Patents

Literature

113results about How to "Reduce on-site wet work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

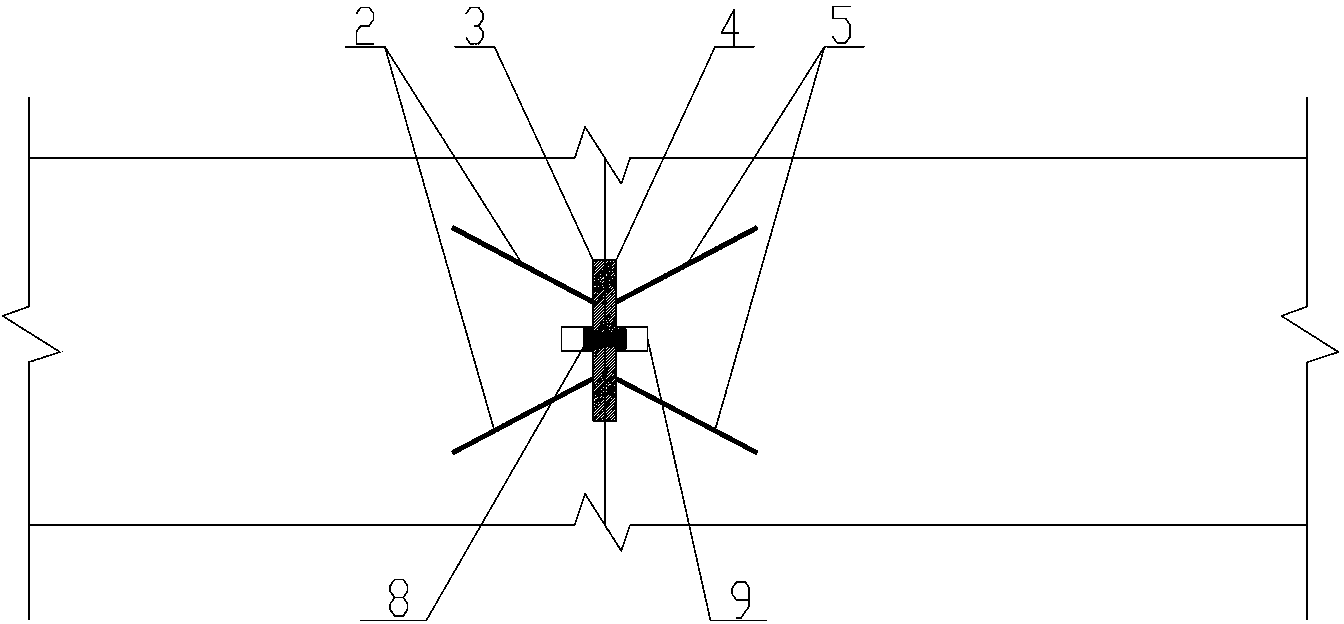

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

Prestressed prefabricated ECC-RC combination beam column joint component

InactiveCN103774755AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

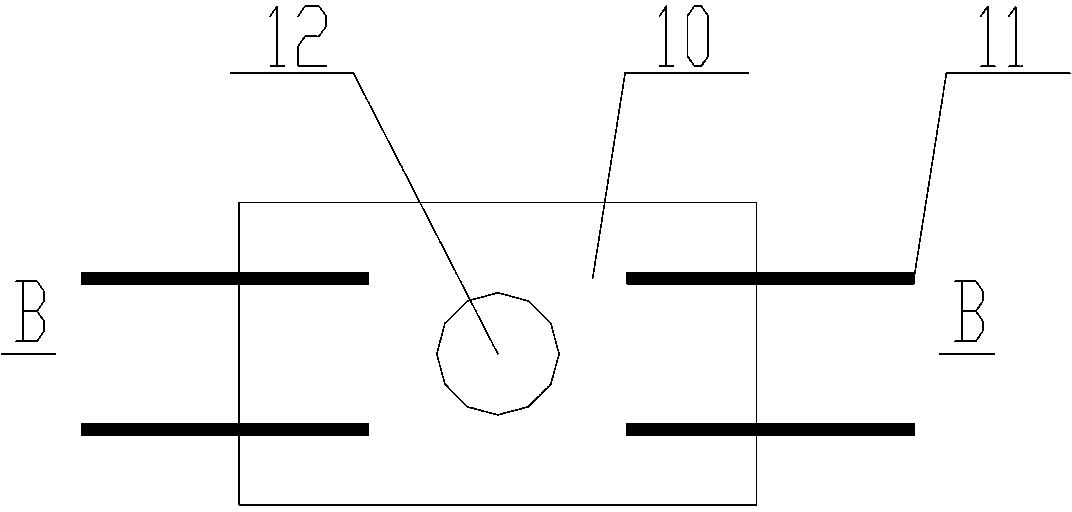

The invention relates to a prestressed prefabricated ECC-RC combination beam column joint component which comprises a prestressed rib and a joint with a bracket. The joint with the bracket is composed of an ECC material, longitudinal bars and stirrups. The joint with the bracket comprises an outward-extending column, wherein the length of the outward-extending column is about 1-2 times of the height of the column section. A hole channel is required to be reserved between the joint and a prefabricated RC beam connected with the joint. The prefabricated ECC joint is connected with the prefabricated RC beam through the post-tensioned prestressed rib which penetrates through the hole channel. H-shaped steel is embedded in the end of the outward-extending column and the end of a prefabricated RC column, wherein the embedded depth and the outward-extending length both range from 10 cm to 15 cm, the longitudinal bars at the end of the outward-extending column and the end of the prefabricated RC column respectively extend outwards by 10-15 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of the prefabricated RC column and the embedded H-shaped steel of the prefabricated joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prestressed prefabricated ECC-RC combination beam column joint component, the prestressed prefabricated joint component formed by pouring of the steel bar reinforced ECC material is applied to an assembly type frame structure, so that the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; since prestress is used as an assembly means, residual deformation of the structure after an earthquake can be reduced, the restorable function is achieved, and post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

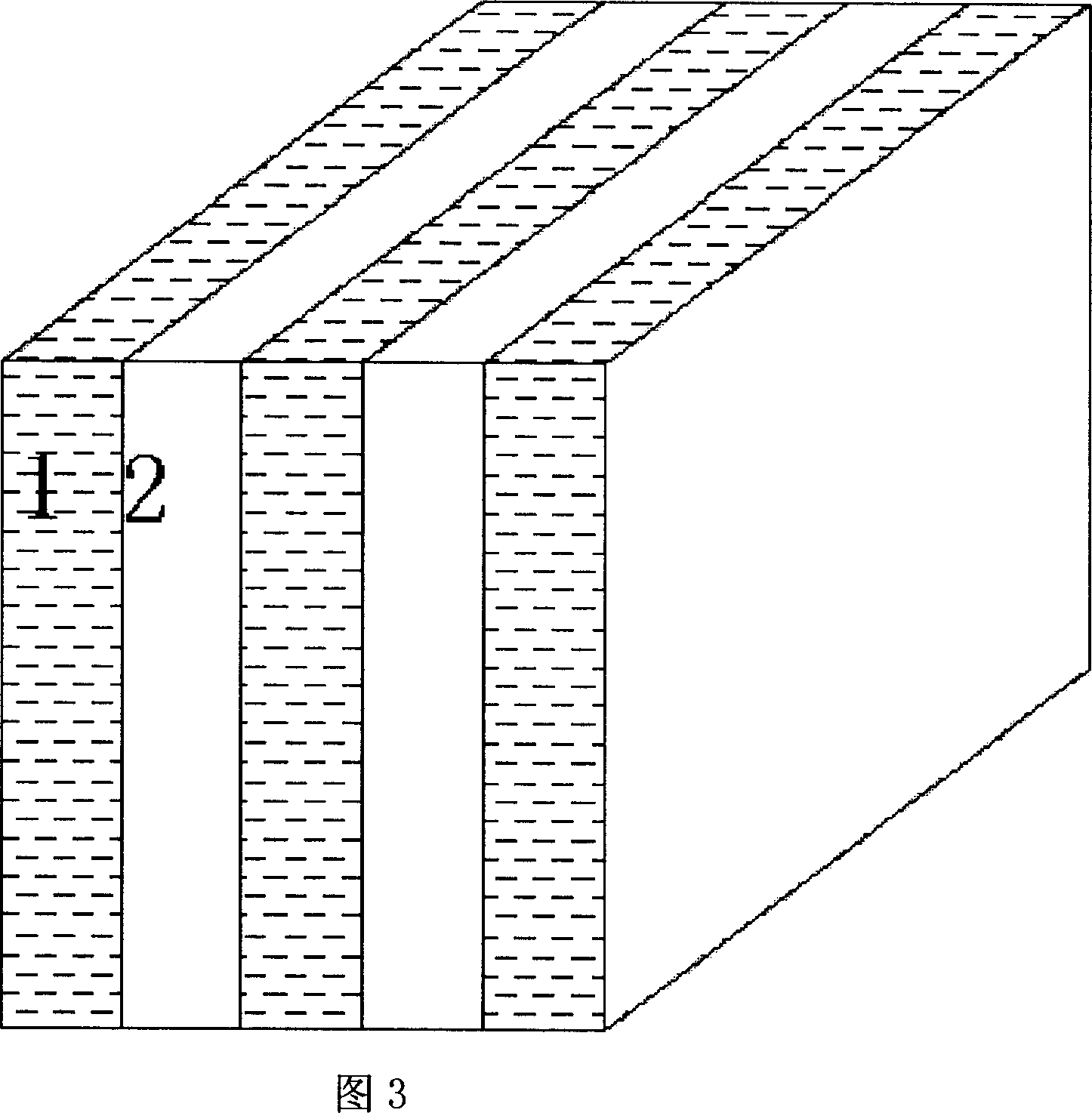

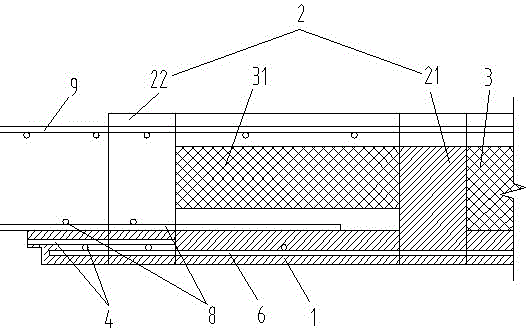

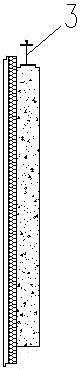

Vitrified micro bubble composite rock wool fireproof insulating plate and manufacturing method thereof

InactiveCN102121280AImprove insulation effectHigh fire ratingCovering/liningsHeat proofingSurface layerFireproofing

The invention provides internal and external wall fireproof insulating plates, and particularly relates to a vitrified micro bubble composite rock wool fireproof insulating plate and a manufacturing method thereof. In the vitrified micro bubble composite rock wool fireproof insulating plate, a rock wool plate is used as a base layer; a vitrified micro bubble layer, an alkaline-resistance mesh cloth layer, a vitrified micro bubble surface layer and a vitrified micro bubble bottom layer are solidified on the outer surface of the base layer; a plurality of laminar structures are solidified into a whole; and a groove is formed on the surface of the vitrified micro bubble bottom layer. The preparation method comprises the following steps: preparing vitrified micro bubble insulating slurry, and applying a layer of interface mortar on the upper surface, the lower surface and the periphery of a rock wool plate; uniformly applying the vitrified micro bubble slurry on the upper surface and the lower surface of the rock wool plate to form an upper vitrified micro bubble bottom layer and a lower vitrified micro bubble bottom layer; respectively bonding and paving two alkaline-resistance mesh clothes on the applied upper and lower vitrified micro bubble bottom layers, and sewing the upper and lower vitrified micro bubble bottom layers together; applying hydrophobic vitrified micro bubble mortar on the alkaline-resistance mesh cloths once again to form an upper vitrified micro bubble surface layer and a lower vitrified micro bubble surface layer; and forming a slot on the lower vitrified micro bubble surface layer. The vitrified micro bubble composite rock wool fireproof insulating plate is used for external wall insulation and fireproofing, can achieve the A-level fireproof requirement, and accords with high-rise building insulation and fireproof standards in China.

Owner:李明军

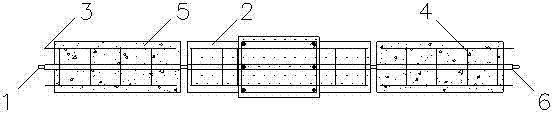

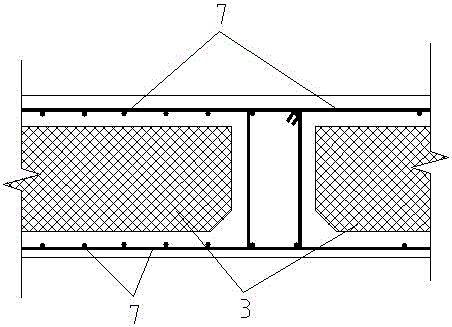

Reinforced concrete assembly type cable duct and manufacturing method

InactiveCN104466869AImprove the degree of factory processingImprove construction progressCable installations on groundArtificial islandsReinforced concreteEngineering

A reinforced concrete assembly type cable duct is formed by connecting sections of U-shaped duct bodies, each U-shaped duct body is formed by splicing two half L-shaped duct bodies in left-and-right symmetry, a plurality of steel bar connection sleeves arranged inwards respectively are correspondingly and transversely reserved on the spliced edges, at the spliced parts, of bottom plates, and when every two half L-shaped duct bodies are spliced together, short steel bars performing the functions of positioning and connecting are inserted in the steel bar connection sleeves corresponding to the two half L-shaped duct bodies. The manufacturing method comprises the steps of factory fabrication, positioning paying off, earth excavation, bedding layer construction, in-place hoisting, connecting joint pouring, cable support fixation, cable laying and cover plate laying. The reinforced concrete assembly type cable duct has the advantages of being convenient to convey, easy and convenient to splice, reliable in water resistance, smooth in water drainage, capable of being assembled on site and the like.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

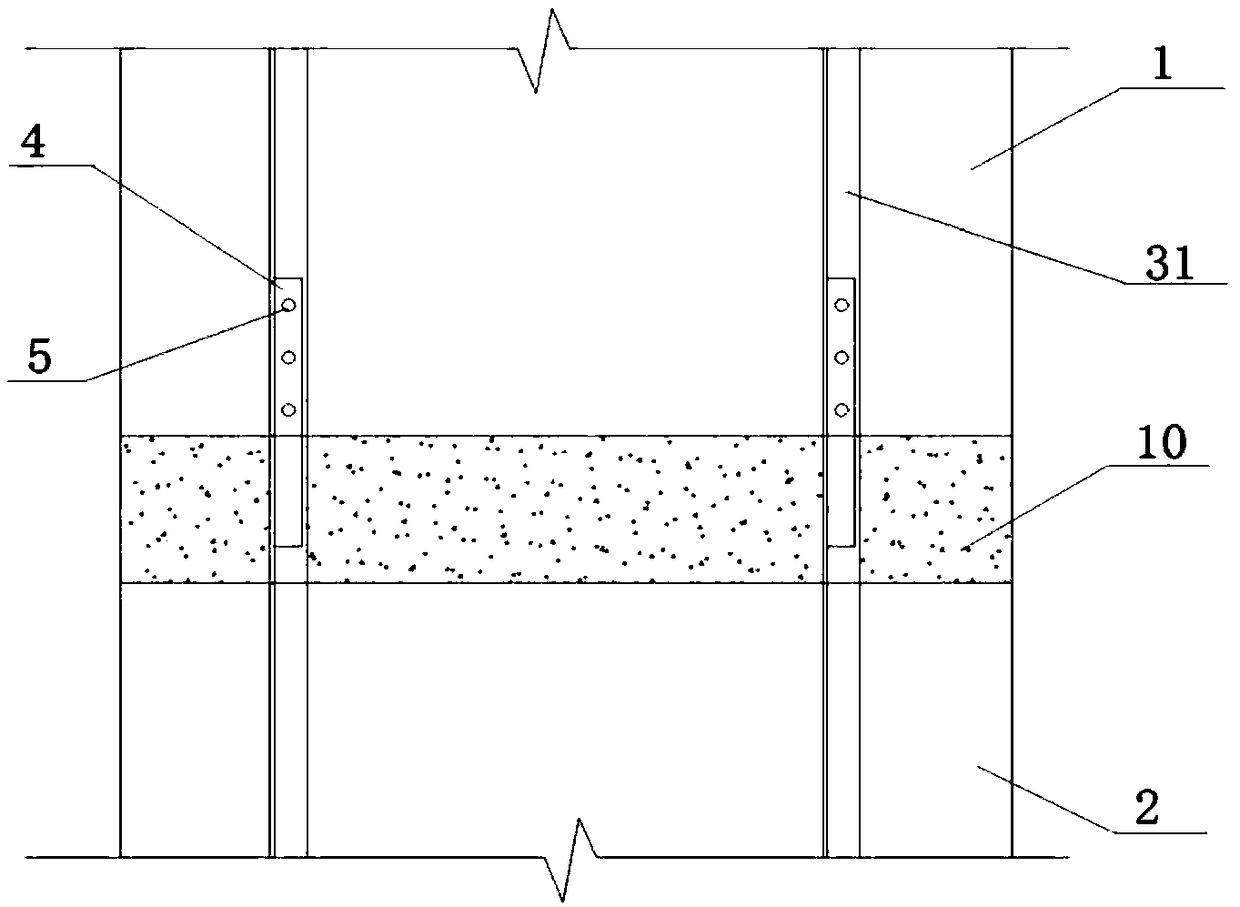

Method for using prefabricated reinforced concrete frame to reinforce existing structure through prestressing assembly

InactiveCN103711330AReduce assembly connection problemsTroubleshoot assembly connectionsBuilding repairsShock proofingReinforced concretePre stress

The invention discloses a method for using a prefabricated reinforced concrete frame to reinforce an existing structure through prestressing assembly, and belongs to the field of reinforced concrete structure aseismatic reinforcement in civil engineering. The method for using the prefabricated reinforced concrete frame to reinforce the existing structure through prestressing assembly comprises the steps that an existing reinforced concrete frame to be reinforced and the newly-added prefabricated reinforced concrete frame used for reinforcement are included, and the existing reinforced concrete frame to be reinforced and the newly-added prefabricated reinforced concrete frame used for reinforcement are connected into a whole in an assembly mode through unbonded prestressed reinforcing steel bars; after rebars on newly-added prefabricated frame beams, rebars on joints of newly-added prefabricated frame columns, rebars on connectors between upper-layer newly-added prefabricated frame columns and lower-layer newly-added prefabricated frame columns are bound, concreting is carried out on the rebars to form a whole; gaps are reserved between the newly-added prefabricated reinforced concrete frame and the existing reinforced concrete frame, and are sealed by mortar; channels are reserved in the newly-added prefabricated frame beams and the newly-added prefabricated frame columns, and channels are formed in existing frame beams and existing frame columns, and correspond to the channels of the newly-added prefabricated reinforced concrete frame in position; the unbonded prestressed reinforcing steel bars penetrate through the channels, are tensioned, and are anchored through anchoring tools. The seismic capacity of the structure reinforced through the method is improved by 1-2 times.

Owner:BEIJING UNIV OF TECH

Reinforced concrete prefabricated road slab and installation and construction method thereof

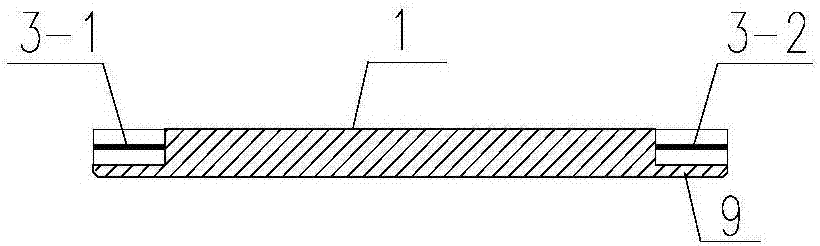

InactiveCN102677565ASuitable for industrial productionImprove integritySingle unit pavingsTemporary pavingsReinforced concreteEngineering

The invention discloses a reinforced concrete prefabricated road slab and an installation and construction method thereof. The reinforced concrete prefabricated road slab is made into a groove and tongue batten, a groove and tongue male groove is arranged in the left middle part of the thickness of the batten, a groove and tongue female groove is arranged in the right middle part of the thickness of the batten, the connector points of the groove and tongue male groove and the groove and tongue female groove are respectively provided with two full-length steel angles for protection, in addition, a rebar pull ring is respectively arranged at the middle parts of the thickness at the upper 1 / 4 span point and the lower 1 / 4 span point of the length of the left groove and tongue male groove, grooves are respectively arranged in the middle parts of the thickness at the right groove and tongue female groove corresponding to the two rebar pull rings, and the middle parts of the grooves are respectively embedded with a steel sleeve perpendicular to the slab surface. The road slab is suitable for industrial production, on-site wet operation is reduced, the engineering cost is reduced, the construction speed is high, the integrity of the road is good, and the reinforced concrete prefabricated road slab has good self-cleaning performance, is easy to clean, and is low-carbon and environment-friendly.

