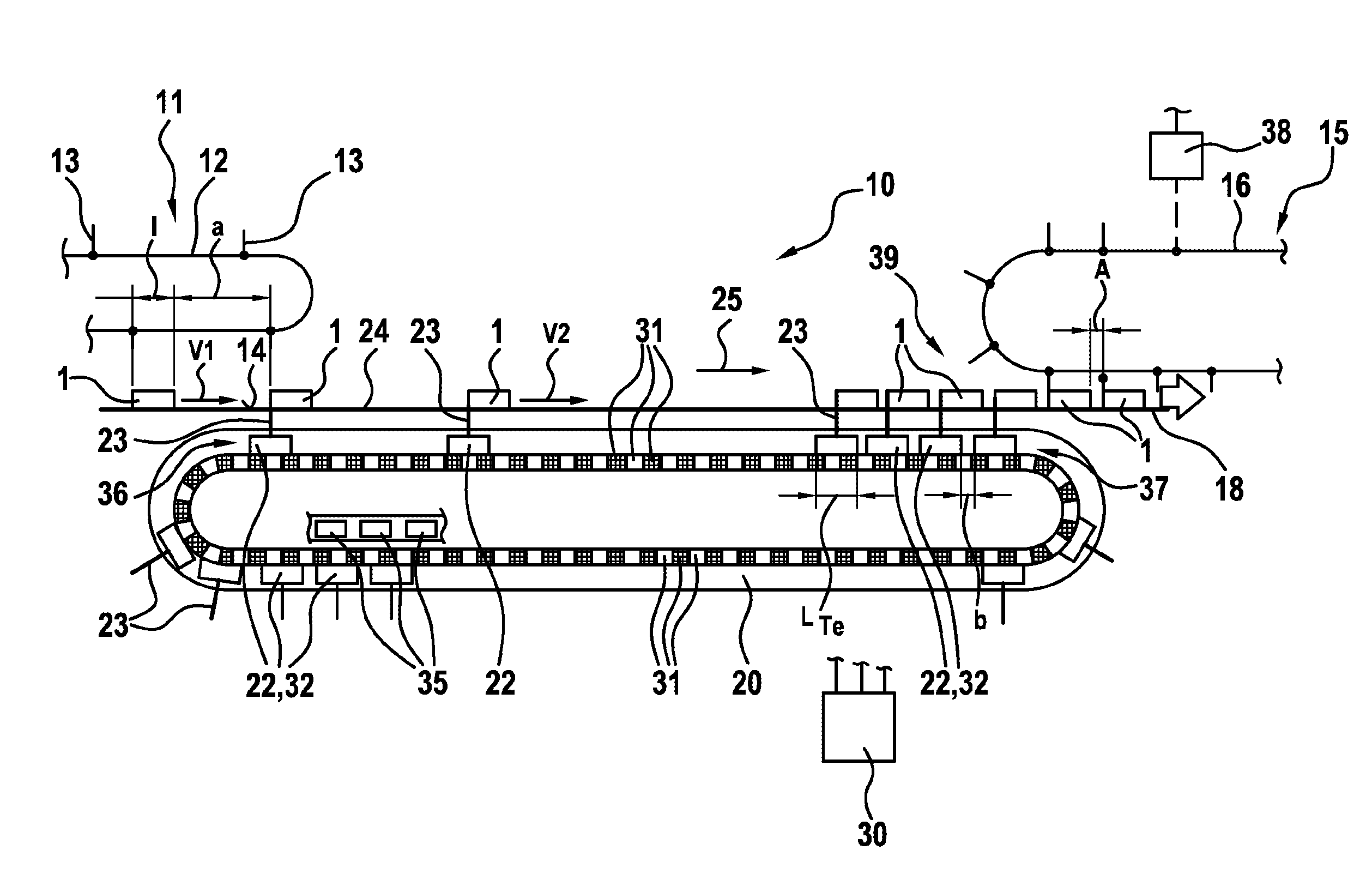

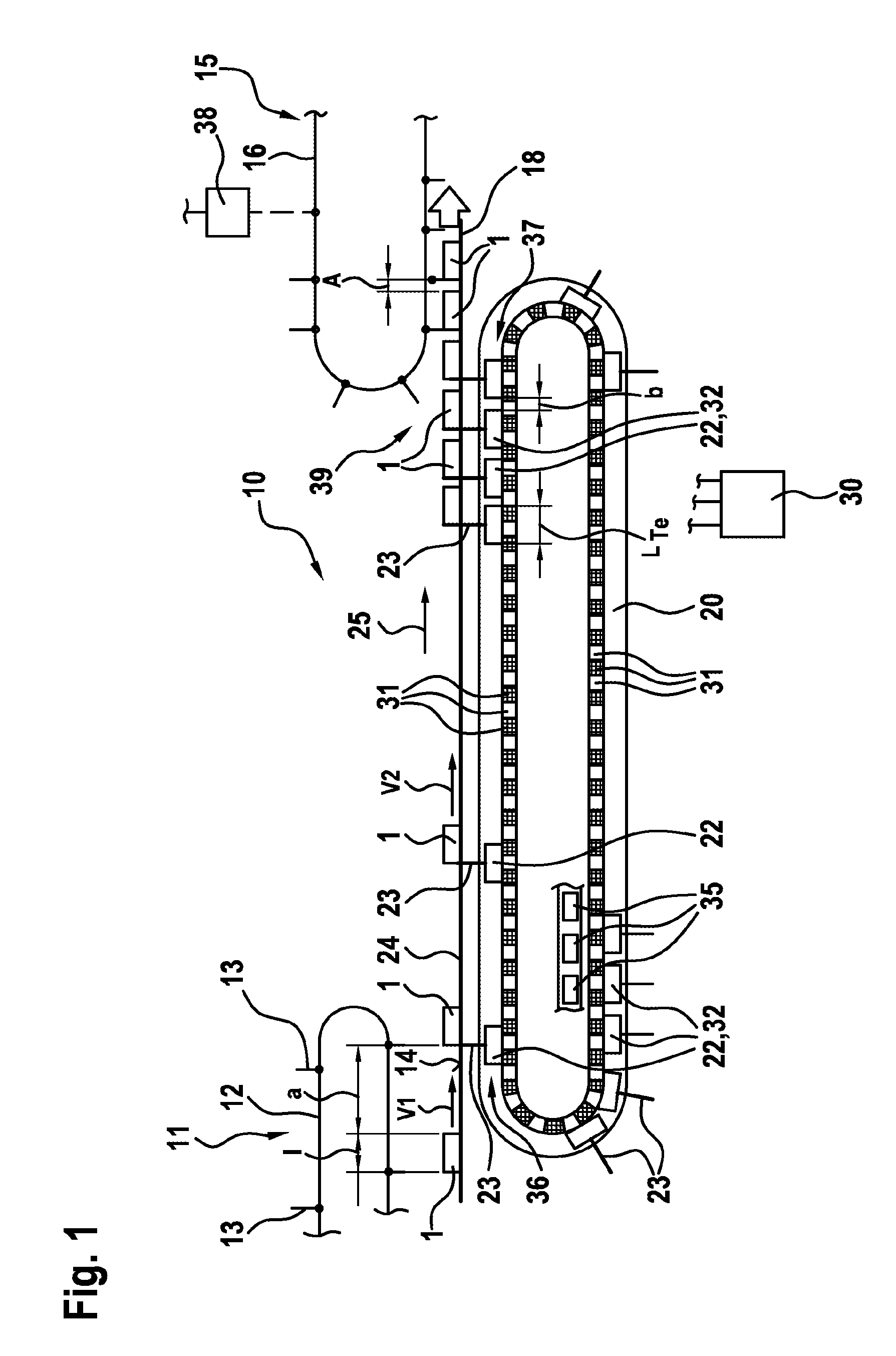

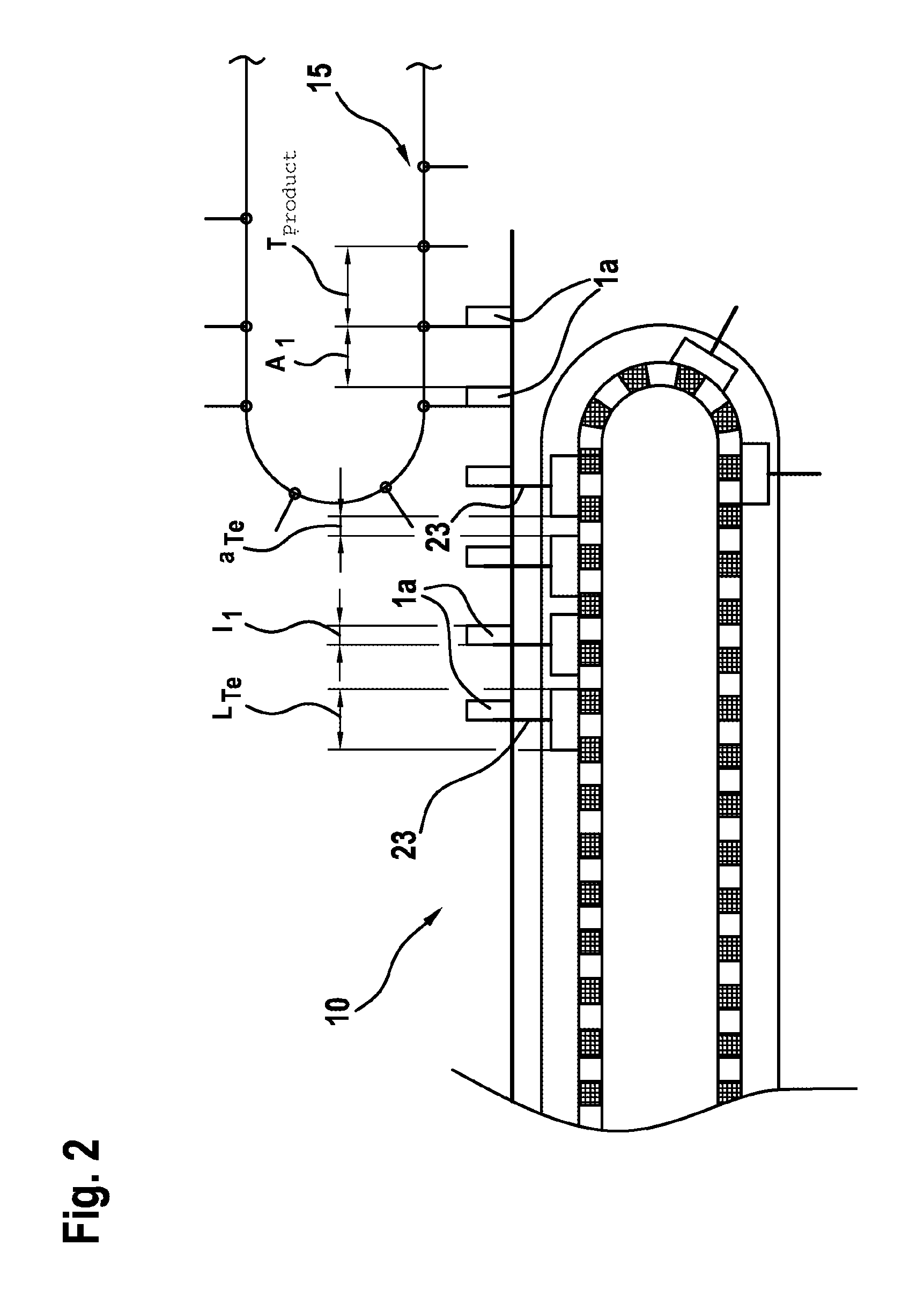

Method for operating an electromagnetic transfer system, and transfer system

ActiveUS9061838B2Reduce mechanical stressIncrease speedNon-mechanical conveyorsConveyor partsIndividual itemTransfer system

The invention relates to a method for operating an electromagnetic transfer system (10) which is used to convey items (1; 1a) to a downstream conveyor device (15), and which comprises a carrier path (20), preferably designed to be closed, on which there is at least one moveable transport element (22) for an item (1; 1a) that is moved along on a transport surface (24) by said transport element (22), said transport element (22) having at least one permanent magnet element (32) that is arranged to be functionally connected to individually-energisable inductor coils (31) which are arranged along the carrier path (20). Position-detecting means (35) are provided to ascertain the position of the transport element (22) on said carrier path (20) and, in a delivery region (37), the item (1; 1a) is delivered from the transport surface (24) to the downstream conveyor device (15), said conveyor device having a separate drive (38). According to the invention, in order to reduce the spacing (A, A1, A2) between individual items (1; 1a) on the downstream conveyor device (15), the conveyor speed (v4) of said conveyor device (15) is reduced intermittently at the point of delivery from the transport surface (24) to the conveyor device (15), in relation to the speed (v2) of the transport element (22), and / or the speed (v2) of the transport element (22) is increased at the point of delivery in relation to the conveyor speed (v4) of the conveyor device (15).

