Container loading-unloading automatic flow-line

A container and assembly line technology, applied in the direction of loading/unloading, storage devices, transportation and packaging, etc., can solve the difficulties in realizing the automation of container terminal loading and unloading operations, affecting the efficiency of container terminal loading and unloading operations, and inaccurate positioning of spreaders and trucks, etc. problems, achieve the effect of shortening alignment time, easy alignment, and improving transportation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

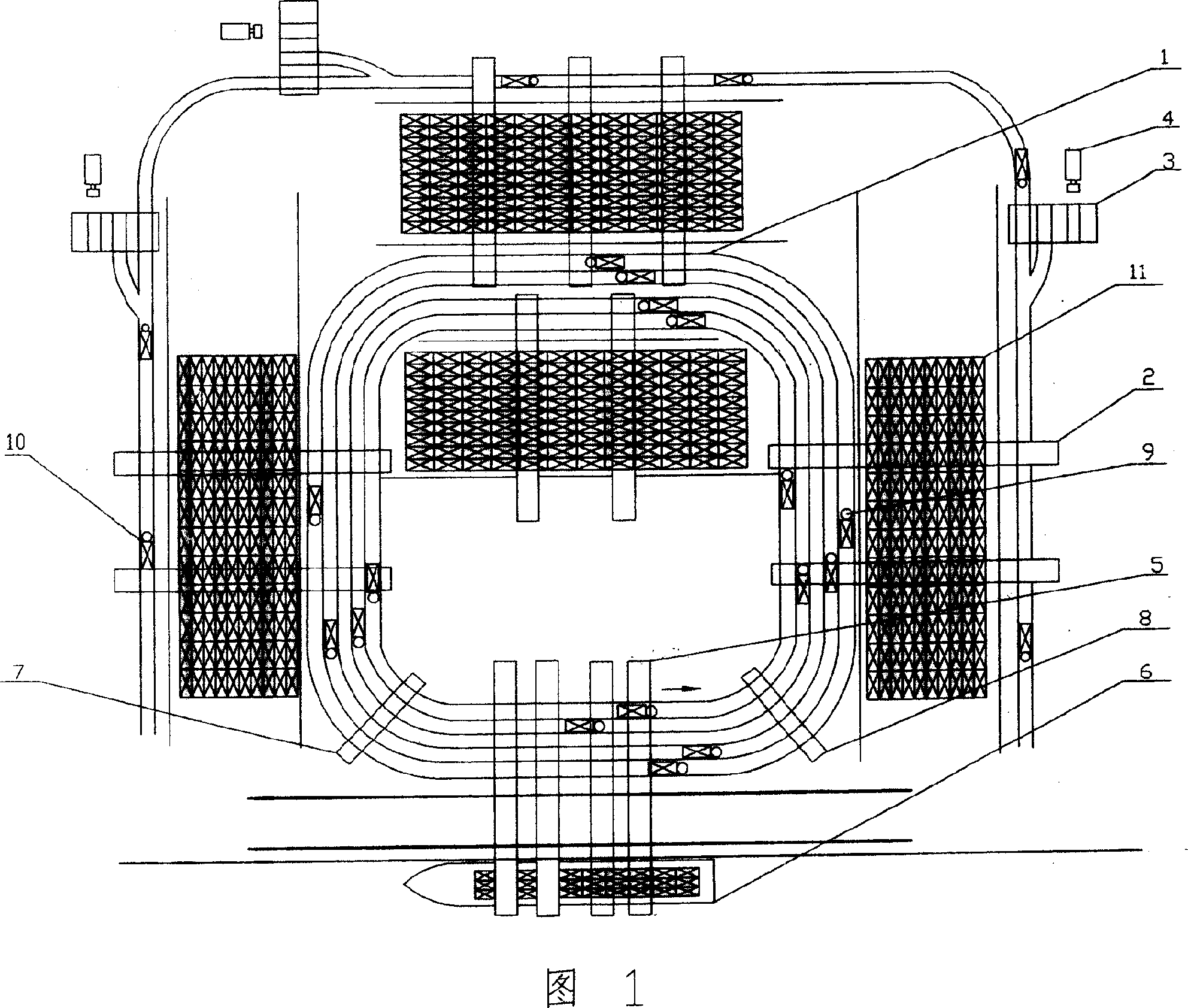

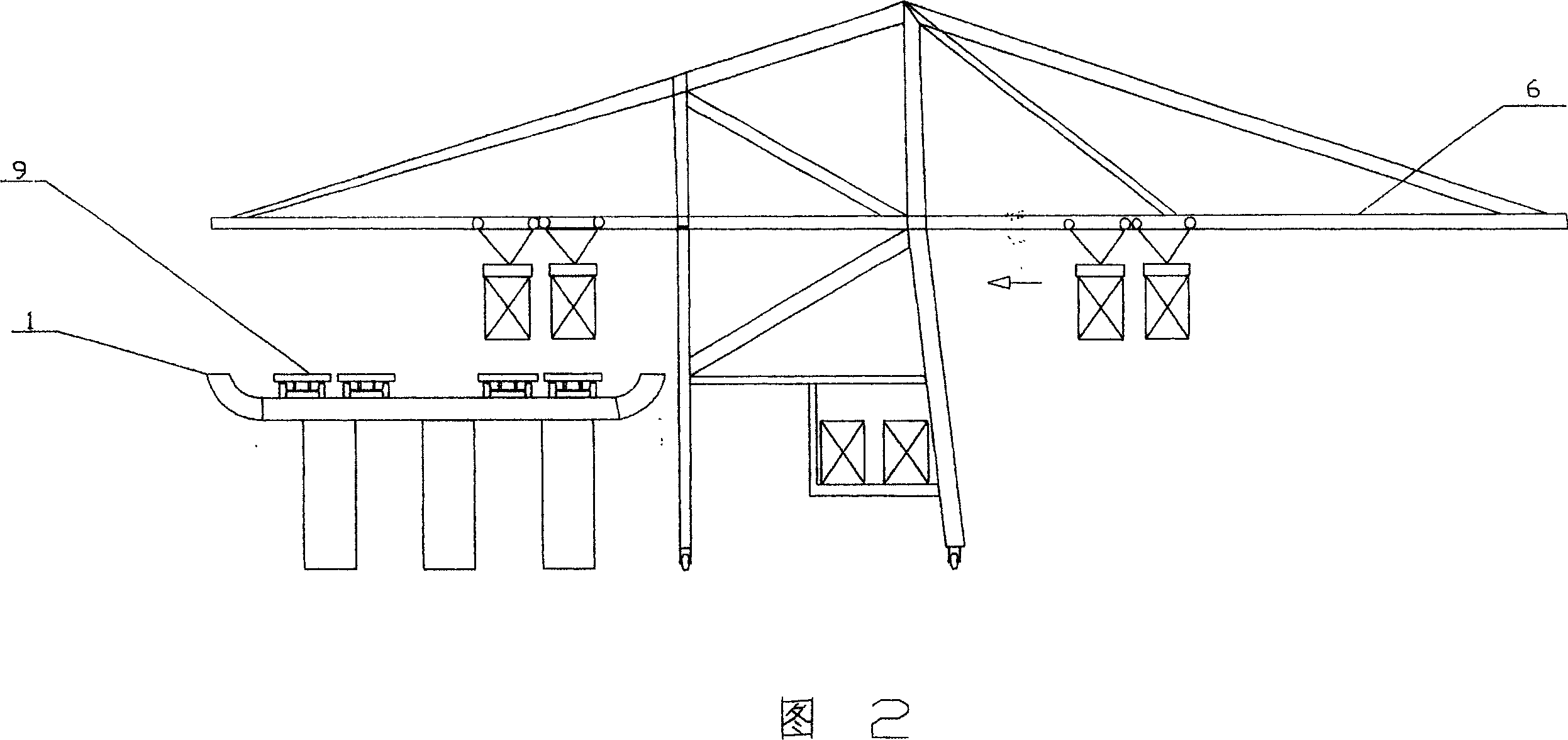

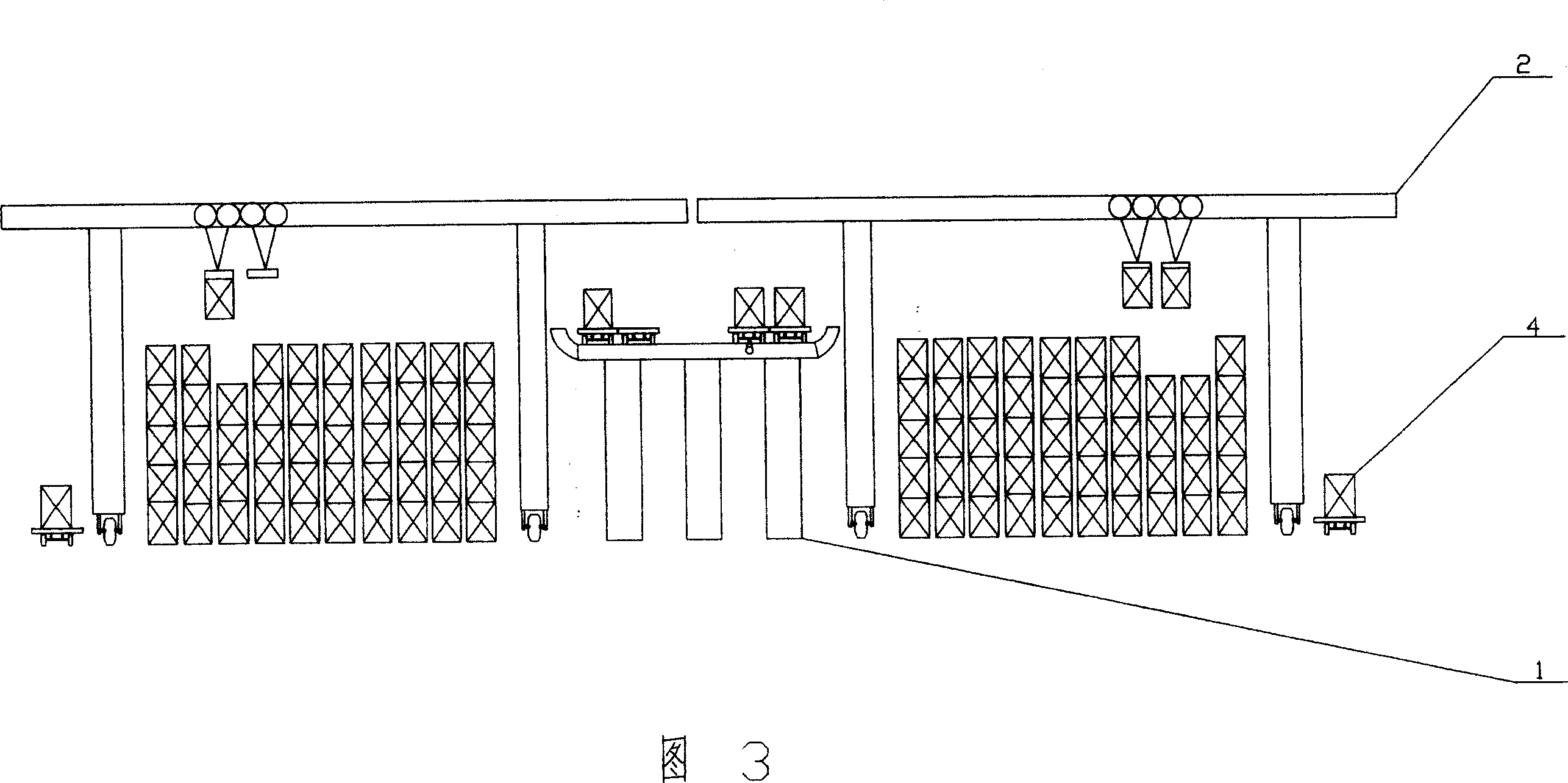

[0013] As shown in Fig. 1, the container is transported to the container dumping device (3) by the truck (4), and the container is placed on the ground rail trolley (10) through the container truck dumping device (3). (10) Transport the container to the operation place of the track site gantry crane (2) for loading and unloading at both ends, and the track site gantry crane (2) stacks the container on the container yard (11) or hangs the container on the elevated electric rail car (9), In the middle of the transport viaduct (1) there is a set of out-of-box identification device (7) to facilitate stacking management, and the ring-shaped elevated electric rail car (9) runs to transport the container to the bottom of the quay bridge (5), and the quay bridge (5) lifts the container During this process, because the height of the viaduct (1) itself shortens the alignment distance between the spreader and the container, it is easier to realize the positioning of the spreader and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com