Owner:CHINA MCC17 GRP

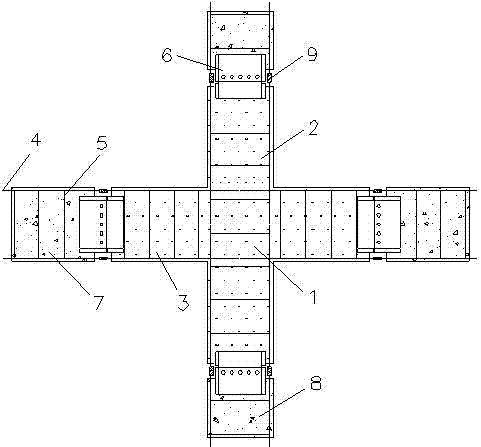

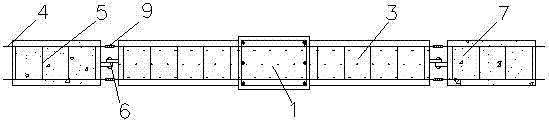

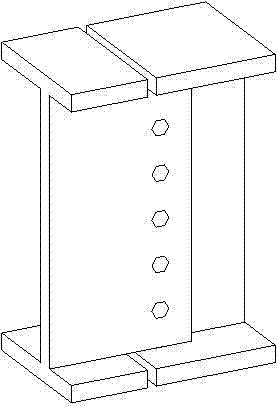

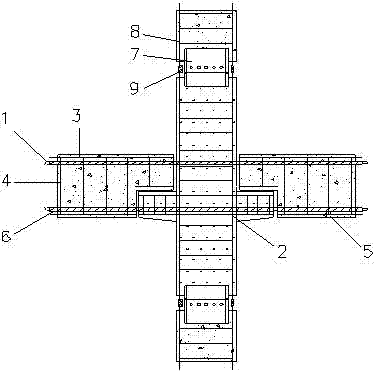

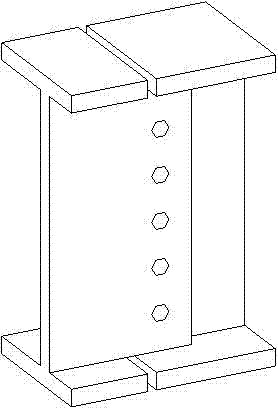

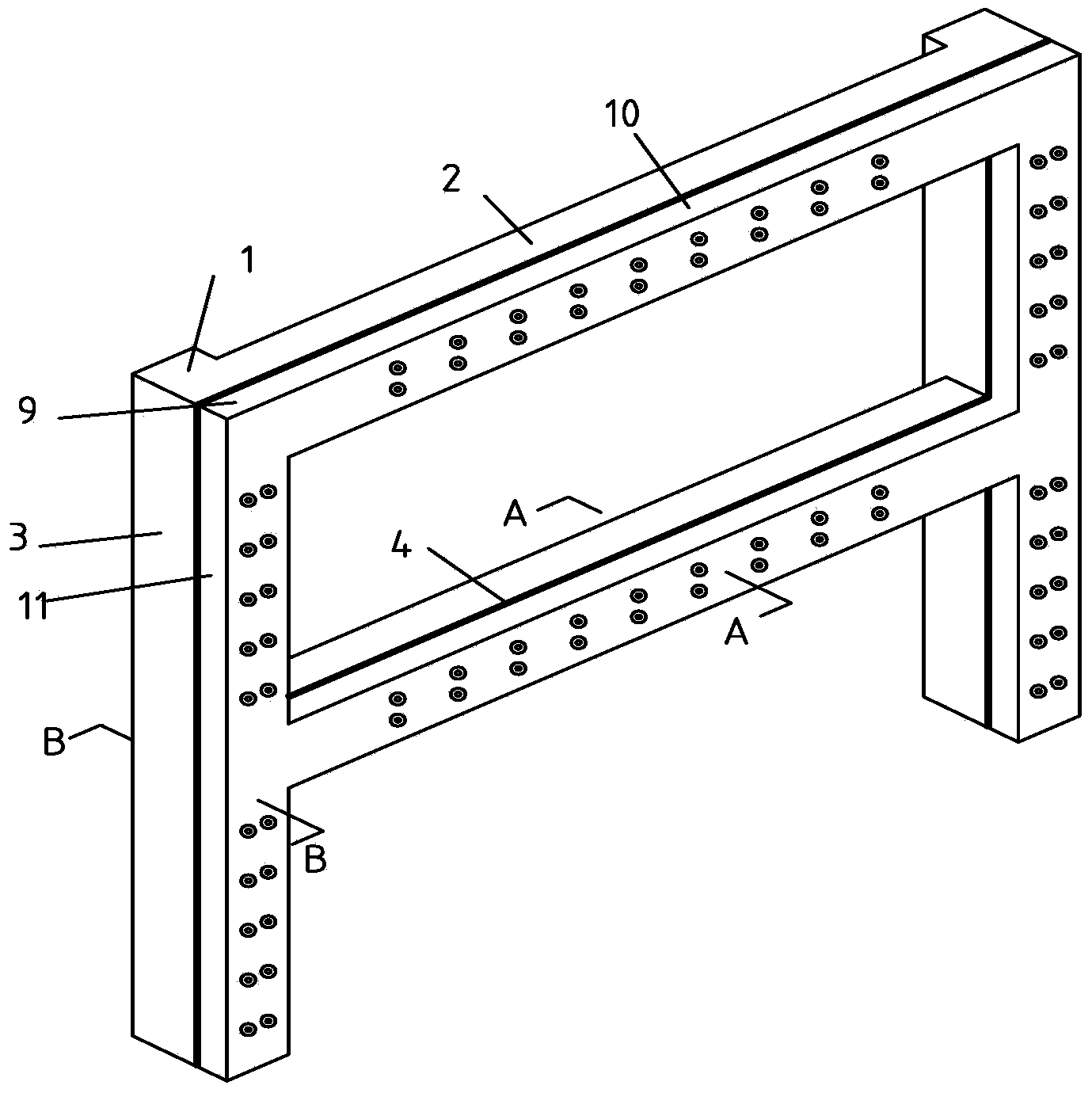

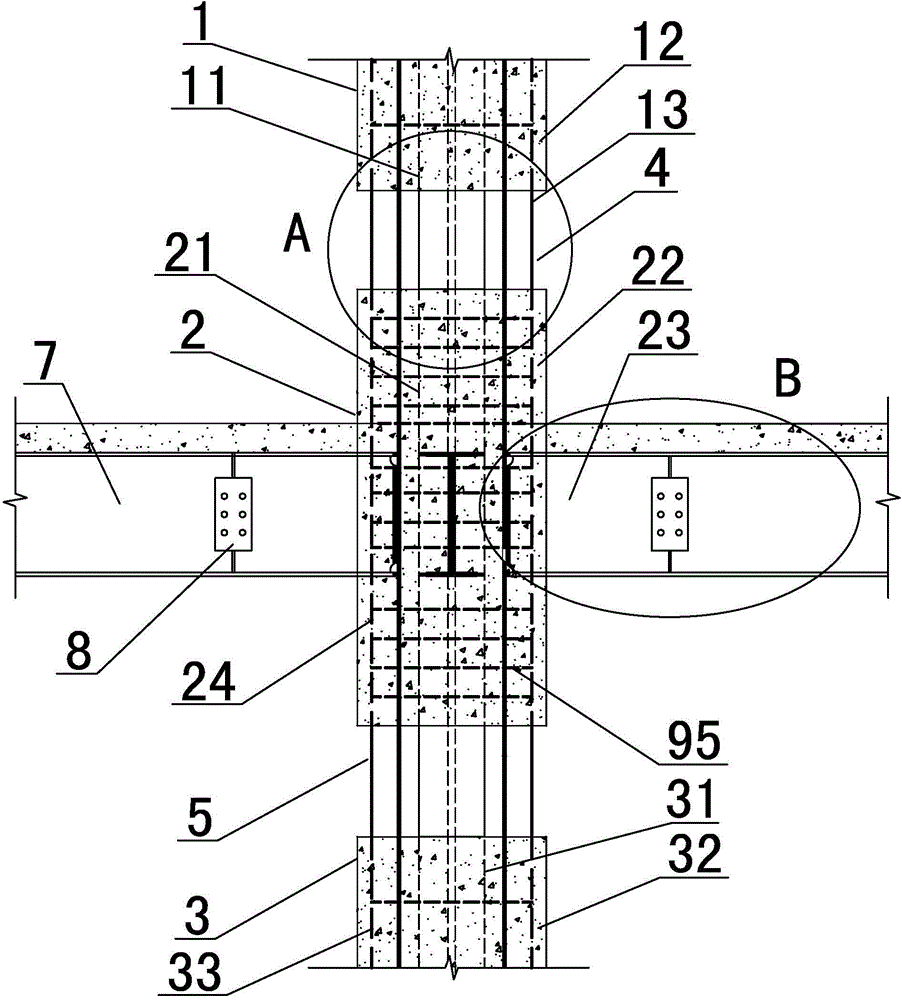

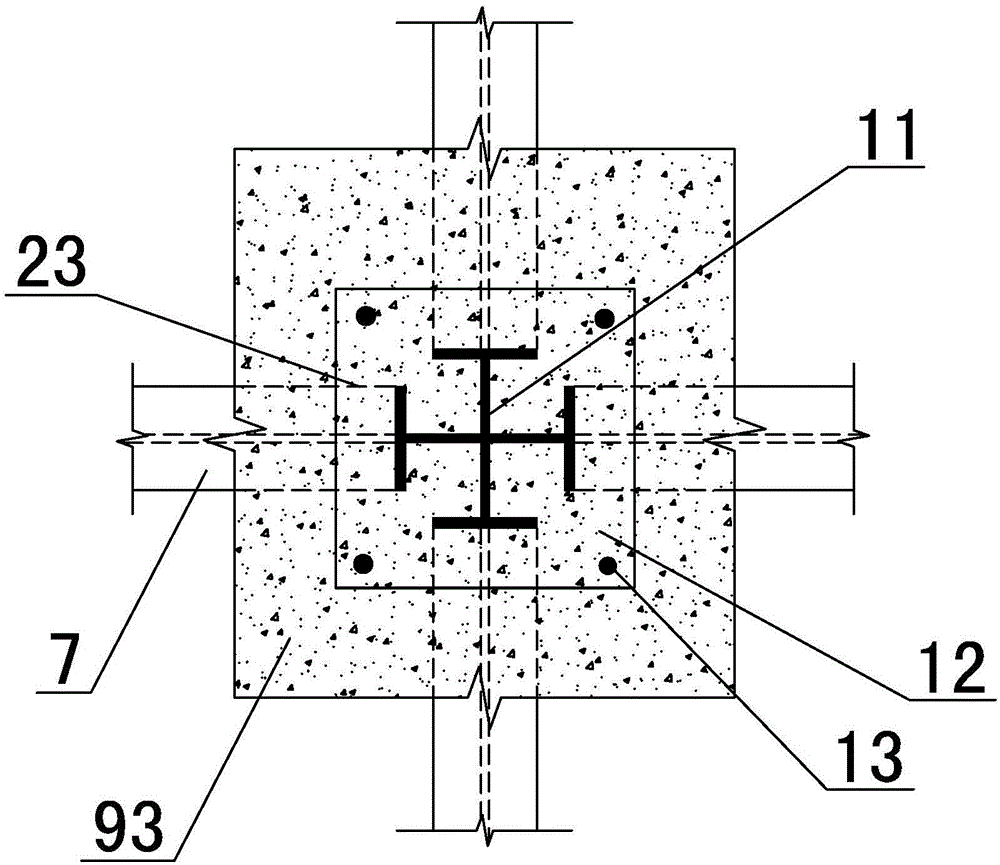

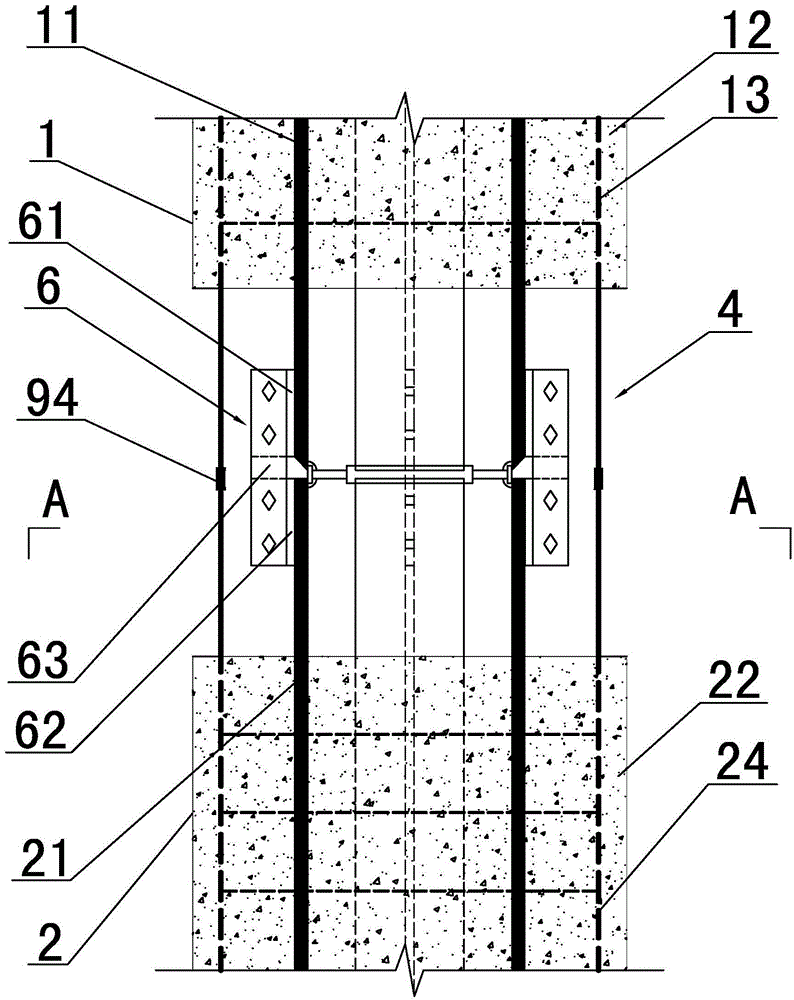

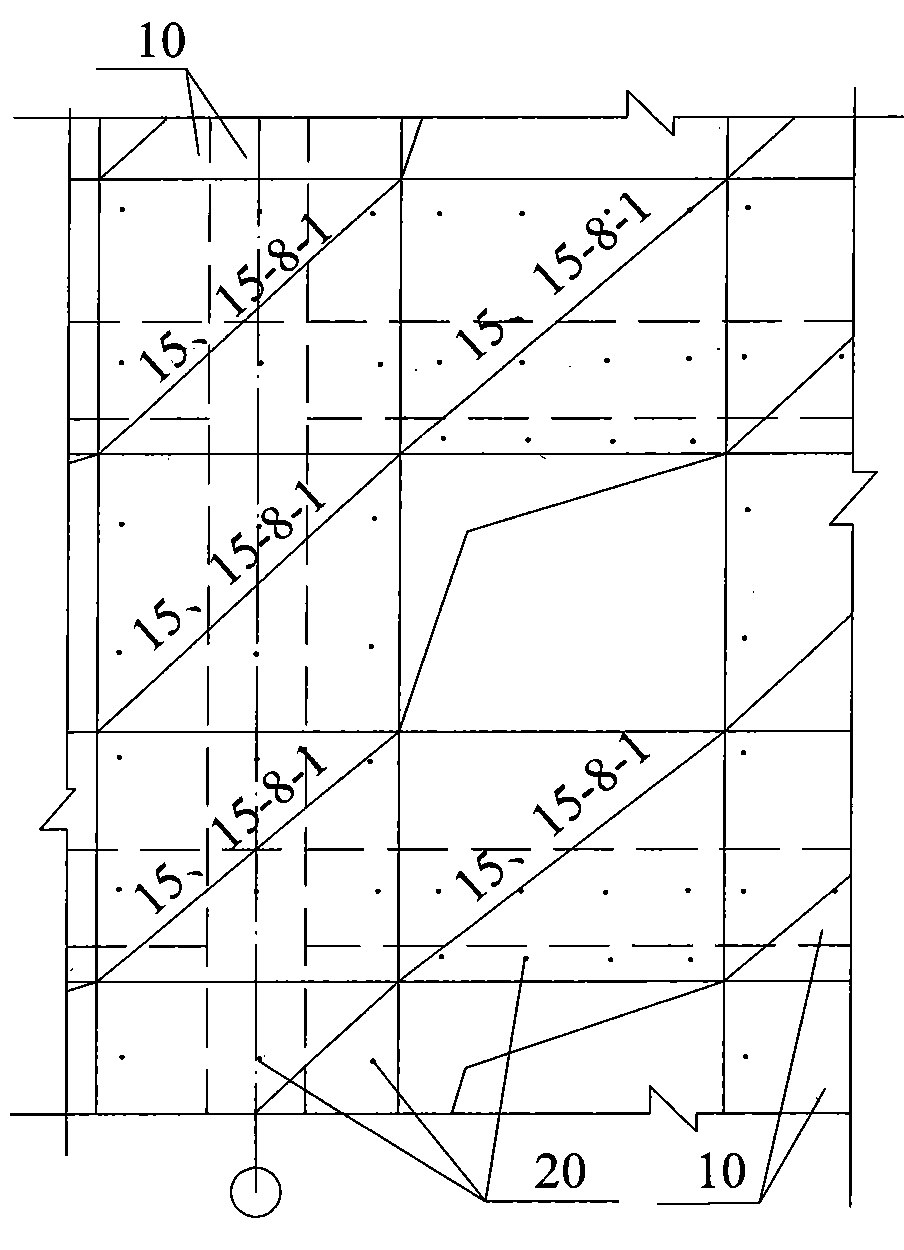

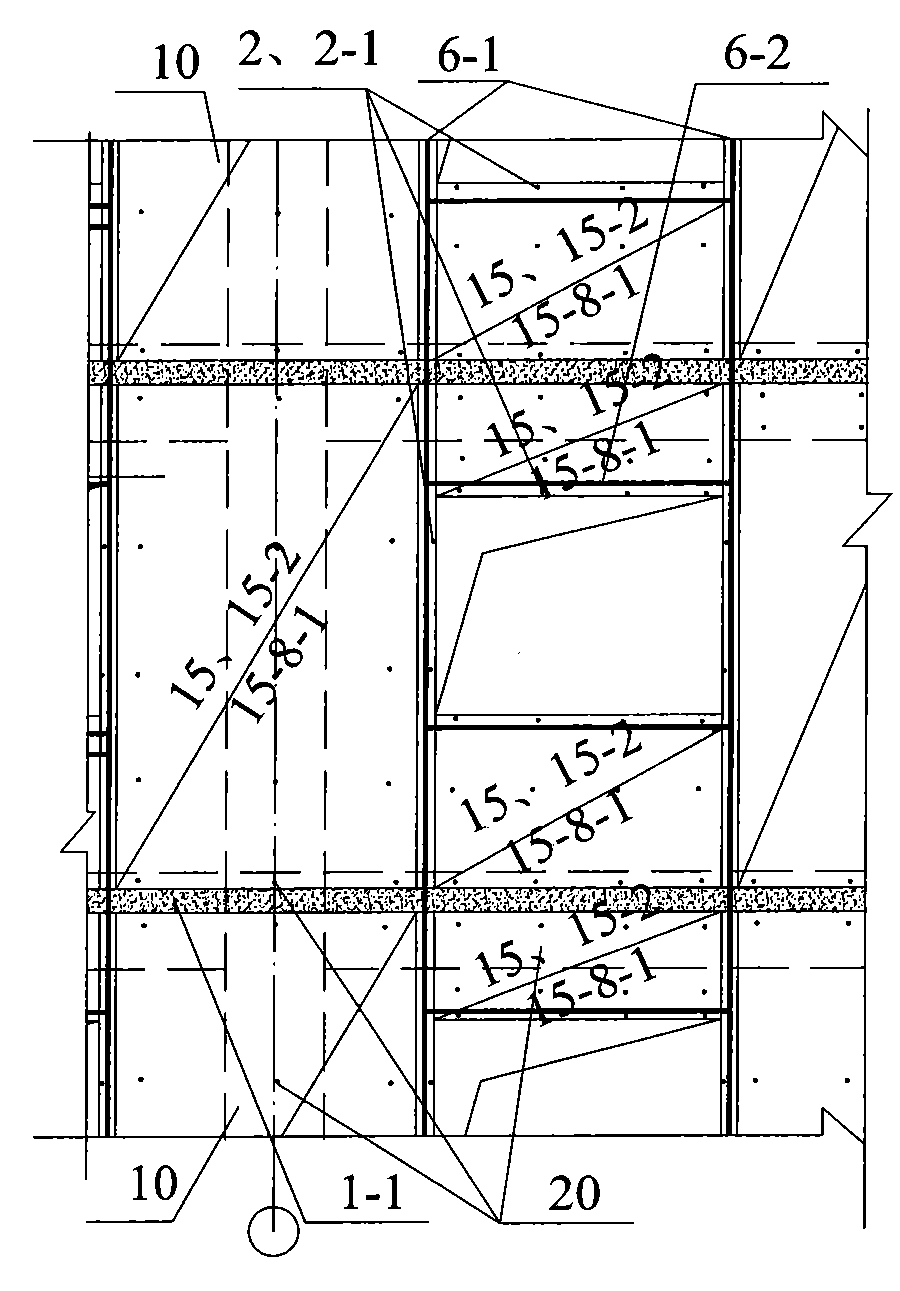

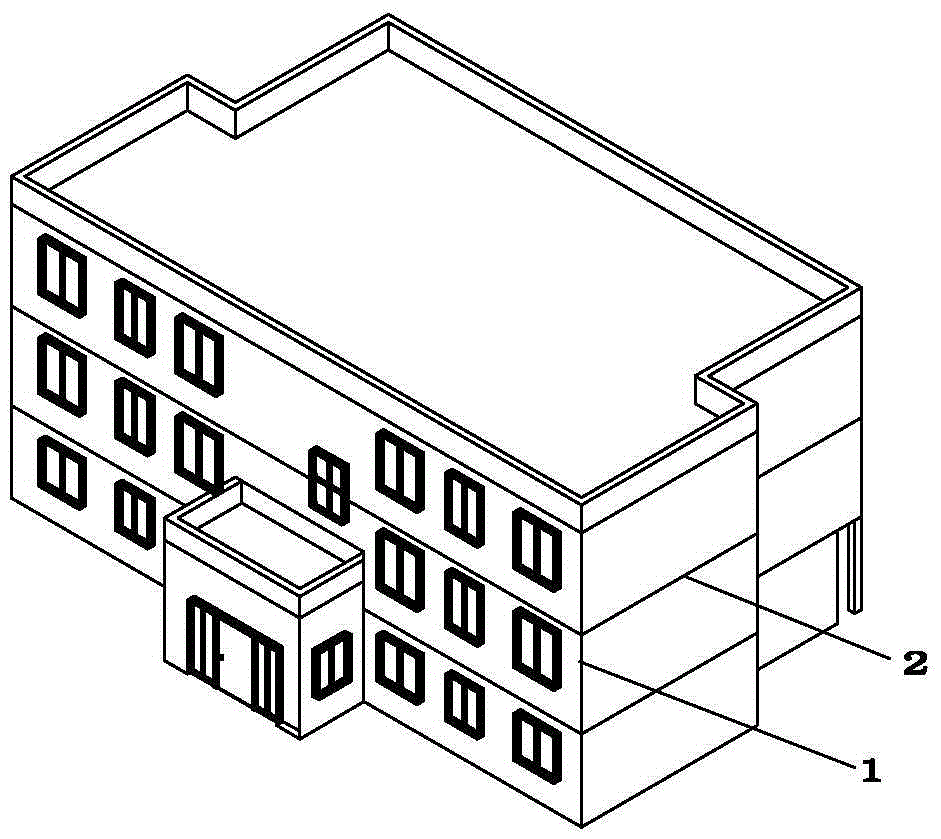

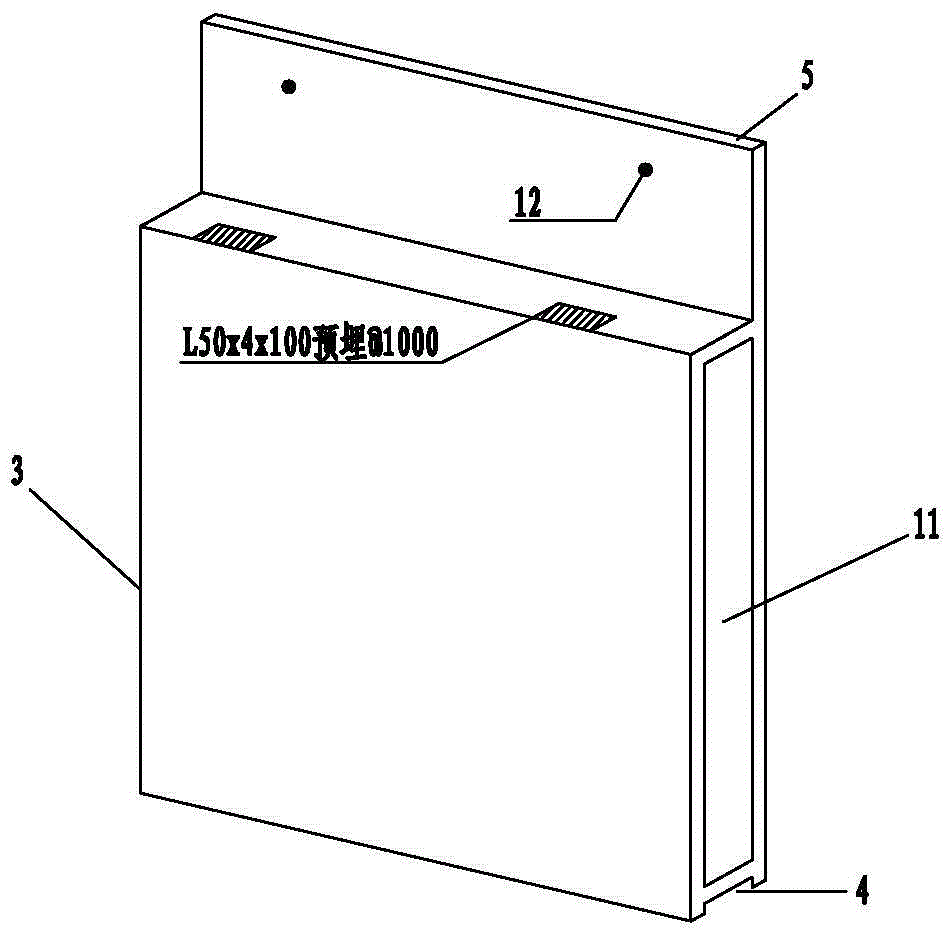

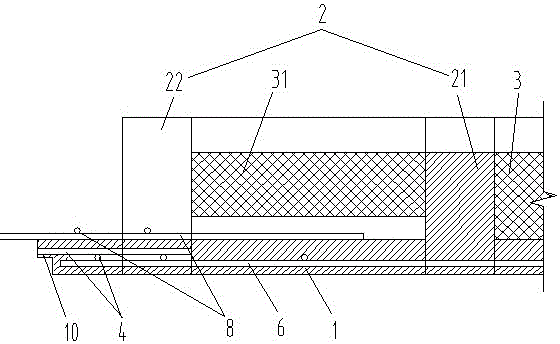

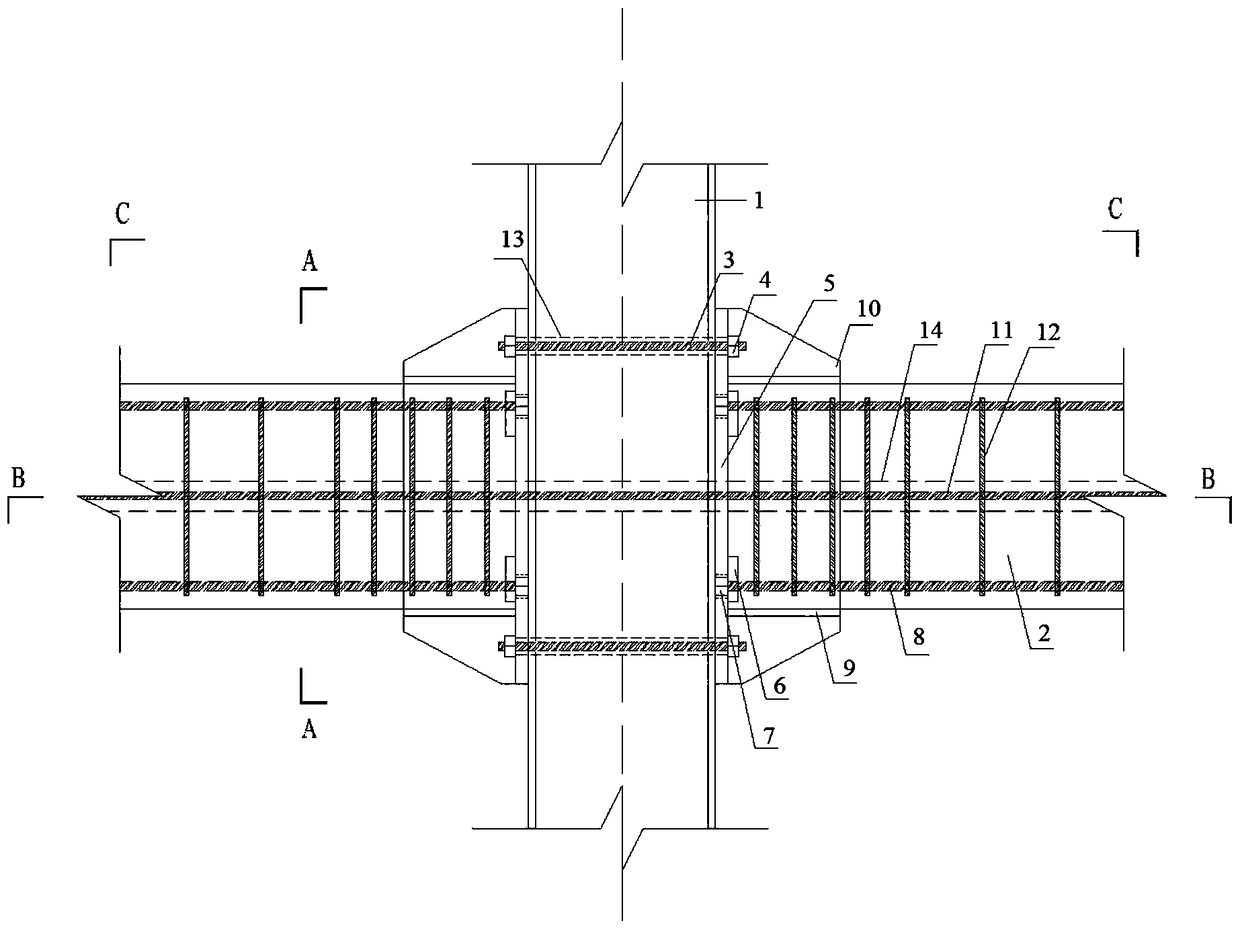

