Patents

Literature

76 results about "Petrifaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geology, petrifaction or petrification is the process by which organic material becomes a fossil through the replacement of the original material and the filling of the original pore spaces with minerals. Petrified wood typifies this process, but all organisms, from bacteria to vertebrates, can become petrified (although harder, more durable matter such as bone, beaks, and shells survive the process better than softer remains such as muscle tissue, feathers, or skin). Petrifaction takes place through a combination of two similar processes: permineralization and replacement. These processes create replicas of the original specimen that are similar down to the microscopic level.

Tung-oil-based polyurethane resin and preparation method thereof

InactiveCN103030777AHigh hardnessImprove water resistanceOrganic compound preparationCarboxylic acid esters preparationPetrifactionAlcohol

The invention discloses tung-oil-based polyurethane resin and a preparation method thereof. The preparation method comprises the following steps: (1) methyl esterification of tung oil; (2) acid anhydridization of methyl eleostearate; (3) preparation of tung-oil-based polyhydric alcohol, i.e. performing the reaction on tung maleic anhydride and polyhydric alcohol under the action of catalysis of an acid catalyst so as to obtain the tung-oil-based polyhydric alcohol; and (4) preparation of the tung-oil-based polyurethane resin, i.e. performing the reaction on a second type of organic solvent, the tung-oil-based polyhydric alcohol, universal polyhydric alcohol, polyisocyanate and a catalyst to obtain the tung-oil-based polyurethane resin. According to the invention, a route of replacing a petrifaction raw material with a natural renewable raw material has important environmental significance; and moreover, when polyurethane prepared or modified by adopting the tung oil is used as a coating, hardness of a paint film, waterproofness and the like are all improved. According to the invention, in the esterification process, technology is simple and yield is high; subsequent reaction has a simple process; reaction conditions are mild; controllability is strong; and prepared polyurethane can be used for paints, coatings, adhesives and other related fields.

Owner:TIANJIN UNIV

Fluorinated polyurethane thickener applied to supercritical CO2 tackification and preparation method thereof

ActiveCN105294948AGood miscibilityIncrease the degree of cross-linkingDrilling compositionBulk chemical productionPetrifactionPolyethylene glycol

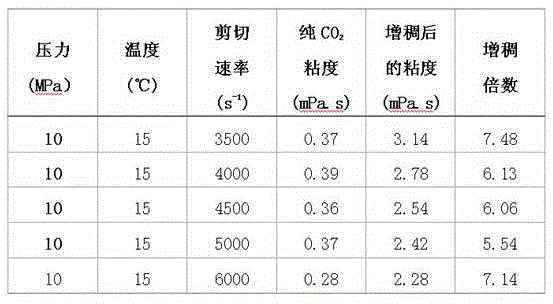

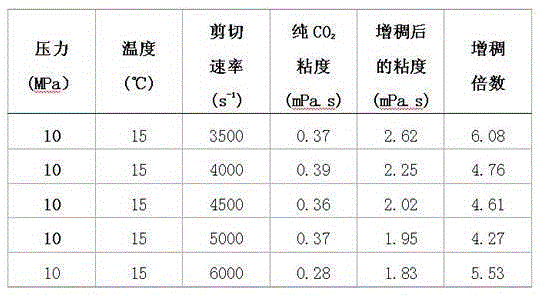

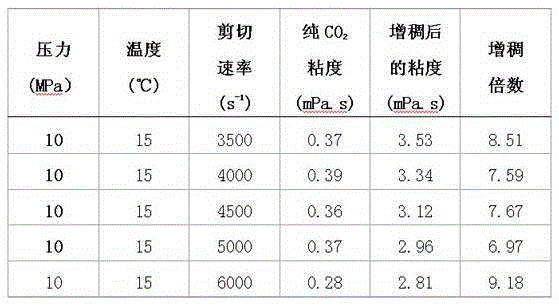

The invention discloses a fluorinated polyurethane thickener applied to supercritical CO2 tackification and a preparation method thereof, belongs to the field of petrifaction, and in particular relates to a thickener for supercritical CO2 dry-method fracturing and a preparation method thereof. The invention aims to provide the thickener special for supercritical CO2 dry-method fracturing and the preparation method thereof, wherein the thickener has good tackifying performance, can be easily dissolved in CO2 fluid, and has a stable system. The thickener is prepared from the following components in parts by fraction: 10 to 15 percent of diisocyanate, 5 to 8 percent of polyethylene glycol, 5 to 8 percent of trimethylolpropane, 1 to 2 percent of catalyst, 1 to 2 percent of initiator, 3 to 5 percent of sorbitan polyoxyethylene ether, 3 to 5 percent of perfluor octyl ethylene, 3 to 5 percent of dodecafluoroheptyl acrylate, and the balance of castor oil. The thickener has good tackifying performance, can be easily dissolved in the CO2 fluid, and has the stable system.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Fuel oil based on petrifaction diesel and coarse biodiesel and preparation thereof

InactiveCN101475855AImprove stabilityMake up for the shortcomings of low calorific value and poor low temperature resistanceLiquid carbonaceous fuelsPetrifactionBiodiesel

The invention provides fuel oil based on petroleum diesel oil and crude biodiesel, which consists of the following substances in percentage by weight: 20 to 50 percent of crude biodiesel, 30 to 60 percent of petroleum diesel oil, 4 to 35 percent of composite emulsifying agent, and the balance being methanol or water or a mixture of the methanol and the water. The substances are mixed according to the mass percentage of the mixture and are stirred evenly to be prepared into a transparent solution. The fuel oil has good stability and has no layering, no color change and no turbidity for a long time. The fuel oil can save the petroleum diesel oil and biodiesel which are equivalent to the adding amount of the water and the methanol, and remarkably reduces the discharge amount of harmful substances in exhausted gas; at the same time, the untreated crude biodiesel is used, so equipment and energy sources which need to be consumed during the refining of the biodiesel are also saved, thereby achieving the aims of saving energy, reducing emission, and reducing production cost, and ensuring that the process is more economical.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for producing succinic acid by fermenting straw raw material

InactiveCN101215582AMitigate utilization issuesInsufficient reliefBacteriaMicroorganism based processesChemical synthesisSuccinic acid

A method for using straw raw materials to ferment and produce succinic acid belongs to the technical field of biological engineering. The invention takes straws as raw materials and obtains hydrolysis straw syrup of hexose and pentose through hydrolysis treatment, and then succinic acid actinobacillus CGMCC 1593 is used to ferment and produce the succinic acid in culture medium of the hydrolysis straw syrup which contains reducing sugar. The microorganism CGMCC 1593 of the invention which is obtained through screening from paunches is fed-batched and anaerobically fermentted for 48 hours in a 5L-25L fermenter under the anaerobical circumstance whose pH is kept within 5.5-7.5. The concentration of total reducing sugar which is invested is 68.6-70.9g / L, the concentration of the succinic acid which is produced is 49.5-52.1g / L, the yield of the succinic acid to consumption suger is 80.0%-81.2%( the availability ratio of the sugar is 87.3-93.6%), and the production intensity is 1.03-1.09g / (L h). The invention has the prominent advantages that the raw materials of agricultural wastes straws are utilized to ferment and produce the succinic acid, the method is a producing method which uses renewable raw materials and is environmental friendly, and the problem of petrifaction resources tension of chemosynthesis succinic acid can be alleviated.

Owner:JIANGNAN UNIV

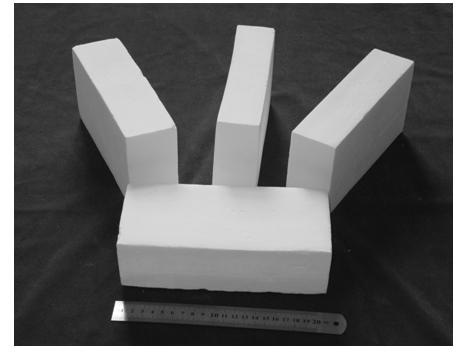

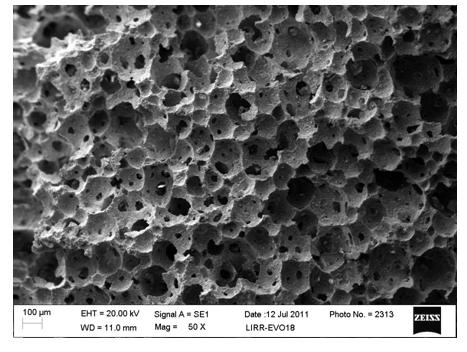

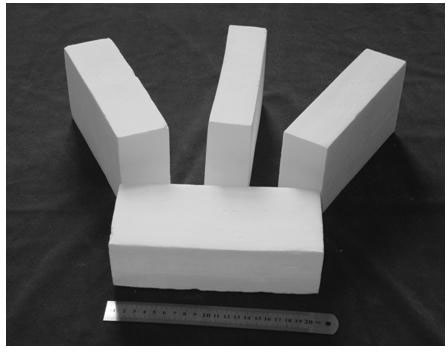

Method for manufacturing light magnesia-alumina spinel insulation materials

The invention belongs to the technical field of insulation material manufacturing, in particular to a method for manufacturing light magnesia-alumina spinel insulation materials. The method includes the following steps: pouring magnesite powder or magnesia powder, alumina powder, water, foaming agents, monomers and cross linking agents successively into a stirring cylinder, and obtaining a foam slurry through mechanical stirring; adding initiating agents and catalytic agents into the foam slurry successively, and pouring the mixture into a mold rapidly; demoulding to obtain green bodies after slurry gel is solidified, and obtaining light magnesia-alumina spinel insulation materials though drying and sintering. The method has the advantages that magnesite or magnesia powder prepared by calcining magnesite which is abundant in our country is used as main materials, cracking problems caused by uneven sintering shrinkage are solved through cubical expansion during spinel petrifaction process, magnesia-alumina spinel insulation products with fixed forms, different shapes and sizes, low density and thermal conductivity and high strength are manufactured, the process is simple, the cost of used materials is low, and insulation materials are suitable for industrialized manufacture.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

