Cationic degree adjustable dual-function type fine particle used starch flocculant prepared with on-step method and synthesizing method thereof

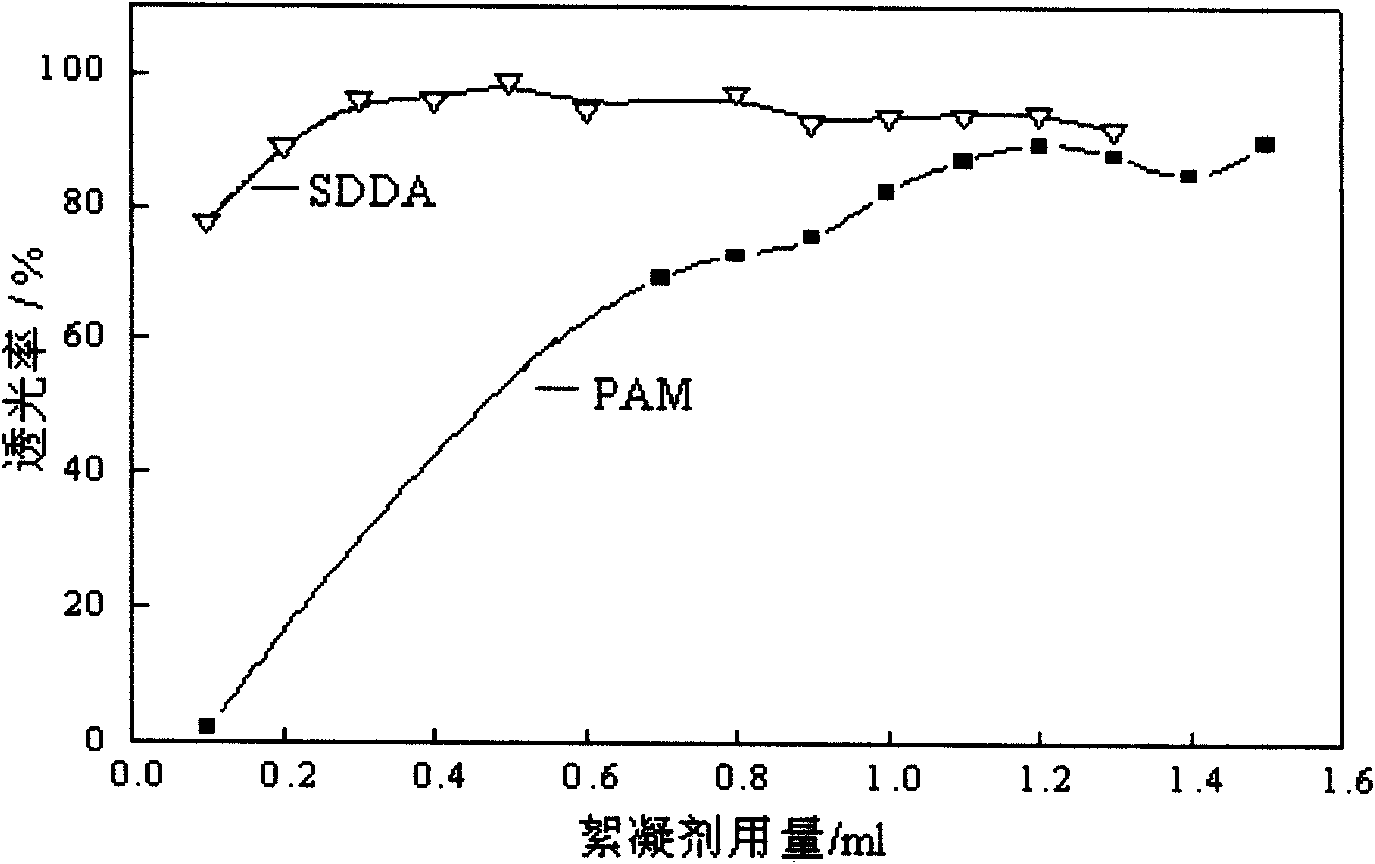

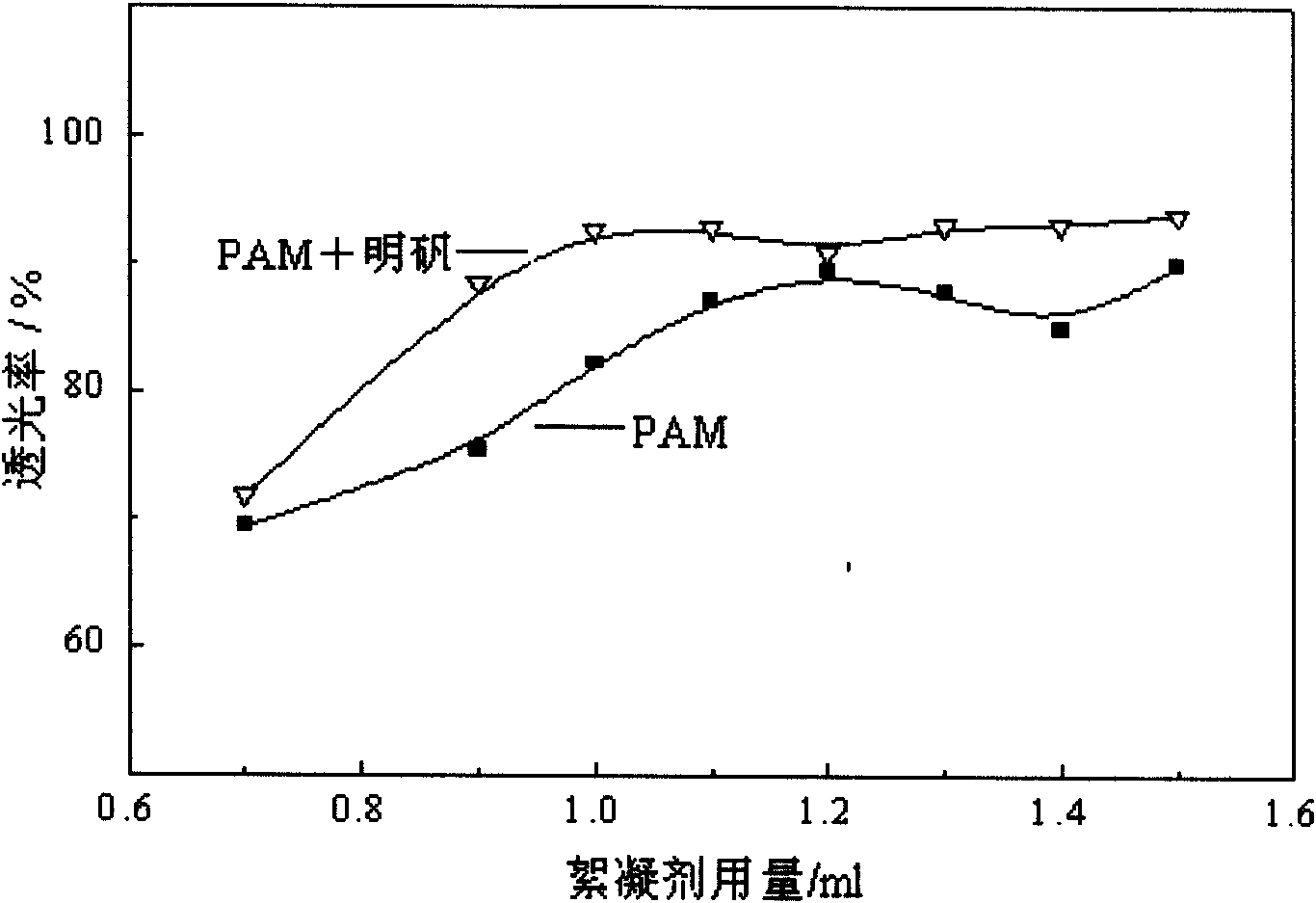

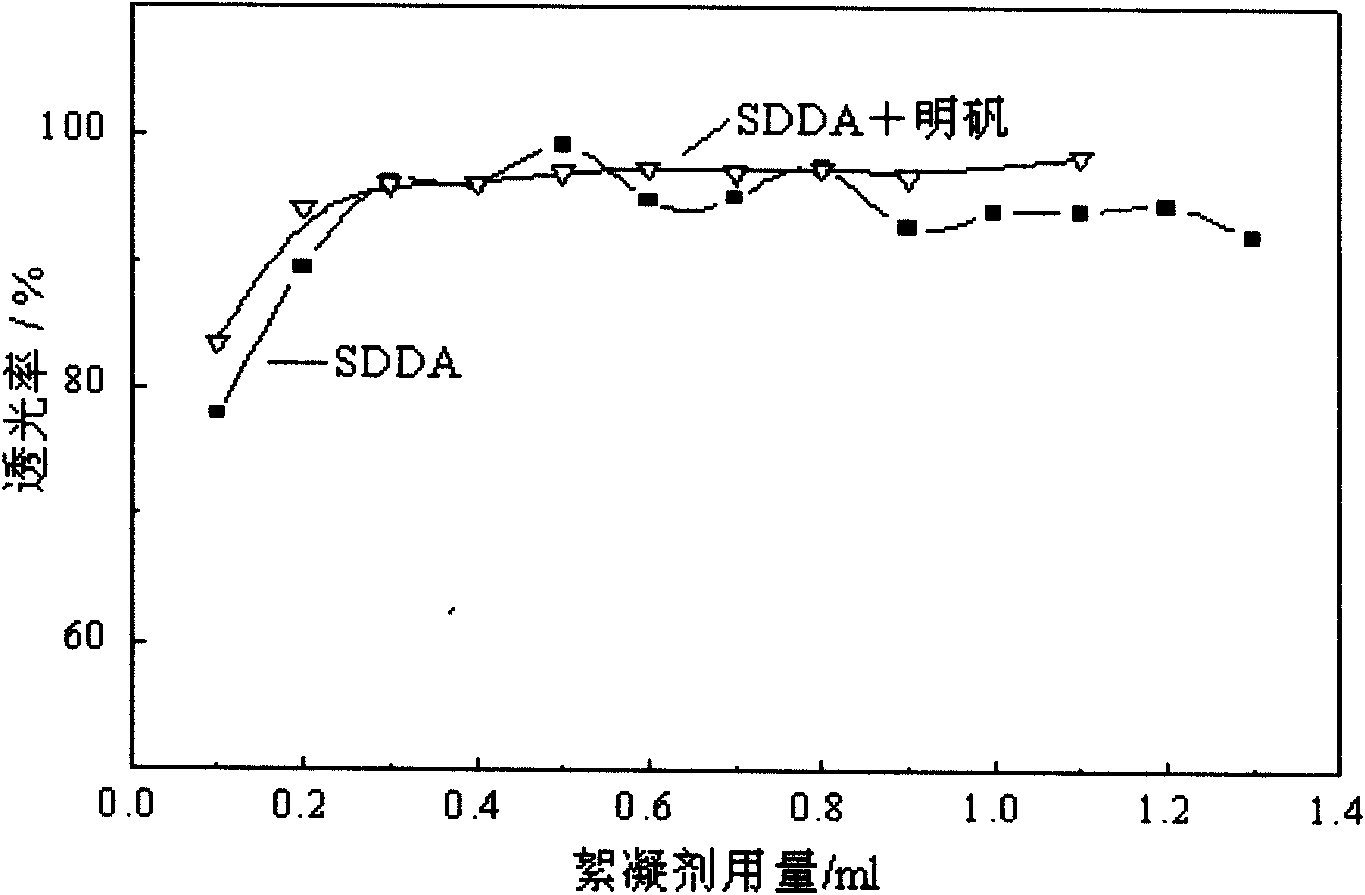

A cationic degree and dual-action technology, applied in flocculation/sedimentation water/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as difficult industrial scale production, slow flocculant initiation speed, harsh reaction conditions, etc. , to achieve the effects of inhibiting the degree of acidolysis, shortening the flocculation and sedimentation time, and shortening the synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Accurately weigh 4.0g of cornstarch (dried at 105°C), dissolve it in 100ml of deionized water, and pour it into a 250ml four-neck bottle (one for agitator, one for a thermometer, one for a nitrogen tube, and