Double-wall oil storage tank made of fiber reinforced composite material and manufacturing method of double-wall oil storage tank

A composite material and fiber reinforced technology, which is applied in the field of oil storage tank and its preparation, fiber reinforced composite material double-walled oil storage tank and its preparation field, can solve the problems of low bearing capacity, poor corrosion resistance and large floor space. , to achieve the effect of reasonable structure design, improved safety performance and good anti-seepage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

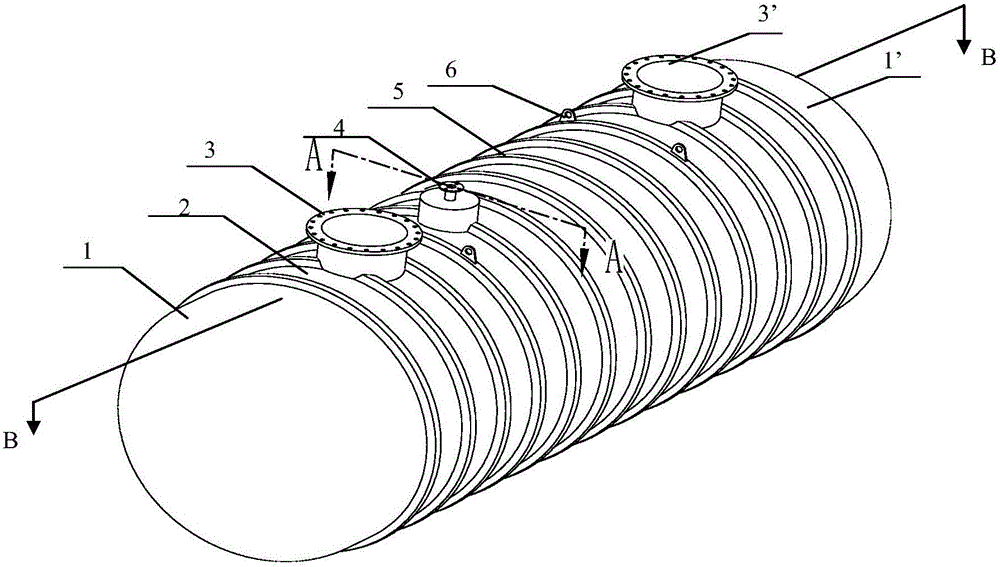

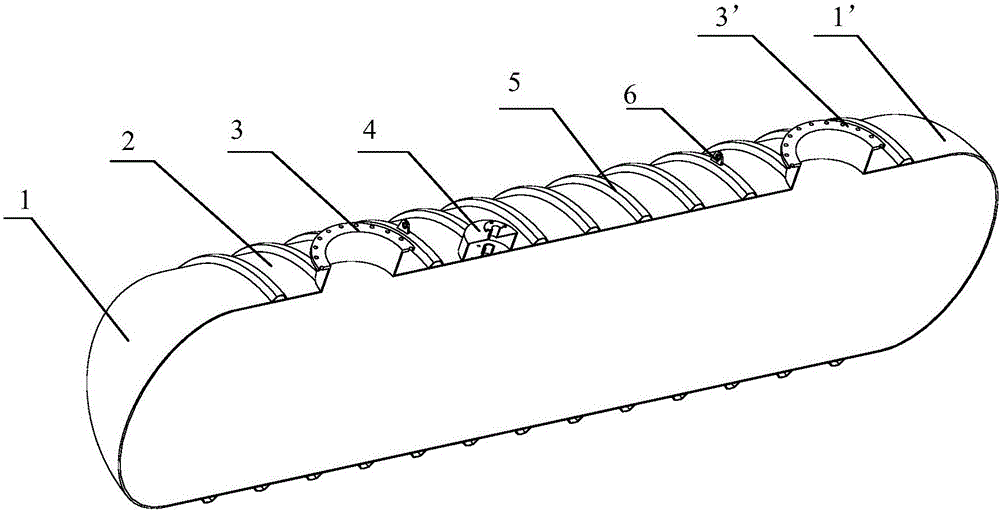

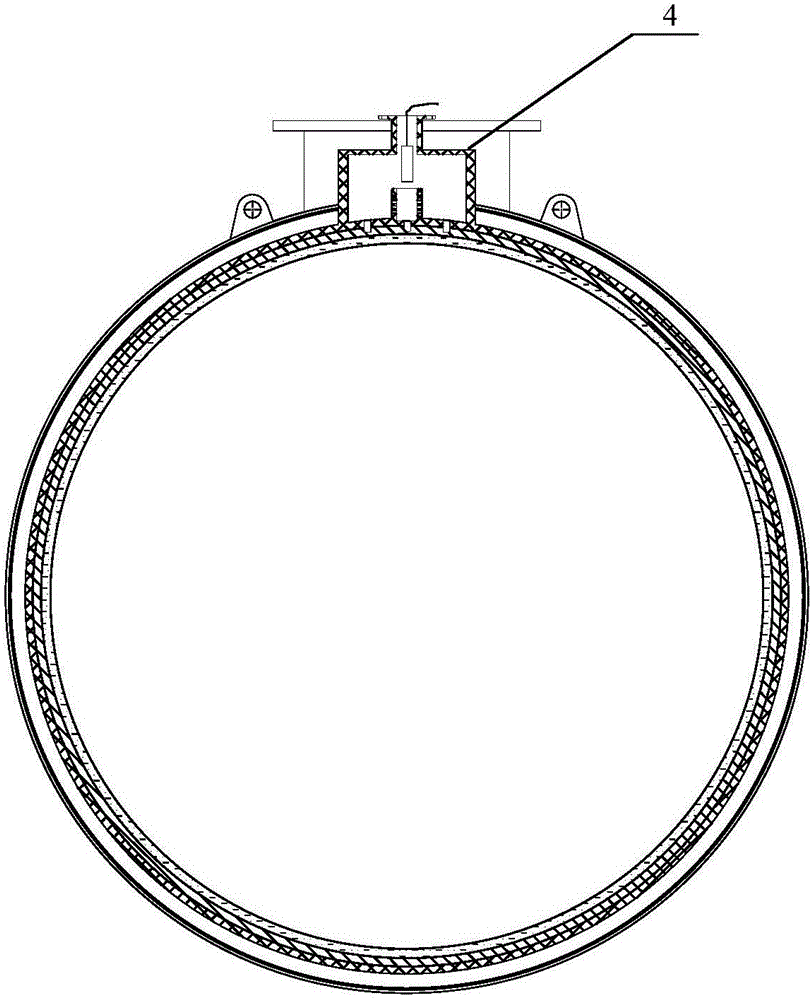

[0030] Such as figure 1 , figure 2 , Image 6 , Figure 7 As shown, the fiber-reinforced composite material double-wall oil storage tank of the present invention is formed by solidifying a cylindrical tank body and the heads at both ends of the tank body, wherein, the heads 1 and 1' at both ends; the cylindrical tank body 2 ; Two manholes 3,3'; Detection pool 4; Rib 5;

[0031] The cylindrical tank body 2 and the heads 1 and 1' at both ends of the tank body are composed of an inner wall, a hollow layer and an outer wall; wherein, the cylindrical tank body 2 is sequentially provided with a tank inner wall 21, a tank The body hollow layer 22 and the outer wall 23 of the tank; the heads 1 and 1' at both ends have the same structure, and they are the inner wall 11 of the head, the hollow layer 12 of the head and the outer wall 13 of the head in sequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com