Patents

Literature

187results about How to "Reduce the number of lifting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

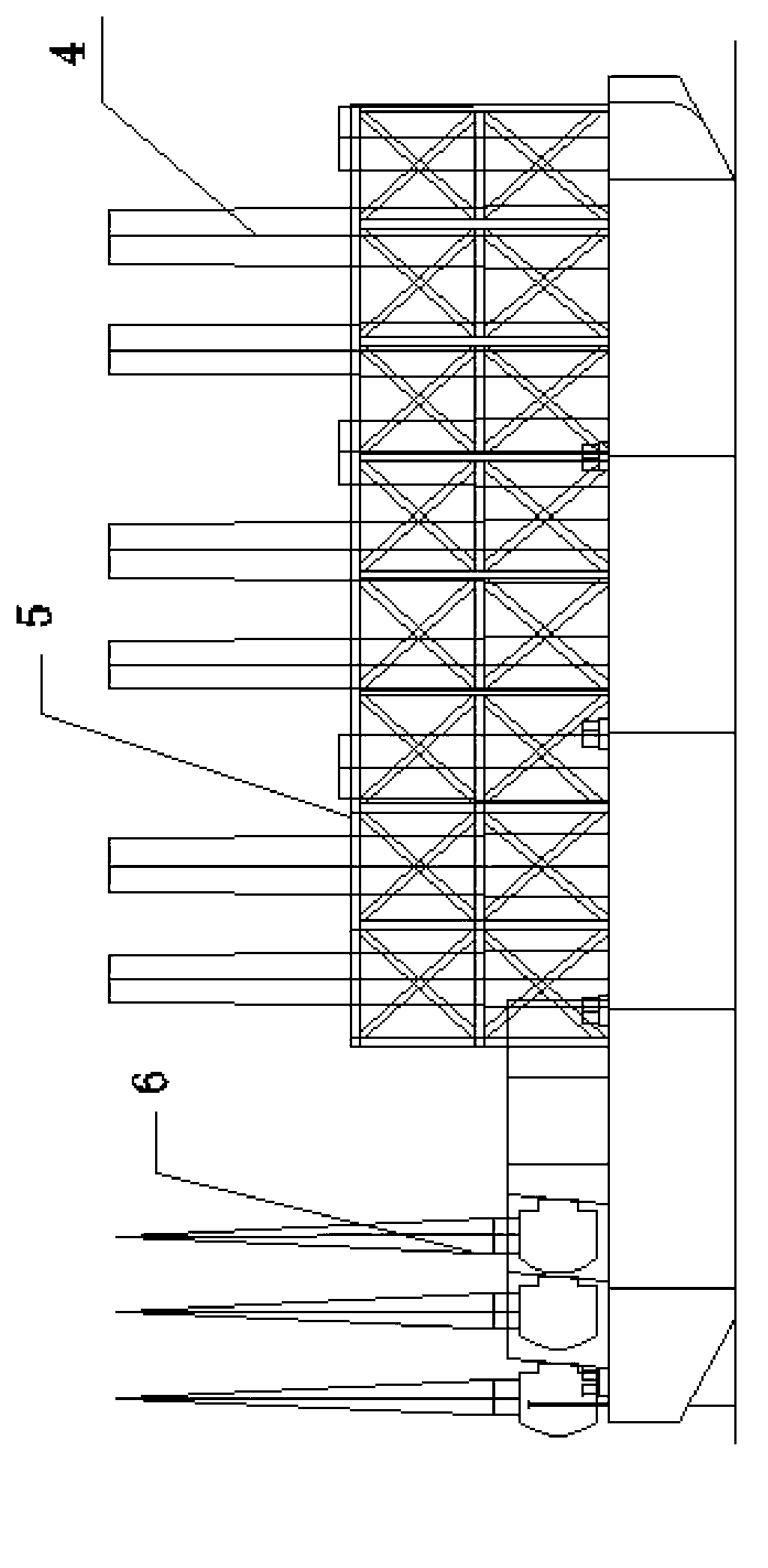

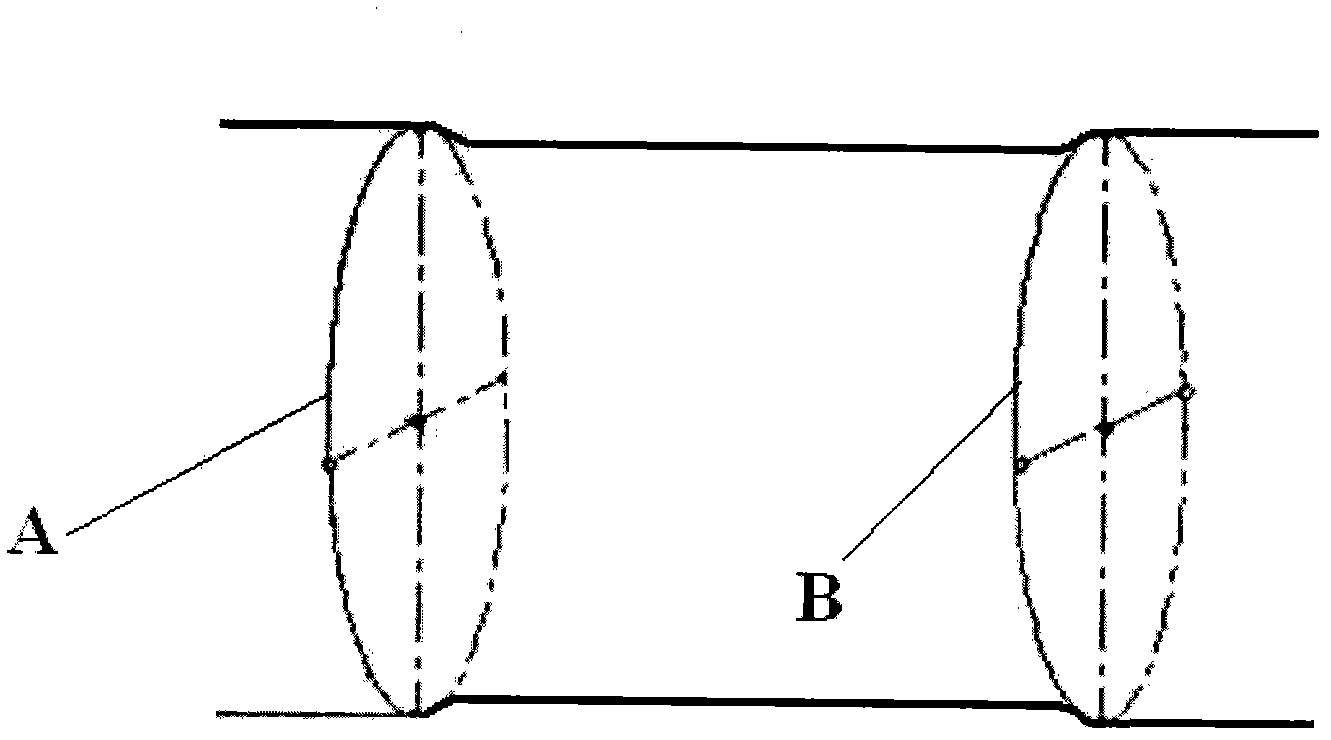

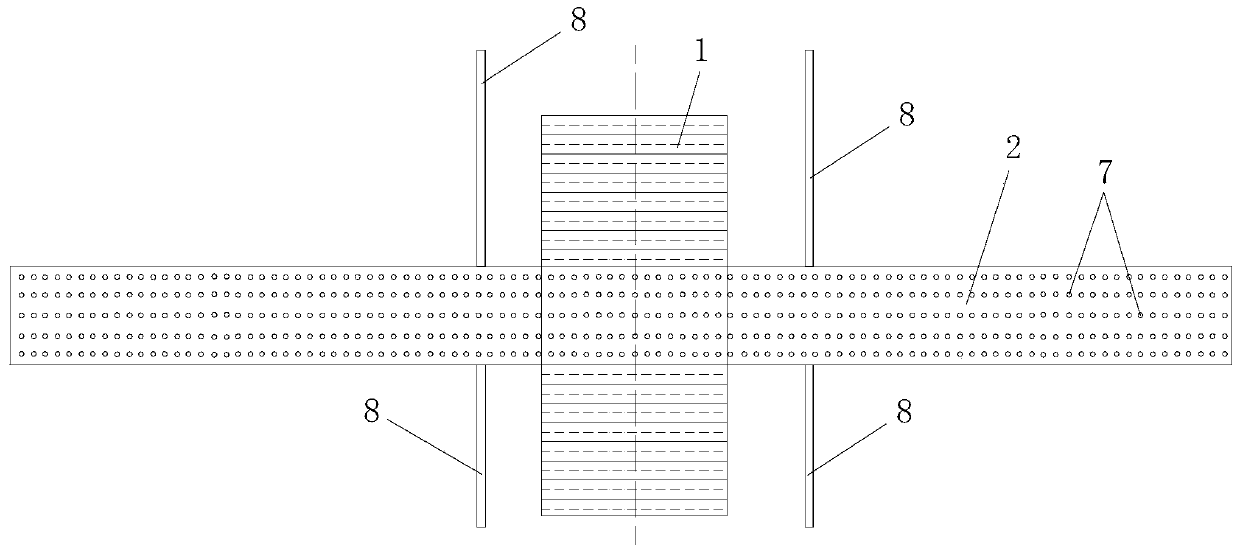

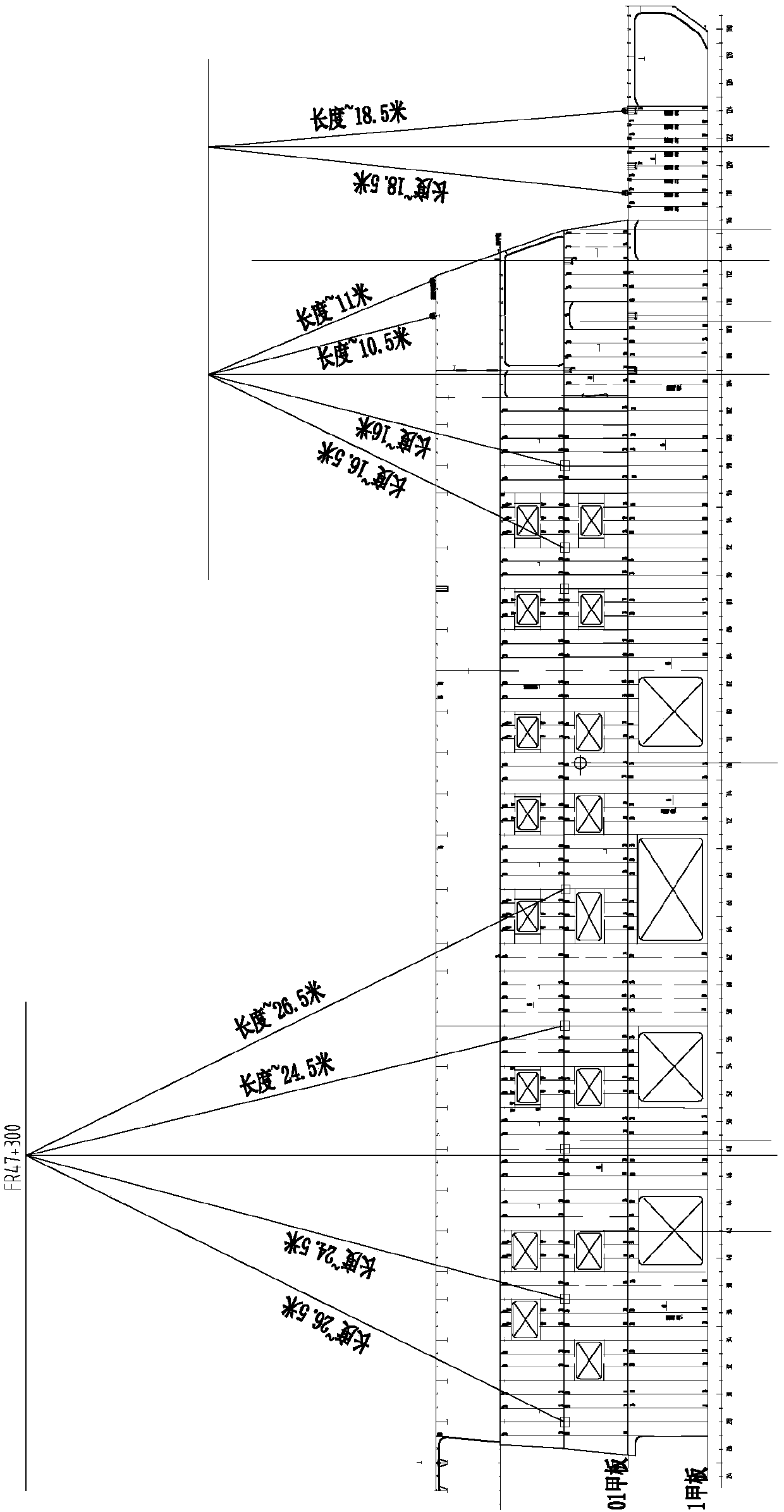

Production technology of hatch coaming and hatch cover

InactiveCN101362505AReduce the number of liftingReduce workloadHull decksVessel hatches/hatchwaysManufacturing technologyHydraulic equipment