Owner:SYNTEGON TECHNOLOGY GMBH

Amino acid-containing water-soluble fertilizer added with sugar alcohol and preparation method thereof

The invention provides an amino acid-containing water soluble fertilizer added with sugar alcohol and a preparation method thereof. The amino acid-containing water-soluble fertilizer added with sugar alcohol is prepared from the following raw materials: amino acid, calcium salt and water as well as 5-10wt% of sugar alcohol. The amino acid-containing water-soluble fertilizer is of a calcium element type, the sugar alcohol is added to be used as a chelating agent of the calcium element; by virtue of reasonable ratio of sugar alcohol to amino acid to calcium salt, the sugar alcohol and the calcium element are chelated to form a stable micromolecule chelate; since sugar alcohol has permeation and wetting properties, absorption and transportation efficiency of the chelated calcium element is improved; meanwhile, amino acid can promote calcium absorption and also can promote photosynthesis, so that chlorophyll content is increased. Therefore, under the combined action of sugar alcohol and amino acid, the amino acid-containing water-soluble fertilizer added with sugar alcohol has high utilization rate, can improve the conveying speed of plant nutrients, can enhance calcium absorption of plants and can increase sugar content of the plants.

Owner:BEYONDCHEM LIFE TECH

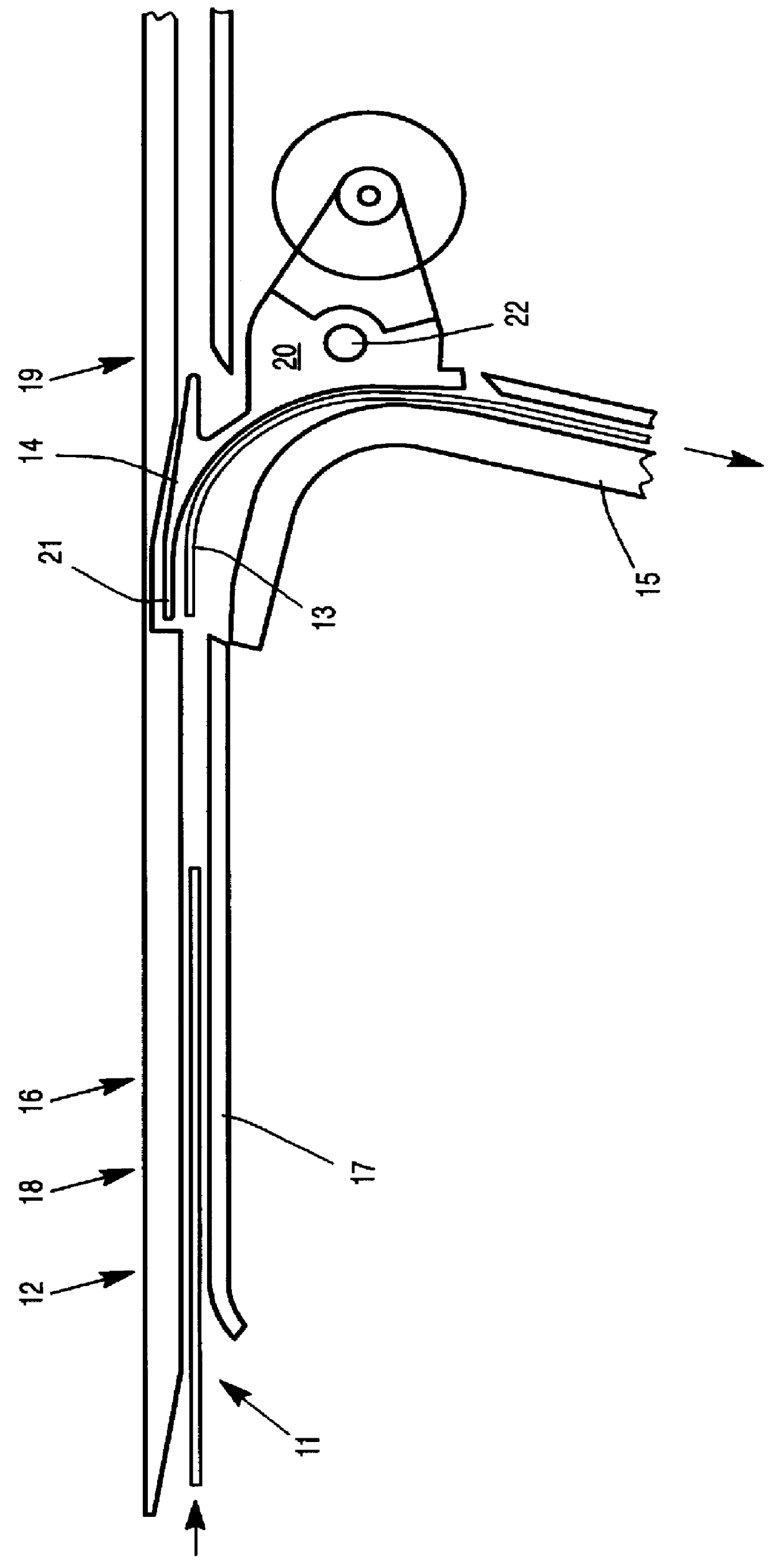

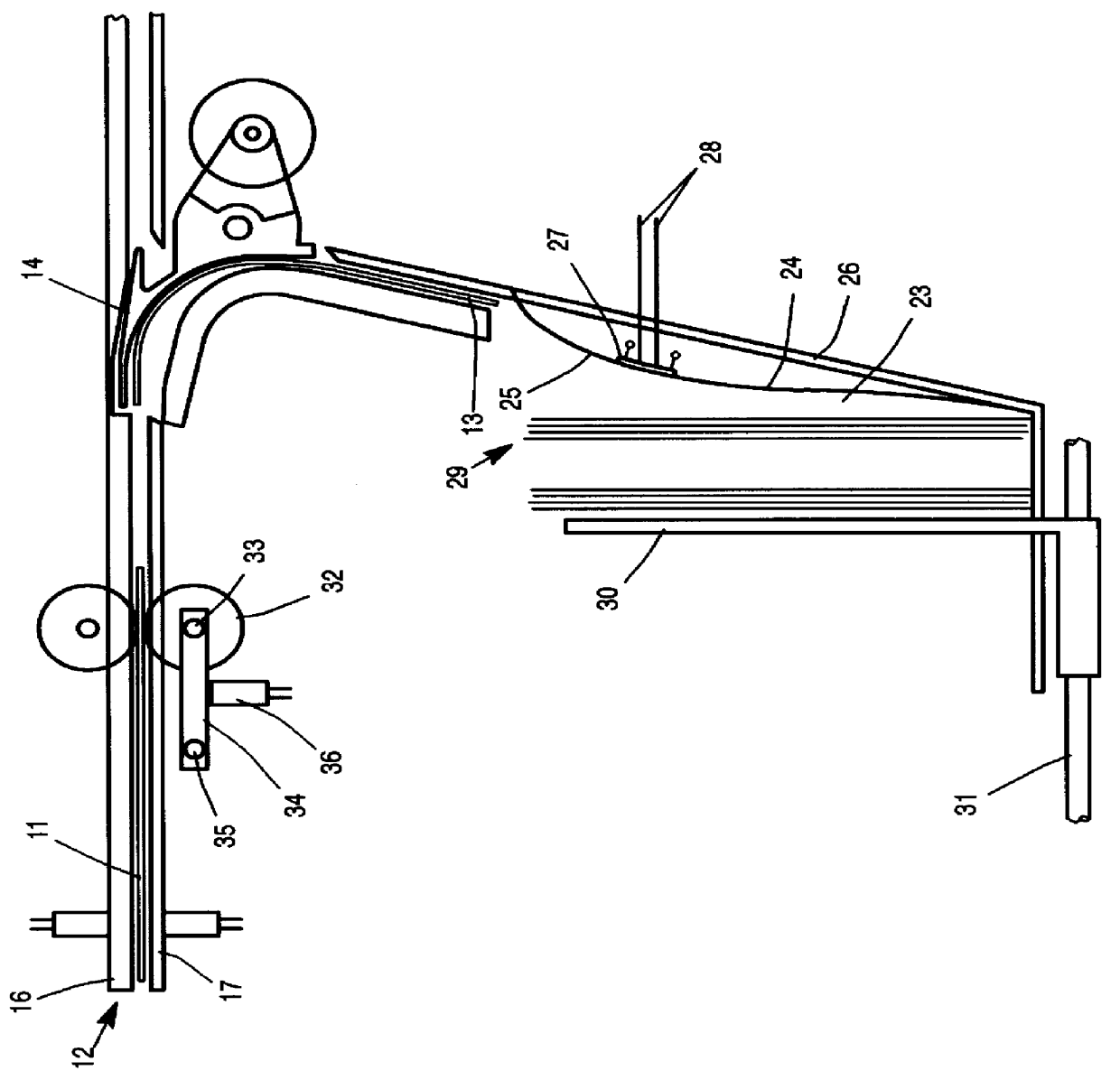

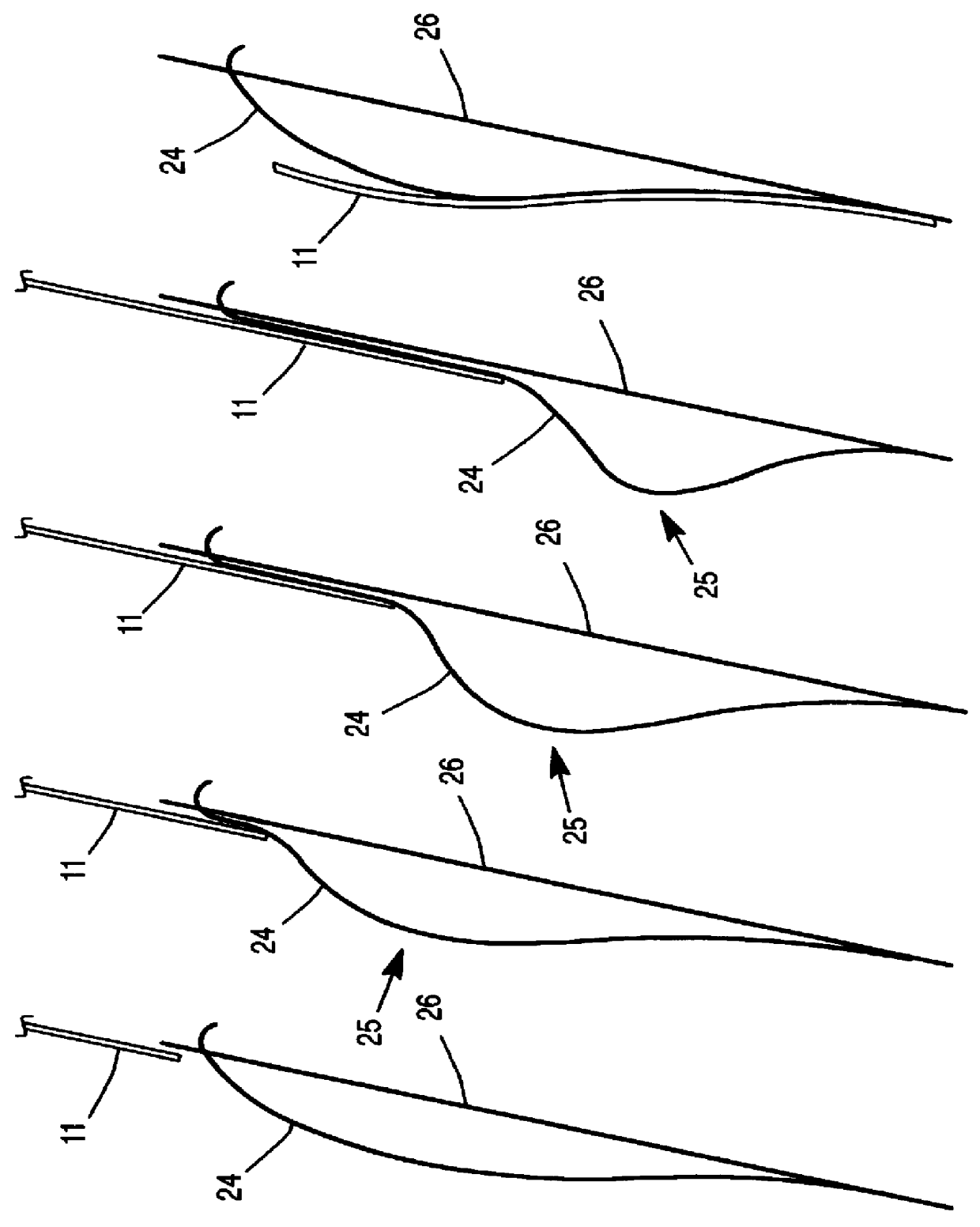

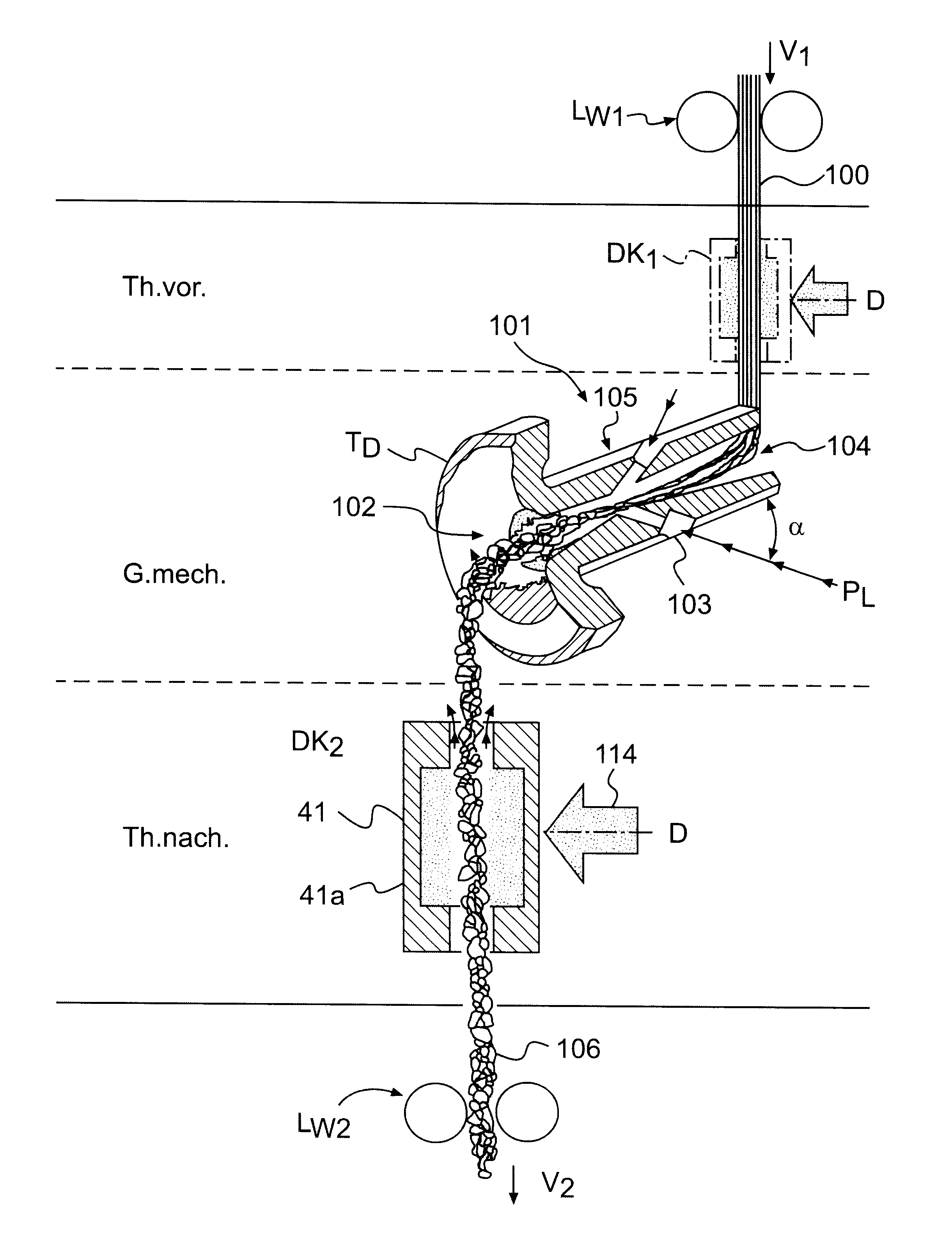

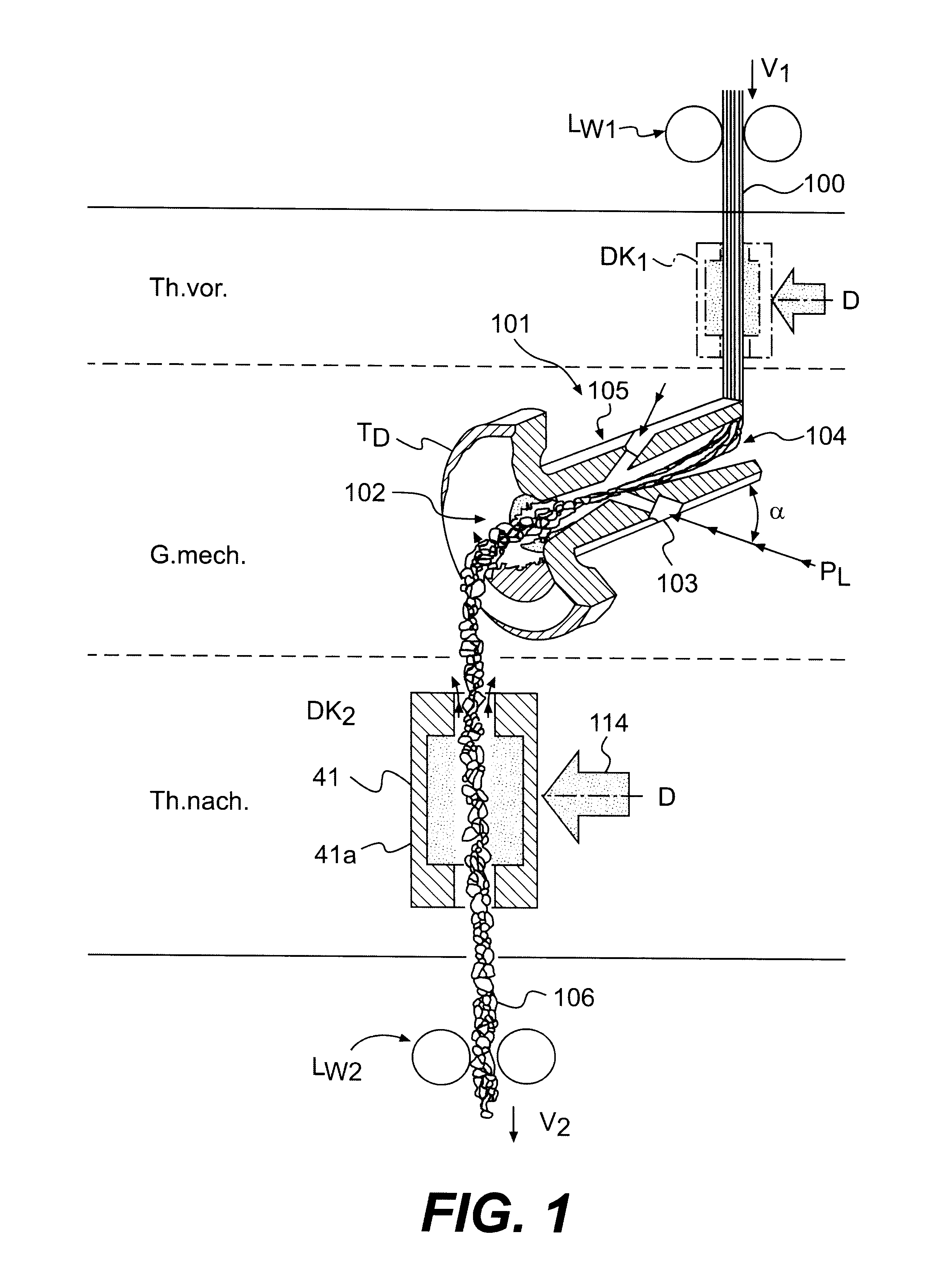

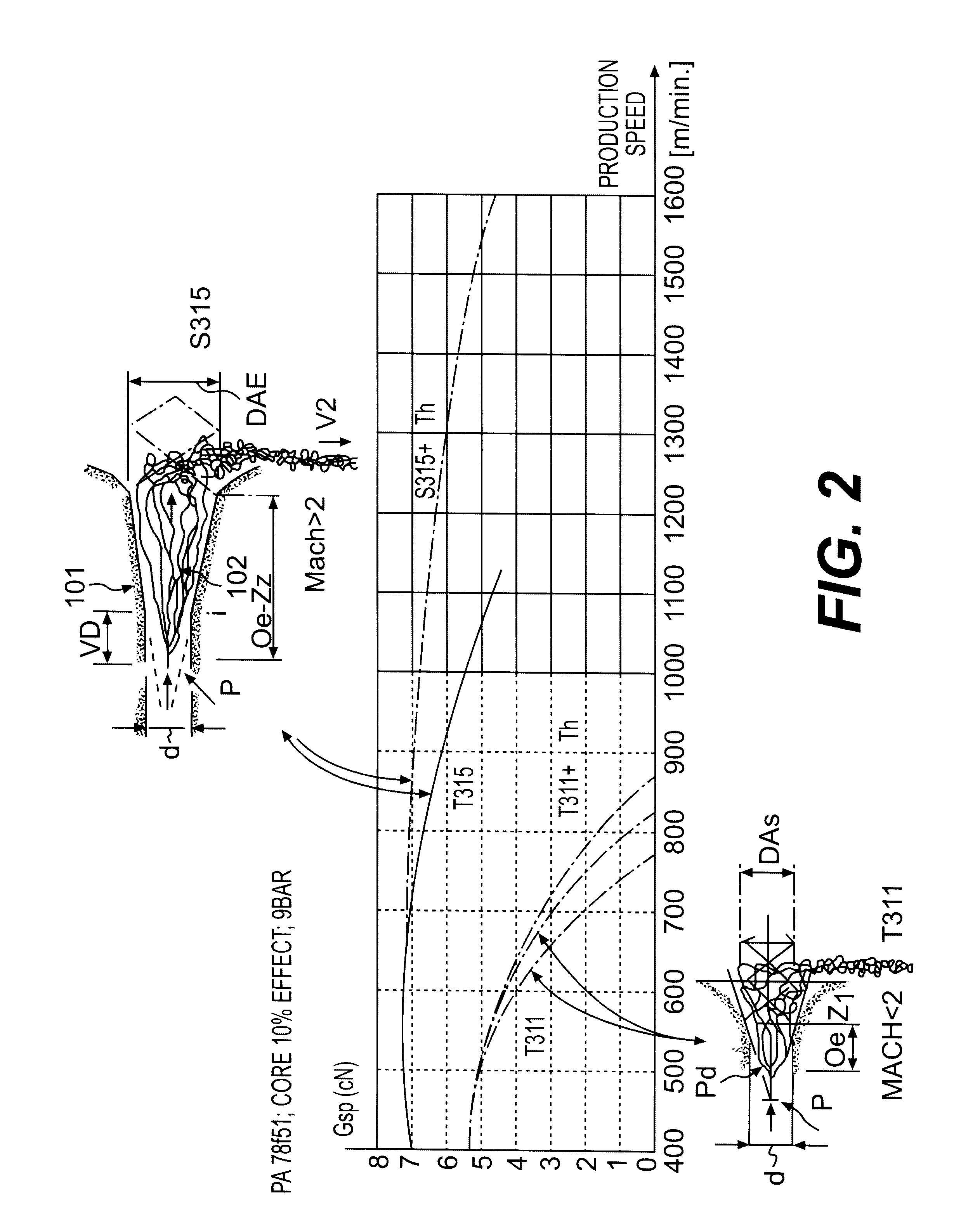

Method for air-bubble texturing endless filament yarn, yarn finishing device and its use

InactiveUS6564438B1Easy to operateHigh yarn transport speedTextiles and paperHeat treatingAir bubble

A method and machine for treating yarn may include feeding the yarn through both a heat treatment and an air jet texturing nozzle. The texturing nozzle may be supplied with compressed air, producing an air jet with a speed greater than Mach 1 in the yarn channel. The heat treatment may be performed before and / or after feeding the yarn through the texturing nozzle.

