Pre-cast shear wall and production method thereof

A technology of prefabricated shear force and production method, applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve problems such as restricting the development of prefabricated houses, and achieve strong structural strength and shear resistance, tight integration, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

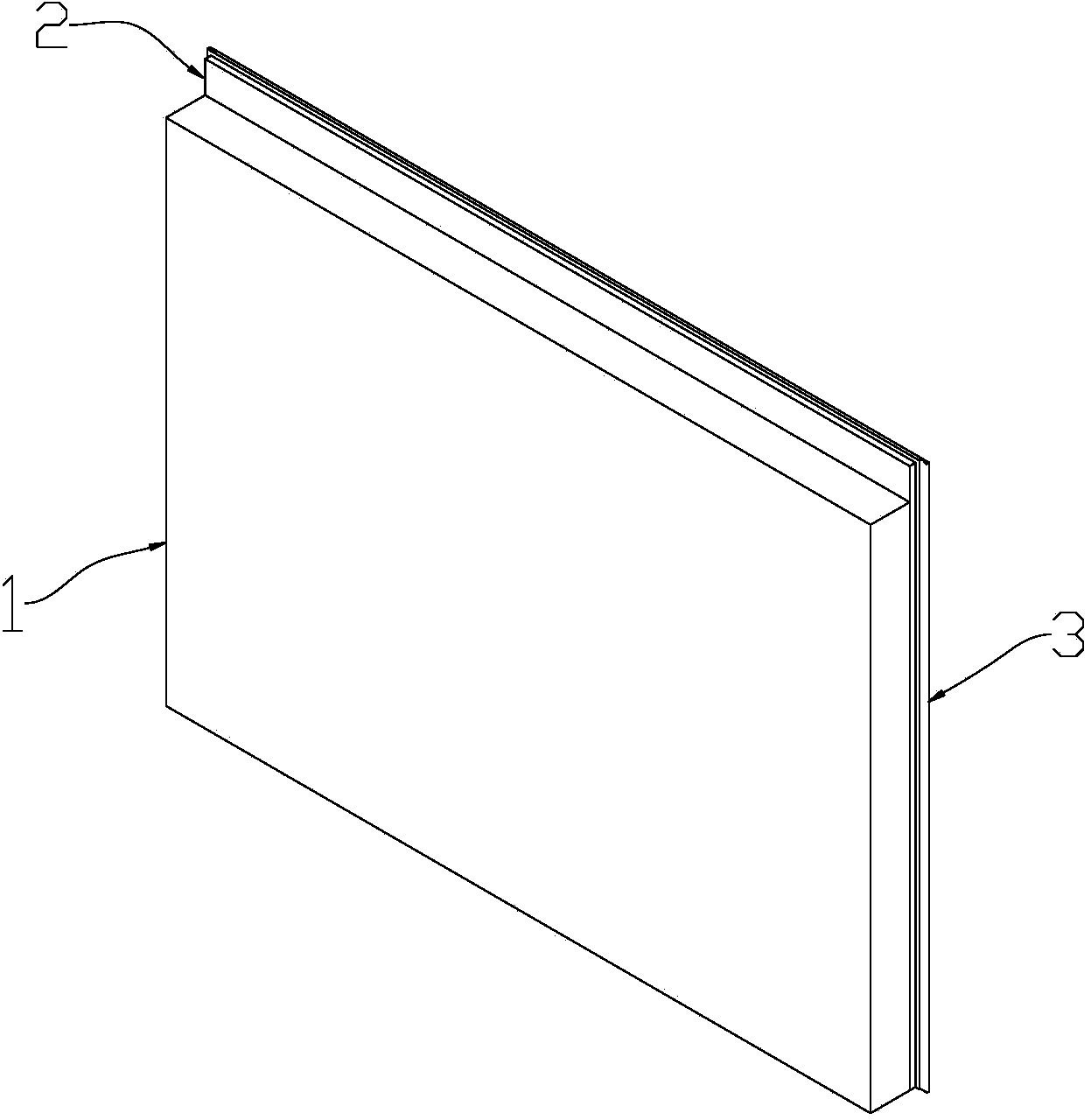

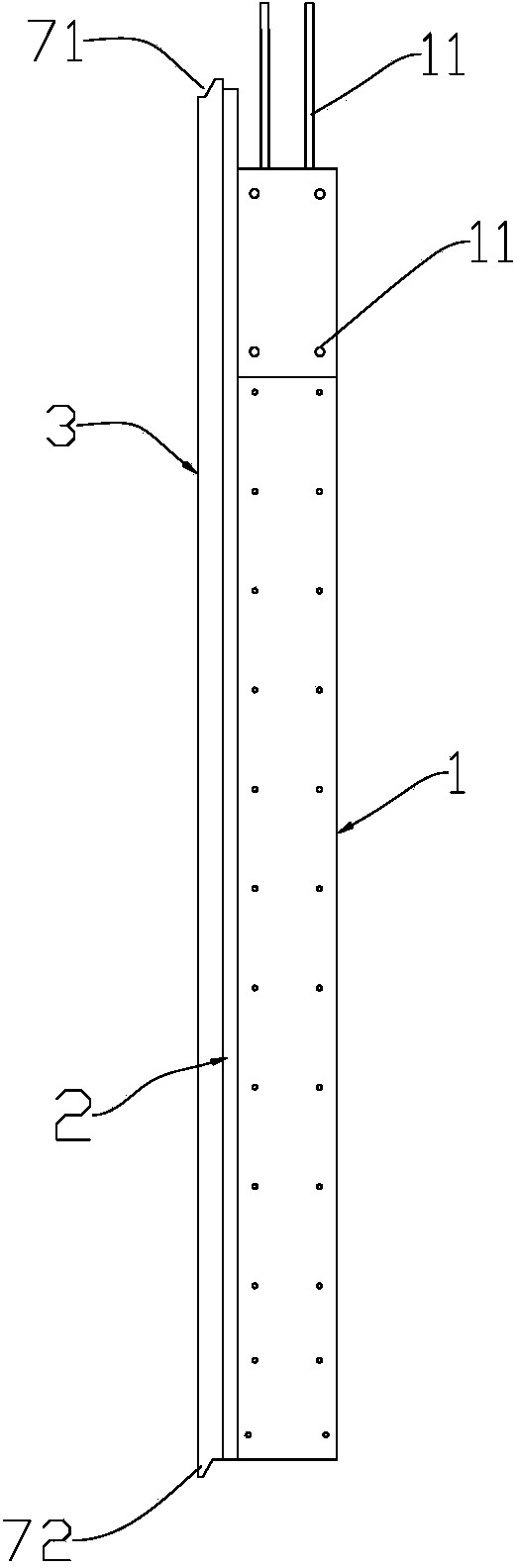

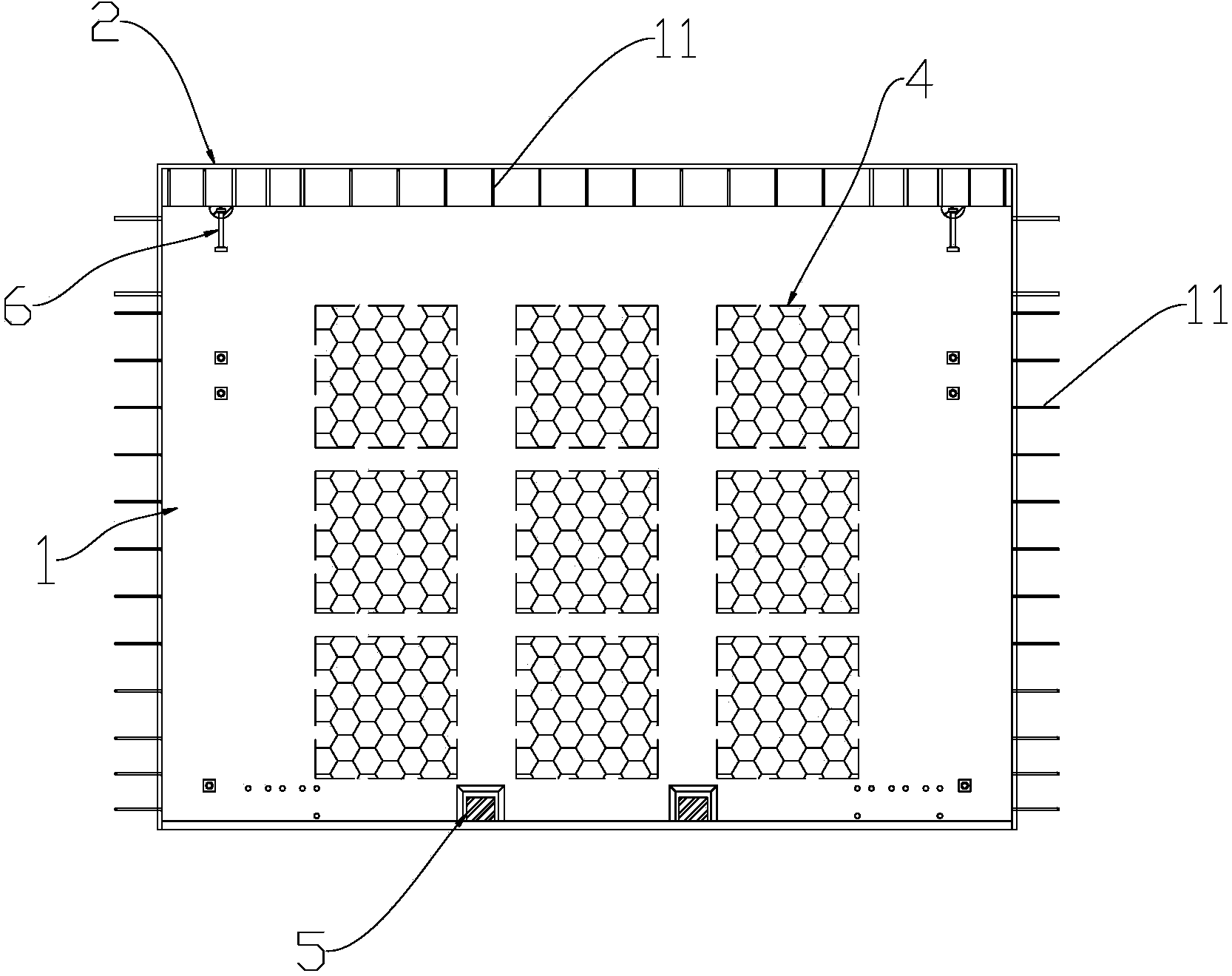

[0032] Such as Figure 1-3 As shown, the prefabricated shear wall according to an embodiment of the present invention includes an inner leaf wall panel 1, a thermal insulation board 2 and an outer leaf wall panel 3 arranged in sequence on the inner leaf wall panel 1, an inner leaf wall panel 1, and a thermal insulation panel 2 Composite with the outer leaf wall board 3 to form an integrated structure, so that the earthquake resistance, structural strength and shear resistance are strong, and it is suitable for low-rise and high-rise buildings.

[0033] In this prefabricated shear wall, the inner leaf wall panel 1 is used as the bottom layer, the outer leaf wall panel 3 is used as the surface layer, and the thermal insulation board 2 is used as the interlayer to play the role of heat preservation. The thickness of the inner leaf wall panel 1 is greater than that of the outer leaf wall panel 3. Plate 2 thickness. The thickness ratio of the inner leaf wall panel 1 and the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com