Construction method of post-cast tooth groove connecting assembling type roof

A construction method and prefabricated technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of increasing the size and reinforcement of beams and columns, the impact of seasons and climates, and the impact of the environment, and achieve reliable connection and transmission. Strength, high degree of industrialization, and the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0046] Please refer to the accompanying drawings, a construction method for post-cast tooth groove connection prefabricated roof, the following steps are adopted:

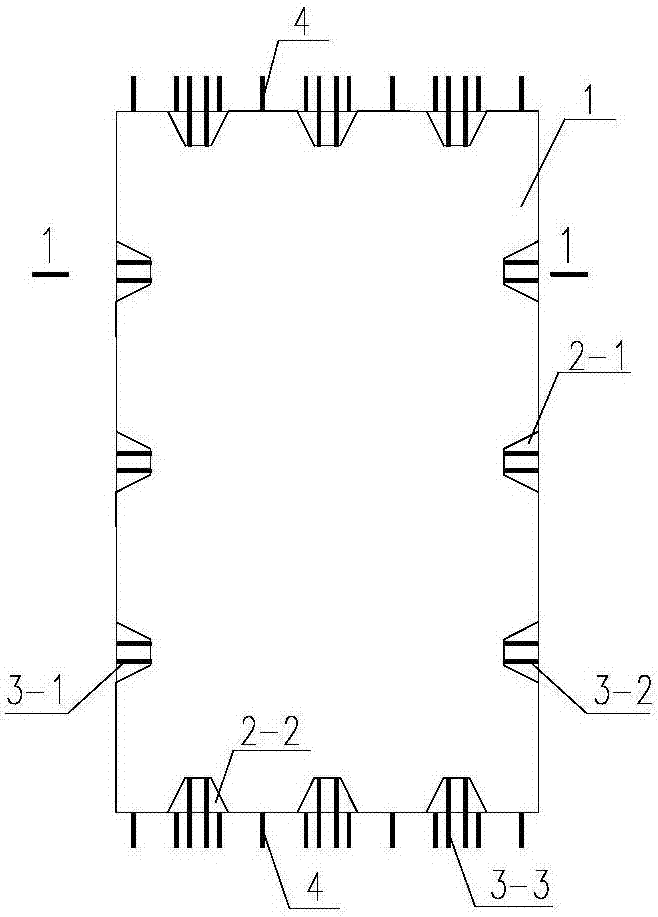

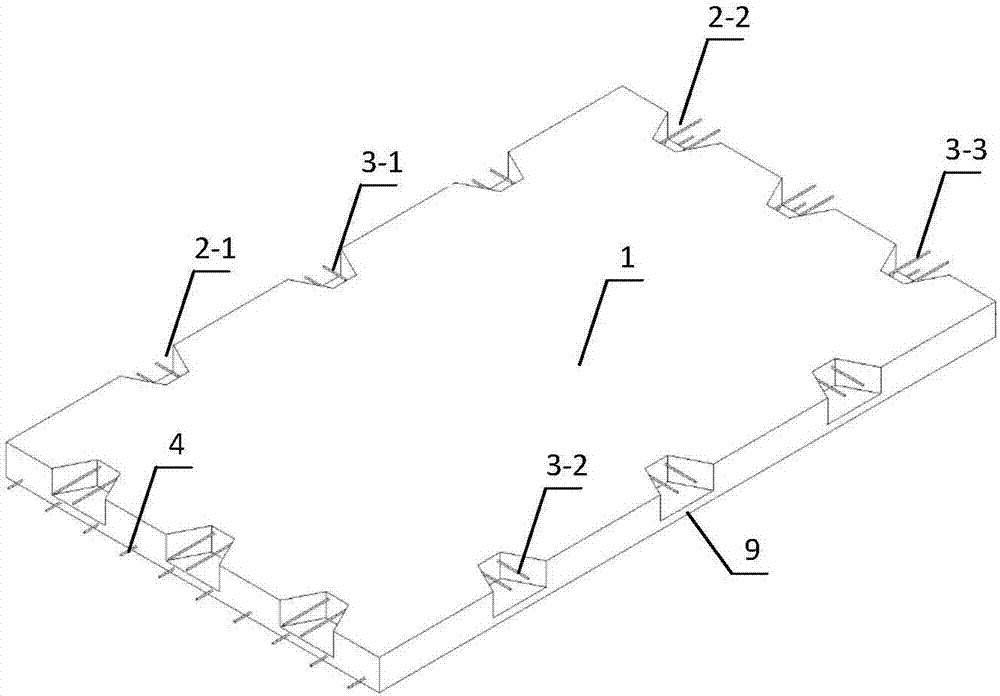

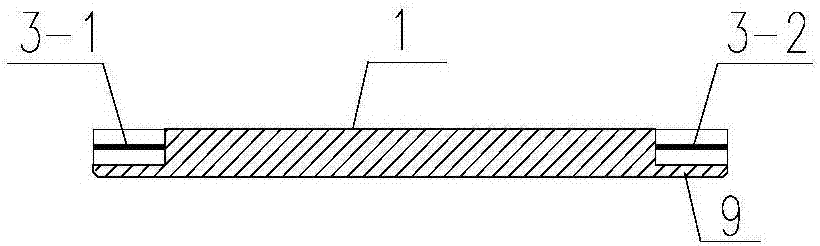

[0047] 1) The precast concrete slab 1 is processed and manufactured in the component processing plant, and the slab end and slab side of the precast concrete slab 1 are provided with tooth grooves, and the slab side tooth groove 2-1 and the slab end tooth groove 2-2 are all provided with The bottom plate 9 is provided with embedded slab side connectors in the slab side alveolar 2-1, and the embedded slab side connectors on the side of the prefabricated concrete slab 1 used to connect with the floor beams are horizontally outstretched Embedded plate side connecting reinforcement I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com