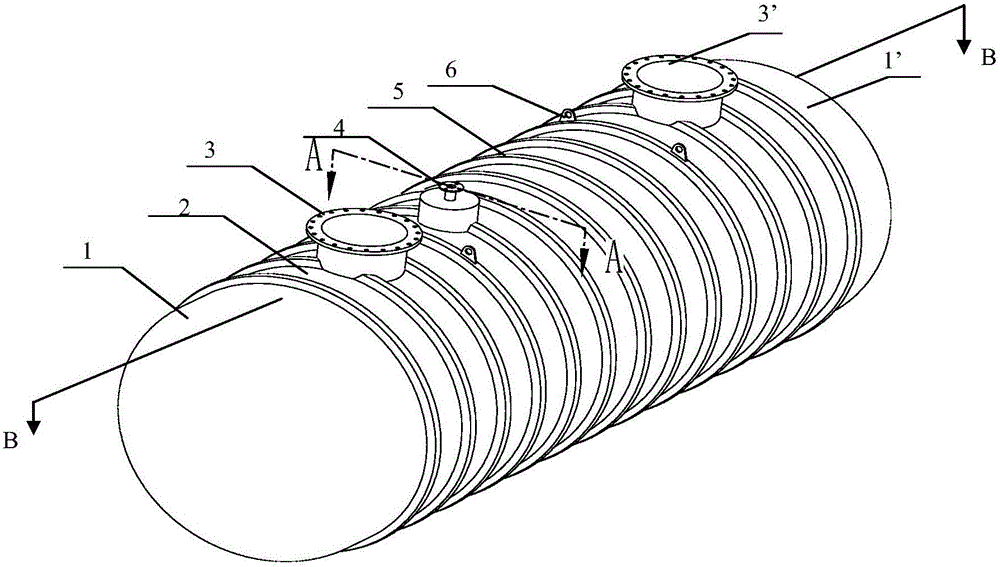

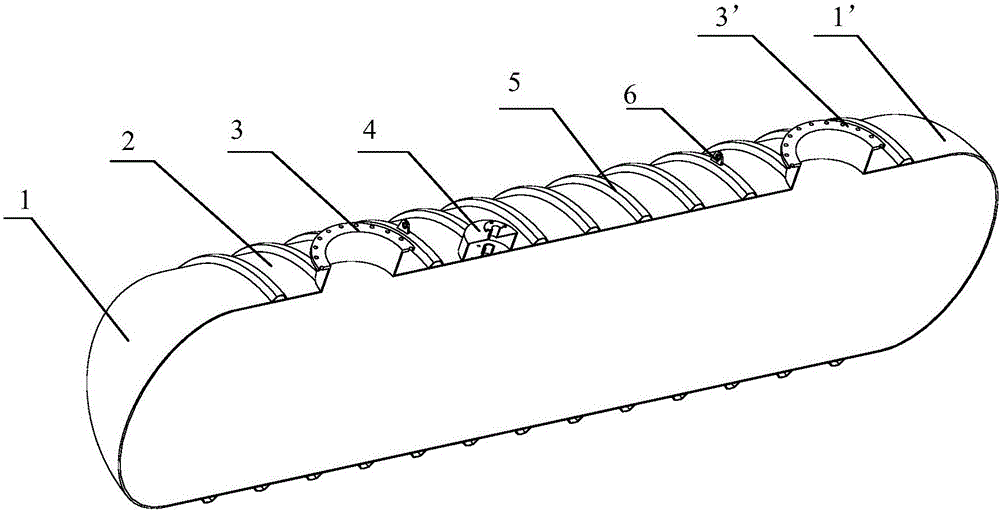

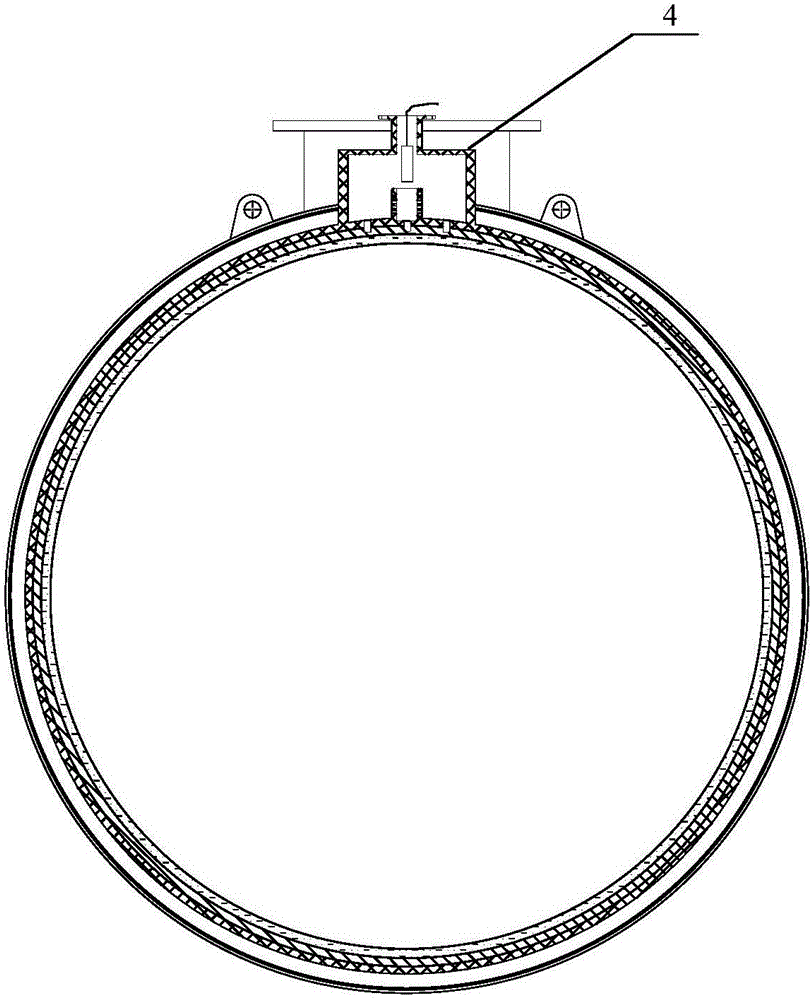

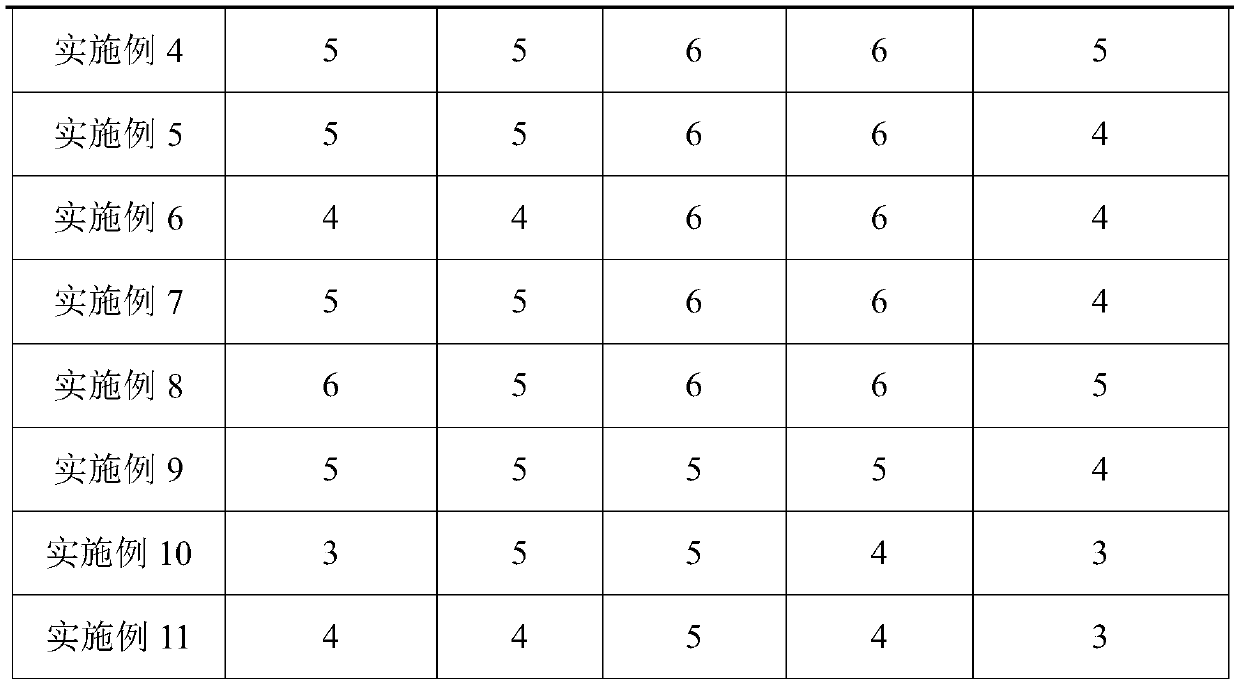

Double-wall oil storage tank made of fiber reinforced composite material and manufacturing method of double-wall oil storage tank

ActiveCN105905456AImprove securityFully exploit the carrying potentialLarge containersPetrifactionButt joint

The invention discloses a double-wall oil storage tank made of a fiber reinforced composite material and a manufacturing method of the double-wall oil storage tank and belongs to the field of petrifaction storage equipment. The oil storage tank comprises a cylindrical tank body and end sockets, wherein the cylindrical tank body and the end sockets are each formed by an inner wall and an outer wall in a combined mode. Hollow layers are arranged between the inner wall and the outer wall of the cylindrical tank body and between the inner wall and the outer wall of each end socket correspondingly, and the hollow layers are made in the mode that 3D hollow fabrics are soaked with heat convertible resin and then cured and formed. The inner wall and the outer wall of the cylindrical tank body are made of the continuous fiber reinforced composite material. The manufacturing method comprises the steps that two semi-cylindrical tank body inner walls are formed through a prefabricated mold, wherein one end of each semi-cylindrical tank body inner wall is provided with the corresponding end socket; after demolding, the two semi-cylindrical tank bodies are in butt joint so as to form the inner wall of the cylindrical tank body with the sealed end sockets; then the hollow layer and the outer wall of the tank body are machined; and finally reinforcing ribs and accessories are installed. According to the double-wall oil storage tank, the cylinder wall structure and the end sockets at the two ends are formed correspondingly, a bearing structure is made of the continuous fiber composite material, and an auxiliary bearing structure part is made of non-continuous fiber; and the double-wall oil storage tank is reasonable in structure, light in weight, long in service life, resistant to corrosion, good in seepage resistance, free of maintenance, high in bearing capacity and easy to implement.

Owner:北京康姆特科技发展有限公司

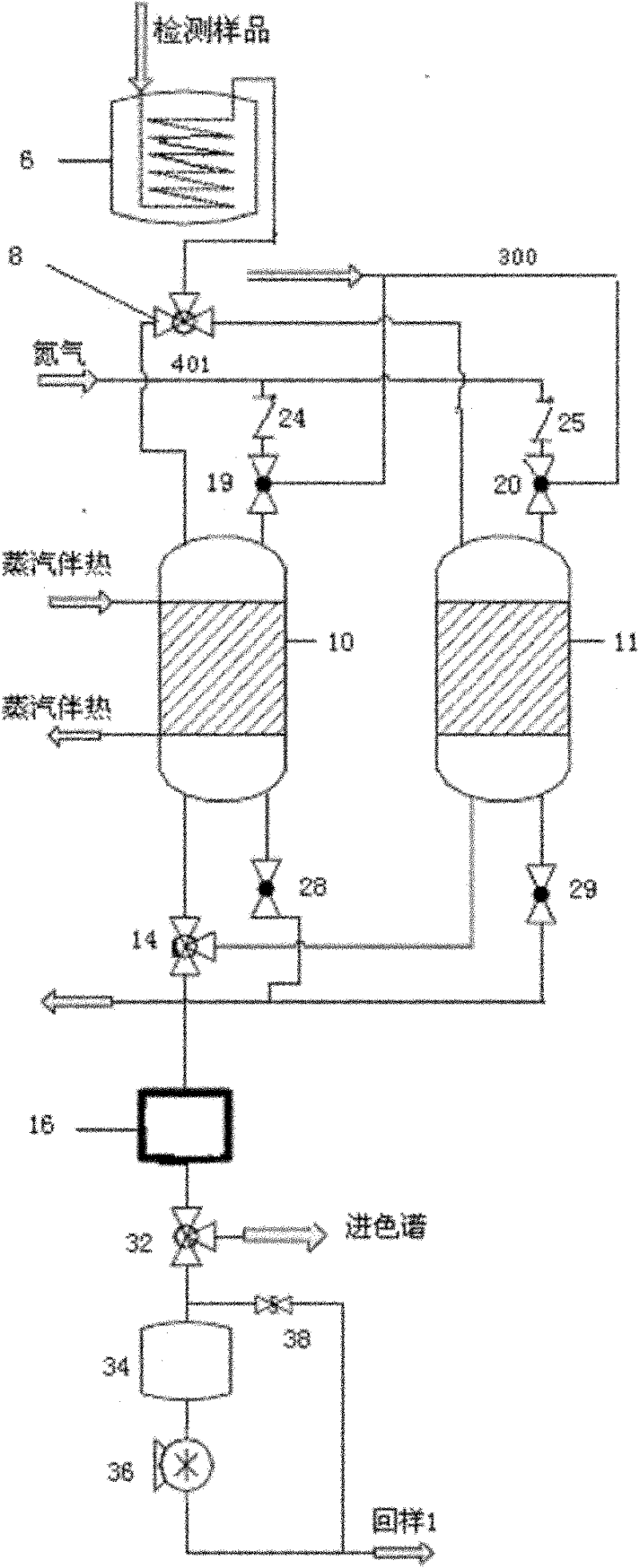

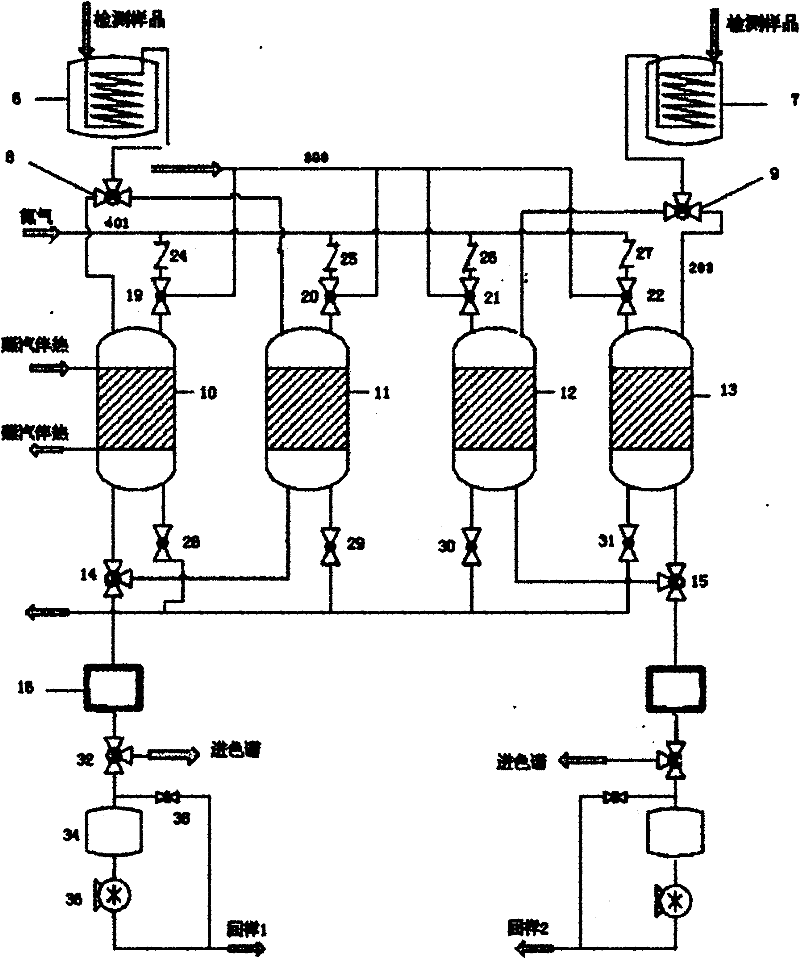

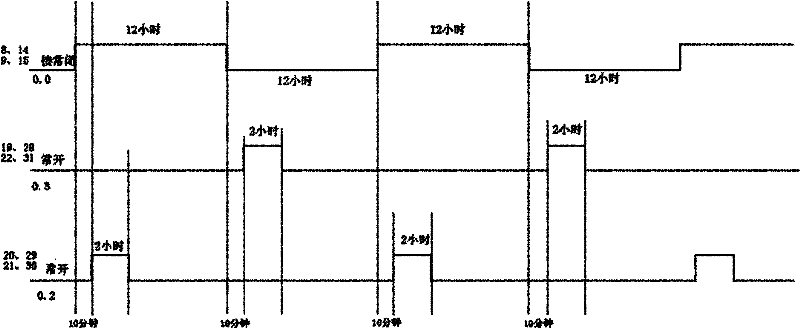

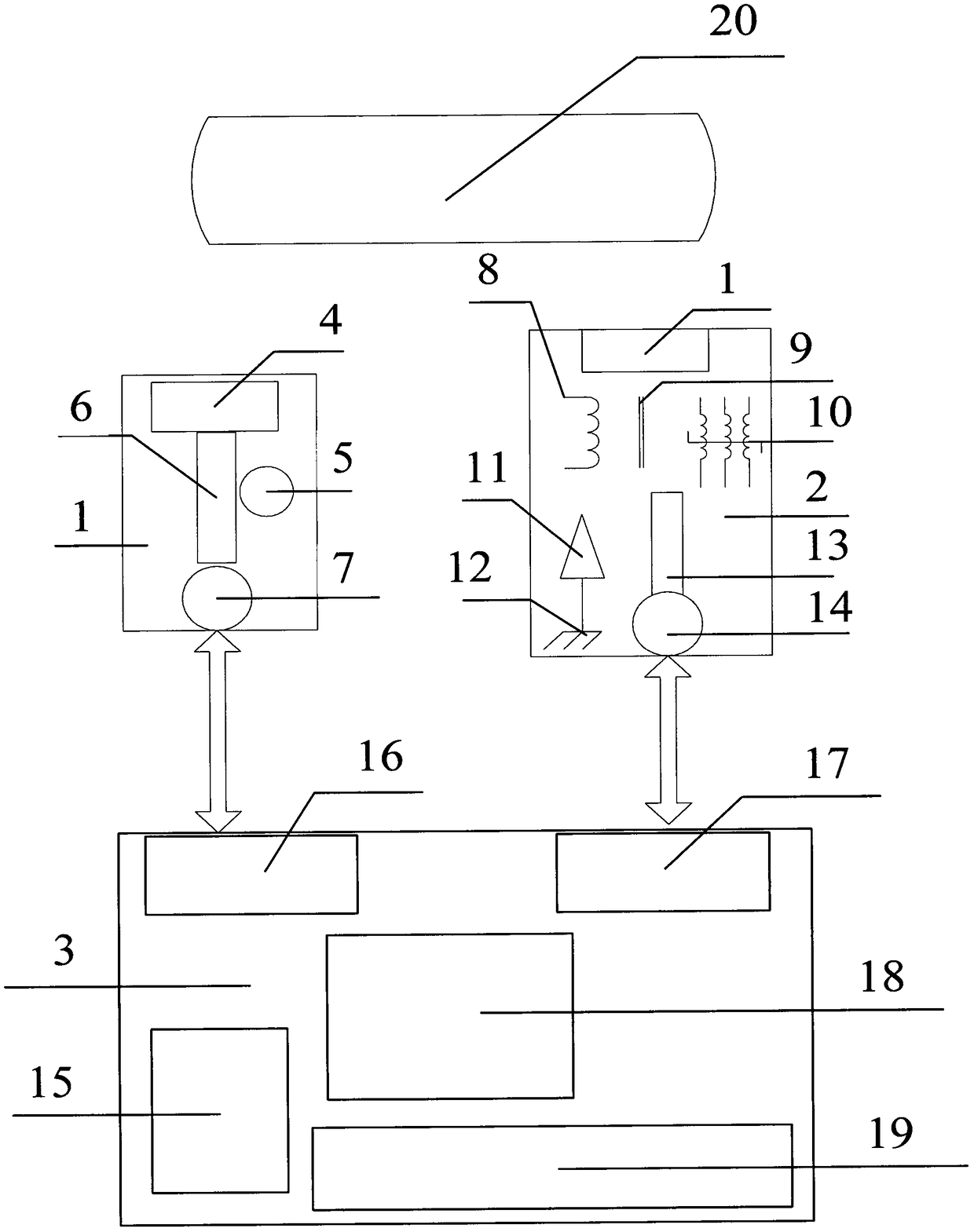

Device and system for preprocessing on-line raman spectrometer as well as preprocessing method thereof

InactiveCN102175504ADoes not affect detection workEasy to implementPreparing sample for investigationRaman scatteringSteelmakingPetrifaction

The invention relates to a device and system for preprocessing an on-line raman spectrometer as well as preprocessing method thereof. The method comprises the following steps: preprocessing a detected sample before detecting the sample of a PX (p-Xylene) device by using the raman spectrometer; and then absorbing and removing the impurities of the detected sample by using adsorption treatment reaction jars, wherein at least two adsorption treatment reaction jars are used for performing the absorption and blowing treatment in turn, so that the whole preprocessing process is free from being influenced by the absorption saturation degree of the adsorption treatment reaction jars and can be continuously performed. The method provided by the invention has the advantages of high recovery, low cost, less investment, no pollution, and the like. The processes of on-site sample collecting, cooling treatment, unsaturated hydrocarbon removing and counter sample treatment are taken into account. The device, system and method provided by the invention can be applied to different fields of petrifaction, metallurgy, mining electric power, steelmaking, and the like, and have the advantages of strong adaptability to user requirements, obvious effect and excellent stability.

