Ecological treatment method of organic solid waste and obtained organic material

A technology for ecological treatment and organic solid waste, which is applied to the treatment of bio-organic parts, organic fertilizers, and invertebrates. It can solve the problems of large one-time investment, lower furnace temperature, and high operating costs, and achieve investment and operation. The effect of low cost, reduced shock and accelerated growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

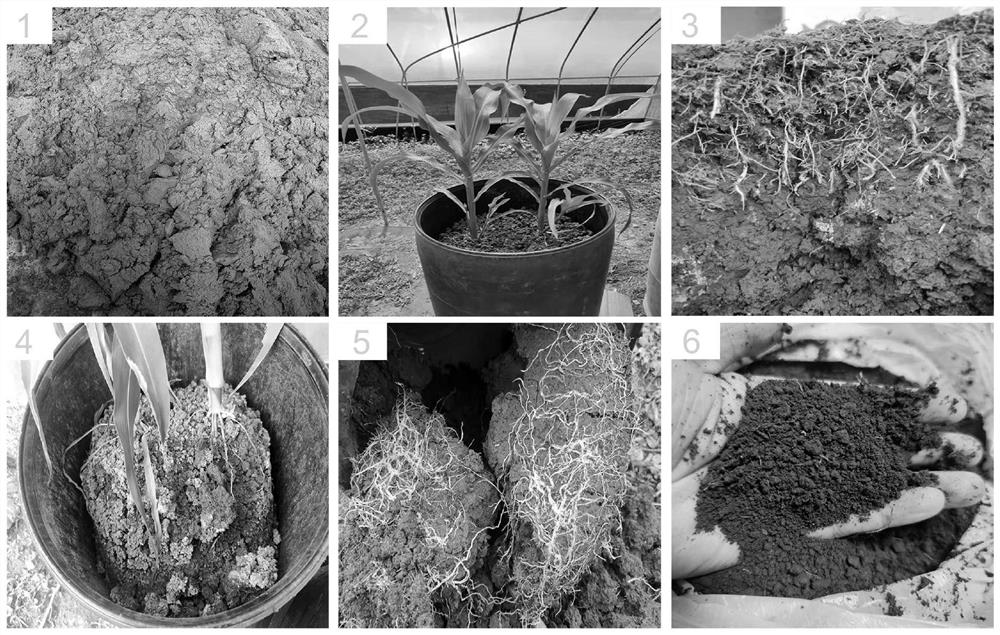

[0036] The present invention also provides a method for preparing the above-mentioned organic material, which includes the following steps: after the plant is harvested and the straw is removed, the remaining material is pulverized to obtain the organic material.

[0037] In the present invention, the plant is preferably a fibrous root system. The fibrous root is slender and fragile, which does not affect the subsequent processing and utilization of the treated product; and when the average humidity of the material is gradually reduced to about 45%, the material will gradually reduce the effect on earthworms. Water and nutrient supply, most earthworms will gradually die and be decomposed by microorganisms in the final stage of treatment, so there is no need to treat earthworms.

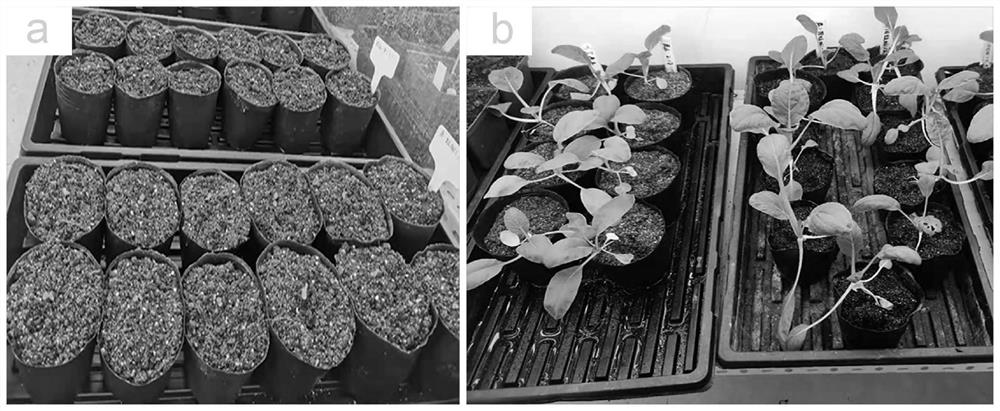

[0038] The present invention also provides the application of the above-mentioned organic material as a seedling substrate.