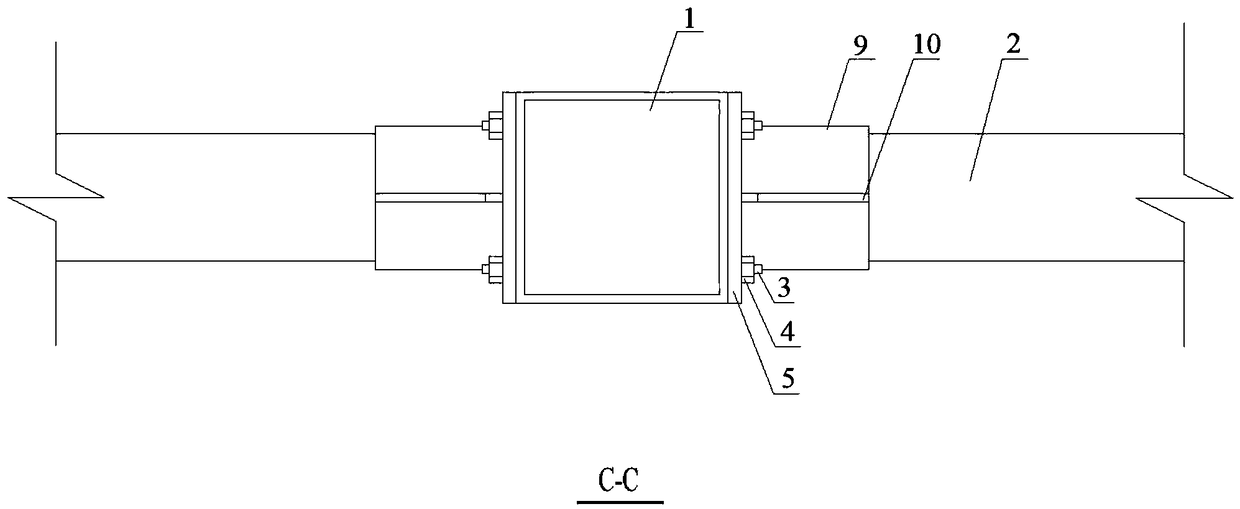

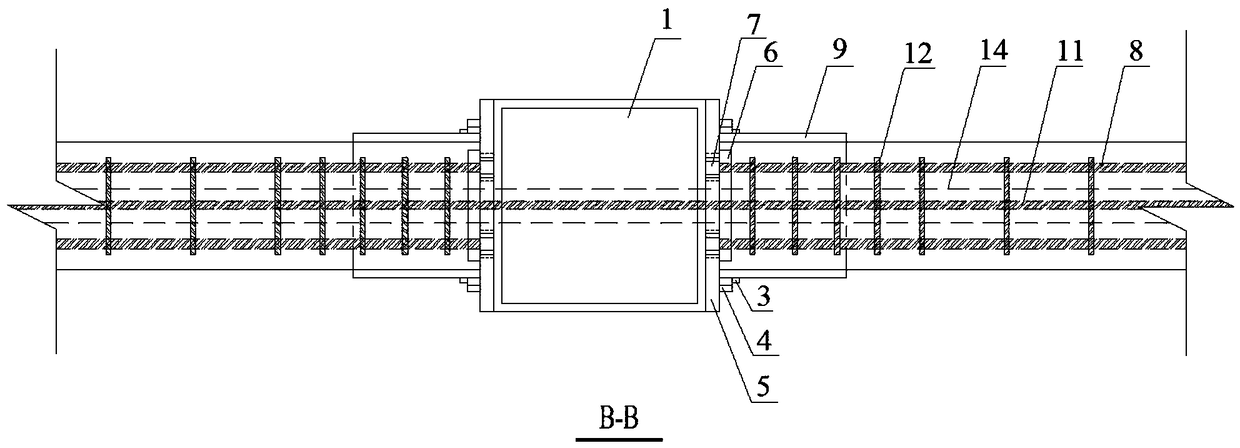

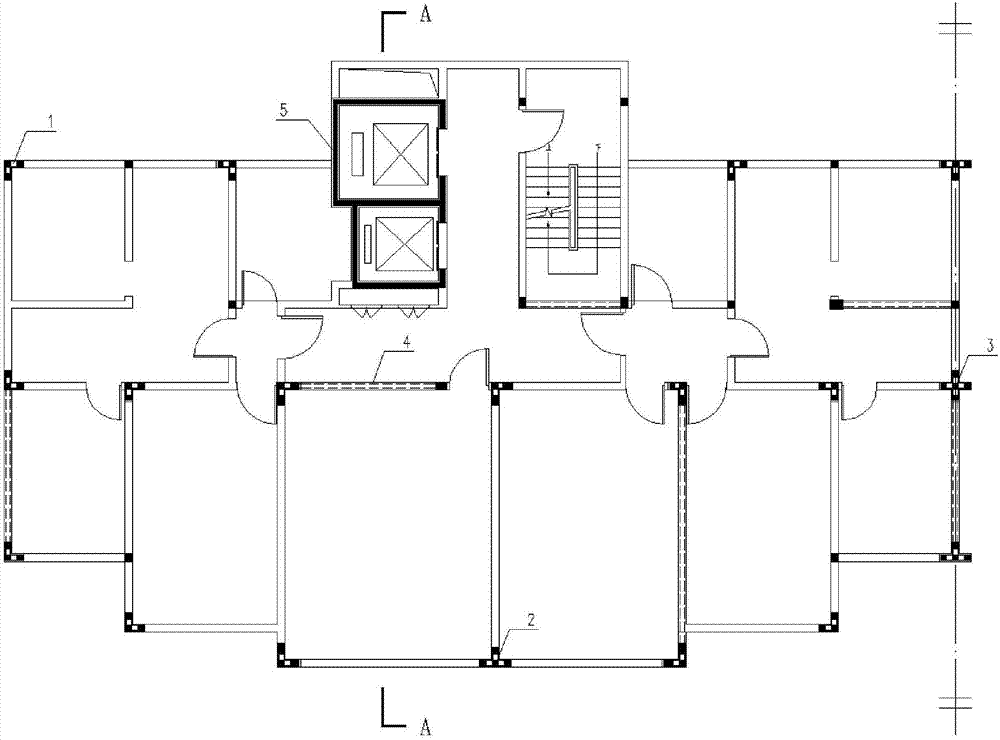

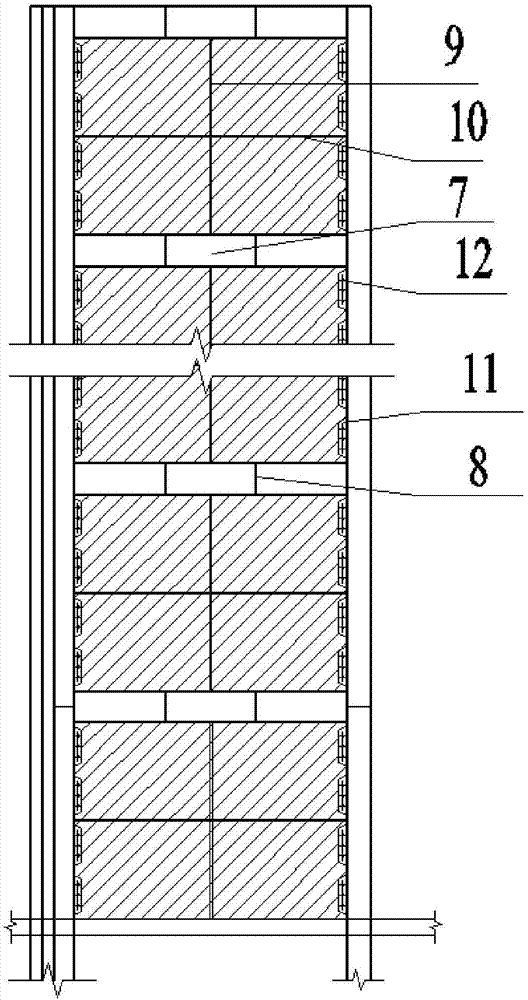

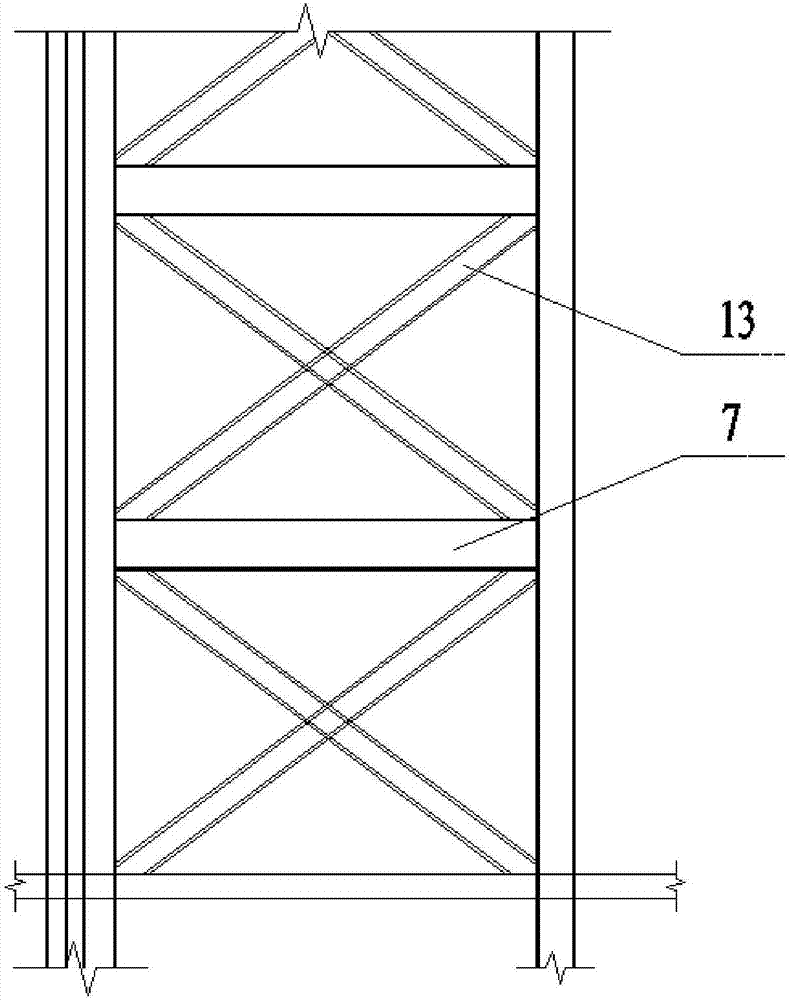

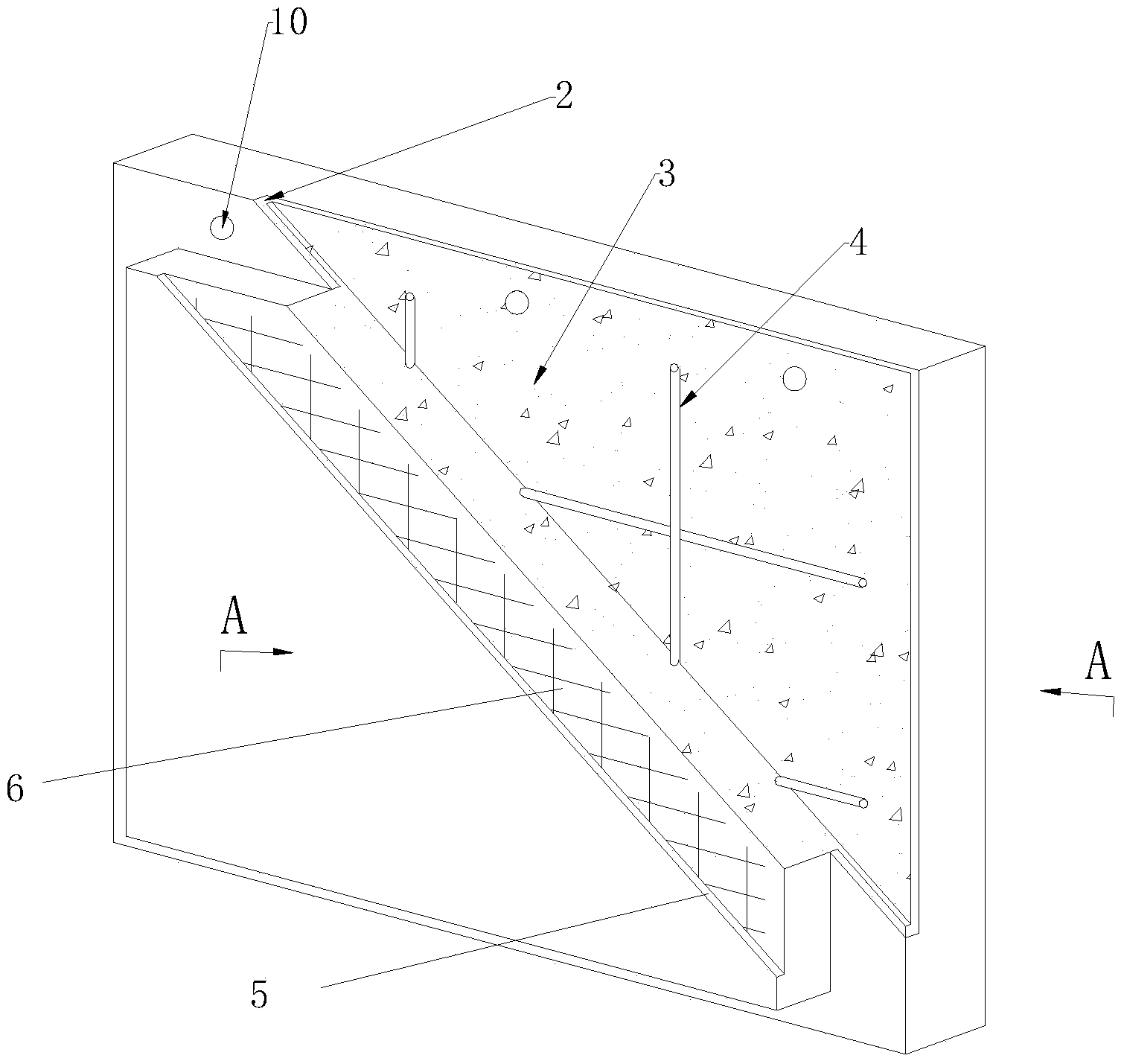

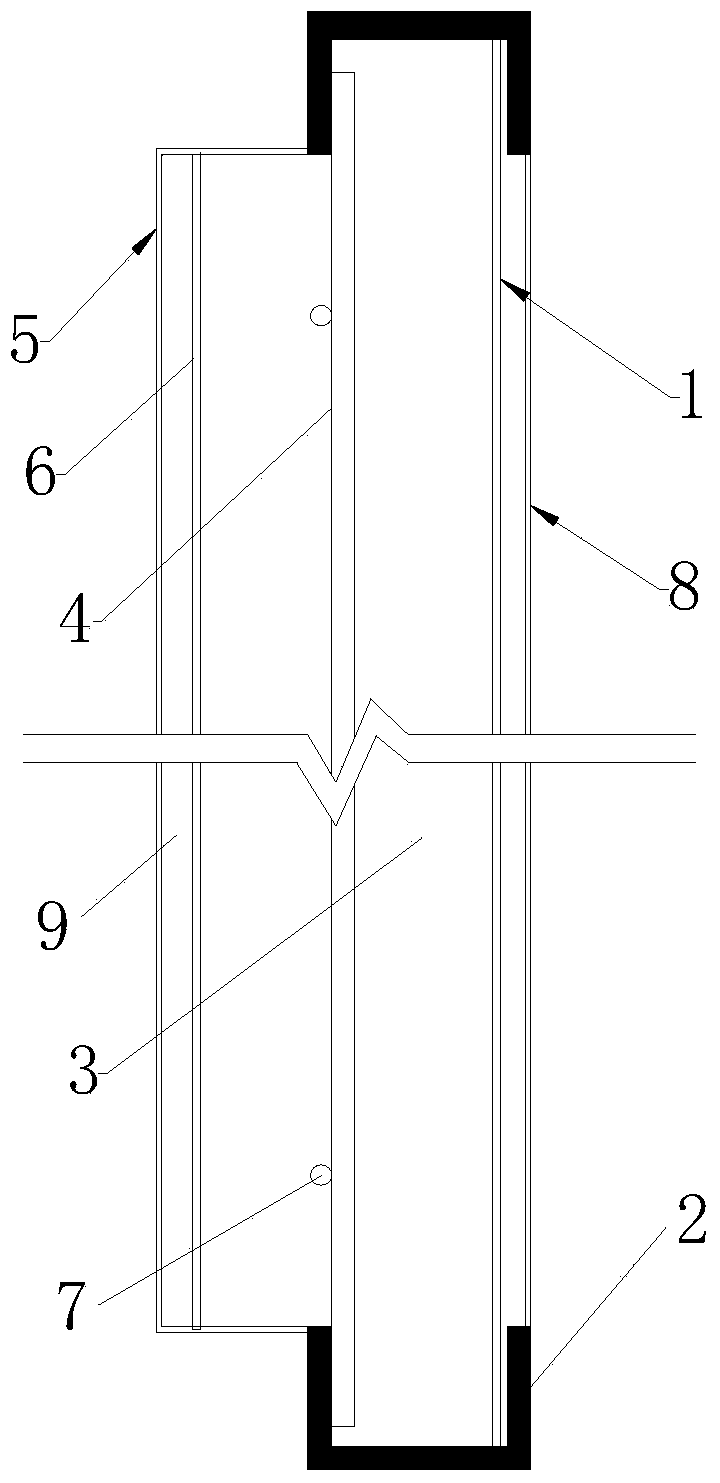

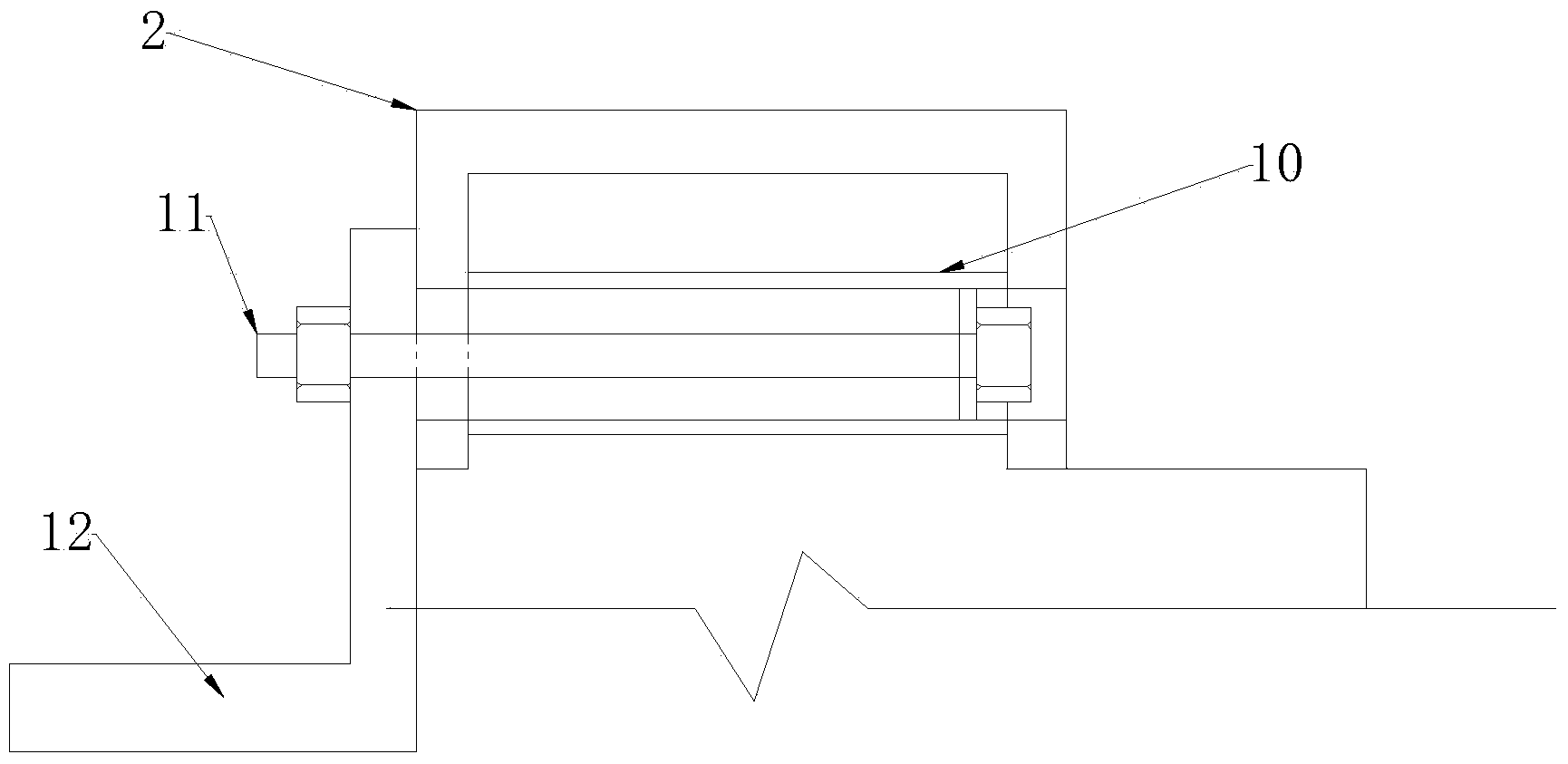

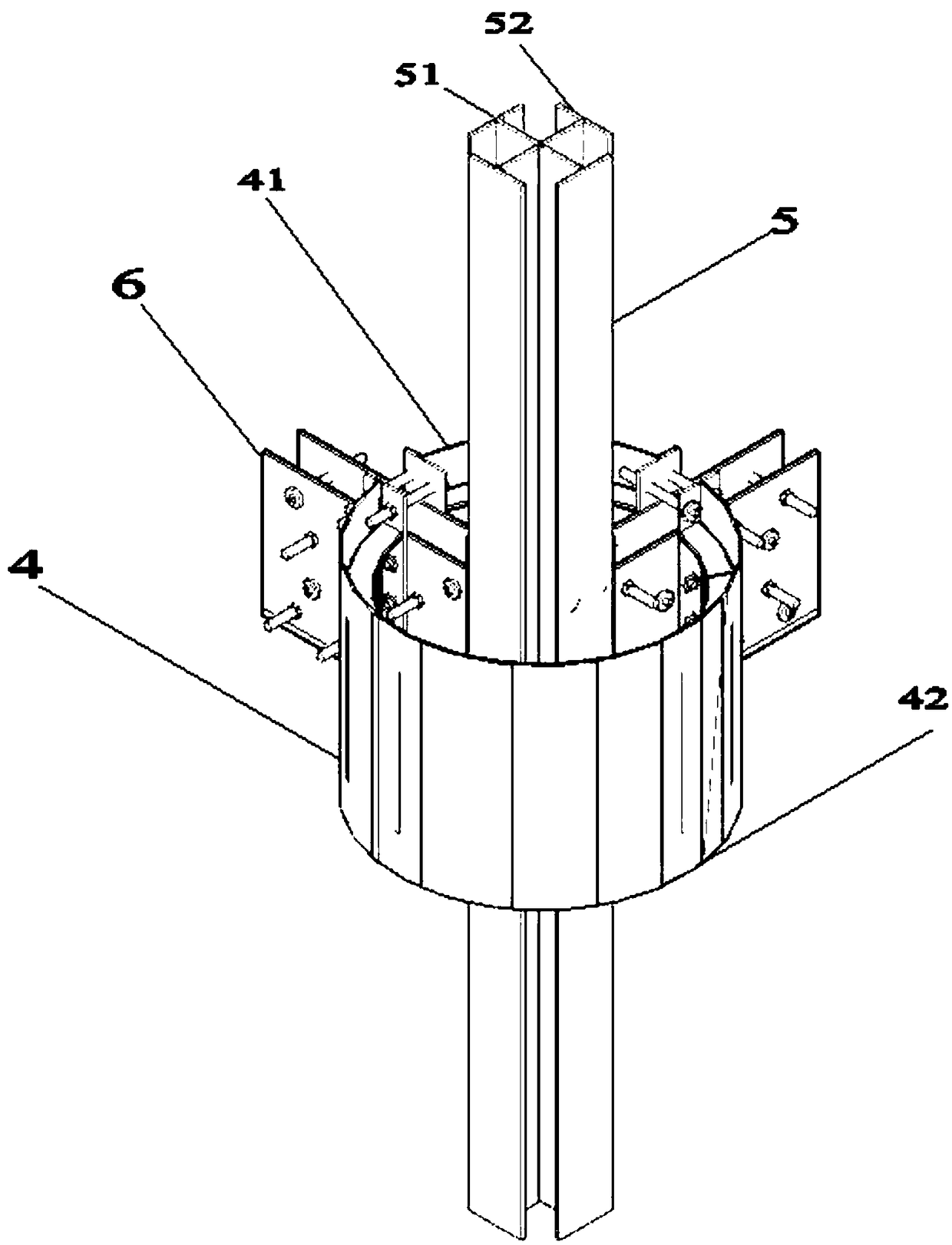

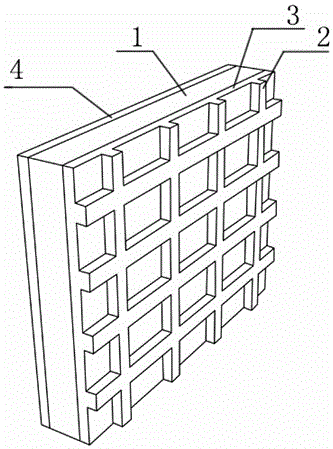

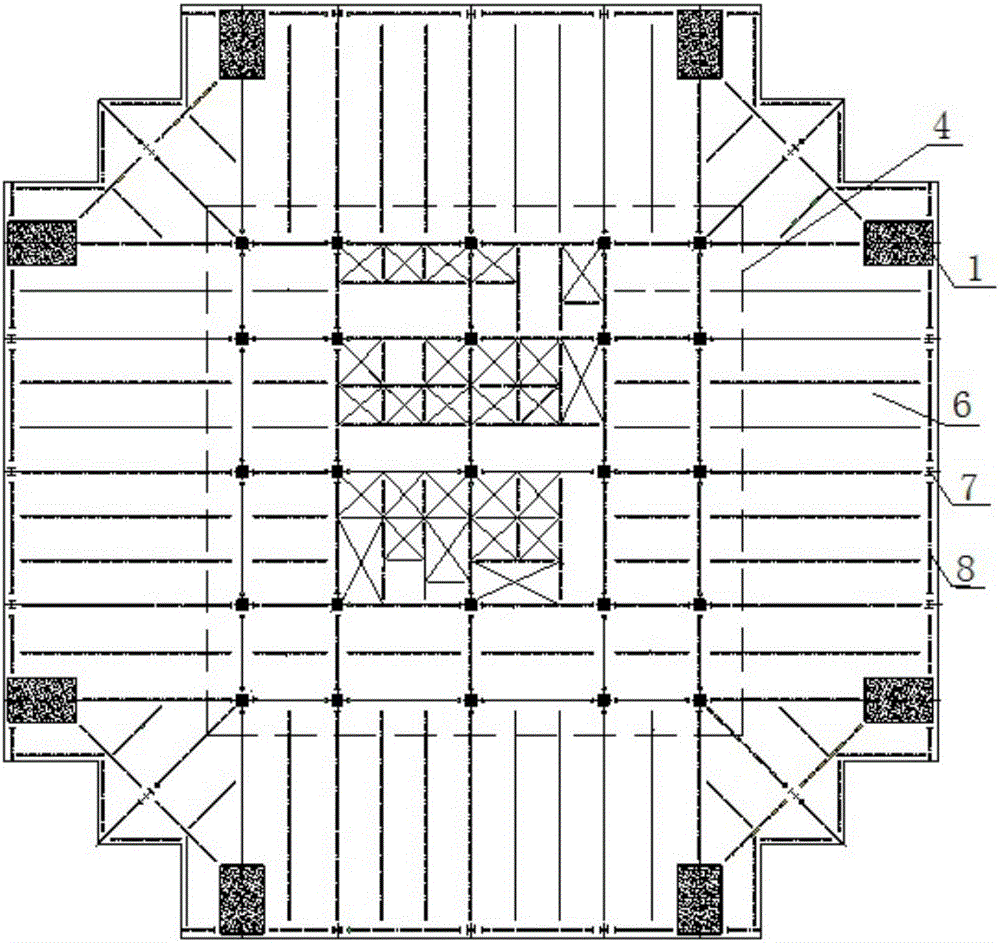

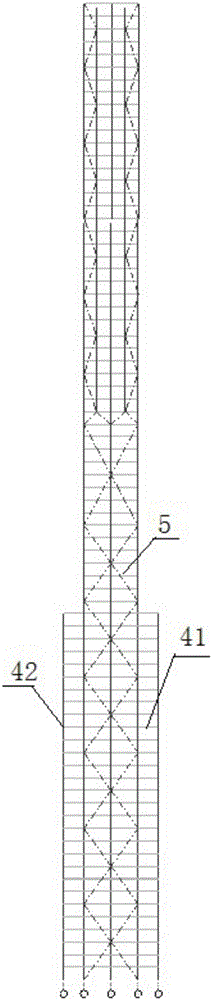

Prefabricated assembling type steel-reinforced concrete column-steel beam frame structure system and construction method