Owner:HEBERLEIN MASCHFAB

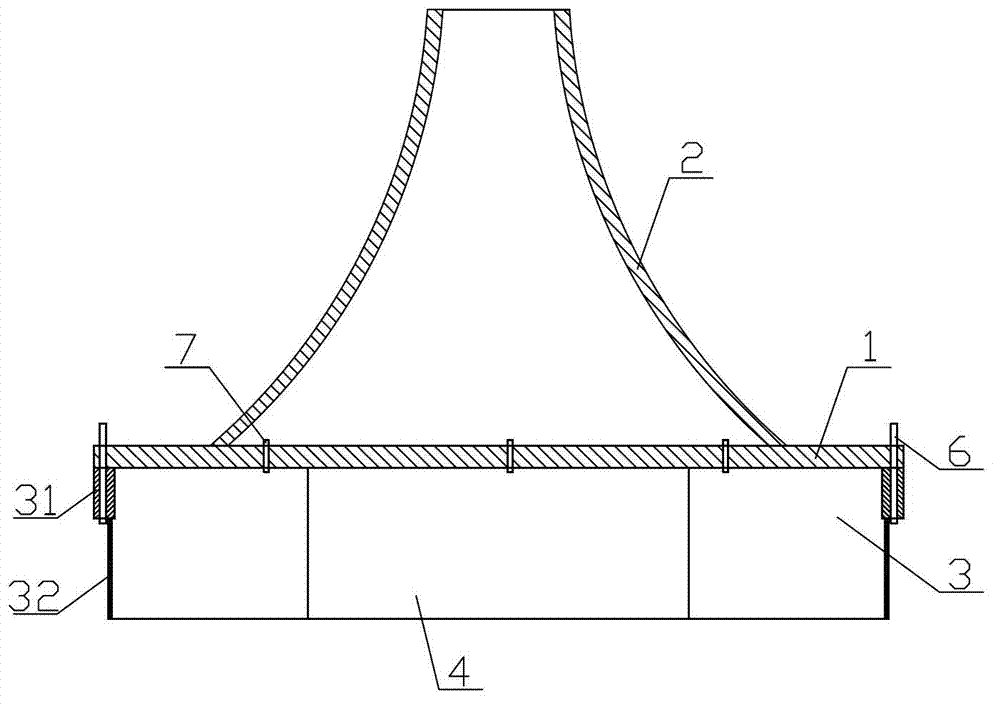

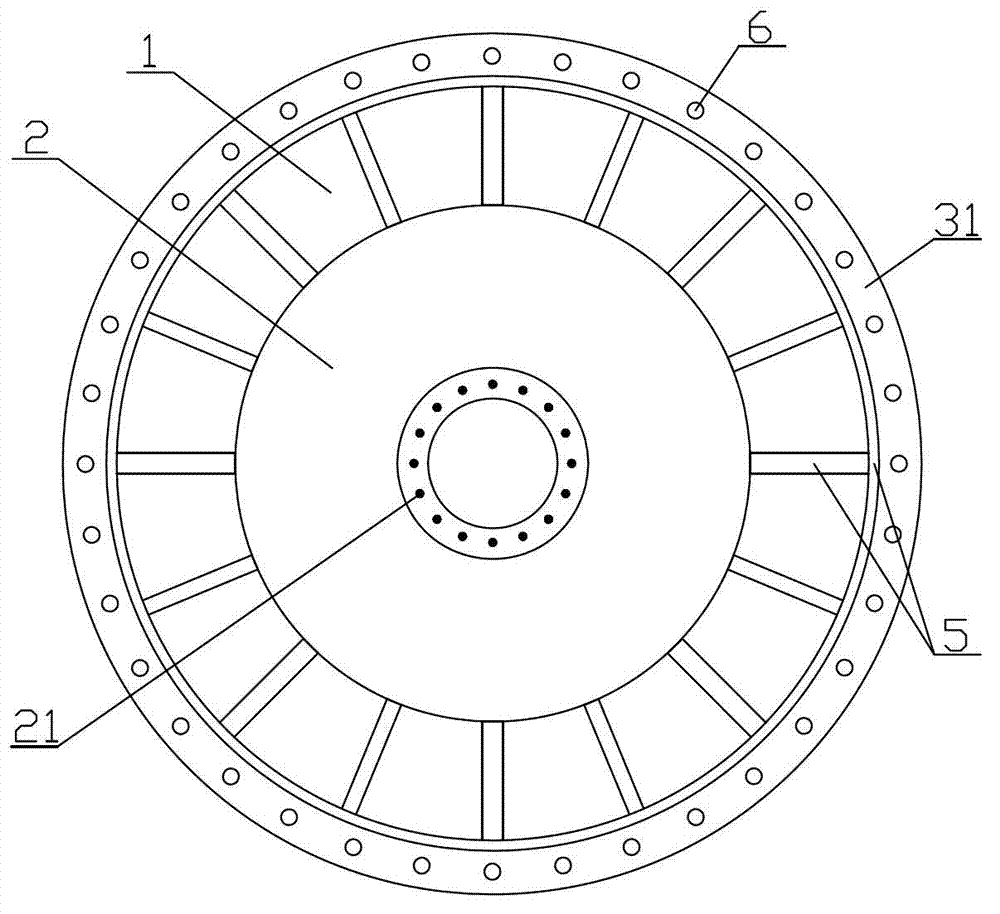

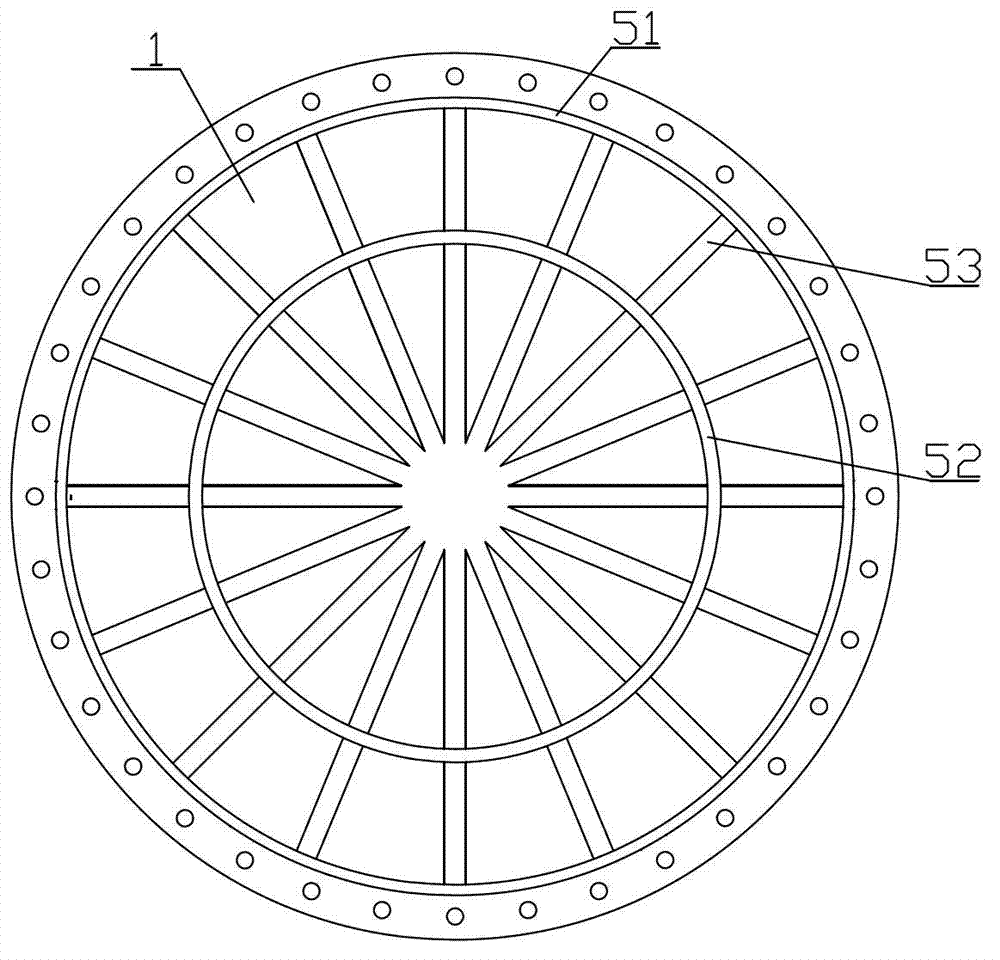

Gravity type foundation structure and construction method thereof

InactiveCN102877482ASpeed up the sinkingImprove stabilityFoundation engineeringGravitationSteel cylinder

The invention discloses a gravity type foundation structure and a construction method thereof. A concrete cylinder-type pressure loading cabin is arranged on a concrete top cover; a cylinder structure formed by a concrete cylinder wall and a steel cylinder wall is arranged on the lower side of the concrete top cover; first pipelines are uniformly arranged in the concrete cylinder wall along the radial direction; and a steel subdivision plate is arranged in the internal space of the steel cylinder wall. The construction method comprises the following steps of: prefabricating the gravity type foundation structure on the land; transporting the whole foundation to a construction site in a floating mode, and performing self-weight sinking construction and negative pressure sinking construction; after the negative pressure sinking construction is stopped, performing groundbreaking sinking construction through the first pipelines; performing grouting operation through the first pipelines and second pipelines on sub-cabins; and filling heavy objects in the concrete cylinder-type pressure loading cabin, performing ballasting operation, and simultaneously performing riprap ballasting operation above the concrete top cover and at the periphery of the concrete cylinder-type pressure loading cabin. By the structure and the method, transportation and construction difficulties can be reduced, transportation and installation speeds can be increased, and the applicability to a soil body can be enhanced, so that a construction period is shortened, and engineering cost is substantially reduced.

Owner:TIANJIN UNIV

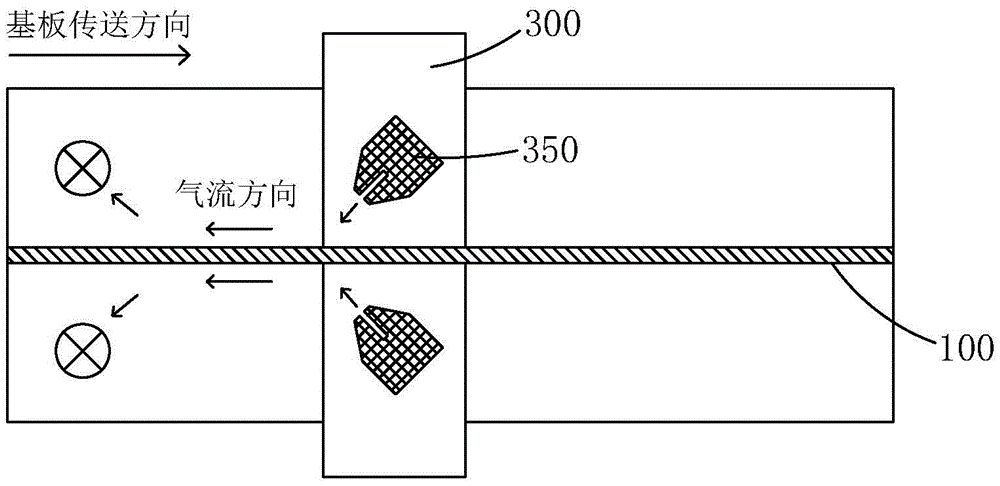

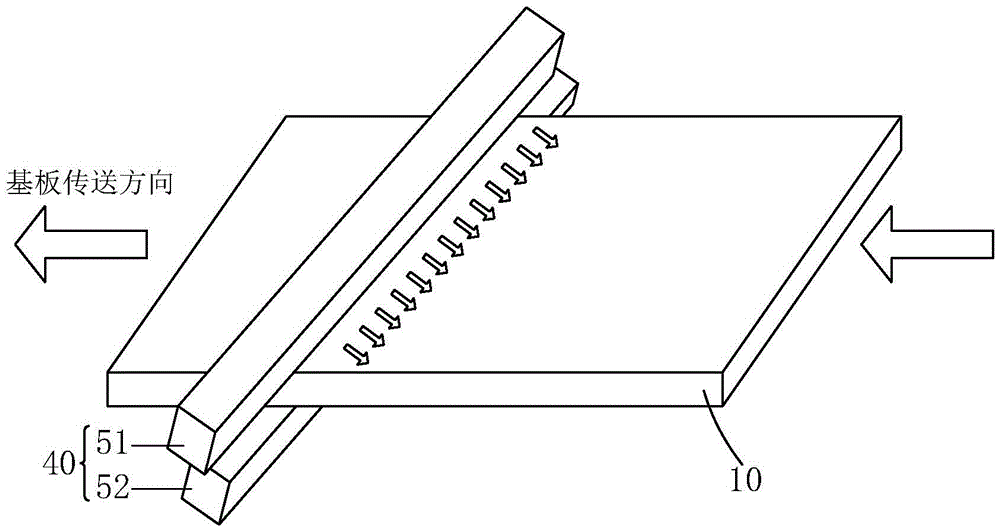

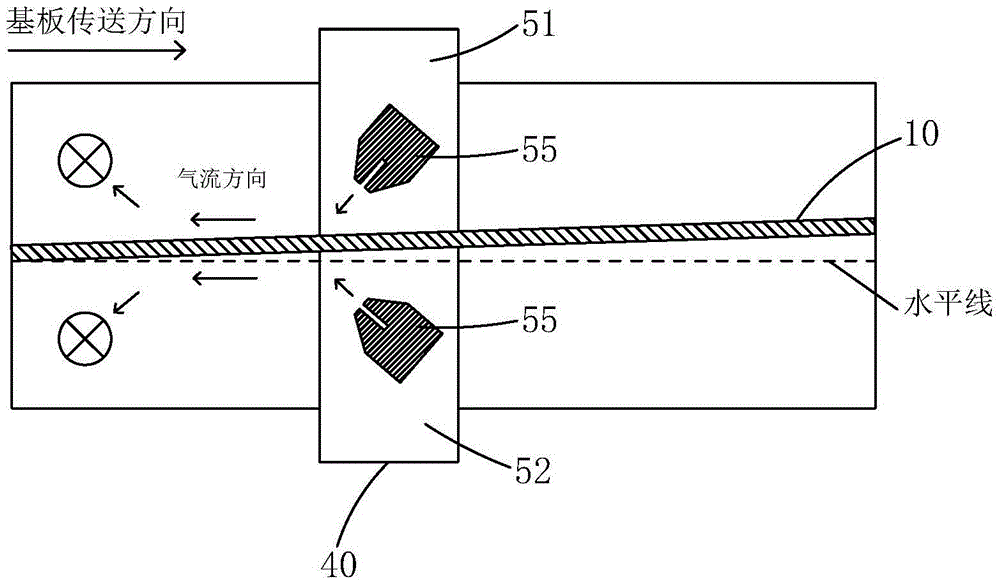

Substrate cleaning method

ActiveCN105605909AImprove shipping speedFast cleaningDrying gas arrangementsCleaning using liquidsEngineeringAir knife

