Patents

Literature

328 results about "Riprap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Riprap, also known as rip rap, rip-rap, shot rock, rock armor, or rubble, is man-placed rock or other material used to armor shorelines, streambeds, bridge abutments, pilings and other shoreline structures against scour and water, wave, or ice erosion. Common rock types used include granite and modular concrete blocks. Rubble from building and paving demolition is sometimes used.

Jackstone-type rockfill concrete construction method

ActiveCN101144279APouring is flexible and fastReduce usageFoundation engineeringEarth-fill damsHigh intensityUltimate tensile strength

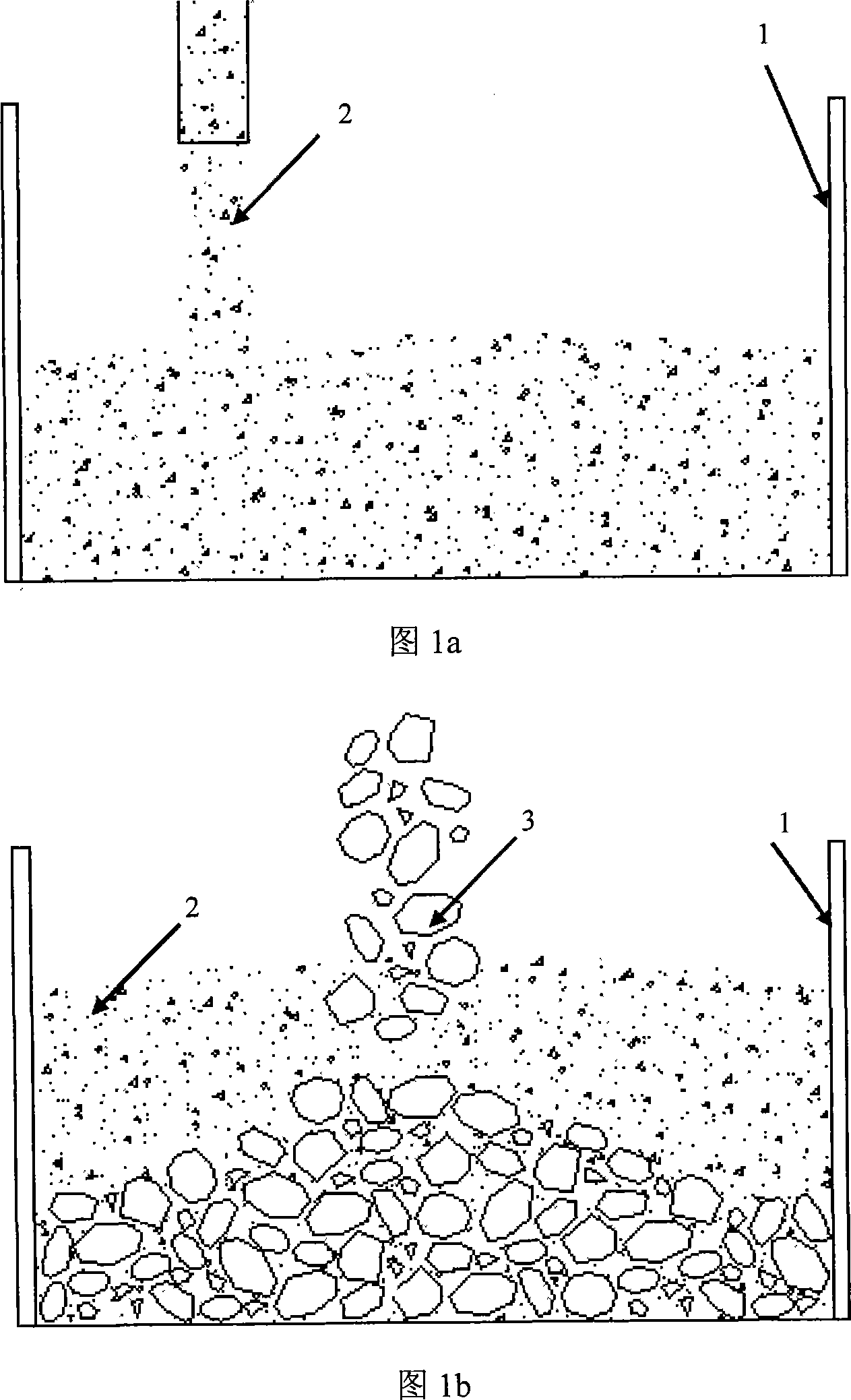

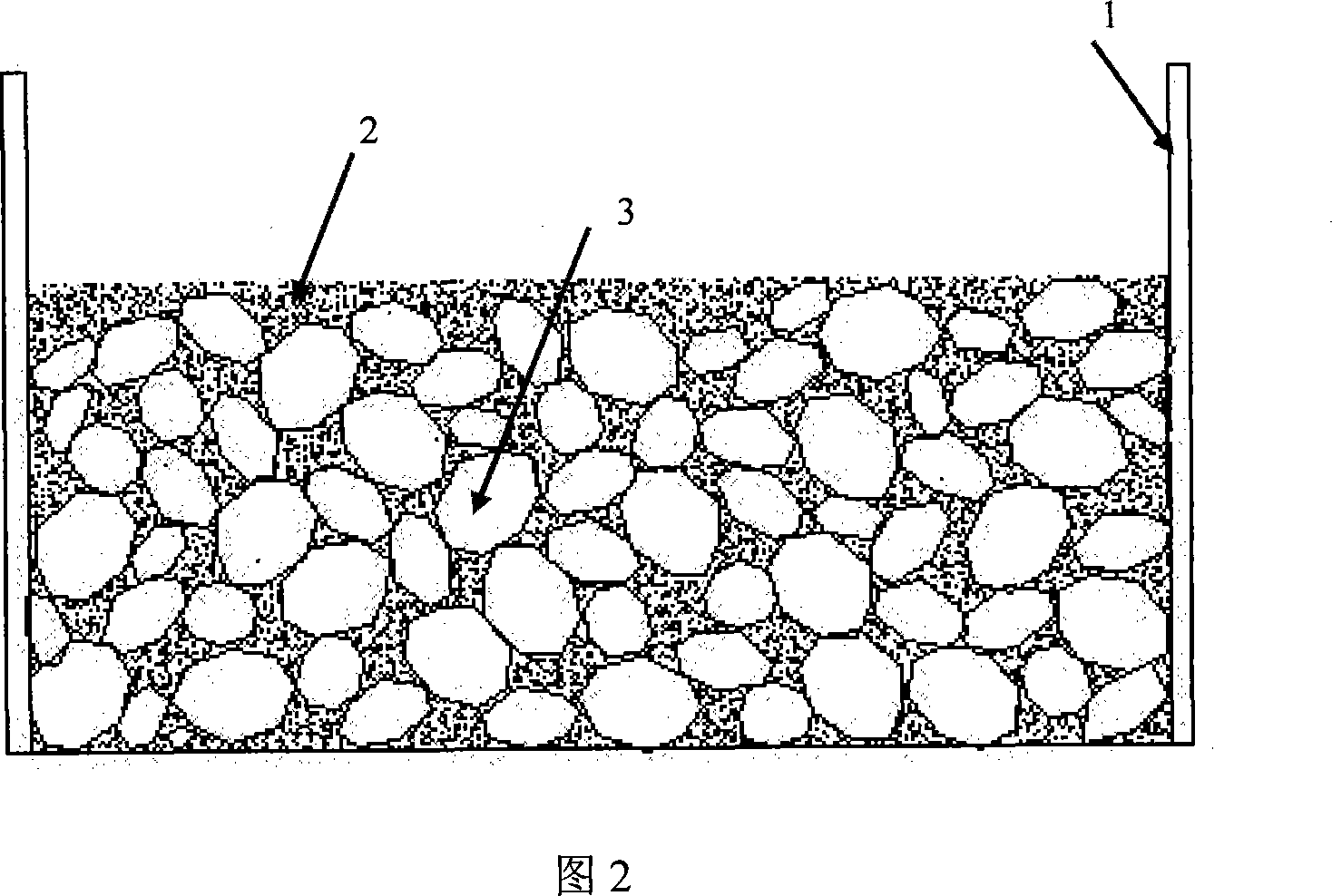

The present invention discloses a riprap rock-fill concrete construction method, which relates to a construction method for the large volume concrete. The present invention adopts self-compacting concrete having superior anti-segregation performance and good plasticity-retention performance, and firstly the concrete is poured into a bin, and then block stones or pebbles with the particle size smaller than 4 cm are poured into the poured self-compacting concrete in a mechanical way or a manual way, and the self-compacting concrete can fill up and compact the vacancies caused in the block stone settlement path at any time, the high anti-segregation performance ensures that the self-compacting concrete does not segregate and bleed water under the impact of the block stones, and finally the self-compacted rock-fill concrete with high intensity is formed. The method has the advantages that the construction is convenient, and the present invention has significant effects on the aspects of improving the construction efficiency and saving the construction cost, and the rock-fill concrete formed has high degree of compaction, the cement used is less, the hydration temperature rise is low, the volume stability is good, and the comprehensive performance is excellent, meanwhile, the present invention also has the advantages of energy-saving, environmental protection and being easy for continuous construction.