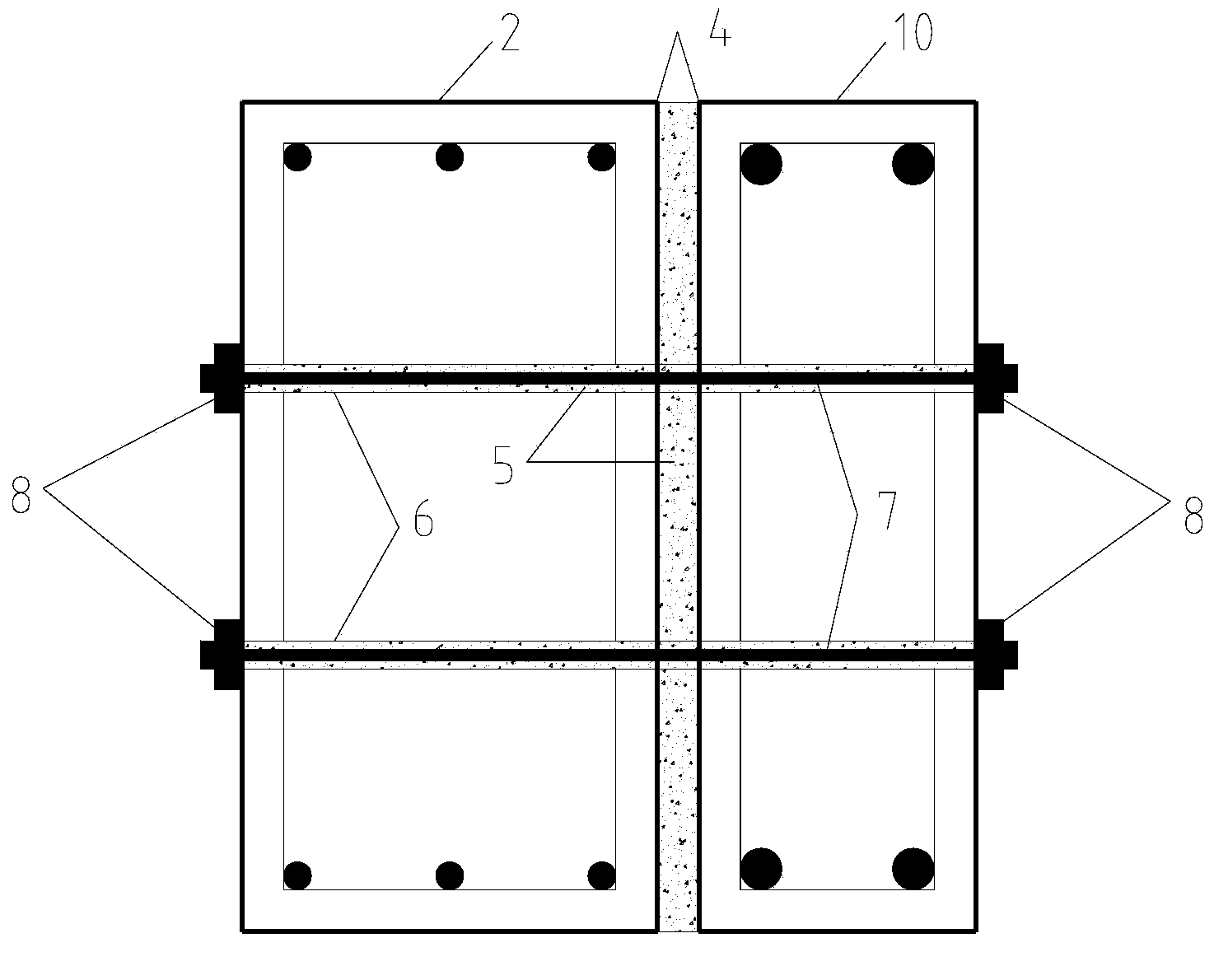

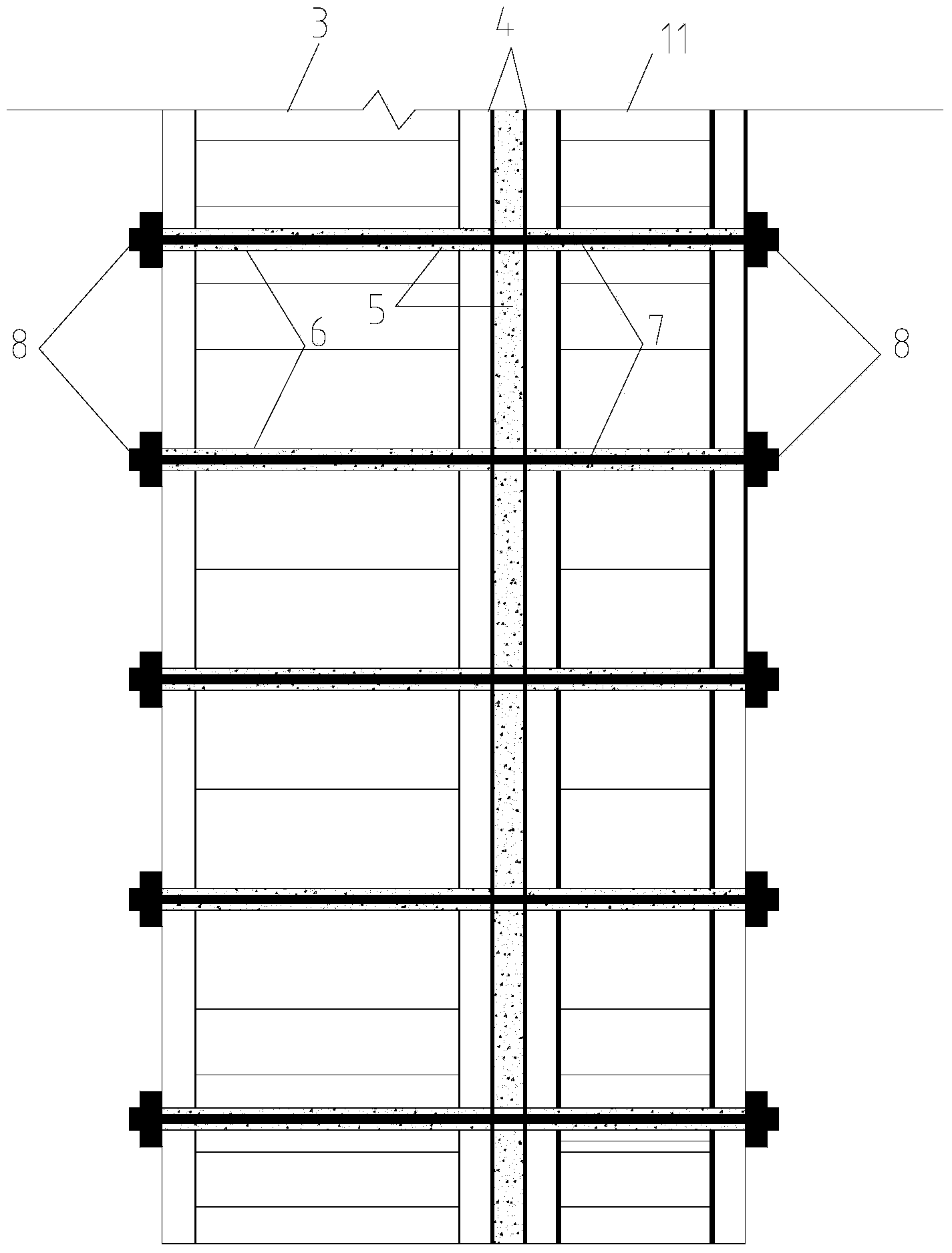

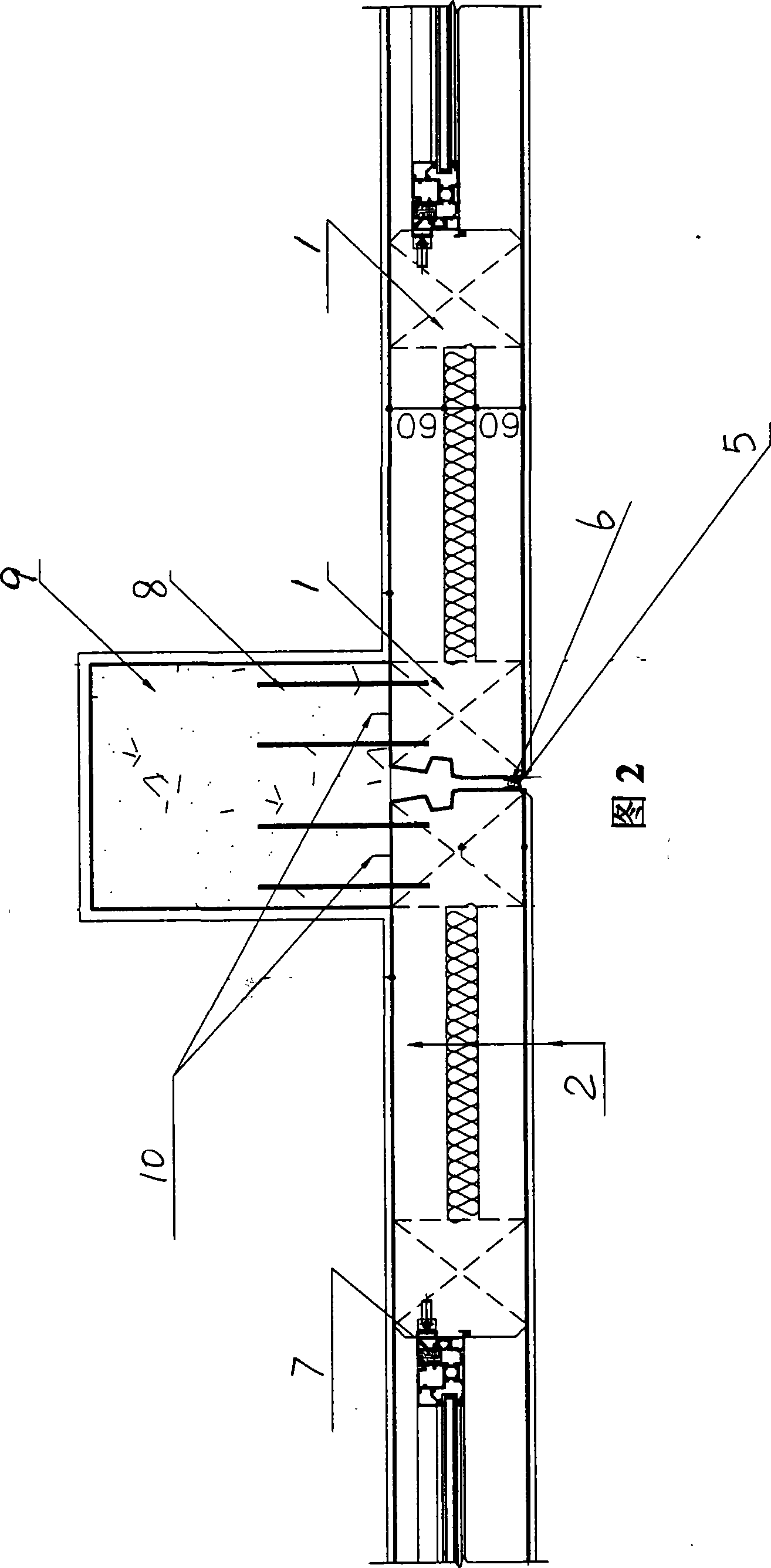

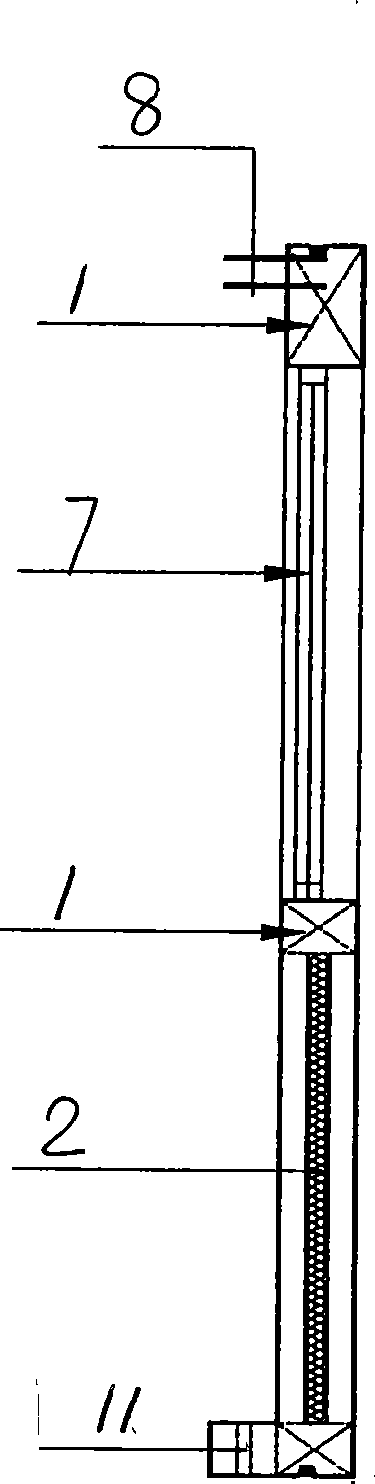

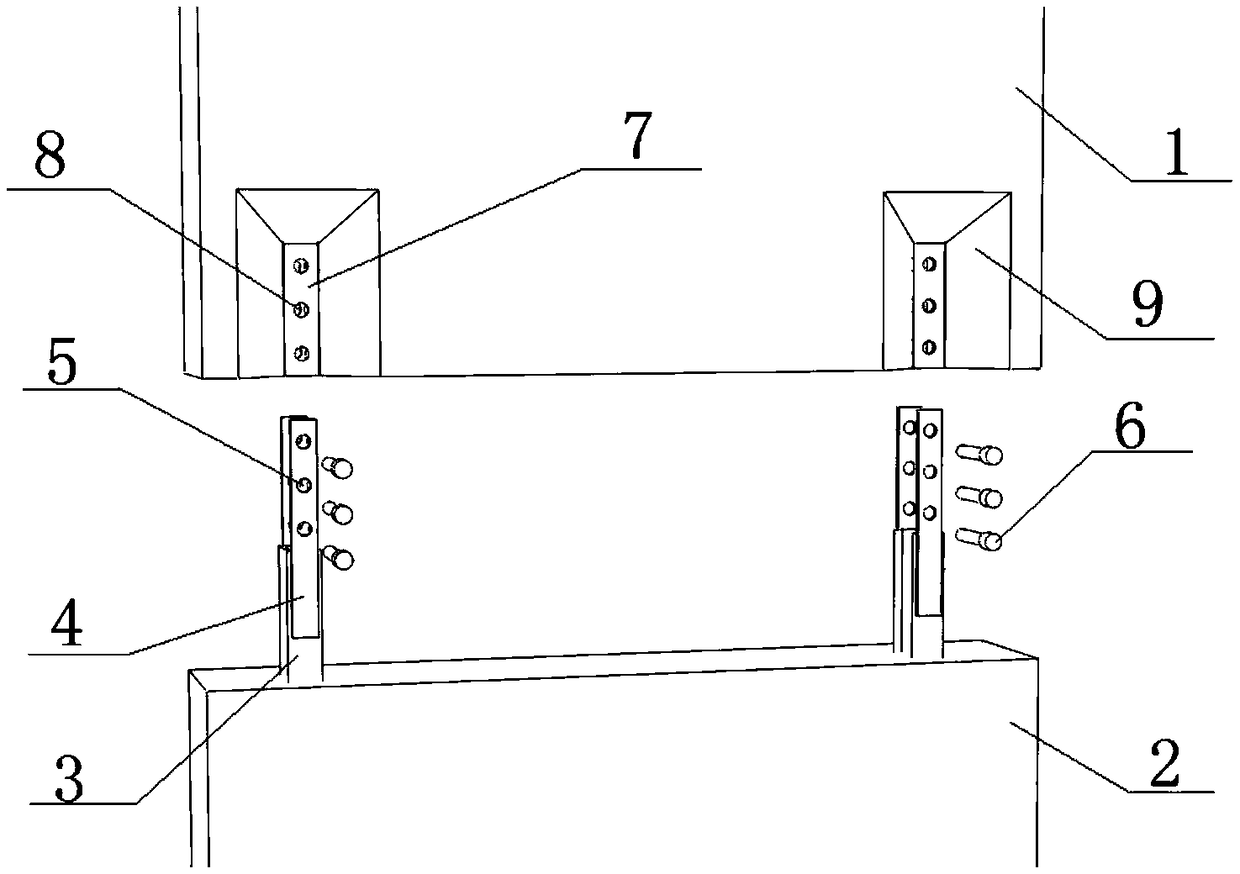

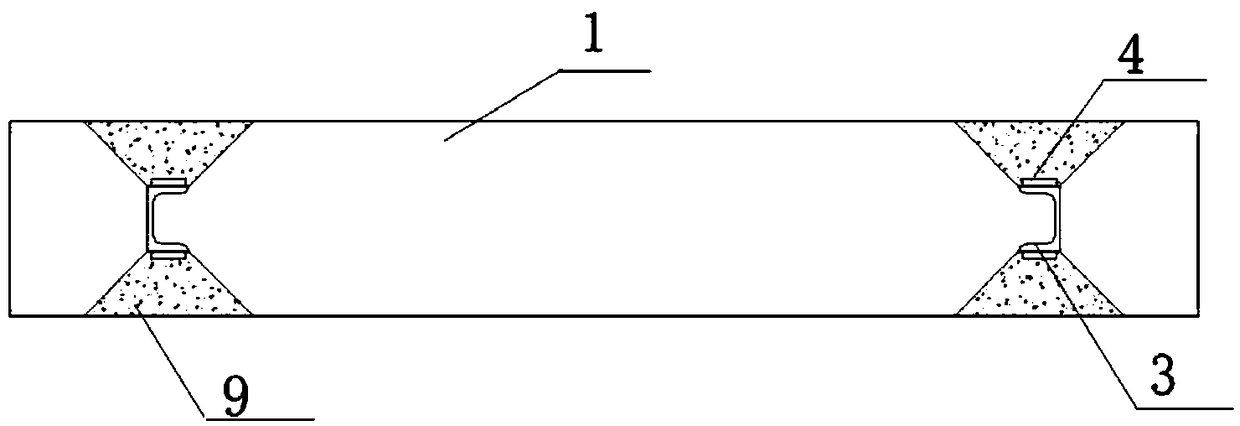

ActiveCN104790522AReduce on-site wet workQuality assuranceStrutsBuilding material handlingSteel columnsReinforced concrete column

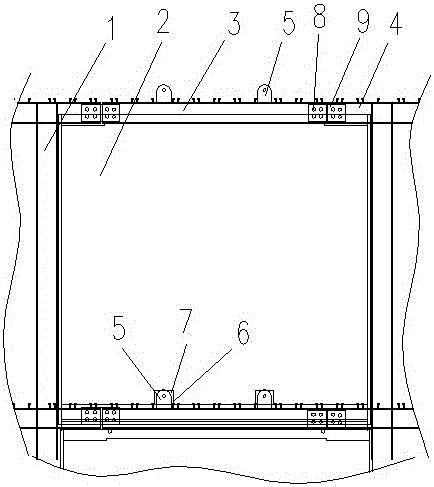

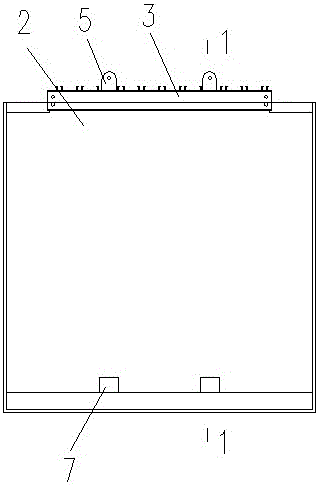

The invention discloses a prefabricated assembling type steel-reinforced concrete column-steel beam frame structure system and a construction method. The prefabricated assembling type steel-reinforced concrete column-steel beam frame structure system comprises an upper prefabricated steel-reinforced concrete column, a prefabricated steel-reinforced concrete joint column and a lower prefabricated steel-reinforced concrete column. In the construction method, the upper prefabricated steel-reinforced concrete column, the prefabricated steel-reinforced concrete joint column and the lower prefabricated steel-reinforced concrete column are manufactured in a factory; in the construction field, the upper prefabricated steel-reinforced concrete column and the prefabricated steel-reinforced concrete joint column are spliced, the prefabricated steel-reinforced concrete joint column and the lower prefabricated steel-reinforced concrete column are spliced, and concrete pouring is carried out on spliced positions. The prefabricated assembling type steel-reinforced concrete column-steel beam frame structure system and the construction method have the advantages that in the field construction, it is only needed to fixedly connect the lower end of an upper center type steel column and the upper end of a joint center type steel column and fixedly connect the lower end of the joint center type steel column and the upper end of a lower center type steel column, and then an upper concrete to-be-poured layer and a lower concrete to-be-poured layer are poured; the field construction is simple, the construction period is short, the field wet operation is little, and transporting is convenient.

Owner:NINGBO UNIV

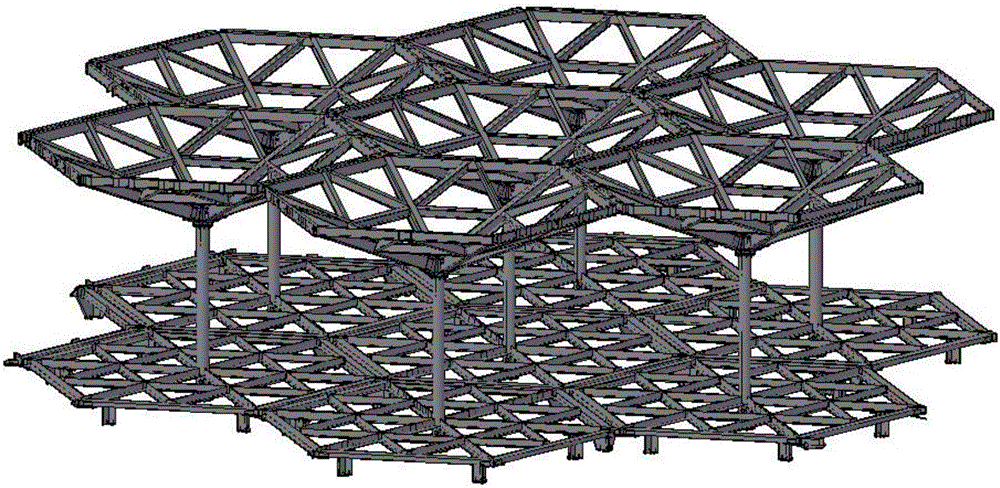

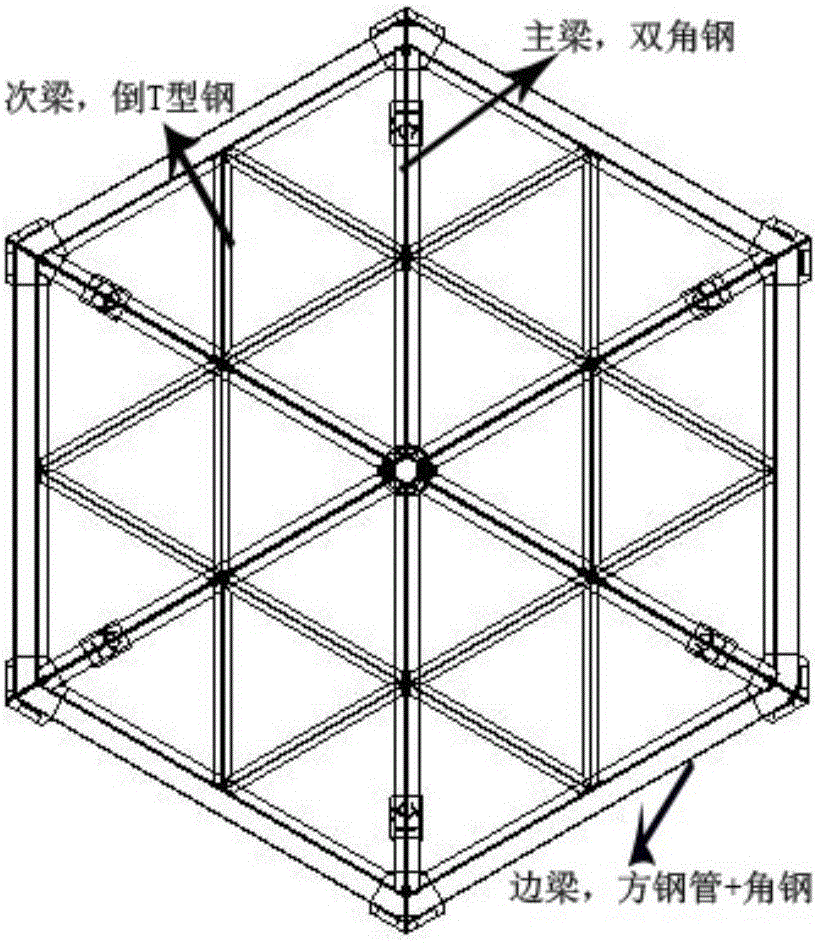

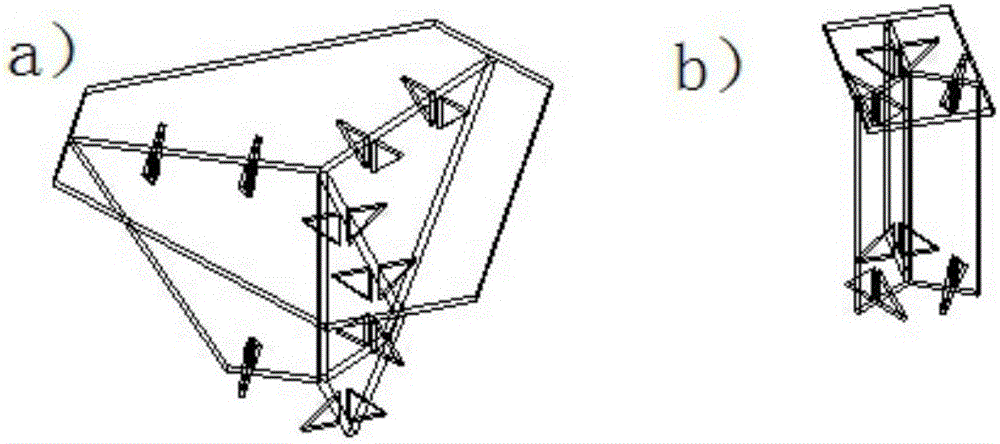

Inverted umbrella-shaped regular polygon steel structure module and installing method thereof

ActiveCN105926765AExtend the life cycleHigh degree of industrializationBuilding material handlingWater dischargeComputer module

The invention discloses an inverted umbrella-shaped regular polygon steel structure module and an installing method thereof. The steel structure module comprises floor surface modules, steel columns and steel structure roof modules, wherein the side frame of each steel structure roof module is in a regular polygon shape; the whole of each steel structure roof module is in an inverted umbrella shape; the lowest point of each inner surface is connected with the corresponding floor surface module through the corresponding steel column; the inside of each steel column is hollow; each steel column is used as a water discharge passage of the corresponding steel structure roof module; each floor surface module is of a regular polygon plane structure. When an inverted umbrella-shaped hexagonal steel structure module system is re-assembled in different places, a completely different form can be realized; higher flexibility is realized; the longer life cycle of the system is realized. Theoretically, the module system can be continuously moved and remolded, so that the building has the longer life cycle; the technical characteristics of high industrialization degree, high assembly speed, few filed wet operations, reproducible utilization, little pollution, light self weight and the like are realized.