Owner:江苏熔盛重工有限公司 +1

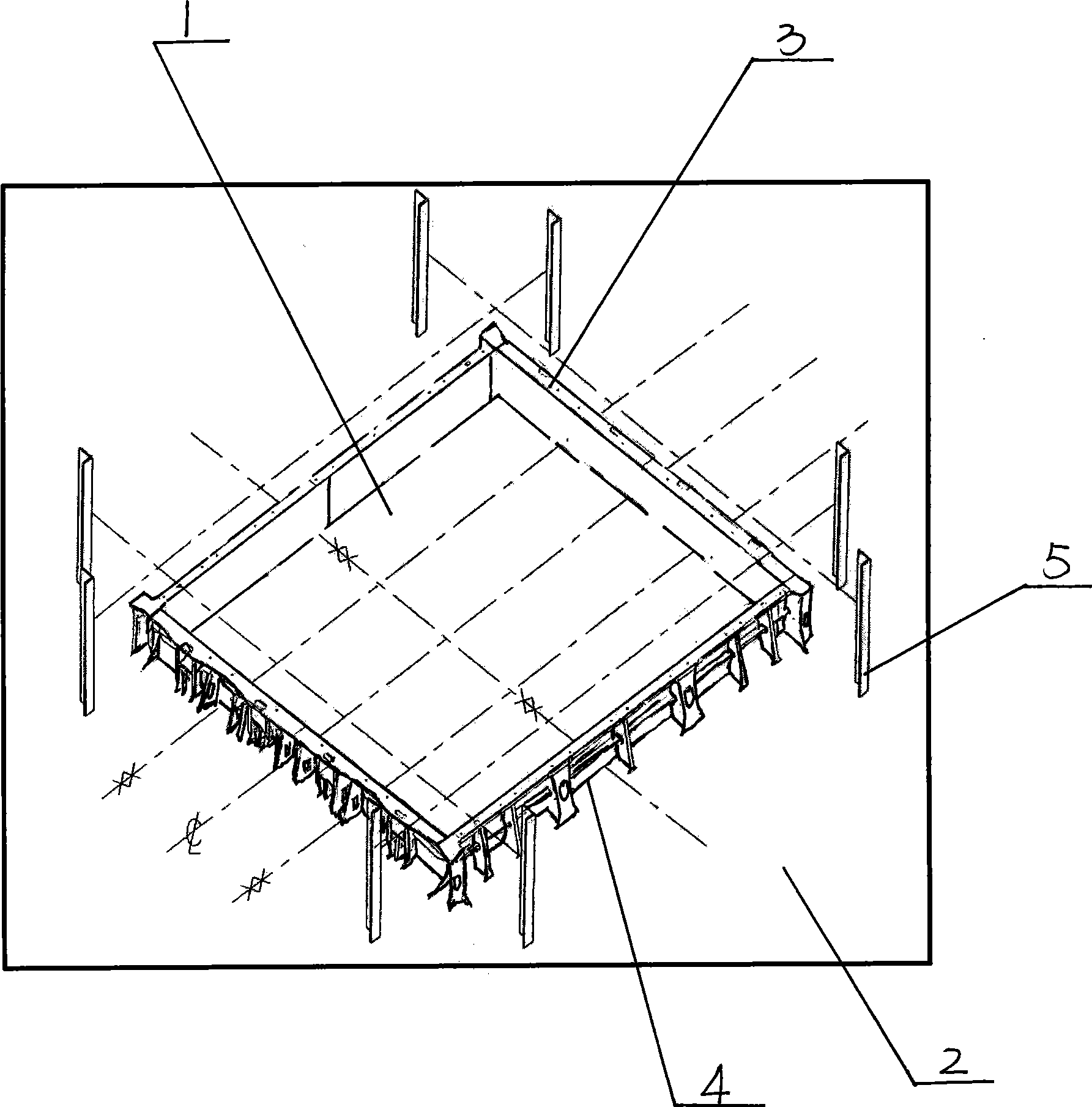

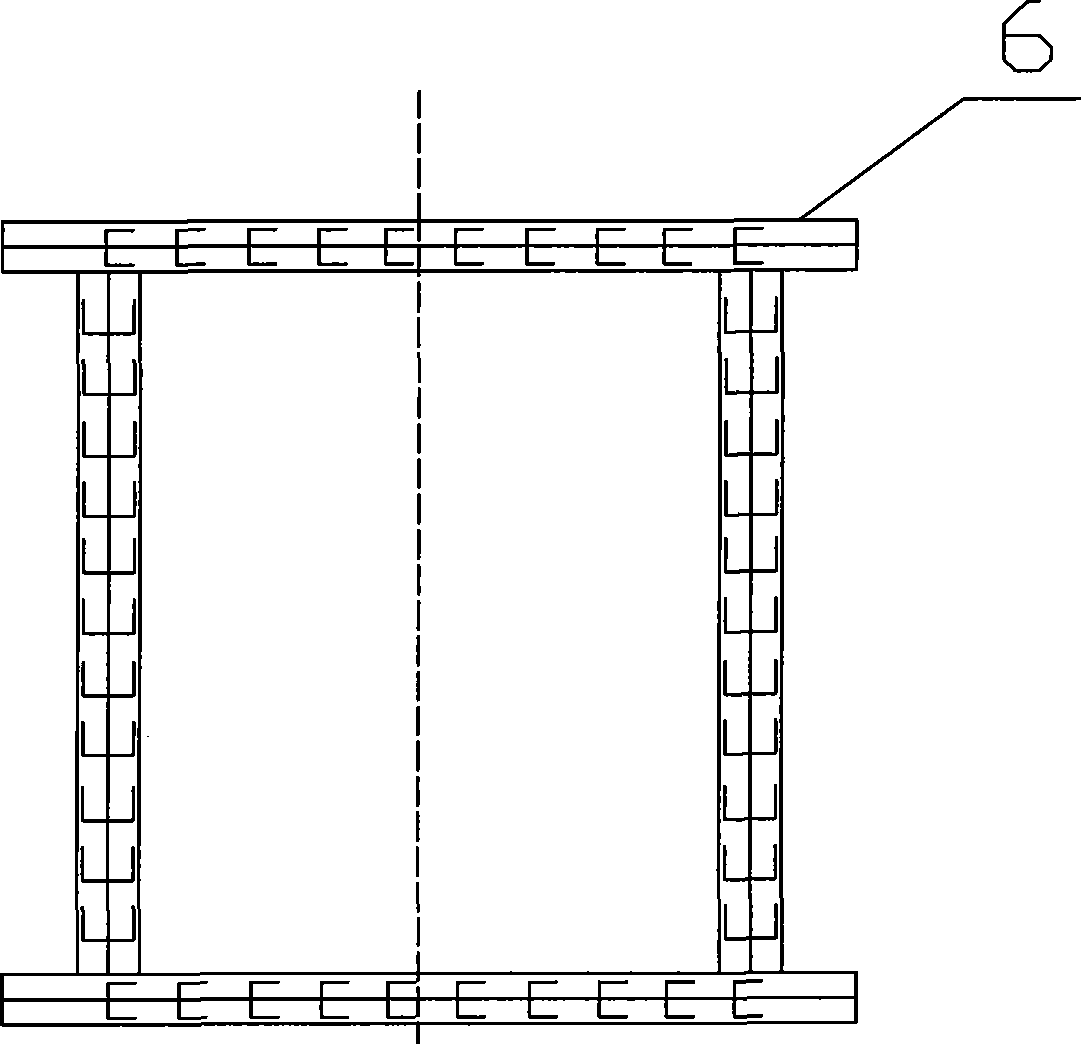

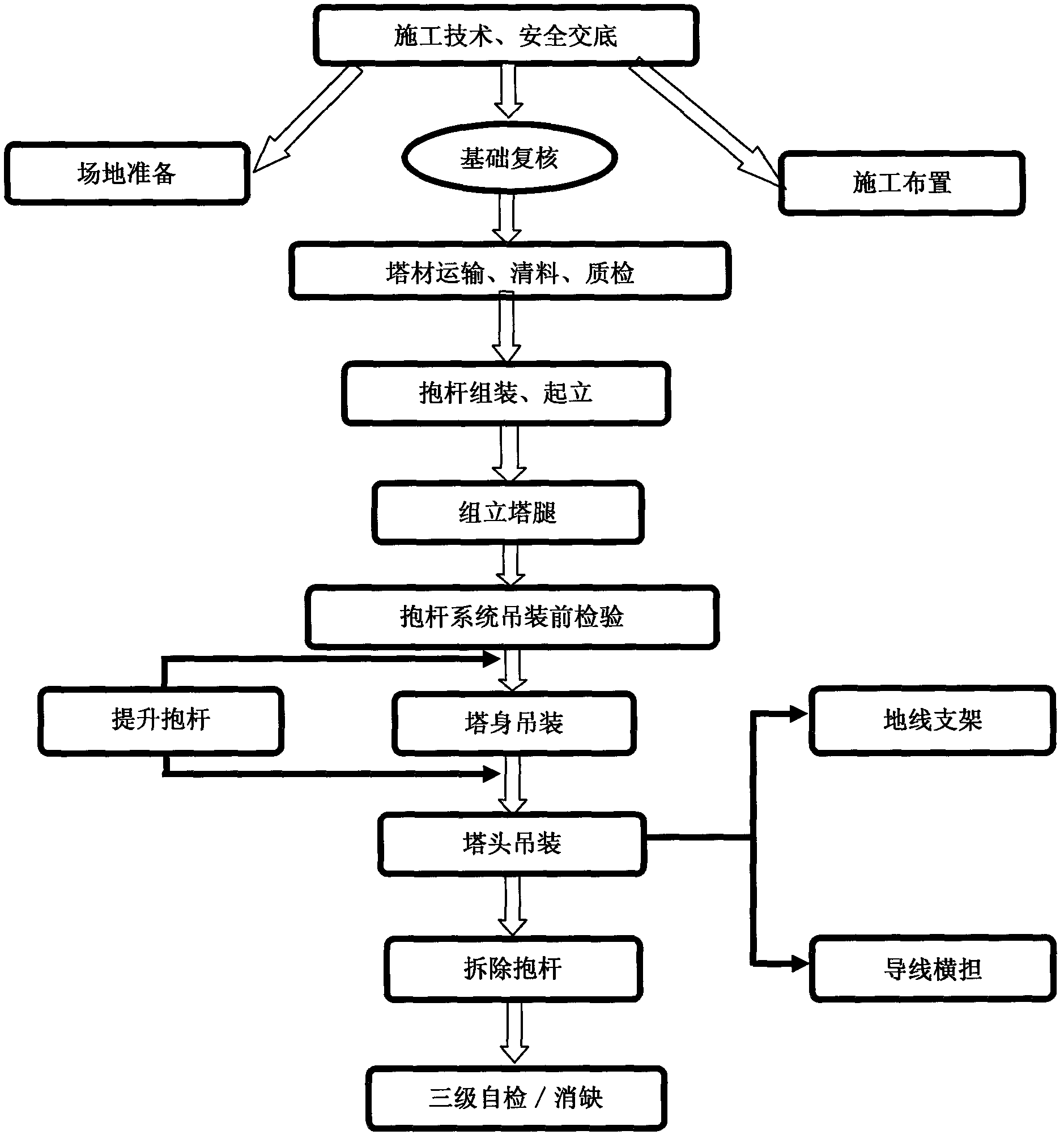

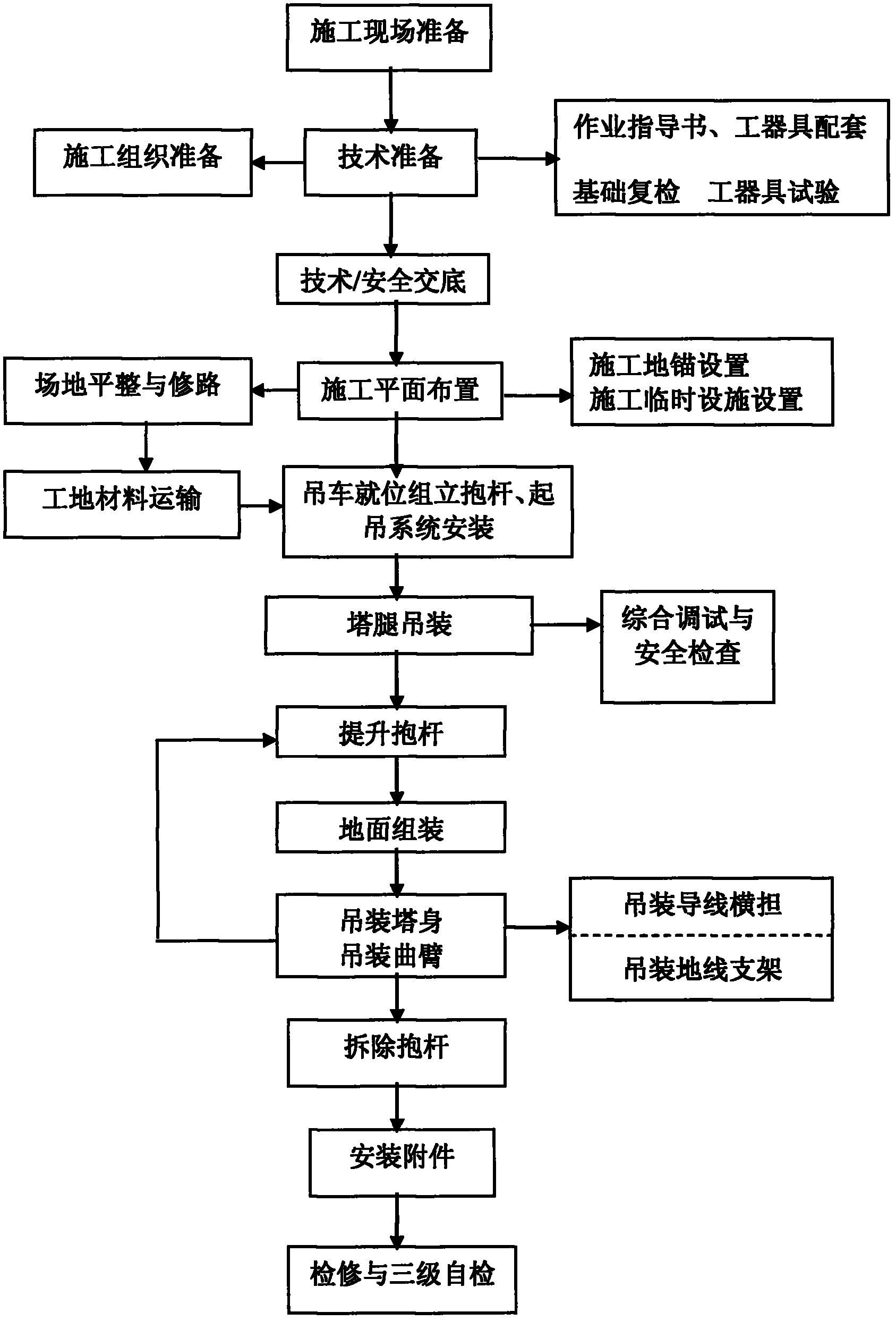

Extra-high voltage common circuit iron tower assembling method

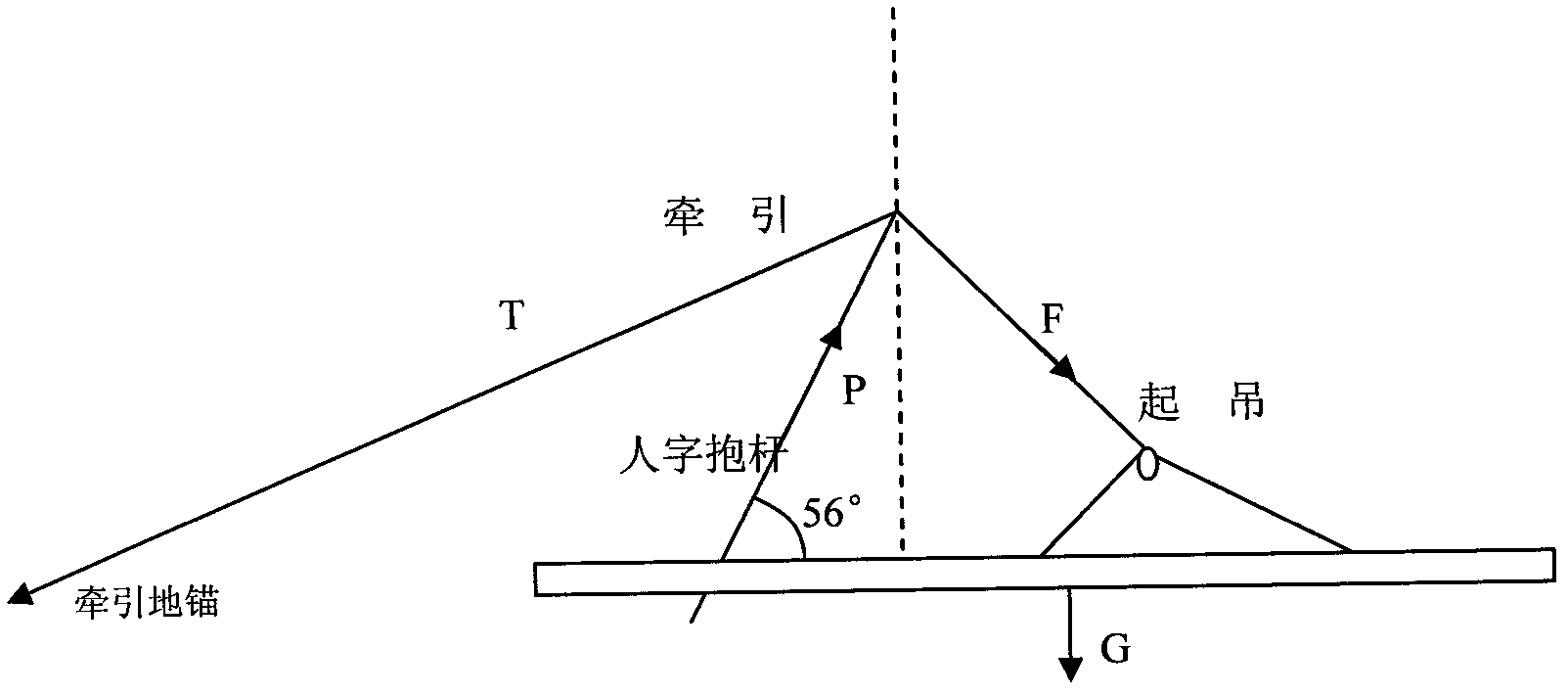

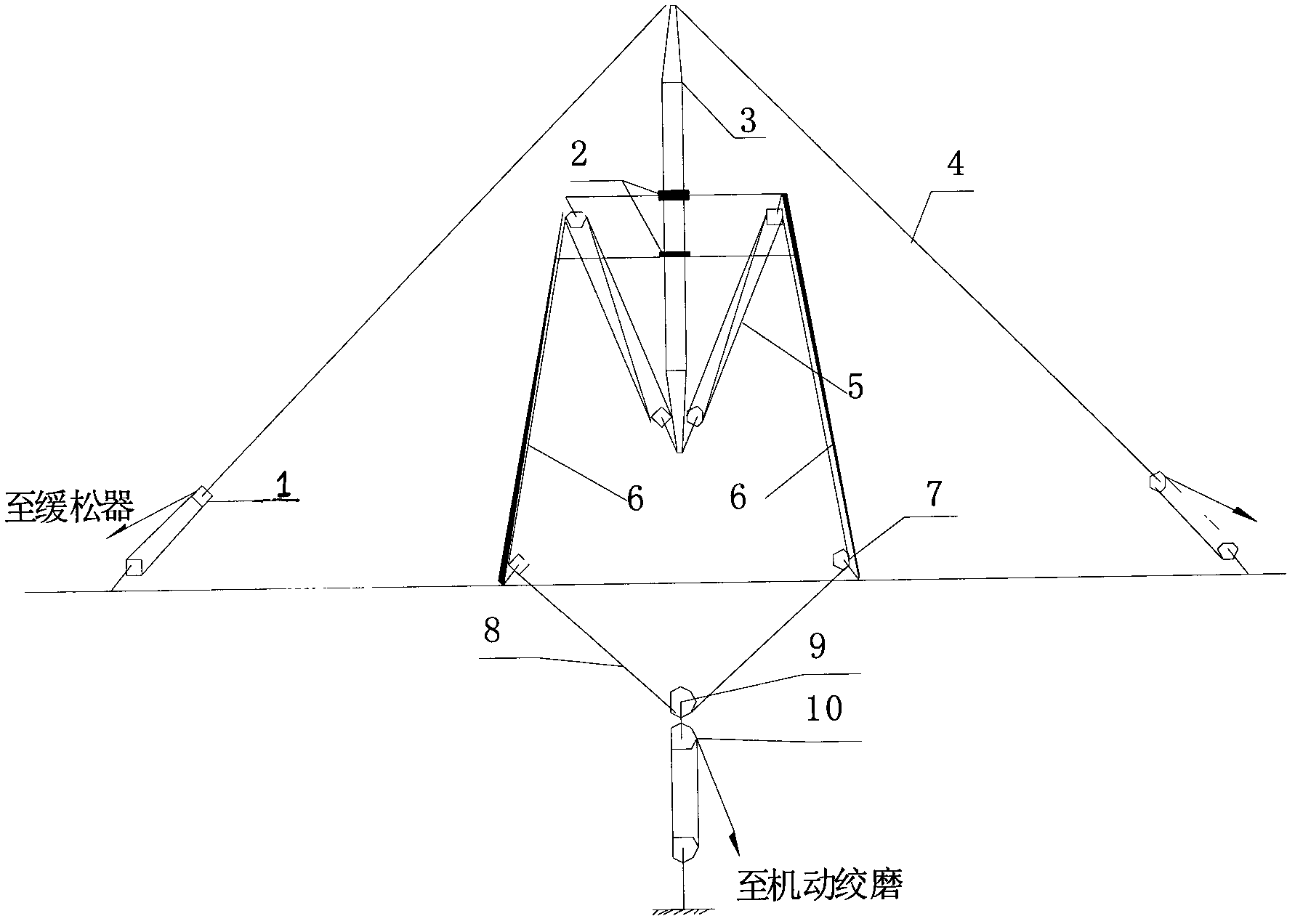

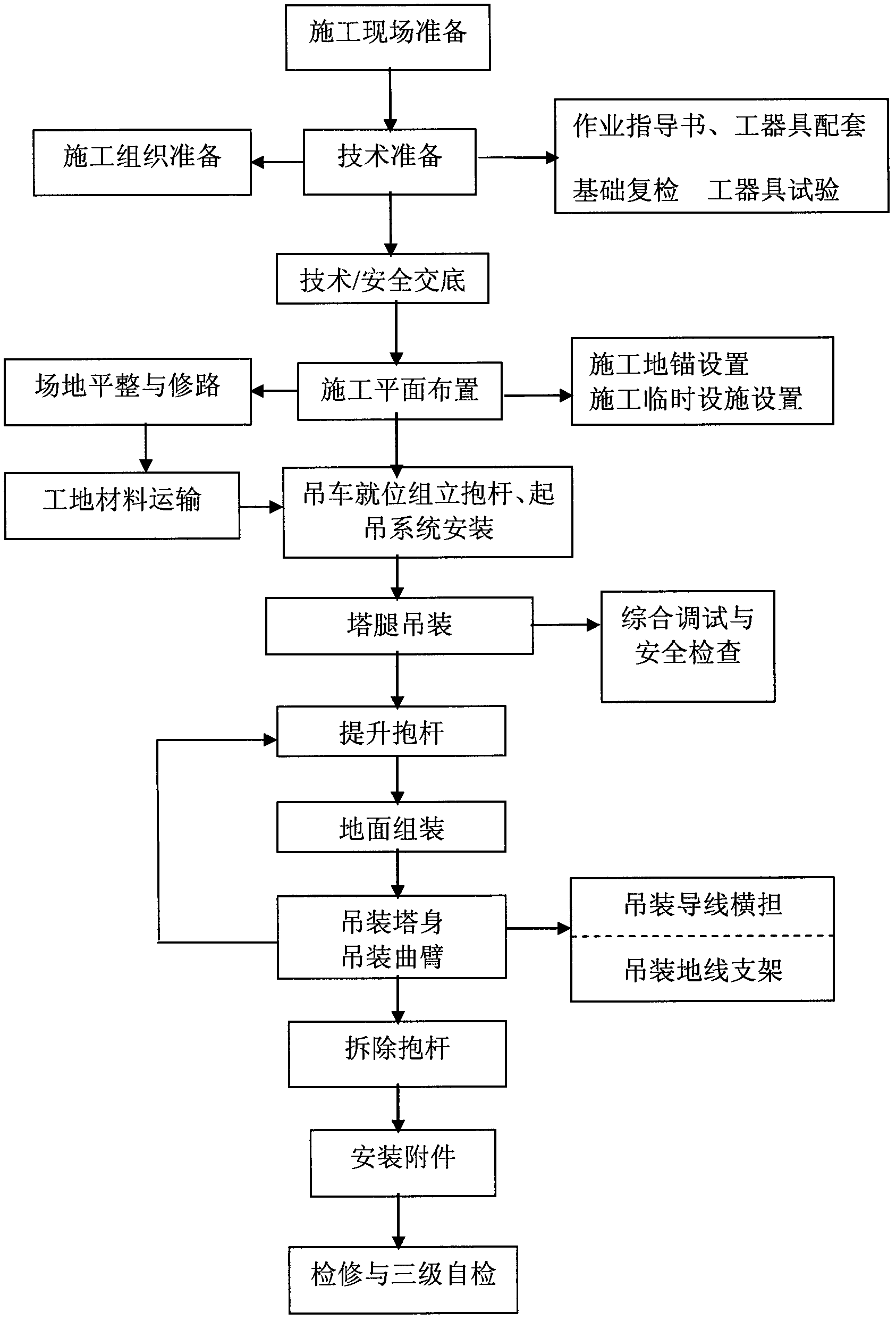

The invention discloses an extra-high voltage common circuit iron tower assembling method, which belongs to the technical field of electric transmission and transformation electric power circuit construction processes. The method comprises the following steps of: 1, performing construction preparation, namely cleaning a construction field, arranging the construction field, preparing a construction ground foundation, and transporting tower materials required by iron tower assembly; 2, assembling a pole, erecting the pole and assembling tower leg lower sections; 3, assembling and erecting towerlegs, lifting the pole, and hoisting iron tower crank arms; and 4, lifting the pole, hoisting a tower head, mounting a ground wire bracket, hoisting iron tower cross arms one by one in a segmentationmode, mounting iron tower accessories and disassembling the pole. The method has the advantages of reducing the working amount of aloft operation, along with a short construction period, a small number of hoisting times and high safety; by the method, safety risks are reduced, required aloft operation personnel is greatly reduced, and labor cost is reduced; and the method has extremely good economic and social benefits.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

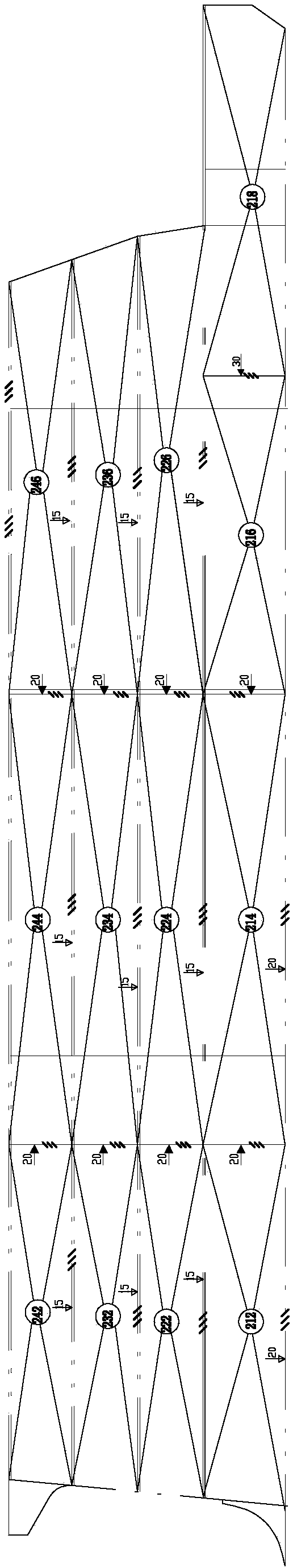

Extra-high voltage large-span iron tower assembling method

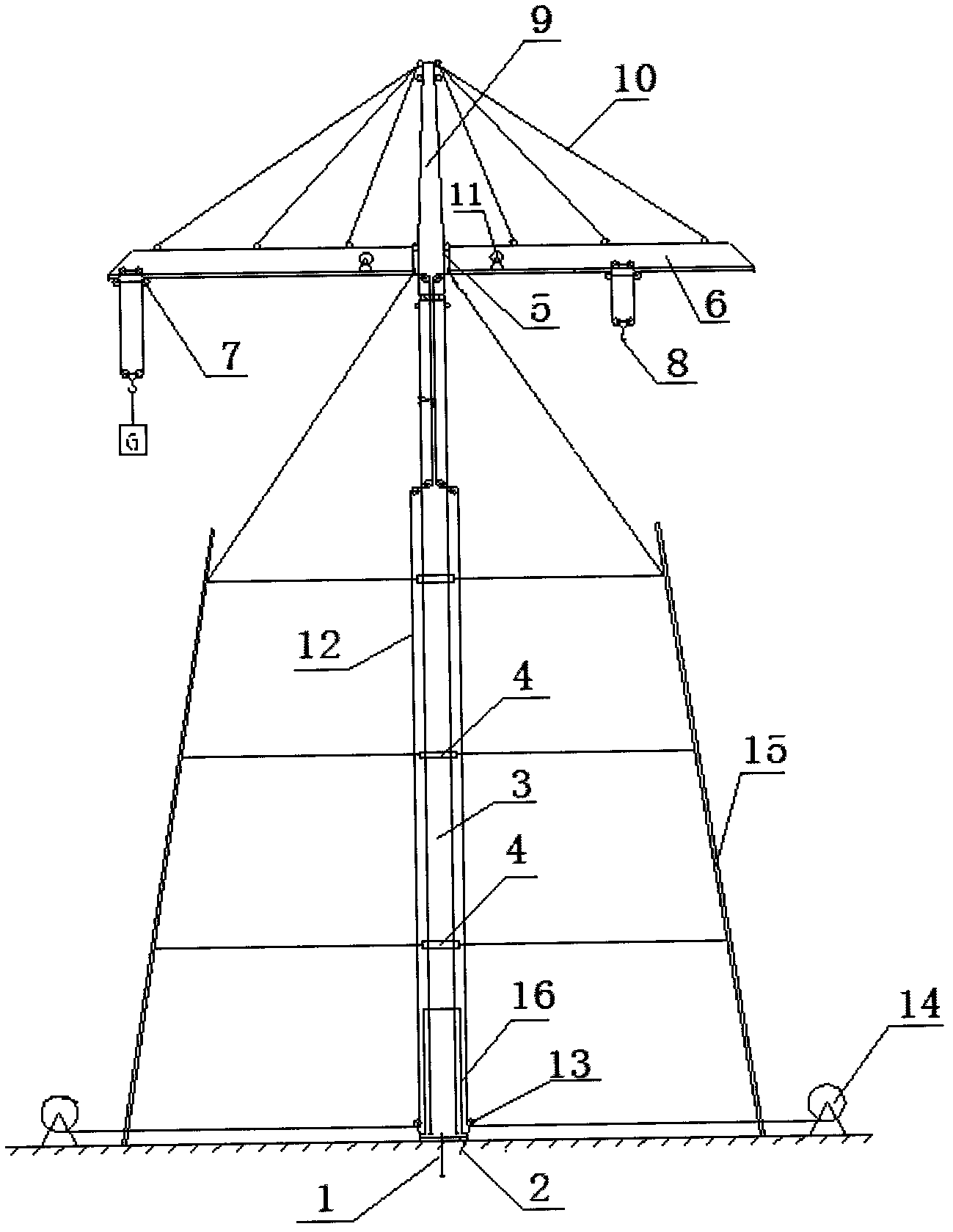

The invention discloses an extra-high voltage large-span iron tower assembling method, which belongs to the technical field of electric transmission and transformation electric power circuit construction processes. The method comprises the following steps of: 1, arranging a construction site, namely arranging a ground anchor, performing pole foundation construction, and arranging main material single pieces and tower sheets of an assembled iron tower body on the ground; 2, assembling a pole, mounting a hoisting system, and hoisting iron tower legs, wherein the assembled pole is a spinning self-elevating ground pole which is provided with horizontal double arms and a hydraulic downward jacking stock; 3, lifting the pole, hoisting the iron tower body section by section, and finally hoistingiron tower cross arms one by one in a segmentation mode; and 4, mounting iron tower accessories, disassembling the pole, and finally overhauling and self-checking to finish the construction. The method has the advantages of reducing the working amount of aloft operation, along with a short construction period, a small number of hoisting times and high safety; by the method, safety risks are reduced, required aloft operation personnel is greatly reduced, and labor cost is reduced; and the method has extremely good economic and social benefits.

Owner:HUBEI ELECTRIC POWER TRANSMISSION & DISTRIBUTION ENG

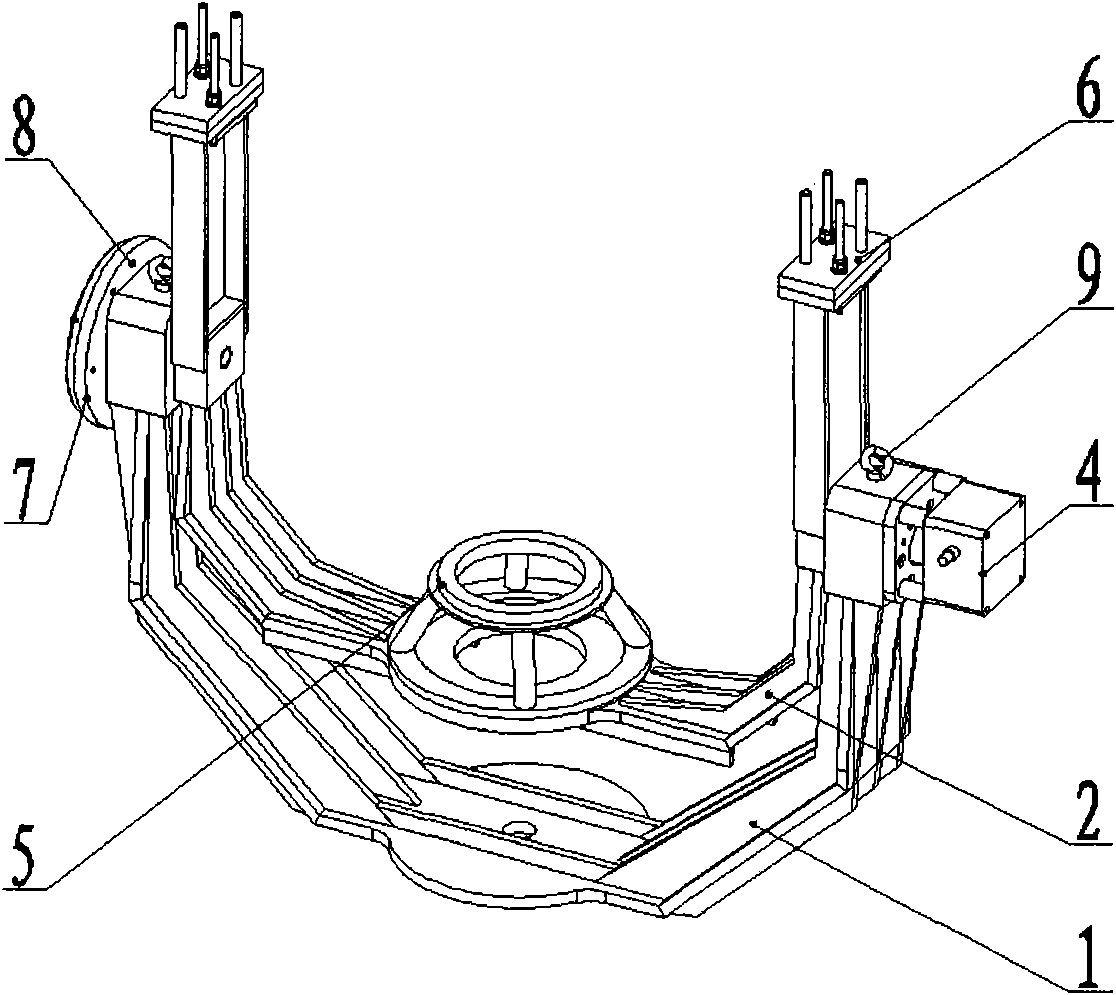

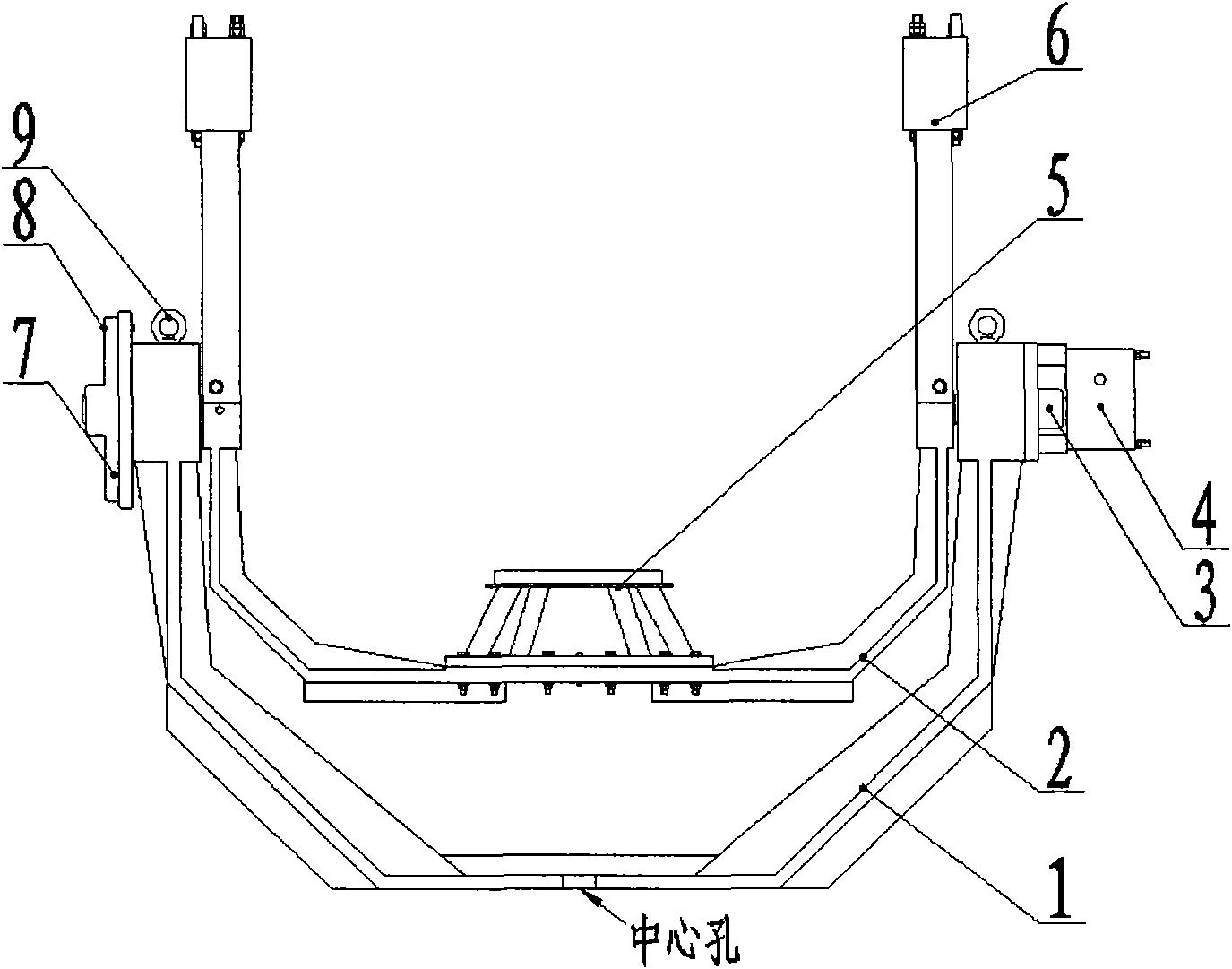

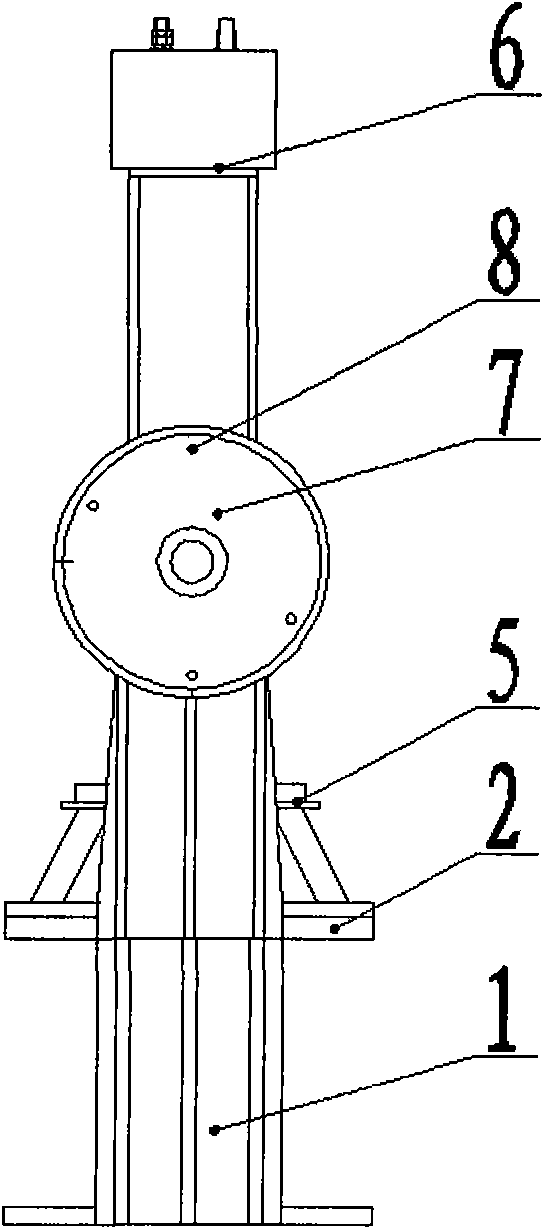

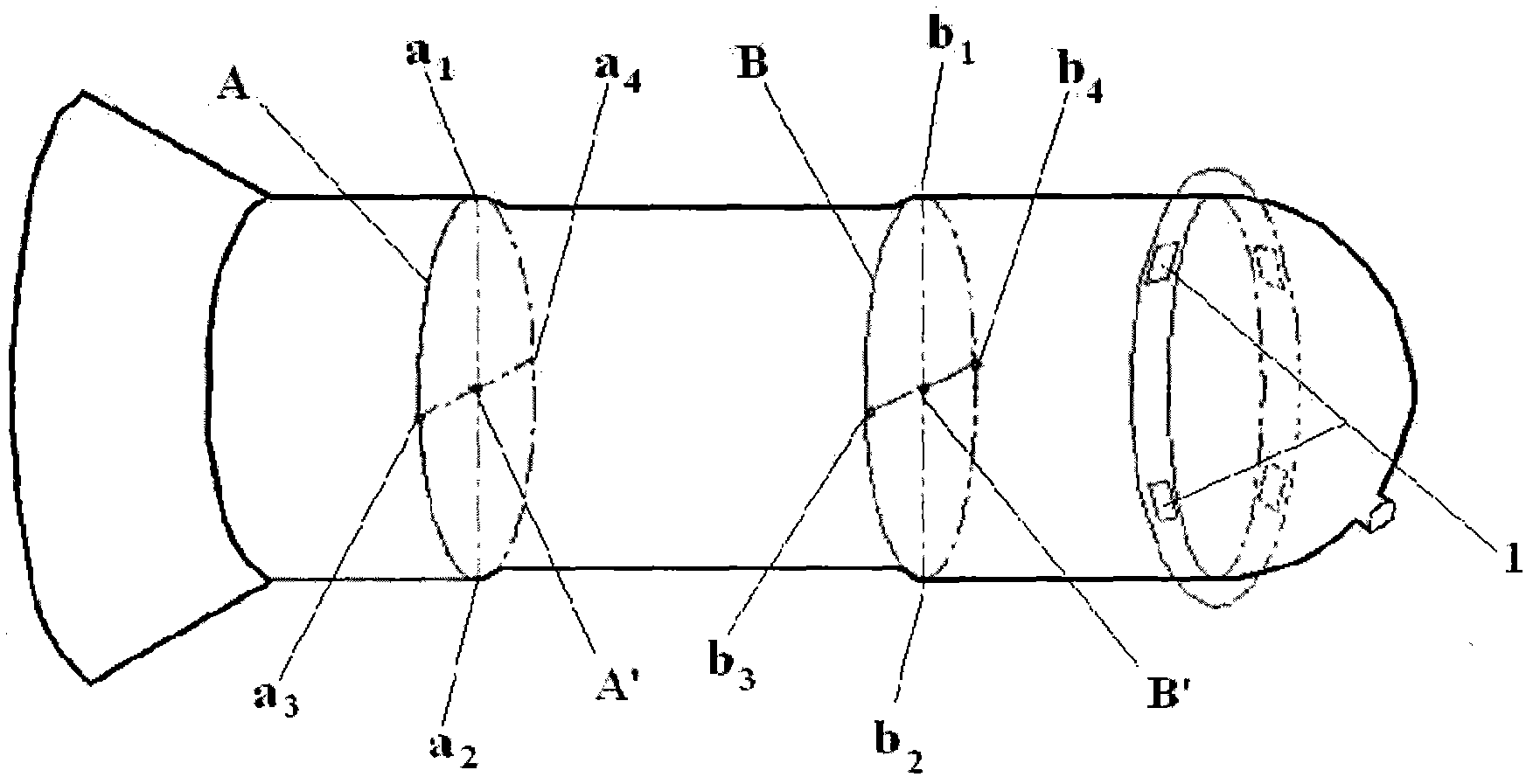

Microsatellite quality characteristic bidirectional testing equipment and method

ActiveCN101975641AReduce size and massReduce the impactGearboxesStatic/dynamic balance measurementQuality characteristicsEngineering

The invention discloses microsatellite quality characteristic bidirectional testing equipment. A U-shaped symmetrical inner and outer supporting frame structure is adopted; an inner supporting frame is driven to rotate around a rotating shaft by a speed-reducing mechanism and is easily positioned in vertical and horizontal directions through a positioning mechanism; and the problem of rapid coordinate conversion in a vertical state and a horizontal state through one-time hoisting is solved. The quality characteristic data in two states is tested through one-time hoisting and clamping in the field of microsatellites, the quality characteristic testing time is shortened, the testing efficiency and testing effect are improved, the safety and reliability of the quality characteristic testing are enhanced, and the labor intensity of personnel is greatly lightened. The microsatellite quality characteristic bidirectional testing equipment has a simple structure, is convenient to operate, and can be used for quality characteristic testing of spacecrafts and other miniature equipment.

