Segmented-assembled high-rise building tube well vertical pipeline structure and construction method thereof

A technology for high-rise building and pipeline construction, which is applied in vertical pipelines, building components, building structures, etc., can solve the problems of long occupation time of vertical transportation equipment, low level of riser production technology, and mechanical and electrical shortcomings of high-rise buildings. Simple construction, less hoisting times, and less on-site welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the embodiments.

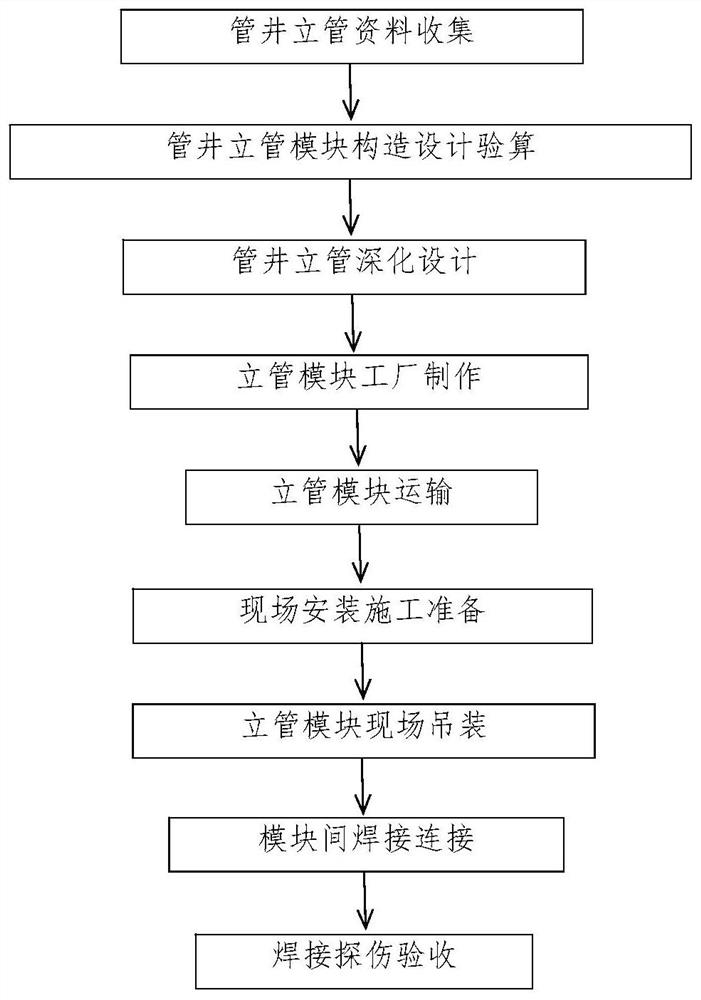

[0032] like Figure 1 to Figure 4 Shown, a kind of segmentally assembled high-rise building tube well vertical pipeline construction method of the present invention, its construction method comprises the following steps:

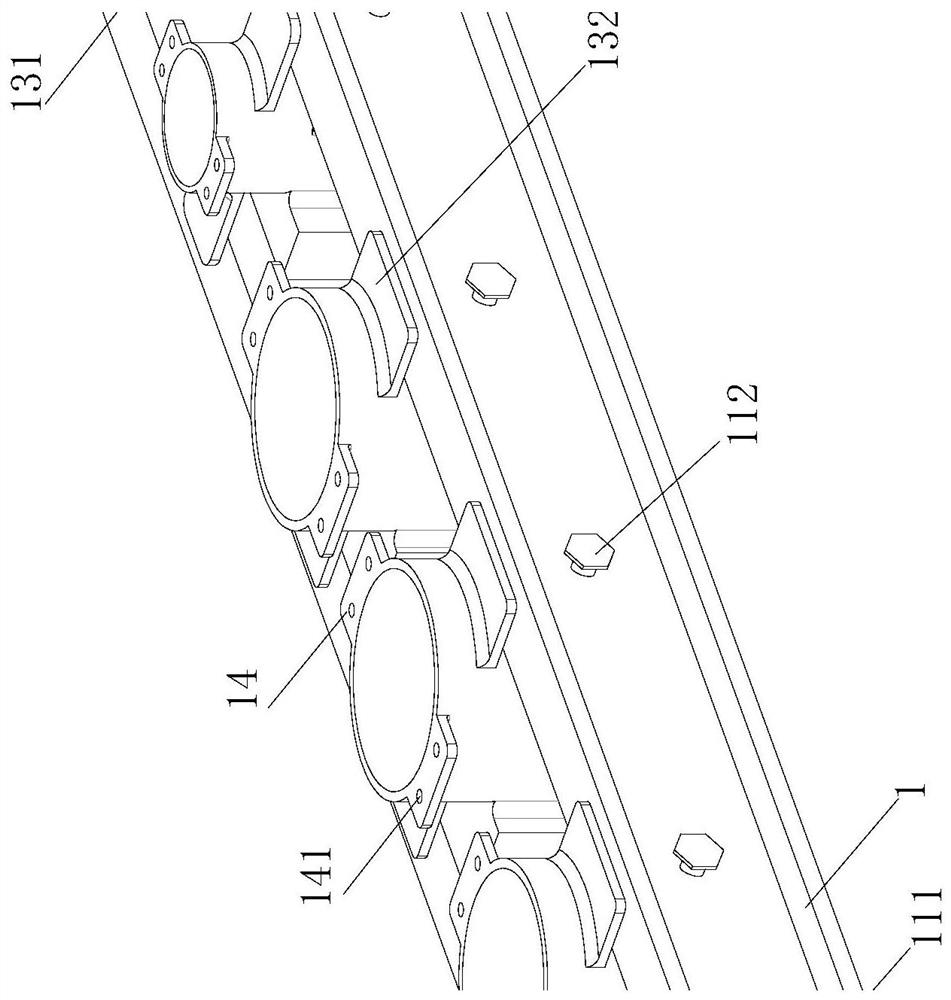

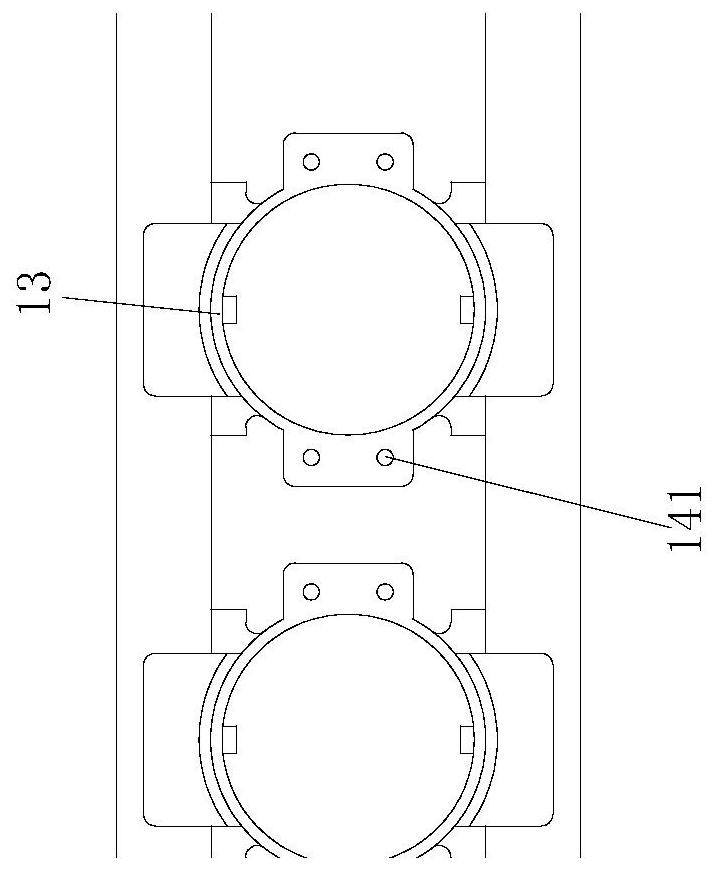

[0033] S1: Collect and organize the relevant data of the riser, confirm the fixed connection method of the riser pipe frame of each layer and the main structural beam, confirm the load calculation, the calculation method of the strength meter image compensation amount, and confirm the different pipe diameters, different materials and insulation The connection method of the lower pipe, the casing 13 and the support, confirm the connection specification of the branch pipe, confirm the water supply and drainage, fire protection and air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com