Owner:ZHONGTIAN CONSTR GRP ZHEJIANG STEEL STRUCTURE

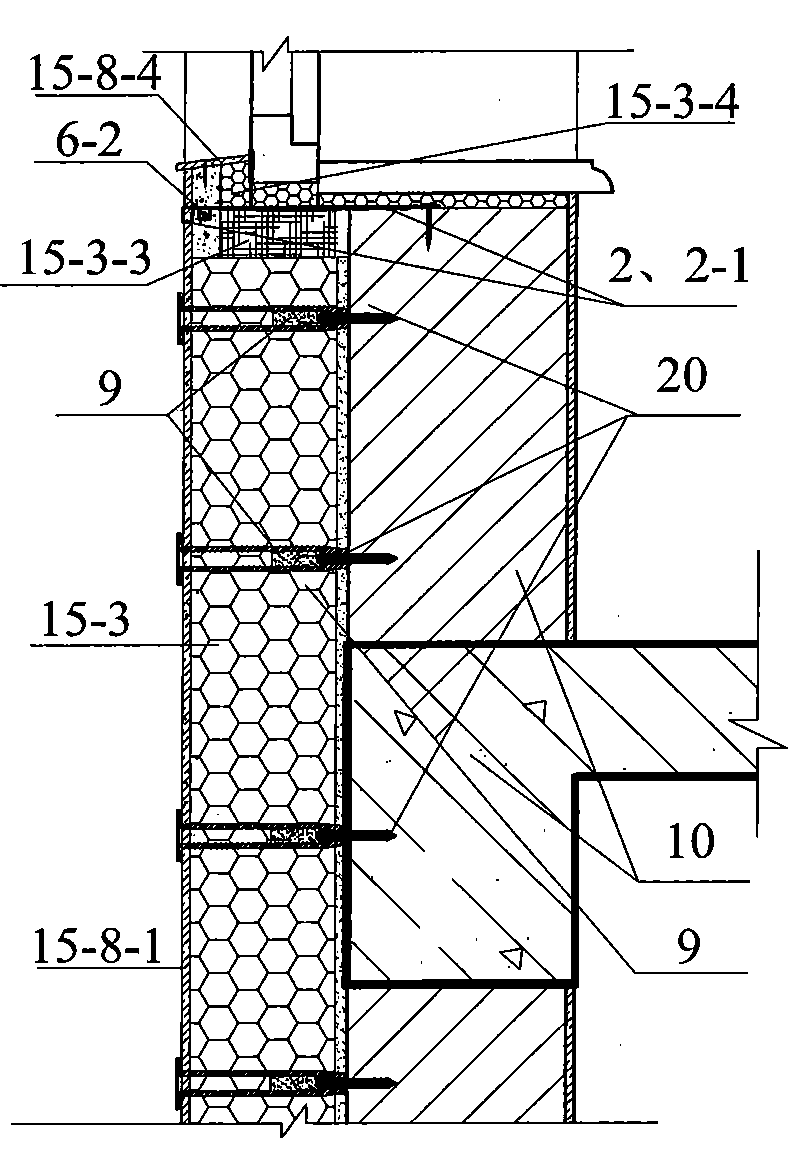

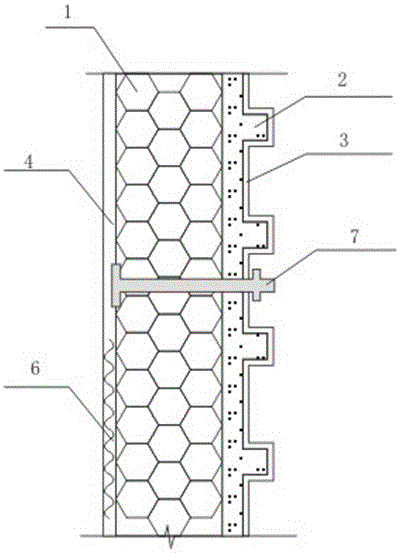

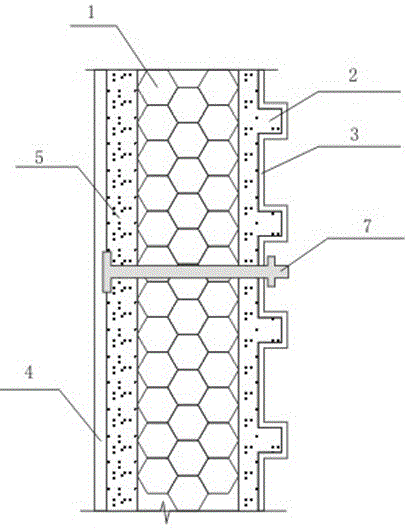

Energy-saving heat-insulating wall body

InactiveCN104234256AEmission reductionEnsure the safety of people's livelihoodWallsHeat proofingThermal bridgeEngineering

The invention provides an energy-saving heat-insulating wall body, relates to a building wall body and aims at solving the problems that the fireproof performance of thin-plaster heat-insulating wall bodies is not good, the durability is poor, the amount of window heat bridges is great and the like. The energy-saving heat-insulating wall body structurally comprises a base layer wall body, a heat-insulating layer, anchor bolts and an external protection layer, wherein the external protection layer is a prefabricated protection layer; the prefabricated protection layer is a prefabricated plate protection layer or a prefabricated plaster protection layer; the external protection layer, the heat-insulating layer and the base layer wall body are sequentially arranged from the outer side to the inner side of the energy-saving heat-insulating wall body; the anchor bolts penetrate through the external protection layer and the heat-insulating layer to fix the external protection layer and the heat-insulating layer on the base layer wall body. An internal protection layer is further installed on the inner side of the heat-insulating layer of a prefabricated heat-insulating board to form a prefabricated heat-insulating wallboard, and the prefabricated heat-insulating wallboard is installed on the outer side of the base layer wall body or a building main body structure to form a fully assembled and mounted energy-saving heat-insulating wall body. The energy-saving heat-insulating wall body has the advantages that the wall body is fireproof and safe and is convenient to install, the durability is good, the energy saving and heat insulating performance is good, and the energy saving and emission reduction of the building and the control of the greenhouse effect are facilitated.

Owner:吴淑环

Embedded steel structure assembling residence

An embedded steel structure assembling residence comprises a steel framework, wall panels, room floor bearing plates, toilet floor bearing plates, room partition plates and stairs, and is characterized in that the steel framework is formed by vertical columns and cross beams, the stand columns are formed by filling rectangular pipe columns with concrete, and joist steel is adopted for the cross beams; each wall panel is embedded between the two corresponding stand columns and is of a sandwich structure; the two ends of the room floor bearing plates are positioned on the inner cross beams, and steel bar trusses are arranged on the surfaces of the floor bearing plates; the two ends of the toilet floor bearing plates are also positioned to the corresponding inner cross beams and are composed of metal bottom plates and steel bar trusses welded to the metal bottom plates; the room partition plates are made of ALC fireproof plates and are positioned between the upper inner cross beams and the lower inner cross beams through hooking parts, and the outer surfaces of the vertical columns and all the cross beams are wrapped with fireproof plates; the structure which is prefabricated in factories and installed on site is adopted for the stairs. According to the embedded steel structure assembling residence, the building speed is high, the field installation wet operation amount is small, and environment friendliness and energy conservation are achieved.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE +1

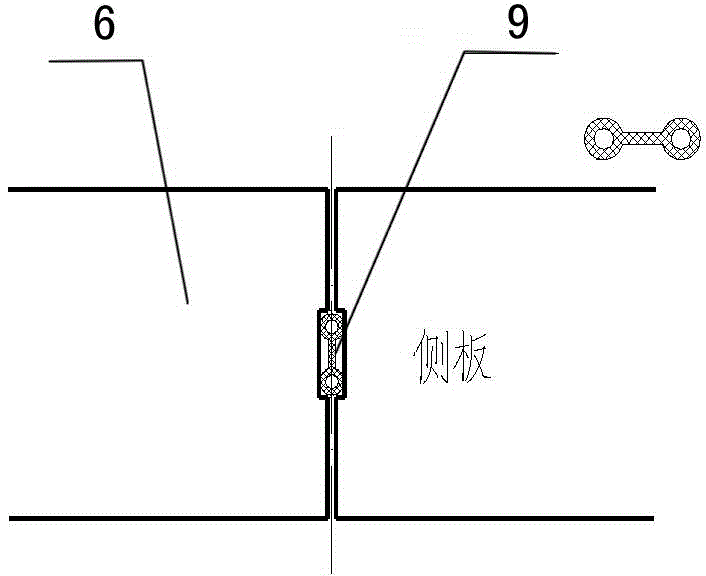

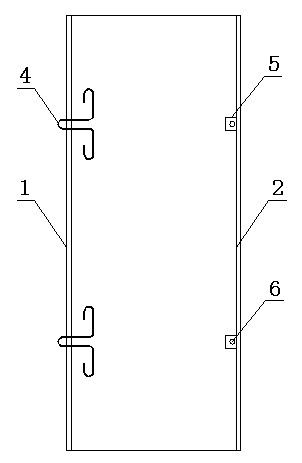

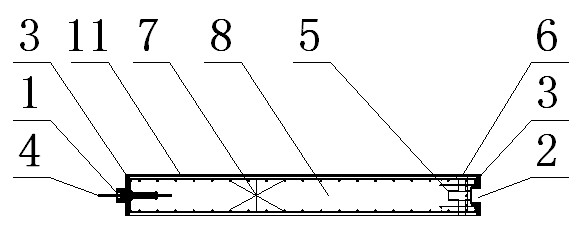

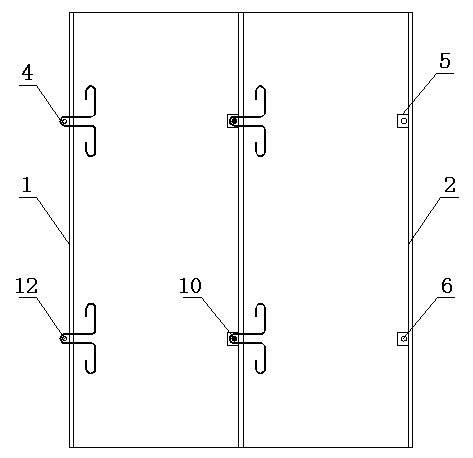

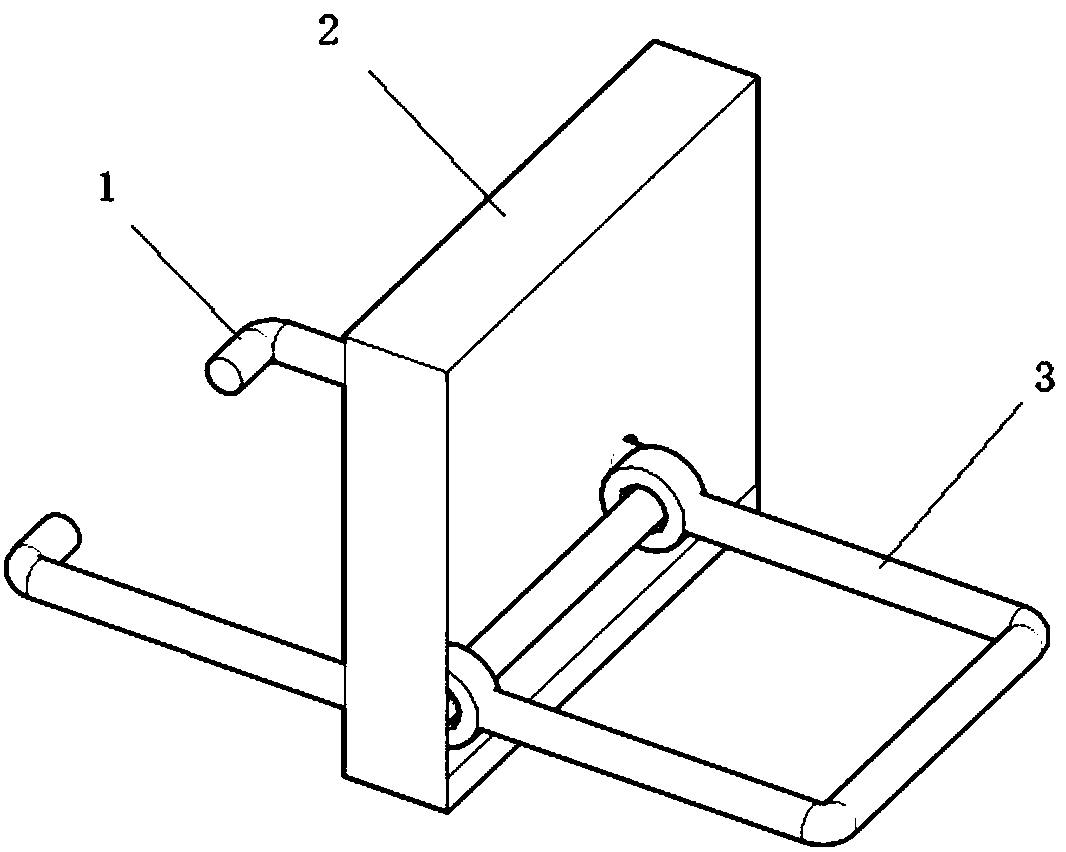

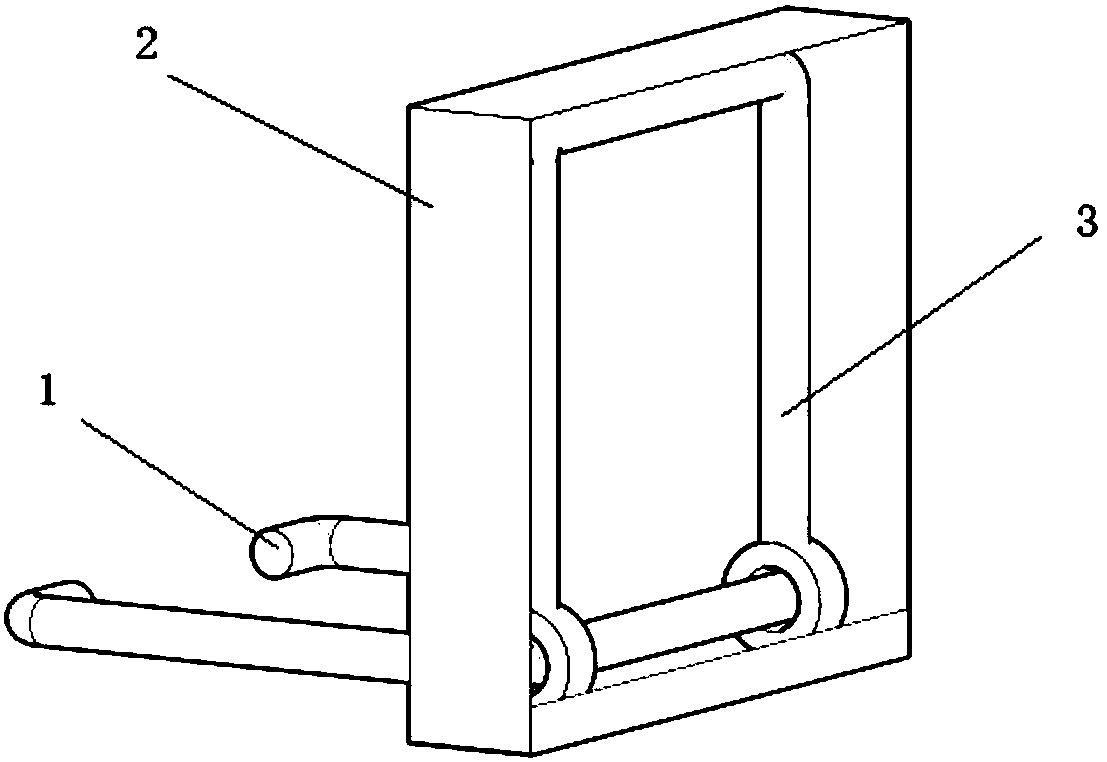

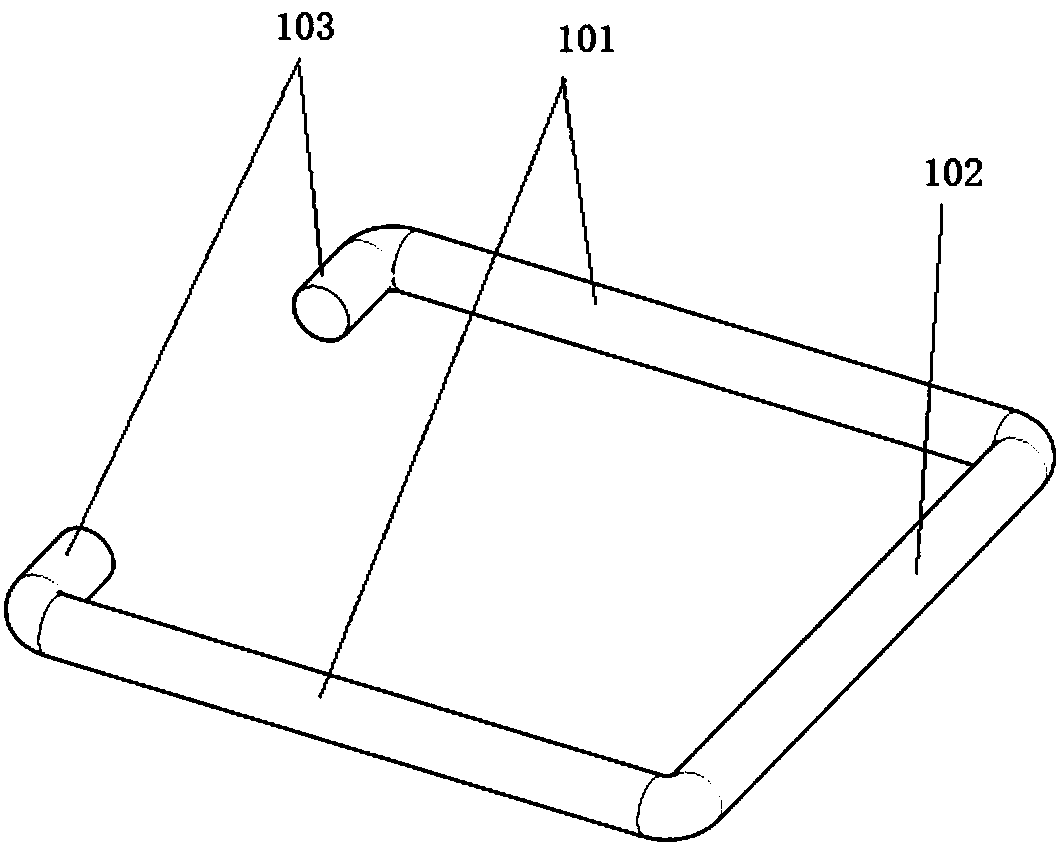

Rotatable pre-embedded external member and prefabricated assembly type wall structure

The invention relates to the technical field of connection of building walls, in particular to a rotatable pre-embedded external member and a prefabricated assembly type wall structure. The rotatablepre-embedded external member comprises a pre-embedded C type anchor bar, a pre-embedded box set and a U-shaped reinforcing steel bar, wherein the pre-embedded C type anchor bar comprises a first vertical part and a first transverse connecting part; the U-shaped reinforcing steel bar comprises a second vertical part and a second transverse connecting part; the first transverse connecting part is arranged in the pre-embedded box set; the first vertical part penetrates through a through hole and is arranged on the outside of the pre-embedded box set; the second vertical part is rotatably connected with the first transverse connecting part; and the U-shaped reinforcing steel bar is rotatably stored in the pre-embedded box set. The rotatable pre-embedded external member is simple in structure,convenient to construct, and convenient to mount, transport and store; the construction speed is increased; the engineering cost is reduced; integrity of a connection part between shear walls is high,and the stress property is good; anti-seismic and safety characteristics are achieved; field wet operation is reduced; and environmental protection is facilitated.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Composite antiknocking material and its production

InactiveCN1940375ASolve the stiffness problemSolving Elasticity ProblemsConstructions elementsMetal layered productsBox modelUltimate tensile strength

The invention relates to an anti-seismic composite material and its manufacturing method. The material is a high-rigidity, high-strength and high-elasticoplastic material and it consists of steel member in a radial arrangement and members with the shock-absorbing performance. The number of two members can be same, or the number of the steel member is more than the number of the members. The method of manufacturing the anti-seismic composite material includes the following steps of preprocessing the steel members; welding the steel members to a box model; pouring melted material liquid with the shock-absorbing performance into the model by casting method and forming by cooling.

Owner:JILIN UNIV

Connecting method of prefabricated composite multi-ribbed floor slabs and steel beams of assembly type steel structure house

The invention relates to a connecting method of prefabricated composite multi-ribbed floor slabs and steel beams of an assembly type steel structure house. Ribbed beams and steel beams at the joints of the multi-ribbed floor slabs and the steel beams are cast in place, and the fire prevention effect of the connecting joints of steel columns and the steel beams and the fire prevention effect of the steel beams are achieved; the multi-ribbed floor slabs are filled with light materials, and the heat insulation effect is achieved; and prefabricated composite multi-ribbed floor slab components are produced in advance and mounted in the field, the field construction speed is increased, lots of revolving materials such as supporting steel tubes, battens, web filmed multilayer boards and bamboo plywood are reduced, the construction speed is increased, and the construction cost is lowered.

Owner:CHINA 22MCC GROUP CORP

Replaceable self-resetting fabricated connecting joint and construction method

ActiveCN108755975ANo brittle failureReduce stress concentrationStrutsProtective buildings/sheltersEarthquake resistancePre stress

The invention relates to the technical field of steel-concrete composite structure in construction engineering, in particular to a replaceable self-resetting fabricated connecting joint and a construction method. The connecting joint comprises a prefabricated steel pipe concrete column and two prefabricated beams. The prefabricated beams are positioned on two sides of the prefabricated steel pipeconcrete column. Terminal plates are in contact with the prefabricated steel pipe concrete column. The prefabricated beams are provided with the terminal plates, steel sleeves and reinforced ribs. Rigidity of the beam ends of the prefabricated beams is improved; the condition of brittle fracture caused by plastic hinge generating at the beam end joint position under the action of an earthquake iseffectively prevented; beam columns adopt energy consumption rebars and prestressing tendons for connection, the energy consumption rebars can consume and dissipate energy during the earthquake, quickreplacement can be achieved after the earthquake; and repairing efficiency is improved; the prestressing tendons keep elasticity in the rare earthquake, and play a role of self-resetting after the earthquake. The replaceable self-resetting fabricated connecting joint and construction method achieve building industrialization, is free of welding and wet work on the construction site, and has the advantages of being excellent in earthquake resistance, environmentally friendly, excellent in component quality, convenient to construct, little in damage after the earthquake, replaceable and self-resetting.

Owner:DALIAN UNIV OF TECH

Assembled hybrid structure system applicable to high-rise residential building

InactiveCN107386447ASmall column sectionReduce noiseExtraordinary structuresDwelling buildingSteel tubeAbnormal shaped

The invention discloses an assembled hybrid structure system applicable to a high-rise residential building. The assembled hybrid structure is applicable to a building structure of which a staircase and an elevator room are arranged and deviated at one side of a building plane. The assembled hybrid structure system comprises steel frame columns, steel beams, supporting structures and an assembled core barrel, wherein each steel frame column comprises a concrete-filled steel tube combined special-shaped column and a concrete-filled steel tube column; each concrete-filled steel tube combine special-shaped column comprises at least three limb columns and can be embedded into a building wall without any exposure; each supporting structure comprises a steel supporting component or a shear wall; the assembled core barrel is arranged between the staircase and the elevator room; the supporting structures are arranged to a separating wall and a headwall; the steel beams are rigidly connected with the concrete-filled steel tube special-shaped columns and are hinged with the assembled core barrel. With the adoption of the assembled hybrid structure, the problems of inconvenient arrangement of lateral force resisting components in the residential building, easy exposing of beams and columns in a room, large workload in field wet construction, loud noise in the staircase and the elevator room, and difficult to treat steel column feet, can be solved.

Owner:TIANJIN UNIV

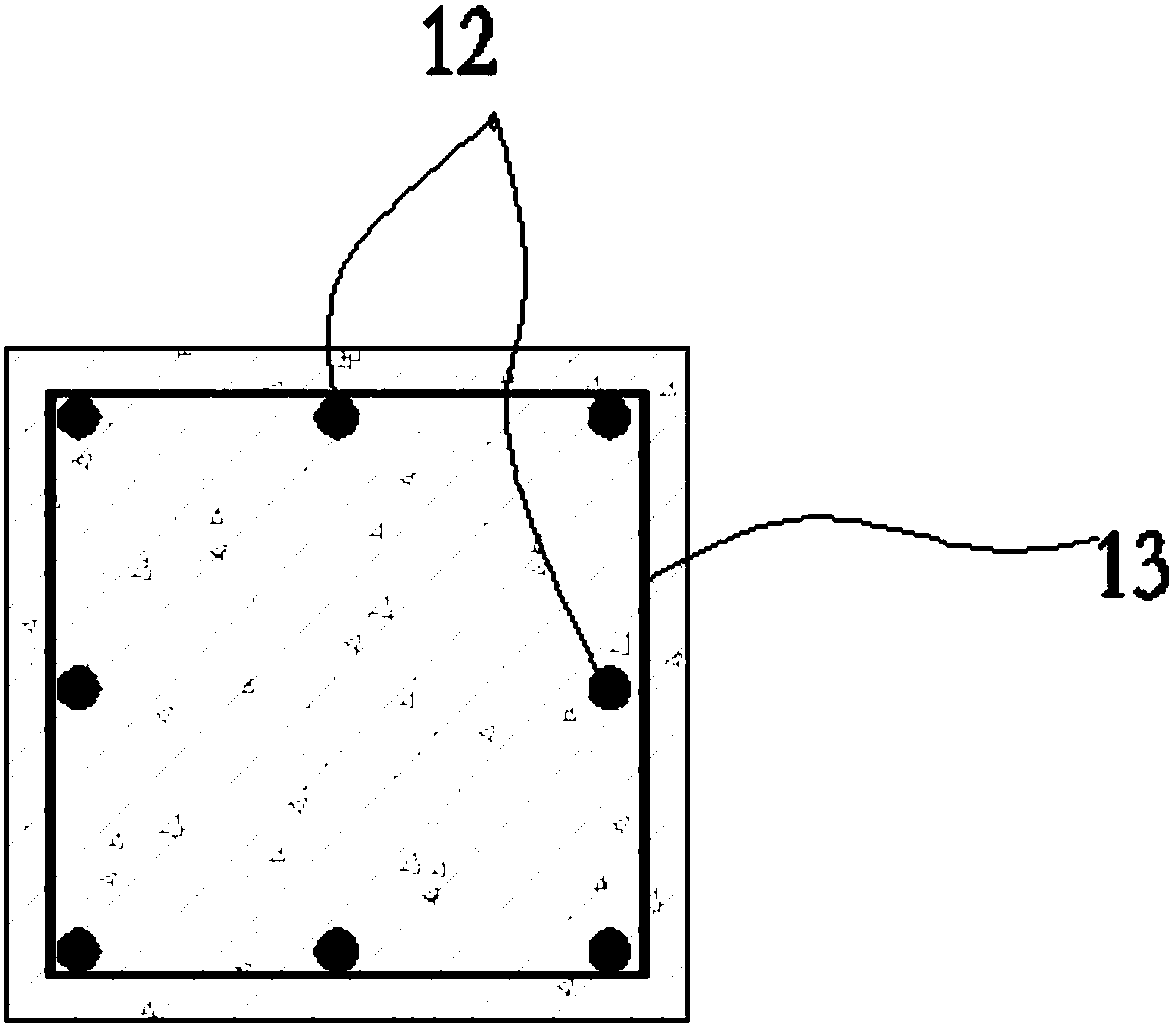

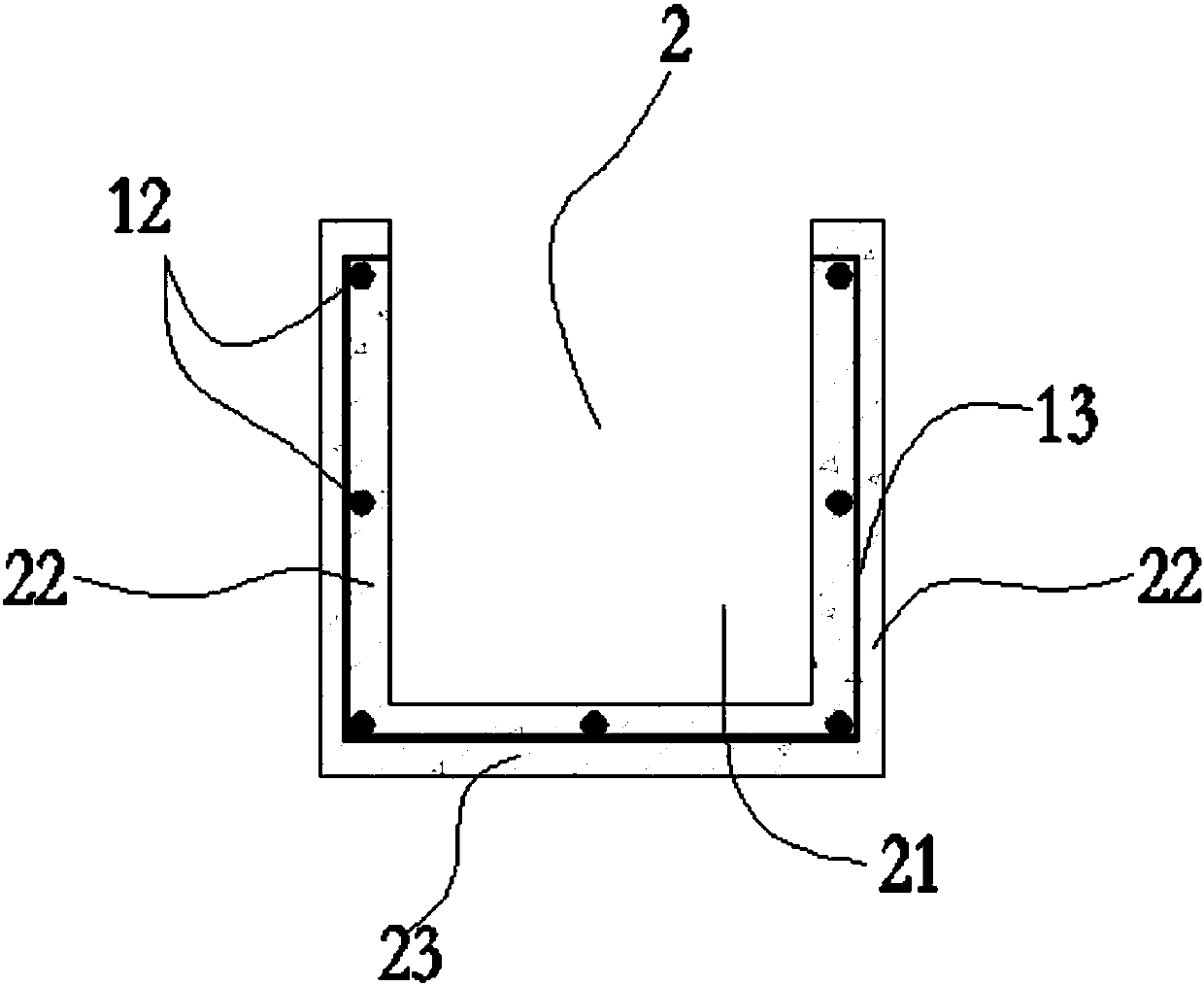

Steel frame whole exterior wall board

ActiveCN103726609AImprove insulation effectPrevent hot and cold bridge phenomenonBuilding componentsFoam concreteSurface layer

The invention discloses a steel frame whole exterior wall board. The exterior wall board is in a square structure encircled by a U-shaped steel frame. The exterior wall board is formed by the following steps: sequentially fixing galvanized steel wire netting, reinforcing bar inner ribs and reinforcing bar trusses in the U-shaped steel frame; pouring EPS foamed concrete to fixedly connect the galvanized steel wire netting, reinforcing bar inner ribs and reinforcing bar trusses into a whole in the U-shaped steel frame; finally, laying an upper steel wire netting layer, forming a board blank after initial set of concrete, spraying waterproof mortar on two sides of the board blank and forming a wall; cutting an XPS board into the same size as the wall, and adhering the board to the wall by virtue of gluing, wherein a pressurized cement board is arranged on the outer side of the XPS board so as to form the exterior wall board. According to the U-shaped groove bridge-cutoff technology, only a single side of the steel frame is contacted with the surface layer, the other end is embedded inside a thermal insulation material, a cold-thermal bridge phenomenon is effectively avoided, and the thermal insulation effect of the whole exterior wall is improved. The building operations are reduced, and the building assembly rate is improved.