Owner:AEROSPACE DONGFANGHONG SATELLITE

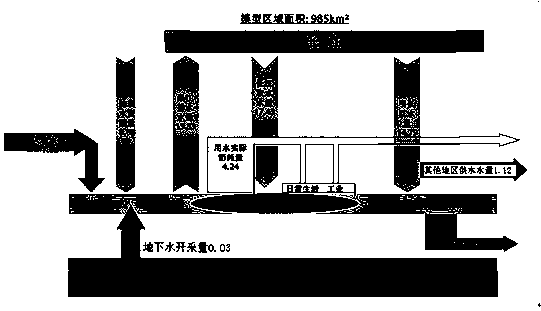

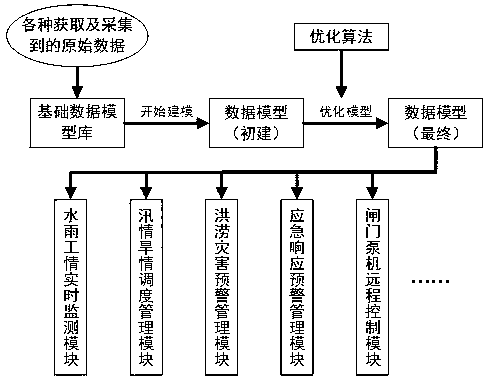

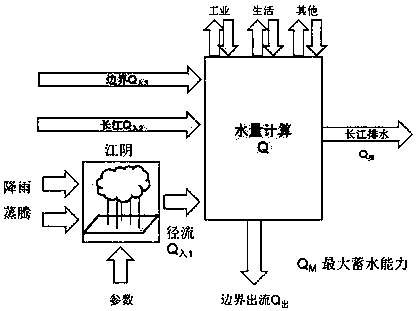

Intelligent scheduling decision-making method for flood and drought control based on extreme climate condition

ActiveCN107657329AGuaranteed to be scientificGuaranteed accuracyClimate change adaptationForecastingDecision schemeOriginal data

The invention discloses an intelligent scheduling decision-making method for flood and drought control based on extreme climate conditions. The intelligent scheduling decision-making method is used inriverside areas and comprises the steps of: step 1) acquiring and collecting various kinds of original data; step 2) preliminarily establishing a virtual reservoir model; step 3) optimizing the virtual reservoir model; step 4) and utilizing a final data model obtained in the step 3) to output various kinds of data to sub-functional modules, thereby achieving the intelligent scheduling decision-making purpose for flood and drought control in the riverside areas under extreme climate conditions. The intelligent scheduling decision-making method can ensure scientificity, precision and reliability of the data, achieves the effects expert early-warning support and decision scheme analysis, can timely respond to the sudden rainstorm process, and immediately starts up a pumping station drainage,not only reduces the water accumulating volume, but also greatly reduce the full-load working process of the pumping station, saves energy and reduces emission, effectively improves the early-warningand handling capacity of flood and drought control in the riverside areas, promotes the improvement of integral level of water resource scheduling management, and has extremely high practicability.

Owner:江苏鸿利智能科技股份有限公司

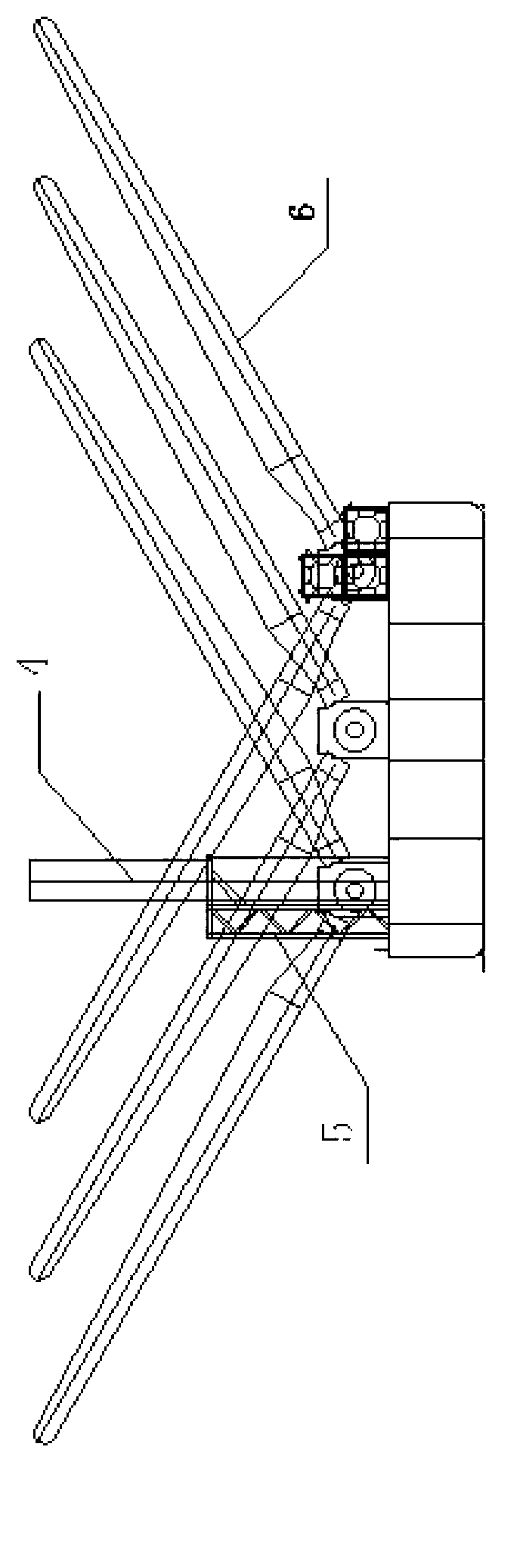

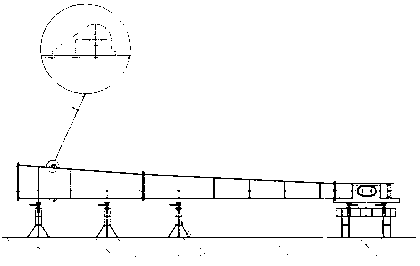

Transition-section-free single-pile foundation construction and fan equipment installation process for shallow sea area wind farm

ActiveCN103015445AReduce on-site workloadThe effect of reduced wind speedFoundation engineeringShallow seaMature technology

The invention discloses a transition-section-free single-pile foundation construction and fan equipment installation process for a shallow sea area wind farm. The process comprises a transportation method. The transportation method comprises the following steps of: arranging single pipe piles on a transportation ship, arranging tracks and pulley devices below the single pipe piles, hanging a rigging after arriving at a construction sea area, and directly erecting piles; dividing a tower into two or three sections, placing each section of tower onto a tower bracket for transporting vertically, erecting, and arranging all small parts including electrical appliance cabinets and the like in the tower to lower field workload; constructing rabbit assemblies by using a cabin, hubs and two blades for transportation to lower field workload and lower the influence of wind speed; and designing a special tool for remaining blades, wherein overlaid transportation can be performed to fully utilize the space of the transportation ship. The transition-section-free single-pile foundation construction and fan equipment installation process for the shallow sea area wind farm disclosed by the invention has the advantages of mature technology, low tool cost, easiness in operating, vertical degree adjusting function, reduction in hoisting times, great increase in the construction efficiency, great saving of ship renting and amortizing cost, and reduction in the construction cost.

Owner:JIANGSU LONGYUAN ZHENHUA MARINE ENG

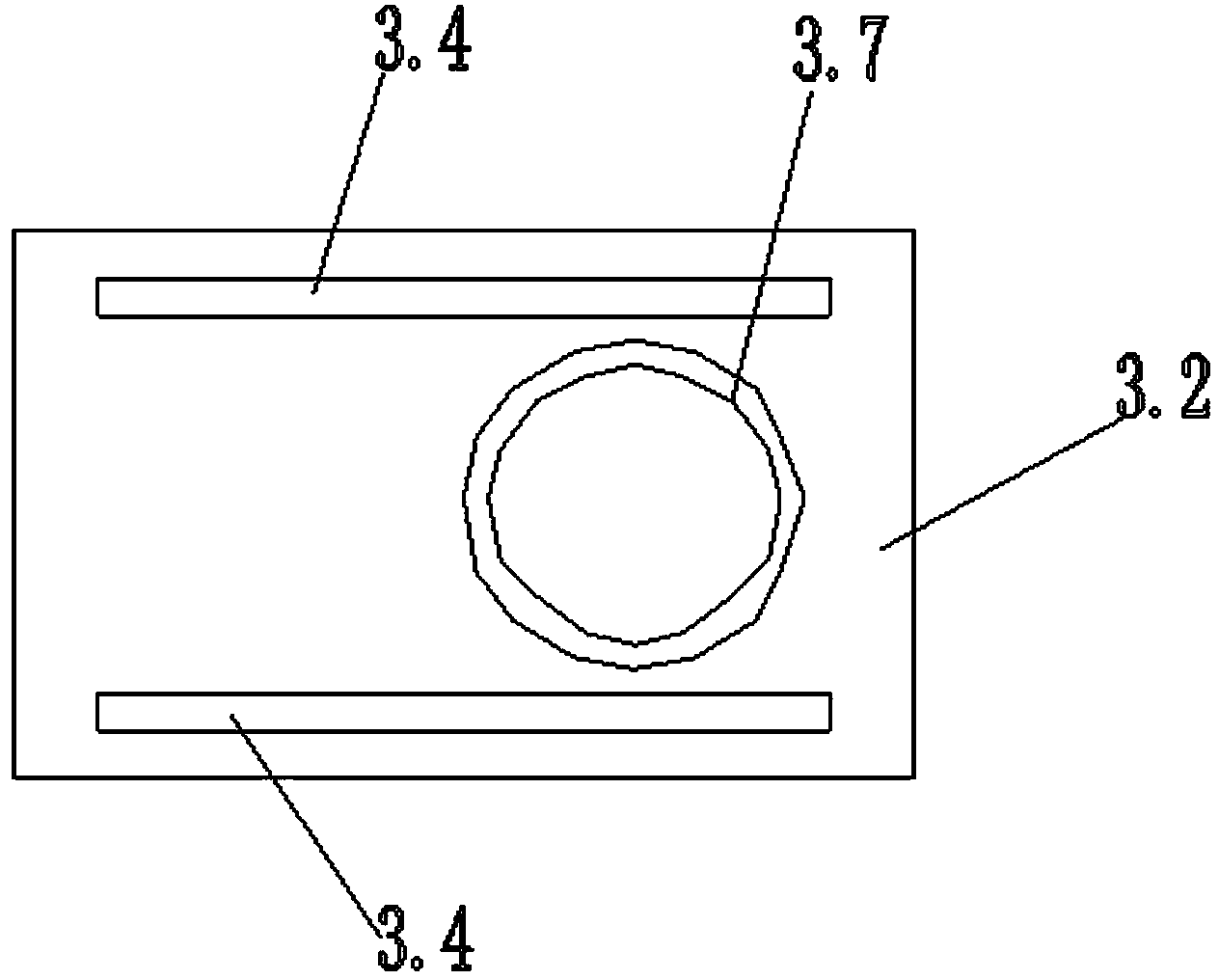

Subway station Y-shaped cast steel combining steel pipe post processing and construction method

ActiveCN104234079AGood pouring compactnessGuarantee the construction qualityArtificial islandsUnderwater structuresConstruction engineeringSubway station

The invention relates to the field of special-shaped steel pipe post processing and concrete construction of the special-shaped steel pipe post, in particular to a subway station Y-shaped cast steel combining steel pipe post processing and construction method, which solves the problems that when the existing steel structure post is applied in underground engineering, the processing process, the welding quality and the hanging conveying installation are very difficult, concrete in the pipe post is not compact, deformation easily occurs, and the like. The method comprises the following steps of design and processing of Y-shaped cast steel combining steel pipe post, splicing welding construction of upper part cast steel sections and lower part steel pipe sections in construction sites, installation and construction of embedded parts, integral hanging conveying installation, butt joint in the air, welding in the air, and concrete casting in the steel pipe post by adopting a concrete jacking device and a pumping jacking method. The processes of segmented processing casting in factories, in-site splicing welding, two-segment integral hanging conveying installation and one-step welding completion in the air is adopted, the construction safety and the structure welding quality are ensured, the construction efficiency is improved, the construction progress is accelerated, and the design, processing and installation blanks of the large-scale steel structure of the underground engineering are filled.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY

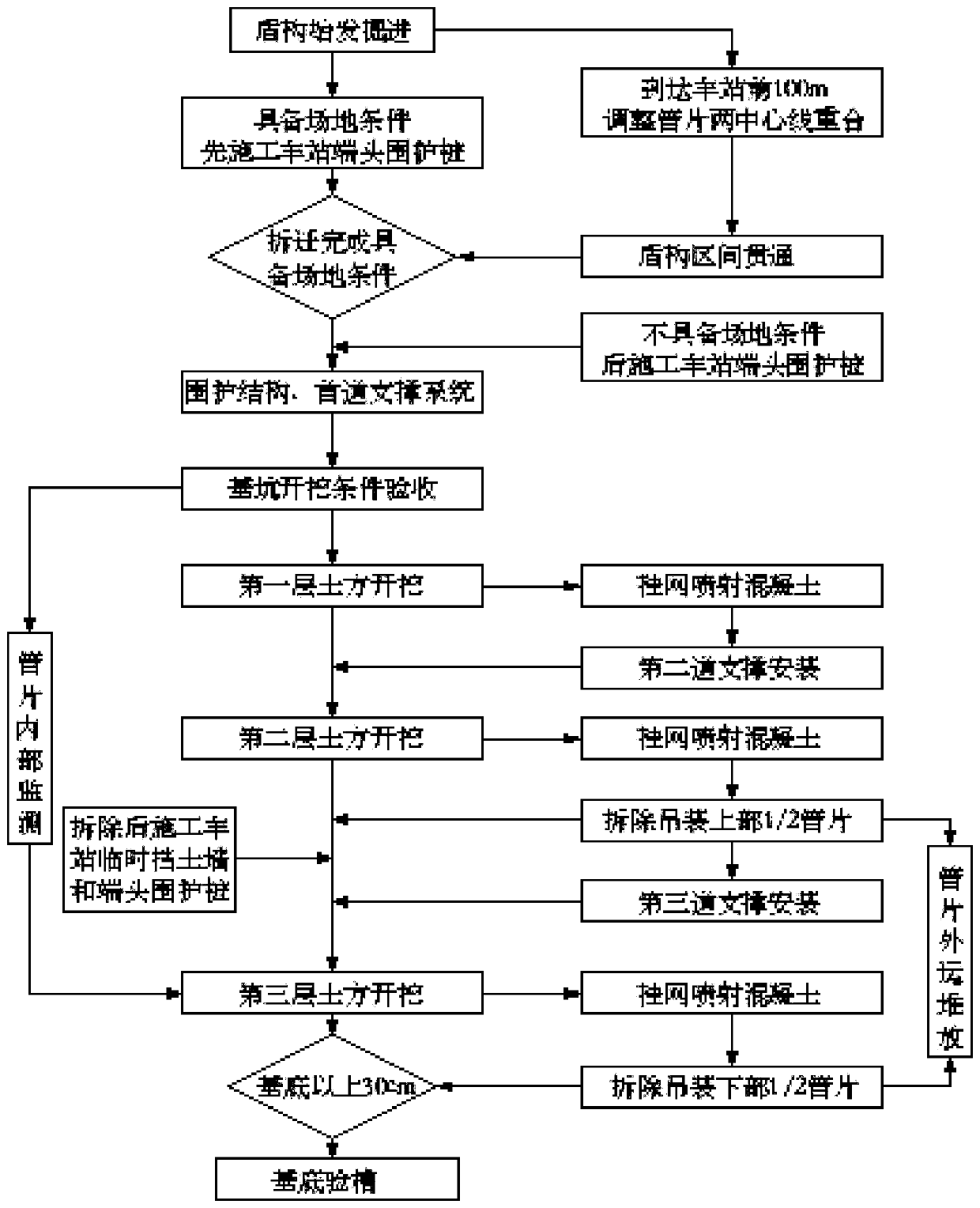

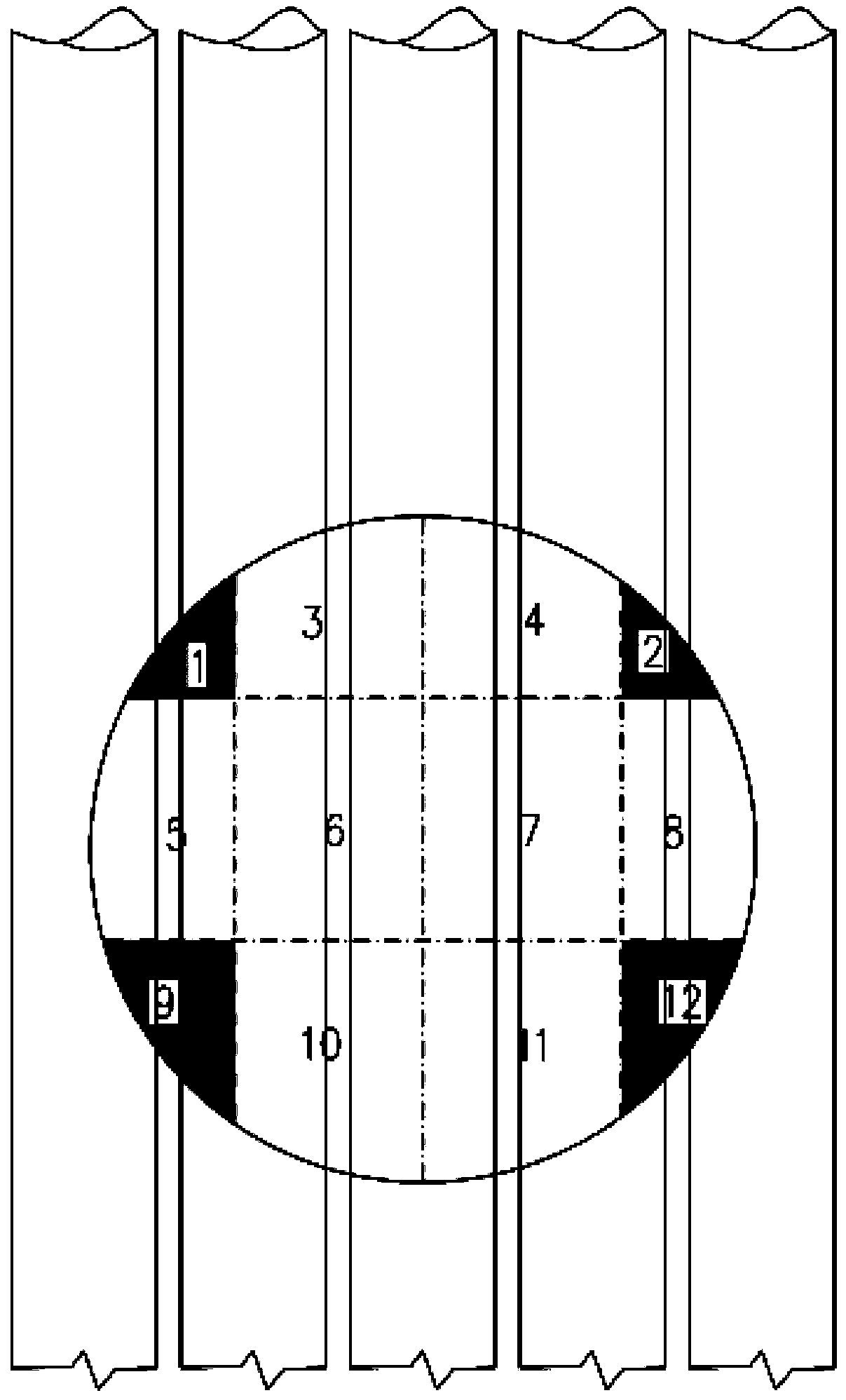

Tunnel-before-station open-cut station construction method

ActiveCN110424969ANot affected by land acquisition and demolitionControllable start timeArtificial islandsUnderground chambersArchitectural engineeringShield tunneling

The invention provides a tunnel-before-station open-cut station construction method. A shield tunneling machine carries out tunneling in advance to pass through the station range, and the problems that a station is influenced by land requisition and demolishing and does not have construction conditions, and starting and receiving conditions cannot be provided for the shield tunneling machine are solved; and the aim that the sections can be cut through firstly, and then the station is constructed is achieved.

