Method for preparing structural color three-dimensional array patterns based on sessile droplets

A three-dimensional array and structural color technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve the problems of poor stability of droplet pixels, cumbersome process, and poor designability of patterns, so as to inhibit particle settlement , The process steps are simple, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

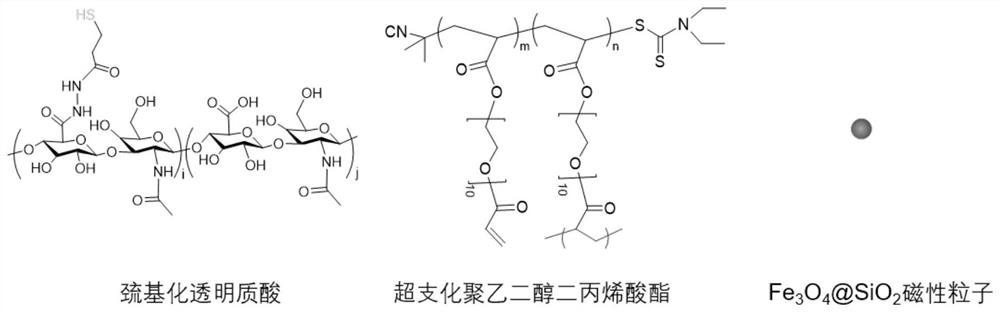

[0027] (1) Preparation of structural color ink

[0028] Take 50 μL of an aqueous solution containing 0.1% silicon dioxide-coated ferric oxide colloidal particles, dissolve 50 μL of 5% hyperbranched polyethylene glycol diacrylate in the above solution, adjust the pH=9, and put it into the first syringe; take 100 μL 1% mercaptolated hyaluronic acid, adjust the mixed solution to pH=7.5 and fill it into the second syringe, place the two syringes on the ink supply device 1 of the microfluidic device, and inject the aqueous solution of the two syringes into the 3D through the ink supply device In the printing nozzle, the structural color ink is made by mixing.

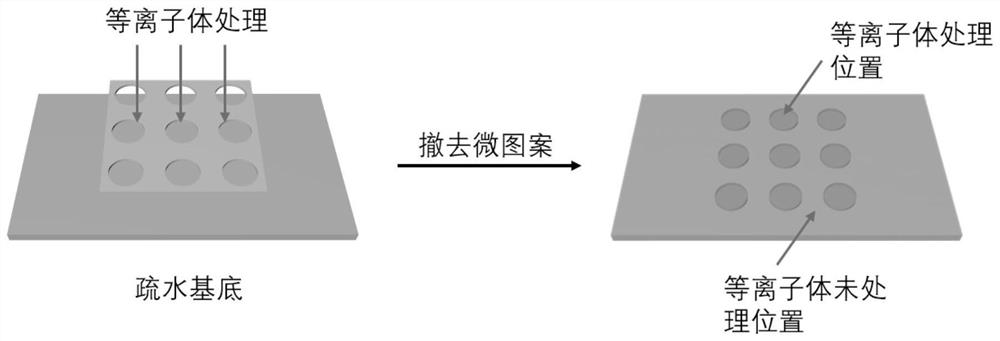

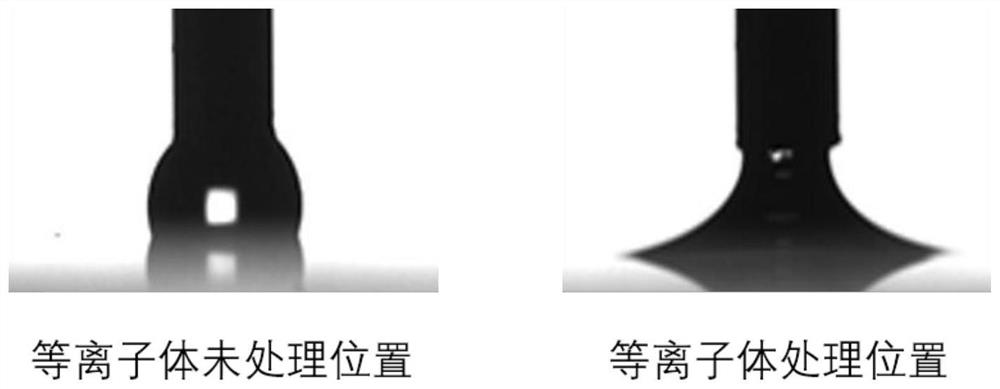

[0029] (2) Preparation of hydrophobic-hydrophilic patterned printing substrate

[0030] Such as figure 1 As shown, the laser perforated paper is attached to the black silica gel plate by using a mask method, and only the micropores are reserved, and it is placed in an oxygen plasma device for treatment. The treated positio...

Embodiment 2

[0034] (1) Preparation of structural color ink

[0035] Take 100 μL of an aqueous solution containing 80% silica colloidal particles, dissolve 10% acrylamide and 1% N,N methylenebisacrylamide in the above solution, and fill it into the first syringe after completely dissolving; 5% light Initiator 2959 was dissolved in 100 μL of water, and filled into the second syringe after it was completely dissolved. The aqueous solution of the two syringes was injected into the 3D printing nozzle through the ink supply device, and the structural color ink was obtained by mixing.

[0036] (2) Preparation of hydrophobic-hydrophilic patterned printing substrate

[0037] The patterned micropores are directly printed on the black silica gel plate by laser etching, the sample is placed in an oxygen plasma device for treatment, and the surface film is torn off to obtain a hydrophobic-hydrophilic patterned printing substrate.

[0038] (3) Preparation of structural color material patterning

[00...

Embodiment 3

[0041] (1) Preparation of structural color ink

[0042] Take 100 μL of an aqueous solution containing 0.01% polymethyl methacrylate colloidal particles, dissolve 5% phenylboronic acid-modified hyperbranched polyethylene glycol diacrylate, 10% acrylamide, and 1% polyvinyl alcohol in the above mixed solution , adjust the pH of the mixture to 8 and put it into the first syringe; dissolve 5% photoinitiator in 100 μL of water, put it into the second syringe after it is completely dissolved, and inject the aqueous solution of the two syringes into the 3D printing nozzle through the ink supply device Inside, the structural color ink is obtained by mixing.

[0043] (2) Preparation of hydrophobic-hydrophilic patterned printing substrate

[0044] Use the mask method to attach the laser-perforated paper to the silica gel plate, leaving only the micropores, and put it into oxygen plasma for treatment. The treated part is hydrophilic, and the untreated part is hydrophobic. Remove the pape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com