The invention provides a substrate cleaning method. A substrate (10) is arranged to be at different inclination angles and in different inclination modes in the drying process, and a traditional air knife device (40) is adopted for thoroughly removing cleaning water remaining on the substrate (10). Or, a frequency-adjustable air knife device (70) is adopted as an air knife device for a first blow-drying procedure in the drying process, the traditional air knife device (40) is adopted as an air knife device for a second blow-drying procedure in the drying process, and the cleaning water remaining on the substrate (10) is thoroughly removed in the two blow-drying procedures; meanwhile, the substrate (10) can be further arranged to be at different inclination angles and in different inclination modes to prevent the cleaning water from flowing back, increase the drying speed and avoid that strip-shaped mura is generated in subsequent procedures. In addition, the substrate (10) conveying speed can be properly increased thanks to the high drying speed of the frequency-adjustable air knife device (70), so that the substrate (10) cleaning speed is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

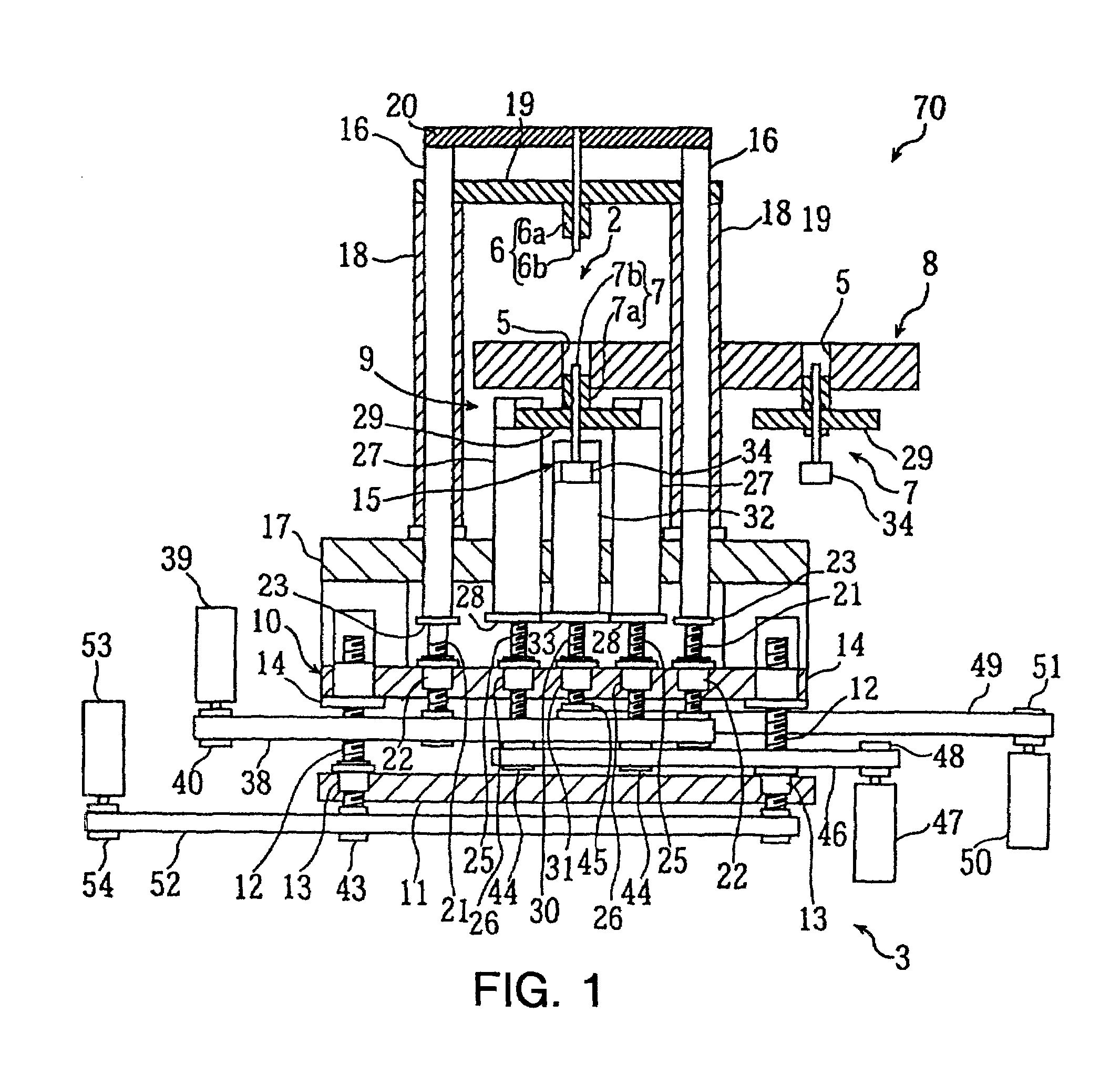

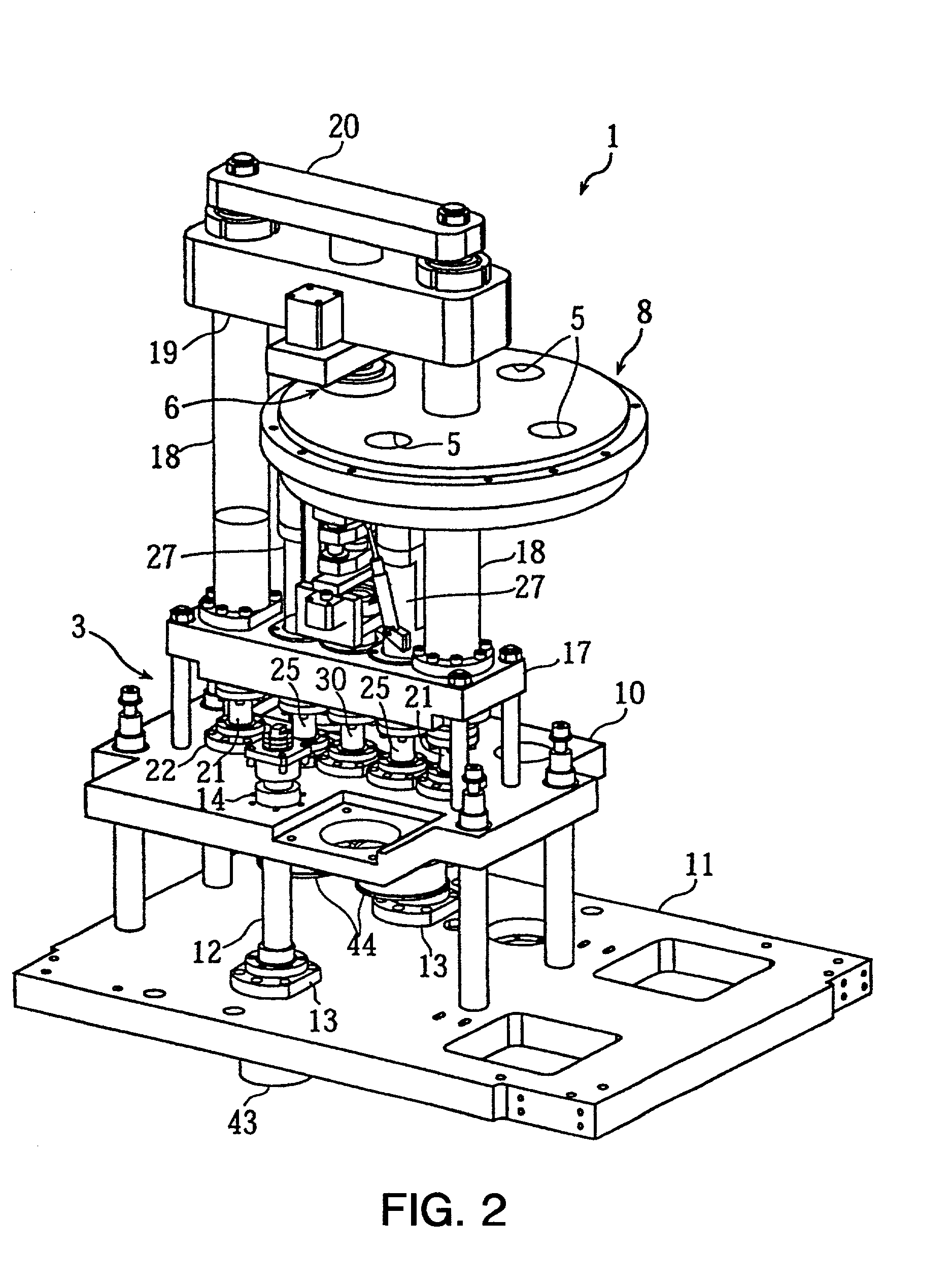

Powder supplying apparatus and powder molding apparatus

InactiveUS7018194B2Amount of supplying be preventSuppress wearConfectionerySweetmeatsShell moldingMaterials science

A powder molding apparatus comprises a mold comprising a die having a powder molding space and upper and lower punch units, and a compression driving mechanism for performing compression molding by driving the upper and lower punch units independently, wherein molded articles formed by the compression molding are held by engaging lower first and second punches serving as a formed article holding mechanism at the time of transporting the molded articles. Thus, the molded articles can be prevented from falling or shifting while being transported between stages, thereby providing a powder molding apparatus capable of high speeds.