Owner:NANJING UNIV OF TECH

Environment-friendly methanol diesel oil

The invention discloses an environmental protection carbinol diesel, which comprises the following parts: 40-90 percent modified biological diesel, 10-60 percent carbinol and 0-30 percent petrifaction diesel. These materials are blended together to stir evenly under normal temperature and normal pressure, which can produce the product. The invention avoids the dependence of oil diesel, which possesses polybasic energy source developing paths.

Owner:TAIYUAN UNIV OF TECH

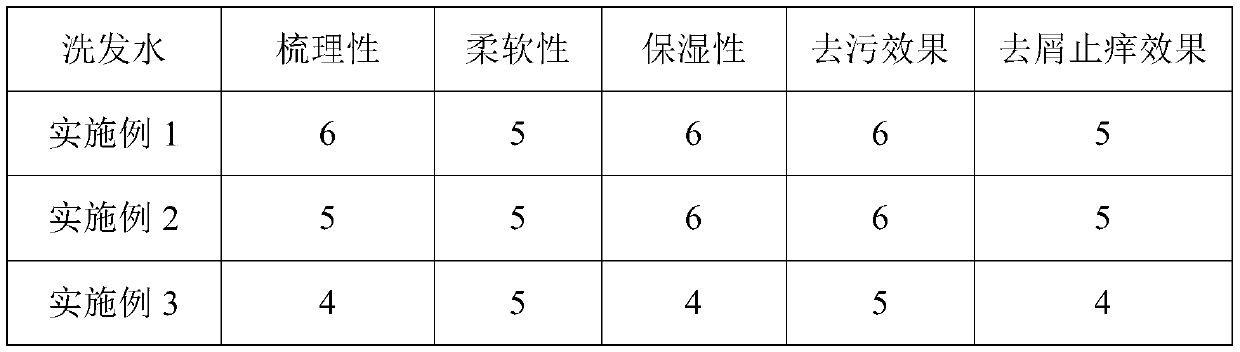

Silicone-oil-free amino acid nourishing and smoothening shampoo and preparation method thereof

The invention discloses silicone-oil-free amino acid nourishing and smoothening shampoo and a preparation method thereof. All the components of the silicone-oil-free amino acid nourishing and smoothening shampoo are matched reasonably and scientifically, petrifaction surfactants which have large irritation and commonly used in shampoo on the market are abandoned, an amino acid surfactant is used as a bubbling cleaning agent, irritation of the surfactant to scalp can be reduced, meanwhile, hydrolyzed wheat protein and shea butter are used to nourish and care scalp, hydrogenated jojoba oil is used as a hair conditioner to replace silicone oil, so that the hair has sense of softness and combing and washing smoothness, sodium hyaluronate and panthenol have a moisturizing function and make hairhave smooth combing and washing sense, all the components cooperate, and the shampoo can help hair to grow and care hair by long-term use.

Owner:森锐健康科技(广州)有限公司

Clean production process for using waste paper boxes to produce corrugating medium paper

ActiveCN107905018AHigh strengthImprove toughnessPaper recyclingPulp beating/refining methodsFiberPetrifaction

The invention discloses a clean production process for using waste paper boxes to produce corrugating medium paper. The process mainly comprises the steps of leather fiber sizing agent preparation, waste paper pulping, screening and purifying, blending of petrifaction addition agents, blending in a pipe, petrifaction, fibrillation, pulp preparation and net erection and shaping. By utilizing the waste paper boxes to produce the corrugating medium paper, the interweaving force and bonding force among fibers in recycled paper during paper manufacturing are enhanced, the strength and tenacity of the produced corrugating medium paper are better, the production resource is saved, the production process is clean and free of pollution, energy is saved, the environment is protected, and the production cost is low.

Owner:东莞顺裕纸业有限公司

Recovery processing method of waste alkaline liquor in ethylene plant

ActiveCN102452673AEmission reductionImprove product qualityAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentChemical industryPetrifaction

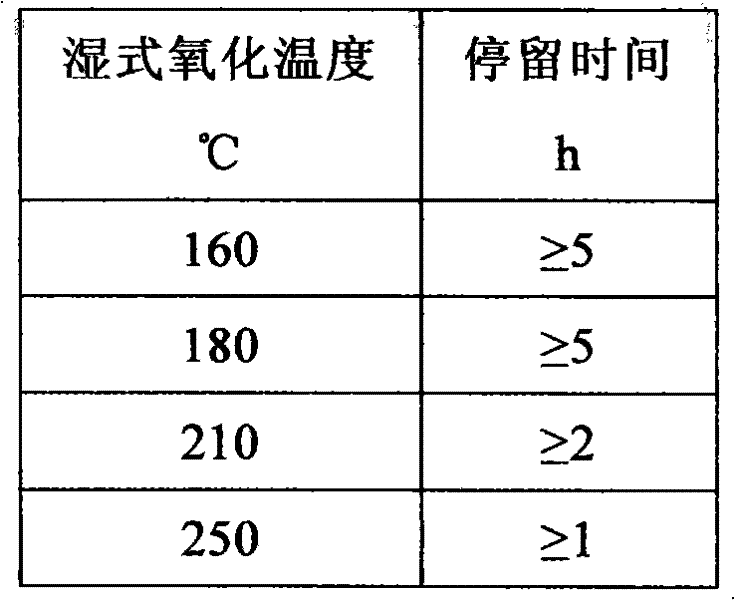

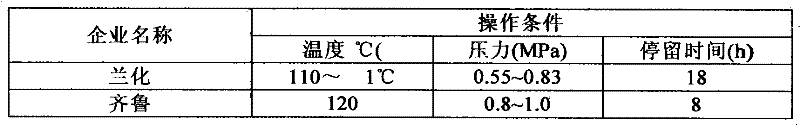

The invention provides a recovery processing method of waste alkaline liquor in an ethylene plant. The method comprises the following steps: (1) under the condition of wet oxidation, carrying out wet oxidation on waste alkaline liquor with air or oxygen so as to obtain oxidized liquid; (2) neutralizing the oxidized liquid so as to obtain a neutralized liquid; (3) crystallizing the neutralized liquid by adopting an evaporation and crystallization method so as to obtain anhydrous sodium sulfate containing entrained water; (4) returning a part of evaporation mother liquid back to a neutralization unit, and carrying out non-biochemical treatment on another part of evaporation mother liquid; and (5) drying the anhydrous sodium sulfate containing entrained water so as to obtain the anhydrous sodium sulfate product. By using the method, the technical problem that high-content salt still generates impact on a biochemical treatment system after the ethylene waste alkaline liquor is deodorized and diluted through wet oxidation and then is subjected to biochemical treatment can be solved; and the method provided by the invention can be used for the fields of petrifaction, chemical industry, environmental conservation, comprehensive resource utilization, light industry and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

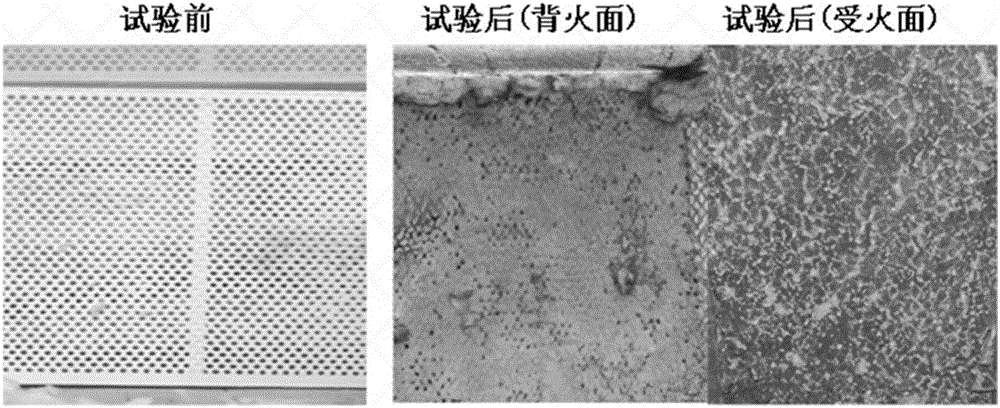

Fireproof paint, preparation method of fireproof paint and flame screen containing fireproof paint

InactiveCN106752429ACirculation isolationInsulate the airFireproof paintsFire proofingThermal insulationCarbonization

The invention discloses a fireproof paint, a flame screen containing the fireproof paint and a preparation method of the fireproof paint. The fireproof paint is prepared from the following raw materials in parts by weight: 30 to 40 parts of dehydration catalyst, 15 to 25 parts of carbonization agent, 30 to 35 parts of foaming agent and 60 to 70 parts of binding agent. According to the flame screen, a porous metal plate or a metal wire mesh structure is utilized as a base layer, the areal density is 1 to 6.0kg / m<2>, the diameter of each mesh is 6.0 to 150.0mm, and the surface of the base layer of the flame screen is coated by the fireproof paint. In a normal use state of the flame screen, air can freely circulate among meshes of the flame screen; when fire happens, a fireproof coating on the flame screen is heated to expand to form thermal-insulation fireproof paint to plug the meshes of the flame screen, heat and smoke are prevented from freely circulating in a breathing cavity of a curtain wall, and the fire is prevented from expanding horizontally or vertically. The flame screen can be widely applied to the places needing fire protection and requiring ventilation of electric power, metallurgy, petrifaction, chemical engineering, buildings and the like.

