Patents

Literature

69 results about "Actinobacillus succinogenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

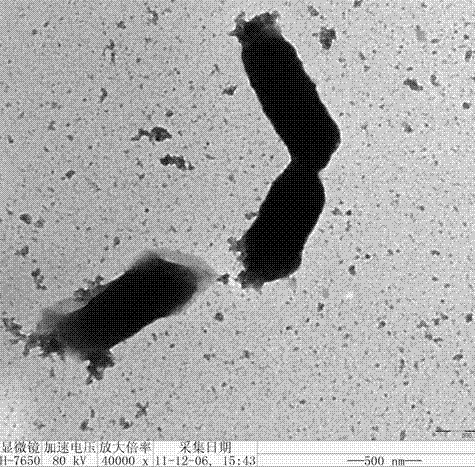

Actinobacillus succinogenes is a bacterium. It is a succinic acid-producing strain first isolated from the bovine rumen. It is a facultatively anaerobic, pleomorphic, Gram-negative rod. Its type strain is ATCC 55618ᵀ.

Bacterial speices and method for producing succinic acid by microbial fermentation

InactiveCN1814747AEfficient accumulationAlleviate resource constraintsBacteriaFermentationMicroorganismButanedioic acid

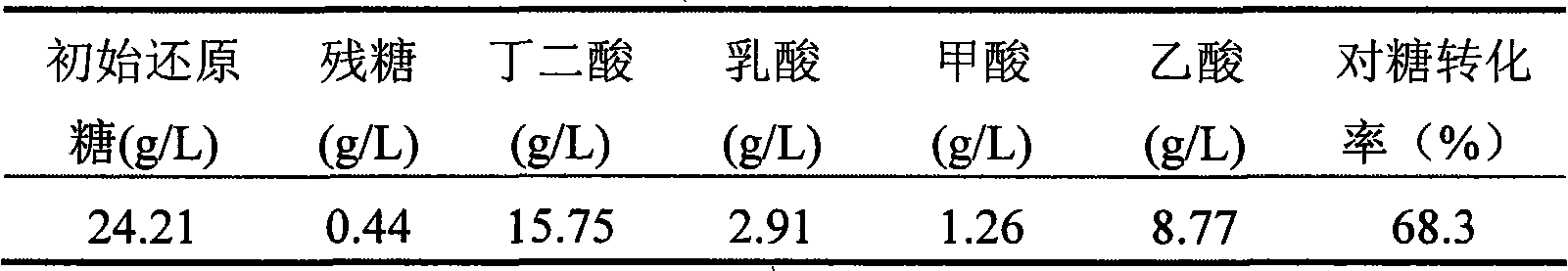

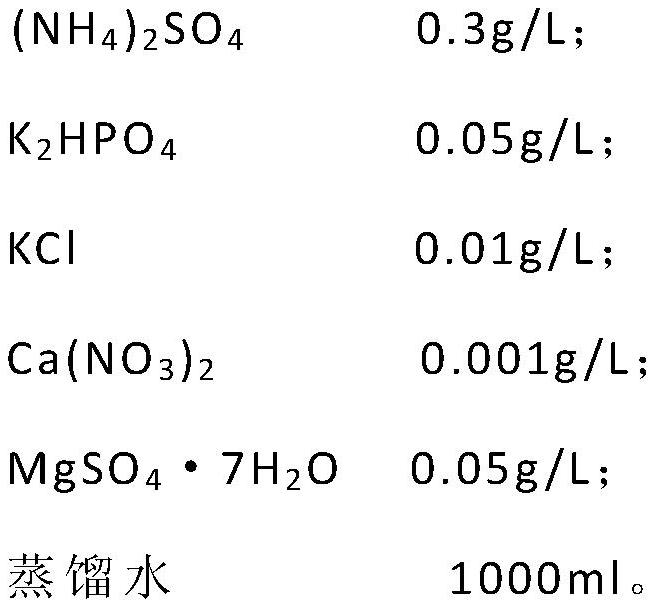

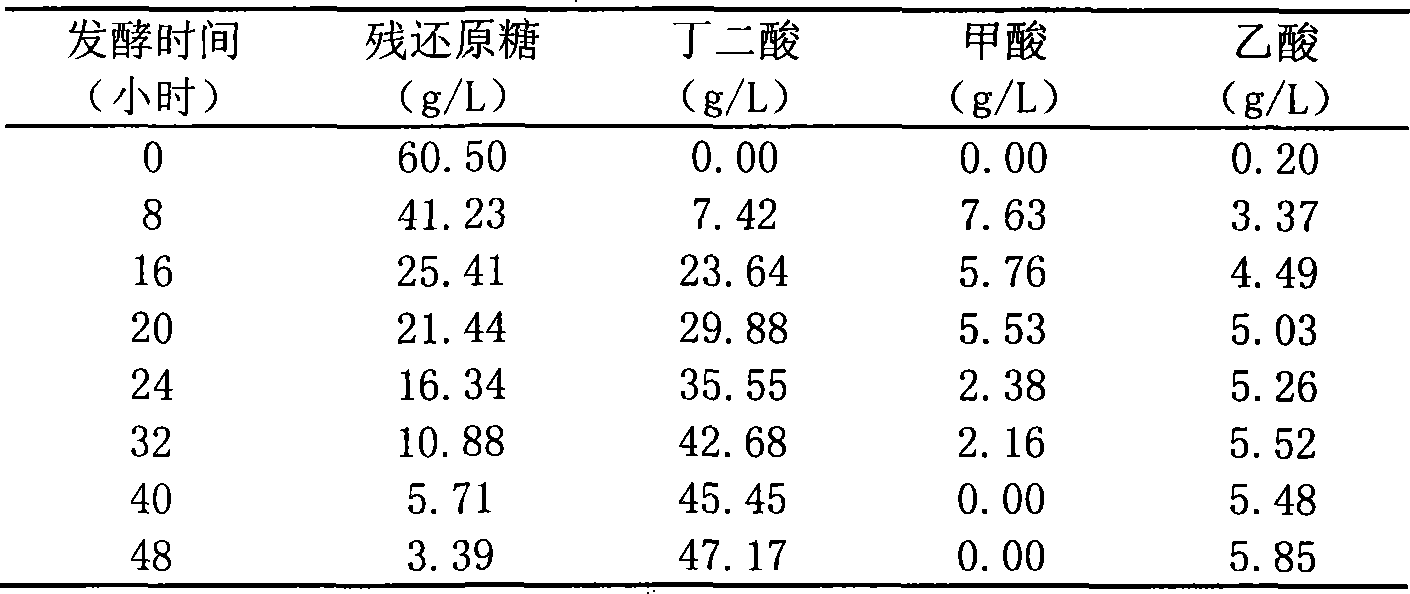

This invention relates to a method for producing succinic acid type culture by animalcule fermentation, especially relating to an animalcule actinobacillus succinogenes SW0580 generating succinic acid by a fermentated sugariness raw material, its preservation number: CGMCC No. 1593 and a method for utilizing said animalcule fermentation to produce succinic acid, in which, said animalcule is the actinobacillus succinogenes separated from the rumen tested and 10-50g / L succinic acid can be produced by anaerobic fermentating 20-100g / L sugariness raw materials.

Owner:JIANGNAN UNIV

Succinic acid-producing strain and its screening method and uses

InactiveCN1884484ASuitable for industrial productionBacteriaFermentationMicroorganismHigh concentration

The invention discloses a strain which can produce amber acid and its sieve method and its application. The said strain is named by classification as Actinobacillus succinogenes NJ113 and has been preserved in China microbial bacterial preservation management committee common microorganism center with CGMCC No.1716 as its preserved number. The invention prepares the ray bacillus which can produce amber acid with a high yield by enrichment culture of strain in animal cud in culture medium containing disodium fumarate and the following classification. The amber acid with higher concentration can be produced by performing fermentation by using the said strain, which is suitable for the commercial manufacture of amber acid.

Owner:NANJING UNIV OF TECH

Succinic acid-producing strain and its screening method and uses

InactiveCN100537744CSuitable for industrial productionBacteriaFermentationBiotechnologyMicroorganism

The invention discloses a strain producing succinic acid, a screening method and application thereof. The strain is classified as Actinobacillus succinogenes NJ113, and has been preserved in the General Microorganism Center of China Committee for the Collection of Microorganisms, with the preservation number CGMCC No.1716. In the invention, the bacterial strains in the animal rumen are enriched and cultivated in the medium containing disodium fumarate and then classified to obtain actinomycetes with high production of succinic acid. Fermentation by using the bacterial strain can produce succinic acid with higher concentration, which is suitable for industrial production of succinic acid.

Owner:NANJING TECH UNIV

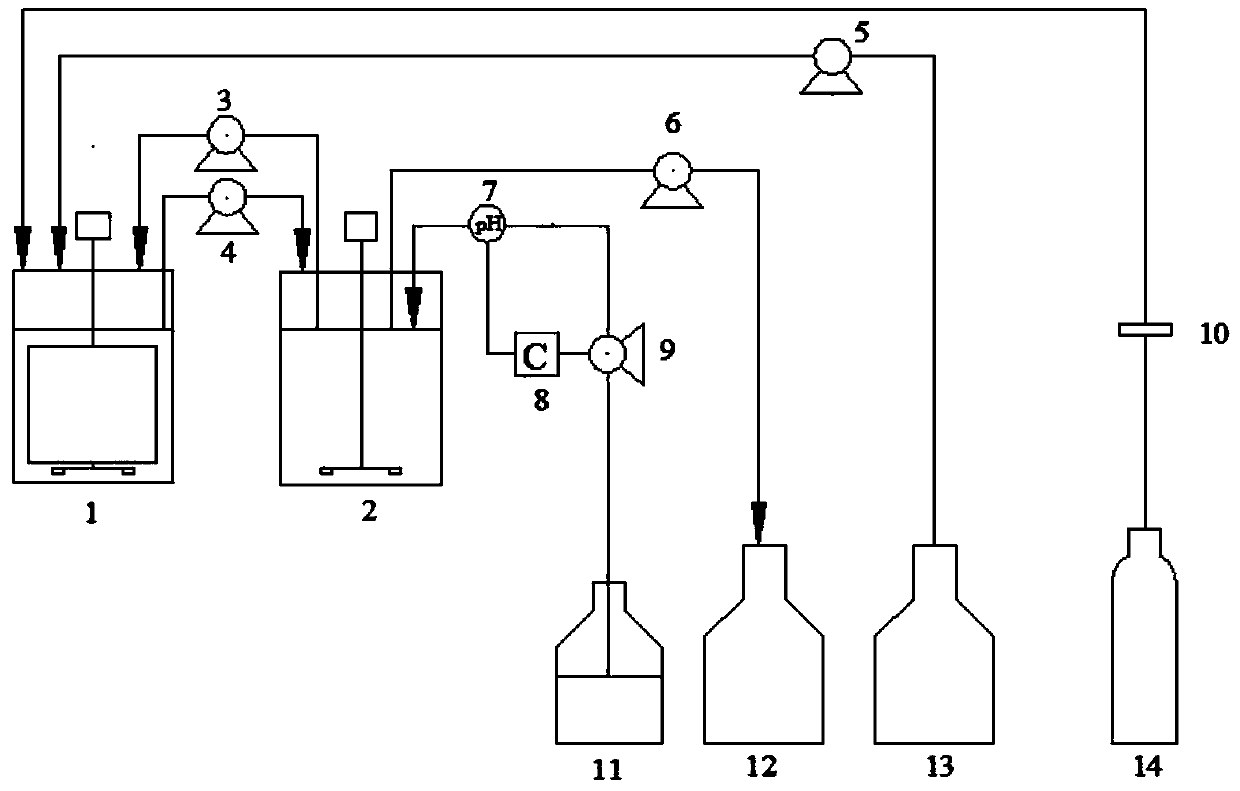

Method for producing amber acid by continuous fermentation or semi-continuous fermentation

InactiveCN101302546AIncrease production intensityLess investmentBacteriaMicroorganism based processesBatch fermentationSweet sorghum

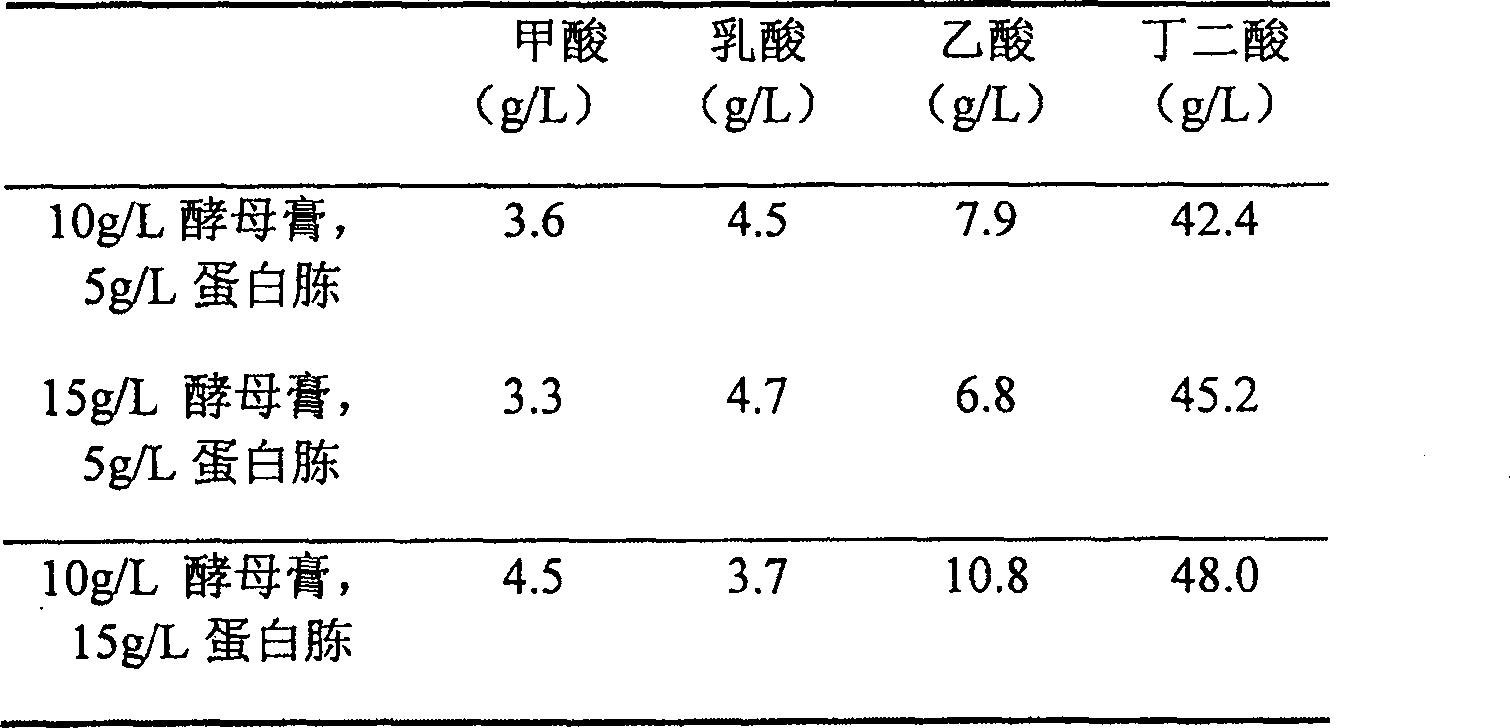

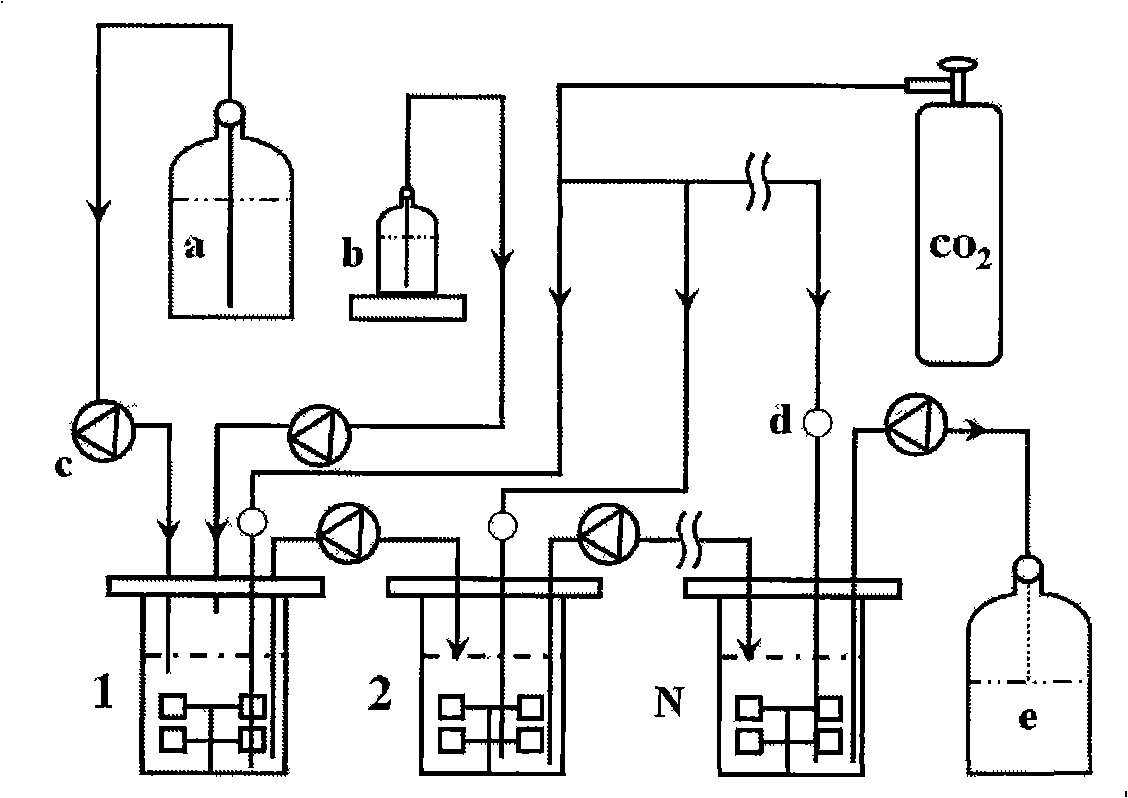

The invention discloses a method for producing butane diacid through continuous fermentation or semi-continuous fermentation, which belongs to the bioengineering technical field. The invention provides application of Actinobacillus succinogenes in the method for continuously or semi-continuously preparing the butane diacid by utilizing carbohydrate raw materials such as cane molasses, corn starch syrup, Jerusalem artichoke hydrolysis syrup, sweet sorghum straw syrup, and lignocellulose hydrolysis syrup and so on. The method utilizes multi-step continuous fermentation or two-step semi-continuous fermentation, which can improve germ concentration and cell activity and can obtain high butane diacid output and high butane diacid production intensity; the method is easy to realize automatic and continuous operation; compared with batch fermentation, the method can save non-fermentation time such as repeated tank cleaning, sterilization and so on, so the production efficiency can be greatly improved; the semi-continuous fermentation for producing the butane diacid is easier to control fermentation parameters than the continuous fermentation, has high sugar utilization rate, target product yield and target product output, has simple and easy equipment and operation, and is suitable for industrialized production.