Owner:TSINGHUA UNIV +1

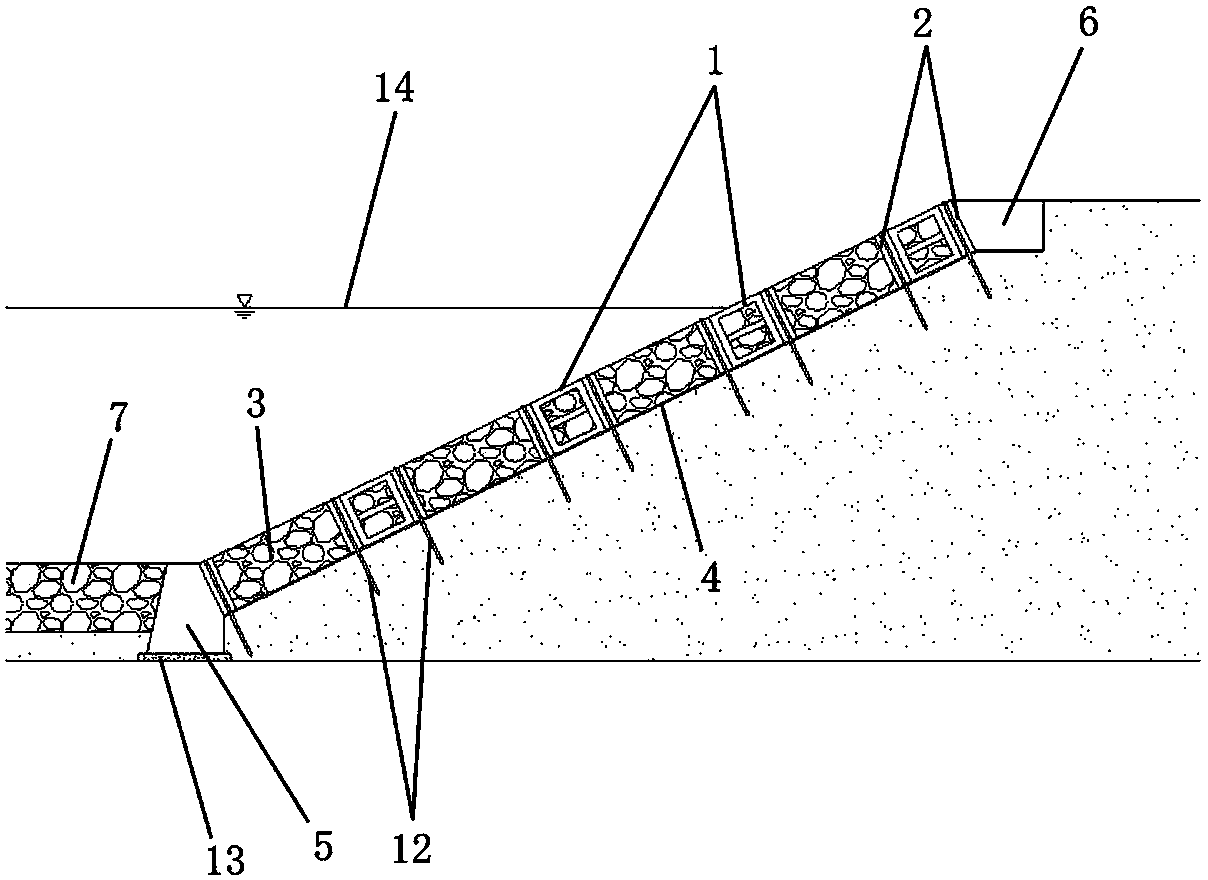

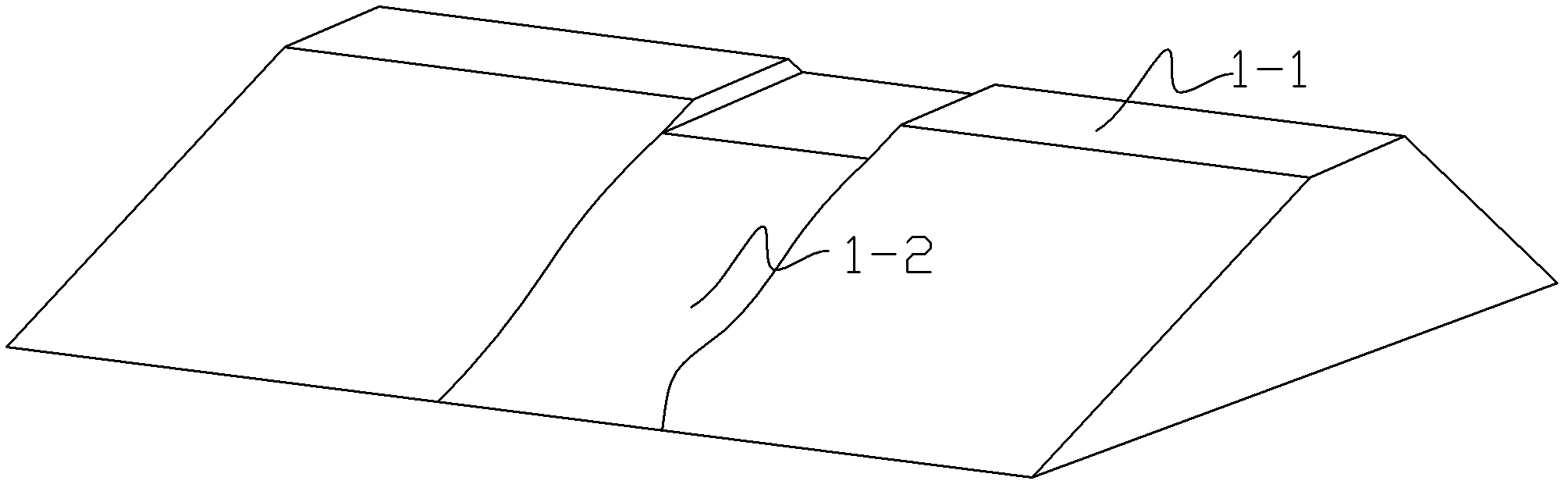

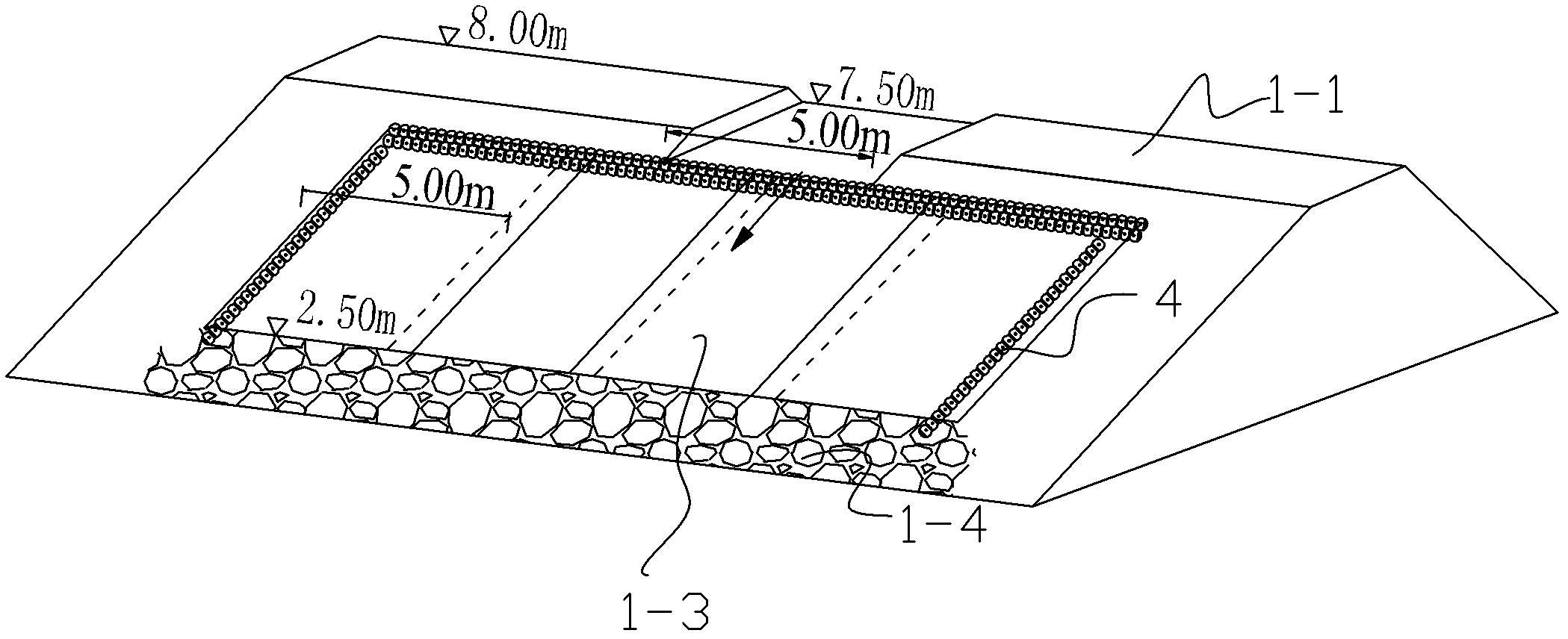

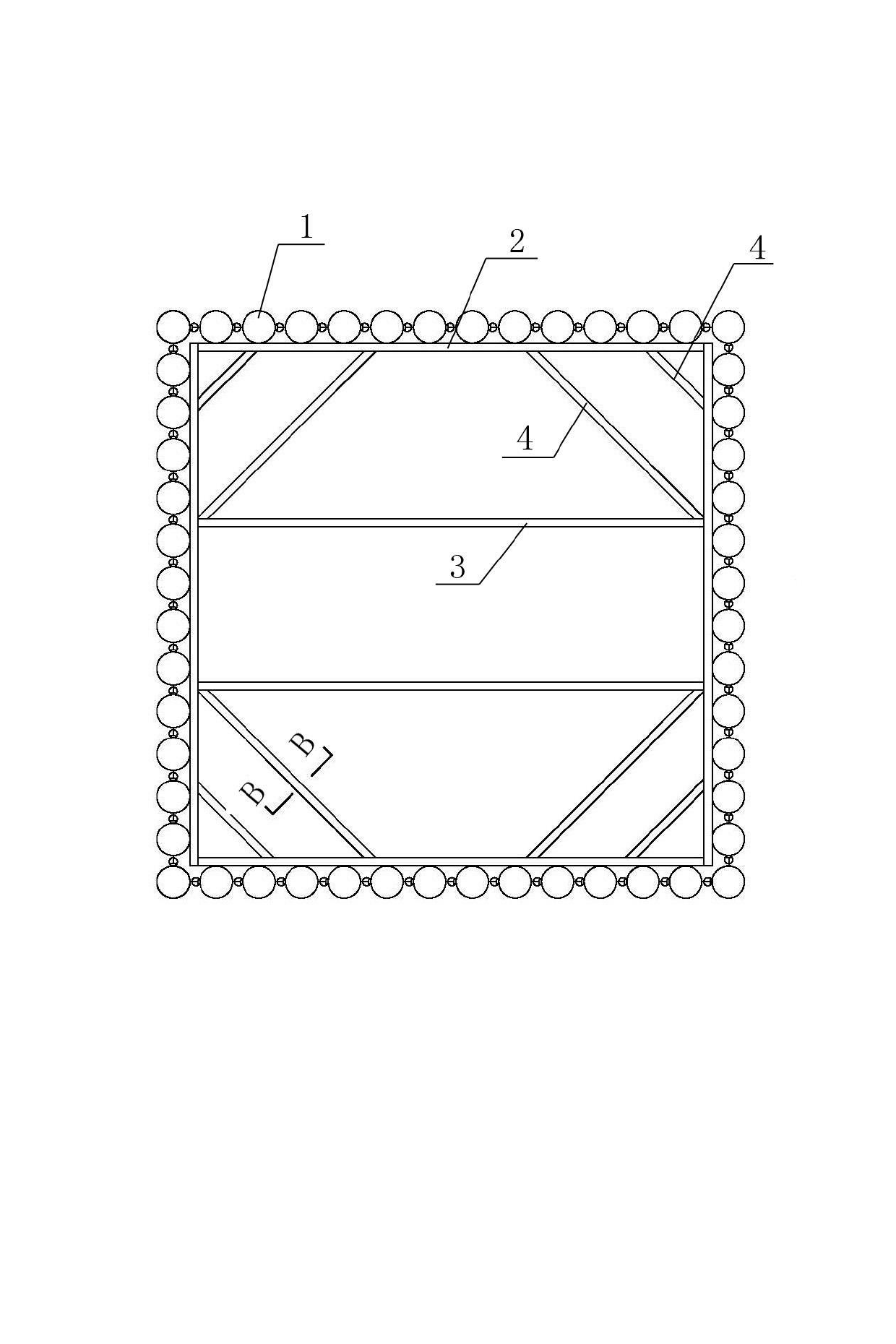

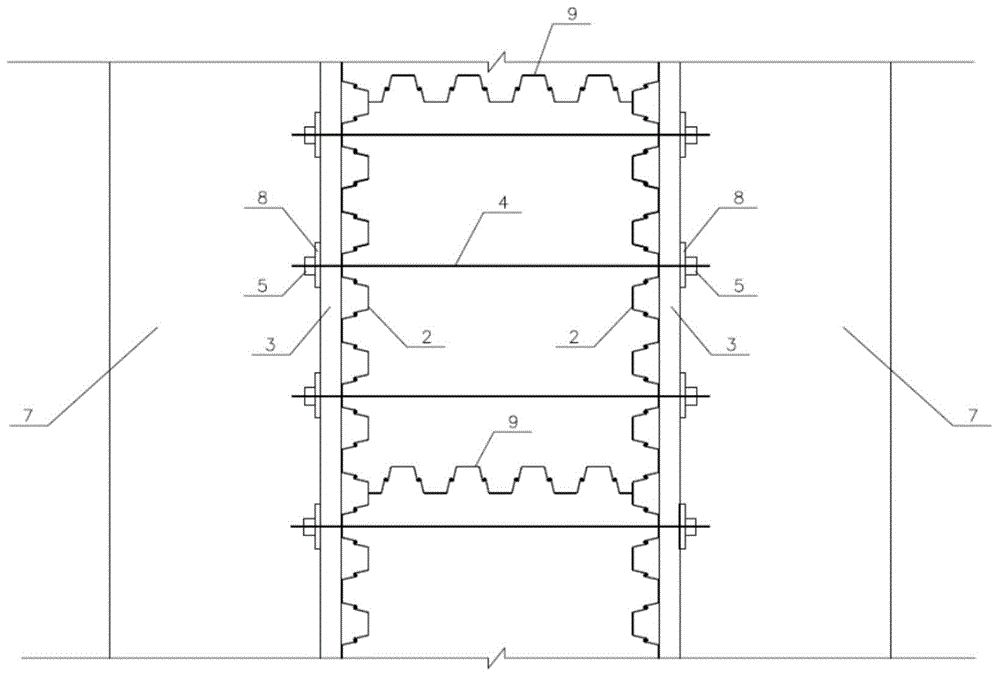

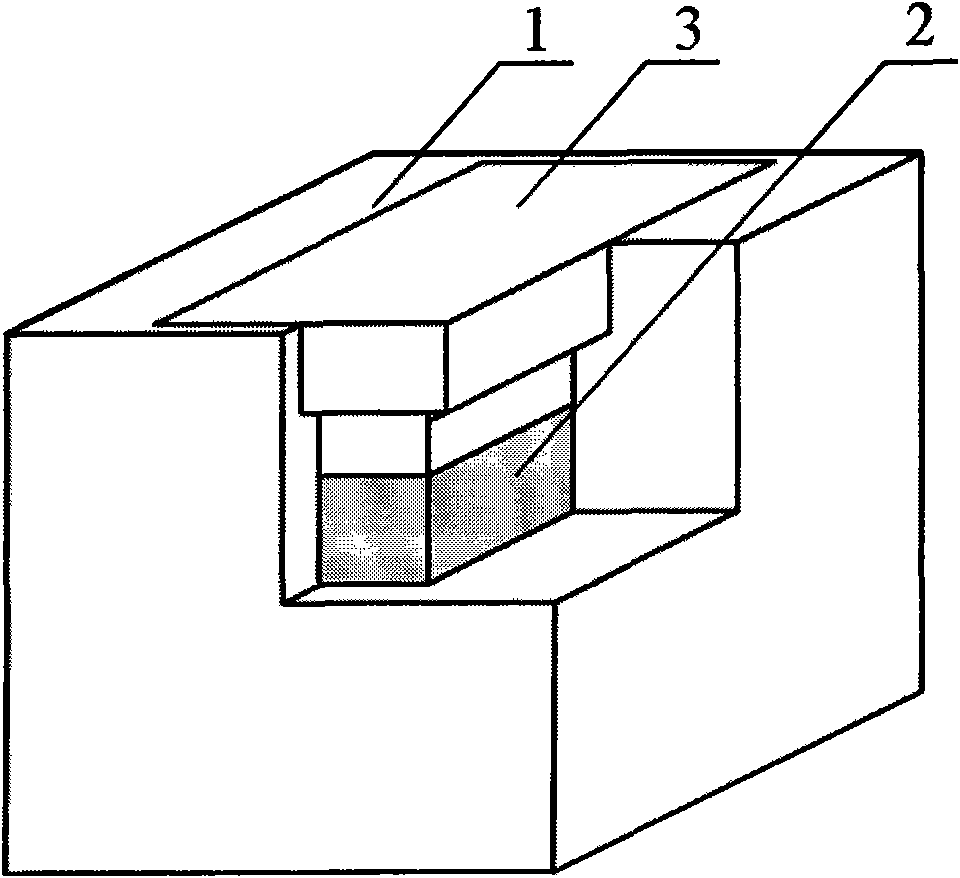

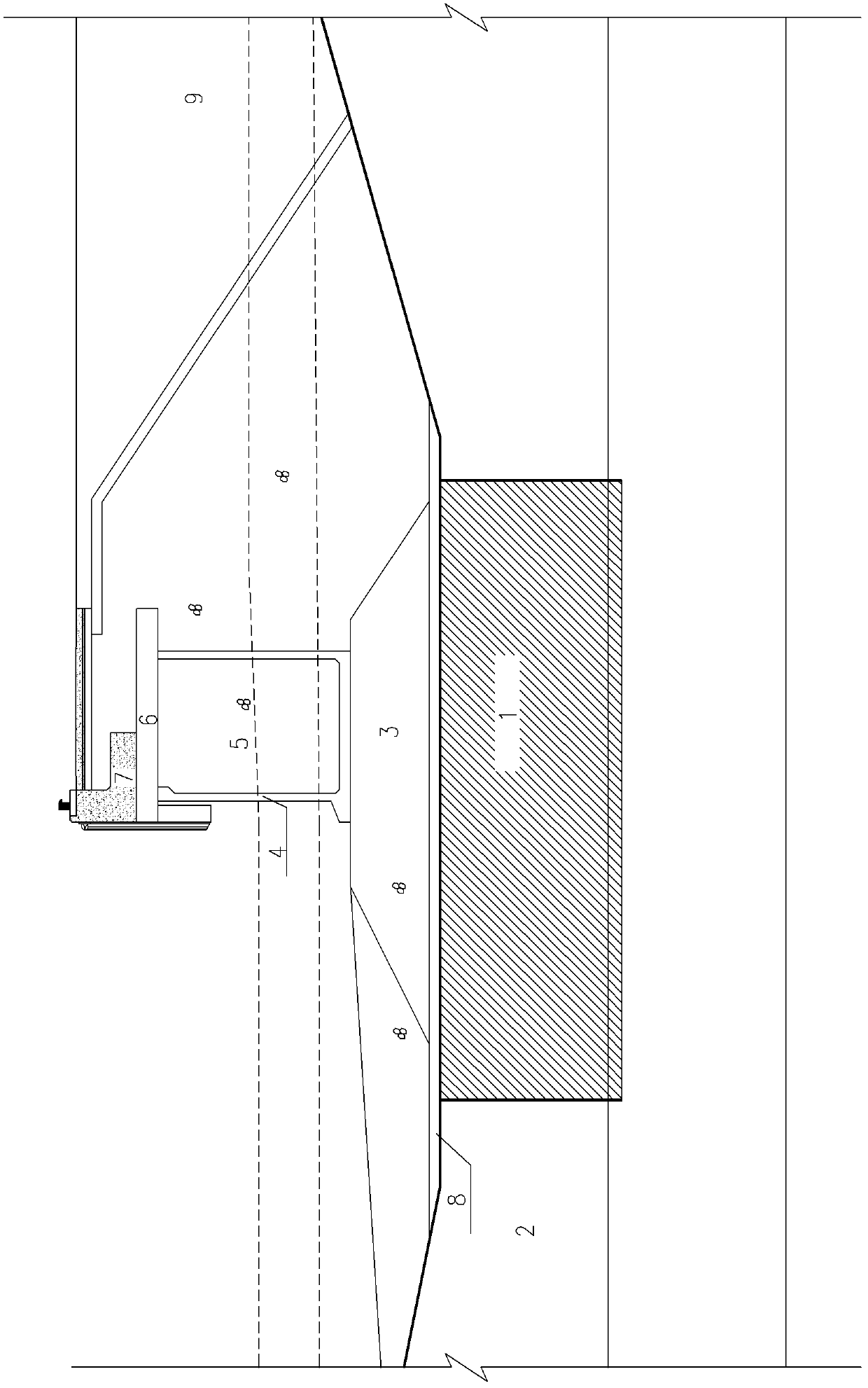

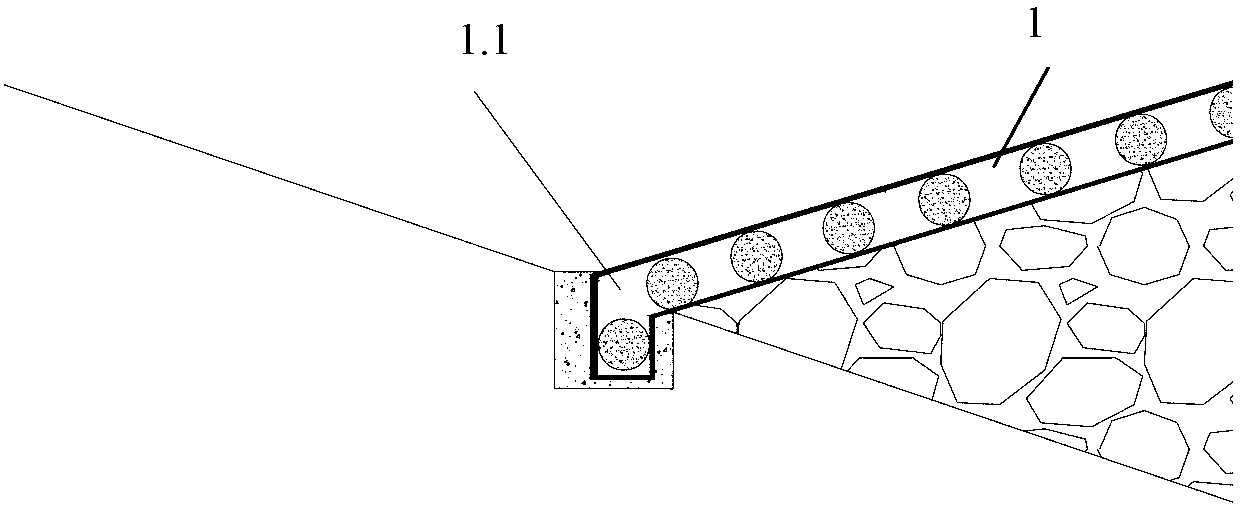

Lattice type river bank revetment structure and construction method thereof

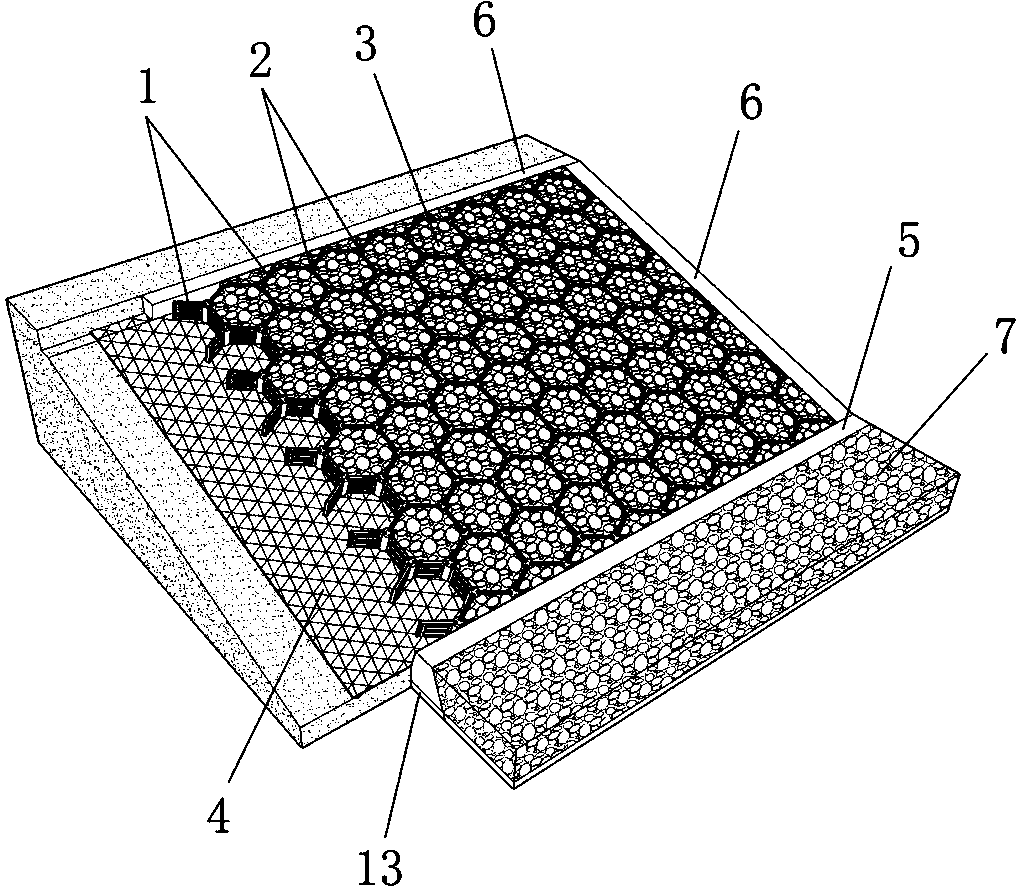

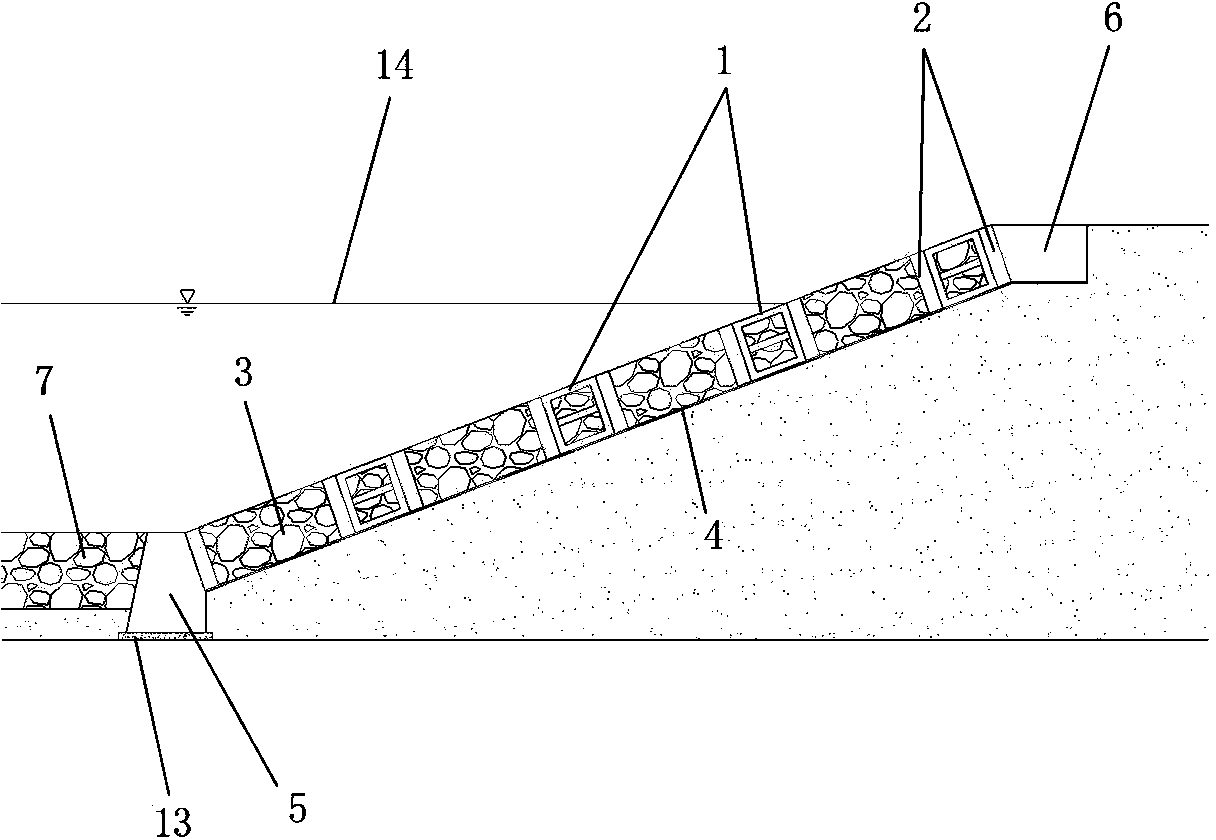

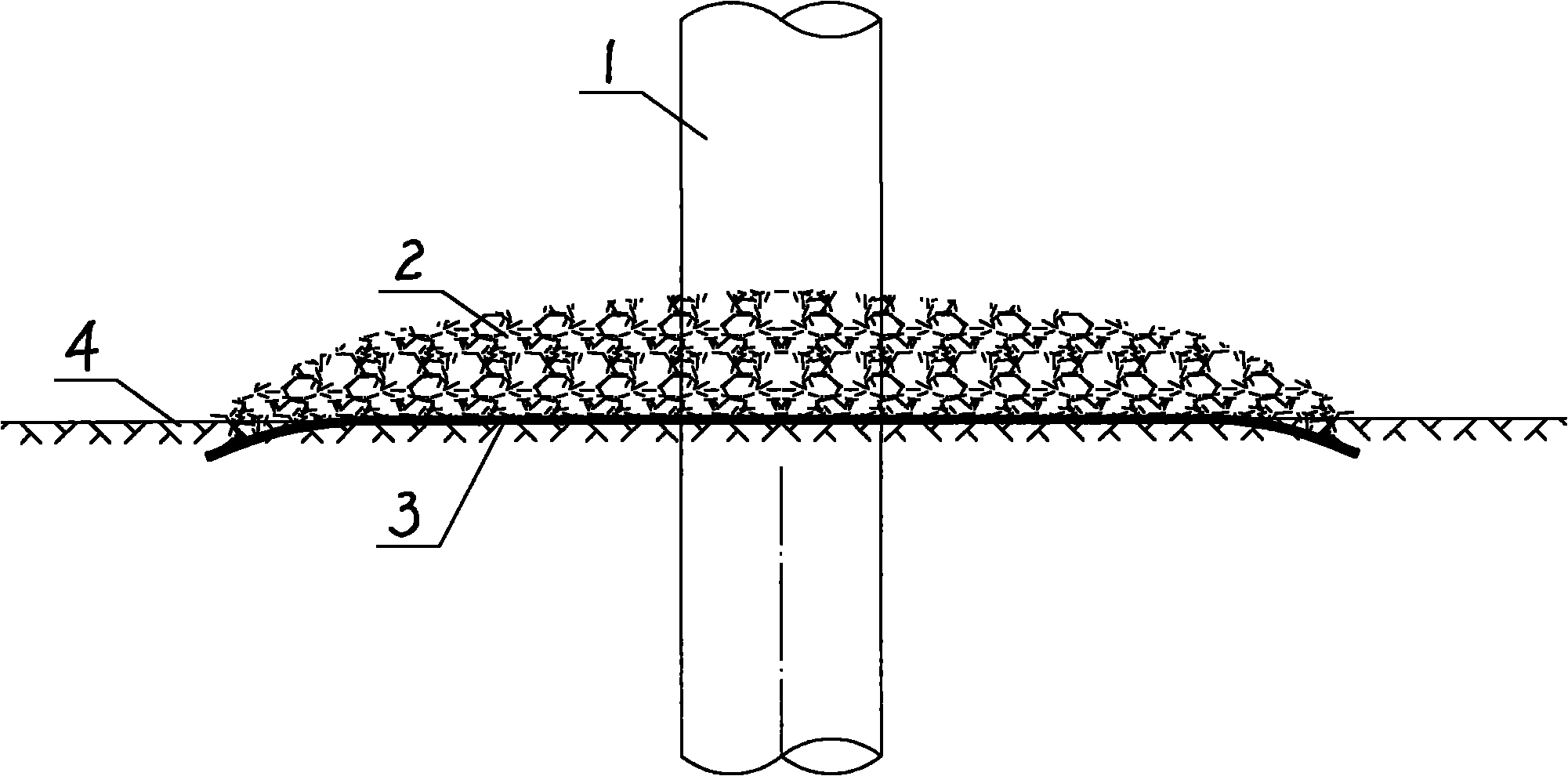

The invention provides a lattice type river bank revetment structure and a construction method thereof. The lattice type bank revetment structure is wide in use, high in construction speed and attractive in appearance. The technical problems that an existing river bank revetment structure is poor in stability and water permeability, complex in construction and tight in construction schedule are solved. The lattice type river bank revetment structure is characterized in that the structure is provided with a slope body frame composed of a ribbed plate 1 and a ribbed plate 2, the slope body frame is filled with polygonal stones 3, geotechnical fabric 4 is laid on the lower portion of a slope body, the two edges of the slope body and the upper end of the slope body are fixed through edge sealing beams 6, the lower end of the slope body is provided with a slope toe foundation 5, and a riprap scour prevention band 7 is paved on the slope toe foundation 5 along one side of a riverway. The two ends of the ribbed plate 1 are provided with symmetric inverted trapezoidal plugs 8, and water permeable through holes 9 are arranged in the centers of the ribbed plate. The ribbed plate 2 is of a column body structure, three trapezoidal concave inserting grooves 10 which are used for fixing the lattice ribbed plates are arranged around a column body, the shape of a groove opening of each trapezoidal concave inserting groove corresponds to the symmetric inverted trapezoidal plugs at the two ends of the lattice ribbed plate, and the groove openings of the trapezoidal concave inserting grooves are mutually embedded with the symmetric inverted trapezoidal plugs at the two ends of the lattice ribbed plate.

Owner:管大为 +1

Method for building sea filling embankment

ActiveCN102116006ATo achieve the purpose of replacing sludgeSmall amount of workRoadwaysBlastingEconomic benefitsEngineering

The invention discloses a method for building a sea filling embankment. The method comprises the following steps: a bearing stratum is selected; an embankment cross section is selected; throw-filling parameters are determined; explosion parameters are determined; and embankment body throw-filling, embankment head explosion-filling, embankment top supplement-filling and embankment side explosion-filling are implemented. The method of silt squeezing and rock filling by blasting disclosed by the invention is conducted in a manner that explosive groups are buried and placed in a muddy soft foundation with a certain distance and depth from the outer edge of a rock body, a cavity is formed in silt at the blasting initiation moment, and then the riprap rock body fill the cavity and form a rock tongue, so as to achieve the aim of replacing the silt. The silt is extruded outwards through explosion, and the quantity of the extruded silt is the engineering quantity within the range of the embankment, so that compared with the dredger operation, the engineering quantity of the silt needing to be cleared is greatly reduced, and affected zones of a water area and that under water are greatly reduced at the same time. Materials such as mounting cutting rocks, and the like are firstly filled into the bearing stratum, and then fillers act on the bearing stratum through silt squeezing by blasting, so that the working steps are reduced, the construction cost is greatly shortened. Therefore, the building method has very obvious advantages on the aspects of construction speed, engineering cost and economic benefit.

Owner:DALIAN MUNICIPAL DESIGN & RES INST

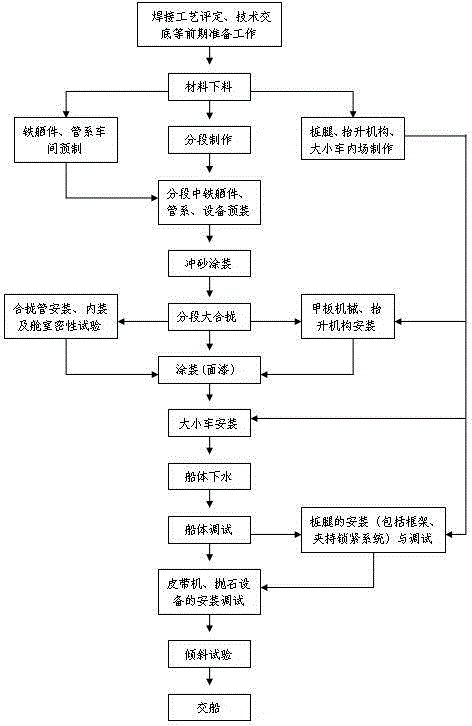

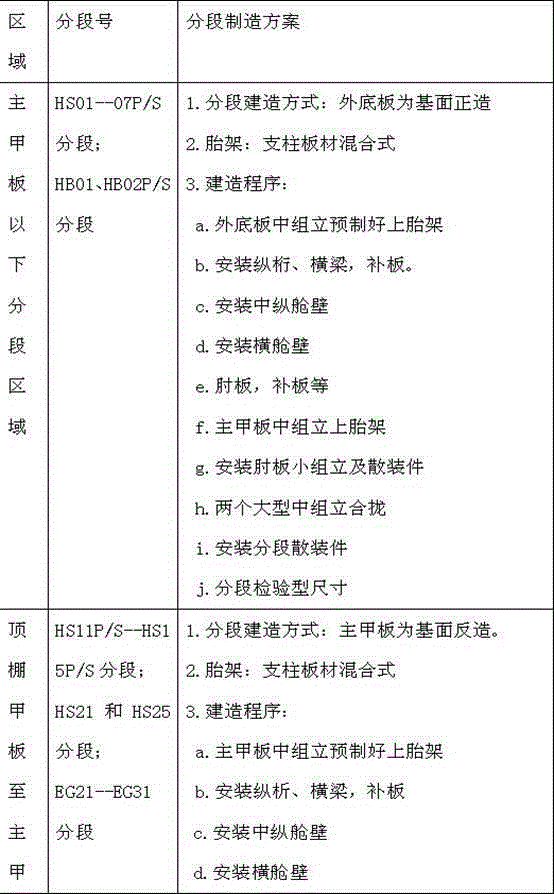

Manufacture method of offshore riprap leveling ship

The invention discloses a manufacture method of an offshore riprap leveling ship. The manufacture method comprises the following steps of: firstly, preparing for works; preparing for materials, to be specific, manufacturing a ship body by sections, manufacturing an iron outfitting and a piping system, manufacturing pile legs, a lifting mechanism, a big vehicle infield and a small vehicle infield; preassembling, carrying out sand washing and coating, largely combining by sections after sand washing and coating, installing a deck machine and the lifting mechanism; carrying out combining pipe installation, internal decoration and cabin tightness test; coating finish after the large combination by sections, the lifting mechanism installation, the combining pipe installation, the internal decoration and the cabin tightness test are completed; and finally, installing a big vehicle and a small vehicle to form the ship body, launching the ship body, debugging the ship body after launching, installing and debugging the pile legs, installing and debugging a belt conveyor and a riprap device on the ship body after the ship body and the pile legs are debugged, then carrying out inclination test, and finally delivering the ship. The manufacture method has the advantages of reducing construction procedures, lowering production cost and increasing production efficiency.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

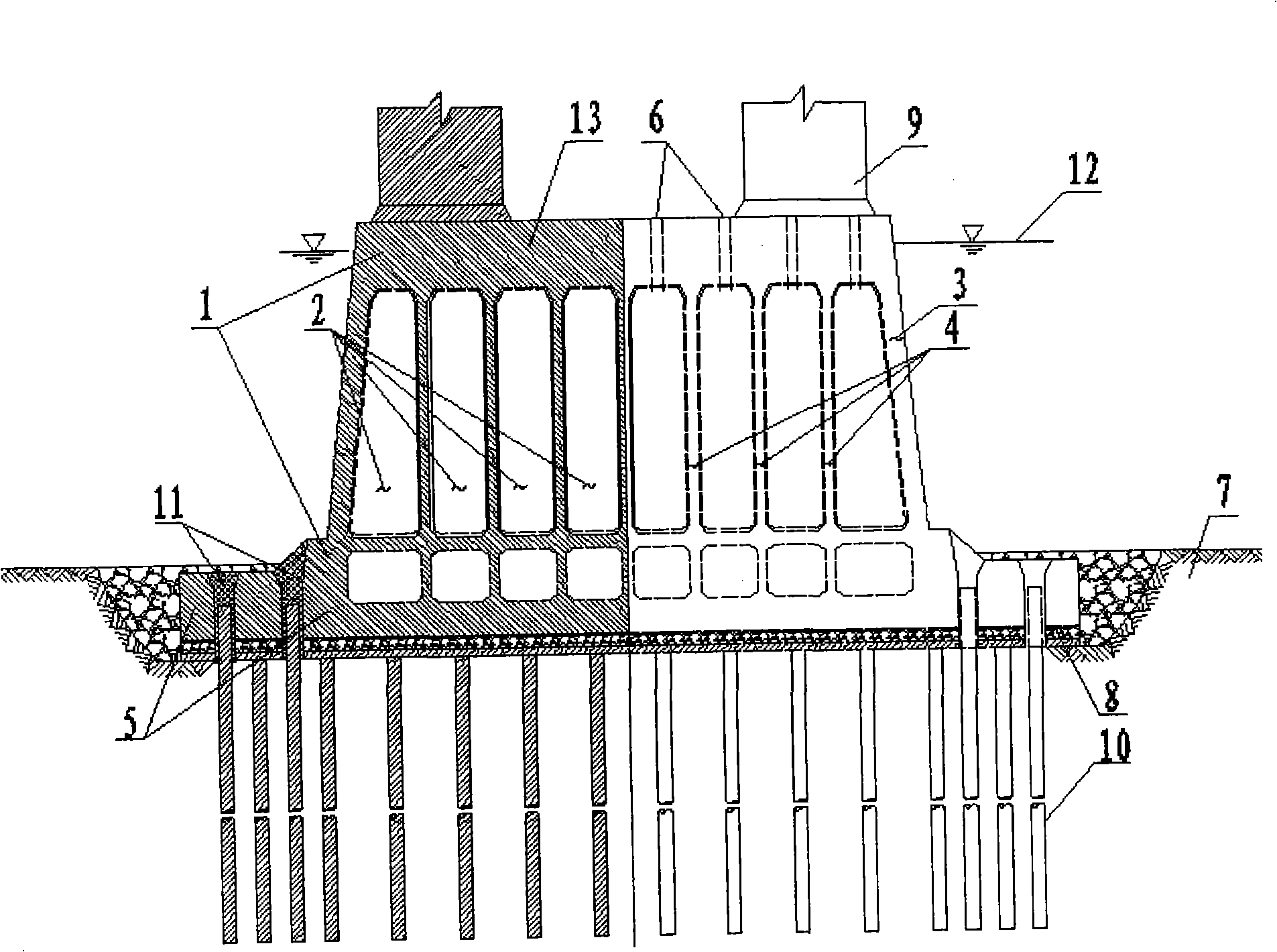

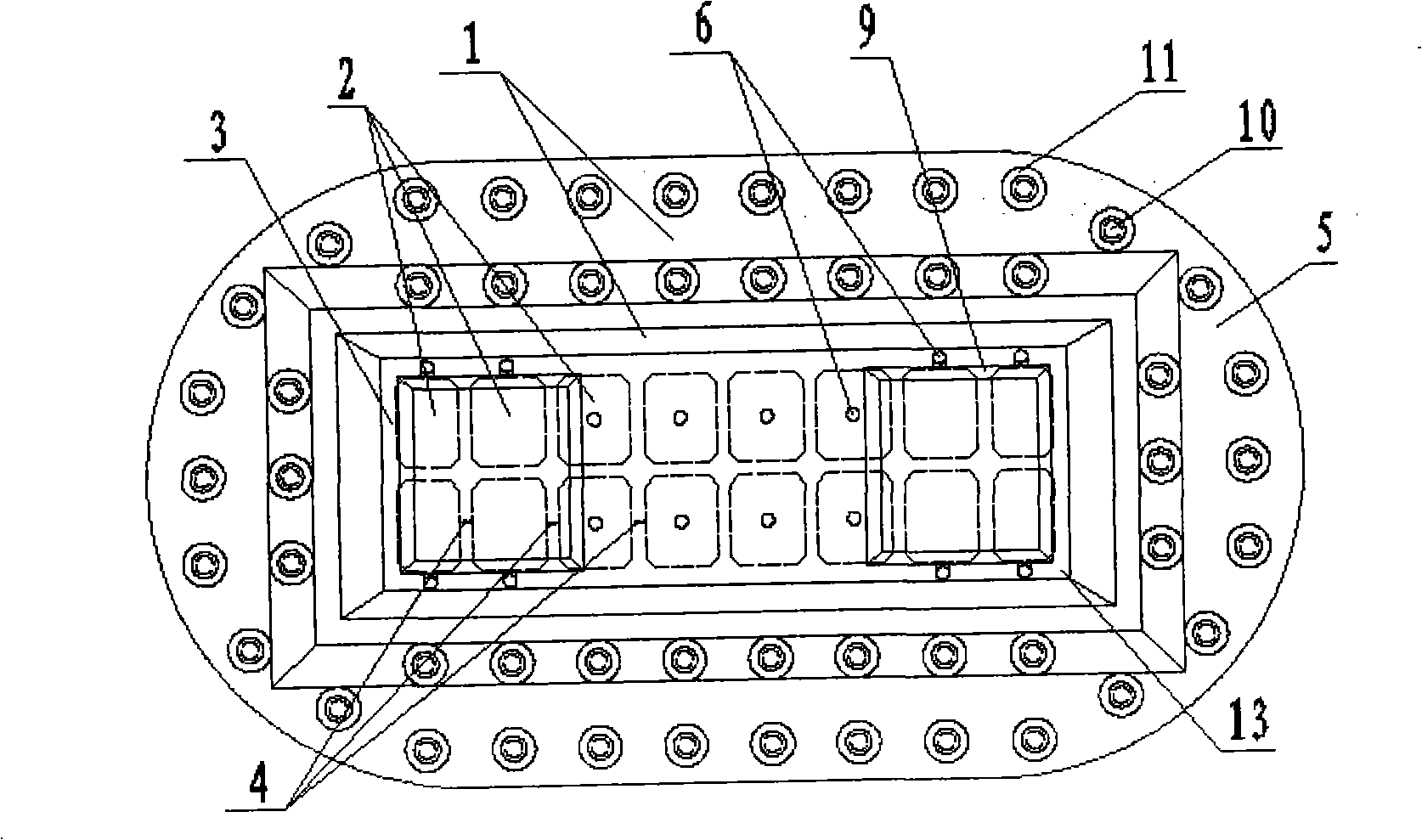

Steel cavity stranded caisson-pile inverse-way composite base and construction method

ActiveCN101294394AEffective control of settlementReduce settlementCaissonsBulkheads/pilesRiver bedEngineering

The invention relates to a composite foundation composed of a caisson with a steel cavity and piles constructed by the reverse operation method, and a construction method thereof, belonging to the bridge construction technology. The composite foundation comprises a caisson, a foundation bed, and piles. The caisson is composed of a steel cavity, an outer wall, an inner wall with a partition wall structure, a caisson cover, and a caisson bottom platform, wherein the caisson cover is preserved with water pumping and gas delivery holes, which are doubled as inspection holes. The caisson is arranged above the foundation bed and placed inside water, bridge piers are arranged on the caisson cover, the periphery of the caisson bottom platform is connected with the piles constructed by the reverse operation method, and the piles are inserted into the foundation bed and the sea bed or river bed through sinking pile preserved holes. After a foundation trench is excavated, a ship is located by riprapping to form the foundation bed, and the foundation bed is leveled by a platform type foundation bed riprapping leveling ship. The piles are connected with the caisson by pouring concrete in the preserved holes in the caisson. The inventive composite foundation utilizes the buoyancy force of the caisson steel cavity and considers the combined action of the piles, soil and the caisson to share partial external load by the sea bed or the river bed. The composite foundation optimizes the pile foundation design, reduces settlement during bridge service period, and reduces construction cost.