Owner:中铁一局集团厦门建设工程有限公司 +1

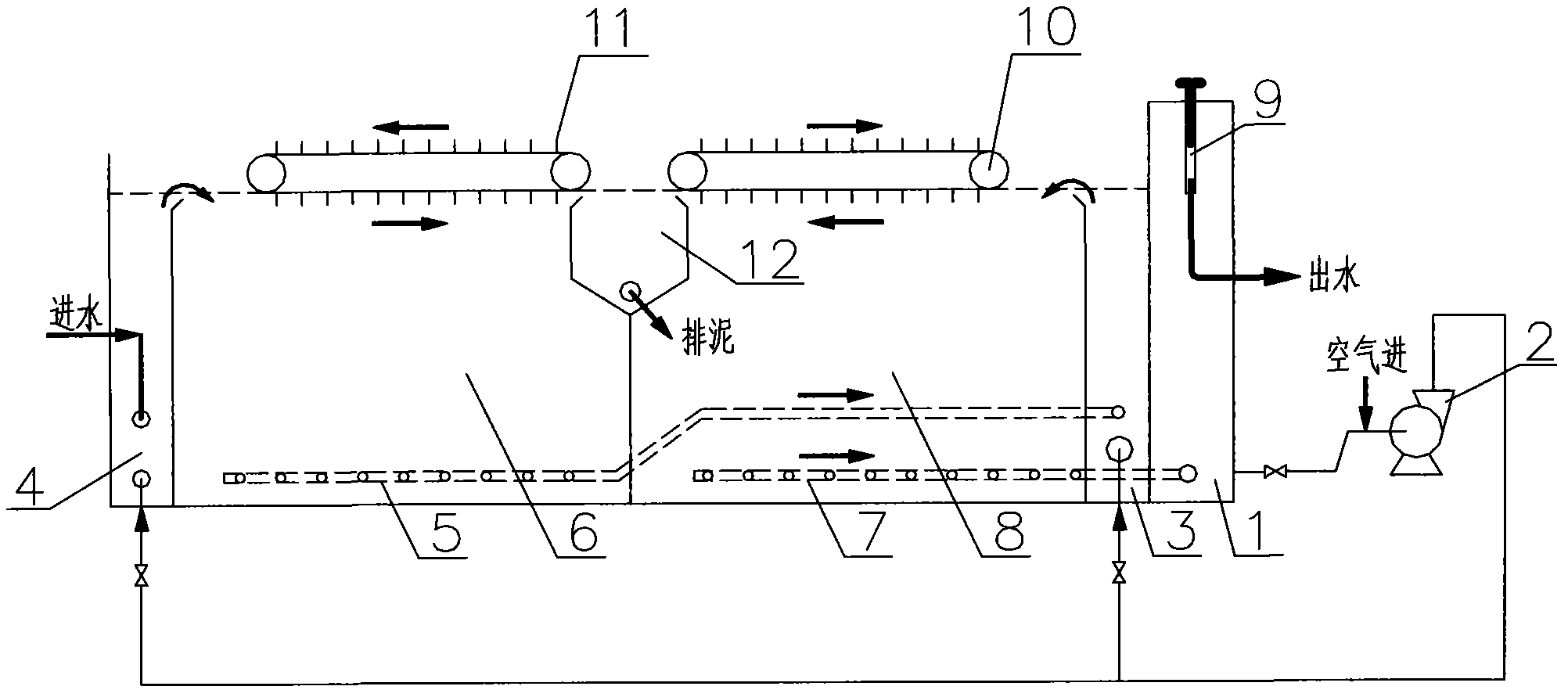

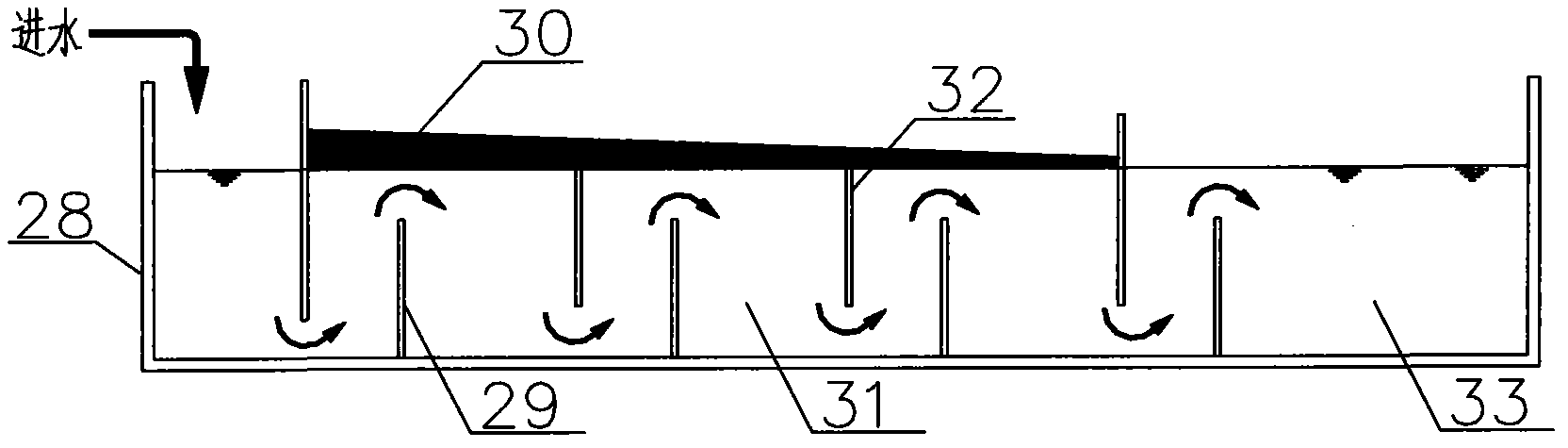

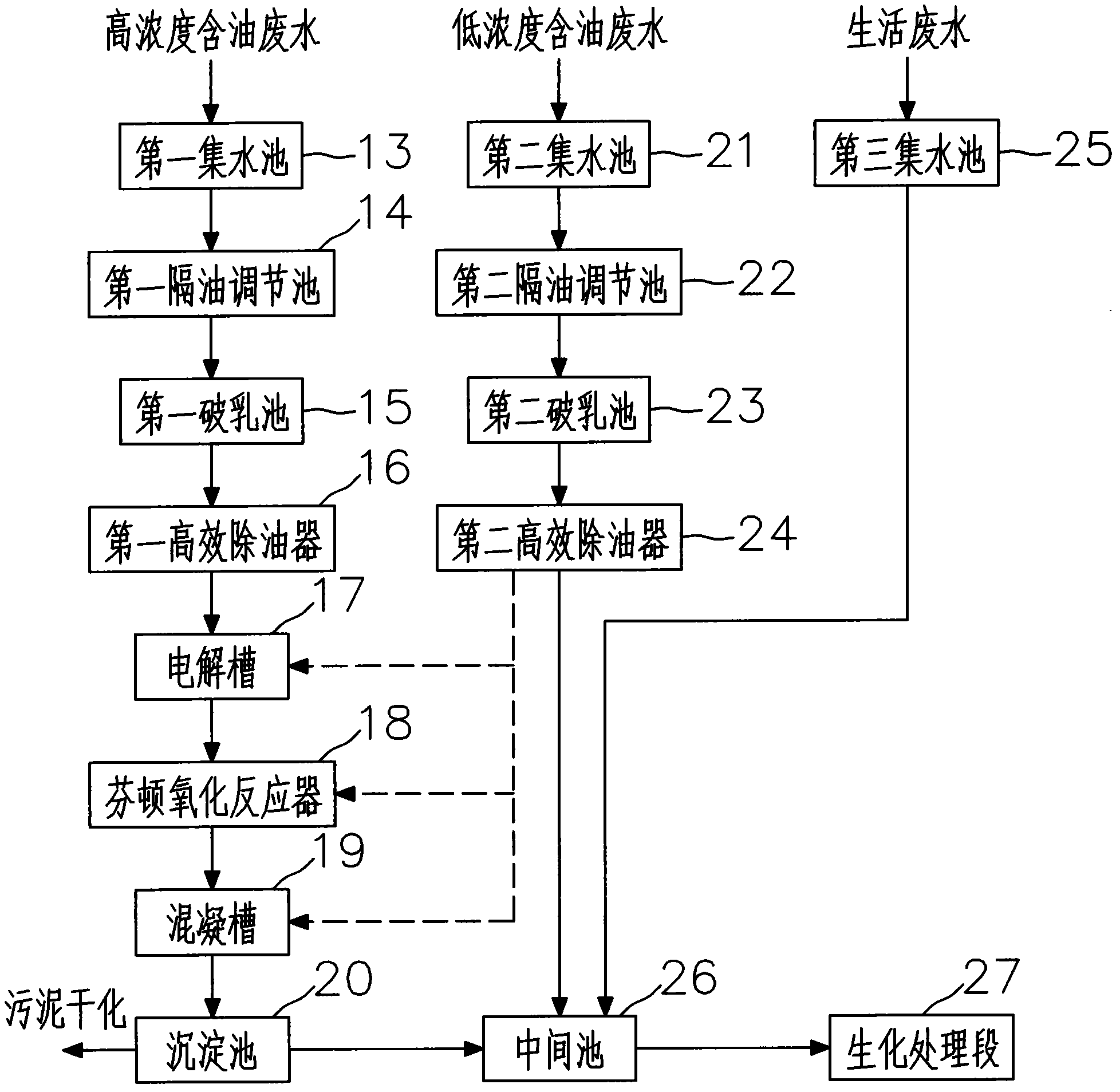

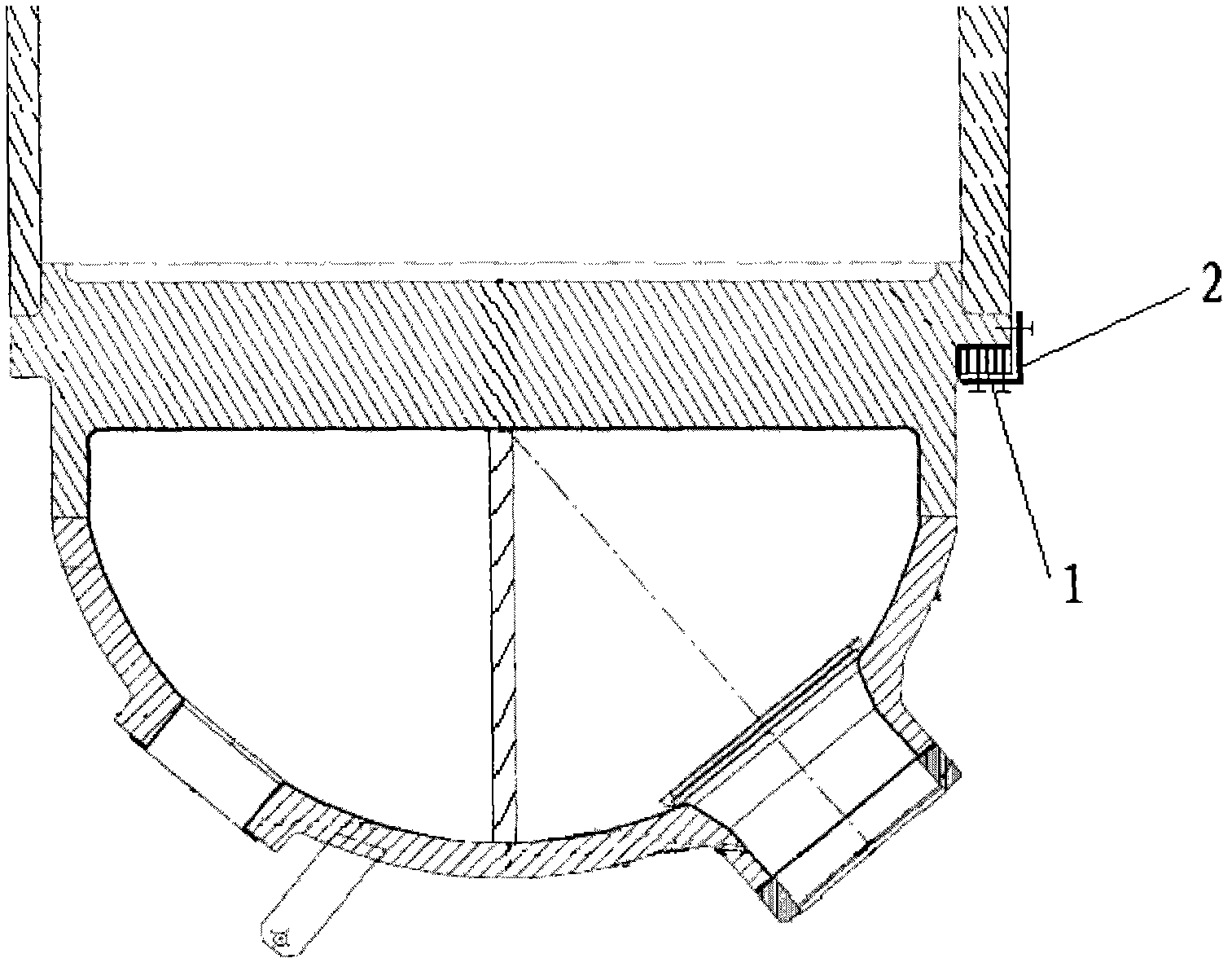

Oily wastewater pretreatment system and high-efficiency oil eliminator arranged in system

ActiveCN102701483APrevent emulsification from reducing the degreasing degree of purificationSimple structureFatty/oily/floating substances removal devicesMultistage water/sewage treatmentHigh concentrationSludge

The invention belongs to the technical field of wastewater treatment and particularly relates to a high-efficiency oil eliminator and an oily wastewater pretreatment system with the high-efficiency oil eliminator. The high-efficiency oil eliminator comprises at least two stages of air floatation treatment devices. An air floatation treatment device at each stage is communicated with an adjacent air floatation treatment device along a water flowing direction. A sludge hopper is arranged on the side of each air floatation treatment device. A sludge scraper which is used for scraping floating sludge in the air flotation treatment device to the sludge hopper is arranged on the upper side of the air flotation treatment device at each stage. The oil eliminator additionally comprises an air dissolving water pump which is used for delivering air dissolving water to the air flotation treatment device through a water delivery pipe. The oily wastewater pretreatment system consists of a high-concentration oily wastewater pretreatment section and a low-concentration oily wastewater pretreatment section. The oily wastewater pretreatment system has the advantages that since a high-concentration and low-concentration oily wastewater quality-based treatment process route is adopted, the operating cost is low and the removal efficiency or degradation efficiency of pollutants is high; and the system is also suitable for pretreatment of all other kinds of high-concentration oily wastewater which is difficult to degrade, or is matched with process units.

Owner:安徽南风环境工程技术有限公司

Method for installing steam generator in nuclear island of nuclear power plant

ActiveCN102592692AShorten the timeReduce the number of liftingMeasurement devicesNuclear energy generationNuclear plantMeasurement device

The invention relates to a nuclear island installation method in a nuclear power plant, and aims to solve the problems of long hoisting time and high installation cost when a steam generator in a nuclear island of the nuclear power plant is installed. The invention discloses a method for installing the steam generator in the nuclear island of the nuclear power plant. The method comprises the following steps of: placing the steam generator to be installed on a support device; detaching a protecting device on the support of the body of the steam generator to be installed; setting a measurement point on the body of the steam generator to be installed; setting a surveying station point at the bottom close to the steam generator to be installed for placing a measurement device; placing a reference scale below the bottom of the steam generator to be installed; measuring the reference scale, the measurement point and the surveying station point by using the measurement device and recording data; processing the measured data by using an industrial measurement system and calculating the thickness of a liner plate; and manufacturing the liner plate and hoisting the steam generator to be installed. Therefore, the installation of the steam generator can be finished by one-time hoisting; and the installation cost is reduced.

Owner:CHINA NUCLEAR IND 23 CONSTR

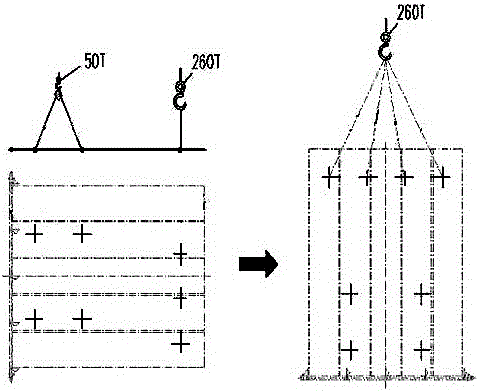

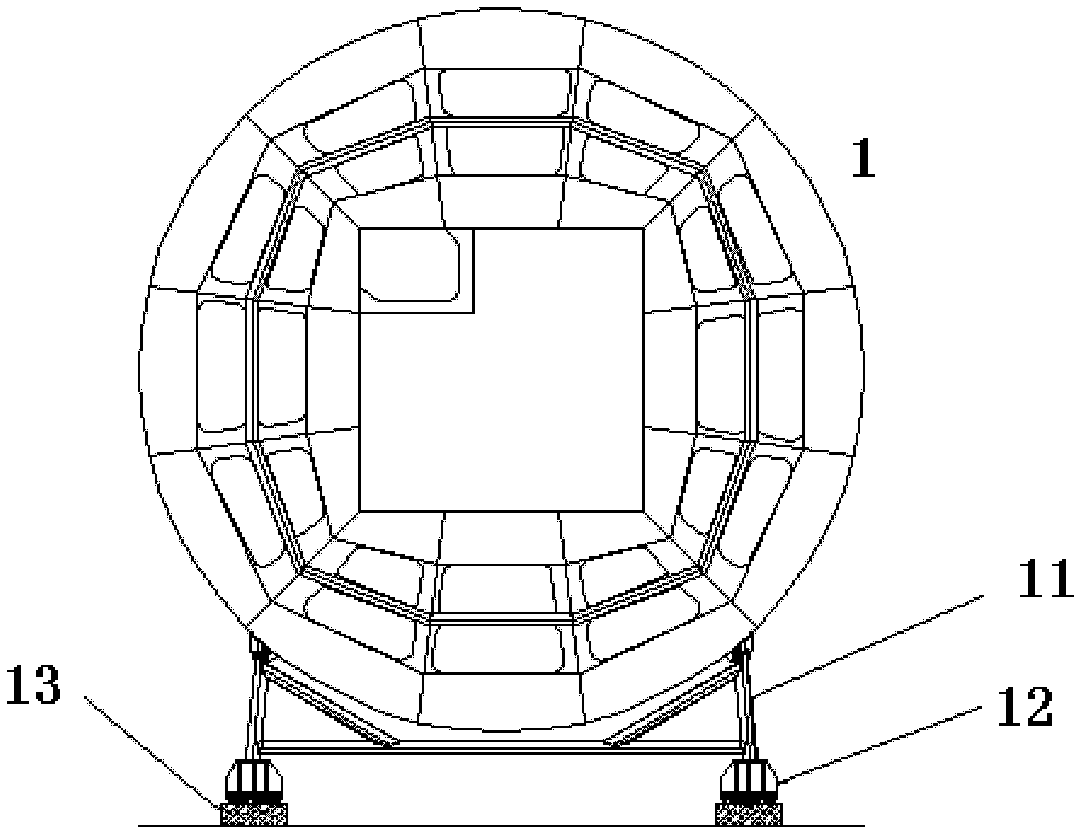

Assembly method of large-scale thin-wall steel containment vessel and auxiliary hoisting pieces

InactiveCN103241644AImprove effective lifting capacityIncreased effective lifting capacityLoad-engaging elementsEngineeringDistributor

The invention discloses an assembly method of a large-scale thin-wall steel containment vessel and auxiliary hoisting pieces, and belongs to the technical field of hoisting and transportation articles. The assembly method comprises the following steps of: arranging the auxiliary hoisting pieces, particularly, uniformly providing a plurality of first lifting lugs on a construction member to be hoisted of the containment vessel, preparing the corresponding riggings, connecting one ends of the riggings with a distributor respectively and the other ends of the riggings with adjustable drawbars respectively, connecting the distributor with a crane, hoisting the distributor and the riggings above the construction member to be hoisted, regulating each adjustable drawbar to enable the adjustable drawbar to extend to a proper length, and connecting each adjustable drawbar to the first lifting lugs respectively. According to the invention, the effective hoisting capability of the crane can be improved, the load of a foundation can be lightened, and deformation of each constructional element of the containment vessel can be reduced.

Owner:CHINA NUCLEAR IND ZHONGYUAN CONSTR +1

Construction method for steel tube confined concrete composite columns

InactiveCN103821280AReduce weldingSolve technical problems such as simultaneous pouringStrutsPillarsRebarTower crane

The invention discloses a construction method for steel tube confined concrete composite columns. The construction method comprises the following steps: step 1, construction preparation; step 2, temporarily fixing steel tube columns; step 3, connecting and fixing steel tube columns; step 4, assembling rebars on an outer frame girder and arranging formworks in a supporting manner; step 5, concrete-pouring the steel tube confined concrete composite columns. According to the invention, steel tube columns in multiple floors are connected, the hoisting frequency of a tower crane is reduced, and the amount of inner lining pipes and the times for welding steel tubes are reduced, so that the construction method has the advantages that the construction period is shortened and the cost is reduced.