Owner:JIANGNAN UNIV

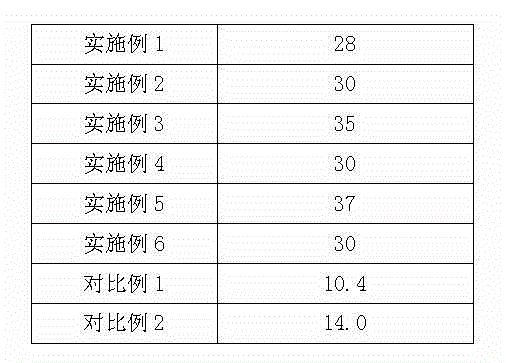

A method for producing succinic acid by fermenting distiller's grain raw materials

InactiveCN102260715ALow costReduce inhibitionMicroorganism based processesFermentationChemical synthesisButanedioic acid

The invention discloses a method for producing succinic acid by fermenting a vinasse raw material, and belongs to the technical field of bioengineering. The method comprises the following steps of: dehydrating fresh vinasse and crushing, pretreating to form a fermentation culture medium, pre-hydrolyzing by using enzymes, and saccharifying with fermenting by using enzyme and actinobacillus succinogenes to obtain the succinic acid at the concentration of 25-40g / L, wherein 0.033 to 0.050g of the succinic acid can be produced by using one gram of dry vinasse. The method has the advantages that: the succinic acid is produced by fermenting industrial waste vinasse which is used as a raw material, the vinasse is used as a carbon source instead of glucose, and a nitrogen source is not required tobe externally added in the fermentation culture medium, so that the problem that the petrochemical resource for chemically synthesizing the succinic acid is tense is solved, the environment pollutioncaused by the vinasse is also prevented, and the using value of the vinasse is enhanced.