Owner:MURATA MFG CO LTD

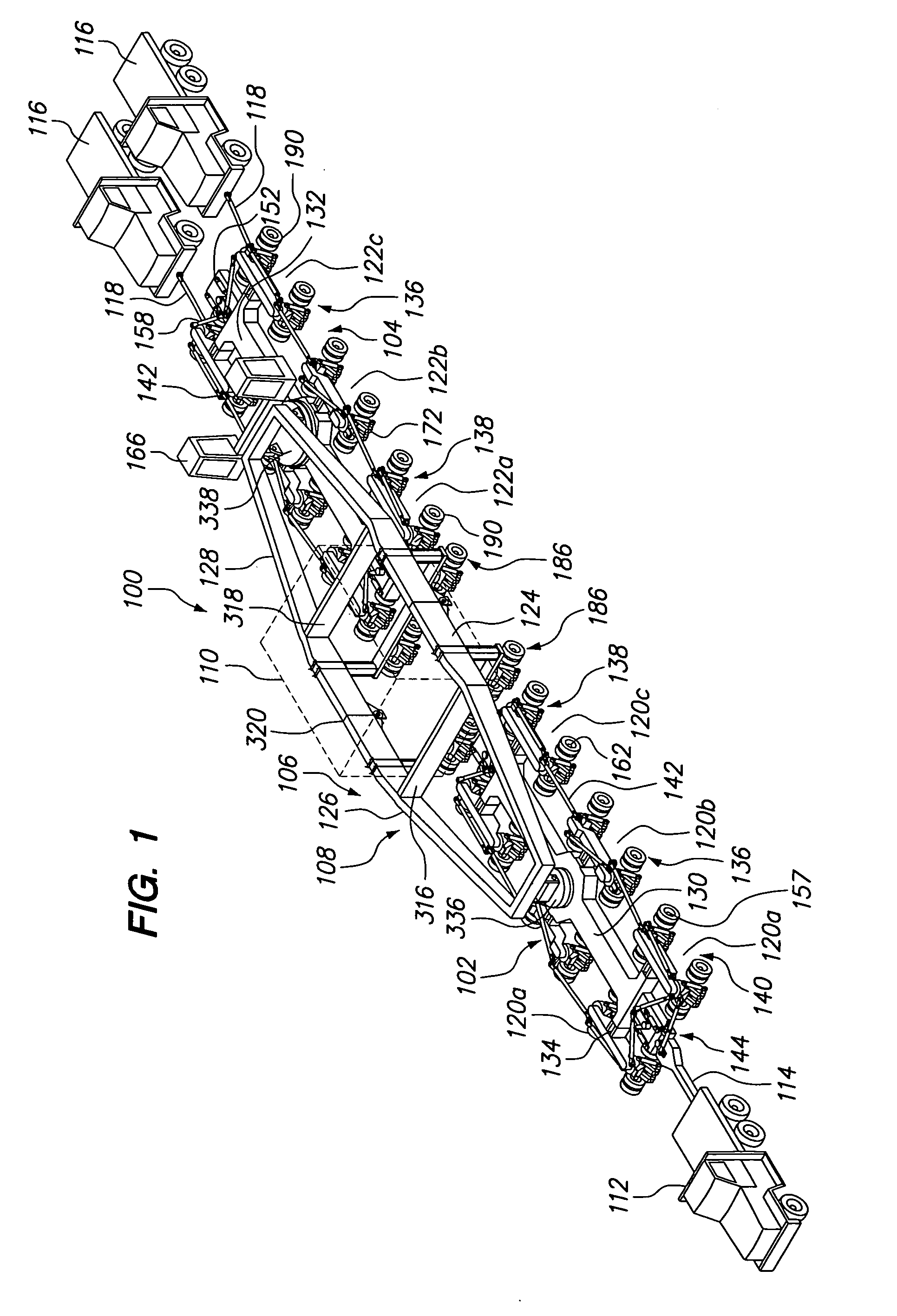

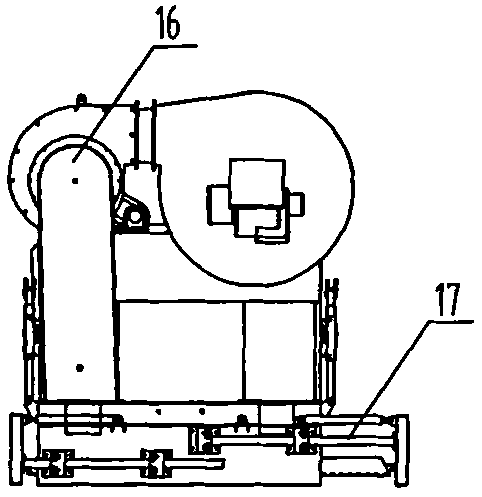

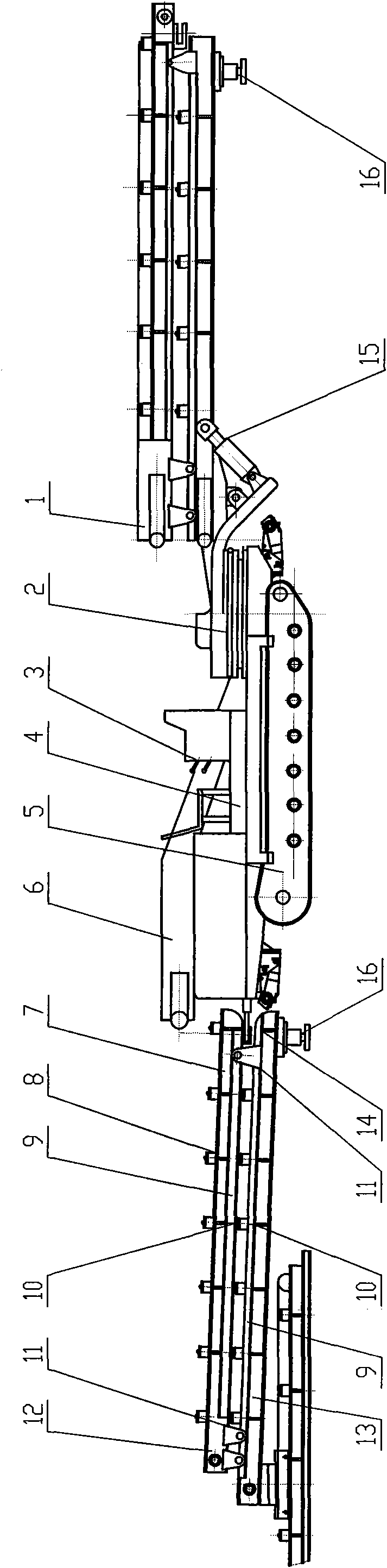

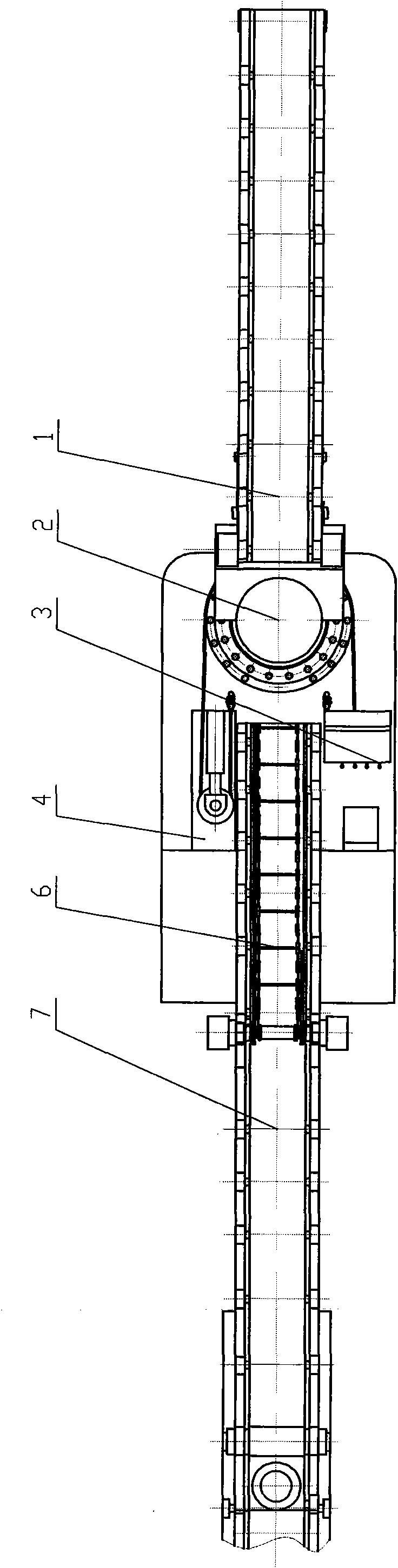

Corner-crossing transfer conveyer

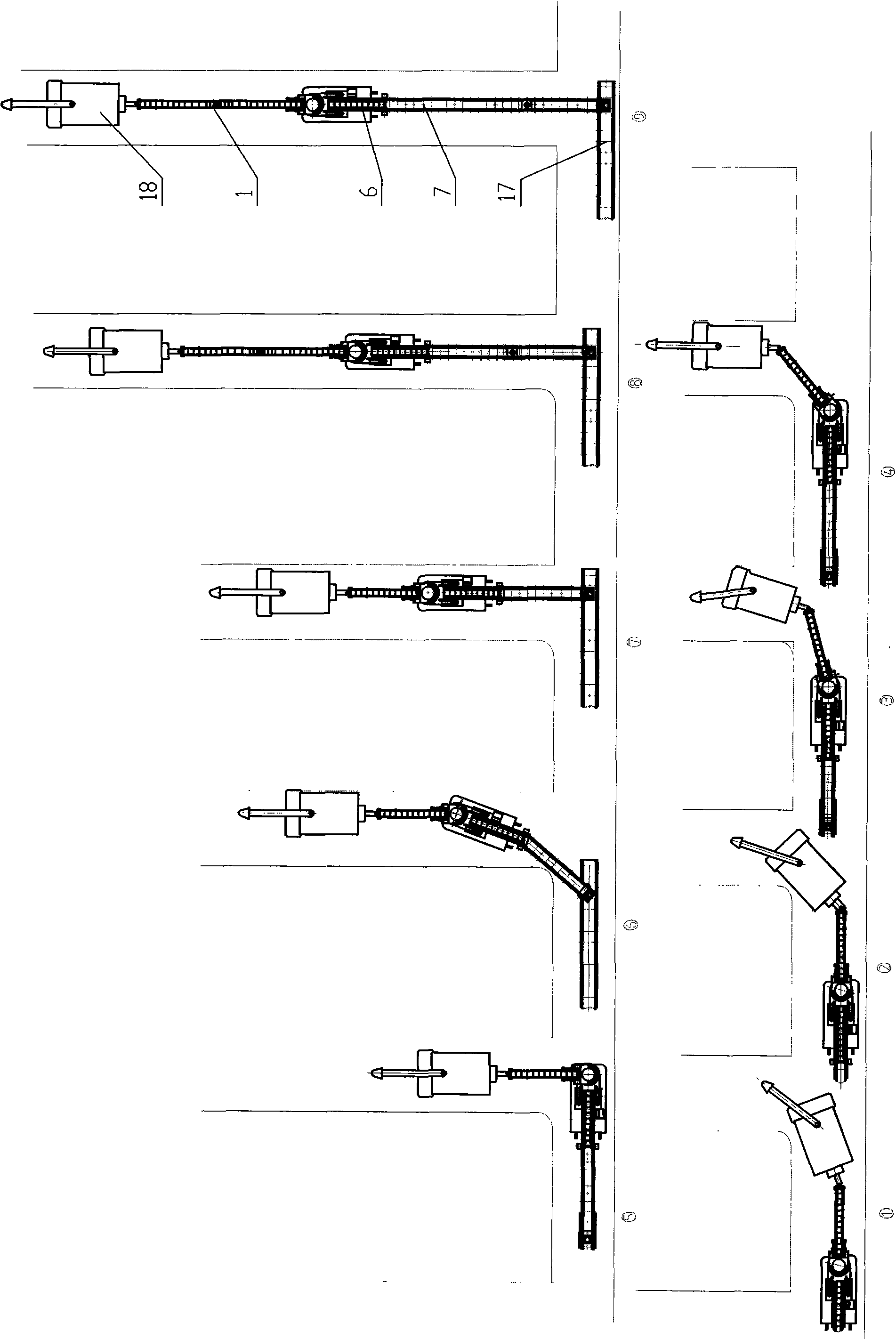

InactiveCN101624138AReduce labor intensityImprove shipping speedControl devices for conveyorsEarth drilling and miningMechanical engineeringEngineering

The invention relates to a conveyer, in particular to a corner-crossing transfer conveyer which comprises a left walking part, a right walking part, a front conveyer, a middle conveyer, a tail conveyer and a hydraulic system, wherein a stand is arranged on the left walking part and the right walking part, a rotary table which can be rotated for 90 degrees left and right is arranged at the front part of the conveyer, the front conveyer is arranged on the rotary table, the middle conveyer is arranged between the left walking part and the right walking part, and the tail conveyer is hung at the tail part of the conveyer. The front conveyer and the tail conveyer are both of telescopic belt conveyers, and conveying distances of the front conveyer and the tail conveyer can be regulated. The invention changes the lagging production mode that coals at the corners need to be shoveled by manpower in the original drifting process, realizes the mechanical production, greatly improves the conveying speed of coals, lightens the labor intensity of workers, saves the manpower, and can be used at both corners and straight tunnels.