Owner:ZHONGTIAN CONSTR GROUP

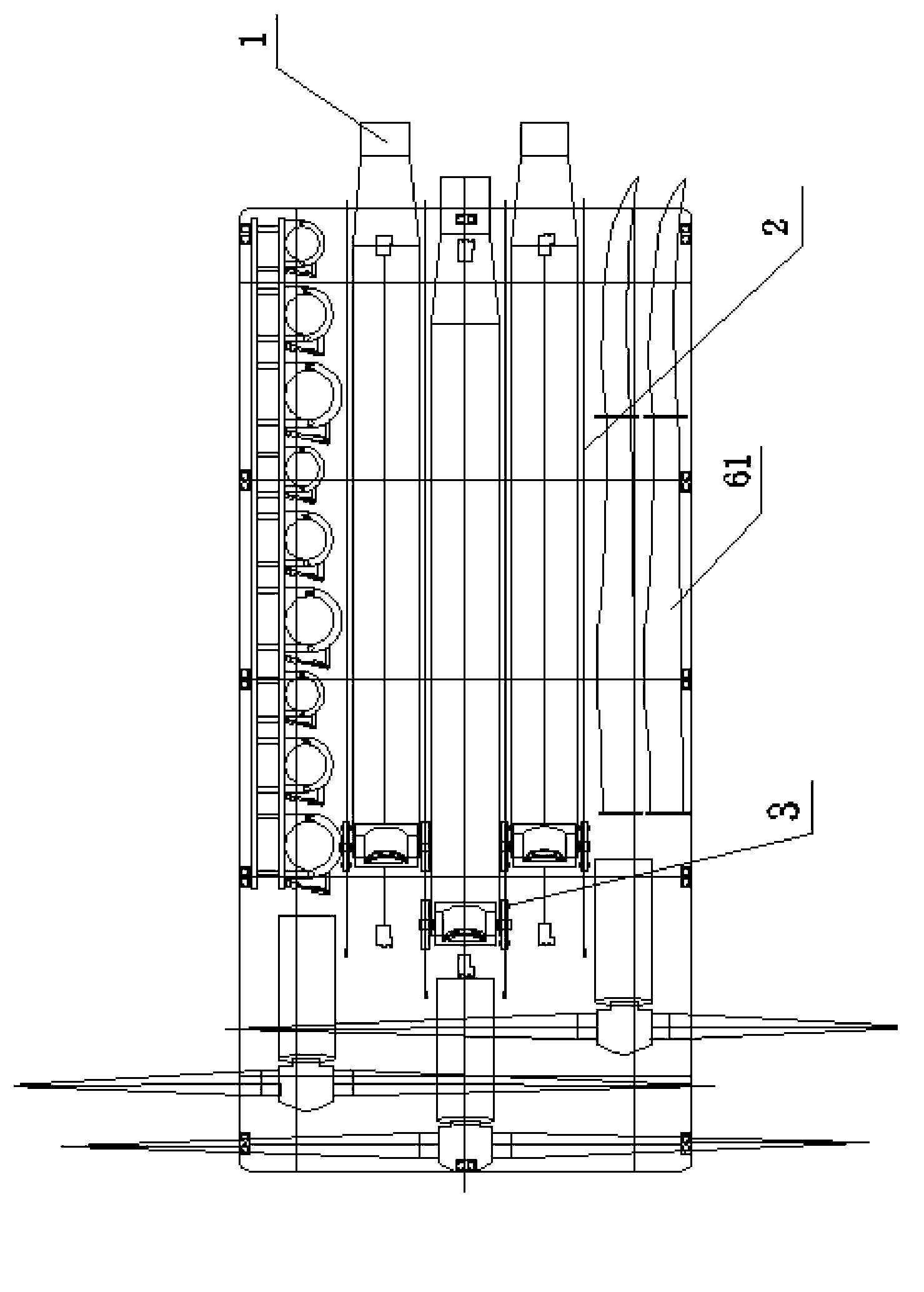

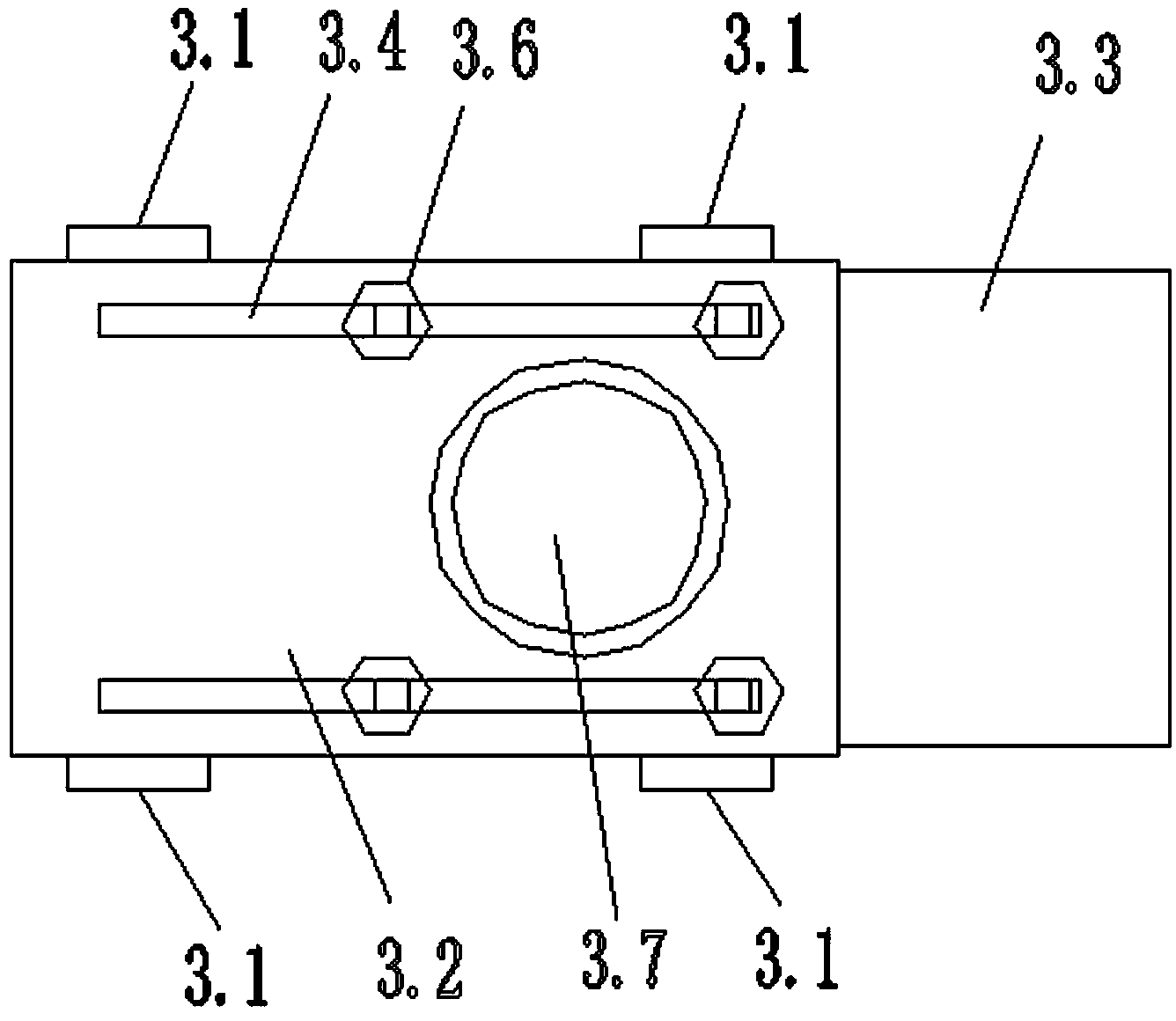

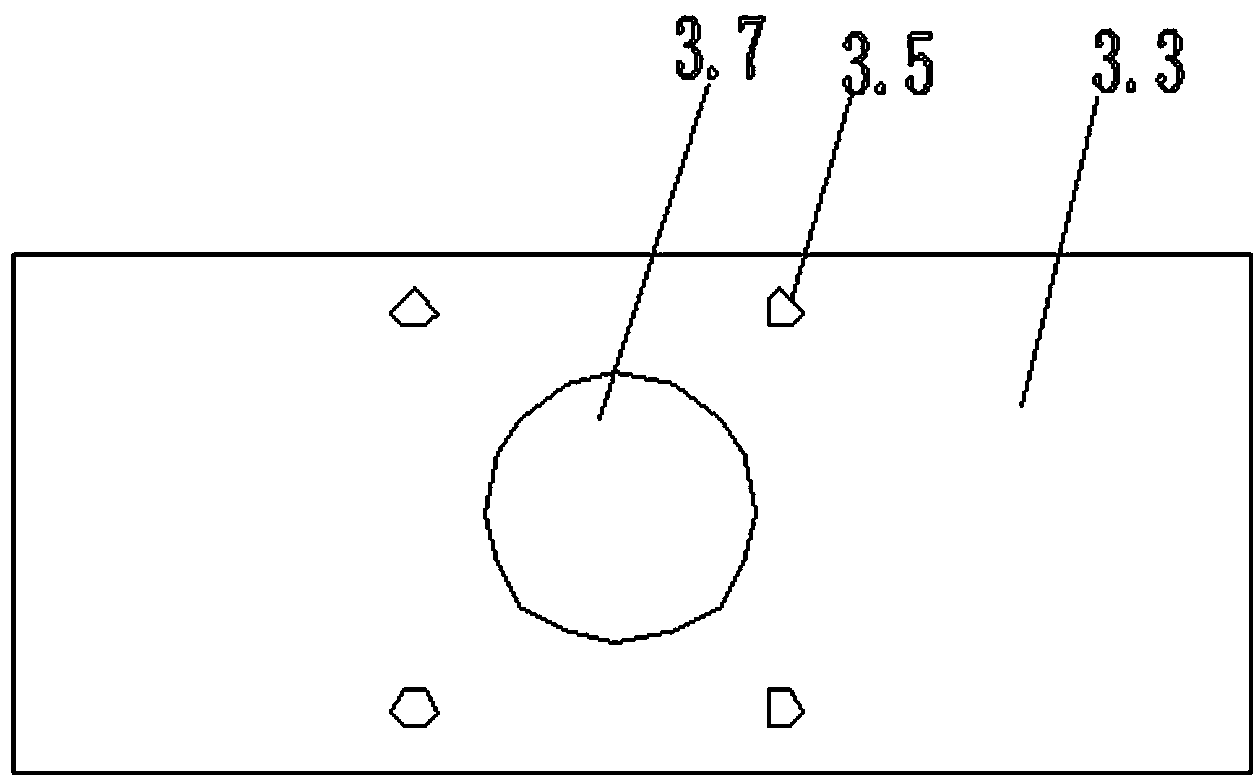

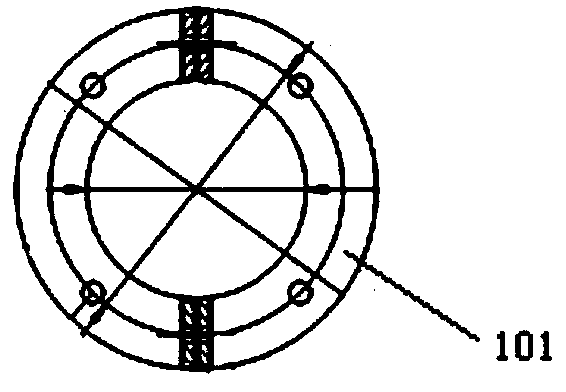

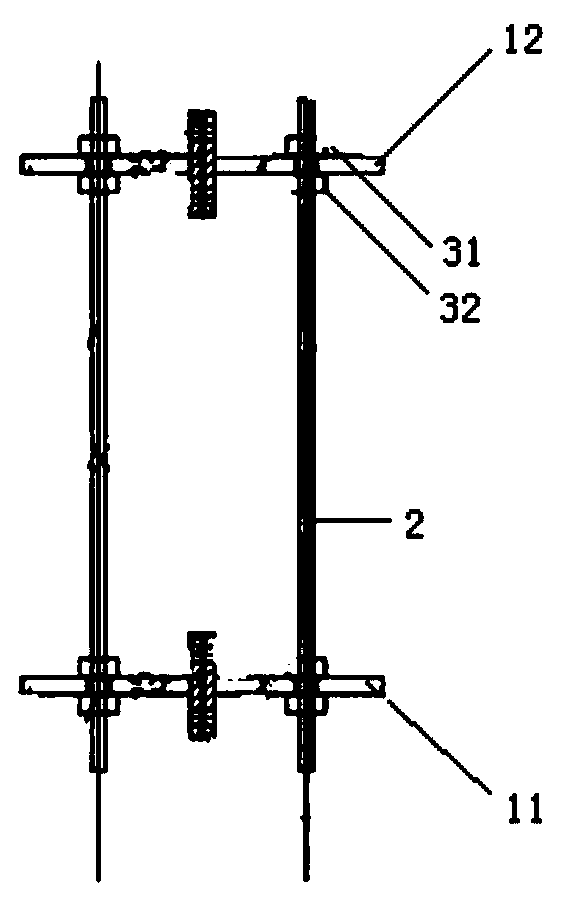

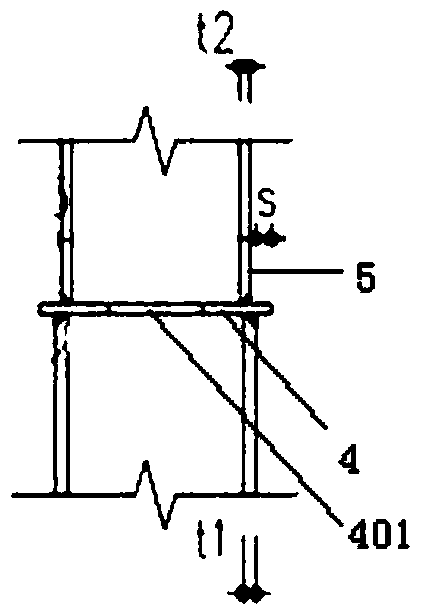

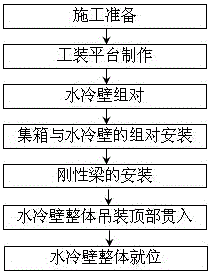

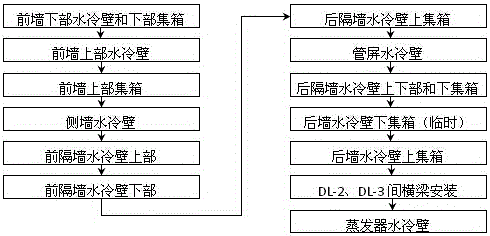

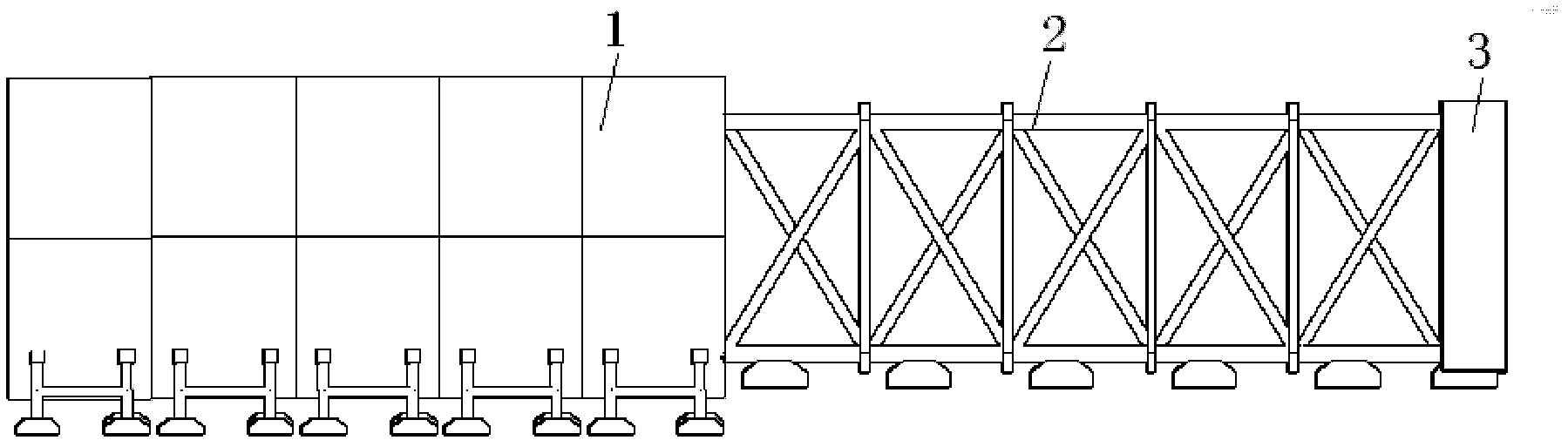

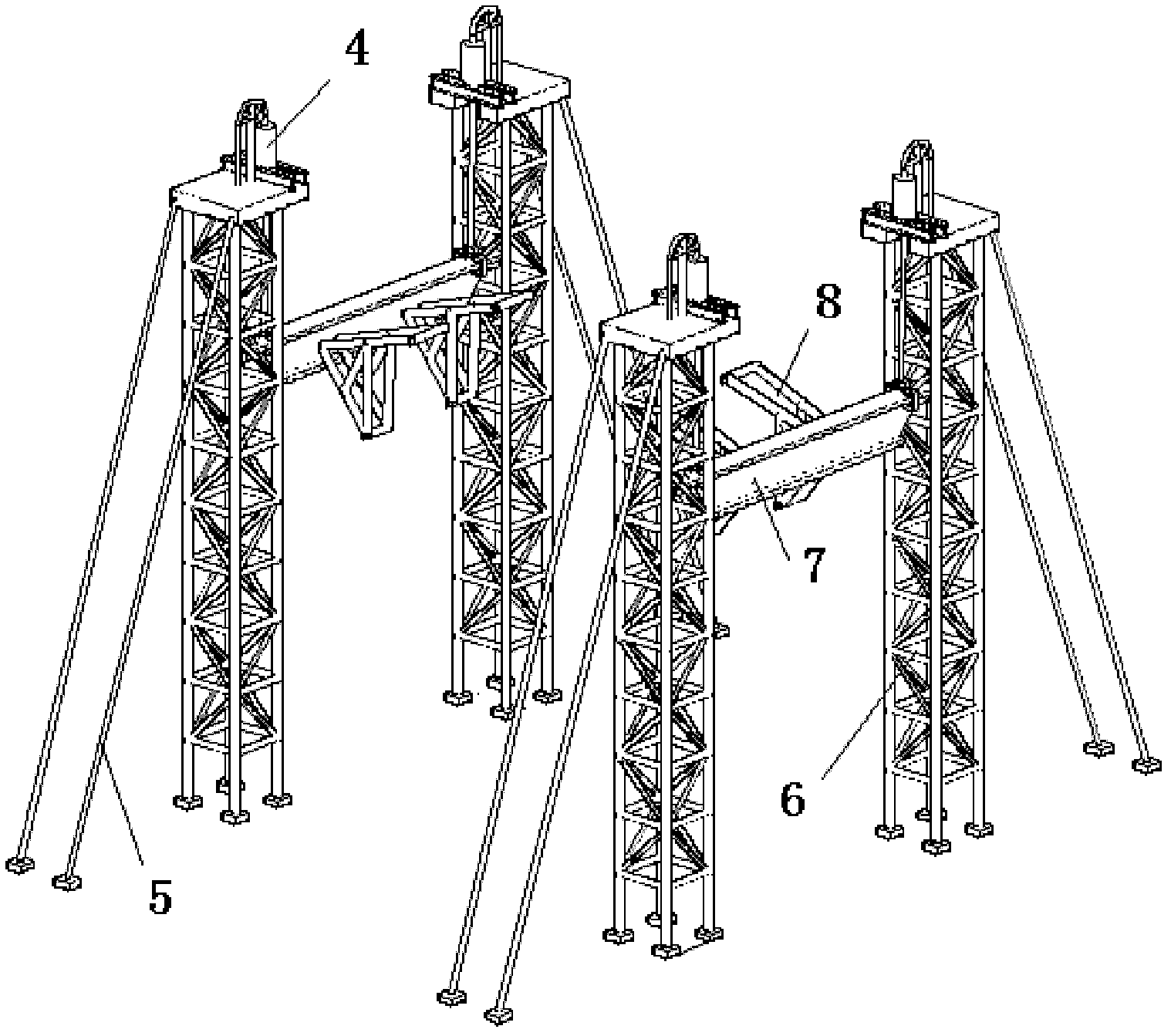

Construction method for enabling water-cooling walls of refuse incineration power generation waste heat boiler to integrally penetrate from top

ActiveCN106322347AReduce the number of liftingEasy to controlBoiler water tubesCasings/liningsButt weldingQuality control

The invention relates to a construction method for enabling water-cooling walls of a refuse incineration power generation waste heat boiler to integrally penetrate from a top. The construction method is characterized by comprising the following steps: step 1, manufacturing a water-cooling wall tool platform; step 2, assembling the water-cooling walls in a segmental mode on ground; step 3, mounting collecting boxes and the water-cooling walls in pairs; step 4, mounting rigid beams; step 5, enabling the water-cooling walls to integrally penetrate from the top; step 6, hoisting the water-cooling walls to the positions; and step 7, arranging an overhead row of tubes in pairs. With the adoption of a mounting method for the water-cooling walls of the waste heat boiler, water-cooling wall hoisting times and quantity of the overhead row of tubes welded in pairs are reduced, pipeline butt-welding quality control is convenient, the problem that part of the water-cooling walls are difficult to put in positions after a boiler steel structure is mounted can be efficiently solved, the construction period is effectively shortened, and potential safety hazards caused by overhead mounting operation and welding operation are further reduced. Meanwhile, a special clamping device for ground pipeline aligning and an overhead pipe row aligner are applied, so that working efficiency and project quality are effectively improved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Building process for deep sea spar platform

InactiveCN102582786ARealize constructionAchieve structural closureVessel partsResource developmentArchitectural engineering

A building process for a deep sea spar platform includes the steps: firstly, respectively building an upper hard tank ring half section and a lower hard tank ring half section on a slide way; secondly, mounting lifting devices on the periphery of the upper ring half section; thirdly, continuously lifting the upper hard tank ring half section to a set position; fourthly, folding and butting the lower hard tank ring half section and the upper hard tank ring half section into an integral ring section; fifthly, leading the integral ring section to slide out of a mounting device; sixthly, repeating the step two to the step five until a plurality of integral ring sections are built; seventhly, folding and connecting the integral ring sections into an integral hard tank; eighthly, respectively mounting a truss and a soft tank on slide shoes positioned on sliders; and ninthly, completing building of a spar platform body by means of butting and folding. By the aid of the building process, building precision of the platform is improved, construction period is shortened, a building procedure is little susceptible to environment (wind) load effect, a requirement on site space is lowered, and important technical support is provided for deep-sea resource development.

Owner:CHINA NAT OFFSHORE OIL CORP +2

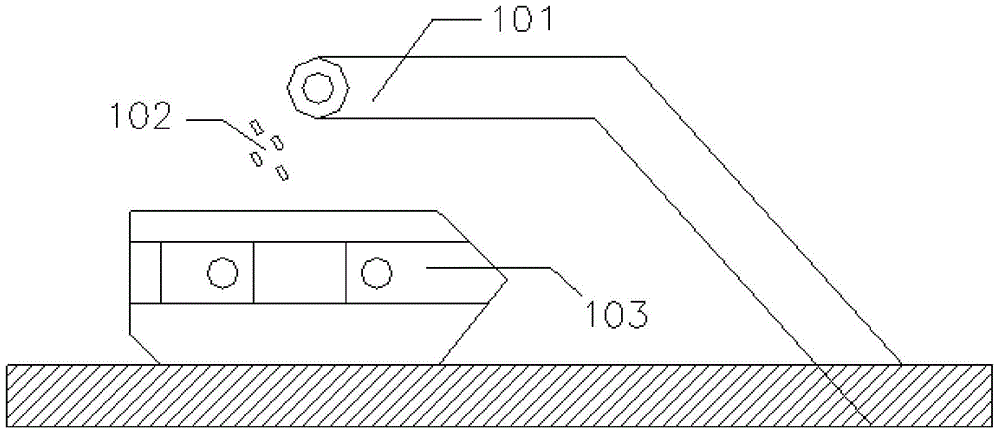

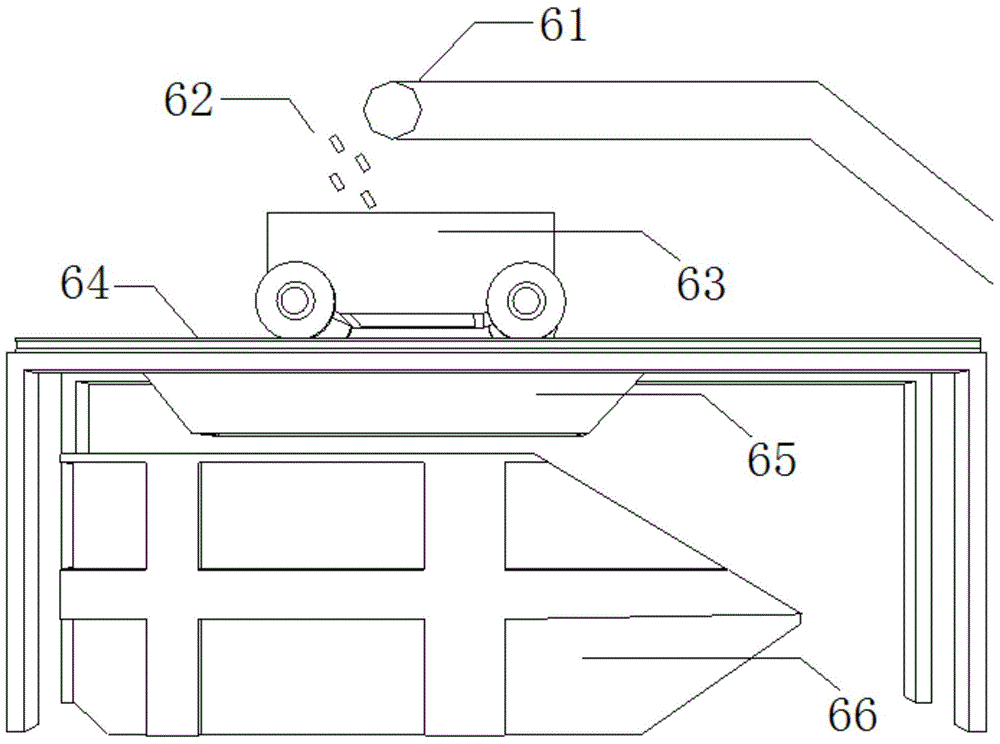

Scrap edge distribution device and distribution method

InactiveCN106477351AImprove efficiencyReduce the number of liftingLoading/unloadingCircular discReciprocating motion

The invention discloses a scrap edge distribution device and distribution method. The device comprises a conveying belt, a distribution trolley, a scrap edge baffle, guide rails and a scrap edge bucket, wherein the guide rails are arranged under the conveying belt and is parallel to the conveying belt; the distribution trolley is arranged on the guide rails and can perform reciprocating motion along the guide rails; the scrap edge baffle is arranged below the guide rails; the coverage of the scrap edge baffle is consistent with the reciprocating motion range of the distribution trolley; and the scrap edge bucket is arranged below the scrap edge baffle. The method comprises the following steps: 1, performing loading and uncoiling; 2, reading the operating speed of a machine set and the edge cutting quantity of disc shears; 3, calculating and judging whether the operating speed of the distribution trolley is appropriate, if yes, carrying out Step 5, if no, carrying out Step 4; 4, increasing the scrape edge conveying speed of the conveying belt and returning to Step 2; 5, the conveying belt starting to convey scrape edges; and 6, the machine set operating for production. Through the device and the method, the service efficiency of the scrap edge collecting bucket is increased, and the lifting frequency of the scrap edge collecting bucket is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

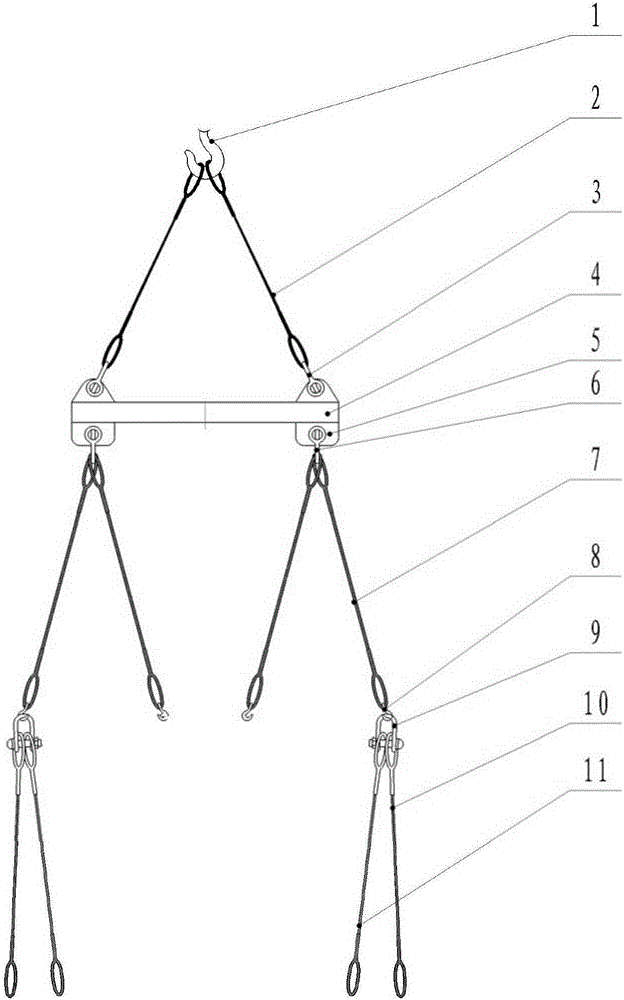

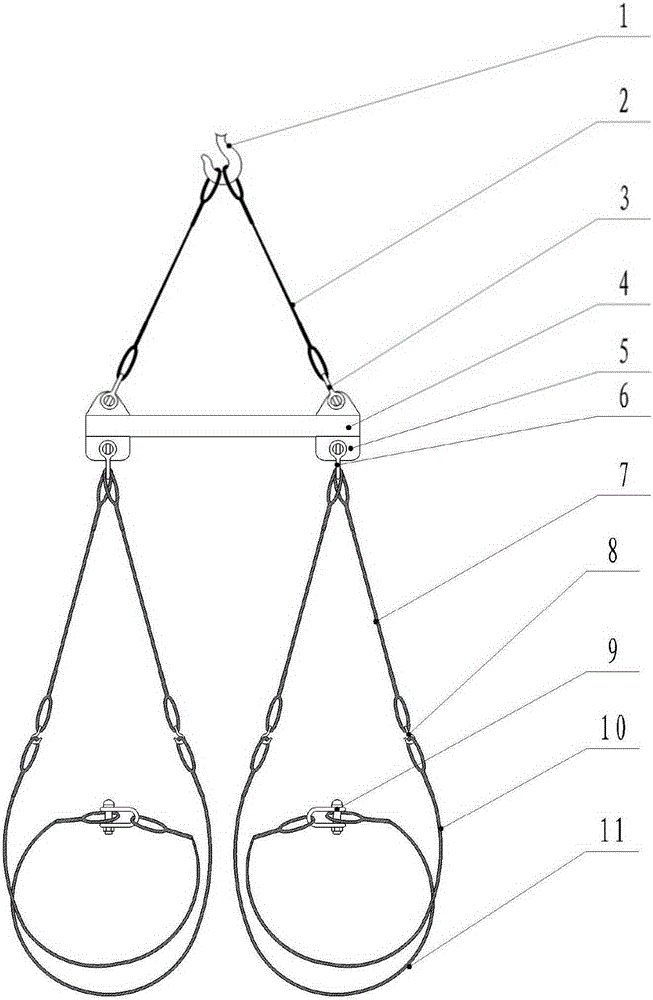

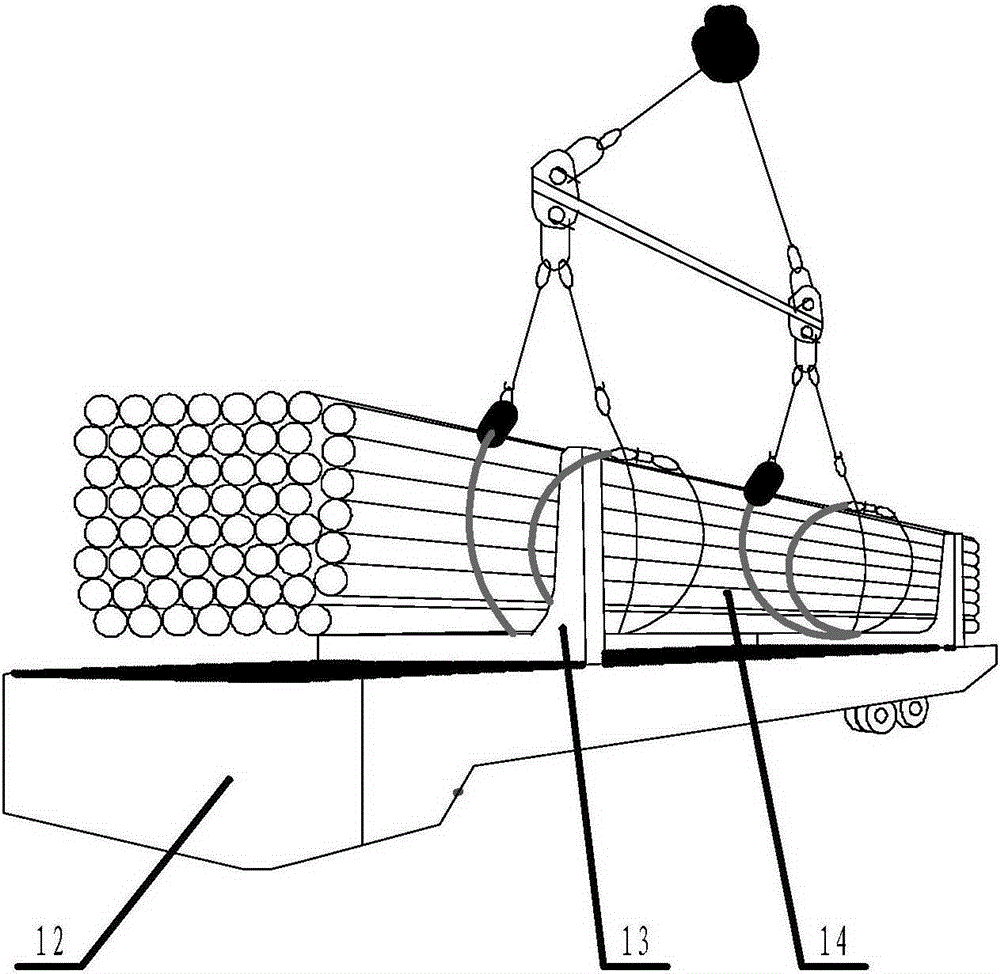

Method for steel pipe winding and pocket hoisting work through steel wire rope buckles

InactiveCN105329765AReduce the number of work cyclesImprove turnover rateLoad-engaging elementsStop timeEngineering

The invention provides a method for steel pipe winding and pocket hoisting work through steel wire rope buckles. The method is finished through a special tool for steel pipe pocket hoisting work. The method comprises eleven steps to finish the work that the steel wire rope is used for buckling and winding to perform steel pipe pocket hoisting. The method has the beneficial effects that under the situation that the weight of goods loaded by each planker is not changed, steel pipes with the length of 12 m only need to be hoisted one time; steel pipes with the length of 6 m only need to be hoisted two times; and the number of the hoisting times is reduced by 2-4, and the loading and unloading efficiency is improved by more than 20%. Due to the fact that the number of the hoisting times is reduced, the frequency of picking off hooks by workers for loading and unloading is reduced accordingly, and the labor intensity of the workers is relieved. Meanwhile, on the basis that the performance of a hoisting machine is brought into full play, the circulation frequency of machine operation is reduced, and therefore the power consumption of the machine is reduced by about 5%, and the labor intensity of an operation driver is relieved. The average shift amount of steel pipe operation is increased to 1,400 tons from 1,000 tons, the harbor stopping time of ships is shortened, the ship circulation rate is increased, and a foundation is laid for the increasing of company loading and unloading throughput capacity.

Owner:天津港第二港埠有限公司

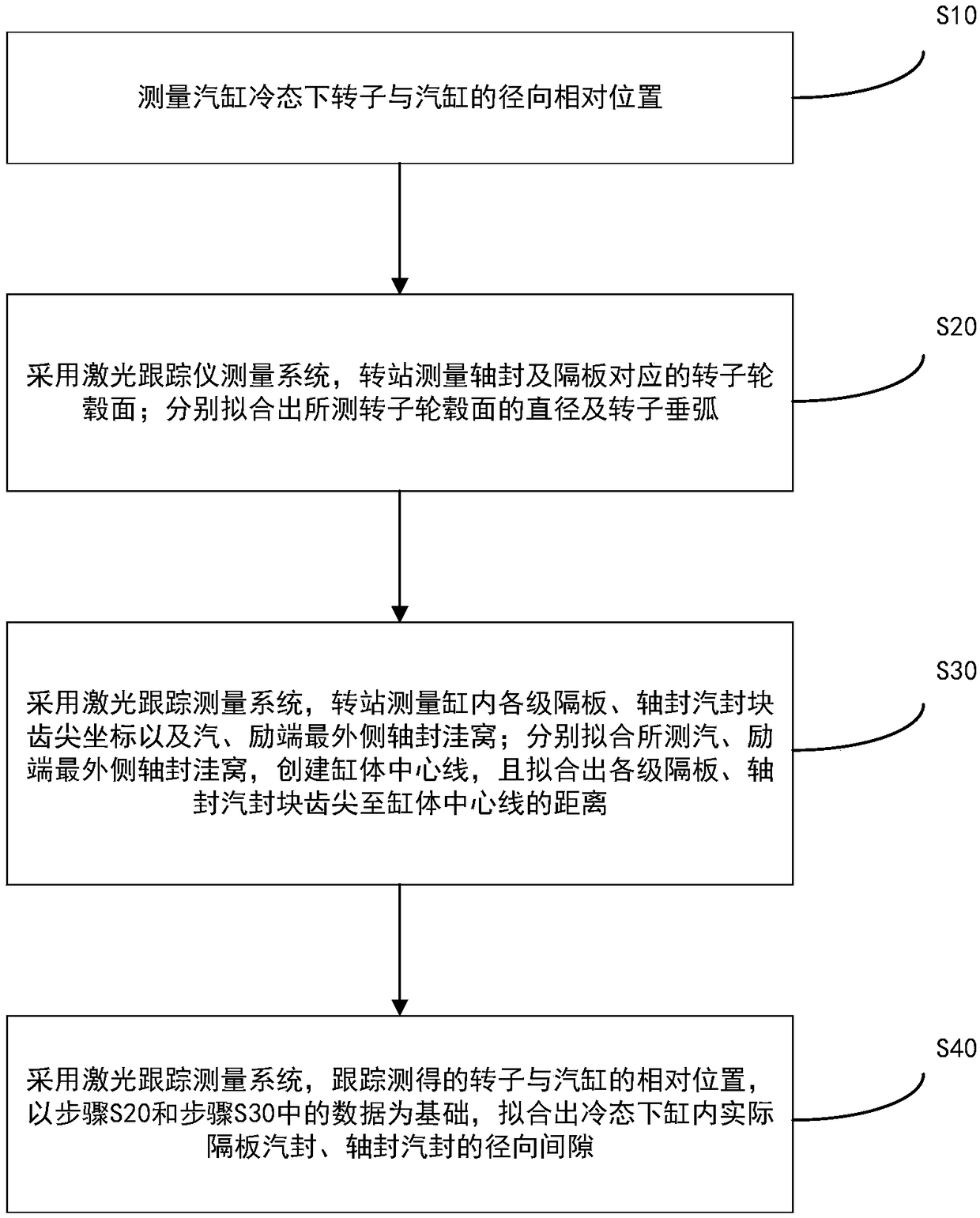

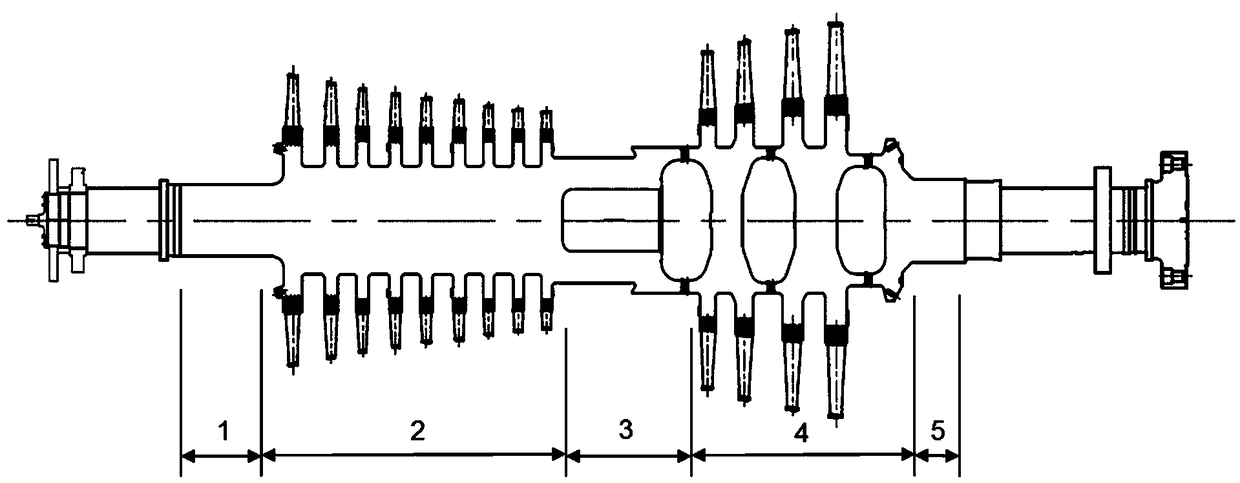

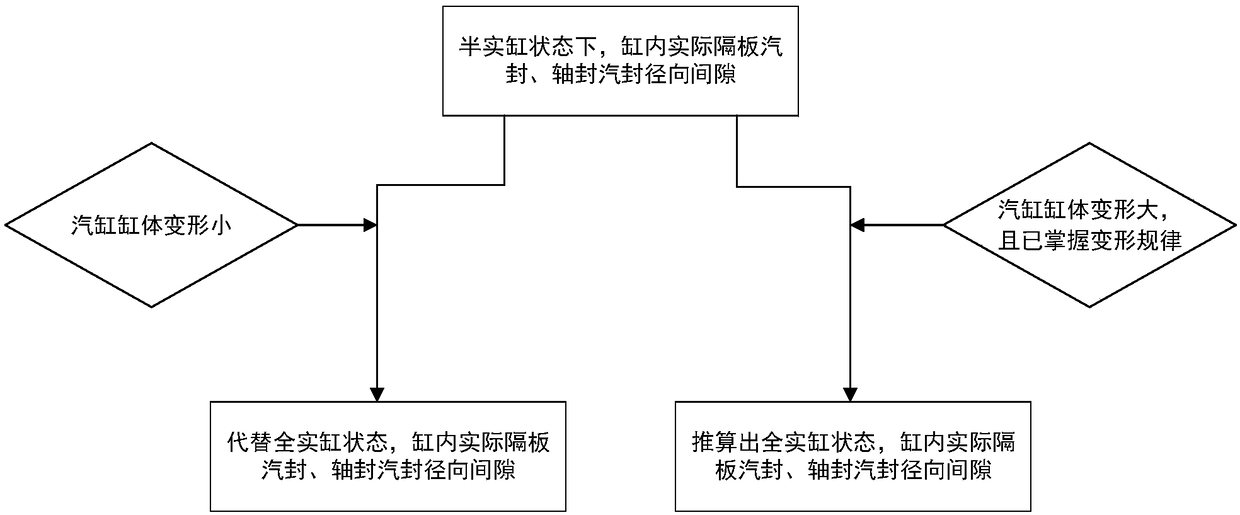

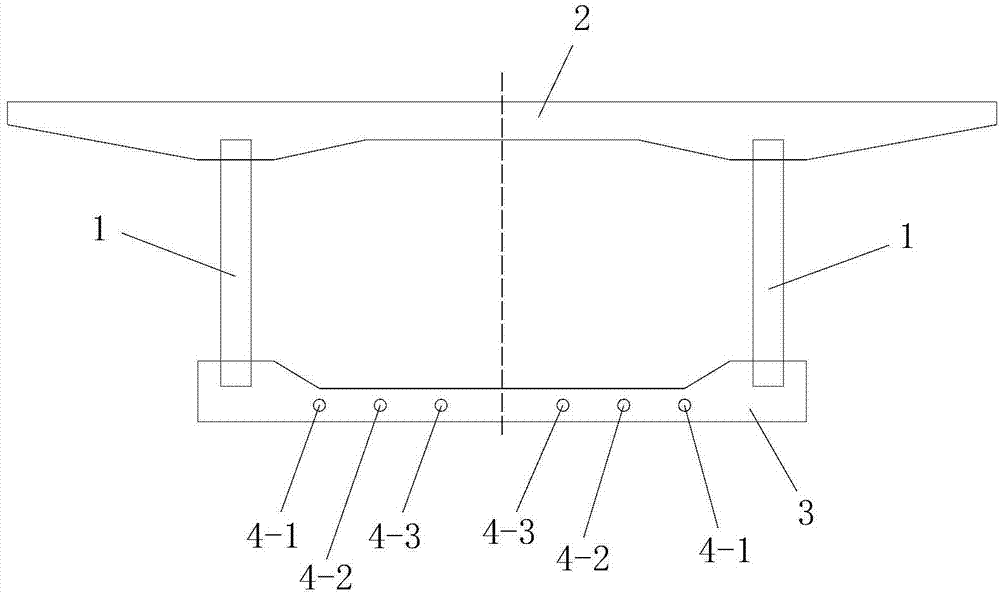

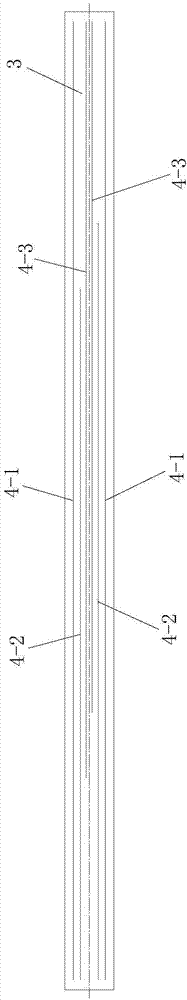

Method for measuring radial flow path clearance of steam turbine through laser tracking measuring system