Owner:应急管理部四川消防研究所

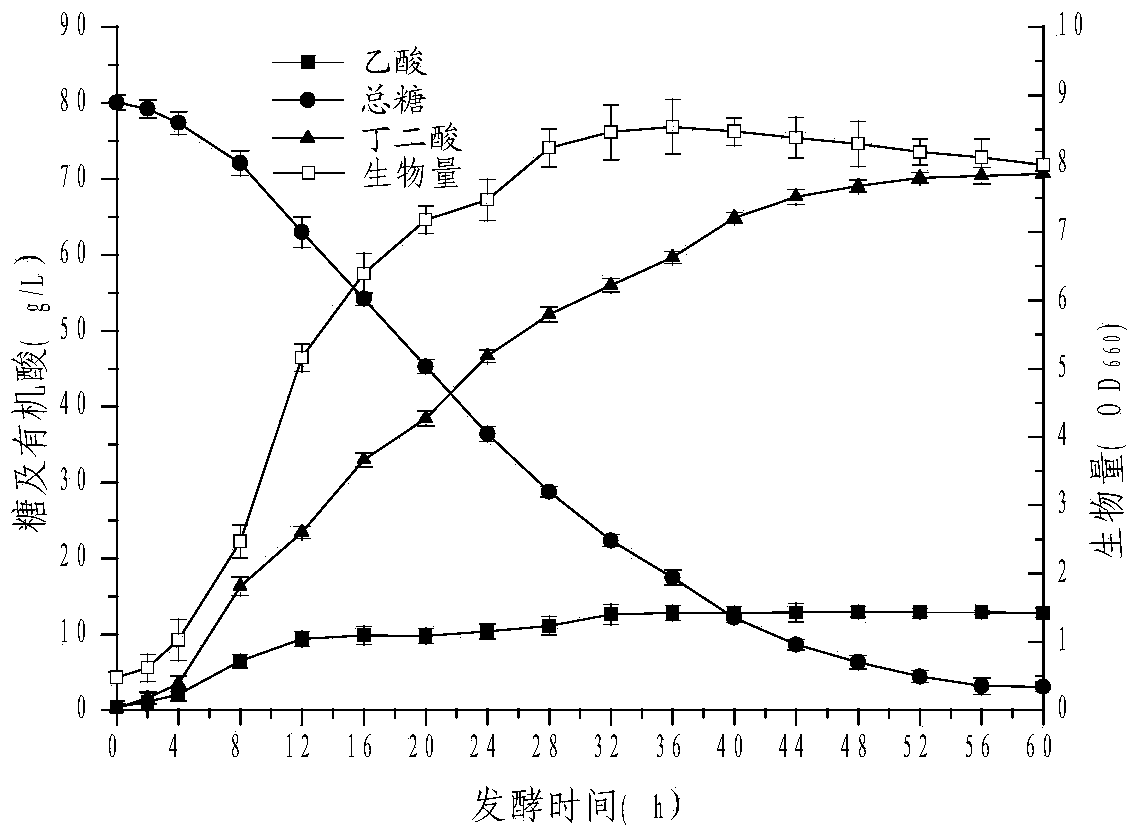

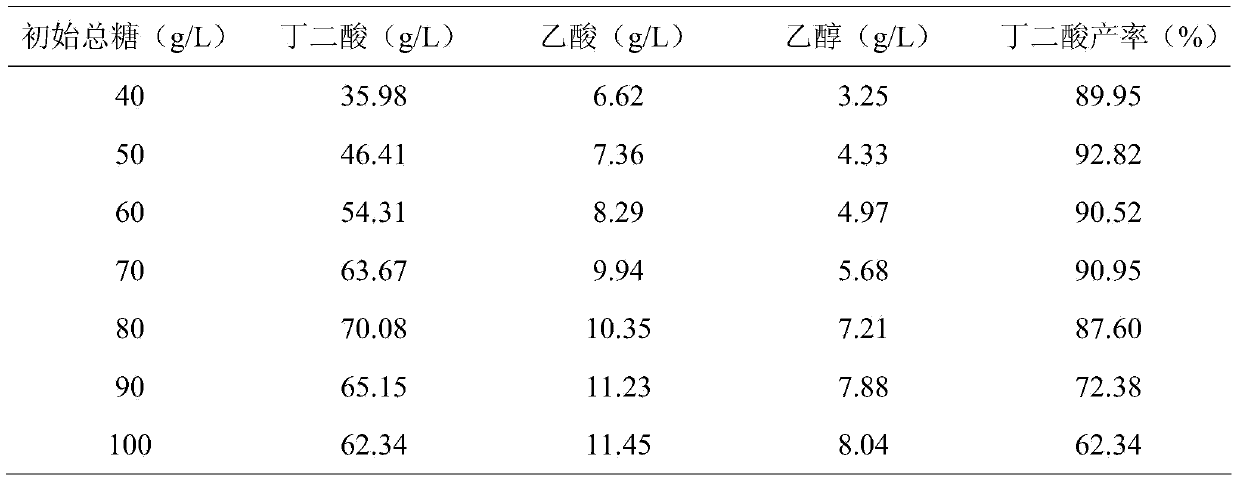

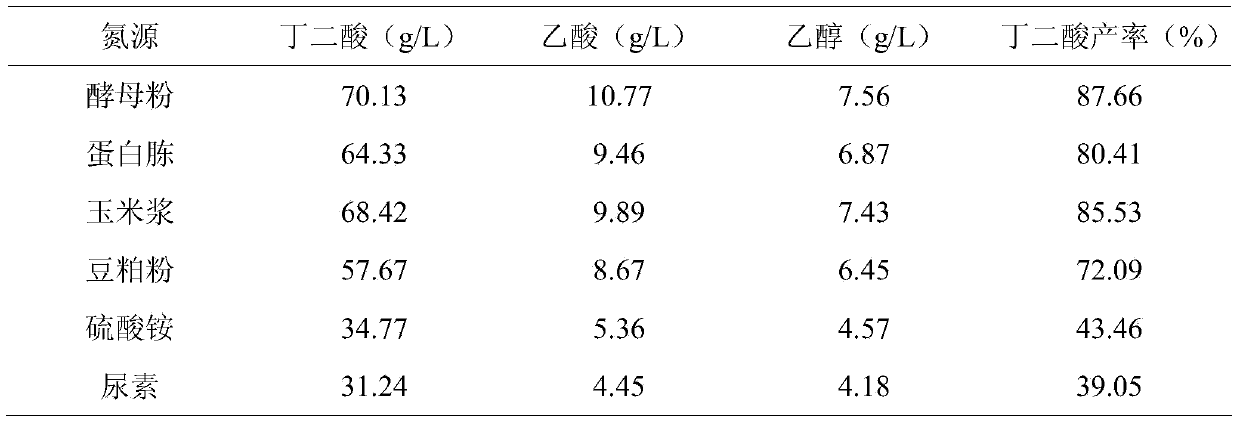

Method for producing succinic acid through fermentation of sugarcane juice

InactiveCN103695481AReduce manufacturing costProtection of rights and interestsMicroorganism based processesFermentationChemistryPetrifaction

The invention relates to a method for producing succinic acid through fermentation of sugarcane juice. The method comprises the steps of using actinobacillus succinogenes CCTCC (China Center for Type Culture Collection) M2011399, adding water to adjust the total sugar concentration of the sugarcane juice to 50-100g / L under a CO2 or N2-bearing anaerobic condition, and producing succinic acid through batch fermentation or fed-batch fermentation. The concentration of succinic acid can reach 30-75g / L through fermentation for 30-60h, the utilization ratio of sugar is 85-92%, and the production intensity reaches 0.73-1.46g / (L*h). The method has the prominent advantages that a sugarcane juice raw material replaces expensive glucose to serve as a carbon source for fermentation to produce succinic acid, and since a renewable biomass resource is employed, the method is environment-friendly, and can alleviate the petrifaction resource tension for chemical synthesis of succinic acid.

Owner:GUANGXI ACAD OF SCI

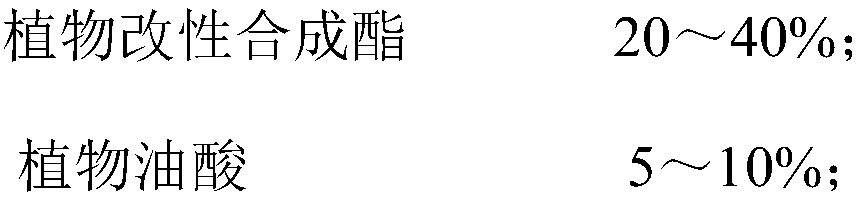

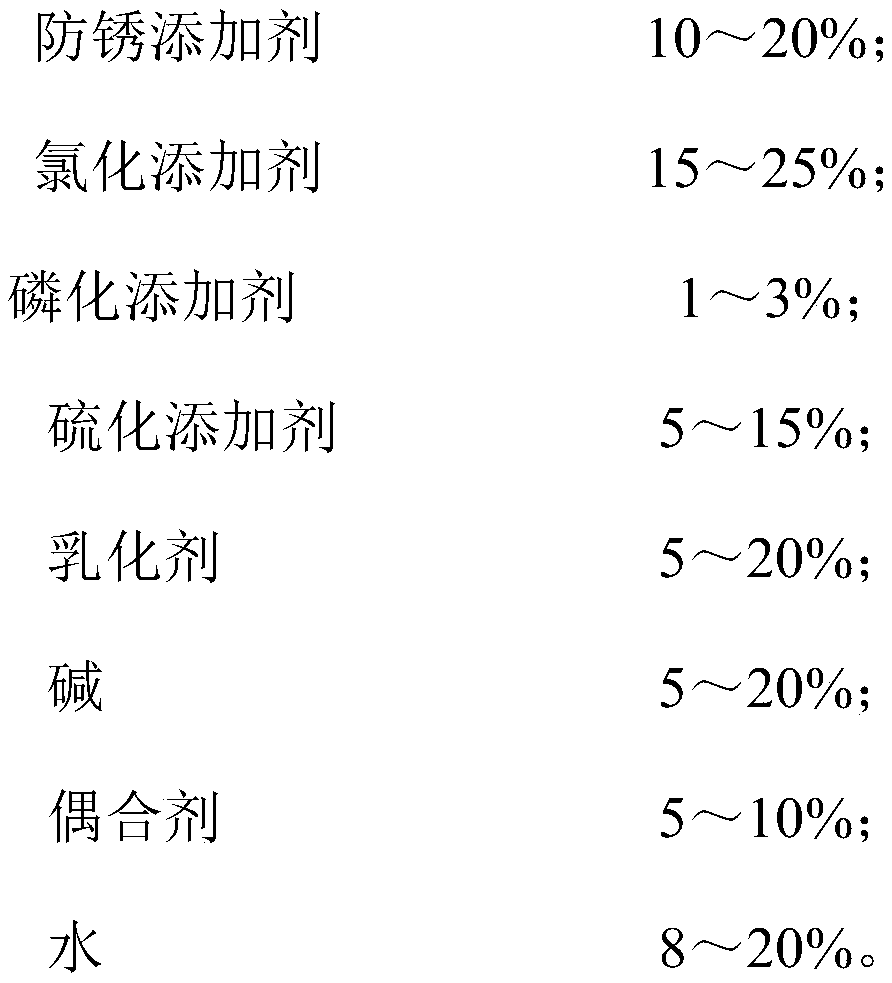

Stainless steel plant-based water-soluble stamping oil and preparation method thereof

InactiveCN108865382APromote degradationReduce dependenceLubricant compositionWater basedCleansing Agents

The invention discloses a stainless steel plant-based water-soluble stamping oil, which is prepared from the components in percentage by weight: 20 to 40 percent of plant modified synthetic ester, 5 to 10 percent of vegetable oleic acid, 10 to 20 parts of a rust-inhabiting additive, 15 to 25 percent of a chlorinated additive, 1 to 3 percent of a phosphating additive, 5 to 15 percent of a vulcanizing additive, 5 to 20 percent of an emulsifier, 5 to 20 percent of alkali, 5 to 10 percent of a coupling agent and 8 to 20 percent of water. A formula is blended through a specific process, can form semitransparent diluent with water; a part of materials of the formula adopts reproducible raw materials which is high in biodegradation rate, so that the dependence of the petrifaction material and theinfluence of the petrifaction material on the environment is reduced; due to the product is water-soluable, a work piece after processing is easy to clean by a water-based cleaning agent, so that theservice life of the water-based cleaning agent can be prolonged, the time for cleaning is reduced, the cost of follow-up cleaning is effectively reduced; a stock solution is used, or water can be added to use, so that the good market prospect can be realized. According to the stainless steel plant-based water-soluble stamping oil, the preparation method is simple, the operation is easy, the production efficiency is high and the percent of pass of the product is high.

Owner:东莞市伟思化学科技有限公司

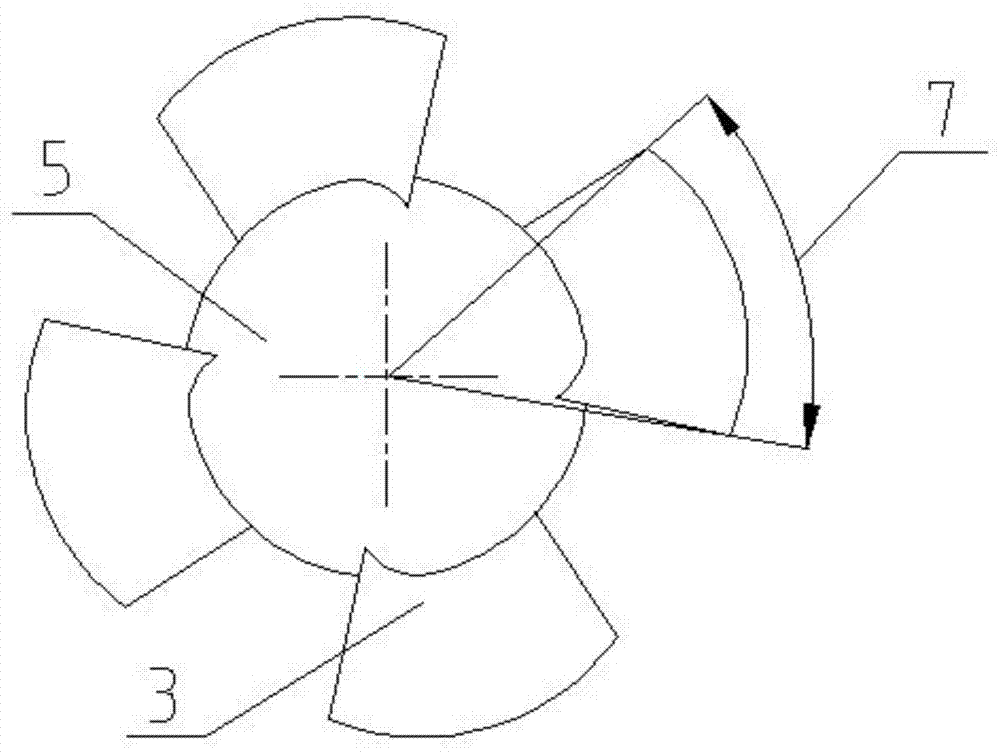

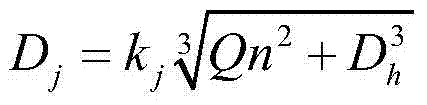

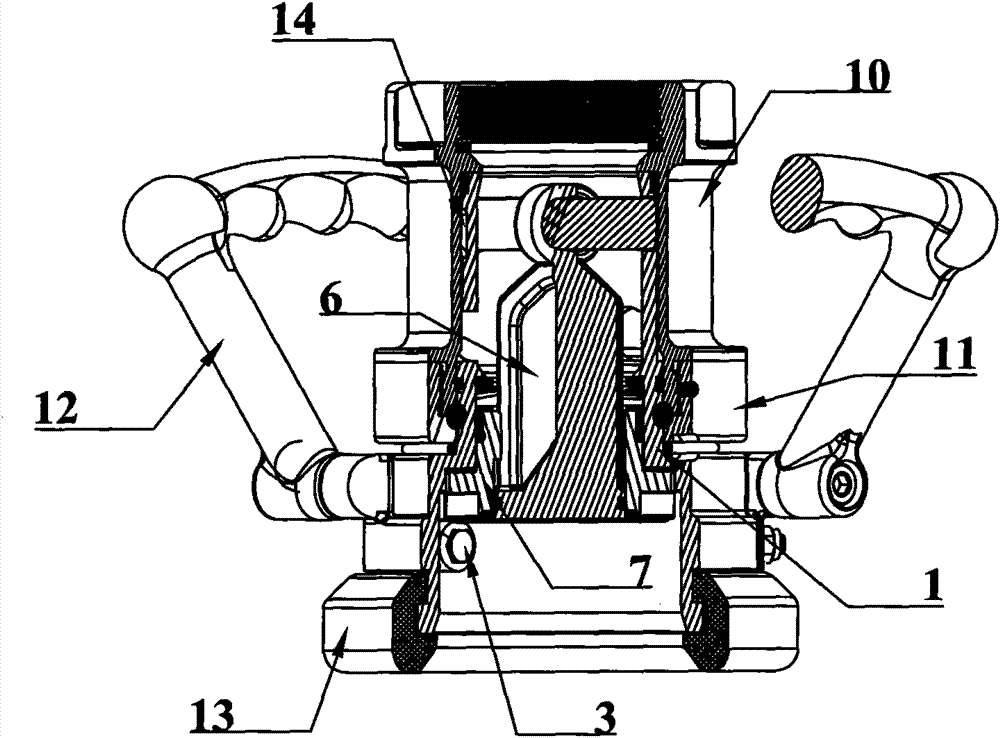

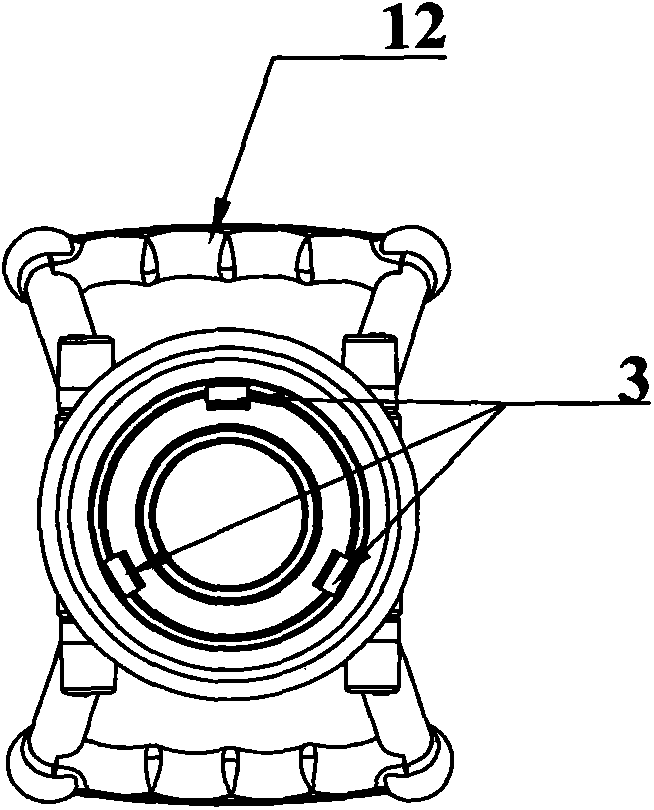

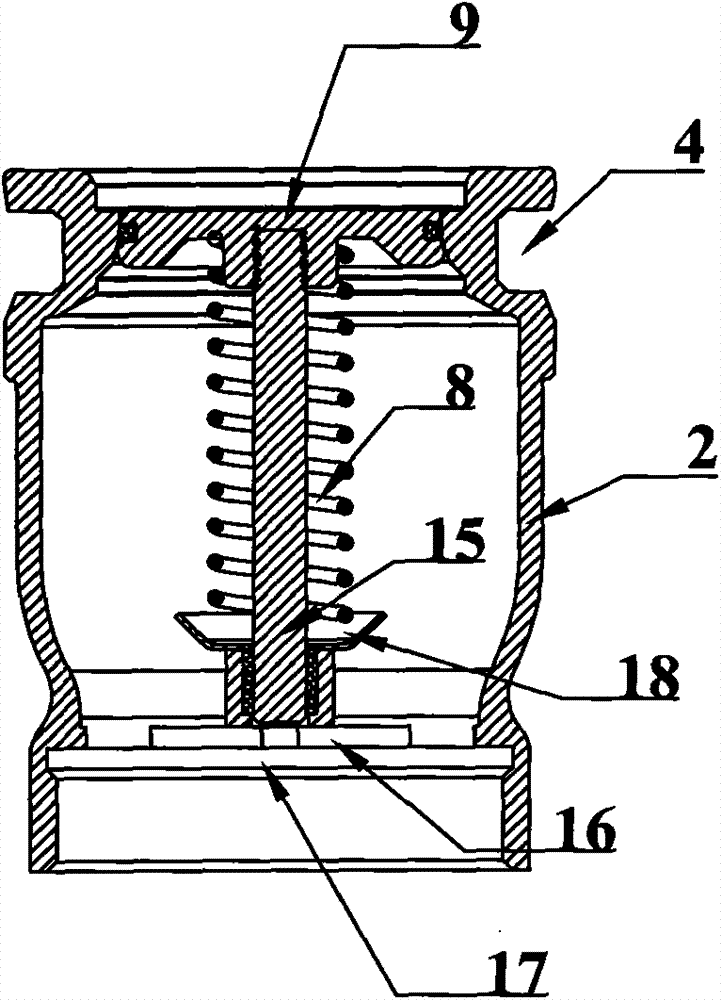

Wear-resistant axial flow pump impeller designing method

ActiveCN103925234AExtended service lifeImprove operational reliabilityPump componentsPumpsImpellerAxial-flow pump

