Patents

Literature

677 results about "Hose coupling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hose coupling is a connector on the end of a hose to connect (or couple) it with another hose or with a tap or a hose appliance, such as an irrigation sprinkler. It is usually made of steel, brass, stainless steel, aluminium or plastic.

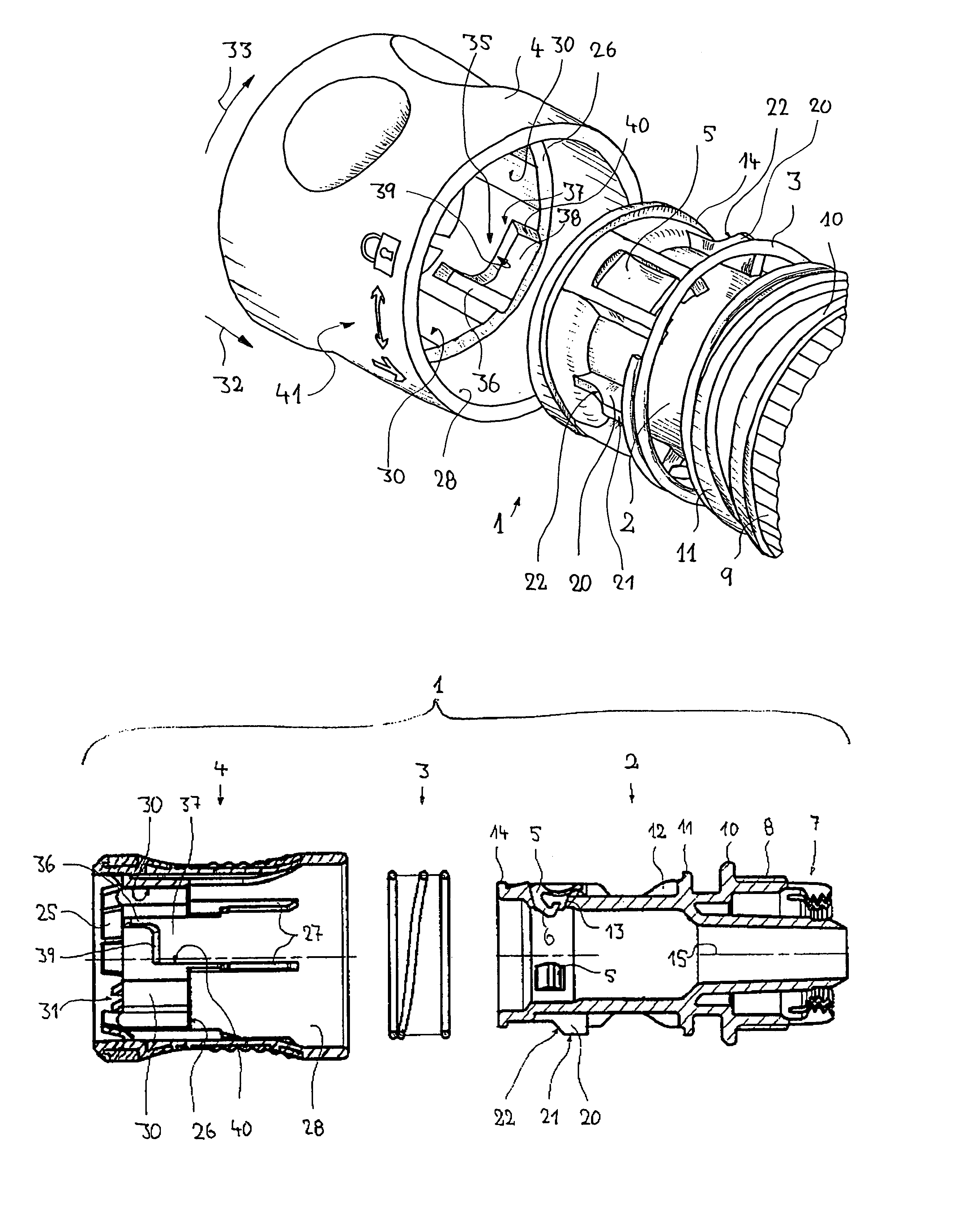

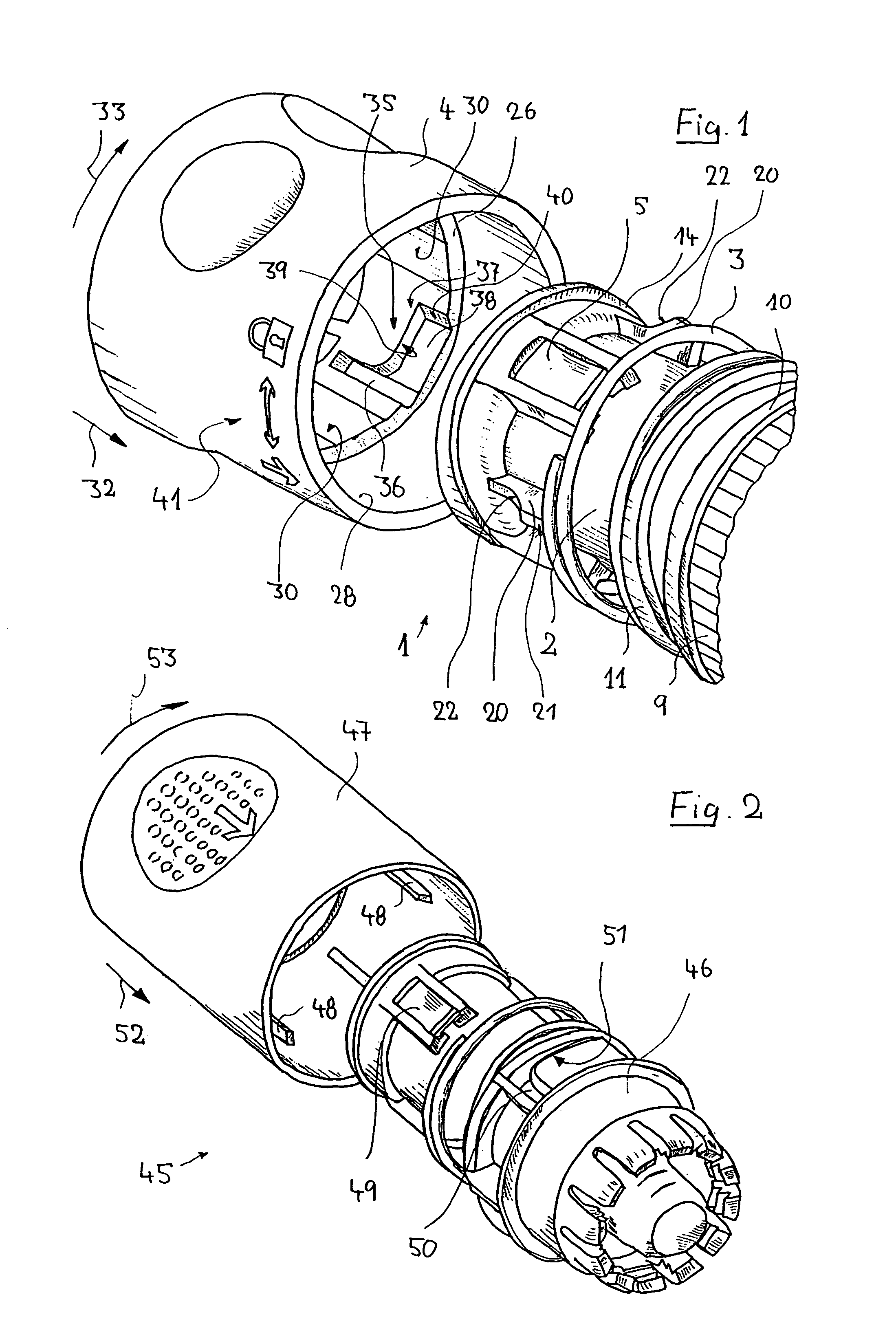

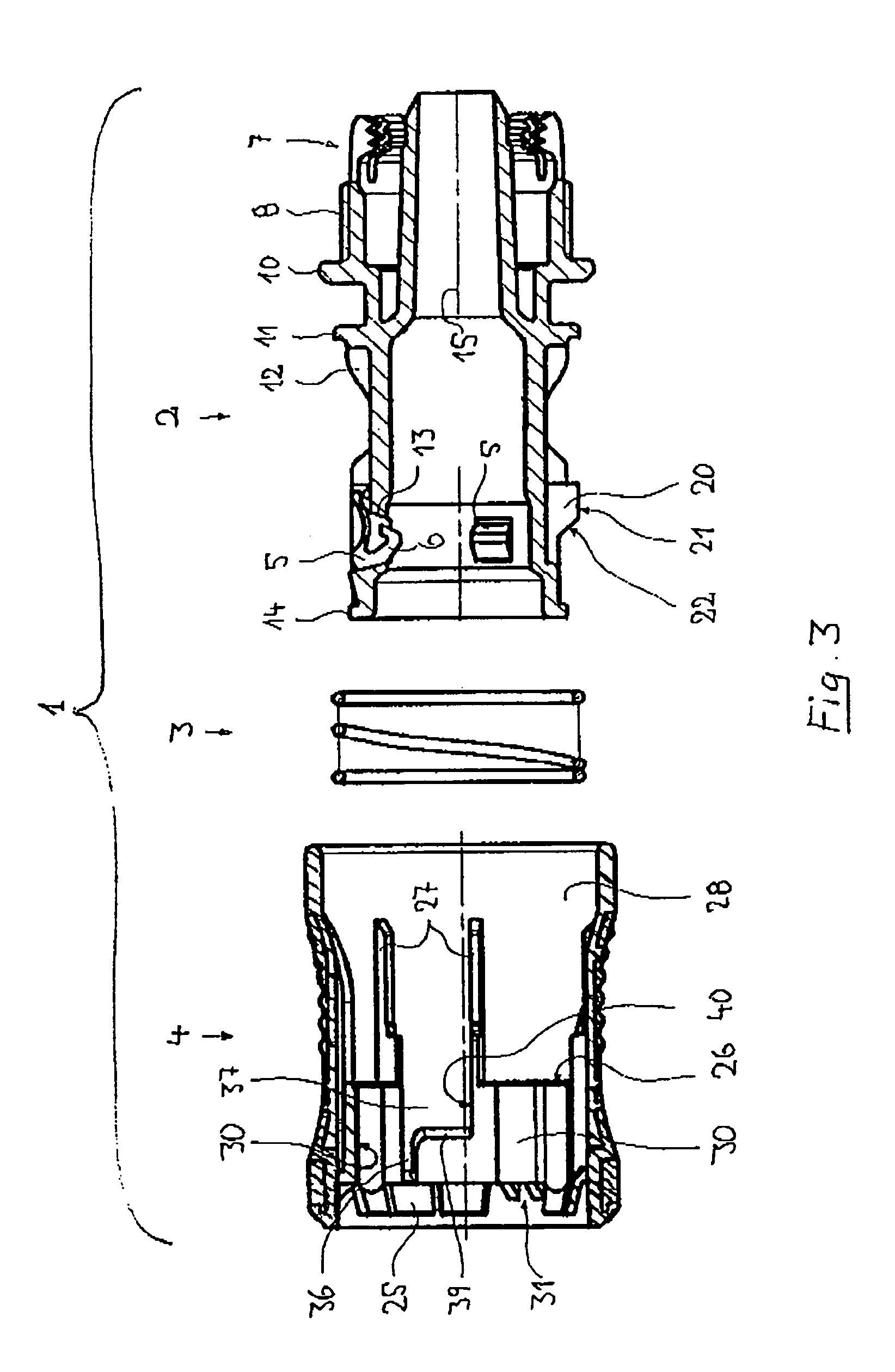

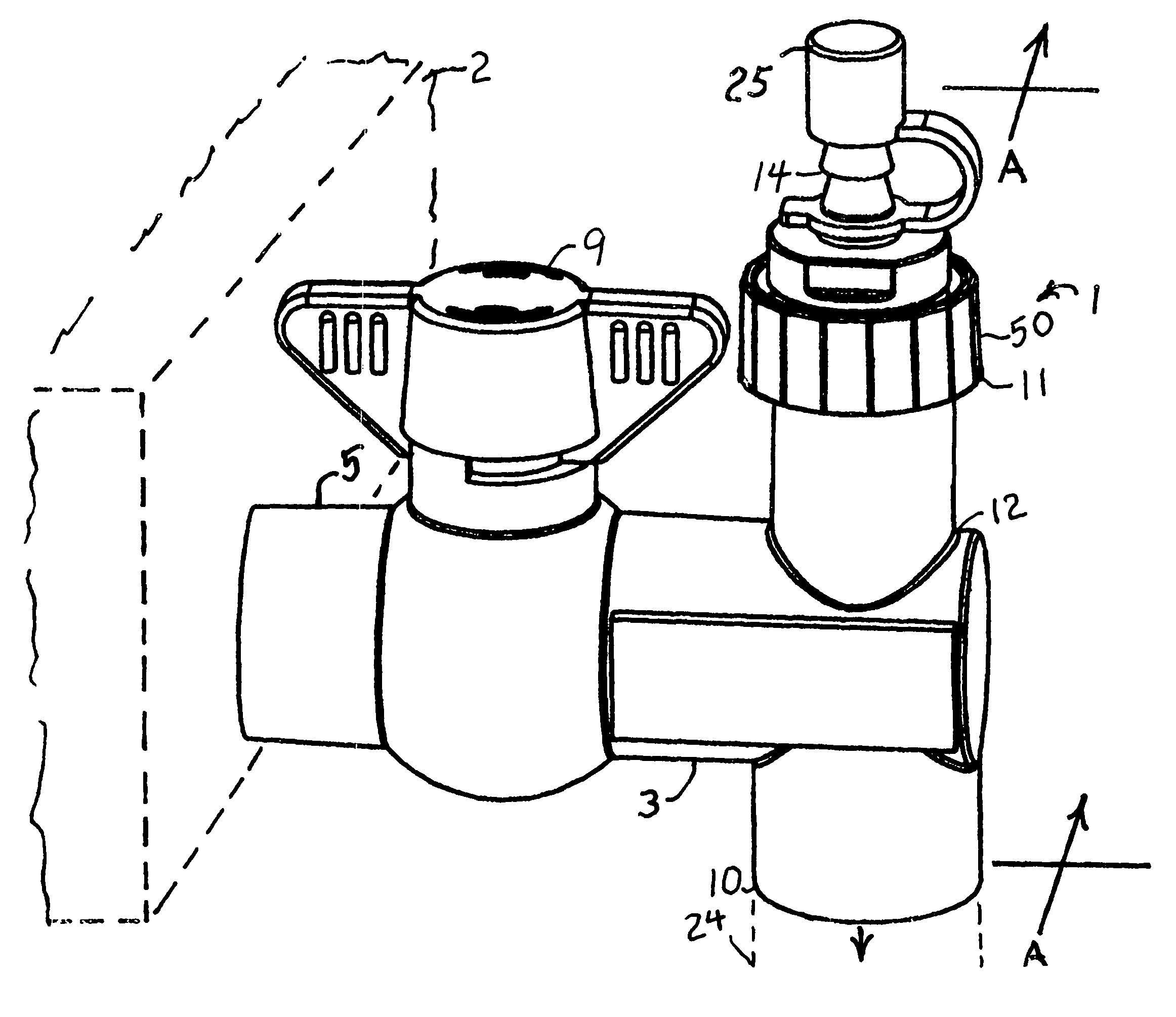

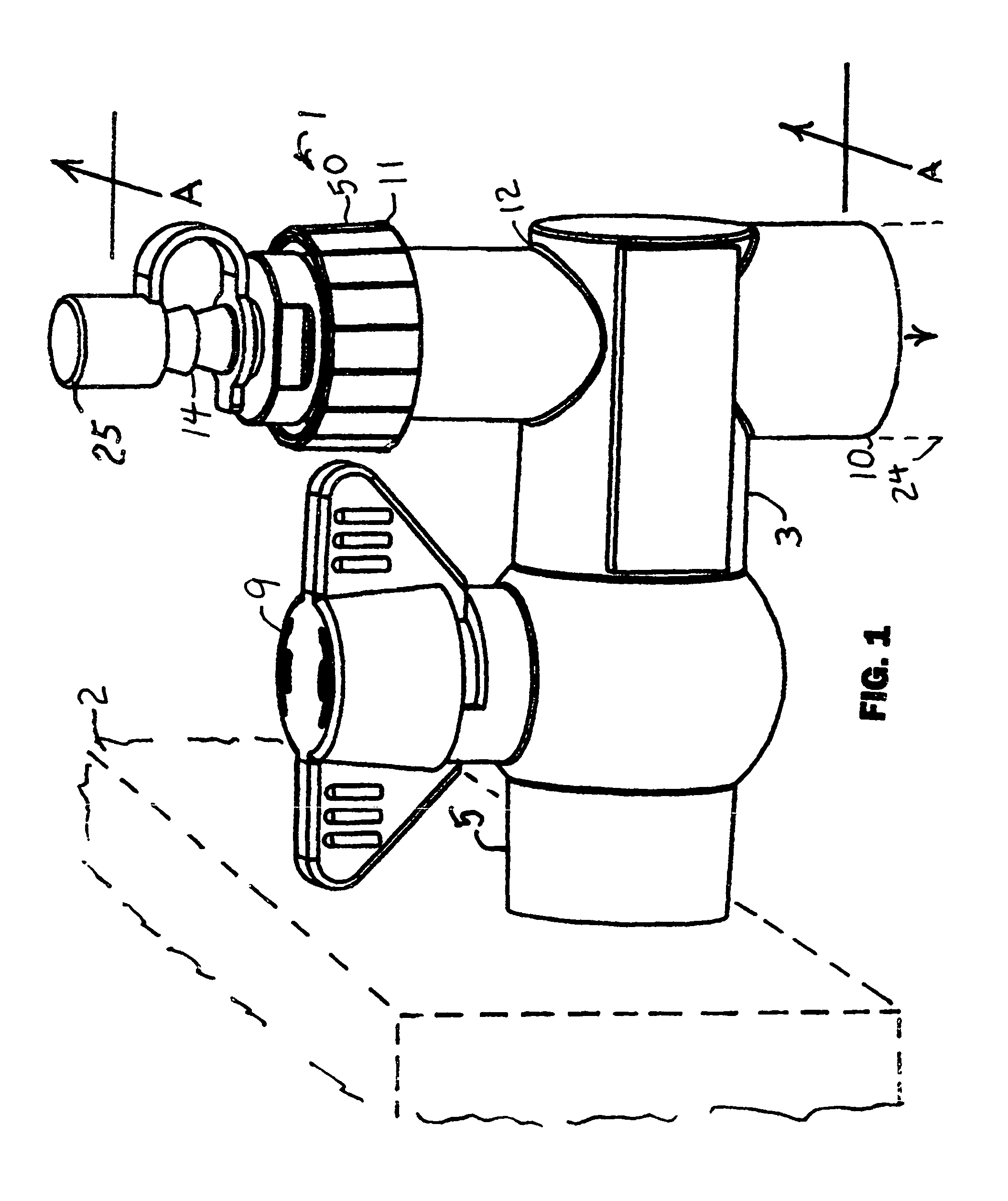

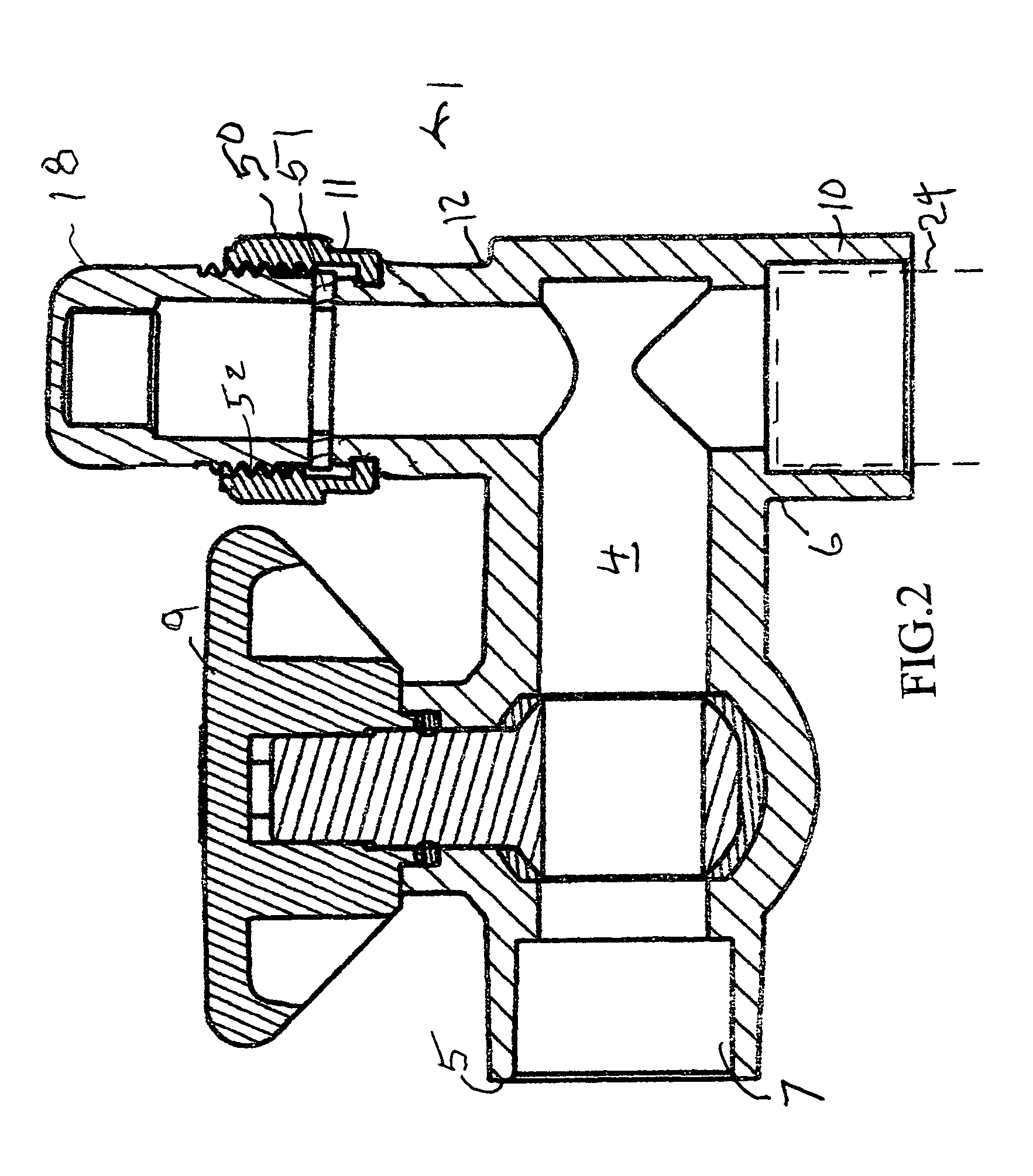

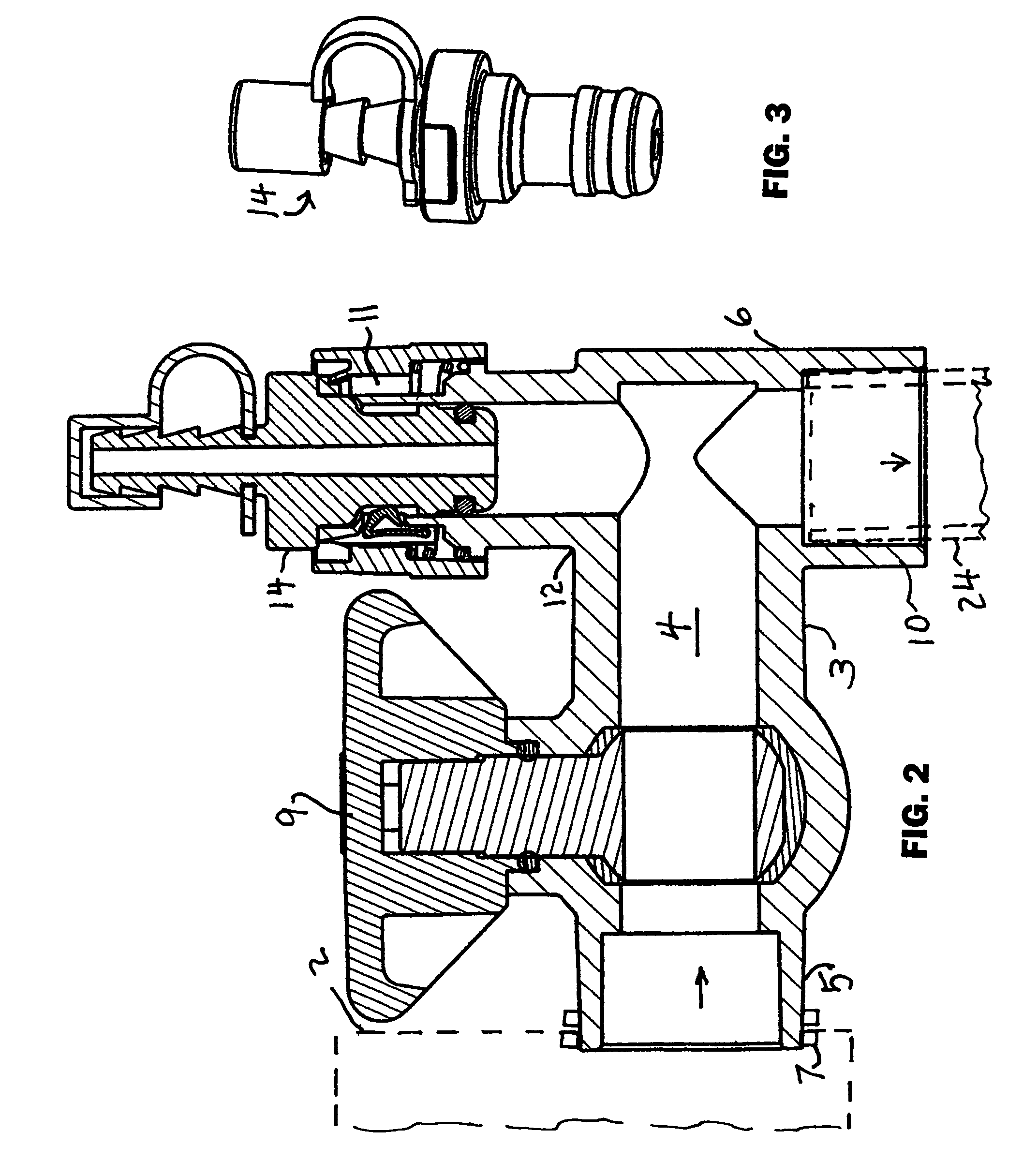

Coupling part for a fluid coupling device

InactiveUS7021669B1Avoid disconnectionGuaranteed uptimeSleeve/socket jointsEngine sealsFluid couplingEngineering

A coupling part for a fluid coupling device, especially a hose coupling, which has a looking device switchable between two positions. The locking device has locking elements mounted on a base body, and a socket-shaped actuating element that interacts with the locking elements. The coupling part is switchable between a retaining and releasing positions by an axial releasing movement of the actuating element. In the retaining position, the locking elements hold the counterpart of the coupling, e.g. a hose stem, to prevents it from being pulled out and, in the releasing position, the locking elements release the same in order to disengage the coupling. The actuating element can be moved from the retaining position into a locking position, prohibiting a releasing movement, by rotating the actuating element in a limited manner around the longitudinal axis of the coupling. As a result, the coupling is prevented from being unintentionally disengaged.