one for a condenser). Under nitrogen protection, under the condition of stirring, the water bath was heated to 85°C, kept for 1 hour, and cooled to room temperature after gelatinization. Add 1ml of methacryloyloxyethyltrimethylammonium chloride (80% aqueous solution) and 2ml of dimethyl diallyl ammonium chloride (60% aqueous solution) dropwise into the four-necked bottle respectively, stir well and add propylene Amide 9g, continue stirring with nitrogen gas, dissolve 0.06g of cerium ammonium nitrate in dilute nitric acid solution, add dropwise to the reaction system, adjust the pH of the solution to 5.7, and then keep the temperature for 1 to 3 hours at a reaction temperature of 20 to 35°C. . After the reaction, heat preservation and aging for 2 hours, the product ...

Embodiment 2

[0045] (1) Accurately weigh 16.0g of sweet potato starch (dried at 105°C), dissolve it in 400ml of deionized water, and pour it into a 500ml four-neck bottle (one mouthful for agitator, one mouthful for a thermometer, one mouthful for a nitrogen tube, and one mouthful for a condenser) In the process, under stirring conditions, the water bath was heated to 85°C, kept for 1 hour, cooled to room temperature after gelatinization, and bottled for later use.

[0046] (2) Take 100ml of the gelatinized starch aqueous solution in (1), put it in a 250ml four-necked bottle, stir it to a constant temperature at a temperature of 20-35°C, and blow nitrogen to drive oxygen for 10 minutes, and then pour it into the four-necked bottle respectively Add 1.5ml of methacryloyloxyethyltrimethylammonium chloride (80% aqueous solution) and 2ml of dimethyl diallyl ammonium chloride (60% aqueous solution) dropwise, stir evenly, add 8g of acrylamide, and continue to pass Stir with nitrogen, dissolve 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com