Owner:SHANXI DONGHUA MACHINERY

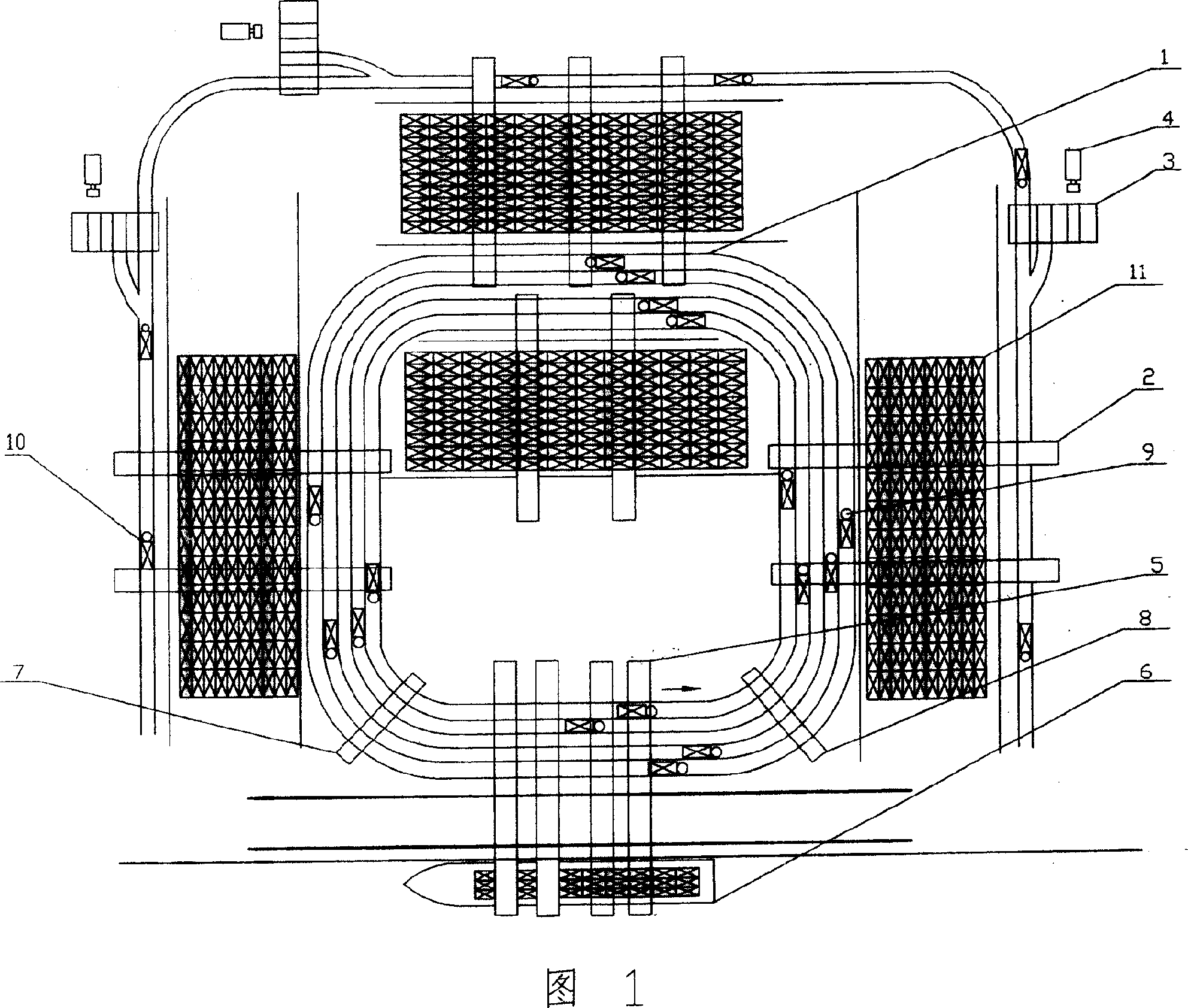

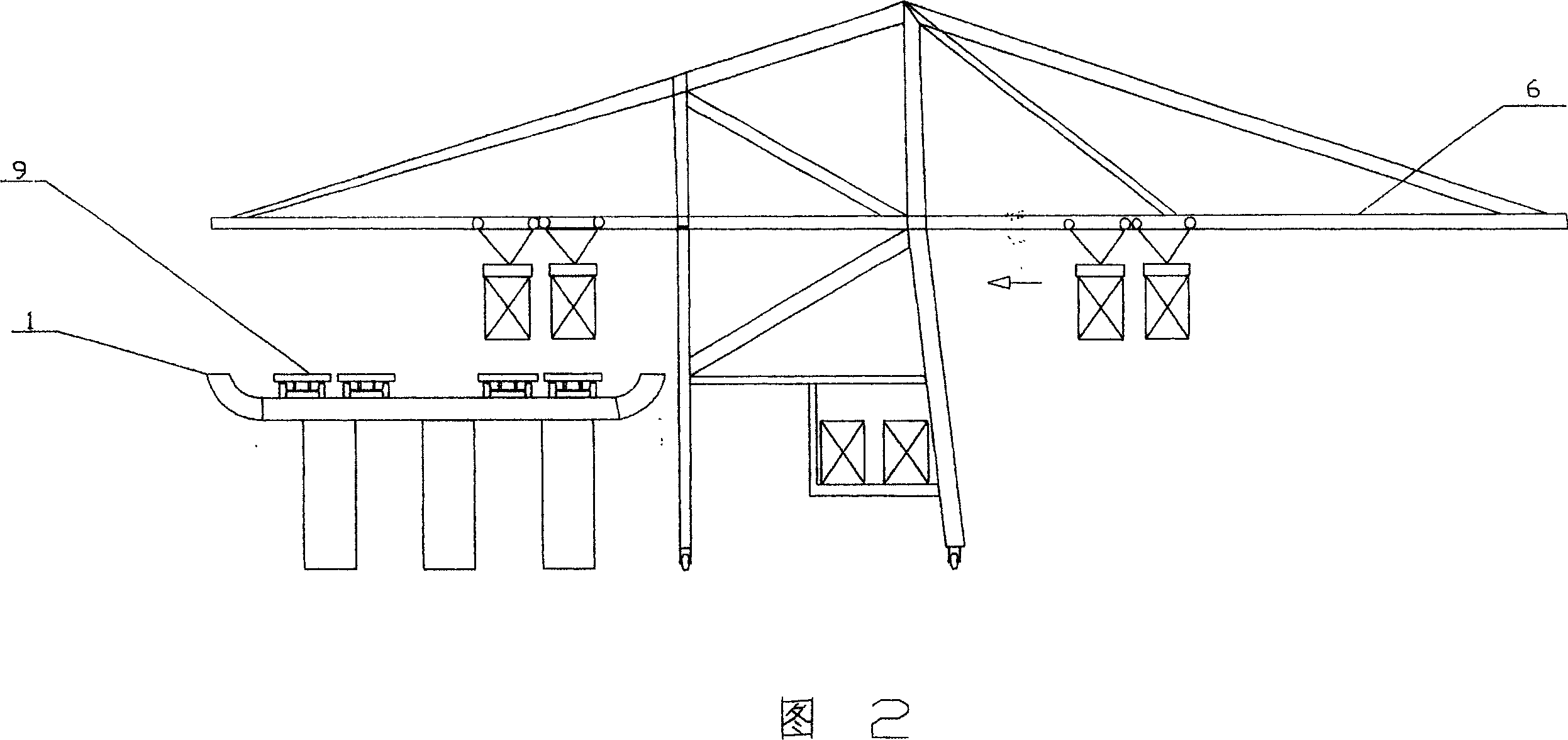

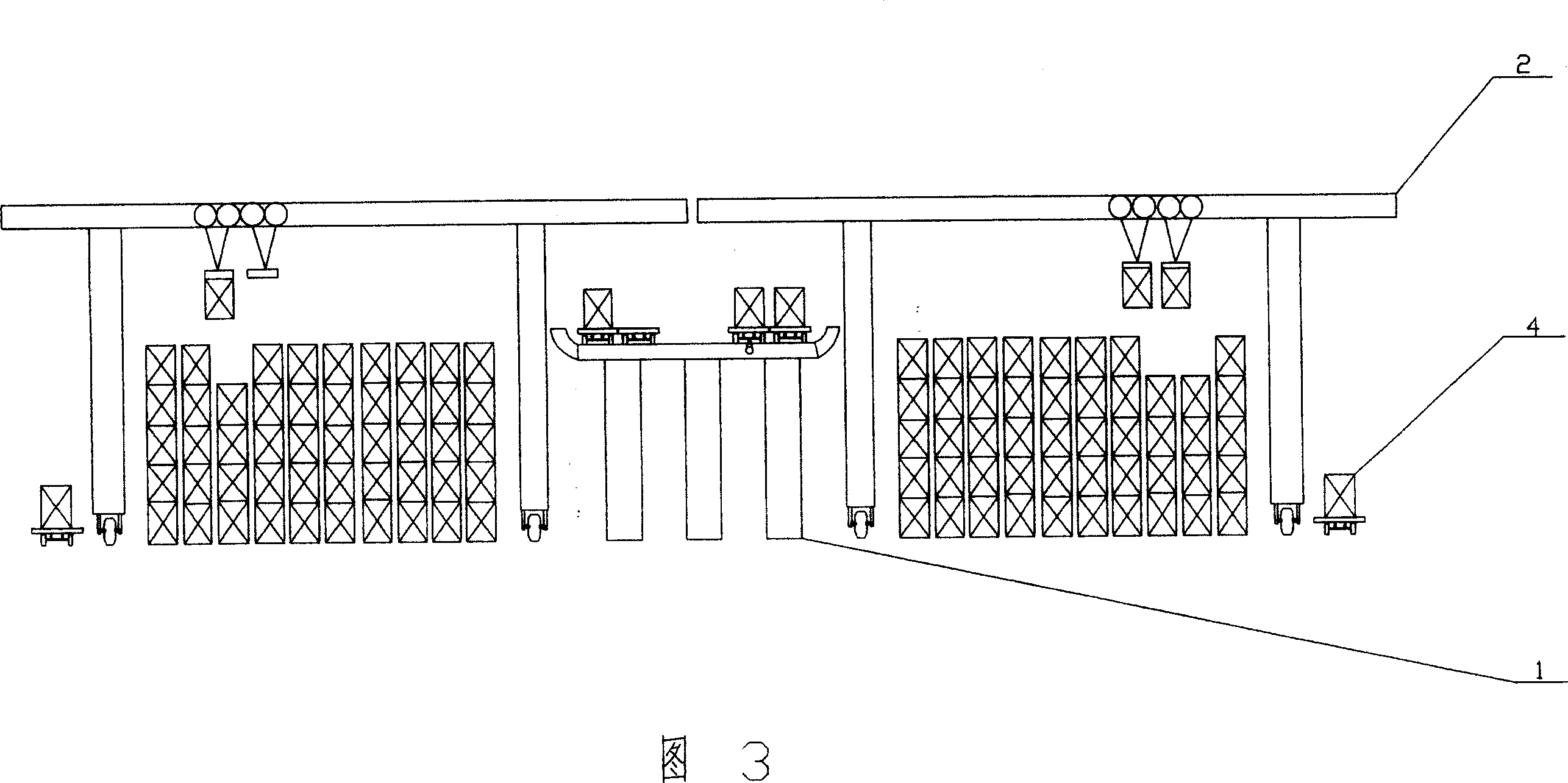

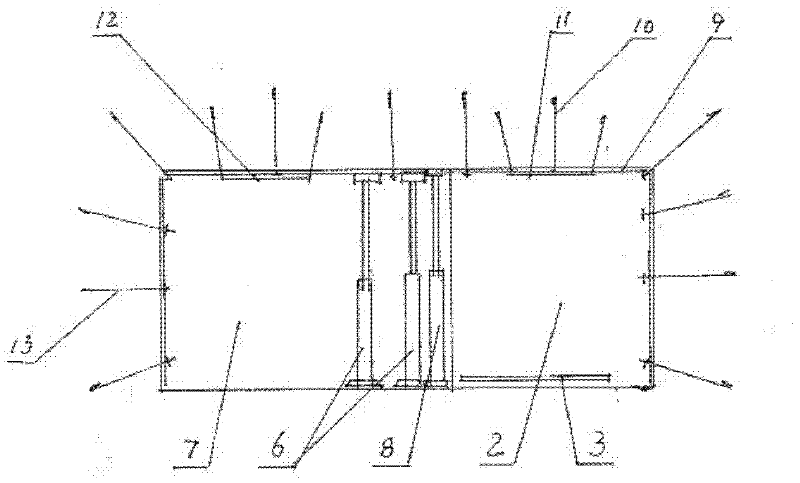

Container loading-unloading automatic flow-line

InactiveCN101070122AReduce distanceSimple counterpointStorage devicesLoading/unloadingElectric carsLoading unloading

A container loading and unloading automatic pipeline is to transfer the container to the stack field through the aerial conveyor electric car matched by the ring viaduct, the bulkhead bridge and the gantry crane with load and unload at two ends in the track field. Then the container is transfer to the changing platform from the stack field and next to install it to the collecting block. The pipeline has not only decreased the distance between the hanger and the container, decreased the inertia of the container, reached the container allocation in pipeline by the laser to improve the efficiency, save the energy and decrease the pollution but improved the work safety to reach the loading and unloading automatically.

Owner:SHANGHAI HAILEI LASER TECH

Highly automatic plate-overturning and plate-picking production line for producing large-size decorative plates

The invention discloses a highly automatic plate-overturning and plate-picking production line for producing large-size decorative plates. The highly automatic plate-overturning and plate-picking production line comprises a material mixing machine set, a material distribution mechanism, a kiln, a kiln tail fixed roller table, a kiln furniture, a plate-picking mechanism, a deviation-correcting mechanism and an overturning mechanism, wherein a belt conveyor is disposed between the material mixing unit and the material distribution mechanism; an inlet and an outlet of a material distribution machine position of the material distribution mechanism are respectively equipped with a deviation-correcting roller table and a receiving roller table; the other end of the receiving roller table is connected with a conveying roller table in a matching manner; a kiln inlet and a kiln outlet are respectively equipped with a kiln-incoming roller table and a kiln-outgoing roller table; shuttling roller tables are disposed between the kiln-incoming roller table and the conveying roller table and are used for conveying in a matching manner; the kiln-outgoing roller table is equipped with the shuttling roller tables and the kiln tail fixed roller table which are used for conveying in a matching manner; the kiln tail fixed roller table is sequentially matched with the plate-picking mechanism and the deviation-correcting mechanism for conveying along the movement direction of rollers; and the overturning mechanism and the shuttling roller tables are also disposed between the kiln tail fixed roller table and the deviation-correcting roller table.