Owner:GARDENA KRESS KASTNER GMBH

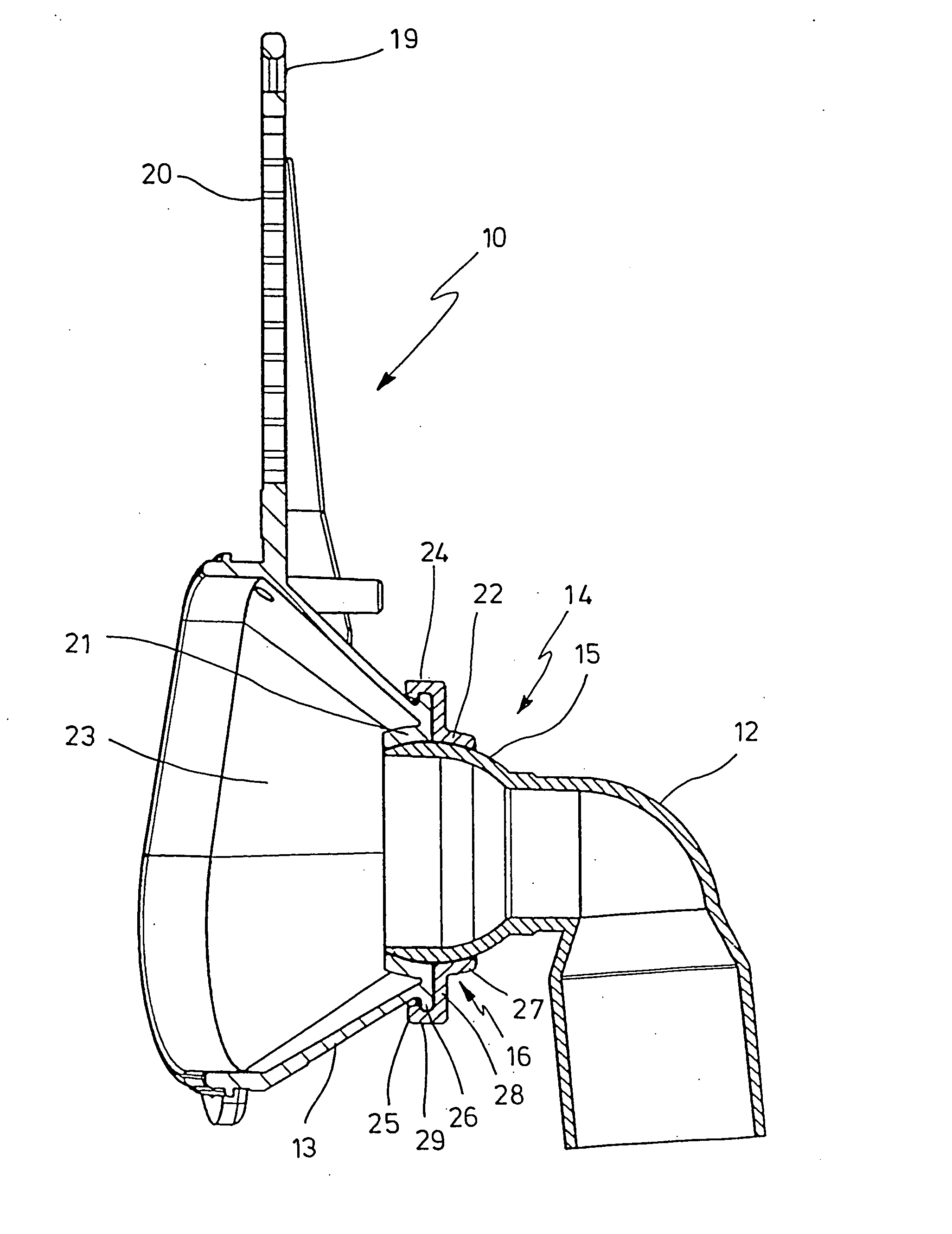

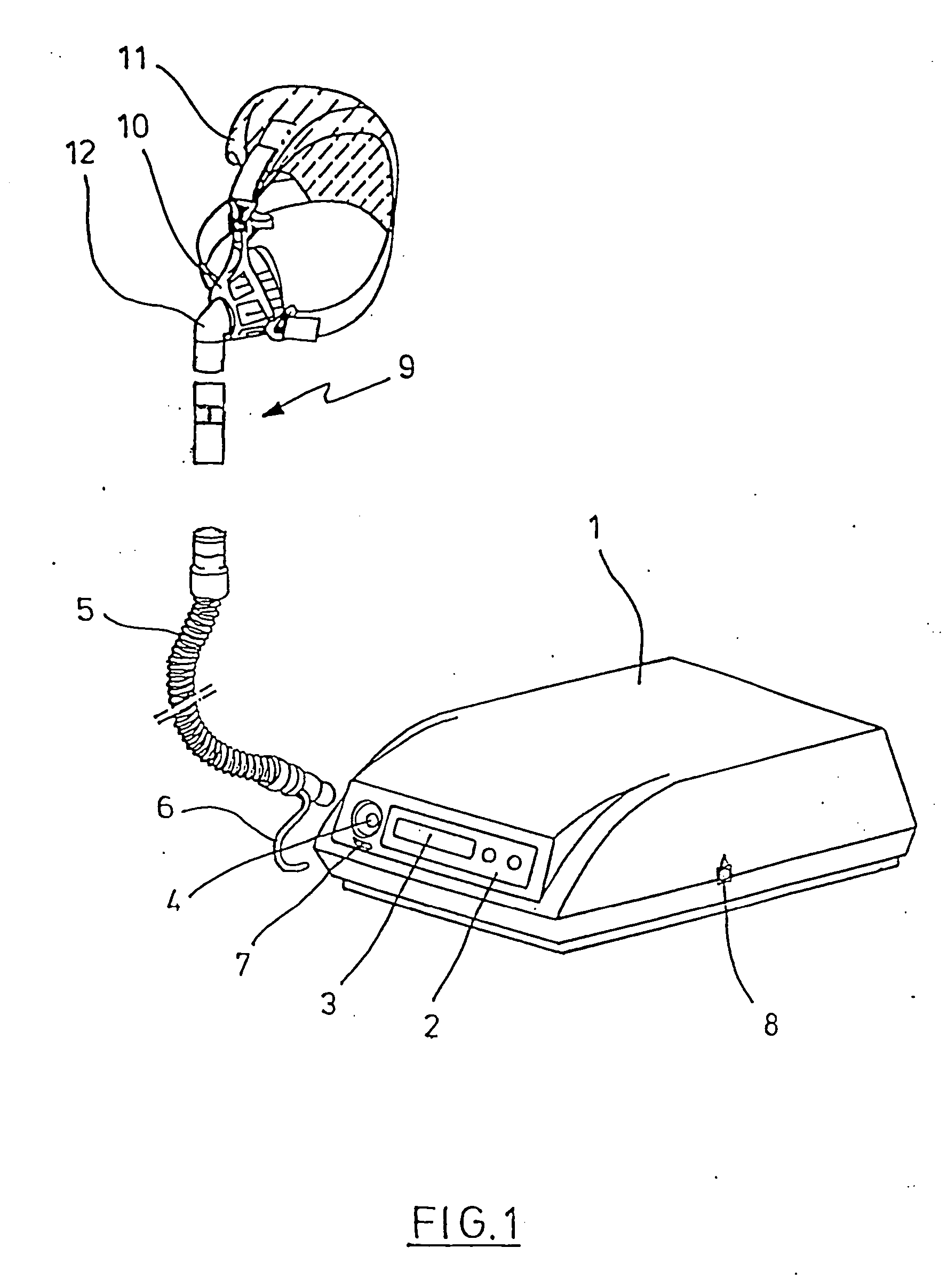

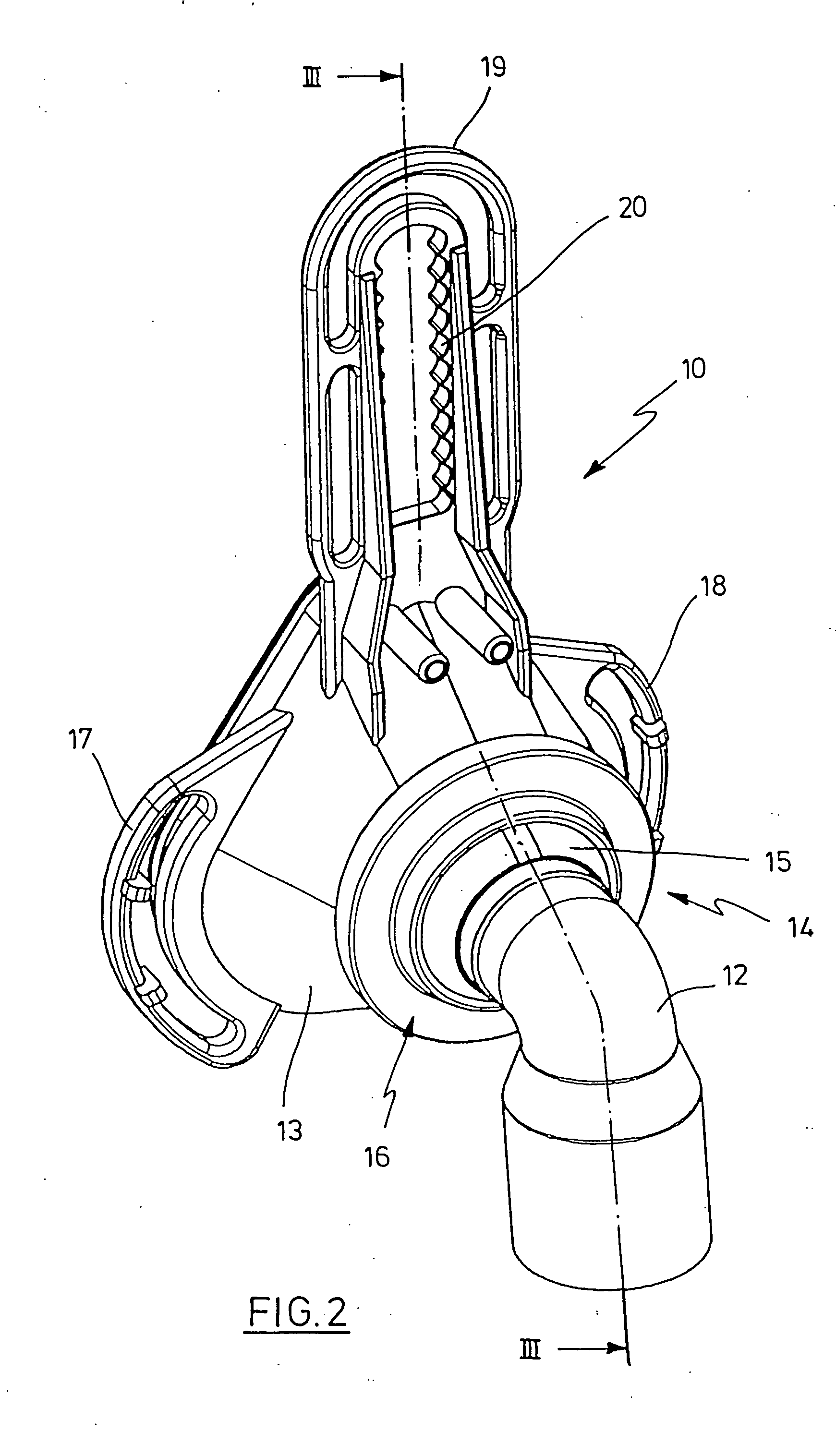

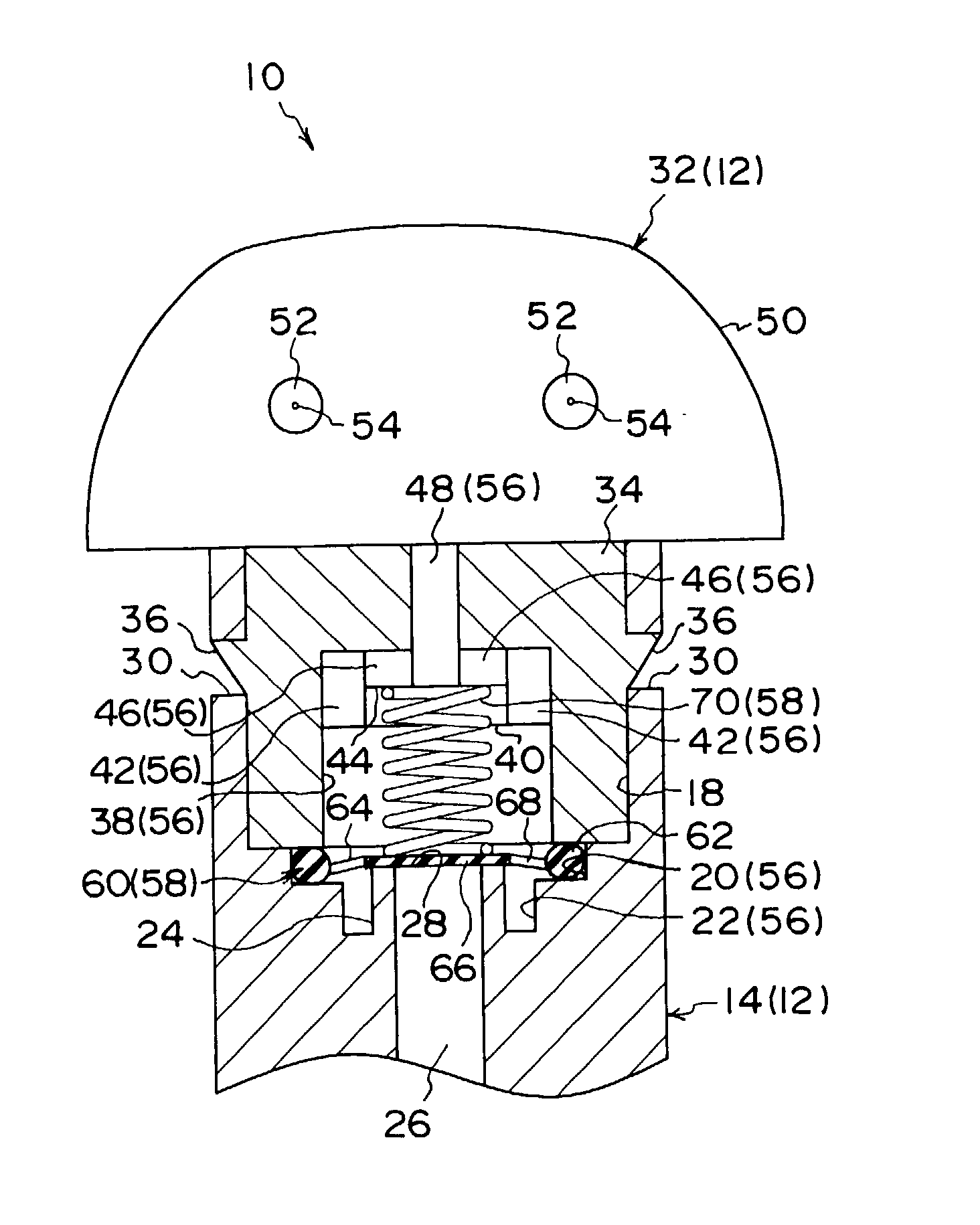

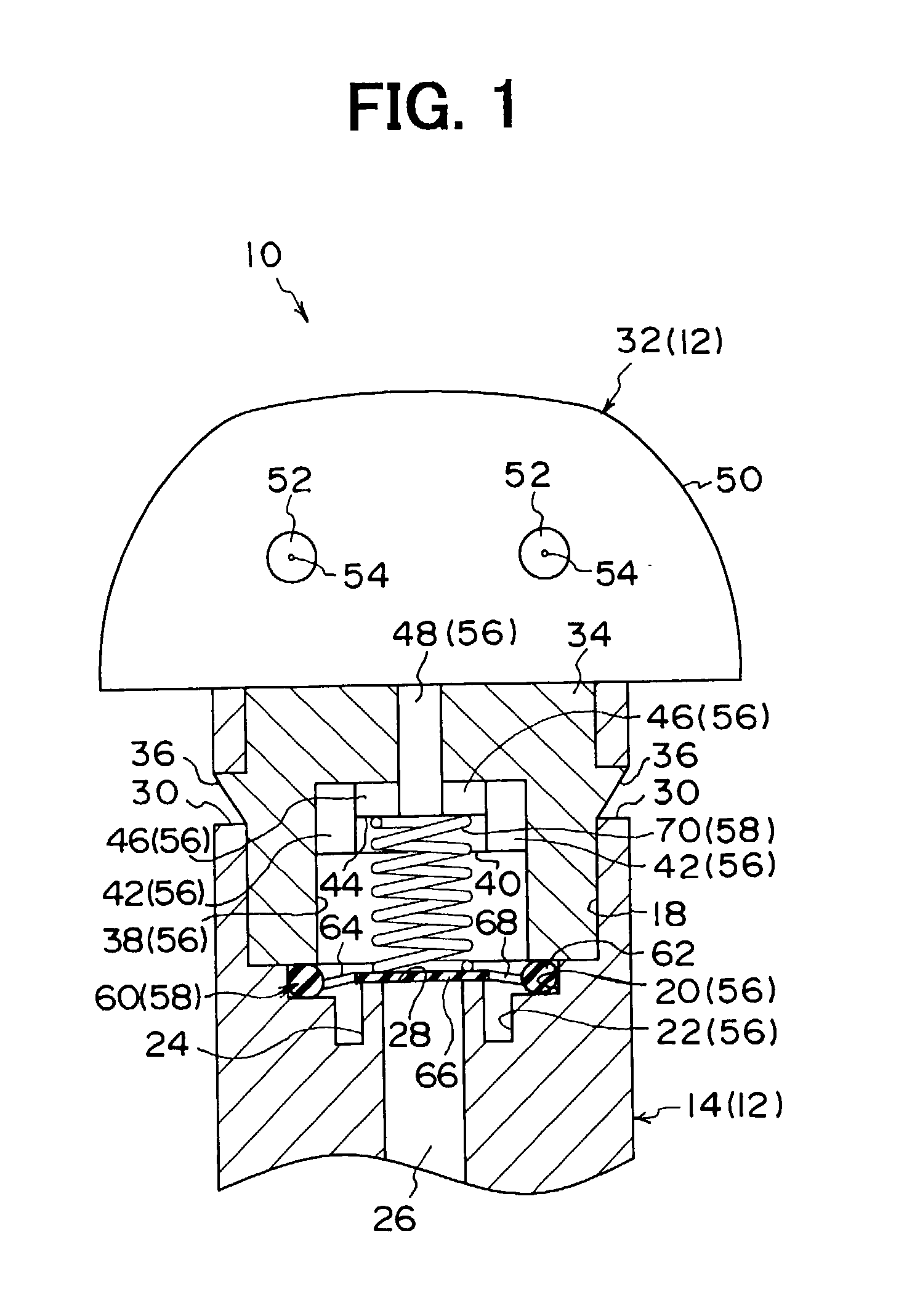

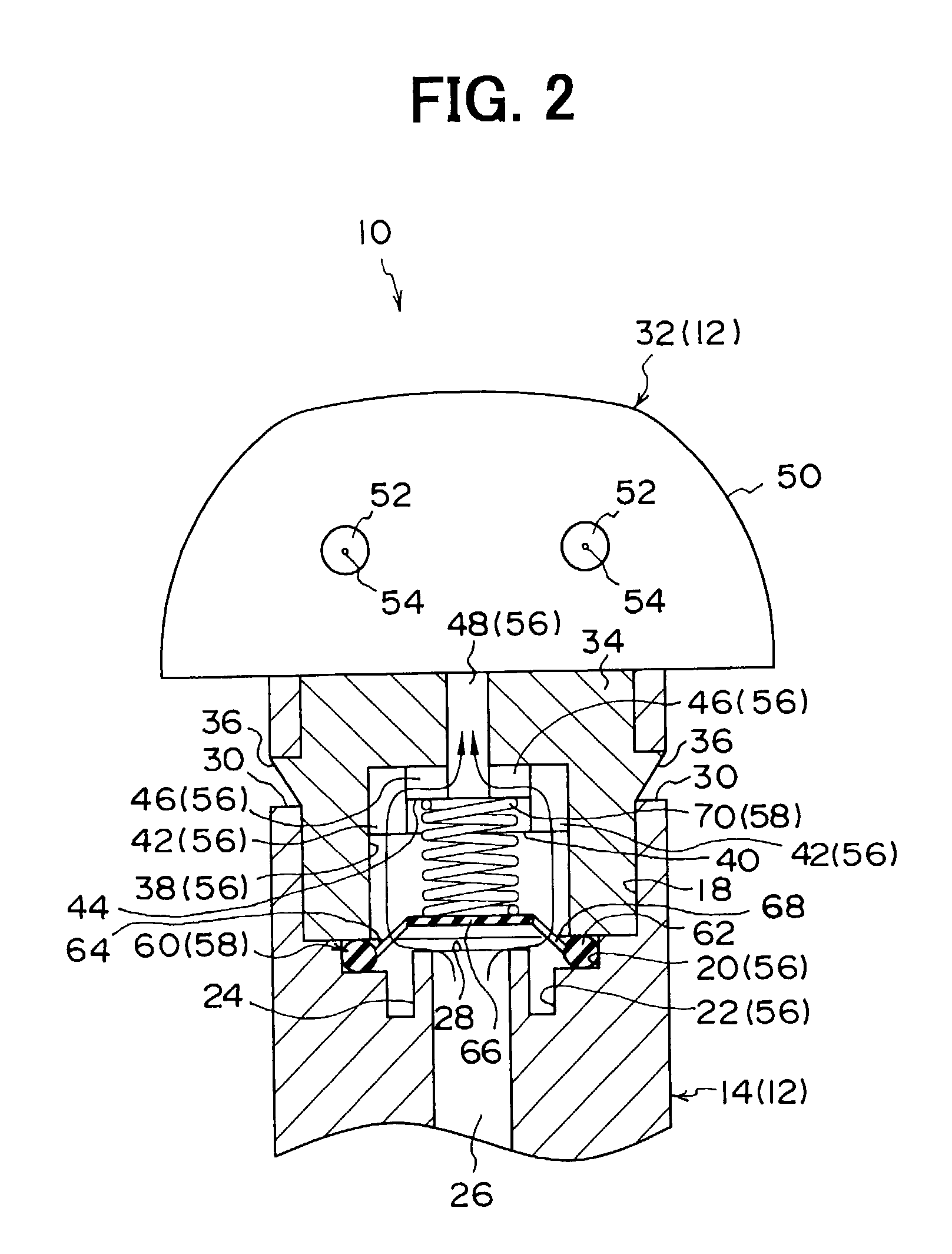

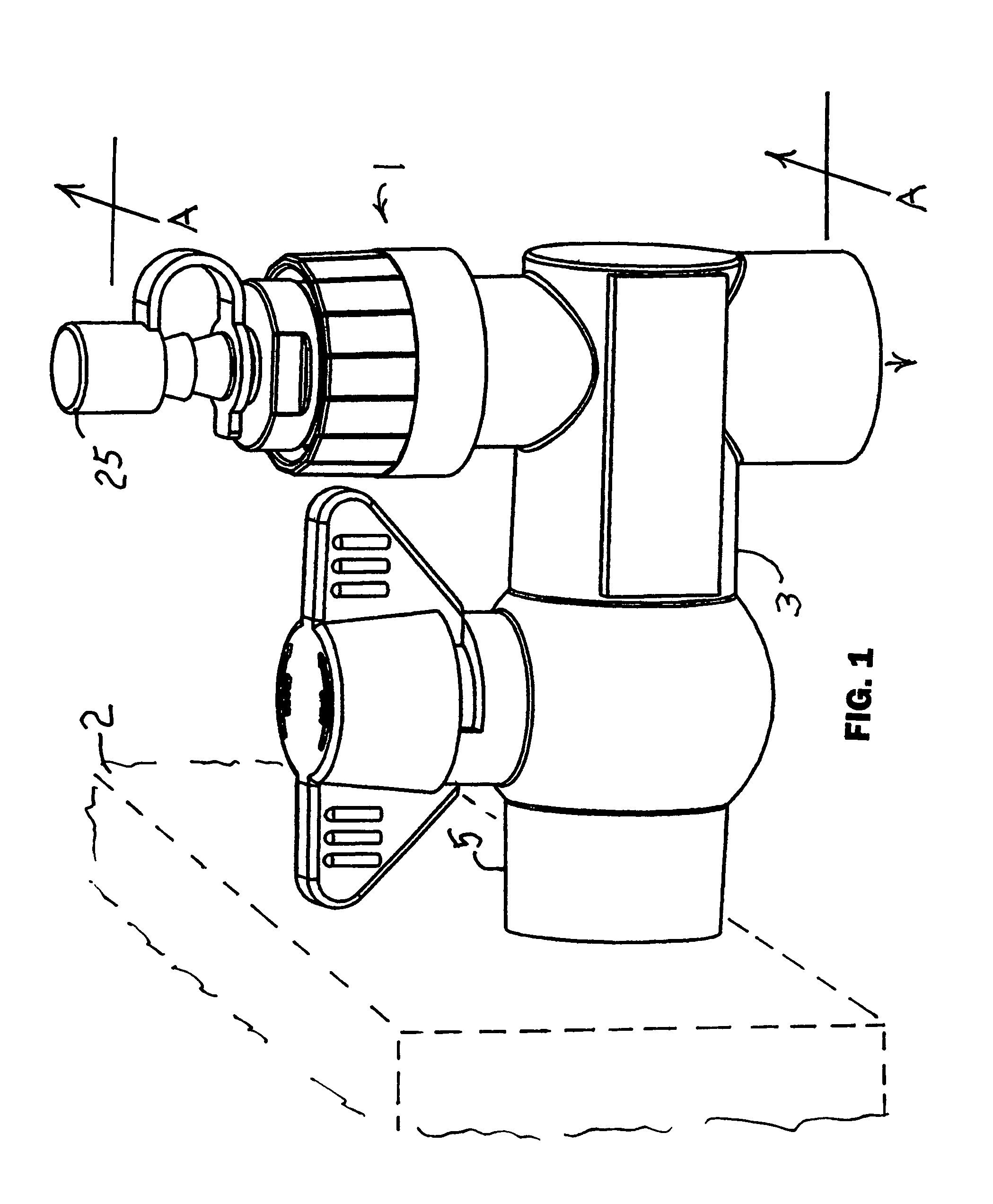

Ventilation device

InactiveUS20050150497A1Improve mechanical stabilityEasy to assembleRespiratory masksBreathing masksBreathing gasEngineering

A device used for ventilation includes a ventilation mask that can be connected to a respiratory gas hose. The ventilation mask has a respiratory gas hose coupling that is movably connected by a joint with the base of the ventilation mask. The joint is a ball-and-socket joint, which has an inner part that is shaped like a spherical segment and an outer shell for guiding the inner part. The outer shell is constructed from at least two shell segments that can be connected with each other.

Owner:WEINMANN GERATE FUR MEDIZIN

Breakaway hose coupling with a magnetic connection

ActiveUS7252112B1Simplifies reconnectionSimplifies recouplingValve arrangementsPipe elementsRare earthCoupling system

A breakaway coupling for a fuel supply hose includes a male valve body interfitting with a female valve body for defining a fuel passage, and the valve bodies enclose axially movable spring biased poppet valve members. The valve bodies are connected by a permanent magnetic coupling system which provides for moving the valve bodies from a connected position to a disconnected position in response to a substantial axial tension force on the valve bodies. In one embodiment, the coupling system includes an annular strike member surrounding the fuel passage and a mating annular magnet member supporting a plurality of circumferentially spaced permanent magnets of rare earth materials. In another embodiment, the valve bodies define a vapor return passage with a poppet valve member and disposed either radially outboard or inboard of the fuel passage. The magnetic coupling system also simplifies reconnecting the valve bodies.

Owner:GILBARCO

Valve device with check valve, used for washer nozzle and hose joint

A valve device with a check valve can be used for a washer nozzle and a hose joint. In the valve device, first and second body portions are detachably attached to each other by an attachment of a joint portion to a joint hole and by an engagement of engagement protrusions with engagement holes. A circular fixing portion of the check valve is clamped between the first and second body portions, thereby sealing an attachment portion between the first and second body portions. Further, the check valve includes plural connection portions connected to the fixing portion at a radial inside to be elastically deformed, and a valve body connected to the connection portions to open and close a supply port of the first body portion. Accordingly, the valve device has a simple structure, and it is possible to perform a maintenance in the valve device.

Owner:ASMO CO LTD

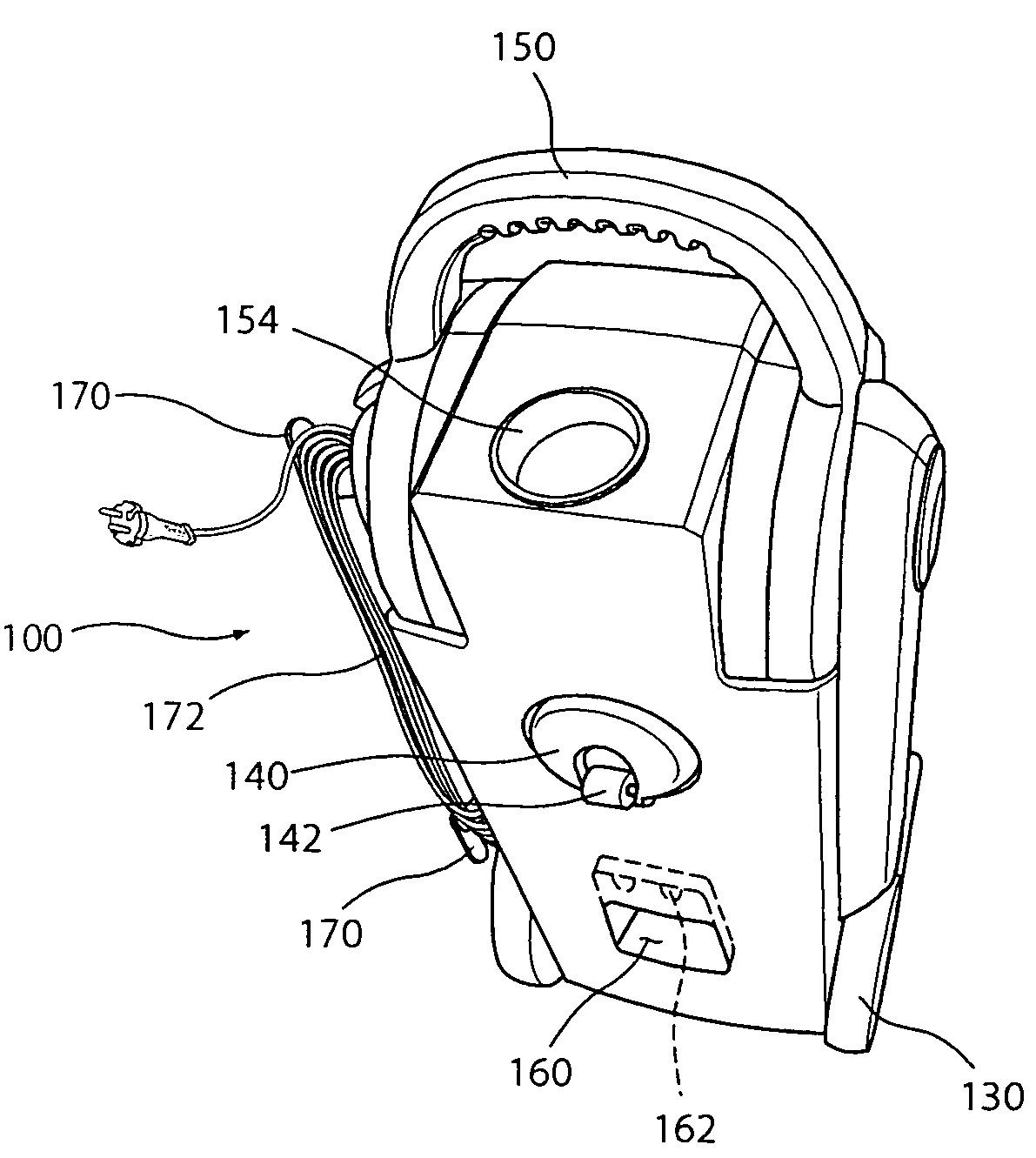

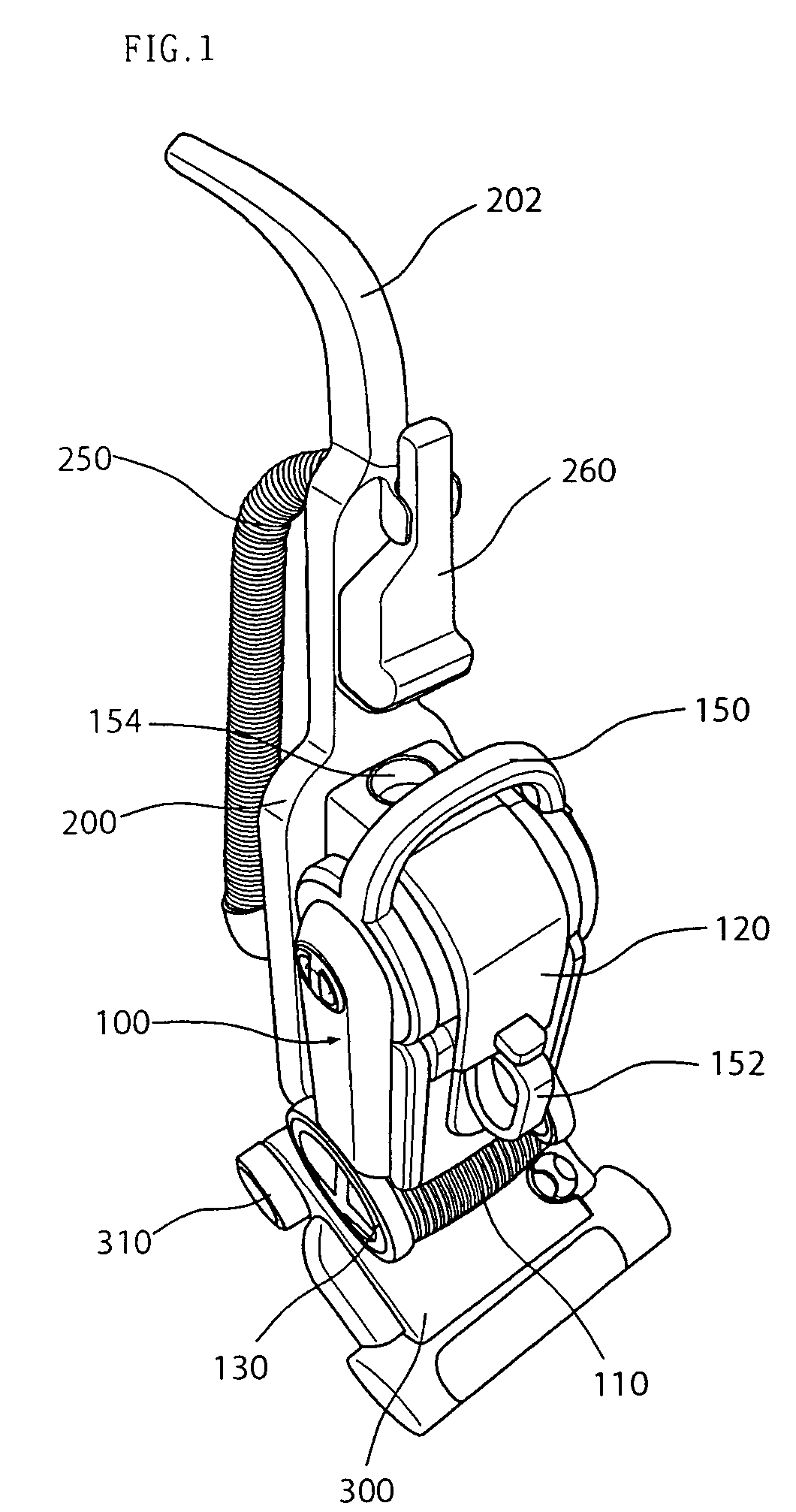

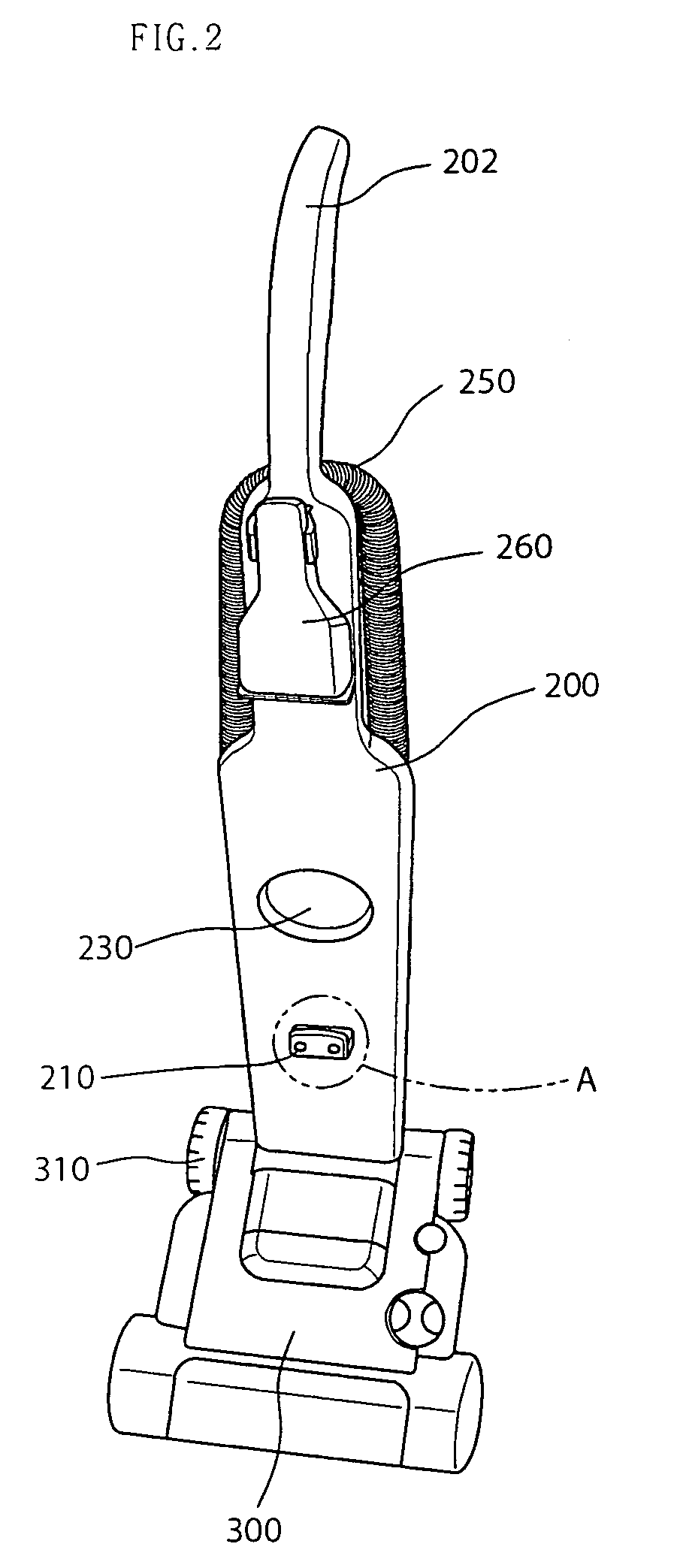

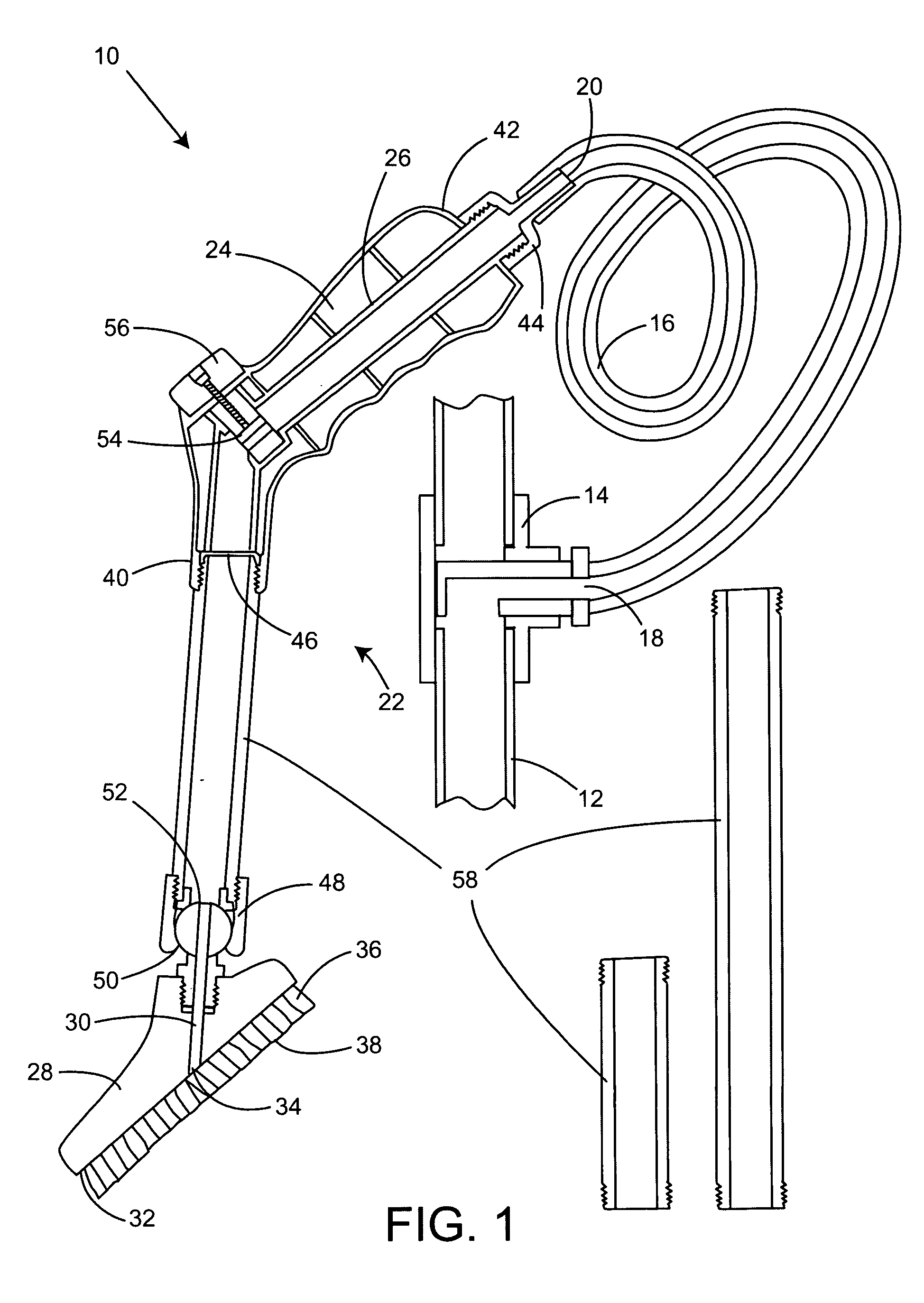

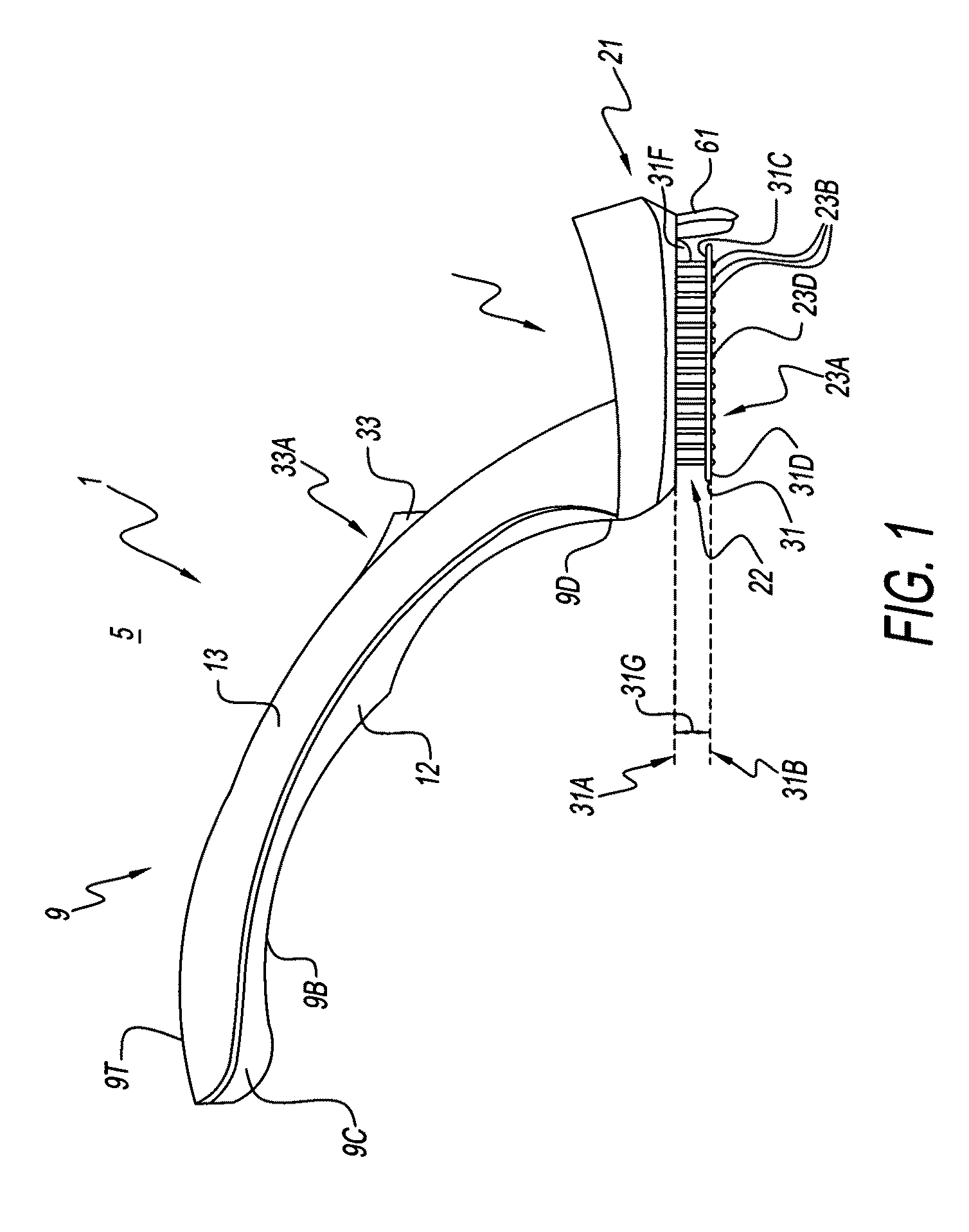

Convertible vacuum cleaner

InactiveUS7594296B2Securely detachably supportedSimple structureSuction cleaner storing devicesSuction forceEngineering

A convertible vacuum cleaner is provided. The vacuum cleaner includes a support base extending in a vertical direction, a main body selectively installed on the support base, a power generating unit disposed in the main body to generate a suction force, a suction nozzle unit that uses the suction force to draw in external air, a dust collection unit disposed in the main body to filter and collect dust and dirt contained in the external air, a flexible connection hose transmitting the suction force to the suction nozzle unit, a hose coupling portion formed on the main body to receive a first end of the connection hose, and a hook unit for supporting the main body on the support base.

Owner:LG ELECTRONICS INC

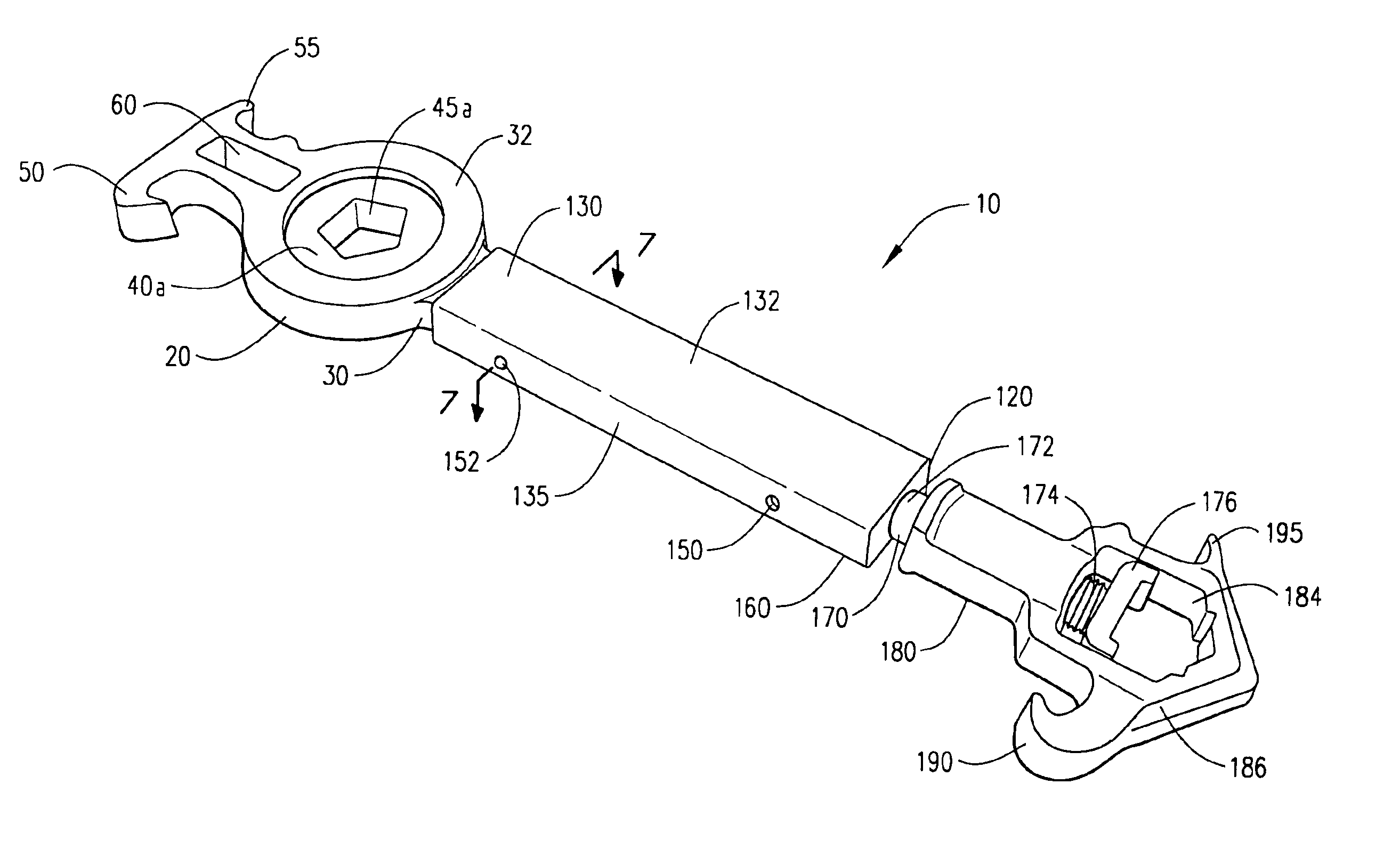

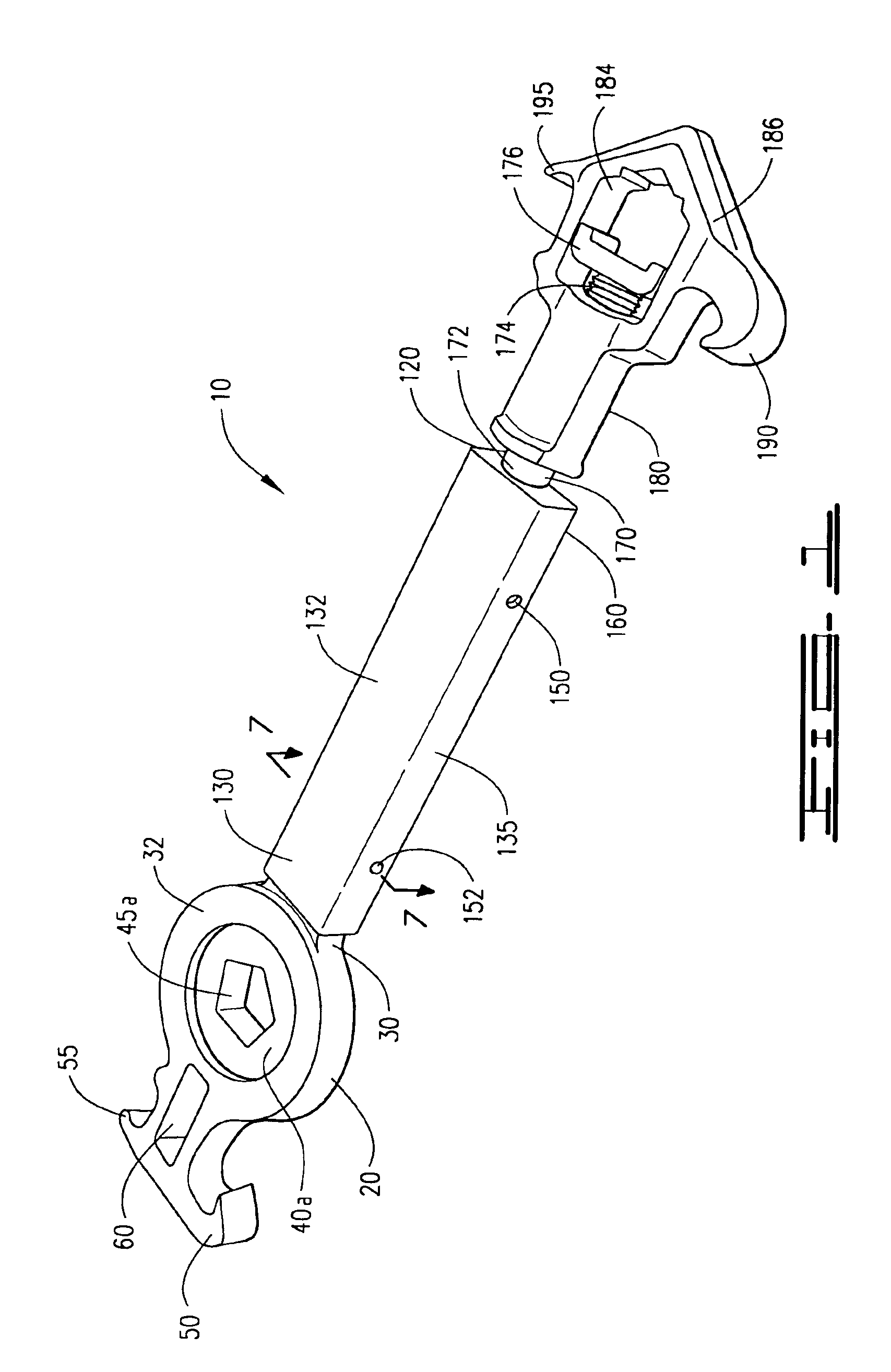

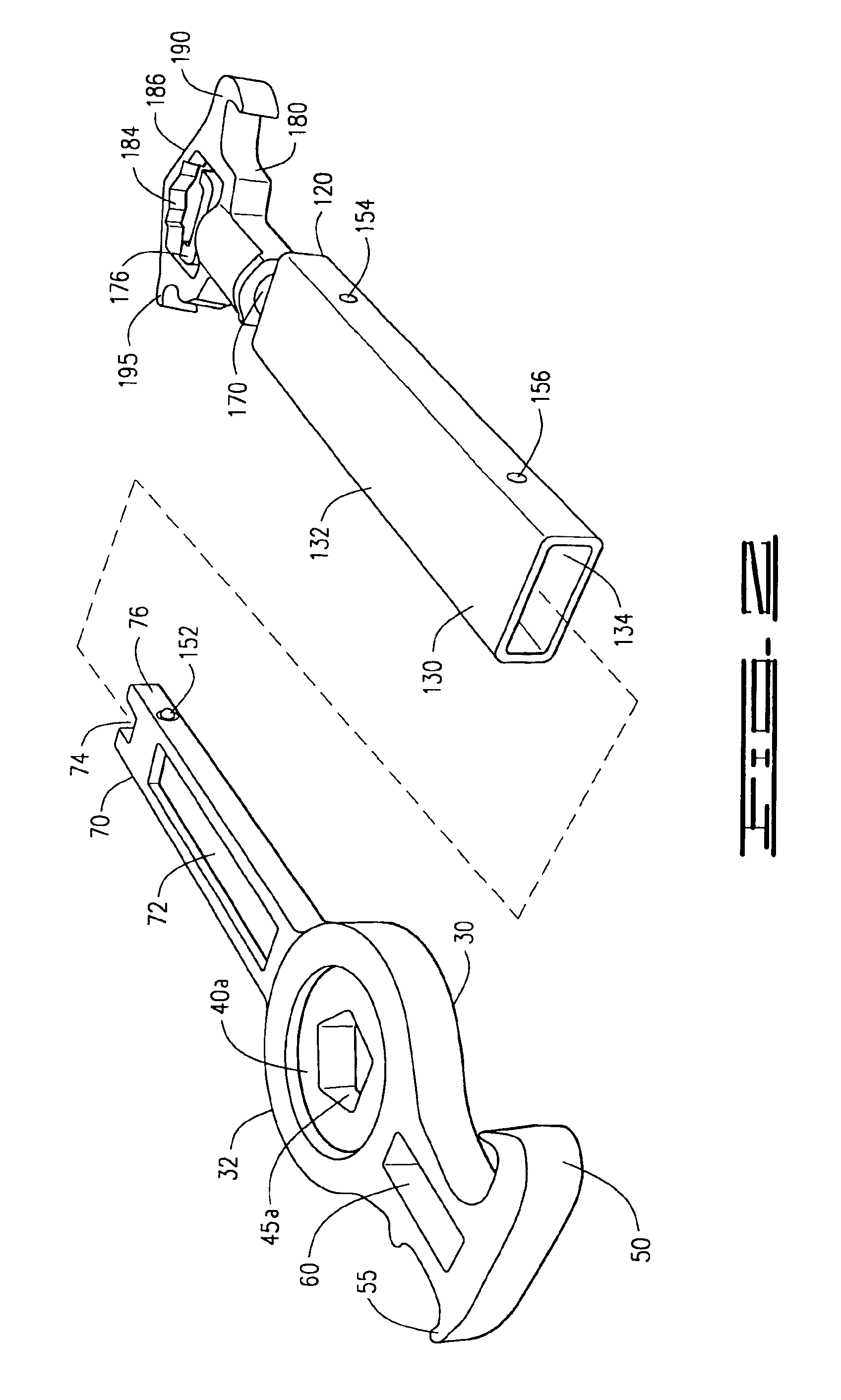

Firefighter's wrench

A multiple component wrench is adapted for use to attach and disconnect fire hose and hydrant coupling using this singular tool in lieu of several tools currently used by firefighters. The wrench has a sliding portion and a receiver portion presented as one tool, yet allowing multiple wrenches adapted for use on Storz and spanner hose couplings, rocker lug couplings, water meter shutoff valves, gas cock valves, pentagonal nuts and square nuts, and includes a multiple ratchet mechanism with multiple removable ratchets adapted to a variety of different nuts encountered on the multiple hydrants installed in various municipalities. The wrench is also extendable to provide additional leverage during use, the wrench further capable of separation forming two independent wrenches.

