Manufacture method of offshore riprap leveling ship

A production method, riprap leveling technology, applied to ship parts, ship construction, ships, etc., can solve the problems of uneven production levels in shipyards, restrictions on the development of the ship industry, and gaps in ship construction cycles, etc. The effect of construction efficiency, reduction of hoisting times, and lower hoisting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

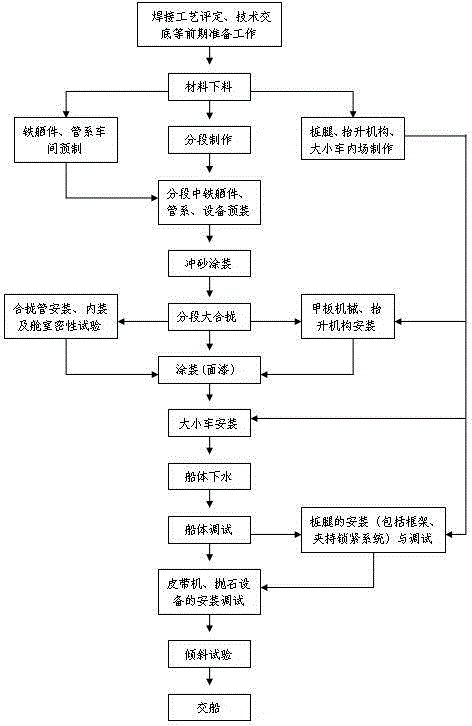

[0036] Such as figure 1 It shows a manufacturing method of a sea riprap leveling ship according to the present invention, which includes the following steps: first carry out preparatory work, and then material blanking, the blanking is mainly used for hull section fabrication, iron outfitting and piping system fabrication, Pile legs and lifting mechanisms and large and small vehicles are fabricated in the field, and then the steel outfitting, piping and equipment are pre-assembled in the berth section, and then sand-washed and painted. Legs and lifting mechanisms, as well as the deck machinery and lifting mechanisms produced in the production of large and small vehicles, as well as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Straightness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com