Owner:JIANGNAN UNIV

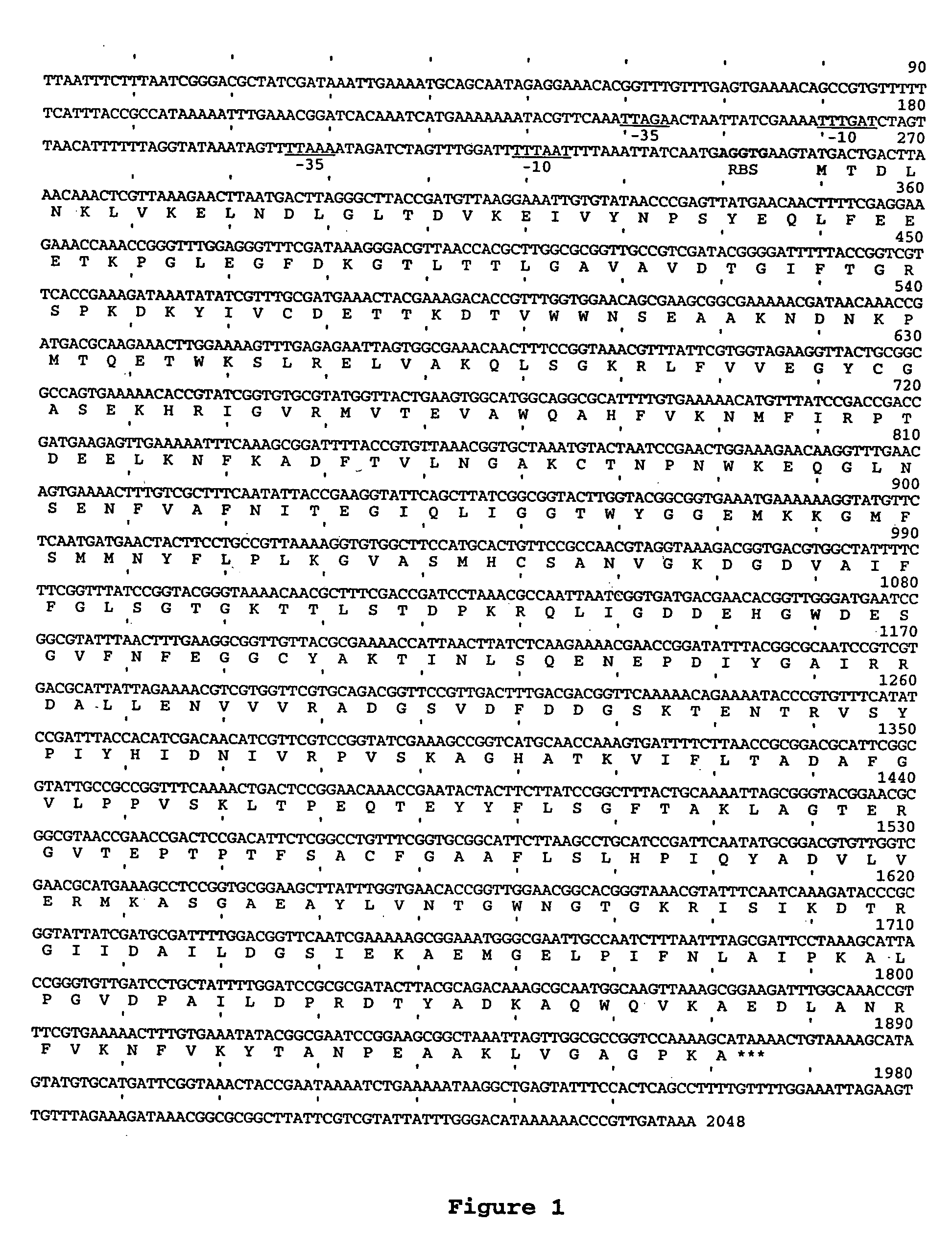

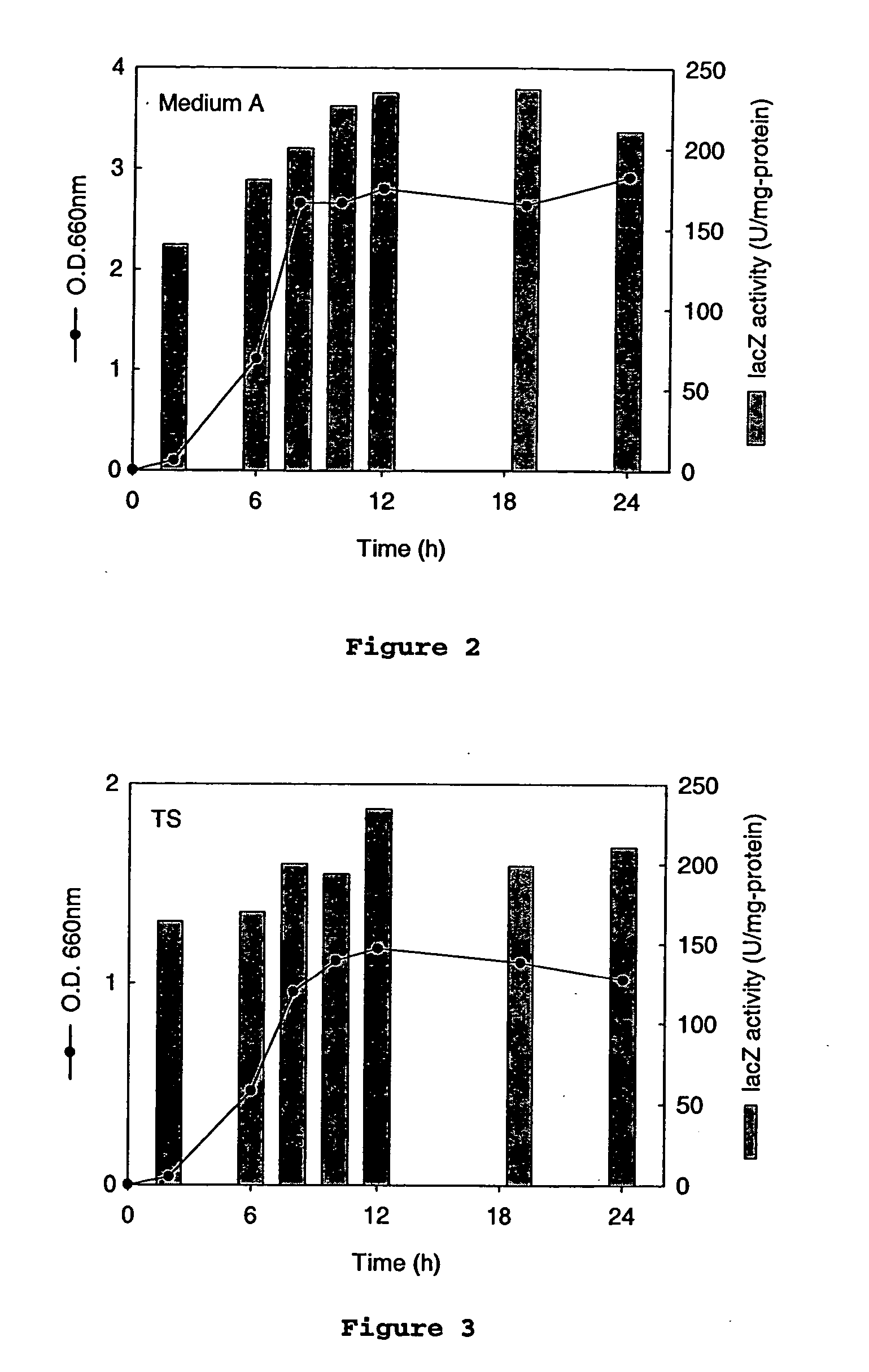

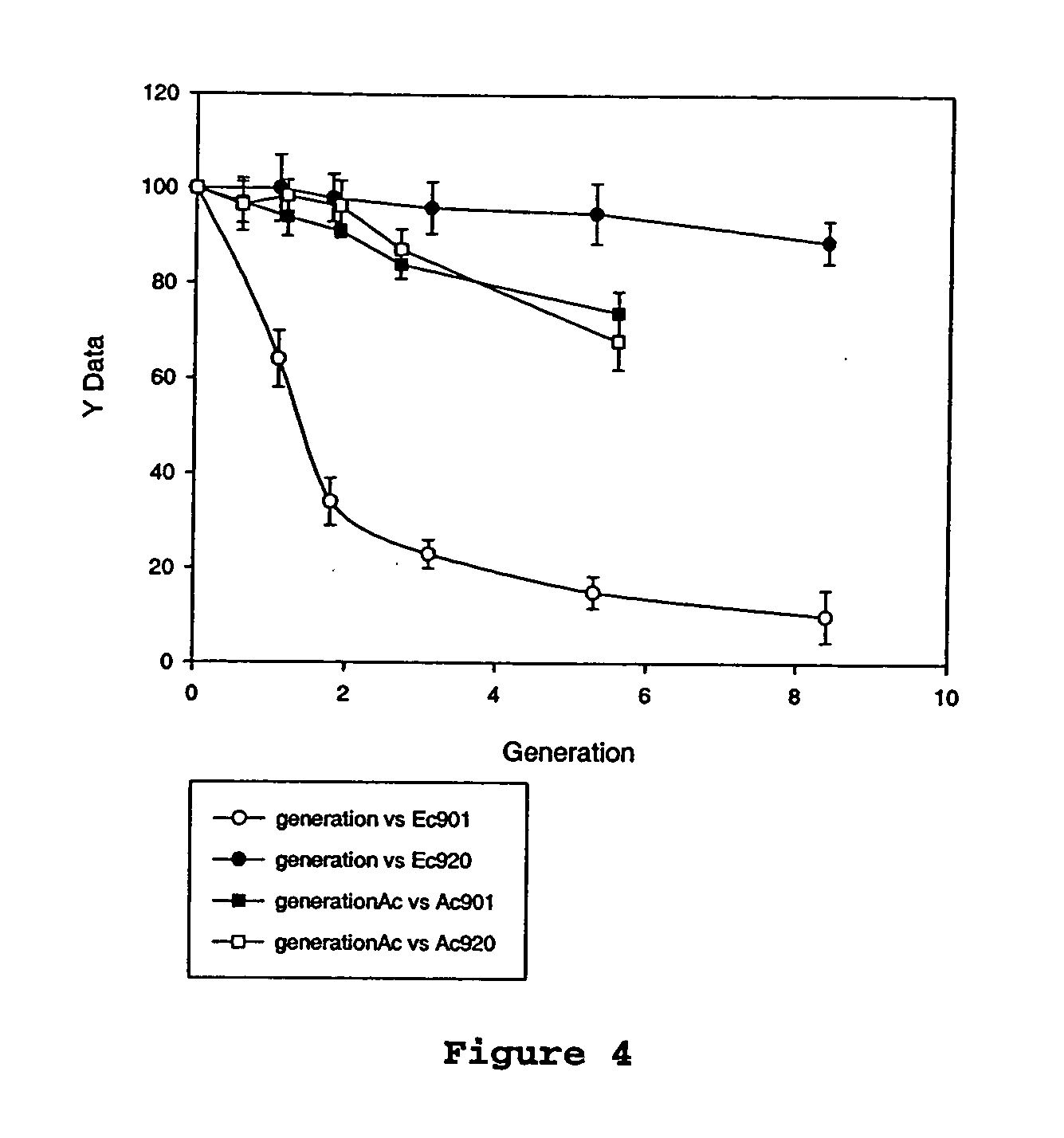

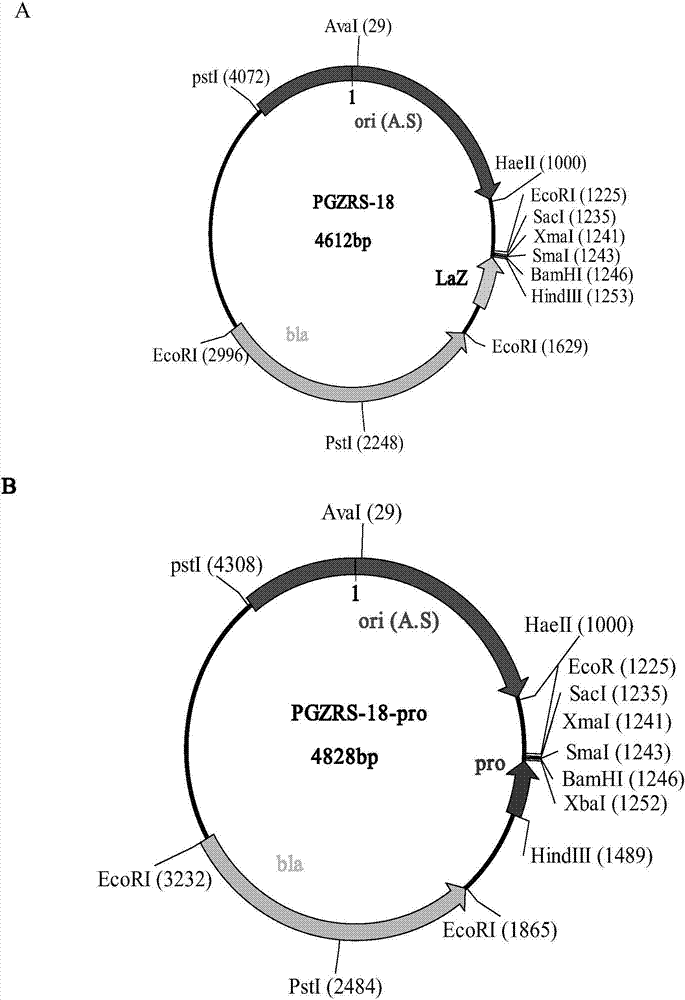

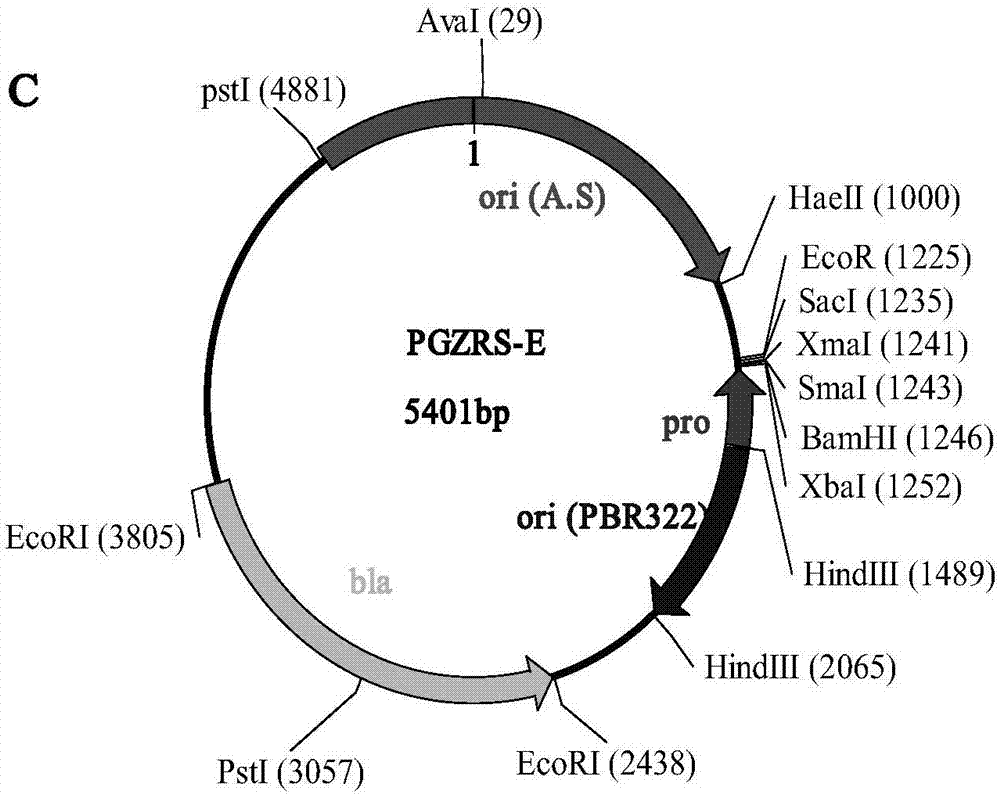

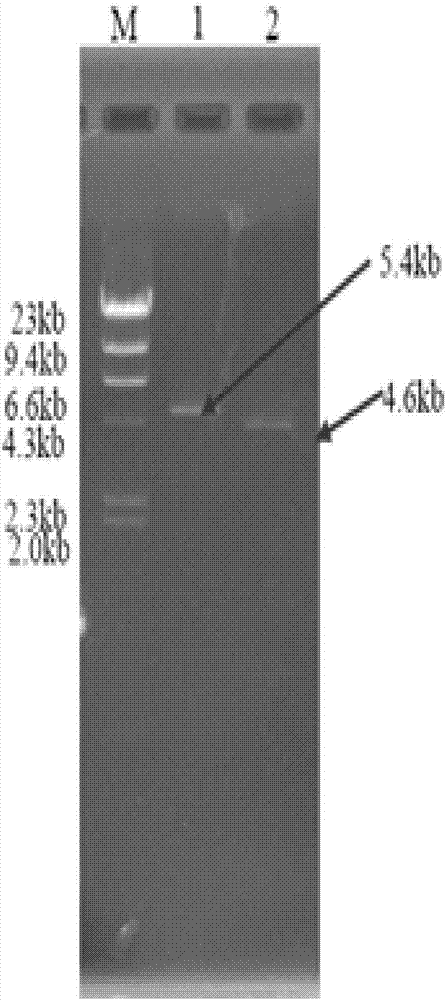

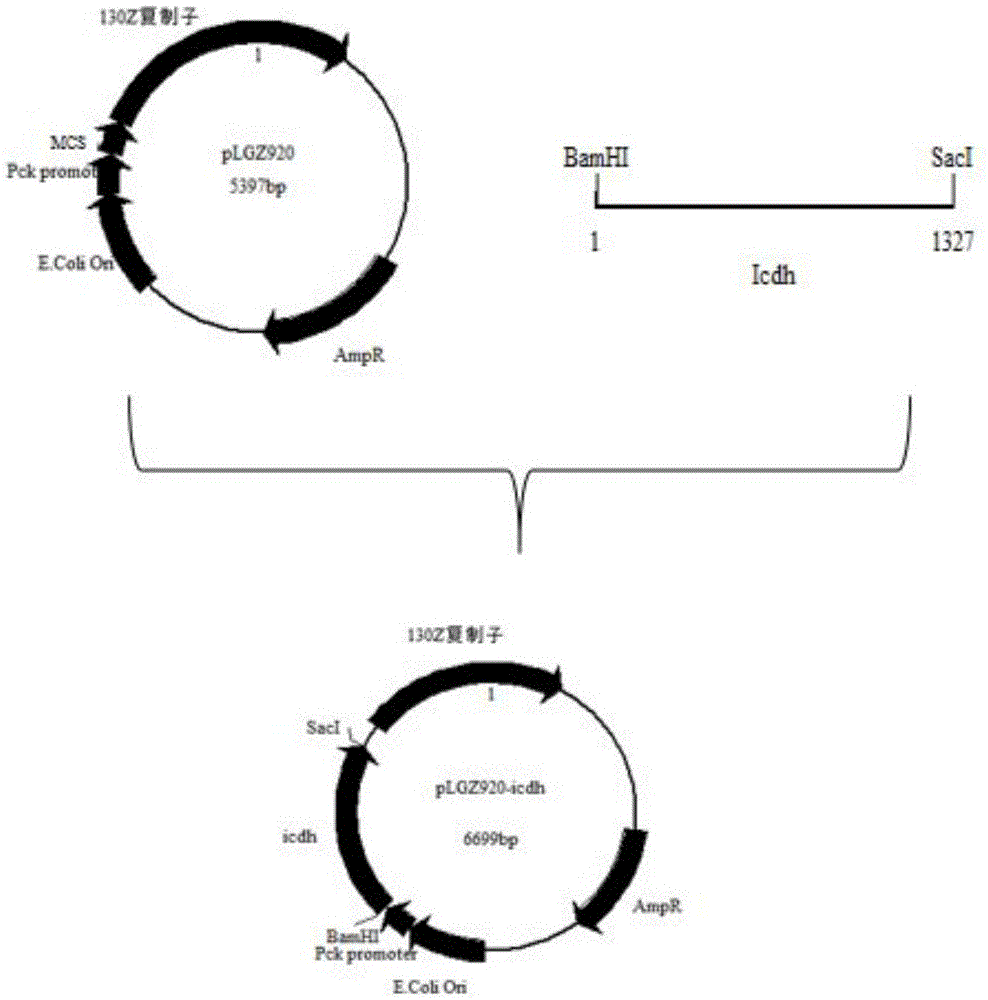

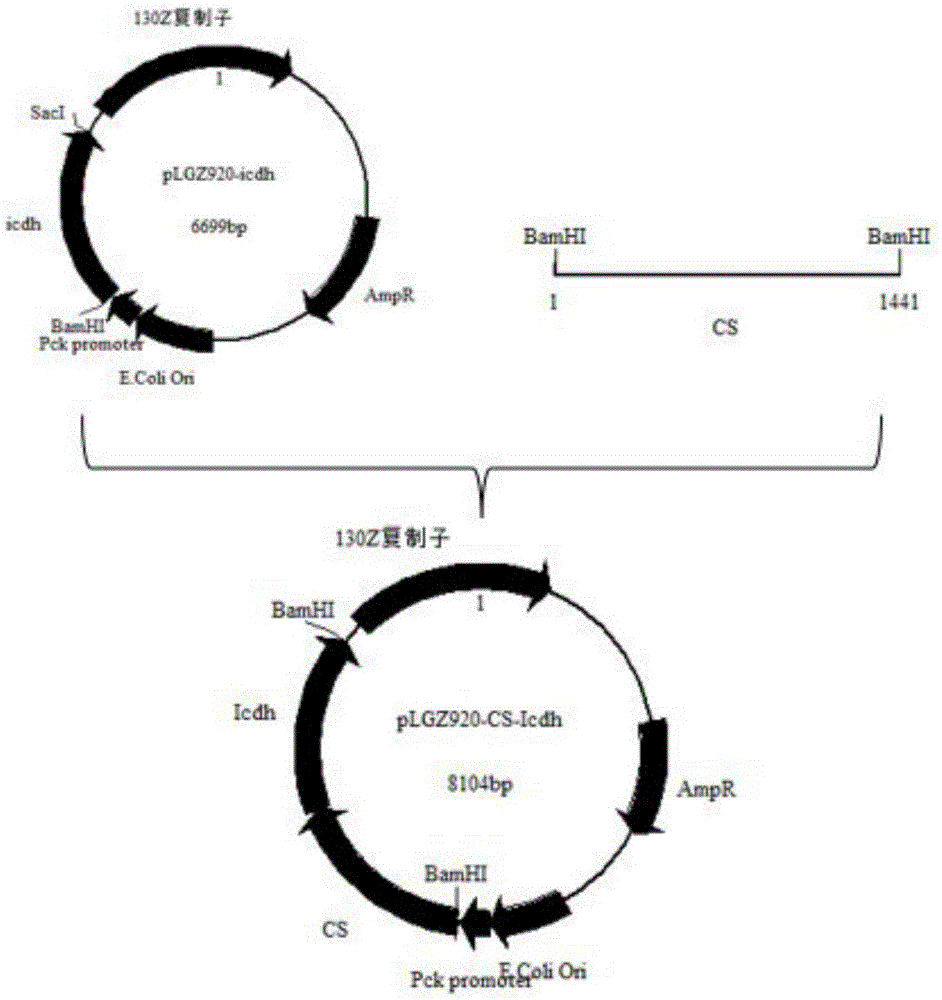

Actinobacillus succinogenes shuttle vector and methods of use

An Actinobacillus succinogenes plasmid vector which provides a means to overexpress proteins in A. succinogenes. The plasmid can be transformed efficiently by electroporation, and replicates in a stable manner in A. succinogenes. The plasmid comprises at least one marker gene, operably linked to a first promoter functional in Actinobacillus succinogenes, an origin of replication functional in Actinobacillus succinogenes, a second promoter isolated from Actinobacillus succinogenes, and a cloning site downstream from the second promoter. Plasmids pLGZ901, pLGZ920, pLGZ921, and pLGZ922 are disclosed. The pckA gene polypeptide sequence and nucleic acid sequence of Actinobacillus succinogenes, including the promoter and ribosome binding site, is disclosed. Furthermore, a method for producing a recombinant Actinobacillus succinogenes is described, including a method of transformation. Additionally, a recombinant Actinobacillus succinogenes is disclosed and a method for producing succinate utilizing this recombinant Actinobacillus succinogenes is described.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Method for restructuring/breeding Actinobacillus succinogenes strain, and method for producing succinic acid by fermenting Actinobacillus succinogenes strain

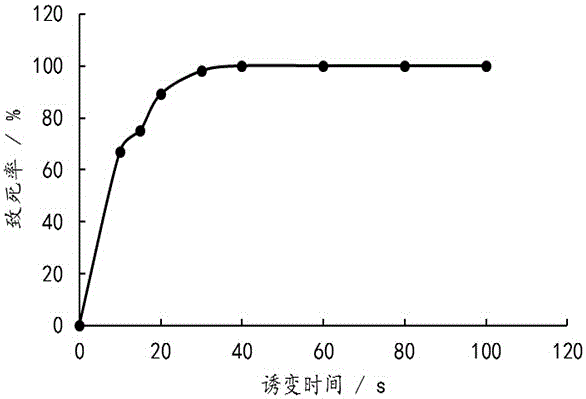

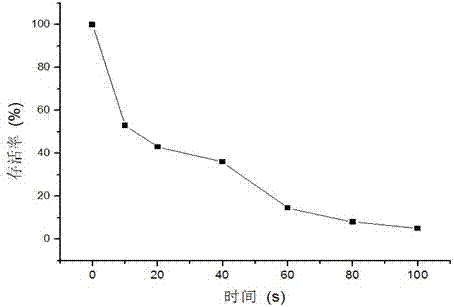

InactiveCN101531972AImproved sodium toleranceImprove fermentation characteristicsBacteriaMutant preparationGenome shufflingX-ray

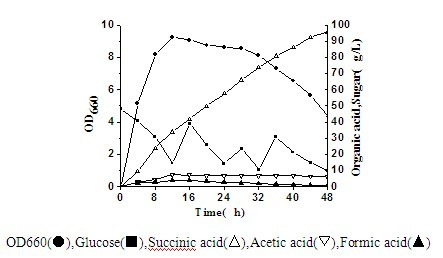

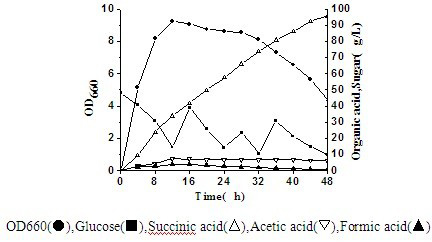

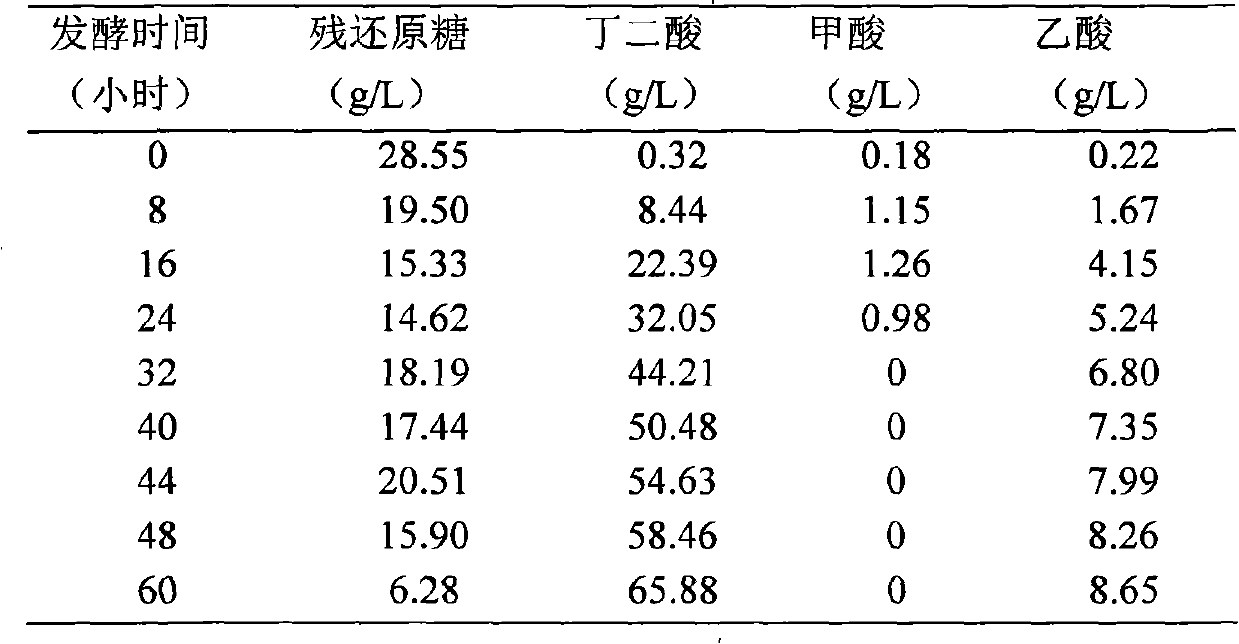

The invention relates to an Actinobacillus succinogenes strain CGMCC 2653 (namely F3-10) with better sodium-ion tolerance and acid-producing performance, a method for breeding the strain and a method for producing succinic acid by fermenting the strain. Actinobacillus succinogenes CGMCC 1593 is taken as an original strain and then subjected to X-ray mutation, ultraviolet mutation, diethyl sulfate (EMS) chemical mutation and nitrosoguanidine (NTG) chemical mutation respectively; three strains X-8, UV-17 and SE-6 with improved fermentative acid-producing performance and particularly improved sodium-ion tolerance, as well as a high-yield strain SF-9 with fluoroacetate resistance, are obtained by screening the obtained product; and a genome restructuring method is used for breeding the strains so as to obtain the strain F3-10 with high yield, sodium tolerance and fluoroacetate resistance. The strain F3-10 takes sugarcane molasses as raw material, adopts Na2CO3 to control fermentation pH, and performs fed-batch fermentation in a 5L fermenter, and produces 53.96 grams of succinic acid per liter in 48 hours; the yield of consumed sugar is 89.2 percent; the utilization rate of sugar is 94.0 percent; and the ratio of succinic acid to heteroacid is 6.58:1. Therefore, the strain F3-10 is remarkably improved as compared with the original strain CGMCC 1593.

Owner:JIANGNAN UNIV

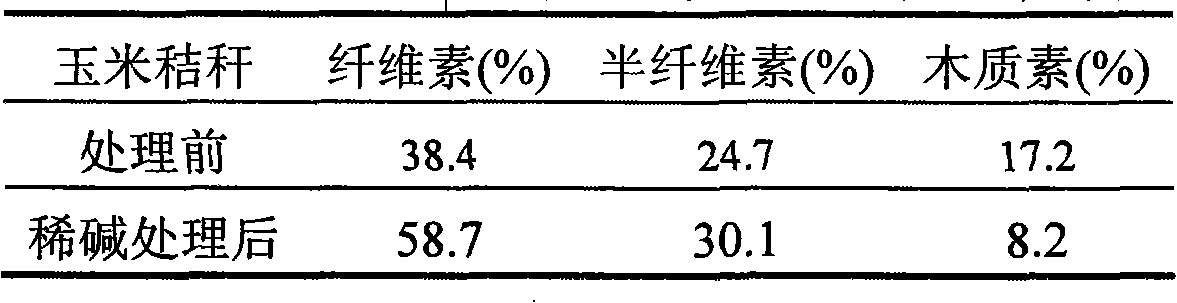

Method for producing succinic acid by simultaneous saccharification and fermentation of straw raw material

InactiveCN101603059AReduce dependenceIncrease incomeMicroorganism based processesFermentationChemical synthesisMicroorganism

The invention discloses a method for producing succinic acid by the simultaneous saccharification and fermentation of a straw raw material and belongs to the technical field of bioengineering. In the method, a straw agricultural waste serving as a raw material is synchronously saccharified and fermented by microorganisms to form the succinic acid; or straws are cut, grounded and pretreated by a diluted alkali to form succinic acid under the coactions of cellulose generated by trichoderma reesei and trichoderma viride and actinobacillus succinogenes; or the straws pretreated by the 70g / L diluted alkali forms 35.5g / L succinic acid through anaerobic fermentation at 38 DEG C. The method has the advantages of cheap and non-grain raw material, low equipment investment and operation cost, environment protection and alleviation of the dependency of chemical synthesis on petrochemical resources.