Owner:SANDERS ALAN +1

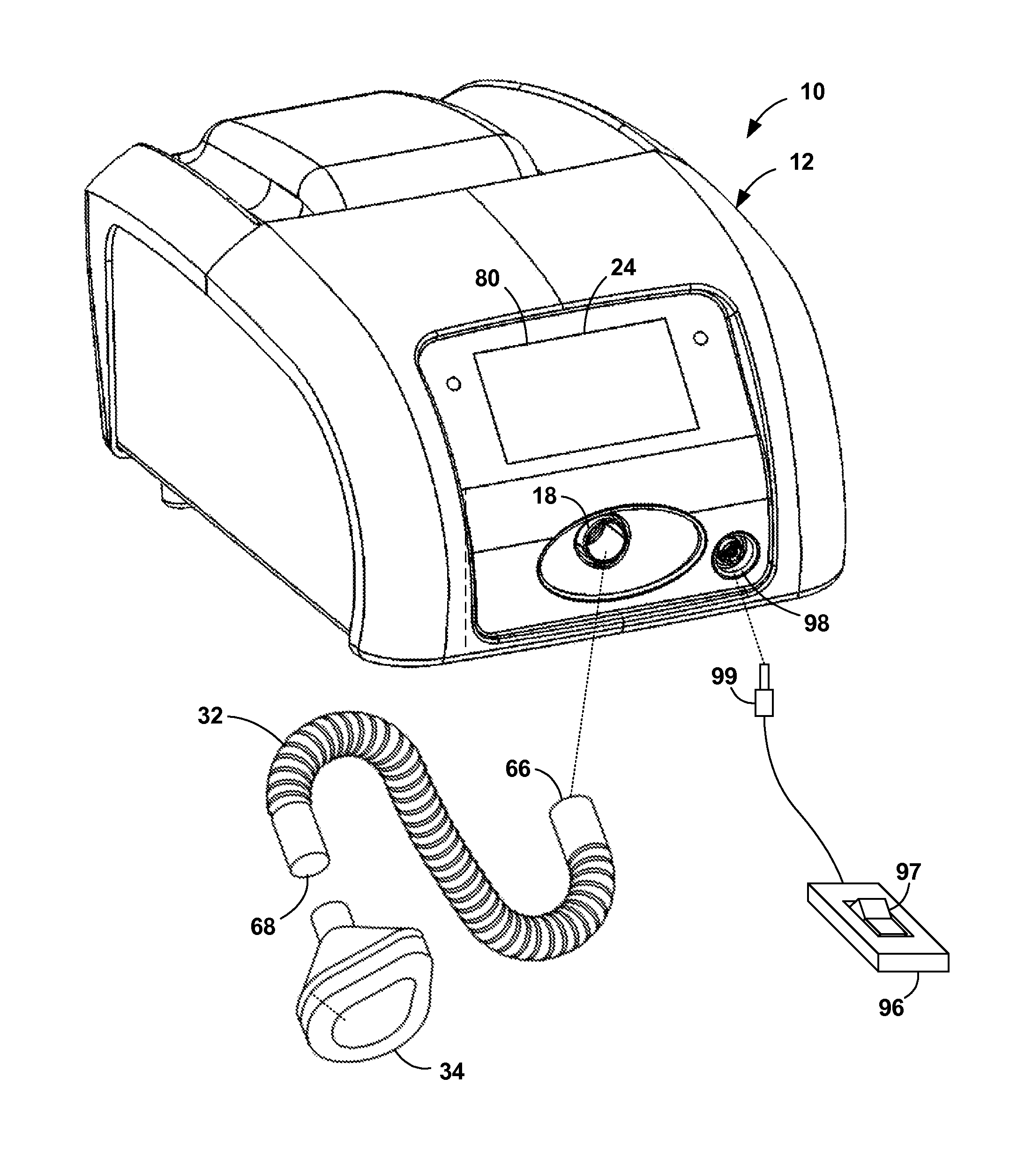

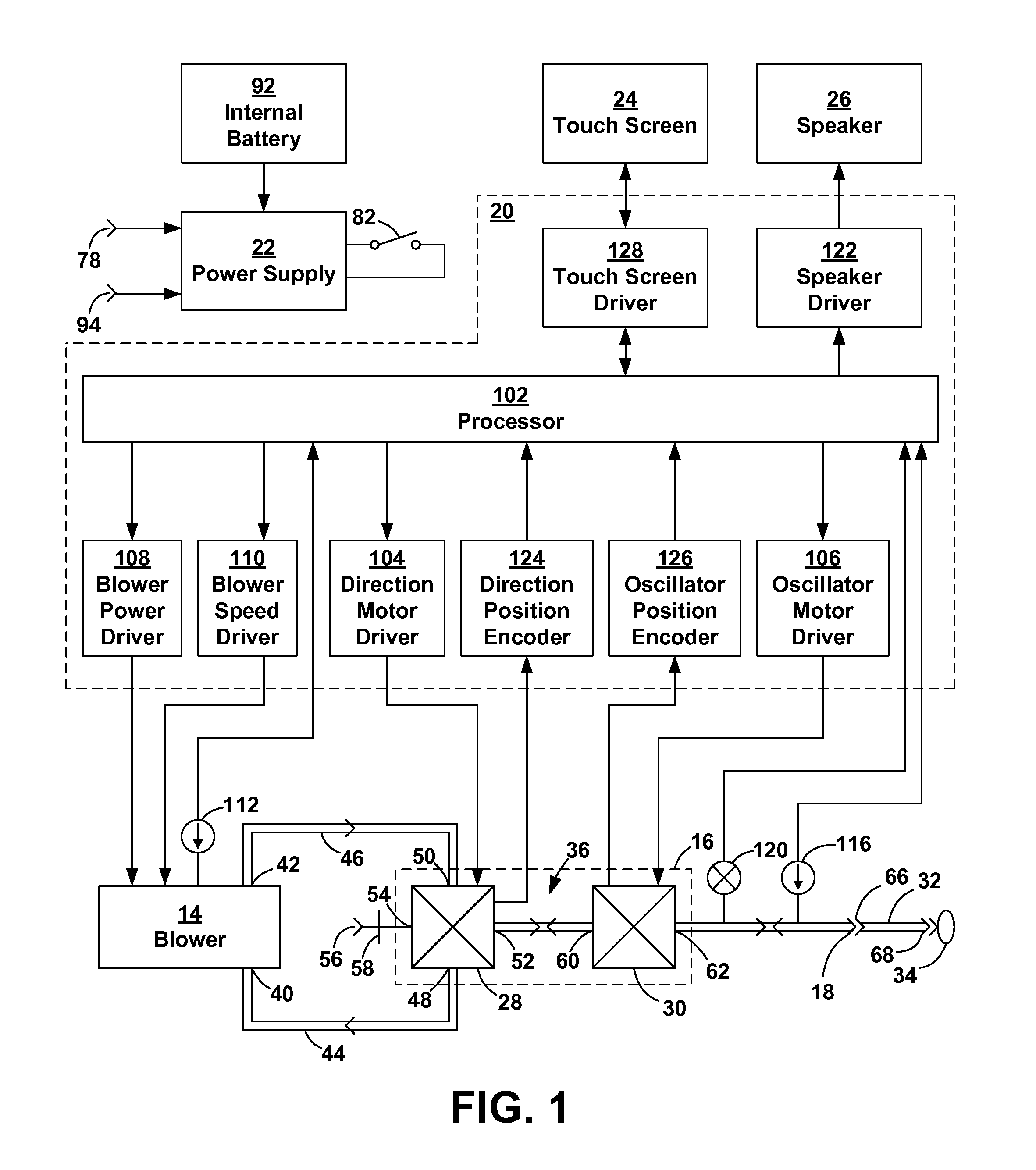

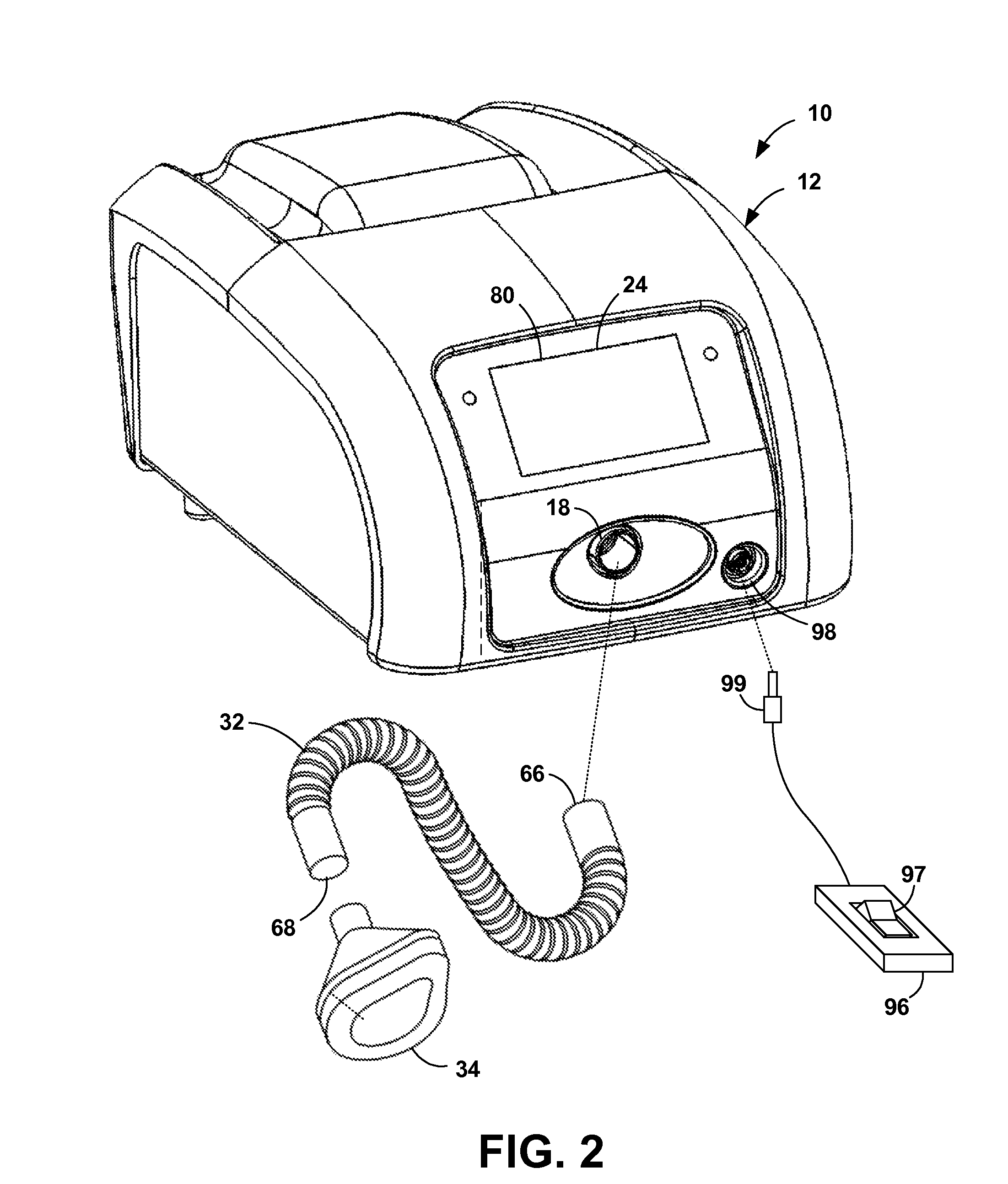

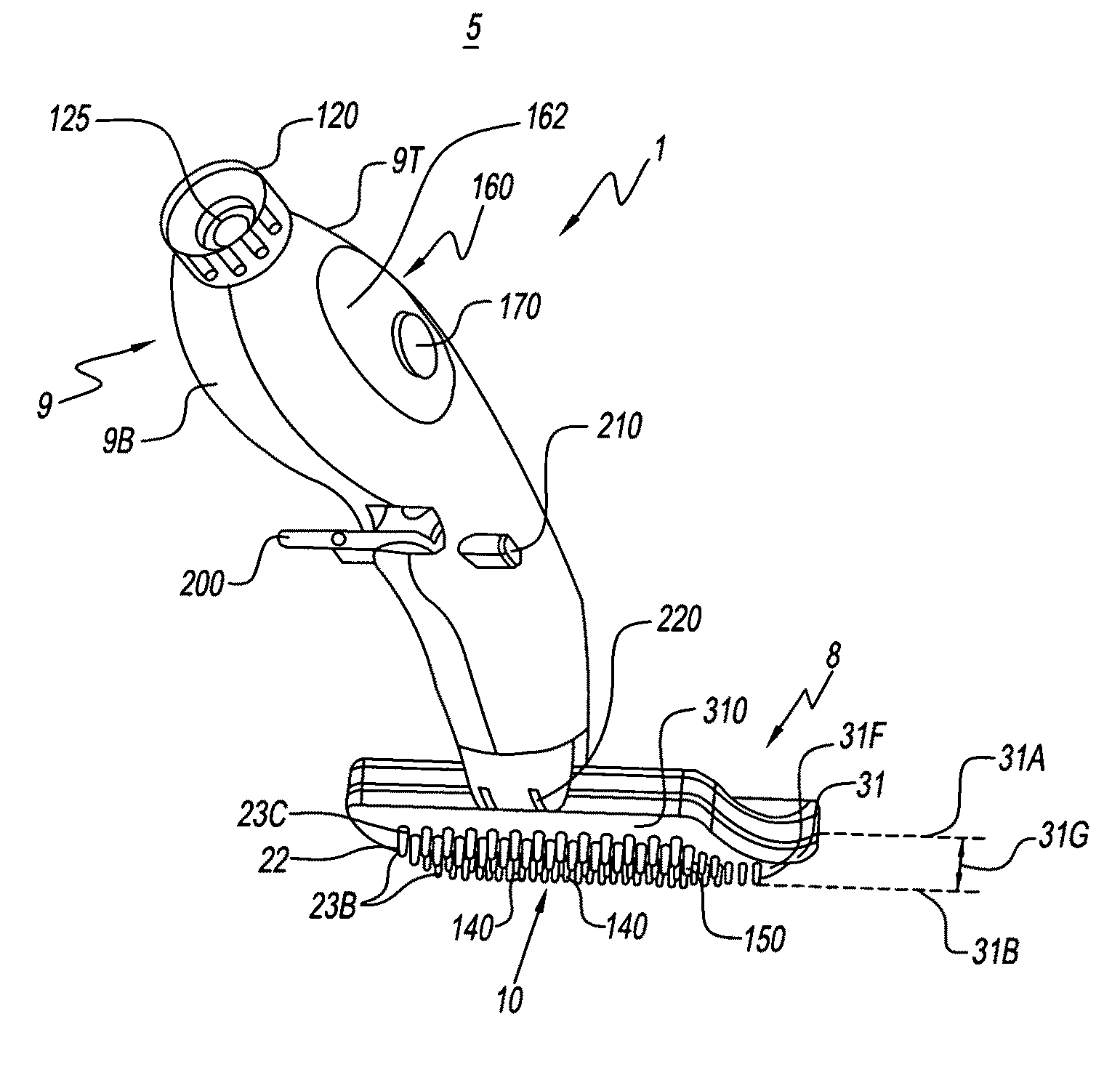

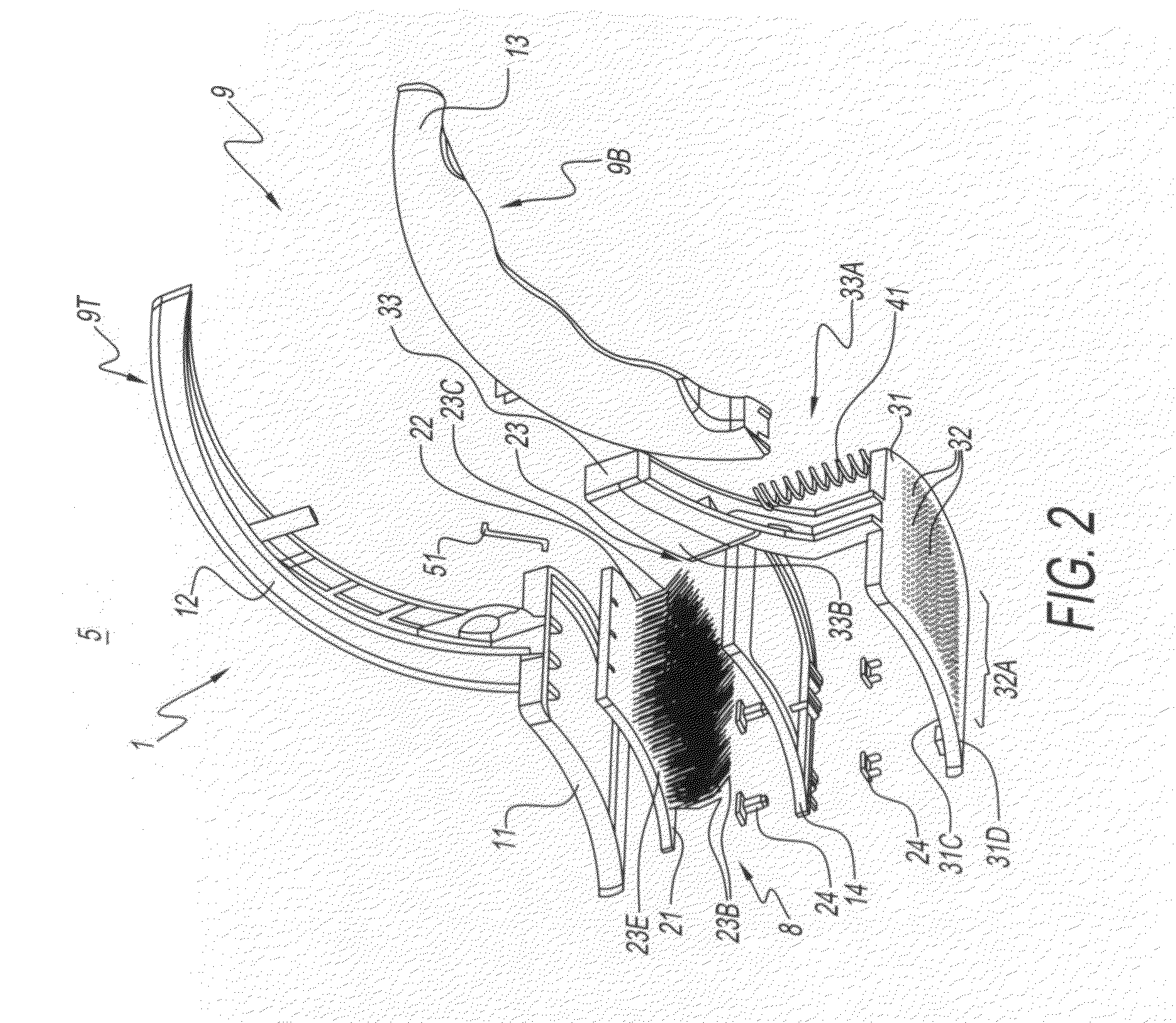

Mechanical insufflation/exsufflation airway clearance apparatus

ActiveUS8539952B2Operating means/releasing devices for valvesBreathing filtersPositive pressureEngineering

An MIE apparatus has a blower, a direction valve, an oscillator, and a mask hose connector. The blower is connected to the direction valve, which is connected to the oscillator, which is connected to the hose connector. During insufflation, a direction valve connects exhaust of a blower to an oscillator, causing positive pressure at the hose connector. During exsufflation, the direction valve connects the blower intake to the oscillator, causing negative pressure at the hose connector. The oscillator is a butterfly valve with a 360° rotating disc. During insufflation, the disc is fixed to steadily modulate the airflow. During exsufflation, the oscillator is inactive or in flutter mode. When inactive, the disc is fixed to allow maximum air flow. In flutter mode, the disc continuously rotates so that the air flow rapidly alternates between maximum and minimum.

Owner:HILL ROM SERVICES

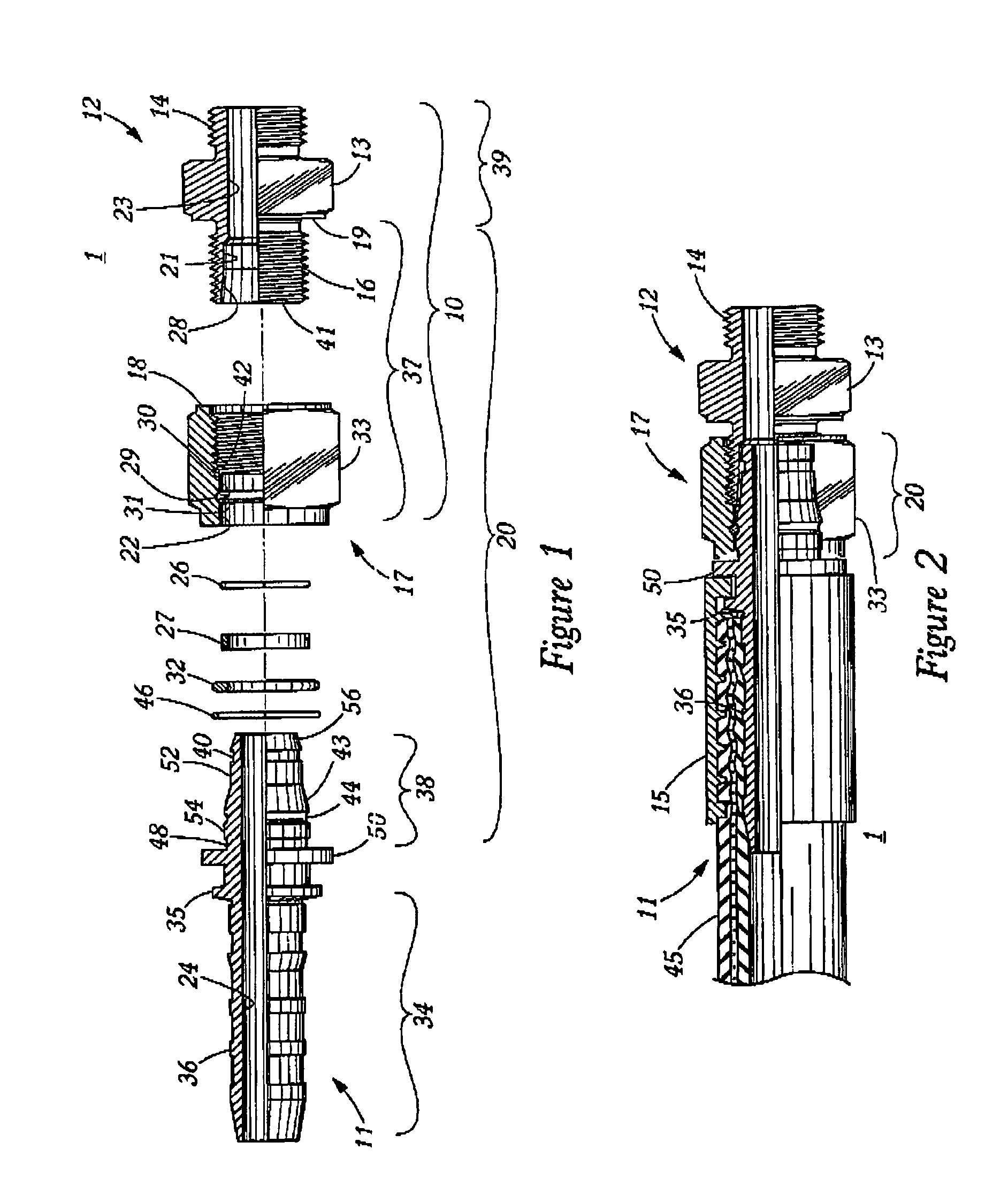

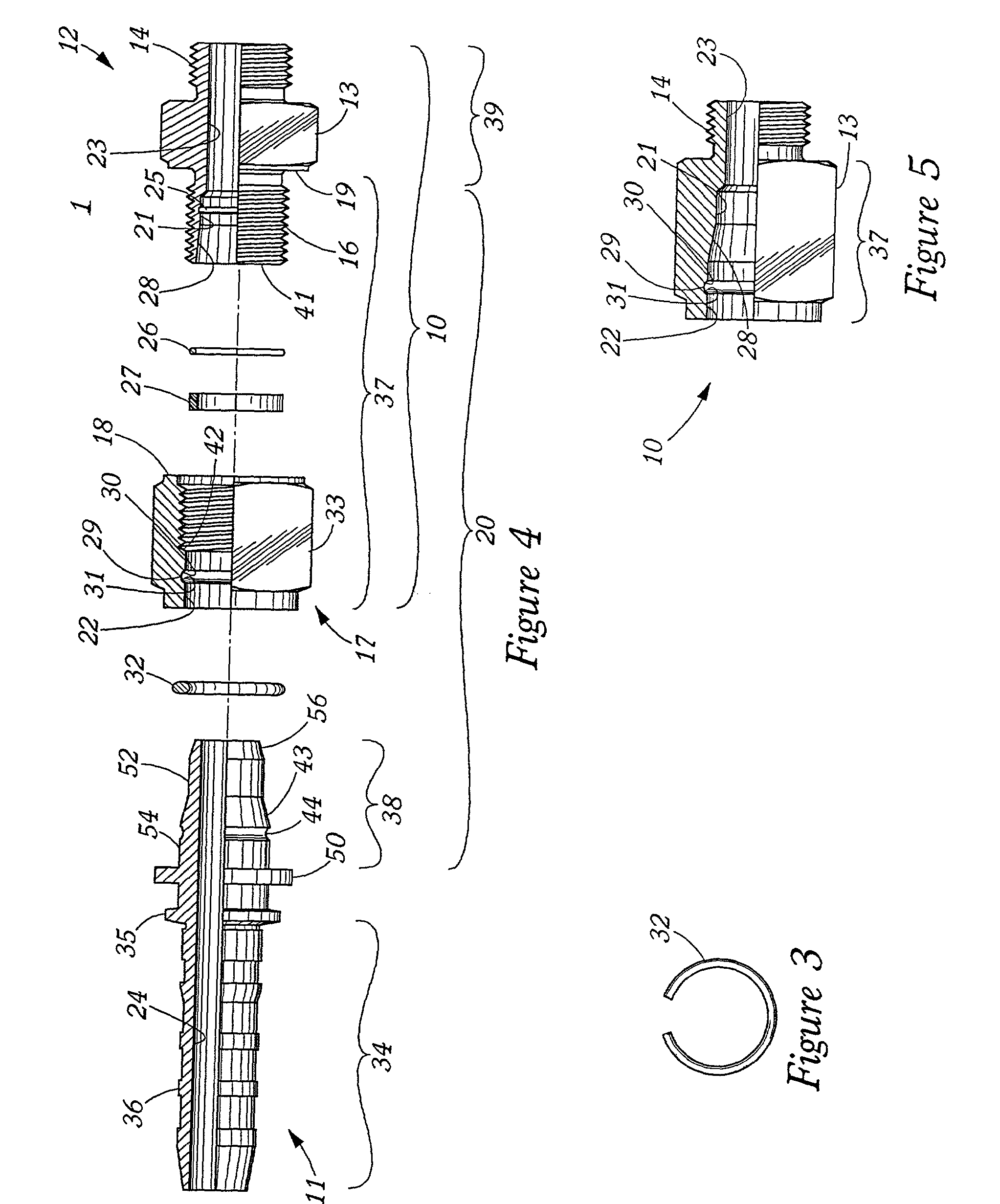

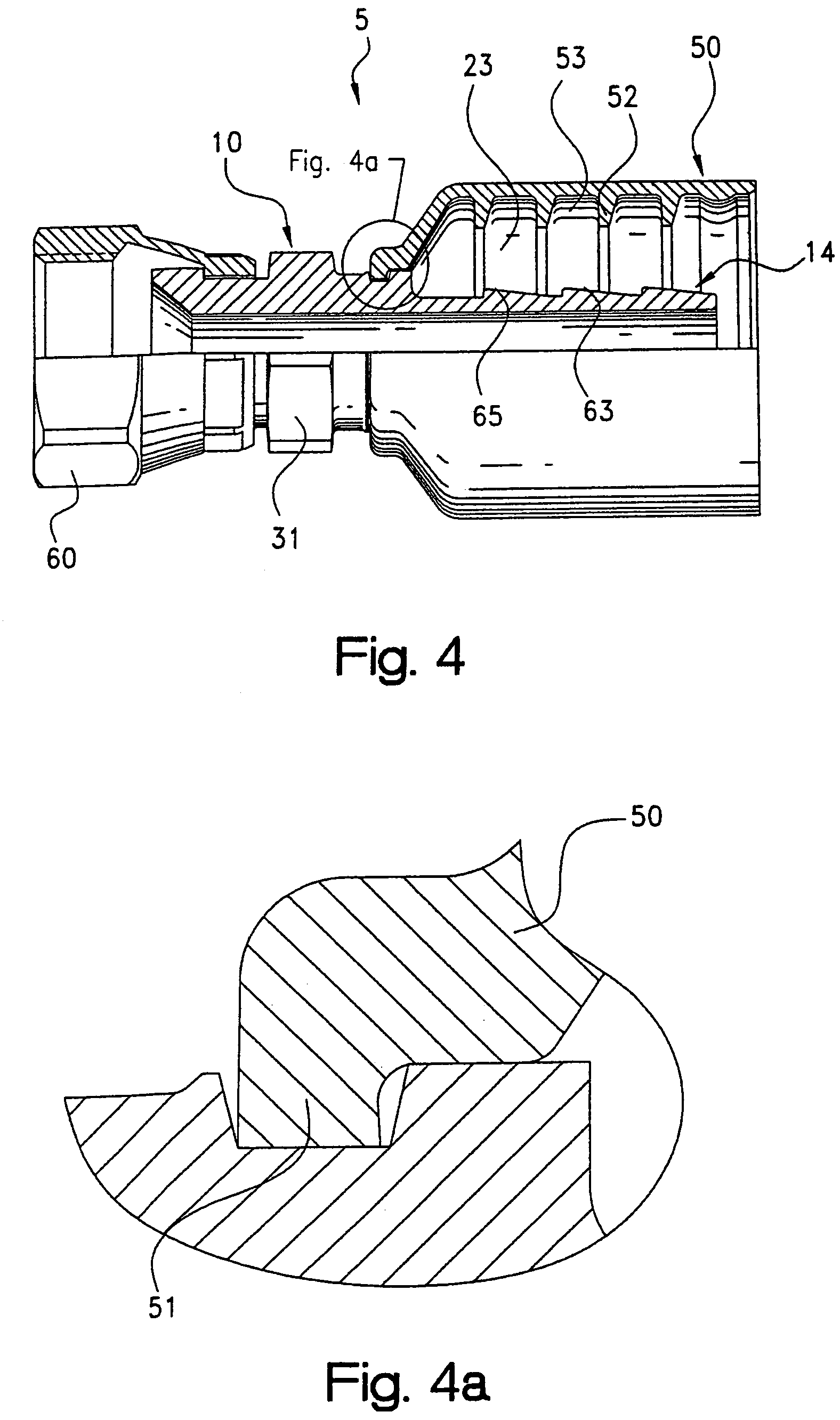

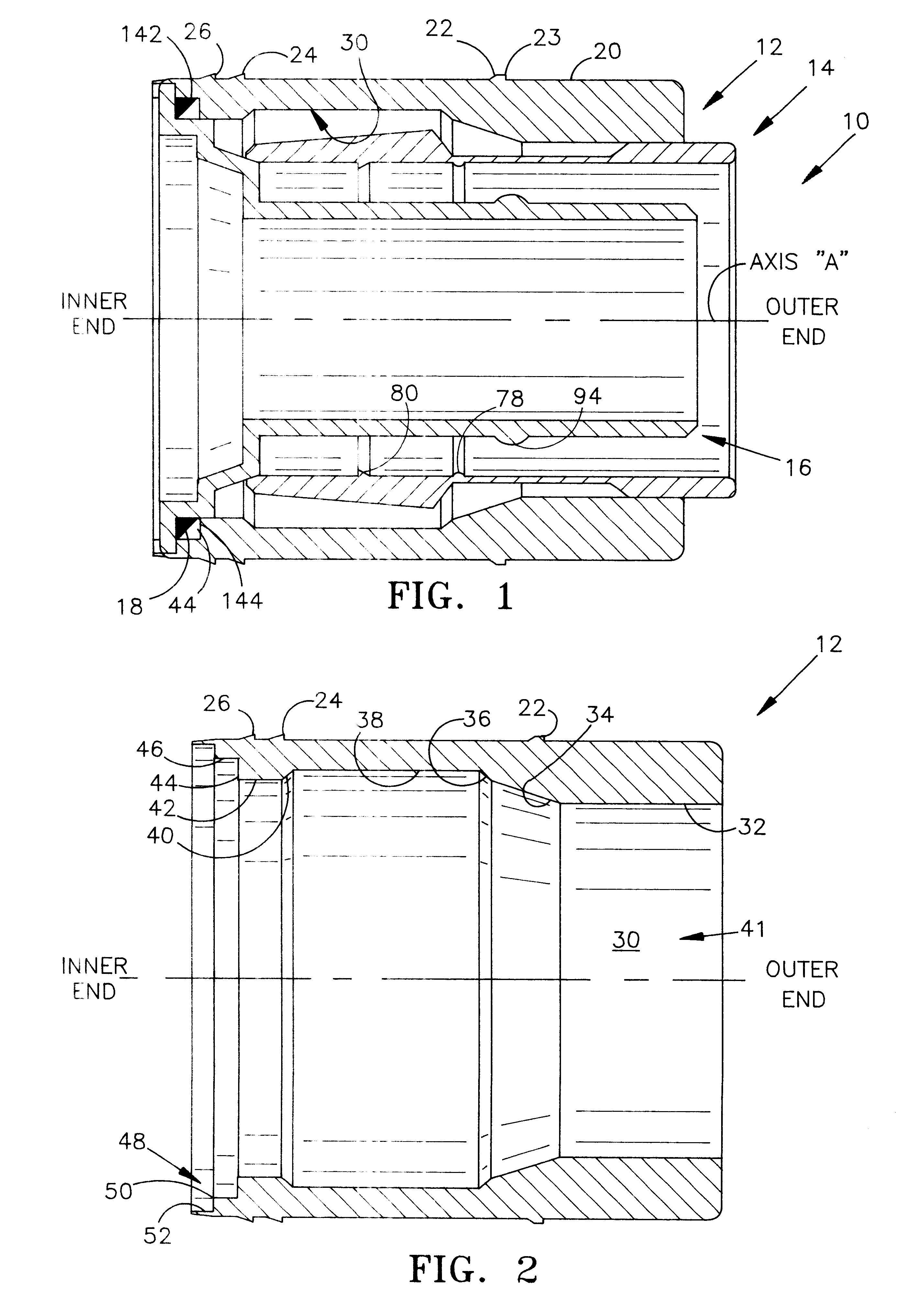

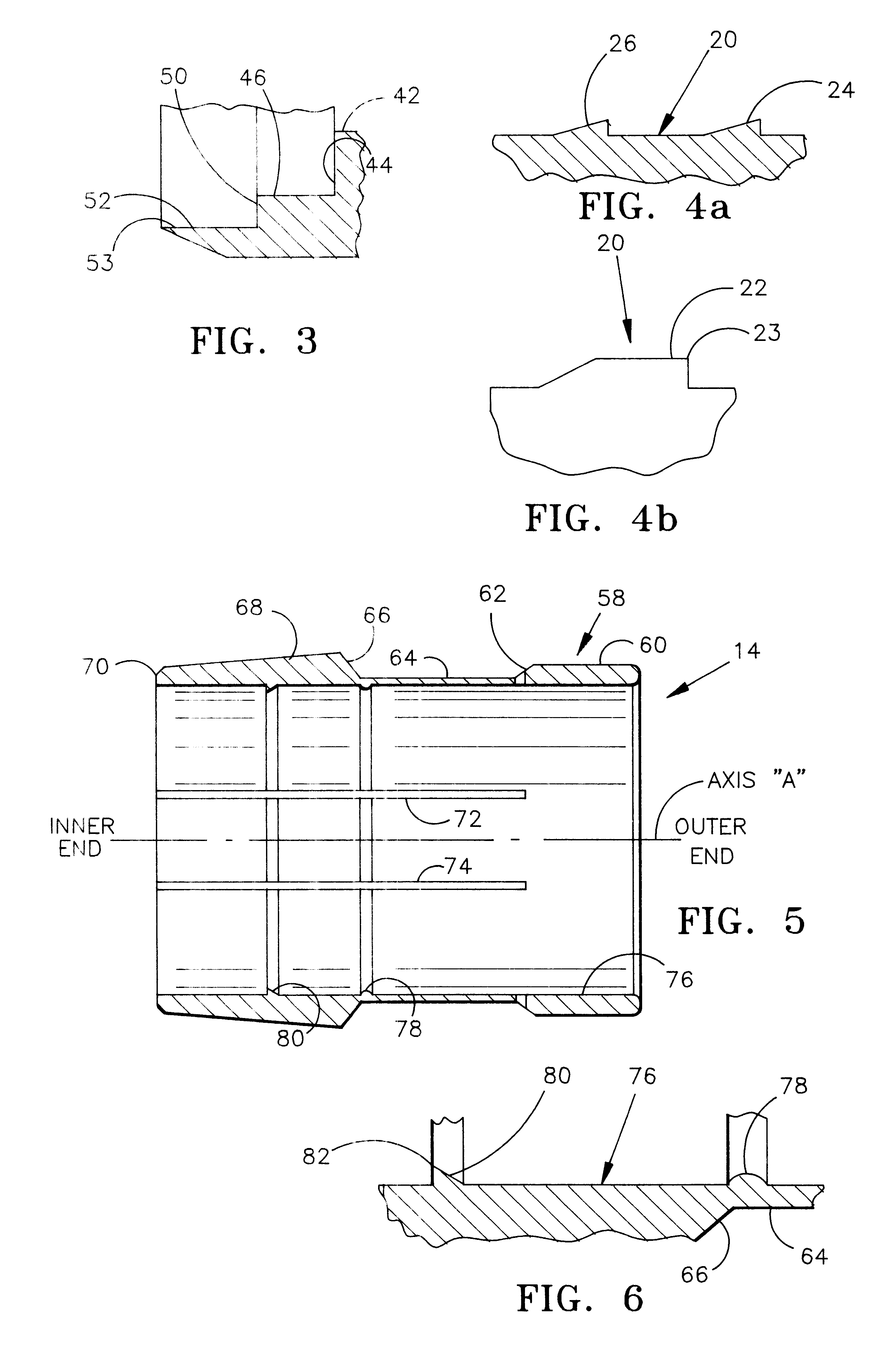

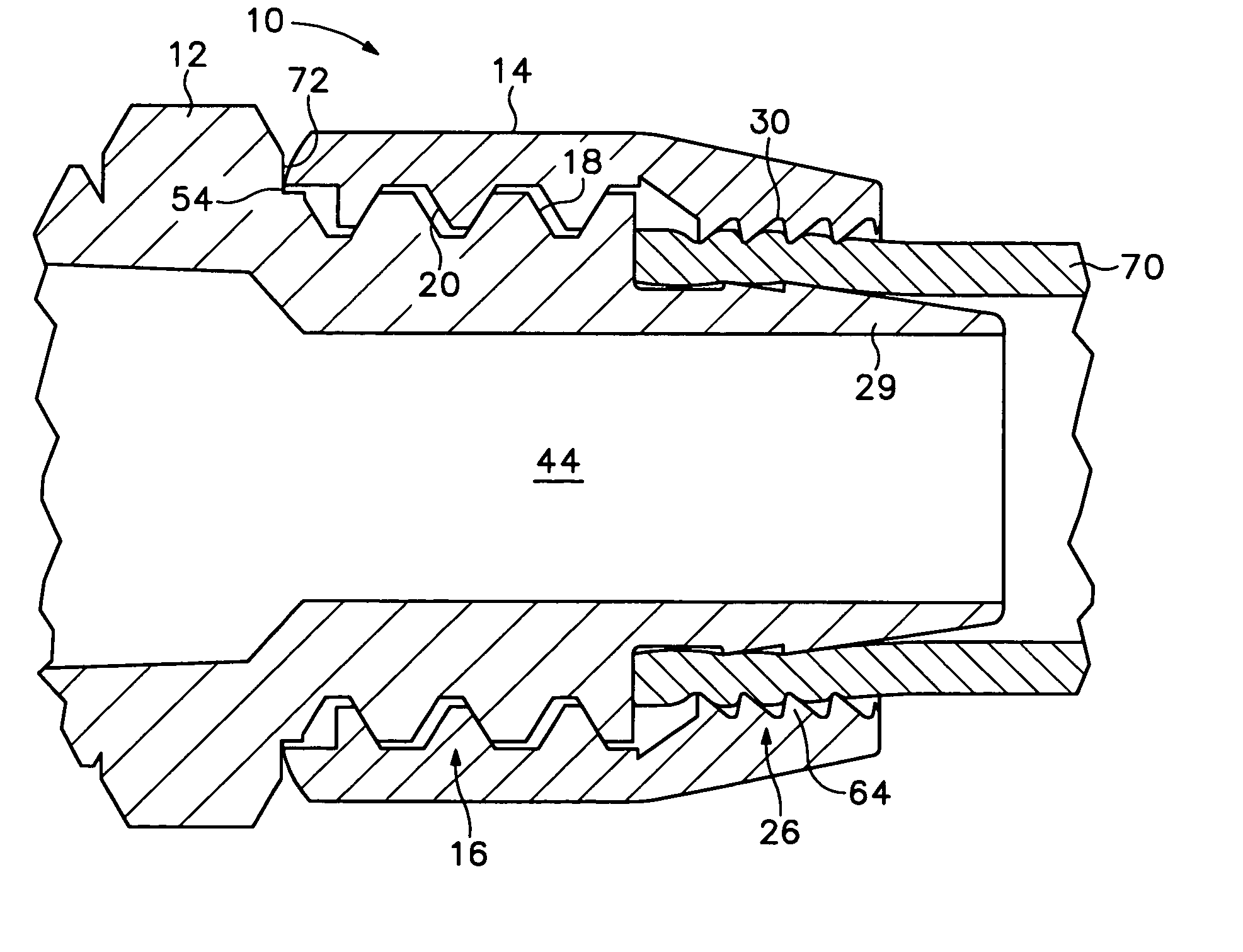

Quick connect coupling

InactiveUS7014215B2Improve stabilityImprove featuresFluid pressure sealed jointsJoints with sealing surfacesEngineeringScrew thread

A quick connect hose coupling for connecting a hose to a fixture of the type having a hose stem portion including a hose insert portion, having a fixture portion including a fixture connection portion, and having a joinder portion is disclosed. The joinder portion includes a male connection portion and a female connection portion. Each of male connection and female connection portions are adapted to join in a sealing and locking manner upon being pushed together. The coupling further includes threads and wrench mating flats adapted to disconnect the hose from the fixture. It is improved by the male connection portion being a unitary structure having a leading support cylindrical surface, a following support cylindrical surface, and a transition surface intermediate therein between. The leading support cylindrical surface has a leading radius. The following support cylindrical surface has a following radius. The following radius is larger than the leading radius.

