Building process for deep sea spar platform

A floating platform and deep-sea technology, which is applied to ship construction, ship parts, ships, etc., can solve the problems of difficult control of construction accuracy, heavy construction and hoisting work of the general section of the hard cabin ring, so as to improve the utilization rate of the slideway and reduce the The effect of hoisting times and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

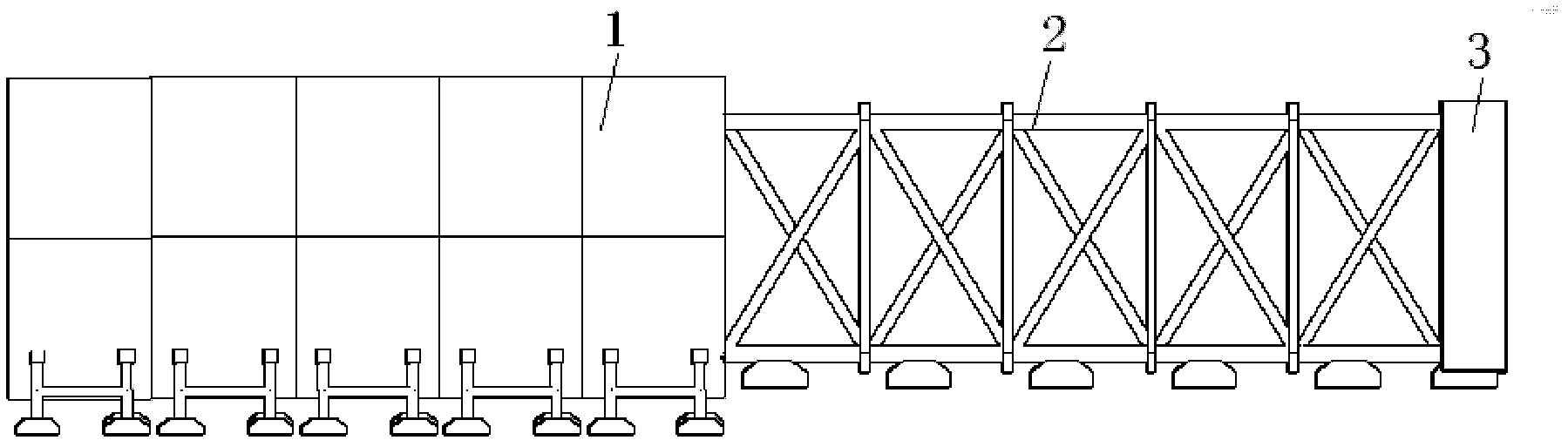

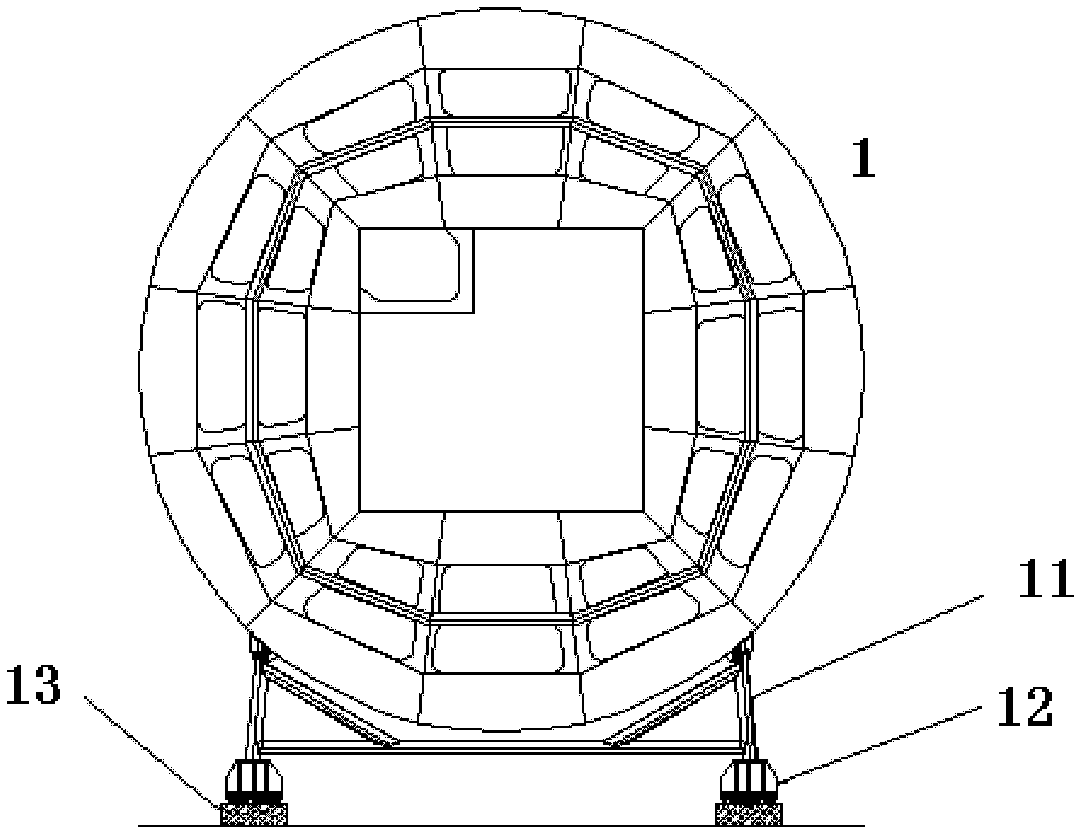

[0056] Such as figure 1 As shown, the main structure of the floating platform 16 includes three parts: a hard cabin 1, a truss 2, and a soft cabin 3; wherein, the hard cabin 1 is composed of several ring segments connected to form a whole, and the truss 2 is installed on the hard cabin 1. One end of the soft cabin 3 is installed on one end of the truss 2.

