TC4 titanium alloy plate machining method

A processing method and technology for titanium alloy plates, applied in the field of metal material processing, can solve problems such as product quality decline, and achieve the effects of good weldability, good corrosion resistance and good thermoplasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

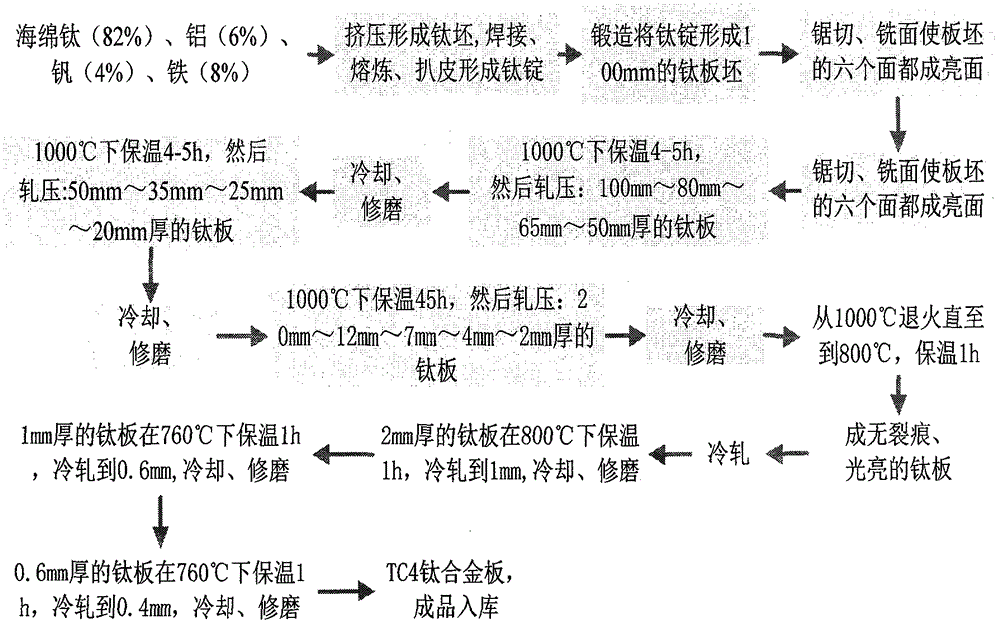

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in combination with specific embodiments.

[0018] A TC 4 The processing method of titanium alloy plate includes the following steps: the first step is to mix titanium sponge, aluminum powder, vanadium powder and iron powder according to a certain proportion, extrude to form a titanium billet, and then weld, smelt and peel the titanium billet to form a titanium ingot ;The second step is to open the titanium ingot and forge it to form a thickness of 100mm, and then go through sawing and milling to form a bright titanium slab; the third step is hot rolling, and finally make it into a 2mm thick titanium slab after three times of grinding , and then annealed at 800°C, and held for 1 hour to form a crack-free, bright titanium plate; the fourth step is cold rolling, and the titanium plate is cold-rolled to a thickness of 0.4mm at three different annealing temperatures.

[0019] According to the mass percentage ratio, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com