Owner:CCCC HIGHWAY CONSULTANTS

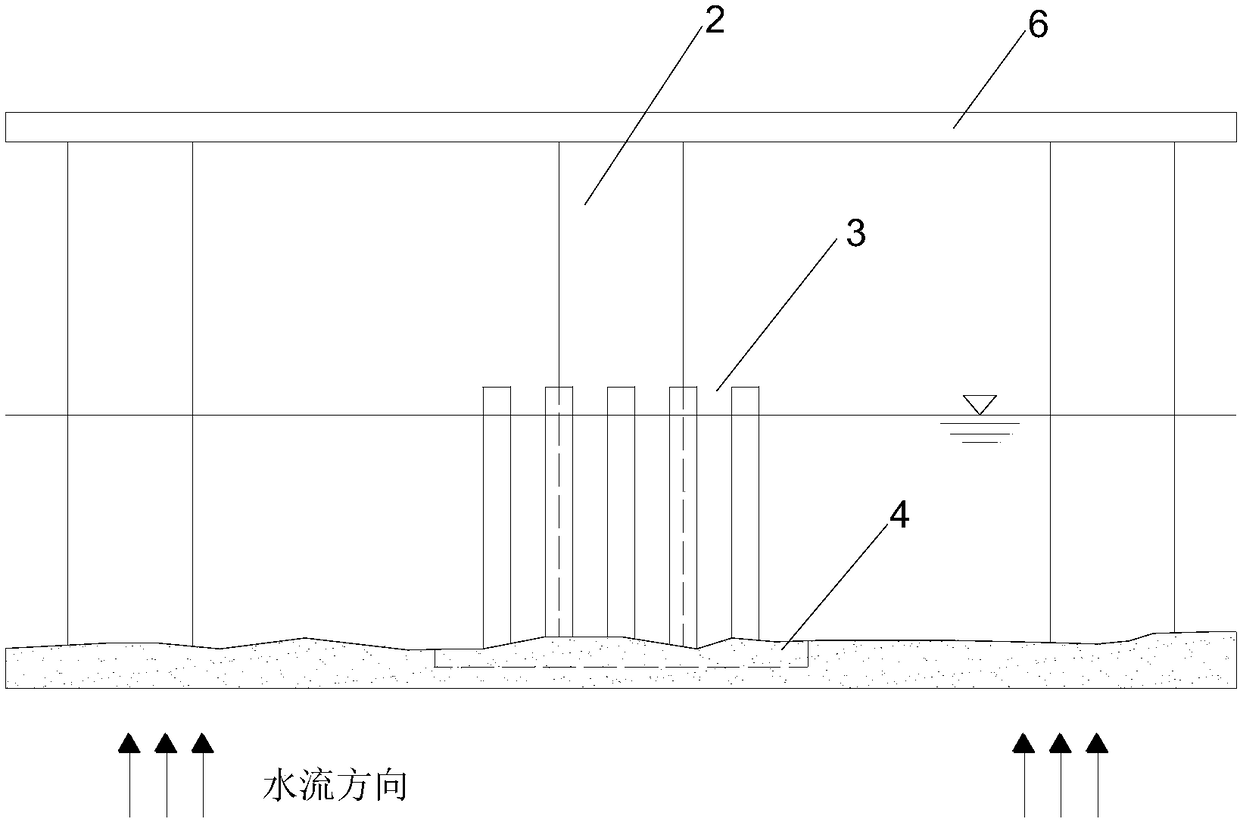

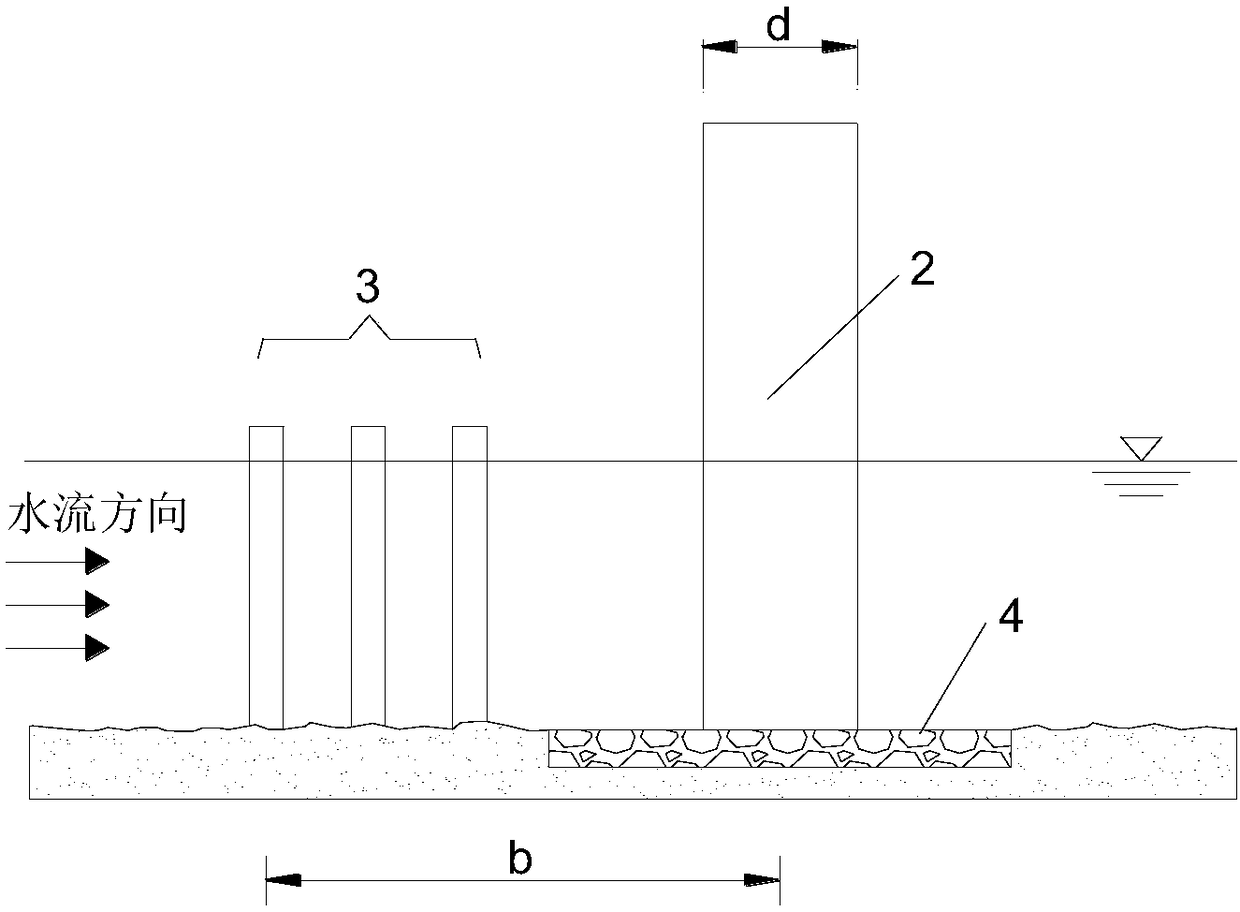

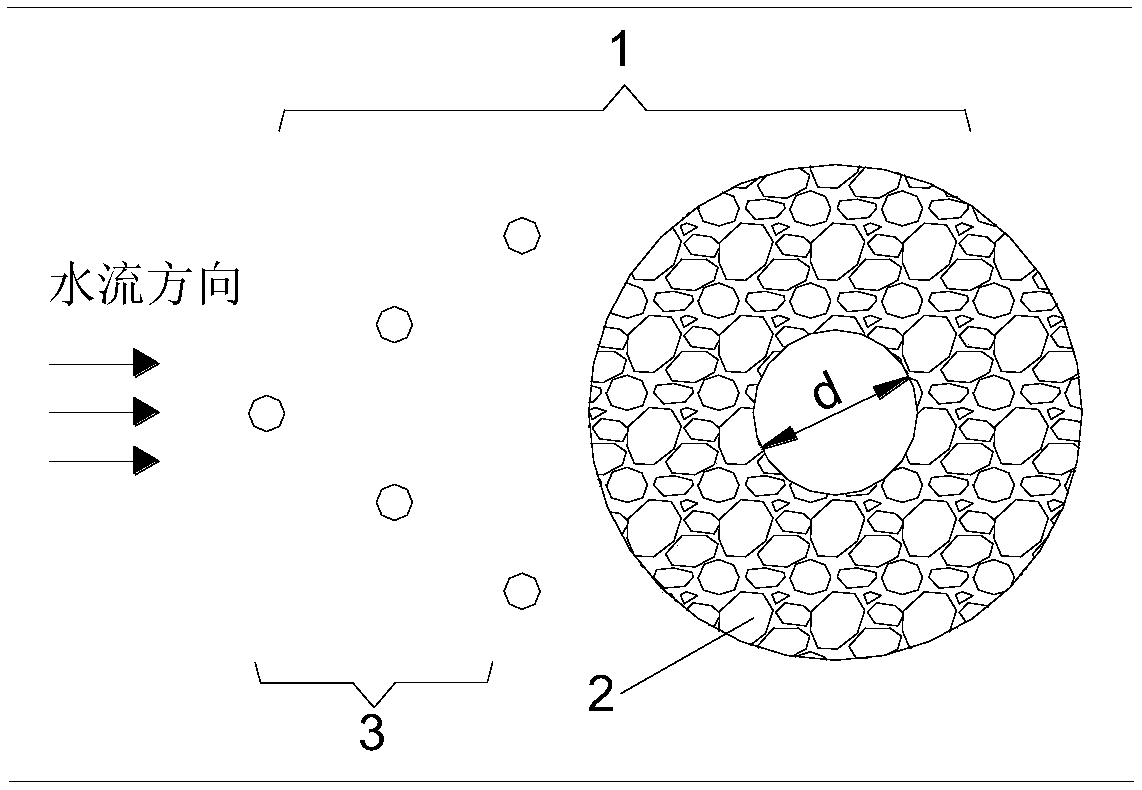

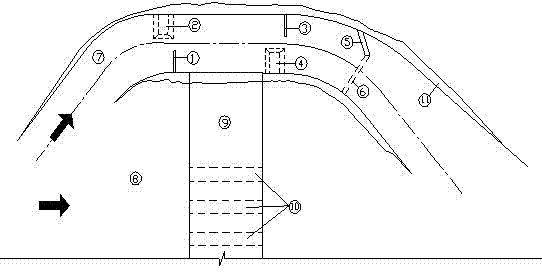

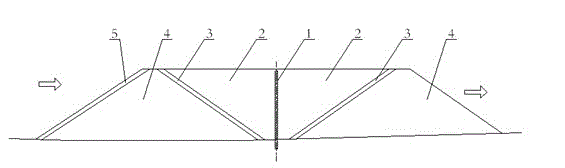

Protection method capable of combing sacrifice pile group with bottom protection ripraps to resist local scour of pier foundation

InactiveCN108442326AEasy production and constructionGood practical protectionClimate change adaptationShipping equipmentFully developedEngineering

The invention relates to a protection method capable of combing a sacrifice pile group with bottom protection ripraps to resist local scour of a pier foundation. The protection method comprises the following steps that the sacrifice pile group is arranged at the front of a bridge main pier; the bottom protection ripraps are arranged around the pier foundation; the sacrifice pile group determined based on a flow direction and a hydraulic condition is a first defense line; a triangular arrangement mode, a quincuncial arrangement mode or a height variation arrangement mode can be adopted according to practical natural conditions so as to guide a flood torrent and to dissipate the energy of the flood torrent; and the shapes, the sizes and the grades of the bottom protection ripraps are selected near the pier foundation according to a riverbed condition, so that the bottom protection ripraps cooperate with the sacrifice pile group at the front of the bridge main pier, and the effects of energy dissipation, scour reduction, bottom protection and corrosion protection are exerted. Compared with the prior art, according to the protection method, the advantages of an active protection methodand a passive protection method are fully developed, the factory preprocessing can be carried out, the field processing can also be carried out, the production and the construction are simple and convenient, the long-term use can be achieved after the one-time investment, the practical protection effect is good, and the required repair and maintenance cost is low.

Owner:TONGJI UNIV

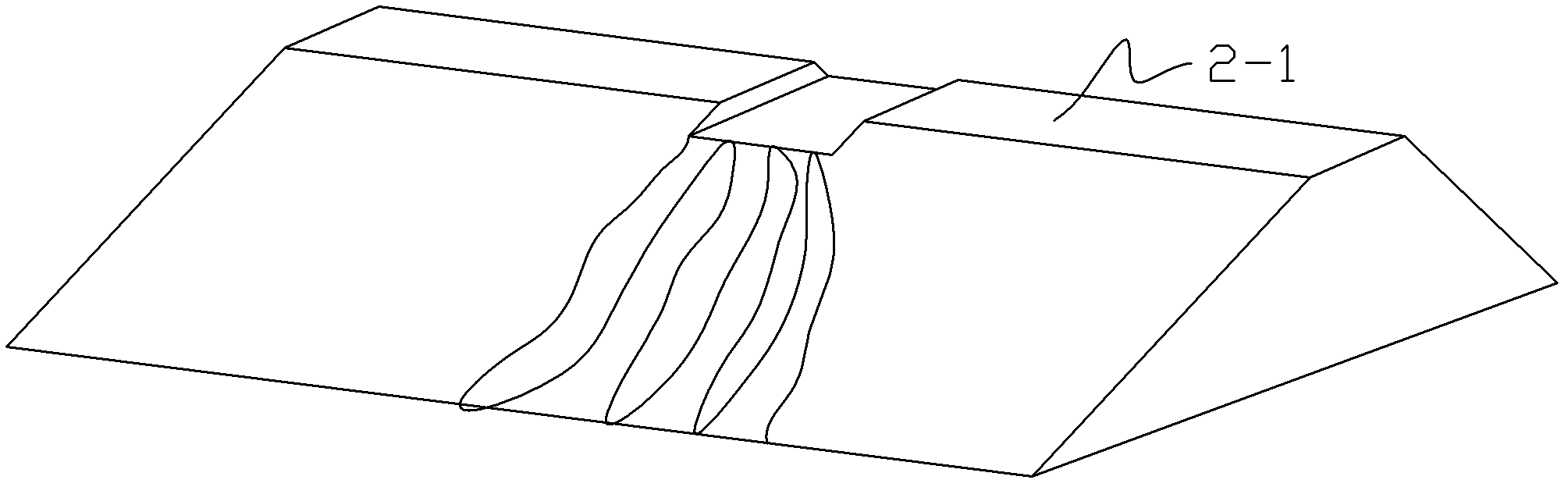

Passive-drainage emergency rescue method in case of earth-rock dam break

ActiveCN102409640AAvoid the risk of dam failureGuarantee the safety of life and propertyEarth-fill damsRock-fill damsEmergency rescueDam break

The invention provides a method for eliminating risk of dam break, and belongs to the field of flood fighting of an earth-rock dam in hydraulic engineering. In the method, a drainage channel is pre-arranged in the case of higher overtopping risk of the earth-rock dam, or a drainage channel is emergently arranged before the earth-rock dam reaches a second stage of dam break due to overtopping so as to lower the reservoir level. The method mainly comprises the following steps of: (1) determining the position of a drainage groove and the size of a drainage groove opening; (2) anchoring waterproof geotextile at the predetermined position of the drainage groove body at a downstream dam slope by a continuous anchor rod; (3) carrying out paving protection or riprap protection on a dam toe; and (4) lowering elevation of a dam crest by blasting or machinery excavation so as to form the drainage groove opening. By adopting the brand-new passive-drainage emergency rescue method in case of earth-rock dam break, the construction period is shortened, and the risk of dam failure can be prevented in the case of forced overflow of the earth-rock dam so as to guarantee safety of life and property of people in the downstream.

Owner:NANJING HYDRAULIC RES INST

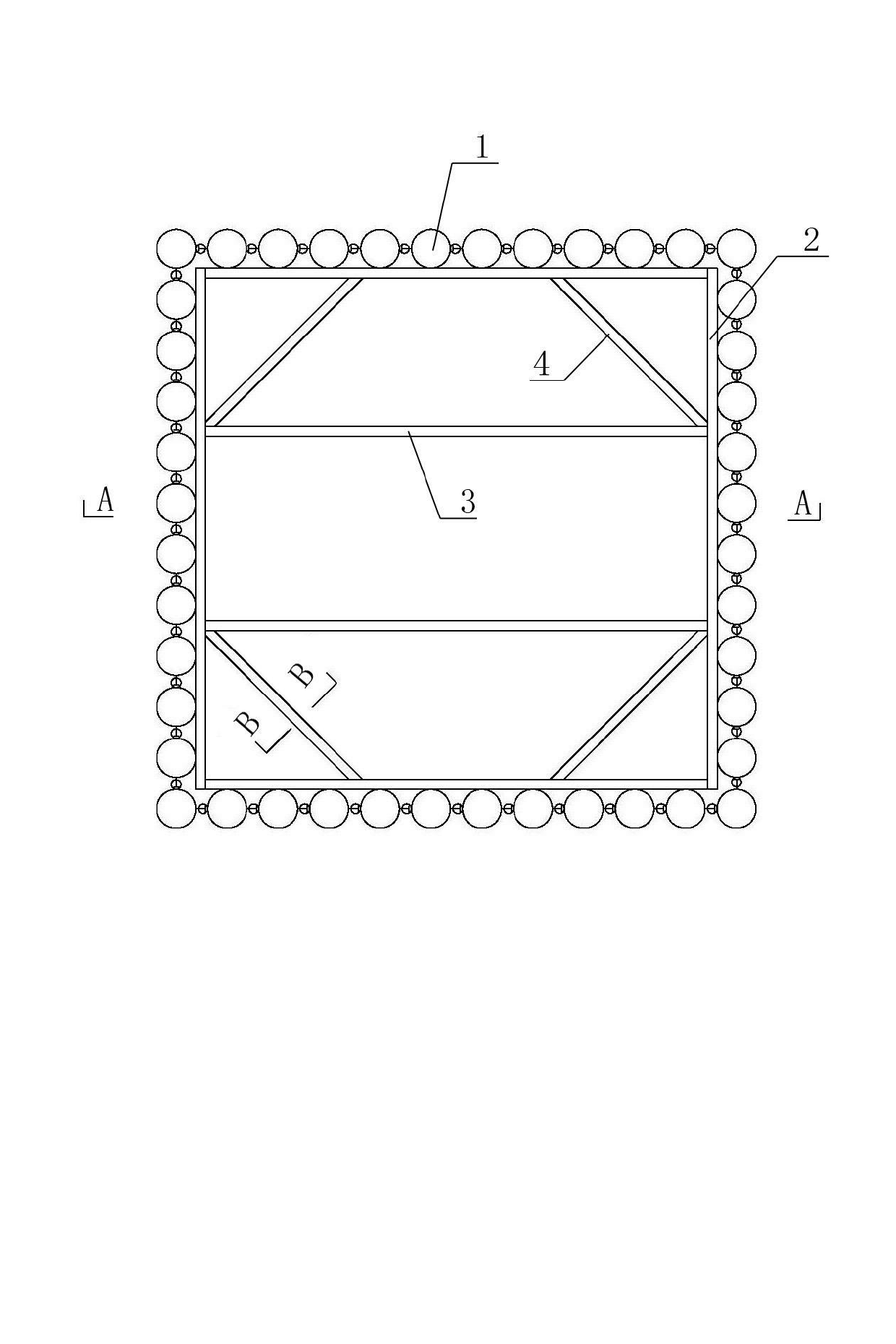

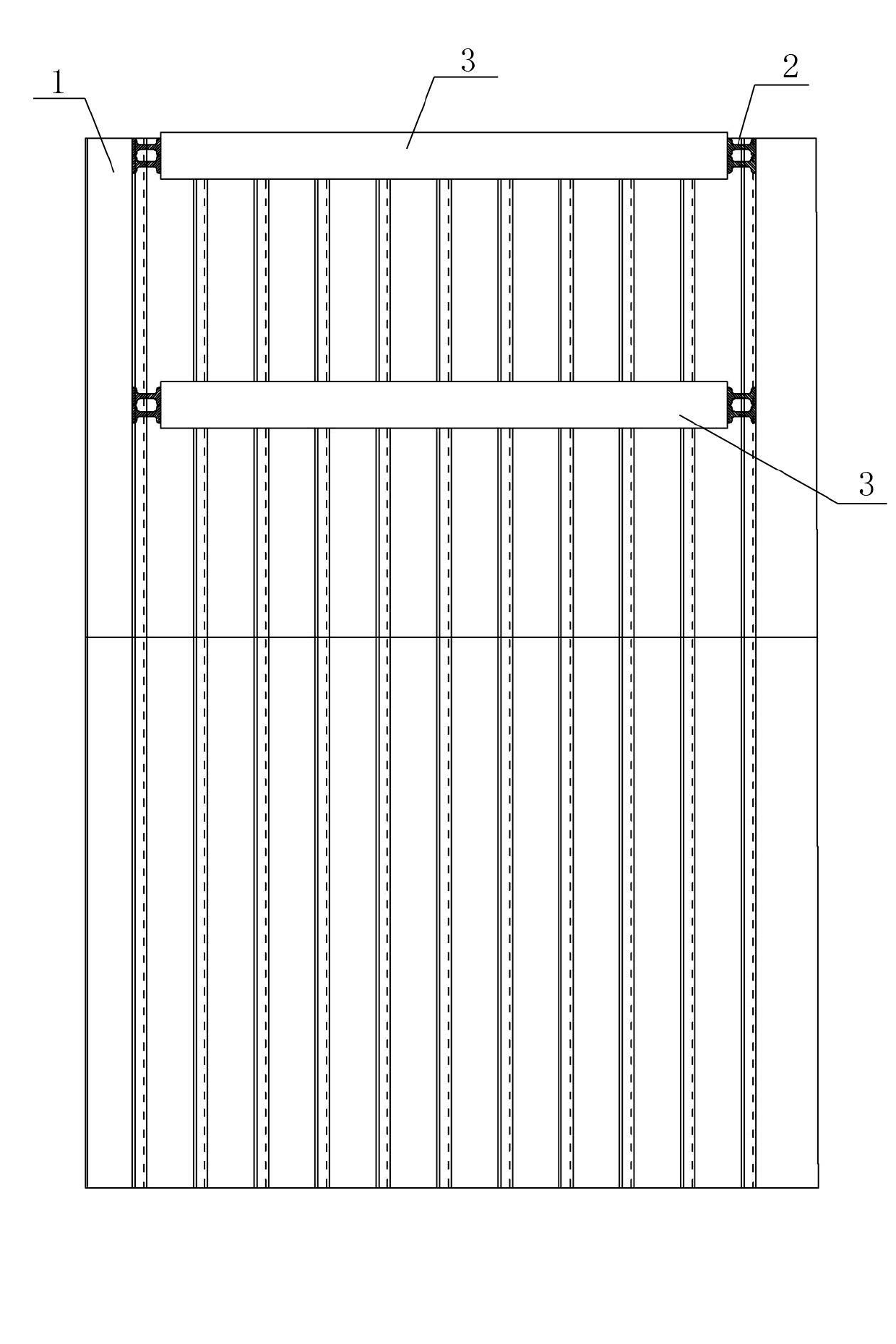

CT sealed steel pipe pile foundation pit water stop supporting device and construction method thereof

The invention relates to a CT sealed steel pipe pile foundation pit water stop supporting device and a construction method thereof. The CT sealed steel pipe pile foundation pit water stop supporting device comprises a closed water stop curtain which is formed by enclosing steel pipe piles, and a supporting structure, wherein the supporting structure comprises at least two internal enclosing purlins and internal supports; the internal enclosing purlins are tightly adhered to the internal surfaces of the steel pipe piles through the internal supports; each steel pipe pile comprises a main steel pipe and an occluded steel pipe; occluded I-steel is welded on the external surface of the main steel pipe; and the occluded steel pipe is externally tangent to the main steep pipe and is welded on the external surface of the main steel pipe through a connecting steel bar. The device has the advantages of simple structure, smart concept and good water stop and supporting effects, and can be widely applied to the water stop and supporting of a soft formation, an artificial sea reclamation formation, an artificial hydraulic reclamation riprap formation and the like with the excavating depth of 8 to 15m.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP

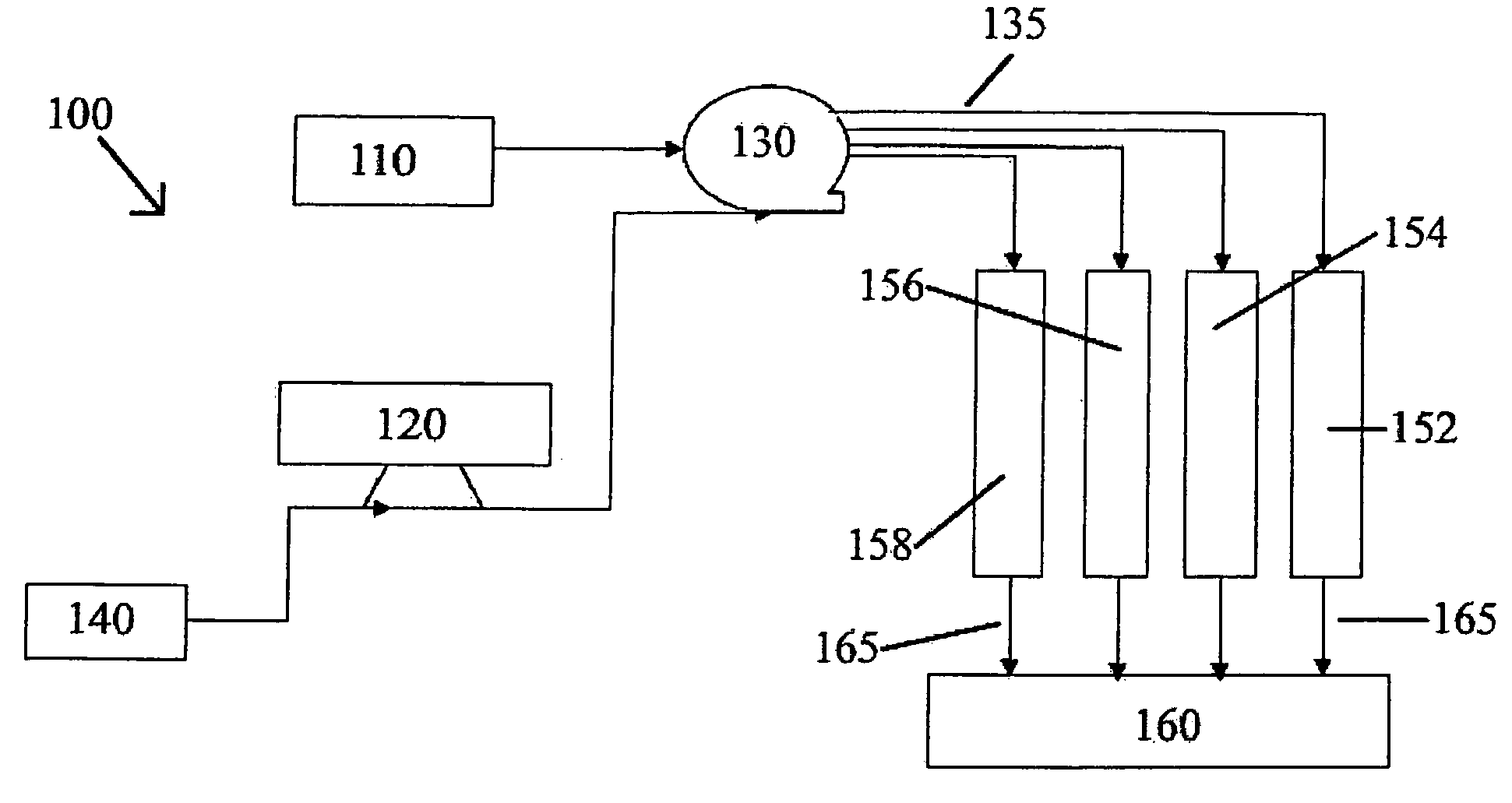

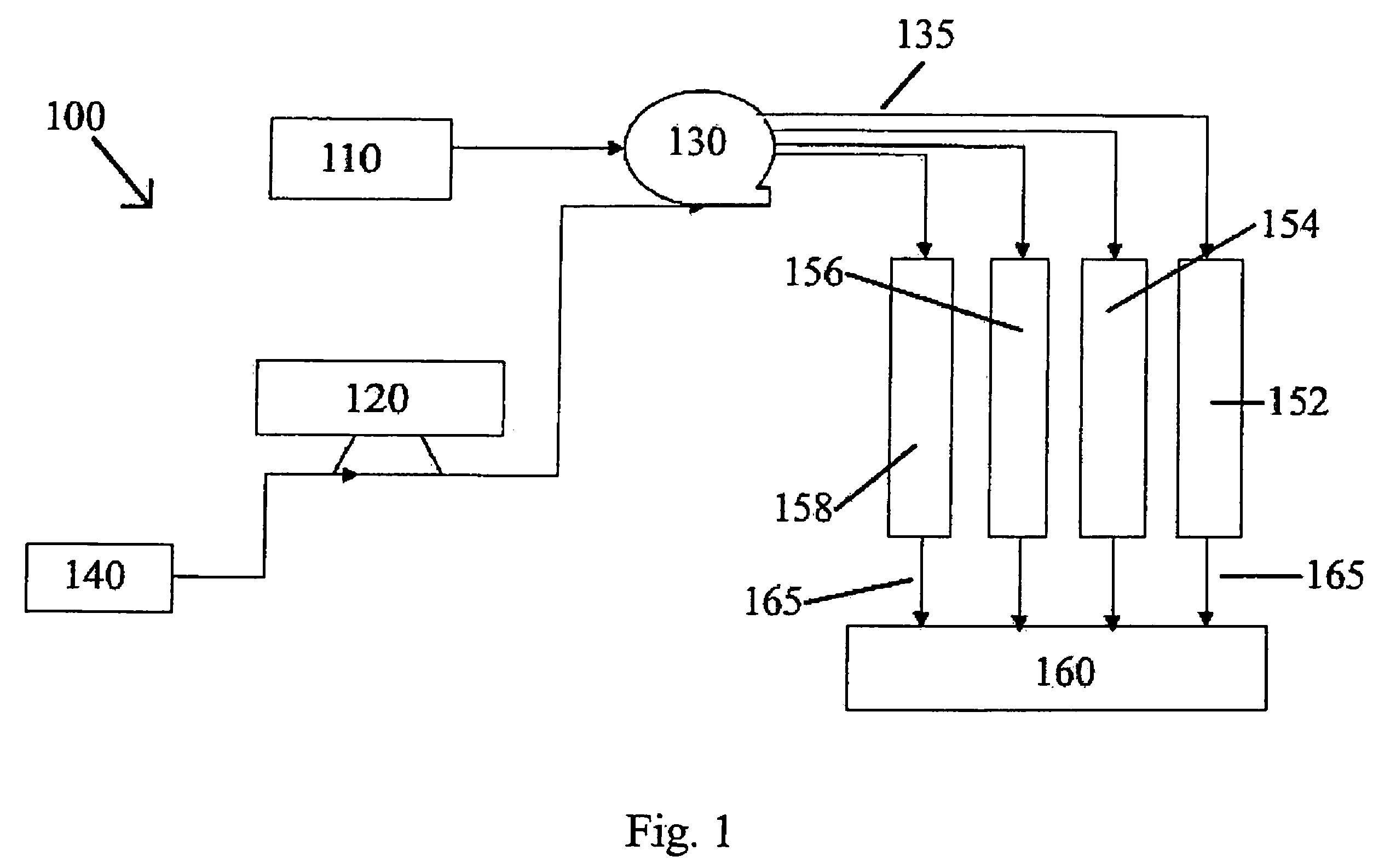

Retention/Detention Pond And Green Roof Passive Nutrient Removal Material Mixes

ActiveUS20100051540A1Improve sustainabilityIncrease flexibilityCalcareous fertilisersWater cleaningFiltrationEngineering

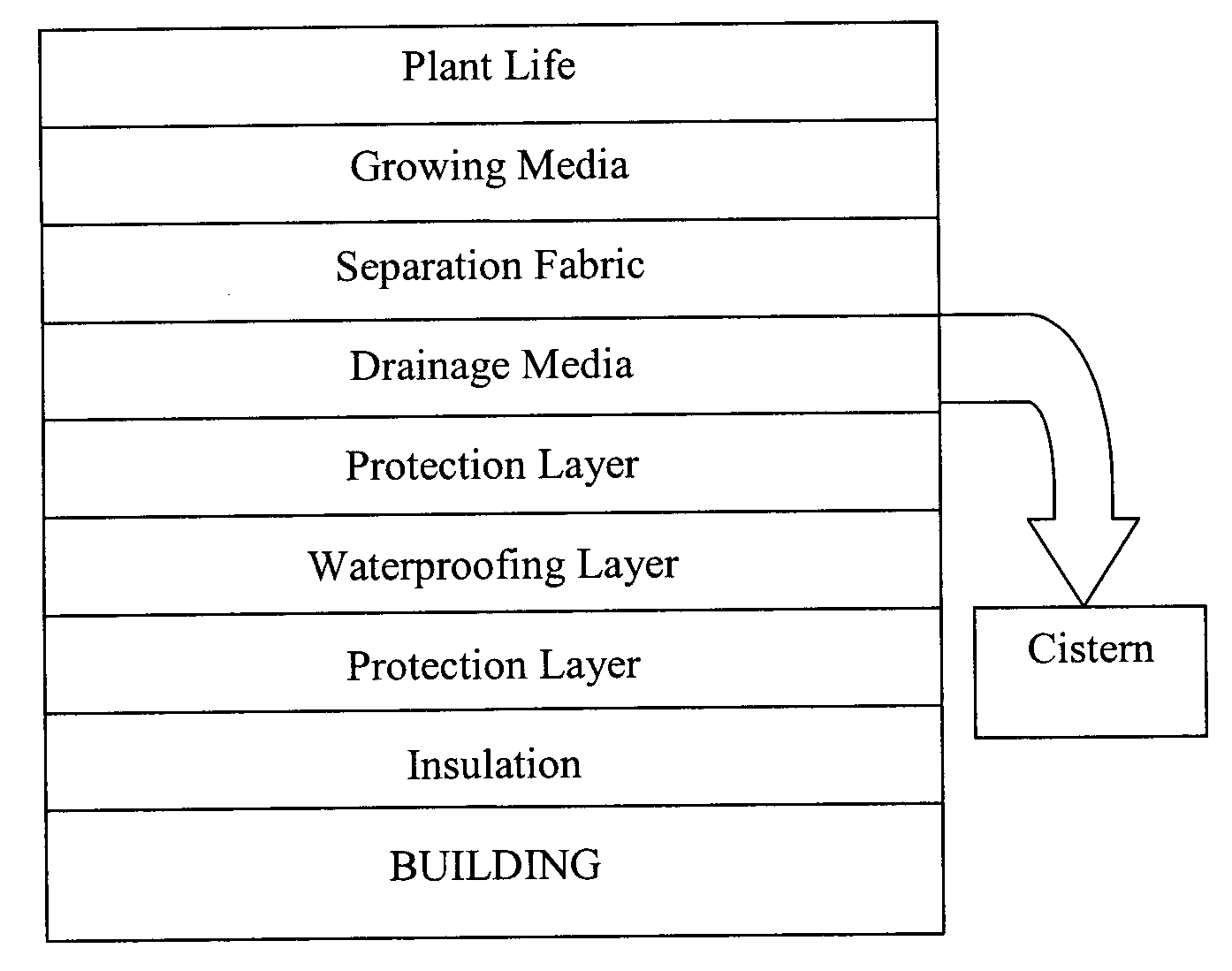

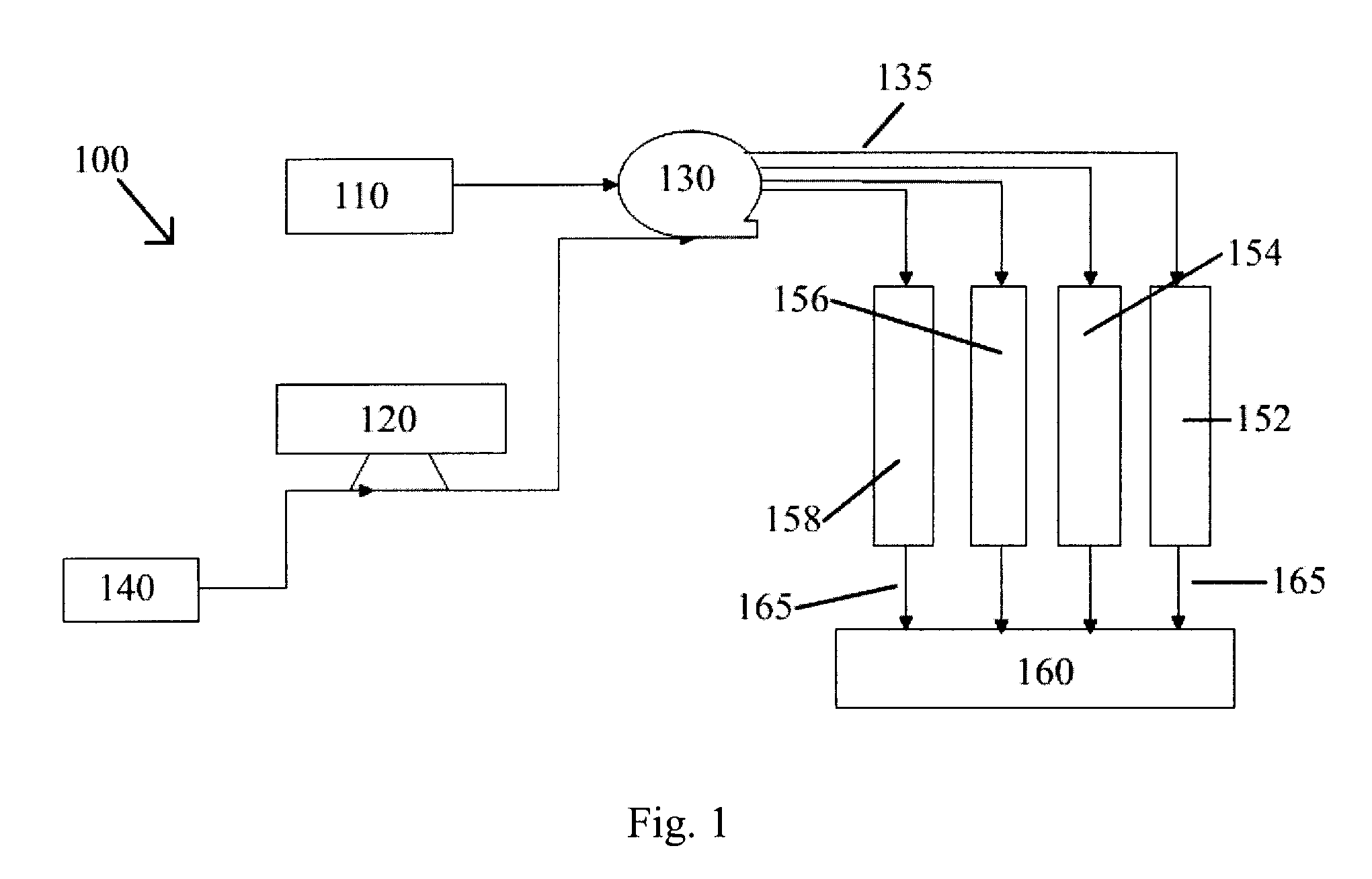

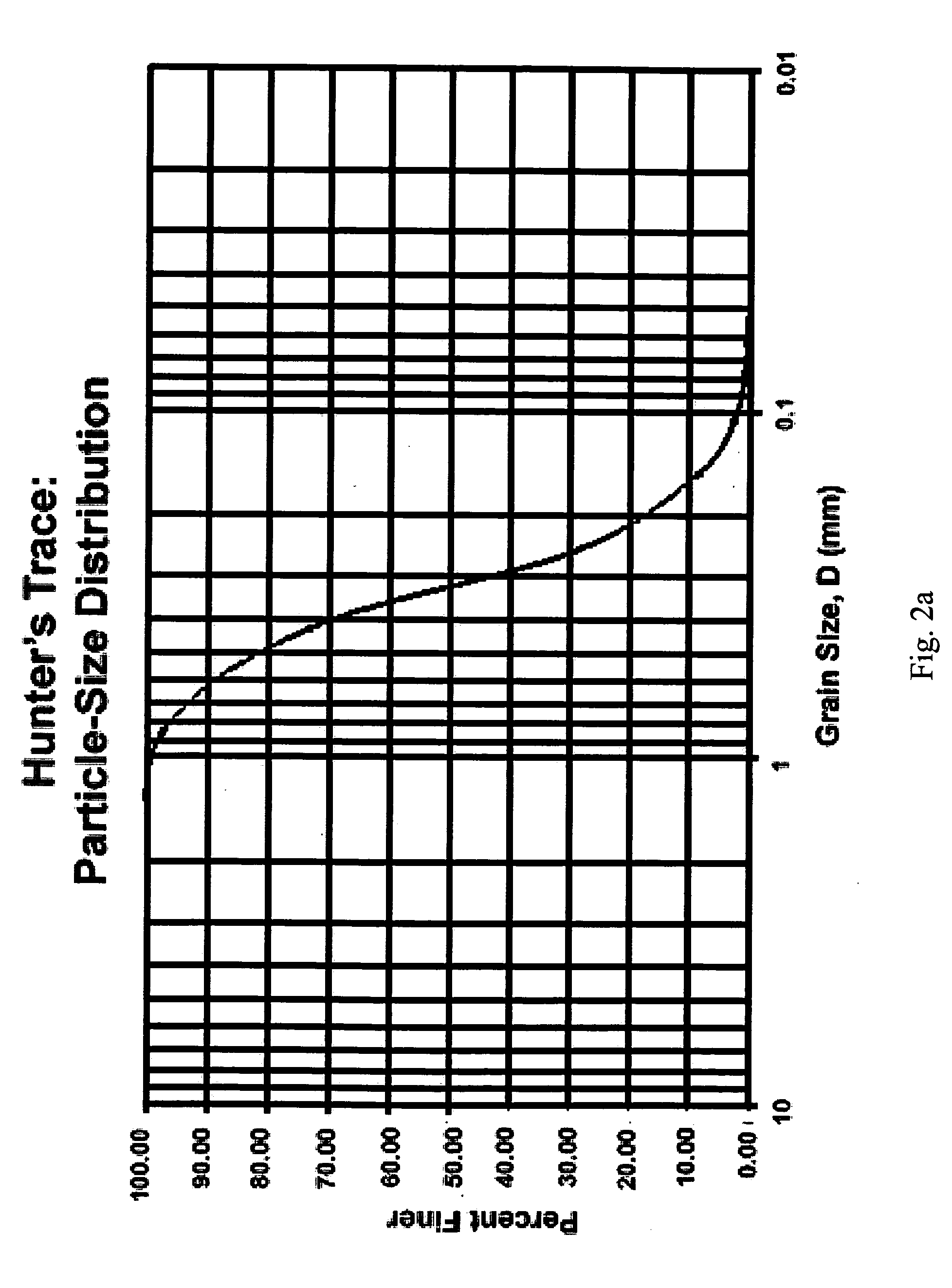

Materials, compositions, substances and methods and systems for stormwater treatment in wet ponds, dry ponds and a green roof system. A first embodiment provides in-situ treatment unit within the retention pond by withdrawing the stored stormwater to circulate the stored stormwater into the in-situ treatment unit to sorb nitrogen from the stored stormwater. A second embodiment provides uses a riprap apron, a perforated riser located at the bottom of the riprap apron and a goetextile media encased in a sorption media jacket around the perforated riser. A third embodiment provides a green roof stormwater treatment system that includes protection for waterproofing and insulating the roof, a pollution control media layer for filtration and sorption of solids and dissolved materials found in stormwater, a growing media for growing vegetation, and a cistern to store the runoff stormwater between irrigation events. The green roof system includes recycling runoff stormwater by irrigating the green roof with the stored stormwater.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

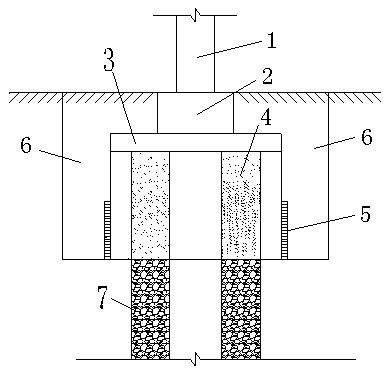

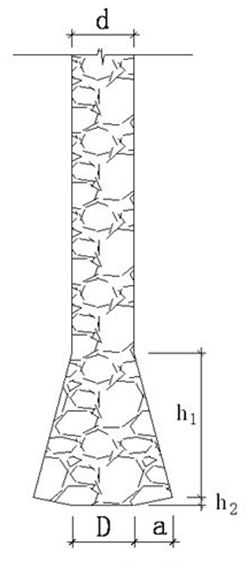

Method for consolidating existing building foundation

InactiveCN102071679AMeet mechanical needsReduce usageBulkheads/pilesSoil preservationStructural engineeringSoil horizon

The invention belongs to the field of consolidating existing building foundation, in particular relates to a method for consolidating the existing building foundation of which the upper structure cannot provide large counter-force. In the method, riprap concrete is adopted as a main material of a pile; holes are dug manually; and block stones or cobbles with the diameter of between 2 and 20cm are thrown into the dug holes in a mechanical or manual mode, and the poured concrete can be compactly filled in gaps generated in a block stone settling path at any time so as to form a compact riprap concrete pile with higher strength. Therefore, the pile end can be placed in a better bearing stratum on the deep part of the foundation, and complete or partial load of a building is transferred to the stratum to fulfill the aims of reducing additional stress of foundation soil under the substrate, reducing settlement and consolidating.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

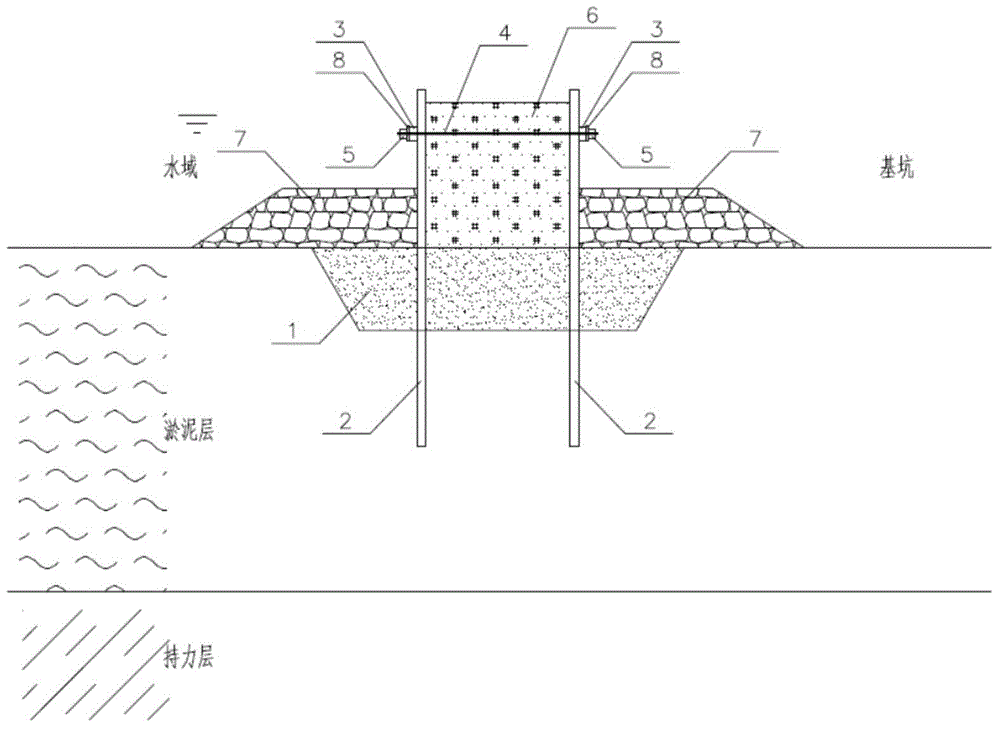

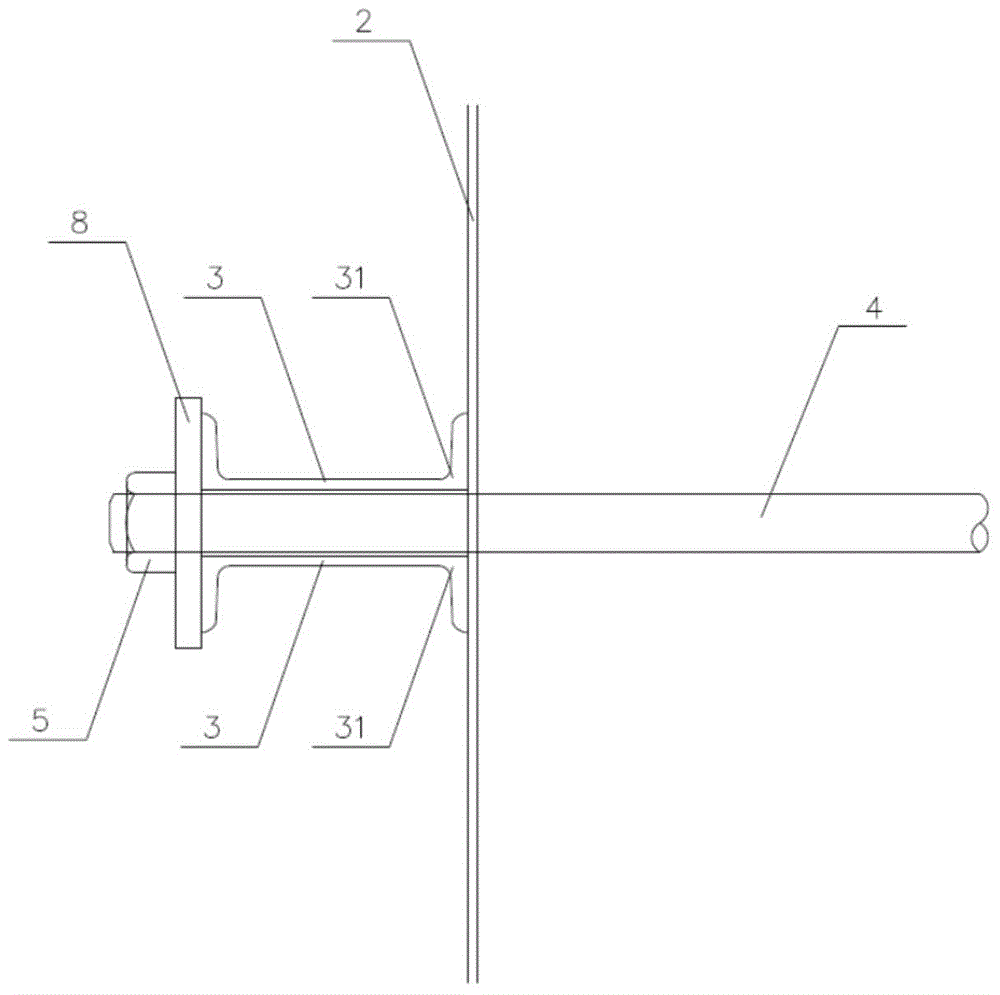

Seaside ultra-deep soft foundation floating type steel sheet pile cofferdam and construction method thereof

InactiveCN104631476AImprove bearing capacityIncrease stiffnessFoundation engineeringSheet steelSurface layer

The invention discloses a seaside ultra-deep soft foundation floating type steel sheet pile cofferdam and a construction method thereof. The cofferdam comprises two rows of steel sheet pile walls, and the space between the two rows of steel sheet pile walls is filled with backfill to form a wall-soil-wall dam body structure. A replacement sand layer is arranged on a foundation of the cofferdam, and the two rows of steel sheet pile walls penetrate through the replacement sand layer and are inserted in a mud layer side by side. The outer side of the steel sheet pile walls is filled with a riprap compressing body, and the riprap compressing body and the replacement sand layer together form a soil and rock compressing structure. Horizontal steel sheet piles are arranged between the two rows of steel sheet pile walls and perpendicular to the axial direction of the cofferdam. The cofferdam can float on the ultra-deep mud layer, the defect that in the prior art, steel sheet piles need to be inserted in a supporting layer to ensure stability is overcome, the cofferdam is not affected by the thickness of mud on the surface layer of the foundation, and the application range is wide. The seaside ultra-deep soft foundation floating type steel sheet pile cofferdam is high in stability, short in construction cycle and low in engineering manufacturing cost, construction quality is easily guaranteed and, the construction difficulty is low.

Owner:浙江省水利水电勘测设计院有限责任公司

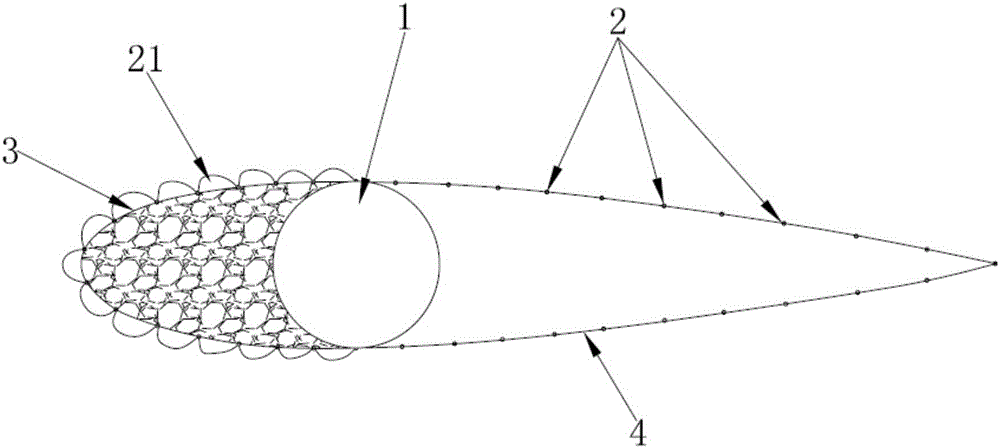

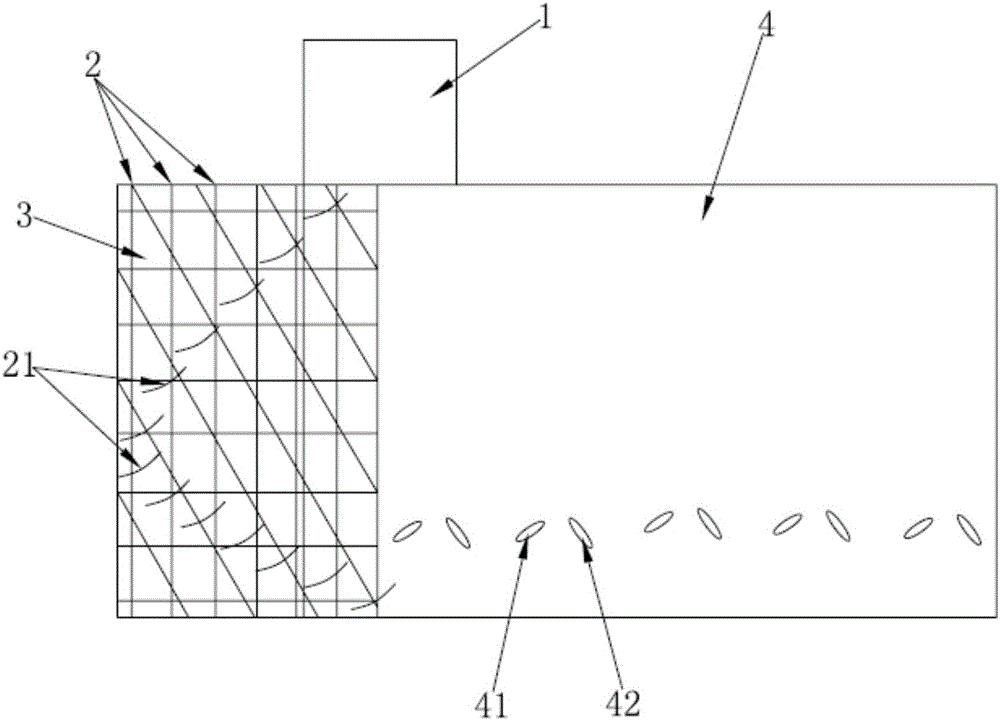

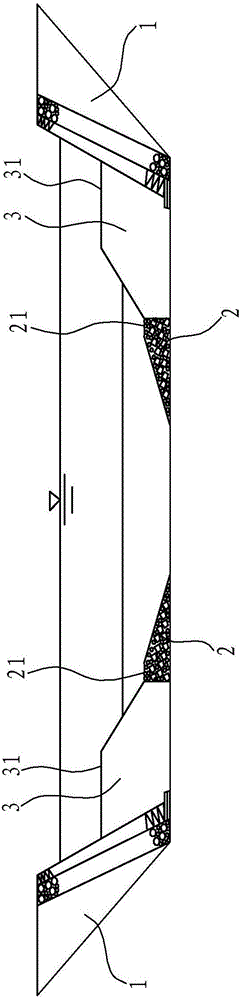

Bridge pier anti-collision and anti-scouring device

InactiveCN106012812APrevent washoutApplicable supplementary protectionClimate change adaptationBridge structural detailsWater flowStructural engineering

The invention discloses a bridge pier anti-collision and anti-scouring device. The bridge pier anti-collision and anti-scouring device comprises a bridge pier body (1), multiple fixing piles (2), a cage frame (3) and an elastic plate (4), wherein the multiple fixing piles (2) surround the outer side of the bridge pier body (1); the fixing piles (2) are provided with flow blocking pieces (21); the steel cage frame (3) is fixed to the fixing piles (2) which are arranged at a water facing side of the bridge pier body (1); the cage frame (3) is filled with a first anti-collision body formed by irregular riprap; the elastic plate (4) is fixed to the fixing piles (2) arranged at a water backing side of the bridge pier body (1), so that a second anti-collision body is formed; water inlet holes are formed in the elastic plate(4). According to the bridge pier anti-collision and anti-scouring device disclosed by the invention, a scouring action on a bridge pier by water flow can be avoided, a collision action on the bridge pier by a collision body in water can also be avoided, the structure is simple, the cost is low, and the bridge pier anti-collision and anti-scouring device not only is suitable for the protection of newly-constructed bridge pier, but also is suitable for complementary protection of a constructed bridge pier.

