Novel leakage-free dry type hose connector assembly

A hose joint, dripping technology, applied in the direction of pipes/pipe joints/fittings, pipe joints, hose connection devices, etc., can solve the problems of gasoline or diesel leakage, fluid material leakage, etc. Small size and mass, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

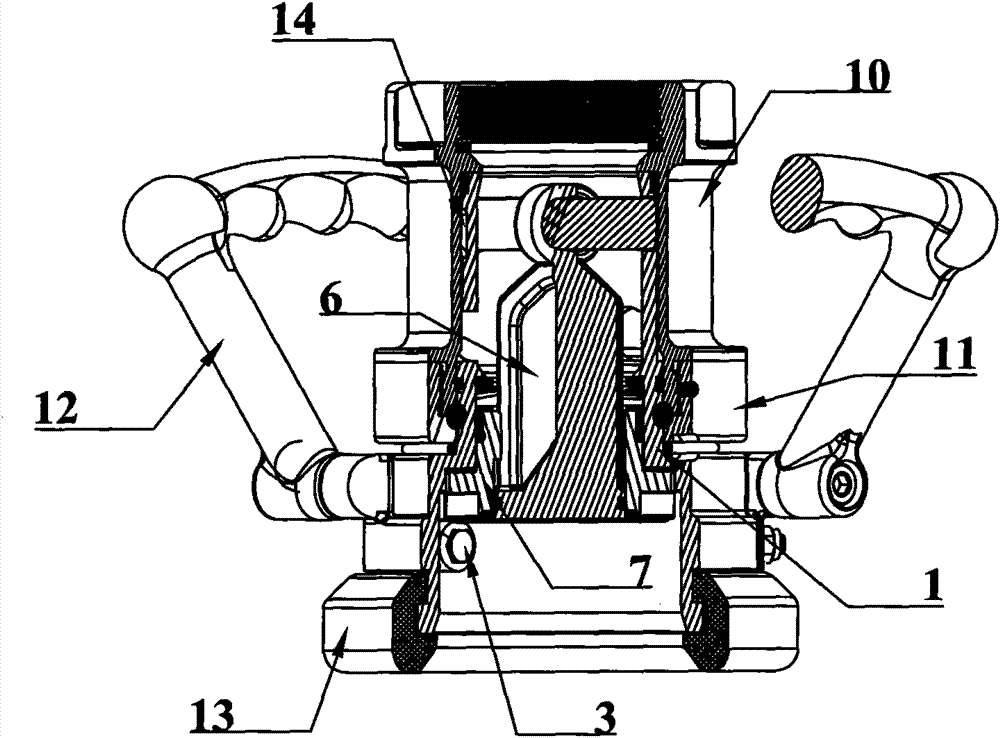

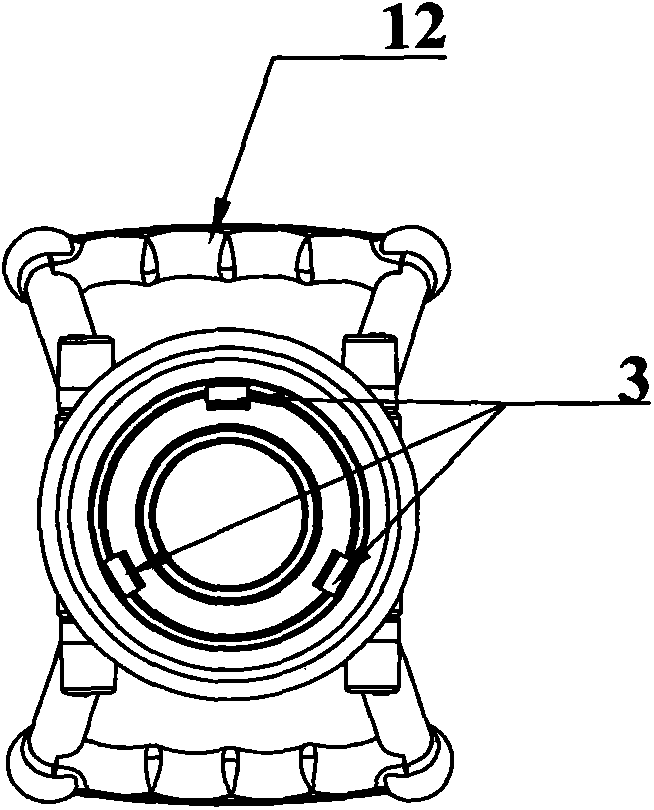

[0030] like Figures 1 to 5 As shown, the new type of non-drip dry hose joint assembly includes a female joint 1 and a male joint 2. There are several protruding copper sleeves 3 on the inner wall of the lower part of the female joint 1. The male joint 2 is ring-shaped along the outer wall. An inset card slot 4 is provided, and