Patents

Literature

70results about How to "Improve particle distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese-included multi-element metal oxide, lithium ion secondary battery anode material and its preparing method

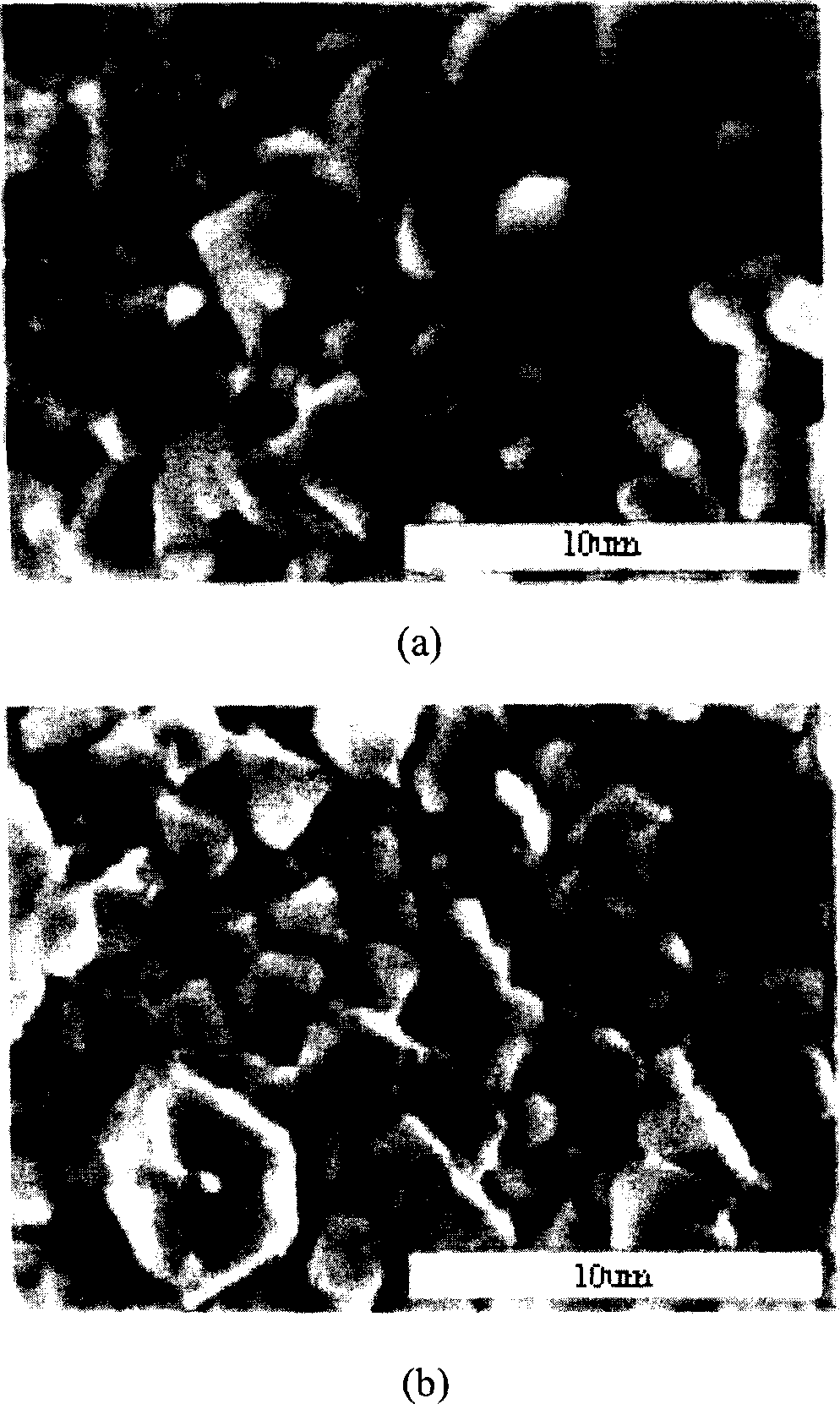

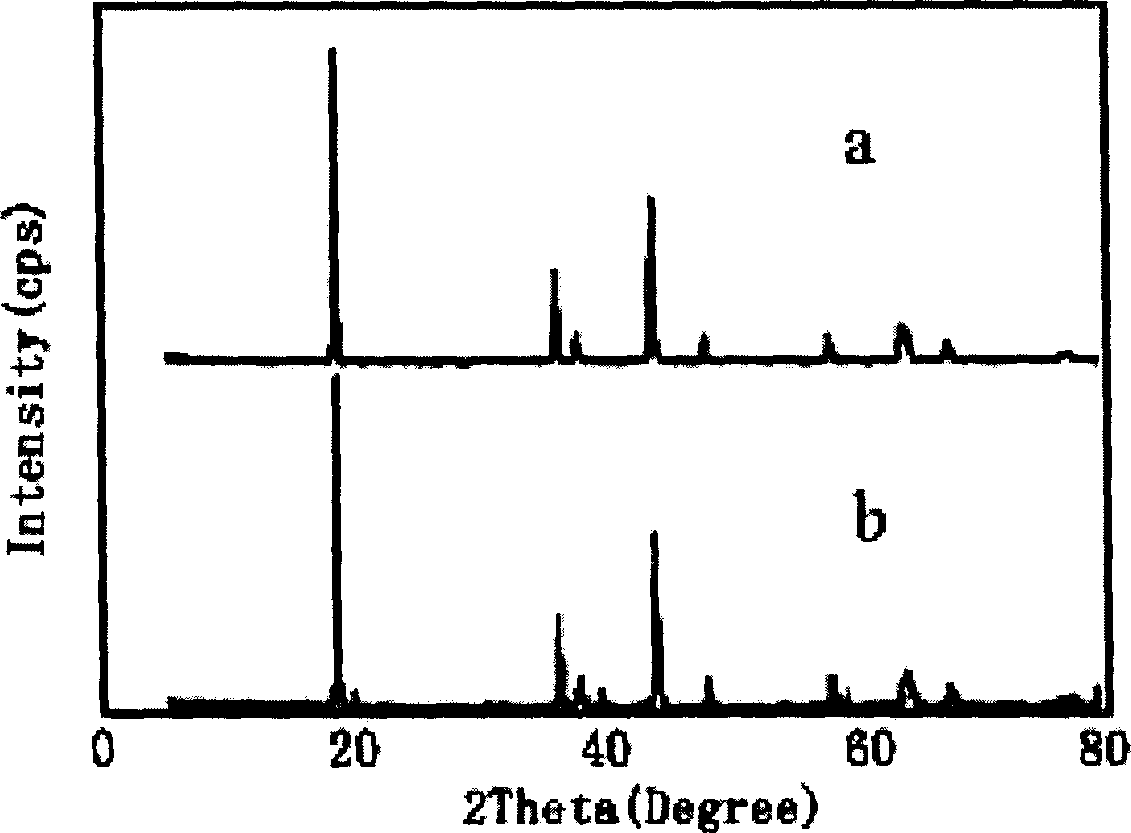

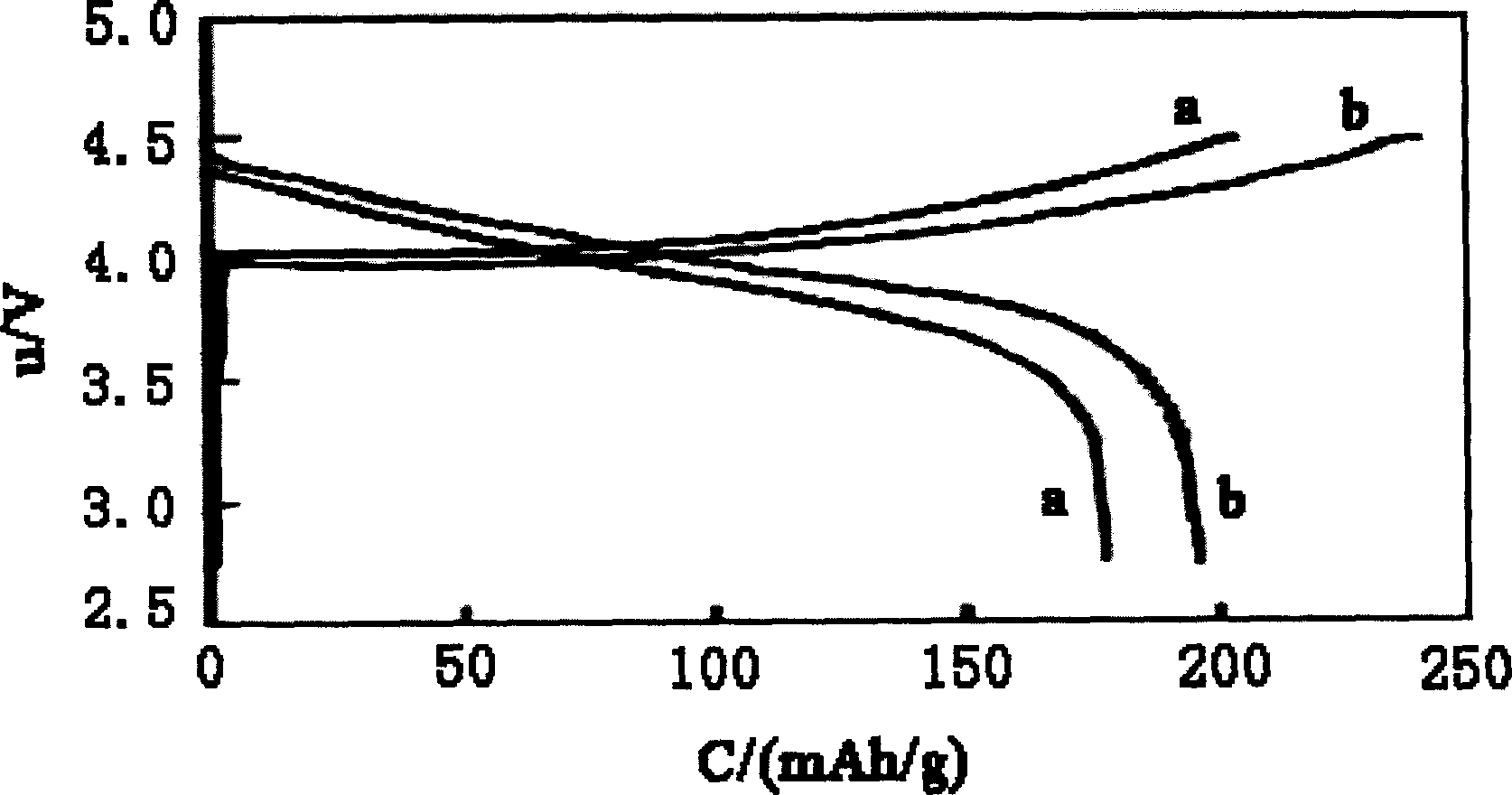

ActiveCN1770513AImprove cycle performanceUniform particle sizeCell electrodesSecondary cellsNickel saltLithium hydroxide