ActiveCN109184819AReduce the number of liftingShorten maintenance periodLeakage preventionMachines/enginesTransfer modeEngineering

The invention discloses a method for measuring the radial flow path clearance of a steam turbine through a laser tracking measuring system. The method comprises the steps that S10, the radial relativeposition of a rotor and a steam cylinder in r the cold state of the steam cylinder is measured; S20, the laser tracking measuring system is adopted to measure a shaft seal and rotor hub surfaces corresponding to partition plates in a station transferring mode, and the diameters and rotor vertical arcs of the measured rotor hub surfaces are fitted; S30, the laser tracking measuring system is adopted to measure tooth tip coordinates of all stages of partition plate steam seal blocks and shaft seal steam seal blocks in the cylinder, and shaft seal bores on the outermost side of the steam end andthe exciter end in a station transferring mode, the shaft seal bores on the outermost side of the steam end and the exciter end are fitted, a cylinder body center line is created, and the distances from the tooth tips of all the stages of partition plate steam seal blocks and the shaft seal steam seal blocks to the cylinder body center line are fitted; and S40, the laser tracking measuring systemis adopted to fit the radial clearance of an actual partition plate steam seal and the shaft seal steam seal in the cylinder under the cold state according to the measured relative position of the rotor and the steam cylinder and based on data in the step S20 and the step S30. By applying the method for measuring the radial flow path clearance of the steam turbine through the laser tracking measuring system, the measuring precision is improved.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

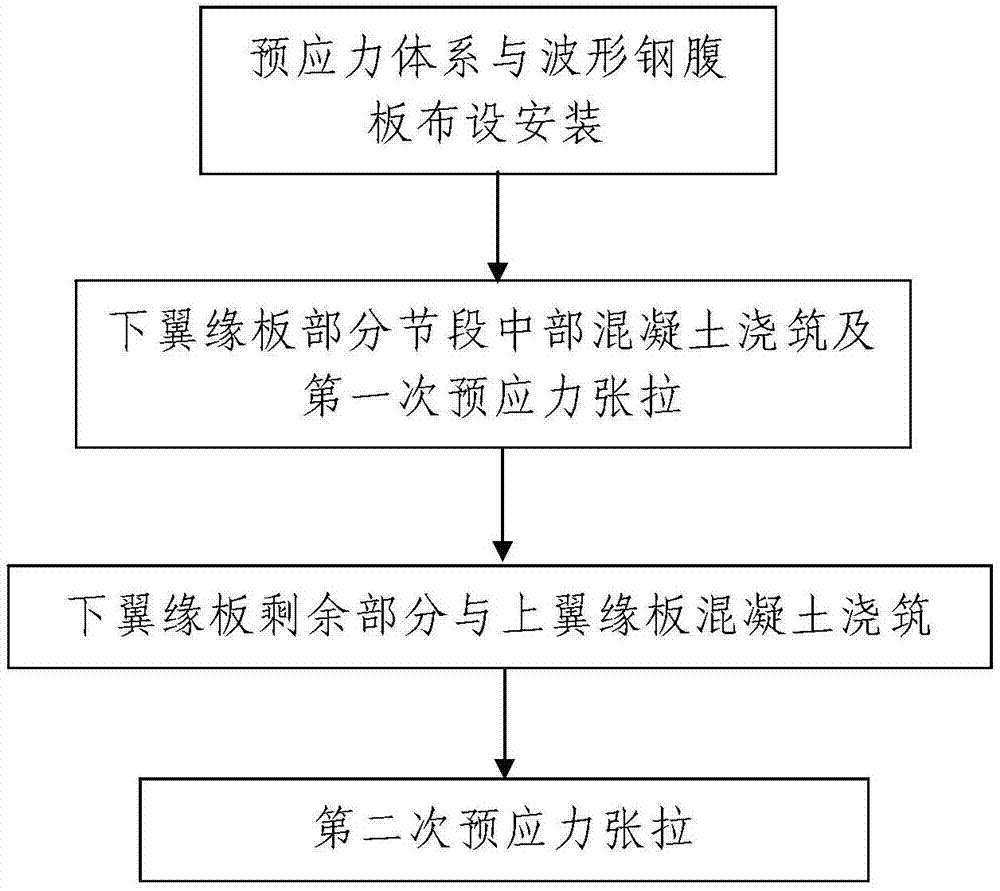

Composite corrugated steel web box girder and construction technology thereof

The invention discloses a composite corrugated steel web box girder and a construction technology of the composite corrugated steel web box girder. The composite corrugated steel web box girder comprises a bottom flange plate, a top flange plate and two corrugated steel webs which are symmetrically supported between the bottom flange plate and the top flange plate. A prestress system is arranged in the bottom flange plate and comprises a middle prestress structure and two side prestress structures. The construction technology of the composite corrugated steel web box girder comprises the steps of (1) arranging and installing the prestress system and the corrugated steel webs; (2) constructing the bottom flange plate, wherein the construction of the bottom flange plate comprises the steps that firstly, pouring of concrete in the middle of a part of sections of the bottom flange plate and primary prestress tension are conducted, and secondly, pouring of concrete in the middle of the remaining sections of the bottom flange plate and secondary prestress tension are conducted; (3) constructing the top flange plate before construction of the bottom flange plate or in the process of construction of the bottom flange plate or after construction of the bottom flange plate. According to the composite corrugated steel web box girder and the construction technology of the composite corrugated steel web box girder, the design is reasonable, construction is convenient, the constructed and formed composite corrugated steel web box girder is reasonably stressed and good in use effect, and multiple kinds of problems of an existing concrete box girder can be solved.

Owner:XIAN HIGHWAY INST +2

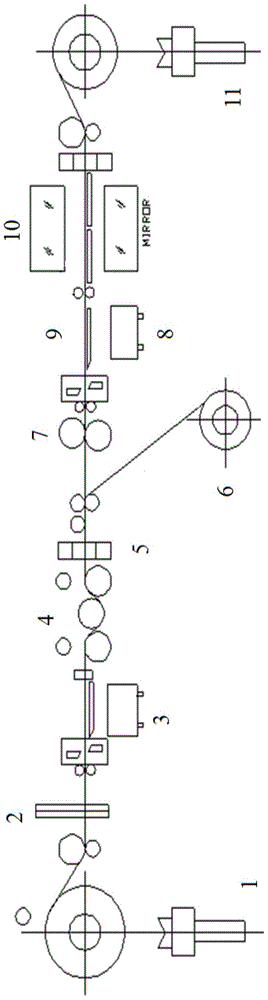

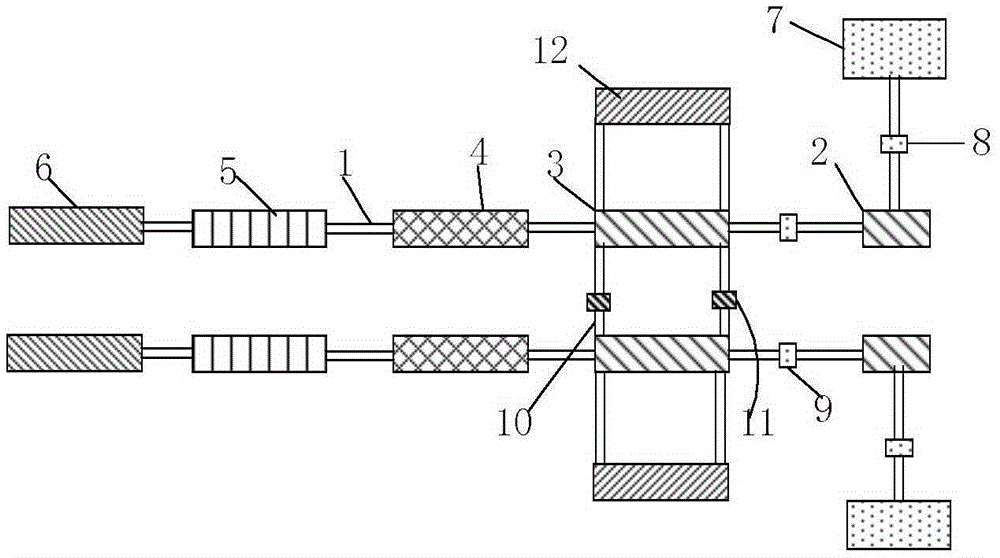

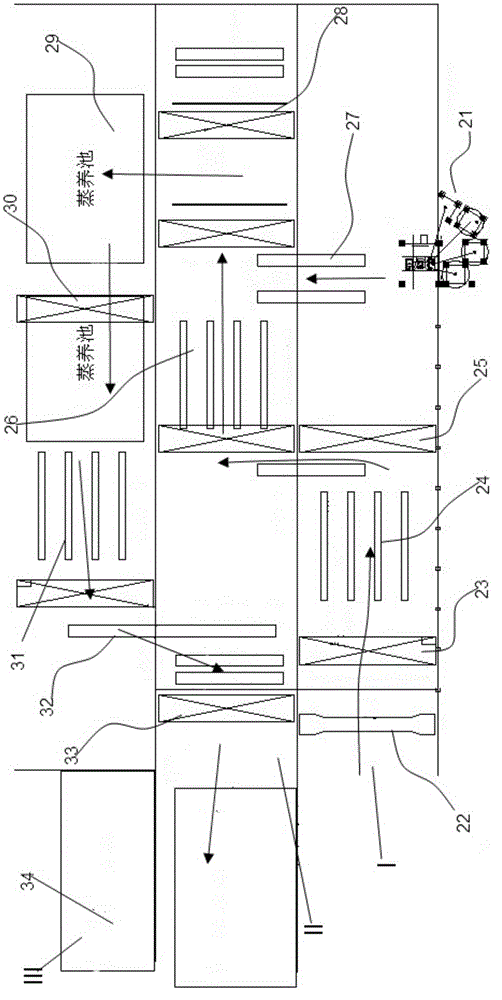

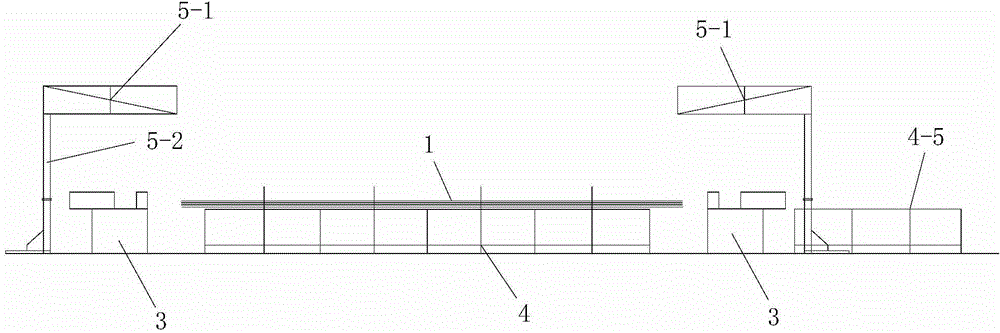

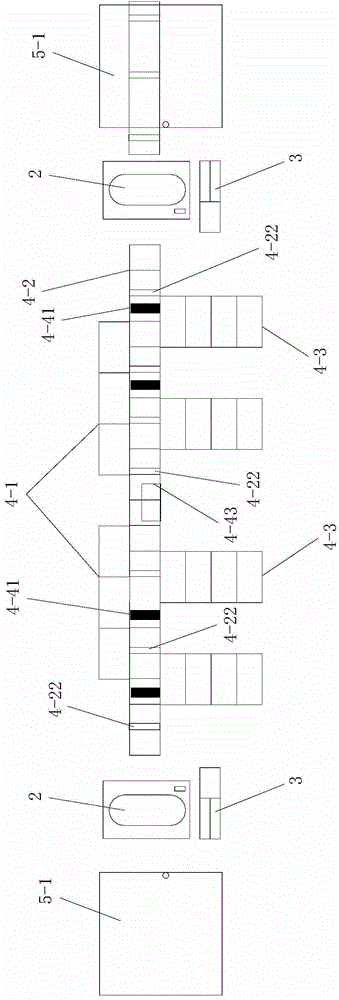

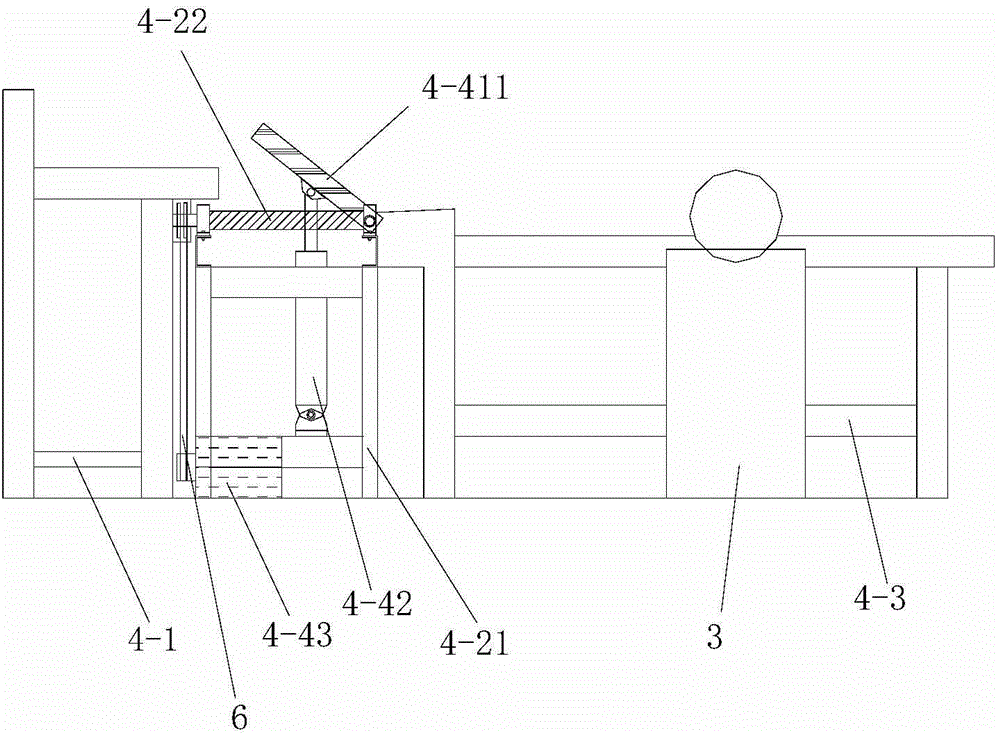

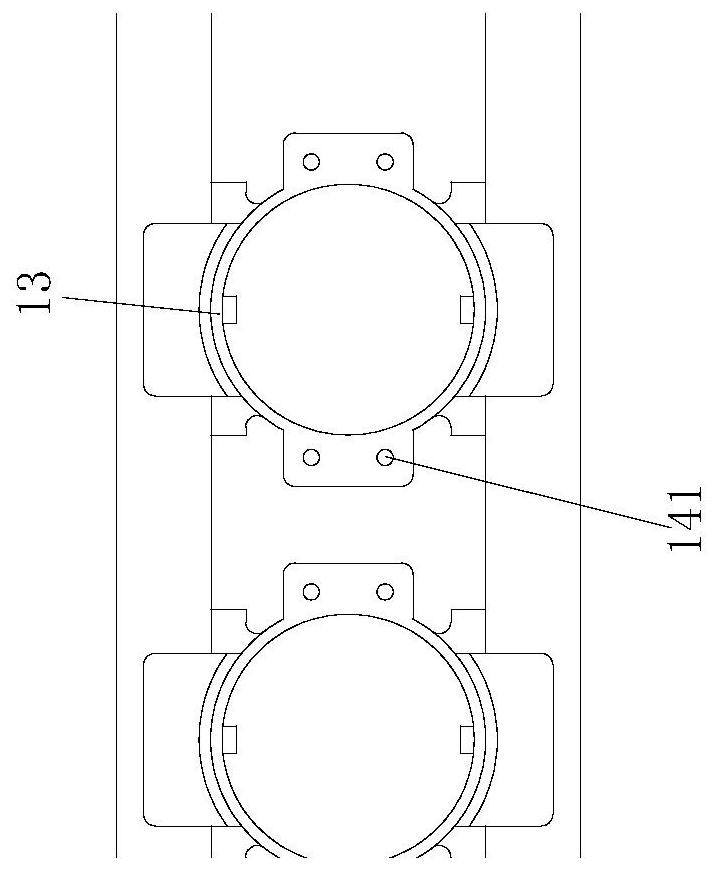

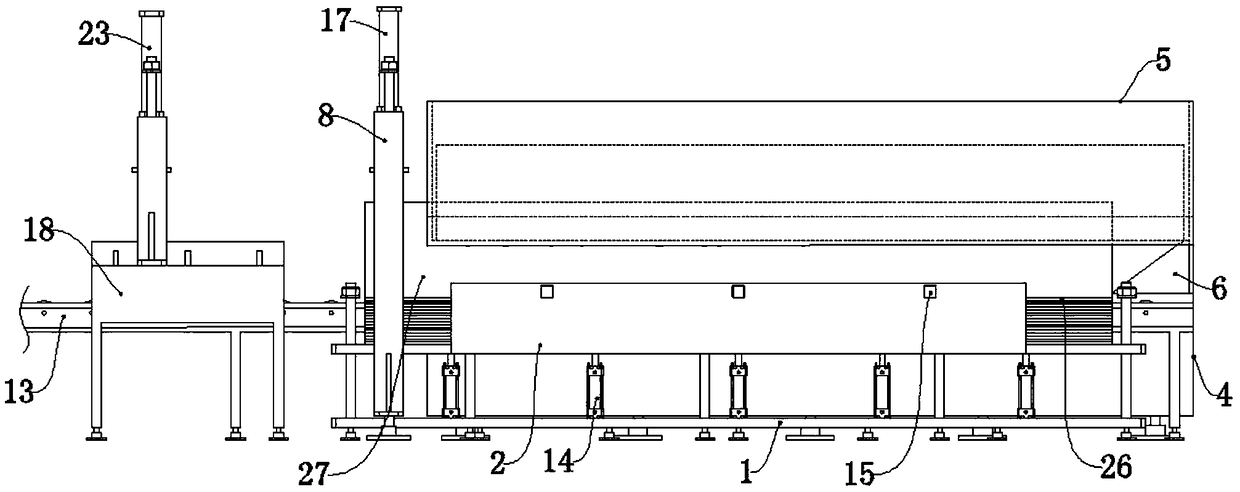

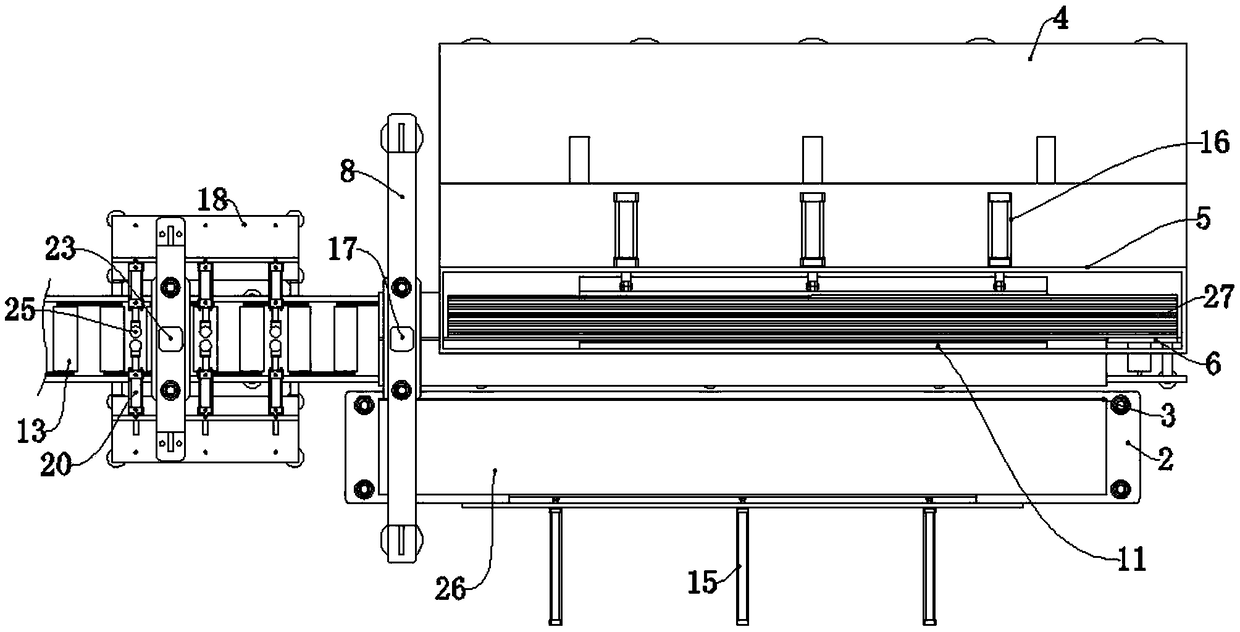

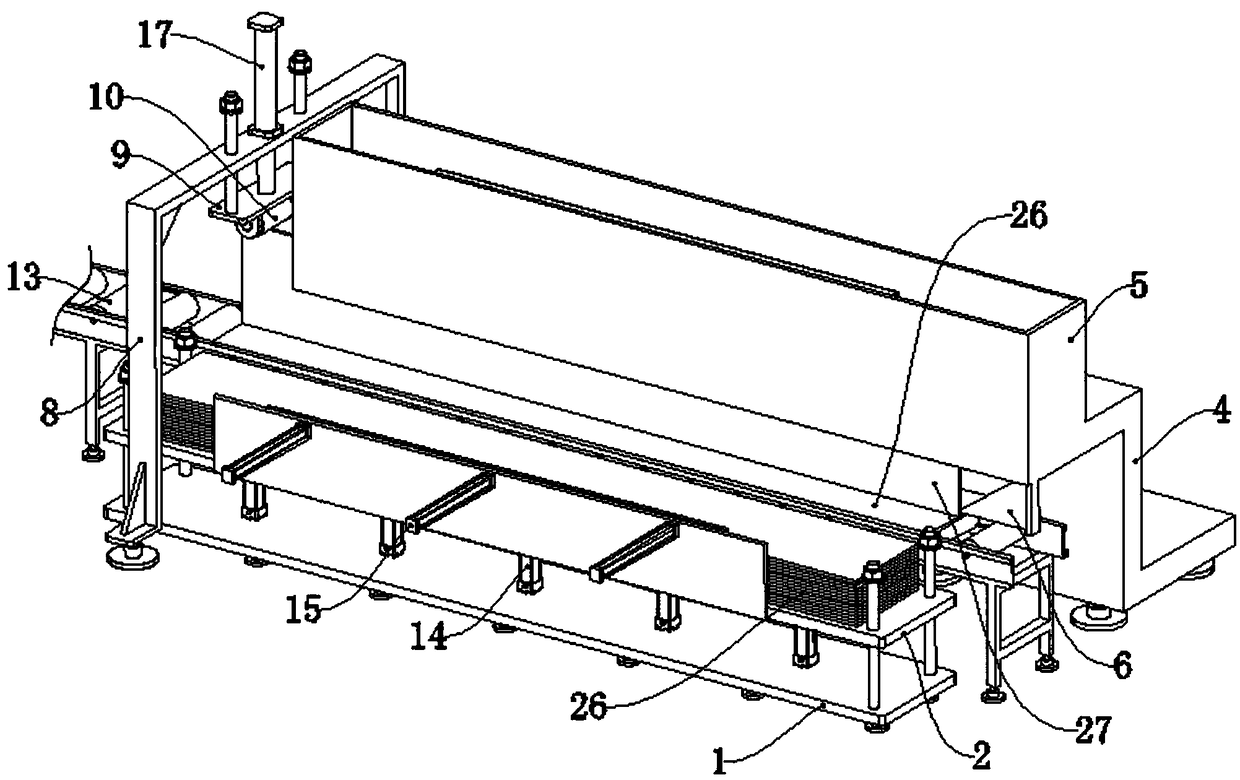

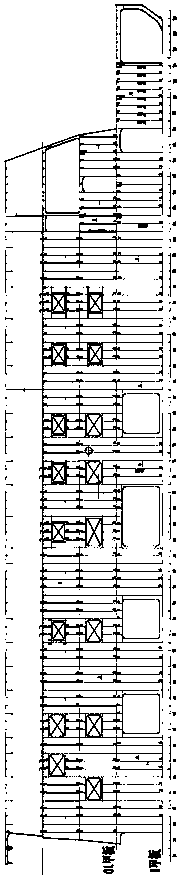

Prestressed concrete anti-corrosion pipe pile automatic assembly line operation platform

ActiveCN103624872BEmission controlSimple and fast operationCeramic shaping plantsInformatizationOperational system

Owner:JIANGSU DONGPU PILE

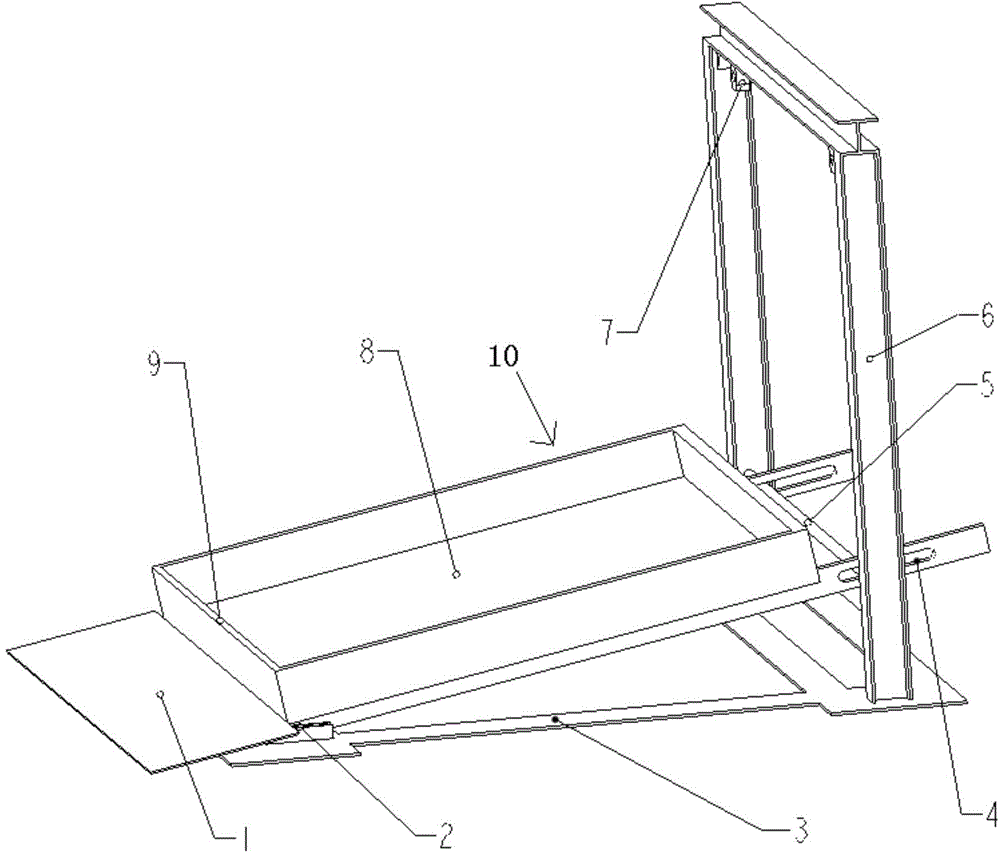

Angle-adjustable slope used for assessing performance of lunar rovers

The invention provides an angle-adjustable slope used for assessing the performance of lunar rovers, comprising a portal frame, a slope body, a reference flat plate and a driving device. The slope body includes a main plate body and a plurality of bearing beams fixedly arranged at the bottom of the main plate body. One end of each bearing beam is connected with the driving device through a connector. One end of the reference flat plate is fixedly connected with the lower ends of the side plates of the portal frame, and the other end is hinged with the main plate body. The driving device is arranged on the portable frame, is connected with one end of each bearing beam, and can drive the end of each bearing beam to move up and down to adjust the slope degree of the main plate body, wherein the slope degree is 5-45 degrees. Compared with the prior art, according to the angle-adjustable slope, a slope of any value of slope between 5 degrees and 45 degrees can be constructed, slopes of different values of slope can be constructed by rotating the slope body, operation and test are facilitated, a series of work such as lunar rover lifting and lunar rover attitude reconfiguration is not needed before each test, and the angle-adjustable slope is simple in structure and low in cost.