The invention provides a wear-resistant axial flow pump impeller designing method. An axial flow pump is used for the field of petrifaction, mining, smelting and the like. A designing formula of main symmetric size parameters, like impeller inlet diameter Dj, impeller maximum diameter D, hub diameter Dh, blade axial length L and blade wrap angle phi, of an impeller is provided. By using a wear-resistant axial flow pump impeller designed by the method, wear-resistant performance of the pump can be improved, the problem of impeller wear when the axial flow pump is in media containing solid particles can be improved, and hydraulic efficiency and reliability of the impeller can be improved.

Owner:常州市长江热能有限公司

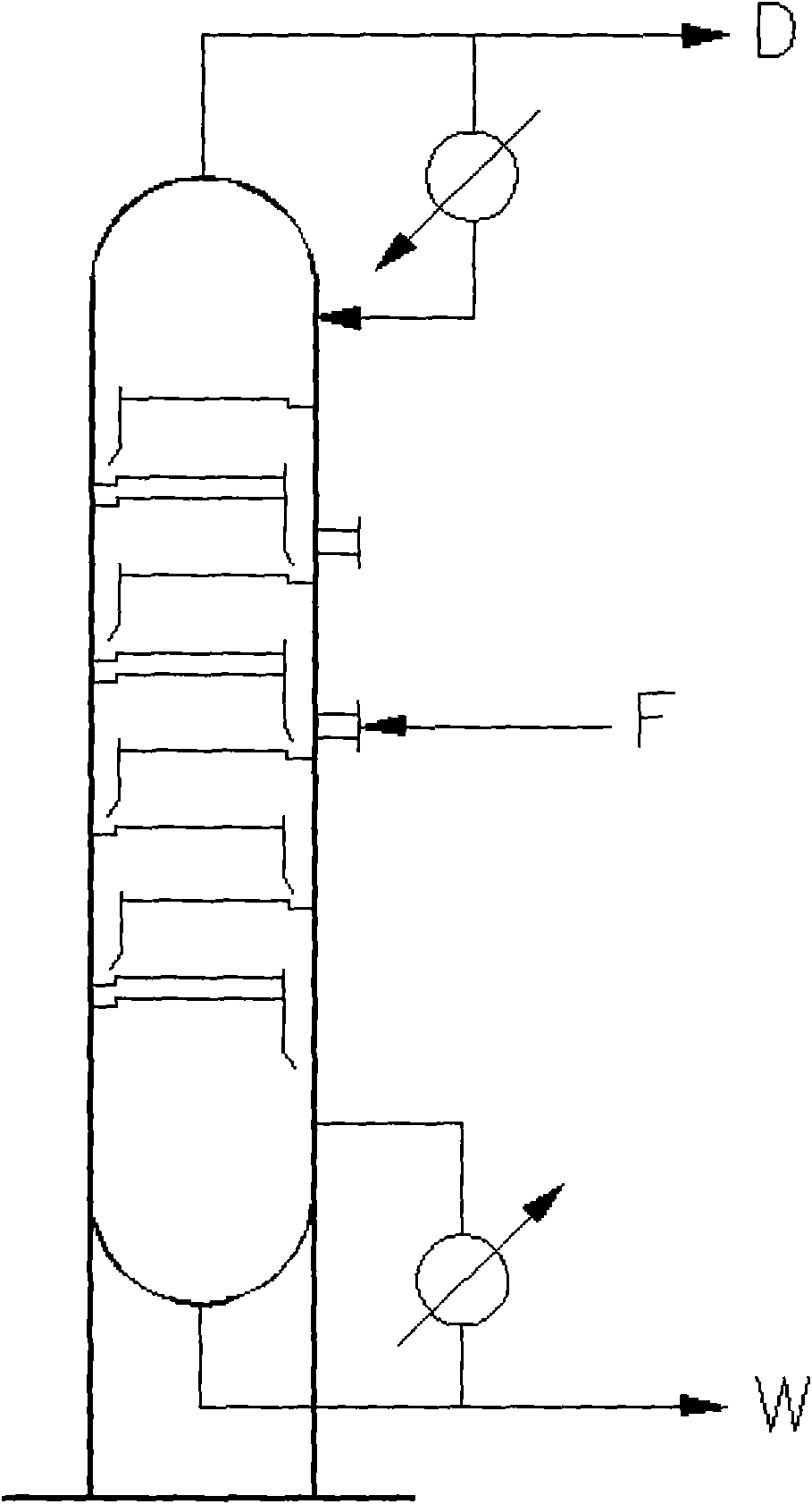

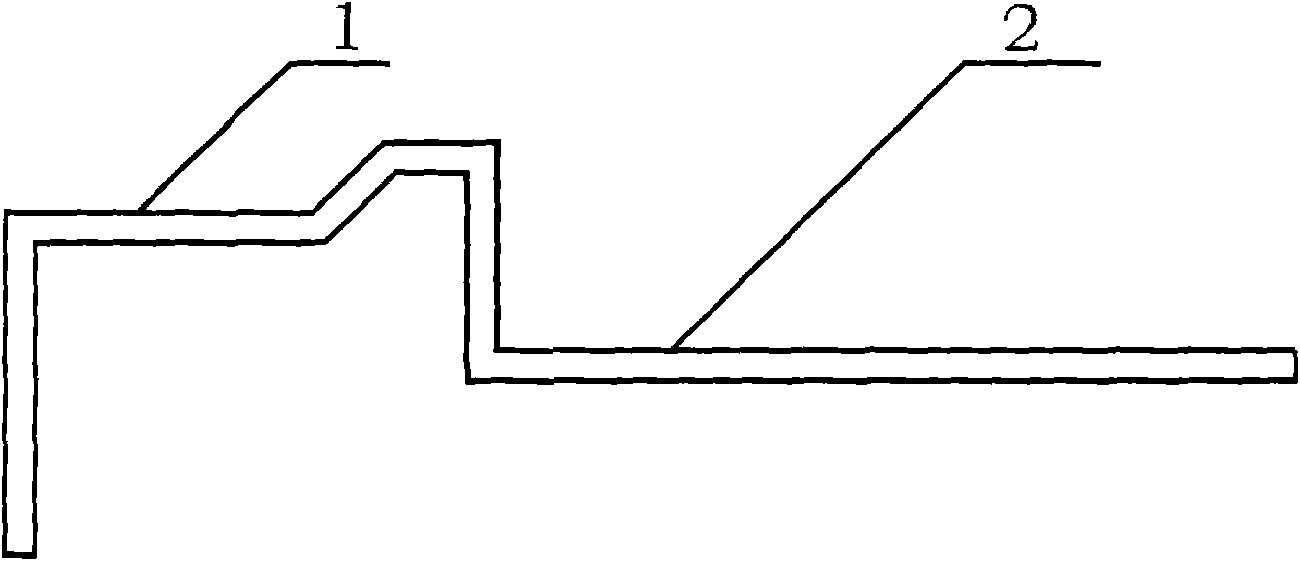

Novel tower equipment

ActiveCN101934158AImprove the level ofEasy to assembleFractional distillationPetrifactionChemical industry

The invention discloses novel tower equipment and relates to a mass transfer process in industrial processes, belonging to the field of gas-liquid mass transfer devices. In the tower equipment, supporting angle iron and a liquid receiving disk are manufactured into a piece, thus the processing efficiency and the levelness of a tower plate can be improved; a liquid downcomer plate and the liquid receiving disk are manufactured to be detachable so as to be convenient to assemble, maintain and clean the equipment; and a safety plate is arranged above each manhole, i.e. below a lowest tower plate on the part of the tower body for protecting workers while mounting and maintaining. The equipment can be used for the mass transfer process in industries of chemical industry, petrifaction, light industry, metallurgy, and the like and has the characteristics of simple structure, low manufacturing cost, obvious economic benefit, and the like.

Owner:北京先锋创新科技发展有限公司

Heat-preserving, flame-retardant, water-proof and corrosion-resistant functional gel material and preparation method thereof

The invention discloses a heat-preserving, flame-retardant, water-proof and corrosion-resistant functional gel material and a preparation method thereof. The functional gel material is prepared from polyether glycol, epoxy resin, polyisocyanates, water, a reactive flame retardant, a flame-retardant antismoke agent, a compound catalyst, a foam stabilizer and a physical foaming agent serving as raw materials through a polymerization reaction. The gel material has the characteristics of flame retardancy, corrosion resistance, waterproofness, field foaming property and the like, and can be applied in the fields of heat preserving, cold preserving and the like for various pipelines in building wall bodies, cold storage warehouses, central air conditioners, petrifaction, metallurgy and the like.

Owner:江苏瑞丰科技实业有限公司

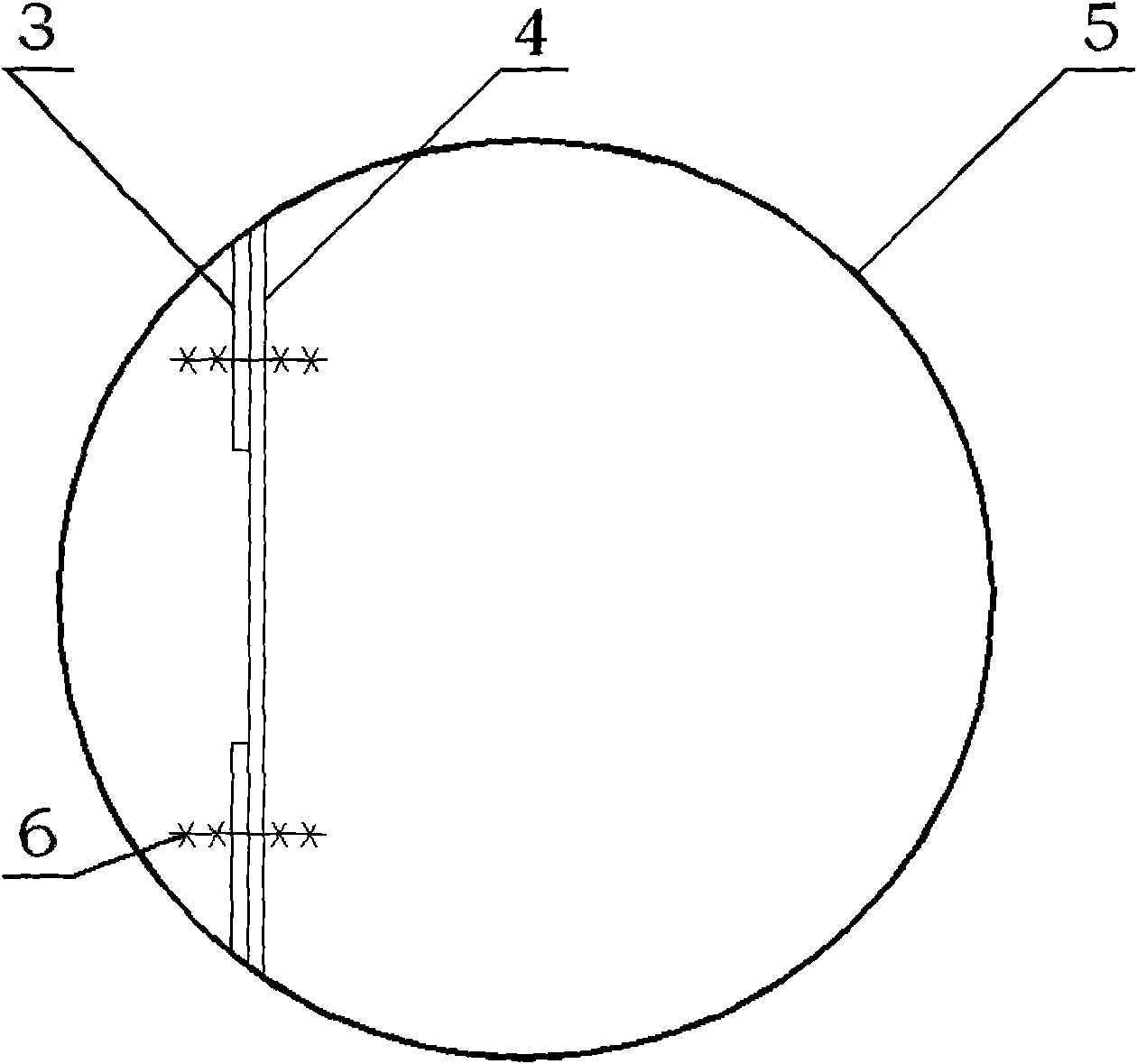

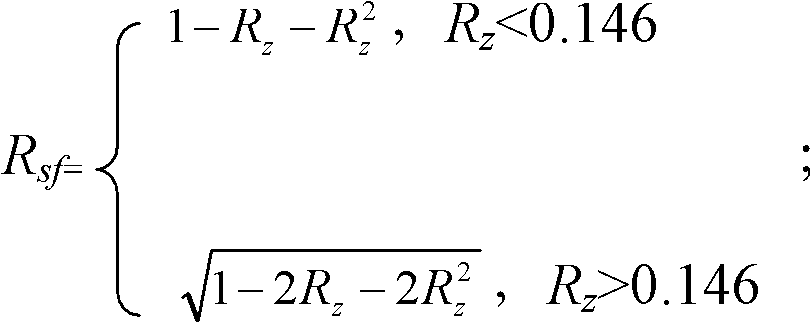

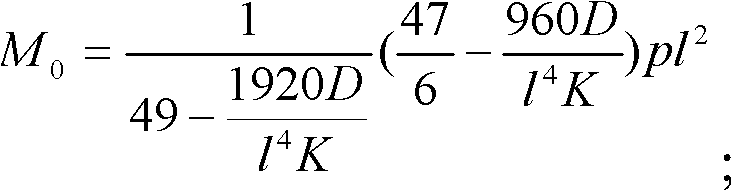

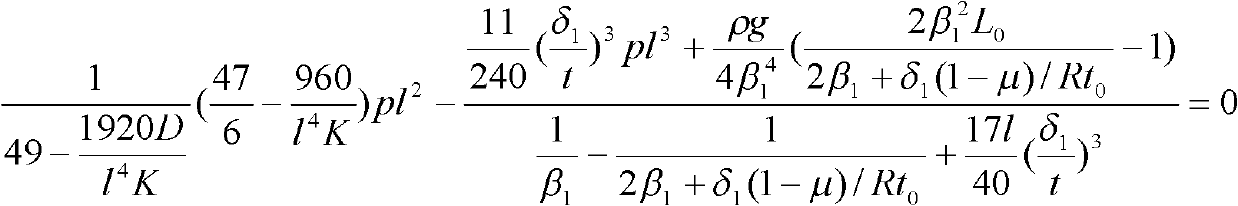

Method and system for evaluating safety of oil storage tank bottom plate with corrosion defect

