Integrally-tensioned integrated chimney and cooling tower structure system and construction method thereof

An integral tension and smoke tower technology, applied in the dome roof structure, arch structure, tower and other directions, can solve the problems of large consumption of concrete air cooling tower materials, a large number of aerial operations, high safety risks, etc., to shorten the construction period, The effect of saving land and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

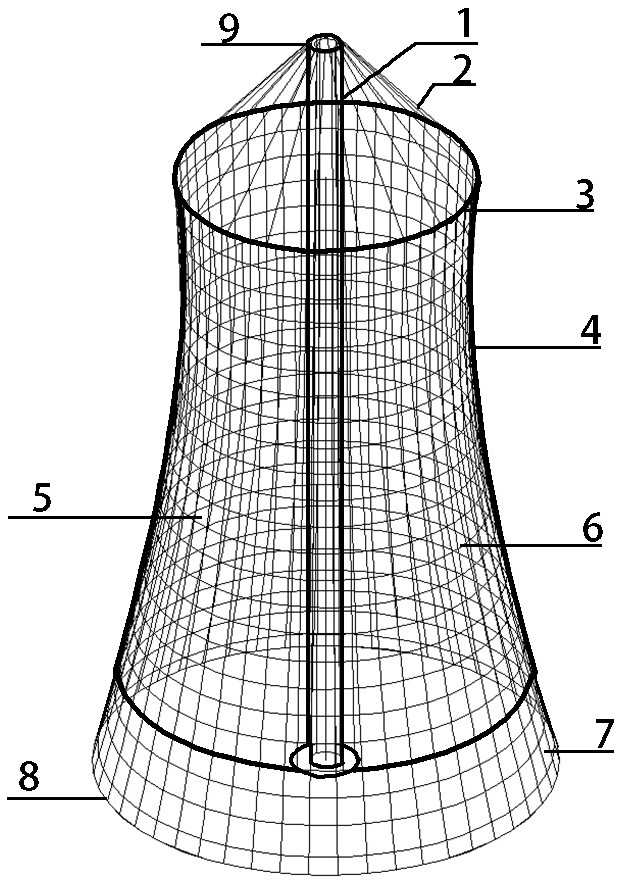

[0053]The diameter at the bottom of the air cooling tower (pillar center) is 138.5m, the outlet diameter of the air cooling tower is 90m, the air inlet diameter of the air cooling tower is 121.6m, the throat diameter of the pit cooling tower is 86m, and the height is 148.5m. The height of the pit cooling tower is 198m. The height of the tower air inlet is 30.5m; the bottom diameter of the chimney 1 is 20m, the top diameter is 10m, the wall thickness is 3m-5m, and the height of the chimney 1 is 248m. The chimney 1 provides tensile support, and a single-layer straight cable is used as the bus bar to stretch the latitude and longitude cables between the upper and lower ring beams to form a single-layer hyperboloid. Membrane materials are laid on the inside or outside of the cable net. The specific construction methods are as follows:

[0054](1) First, carry out the construction of the chimney 1. The chimney 1 is a cast-in-place concrete structure or a fabricated structure. A rigid steel ...

Embodiment 2

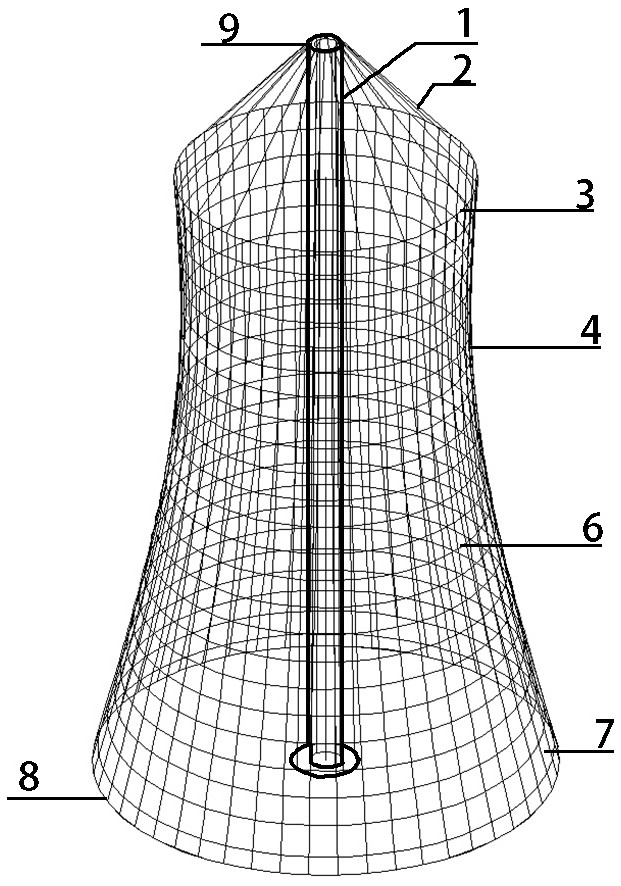

[0062]The diameter at the bottom of the air cooling tower is 138.5m, the outlet diameter of the air cooling tower is 90m, the air inlet diameter of the air cooling tower is 121.6m, the throat diameter of the pit cooling tower is 86m, the height is 148.5m, the height of the air cooling tower is 198m, and the air inlet height of the air cooling tower is 30.5. m; The bottom diameter of chimney 1 is 20m, the top diameter is 10 meters, the wall thickness is 3m-5m, and the height of chimney 1 is 248m. The chimney 1 provides tensile support, and two layers of straight cables are used as the busbars to be diagonally and cross-tensioned between the upper and lower ring beams to form a double-layer hyperboloid. Membrane materials are laid on the inside or outside of the cable net. The specific construction methods are as follows:

[0063](1) First, construct the chimney 1 structure. The chimney 1 is a cast-in-place concrete structure or a fabricated structure. A rigid steel beam is embedded at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com