Owner:佛山市创瓷窑炉有限公司

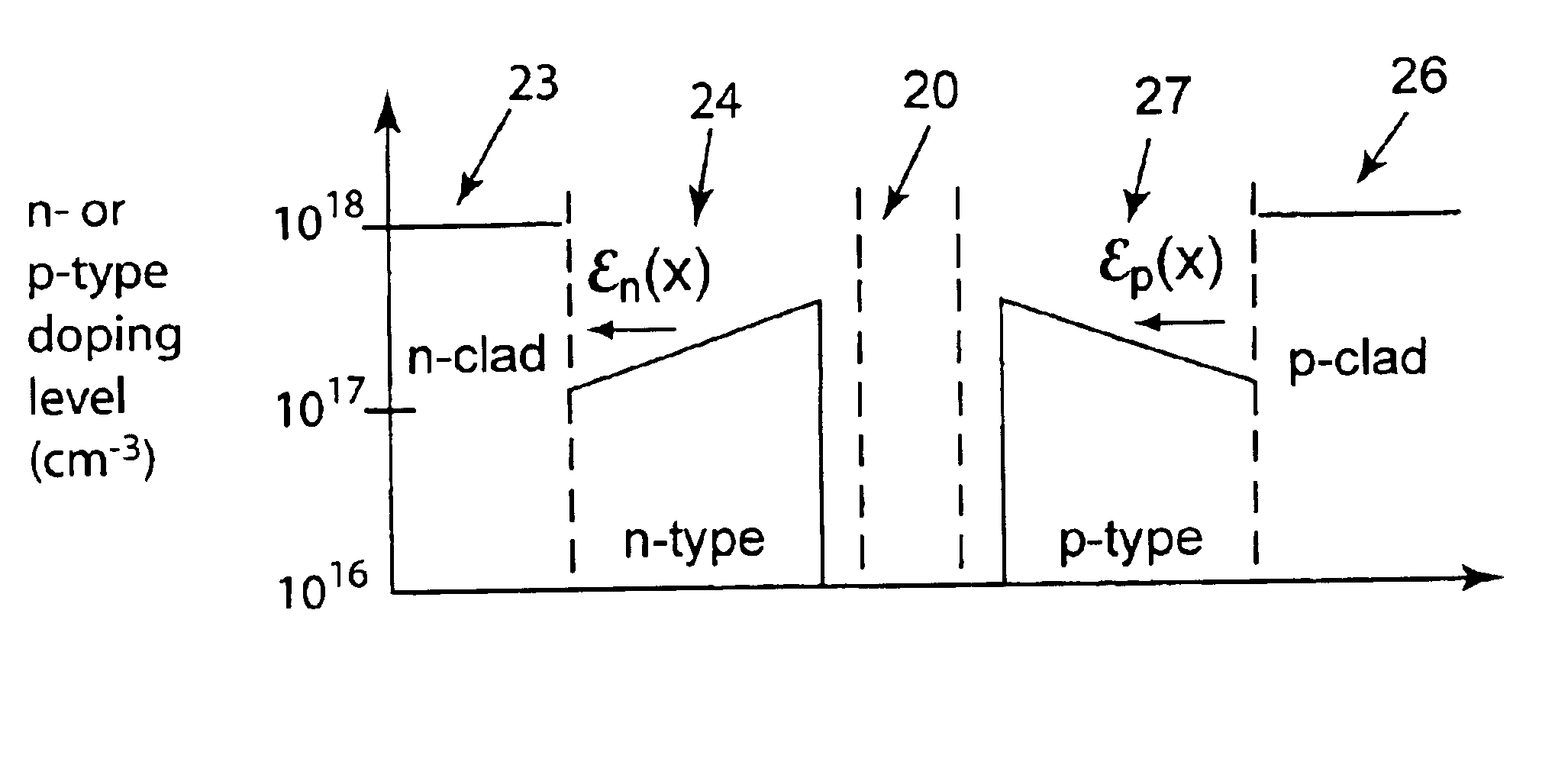

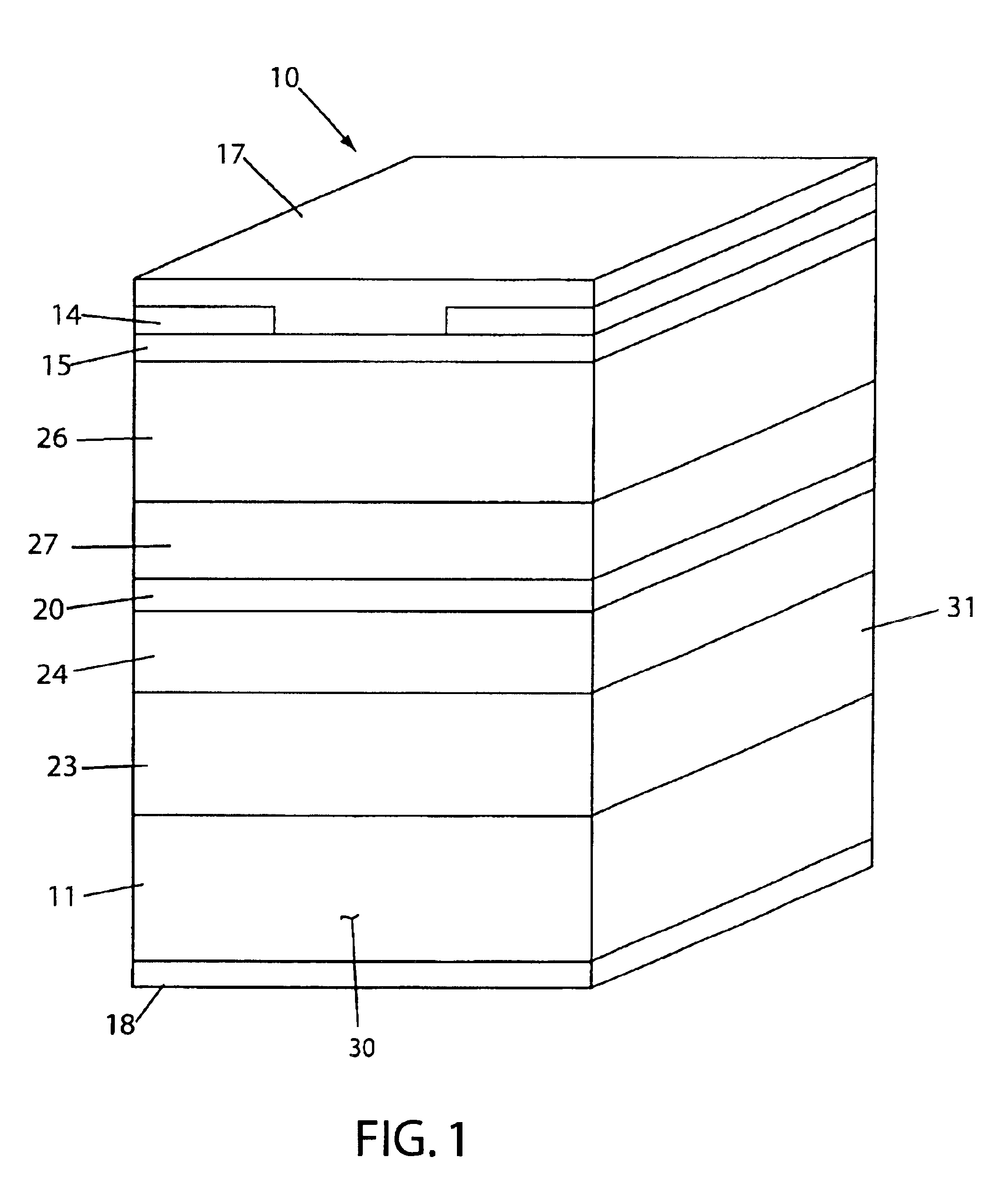

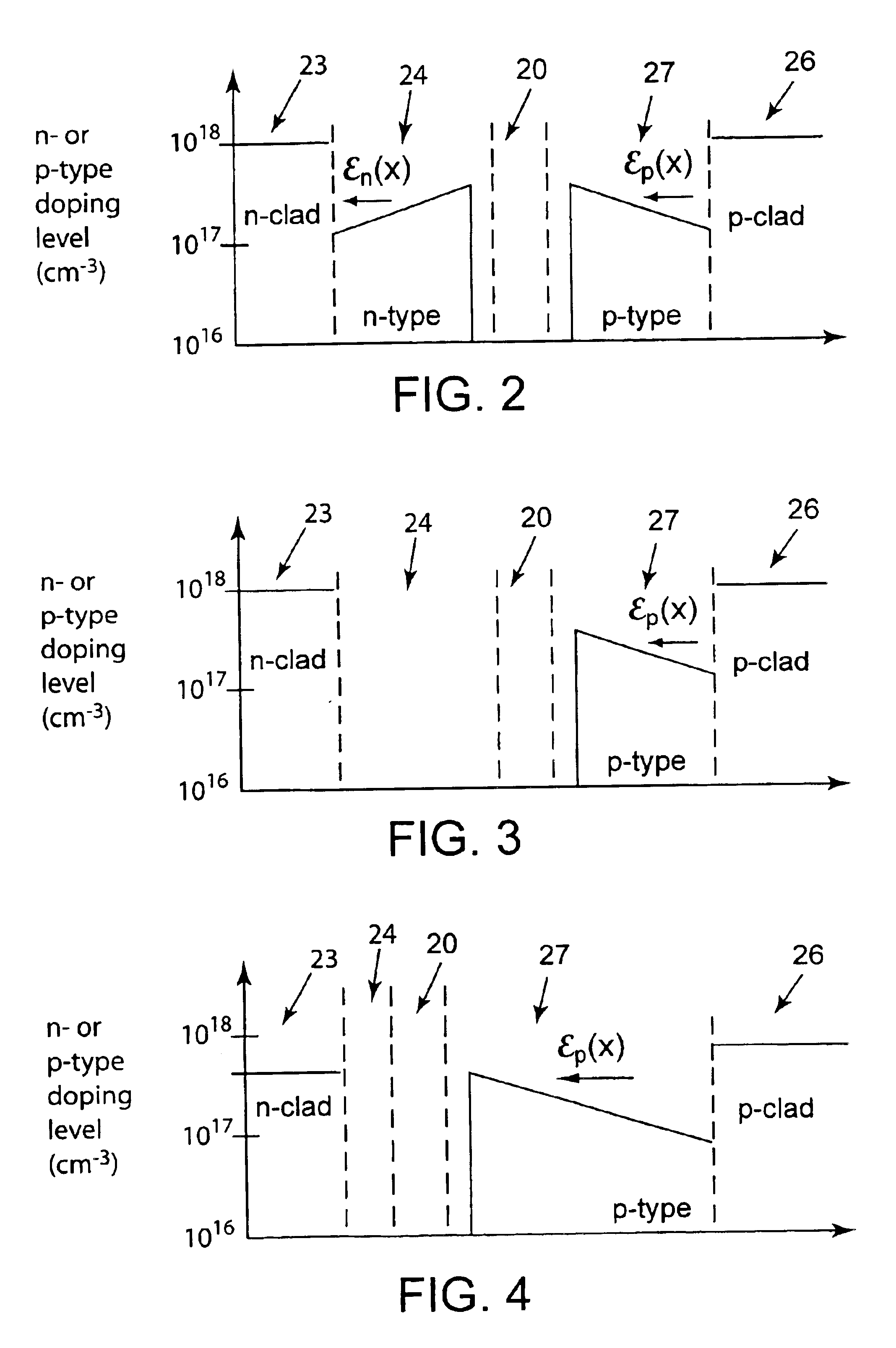

Semiconductor light sources with doping gradients in optical confinement layers for improved device efficiency

ActiveUS6907056B2Improve shipping speedImprove efficiencyOptical wave guidanceLaser cooling arrangementsElectron holeQuantum well

Semiconductor light emitting sources are formed to have a substrate, an active region layer having one or more quantum wells, optical confinement layers surrounding the active region layer, and a p-type cladding layer and an n-type cladding layer surrounding the confinement layers and the active region layer. At least one of the optical confinement layers has a region of doping therein that is formed to provide a built-in electric field in the confinement layer that is directed to cause drift of carriers toward the active region. The electric field increases the transport speed of the injected holes or electrons, thereby reducing the non-ohmic voltage drop and increasing the overall efficiency of the light emitting source.

Owner:WISCONSIN ALUMNI RES FOUND

Dual lane multi-axle transport vehicle

InactiveUS8424897B1Increase profitReducing axle yawAgricultural machinesVehicle to carry long loadsSuspension (vehicle)Heavy load

A dual lane, multi-axle transport vehicle for moving heavy loads includes a forward module mounted on a plurality of axles and a rearward module mounted on a plurality of axles. The forward module is mechanically connected to the rearward module for providing a dual lane transport body. The forward module and the rearward module of the transport body each have a single central spine wherein the axles of both the forward module and the rearward module are each attached to the corresponding single central spine. The axles of both the forward module and the rearward module have an axle spacing of at least six feet. A hydraulic suspension is provided for dynamically stabilizing the axles for reducing axle yaw. An axle steering system having a plurality of steering rods controls the position of the axles of both the forward module and the rearward module.

Owner:FAYMONVILLE DISTRIBUTION

Fast installation method of ten-million-ton scale fully mechanized caving face equipment

InactiveCN102392667ARealize parallel operationSpeed up the installation processMine roof supportsAnchoring boltsMode of transportTon

The invention discloses a fast installation method of ten-million-ton scale fully mechanized caving face equipment and belongs to sinking and driving engineering of mines. The method is innovatively characterized in that open-off cuts on a working surface are widen to improve the transportation mode and installation method of a hydraulic support and the supporting mode of the open-off cuts. By virtue of the improvements, the installation time of the ten-million-ton scale fully mechanized caving face equipment is realized, the construction period is shortened and the installation progress of the working surface is accelerated.

Owner:SHANDONG XINJULONG ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com