Owner:JIANGNAN UNIV

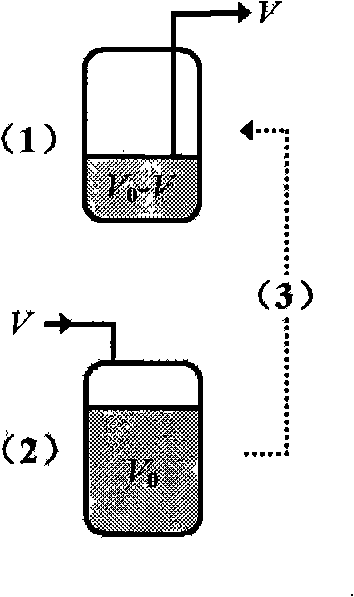

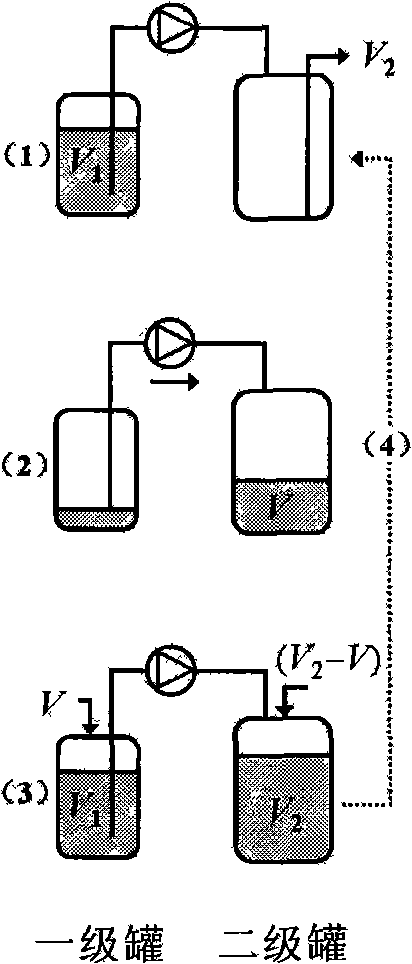

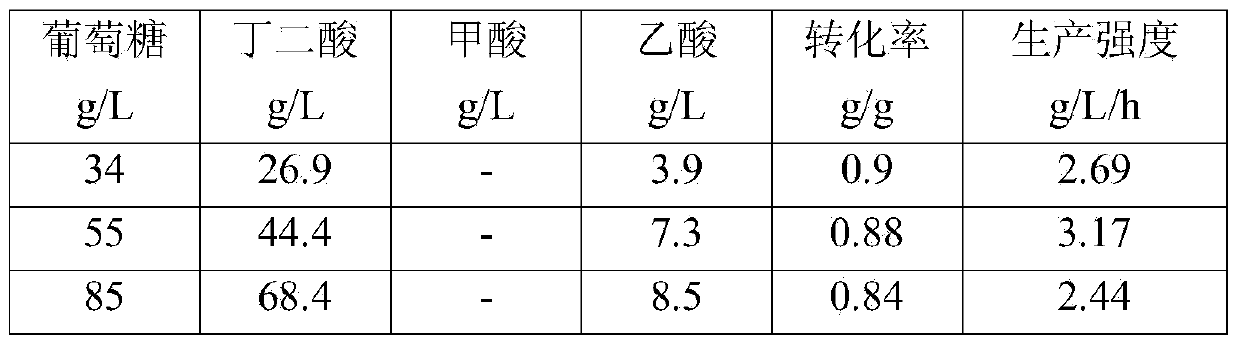

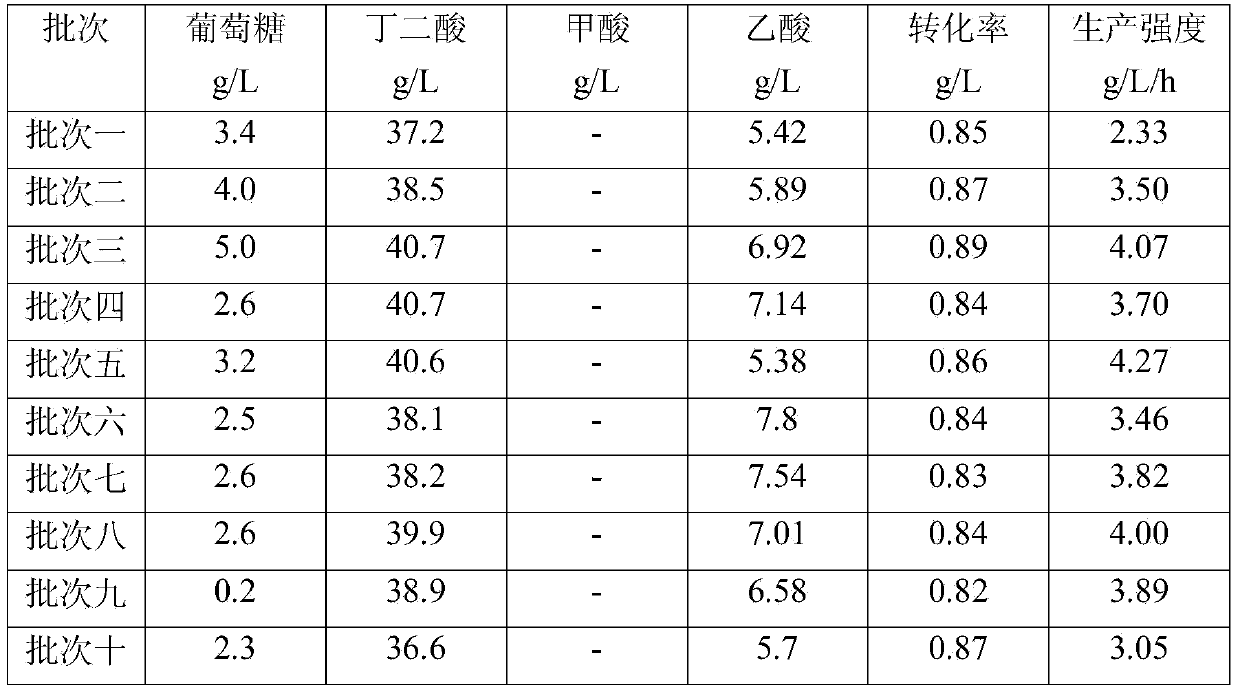

Method for fermentation production of succinic acid by using cotton fiber material to fix actinobacillus succinogenes

The invention discloses a method for fermentation production of succinic acid by using a cotton fiber material to fix actinobacillus succinogenes, belonging to the fermentation engineering field. The actinobacillus succinogenes is placed in a fermentation tank which contains a cotton fiber carrier for culturing, adsorbing and fixing; the fermentation cell concentration is improved through a repeated batch fermentation process, a repeated fed-batch fermentation process, a continuous fermentation process or a double-tank circulating continuous fermentation process; meanwhile, high acid production concentration, high production strength and high conversation rate are obtained. The conversation rate is 90% to a maximum, the production strength is 4.27g / L / h to a maximum, and the butyric acid yield is 98.7g / L to a maximum.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

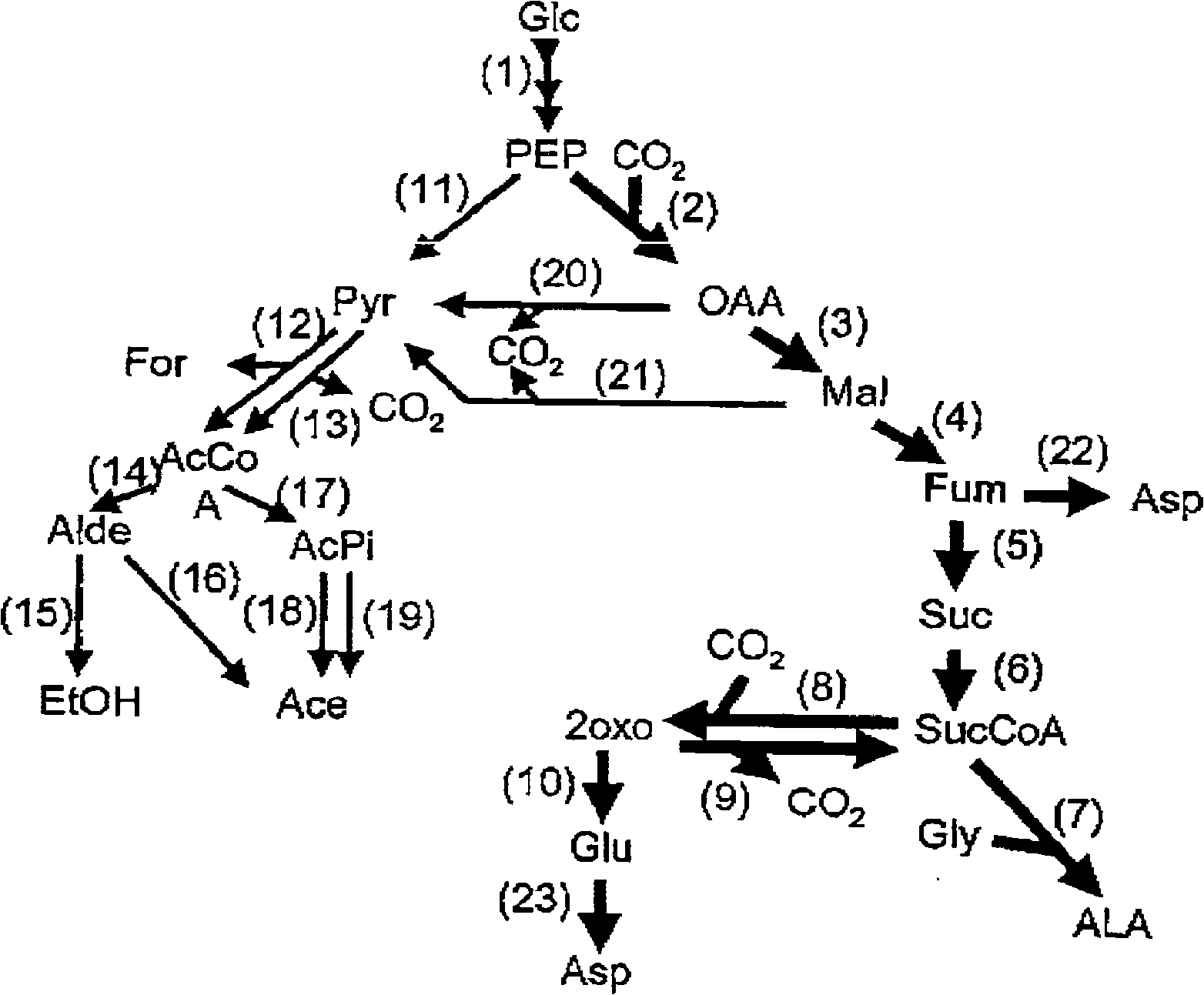

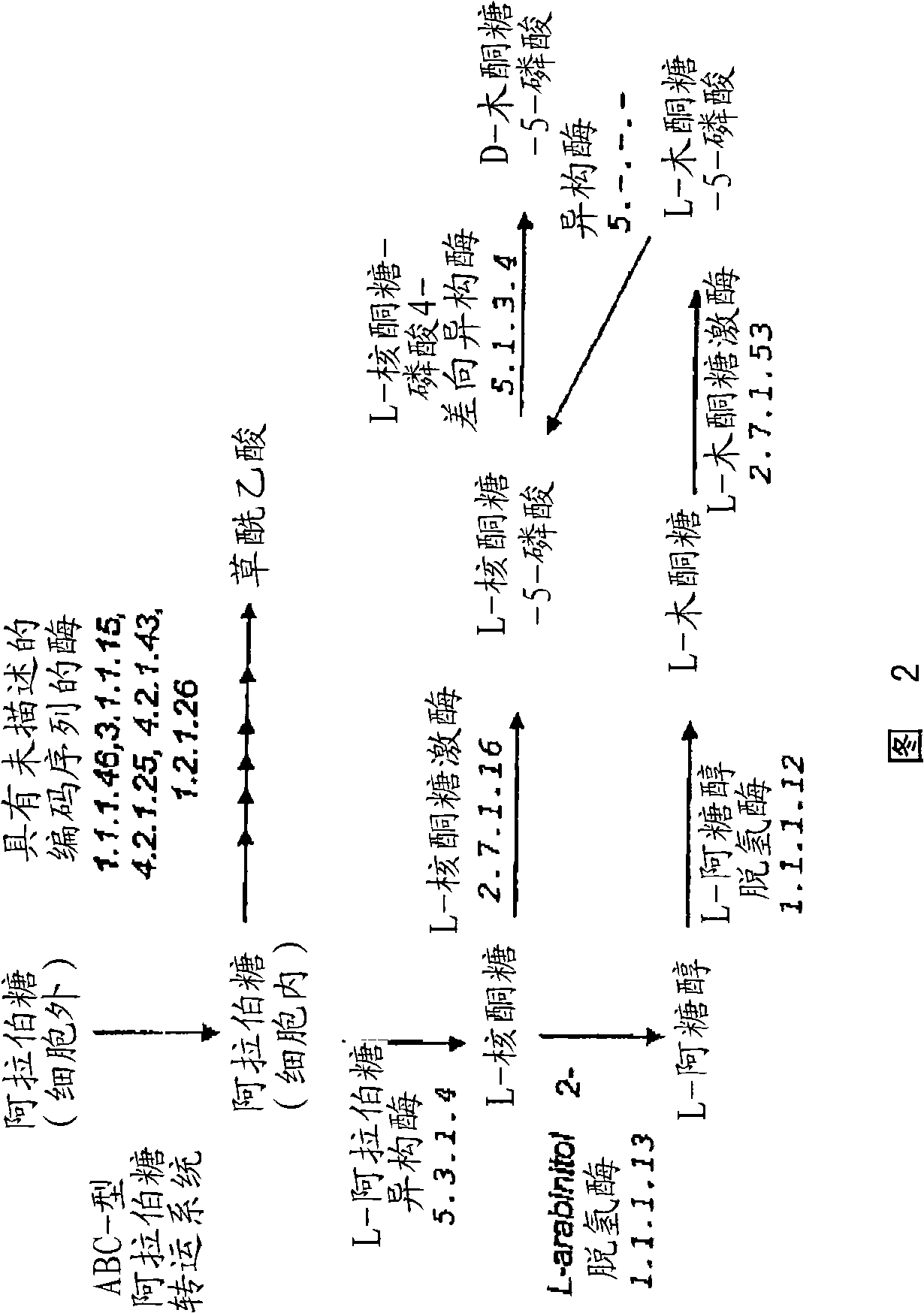

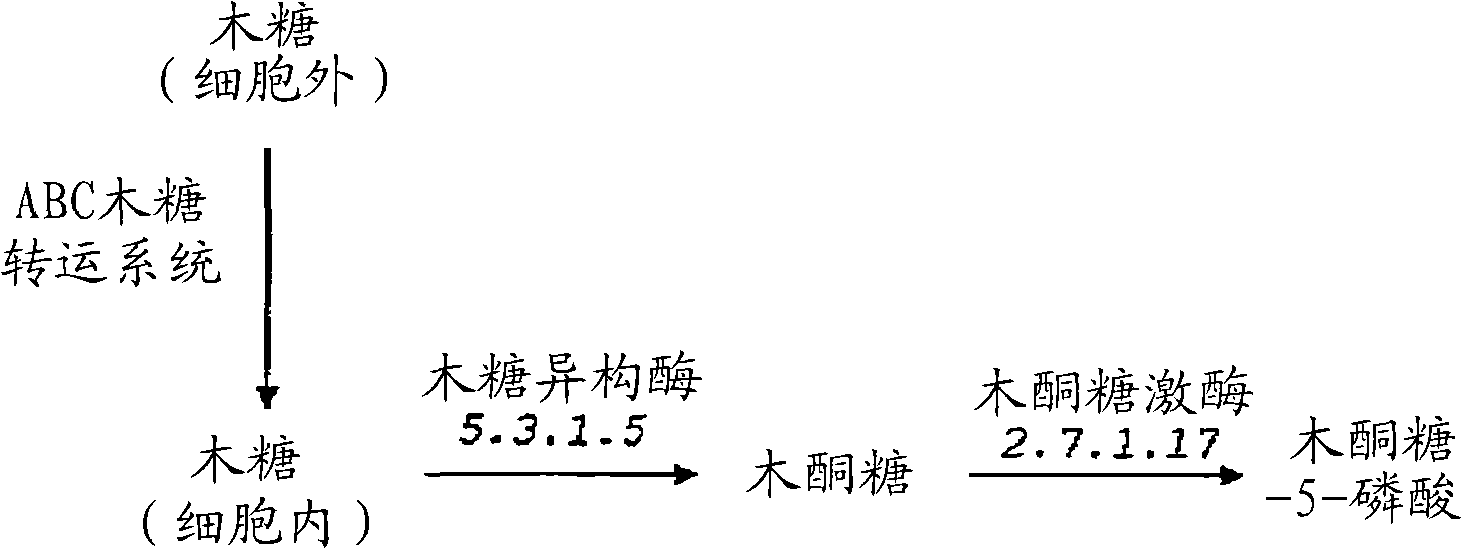

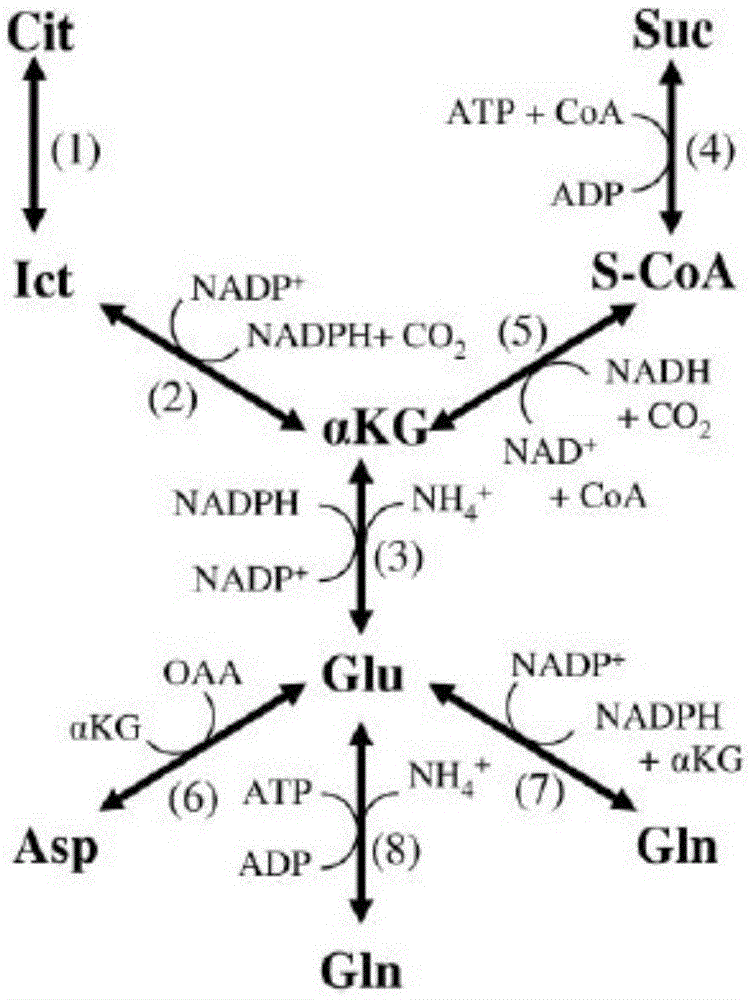

Genes from actinobacillus succinogenes 13oz (atcc 55618) for production of chemicals from the a. succinogenes C4-pathway

InactiveCN101278041AIncrease intakeBacterial antigen ingredientsBacteriaBiotechnology5-aminolevulinate

Actinobacillus succinogenes genes and methods of using the genes in genetically engineered A. succinogenes so as to improve production of chemicals such as succinate, fumarate, malate, 5-aminolevulinate, 2-oxoglutarate, glutamate, and aspartate. The genetically engineered A. succinogenes strains are capable of overexpressing C4 enzymes. The genetically engineered A. succinogenes can have one or more gene knockouts or modifications that inhibit C3 enzymes. The fluxes supplying substrate to the C4 pathway can also be improved in some of the genetically engineered A. succinogenes.