Owner:CHONGQING JIAOTONG UNIVERSITY

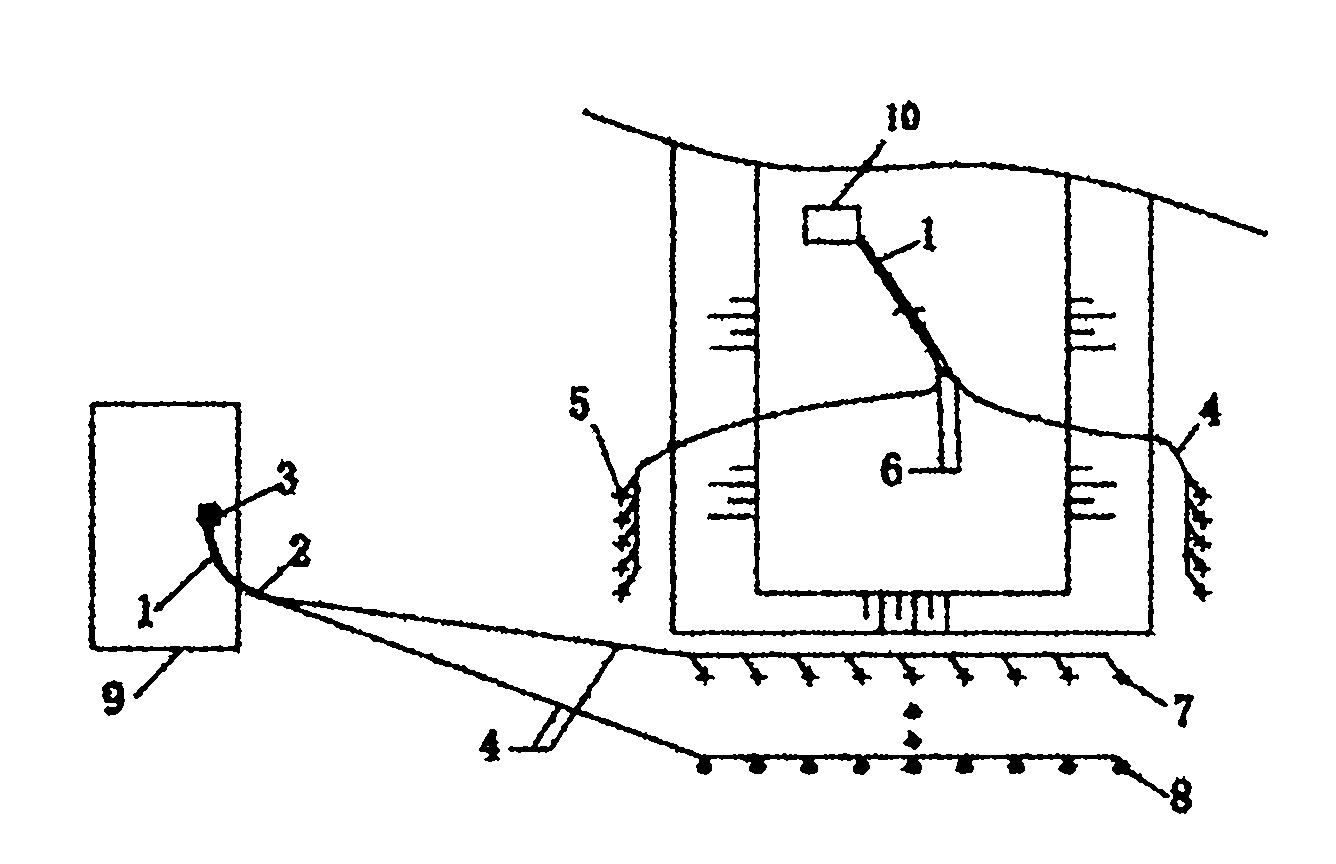

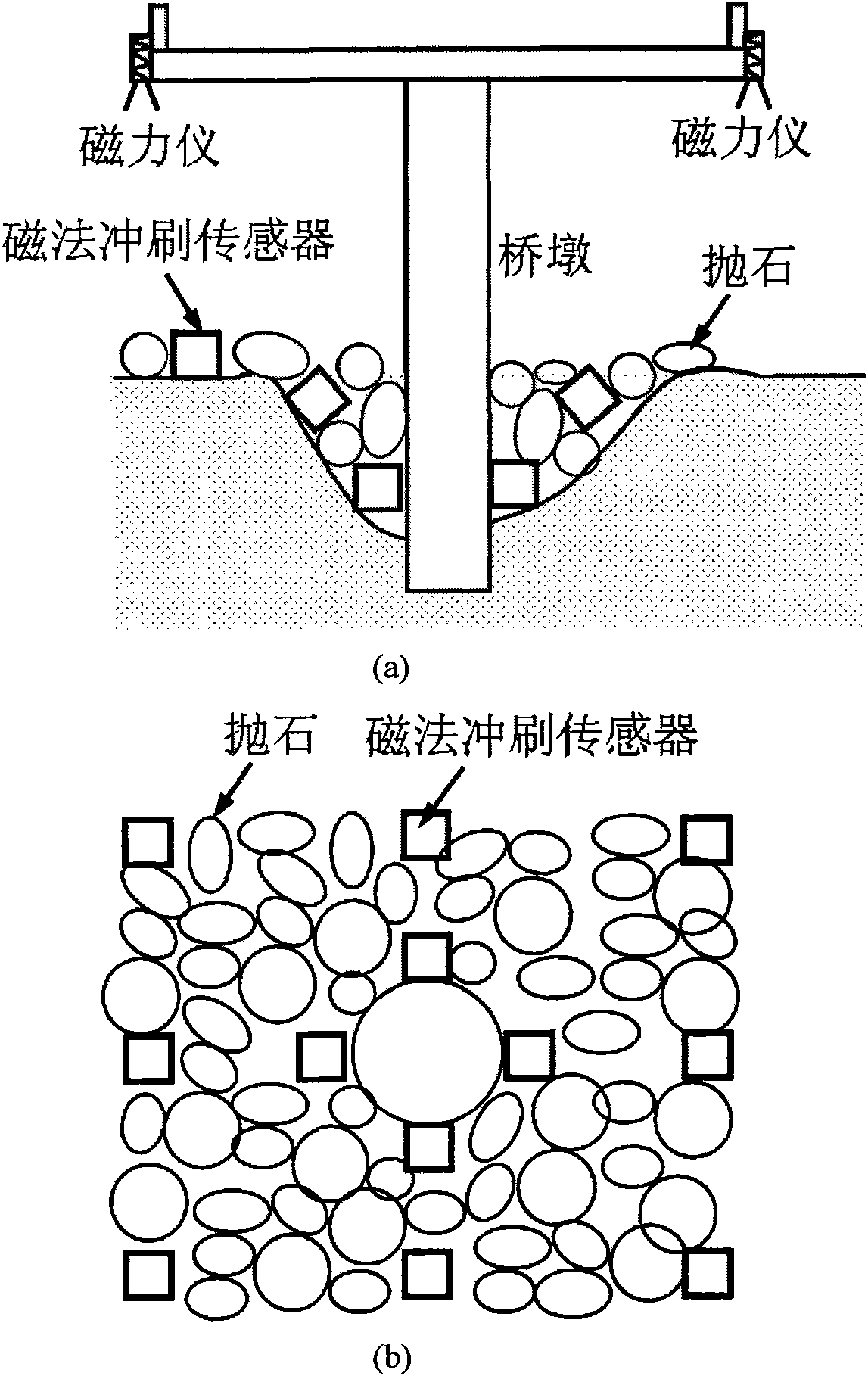

Magnetic prospecting-based erosion monitoring method

InactiveCN102071661AImprove waterproof performanceImprove corrosion resistanceFoundation testingHydraulic engineering apparatusMonitoring systemEngineering

The invention discloses a magnetic prospecting-based erosion monitoring method, which belongs to the technical field of structure safety monitoring. The method is characterized by comprising the following steps of: manufacturing a magnetic erosion sensor with self-sensing features by directly embedding a ferromagnetic substance serving as a sensor element into a natural stone or a concrete precast block and encapsulating the ferromagnetic substance; structuring an erosion monitoring system by compounding the sensor and a magnetometer; when monitoring erosion, prearranging or throwing the magnetic erosion sensor together with protection riprap together in an area of which a structural base is easily eroded; detecting the position change information of the magnetic erosion sensor by adopting the magnetometer; and monitoring the erosion state of the structural base in real time. The method has an effect and an advantage of avoiding an influence on structure erosion monitoring caused by severe environmental factors such as silt stratification thickness, flood and the like, and has the outstanding advantages that the method is simple in operation, the test precision is high, the performance is stable and the like, and can be widely used in structure erosion monitoring and protection of major projects such as reservoir dams, river dikes, bridge and ocean platforms and the like.

Owner:DALIAN UNIV OF TECH

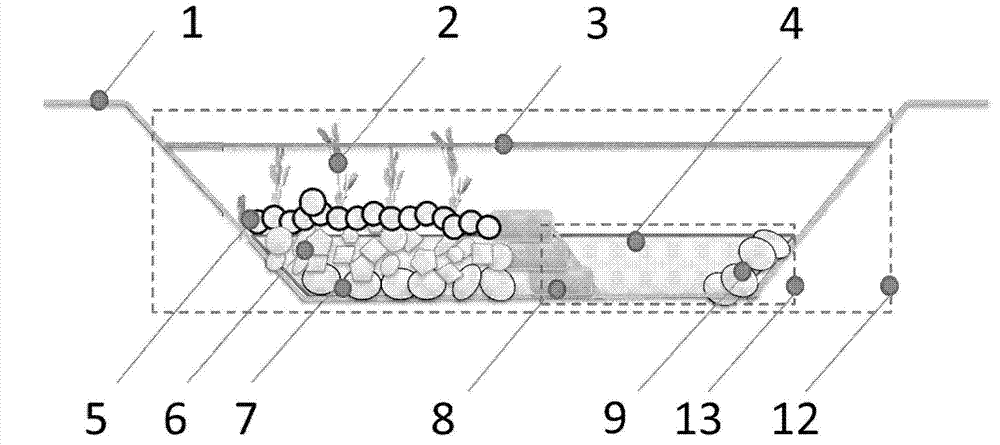

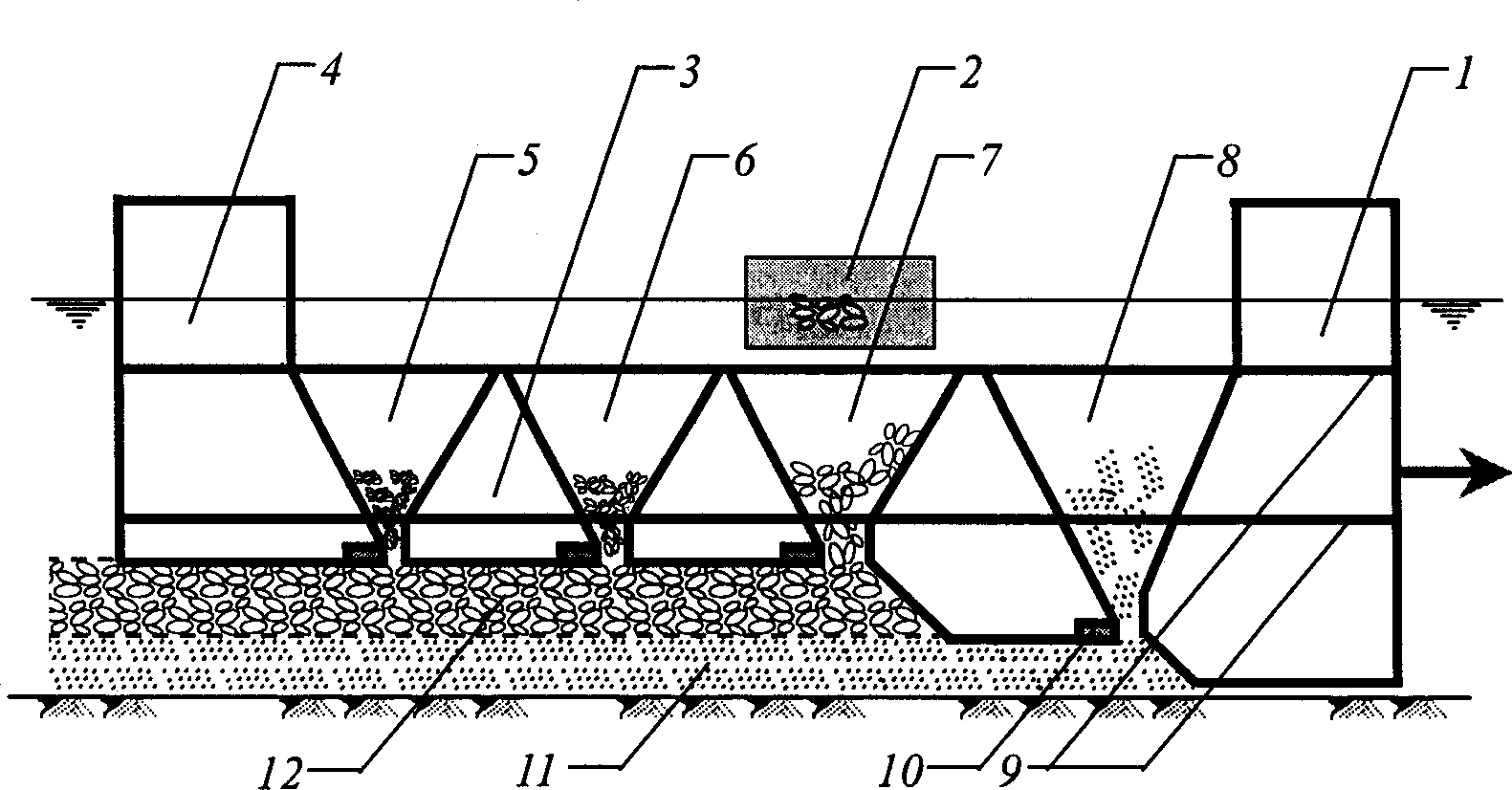

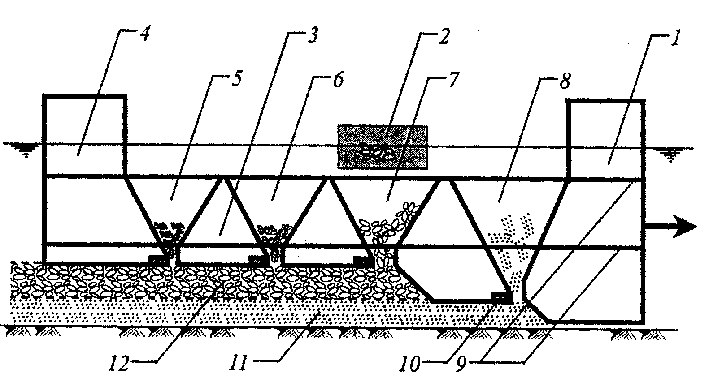

Simulative nature river course water purification system

ActiveCN102730823ADoes not affect flood dischargeEnsure flood safetySustainable biological treatmentBiological water/sewage treatmentMain channelWater quality

The invention discloses a simulative nature river course water purification system. A river section is based on the trapezoidal compound section, multiple segments of filler purification regions are arranged at two sides in a main channel in a staggered manner so as to form sub-channels meandering on a plane, and the height of the filler purification region is higher than the low water level of the river; the filler purification region is filled with ripraps, broken stones and surface fillers from the bottom to the top; and a riprap banket is arranged between each two segments of filler purification regions. The simulative nature river course water purification system provides diversified habitat environments while strengthening the self cleaning capacity of the river and improving the river water environment quality, and plays an active role in repairing the biological diversity recovery of the stream segment. The simulative nature river course water purification system has the following remarkable advantages that the system operates in a passive unpowered manner, can improve the flow state, has no influence on the flood discharge of the main stream in the flood season, and has the advantages in multiple aspects, such as excellent water purification and ecological restoration effect and so on, especially, the system is suitable for the small rivers with low sediment amount and low flow velocity, or the scenic rivers.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

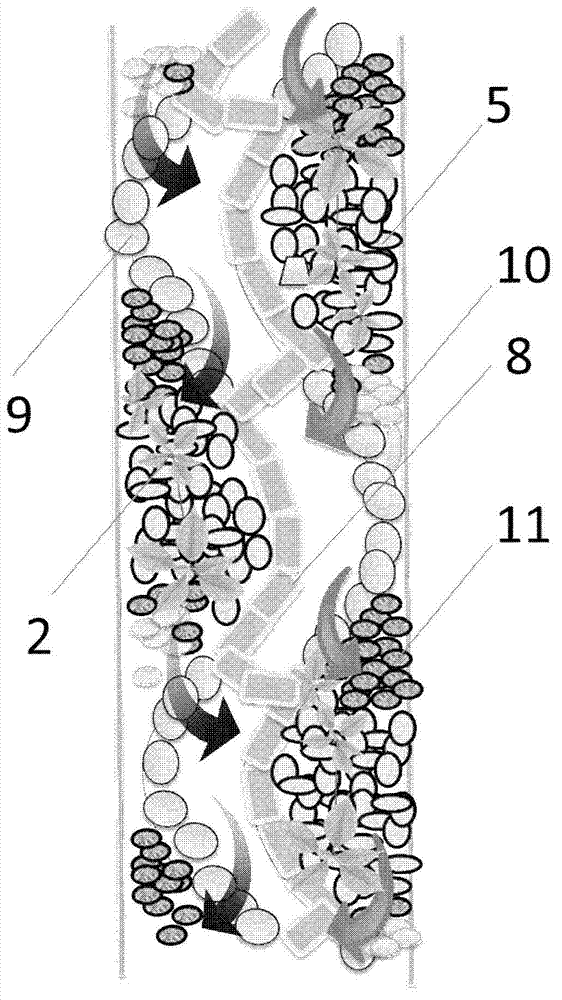

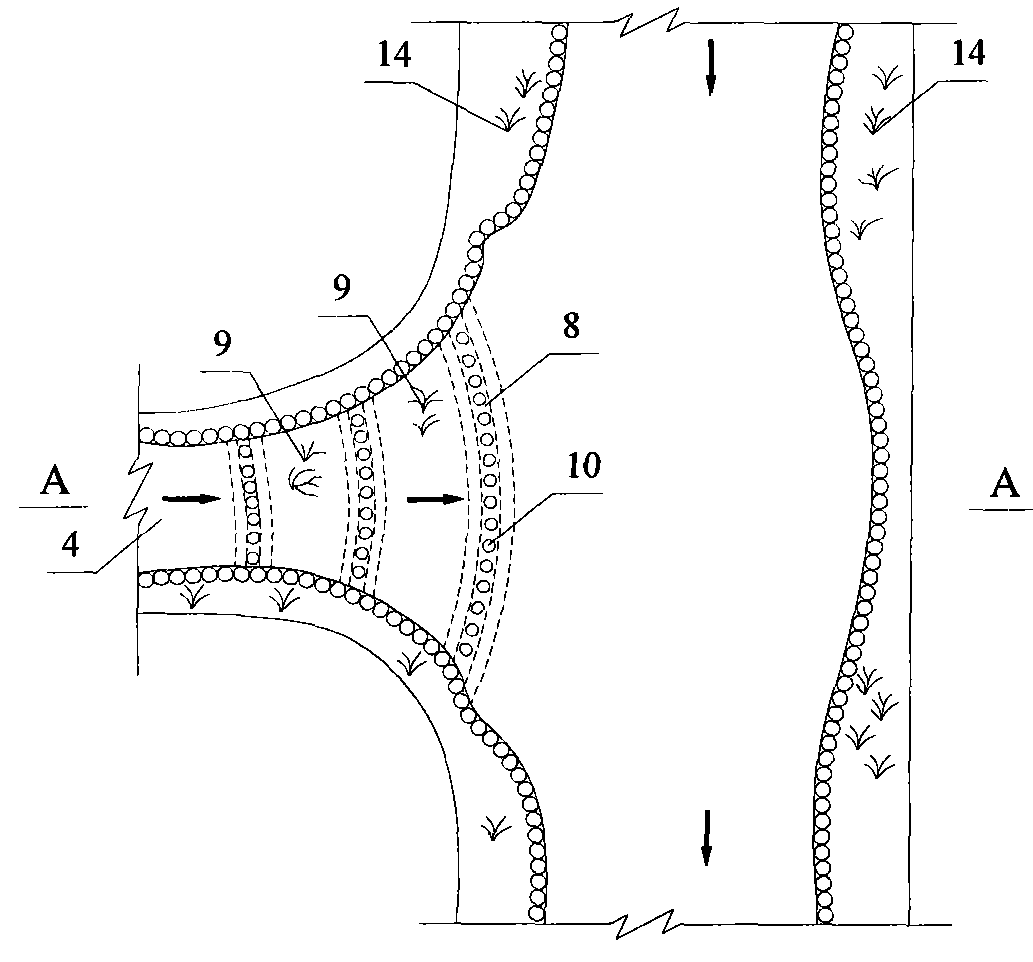

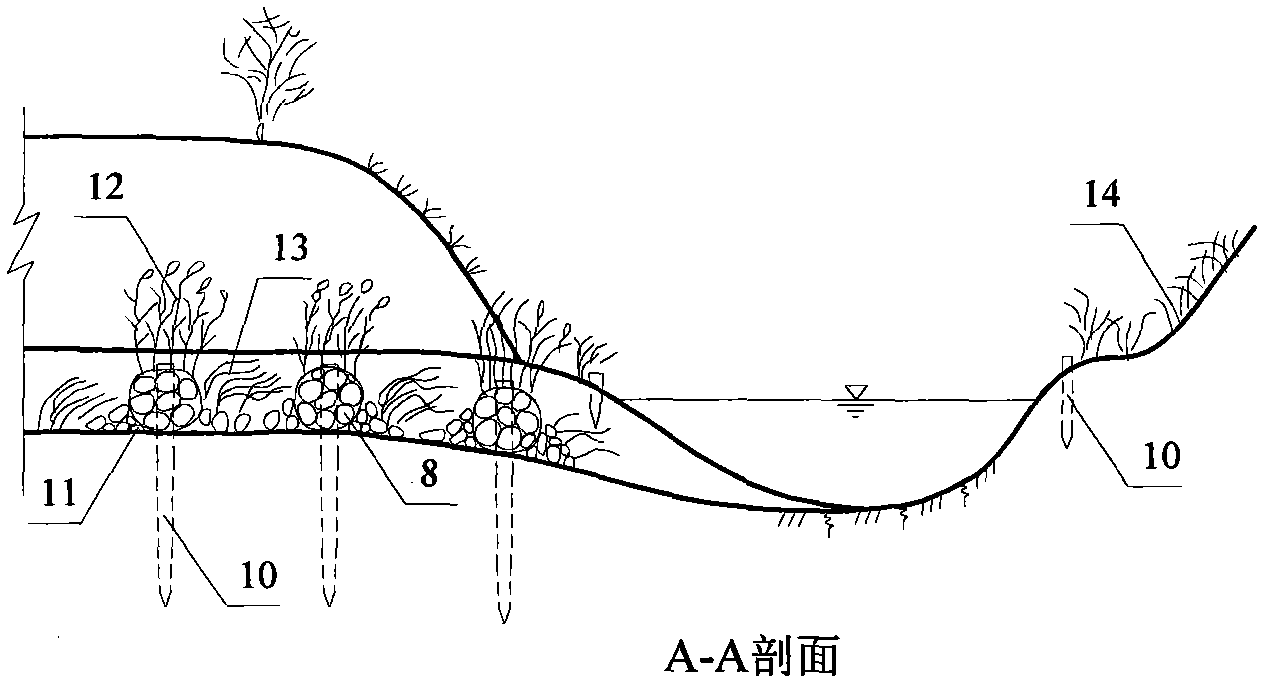

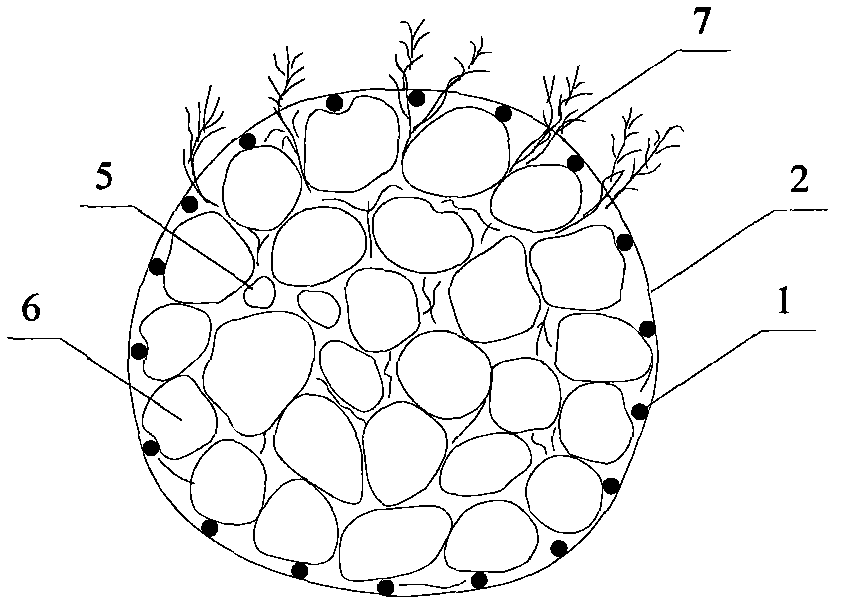

Multilayer vegetation zone water quality in situ purification method for highly polluted tributary inlet

InactiveCN102139961AImprove the water environmentImprove cold resistanceTreatment with aerobic and anaerobic processesSustainable biological treatmentPurification methodsWater quality

The invention relates to a multilayer vegetation zone water quality in situ purification method for a highly polluted tributary inlet, which is characterized in that reinforcing steel bars with the diameter of 6 and steel wires are manufactured into gabion frames with the diameter of about 1m; one end of each gabion frame is sealed; the other end of each gabion frame is movable; rock blocks, gravels and soil are added to the gabion frames; emergent aquatic plant root systems such as reeds, acorus calamus and the like are planted in soil; and each movable end is sealed and is manufactured into a gabion body with the length which is determined according to the river width of the tributary inlet to be purified. A plurality of gabion bodies are combined by timber piles and fixed at the tributary inlet to be repaired; ripraps are used for side pressing; submerged plants such as tape grasses, waterweeds an the like are planted between two gabion bodies so as to form a multilayer vegetation zone water quality in situ purification system which takes the plurality of gabion bodies and emergent aquatic plants on the gabion bodies as the main parts and is assisted by the submerge plants among the gabions. The method has the advantages of gradually purifying water body of the highly polluted tributary inlet under of physical chemistry and biological functions including matrix interception, micro-biological degradation, plant system absorption, root system adsorption and the like and improving water environments of the tributary inlet so as to provide effective guarantee for the quality of water flowing into a main stream.

