Composite material flaw detector based on a variety of ultrasonic techniques

A composite material and flaw detector technology, applied in the field of flaw detection and scanning, can solve problems such as unclear display, inability to accurately determine flaw detection status, single scan, etc., and achieve clear and intuitive defect information images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and using the best embodiments.

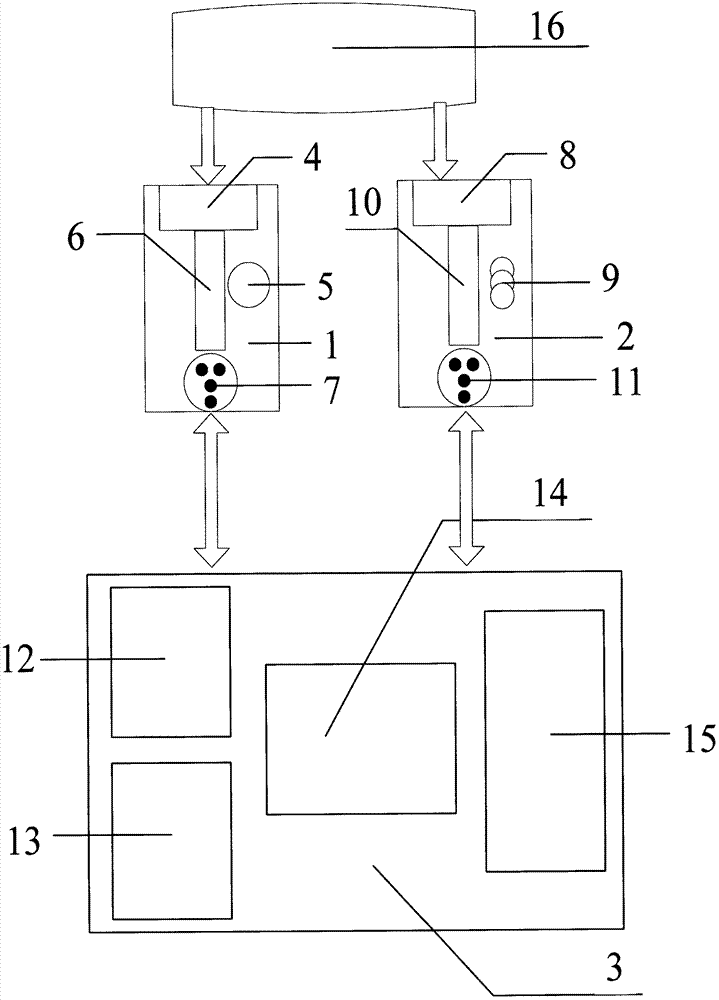

[0010] see figure 1 The purpose of the present invention is to provide a composite material flaw detector, which perfectly integrates conventional ultrasonic scanning and phased array scanning technology, and is applied to the flaw detection scanning detection of composite materials, which can clearly and intuitively reflect the damage of the detected parts. A composite material flaw detector based on a variety of ultrasonic technologies, including a conventional ultrasonic probe (1), a phased array ultrasonic probe (2), and a flaw detection host device (3). The conventional ultrasonic probe (1) is composed of a conventional ultrasonic scanning interface (4), a piezoelectric chip (5), a conventional ultrasonic cable (6) and a conventional ultrasonic and host connection interface (7); the phased array ultrasonic probe (2) consists of A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com