InactiveCN102621021ASpecial data processing applicationsInvestigating abrasion/wear resistancePetrifactionPetroleum

The invention discloses a method and a system for evaluating the safety of an oil storage tank bottom plate with a corrosion defect and belongs to the technical field of evaluation on in-service defective containers in petroleum and petrifaction industry. The method comprises the following steps of: determining parameters E, t, mu, K, Rho, L0, 1, Phi, sigma s, nF, FCA, t0, Z, R and theta 1; calculating parameters D, p, [sigma], Rz, beta 1 and Rsf; calculating N, NL, M0 and ML; and when the square of N / NL is less than or equal to 0.44, determining that the defect of a center plate can be accepted, and when the sum of the square of N / NL and the square of Mo / ML is less than or equal to 0.44, determining that the defect of an edge plate can be accepted. The invention provides the method and the system for evaluating the safety in order to deal with the condition that the corrosion depth of the oil storage tank bottom plate exceeds the defect standard specified as SY / T 5921-2000, and suggestions about safety running of an oil storage tank can be provided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

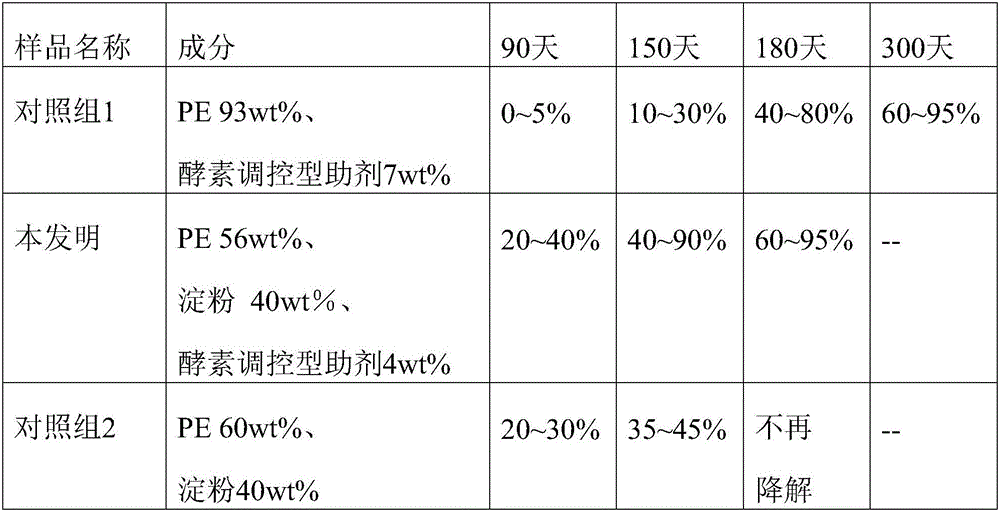

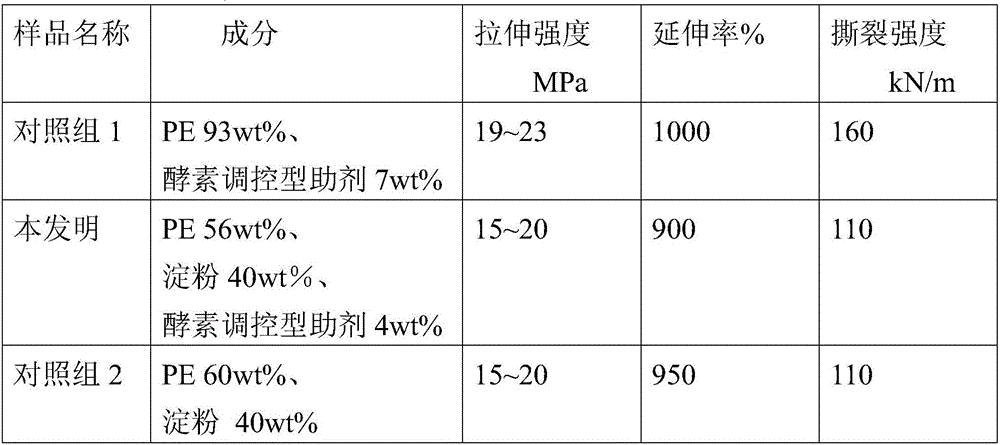

Novel low-carbon degradable sheet material and product thereof

The invention discloses a novel low-carbon degradable sheet material, thickness of which is within 0.01-0.15 mm. the sheet material is composed of 20-80 wt% of a plastic material, 10-70 wt% of a biobased material and 1-10 wt% of a biodegradation aid. The plastic material is a petrifaction- or plant-source plastic material. The biobased material contains starch, plant fiber powder or a composition of starch and plant fiber powder. The biodegradation aid contains polyolefin resin, ferment or microbes and related nutrient composition. Degradation rate of the novel low-carbon degradable sheet material is at least 90%.

Owner:HONG MING ECO TECH

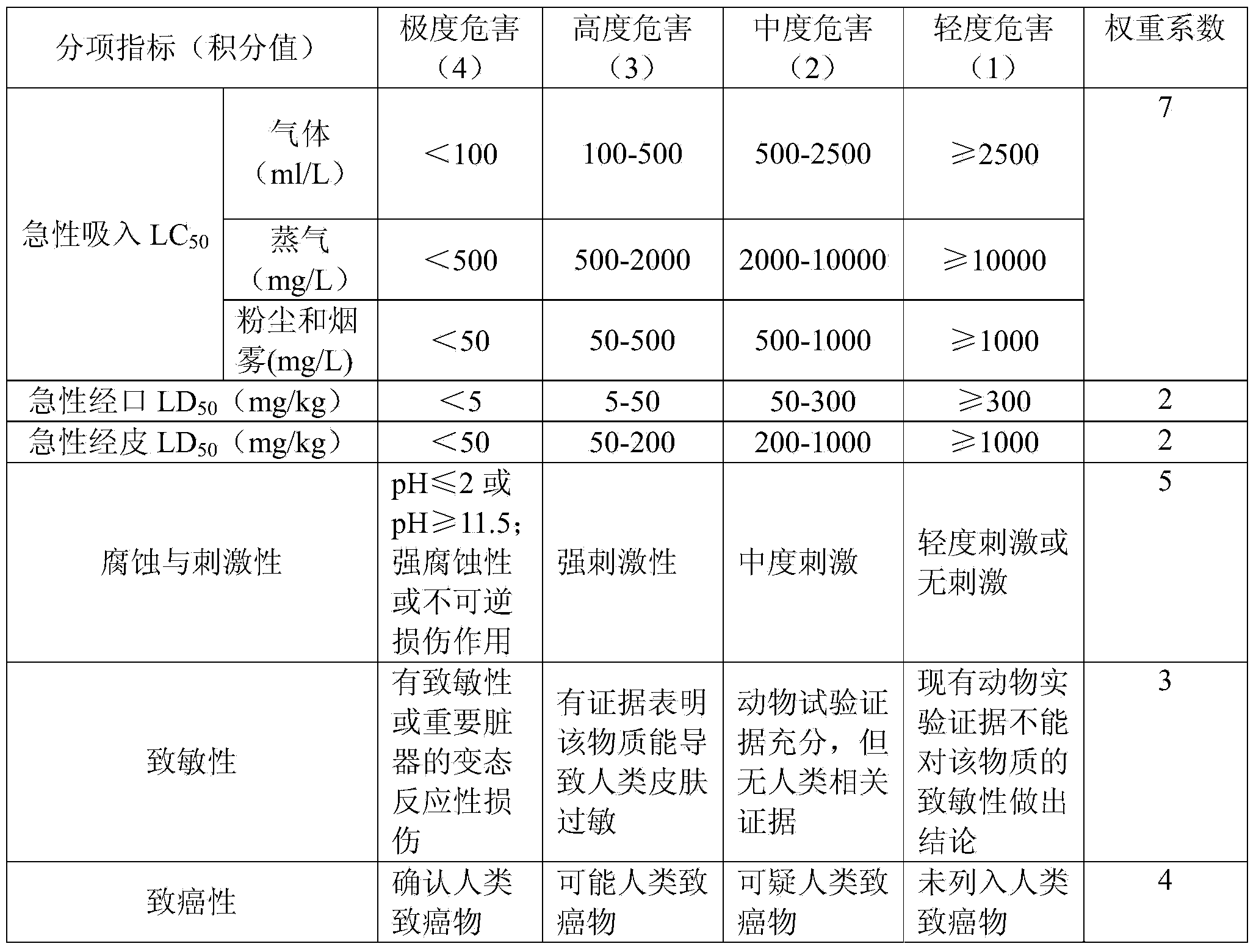

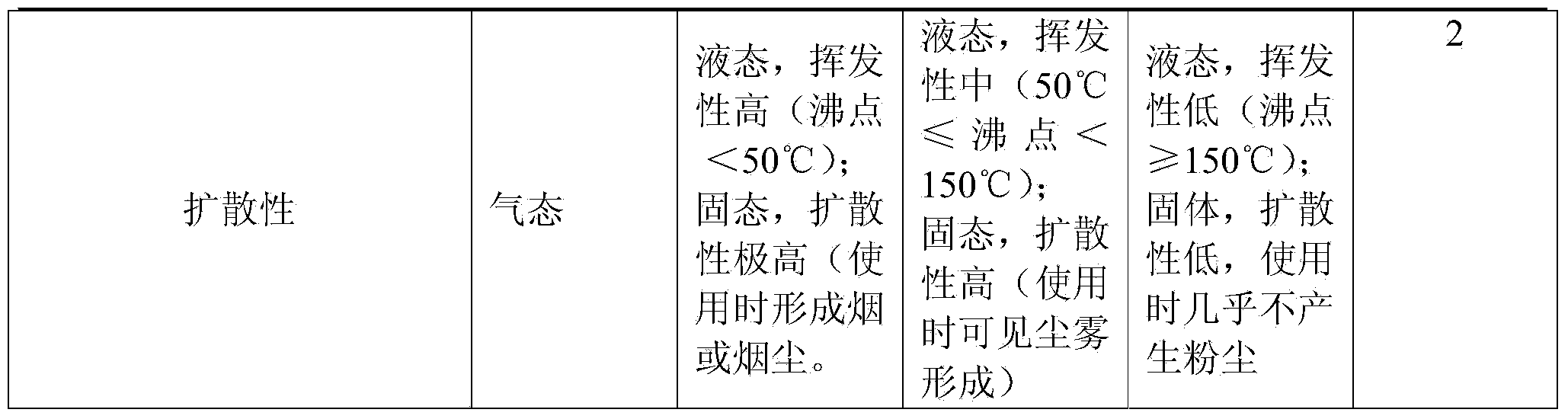

Grading treatment method of toxic chemicals of petrochemical enterprise

InactiveCN104361431AEmbody layeringEmbody the idea of differentiated managementResourcesPetrifactionAcute toxicity testing

The invention discloses a grading treatment method of toxic chemicals of a petrochemical enterprise, and belongs to the technical field of dangerous chemical grading treatment. The grading treatment method of the toxic chemicals of the petrochemical enterprise includes: dividing the toxic chemicals into acute toxicity chemicals, corrosion and irritation chemicals, sensitization chemicals, carcinogenicity chemicals and diffusivity chemicals, selecting three hazard index points equal to 25, 45 and 65 as marking nodes of grading of the toxic chemicals by calculating hazard indexes of the toxic chemicals, and then dividing the toxic chemicals into slight hazard chemicals, moderate hazard chemicals, high hazard chemicals and extreme hazard chemicals, and thereby meeting the requirement of the petrochemical enterprise for improving toxicant safety management efficiency on the premise of not increasing management costs. The grading treatment method of the toxic chemicals of the petrochemical enterprise is provided with petrifaction characteristics, fully reflects a thought of managing the toxic chemicals by different levels and in differentiated mode, and simultaneously provides decision basis for further providing grading management measures.