Owner:MICHIGAN STATE UNIV

Actinobacillus succinogenes strain and method for producing succinic acid by screening and fermentation of same

InactiveCN102851224APotential for industrial productionSolve the problem of resource shortage and environmental pollutionProductsBacteriaBiotechnologyButanedioic acid

The invention discloses an actinobacillus succinogenes GXAS-137, and a method for producing succinic acid by screening and fermentation of the strain; the strain is obtained by enrichment and screening from a cattle rumen; the method comprises the following steps: inoculating the actinobacillus succinogenes strains in a seed medium, culturing for 24-36 hours in an anaerobic incubator or a common incubator at 30-38 DEG C in a static manner, inoculating into a fermentation medium with an inoculation amount of 1-10%, adjusting the pH to 6.0-7.0, and performing fermentation at 30-38 DEG C for 24-120 hours to obtain succinic acid. Fermentation research is performed with different raw materials and in different media; the succinic acid yield is up to 70 g / L; and the method has potential for industrial production.

Owner:GUANGXI ACAD OF SCI

Actinobacillus succinogenes capable of producing succinic acid

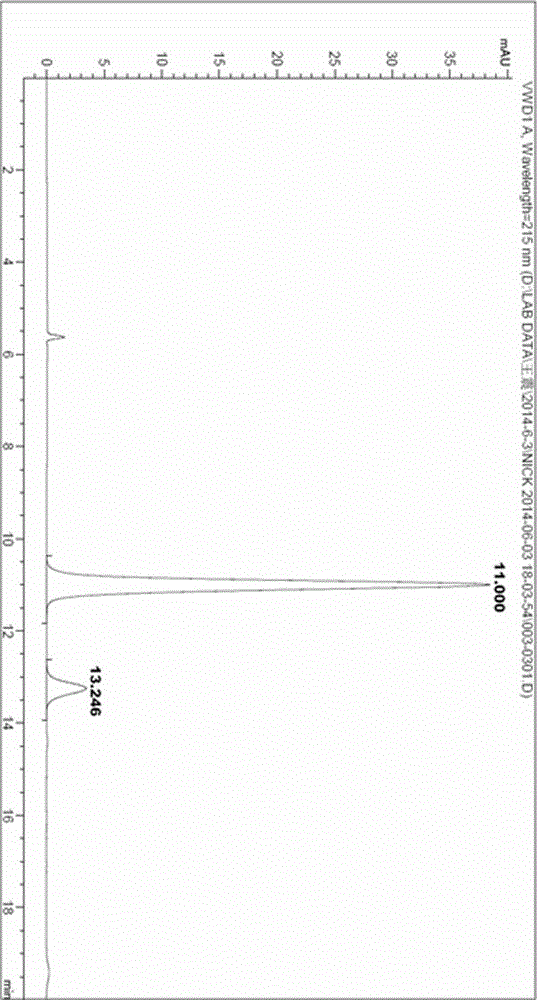

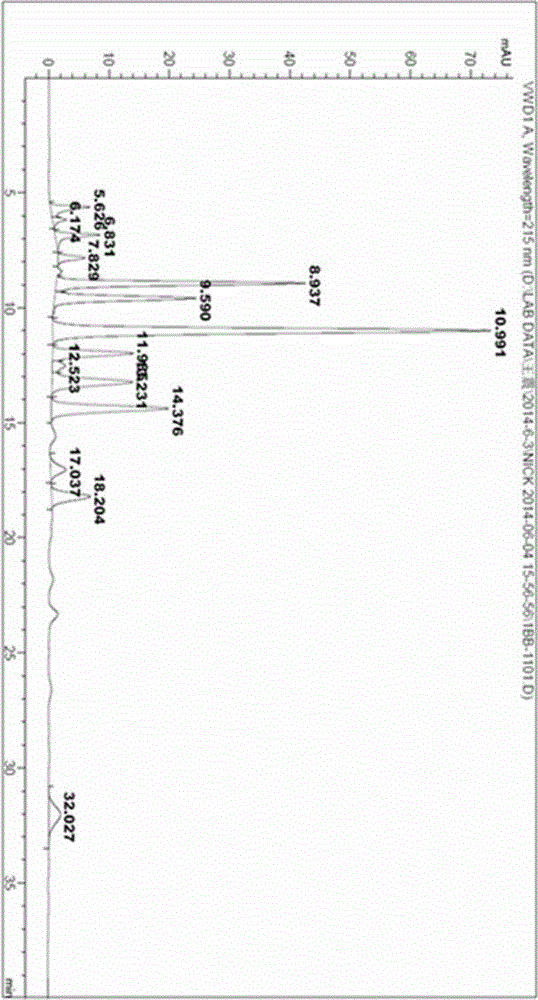

ActiveCN102533622AReduce manufacturing costIncrease production intensityBacteriaMutant preparationSaccharic acidD-Glucaric Acid

The invention discloses actinobacillus succionogenes capable of producing succinic acid with high yield and a method for screening and producing the succinic acid by a fermentation method. The actinobacillus succinogenes takes CGMCC1593 as the original strain and is obtained by blending a plurality of turns of protoplast in a progressive way through a method of '96-pore plate culture, HPLC concentration detection and then anaerobic bottle re-screening'. The actinobacillus succinogenes has already been preserved on February 26, 2012 in China Center for Type Culture Collection with the preservation number CCTCCNO: M2012036. The actinobacillus succinogenes adopts fed-batch culture in a 5 to 15 L fermentation tank, 95.6 g / L succinic acid is produced in 48 hours, the production intensity is 1.99 g / (L.h), and the saccharic acid transformation rate is 0.71 g / g. Compared with other bacterial strains at home and abroad, the actinobacillus succinogenes has the advantages of high yield and lowerproduction cost.

Owner:JIANGNAN UNIV

Method for producing succinic acid by using ferment of molasses raw material

InactiveCN101092638ALow costAlleviate the shortage of petrochemical resourcesMicroorganism based processesFermentationChemical synthesisRumen

This invention discloses a method for producing succinic acid from waste syrup by fermentation. The method comprises: screening rumen to obtain Actinobacillus succinogenes (CGMCC 1593), and performing fed batch anaerobic fermentation on waste syrup (reducing sugar concentration = 50-100 g / L) in the presence of CO2 or N2 at a pH value of 5.5-7.5 for 30-60 h. The concentration of succinic acid can reach 30-60 g / L. The conversion rate is 70-84%, the productivity is 0.9-1.2 g / L.h, and the sugar utilization rate is 90-95%. The method utilizes renewable resource (waste syrup) instead of pure glucose as the carbon source to produce succinic acid. The method has a low cost, and is environmentally friendly.

Owner:HANGZHOU XINFU TECH CO LTD +1

Immobilized cell single-tank high-strength continuous fermentation process for succinic acid

InactiveCN101153294ANutrition easyReduce fermentation costsMicroorganism based processesFermentationCurrent velocityContinuous fermentation

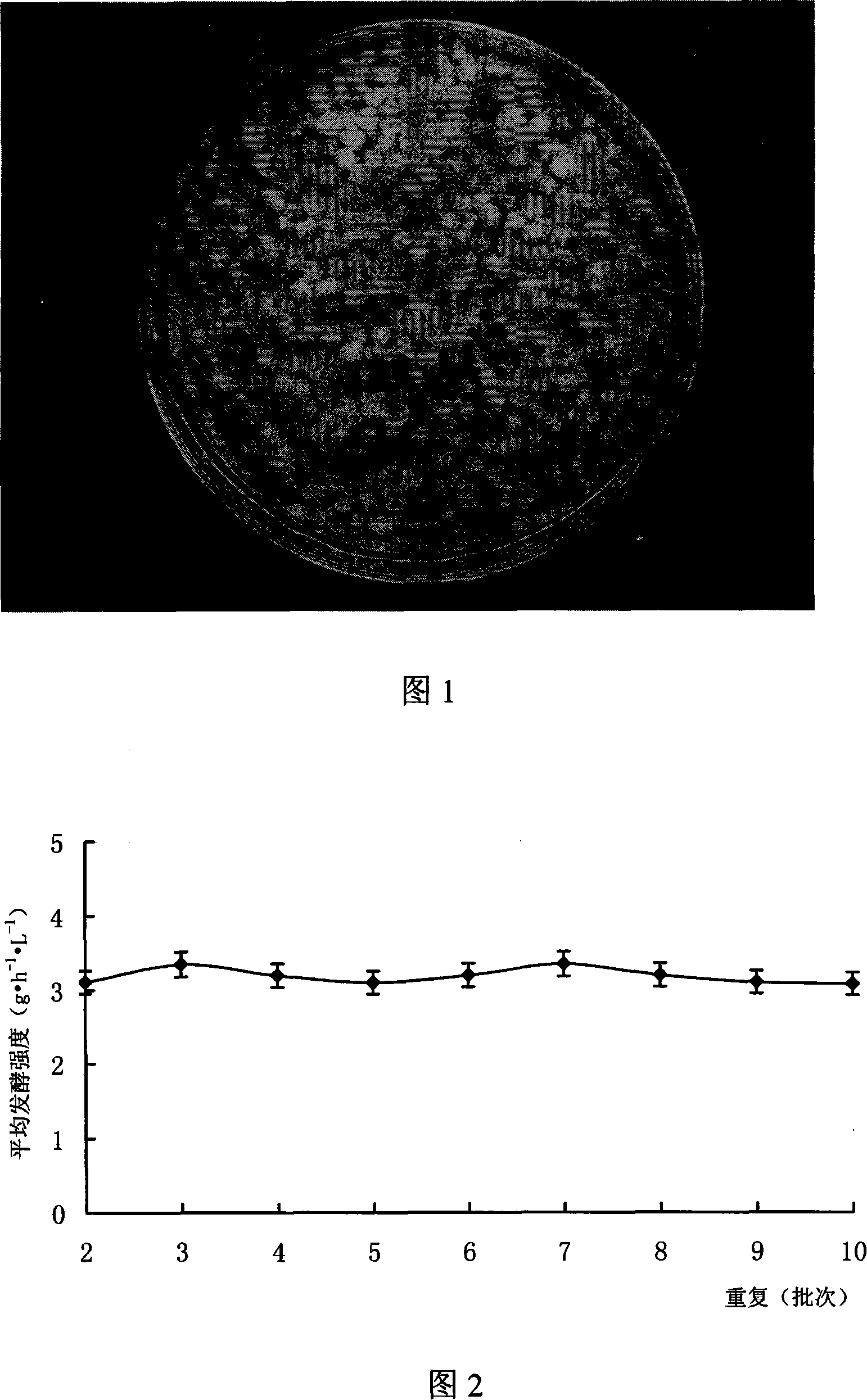

The invention discloses a single-pot high-intensity continuous fermentation technology used for solidified cells with succinic acid, which comprises the procedures including that: firstly, seed liquid of high-activity actinobacillus capable of producing succinic acid is prepared; secondly, the seeds are proliferated in cultivation with a10L pot; thirdly, the 10L-pot solified cells are prepared; fourthly, the repeated single-pot fermentation with the 10L pot is carried out, then the seeds are inoculated into a fresh substrate, the first batch of fermentation is controlled within 24 hours, followed by 9 batches of continuous fermentation, each of which lasts for 16 hours, then the amphoteric anaerobic cultivation pattern is controlled through the current velocity of the combined air of CO2 and H2, the pH of the fermentation liquid is controlled with fed-batch of calcium oxide, wherein, at the end of each batch of fermentation, the next batch of fermentation is carried out through intercepting the solidified cells with positive-pressure sterilized operation with a propeller filter arranged inside the pot, the fermentation intensity is stabilized above 3.10g / (h.L), and the single-pot high-intensity continuous fermentation technology used for solidified cells with succinic acid is completely accomplished.

Owner:HEFEI UNIV OF TECH

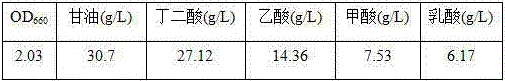

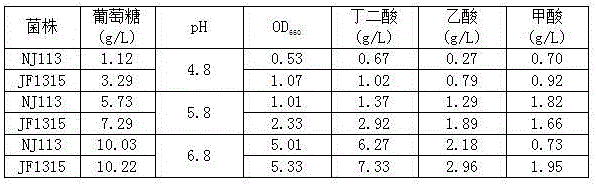

Bacterial strain capable of enhancing glycerin metabolism and application thereof

ActiveCN105838652APromote accumulationChange growthBacteriaMicroorganism based processesOrganic acidNormal growth

The invention discloses a bacterial strain capable of enhancing glycerin metabolism. The bacterial strain is classified and names as Actinobacillussuccinogenes JF1315, already collected at the China Center for Type Culture Collection on 31th, Mar. 2016 under CCTCC NO: M 2016160. The invention further relates to application of Actinobacillussuccinogenes JF1315 in producing organic acid through fermentation. Compared with control bacterial strains, under an anaerobic condition, the bacterial strain can grow and metabolizes at low pH, and reductive organic acid can be synthesized efficiently by utilizing glycerin fermentation. When pH is 4.8-6.8, the bacterial strain can normally grow and metabolize glucose to synthesize the organic acid like succinic acid; in addition, under the condition, the bacterial strain can efficiently utilize glycerin for anaerobic fermentation to synthesize and accumulate the organic acid.