Owner:THE GATES CORP

Vacuum cleaner adapter set

InactiveUS20020170140A1Easy to cleanReduce gapMechanical cleaningPressure cleaningEngineeringHose coupling

This invention relates to a set of related new and useful vacuum cleaner adapters and accessories, designed for vacuum cleaning areas that are high clearance, low clearance, narrow clearance, or surfaces with special cleaning needs. The various embodiments disclosed may be fit onto the terminal end of a standard hose fitting of a vacuum cleaner, and used to clean heretofore inaccessible areas. There is also an associated flashlight assembly disclosed herein that may be affixed to the other adapters disclosed, or may be affixed to a vacuum cleaner hose or a portion of the hose fitting. The flashlight assembly may be used to provide illumination to the otherwise non-illuminated area being cleaned with an adapter, and may also be useful for vacuum cleaners that do not have lights incorporated therein such as the canister variety of vacuum cleaners. There are a number of embodiments, shapes, and configurations for these related adapters disclosed, including an article retrieval screen, and with a variety of specialized new and useful cleaning applications disclosed.

Owner:DIAZ JAMIE +1

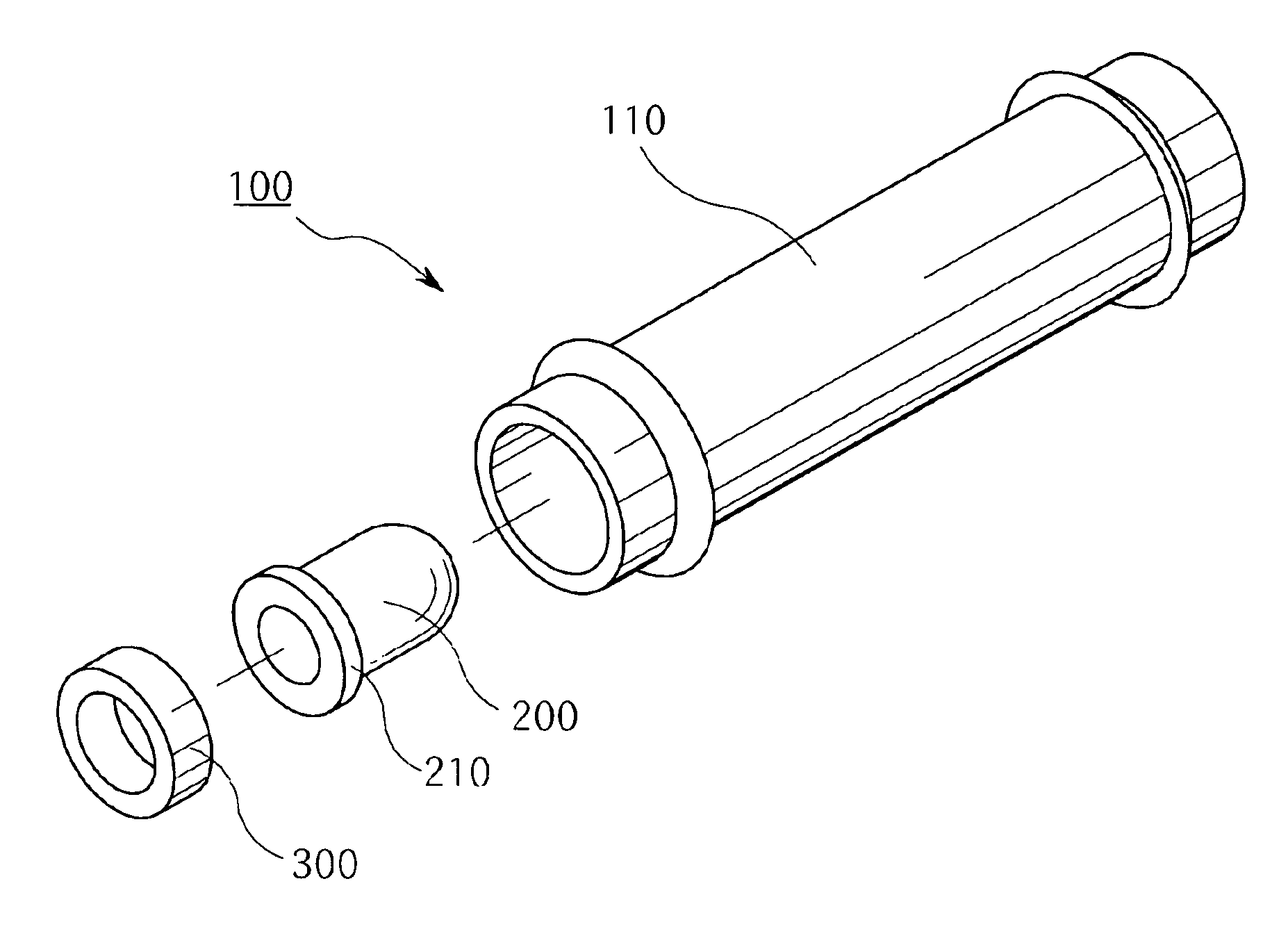

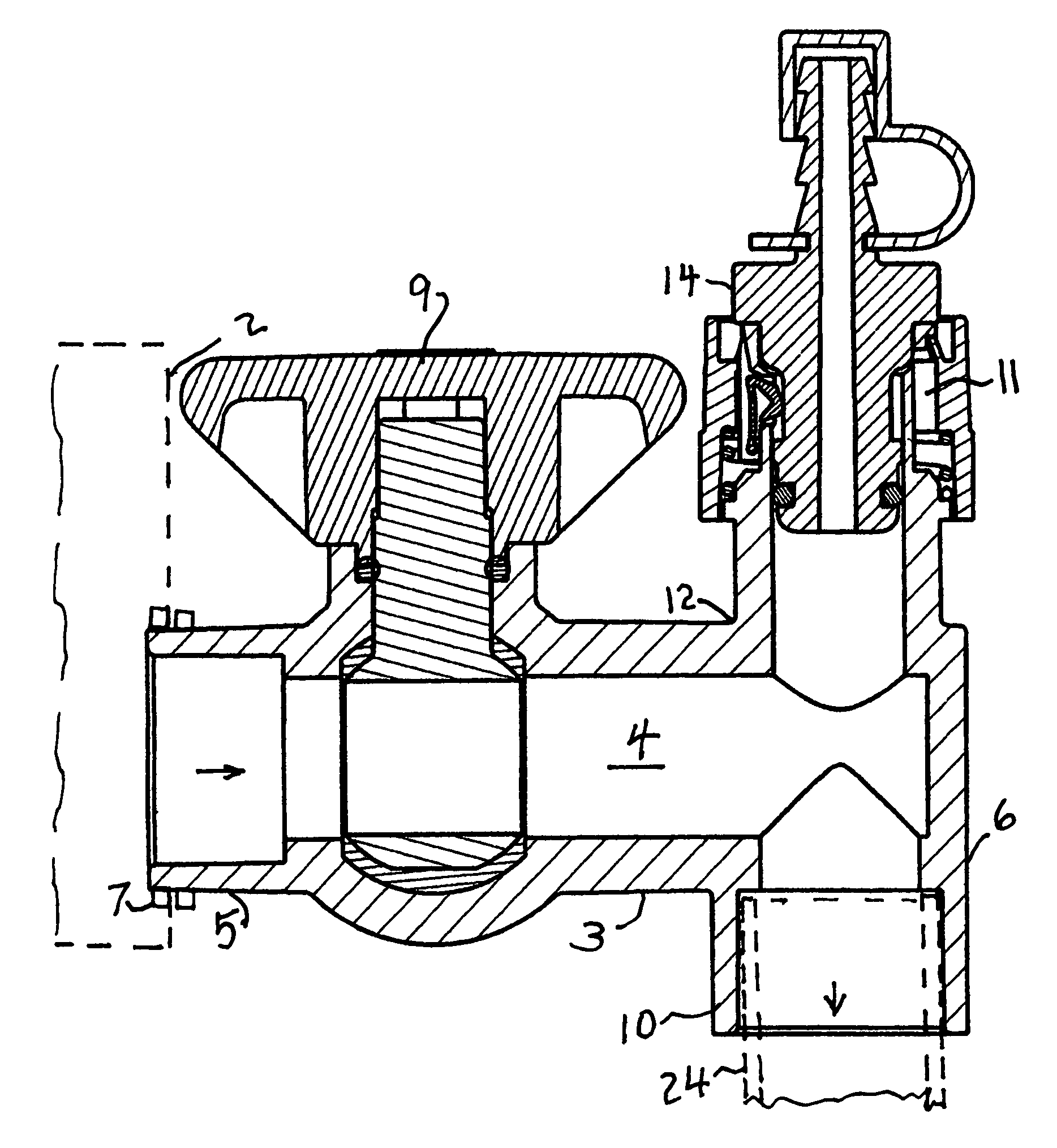

Hydraulic control valve for drip hoses

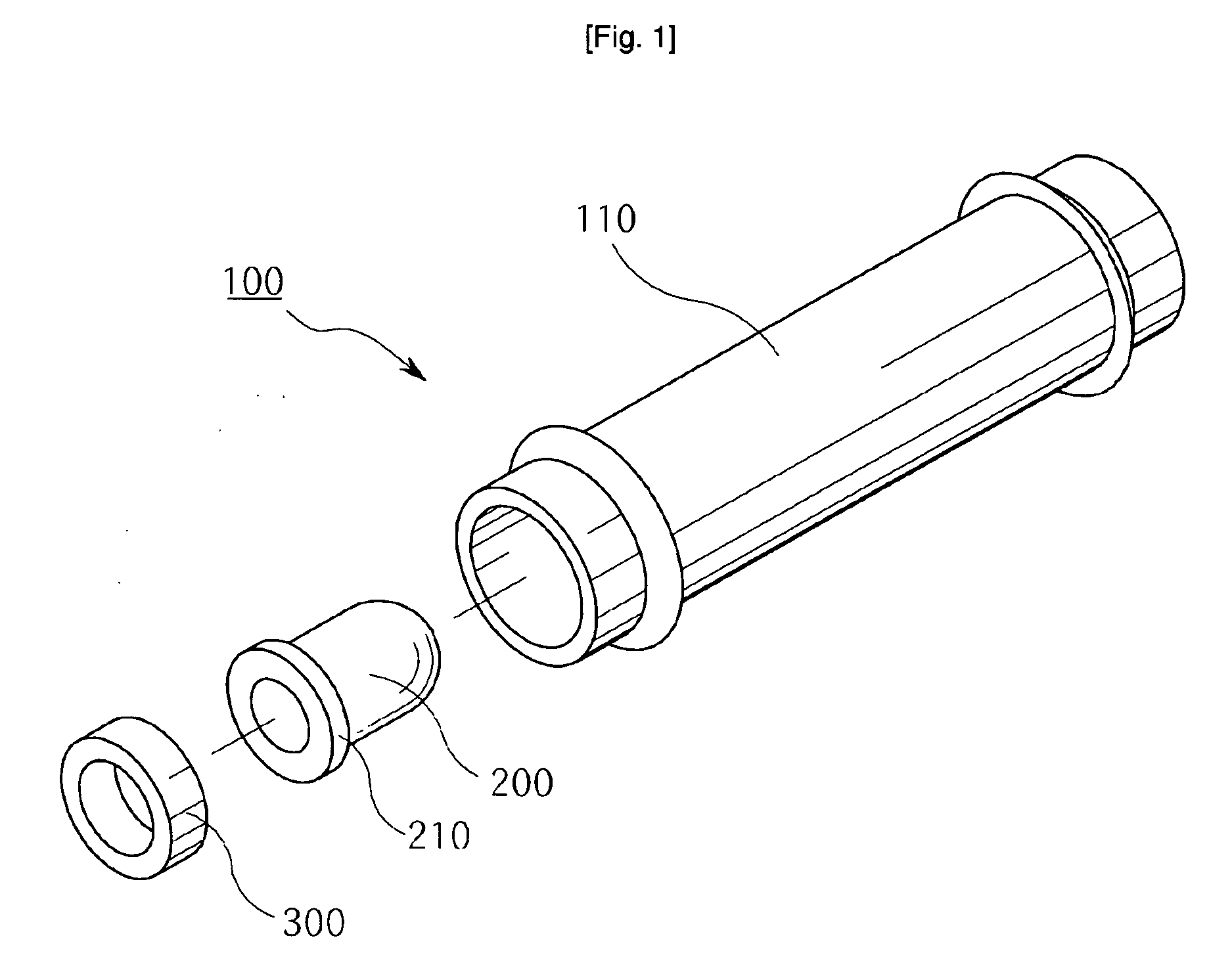

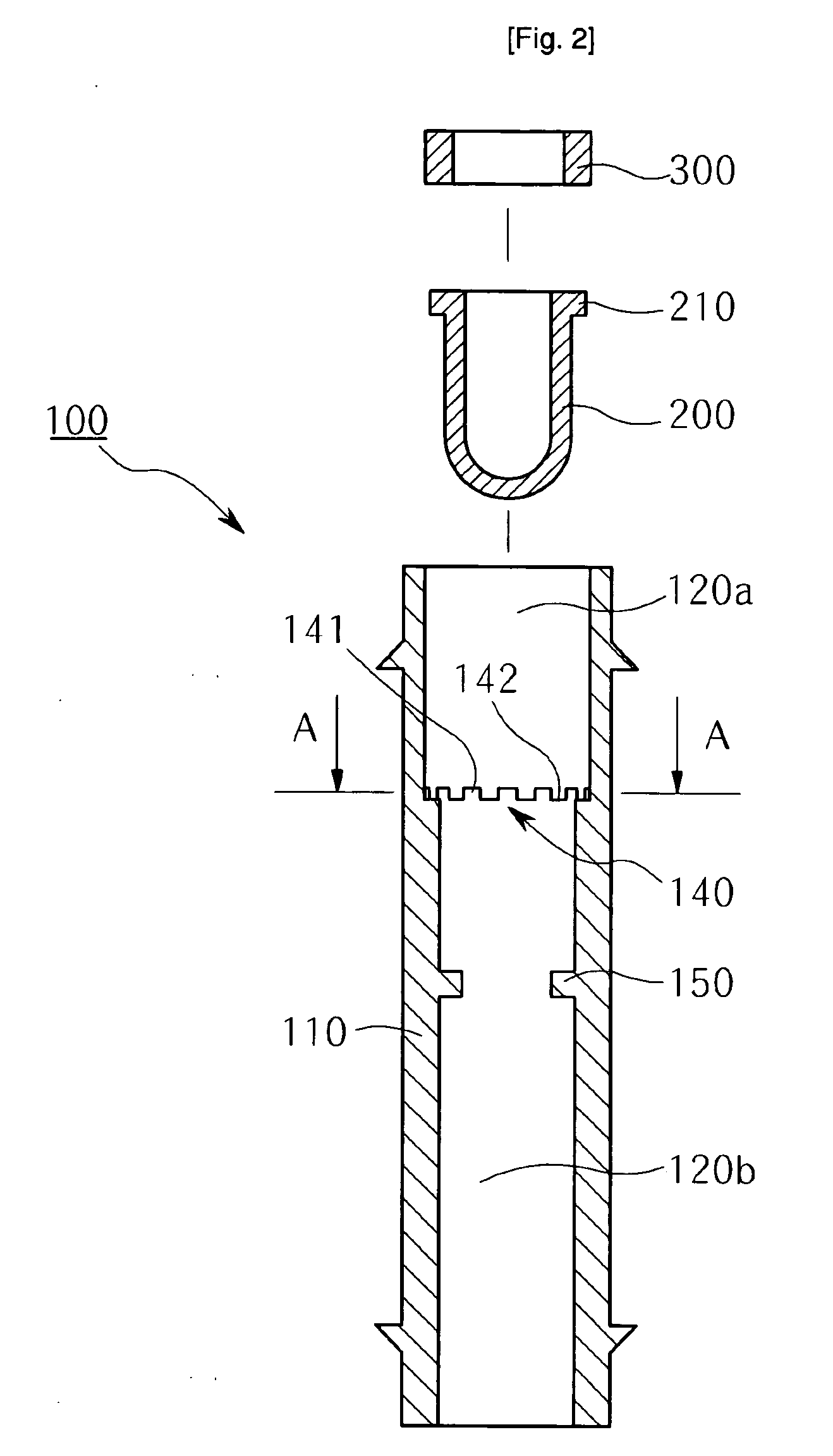

The object of this invention is to provide a hydraulic control valve for drip hoses, which controls a flow of water according to a water pressure, thus keeping a pressure of water fed to a drip hose constant. The hydraulic control valve includes a hose connector (110) clamped at opposite ends thereof to a branch hose (H / S) and a drip hose (H / N), a water supply path having a larger-diameter path (120a) and a smaller-diameter path (120b), a U-shaped flexible cup (200), and a support ring (300). The larger-diameter path includes a stepped seat (142) having projections (141) and depressions (142). The smaller-diameter path includes an inward projecting step (150). The cup is placed at an end thereof to be near to the inward projecting step, and includes a flange (210). The support ring (300) is fitted into the larger-diameter path to prevent a removal of the cup.

Owner:KIM CHOON IL

Cable and flexible conduit gland

ActiveUS8367944B2Improve waterproof performanceIncrease pressureRelieving strain on wire connectionElectrically conductive connectionsEngineeringHose coupling

A cable and flexible conduit gland for securing a cable and a flexible conduit to a box member is disclosed to include a casing having a middle stop flange extending around the periphery thereof, a first fastening member and a second fastening member formed integral with the periphery thereof and respectively disposed at two opposite sides relative to the middle stop flange ad and a tapered inner surface portion located on the inside wall, a collar inserted into the casing and having a tapered front extension fitting the tapered inner surface of the casing, an elastic packing ring stopped against the rear end of the collar, and a holding-down cap fastened to the first fastening member of the casing to hold down the collar and the packing ring and to lock the inserted flexible conduit and cable together.

Owner:AVC INDAL CORP

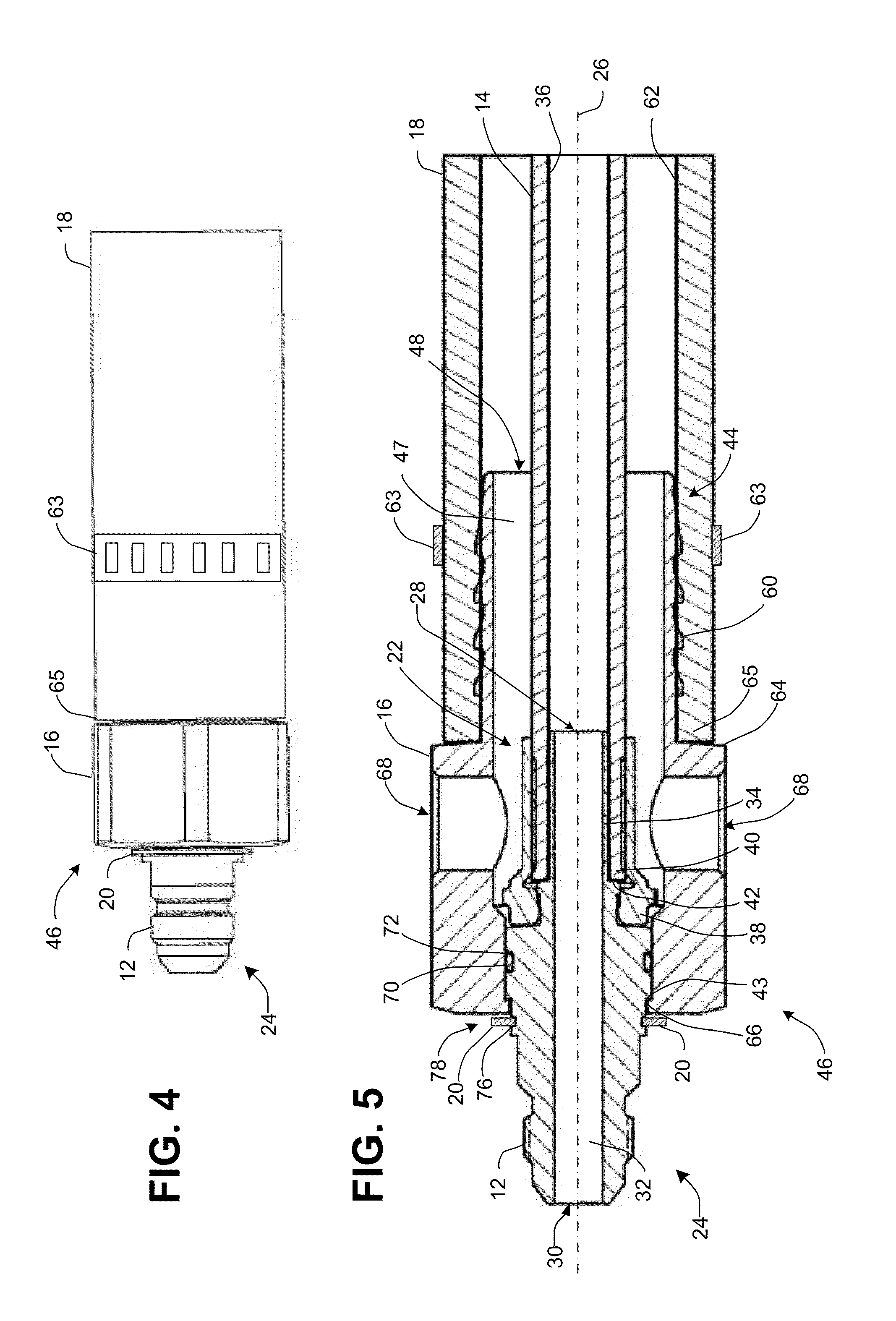

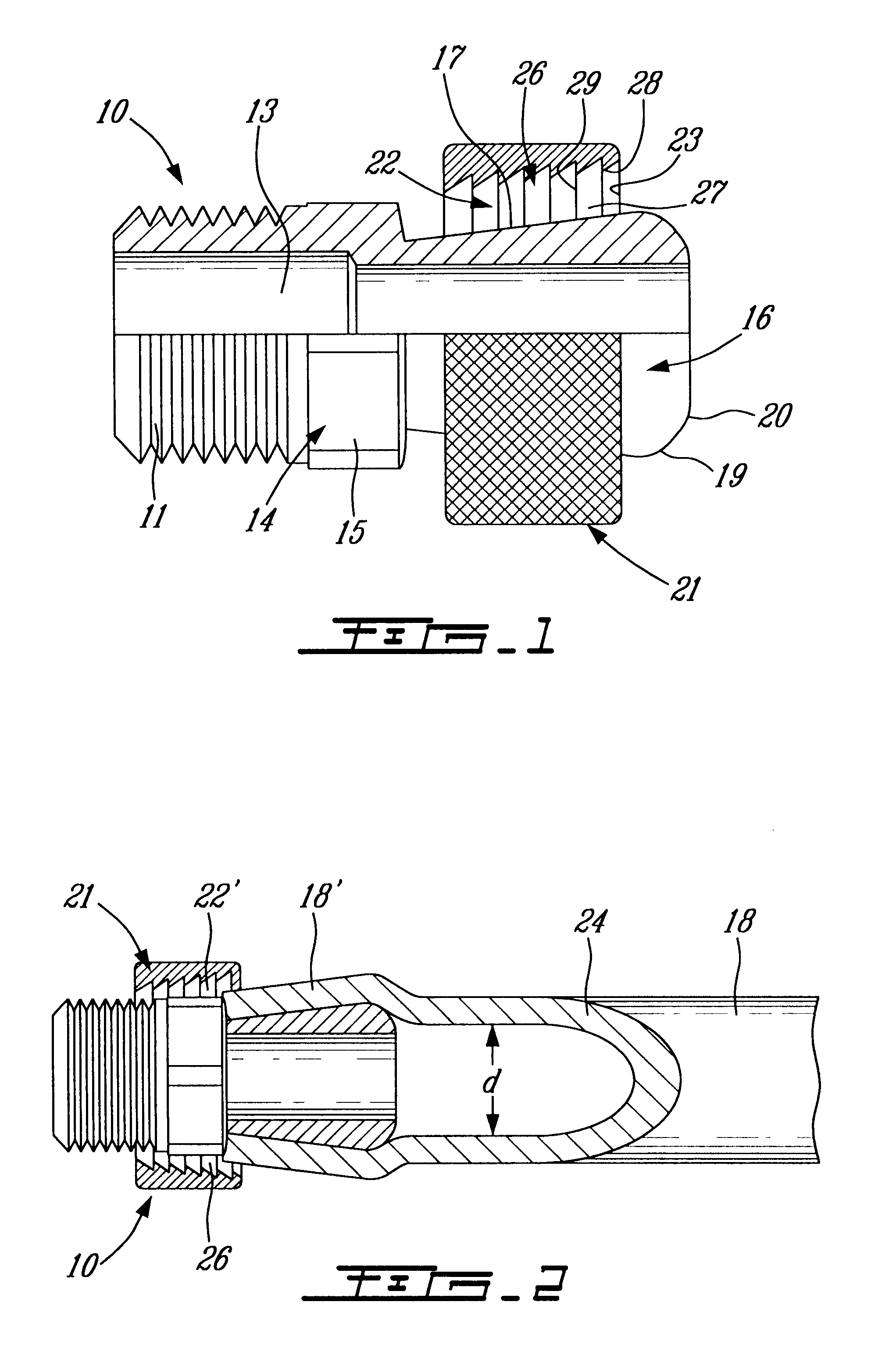

Universal fitting nipple

A permanently attachable hose coupling for a pressurized conduit end having a generally tubular nipple and a generally cylindrical shell permanently attached to the nipple and generally surrounding the conduit end. The nipple has a longitudinal axis, first and second ends, a series of circumferential grooves located between the first and the second ends, a longitudinal through bore, and an insert portion adjacent the plurality of grooves for insertion in the conduit. Each of the series of circumferential grooves fixedly receive at least one of an inside surface, an end surface and an outside surface of the generally cylindrical shell and each of the grooves has a generally flat base portion parallel to the longitudinal axis, a first substantially vertically oriented sidewall adjacent the generally flat base portion and a second substantially vertically oriented sidewall.

Owner:PARKER INTANGIBLES LLC

Superscrubber

InactiveUS20060026750A1Quickly and conveniently useablePrevent leakageBathsDouchesMechanical engineeringHose coupling

The present invention is directed to a cleaning system adapted to communicate with a water conduit forming a part of a residential type plumbing system. The cleaning system is made up of a water conduit forming part of a residential plumbing system; a quick connect hose coupling in communication with the water conduit; and a cleaning implement having a hose with an inlet end and an outlet end, the hose inlet end being connectable to the quick connect hose coupling. Preferably, the cleaning implement is made up of a handle having a fluid conduit in communication with the hose outlet; a body section having at least one internal fluid passageway in communication with the handle fluid conduit and a bottom surface having at least one orifice in communication with the at least one internal fluid passageway; and a cleaning section having a cleaning surface, the cleaning section being releasibly attachable to said body section bottom surface.

Owner:BALLANCE RODNEY

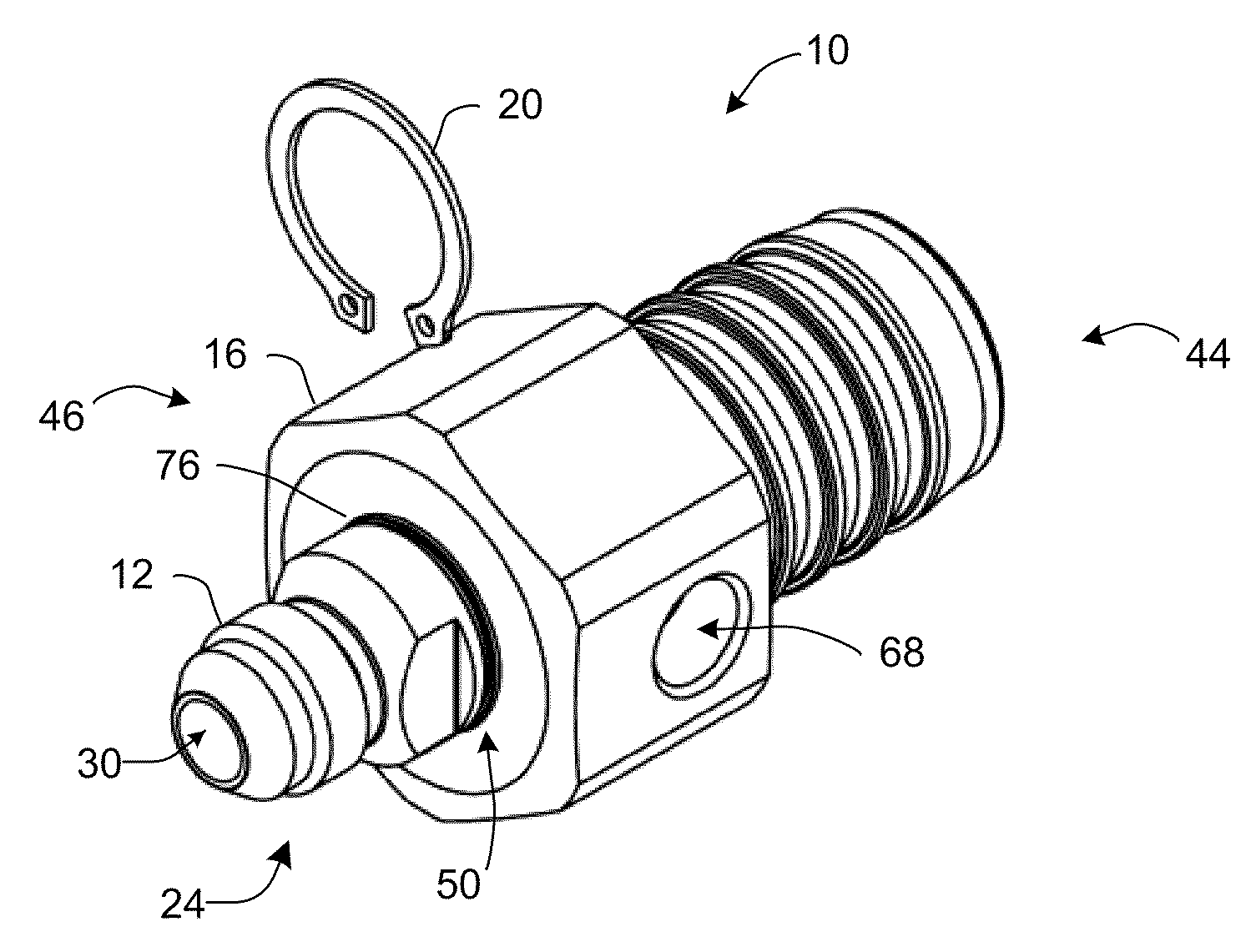

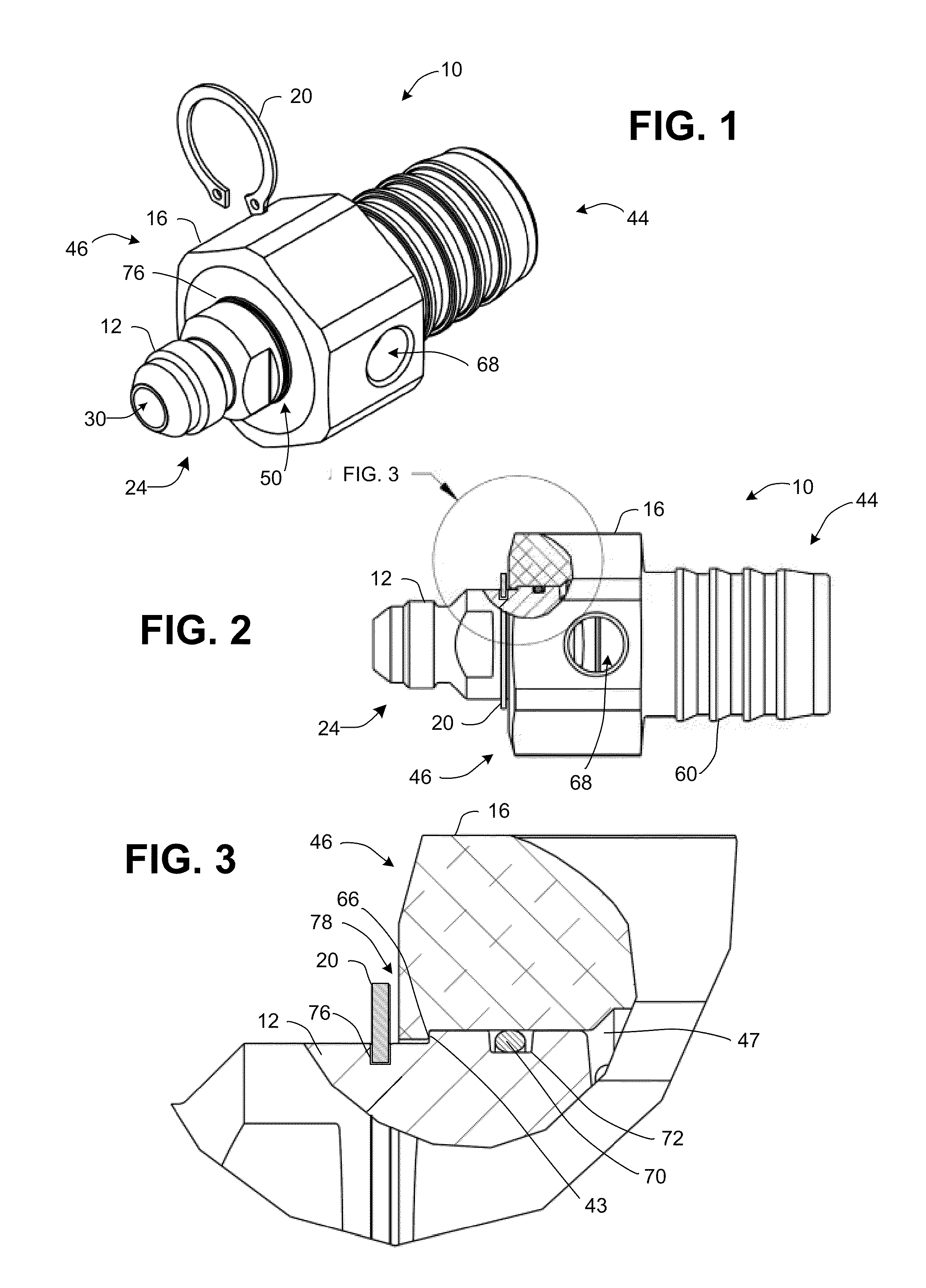

Refrigeration condensate line connectors

InactiveUS8156956B1Improve conductivityImproves overall sensor functionPlug valvesCondensate preventionNitrogenEngineering

An assembly mounts between the drain pan that collects condensate water from an air conditioner and the drain line. It includes a housing with a first end connected to the pan. A second end connects to the drain line. A shut off valve shuts off the passage to the pan while maintenance is performed. A connector is mounted on the housing between the valve and the second end. It is a female member of a water hose coupling. A male member of the coupling may be screwed in to seal it in place. Male members may have different terminations at a second end, including a barbed tube for resilient tubing, a compressed air tire valve for delivering gas, a compressed nitrogen coupling, a tapered funnel for the nozzle of vacuum / blower, and a water sensor.

Owner:COOGLE GREGORY

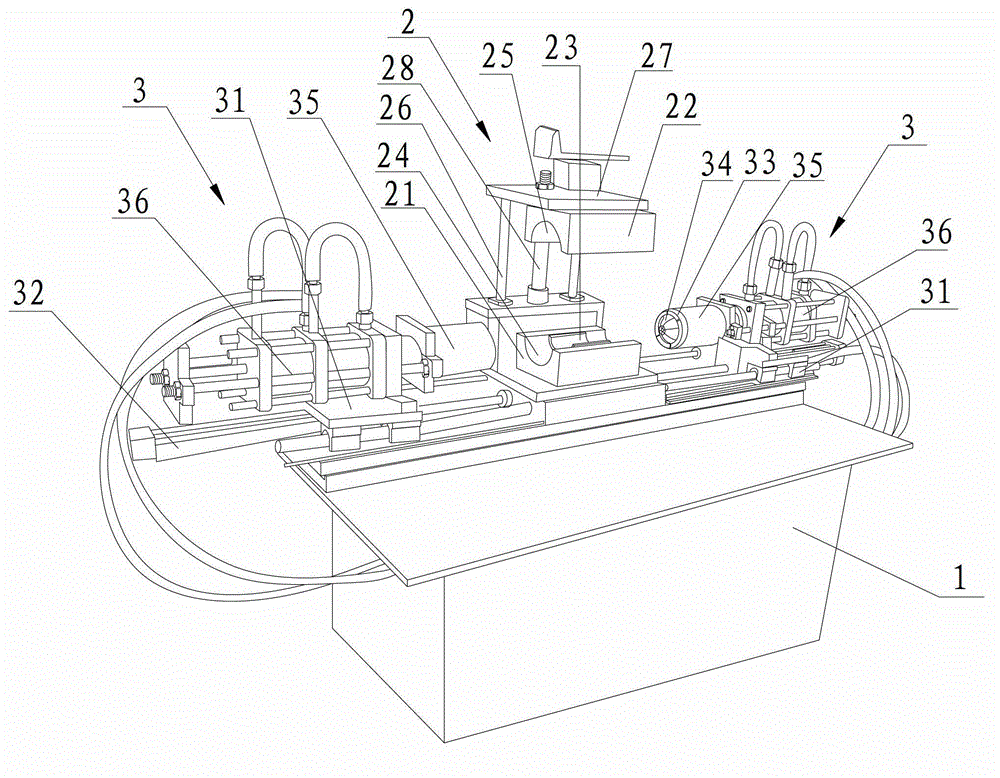

Automobile hose and coupling assembly equipment

ActiveCN102873527ASimple structureEasy to operateMetal working apparatusStructural engineeringHose coupling

The invention discloses automobile hose and coupling assembly equipment. A hose body of a hose is clamped by a hose clamping component of the automobile hose and coupling assembly equipment, tensioning and fastening compression devices are arranged on two sides of the hose clamping component, tensioning tubes and fastening tubes are arranged in the tensioning and fastening compression devices, ends of outer sides of the tensioning tubes and the fastening tubes can be opened or closed, the tensioning tubes can axially penetrate into a central through hole of the hose when the ends of the outer sides of the tensioning tubes are closed, and the fastening tubes can be axially sleeved on the periphery of the outer side of the hose when the ends of the outer sides of the fastening tubes are opened. When the tensioning and fastening compression devices are in a compression working state for compression assembly of the hose body of the hose and couplings, the ends of the outer sides of the fastening tubes are closed and fastened on the periphery of the outer side of the hose, and the ends of the outer sides of the tensioning tubes are opened and are abutted to the periphery of the inner side of the hose, so that internally tensioning and externally fastening compression force is exerted to joints of the hose body of the hose and the couplings, the couplings are compressed at ends of the hose body, and the hose and the couplings are assembled. The automobile hose and coupling assembly equipment is simple in structure and convenient to operate.