the upper wall of the card slot 4 is provided with a gap 5 matching the copper sleeve 3 in number and size, and the female joint 1 and the male joint 2 rely on the copper sleeve 3 Connect with card slot 4.

[0031] A through cavity is formed inside the female joint 1, and a tie rod sealing valve 6 is arranged in the through cavity, and a fixing frame 7 is arranged on the inner wall of the through cavity, and the tie rod sealing valve 6 is slidably fitted on the fixing frame 7 .

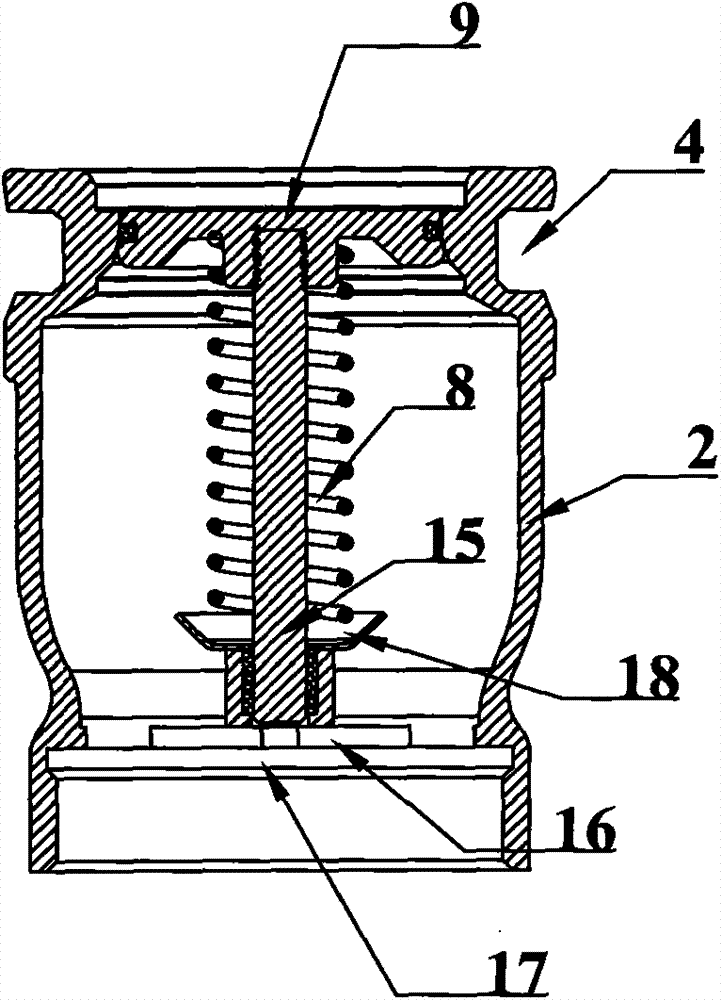

[0032] A cavity is formed inside the male joint 2, and a telescopic return spring 8 is fixed in the cavity. The lower end of the telescopic return spring 8 is fixed on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com