Owner:SHENYANG ZHONGCHEN STEEL STRUCTURE ENG

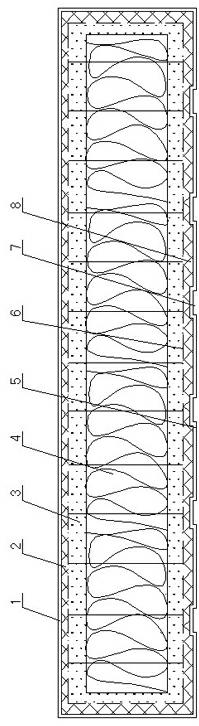

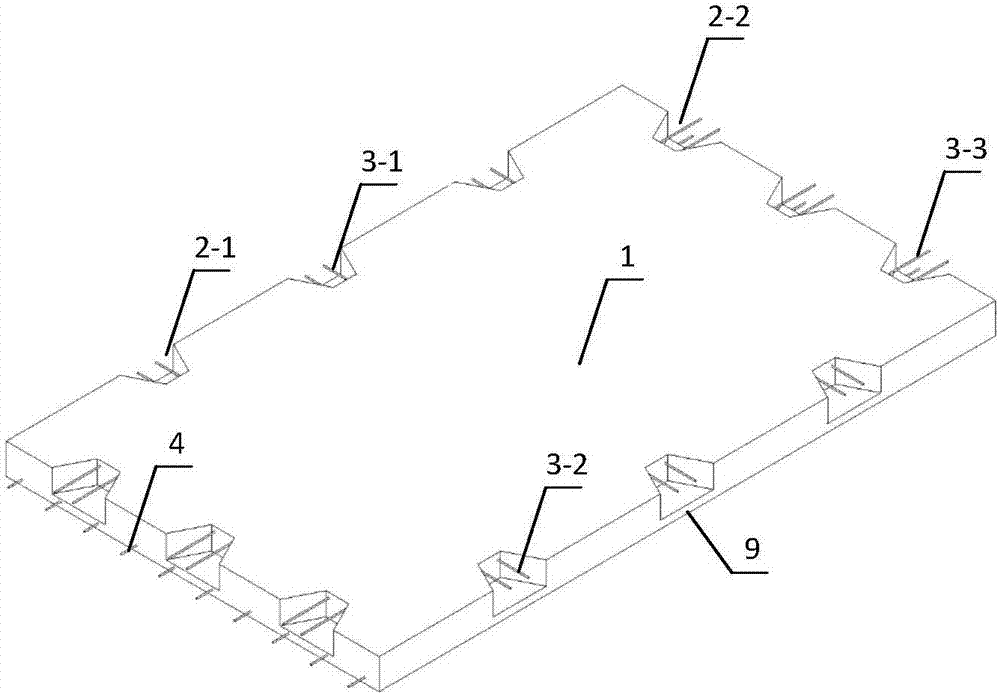

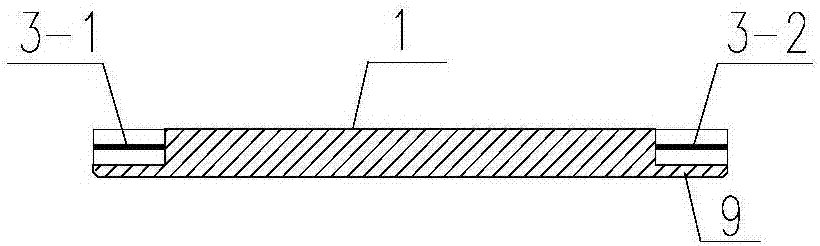

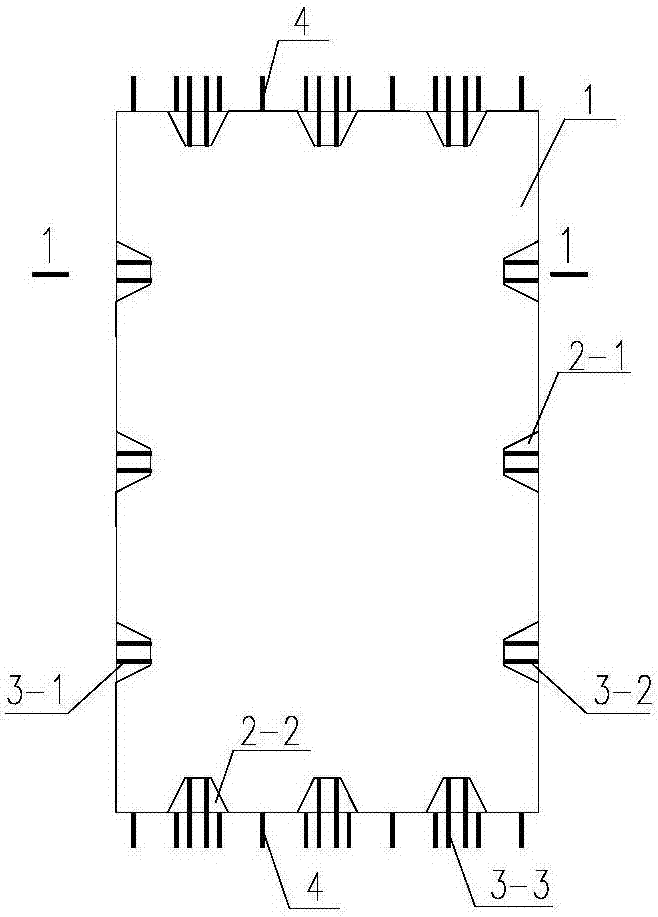

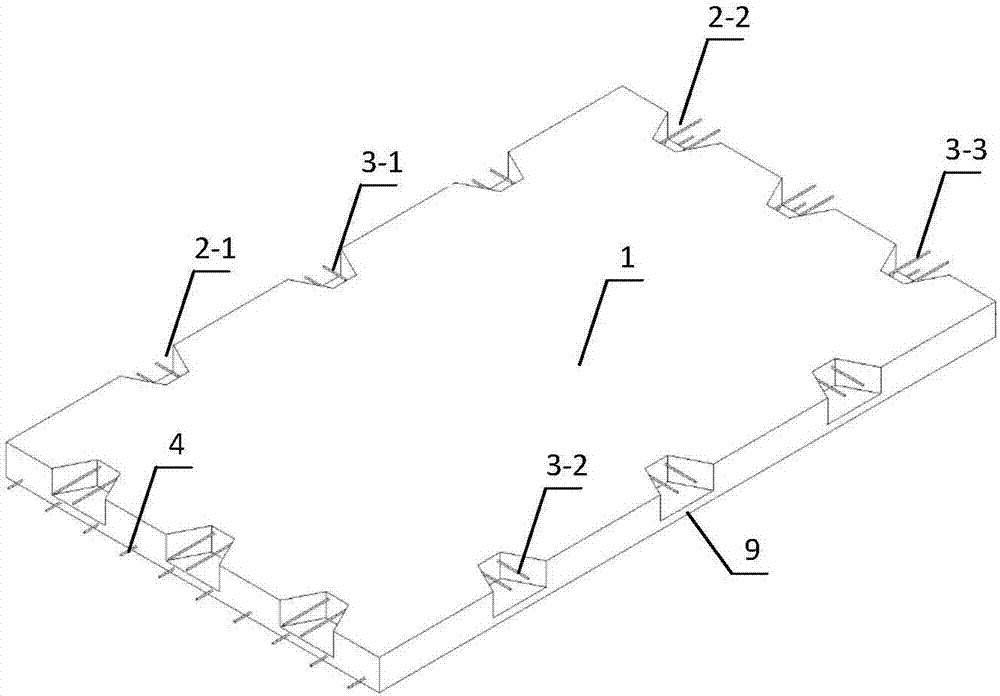

Post-poured toothed groove-connected assembled floor or roof

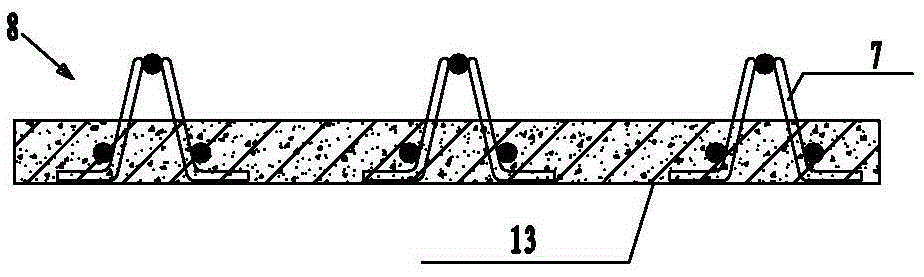

ActiveCN107130716AGood mechanical performance in the planeStrong shear resistanceFloorsSteel barEngineering

The invention discloses a post-poured toothed groove-connected assembled floor or roof. The post-poured toothed groove-connected assembled floor or roof is formed by splicing a plurality of prefabricated concrete slabs; toothed grooves are formed in the slab ends and the slab sides of the prefabricated concrete slabs; the slab-side toothed grooves and the slab-end toothed grooves are provided with bottom plates; embedded slab-side connecting components are arranged inside the slab-side toothed grooves; the embedded slab-side connecting components, connected with floor beams, on one sides of the prefabricated concrete slabs adopt embedded slab-side connecting steel bars I extending outwardly horizontally; embedded slab-end connecting steel bars are arranged inside the slab-end toothed grooves; embedded slab-end connecting steel bars are provided with outwardly extending sections; and outwardly extending longitudinal steel bars are arranged at the bottoms of the two ends of the prefabricated concrete slabs; and the post-poured toothed groove-connected assembled floor or roof comprises four connecting structures: 1), a connecting structure of the slab ends I and the floor beams I; 2), a connecting structure of the slab sides I and the floor beams II; 3), a connecting structure of two adjacent slab ends II; and 4), a connecting structure of two adjacent slab sides II. The post-poured toothed groove-connected assembled floor or roof is light in weight, high in seismic performance, easy and convenient to construct, less in on-site wet workload and good in environment-friendly effect.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

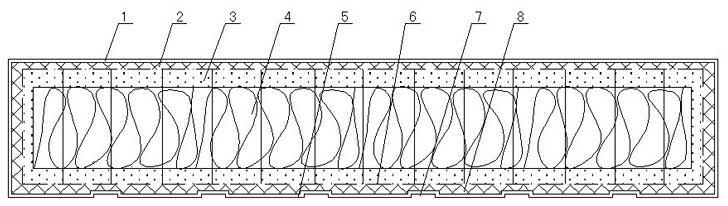

Construction method of post-cast tooth groove connecting assembling type roof

InactiveCN107130715AGood mechanical performance in the planeStrong shear resistanceFloorsPrecast concreteProcess plant

The invention discloses a construction method of a post-cast tooth groove connecting assembling type roof. The method comprises the following steps: 1) processing precast concrete planks in a component processing factory; 2) splitting and abutting the precast concrete planks and the precast concrete planks and a floor beam to form four types of splitting abutting structures; 3) connecting embedded connectors at the split abutted parts; 4) pouring concrete in a post-cast area. Compared with currently-used prefabricated composite concrete plank, the method has the advantages that the roof constructed by the method is free from a post-cast layer, and the concrete is poured in the tooth groove type post-cast area between the planks or between the planks and the floor beam, therefore, the roof and the whole structure are sufficient in rigidity and high in earthquake proofing performance; the post-cast layer, a die plate and a support are not required, so that the construction speed can be effectively increased; the field wet works can be decreased; the dead weight of the roof can be reduced; the earthquake proofing performance of the structure can be improved.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

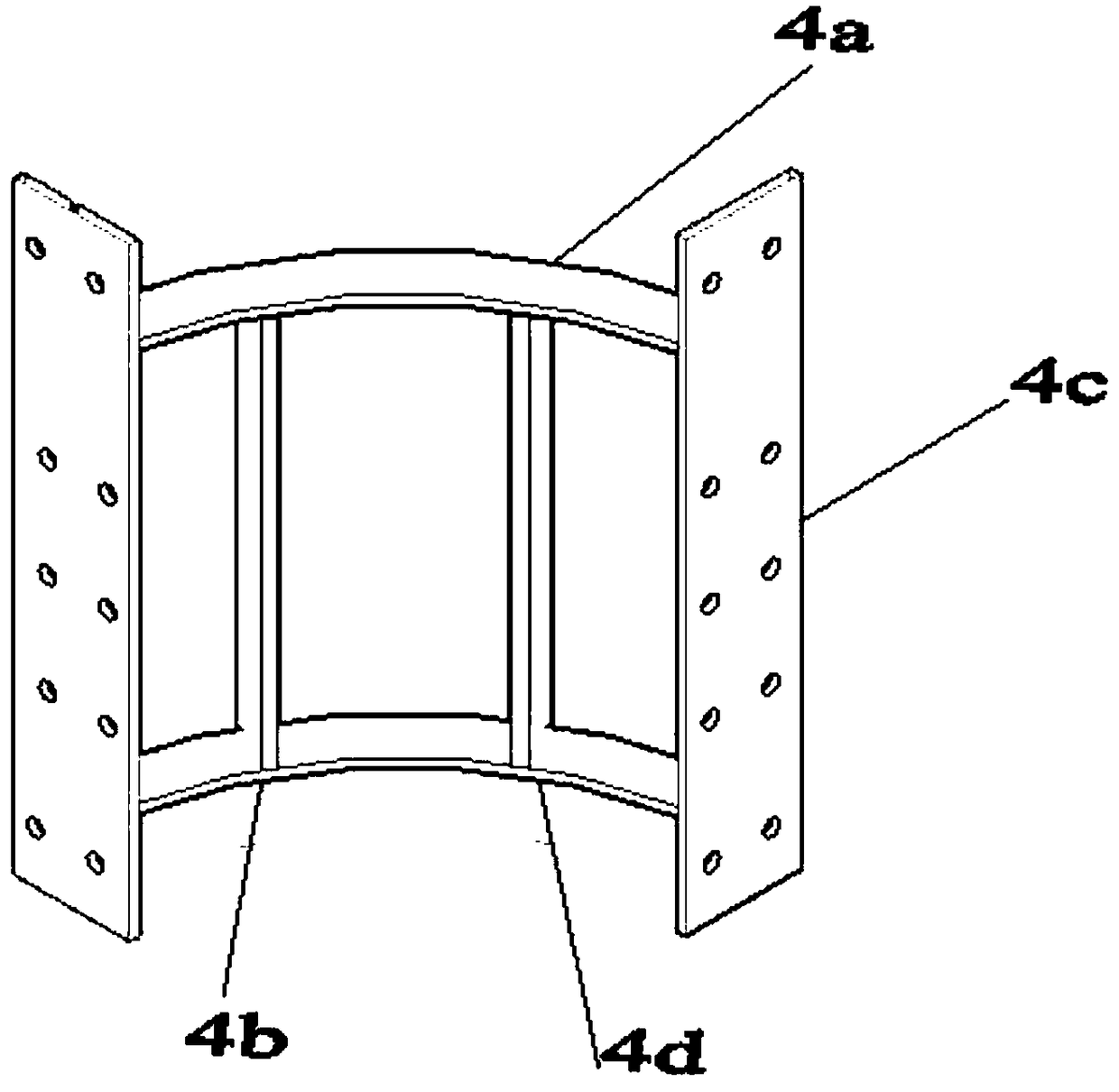

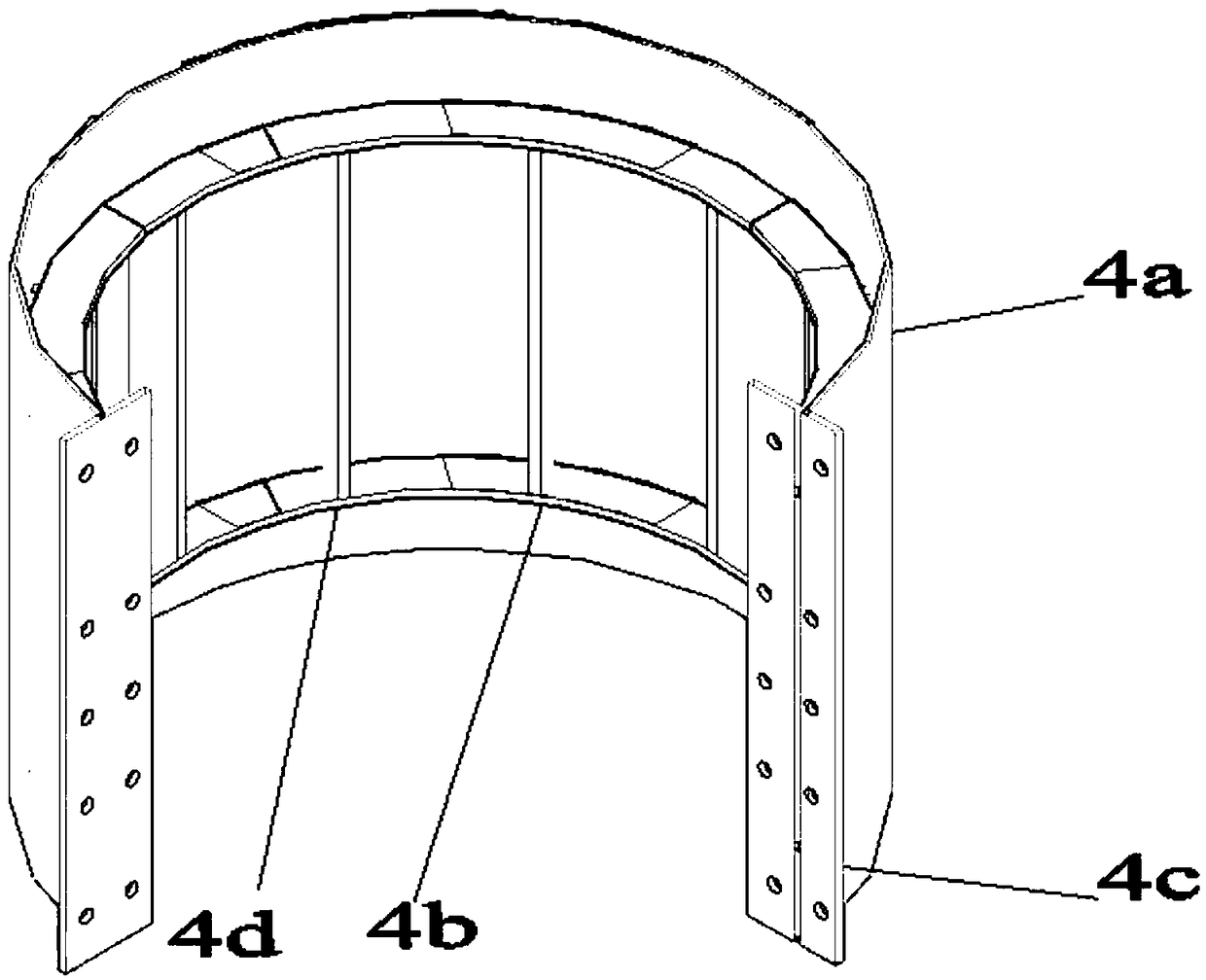

PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam L-shaped node

ActiveCN109024915ASimple structureRealize the purpose of "strong node"StrutsGirdersReinforced concreteHigh intensity

The invention discloses a PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam L-shaped node which comprises the components of two sets of circular steel pipe fasteners, a PVC-FRP pipe, core section steel, two sets of U-shaped hidden brackets, a column longitudinal rib, a column tie-rib, a beam longitudinal rib, a beam tie-rib, high-strength bolts, core-crossing anchor bolts and a stiffening rib plate. The core section steel penetrates through the center of the circular steel pipe fastener. The PVC-FRP pipe sleeves the core section steel. The two sets of U-shaped hidden brackets are fixedly connected with the two sets of circular steel pipe fasteners through high-strength bolts. The two sets of U-shaped hidden brackets are arranged in an L-shape. Core passing anchor bolt pass through the U-shaped hidden bracket. The directions of the core-passing anchor bolts in the same layer are same. The directions of the core-passing anchor bolts are opposite. The circularsteel pipe fasteners are connected through the core-crossing anchor bolt. The PVC-FRP pipe restrained section steel concrete column-reinforced concrete beam L-shaped node can realize quick splicing of steel components in the node and further has advantages of high bearing force, high integrity, convenient construction, high industrialization degree, etc.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