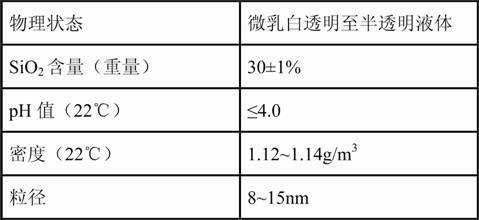

This invention relates to one multi-element metal oxidation and discloses The process method, which comprises the following steps: a, in nitrogen or inertance gas depositing the mixture of cobalt salt, nickel salt and maganism salt to generate Ni-Co-Mn compound hydrogen oxidation to process front drive after drying and grinding; b, adding lithium hydrate into the front drive grinding and processing mixture to remove absorbed water and structure water; c, processing products under degrees of 650 to 850 degrees; d, using high polymer as assistant agent to process surface covering on product; e, processing the product to remove solvent to process multi-metal oxidation.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

Lithium-based concrete sealing solidifying agent

The invention discloses a lithium-based concrete sealing solidifying agent. The lithium-based concrete sealing solidifying agent comprises the following components in percentage by weight: 50.0-90.0 percent of lithium silicate sol, 0.01-1.0 percent of wetting and dispersing agent, 0.01-1.0 percent of defoaming agent, 0.01-1.0 percent of permeability-resistant agent, 0.0-10.0 percent of stabilizing agent, 0.0-1.0 percent of accelerating agent and the balance of water. The lithium-based concrete sealing solidifying agent can produce C-S-H gel through the effective permeability and the hydration reaction with dissociative calcium ions in concrete to seal capillary pores in the concrete, so that the permeability resistance, the wear resistance, the hardness and other performance of the concrete can be improved.