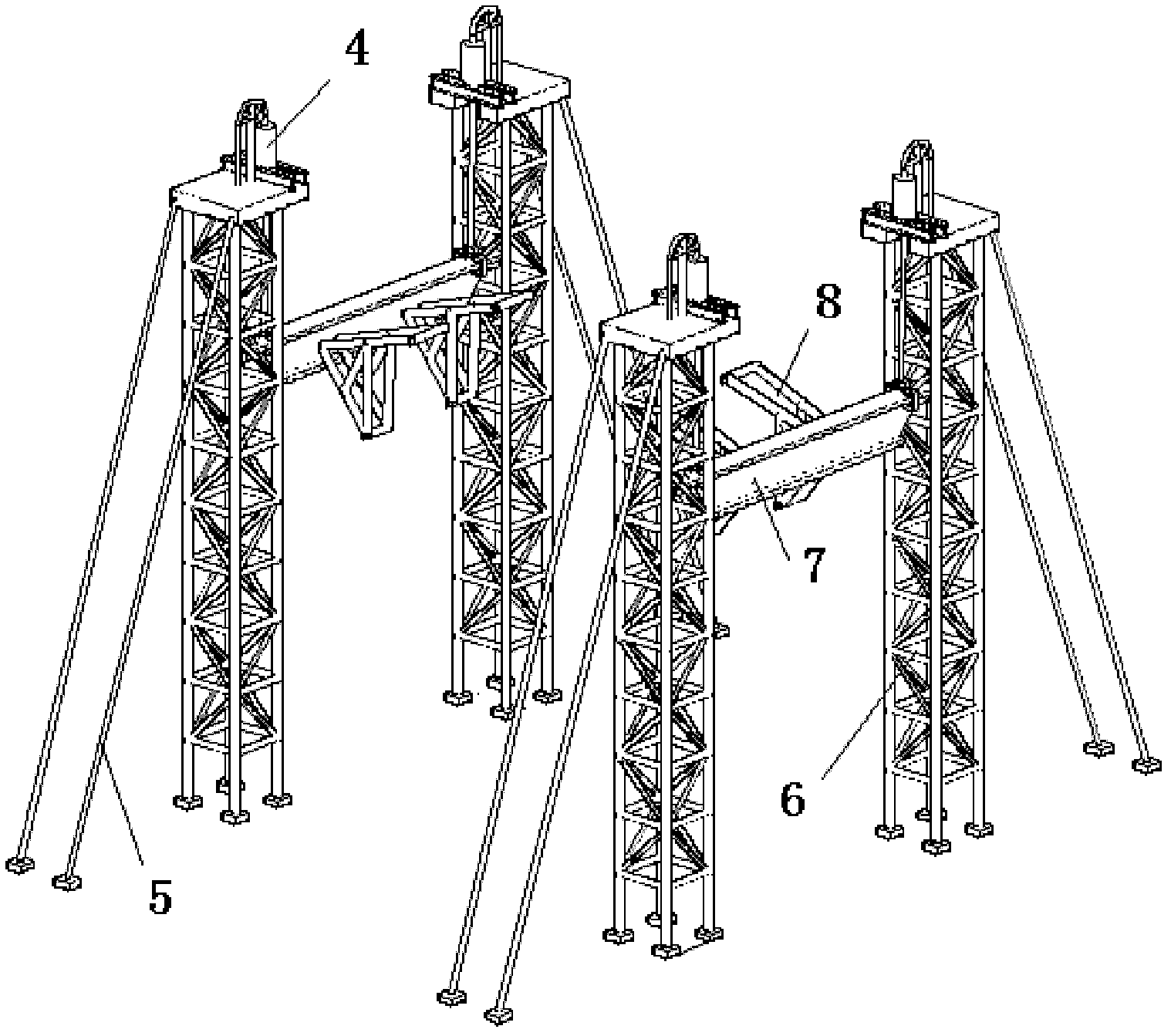

[0057] Such as figure 2 As shown, the lifting device is mainly composed of an array of lifting towers 6 corresponding to each other, a lifting beam 7 installed between every two groups of lifting towers 6 corresponding to each other, and a lifting beam 7 installed on the lifting beam 7 for lifting the hard cabin ring. Segmented lifting brackets 8 are formed, and a fixed wire rope 5 is connected between the top of each group of lifting towers 6 to the ground, and tension jacks 4 are installed on the platform at the top of each group of lifting towers 6 . Present embodiment: the lifting tower 6 is four groups, also can ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com