Owner:CHINA PETROLEUM & CHEM CORP +1

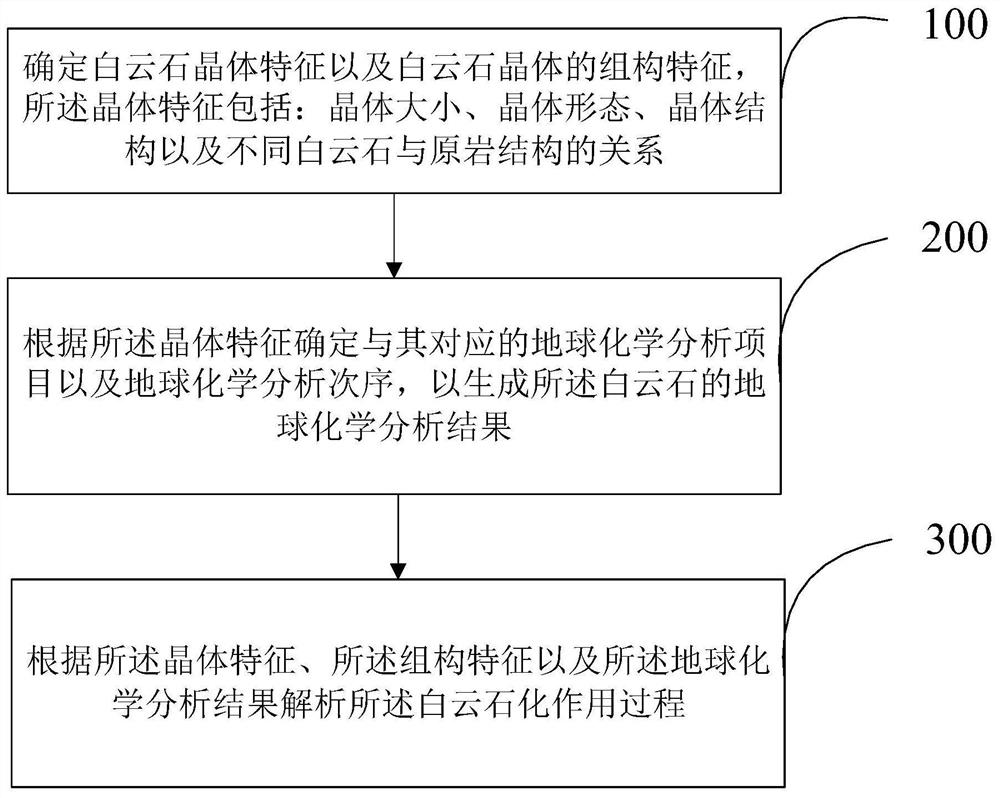

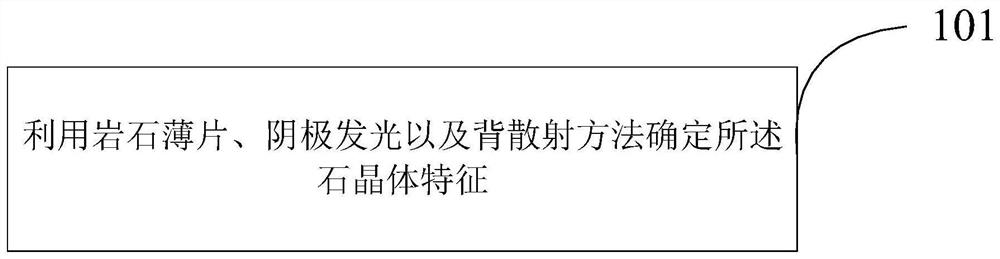

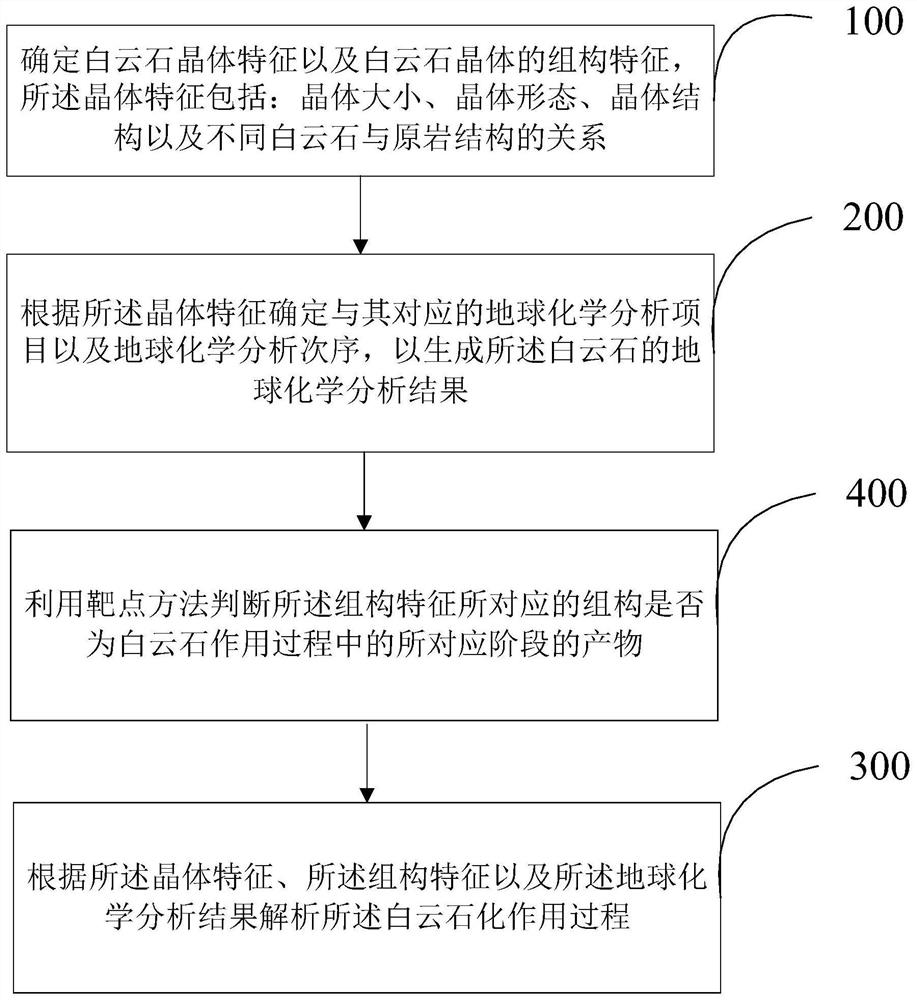

Method and device for identifying dolomite petrifaction action process

ActiveCN113791189AMaterial analysis using wave/particle radiationInvestigating crystalsDolostoneCrystal morphology

The invention provides a method and device for identifying the dolomite petrifaction action process, and the method comprises the steps: determining the characteristics of a dolomite crystal and the structure characteristics of the dolomite crystal, the crystal characteristics comprising the crystal size, the crystal form, the crystal structure and the relation between different dolomite and a protolith structure; determining a geochemical analysis project and a geochemical analysis sequence corresponding to the crystal characteristics according to the crystal characteristics so as to generate a geochemical analysis result of the dolomite; and analyzing the dolomite petrifaction process according to the crystal characteristics, the fabric characteristics and the geochemical analysis result. According to the dolomite petrifaction process identification method and device provided by the invention, the dolomite formation period and the dolomite petrifaction process can be reliably known.

Owner:PETROCHINA CO LTD

Environment-friendly methanol diesel oil

The invention discloses an environmental protection carbinol diesel, which comprises the following parts: 40-90 percent modified biological diesel, 10-60 percent carbinol and 0-30 percent petrifaction diesel. These materials are blended together to stir evenly under normal temperature and normal pressure, which can produce the product. The invention avoids the dependence of oil diesel, which possesses polybasic energy source developing paths.

Owner:TAIYUAN UNIV OF TECH

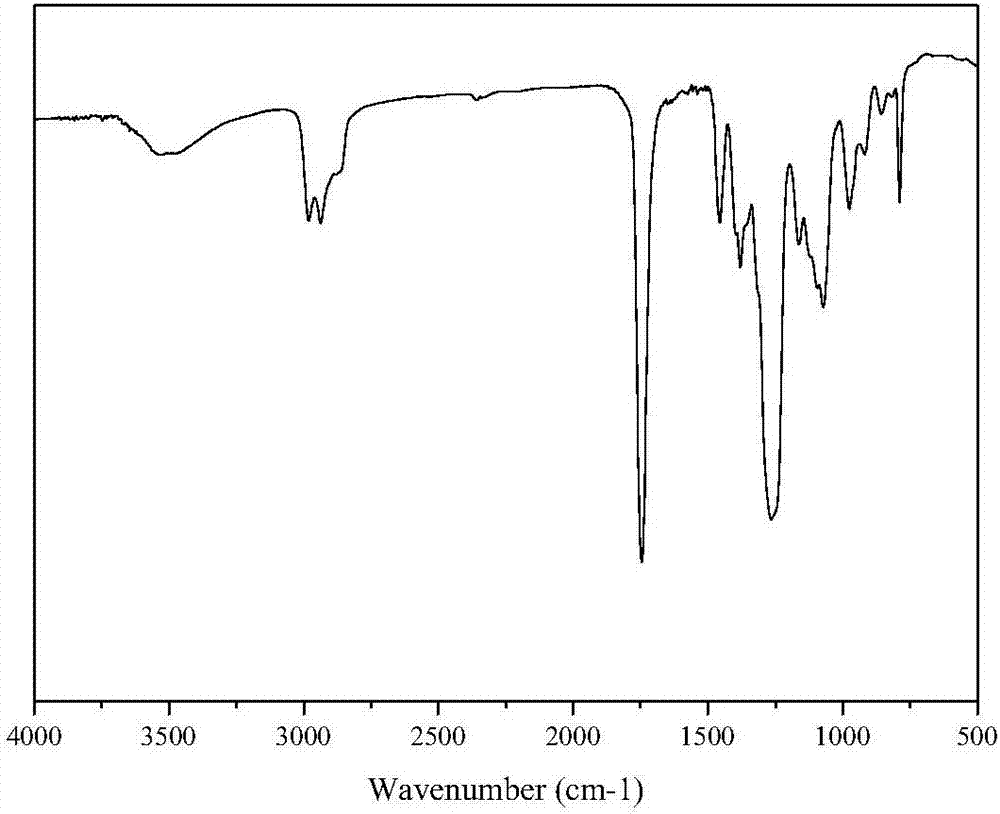

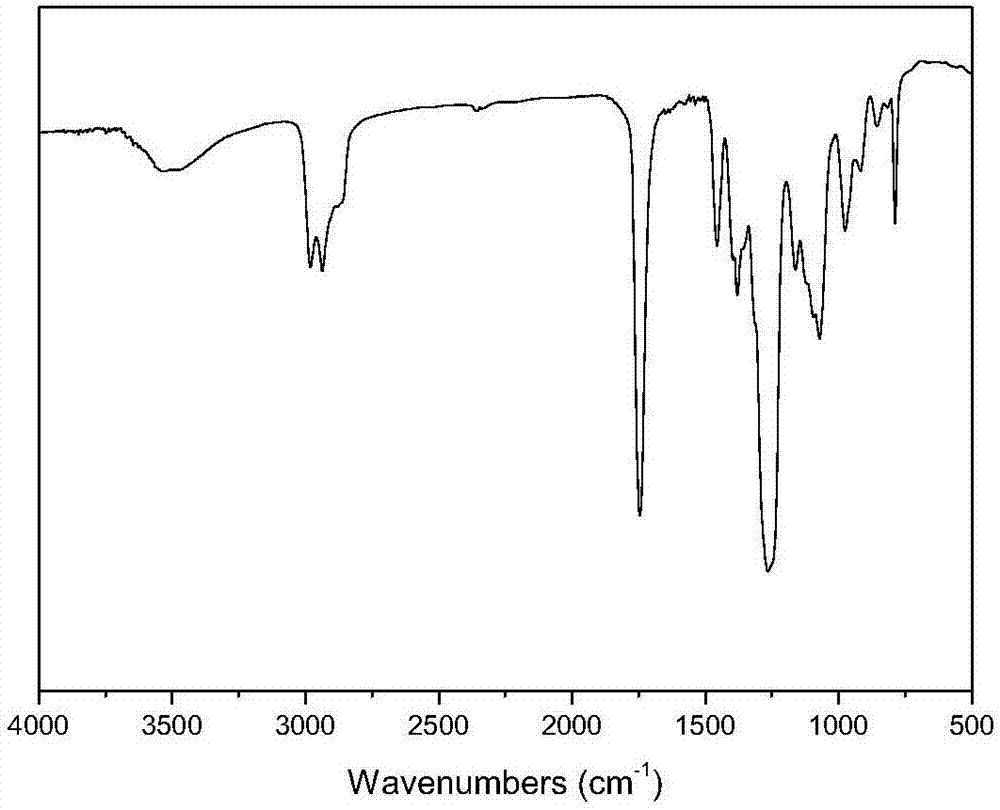

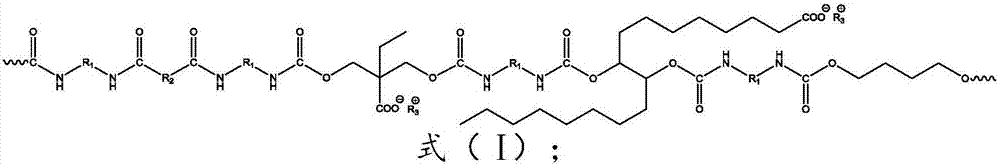

Modified carbon dioxide-based waterborne polyurethane and preparation method thereof

The invention provides modified carbon dioxide-based waterborne polyurethane, which has a structure as shown in a formula (I). Carbon dioxide and epoxypropane are copolymerized so as to prepare carbon dioxide-based polyatomic alcohol, and 9,10-dioxystearic acid and dimethylolbutanoic acid are matched jointly as a hydrophilic group chain segment, so that not only the dependence on petrifaction resources be reduced, but also compared with traditional waterborne polyurethane prepared from polyester polyatomic alcohol and polyether polyol, the modified carbon dioxide-based waterborne polyurethane has excellent water resistance and mechanical property. The formula (I) is shown in the specification.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

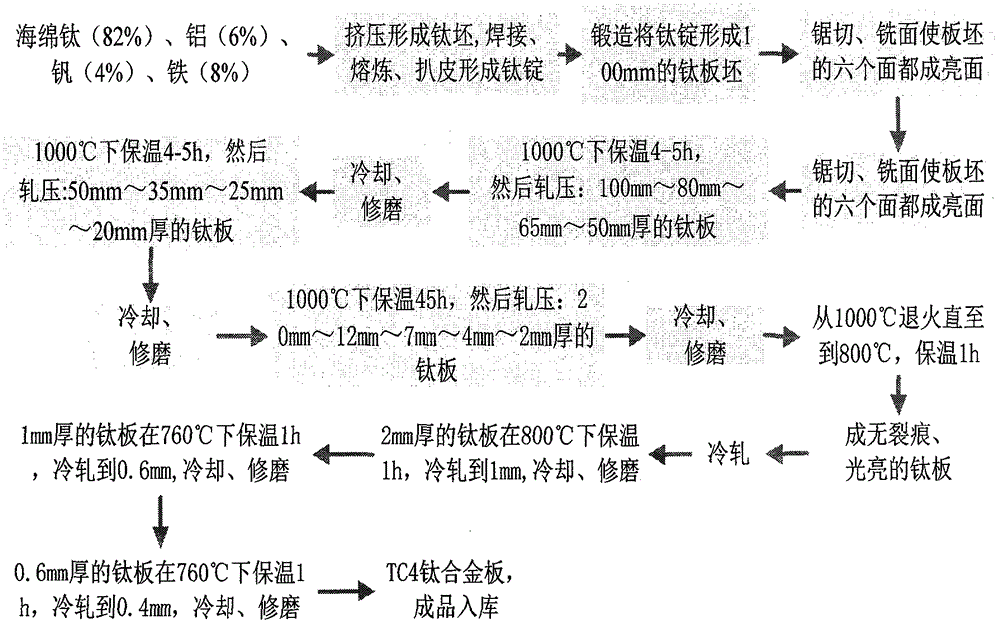

TC4 titanium alloy plate machining method

The invention discloses a TC4 titanium alloy plate machining method. The method includes the following steps that firstly, sponge titanium, aluminum powder, vanadium powder and iron powder are mixed according to the mass percent and extruded to form titanium blank, and then the titanium blank is welded, smelted and scalped to form a titanium ingot; secondly, cogging and forging are carried out on the titanium ingot to form a titanium slab, and then a smooth titanium slab with the thickness being smaller than or equal to 100 mm is formed through sawing and milling; thirdly, the smooth titanium slab is hot-rolled and ground at least three times after hot rolling to form a titanium plate with the thickness being smaller than or equal to 2 mm, annealing is conducted at the temperature of 800 DEG C, and heat is preserved for 0.8-1.2 hours to form a smooth titanium plate without cracks; and fourthly, cold rolling is conducted, and the smooth titanium plate is cold-rolled into the titanium plate with the thickness being smaller than or equal to 0.4 mm under at least three times of different annealing temperature conditions. The method reduces oxide skin formed during heating, has the advantages of being good in corrosion resistance, small in density, high in specific strength and good in toughness and welding performance, and is widely used in aerospace, petrifaction, shipbuilding and the automobile industry.