Owner:SHANGHAI SUNRISE CHEMISTRY CO LTD

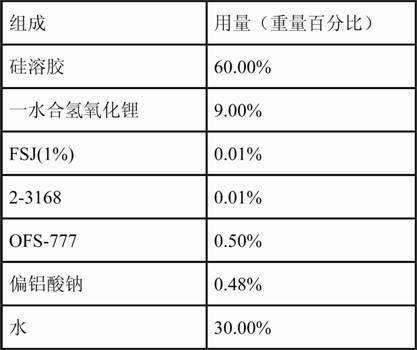

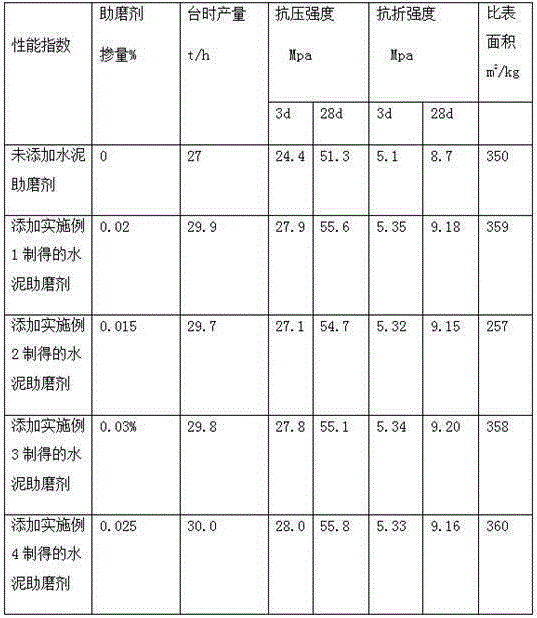

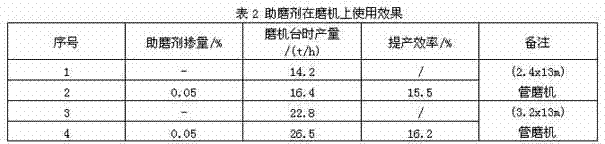

Cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

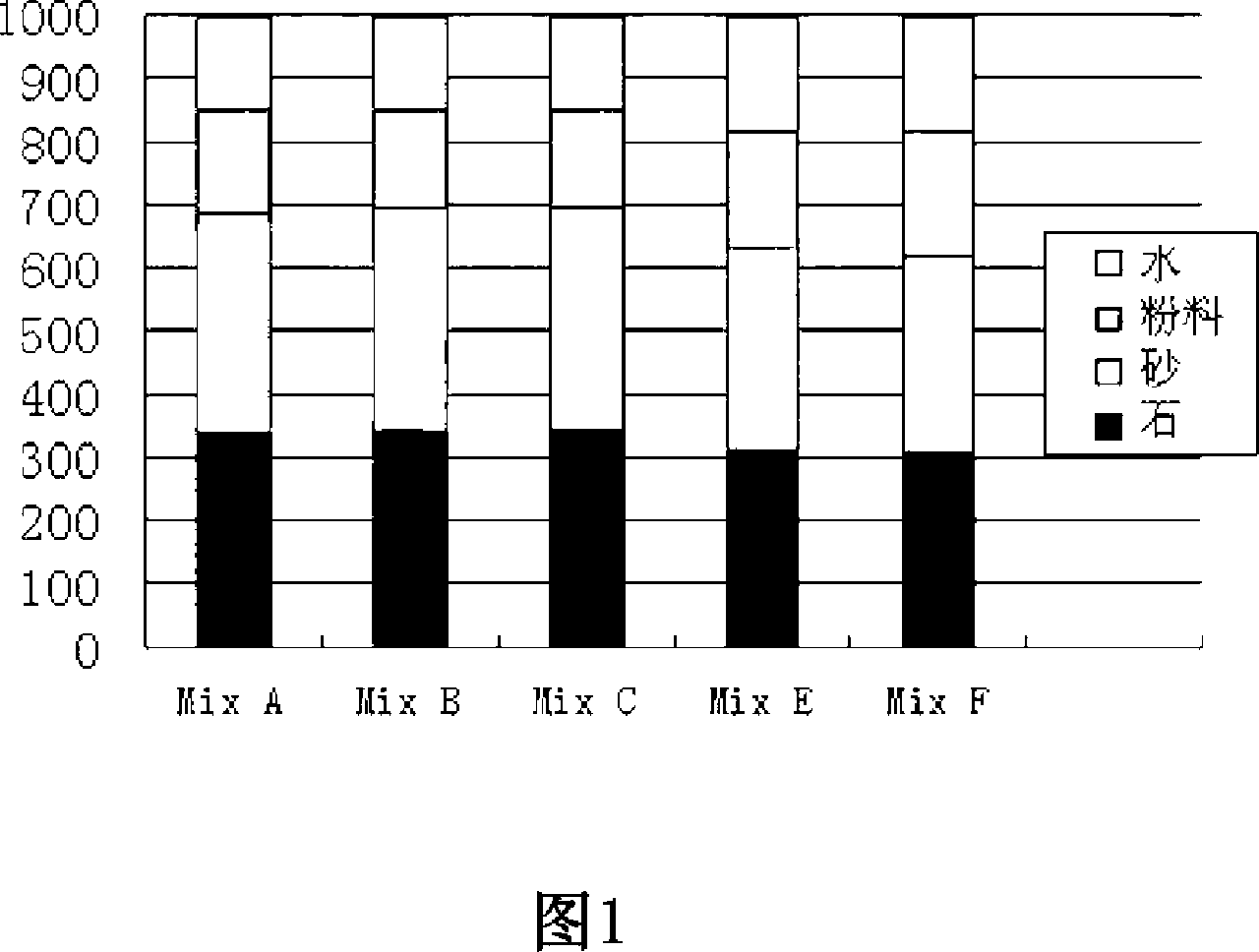

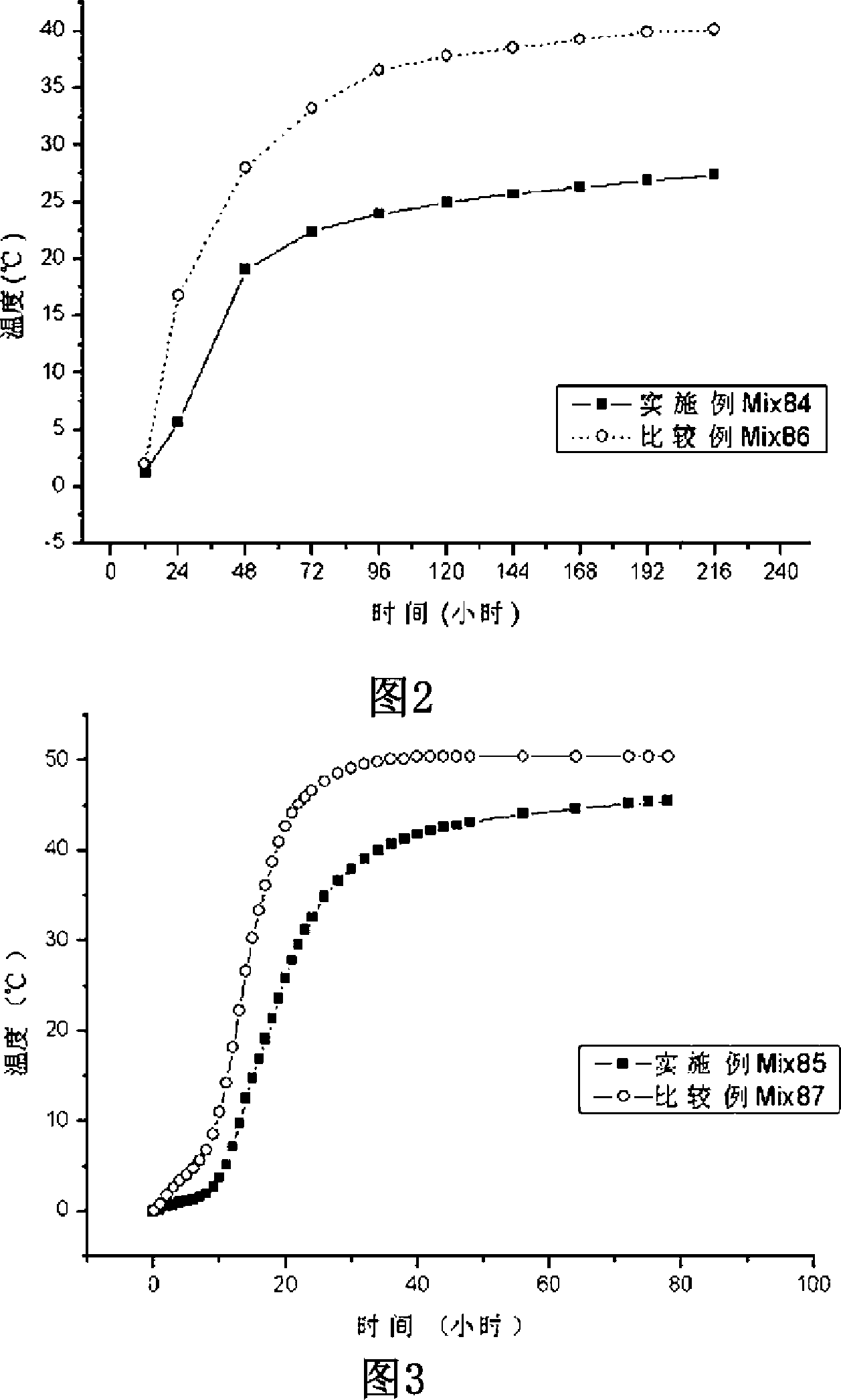

Concrete composition containing ultra-fine carbonate rock powder and preparation method thereof

The invention discloses a concrete composition with hyperfine carbonate rock powder and allocating method, which comprises the following parts: polyvalent powder, additive, rough aggregate, fine aggregate and water, wherein the scale of polyvalent powder in per cubic meter concrete is 300kg / m3-550kg / m3, which contains 70kg / m3-150kg / m3 hyperfine carbonate rock powder, 20%-100% cement and mineral material.

Owner:北京恒坤混凝土有限公司 +2

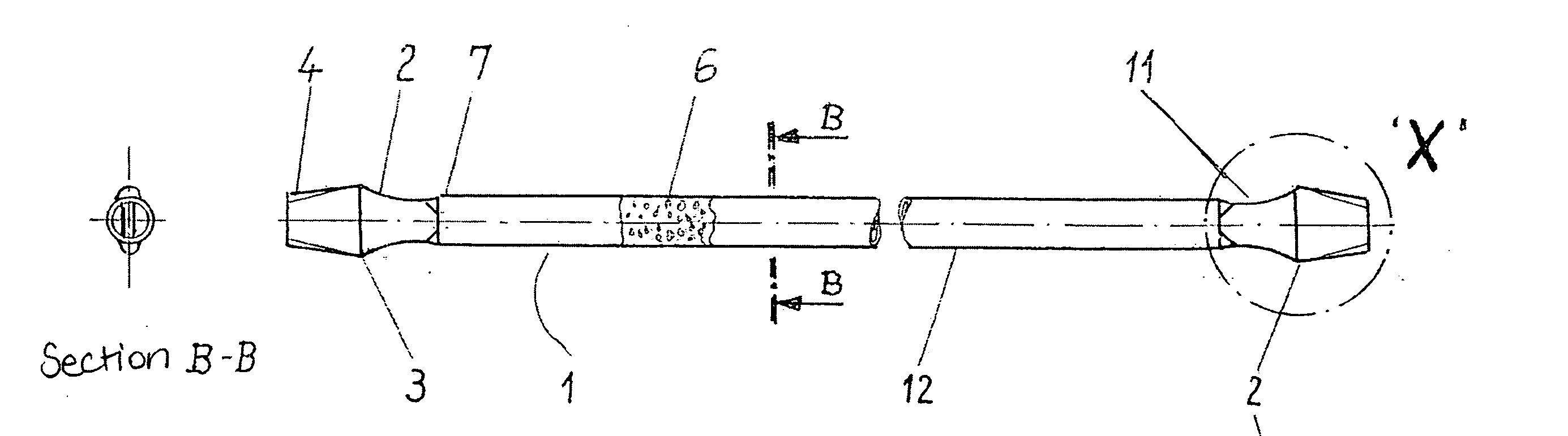

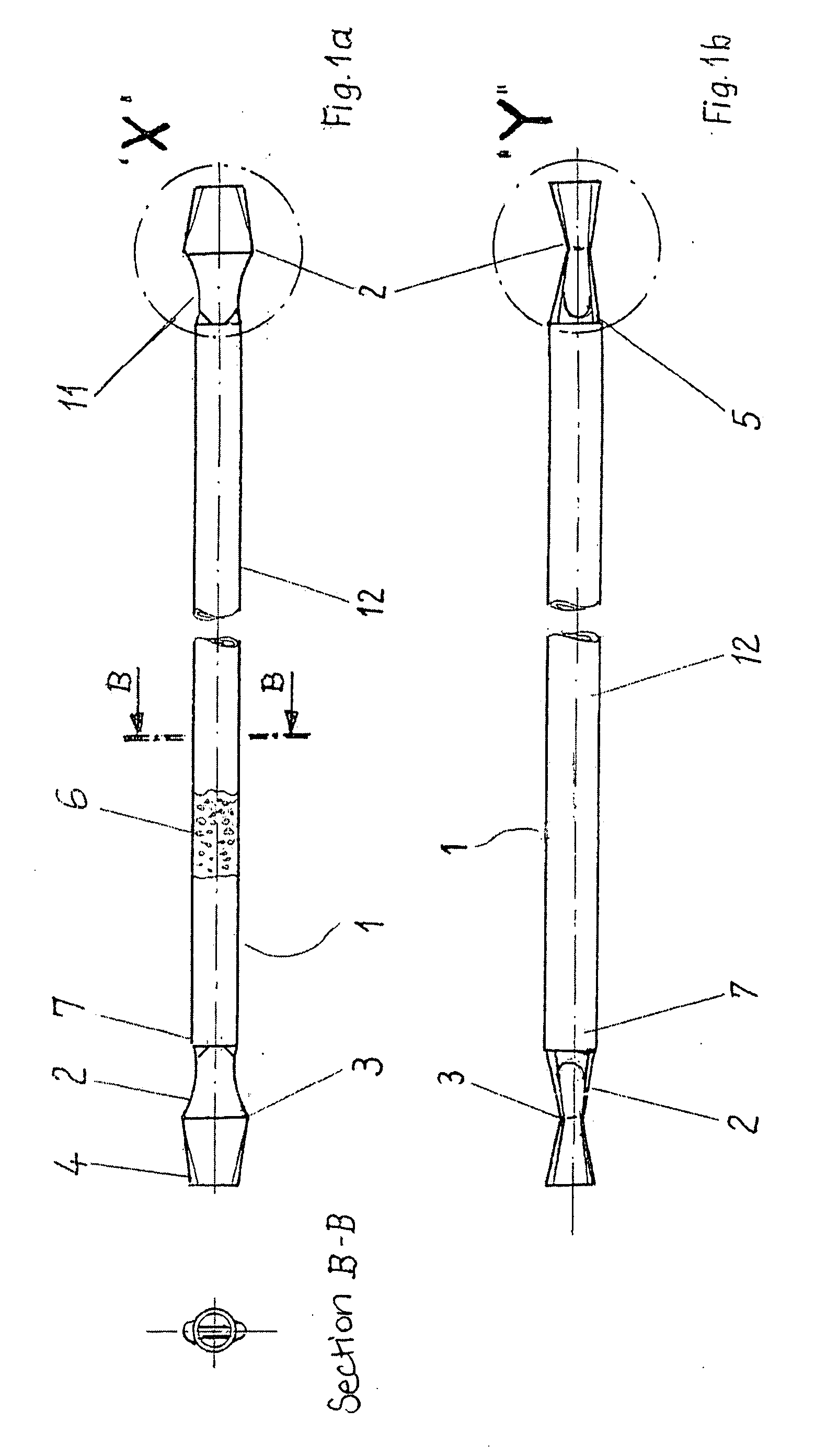

Drinking Straw

InactiveUS20080197141A1Long storageGreat stabilityDrinking vesselsTablewaresDrinking strawEngineering

The invention relates to a drinking straw which is sealed and / or re-sealable at the ends and which can serve as a supply container for a dry food product or which can comprise multiple parts, and to its use.