Owner:SHANGHAI AEROSPACE SYST ENG INST

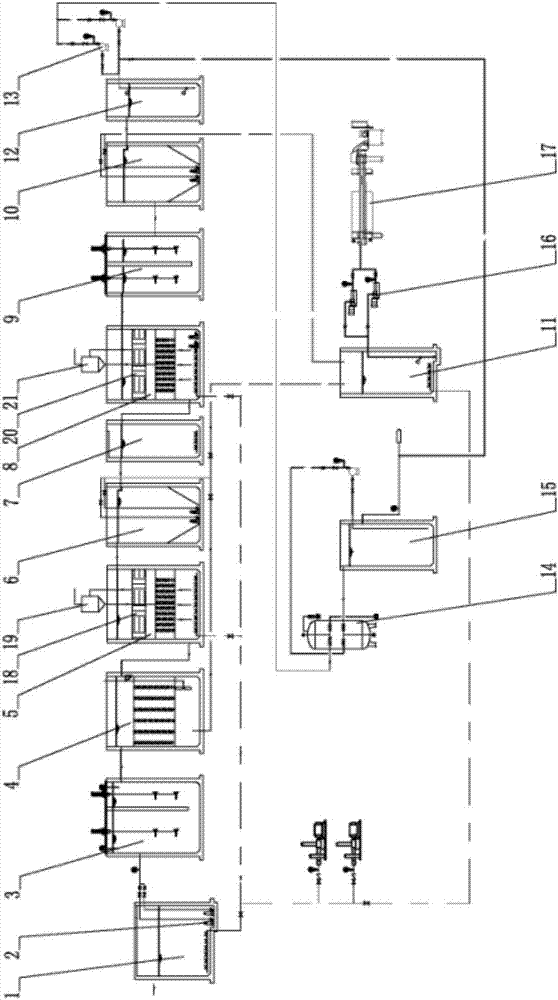

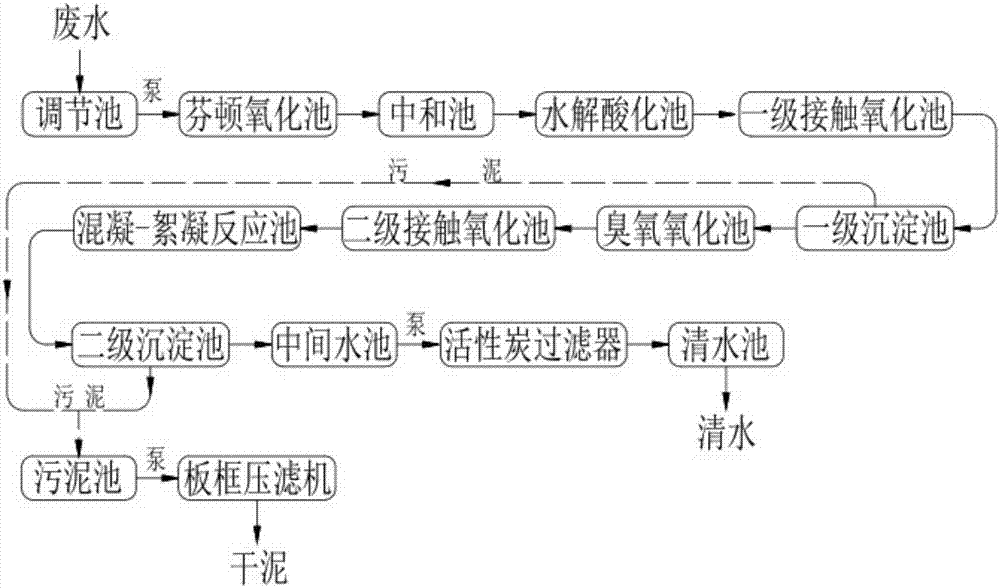

Integrated deep treatment method and treatment device for wastewater containing formaldehyde and methanol

PendingCN107304093AReduce the number of liftingSimple processTreatment using aerobic processesWater treatment compoundsActivated carbon filtrationSludge

The invention relates to the technical field of wastewater treatment, in particular to an integrated deep treatment method and treatment device for wastewater containing formaldehyde and methanol. The treatment device comprises an adjusting tank, a Fenton oxidation tank, a neutralization tank, a hydrolysis acidification tank, a primary contact oxidation tank, a primary sedimentation tank, an ozone oxidation tank, a secondary contact oxidation tank, a coagulation-flocculation reaction tank, a secondary sedimentation tank, an intermediate water tank, an activated carbon filter and a clear water tank which are sequentially arranged along a water flow direction and also comprises a sludge tank used for storing sludge discharged by the primary sedimentation tank and the secondary sedimentation tank. The treatment device is low in operating cost, system operation is safe and reliable, and stable effluent quality and up-to-standard discharge can be guaranteed.

Owner:JIANGSU DUBLE ENG +1

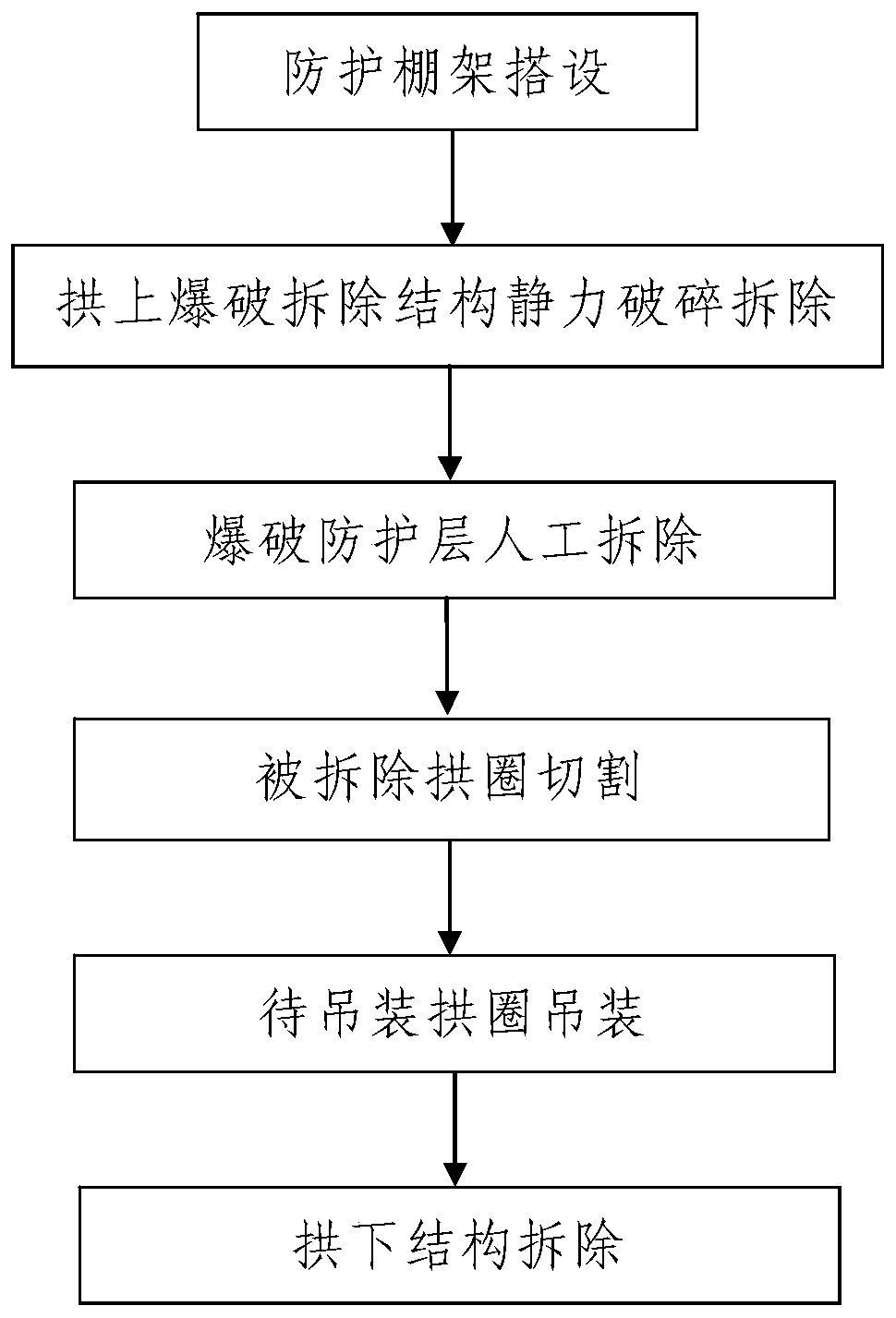

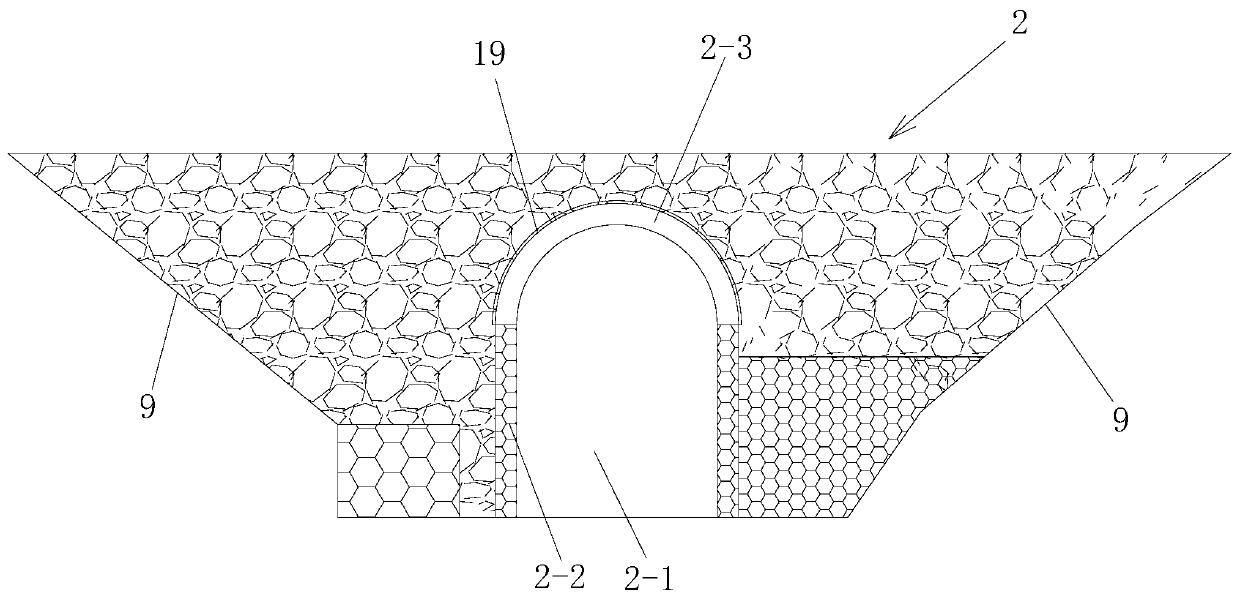

Demolition construction method for overpass existing line arch bridge

ActiveCN110904867AThe method steps are simpleReasonable designBuilding repairsBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a demolition construction method for an overpass existing line arch bridge. The demolition construction method comprises the steps: 1, erecting a protective shed frame; 2, carrying out static crushing demolition on the arch blasting demolition structure; 3, manually removing the blasting protection layer; 4, cutting the removed arch ring; 5, hoisting the arch ring to be hoisted; and 6, dismantling the under-arch structure. The method is simple, reasonable in design, easy and convenient to construct and good in using effect; the protection shed frames fixed to the frontside and the rear side of the removed arch bridge are adopted for effective protection, meanwhile, the structure on the arch of the removed arch bridge is removed in the mode that static crushing andmanual chiseling are combined, it is guaranteed that a plain concrete arch ring cannot be damaged in the static crushing process, and an existing spanned railway line cannot be disturbed. After the arch ring is exposed, the removed arch ring is cut and decomposed through a rope saw and then hoisted and removed, then the under-arch structures on the left side and the right side are rapidly removed,the construction period can be effectively shortened, the arch bridge removing efficiency is improved, and the removing process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

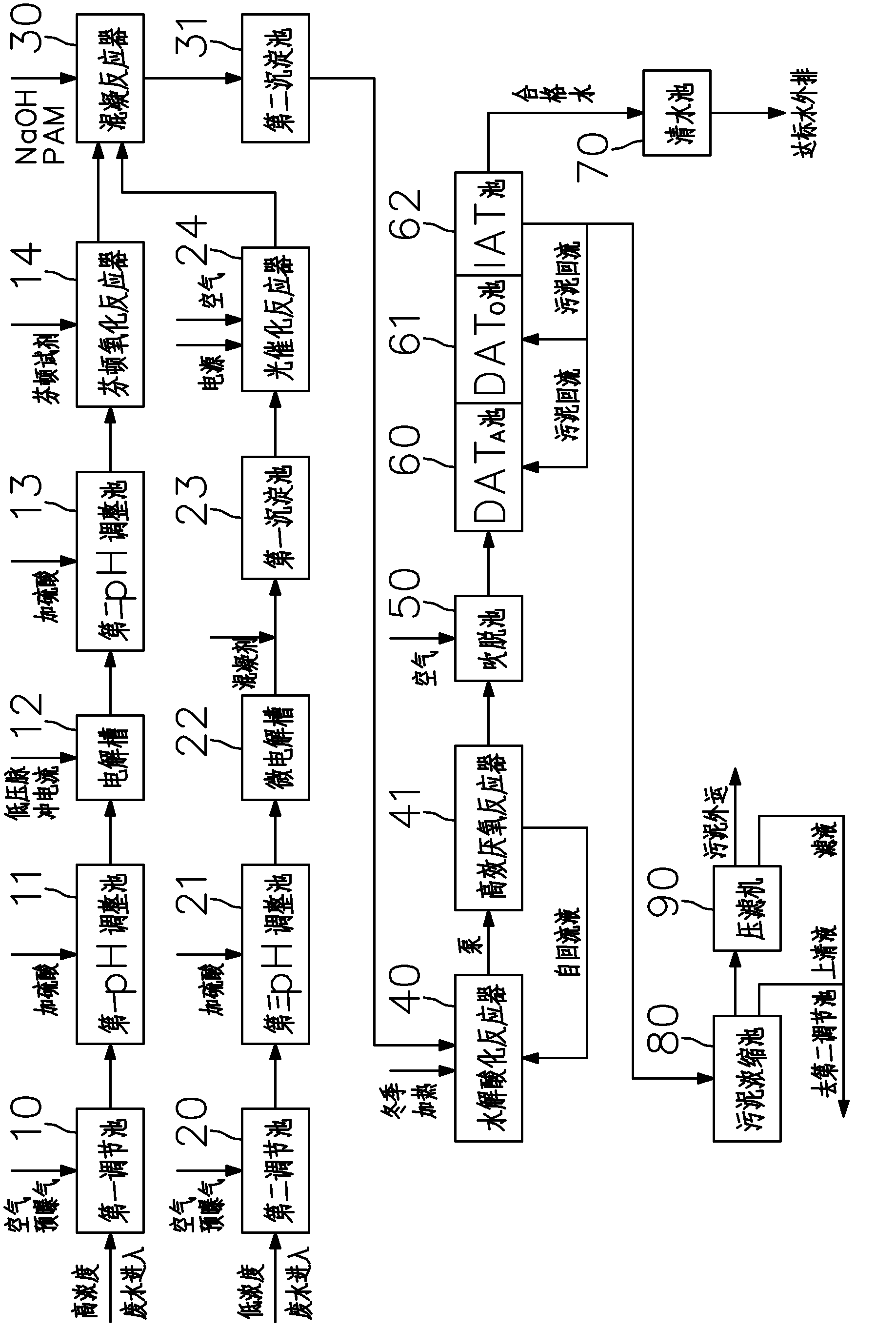

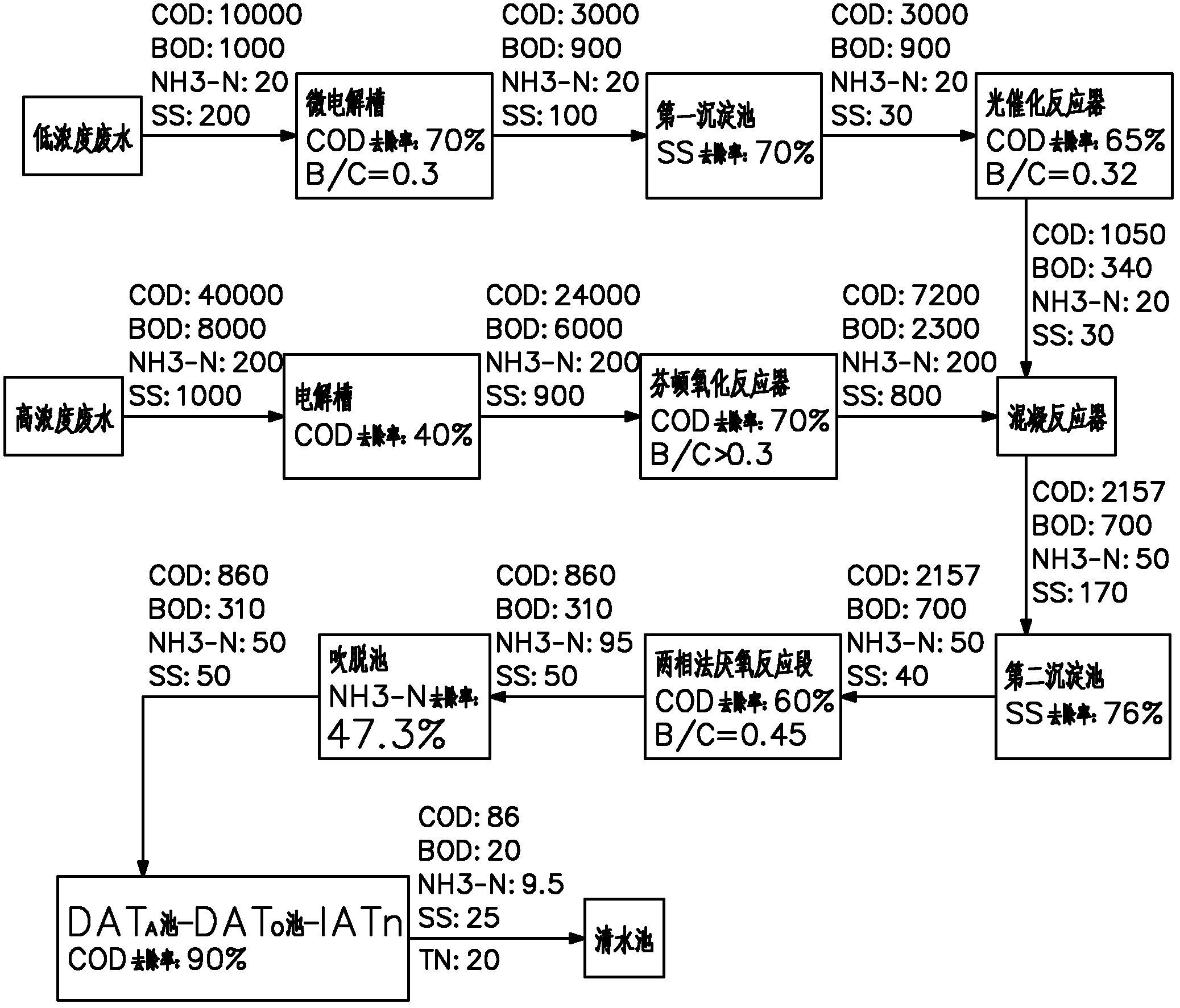

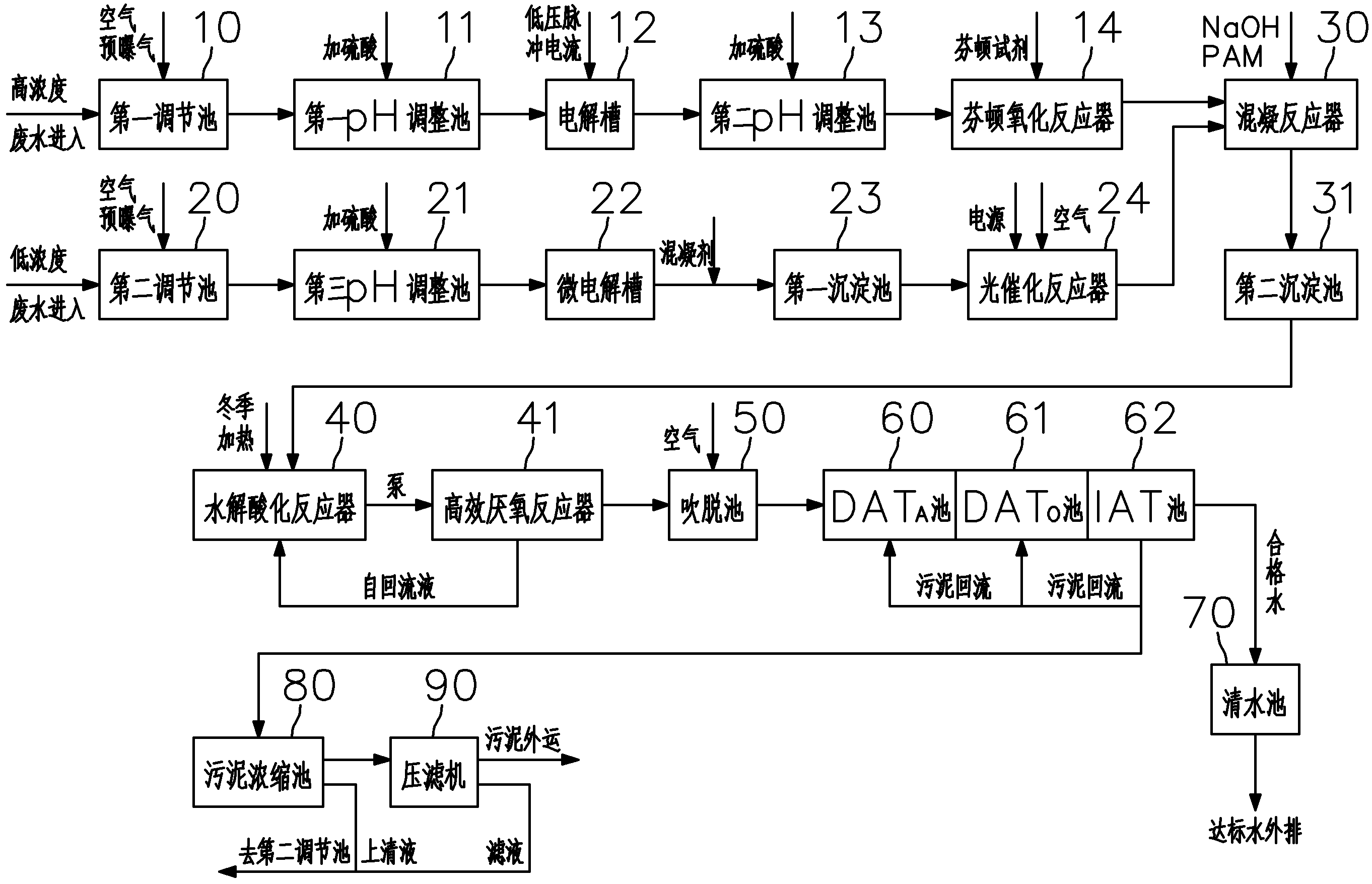

Wastewater processing system during production of HIV (Human Immunodeficiency Virus) prevention medicament

ActiveCN102616988AImprove biodegradabilityGood removal effectMultistage water/sewage treatmentHigh concentrationAmmonia nitrogen

The invention belongs to the technical field of wastewater processing, particularly relates to a wastewater processing system during production of an HIV (Human Immunodeficiency Virus) prevention medicament. The wastewater processing system comprises the following parts of a high-concentration wastewater pre-processing section and a low-concentration wastewater pre-treating section which are mutually connected in parallel, mixed wastewater can automatically flow into a coagulating sedimentation section to be subjected to coagulating sedimentation processing after being processed by the high-concentration wastewater pre-processing section and the low-concentration wastewater pre-processing section, the processed wastewater flows into a two-phase anaerobic reaction section to be subjected to anaerobic processing and then flows into a blow-off tank to be subjected to blow-off processing of ammonia nitrogen and escaping gas, the wastewater flows into a DATA-DATO-IATn processing section tobe subjected to biochemical processing after being subjected to the blow-off processing, the water which is subjected to the biochemical processing can be discharged with the standard, and the sludgecan be discharged into a sludge thickening tank to be subjected to dewatering processing. According to the wastewater processing system during production of the HIV prevention medicament, disclosed by the invention, the flow procedure is distributed by the adoption of the principle of preprocessing and the biochemical processing, the promoting times of the material is less, the material is mostlyin automatic flow mode, the convenience is brought for the operation and the maintenance, the dosage is less, the system runs stably, and secondary pollution cannot be caused.

Owner:安徽南风环境工程技术有限公司

Batch machining device and technology for reinforcing-steel-bar straight threads

ActiveCN104786107ASimple structureReasonable designOther manufacturing equipments/toolsMetal working apparatusRebarScrew thread

The invention discloses a batch machining device and technology for reinforcing-steel-bar straight threads. The machining device comprises a left reinforcing-steel-bar straight thread machining device body, a right reinforcing-steel-bar straight thread machining device body, a left protective shed, a right protective shed and an automatic conveying platform for conveying to-be-machined reinforcing steel bars. The left reinforcing-steel-bar straight thread machining device body and the right reinforcing-steel-bar straight thread machining device body are used for machining the two ends of the to-be-machined reinforcing steel bars respectively. The automatic conveying platform is located between the two reinforcing-steel-bar straight thread machining device bodies. Each reinforcing-steel-bar straight thread machining device body comprises a reinforcing-steel-bar cutting device for cutting the to-be-machined reinforcing steel bars and a straight-thread threading machine for carrying out threading on the to-be-machined reinforcing steel bars. The automatic conveying platform comprises a reinforcing-steel-bar containing frame, a first transverse conveying frame, a threading machining frame and a reinforcing-steel-bar longitudinal movement mechanism. The machining technology includes the steps of 1, reinforcing-steel-bar lifting; 2, reinforcing-steel-bar cutting; 3, reinforcing-steel-bar secondary forward moving; 4, reinforcing-steel-bar threading; 5, reinforcing-steel-bar third-time forward moving. The machining device and technology are reasonable in design, easy and convenient to machine, manufacture, use and operate and good in use effect; the reinforcing-steel-bar straight thread batch machining process can be easily, conveniently and rapidly completed.