Owner:苏州市环宇汽车配件有限公司

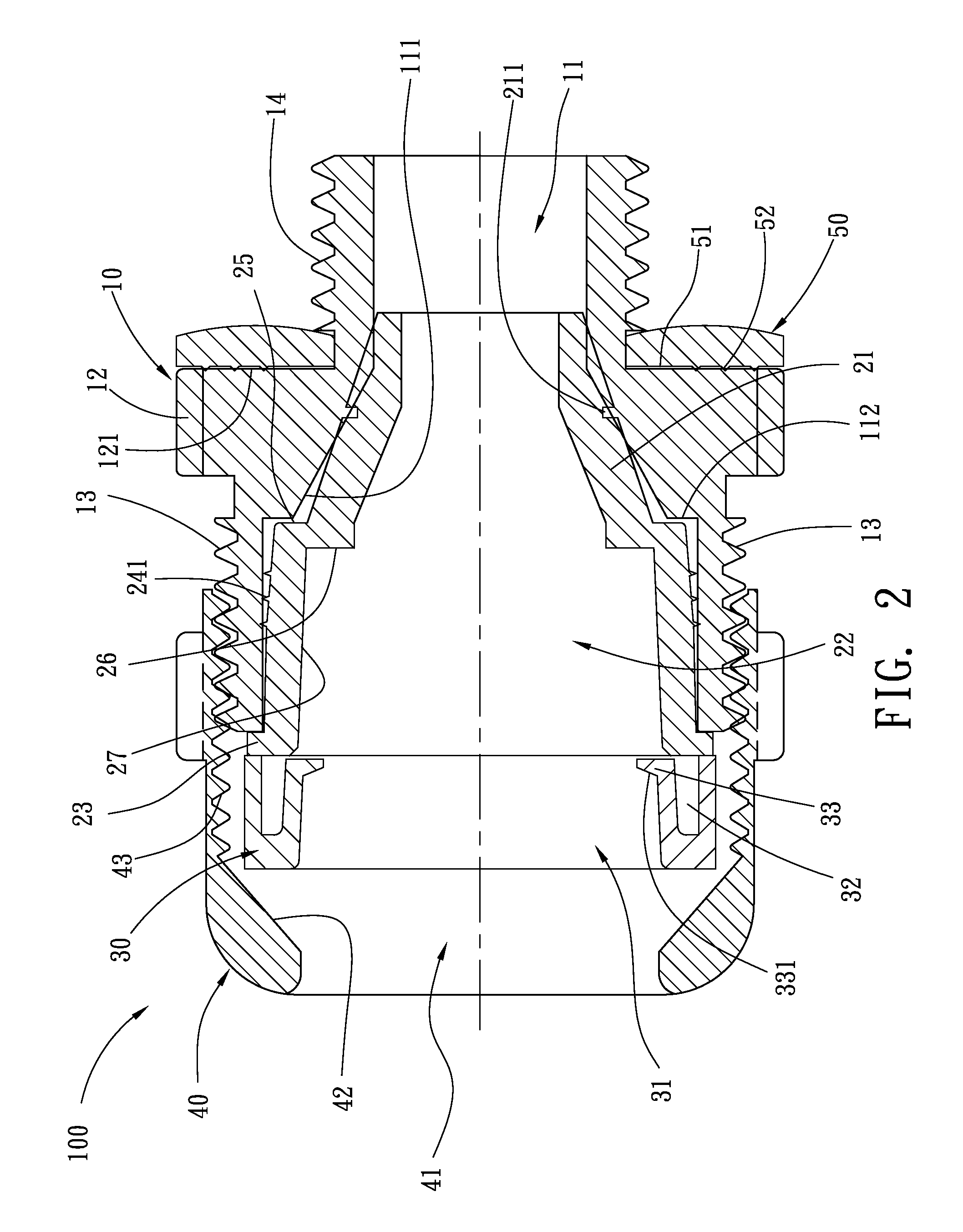

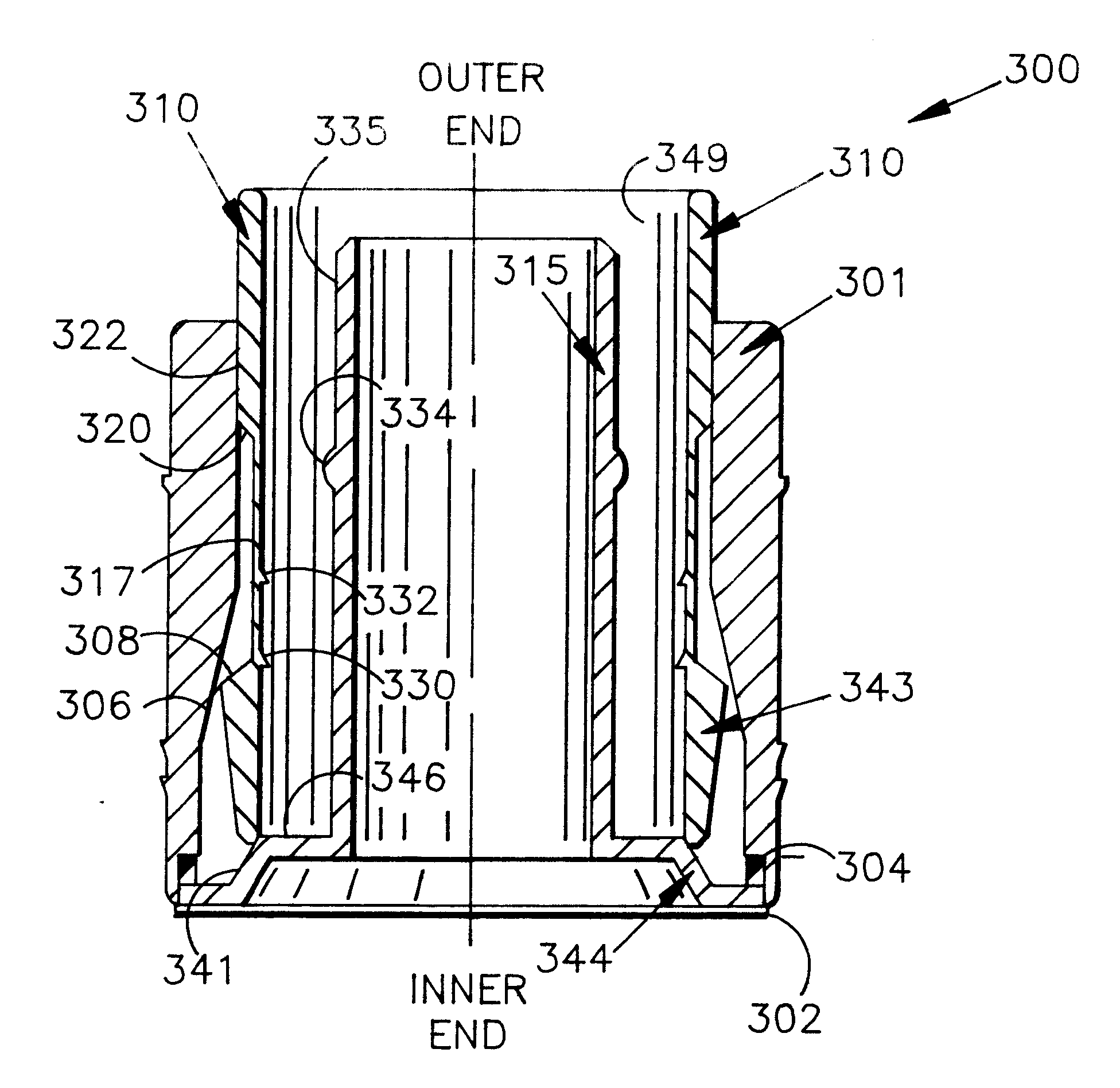

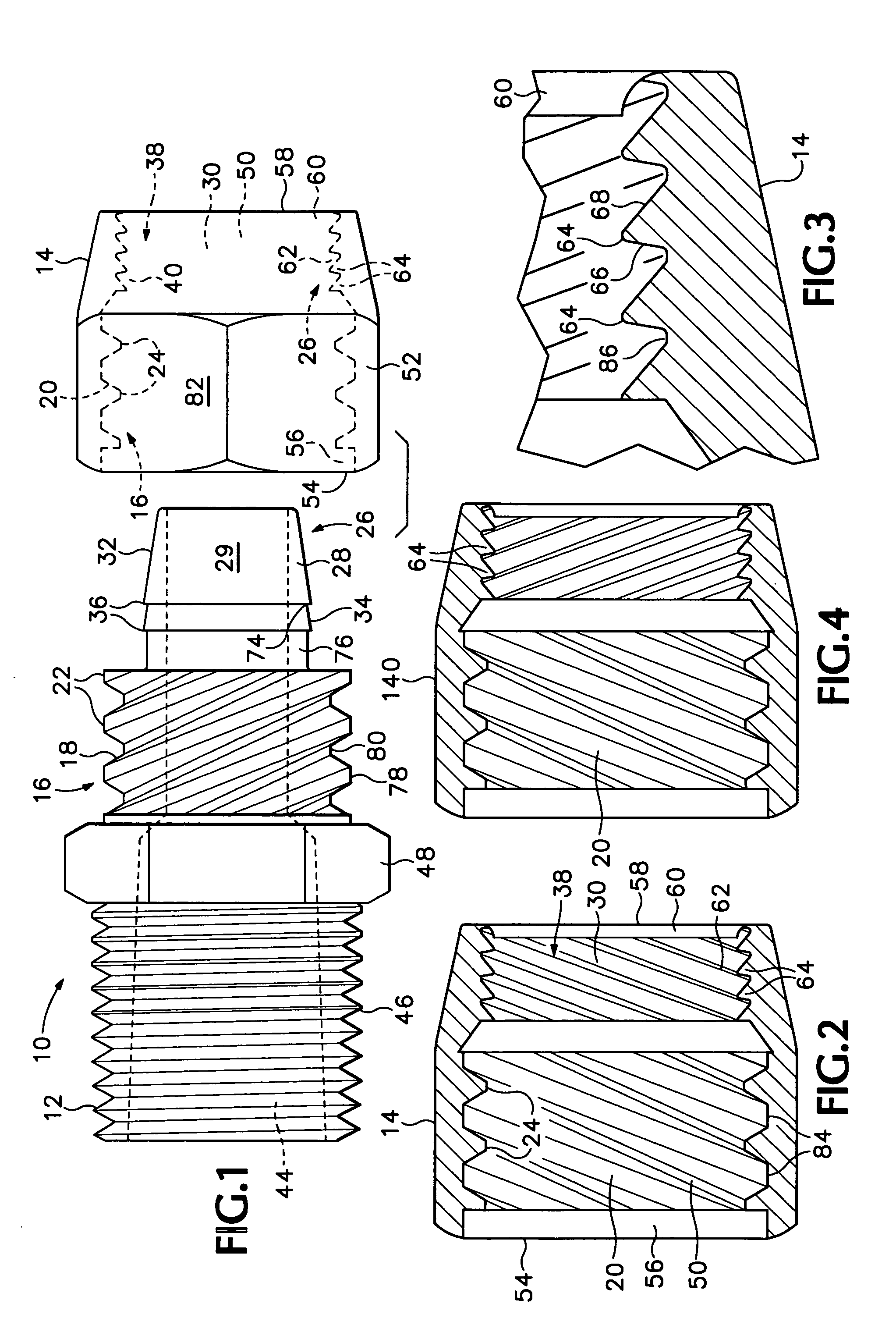

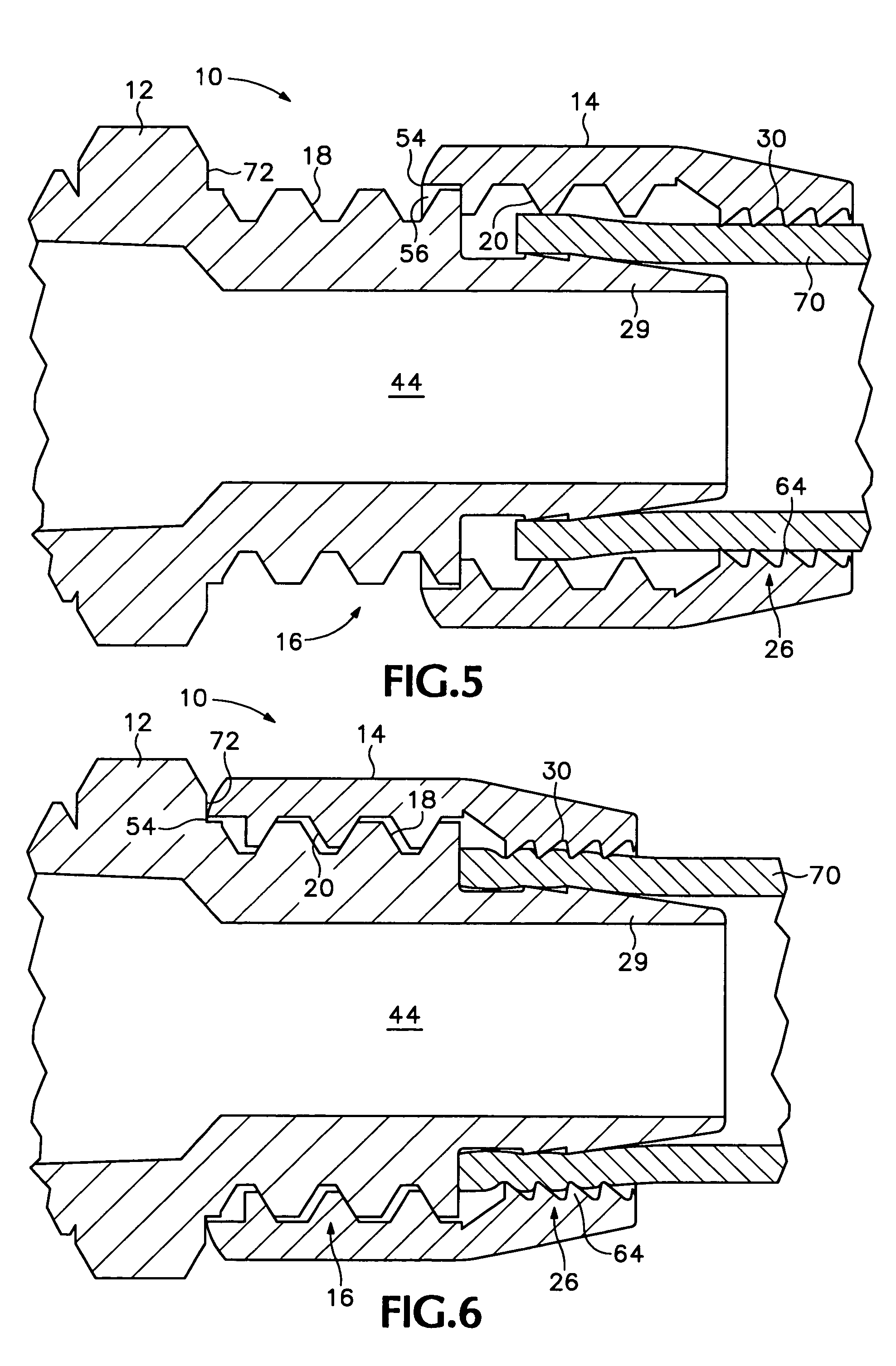

Hose coupling

InactiveUS6254144B1Improve gripGood adhesionSleeve/socket jointsBraking componentsMechanical engineeringHose coupling

A hose coupling secures a flexible hose member having a radially outwardly facing exterior hose surface and a radially inwardly facing interior hose surface. The hose coupling includes a housing having a radially outwardly facing exterior surface and a radially inwardly facing interior surface defining a longitudinal passageway, a first axial end, and a second axial end. The interior surface includes a first ramped portion and a first seating portion. A tube support member has a tube portion disposed in the interior longitudinal passageway of the housing and a base portion fixedly coupled to the housing at the second axial end of the housing. The base portion has a seal seat region, and the tube portion has a radially outwardly facing exterior surface that includes a first grip ring for supporting the interior hose surface. The first grip ring is circumferentially disposed about the exterior hose surface. A seal is disposed between the first seating portion of the housing and the seal seat region of the tube support member. A grip / release mechanism is disposed in the longitudinal passageway of the housing concentrically exteriorly of the tube portion of the tube support member. The grip / release member is axially moveable relative to the housing and has a third axial end, a radially inwardly facing, axially extending interior surface defining an interior longitudinal passageway, and a radially outwardly facing, axially extending exterior surface. The grip / release member interior surface includes a circumferentially disposed sealing grip ring and a circumferentially disposed barbed grip ring disposed toward the third axial end relative to the grip ring. The sealing grip ring exerts a compressive force on the exterior hose surface and the barbed grip ring grips the exterior hose surface by exerting an expansive force. The grip / release mechanism exterior surface includes a second ramped portion.

Owner:KILGORE MFG

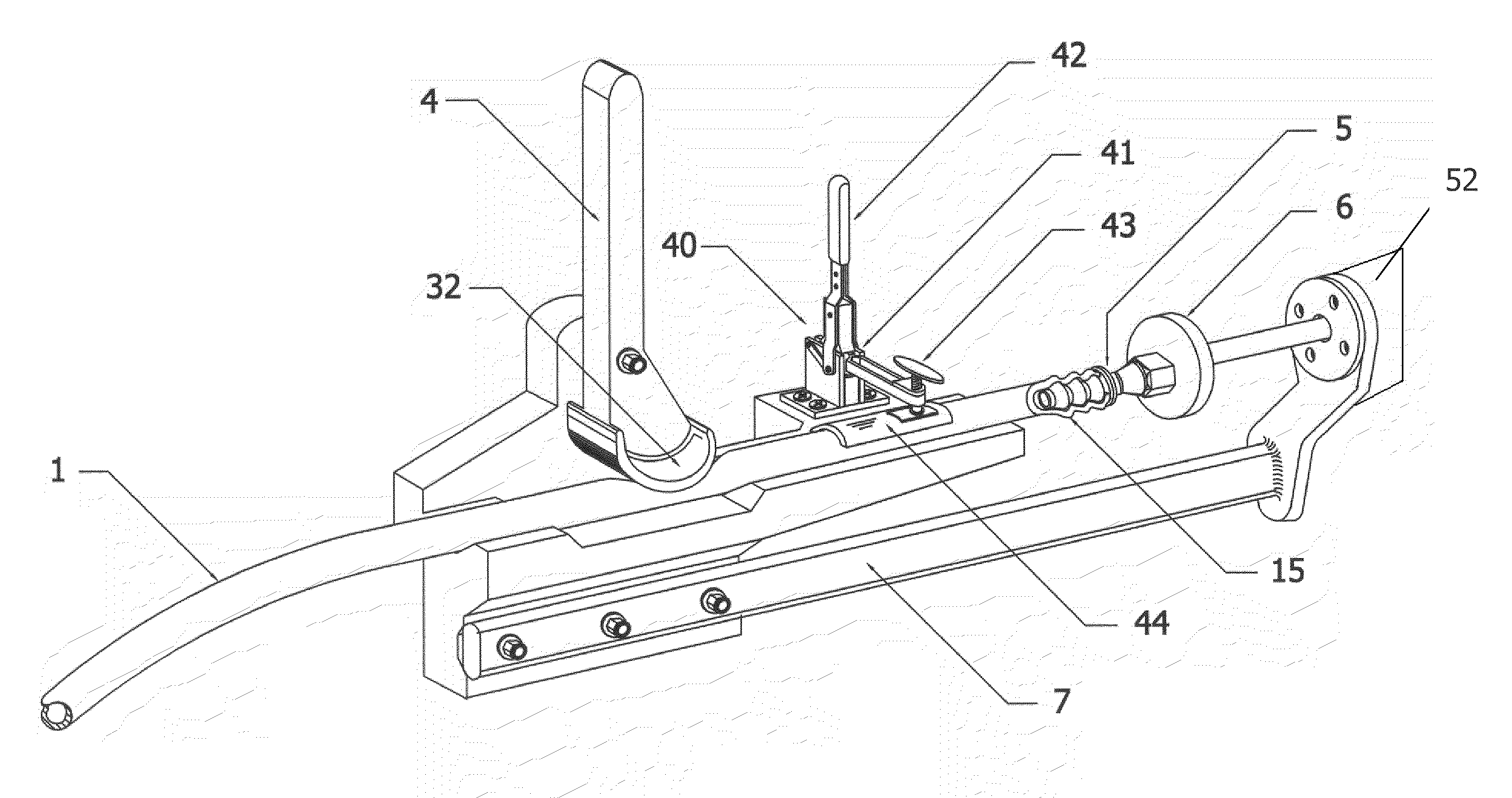

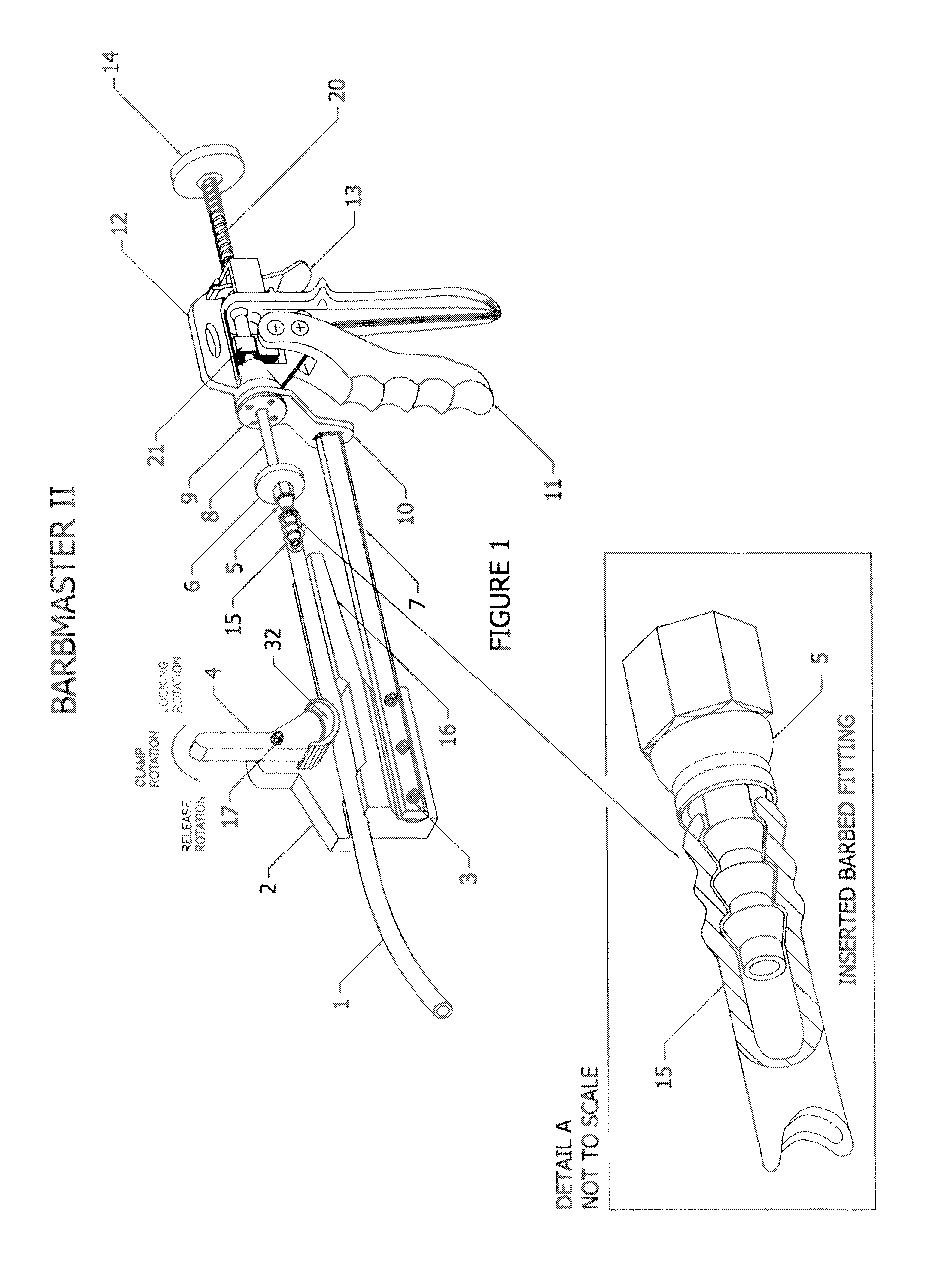

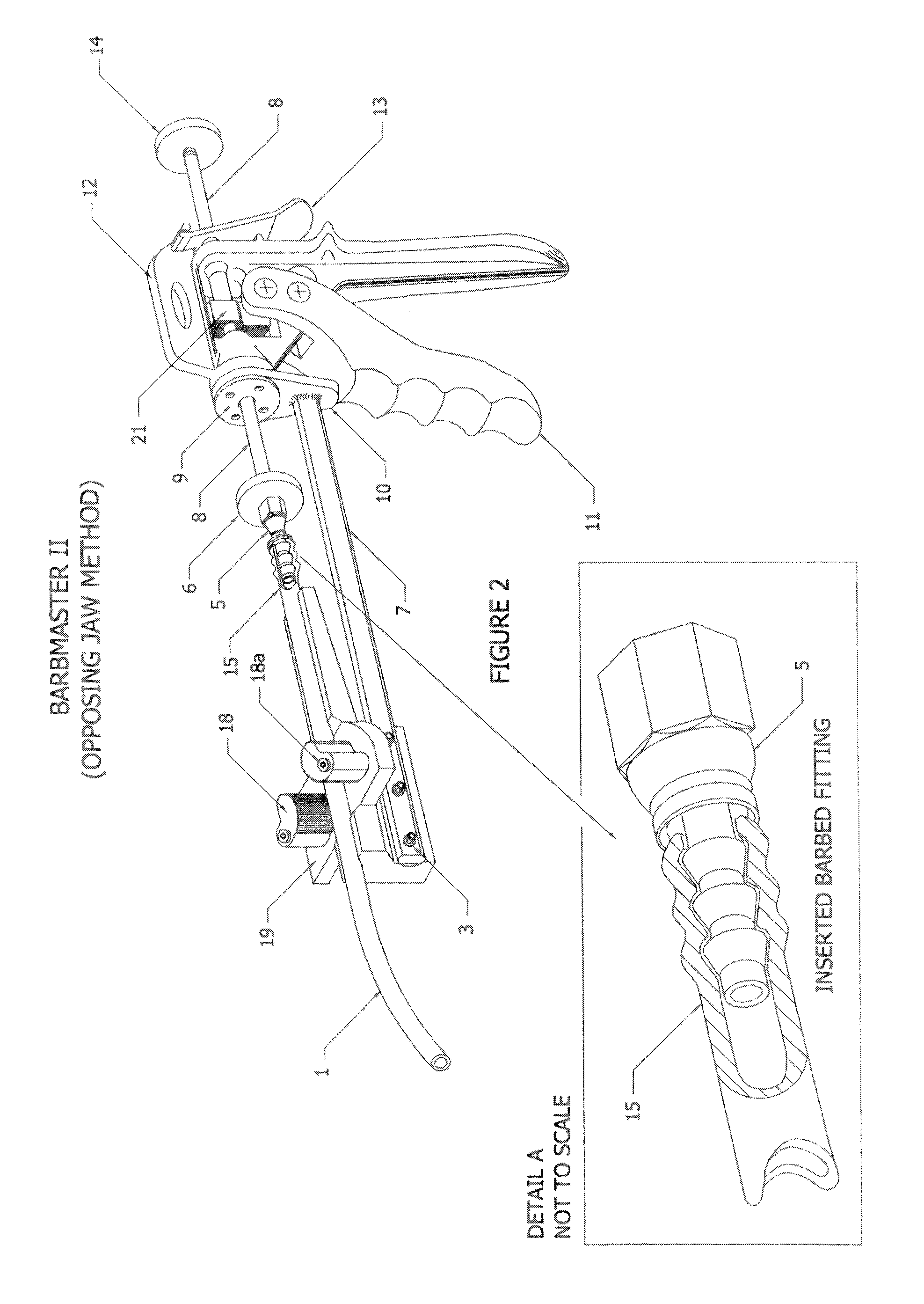

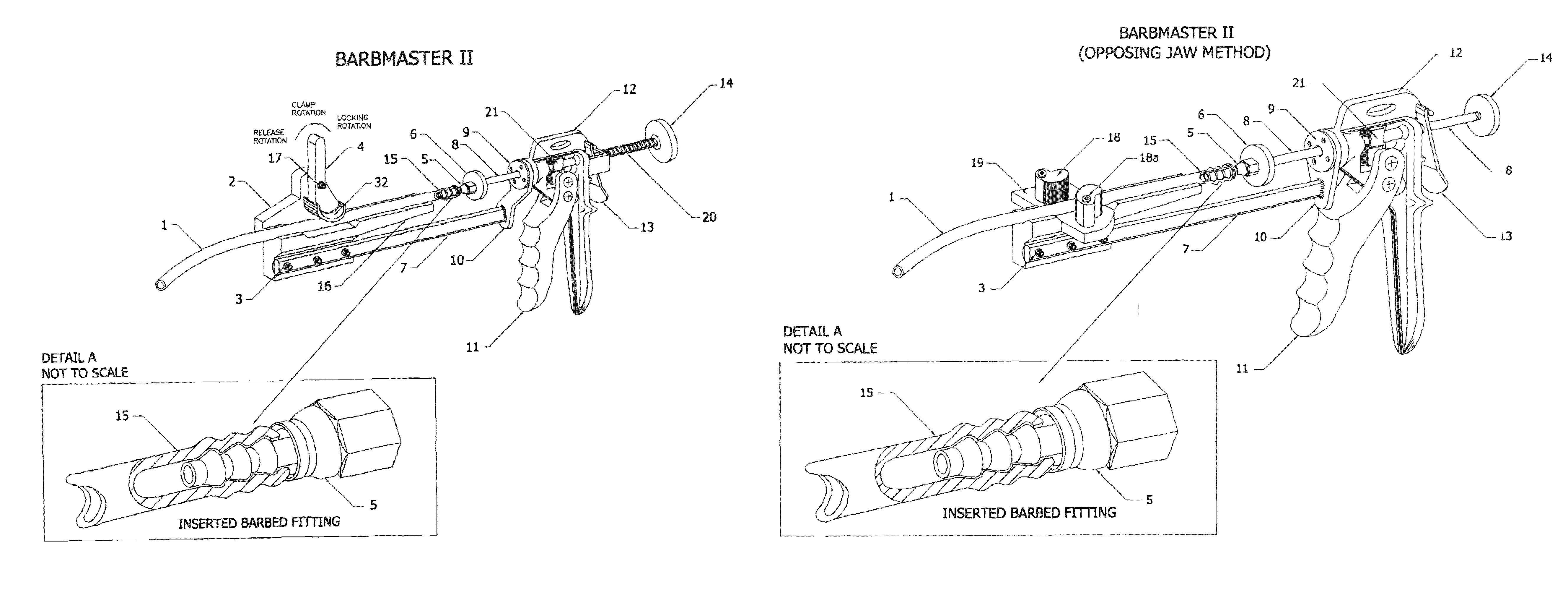

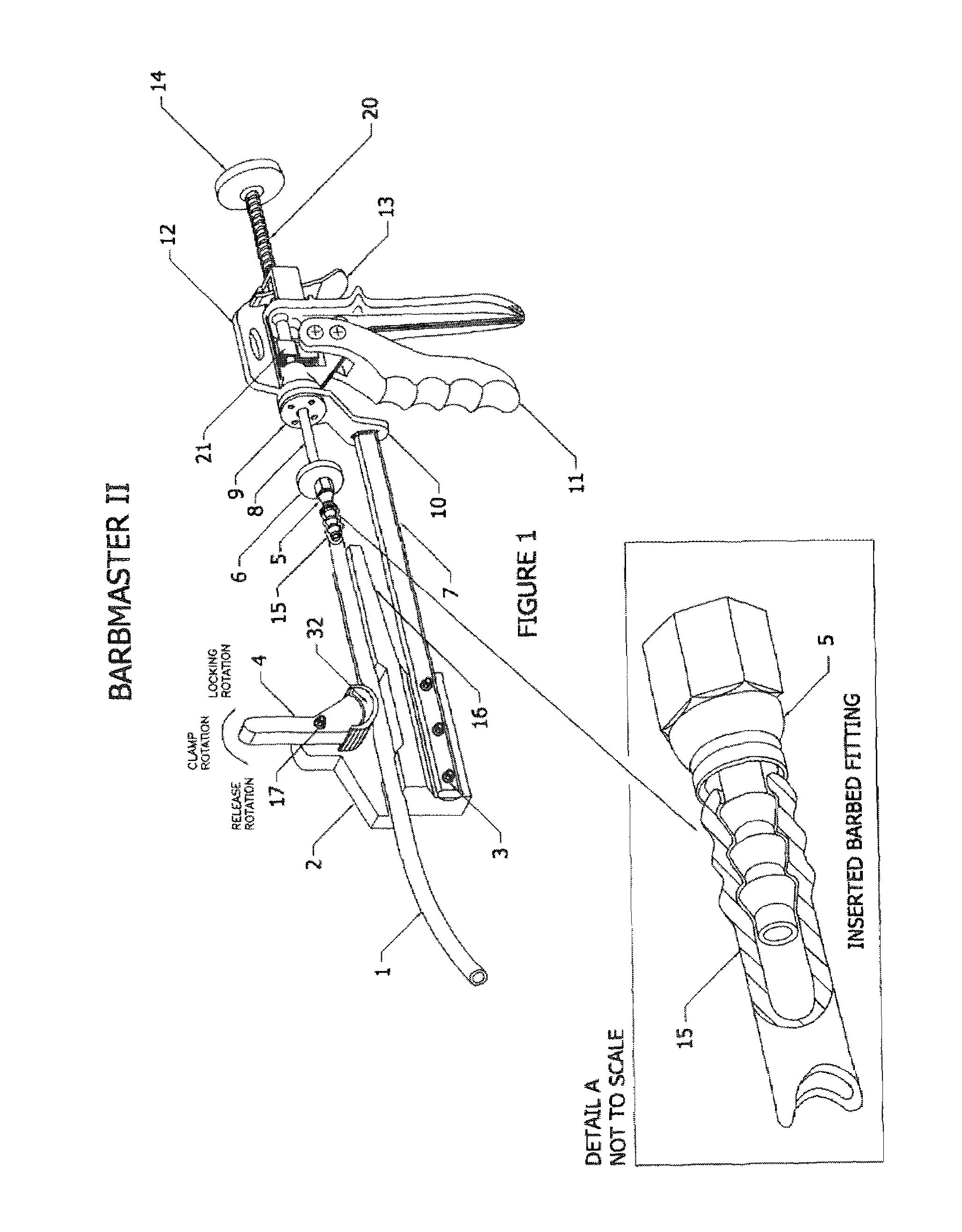

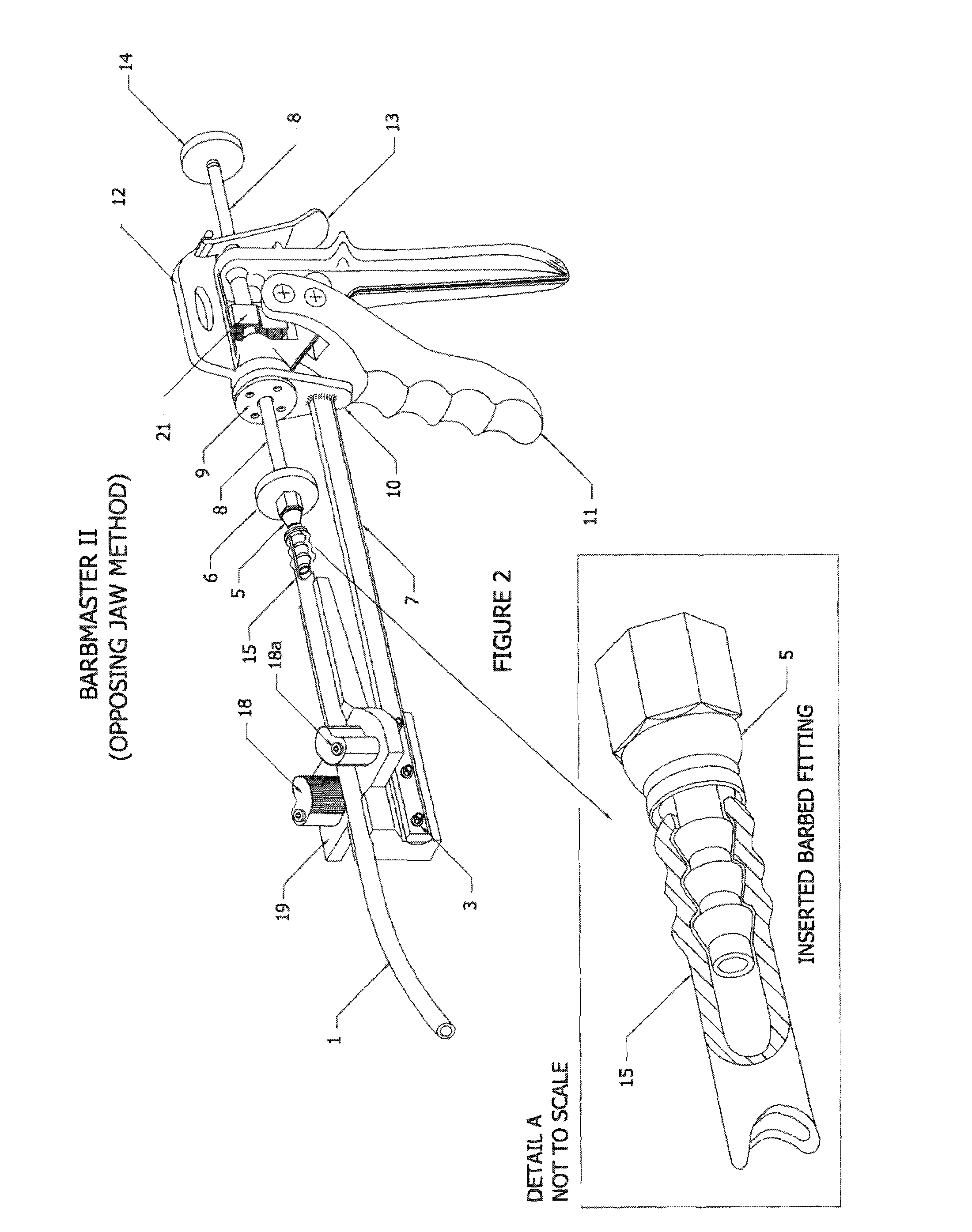

Hose fitting inserter

A powered or hand-activated stationary and / or portable hose fitting insertion apparatus and method. A hose is preferably held in place with a clamp, strap or other apparatus on a platform or in a trough and a fitting is caused to be inserted into an end of the hose by a force applied to the fitting from a pad.

Owner:BENSON JOY FRANCES

Hose-in-hose termination fitting

InactiveUS20100276026A1Easy to disassembleEasy to operatePipe heating/coolingPipe elementsEngineeringHose coupling

Owner:PARKER HANNIFIN CORP

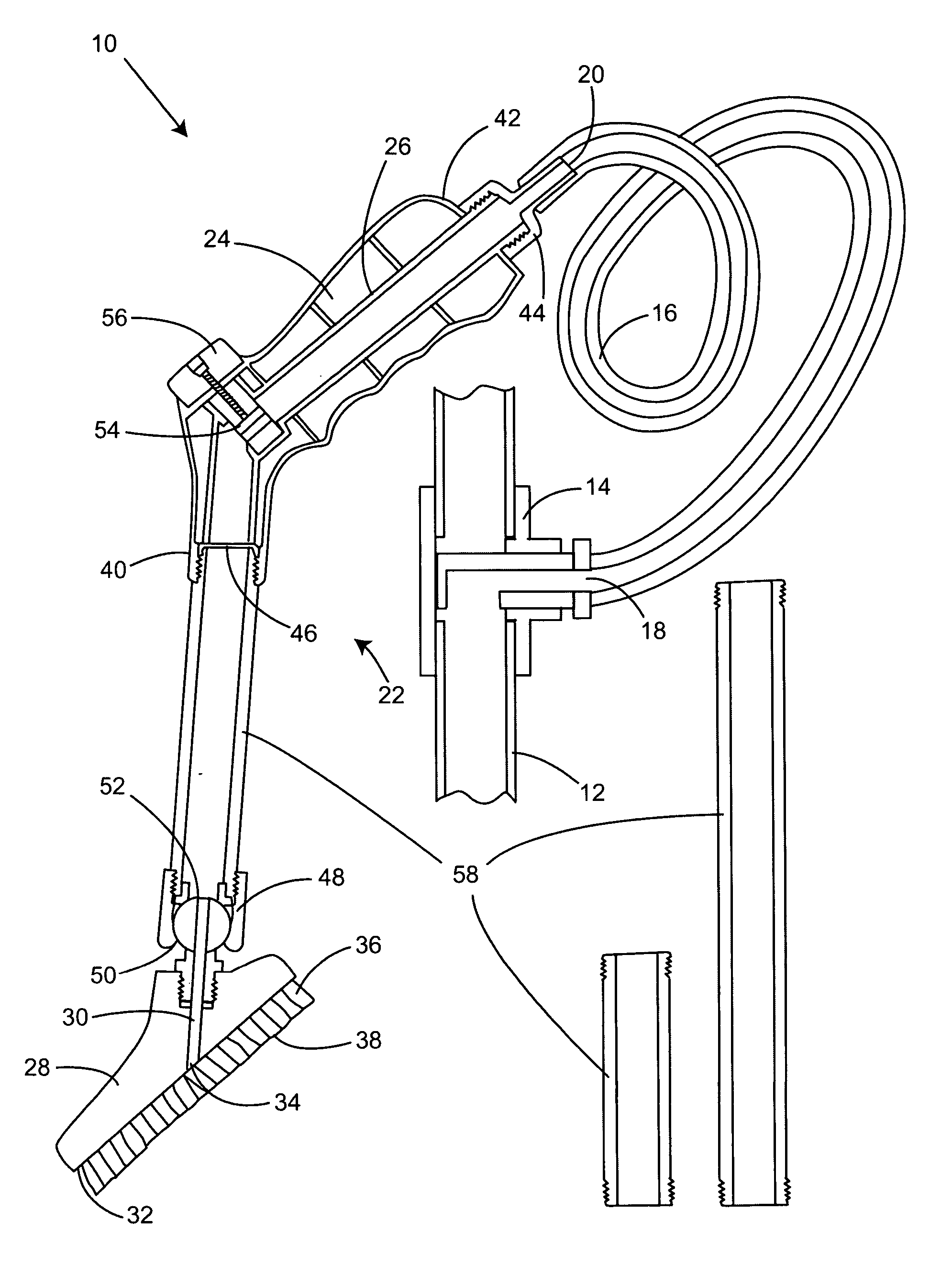

Portable hose fitting inserter

A portable hose fitting insertion apparatus and method. The apparatus can be hand held and operated in areas such that hose repairs can be made without removal of the hose. A friction operated ratcheting mechanism is preferably used to drive a shaft forward. A pad is preferably disposed on an end of the shaft and pushes on an outer surface of the fitting. A clamping mechanism is preferably disposed on a terminal portion of the apparatus and holds an end portion of a hose in place while a fitting is inserted.