Owner:BAOJI CITY FUYUANTONG IND & TRADE

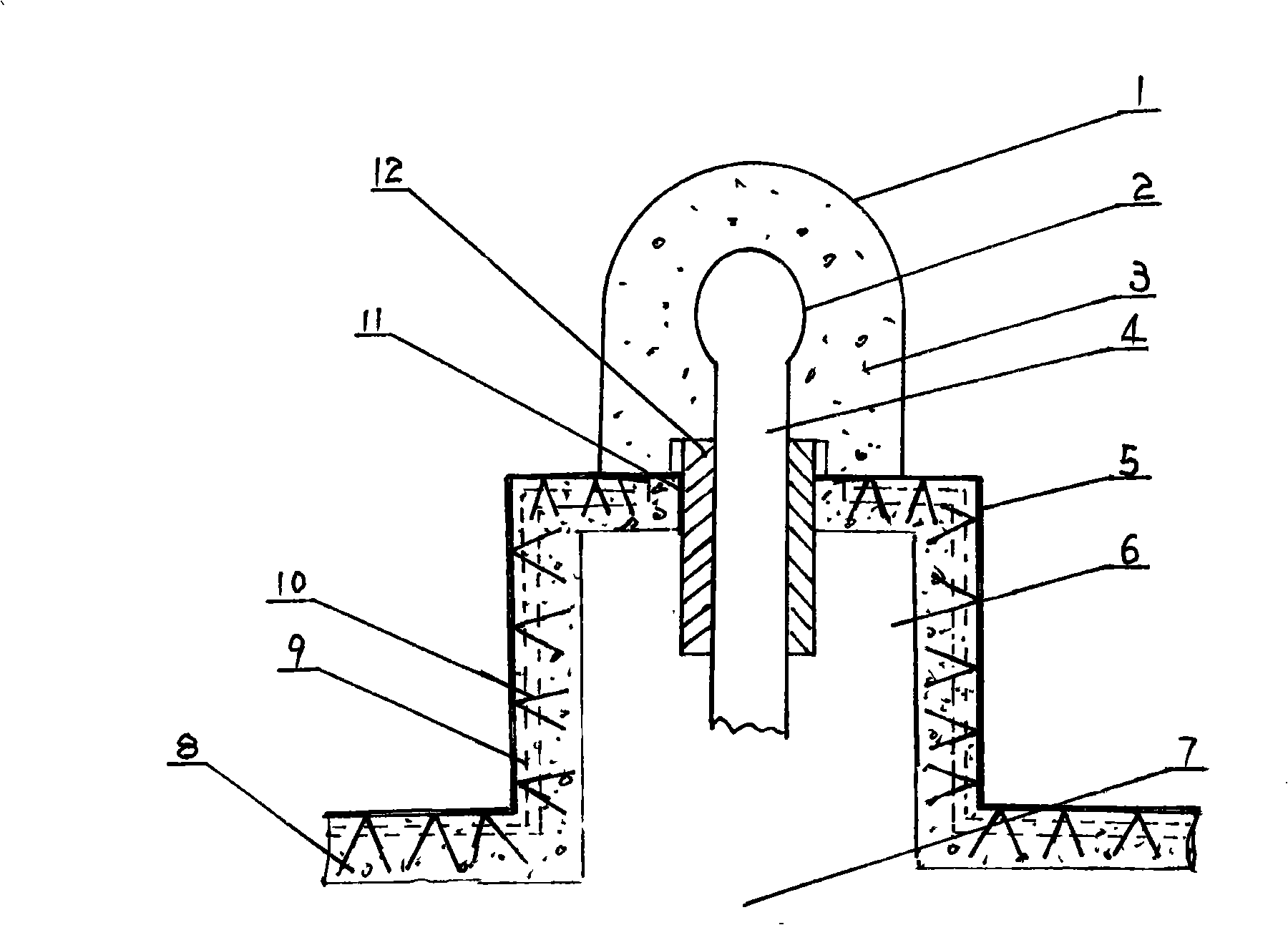

Sealing method of petrifaction ethylene pyrolysis furnace tube and furnace roof liner portion

InactiveCN101353287AExtend the life cycleSolve the sealing problemLinings repairHydrocarbon by hydrocarbon crackingFiberPetrifaction

The invention belongs to a method for sealing linings of a furnace tube and a furnace roof of an ethylene cracking furnace in the petrochemical industry. The method comprises the steps as follows: an anchor nail is welded and fixed at the inner wall of the lining part of the furnace roof of the furnace; the corresponding furnace tube running through a perforation at the furnace roof is wrapped by combustible material, or the furnace tube at the position is sheathed and fixed by a sleeve made from the combustible material, or the furnace tube at the position is sheathed and fixed by a detachable sleeve, wherein, the thickness of the combustible material or the sleeve is the permissible length between the outer wall of the furnace tube and an insulation layer of the inner wall of the perforation of the furnace roof; an insulation layer with zirconium fiber is sprayed on the inner wall of the lining of the furnace roof of the furnace, a steel wire mesh is fixed between the insulation layer with the zirconium fiber and the anchor nail, and another insulation layer with the zirconium fiber is sprayed on the steel wire mesh, the steps are carried out repeatedly in sequence until the insulation layer with the zirconium fiber covers the anchor nail and meets the required thickness. The method can effectively solve the sealing problem of the linings of the furnace tube and the furnace roof, and has the advantages of simple and easy operation, rapid operation speed and greatly improving the service life of the furnace.

Owner:北京达斯特炉衬工程技术有限责任公司

Water-proof heat-insulating composite material

InactiveCN101993681ANo pollution in the processNo smellOther chemical processesSolid waste managementFiberAdhesive

The invention discloses a water-proof heat-insulating composite material, which is particularly suitable for the industrial fields such as petrifaction, electric power, metallurgy, building materials and the like, and provides the water-proof heat-insulating composite material which can effectively save energy and preserve the heat and has the effect of water proofing. The material is prepared from the following raw materials: 10 to 50 percent of perlite, 0.1 to 0.3 percent of high-temperature glue, 1 to 10 percent of diatomite, 1 to 3 percent of adhesive, 1 to 6 percent of composite rare earth additive, 1 to 5 percent of mineral wool, 2 to 10 percent of gypsum powder, 2 to 5 percent of aluminum silicate fiber, 0.8 to 1.3 percent of succinic acid, 15 to 22 percent of calcium hydroxide, 15 to 22 percent of kaoline, 0.1 to 0.2 percent of foaming agent and 0.1 to 0.4 percent of air entraining agent.

Owner:王猛

Portable composite nondestructive detector based on eddy current technology and ultrasonic technology

InactiveCN109254073ARealize the detection function of scanning flaw detectionThe image is clear and intuitiveAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesAviationElectrical conductor

The invention relates to a portable composite nondestructive detector based on eddy current technology and ultrasonic technology and relates to a nondestructive detector for scanning and detecting pipes in the field of industrial metallic materials, electric power and petrifaction and metal members in the field of aviation. The detector comprises an eddy current probe, an ultrasonic probe and nondestructive detection host equipment; the eddy current probe is used for displaying a defect state of a detected conductor by analyzing and processing an eddy current signal generated when being located at a defect position of the detected conductor; the ultrasonic probe uses ultrasonic waves generated by a single piezoelectric crystal plate to carry out flaw detection and scanning; and the nondestructive detection host equipment is a piece of host equipment integrated with an electronic system control module, a signal collecting and processing module, a main controller and a human-computer interaction module. The electronic system control module stimulates the piezoelectric crystal plate in the ultrasonic probe according to a certain rule and timing sequence; the signal collecting and processing module is used for collecting and processing signals output by the eddy current probe and the ultrasonic probe; and the main controller is used for displaying and setting parameters of the human-computer interaction module, thereby bringing convenience for a user to operate.

Owner:武汉展科科技有限公司

Environment-friendly rotary screen printing coating

InactiveCN105040475AInhibition releaseAvoid harmDyeing processScreen printingEnvironmental resistance

The invention discloses an environment-friendly rotary screen printing coating. The environment-friendly rotary screen printing coating is formed by mixing 50-300 ml of plant pigment, 5-20 g of a natural thickening agent, 30-250 g of a water soluble bonding agent, 5-20 g of a wetting agent, 120-260 g of pearl powder, 1-10 g of nanometer TiO2 and 1L of water. The environment-friendly rotary screen printing coating has the main advantages that the plant pigment is adopted, so that safety and environmental protection are achieved, the phenomenon that synthetic dyestuff or petrifaction dyestuff releases toxic and harmful substances in the using process is avoided, the method is simple and efficient and can extract pigment from plants for preparing the coating, and the water soluble additive agent is adopted, so that damage caused by adopting formaldehyde to the human body is avoided.

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

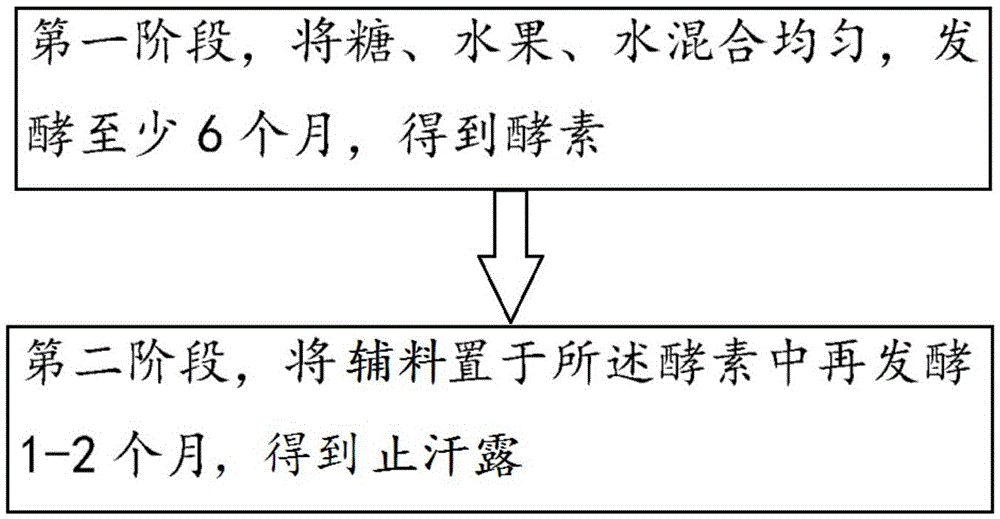

Antipersprant deodorant and preparation method thereof

The invention discloses antipersprant deodorant. The antipersprant deodorant is prepared from, by weight, 1-5 parts of sugar, 3-16 parts of fruits, 15-50 parts of water and 3-10 parts of auxiliaries, wherein the fruits include one or more of apple, pear, strawberry, banana, pineapple, arrange, tangerine, papaya, watermelon, mango, plum, green date, sour haw apple, olive, white pitaya, red pitaya and lemon, and the auxiliaries include one or two of lemon and mint leaves. Raw materials of the antipersprant deodorant do not contain harmful petrifaction components, and harms to human bodies can be avoided.

Owner:YUNNAN RENBEN BIOTECH CO LTD

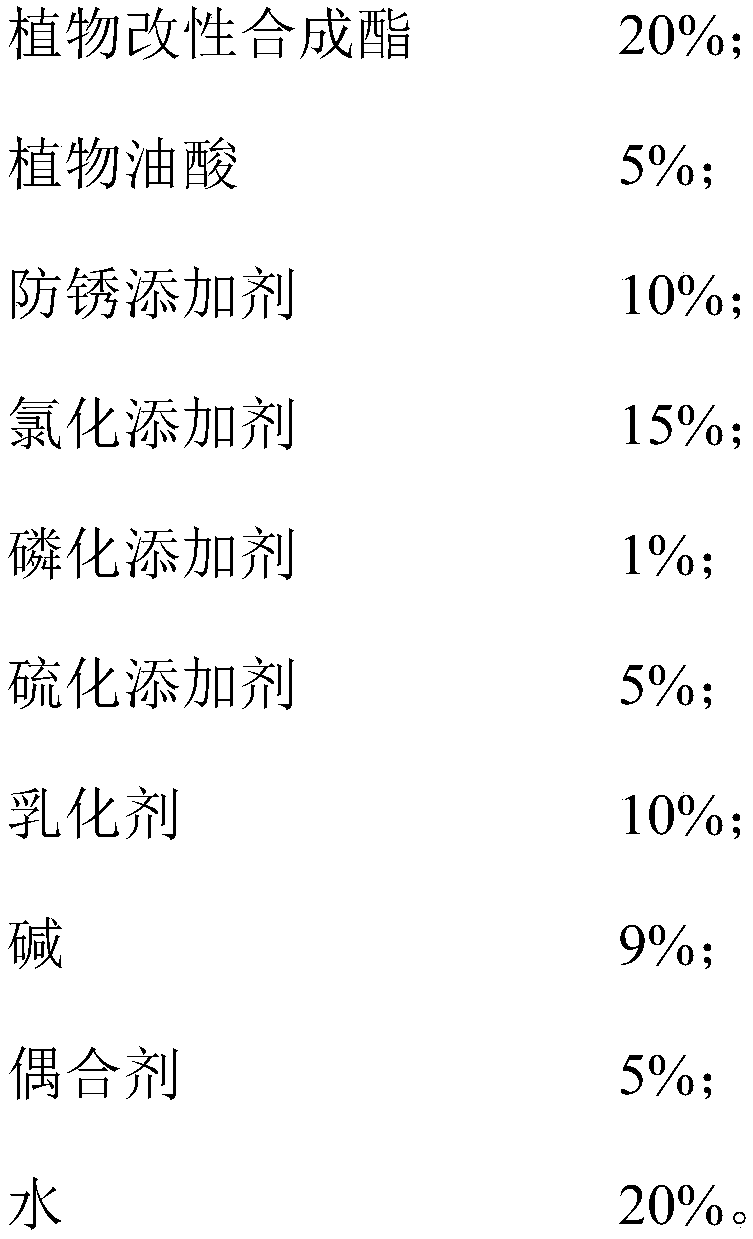

Novel leakage-free dry type hose connector assembly

The invention relates to a novel leakage-free dry type hose connector assembly. In China, a traditional design manner is basically adopted in an existing hose connector, an automatic interlocking mechanism does not exist, a coupler and an adapter often cannot be closed when the connector is cut off, accidental leakage of liquid materials is caused, the phenomenon can be frequently seen in a gas station, and gasoline or diesel oil leaks from a connection sleeve of a fuel filling hose. The novel leaking-free dry type hose connector assembly comprises a female connector and a male connector. A plurality of protruding copper sleeves are arranged on the inner wall of the lower portion of the female connector, an inwards-concave clamping groove is annually formed in the outer wall of the upper edge of the male connector, notches matched with the copper sleeves in terms of amount and size are formed in the upper wall of the clamping groove, and the female connector and the male connector are mutually connected through the copper sleeves and the clamping groove. According to the novel leaking-free dry type hose connector assembly, leaking of liquid in conveying is reduced to the maximum, and in addition, a safety guarantee is provided for operators and the environment. The novel leaking-free dry type hose connector assembly is widely applied to dripping-free and leaking-free conveying of liquid of industries of petrifaction, medicine, food and the like.

Owner:高安市璐克斯机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com