Owner:NANJING UNIV OF TECH

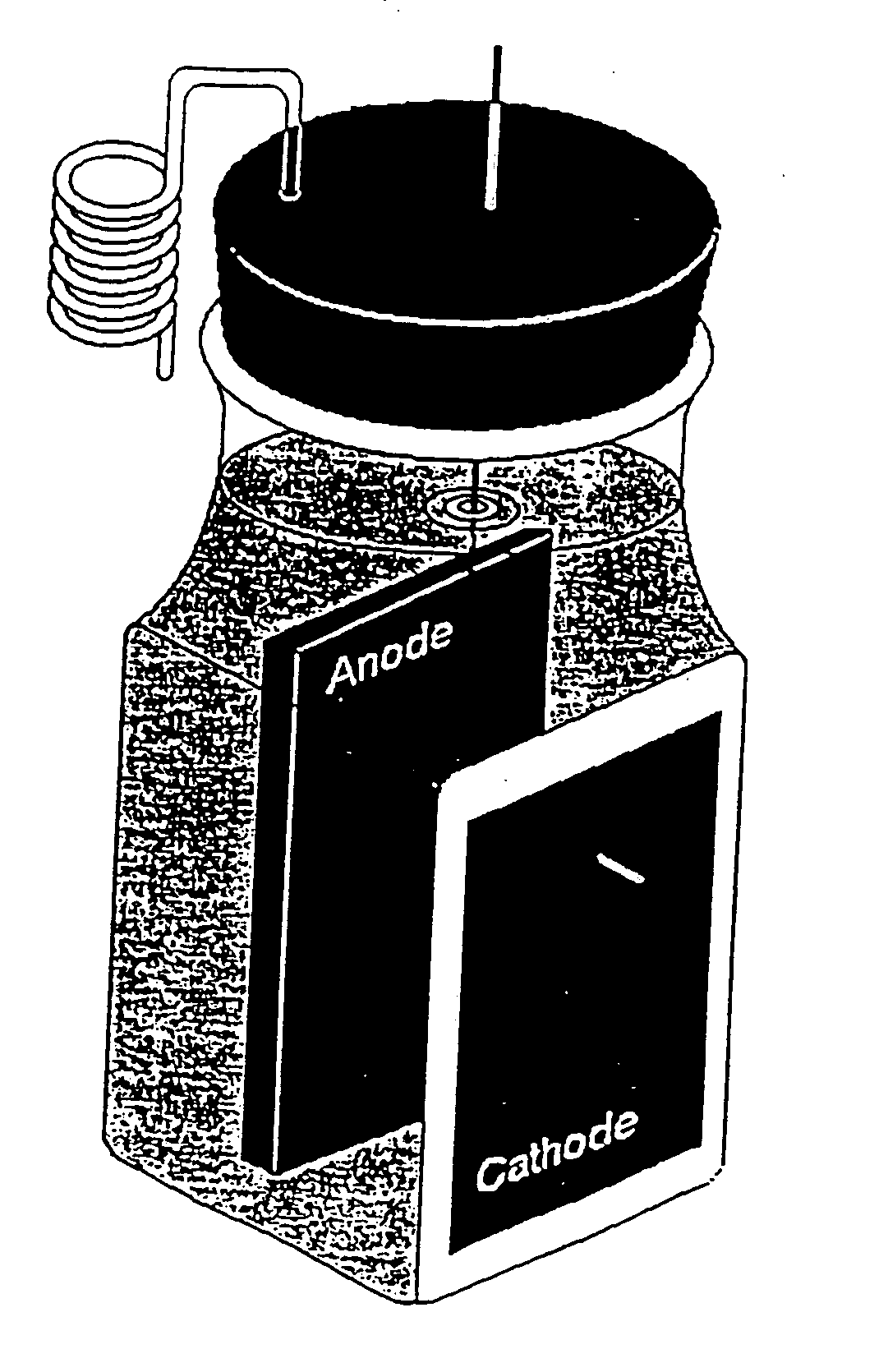

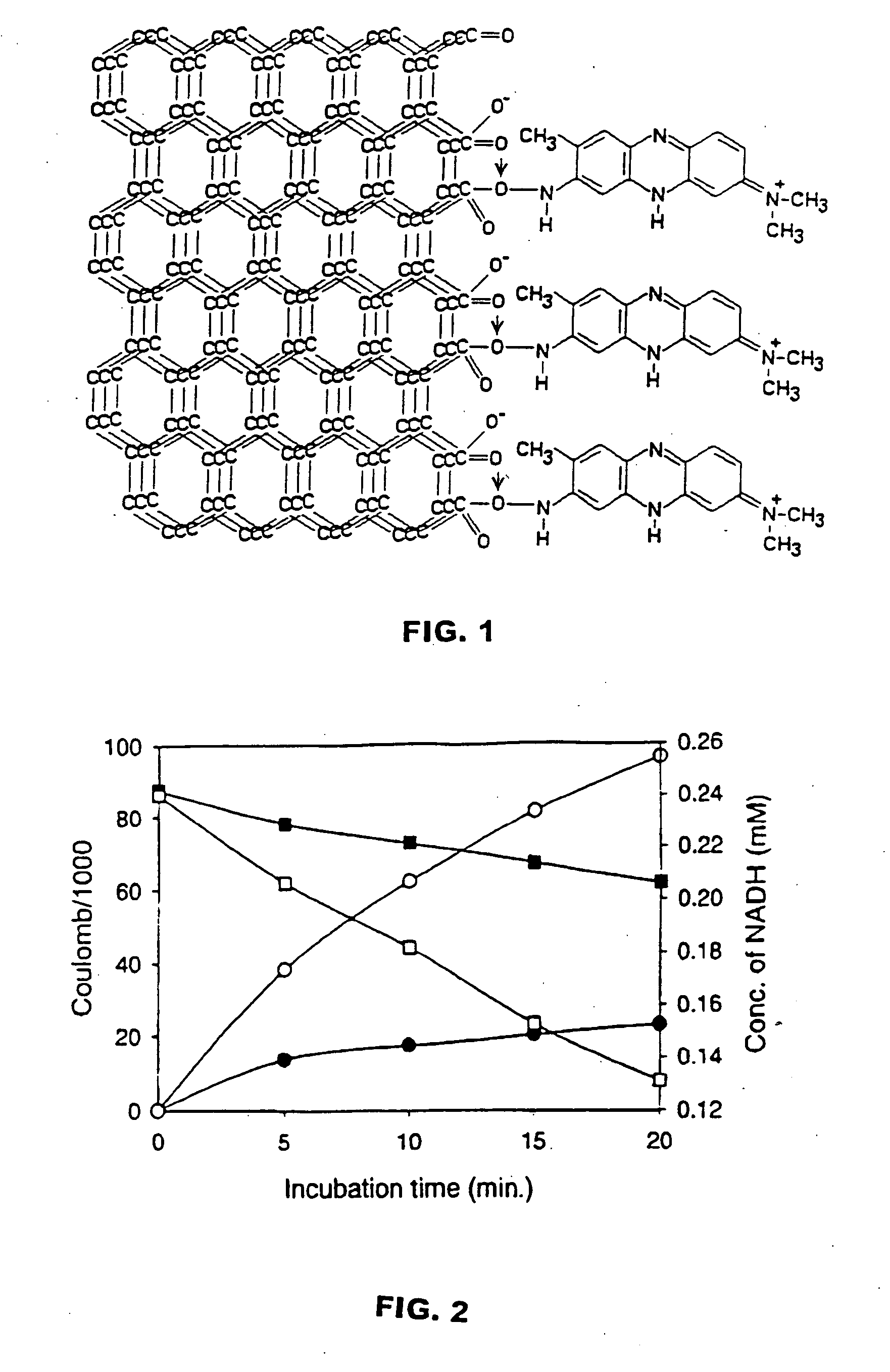

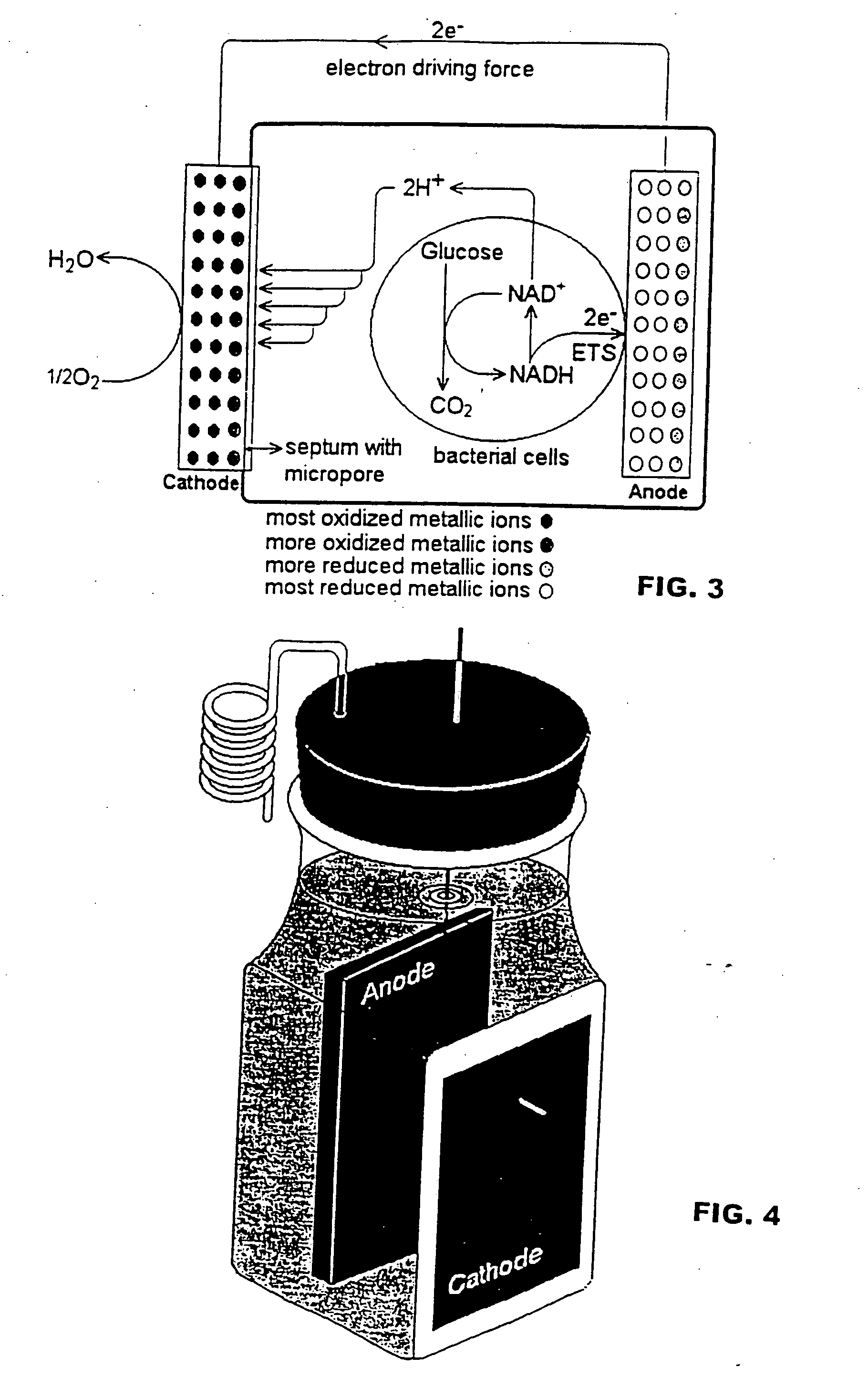

Electrode compositions and configurations for electrochemical bioreactor systems

InactiveUS20070298472A1Increase ratingsImmobilised enzymesBioreactor/fermenter combinationsEscherichia coliCellulose

Electrodes and configurations for electrochemical bioreactor systems that can use electrical energy as a source of reducing power in fermentation or enzymatic reactions and that can use electron mediators and a biocatalyst, such as cells or enzymes, to produce electricity are disclosed. Example electrodes in the system may comprise: (1) neutral red covalently bound to graphite felt; (2) a carboxylated cellulose bound to the graphite felt, neutral red bound to the carboxylated cellulose, NAD+ bound to the graphite felt, and an oxidoreductase (e.g., fumarate reductase) bound to the graphite felt; or (3) a metal ion electron mediator bound to graphite. Various biocatalysts, such as an oxidoreductase, cells of Actinobacillus succinogenes, cells of Escherichia coli, and sewage sludge, are suitable for use in the electrochemical bioreactor system.

Owner:MICHIGAN STATE UNIVESITY BOARD OF TRUSTEES OF

Method for producing succinic acid by multistage continuous fermentation

InactiveCN104152497AIncrease productionSimple methodMicroorganism based processesFermentationBiotechnologyContinuous fermentation

The invention discloses a method for producing succinic acid by multistage continuous fermentation. The method comprises the following steps: firstly, preparing a seed culture medium, a primary fermentation culture medium, a carbon source replenishing tank culture liquid and a medium replenishing tank culture liquid; secondly, sterilizing a serial fermentation tank set, a carbon source replenishing tank, a culture medium replenishing tank, the seed culture medium, the primary fermentation culture medium, the carbon source replenishing tank culture liquid, the medium replenishing tank culture liquid and a serum bottle; thirdly, inoculating the sterilized seed culture medium into the sterilized serum bottle, introducing CO2, inoculating actinobacillus succinogenes NJ113, and performing shake cultivation to serve as a fermentation strain; fourthly, performing multistage continuous fermentation. As the production method is simple and the yield and purity of succinic acid are high, the method is suitable for industrialized production.

Owner:NANJING UNIV OF TECH

Method for producing high-performance white carbon black and succinic acid by comprehensively utilizing white spirit lees

The invention discloses a method for producing high-performance white carbon black and succinic acid by comprehensively utilizing white spirit lees, which comprises the following steps of: taking lees after fermenting white spirit as a raw material, and separating lees residues and rice husks after carrying out water washing; taking the lees residues for carrying out filter pressing, then carrying out airflow drying, pulverizing, sieving by a sieve with 80 to 100 meshes, fermenting by using actinobacillus succinogenes, carrying out filter pressing again, afterwards discoloring by active carbon and extracting so as to obtain succinic acid; and taking the rice husks after separating, burning, pulverizing the ashes of the rice husks, sieving by a sieve with 80 to 100 meshes, carrying out acid washing, filtering, carrying out alkali dissolving, leaching, adding a chelating agent for curing, aging, washing and carrying out spray drying so as to obtain high-performance white carbon black. According to the method for producing the high-performance white carbon black and the succinic acid by comprehensively utilizing the white spirit lees, industrial solid waste white spirit lees are taken as the raw material, high and new technologies, such as a biological fermenting technology and the like, and an advanced process for the full utilization and the zero discharge of products generatedin procedures are adopted in an integrated way, and products, such as the high-performance white carbon black, the succinic acid and the like, are developed. The method for producing the high-performance white carbon black and the succinic acid by comprehensively utilizing the white spirit lees has higher popularization value.

Owner:江苏谷硅新材料股份有限公司

Fermentation production method of succinic acid with whey

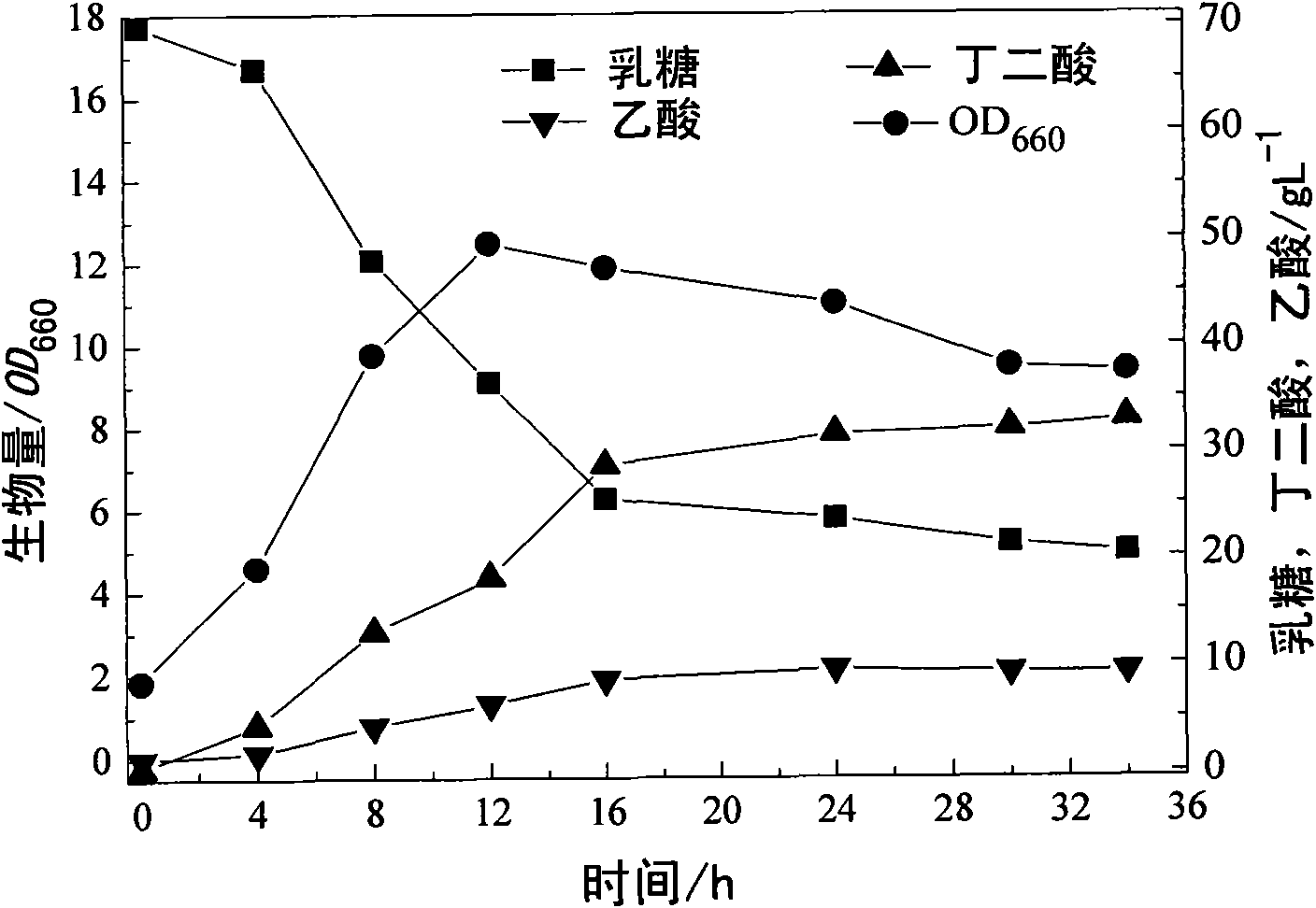

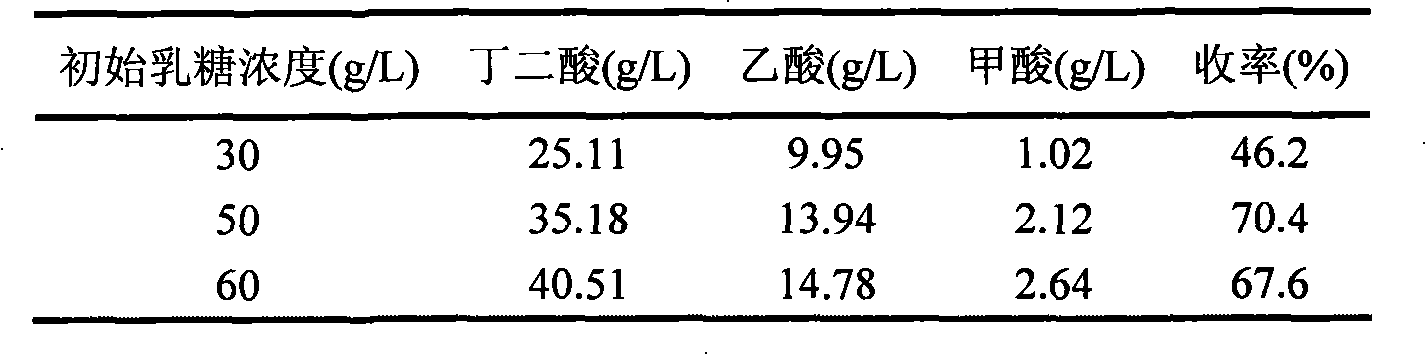

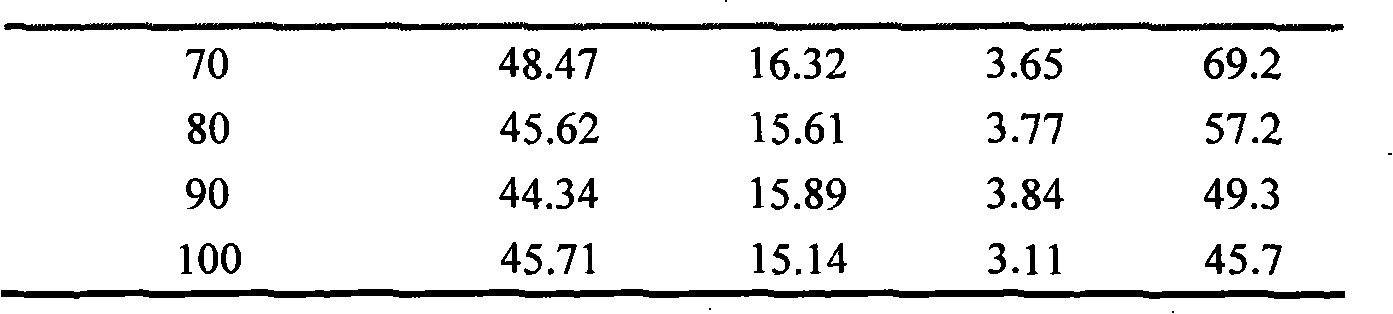

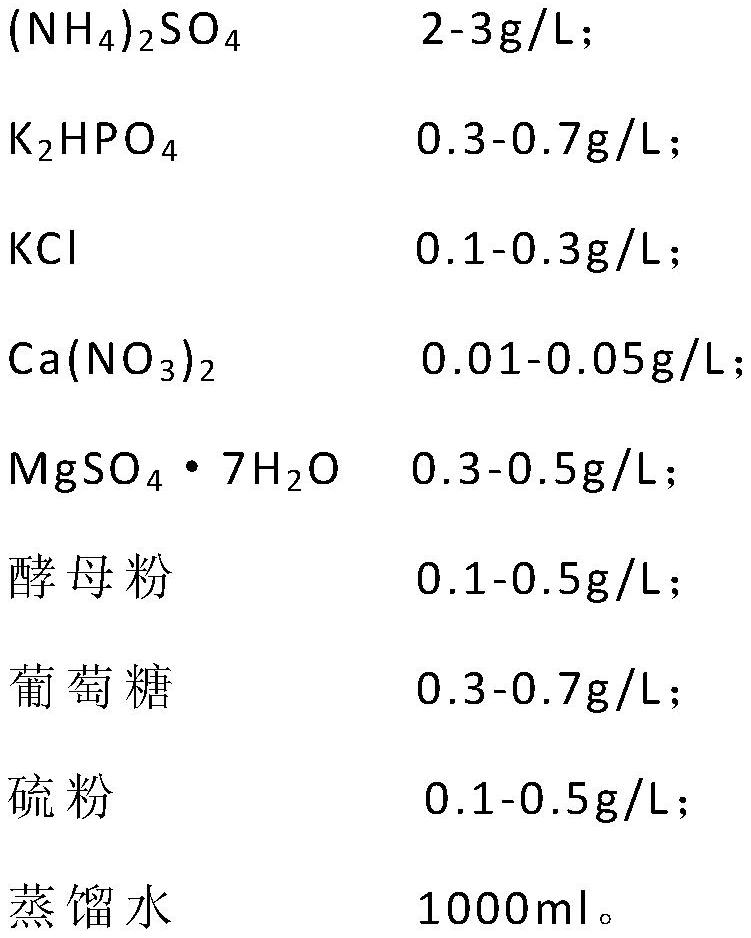

InactiveCN101857888AIncrease concentrationSuitable for industrial productionMicroorganism based processesFermentationChemical synthesisRumen

The invention relates to a fermentation production method of succinic acid with whey, which adopts the technical scheme that: actinobacillus succinogenes NJ113 is put in a culture medium of whey containing 30-100g / L of lactose to produce succinic acid by fermentation. The invention utilizes actinobacillus succinogenes selected from rumen which is suitable for fermenting whey raw material to produce the succinic acid, so that the consumption of a nitrogen source can be effectively reduced, the product concentration is up to 47.51g / L, and the yield is up to 67.9%; and the actinobacillus succinogenes is very suitable for industrial production of the succinic acid in low cost. The invention has outstanding advantages that: cheap whey raw material is utilized to produce the succinic acid by fermentation, and the whey as an cheap crude raw material can substitute glucose to be used as a carbon source to produce the succinic acid by fermentation; the method is a production method utilizing renewable raw materials, can alleviate the shortages of petroleum resources for chemical synthesis of the succinic acid, and is environmentally friendly; and the whey contains the nitrogen source and other nutrients which can be utilized by microorganisms, thereby obviously reducing the fermented culture medium components.