Owner:BENSON JOY FRANCES

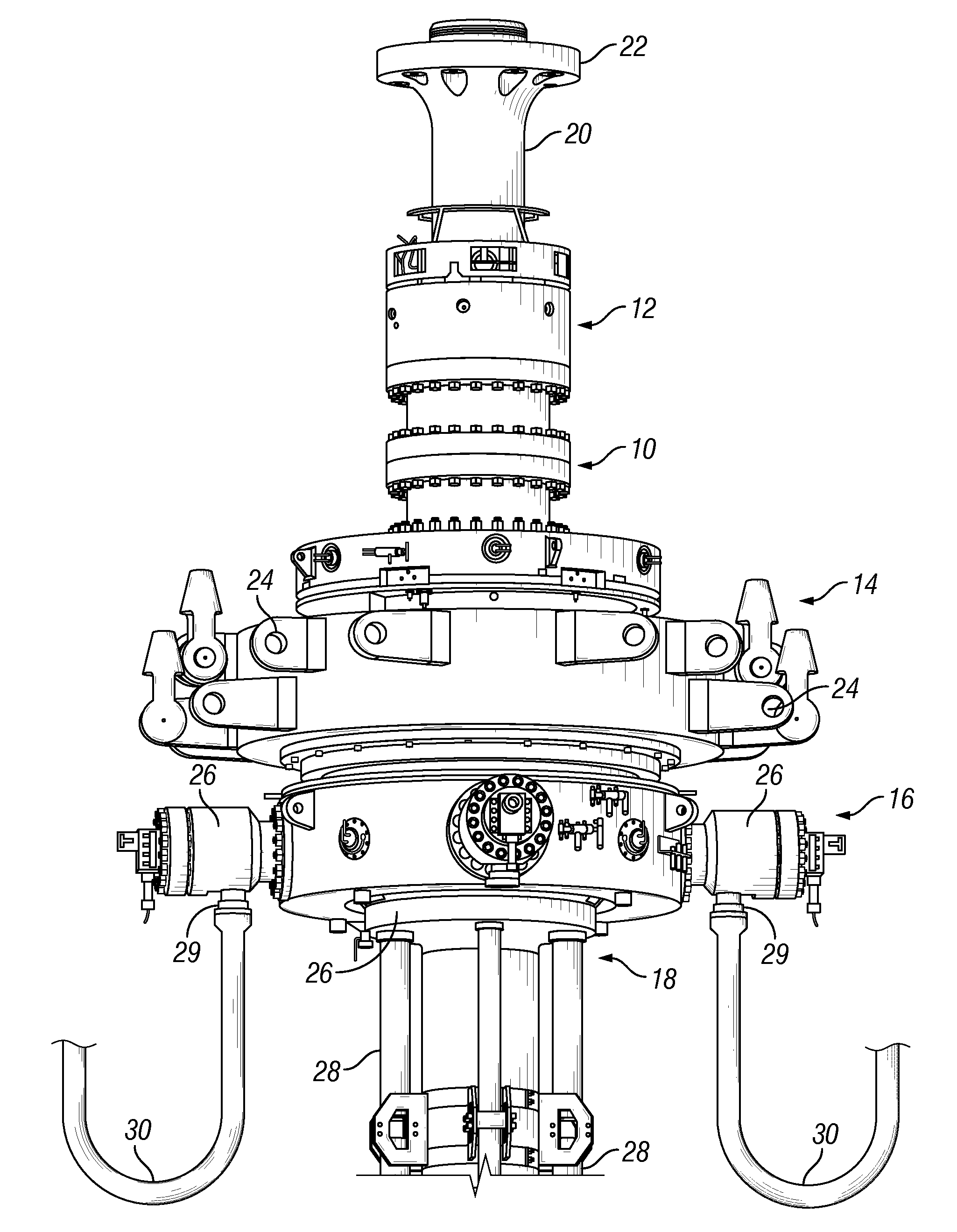

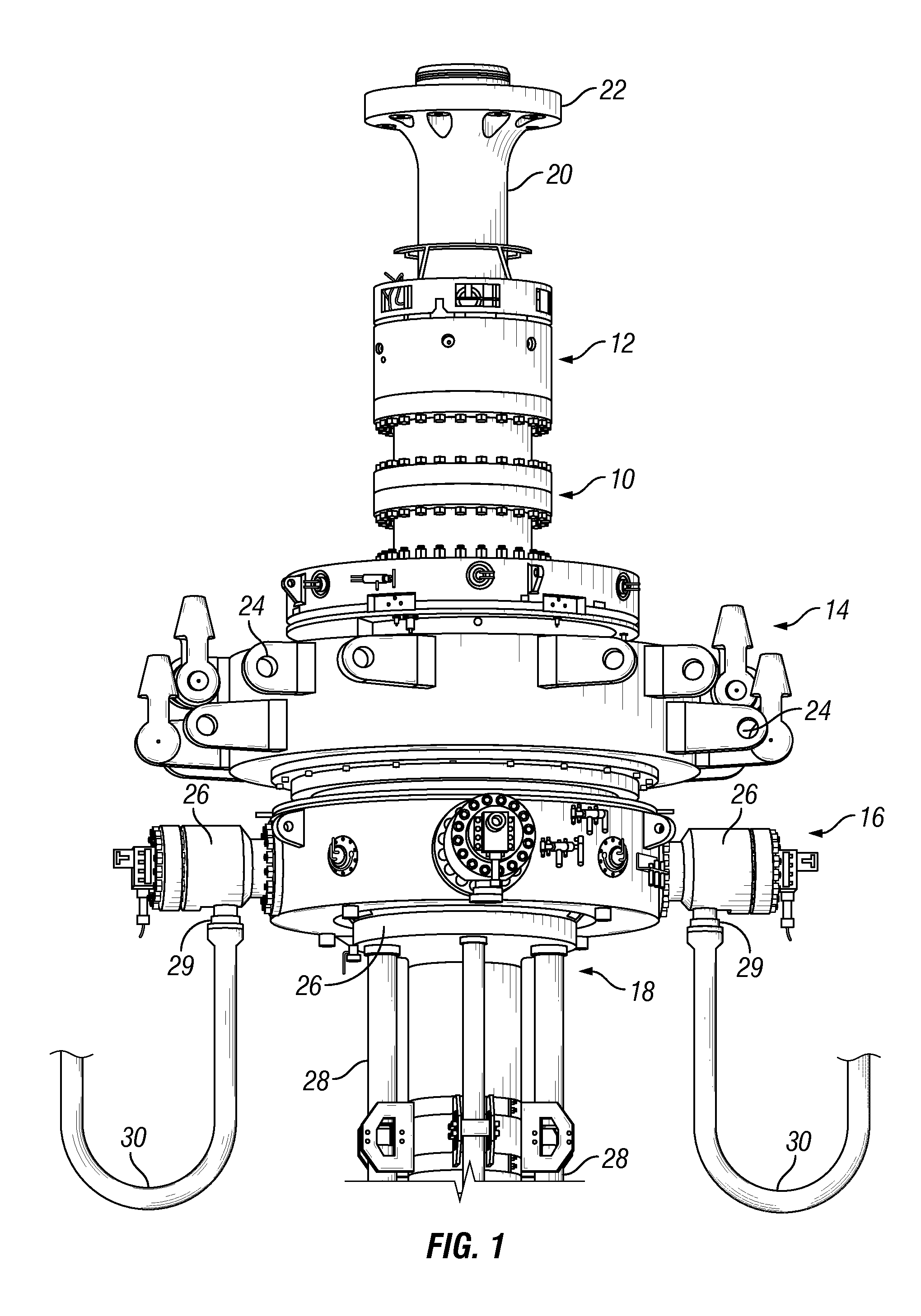

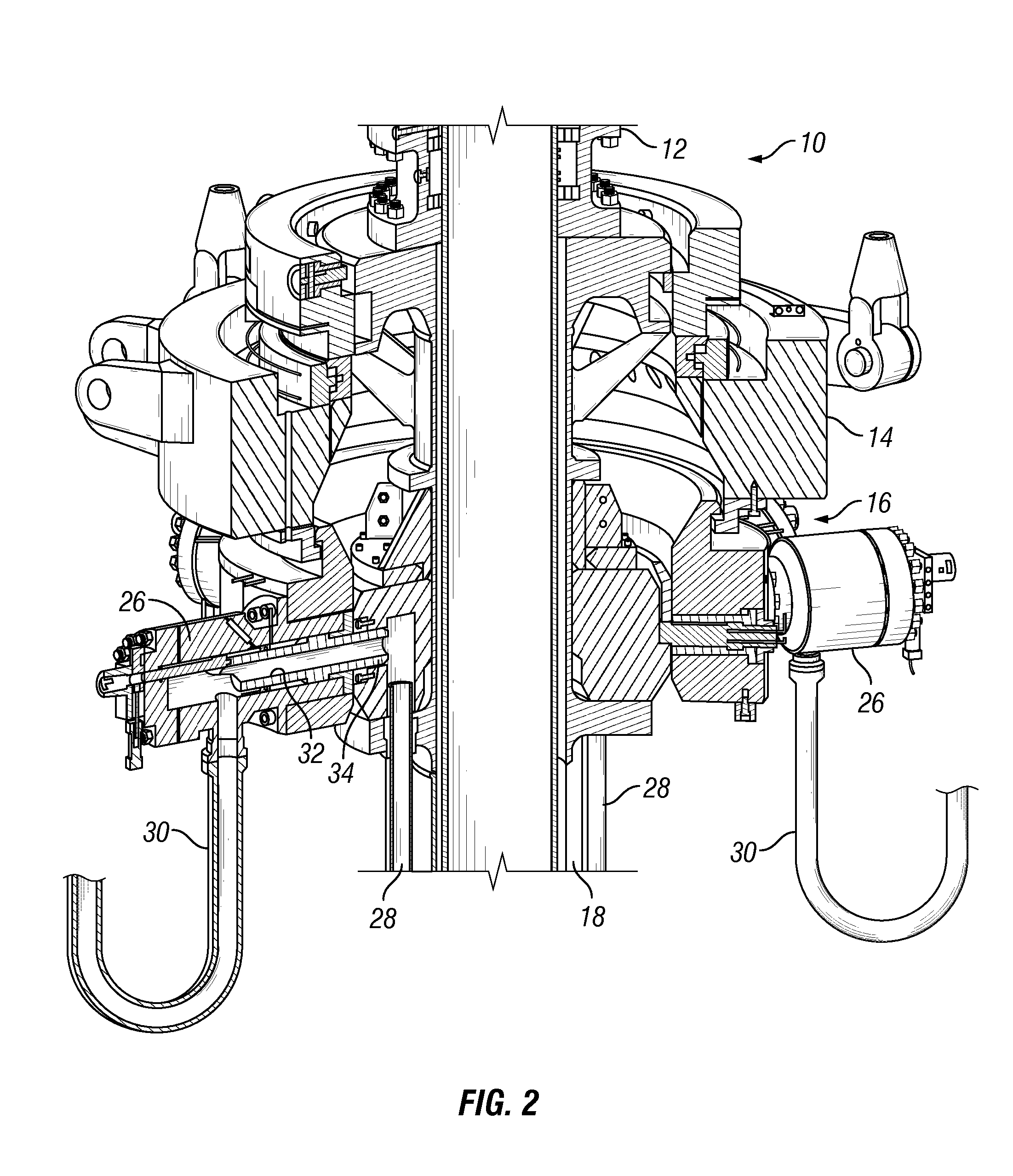

Hands free gooseneck with rotating cartridge assemblies

A gooseneck assembly having a body disposed circumferentially about a portion of a riser string. A stab member is inwardly radially extendable relative to the body and engages a receptacle disposed on the riser string. A cartridge assembly engages the stab member and has a flexible hose coupling that is rotatable relative to a central axis of the stab member. The coupling is in fluid communication with the receptacle via the stab member. The assembly includes an actuator that is operable to rotate the flexible hose coupling relative to the central axis of the stab member.

Owner:NAT OILWELL VARCO LP

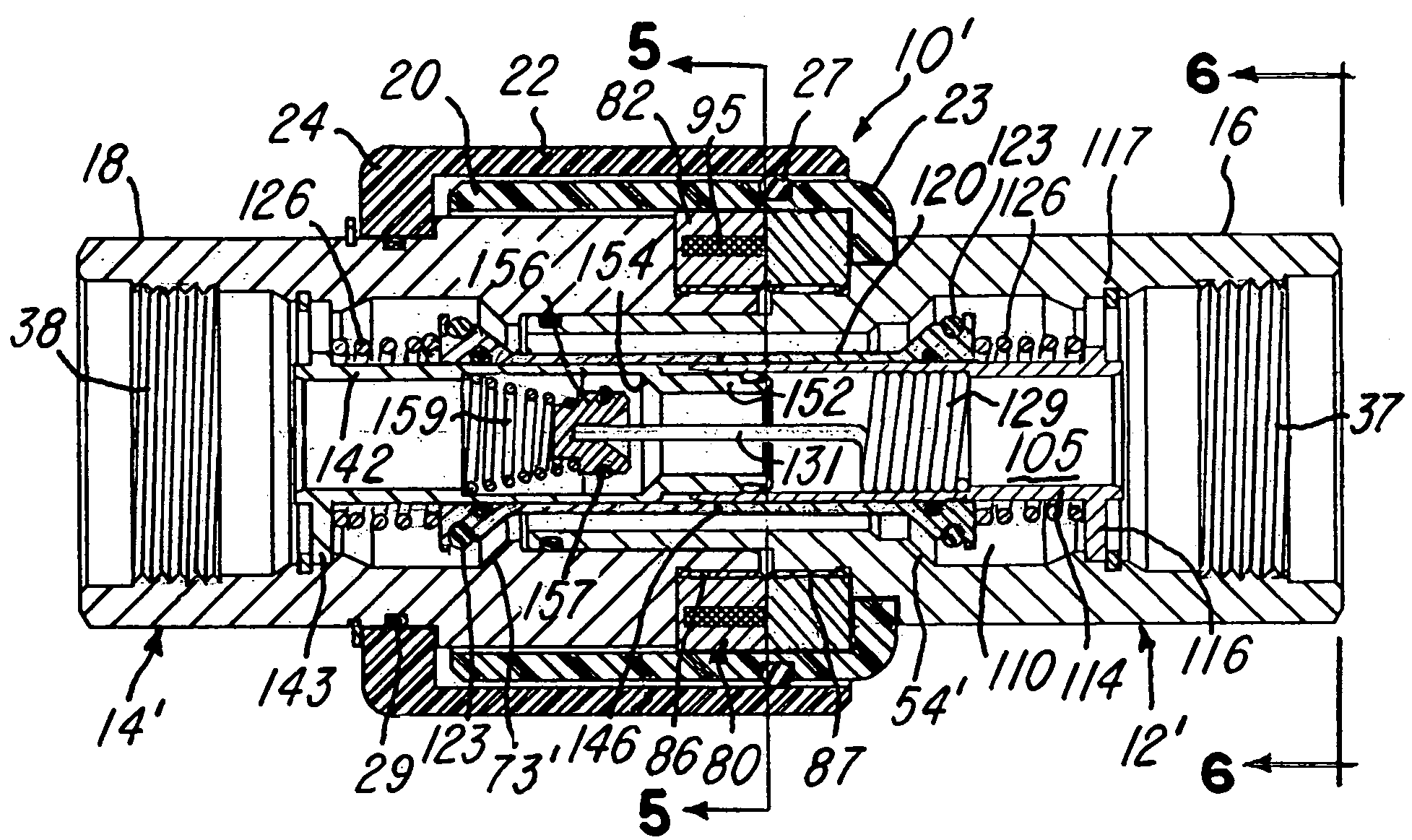

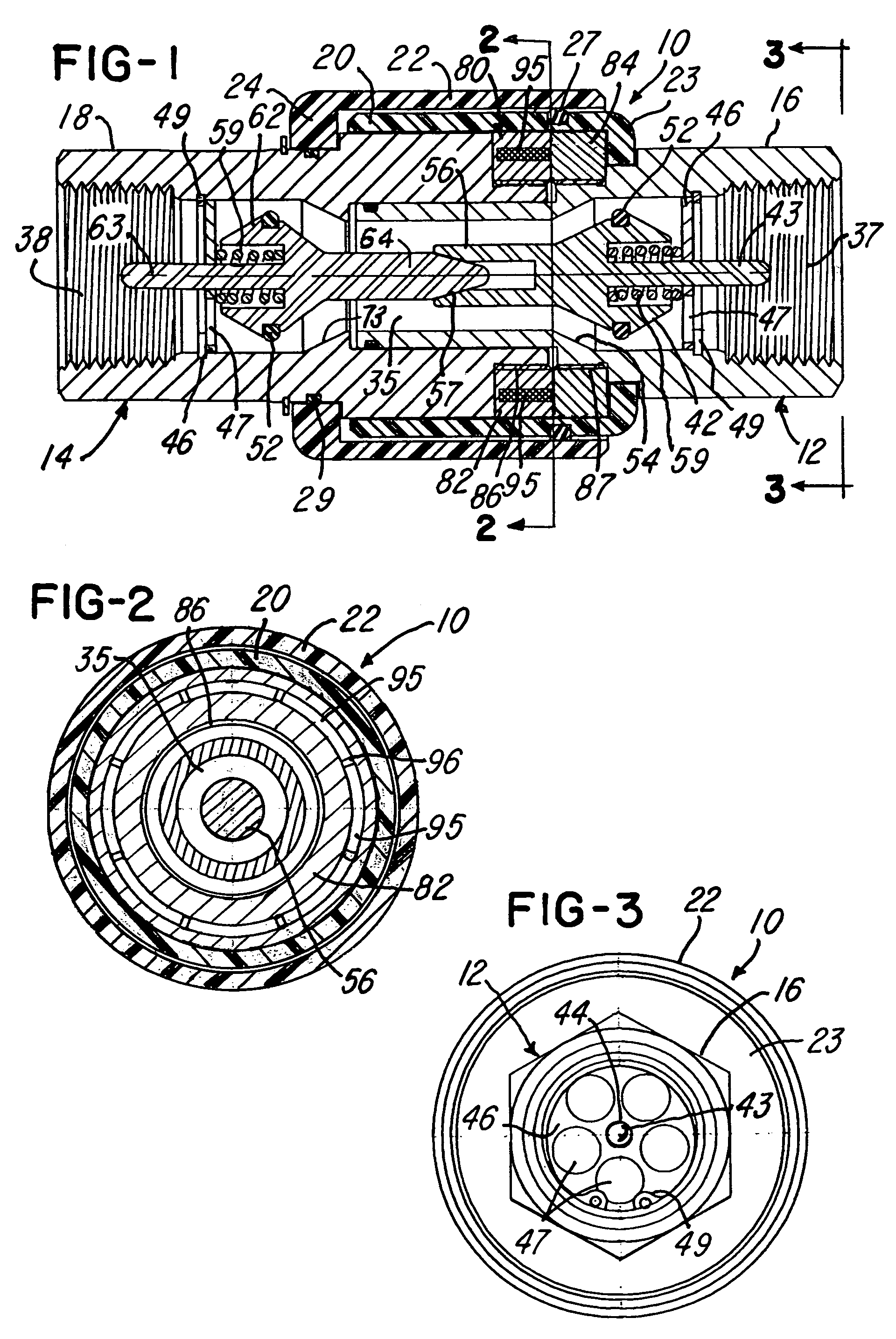

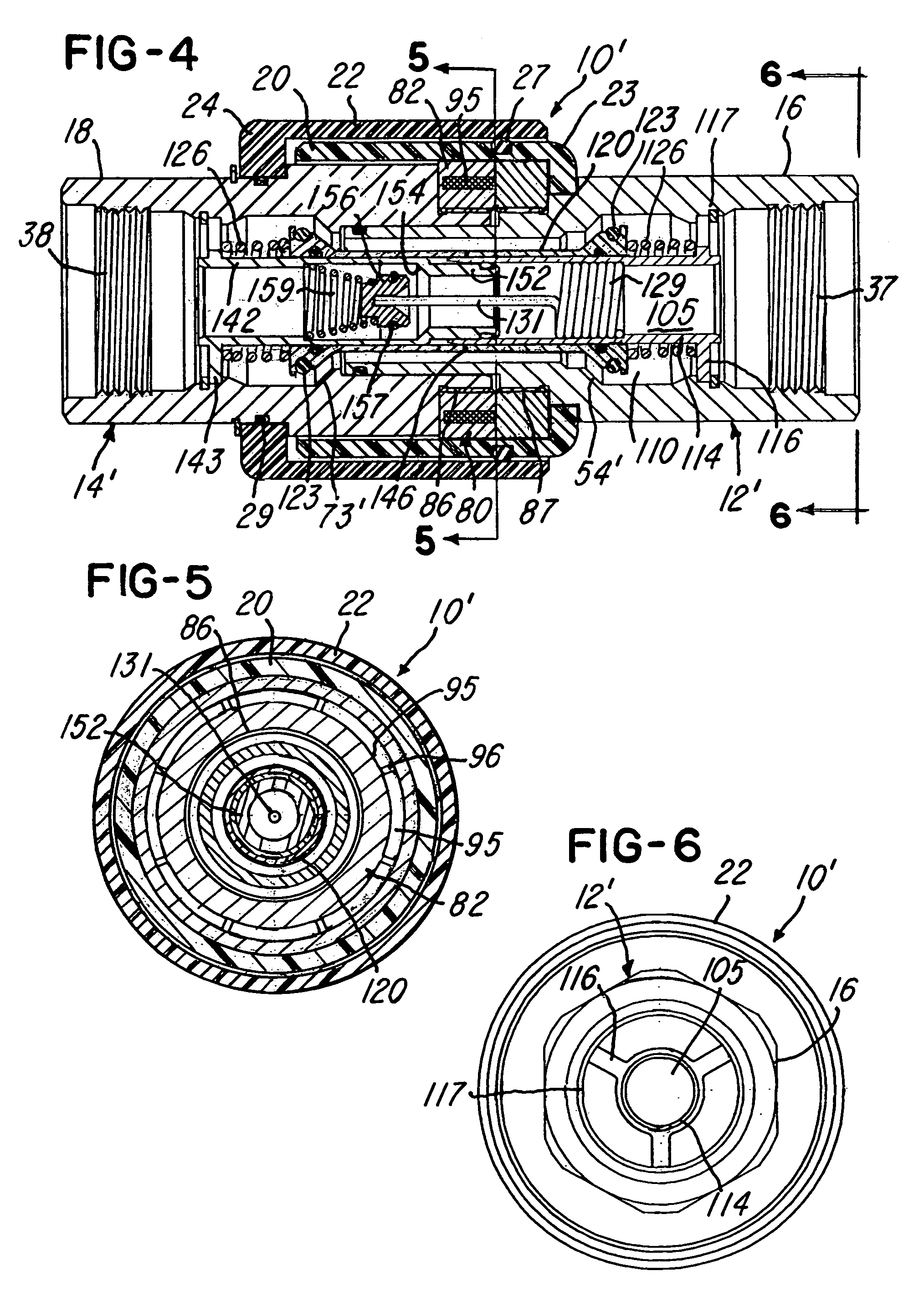

Pressurized hose coupling

InactiveUS6416085B1Easy constructionFew partsFluid pressure sealed jointsHose connectionsEngineeringHose coupling

A fluid pressure hose coupling for connecting a flexible hose to a pressurized fluid line. The coupling has a connecting end section for securement to a pressurizable line and a cylindrical nipple end section for securing an end section of a flexible hose thereto. The nipple end section has a tapered cone-like outer surface having a larger outer diameter section at a free end thereof. A cylindrical hose clamping sleeve is positionable about the nipple end section and also has an inwardly tapered inner surface whose diameter is larger at the front end thereof and wherein the inner surface of the clamping sleeve and the outer surface of the cylindrical nipple end section extend parallel to one another. By positioning a flexible hose end section over the nipple and placing the hose clamping sleeve over the hose end section and by applying pressure in the line and pulling the sleeve and hose sections together, in an outward direction, the hose end section becomes clampingly secured between the clamping sleeve and the tapered outer surface of the nipple end section. To disconnect the hose pressure is removed and the hose clamping sleeve is pushed rearwardly to clear the hose end section which may then be pulled off the nipple end. The clamping sleeve may also have a piston end located in a channel which is in communication with the pressurized fluid whereby the pressurized fluid displaces the sleeve in clamping engagement with the end section of the hose.

Owner:MARKOVIC BRANIMIR

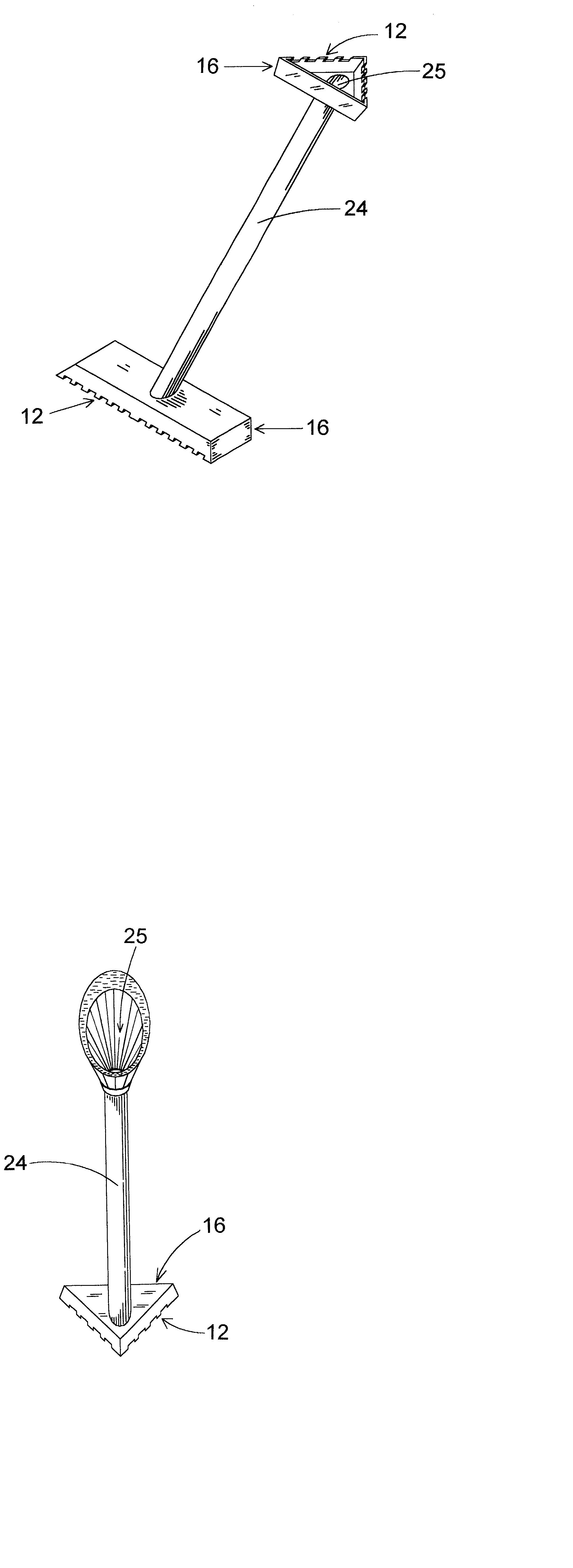

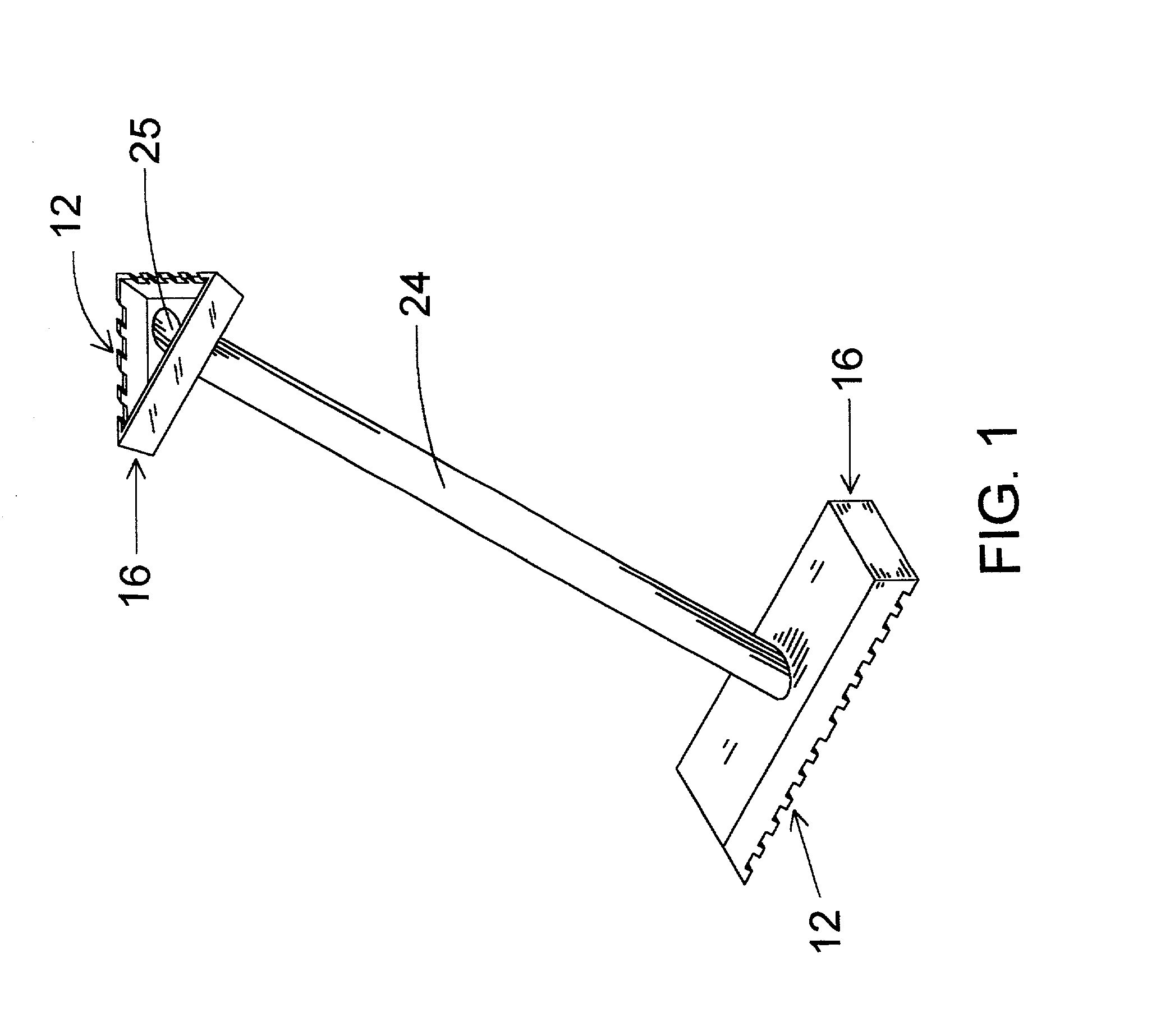

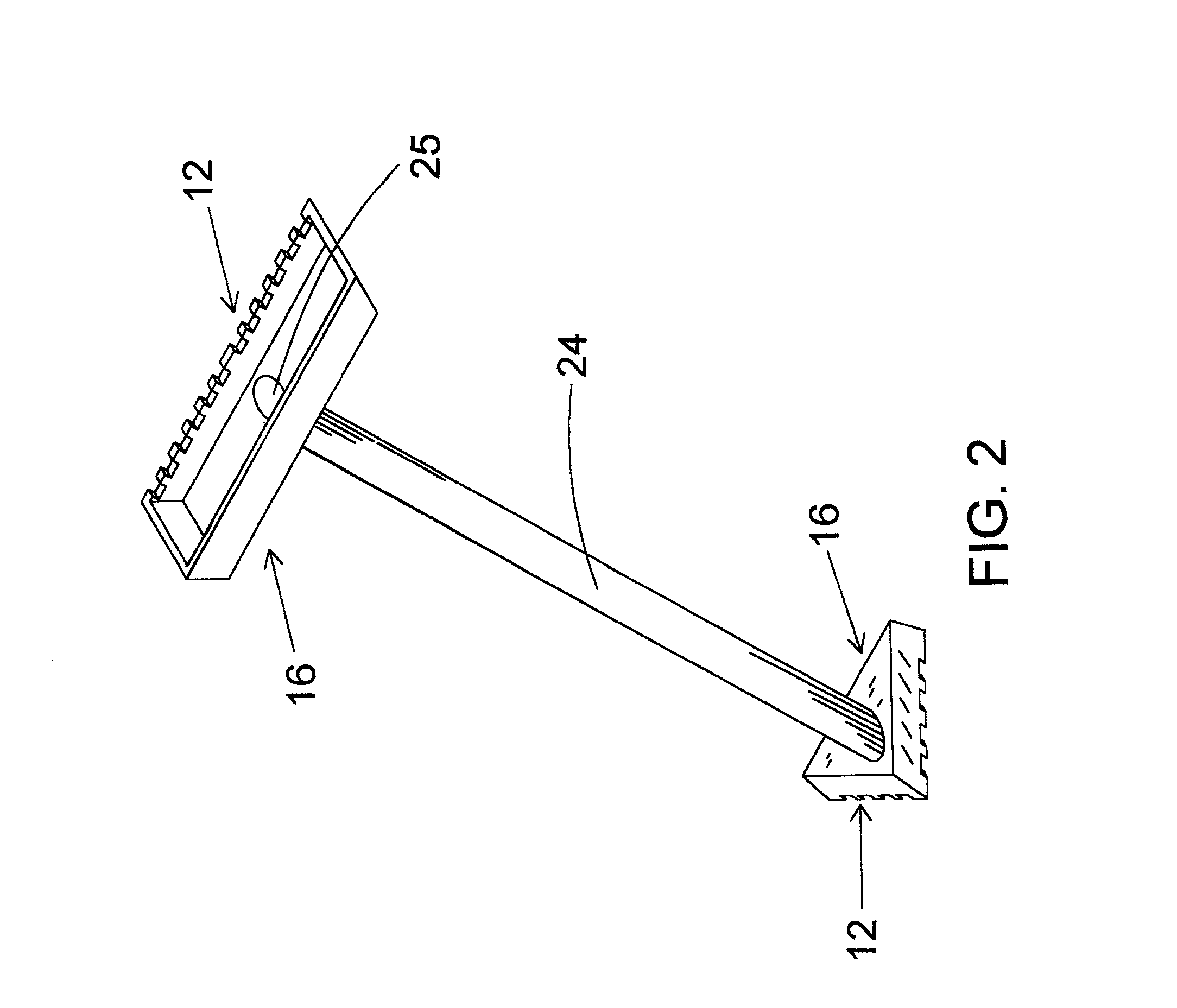

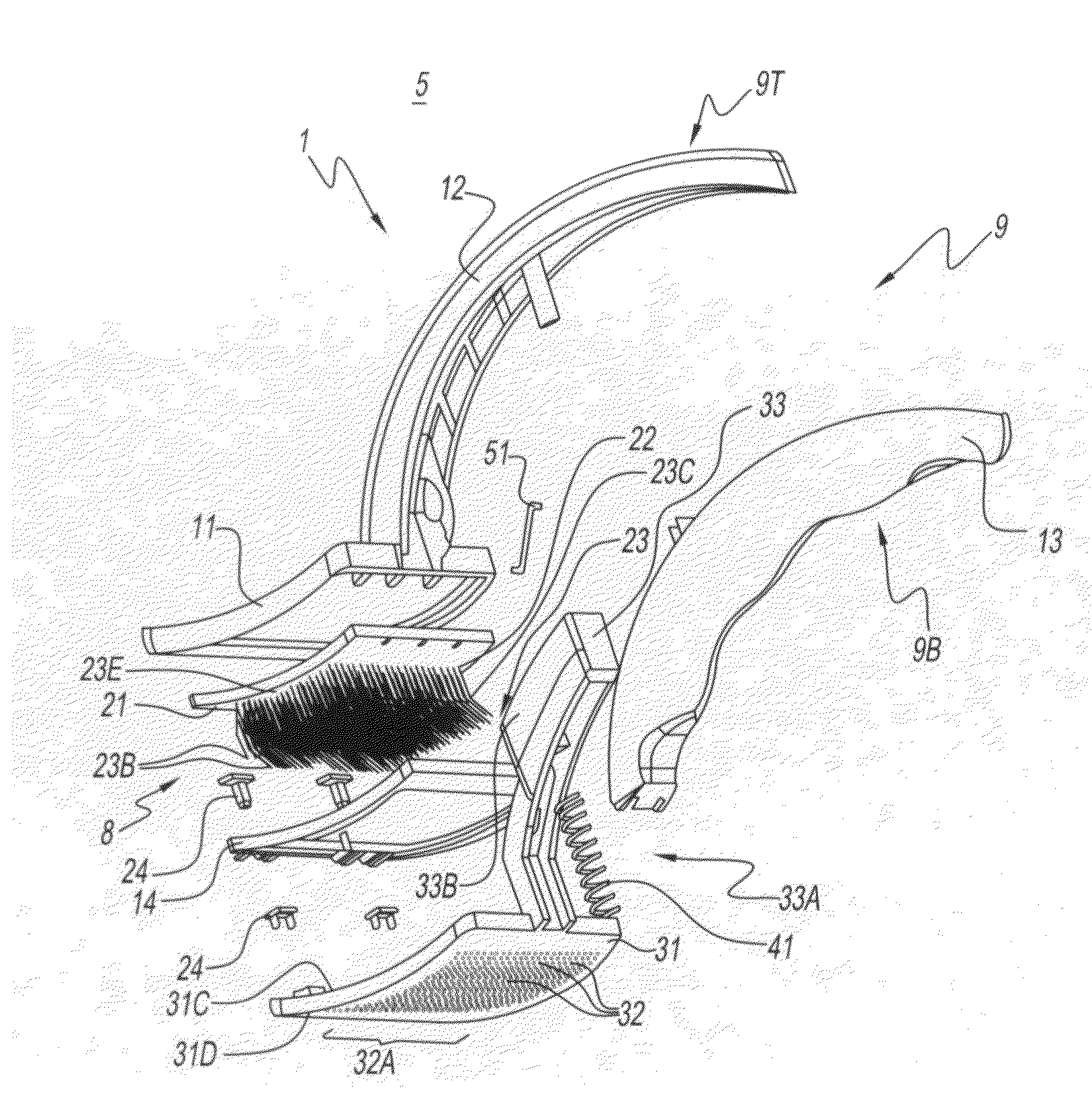

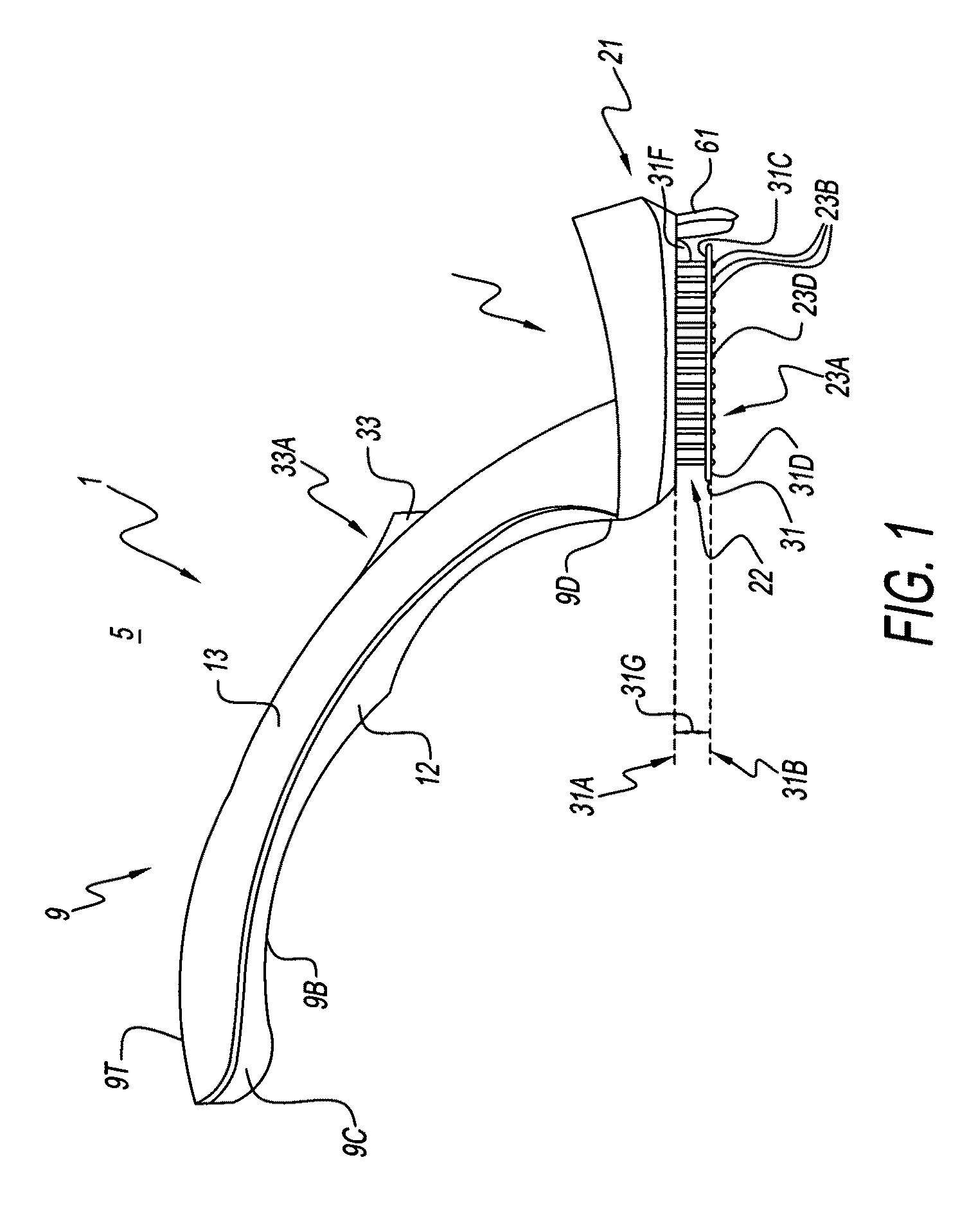

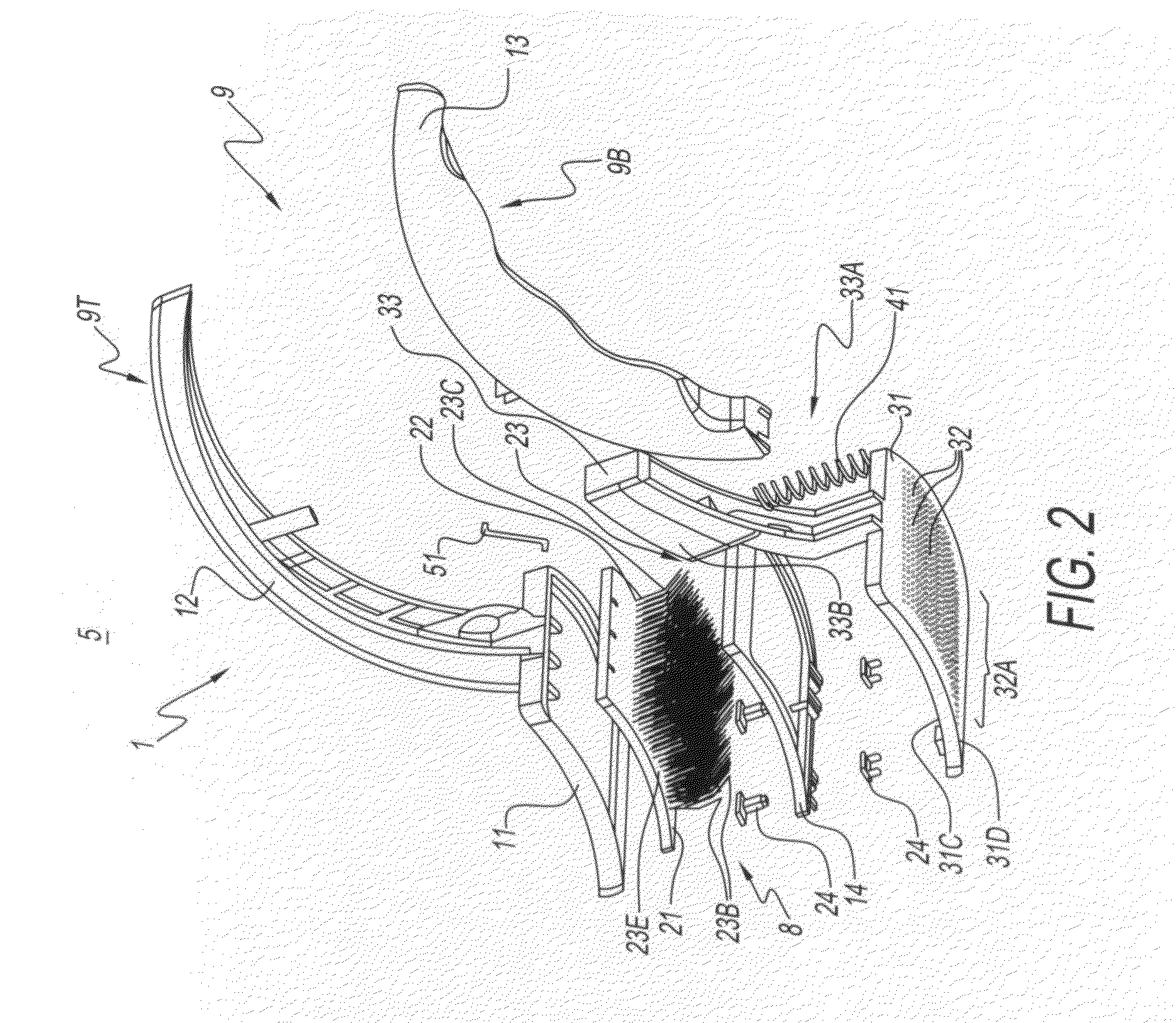

Grooming device

InactiveUS8082887B2Increase the lengthControl concentrationOther apparatusGrooming devicesBristleEngineering

The invention is an apparatus for grooming an animal having a brush head, the brush head having a plurality of bristles, each bristle having a midpoint and an endpoint, where the bristles are in general perpendicular orientation to the brush head, a cleaning plate, in general parallel orientation to the brush head, the cleaning plate able to move from a contracted to an extended position, the cleaning plate further having material removed to allow the bristles to protrude through the cleaning plate when it is in the retracted position; and a mechanism for extending and contracting the cleaning plate, wherein the cleaning plate has a bottom surface and the bottom surface does not extend past the bristle endpoint when the cleaning plate is in the extended position. In one embodiment, at least some bristles are wire, and in further embodiments the wire bristles have round coated tips. The brush head may further have a water outlet and a hose coupling for intake and dispensing of liquids. Furthermore, the present invention may have means for conducting water through the handle and out the water outlet, which may be a plurality of hollow bristles.

