Method for producing succinic acid through fermentation of sugarcane juice

A sugarcane juice and succinic acid technology is applied in the field of microbial fermentation to achieve the effects of protecting farmers' rights and interests, saving grain and ensuring food security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

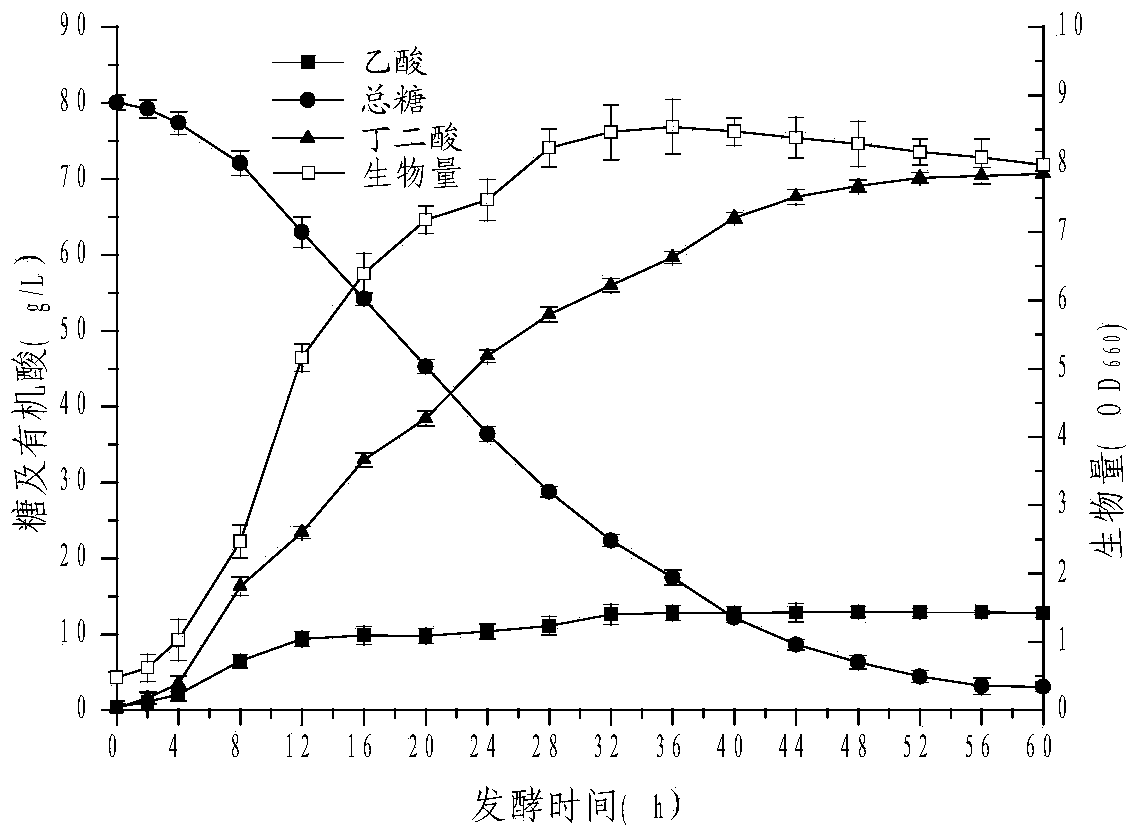

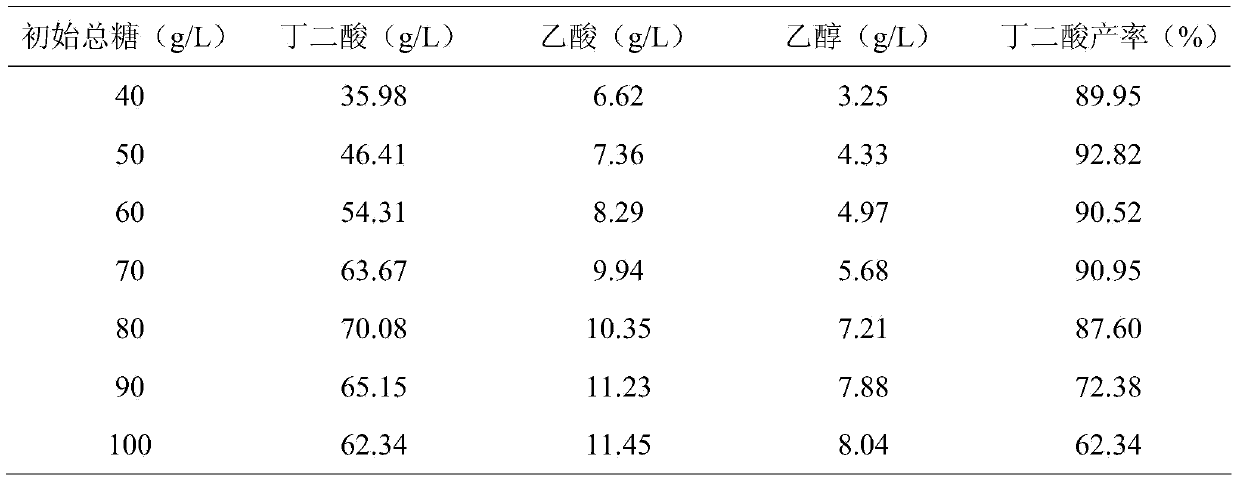

[0036] Effects of Different Initial Total Sugar Concentrations on the Production of Succinic Acid by Sugarcane Juice Fermentation

