Portable composite nondestructive detector based on eddy current technology and ultrasonic technology

A non-destructive testing, portable technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. It can solve problems such as unclear display, slow detection speed, and limited detection objects. , to achieve the effect of clear and intuitive defect information image and enlarged scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

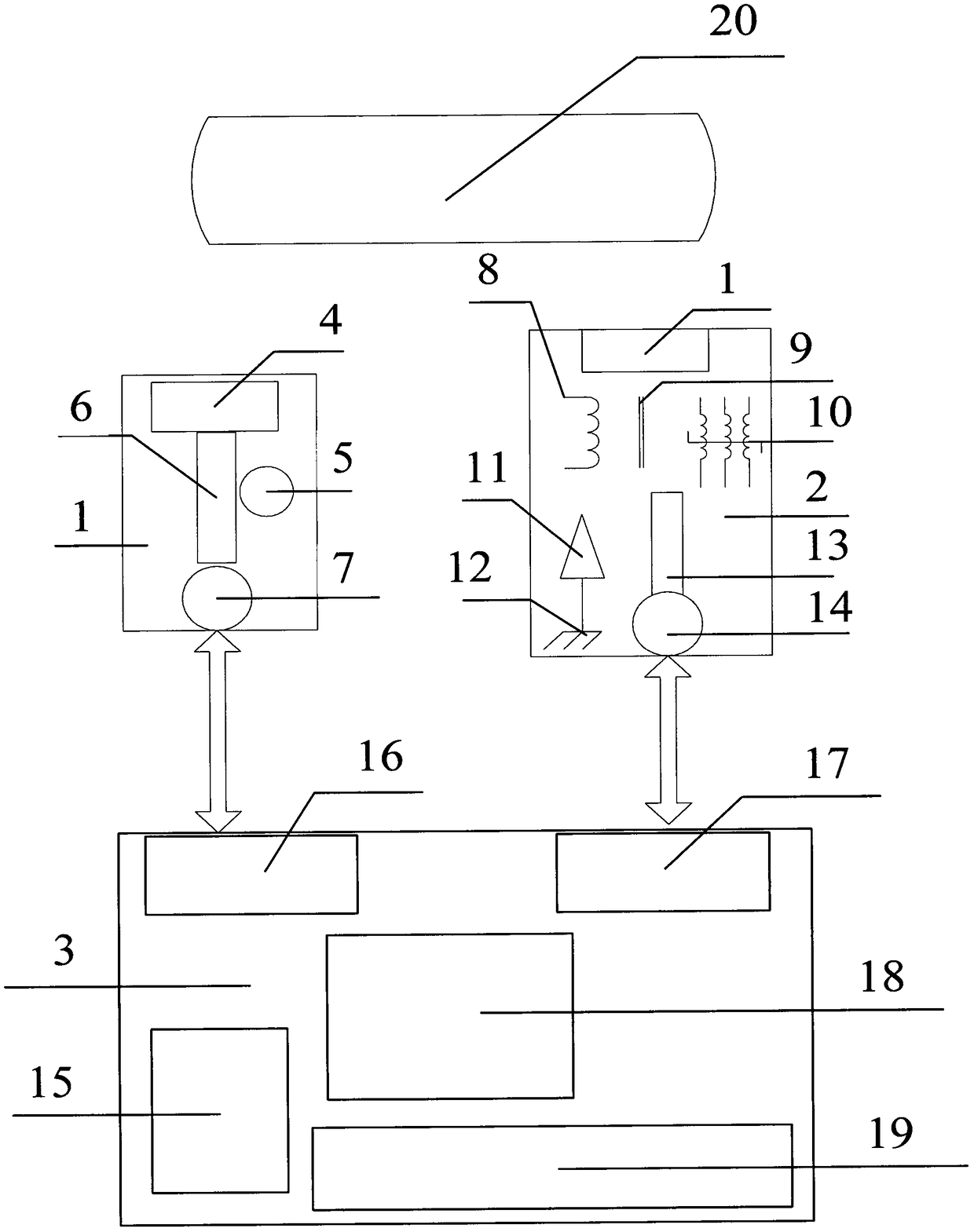

[0010] refer to figure 1 The purpose of the present invention is to provide a portable composite non-destructive testing instrument, which perfectly integrates ultrasonic scanning and eddy current testing technology, and is applied to the flaw detection and scanning detection of multiple types of materials, which can clearly and intuitively reflect the damage of the detected parts. A composite nondestructive testing instrument based on eddy current technology and ultrasonic technology, comprising an ultrasonic probe (1), an eddy current probe (2) and a nondestructive testing host device (3). The ultrasonic probe (1) is composed of an ultrasonic scanning interface (4), a piezoelectric wafer (5), an ultrasonic cable (6) and an interface between the ultrasonic and the host (7); the eddy current probe (2) is composed of an exciting winding (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com