Vanadium selenide/carbon-based composite material, preparation method of material, and negative electrode of lithium ion battery

A technology of carbon-based composite materials and lithium-ion batteries, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of less research and achieve the effects of uniform distribution, high rate, and high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

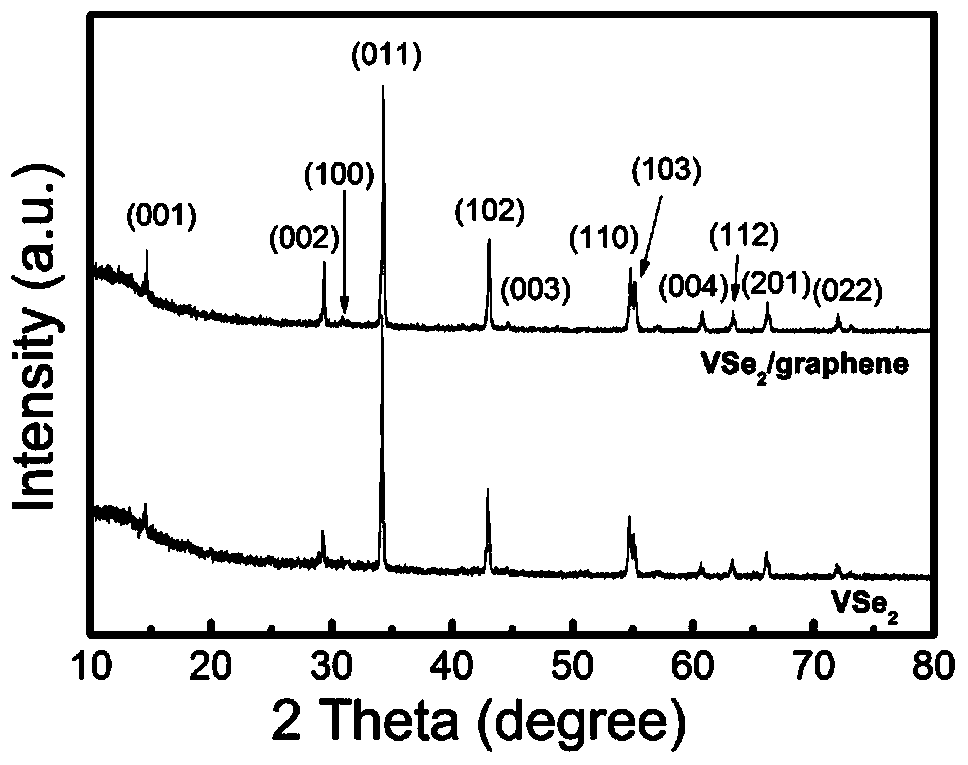

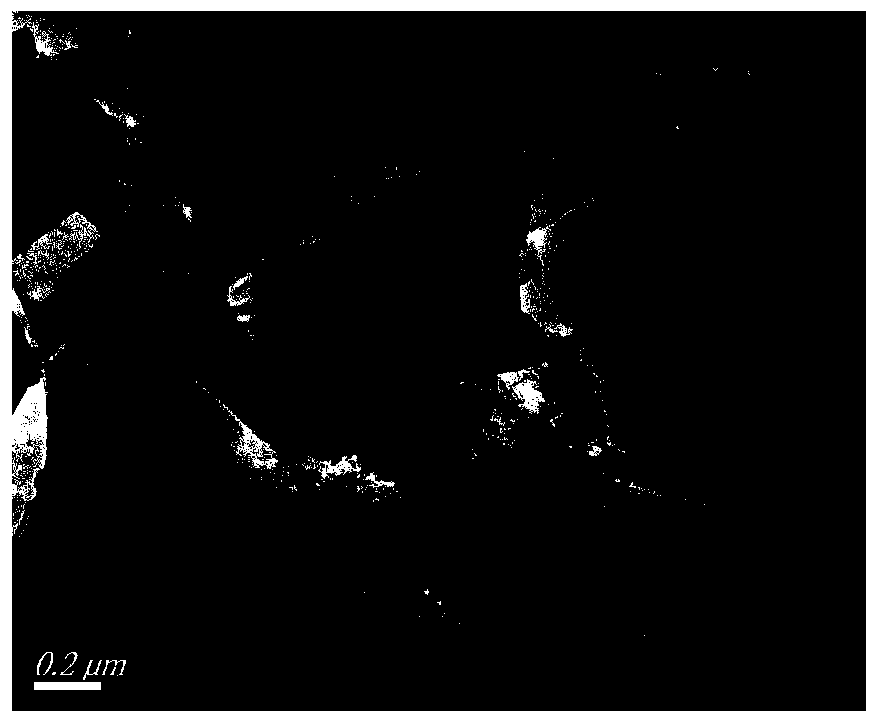

[0037] Weigh NH according to molar ratio (1~2):(1~2):(1~2) 4 VO 3 , SeO 2 and a formic acid reducing agent, and then dissolved in distilled water to form a solution with a vanadium ion concentration of 0.01mol / L-0.1mol / L, adding graphene oxide as a carbon source, and controlling the carbon content of the final product to be 3-10wt%. Transfer the mixture to a 20-100 ml autoclave, heat at 100-220°C for 10-72 hours, cool naturally to obtain a black product, centrifuge, wash, and vacuum-dry at 50-120°C to obtain vanadium diselenide / graphene composites. The resulting product was analyzed by X-ray diffraction to obtain figure 1 The XRD pattern shown shows that it is hexagonal VSe 2 Phase, and fully consistent with the no.89-1641 standard card without any other miscellaneous phase. pass figure 2 The shown SEM figure shows that the product is a plate-shaped particle, and further passed image 3 The TEM image shown shows plate-like particles deposited on graphene sheets. Sin...

Embodiment 2

[0040] Graphene in embodiment 1 is replaced by porous conductive carbon black Ketjenblack EC600JD, others are like embodiment 1, under 100 milliamperes / gram current density, the first three weeks charge and discharge test results are as follows Figure 7 shown. The charge and discharge capacities in the first three weeks were 384 / 586, 388 / 435, and 382 / 416 mAh / g, respectively.

Embodiment 3

[0042] Graphene in embodiment 1 is replaced by microporous superconducting carbon black BP2000, and others are as embodiment 1, and under 100 milliamps / gram current density, the first three weeks charge and discharge test results are as follows Figure 8 shown. The charge and discharge capacities in the first three weeks were 480 / 794, 479 / 540, and 471 / 509 mAh / g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com