Owner:NANJING UNIV OF TECH

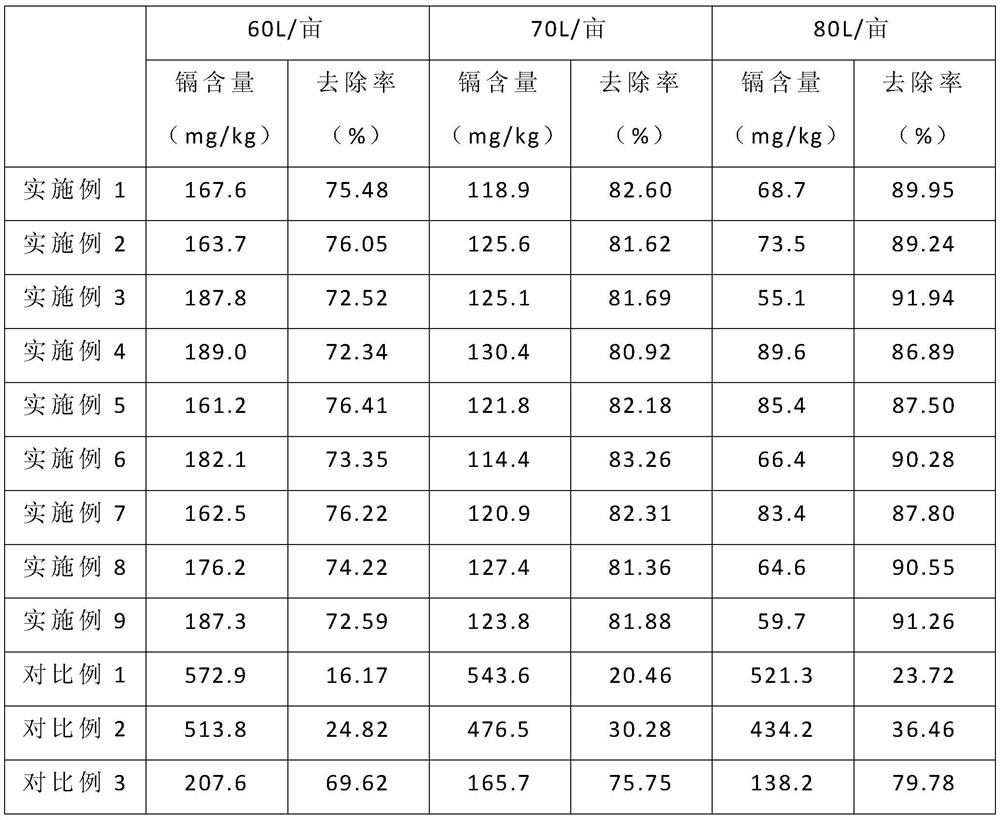

Complex microbial agent for efficiently converting heavy metal chromium in soil as well as preparation method and application thereof

PendingCN113265362AGood synergyImprove adaptabilityBacteriaContaminated soil reclamationThiobacillus ferrooxidansMicrobial agent

The invention belongs to the technical field of soil remediation, and particularly relates to a complex microbial agent for efficiently converting heavy metal chromium in soil as well as a preparation method and application thereof. The complex microbial agent is obtained by mixing and carrying out enrichment culture on the following two florae: a flora A consisting of bacillus, pediococcus acidilactici, clostridium coriolis, actinobacillus succinogenes and bacillus aceticus; a flora B consisting of acidophilic iron bacteria, thiobacillus ferrooxidans, acid-thiobacillus thiooxidans, sulfur-oxidizing acid-thiobacillus thiooxidans, sulfur-oxidizing bacteria and acidophilic thiobacillus ferrooxidans. After the complex microbial agent is used for treating the chromium-contaminated soil, the chromium removal rate can reach 91% or above. The complex microbial agent is formed by culturing and mixing a plurality of strains, and the strains have a good synergistic effect and do not generate antagonism; after compounding, the adaptability to heavy metals can be improved, so that the survival and removal effects of the soil in heavy metal contaminated soil are improved. The microbial agent is simple in preparation and application method, short in culture period and treatment period and low in cost, prevents secondary pollution, and has a wide application prospect.

Owner:CENT SOUTH UNIV +2

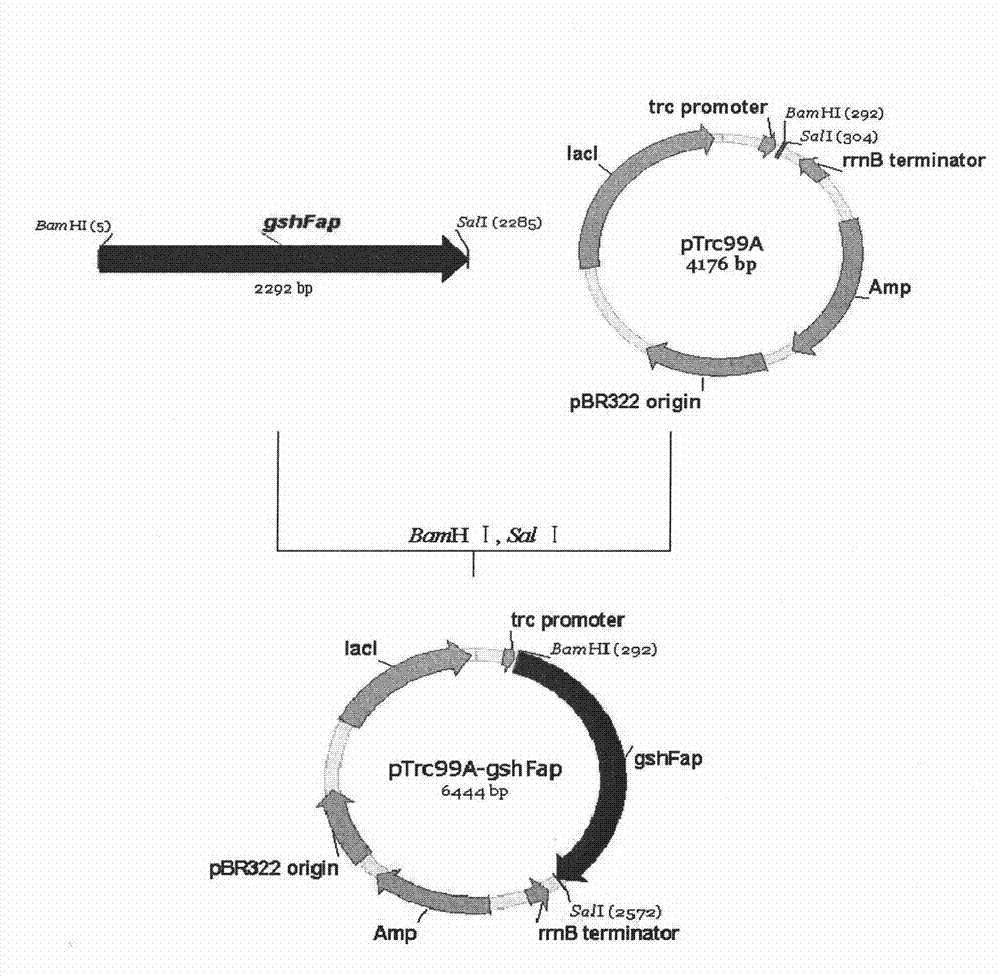

Actinobacillus succinogenes PZ improving yield of succinic acid, and construction method and application thereof

ActiveCN106995794AIncrease productionHigh activityBacteriaTransferasesMicrobiologyRate limiting enzyme

The invention provides an actinobacillus succinogenes PZ improving yield of succinic acid, and a construction method thereof. The construction method comprises the steps of constructing an expression carrier, constructing recombinant plasmid and constructing the actinobacillus succinogenes PZ. The actinobacillus succinogenes starting strain is connected in series with and expressed excessively by gene pepck of a key rate-limiting enzyme, PEPCK, for generating succinic acid by using the actinobacillus succinogenes, and gene zwf of G6PDH improving the restoring force level in a body, so as to acquire the actinobacillus succinogenes PZ. The actinobacillus succinogenes PZ can improve the yield of succinic acid, and has the potential of industrial production application.

Owner:GUANGXI ACAD OF SCI

Method for producing succinic acid by utilizing fermentation of actinobacillus succinogenes

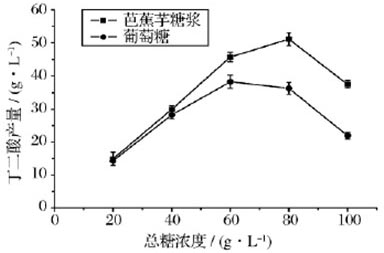

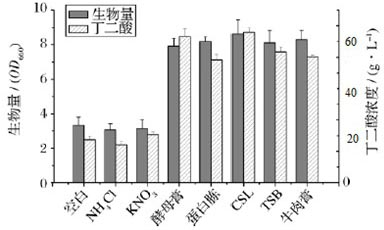

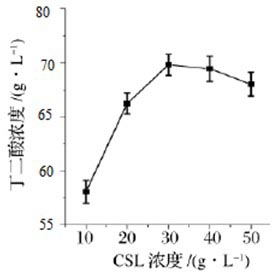

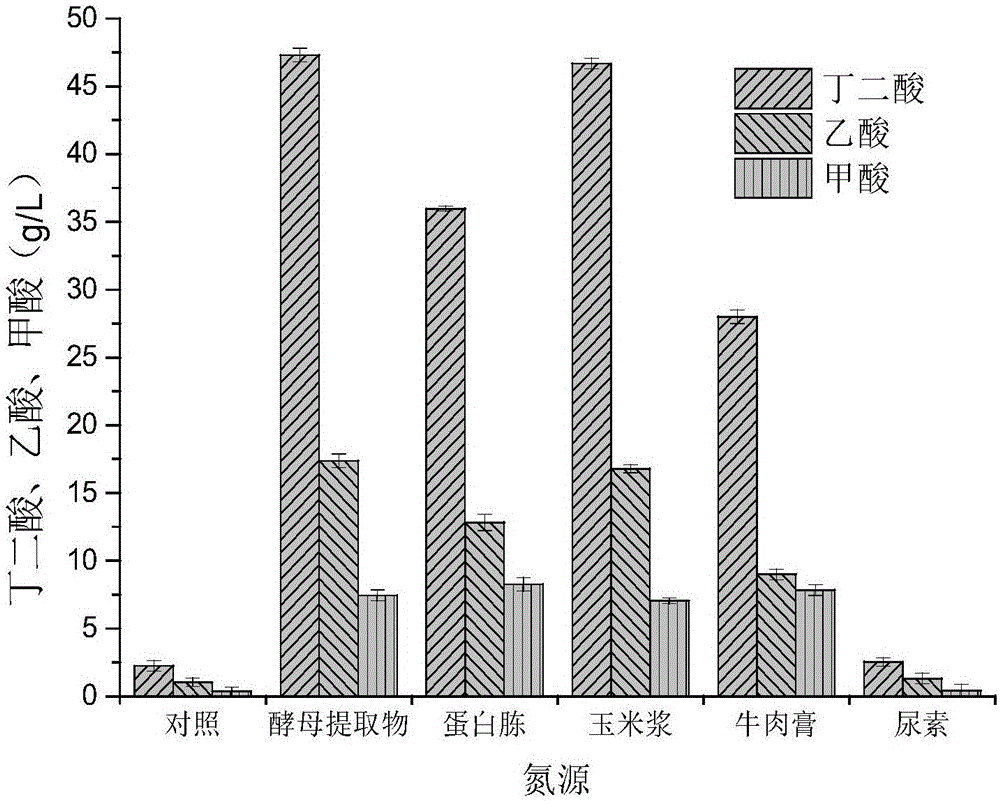

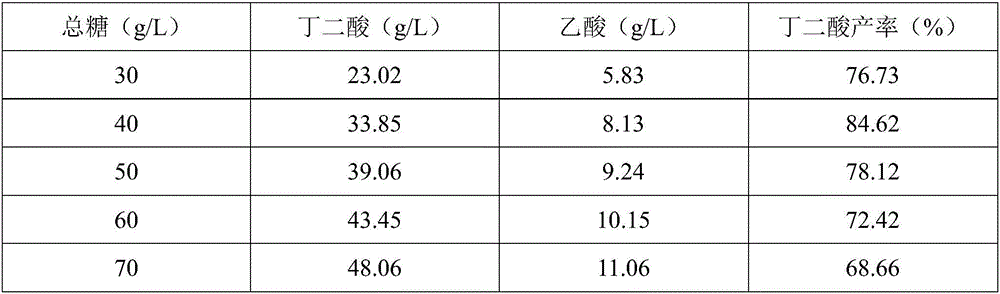

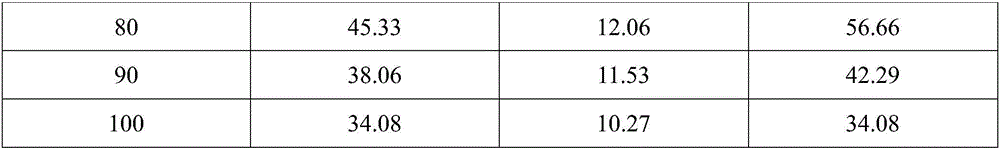

The invention provides a method for producing succinic acid by utilizing fermentation of actinobacillus succinogenes. The method includes taking canna edulis ker syrup as a main material, producing the succinic acid by using the fermentation of actinobacillus succinogenes CICC11014, determining the optical fermentation medium for bacterial strains through research for medium of bacterial strains; and fermenting the medium after optimization, wherein the medium comprises 89.66g / L of canna edulis ker syrup (by total suger), 38.55g / L of CSL, 2.23g / L of Na2HPO4*12(H2O), 2.23g / L of KH2PO4*3(H2O),60g / L of MgCO3, and 6.5 of the pH; and performing moist heat sterilization at a temperature of 115 DEG C for 20 minutes. The conversion rate of sugar can be improved through fermentation under the optical medium condition, so that the yield of the succinic acid can reach 70g / L.

Owner:苏州百趣食品有限公司

Strain and method for producing succinic acid by fermenting xylose mother liquor

ActiveCN106801026AEfficient resource utilizationSave foodBacteriaMicroorganism based processesHigh concentrationProduction rate

The invention discloses a strain and a method for producing succinic acid by fermenting xylose mother liquor. The strain is actinobacillus succinogenes PZ, and has a preservation number of CCTCC (China Center For Type Culture Collection) No: M2016396. The actinobacillus succinogenes can be used for producing the succinic acid by fermenting the high-concentration xylose mother liquor; the maximum yield of the succinic acid can reach 95g / L, and the maximum production rate of the succinic acid is 85%. The method provided by the invention is low in cost, high in yield and simple in technology, realizes the efficient resource utilization of the xylose mother liquor, and has great significance on resource optimization and environmental protection.

Owner:GUANGXI ACAD OF SCI

Method for producing succinic acid by multistage continuous fermentation

InactiveCN104372037AIncrease productionSimple methodMicroorganism based processesFermentationBiotechnologyContinuous fermentation

The invention relates to a method for producing succinic acid by multistage continuous fermentation, which comprises the following steps: 1. preparing a seed culture medium, an initial fermentation culture medium, a carbon source supplementation tank culture solution and a culture medium supplementation tank culture solution; 2. sterilizing the cascade fermentation tank set, carbon source supplementation tank, culture medium supplementation tank, seed culture medium, initial fermentation culture medium, carbon source supplementation tank culture solution, culture medium supplementation tank culture solution and serum bottle; 3. taking the sterilized serum bottle, inoculating the sterilized seed culture medium, introducing CO2, inoculating the Actinobacillus succinogenes NJ113-producing oscillating table, and culturing to obtain a fermentation strain; and 4. carrying out multistage continuous fermentation. The production method is simple, has the advantage of high yield and purity of succinic acid, and thus, is suitable for industrialized production.

Owner:NANJING TECH UNIV

Method for producing succinic acid by Canna edulis ker fermentation

ActiveCN101948879ALow priceAlleviate resource constraintsMicroorganism based processesFermentationMicroorganismRumen

The invention discloses a method for producing succinic acid by Canna edulis ker fermentation, belonging to the technical field of microbial fermentation. The invention utilizes Actinobacillus succinogenes CGMCC1593 screened from a beef rumen to ferment Canna edulis ker hydrolysed syrup or Canna edulis ker liquefied mash or a mixture of the Canna edulis ker hydrolysed syrup and one or more than one sugar raw material. The concentration of the product succinic acid reaches 40-66 g / L, the sugar yield is 70-90% (the sugar use ratio is 80-95%), and the production strength reaches 0.9-1.2 g / (L.hour), so that the invention is very suitable for the industrial production of low-cost succinic acid.