Owner:PRODS OF TOMORROW

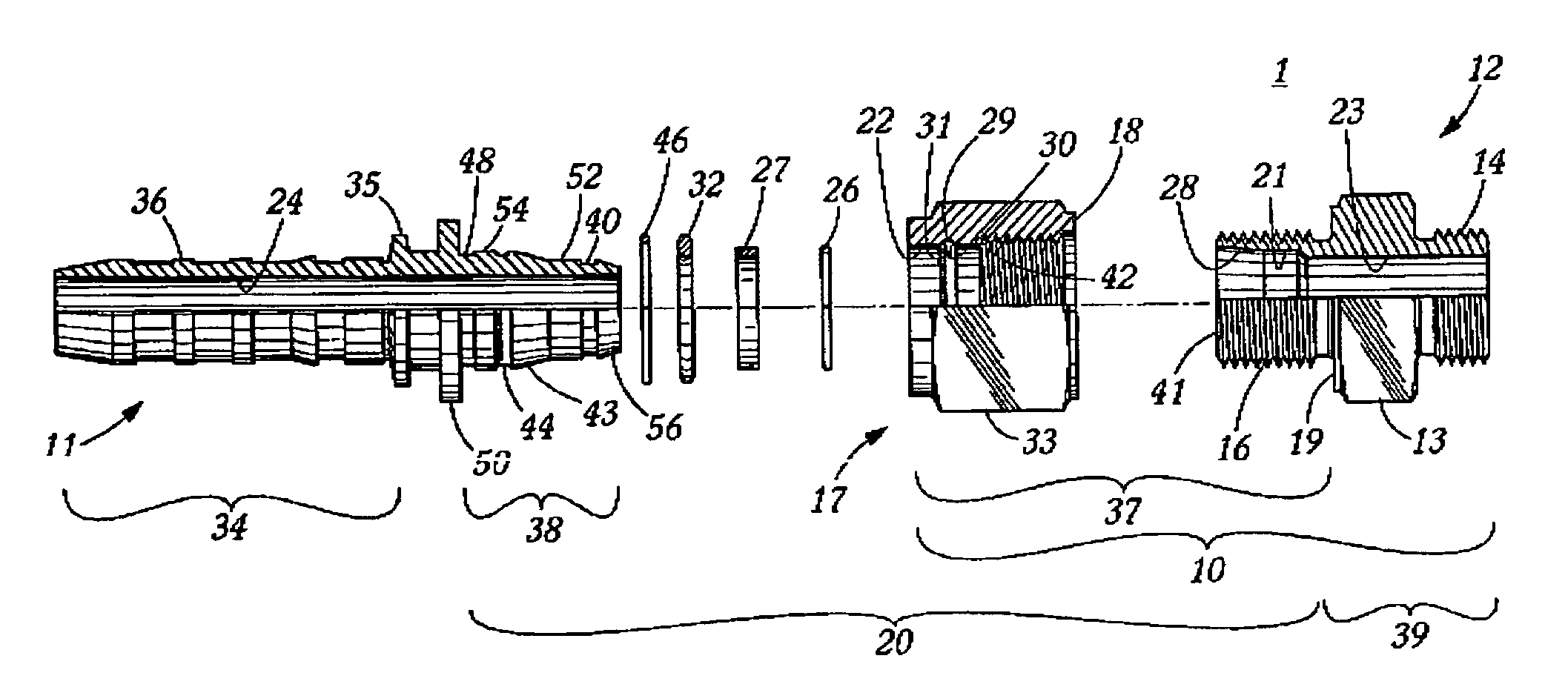

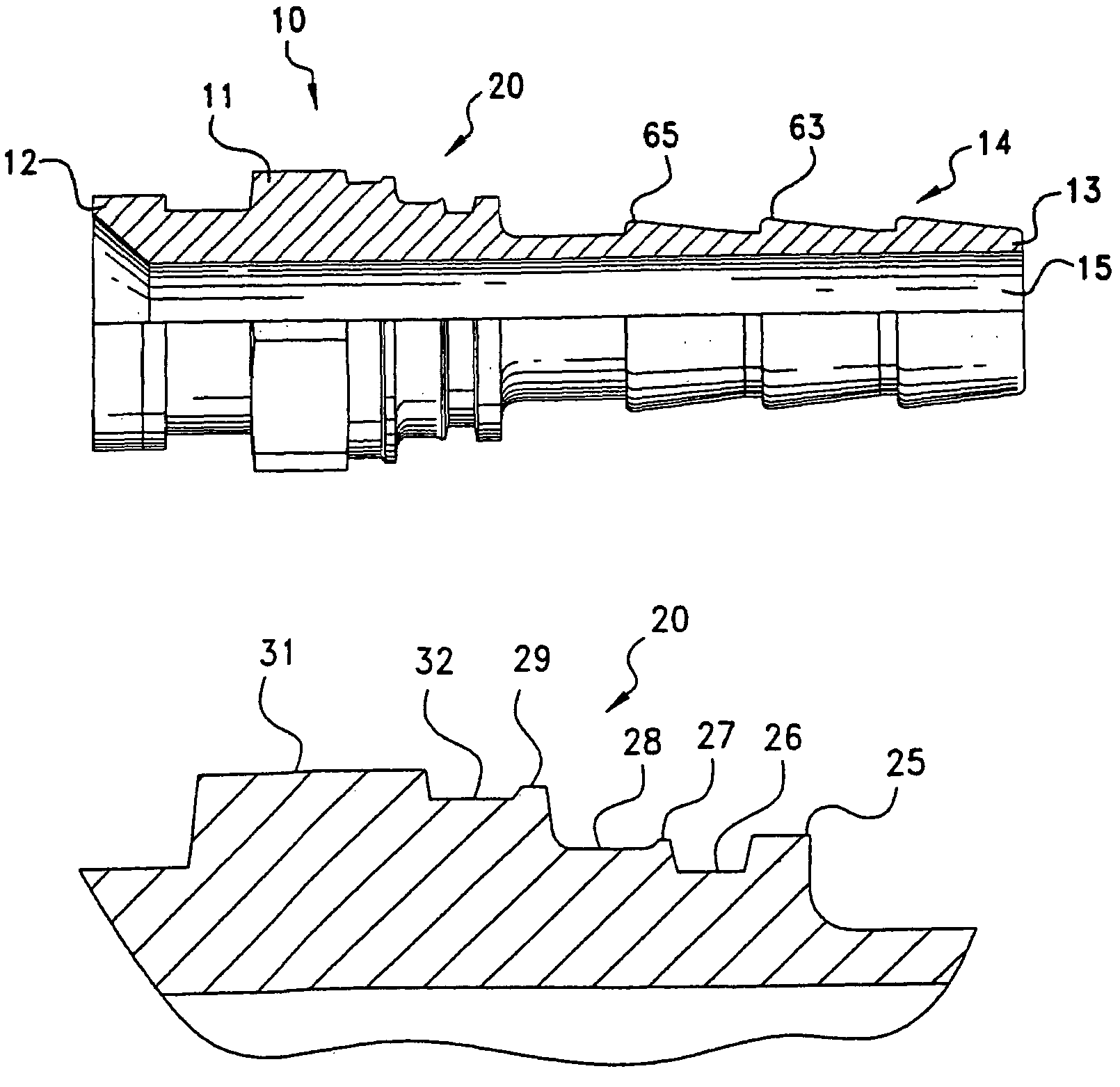

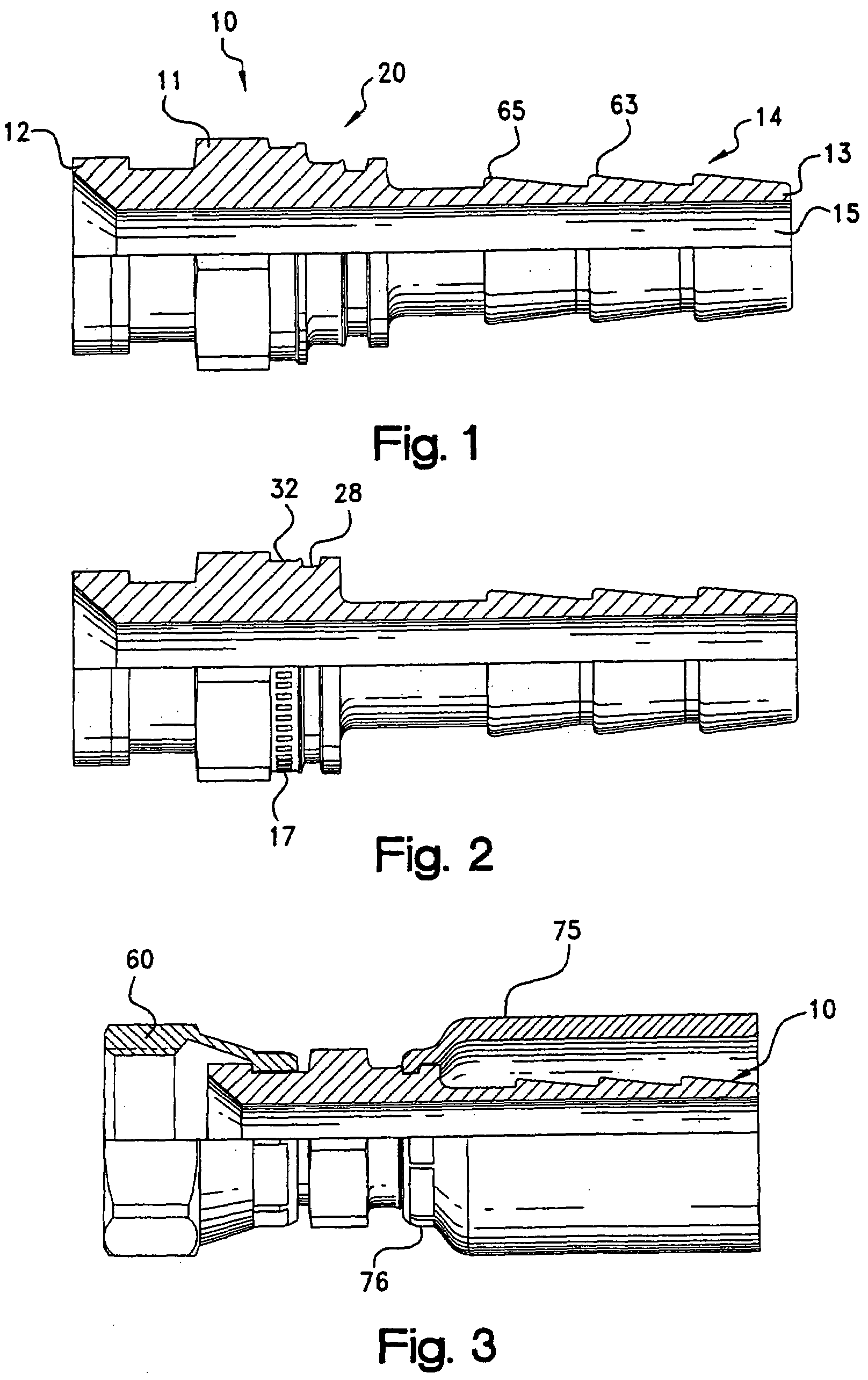

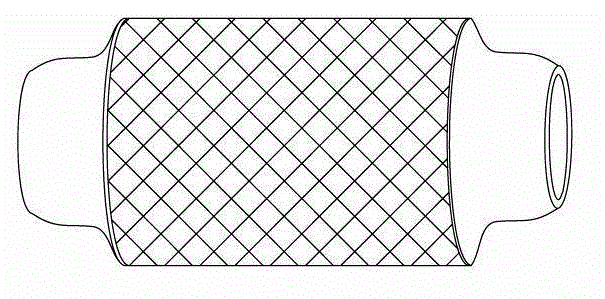

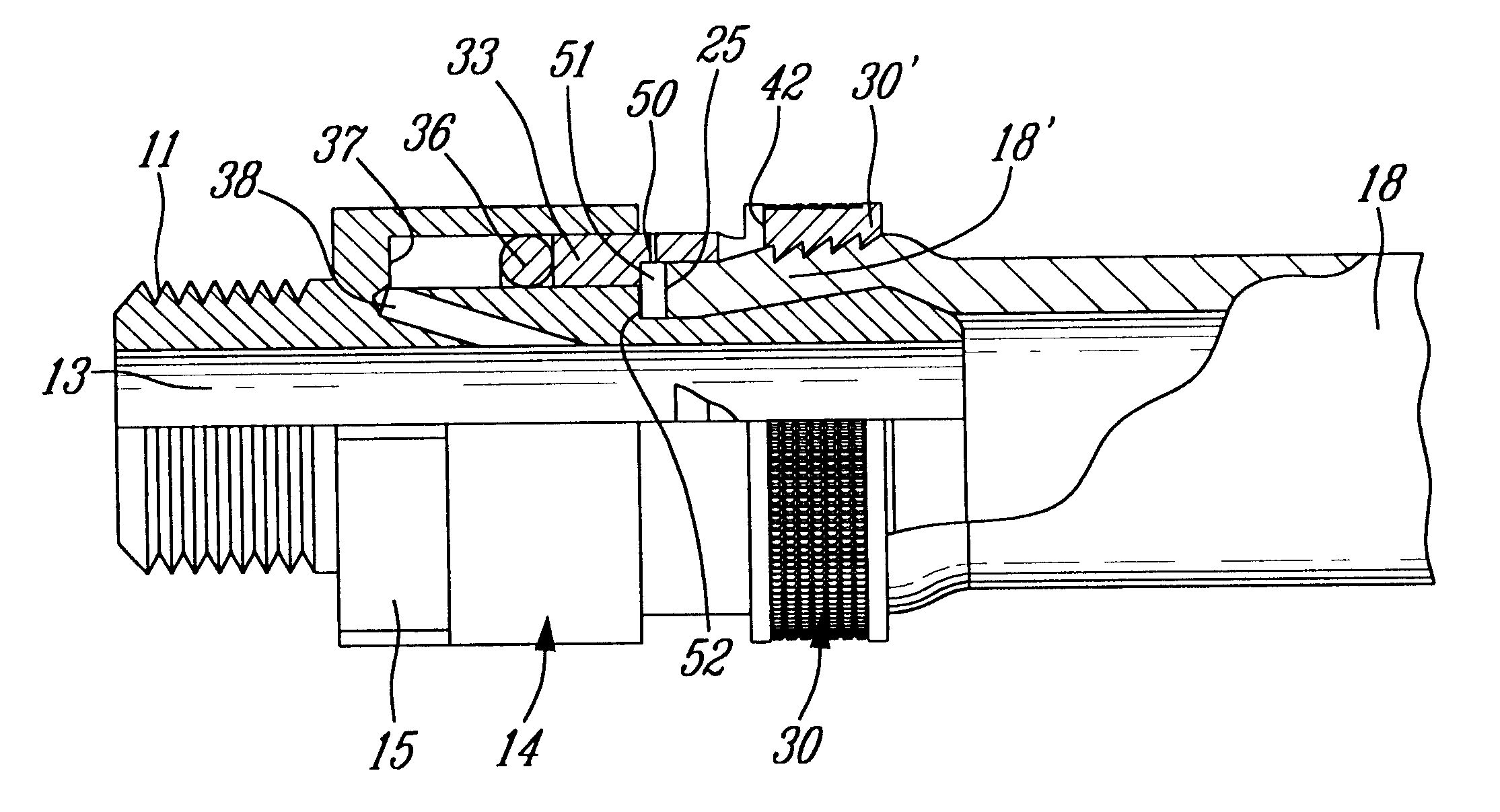

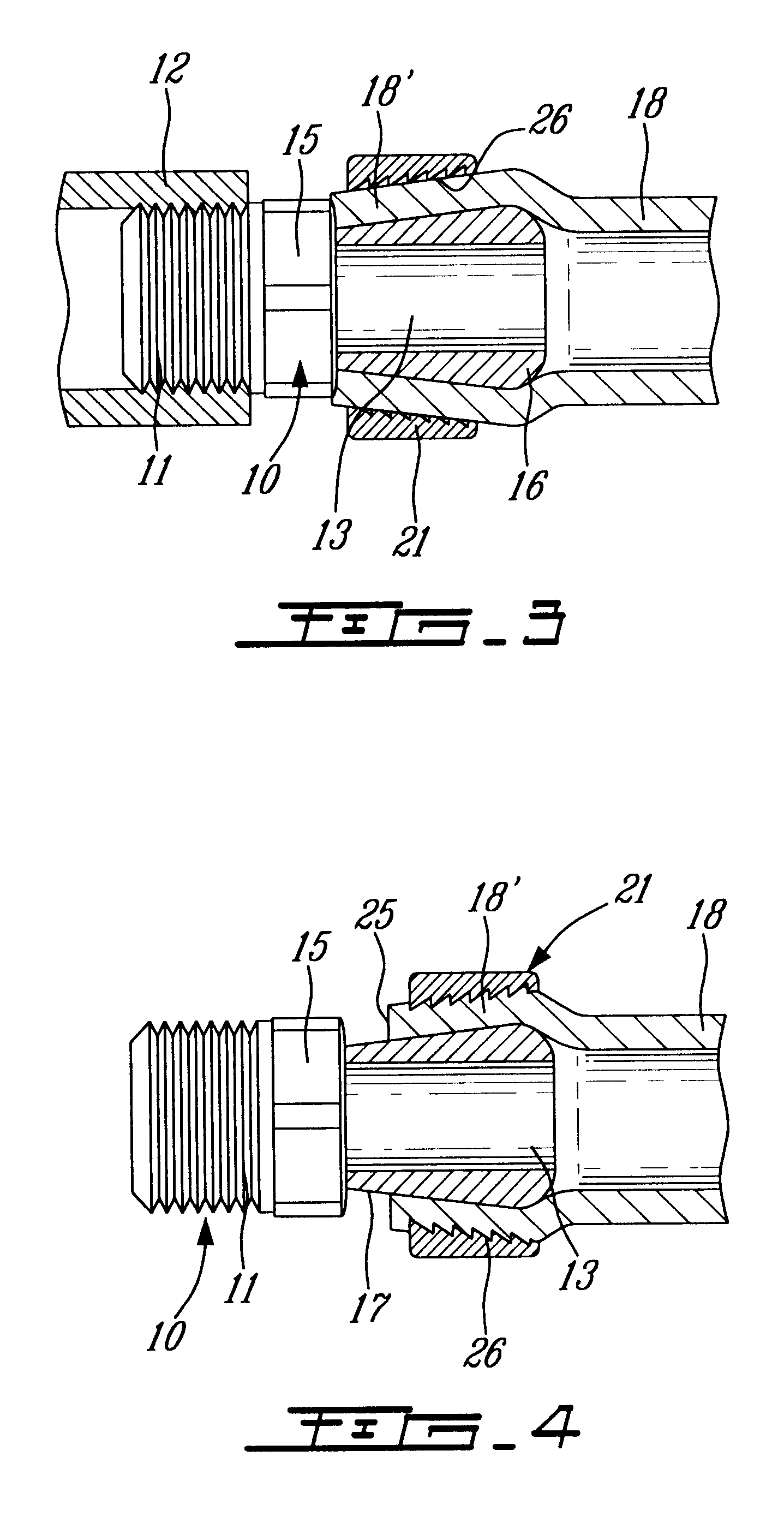

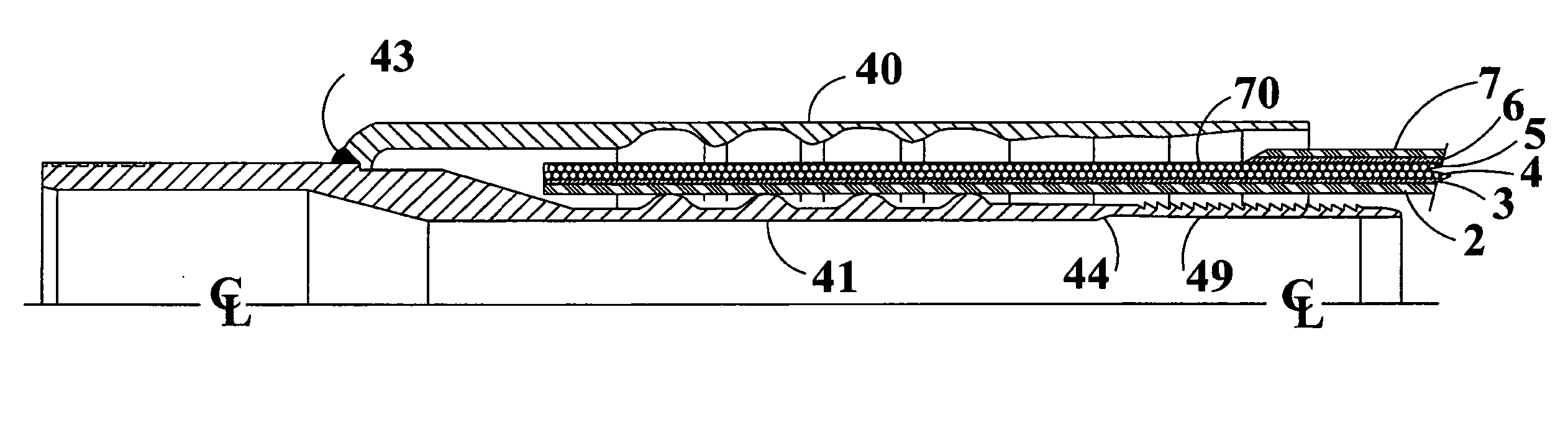

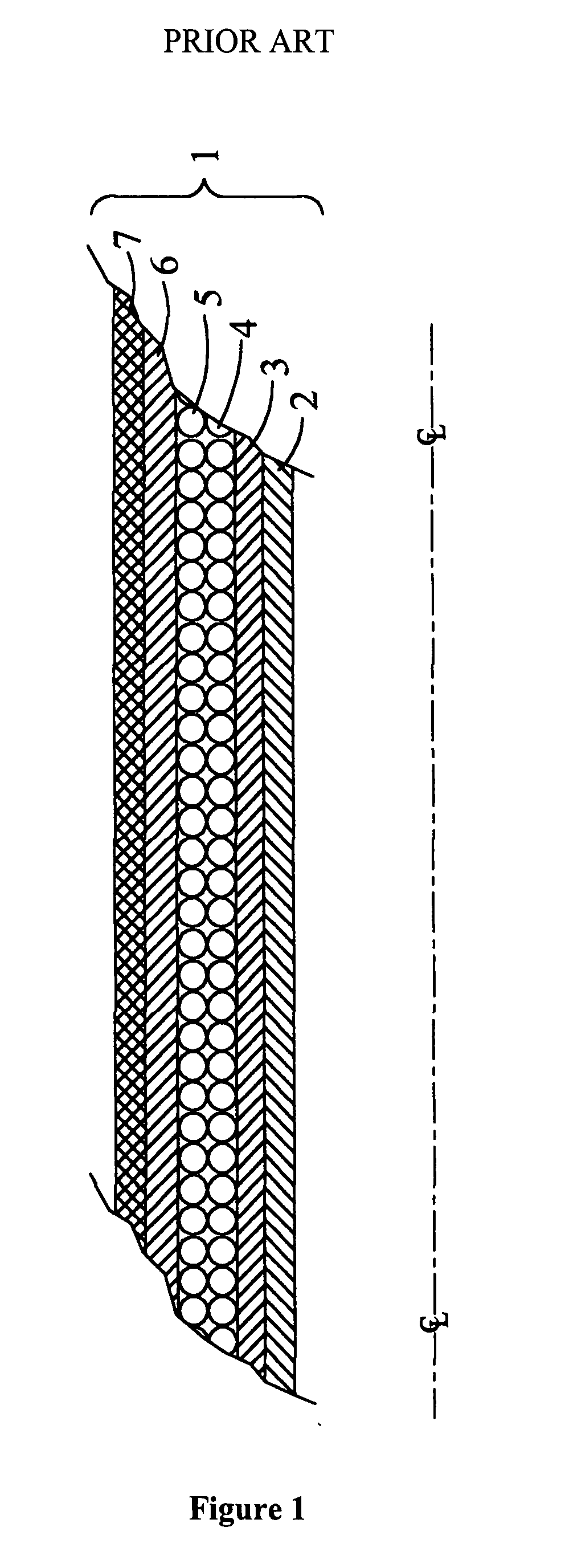

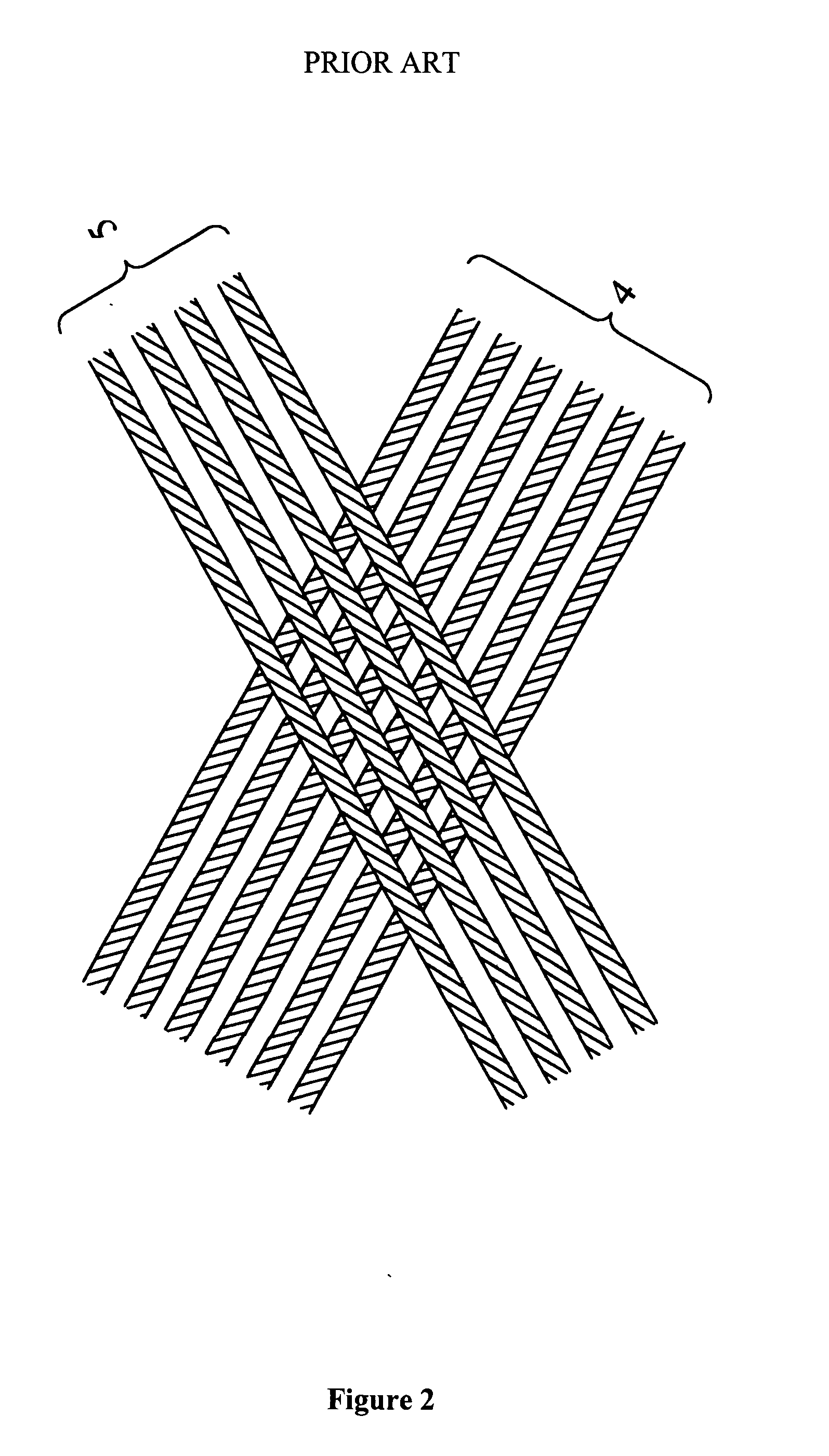

Method of attachment for a high pressure reinforced rubber hose coupling

InactiveUS20070157443A1High possible lockExtended diameter rangePipe-jointsHose connectionsTO-18Engineering

A method of attachment for swage end-connector for high pressure reinforced flexible hose particularly suitable in the petrochemical and drilling industries for hoses is disclosed. Two connectors are discussed one for intermediate hose pressure burst ratings up to 12,500 psi and internal diameters up to 3½ inches and higher hose pressure burst ratings up to 18,750 psi and internal diameters up to 4 inches. Both embodiment connectors will withstand the rated burst pressure of the hose to which they are connected and will withstand a pump-off force that exceeds the burst pressure of the hose. That is, the hose will fail before the connector pops off the hose.

Owner:BALDWIN & LOKE

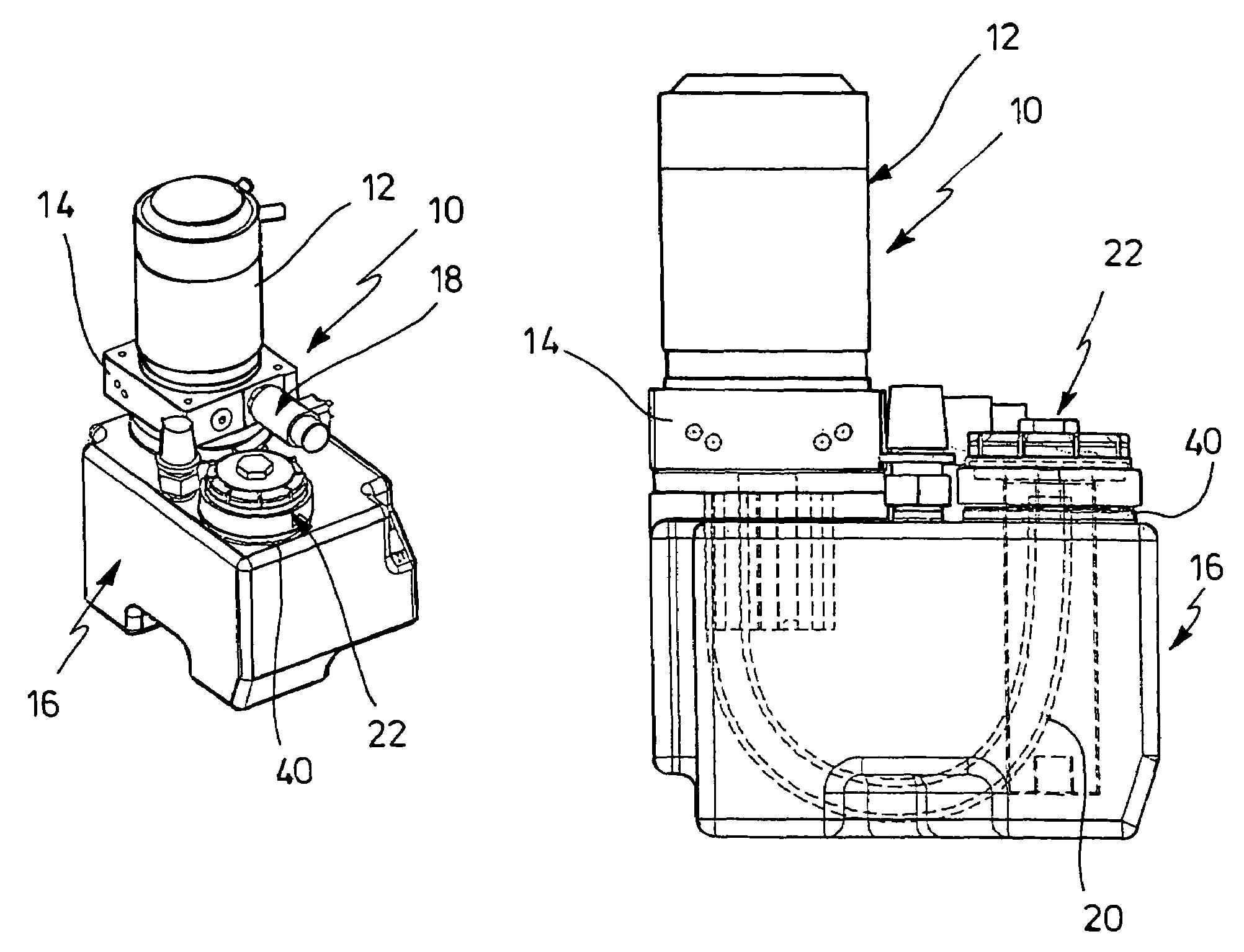

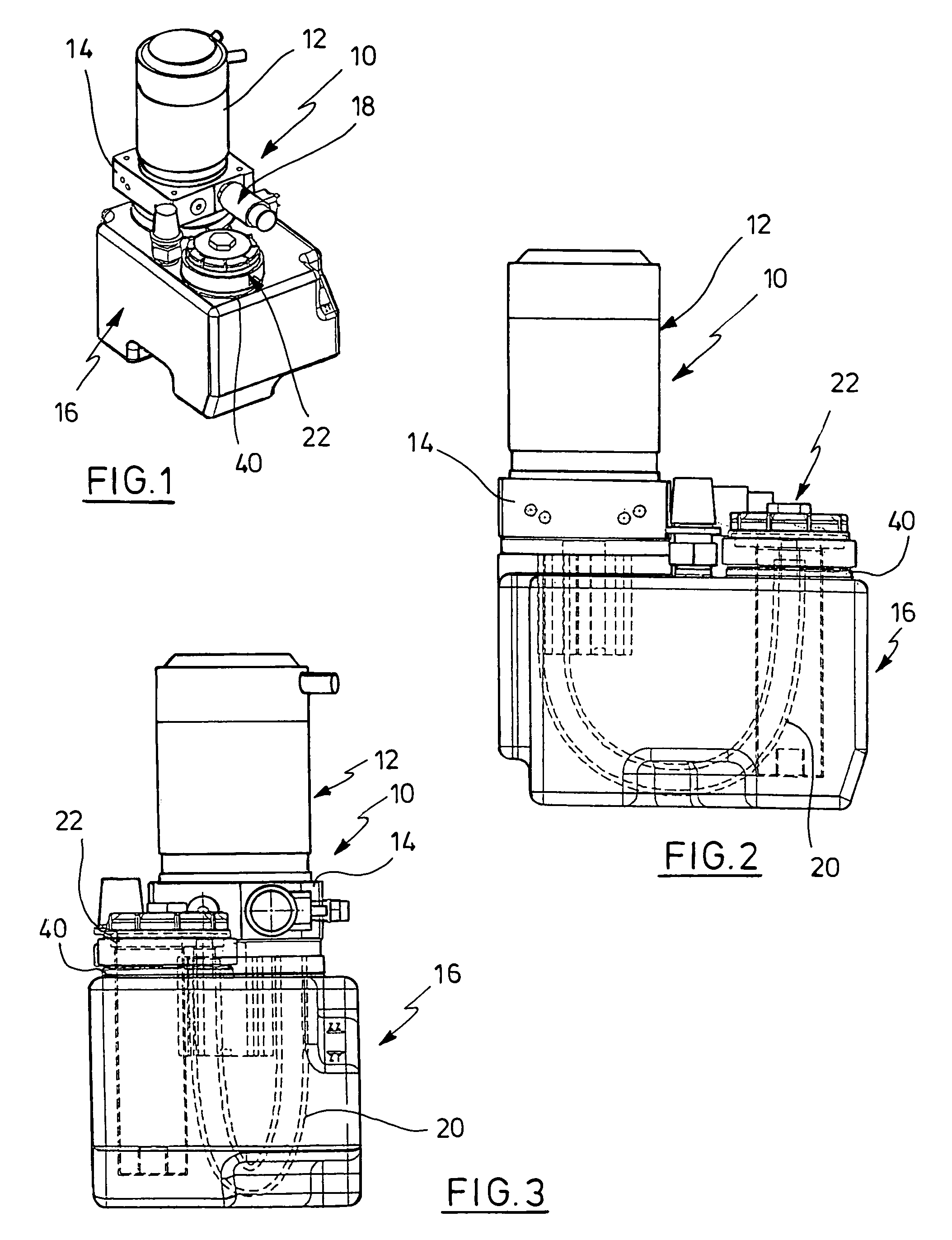

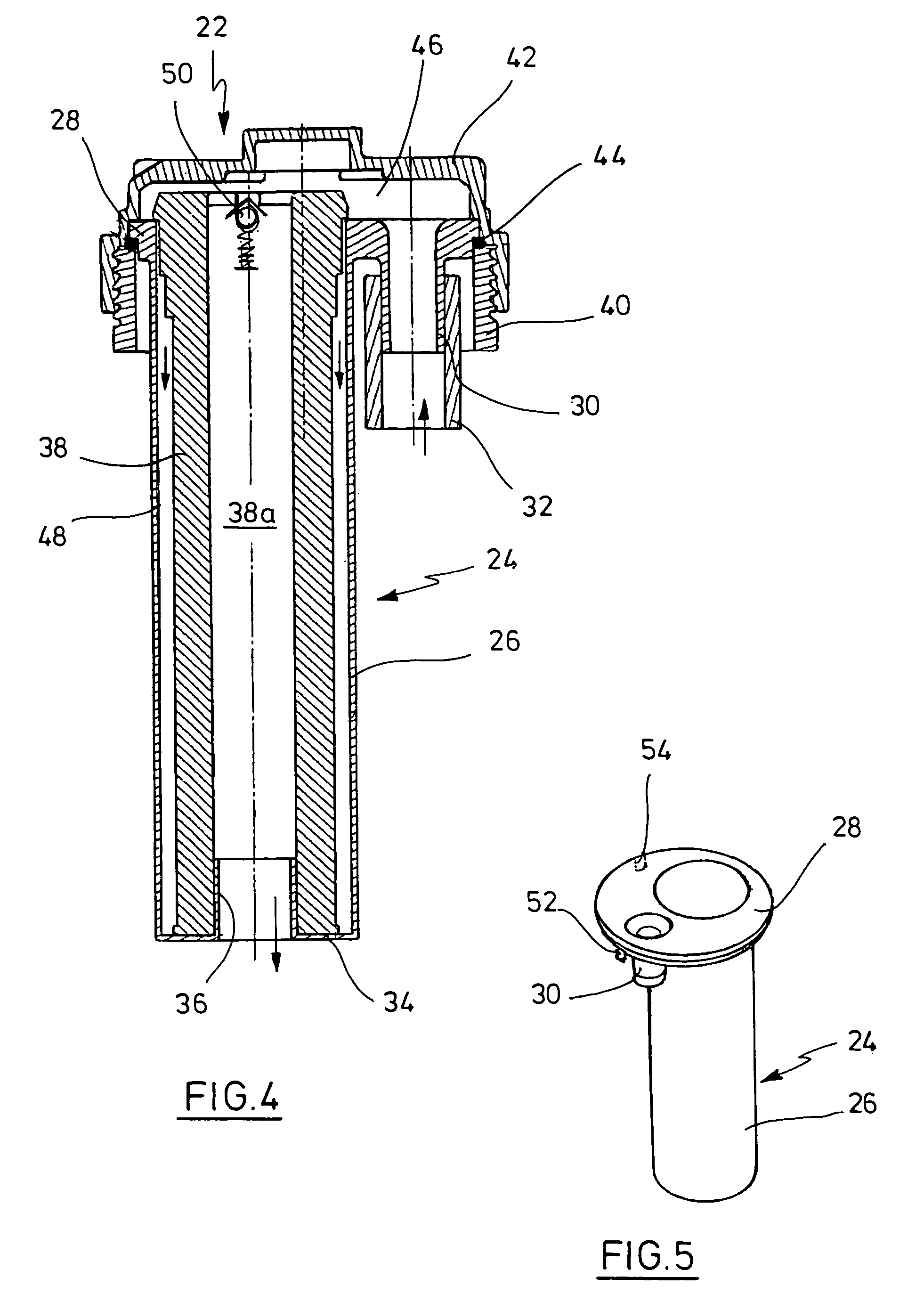

Hydraulic unit for industrial trucks

A hydraulic unit for industrial trucks, comprising a motor pump unit which is directly attached to a tank, a reflux filter which has an elongate filter casing for a filtering element adapted to be introduced into the tank through an opening, a hose coupling, and an outlet opening, wherein the filtering element is disposed in the flow path between the hose coupling and the outlet opening, a reflux hose between the motor pump unit and the hose coupling, and a closure for the reflux filter, wherein the reflux hose extends within the tank and the hose coupling is disposed within the tank.