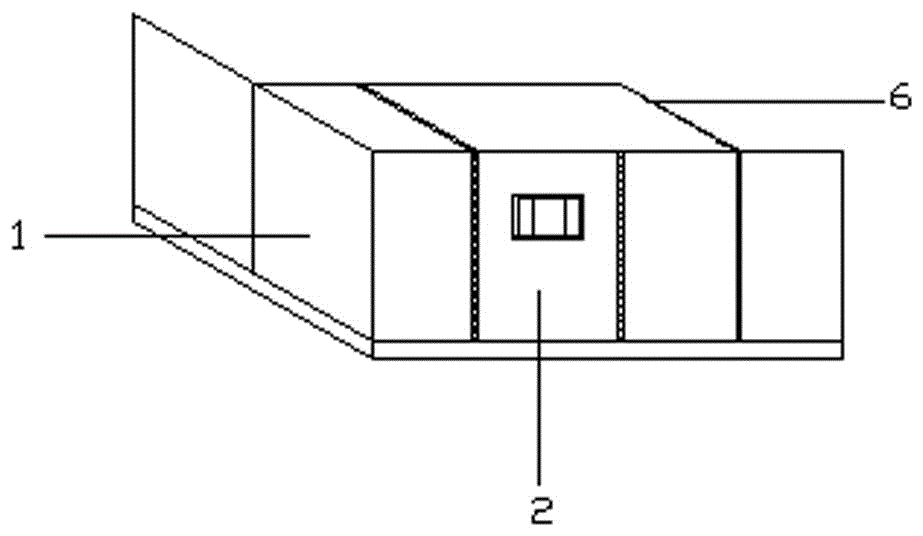

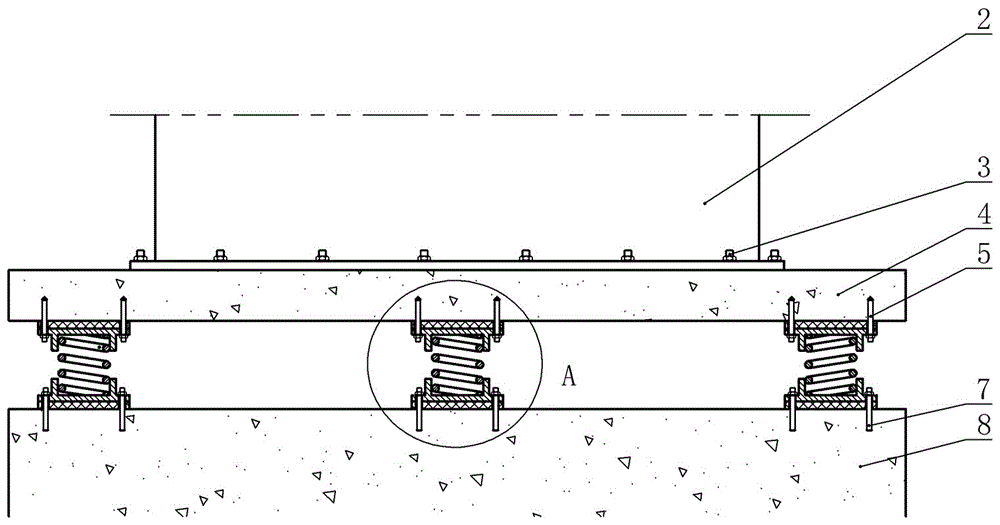

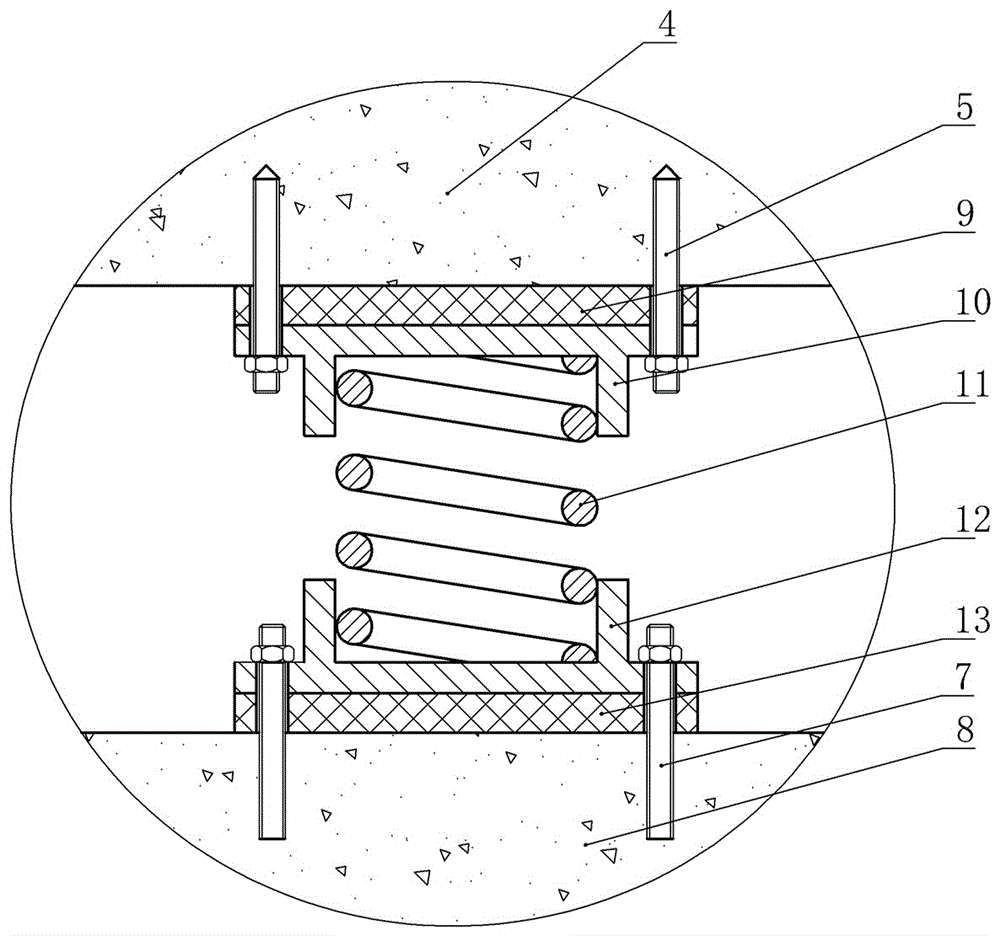

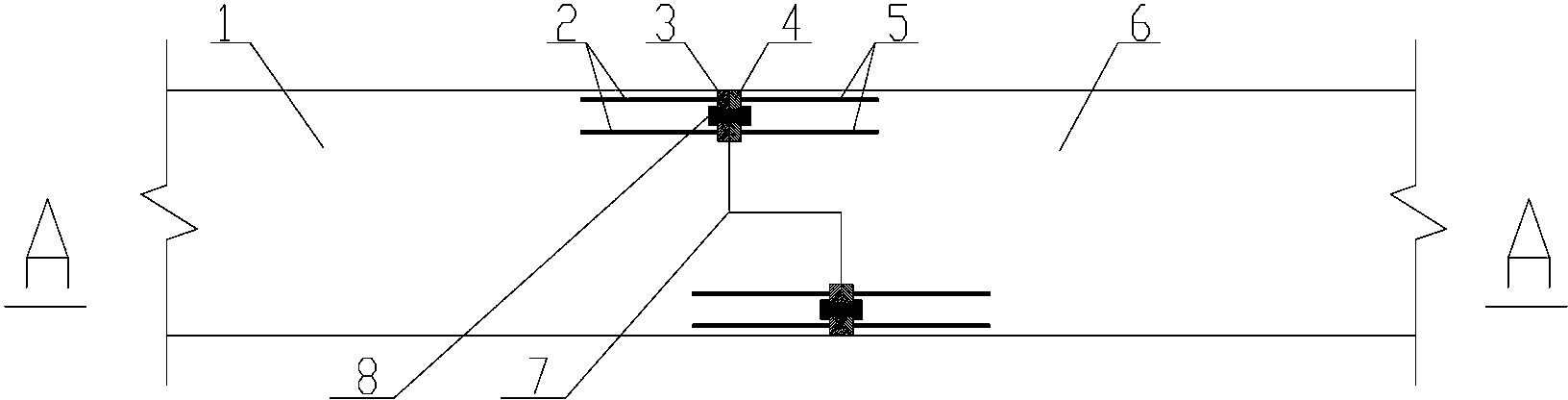

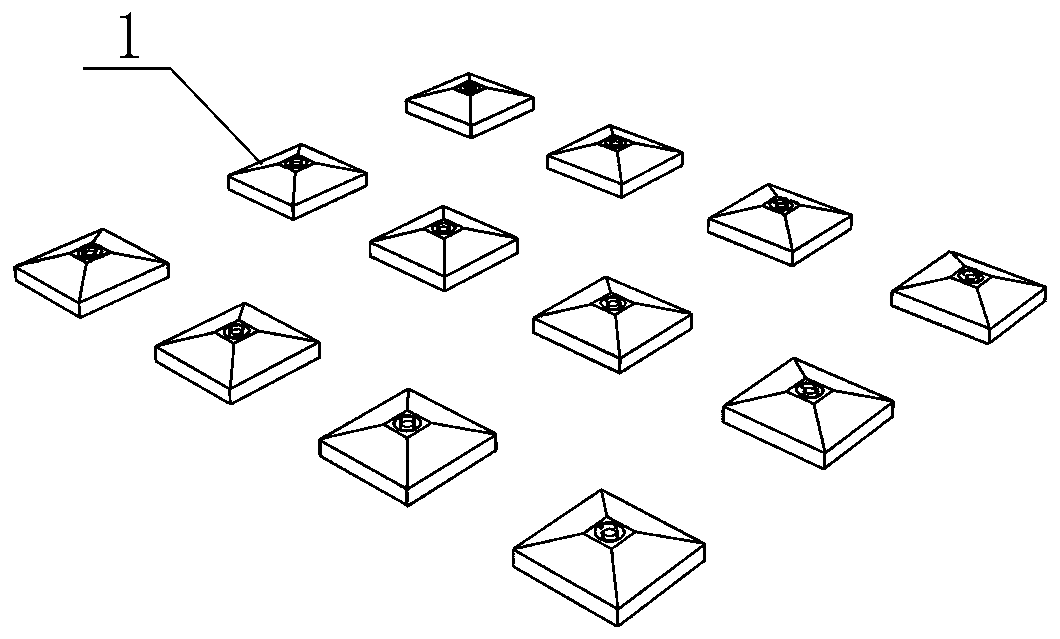

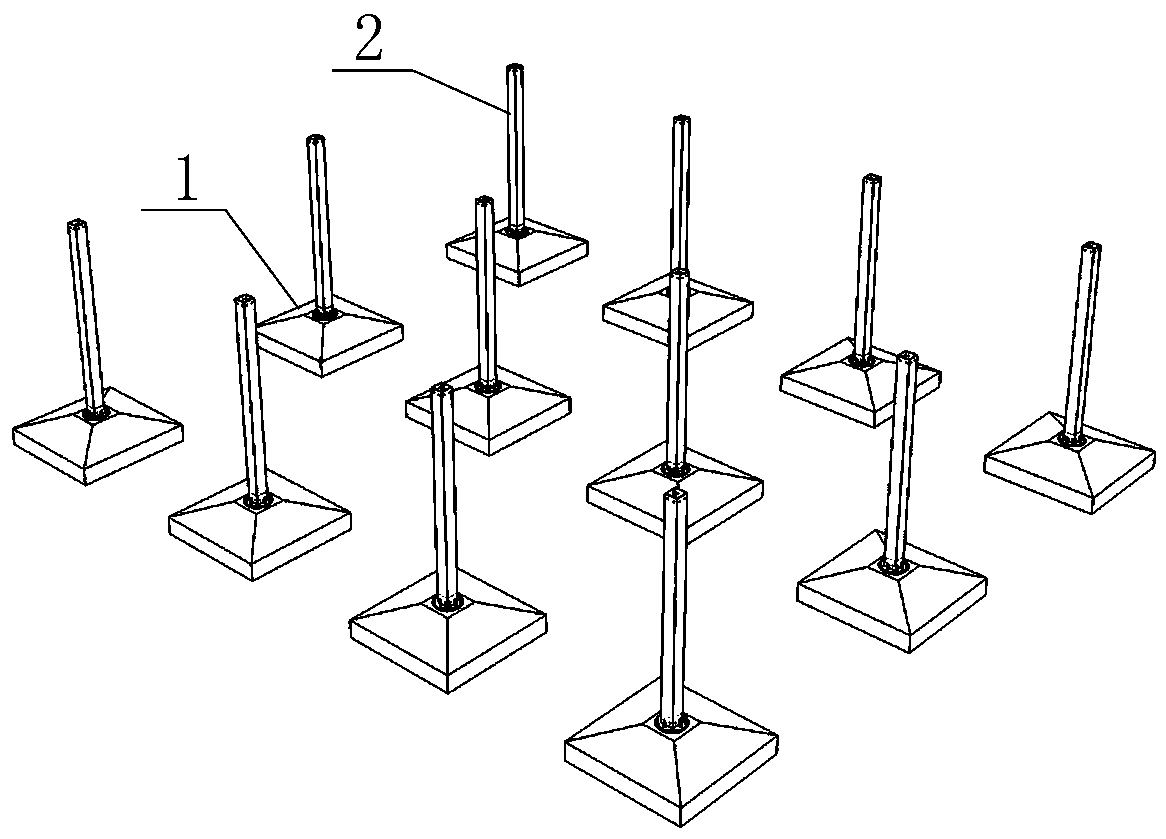

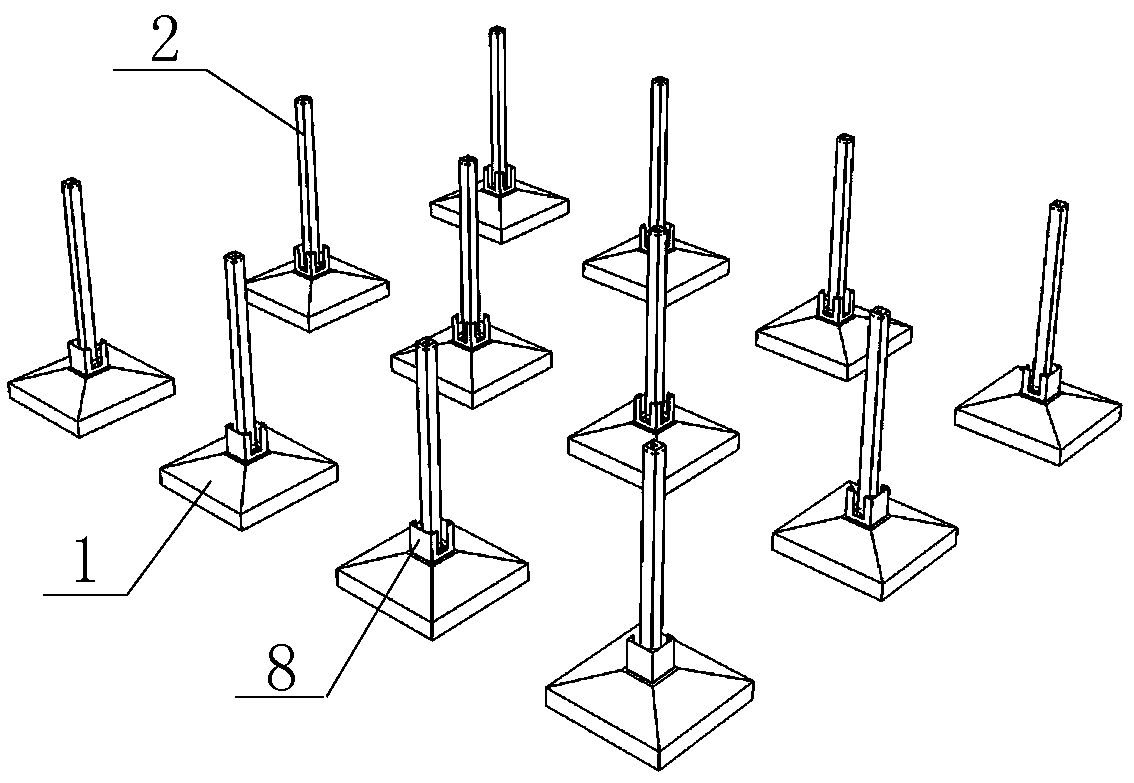

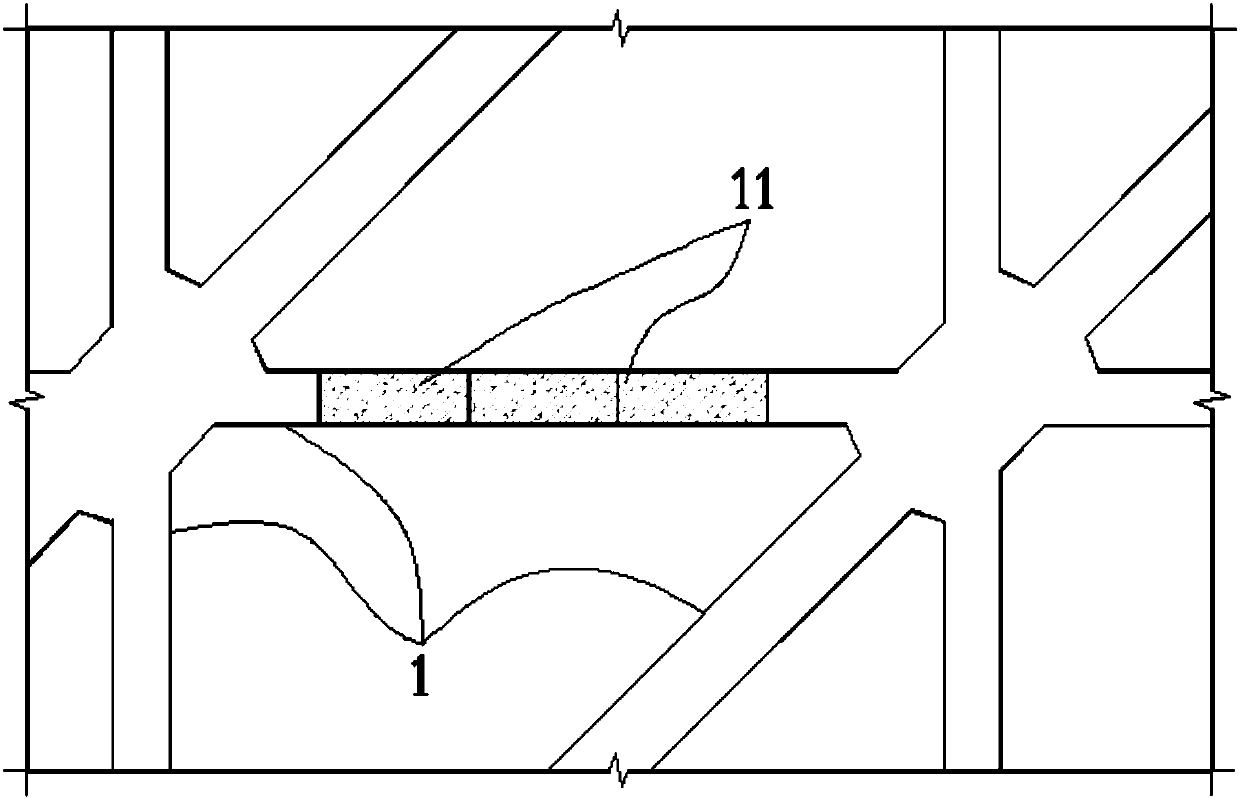

Assembled integrated house component device

InactiveCN106013459AReduce varianceImprove performanceProtective buildings/sheltersShock proofingWastewaterEconomic benefits

The invention relates to an assembled integrated house component device, which comprises a foundation, a main wallboard, a floor deck, an external wallboard and a door / window plate, wherein the main wallboard is fixedly arranged on the foundation through L-shaped connecting pieces and first embedded bolts; the external wallboard is fixedly arranged on the outer side of the main wallboard; a sound insulation and heat preservation layer is arranged between the external wallboard and the main wallboard; the foundation comprises a foundation bed, a base and multiple seismic stabilizer brackets; the main wallboard is fixedly arranged on the upper surface of the base; the seismic stabilizer brackets are uniformly arranged between the foundation bed and the base at intervals; each seismic stabilizer bracket comprises a damping spring and upper and lower vibration isolation cushions; the upper ends of the damping springs are fixedly arranged on the lower surface of the base through upper spring seats, and the lower ends of the damping springs are fixedly arranged on the foundation bed through lower spring seats. The assembled integrated house component device is high in prefabrication rate and overall house performance, less in field wet operation, rapid in construction, easy to operate, low in labor intensity of a worker, material-saving and labor-saving, and has remarkable economic benefits, the quality of a building is improved, production of a large amount of construction waste and wastewater is avoided, noise pollution is reduced, and consumption is reduced.

Owner:HENAN GUOLONG IND

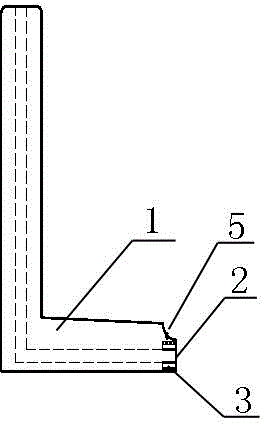

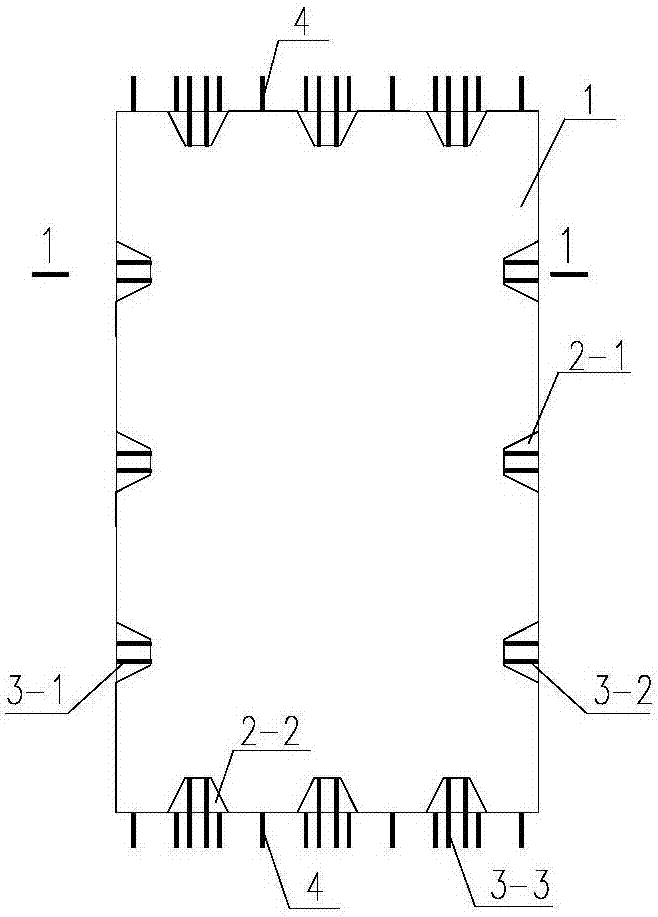

Prefabricated shear wall dry type vertical connecting node and construction method

ActiveCN104032850AReduce pollutionReduce on-site wet workWallsBuilding material handlingButt jointTongue and groove

The invention discloses a prefabricated shear wall dry type vertical connecting node and a construction method. The vertical connecting node comprises mutually connected prefabricated shear walls, wherein a tongue and groove joint is arranged at a connecting interface of the prefabricated shear walls; the tongue and groove joint is subjected to hacking treatment; hairpin type connecting elements are respectively buried in positions, near the inner and the outer facades of the prefabricated shear walls, of the tongue and groove joint; the hairpin type connecting elements comprise mutually welded anchor plates and anchor bars; the outer sides of the anchor plates are exposed out of the end surface of the tongue and groove joint; the anchor bars are anchored in the prefabricated shear walls arranged at the inner sides of the anchor plates; the centers of the anchor plates are provided with screw bolt holes; grooves are formed in the prefabricated shear walls positioned at the inner sides of the screw bolt holes; the hairpin type connecting elements arranged at the two sides of the connecting interface are mutually symmetrical; in addition, screw bolts are arranged in a pair of screw bolt holes; and the two ends of the screw bolts are positioned in the grooves. The construction method comprises the steps of prefabricated shear wall manufacturing, butt joint of the hairpin type connecting elements at the tongue and groove joint part, screw bolt installing, mortar filling and the like. The vertical connecting node basically realizes a fully dry type connecting method, the connecting intensity and the bearing force are high, and the node conforms to the requirements of building industrialization and housing industrialization.

Owner:SOUTHEAST UNIV

Construction method for thermal insulating sandwich concrete external wall panel with steel beams and steel columns

InactiveCN106351339AFast installation and construction on siteFast installation and constructionBuilding material handlingSheet steelControl line

The invention relates to a construction method of a sandwich thermal insulation concrete outer wall panel, steel beams and steel columns, comprising the following steps: hoisting the steel columns in place, popping up the steel columns, steel beam axes and wall installation control lines on the floor; Hoisting of thermal insulation concrete external wall panels; steel beams of sandwich thermal insulation concrete external wall panels and steel column corbels are connected by bolts; upper sandwich thermal insulation concrete external wall panels reserve gaps and reserved steel plates on the sides of the gaps and lower sandwich thermal insulation concrete external wall panel steel beams The lifting lugs are connected; the openings at the joints between steel beams and steel columns are sealed; the openings at the steel beam lifting lugs at the bottom of the sandwich insulation concrete exterior wall panels are sealed. The construction method of the sandwich thermal insulation concrete external wall panels, steel beams and steel columns of the present invention solves the problems of the horizontal connection between the prefabricated sandwich thermal insulation external wall panels and the steel columns and the vertical connection of the steel beams, and the on-site installation and construction speed of the external wall panels It is faster than traditional masonry, reduces on-site wet work, protects the environment, and is conducive to on-site civilized construction.

Owner:CHINA 22MCC GROUP CORP +1

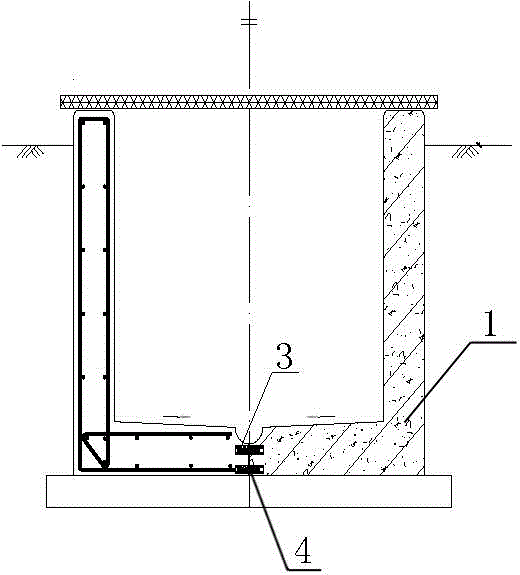

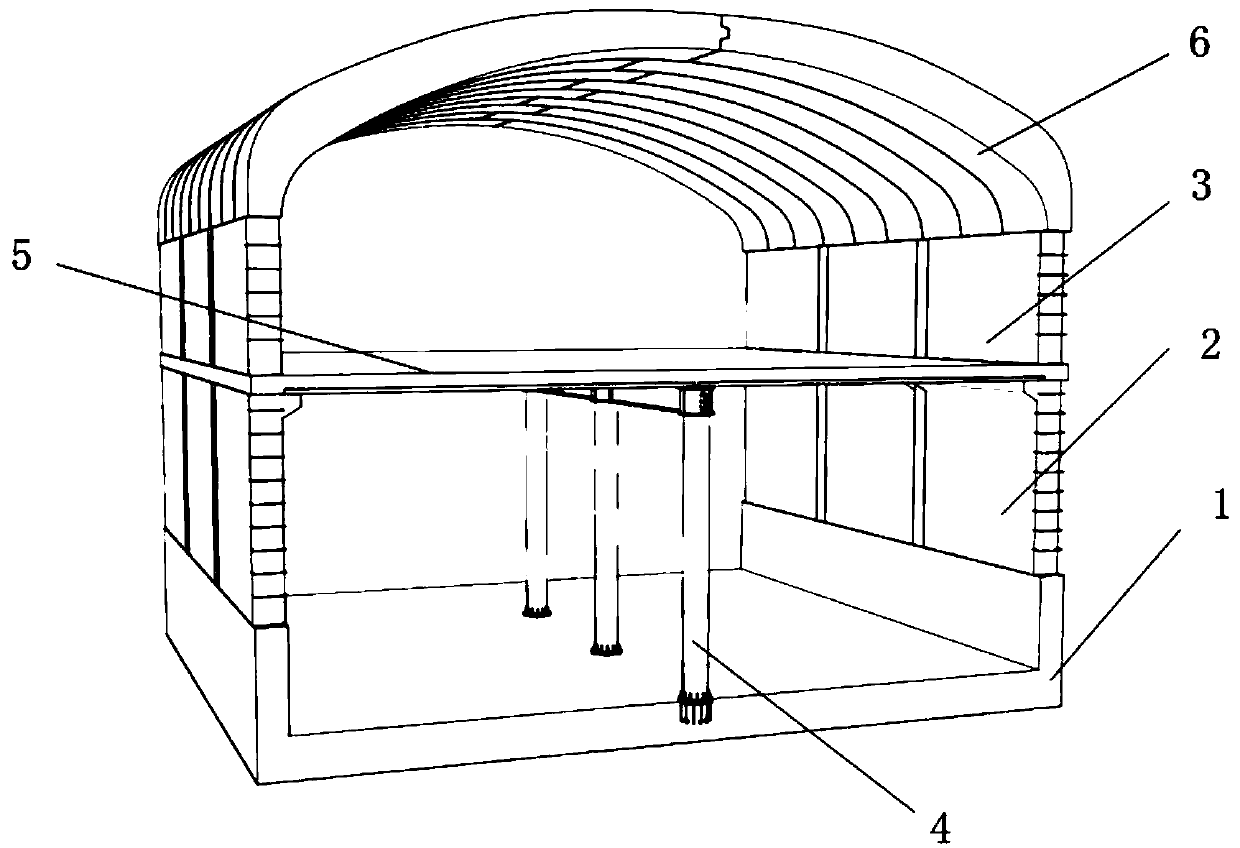

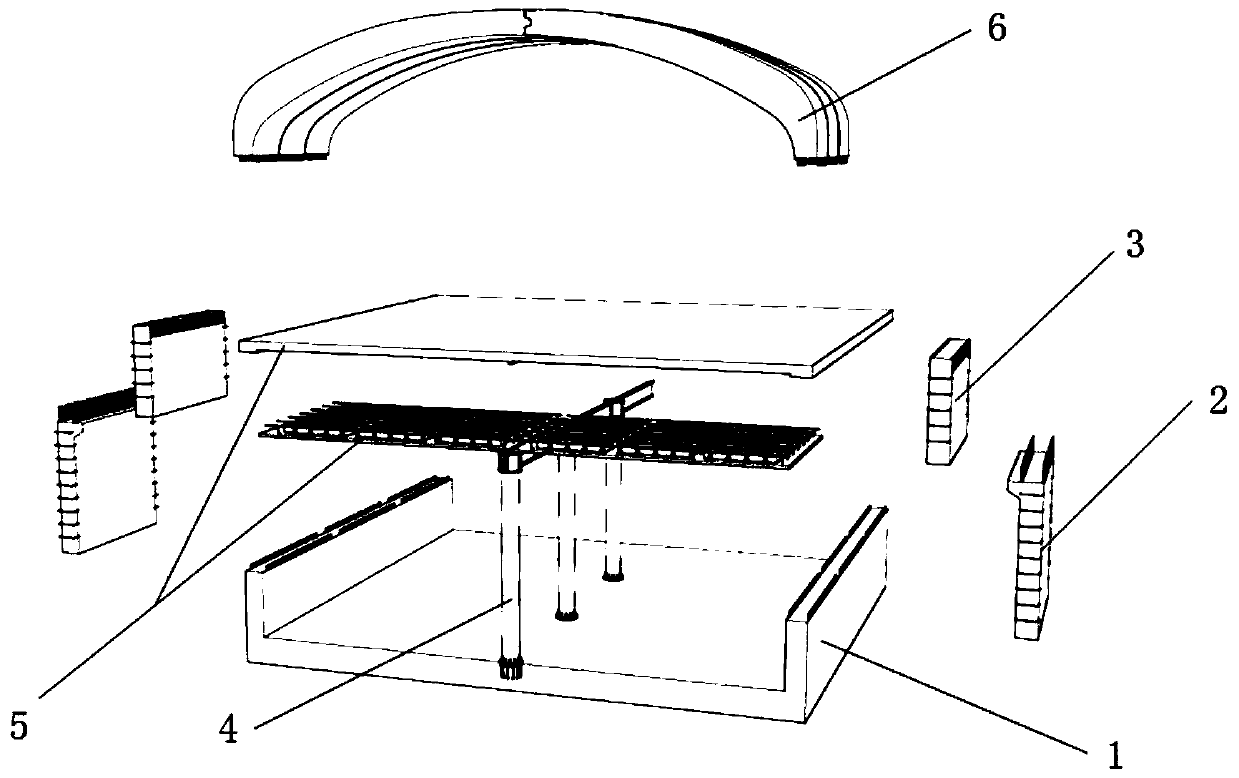

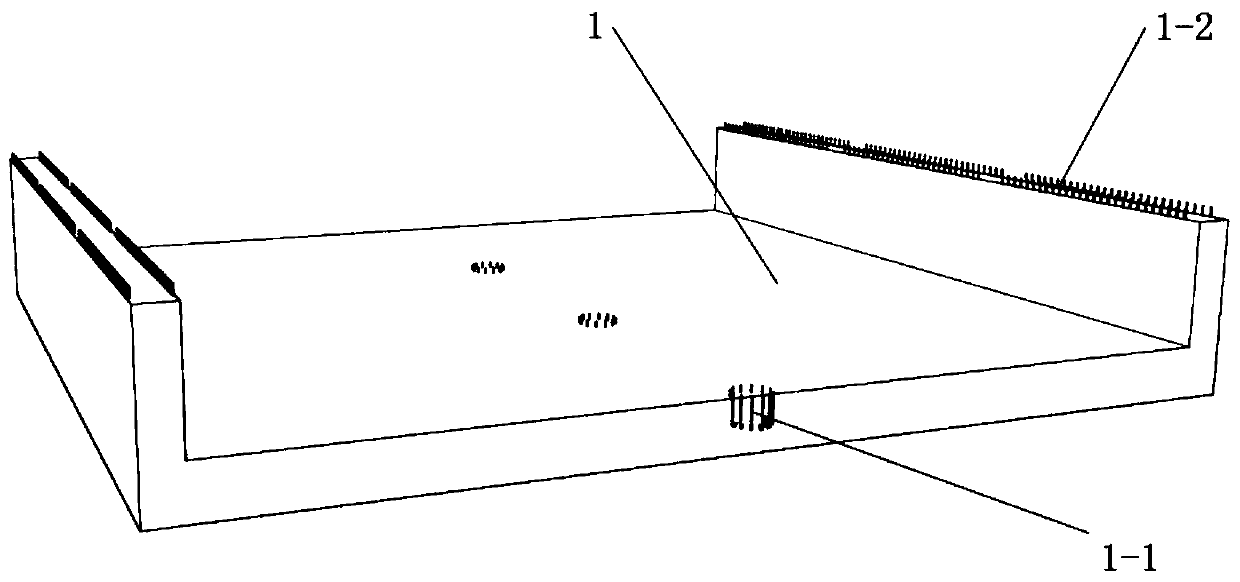

Assembled steel-concrete composite structure metro station and assembling method

PendingCN110318426AGuaranteed waterproof performanceImprove bearing capacityArtificial islandsUnderwater structuresMetro stationRebar

The invention discloses an assembled steel-concrete composite structure metro station and an assembling method, belongs to the technical field of assembled metro station construction, and aims at solving the problems that the existing assembled metro stations are low in industrialization degree and bad in field operation environment and the problems such as environment pollution and noise pollution caused by the construction are on the rise. The assembled steel-concrete composite structure metro station comprises a bottom plate and lower secondary side walls, wherein the lower secondary side walls are connected with lower primary side walls by adoption of grouting sleeves or slurry anchors; concrete filled steel tubular columns of a concrete filed steel tube composite beam and girders adopt outer reinforcing ring nodes; prefabricated slabs of concrete hollow laminated slabs are supported on concrete walls and the girders; reinforcing steel bars are reserved at and extends out from twoends of the prefabricated slabs; and prefabricated arc-shaped top plates of arc-shaped structures adopt joggle joint at the arc top positions. According to the novel assembled steel-concrete composite structure metro station, the components are prefabricated in the factories and assembled and connected on the spot, so that the construction speed can be greatly improved, the spot wet operations are decreased and the influences on the surrounding traffic and environment are reduced.

