Method for producing succinic acid by means of fermentation

A technology of succinic acid and anaerobic fermentation, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of difficult cultivation of bacterial strains and low acid production capacity, and achieve simple and convenient methods and high acid production capacity Strong, simple and feasible fermentation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

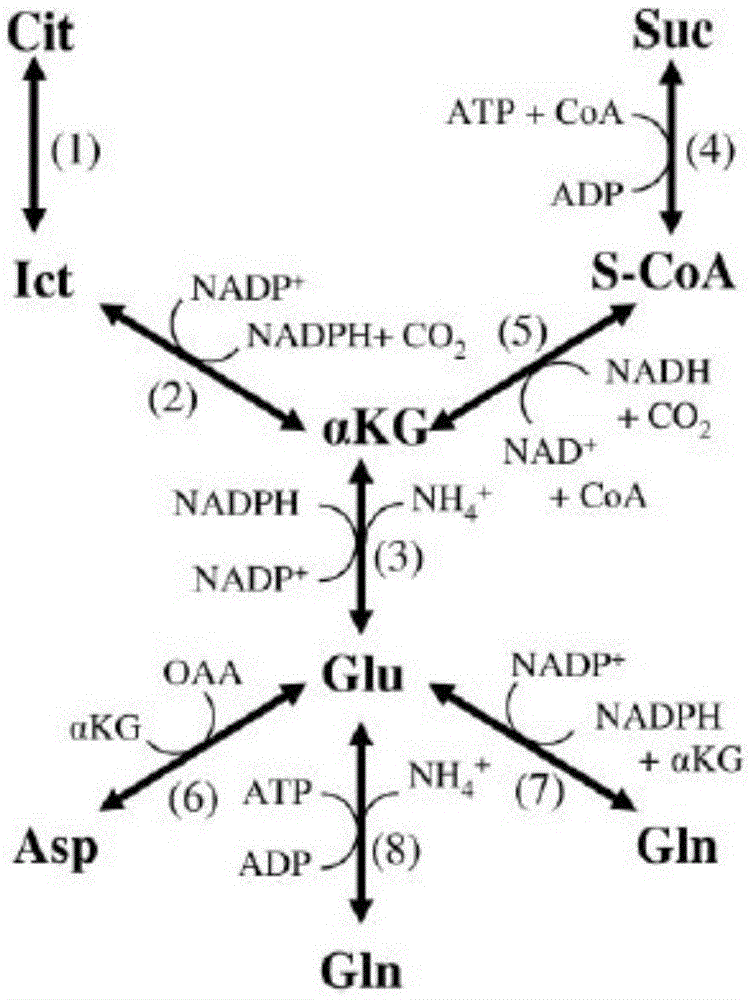

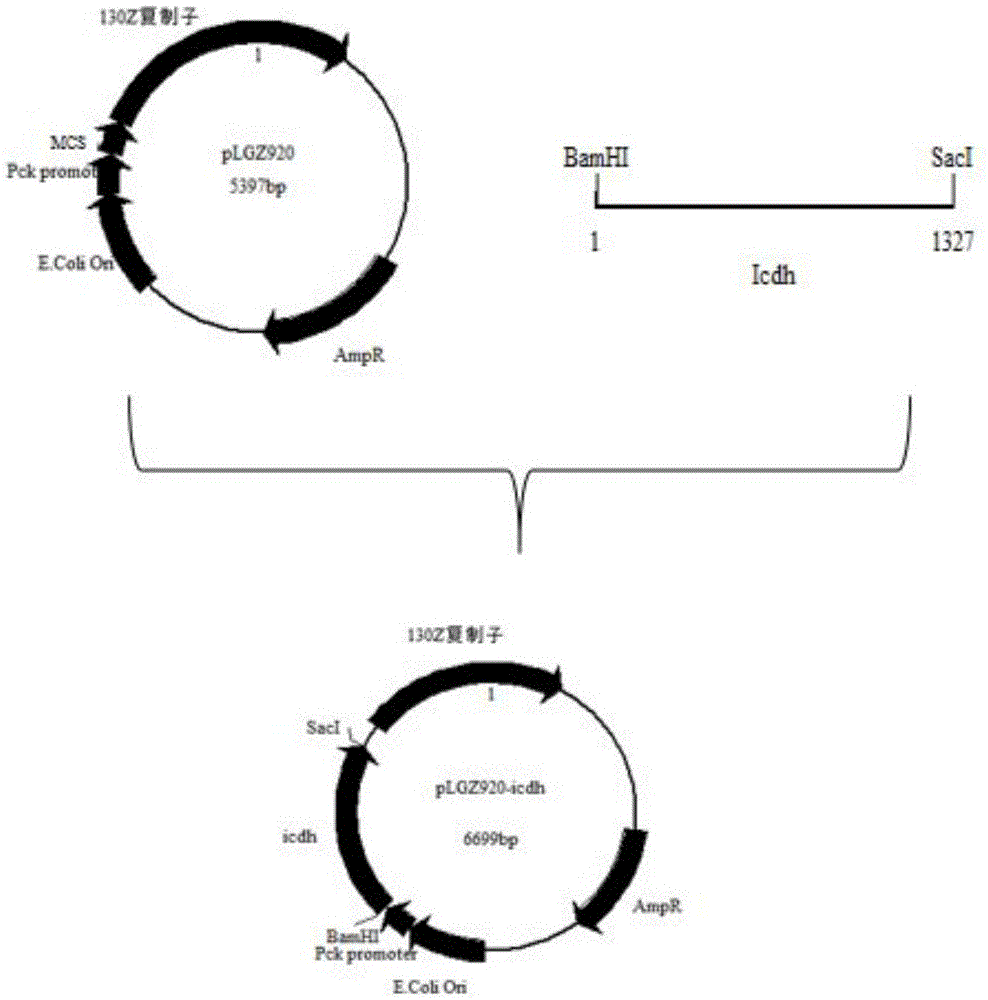

[0030] This example illustrates the method of constructing an expression plasmid co-expressing isocitrate dehydrogenase to obtain a recombinant strain producing succinic acid.

[0031] Construct pLGZ920-icdh plasmid (such as figure 2 ), its process comprises: (1) synthesis has the primer of SacI and BamHI restriction site:

[0032] Upstream primer: 5'-CGGGATCCCAAACCAGTAGCGCTCGAAGGAGAG-3';

[0033] Downstream primer: 5'-CGAGCTCCGCCCGTTGCAATATTAAACACATG-3';

[0034] (2) Using E.coliBL21 genomic DNA as a template, PCR amplifies the target gene fragment. The reaction conditions are: 94°C, 10min; (94°C for 45s, 62°C for 45s, 72°C for 80s, 35 cycles); 72°C, 10min .

[0035] After purifying the amplified icdh gene (such as Figure 4 ), the expression plasmid pLGZ920 was digested with SacI and BamHI, and connected to obtain the recombinant plasmid pLGZ920-icdh (such as Figure 6 ).