Owner:HOHAI UNIV

Passive nutrient removal material mixes

ActiveUS7824551B2Improve sustainabilityIncrease flexibilityCalcareous fertilisersSolid sorbent liquid separationFiltrationStormwater treatment

Materials, compositions, substances and methods and systems for stormwater treatment in wet ponds, dry ponds and a green roof system. A first embodiment provides in-situ treatment unit within the retention pond by withdrawing the stored stormwater to circulate the stored stormwater into the in-situ treatment unit to sorb nitrogen from the stored stormwater. A second embodiment provides uses a riprap apron, a perforated riser located at the bottom of the riprap apron and a geotextile media encased in a sorption media jacket around the perforated riser. A third embodiment provides a green roof stormwater treatment system that includes protection for waterproofing and insulating the roof, a pollution control media layer for filtration and sorption of solids and dissolved materials found in stormwater, a growing media for growing vegetation, and a cistern to store the runoff stormwater between irrigation events. The green roof system includes recycling runoff stormwater by irrigating the green roof with the stored stormwater.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

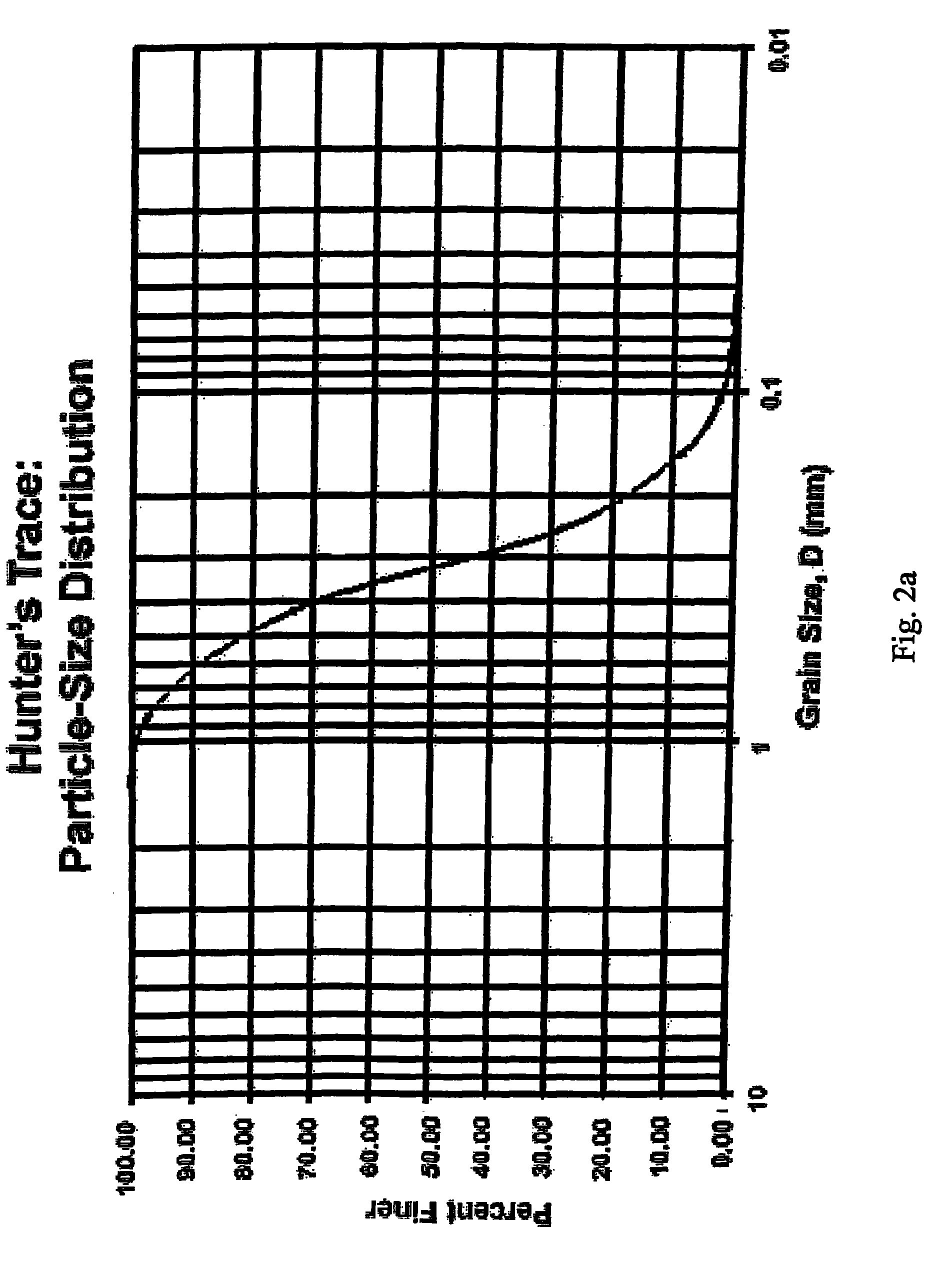

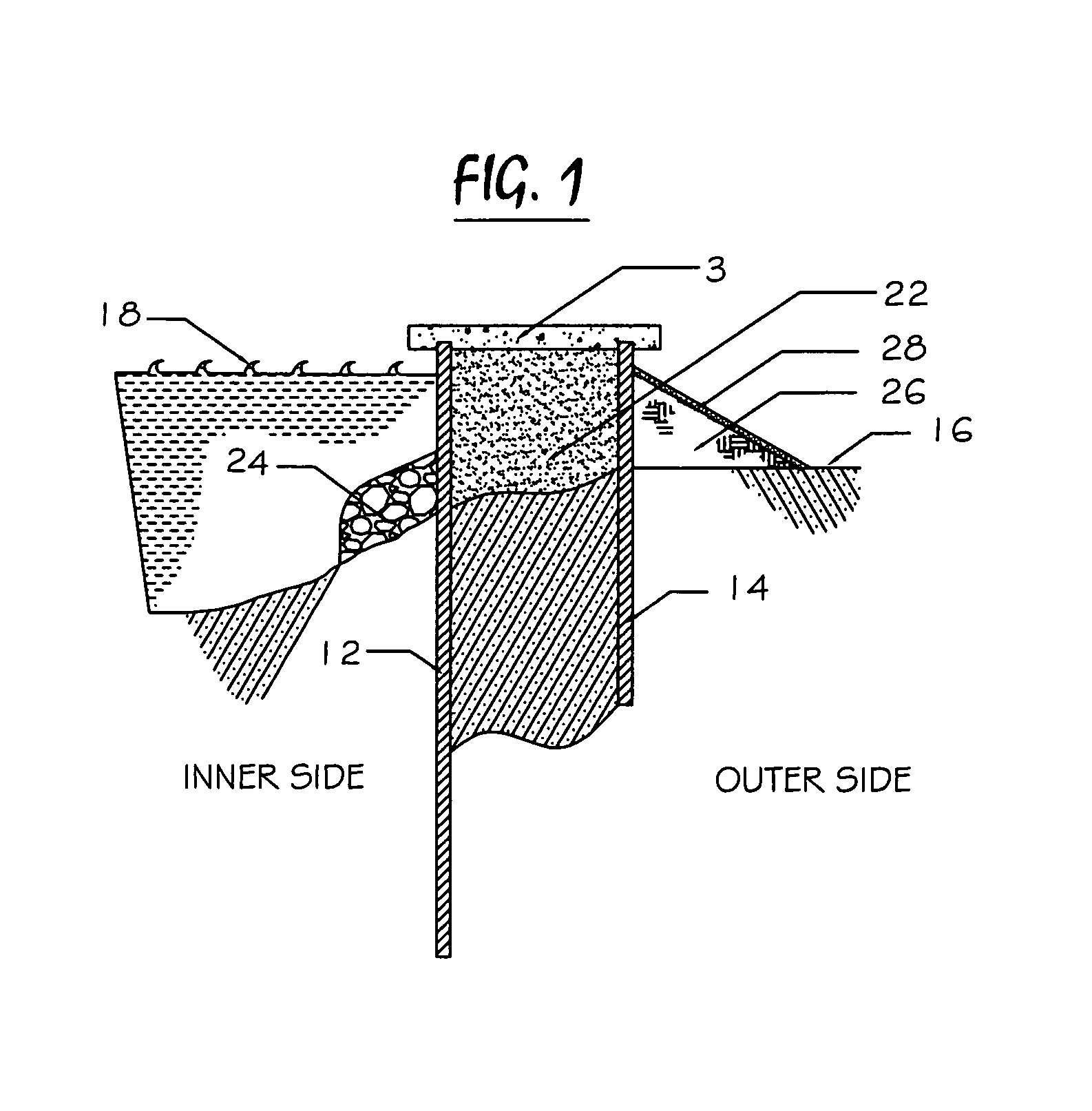

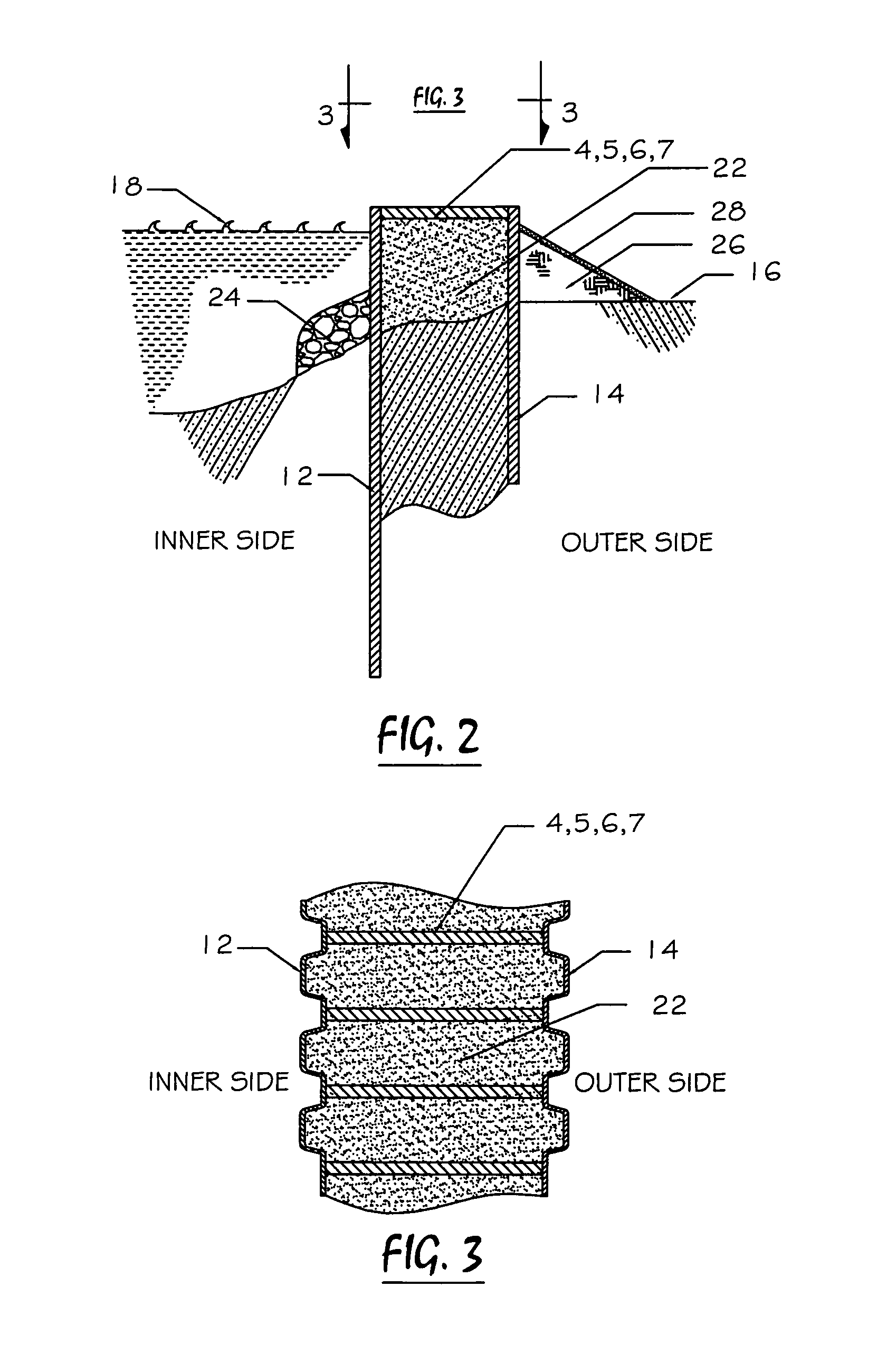

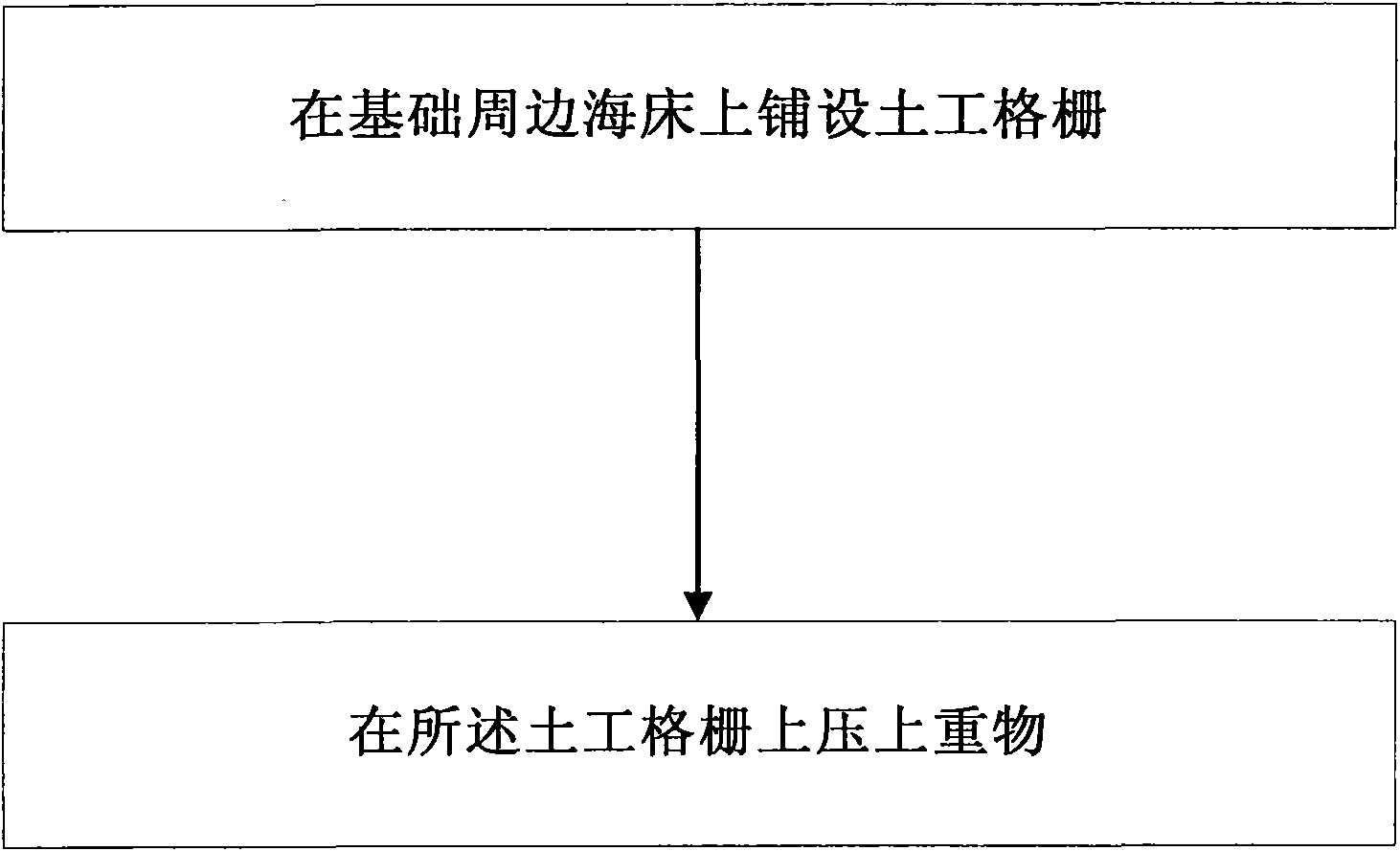

Double-wall protection levee system

A double-wall protection levee floodwall has a pair of piles placed into soil at the bank at the edge of a water body or formed by a levee. The piles of the pair are oriented parallel to each other, are spaced apart transversely, and are rigidly connected together by a connector so that when the force of rising water or a water-borne object is applied to a face of one of the piles, a force couple develops that places one of the piles in tension and the other pile of the pair in compression. The distance between the force-coupled piles and the depth of the piles in the soil provide the ability to withstand predetermined transverse forces while conserving materials and space. Fill material, riprap, earthen support, and erosion control matting can improve the function of the double-wall floodwall. Multiple pairs of piles can be longitudinally placed to form a continuous floodwall.

Owner:SCANDALIATO SAMUEL ZENGEL

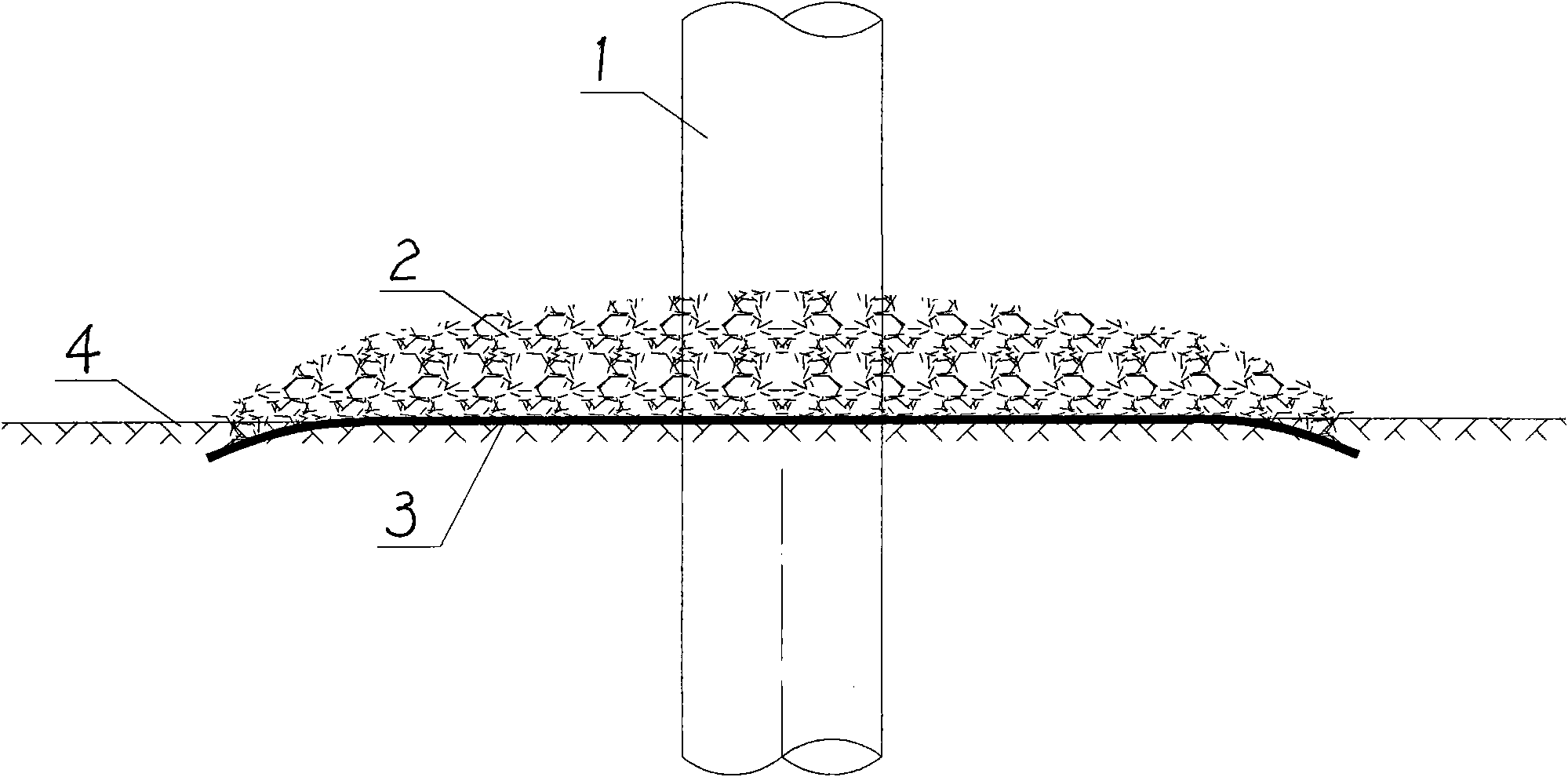

Erosion protection processing method for offshore wind turbine foundation

InactiveCN101892673AImprove anti-scouring effectCostlyProtective foundationEconomic benefitsHeavy load

The invention relates to an erosion protection processing method for an offshore wind turbine foundation, which is used for reinforcing the offshore wind turbine foundation. The method comprises the following steps: (1) paving a covering on a seabed around the foundation; and (2) placing weights on the covering, wherein the covering is at least one of a geogrid, geotextile or a flexible pad. The erosion protection processing method for the offshore wind turbine foundation has the following advantages: a good erosion protection effect is ensured; good economic benefits are achieved, because only the cost of the geogrid is increased, but the later maintenance cost is greatly lowered; and the later maintenance is so convenient that only an amount of riprap needs to be additionally arranged according to monitoring conditions when the mud elevation changes a lot.

Owner:BAOSTEEL ENG & TECH GRP

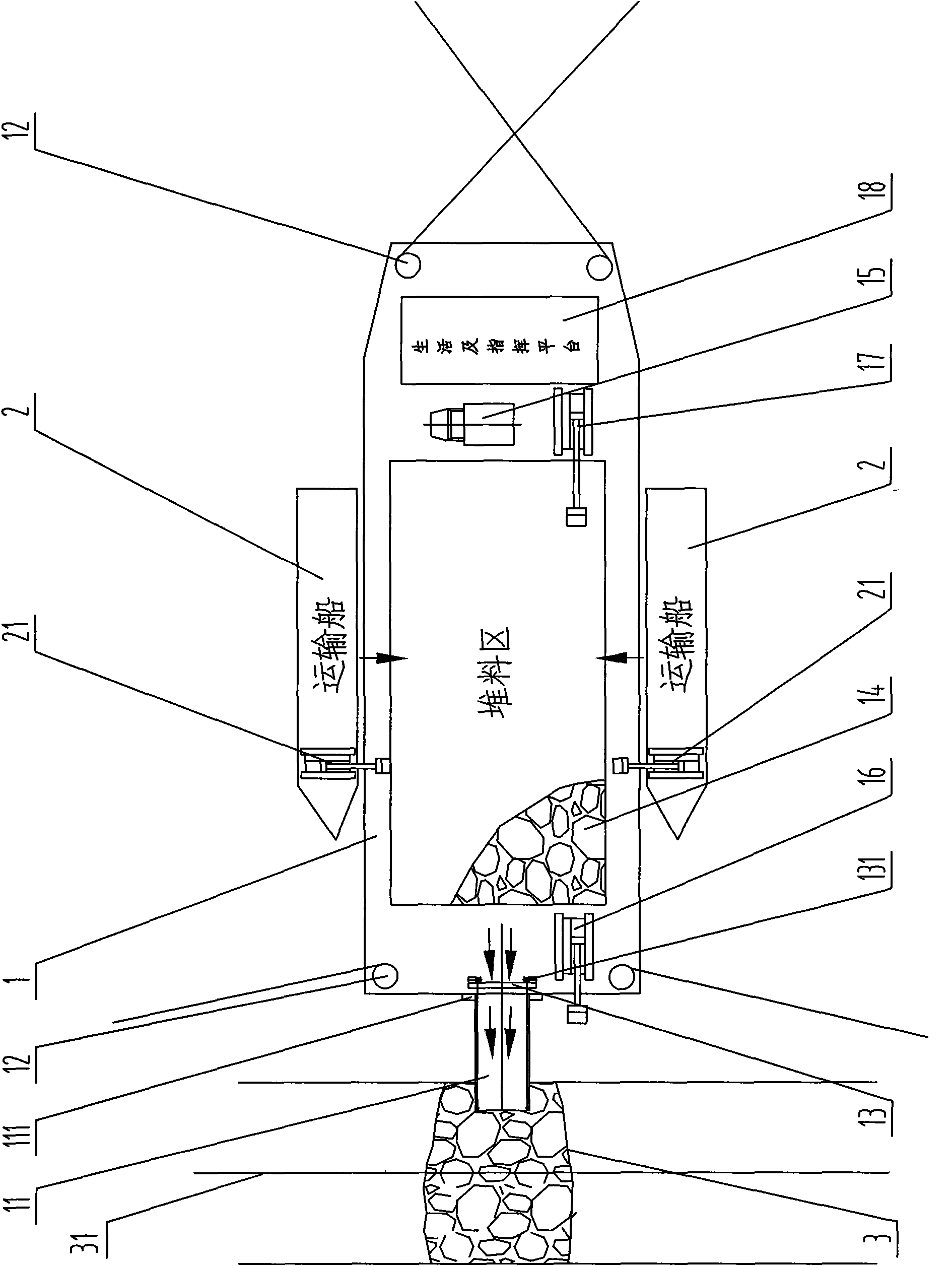

Method for building riprap levee island wall of offshore artificial island by large box barge

InactiveCN101597896AUndisturbedSpeed upArtificial islandsCargo handling apparatusTremieEngineering

The invention discloses a method for building riprap levee island wall of an offshore artificial island by a large box barge, comprising the following steps: (1) remodeling a large box barge; (2) dragging the large box barge to an area for building the riprap levee island wall of the offshore artificial island to facilitate the longitudinal centerline to be vertical to the axis of the riprap levee island wall of the offshore artificial island; (3) respectively parking transport ships at the both sides of the large box barge to unload stone material to the large box barge; (4) with excavators and waggon tremie riprap construction stone material piling platform of the large box barge provided, facilitating the large box barge to be driven to the stone piling platform by steel butt straps to riprap and deal with the slopes to build a section of riprap levee, repeating the process so as to facilitate the riprap levee island wall to move forward section by section to be formed and finally completed. In the invention, the on-water construction of the island wall of the offshore artificial island is transformed into onshore advance, thus reducing influence of stormy weather on the construction and greatly accelerating construction speed of the artificial island.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

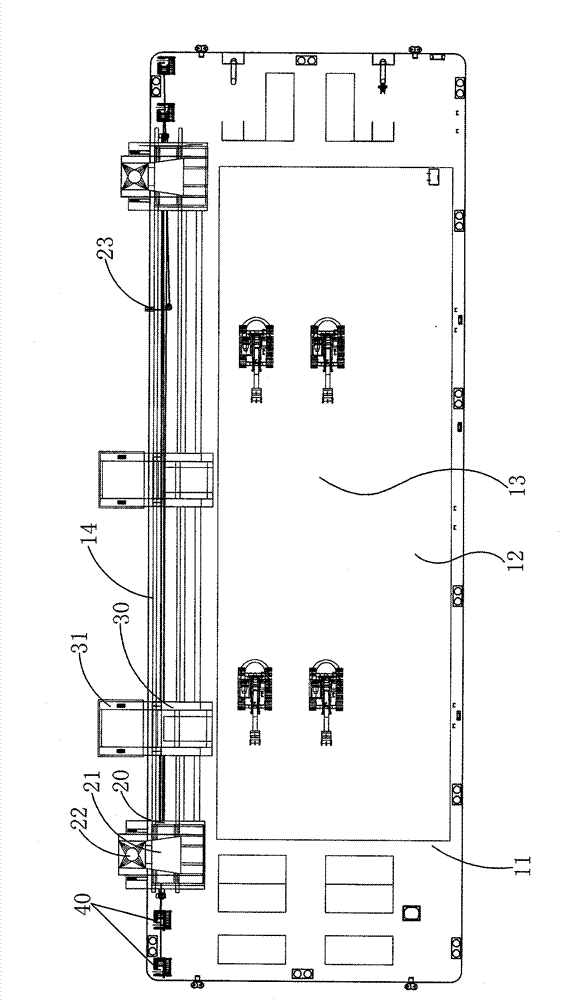

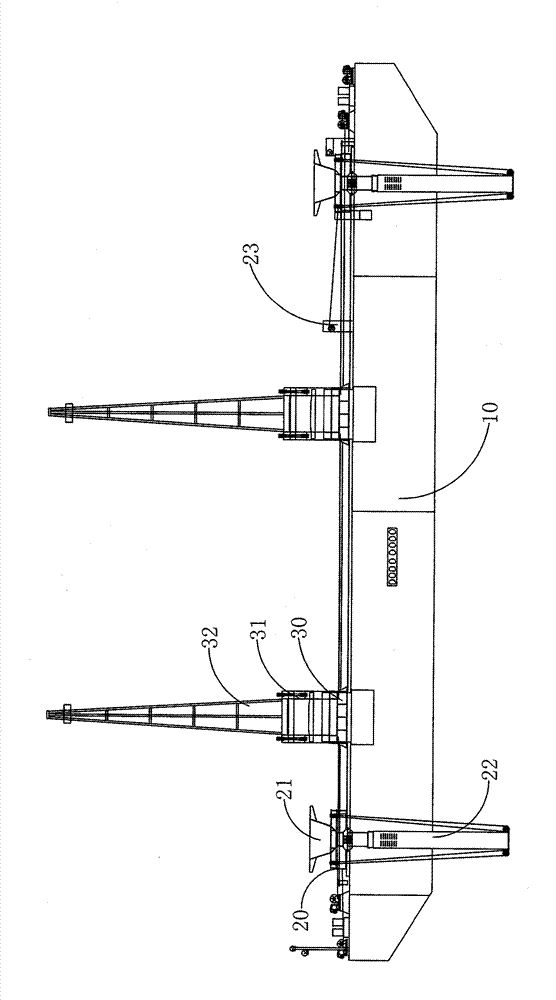

Foundation construction barge for immersed tube

InactiveCN102758439AReasonable structural designReasonable layoutFoundation engineeringImmersed tubeWinch

The invention discloses a foundation construction barge for an immersed tube, which is characterized in that a rail extending in the barge direction is arranged on one side of the barge main deck; a travelling mechanism is arranged on the rail and driven by a cable winch; the travelling mechanism comprises an elephant trunk trolley and a flat rammer trolley; the elephant trunk trolley is connected with an elephant trunk system located on one side of the barge; and the flat rammer trolley is loaded with a vibratory hammer and a vibratory hammer lifting system. The foundation construction barge for the immersed tube is reasonably designed in structure, has multiple functions, and meets the engineering requirements of stone transportation, accurate riprap and hammering. The barge is highly effectively to operate, flexible and can realize the area construction requirement of a fixed point. The barge can be formed by modifying the prior ship; each device on the barge is reasonably distributed; and the barge can meet the requirements of island tunnel construction, construction safety and reliability.