Owner:HARBIN INST OF TECH

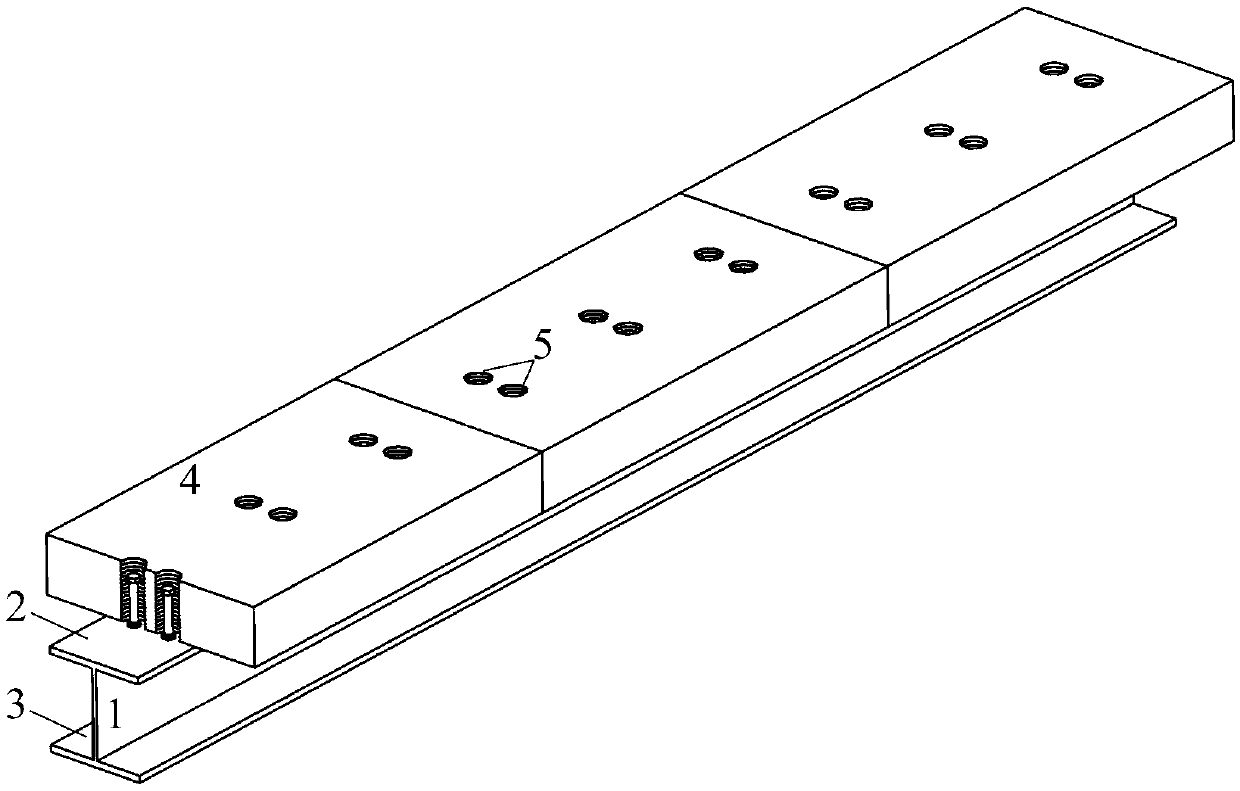

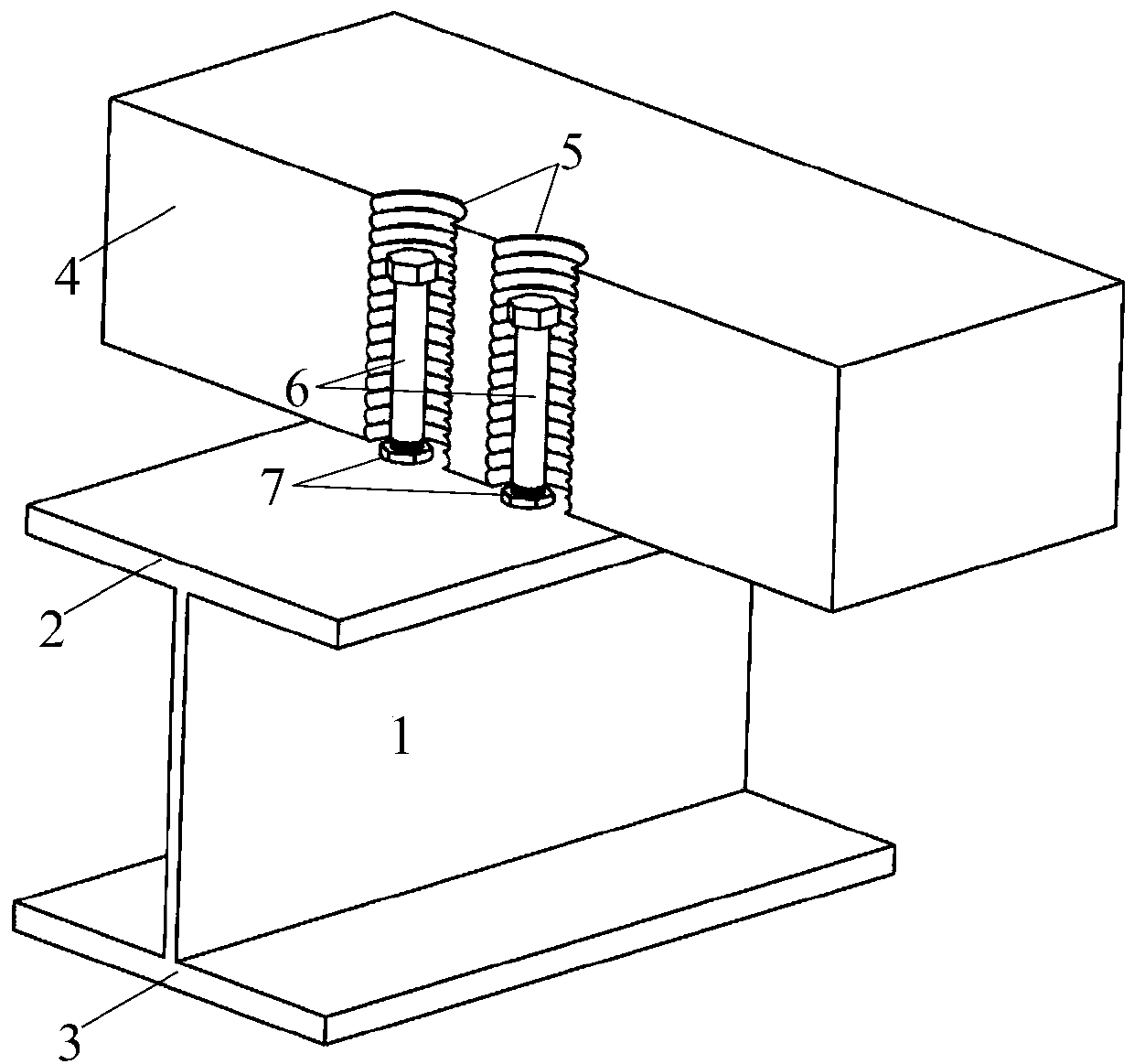

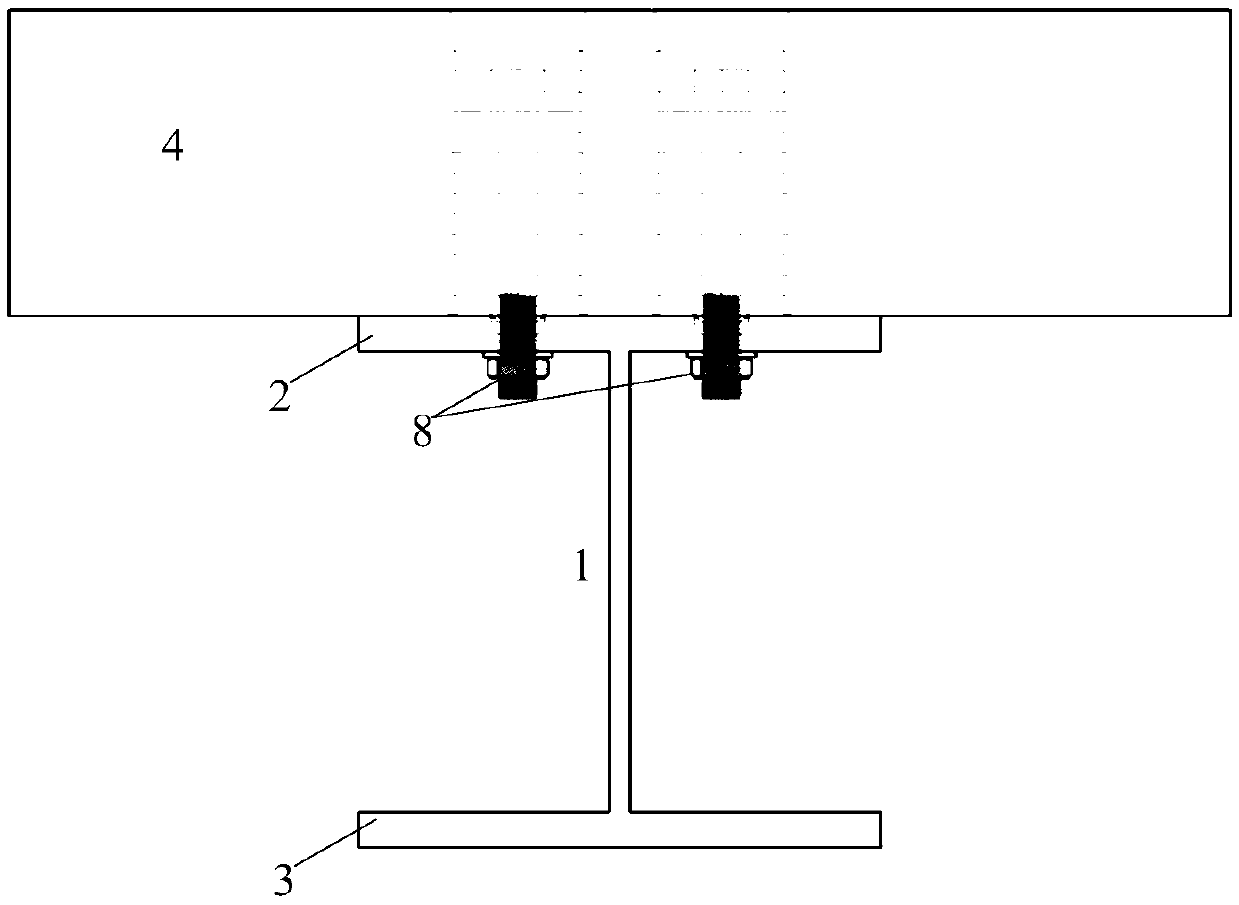

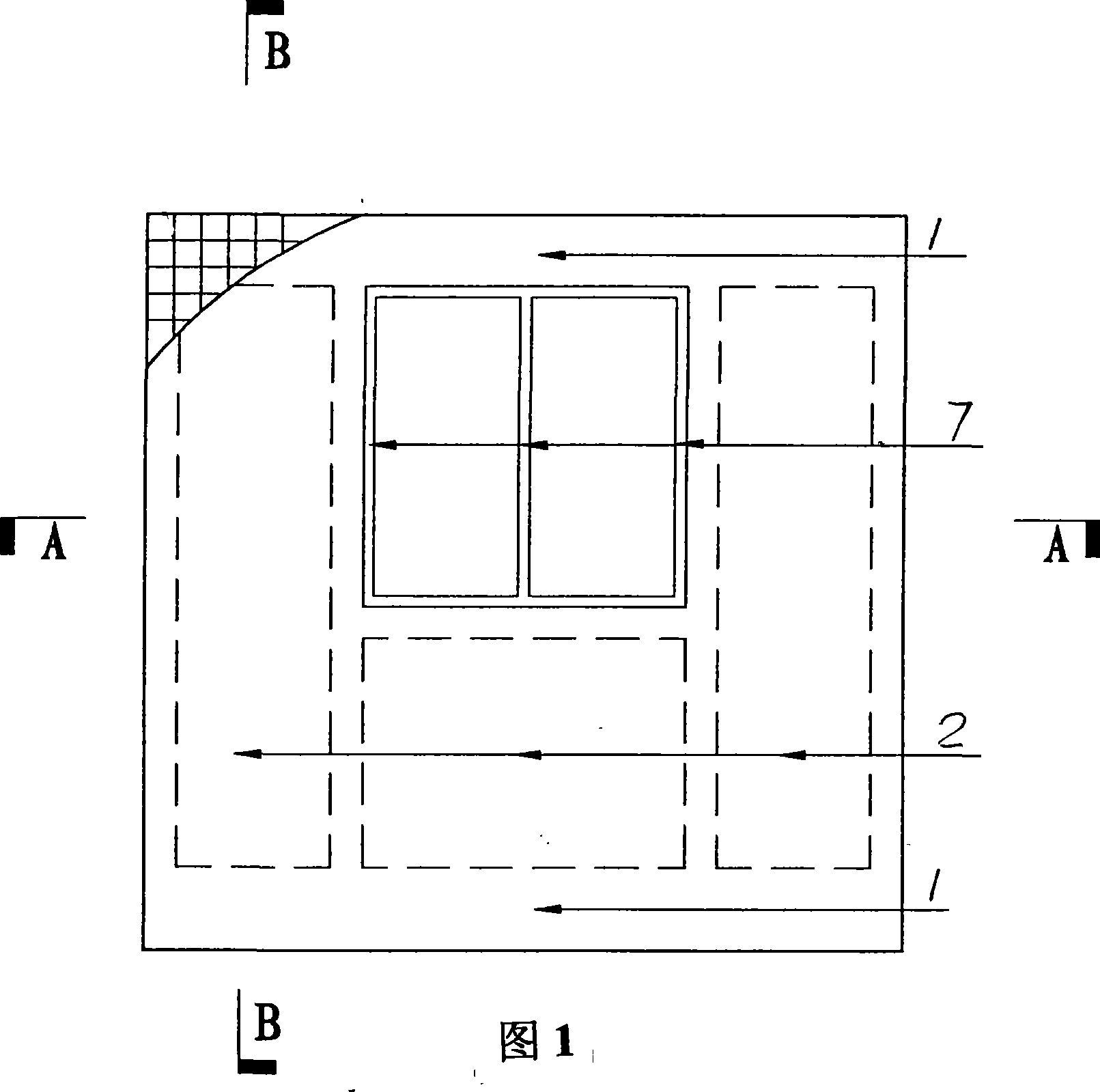

Detachable steel-concrete composite beam adopting conical nut and bolt connectors

PendingCN109555265AReduce the chance of clippingImprove adhesionLoad-supporting elementsEngineeringPrecast concrete

The invention discloses a detachable steel-concrete composite beam adopting conical nut and bolt connectors. The detachable steel-concrete composite beam comprises the bolt shear force connectors, a steel beam and precast concrete slabs. According to the detachable steel-concrete composite beam, the prefabricating rate of components is increased, site construction wet operation can be reduced, andthus pollution caused by construction flying dust to the atmospheric environment is avoided; shear surface areas of the shear force connectors at the steel-concrete interface can be effectively enlarged through conical hexagonal locking nuts, and the risk that roots of the shear force connectors are shorn off is lowered; the bonding effect between grout and the precast concrete slabs can be enhanced through corrugated pipes; dismantling and repairing are convenient; and the components can be recycled, generation of building waste is reduced to a certain extent, and resources are saved.

Owner:TIANJIN UNIV

Prefabricated thermal insulation exterior wall and method for producing the same

InactiveCN101429787AImprove waterproof performanceImprove thermal insulationWallsHeat proofingRebarThermal insulation

The invention relates to a manufacturing method, which comprises the following steps: a. a formed steel die is assembled; b. a lower formed reinforcement cage is assembled inside the formed steel die; c. window frames and embedded parts are arranged on a bottom die of the formed steel die; d. the lower layer of concrete is subjected to casting and compacting; e. a heat-insulated board is arranged on a lower concrete board; f. an upper formed reinforcement cage is arranged inside the formed steel die, and the upper formed reinforcement cage is connected with the lower formed reinforcement cage by a galvanized iron wire; g. the upper layer of concrete is subjected to casting and compacting, and a prefabricated heat-insulated wallboard is formed; h. the prefabricated heat-insulated wallboard is subjected to vapor curing; i. the formed steel die is disassembled; j. the prefabricated heat-insulated wallboard is lifted and stacked; and k. the prefabricated heat-insulated wallboard is loaded and transported. When used, the prefabricated heat-insulated wallboard has good heat-insulating performance, superior anti-crack performance and anti-seepage performance, and can reduce on-site wet construction and improve the construction efficiency because veneer materials, doors, the window frames and prefabricated parts are subjected to casting together.

Owner:瑞安管理(上海)有限公司 +1

Prefabricated steel rib-concrete combined shear wall splicing device and application method

PendingCN109356281AGuarantee the construction qualityEasy splicingBuilding constructionsFloor slabSheet steel

The invention relates to a prefabricated steel rib-concrete combined shear wall splicing device and an application method, and belongs to the technical field of fabricated buildings. Reserved wedge-shaped post-pouring areas are arranged at the lower parts of splicing steel plates and a prefabricated shear wall, the lower ends of steel ribs in an upper prefabricated concrete wall body and the lowerend of the prefabricated concrete wall body are flush, the wedge-shaped post-pouring areas are arranged at the lower end of the wall body, the steel ribs in the wall body are exposed, and concrete pouring is carried out to level after the splicing is completed; the upper ends of steel ribs in a lower prefabricated concrete wall body extend out of the prefabricated concrete wall body, and the upper ends of the steel ribs are connected with the splicing steel plates for being connected with the steel ribs in the upper prefabricated wall body; the splicing steel plates can be connected to both sides of flanges of the steel ribs or middle web plates of the steel ribs; and the wedge-shaped post-pouring areas are arranged at the lower end of an upper layer prefabricated concrete wall. Accordingto the prefabricated steel rib-concrete combined shear wall splicing device and the application method, the shear wall can be directly placed on a floor slab, and the self-weight of the wall body andthe construction load do not act on splicing joints, so that the construction quality of the joints is ensured, and the construction safety problem is effectively solved.

Owner:SHANDONG UNIV

Fixed model quasi-non-combustible high thermal-resistance decoration integral composite template

InactiveCN104963474ARealize industrializationIncreased combustion performance levelCovering/liningsCeramic layered productsSurface layerFire protection

The invention discloses a fixed model quasi-non-combustible high thermal-resistance decoration integral composite template comprising a warming layer (1). The template is characterized in that the inner side of the warming layer (1) is provided with a cross rib or a longitudinal cross rib (2) having a projecting layer surface; a protection layer (3) is composited on the surface; the warming layer, the cross or longitudinal cross rib and the protection layer are integrated; a decoration surface layer (4) is composited on the external side surface of the warming layer (1); an anchor bolt (7) is installed in the composite template; polyurethane foam is filled in a dividing joint cavity of the composite template surface; with the above arrangements, the functions of templates, fireproofing, warming and decoration are integrated; the building warming decoration has the same service life as a wall body structure, so long term maintenance cost is reduced and secondary warming, plastering and decoration procedures are avoided; the composite template is characterized by short construction period, high construction efficiency, low comprehensive cost, light weight, high strength, low contraction percentage and great durableness; problems related to quality and fire protection, such as wall body cracking, seepage and wall body falling-off can be effectively solved; the composite template can be manufactured in factories one for all; and the composite template meets requirements for building industrialization and housing industrialization.

Owner:SHANDONG TIANQI ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Prefabricated steel structure and construction method thereof

The invention discloses a prefabricated steel structure and a construction method thereof. The prefabricated steel structure comprises independent foundations, steel columns, foundation beams, steel I-beams, composite floor slabs and wall board structures; embedded parts are embedded in the independent foundations; each embedded part comprises an embedded part bottom plate, vertical anchor rods and a sleeve; outer threads are arranged at the upper parts of the outer side walls of the sleeves; circular plates are arranged in the positions, close to the upper ends, inside the sleeves; column bottom steel dies are arranged at the tops of the independent foundations; the sleeves are sleeved with the column bottom steel dies and are in threaded connection with the column bottom steel dies; thebottommost-layer steel columns are correspondingly inserted in the column bottom steel dies; every two adjacent layers of the steel columns are connected through connecting sections; the steel I-beamsare in bolted connection with connecting section main bodies through vertical end plates; and the composite floor slabs are in bolted connection with top flanges of the steel I-beams. By the aid of the prefabricated steel structure and the construction method, the technical problems that traditional prefabricated steel structures are low in factory prefabrication rate and field assembly rate, high in environmental pollution and low in construction efficiency, secondary fireproof coating is required for exposed beams and exposed columns of the steel structures, the building beauty is affectedand embedded walls in the steel structures are cracked from main bodies easily are solved.

Owner:班来科技(北京)有限公司

Prefabricated highway intercepting ditch and manufacturing method thereof

InactiveCN107869101AEmission reductionReduce on-site wet workPaving gutters/kerbsRoads maintainenceReinforced concreteRebar

The invention discloses a prefabricated highway intercepting ditch and a manufacturing method thereof. To-be-dismantled reinforced concrete members are reused for manufacturing intercepting ditch members. Therefore, discharge of construction waste can be reduced, construction materials are saved, and energy conservation and environment-friendliness are achieved; the fabricated intercepting ditch members are completed in a pre-fabricating factory and then assembled on site, less on-site wet operation is performed, the construction period can be greatly shortened, and the construction cost can be reduced; meanwhile, the intercepting ditch members contain steel bars meeting requirements higher than general structural requirements, so that cracks or fractures in the intercepting ditch due to differential settlement or other reasons can be avoided in the specific use process, and durability is better.

Owner:GUANGZHOU PANYU POLYTECHNIC

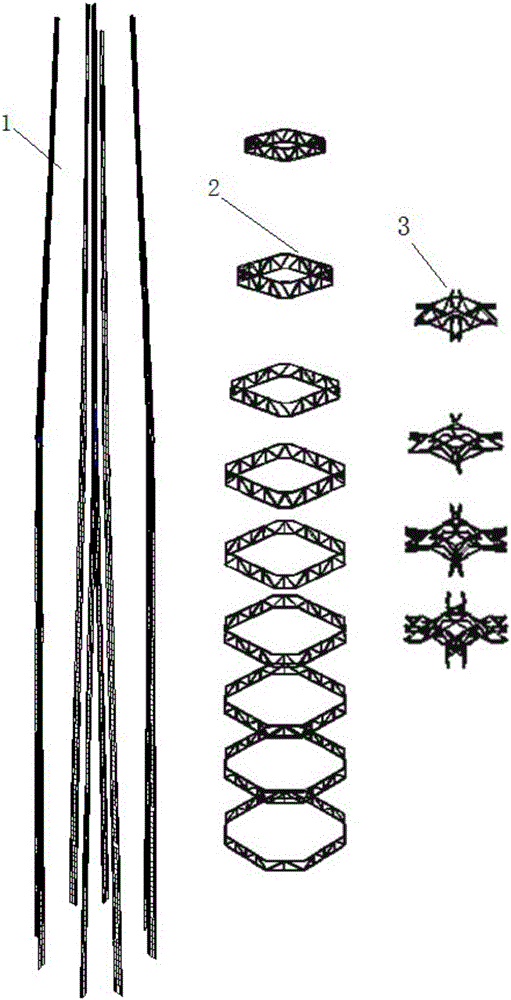

Ultrahigh and huge steel structure vibration attenuation integrated system

InactiveCN106760839ASmall sizeSimple structureProtective buildings/sheltersShock proofingViscous dampingVibration attenuation

The invention relates to an ultrahigh and huge steel structure vibration attenuation integrated system. The ultrahigh and huge steel structure vibration attenuation integrated system is applied to a super high-rise building and comprises ultrahigh and huge steel structure units and vibration attenuation device units arranged on the ultrahigh and huge steel structure units, wherein each ultrahigh and huge steel structure unit consists of a main structure sub-unit and a secondary structure sub-unit arranged on the main structure sub-unit, the main structure sub-unit comprises a huge steel frame and a steel core cylinder arranged in the huge steel frame, the huge steel frame consists of multiple huge columns and annular belt trusses arranged on the huge columns, and each vibration attenuation device unit comprises a viscous damping mechanism and / or tuning vibration attenuation mechanism. Compared with the prior art, the ultrahigh and huge steel structure vibration attenuation integrated system has good structural economy and air vibration comfort level, is high in structural efficiency, strong in structural wind resistance and anti-seismic property, low in structural steel consumption, flexible in building arrangement, high in construction speed, high in in vibration attenuation efficiency and the like.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com