Owner:陕西华鑫鼎业建筑物资有限公司

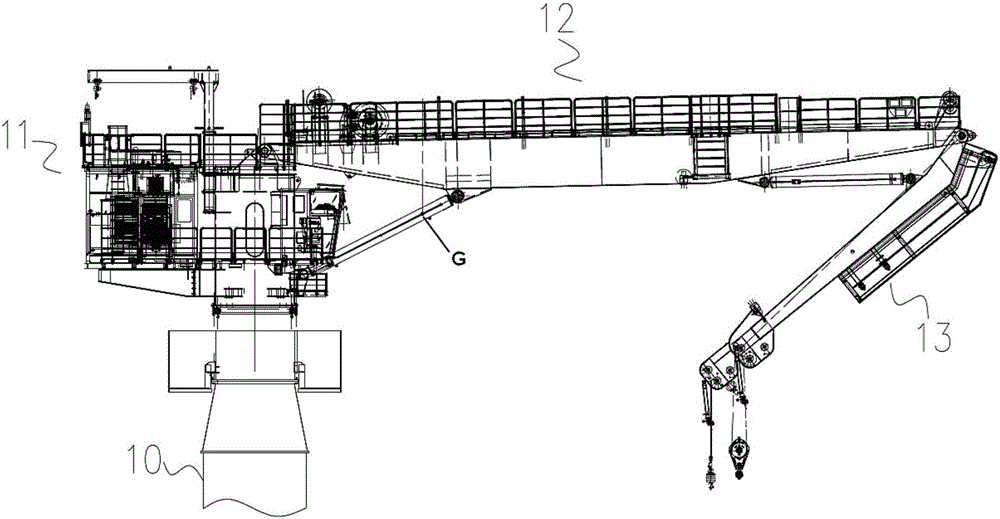

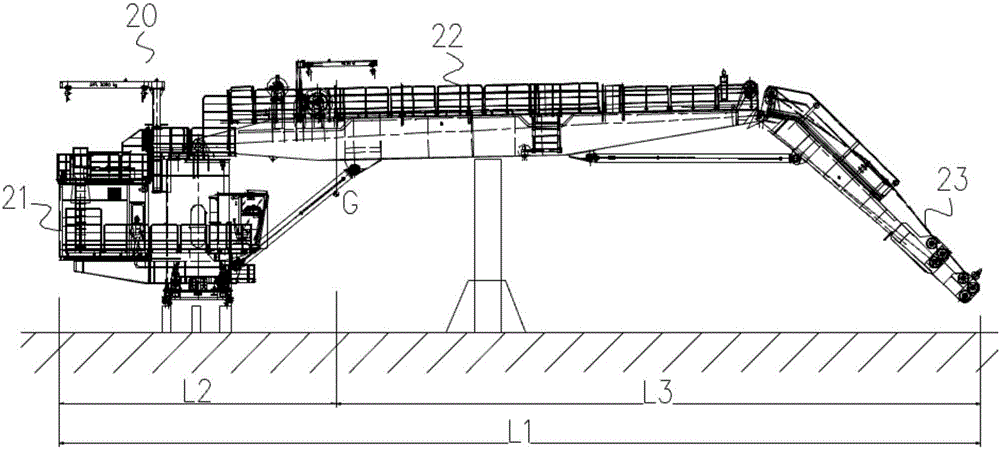

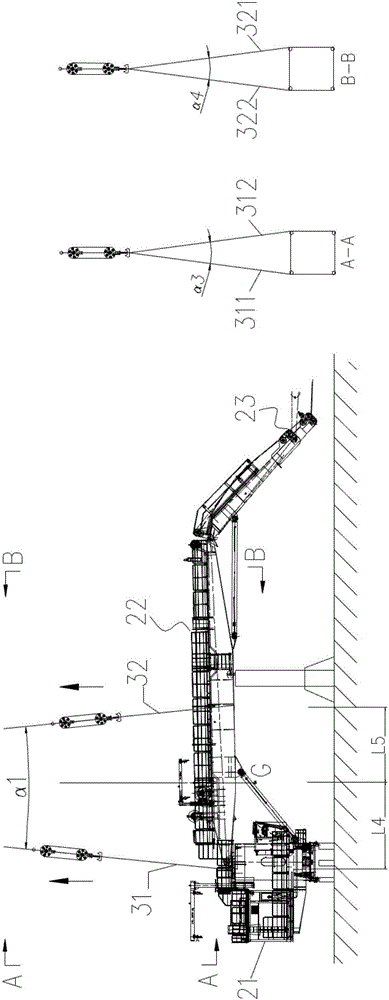

Lifting process of upper structure of FPSO crane

ActiveCN105947910AShorten the installation cycleReduce hoisting costsLoad-engaging elementsCranesButt jointGravity center

The invention discloses a lifting process of an upper structure of a FPSO crane. The lifting process comprises the following steps: (S1) a main lifting rope set is mounted on the upper structure; a first lifting rope set is positioned on the left side of the gravity center G by 6834 mm; and a second lifting rope set is positioned on the right side of the gravity center G by 6834 mm; (S2) a first adjusting rope and a second adjusting rope are mounted on the upper structure; (S3) the upper structure is wholly lifted, and an included angle between a main lifting arm and a joint lifting arm is adjusted in air, so that an original included angle between the main lifting arm and the joint lifting arm is reduced from an obtuse angle to 75 degrees; and (S4) the upper structure is in butt joint. The lifting process of the upper structure of the FPSO crane lifts the upper structure of the crane as a whole part, reduces the lifting times, can control and adjust the levelness of a flange at the bottom of an operation platform by only adjusting a folding angle of the joint lifting arm in air in the whole lifting process, reduces the mounting period and the lifting cost of the crane, and reduces potential safety hazards in aerial operations.

Owner:广州文冲船舶修造有限公司

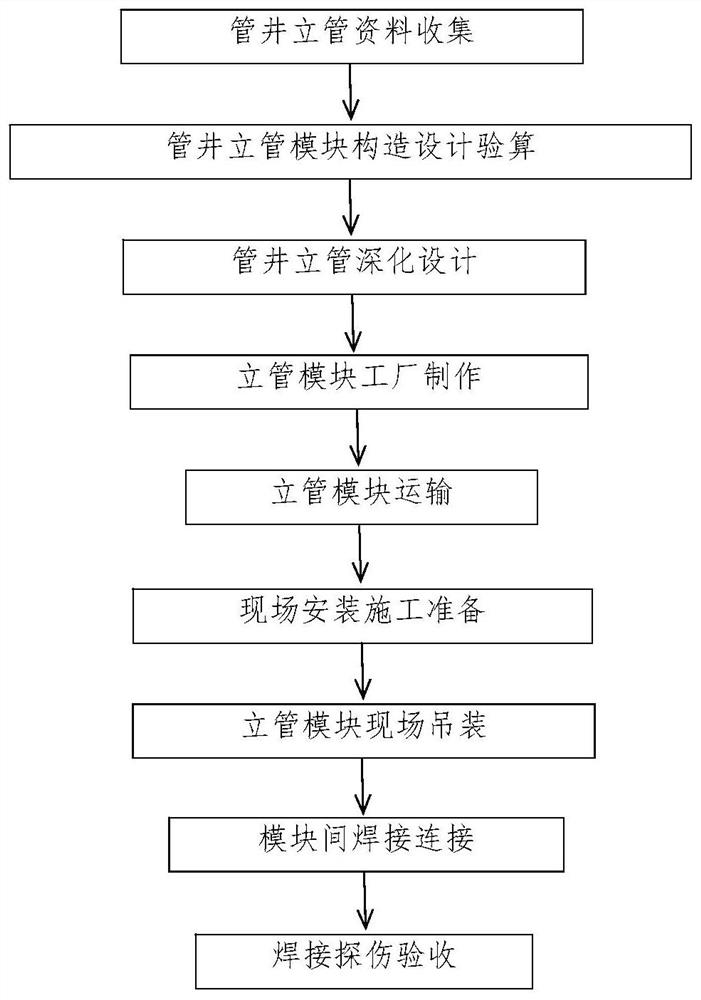

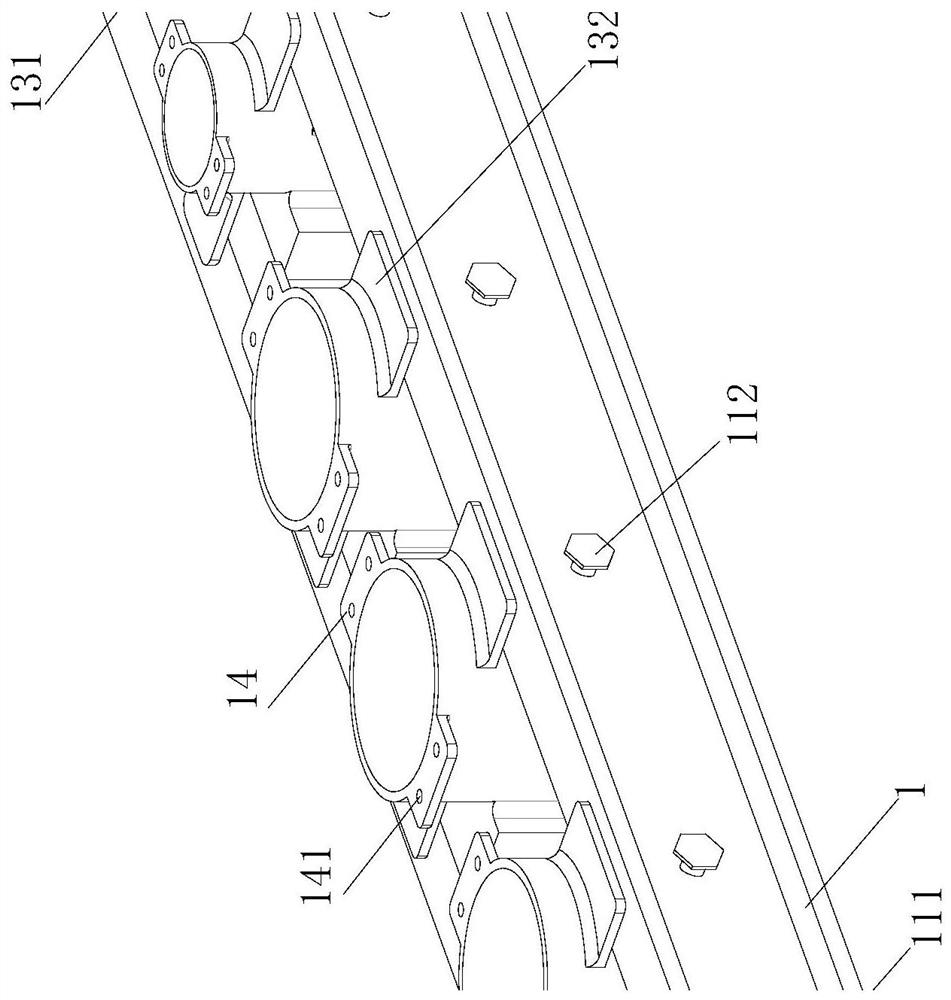

Segmented-assembled high-rise building tube well vertical pipeline structure and construction method thereof

PendingCN112049367AIncrease lossReduce lossBuilding material handlingVertical ductsConstruction engineeringStructural engineering

The invention belongs to the technical field of high-rise building pipeline laying, and particularly relates to a segmented-assembled high-rise building tube well vertical pipeline structure and a construction method thereof. The construction method comprises the steps of tube well vertical pipe data collection, tube well vertical pipe module structure design checking calculation, tube well vertical pipe deepening design, vertical pipe module factory manufacturing, vertical pipe module transportation, field installation construction preparation, vertical pipe module field hoisting, welding connection between modules and welding flaw detection acceptance. According to the construction method of the segmented-assembled high-rise building tube well vertical pipeline, modular factory machiningis adopted, the manufacturing precision is high, the machining quality is good, the efficiency is high, modular field installation is achieved, the hoisting frequency is small, field welding is small, construction is easy and convenient, the efficiency is high, the quality is good, the field construction safety is good, the operation risk in the construction process is low, the material loss is small, the construction period is short, the economic efficiency is good, and energy conservation and environmental protection are achieved.

Owner:CHONGQING NO 3 CONSTR +1

T-shaped steel assembly machine

PendingCN108655694AReduce labor intensityIncrease frictionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly machine

The invention relates to the technical field of steel structure processing equipment, and specifically relates to a T-shaped steel assembly machine. The T-shaped steel assembly machine comprises a conveyor, a wing plate feeding device, a web feeding device, a vertical prepressing device and a centering device, wherein the wing plate feeding device comprises a wing plate feeding device bracket, a wing plate support frame, a wing plate support frame lifting device and a wing plate horizontal pushing device; the web feeding device comprises a web feeding device bracket, a web box, a web horizontal pushing device and a guide inclined block; the vertical prepressing device is arranged downstream the wing plate feeding device and the web feeding device in the conveying direction of the conveyor,and the vertical prepressing device comprises a prepressing device bracket, a prepressing roller bracket, a prepressing roller and a prepressing roller bracket lifting device; and the centering device is arranged downstream the vertical prepressing device in the conveying direction of the conveyor. According to the T-shaped steel assembly machine, the production efficiency can be improved, the labor intensity of workers is reduced, and webs and wing plates are prevented from misplacing due to relative sliding during transportation.

Owner:SHAN DONG JUXIN GRP STEEL STRUCTURE CO LTD

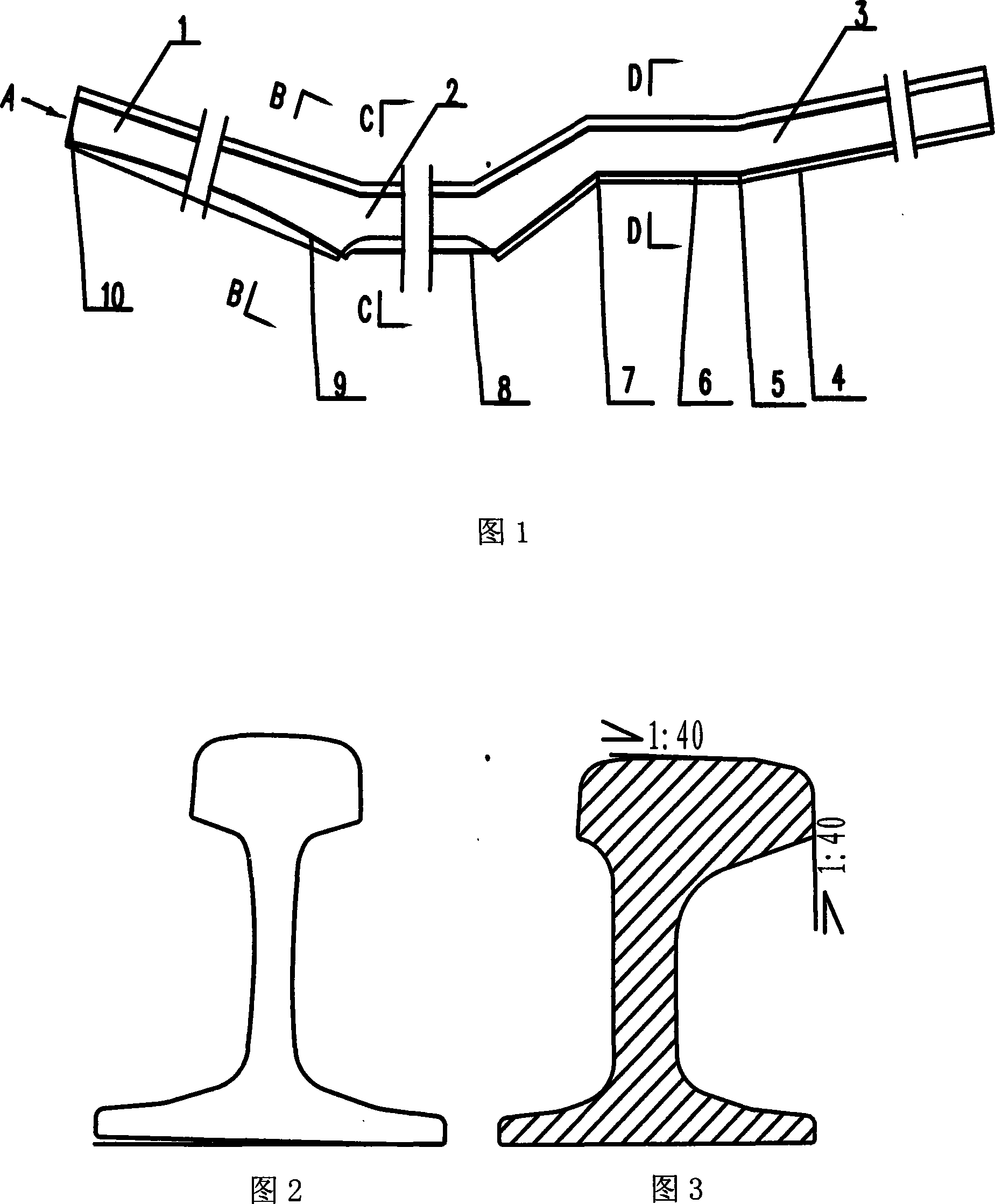

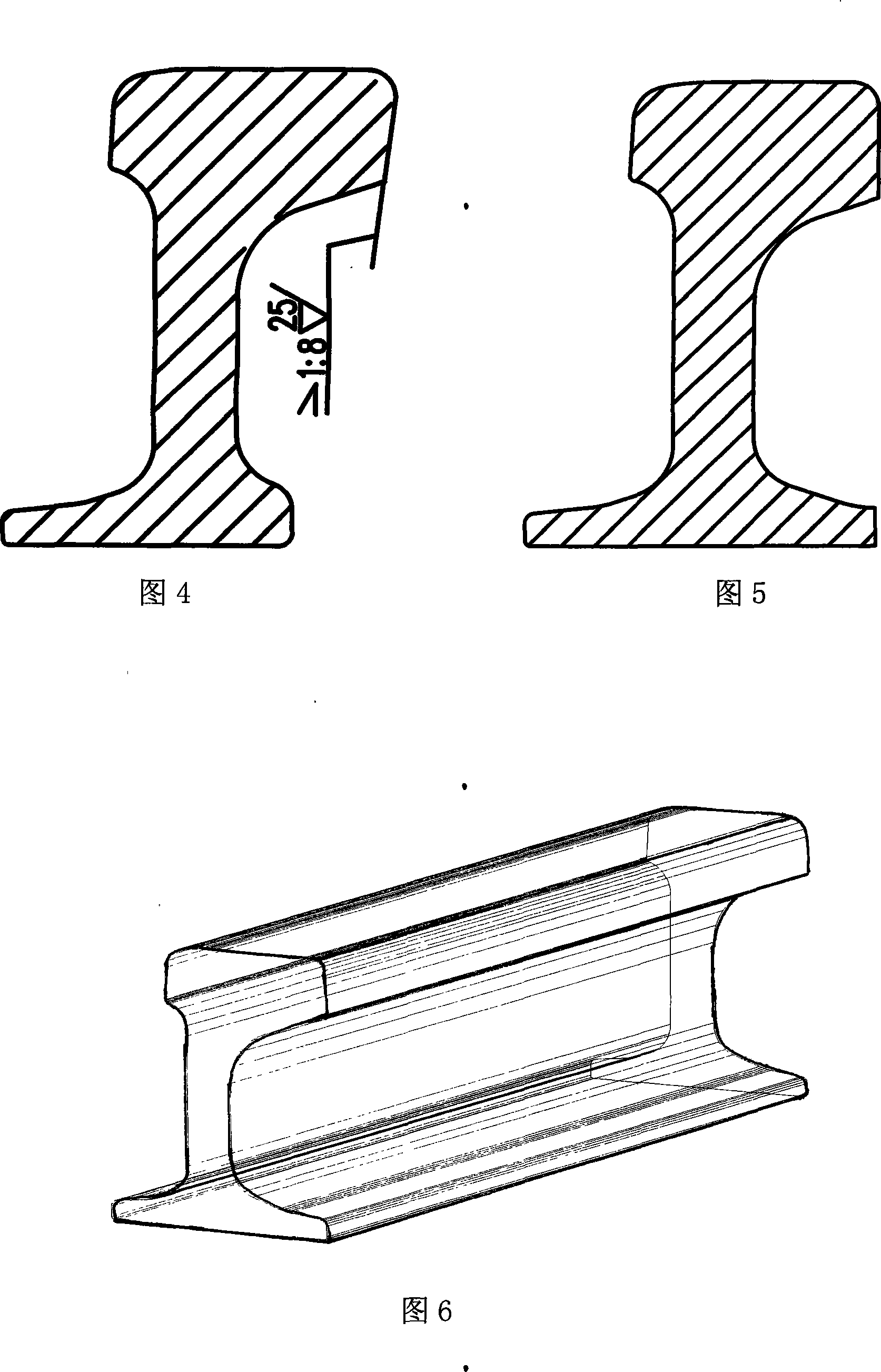

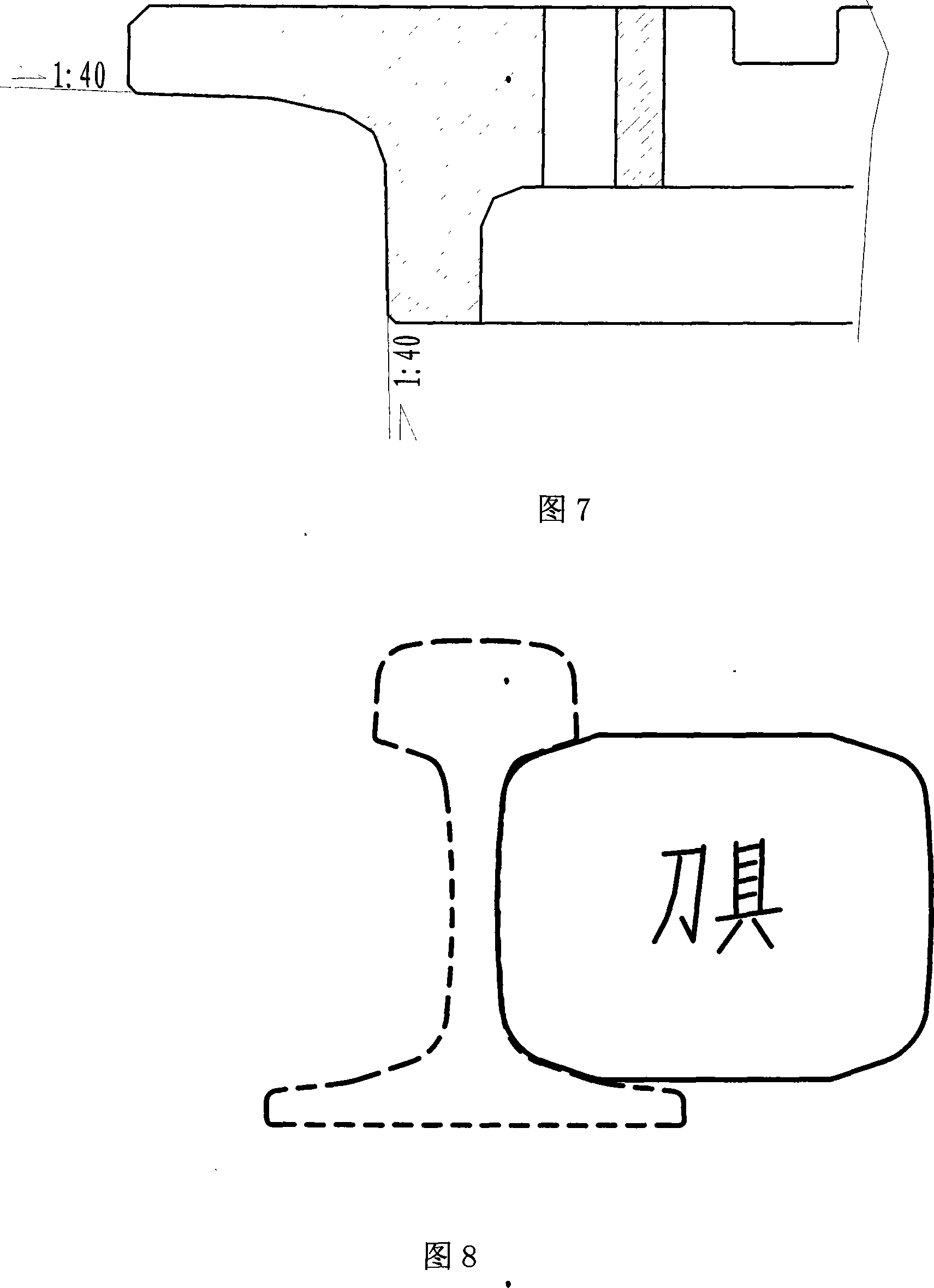

High-speed railway lateral turnout wing rail processing technique

ActiveCN101214608AGuaranteed machining accuracyMeet the requirements of batch processingBatch processingRailhead

A processing technique of the wingrail of the lateral turnout of a high-speed railway includes ten steps: (1) cutting and boring; (2) the milling of a point-hiding section and the inner working edge rail limb of the rear section; (3) the milling of the inner railhead working edge of the rear section; (4) the milling from the front-end rail waist to the rail waist of a standard steel rail; (5) the skewing of the front end; (6) the milling of the front section of inner railhead working edge after the push bending of the front section; (7) the push bending of the rear section; (8) the milling of the point-hiding section; (9) shape-righting adjustment; (10) burnishing and derusting. The present invention is the processing technique method of a whole wingrail, the advantages of a numerically controlled miller are sufficiently exerted, the processing utilizes a moulded cutter, so the processing precision is high, the processing cost is low, as a result, the requirements of batch processing are satisfied, and the productivity effect is increased. The present invention is particularly suitable for the processing of wingrails used by the No. 18 lateral turnout of the 60 kg / m steel rail of the 350 km / h passenger-dedicated line.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Thin plate multilayer upper building integral hoisting method

ActiveCN107600314AShort cycleExpand the scope of the general groupVessel partsThin slabGravity center

The invention discloses a thin plate multilayer upper building integral hoisting method. The thin plate multilayer upper building integral hoisting method includes the following steps: checking hoisting point positions, the hoisting load, and the hoisting margin, segmenting an upper building total combination structure, performing weight and gravity center calculation on the segmentations, iron outfitting members and pre-buried devices, performing local reinforcement on hoisting rings and large openings, performing precision measurement and recording on all transverse bulkheads of the total section, the length, the width and the height of the total section with a central rib line of the total section as a reference line in the length direction; assigning a longitudinal and transverse bulkhead structural line with the ship central line and the central rib line as references in the length direction of the total combination structure in a deck surface where the total combination structureis located, comparing the previous total section bulkhead precision measurement data value, considering the corresponding condition of an upper structure and a lower structure of the deck 1, hoistingthe total combination structure, and performing spot welding fixing. The objective of the invention is to provide a thin plate multilayer upper building integral hoisting method which can shorten theberth period, can save reinforcing materials and human resources, and can effectively improve the production efficiency.

Owner:WUCHANG SHIPBUILDING IND

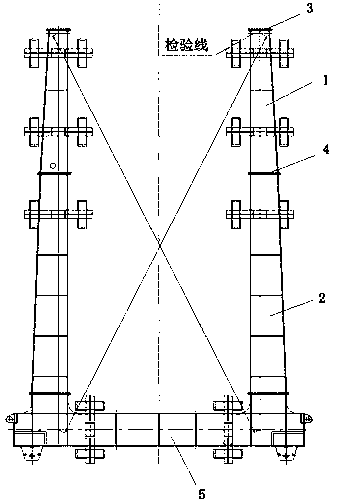

Manufacturing method of upper supporting legs of tire crane

The invention discloses a manufacturing method of upper supporting legs of a tire crane, and relates to the technical field of tire crane components. The method comprises the following steps that firstly, box bodies and flanges of the upper supporting legs are manufactured, and the flanges and the upper supporting leg box bodies are installed; the upper supporting leg flanges are manufactured, specifically, bolt hole positions and web and wing plate mounting lines are scribed on lower flanges according to lower supporting leg upper flanges, and bolt hole positions, web and wing plate mountinglines and supporting leg center lines are scribed on the upper flanges according to main beam flanges; the lower flanges are installed, specifically, the lower flanges of the supporting legs are connected with the upper flanges of the lower supporting legs through bolts and clamping plates, upper supporting leg lower ports are trimmed by using flange plates as a reference, welfding is completed asrequired after correction is qualified; and the upper flanges are installed, specifically, upper flange mounting inspection lines are scribed on the upper supporting legs according to lower cross beam center lines or large axle hole centers, and upper ports and the upper flanges are positioned according to the upper supporting leg center lines. The manufacturing method of the upper supporting legs of the tire crane has the advantages that after the upper flanges and the lower flanges are installed, main beams are directly hoisted to the upper supporting legs for final assembly, so that the hoisting frequency is reduced.

Owner:SHANGHAI ZHENHUA HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com