Owner:CCCC FIRST HARBOR ENG +2

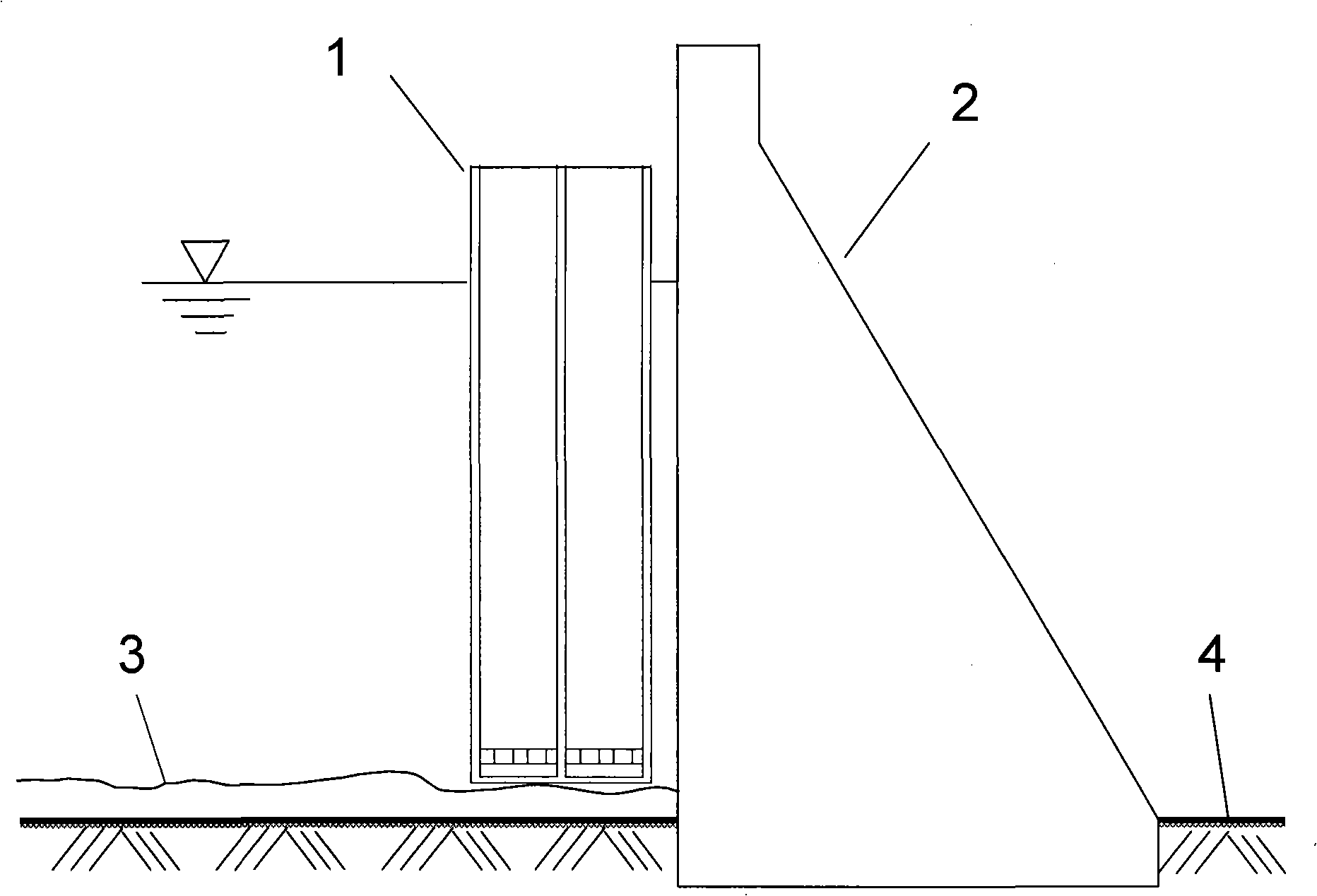

Gravity wharf built on silt foundation and method for constructing gravity wharf

InactiveCN103374900AGuaranteed bearing capacityReduced skid resistanceBreakwatersQuaysWater levelSilt

The invention discloses a gravity wharf built on a silt foundation and a method for constructing the gravity wharf. The method for constructing the gravity wharf includes (1), designing a wharf structure and a foundation, reinforcing a composite foundation of the silt foundation by sand compaction piles and determining the bearing capacity, a sand pile replacement rate and a reinforcing range of the designed foundation of the wharf; (2), excavating a foundation trench, specifically, excavating the foundation trench until the depth of an excavated part of the foundation trench is smaller than a bottom elevation of the foundation trench and the difference between the depth of the excavated part of the foundation trench and the bottom elevation of the foundation trench is not smaller than one times the diameter of each sand compaction pile, constructing the sand piles, detecting the compactness of the sand piles after the sand piles are completely constructed, determining or re-determining the bottom elevation of the foundation trench, and secondarily excavating the foundation trench; (3), constructing a rock rip-rap foundation bed, performing rock rip-rap and leveling the top surface of the foundation bed; (4), mounting a precast caisson and enabling the top surface of the precast caisson to be higher than a construction water level; (5), performing rock rip-rap on the inside of the caisson; (6), constructing an upper structure of the wharf; (7), determining a rear backfill structural form and a backfill loading mode of the wharf, and performing rear backfill loading construction on the wharf. The gravity wharf and the method have the advantages that the bearing capacity of the foundation can be greatly improved, and influence of back-silting in a wharf construction procedure can be overcome.

Owner:CCCC THIRD HARBOR CONSULTANTS

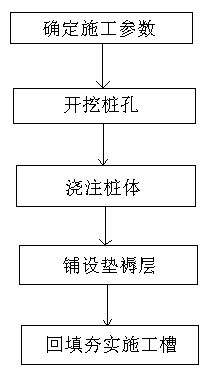

Construction method and equipment for reverse circulation drill to drill hole, hammer to form hole, expand hole and remove slag

The invention discloses a construction method and construction equipment for a reverse circulation drill to drill a hole, hammer to form the hole, expand the hole and remove slag. A power head drives a drill rod to drill the hole; an impact hammer provided with a reaming device hammers to form the hole, and the hole is expanded by a reaming hammer; the drill rod of the drill is connected with a guiding slag removing pipe of an impact reaming hammer; and sediments at the bottom of the hole are sucked out by a drilling mud pump, and then discharged into a movable sediment separation pool by thedrill rod and riprapped at the pile bottom to form a cushion layer. The invention has the advantages that: the reverse circulation drill is combined with the impact hammer, so the reverse circulationdrill has high drilling speed and strong rock embedding capability; the reverse circulation drill is combined with the guiding slag removing pipe of the reaming hammer so as to hammer while removing the slag, and the slag can be removed finally; the impact hammer is combined with the reaming hammer to form an expanded head, a ratio of the diameter of the expanded bottom end surface to the sectionof the pipe body is increased, so the bearing capability of the single pipe is effectively improved; and the reverse circulation drill is combined with impact reaming hammer so as to drill, ream, remove slag and riprap, and the functions are shared; the movable sediment separation pool can separate the sludge cakes and sediments and transport the sludge cakes and sediments out of the field, so the mud is prevented from polluting the environment.

Owner:徐守田

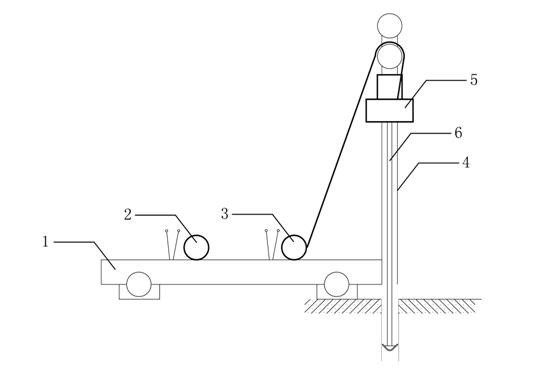

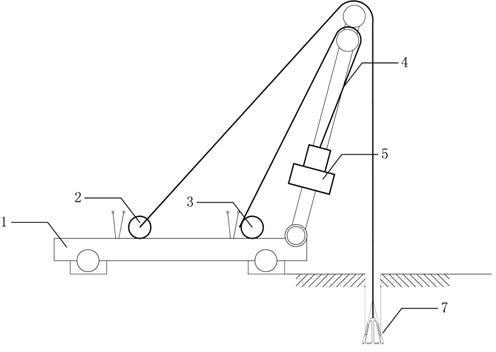

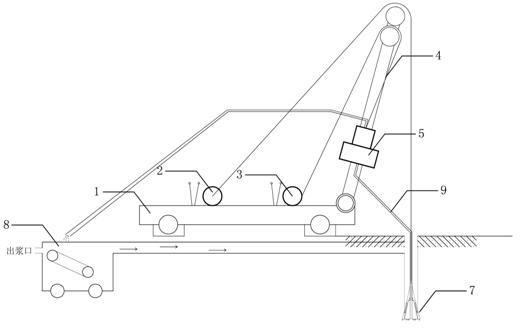

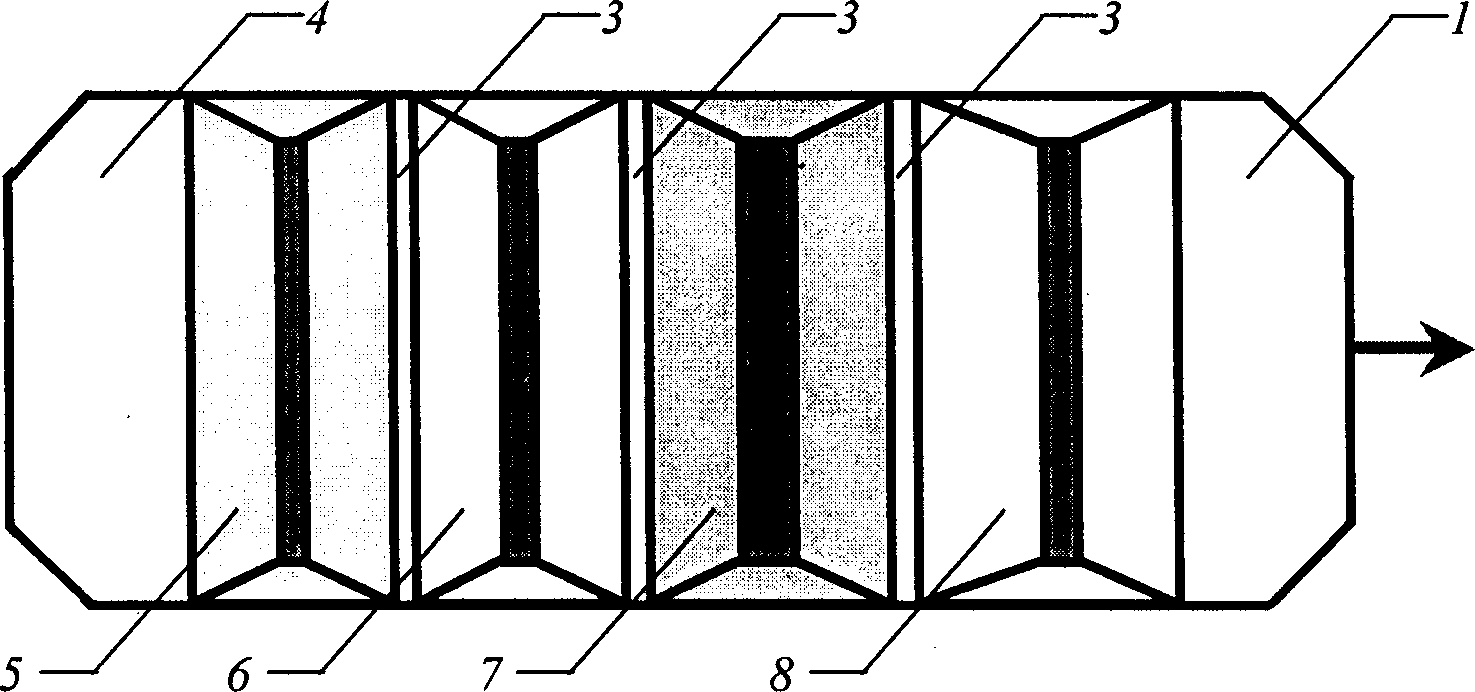

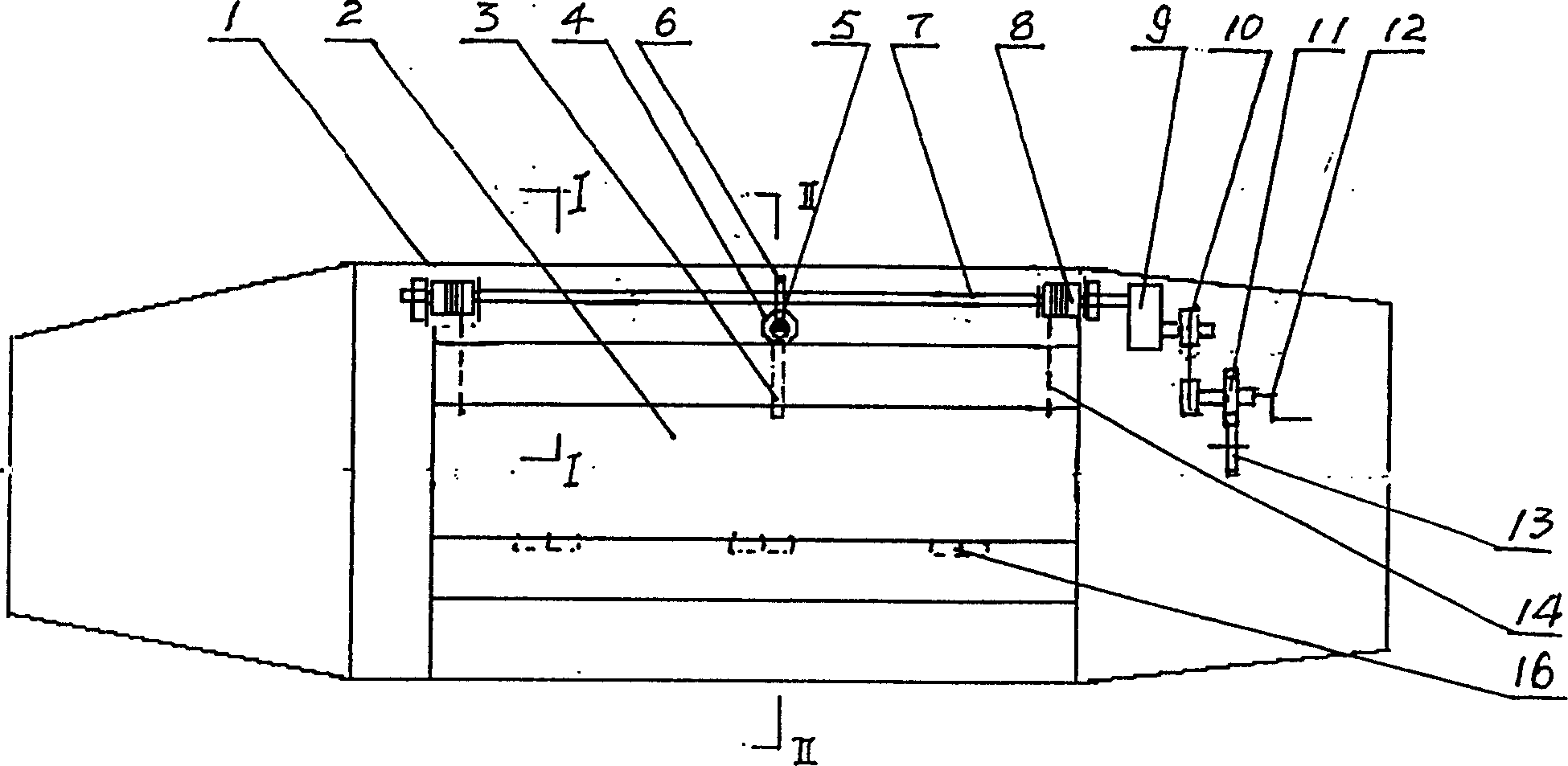

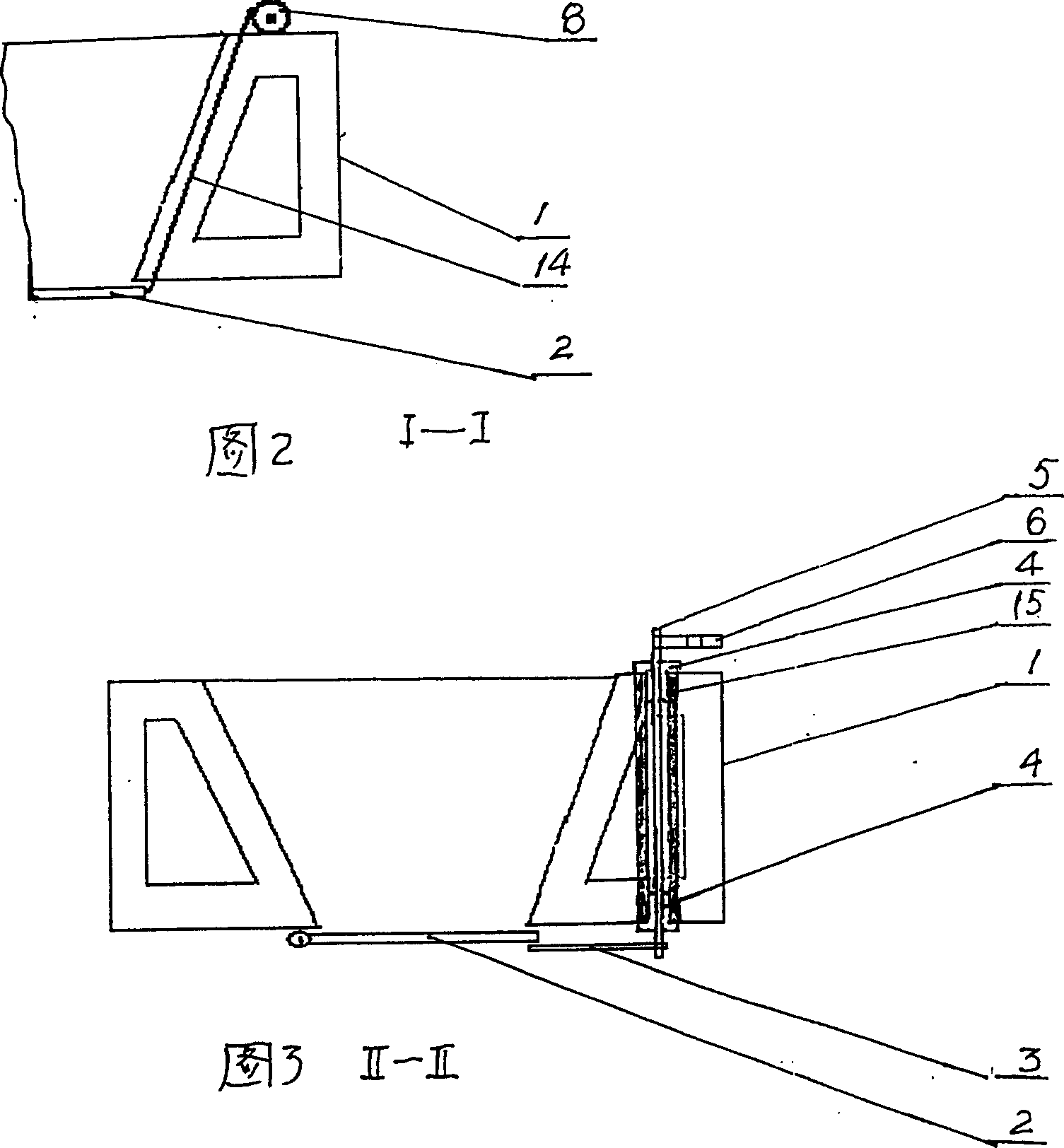

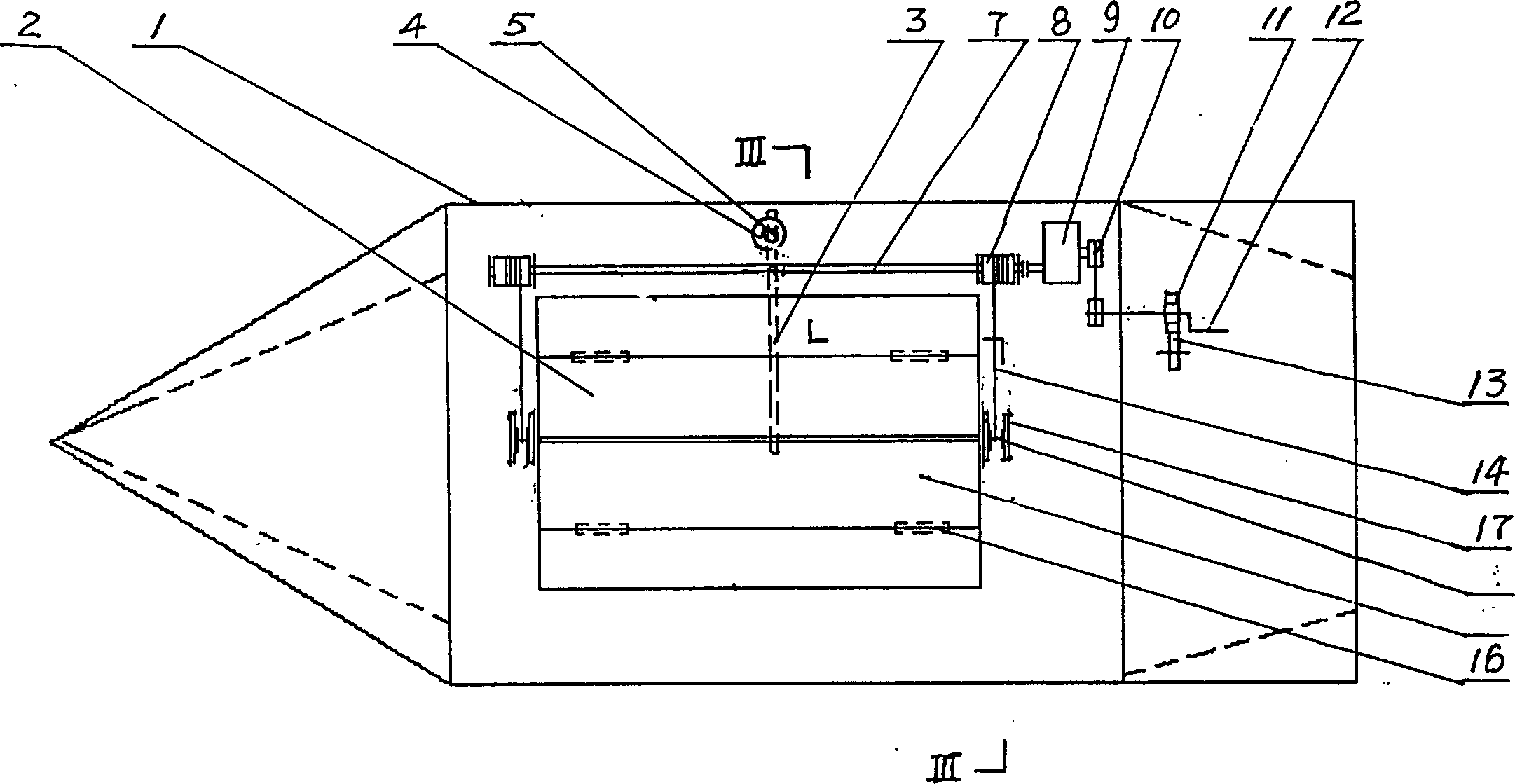

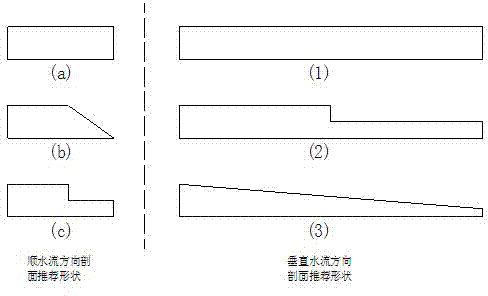

Pontoon cabin row for stone spreading and levelling continuous work of under water riprap foundation bed construction

InactiveCN1413875ARealize fully mechanized constructionImprove construction efficiencyWaterborne vesselsFoundation engineeringEngineeringRiprap

A row of floating cabins for throwing rock in water to spread the foundation bed is composed of front and back floating cabins, three central floating cabins and the counecting beams at both sides of the said floating cabins. The inclined side plates of adjacent two floating cabins constitute a hopper cabin. The sand and rock with different sizes are sequentially thrown in water via relative hopper cabins. Under the floating cabin there is scraper beam for smoothing the foundation bed.

Owner:TIANJIN UNIV

Rapid recovery method of natural river landscape of city

ActiveCN106592511AImprove the habitatRestore diversityClimate change adaptationStream regulationRecovery methodTerrain

The invention relates to a rapid recovery method of a natural river landscape of a city. Firstly, the water width and the water depth of a river are measured, the flow cross section of the river is calculated, under the condition that original hard banks are remained, a riverbed is excavated according to the characteristics of the cross section of an original riverbed, the river flow volume of the excavated riverbed equals to the river flow volume of the original riverbed, and the flood carrying capacity of the river is remained; and then, an earth work generated in the excavation of the riverbed is refilled between the hard banks and a riprap slope, an earth slope with a cross section progressively increasing from top to bottom is formed after roller compaction is conducted. Compared with the prior art, hard slope protection does not need to be removed, on the basis of the original width of the river, the riprap slope and the earth slope are built, a structure with a shallow and a deep pool is formed, diversified river local terrains are created relying on the natural evolution of the river, the biological habitat of the river is improved, the diversity of a water flowing and water ecological system is recovered, and the rapid recovery of a river ecological system is achieved.