Embodiment 2

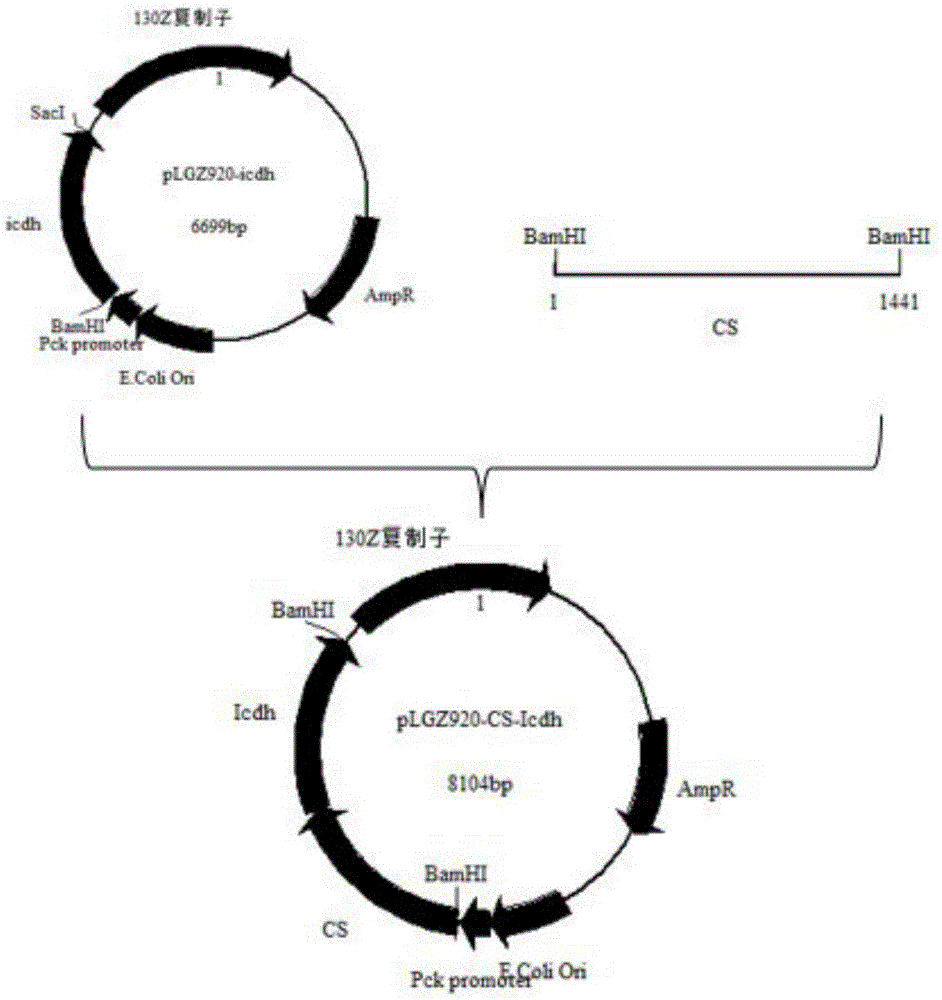

[0037] This example illustrates the construction of an expression plasmid that co-expresses isocitrate dehydrogenase and citrate synthase, restores the ability of wild-type Actinobacillus succinogenes to synthesize glutamate in a synthetic medium, and obtains a recombinant strain that produces butyrate Methods.

[0038] 1. Construct the expression plasmid (such as image 3 ), the process includes:

[0039] (1) Synthesize primers for homologous recombination of one-step cloning with BamHI restriction sites both upstream and downstream,

[0040] Upstream primers:

[0041] 5'-ATGAGGTGATCTAGAGGATCCCAGGTTGATGTGCGAAGGC-3';

[0042] Downstream primers:

[0043] 5'-GCGCTACTGGTTTGGGATCCTCTATTAAAGGCGGGTCCGGAAAG-3';

[0044] (2) Using Escherichia coli E.coliBL21 genomic DNA as a template, PCR amplifies the target fragment, and the reaction conditions are: 94°C, 10min; (94°C for 45s, 55°C for 45s, 72°C for 100s, 35 cycles); 72°C, 10min. Purify the amplified cs (eg Figure 5 ) gene, ...

Embodiment 3

[0047] This example illustrates the comparison of sugar consumption and acid production ability of the overexpressed newly constructed recombinant Actinobacillus succinogenes BD106 and the starting strain NJ113 without adding glutamic acid in the synthetic medium.

[0048] When Actinobacillus succinogenes NJ113 was introduced into the plasmid pLGZ920-icdh-cs, the co-expression of isocitrate dehydrogenase and citrate synthase restored its ability to synthesize glutamate in synthetic medium.

[0049] Seed culture: activate Actinobacillus succinogenes BD106 on a plate, and cultivate overnight in an anaerobic box at 37°C. The activated strains on the plate were inserted into serum bottles, and cultured at 37°C and 200r / min for 12 hours as the primary seeds. Put the primary seeds into the serum bottle with 6% inoculum amount, and cultivate them at 37° C. and 200 r / min for 12 hours as the secondary seeds. The seed medium in the serum bottle was fed with CO 2 2min, culture temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com