[0037] Inoculate the strain of Actinobacillus succinigenes into the seed medium, culture it statically at 30-38°C for 18-20h in an anaerobic incubator or ordinary incubator, and insert 8% of the inoculum into a 250mL triangle with fermentation medium. In the bottle, the liquid volume is 150mL, the basic magnesium carbonate adjusts the pH at 6.0-7.0, and it is placed in an anaerobic incubator at 37°C for 48-60h of fermentation. Anaerobic box culture conditions: anaerobic box (Don Whitley Scientific DG250anaerobic workstation), mixed gas N 2 :CO 2 :H 2 =8.5:1.0:0.5, temperature 37°C. The experimental results are shown in Table 1.

[0038] Table 1 Effect of different sugarcane juice initial total sugar concentration on succinic acid production

[0039]

[0040] As can be seen from Table 1: when sugarcane juice with different initial total red...

Embodiment 2

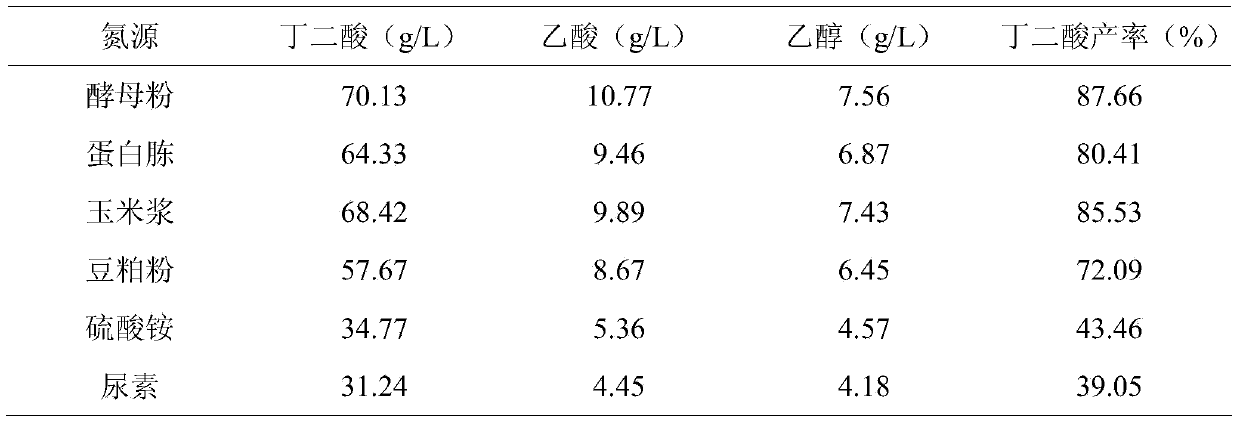

[0042] Effects of Different Nitrogen Sources on the Production of Succinic Acid by Fermentation of Sugarcane Juice

[0043] According to the method for producing succinic acid by fermentation of the Actinobacillus succinigenes strain in Example 1, the plate of the strain with the preservation number CCTCC M2011399 was cultured in an anaerobic box for 48 hours, and then connected to a 30mL seed medium with an inoculation loop, at 37°C Cultivate for 20 hours, add initial total reducing sugar 80g / L according to the inoculation amount of 8%, and use 250mL Erlenmeyer flasks of fermentation media with different nitrogen sources. Determination of succinic acid and main by-product content, the results are shown in Table 2.

[0044] Table 2 Effects of different nitrogen sources on the production of succinic acid by fermentation of sugarcane juice

[0045]

[0046] It can be seen from Table 2 that the most suitable nitrogen source is yeast powder (70.13g / L), followed by corn steep l...

Embodiment 3

[0048] Effects of Different pH Buffers on the Production of Succinic Acid by Fermentation of Sugarcane Juice

[0049] According to the method for producing succinic acid by fermenting the Actinobacillus succinic acid strain in Example 1, in order to facilitate pH monitoring and pH buffer feeding, a 1.3L fermenter was used for fermentation, and water was added to dilute the sugarcane juice. The initial total sugar concentration was 80g / L. The nitrogen source is corn steep liquor, the liquid volume is 700mL, and 100% CO is introduced 2 , the ventilation rate was 0.2mL / min, the fermentation temperature was 37°C, the fermentation time was 60h, and the pH was adjusted at 6.5-7.0. See Table 3 for the buffer used and the fermentation results.

[0050] Table 3 Effects of different pH buffers on the production of succinic acid from sugarcane juice

[0051]

[0052] It can be seen from Table 3 that when basic magnesium carbonate is used as the pH buffer, the yield of succinic acid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com