Grading treatment method of toxic chemicals of petrochemical enterprise

A technology for hierarchical processing and chemicals, applied in data processing applications, instruments, resources, etc., can solve problems such as difficult access to data support, inability to directly judge, and increased management difficulty and cost for enterprises, and achieve the effect of improving the efficiency of poison safety management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention proposes a classification treatment method for toxic chemicals in petrochemical enterprises. The present invention will be further clearly and completely described below in conjunction with specific examples.

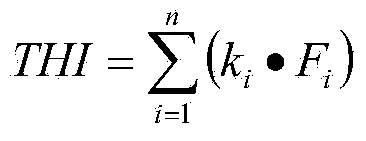

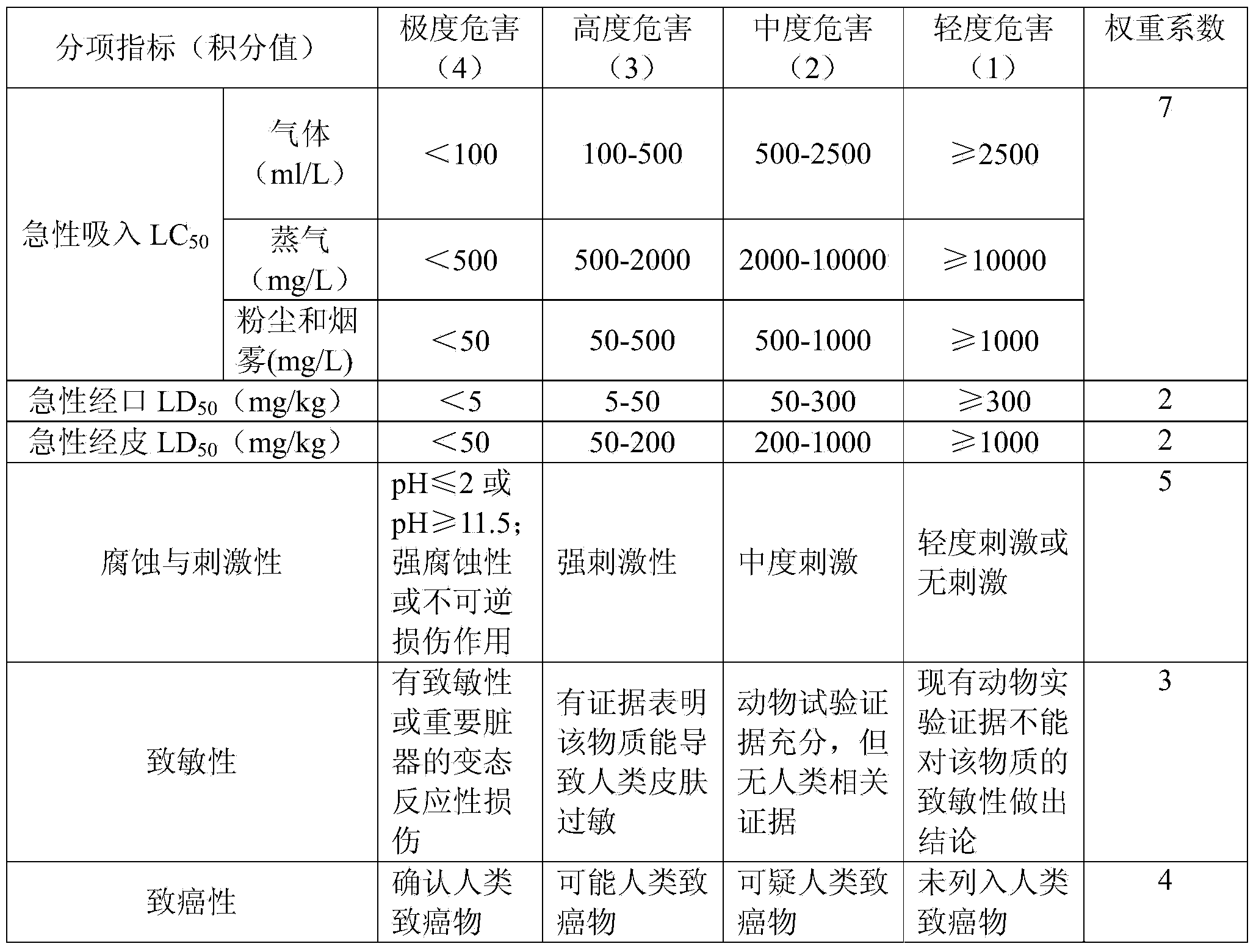

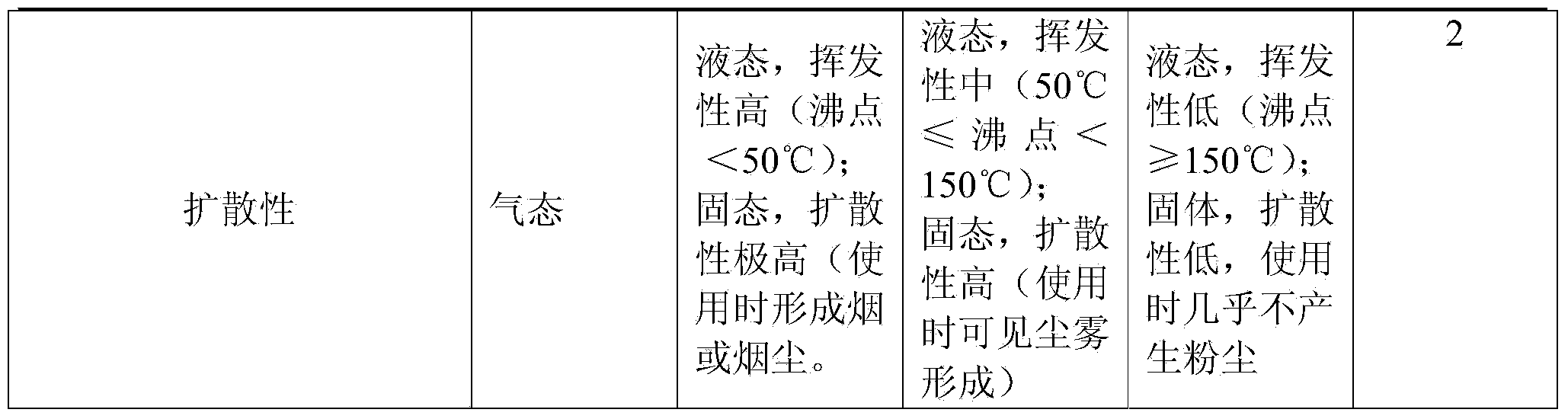

[0026] The present invention is a grading standard based on five indicators of acute toxicity, corrosion and irritation, sensitization, carcinogenicity and diffusivity of toxic chemicals. The grading principle is determined based on the comprehensive analysis of the five grading indicators and the calculation of the toxic hazard index. Each indicator is divided into several grades according to the degree of hazard and given corresponding points (1 point for mild hazard; 2 points for moderate hazard; 3 points for high hazard; 4 points for extreme hazard). At the same time, assign corresponding weight coefficients according to the impact of each index on occupational hazards. Based on the sum of the weighted scores of each indicator, namely t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com