Owner:JUNGHEINRICH AG

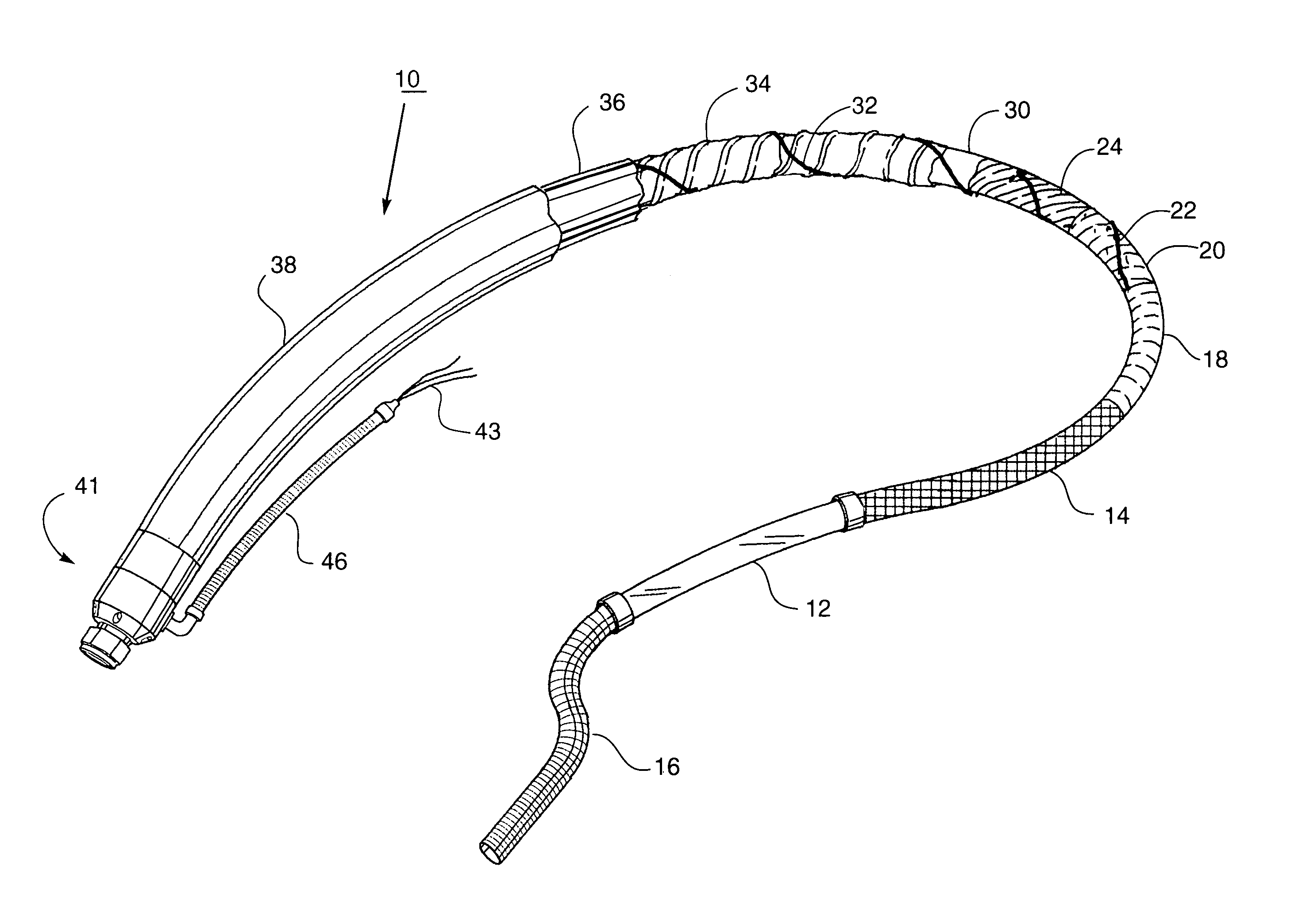

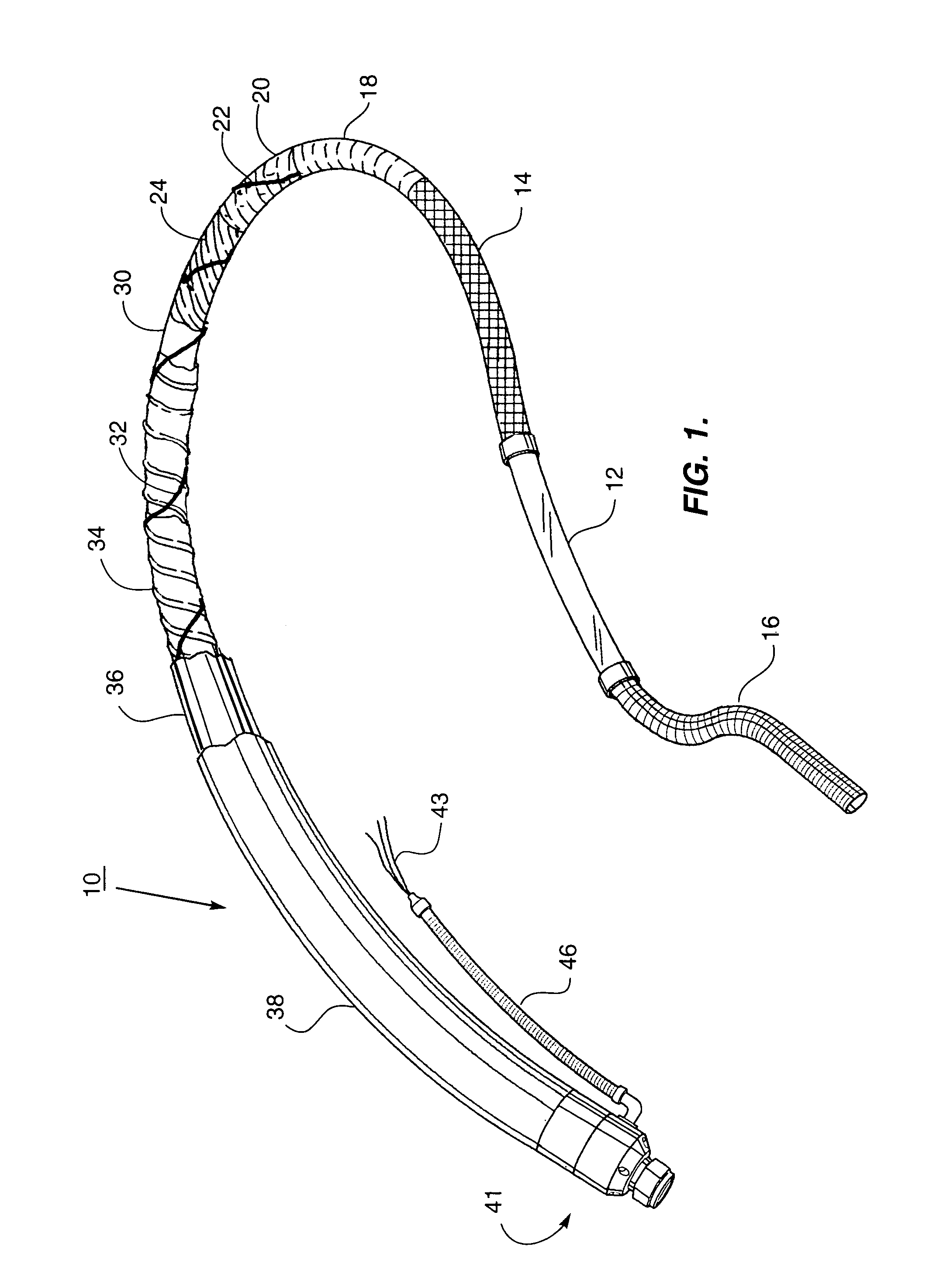

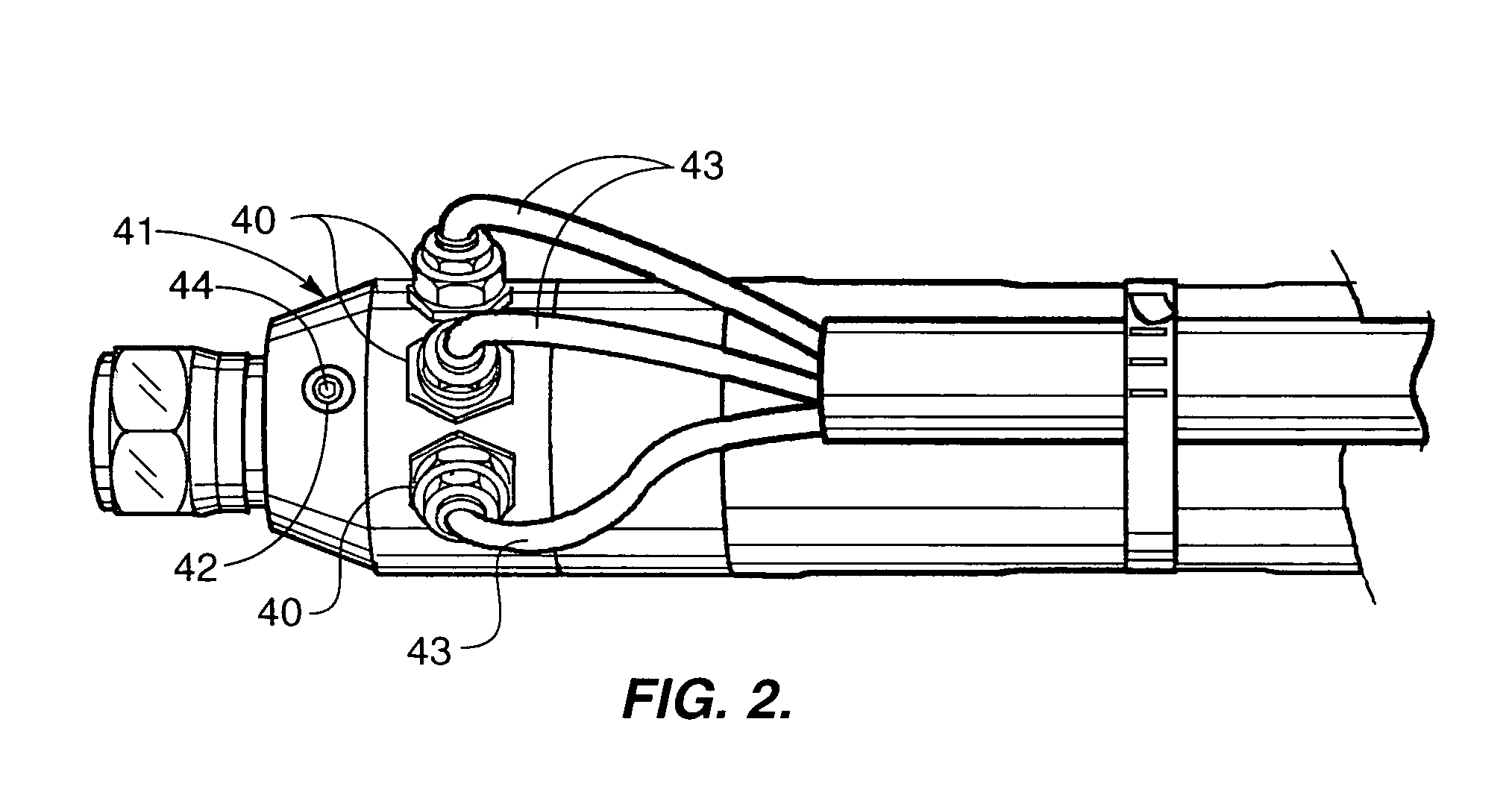

Hose for hot liquids having heating element

ActiveUS7266293B1Temperature controlPipe heating/coolingLiquid transferring devicesElectrical connectionEngineering

A hose for pumping heated liquids therethrough is disclosed which has, in combination, an interior hose construction which is adapted to prevent kinking and collapse of said hose, a heating element which has abrasive protection layers associated therewith, an insulator, a moisture barrier and a safety and containment barrier. At least two hose fittings are positioned at each end of the hose with at least one of said hose fittings having electrical connections in electrical communication with the heating element and a source of electrical power.

Owner:DUNDAS ROBERT D

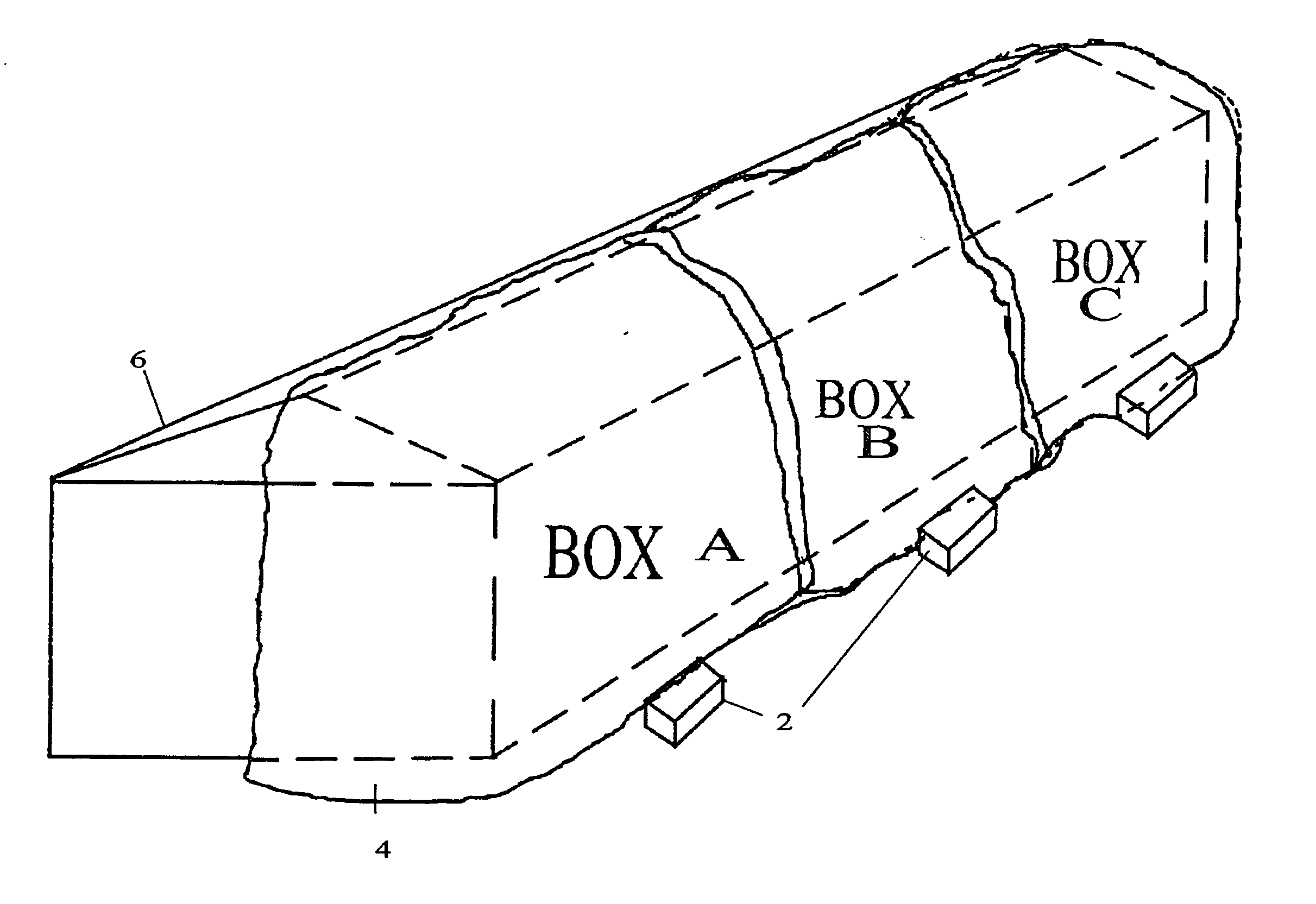

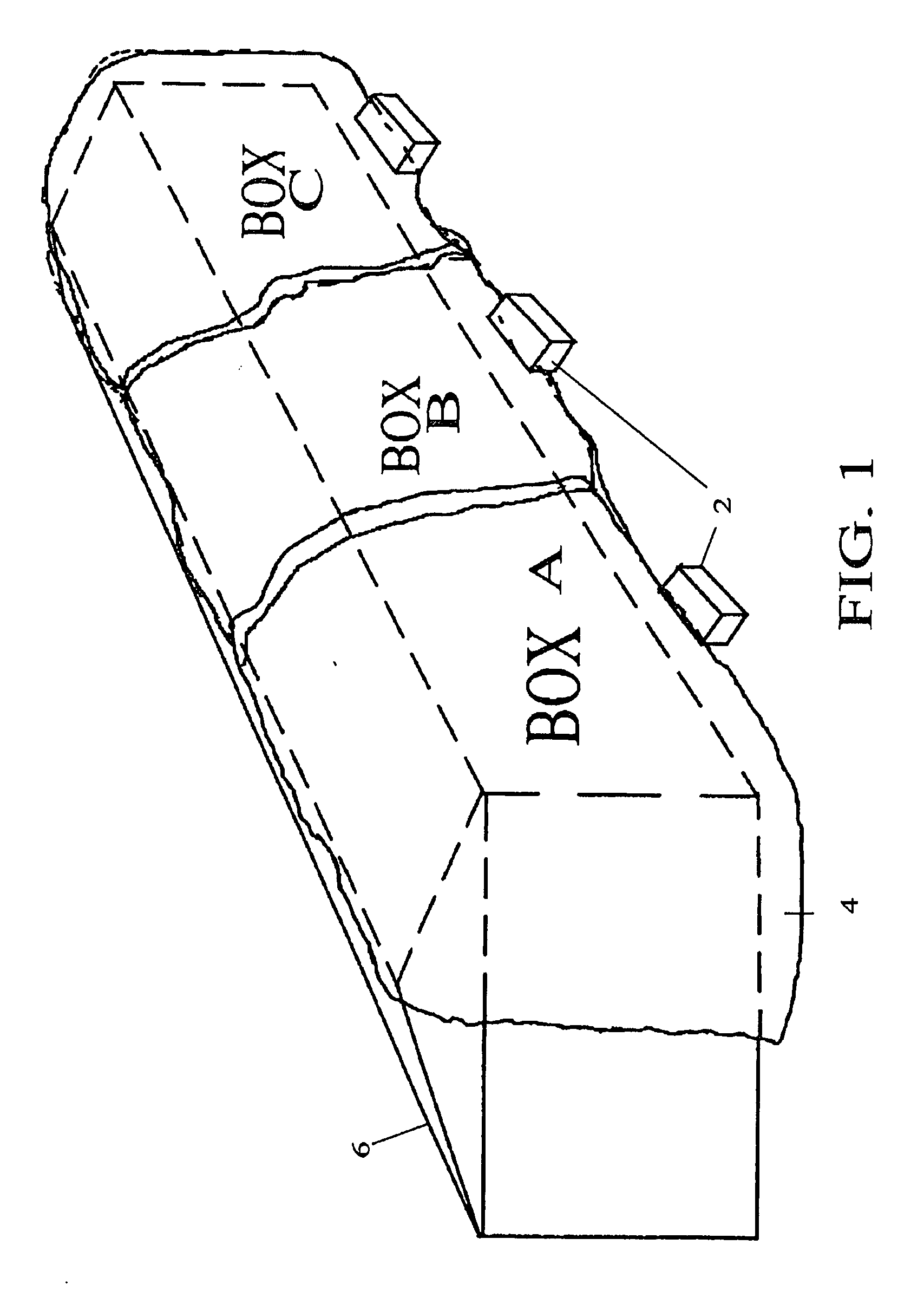

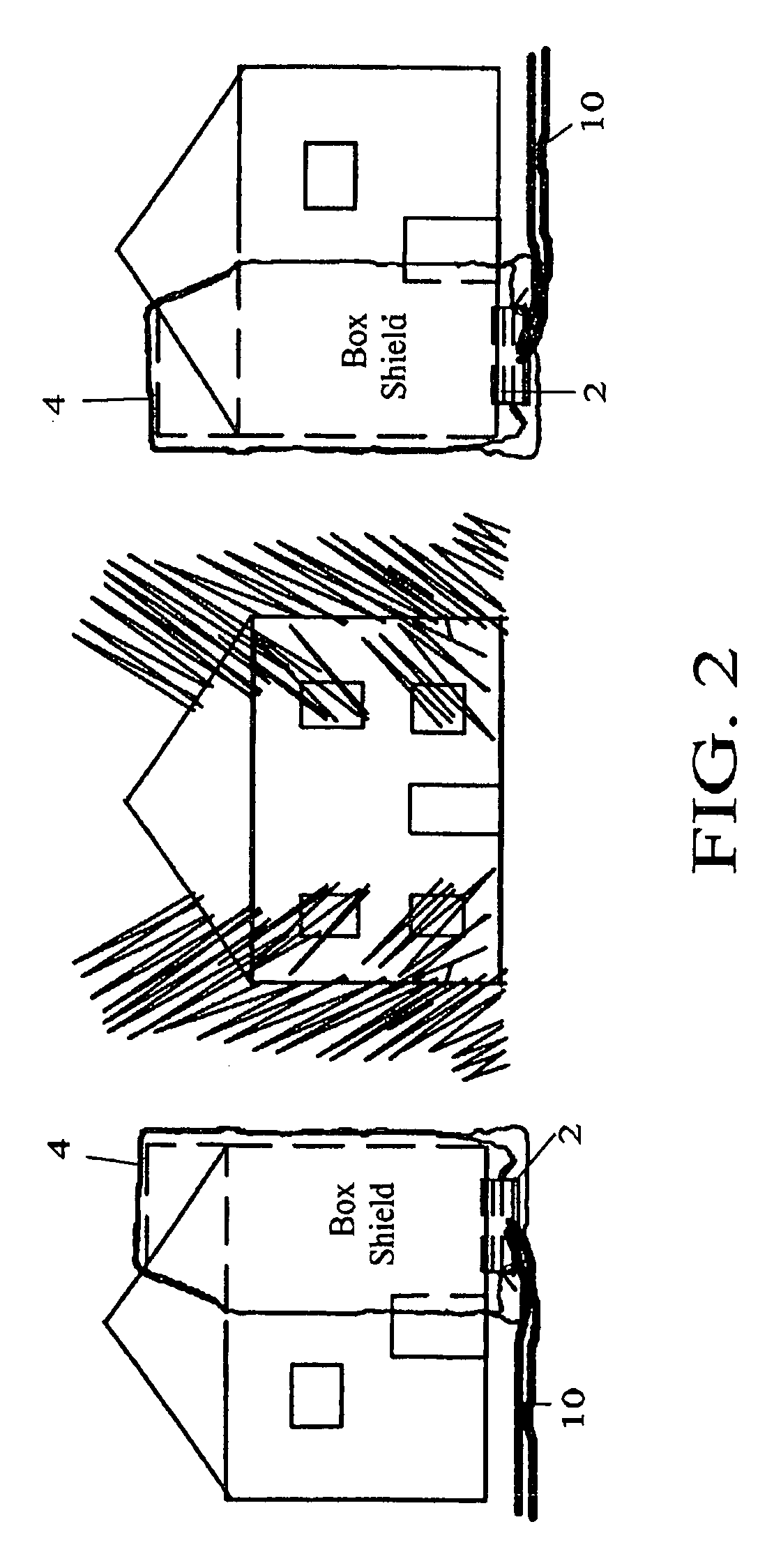

Inflatable protective home barrier

InactiveUS20060277830A1Easy to operateRapid deploymentRoof covering using tiles/slatesTents/canopiesFire protectionEase of Access

A fire protection system for homes and other structures including a pliable multi-layered shroud of fire-resistant material having an inflatable support structure embedded therein. The inflatable support structure includes a web of inflatable channels for rapid deployment from a folded configuration to an inflated configuration in which the fire-resistant material partially envelops a structure. The shroud is packed in an enclosure having a bi-fold top panel for ease of access. The enclosure also has one or more air hose couplings to which the inflatable support structure is connected for rapid inflation and deployment out of the enclosure. A plurality of tethers are also provided as tie-downs, which anchor the heat resistant shroud. The system affords ample rapid deployment protection from neighboring fires and heat exposure therefrom.

Owner:BOGGS JR PATRICK H

Hose coupling device

InactiveUS20050242578A1Effective gripConnection securityHose connectionsPipe connection arrangementsJoint componentEngineering

Hose coupling devices that securely connect an end of a hose to a fitting member using a retention mechanism operated by multi-threaded engagement of the fitting member with a collar member. The multi-threaded engagement also may operate a hose advancement mechanism. The advancement mechanism axially advances a hose during multi-threaded engagement so that the hose may be more effectively gripped by the retention mechanism.

Owner:QL HLDG

Grooming device

InactiveUS20100122663A1Reduce accessRestrict levelOther apparatusGrooming devicesBristleMechanical engineering

The invention is an apparatus for grooming an animal having a brush head, the brush head having a plurality of bristles, each bristle having a midpoint and an endpoint, where the bristles are in general perpendicular orientation to the brush head, a cleaning plate, in general parallel orientation to the brush head, the cleaning plate able to move from a contracted to an extended position, the cleaning plate further having material removed to allow the bristles to protrude through the cleaning plate when it is in the retracted position; and a mechanism for extending and contracting the cleaning plate, wherein the cleaning plate has a bottom surface and the bottom surface does not extend past the bristle endpoint when the cleaning plate is in the extended position. In one embodiment, at least some bristles are wire, and in further embodiments the wire bristles have round coated tips. The brush head may further have a water outlet and a hose coupling for intake and dispensing of liquids. Furthermore, the present invention may have means for conducting water through the handle and out the water outlet, which may be a plurality of hollow bristles.

Owner:PRODS OF TOMORROW

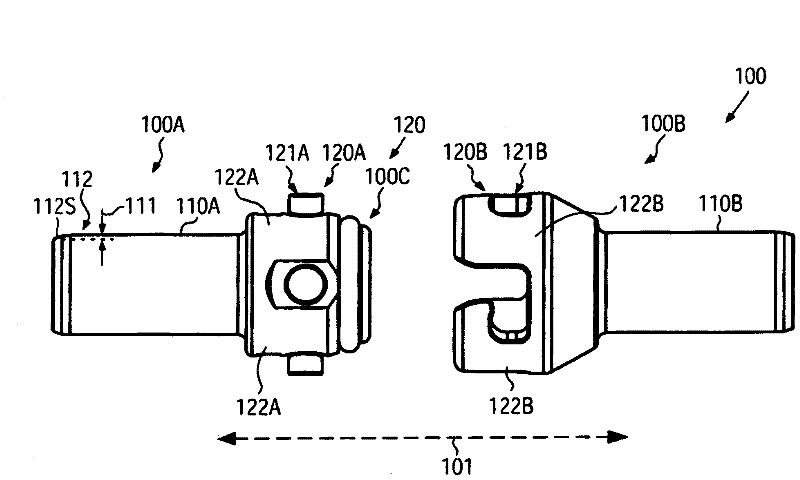

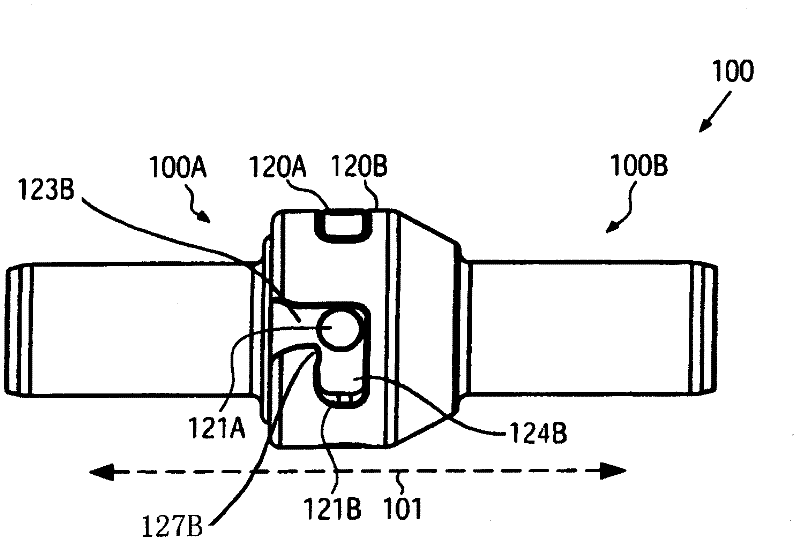

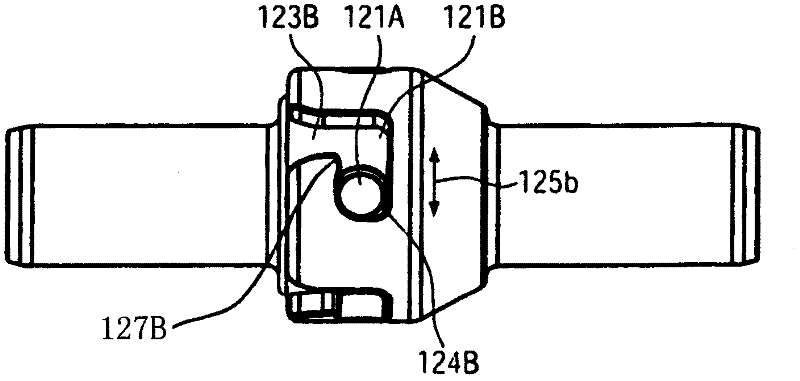

Hose coupling

ActiveCN102186334AAchieve connectionAchieve separationCouplingsMilking devicesDesign methodsHose coupling

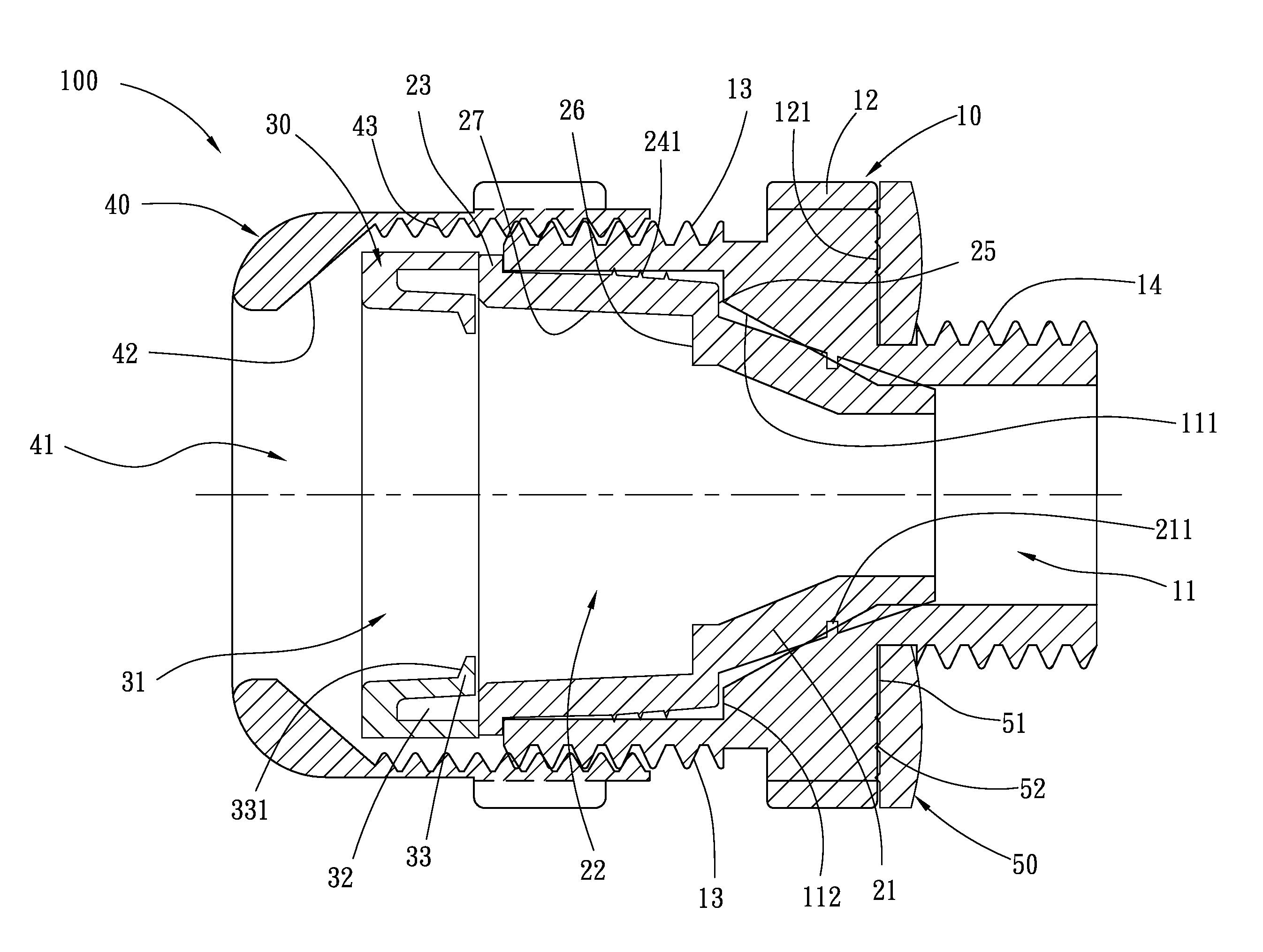

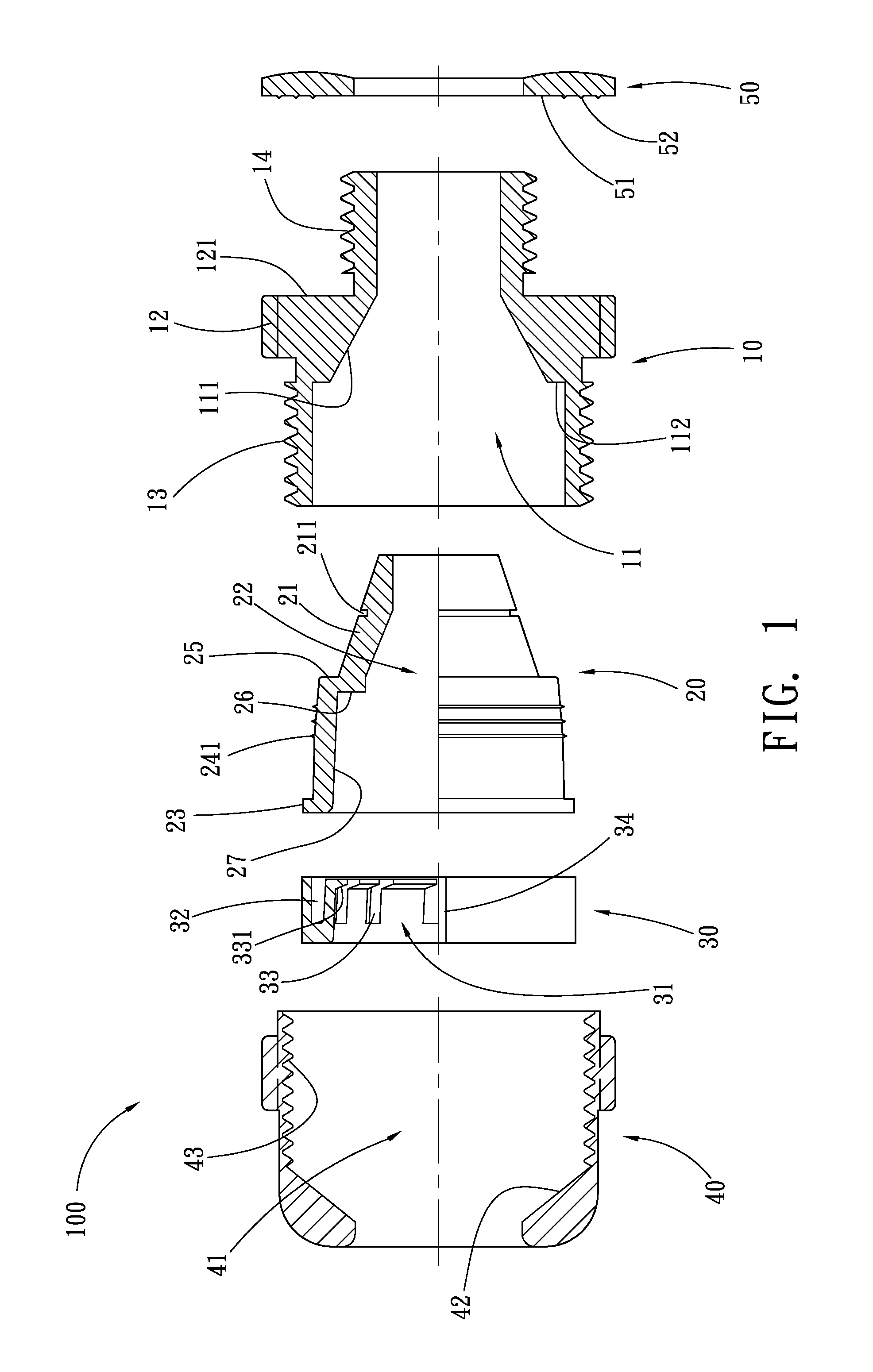

The invention relates to a hose coupling (100), which can be provided with a low number of individual components (100a, 100b, 100c) due to design measurements such that high reliability during operation and simple handling during coupling and decoupling are achieved. The hose coupling can in particular be locked by rotation within a small angle range without the necessity of moveable components. In some illustrative exemplary embodiments, the hose coupling (100) is used as a coupling in fluid lines in the agricultural sector, for example in milk lines.

Owner:LACTOCORDER

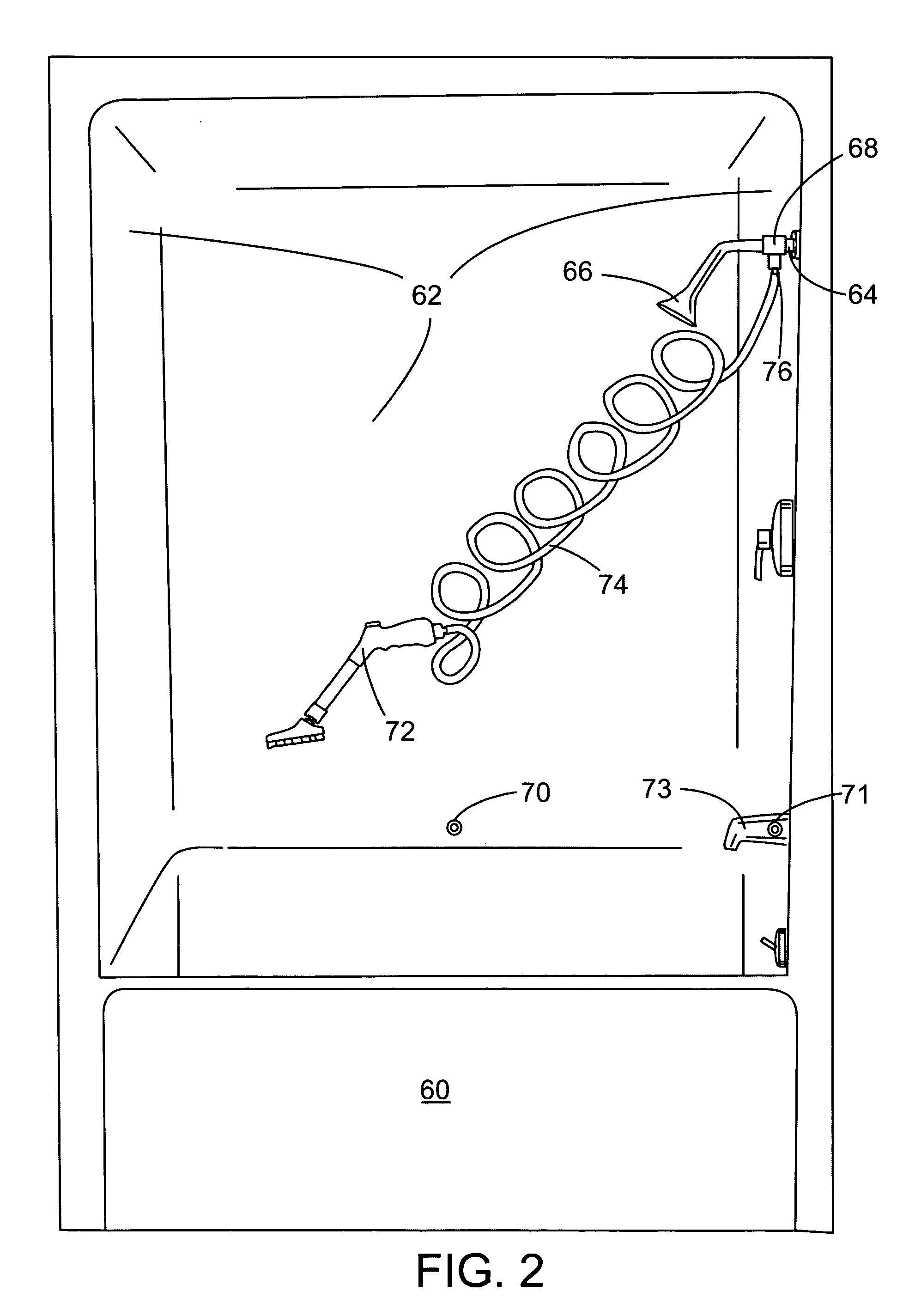

Refrigeration condensate line assembly

InactiveUS7624756B1Improve conductivityImproves overall sensor functionServomotor componentsPipeline systemsLine tubingEngineering

An assembly mounts between the drain pan that collects condensate water from an air conditioner and the drain line. It includes a housing with a first end connected to the pan. A second end connects to the drain line. A shut off valve shuts off the passage to the pan while maintenance is performed. A connector is mounted on the housing between the valve and the second end. It is a female member of a quick-connect coupling. A male member of the coupling may be plugged in with a single motion to seal it in place. Male members have different terminations, including a barbed tube for resilient tubing, a compressed air tire valve for delivering gas, a female water hose coupling, a tapered funnel for the nozzle of vacuum / blower, and a water sensor.

Owner:COOGLE GREGORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com