Owner:无锡金利达生态科技股份有限公司

Cabin storage discharging device for riprap boat

InactiveCN1775621AEasy to unload stoneReduce labor intensityCargo handling apparatusPassenger handling apparatusLocking mechanismShallow sea

The invention relates to a cabin stored stone unloading device for a stone rip-rapping ship, especially applied to carrying stones to fill the sea to compose seafood breeding reefs in deep and shallow sea area, characterized in arranging a square open stone storage cabin whose stone outlet is small and top mouth is big, the cabin bottom is provided with stone outlet, the cabin bottom under the stone outlet is hinged with single-fan or double-fan outlet door through loose-leaf, corresponding to the opening position of the outlet door, symmetrically arranging an outlet door opening and closing mechanism on deck, which is composed of steel wire rope, drum, through shaft, reduction box, chain drive, notch wheel, pawl, and clutch rocking handle (or additional sliding steel wire rope and pulley block), corresponding to the middle under the outlet door, arranging an outlet door locking mechanism on deck, which is composed of locking plate, trapezoidal threaded rod, upper and lower nut sleeves, protective sleeve and crank. The invention replaces human labor with mechanisms to discharge stones, saving labor and time, safe and largely reducing labor strength and remarkably raising productivity and increasing economic benefits.

Owner:王心斌

Method for reinforcing caisson of concrete dam

InactiveCN101285302ALower the volumeGood anti-seepageBarrages/weirsBuilding repairsReinforced concreteEngineering

The invention provides a method for reinforcing a concrete dam by caissons, relating to a method for reinforcing a concrete dam. In the reinforcing method, caissons are arranged in the front dam section of the dam needing to be reinforced, forming a caisson group; reinforced concrete caissons are used as the construction surface of riprap type rock-fill concrete, and the riprap type rock-fill concrete is used to quickly backfill box grids of the caissons and the connection between the caissons and the dam body, and conventional type rock-fill concrete is used to concrete up to the design elevation, and the front-dam reinforcement of the concrete dam is completed. The method does not need to empty a reservoir, thereby the construction is easy and convenient, and effects of improving the construction efficiency and saving the construction cost are obviously; moreover, the method has the advantages of high compaction degree of the formed riprap type concrete filling caisson structure, little cement amount, low hydration temperature rise, good volume stability, good impermeability, excellent comprehensive performance, energy conservation and environmental protection, etc.

Owner:TSINGHUA UNIV

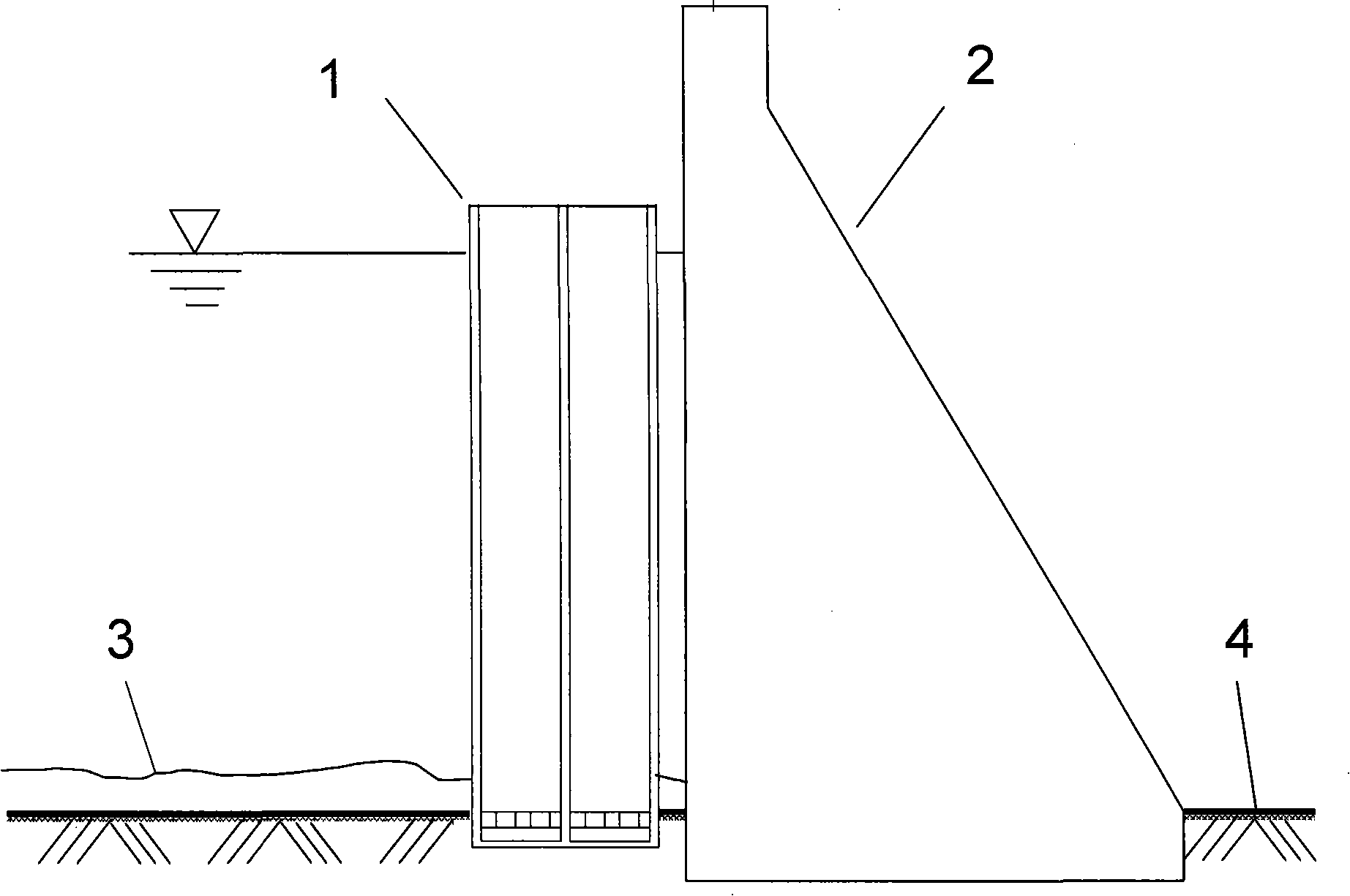

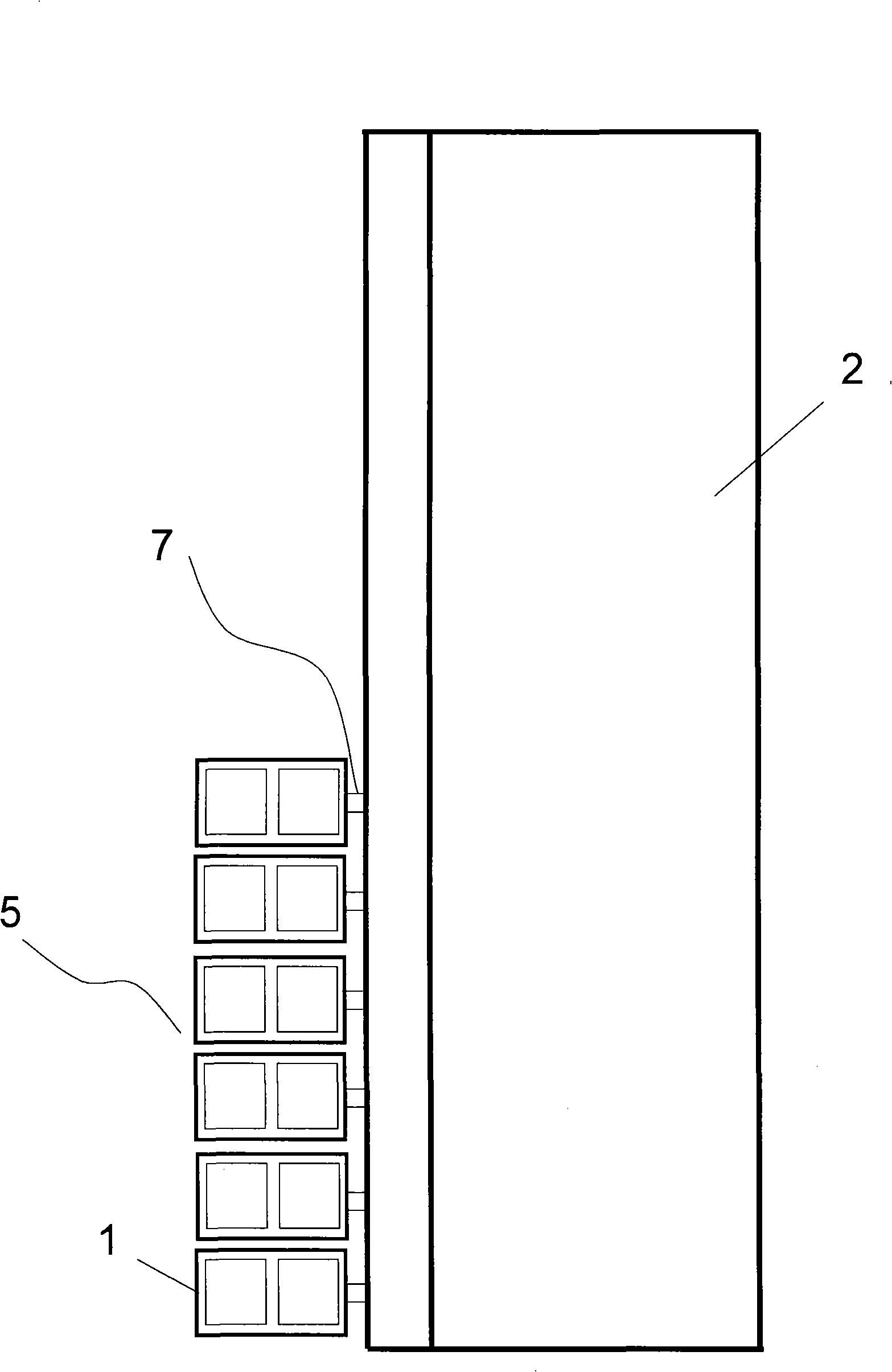

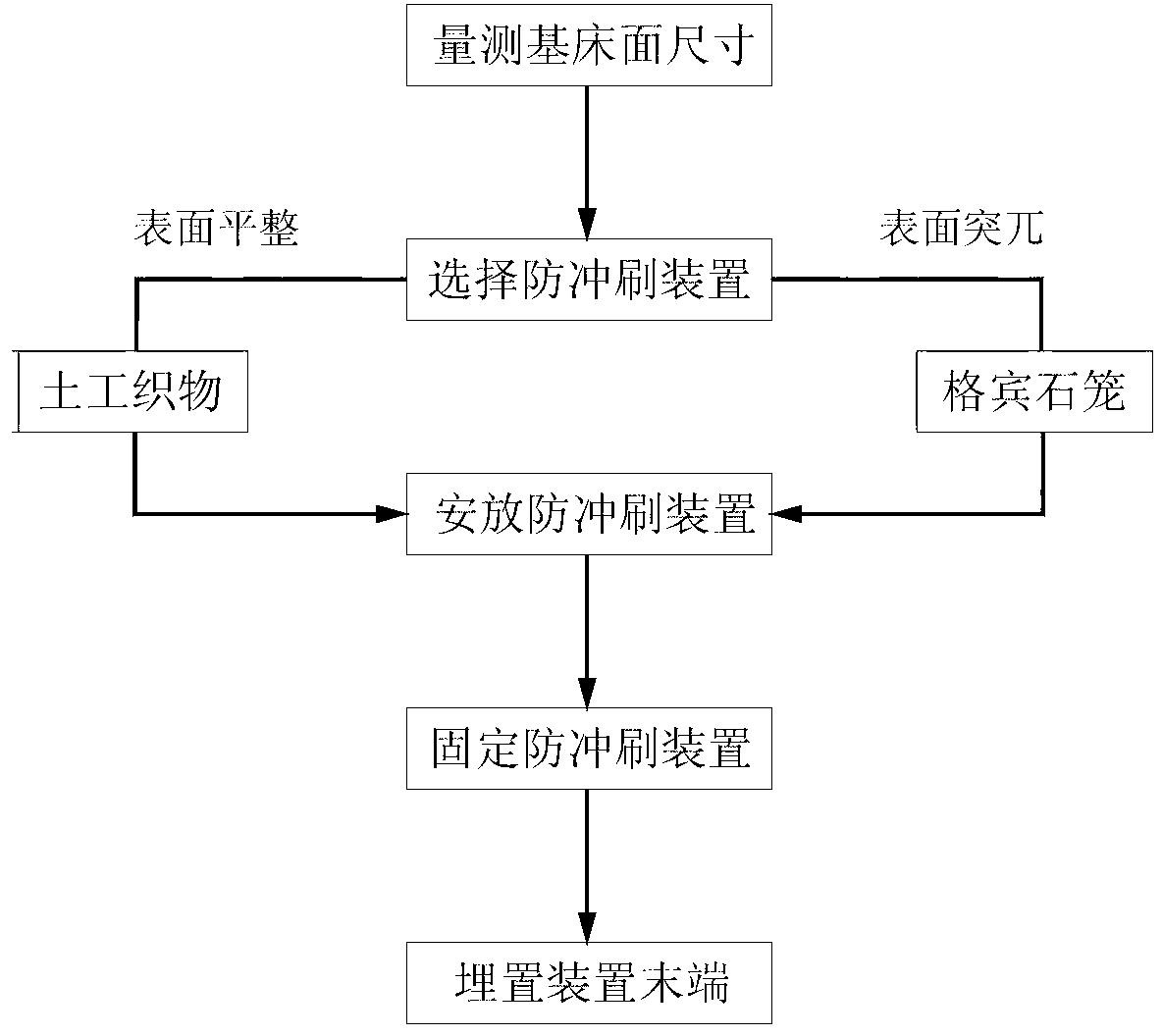

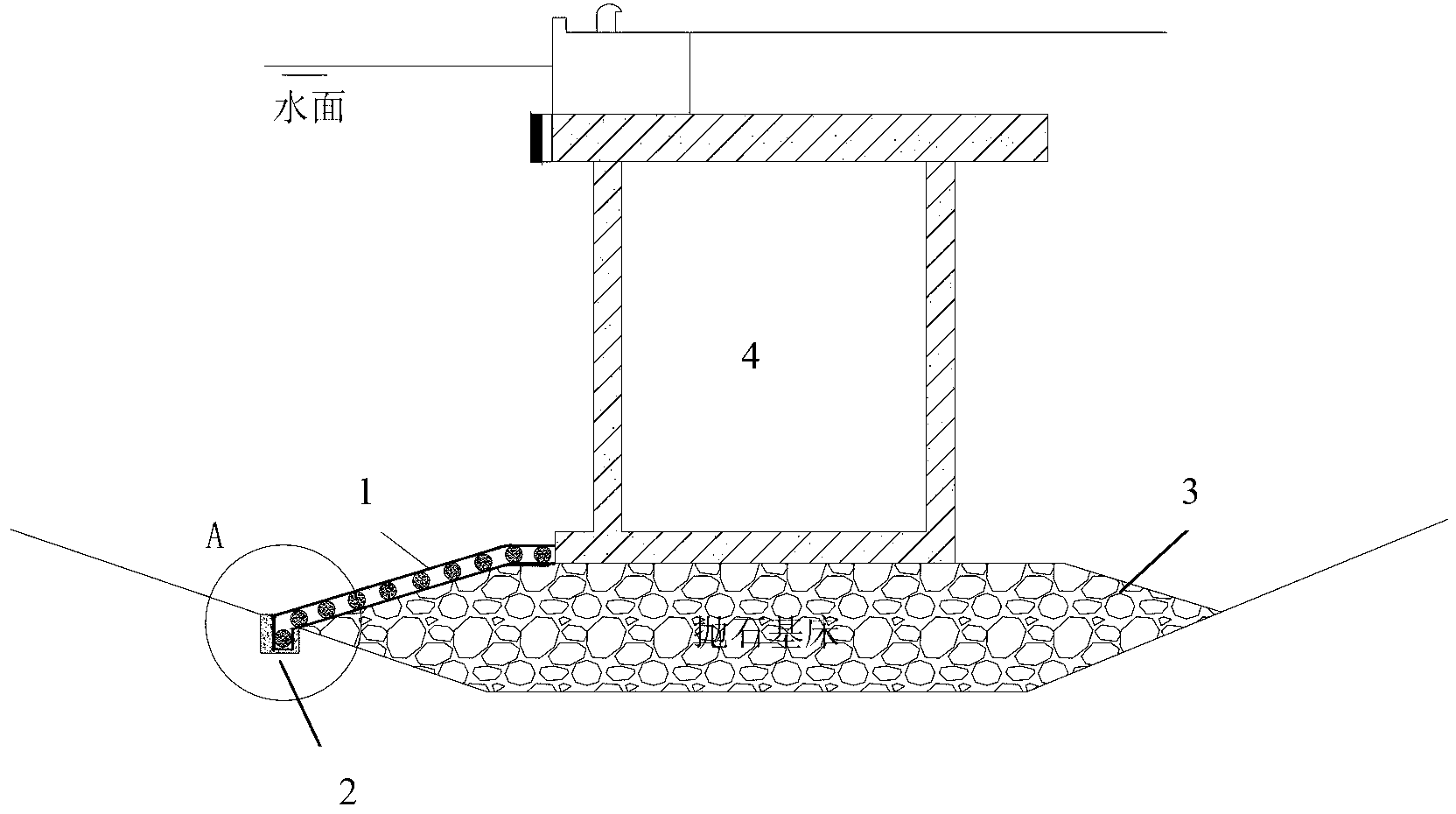

Underwater riprap foundation bed and side slope erosion resisting structure and construction method thereof

ActiveCN103233444AAvoid destructionAvoid start-up flow conditionsCoastlines protectionFoundation engineeringStructure of the EarthUnderwater

The invention discloses an underwater riprap foundation bed and side slope erosion resisting structure which comprises an erosion resisting device arranged on the surface of a foundation bed or the surface of a side slope, a fixing structure for fixing the erosion resisting structure onto the foundation bed or the side slope and a ditch dug along the foundation bed or the lower end of the surface of the side slope, wherein the lower end of the erosion resisting device is embedded in the ditch for fixing, and the erosion resisting device is of a soil engineering structure with a casing formed by soil engineering materials and with sand and stone filled in the casing. By installing and fixing the erosion resisting device onto the surface of a structural object, the peripheral water flow speed can be reduced, so that the aim of resisting erosion damage to the structural object can be achieved. All steps related in the technical scheme do not need large machinery for matching, and construction is easy and economic.

Owner:CCCC FOURTH HARBOR ENG INST +2

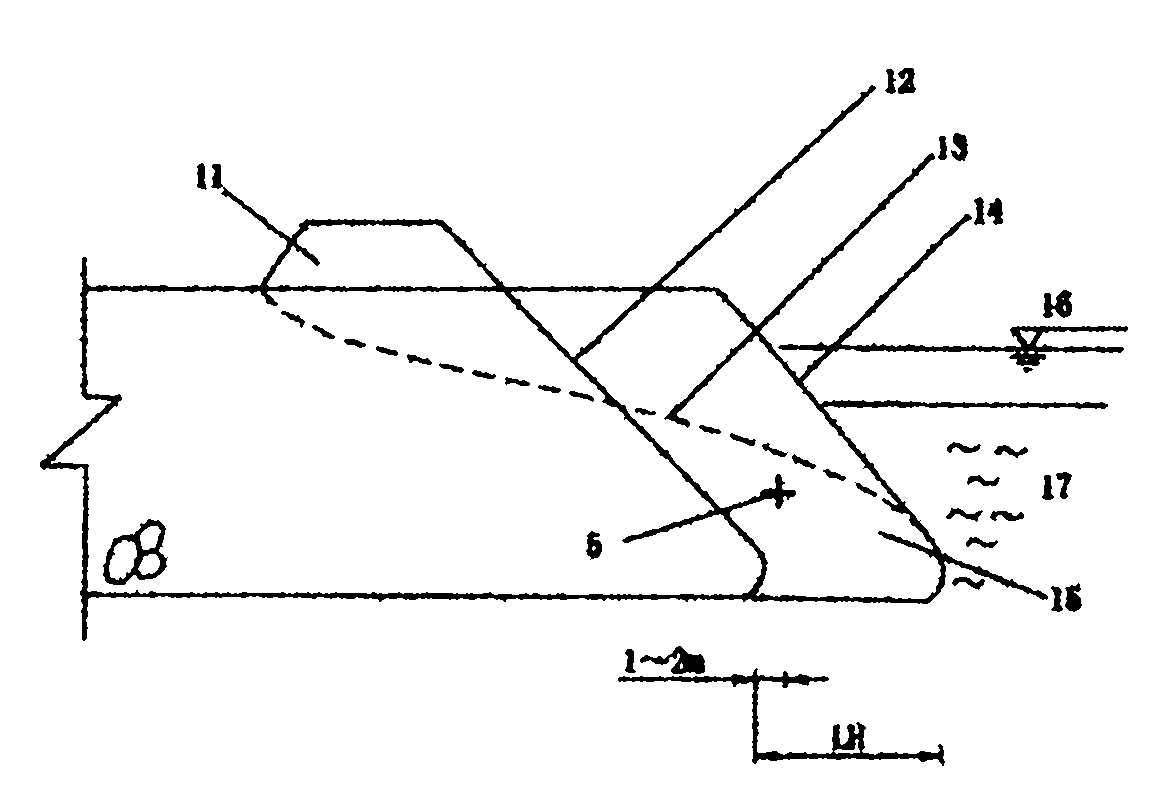

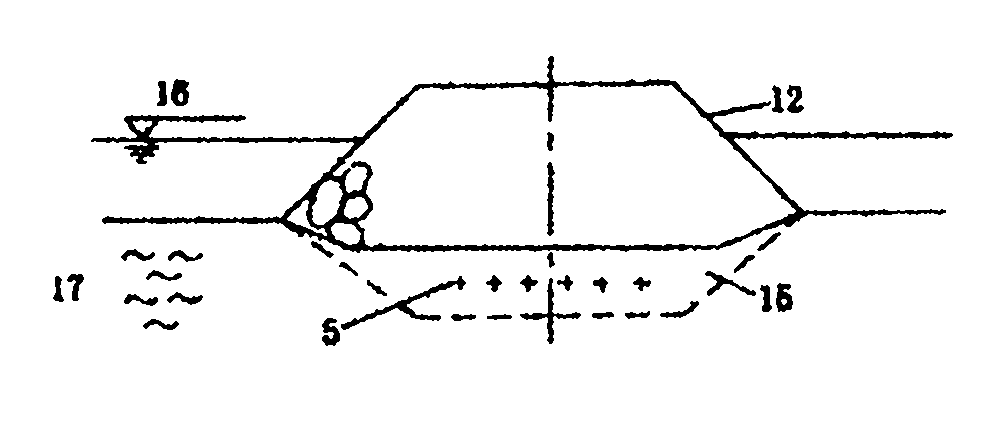

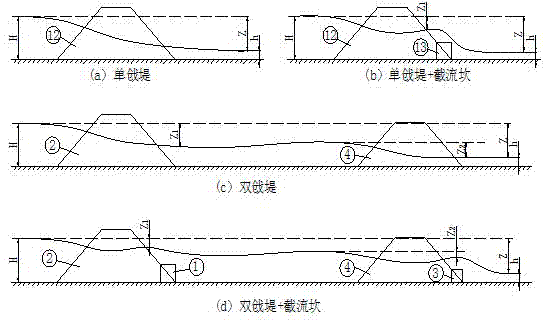

Diversion channel closure method

InactiveCN104762938AReduce flow rateReduce dropBarrages/weirsWater-power plantsWater flowEngineering

The invention discloses a diversion channel closure method. During excavation of a diversion channel, a rock step is reserved to serve as a closure step, a rock step is reserved at the position of an outlet of the diversion channel to serve as a river diversion and slope protection step, and a 30-60-degree angle is formed between the river diversion and slope protection step and the water flow direction. During closure, a berm is built, and the reserved closure step is made to be located at the position of a slope toe on the lower portion of the closure gap section of the berm. When two berms are used for closure, closure gaps are arranged in a stagger mode, reverse occupation is achieved, and the river diversion and slope protection step is lengthened to be a construction trestle. By means of the reserved closure step, the hydraulic index of closure gaps is reduced, riprap stability is improved, the split ratio of a drainage gallery is increased, and closure difficulty is reduced; the flow state at the outlet is changed by means of the river diversion and slope protection step, and bank slope scouring is prevented or reduced; meanwhile, the river diversion and slope protection step is part of a closure trestle, and the length of the trestle is reduced.

Owner:WUHAN UNIV

Construction method and structure of hydraulic core-wall rockfill dam without cofferdams

The invention discloses a construction method of a hydraulic core-wall rockfill dam without cofferdams. The method comprises the following steps: filling an upstream and downstream mixed riprap area (4); filling a transitional rock filling area (3); filling a fine rock filling area (2); filling an upstream large crushed rock revetment area (5); constructing a core-wall anti-seepage area (1). The invention further discloses a core-wall rockfill dam structure without cofferdams obtained according to the construction method. According to the invention, anti-seepage cofferdams do not need to be constructed on the upstream and the downstream of the dam, and the foundation of the dam does not need to be excavated and processed, so that pumping of foundation pits is reduced, the utilization rate of excavated aggregated rock of buildings is improved, the cofferdams do not need to be dismantled in the later period, the construction technology is simplified, the construction period is shortened, and the engineering investment is saved.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

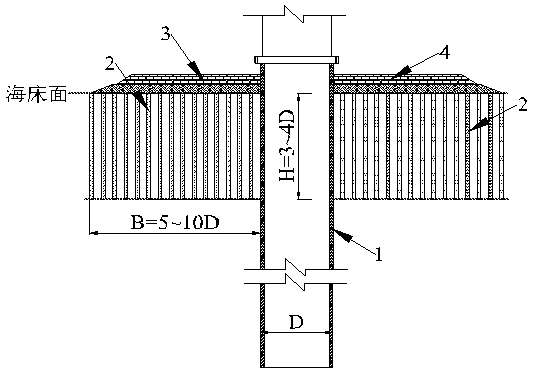

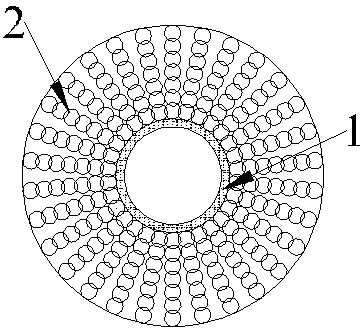

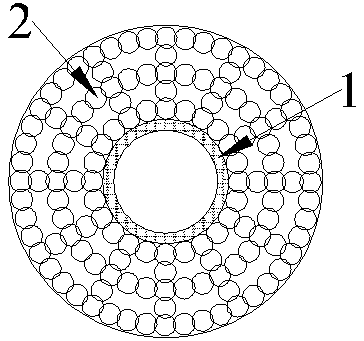

Offshore wind power steel pipe pile foundation reinforcement method with anti-scour ability

InactiveCN109881659AImprove horizontal bearing capacityReduce horizontal distortionBulkheads/pilesSoil preservationElectricitySoil mixing

The invention discloses an offshore wind power steel pipe pile foundation reinforcement method with the anti-scour ability, and belongs to the field of offshore wind plant foundation treatment. The method mainly includes the step of construction of a reinforcement zone, a cushion and a scour protection layer, a cement-soil mixing pile method is preferred for reinforcement, and the cushion and thescour protection layer adopt a riprap method; cement mixing piles are vertically arranged at the equal length or the variable length, and various arrangement forms such as a radial type, a ring type are achieved in the horizontal direction; according to the soil body properties around the piles, an appropriate foundation reinforcement range B and a reinforcement depth H are determined; and the cushion and the scour protection layer are laid on the upper part, and the certain anti-scour ability is achieved. According to the offshore wind power foundation reinforcement method, the physical and mechanical properties of a shallow soil body can be effectively improved, soil body resistance is increased, and the purposes of improving the horizontal bearing capacity of a pile foundation, reducinghorizontal displacement of the pile foundation, and lowering the engineering cost are achieved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com