Novel low-carbon degradable sheet material and product thereof

A new type of sheet technology, applied in the field of degradable sheets, can solve the problems of pollution, high cost of enzyme-regulated additives, and environmental reduction, and achieve the effect of reducing emissions, rapid degradation characteristics, and accelerating decomposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

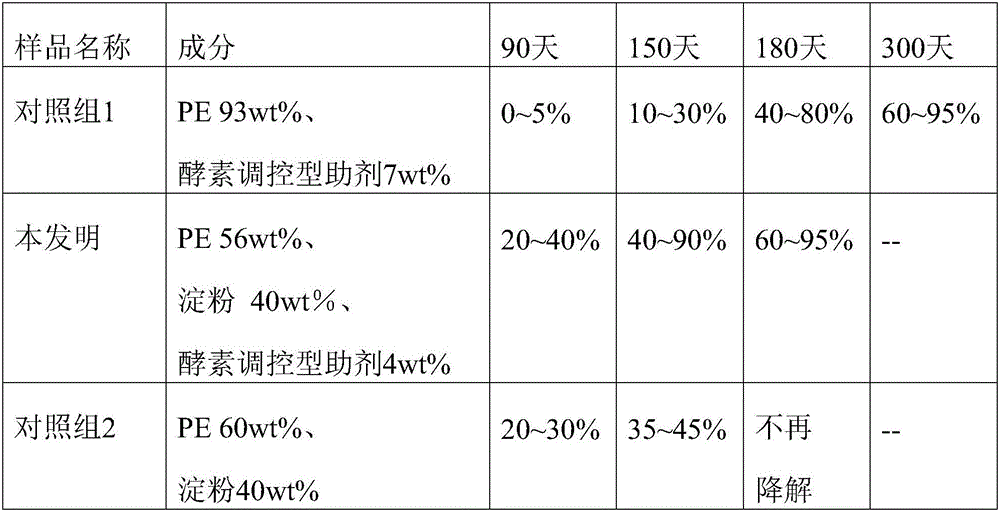

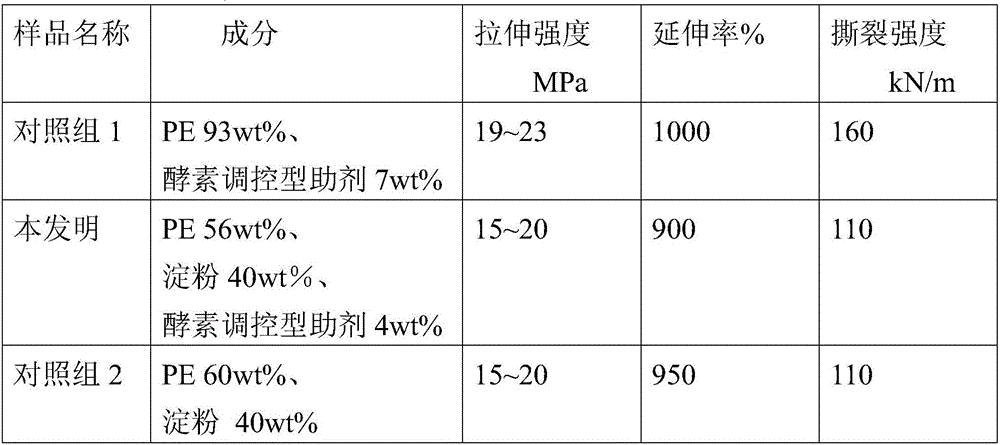

[0018] A new type of low-carbon degradable sheet, the thickness is between 0.01-0.15mm, the specific gravity is between 0.6-1, it contains a plastic material 20-80wt%, a bio-based material 10-70wt%, and an enzyme regulation The biodegradation rate of the novel low-carbon degradable sheet is at least 90%.

[0019] Generally speaking, the sheet material of the present invention can be divided into according to thickness: the thinner sheet material can be referred to as a film material, and the thicker sheet material can be referred to as a plate material, but they are all inseparable from the present invention. revealing spirit.

[0020] Wherein, the above-mentioned plastic material is a general petrochemical or plant-derived plastic material, such as polyethylene (Polyethylene, PE), polypropylene (Polypropylene, PP), polystyrene (Polystyrene, PS), polyvinyl chloride, ethylene-vinyl acetate Copolymer (Polyethylene-co-vinyl acetate, EVA) or polyethylene terephthalate (Polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com