Owner:HANGZHOU XINFU TECH CO LTD

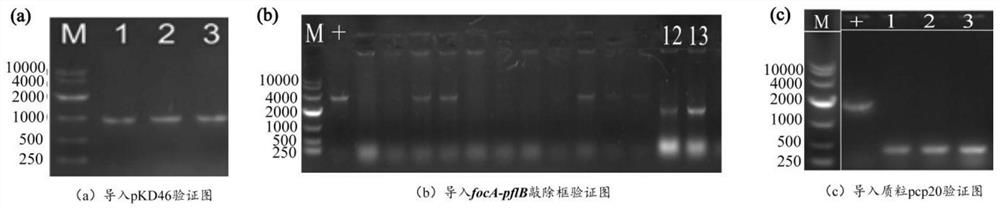

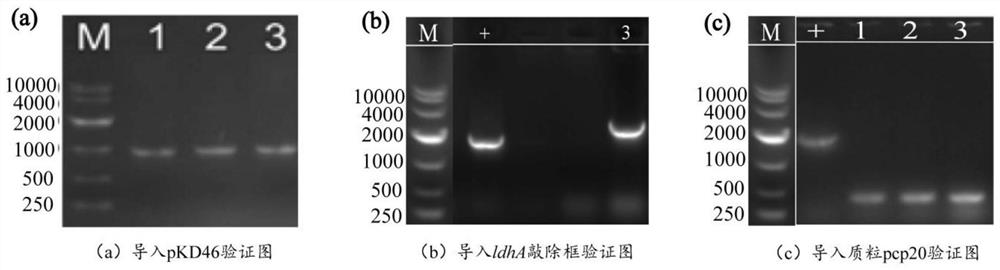

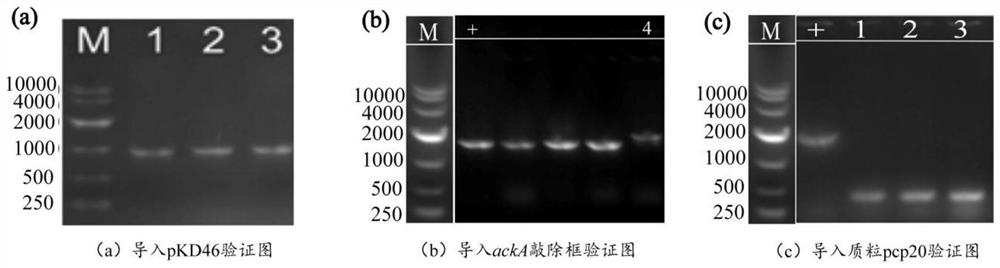

Recombinant escherichia coli for efficiently producing succinic acid and construction method thereof

ActiveCN112280725AReduce accumulationPromote accumulationBacteriaMicroorganism based processesEscherichia coliPhosphite dehydrogenase

The invention discloses recombinant escherichia coli for efficiently producing succinic acid and a construction method thereof, and belongs to the technical field of bioengineering. The method comprises the following steps: knocking out a by-product encoding gene of a succinic acid producing strain E.coli FMME-N-2 to obtain a strain E.coli FMME-N-5(delta foc A-pflB-delta ldhA-delta pta-ackA); performing overexpression from actinobacillus succinogenes phosphoenolpyruvate carboxykinase pck and bacillus stutzeri phosphite dehydrogenase ptxD; introducing the constructed plasmid pTrcHisA-pck-ptxD into an expression host E.coli FMME-N-5(delta foc A-pflB-delta ldhA-delta pta-ackA), and screening through an ampicillin resistance flat plate to obtain an engineering bacterium E.coli FMME-N-5(delta foc A-pflB-delta ldhA-delta pta-ackA)-pck-ptx-D for efficiently producing succinic acid. The engineering strain adopts a two-stage fermentation strategy on a 7.5 L fermentation tank, the fermentation time is 96h, the succinic acid yield reaches 137g / L, the succinic acid yield reaches 1g / g glucose, the production strength is 1.43 g / L / h, byproducts lactic acid and formic acid are not accumulated, acetic acid is 1-2g / L, and the engineering strain has certain industrial production potential.

Owner:JIANGNAN UNIV

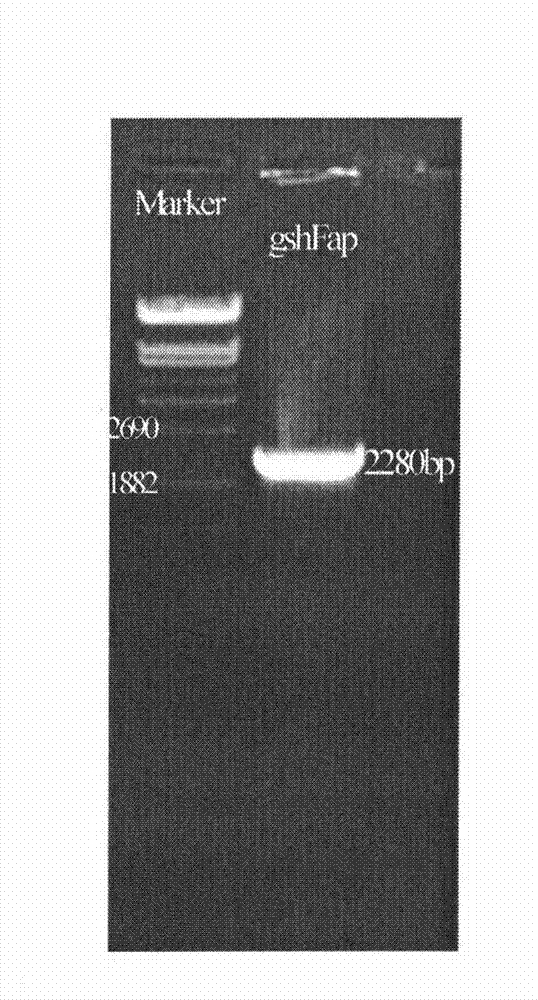

Bifunctional glutathione synthetase and method for producing glutathione by using same

InactiveCN102071171BIncrease production levelsMicroorganism based processesEnzymesHeterologousStreptococcus sanguinis

The invention discloses a method for producing glutathione by using bifunctional glutathione synthetase contained in actinobacillus pleuropneumonia, actinobacillus succinogenes, bacillus cereus, streptococcus sanguis, streptococcus gordonii, streptococcus uberis and streptococcus thermophilus. The method comprises heterologous expression by using the seven microbes or enzymes of the microbes in other microbes. The glutathione synthesized by using the method has the structure of natural glutathione, and has high response rate and high output and yield of the glutathione.

Owner:EAST CHINA UNIV OF SCI & TECH

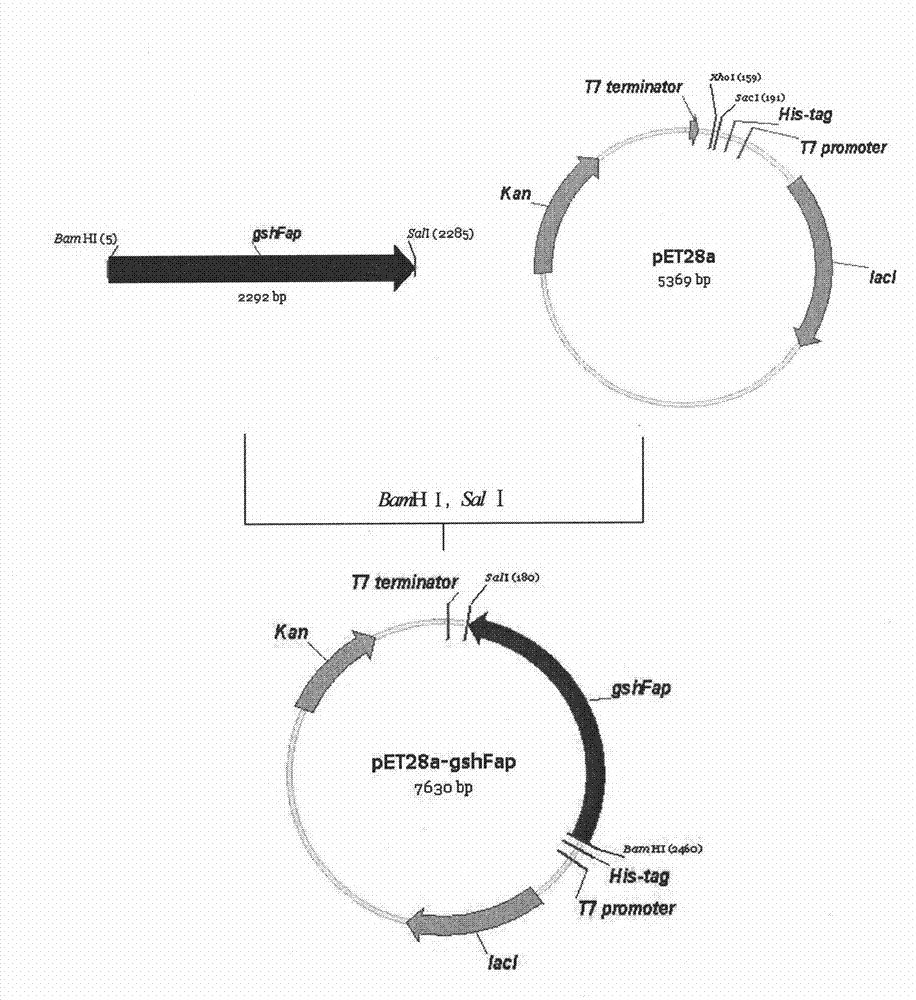

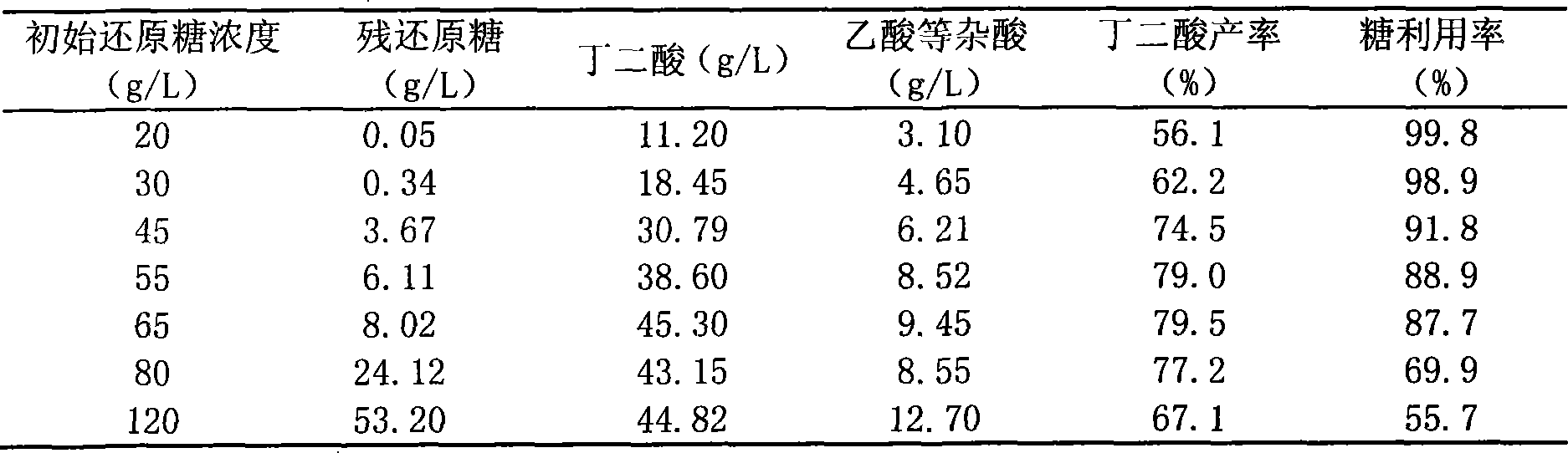

Method for producing butane diacid by fermenting sugar grass raw material

InactiveCN101603058AAlleviate Exploitation IssuesLow costBacteriaMicroorganism based processesFiberChemical synthesis

The invention provides a method for producing butane diacid by fermenting sugar grass raw material. The invention also provides an application of sugar grass raw material on preparing the butane diacid. Meanwhile, the invention also provides an application of actinobacillus succinogenes on preparing the butane diacid by using the sugar grass as raw material. The invention uses the actinobacillus succinogenes CGMCC1593 to ferment sugar grass juicing liquid glucose, or scum fiber hydrolytic syrup and sugar grass kernel hydrolytic syrup obtained by extracting juice from sugar grass straws which is hydrolyzed by enzyme or acid, or mixed syrup of the actinobacillus succinogenes and other carbonhydrate raw materials such as corn and the like, wherein the concentration of prepared butane diacid reaches 30-68g / L, the yield of the sugar is 80-90 percent (utilization rate of the sugar is 90-95 percent), and the production strength reaches 0.9-1.2g / (L / h). The method is environmental-friendly by using cheap and reproducible raw materials, and can release the petrifaction resources shortage problem of the chemical synthesized butane diacid.

Owner:YIFAN XINFU PHARMA CO LTD

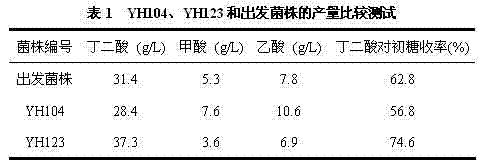

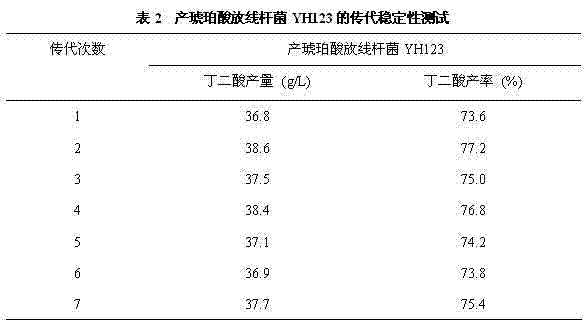

Actinobacillus succinogenes strain YH123 and application thereof

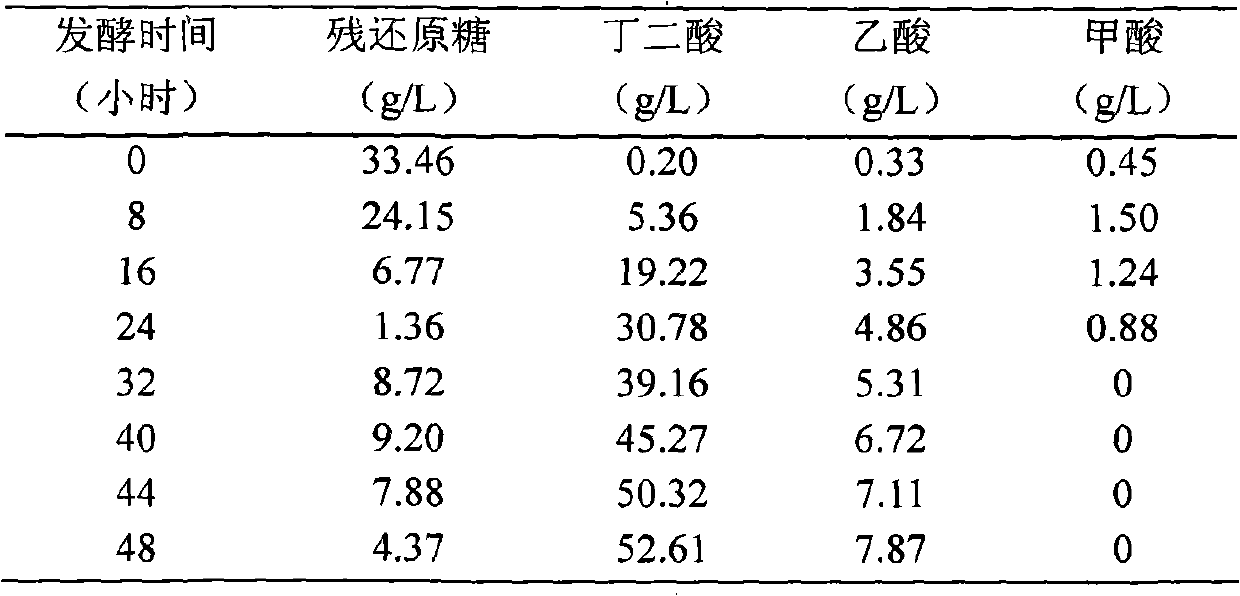

InactiveCN102732449AImprove conversion rateIncrease productionBacteriaMicroorganism based processesBiotechnologyButanedioic acid

The invention relates to an actinobacillus succinogenes strain YH123 with a collection number of CCTCC NO: M2012072. The invention also relates to the application of the actinobacillus succinogenes strain YH123 in the fermentation production of succinic acid. The strain can highly efficiently employ different carbon sources in fermentation productions of succinic acid, and the conversion rate of saccharide is high. When glucose is adopted as a carbon source, in a fermentation tank with a volume of 3L, the output and yield of succinic acid respectively reaches 33.2g / L and 66.7%, which are respectively improved by 18.2% and 10.3% than those of start bacteria.

Owner:NANJING UNIV OF TECH

Method for producing succinic acid by means of fermentation

ActiveCN105567748AThe method is simpleThe fermentation method is simpleBacteriaMicroorganism based processesButanedioic acidEconomic benefits

The invention discloses a method for producing succinic acid by means of fermentation. The method includes steps of constructing acid-producing bacterial strains; producing the succinic acid from the recombinant bacterial strains by means of fermentation. Original bacterial strains for constructing the recombinant bacterial strains are actinobacillus succinogenes NJ113 (with a preservation number of CGMCC No.1716). The method for producing the succinic acid has the advantages that processes for acquiring the acid-producing bacterial strains are simple and convenient, fermentation processes are simple and feasible, the method is high in acid-producing capacity, the production cost can be greatly reduced, and economic benefits can be increased; the recombinant bacterial strains can grow in synthetic culture media without culture media with added exogenous glutamic acid and are high in succinic acid yield; the 19.53 g / L succinic acid can be produced after 27 g / L glucose which is used as a carbon source is fermented in an anaerobic serum bottle for 72 h, and the succinic acid yield can reach 72.33%.

Owner:态创生物科技(广州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com