[0039] The organic material of the present invention can also be used as a...

Embodiment 1

[0042] Time: From August 27, 2021 to November 8, 2021.

[0043] Location: Xiantao City, Hubei Province

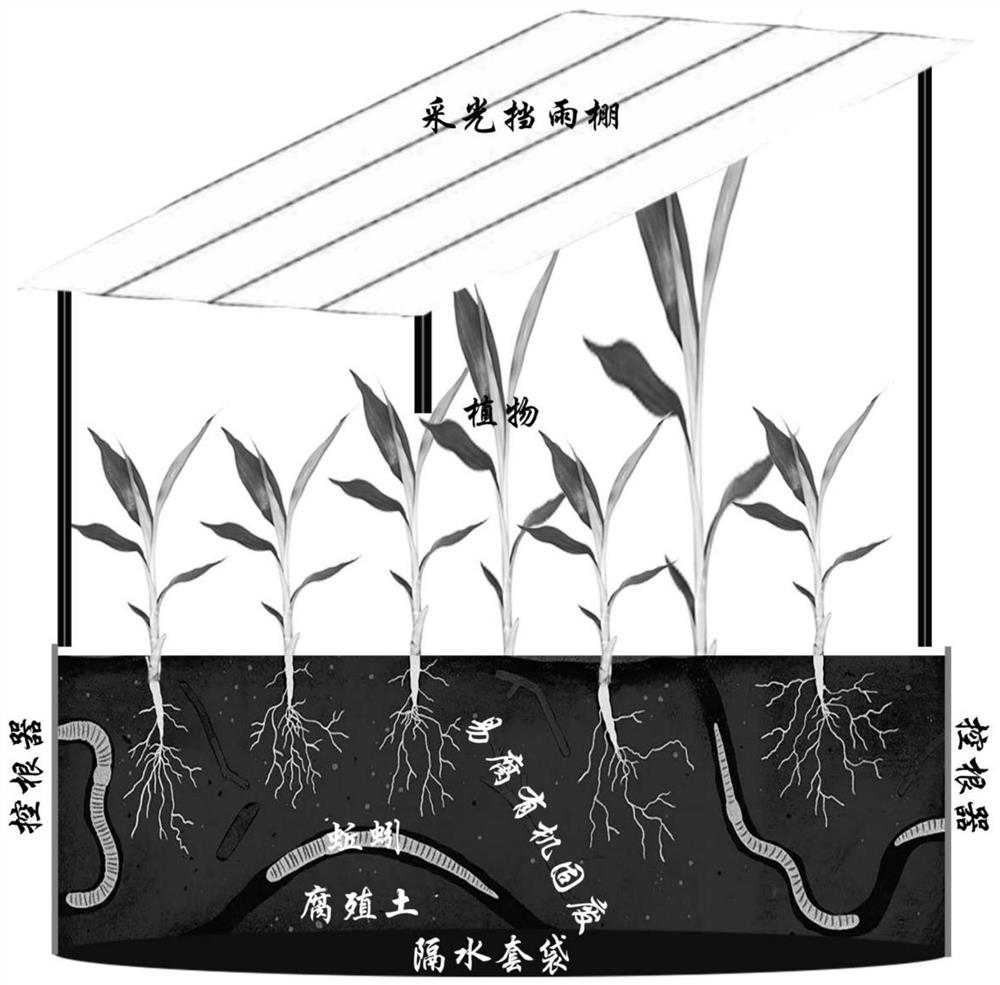

[0044] Disposed organic solid waste: 5 tons of dehydrated activated sludge from Xiantao Chengxi Sewage Treatment Plant, humidity 78% according to figure 1 to operate in the mode shown:

[0045] 1. Tightly wrap the water-proof sleeve on the bottom of the root controller and fix it. The water-proof bag is made of rain-proof plastic cloth, and the root controller adopts a conventional gardening root controller with a width of 1m to form a cylinder with a diameter of 1m.

[0046] 2. Use earthworm soil with a humidity of about 45% and domestic sludge with a humidity of 78% to adjust the humidity and structure. The earthworm adaptability test was carried out on the mixture. When the volume ratio of earthworm soil to sludge was 1:3, earthworms could enter quickly and not come back. The mixture humidity was about 73% at this point.

[0047] 3. Put the adjusted earthworm soil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com