Owner:FELFOLDI EDESSEGGYARTO

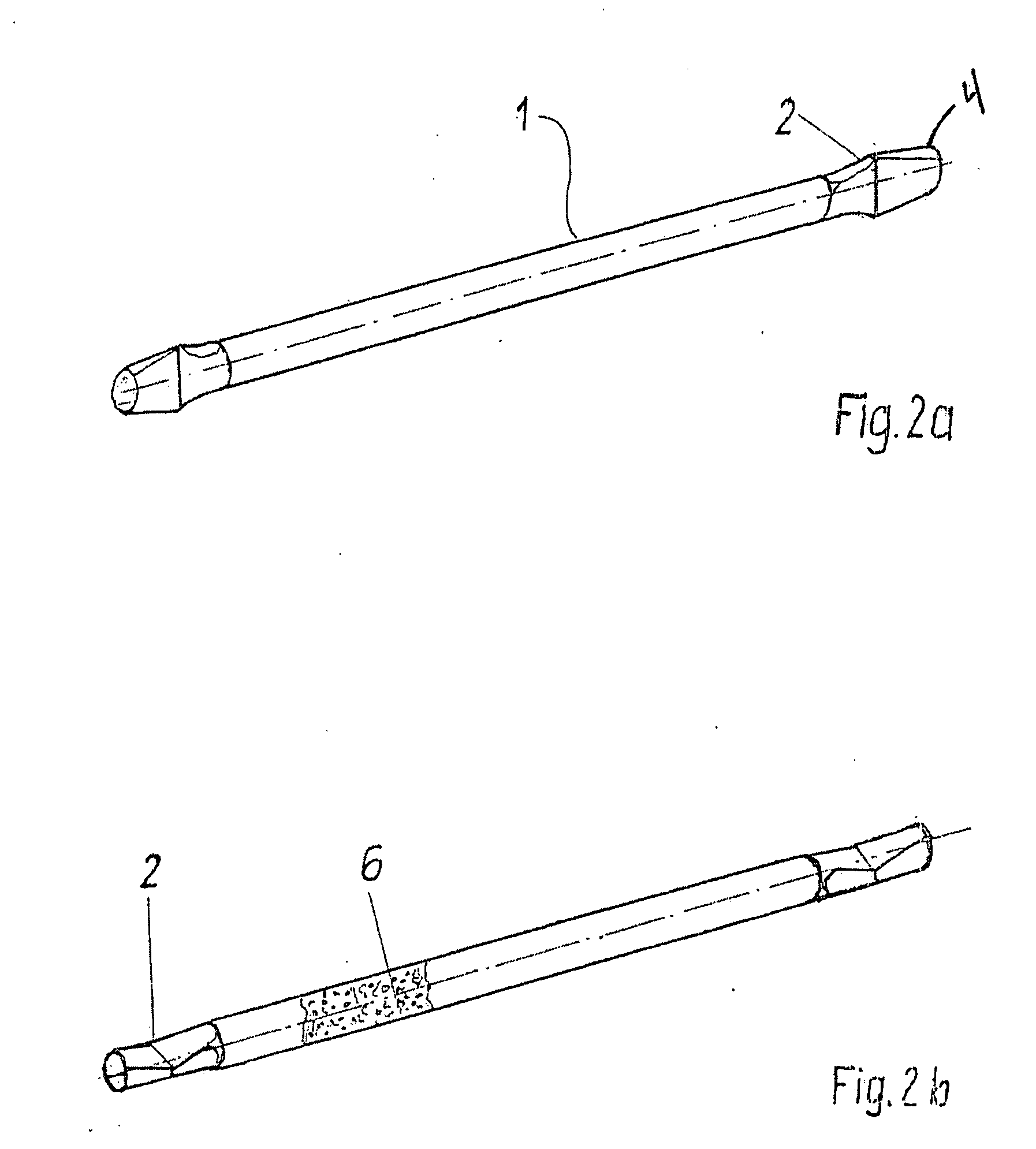

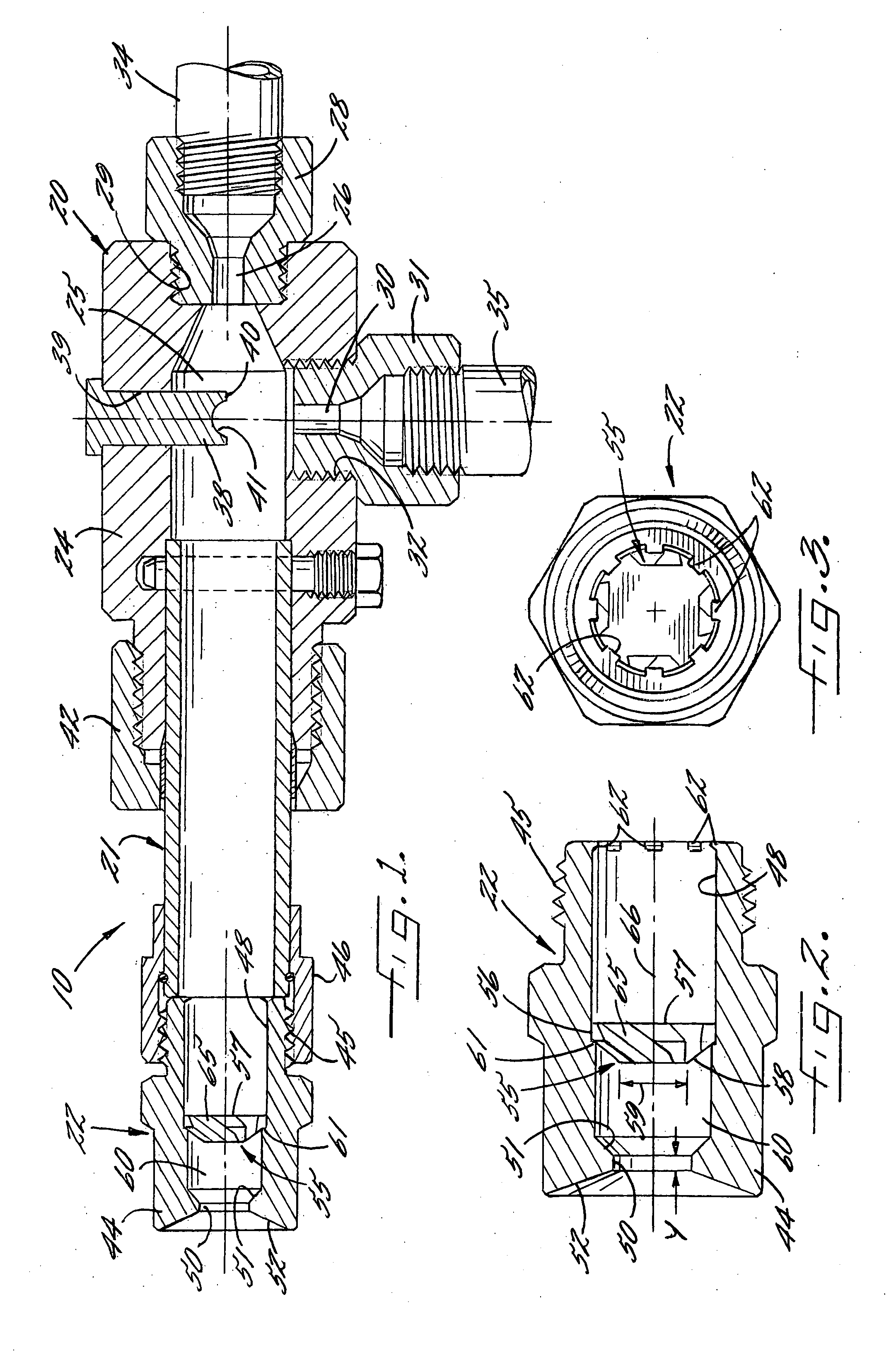

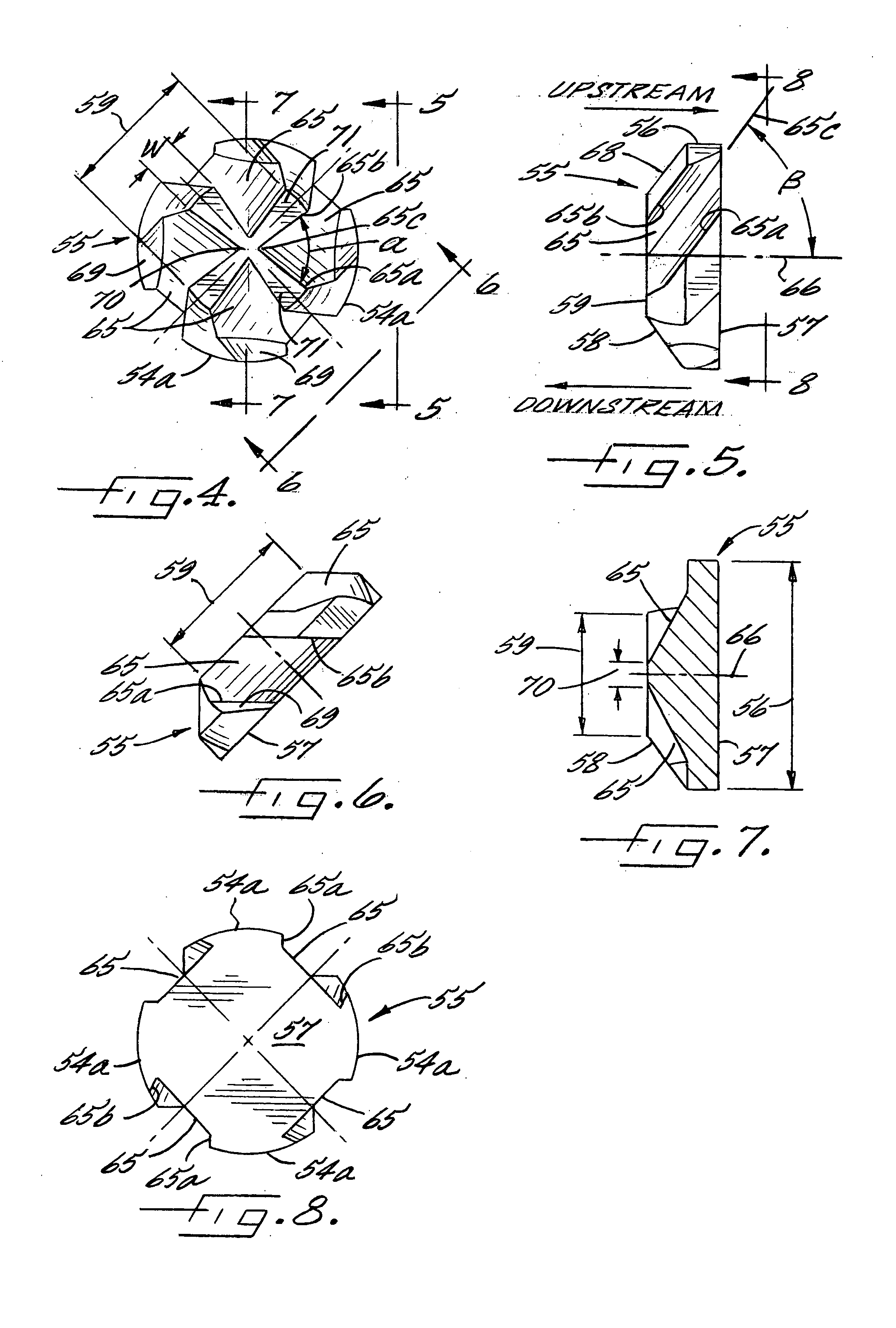

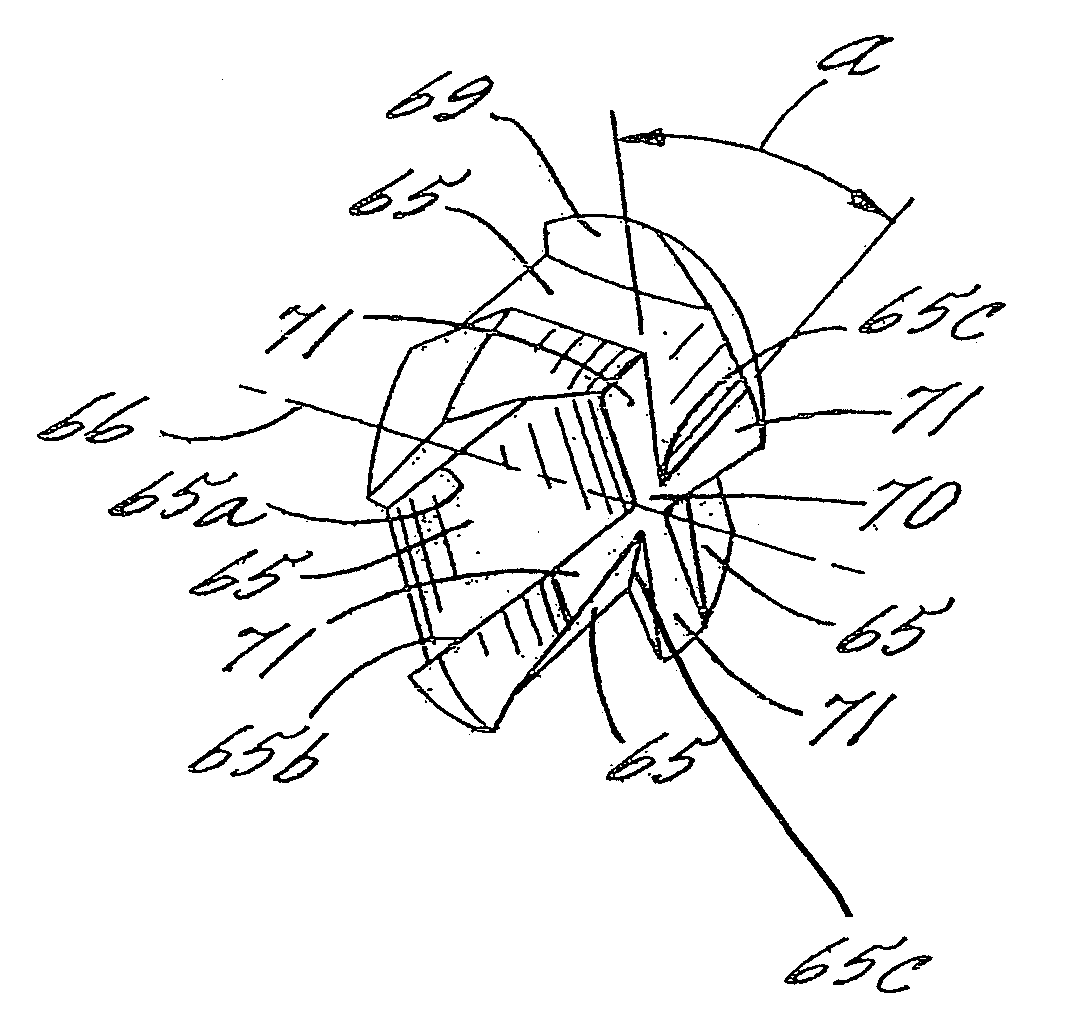

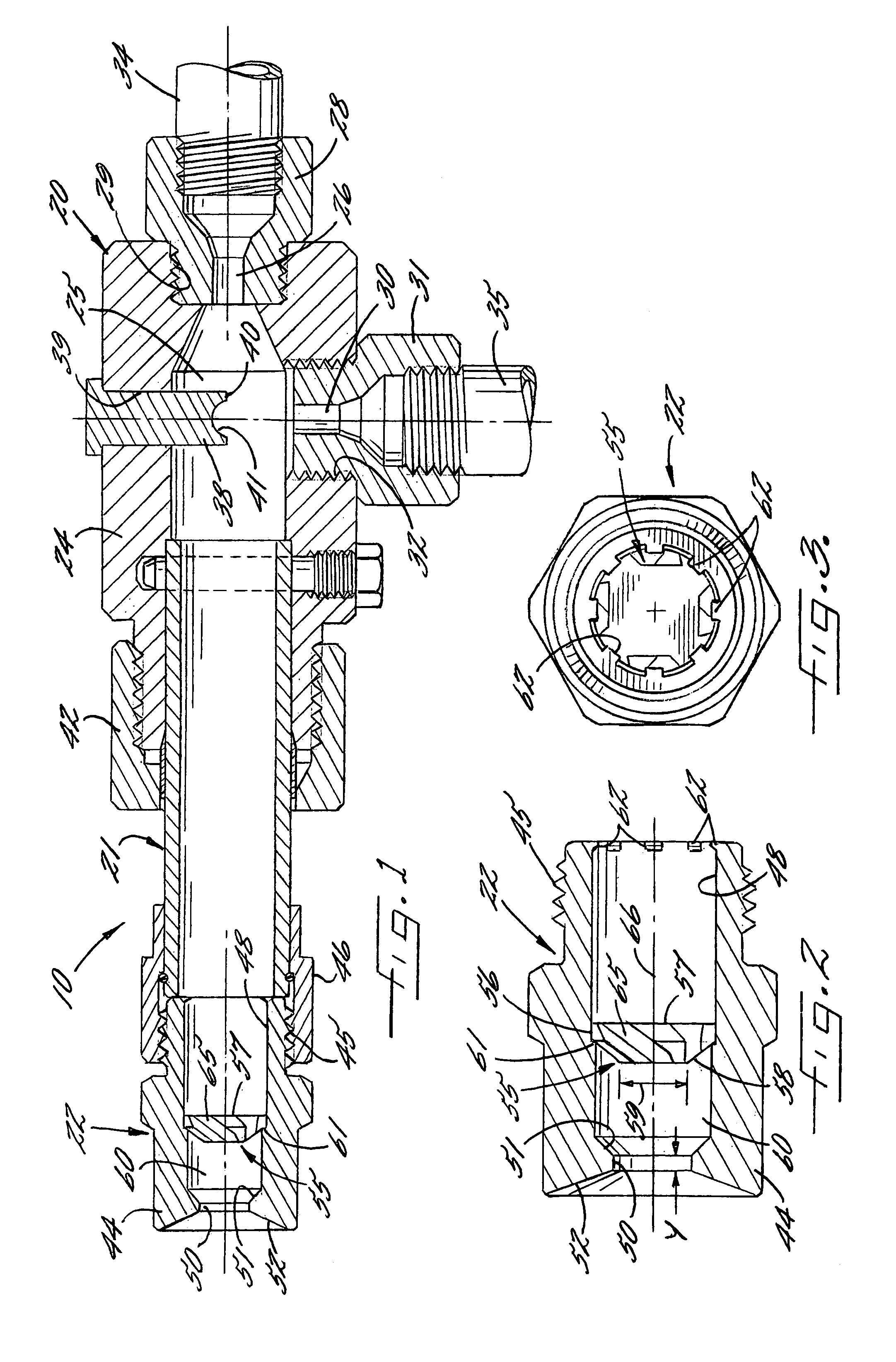

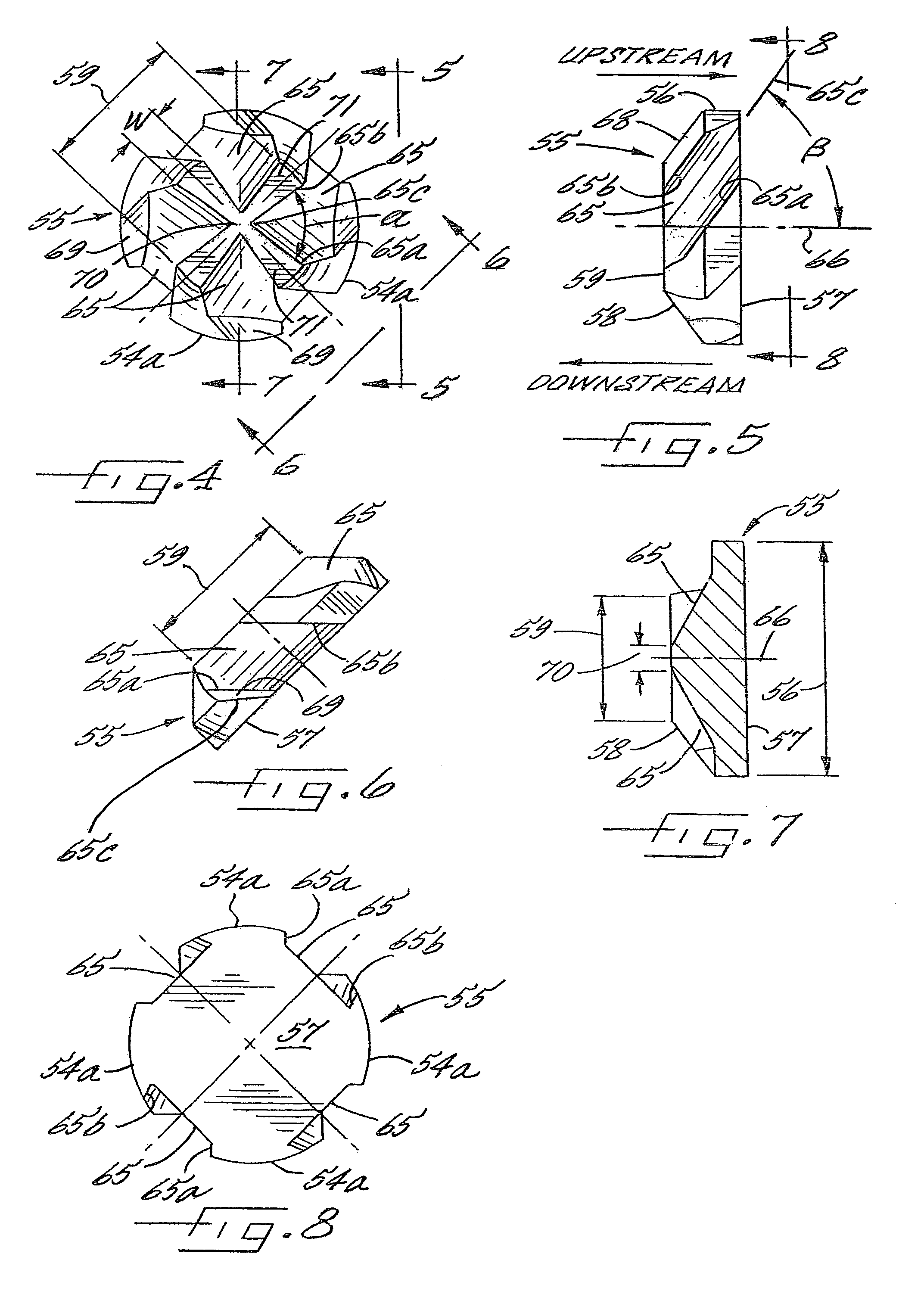

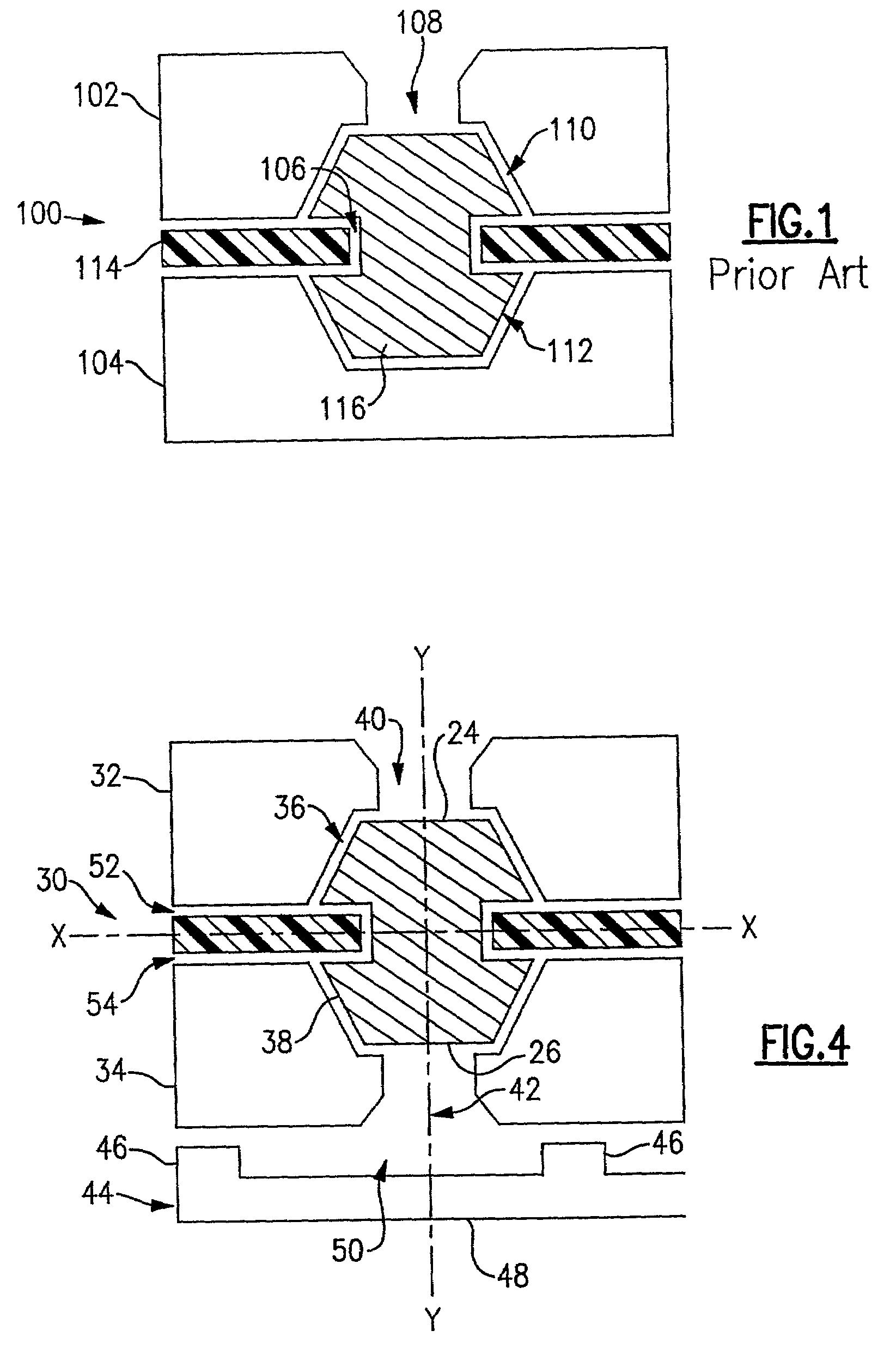

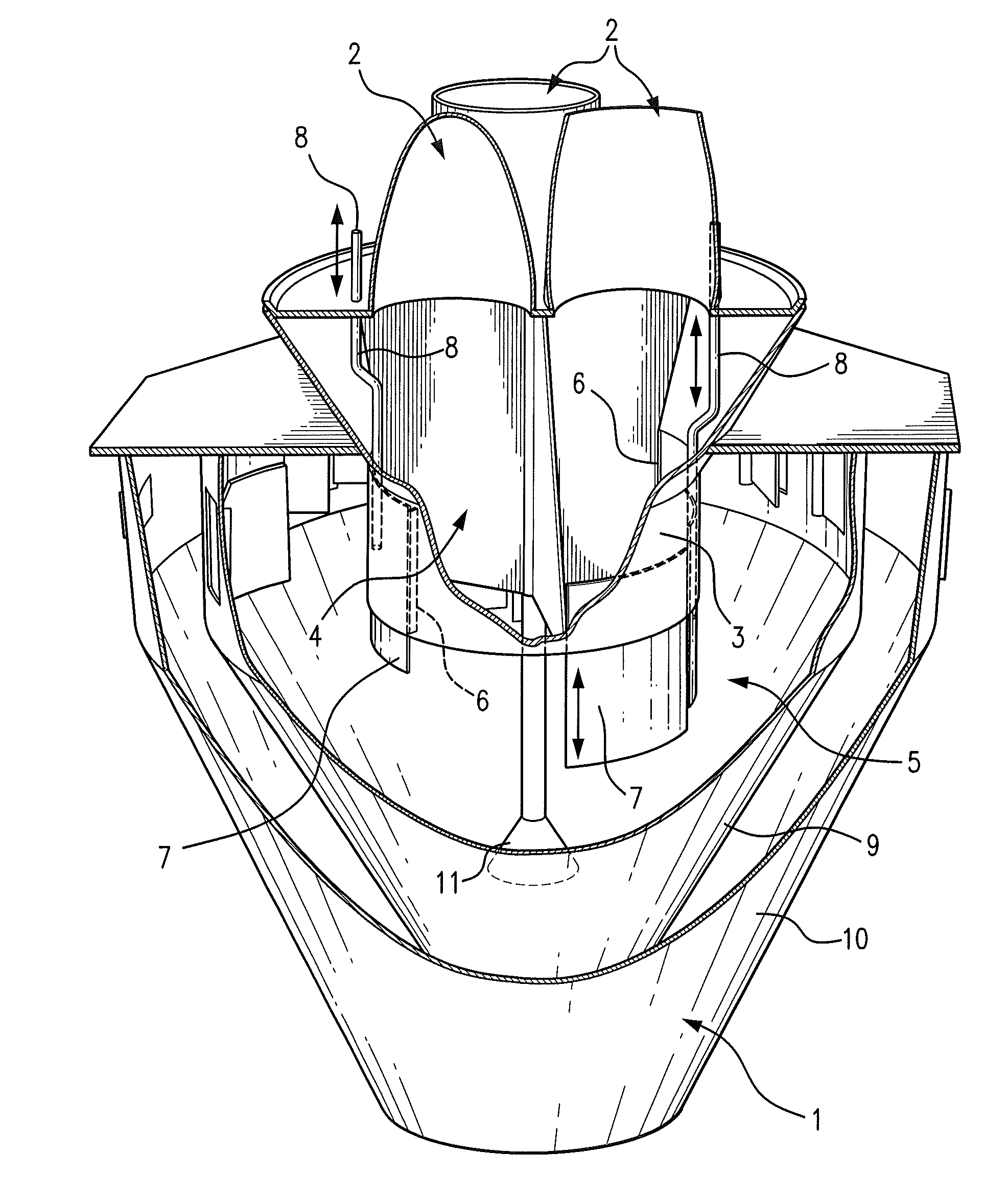

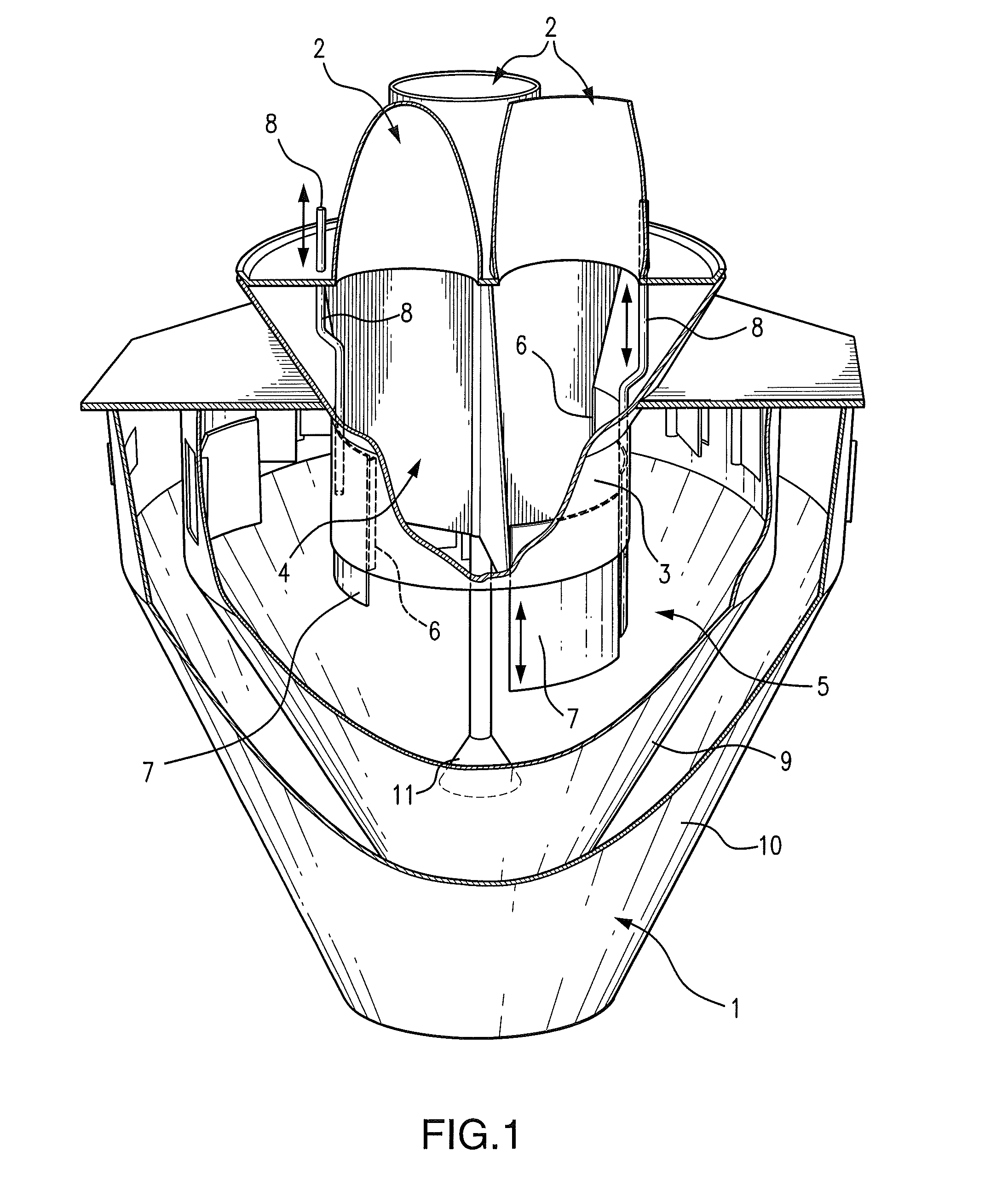

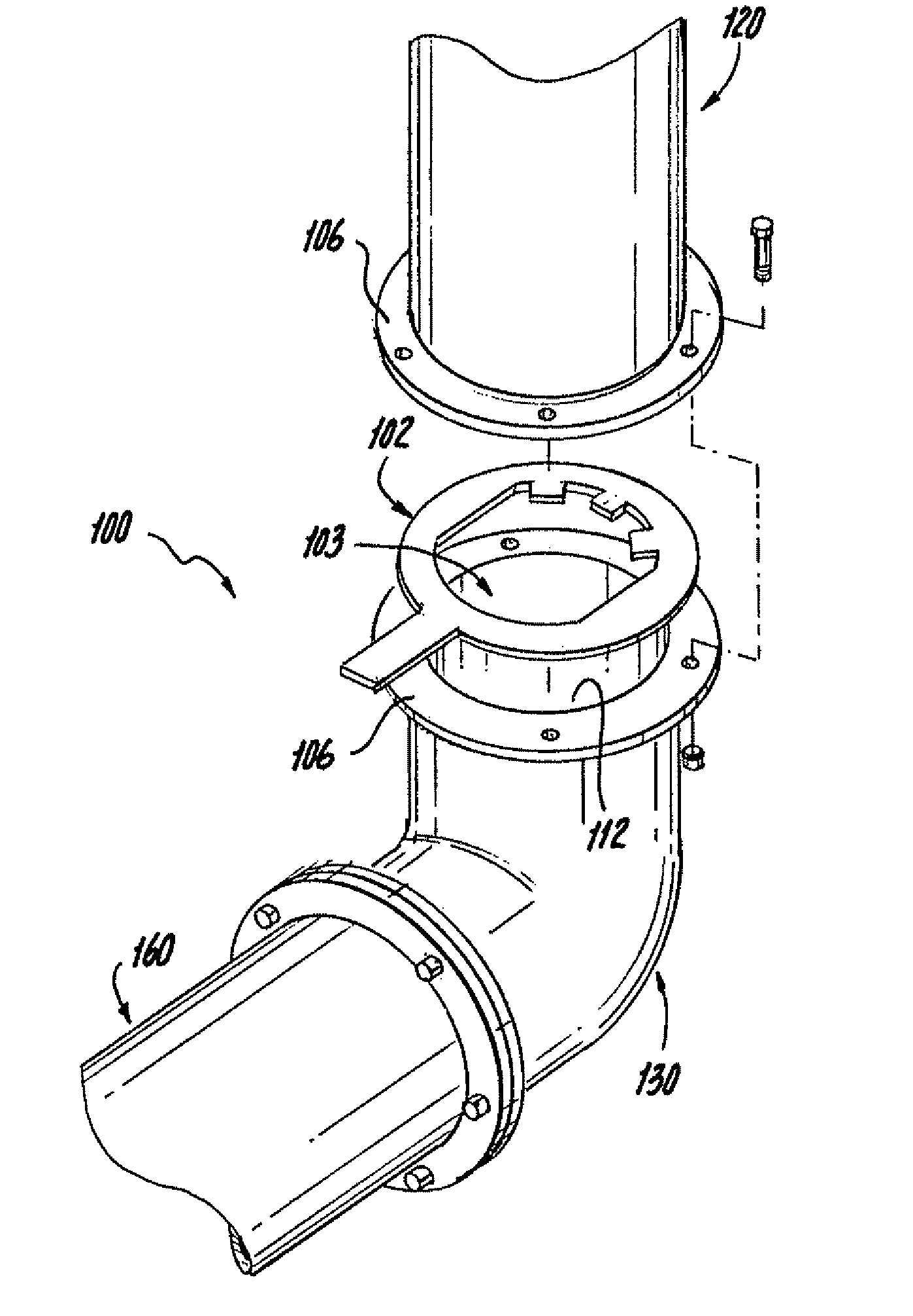

Full cone air assisted spray nozzle for continuous metal casting cooling

ActiveUS20070290073A1Uniform particle distributionImprove particle distributionSpray nozzlesLiquid spraying apparatusMixing chamberNozzle

A full cone liquid spray nozzle is provided. The spray nozzle includes a nozzle body having a discharge orifice at a downstream end and an inlet at an upstream end for connection to a liquid supply. A liquid flow passageway extends through the nozzle body communicating between the inlet and the discharge orifice. A vane is disposed in the liquid flow passageway upstream of the discharge orifice. The vane has a plurality of V-shaped passageways therein. Each V-shaped passageway extends inward at an angle with respect to a longitudinal axis of the vane between an upstream face and downstream face of the vane. A whirl and mixing chamber defined by the liquid flow passageway is arranged between the vane and the discharge orifice.

Owner:SPRAYING SYST

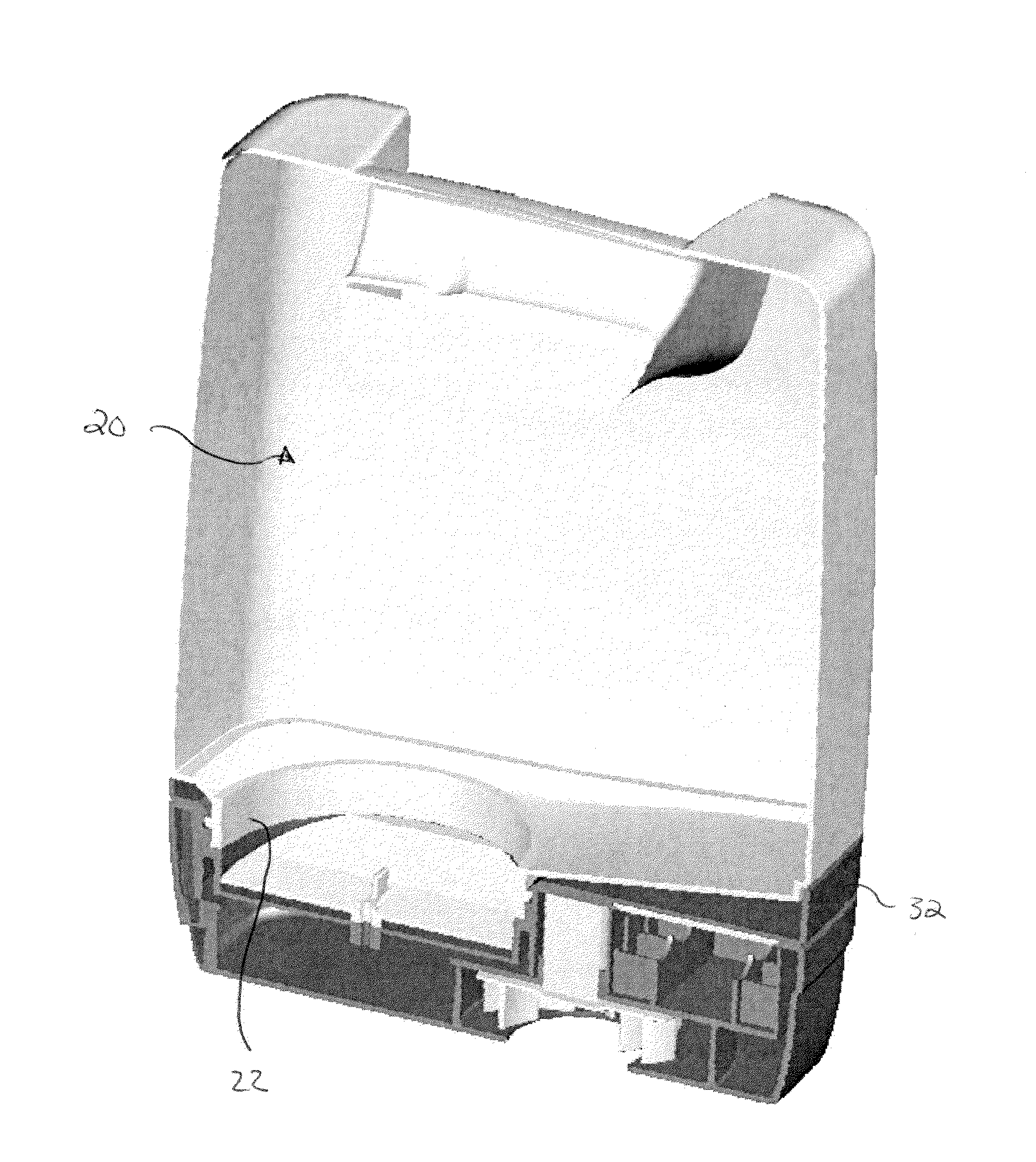

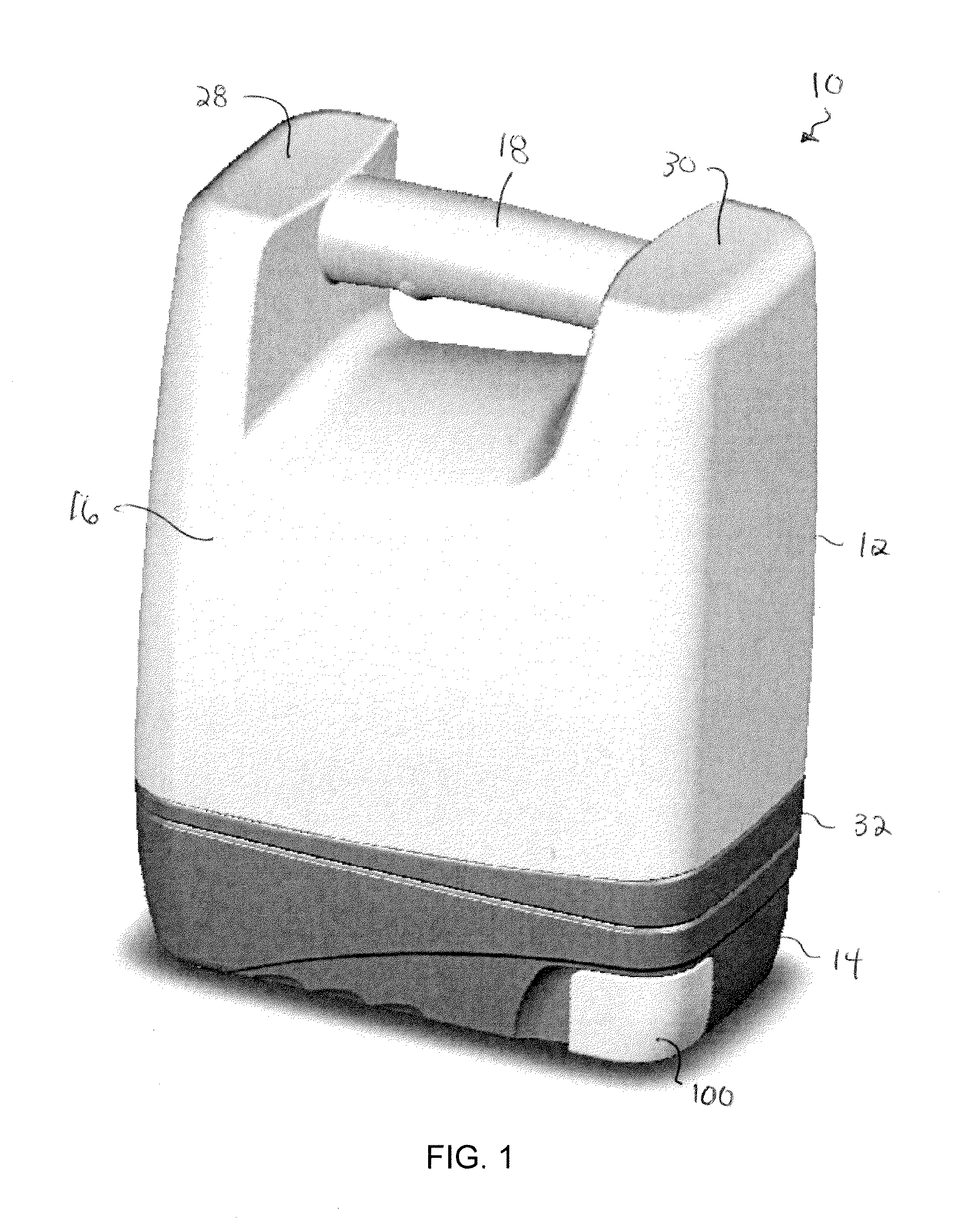

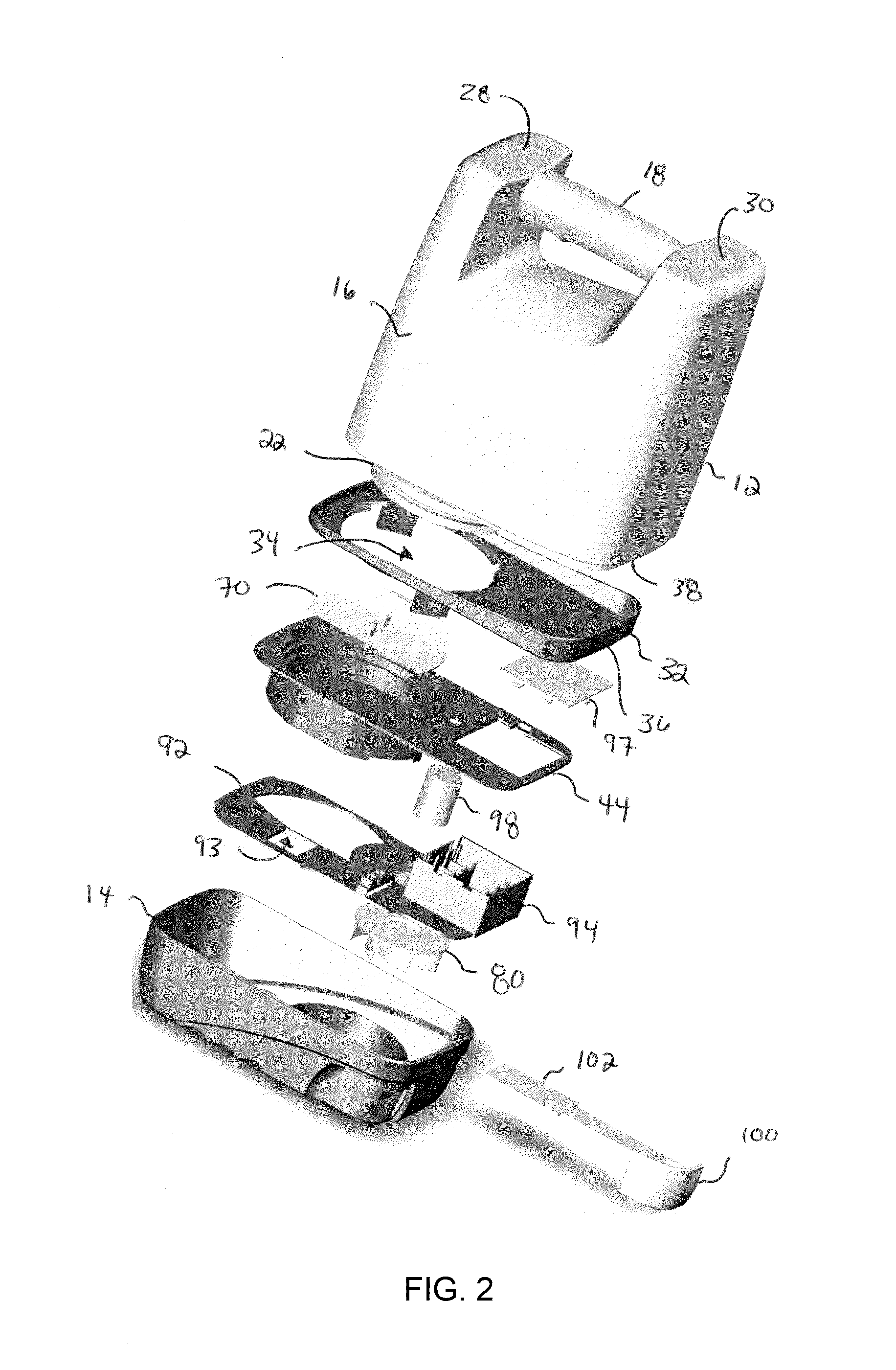

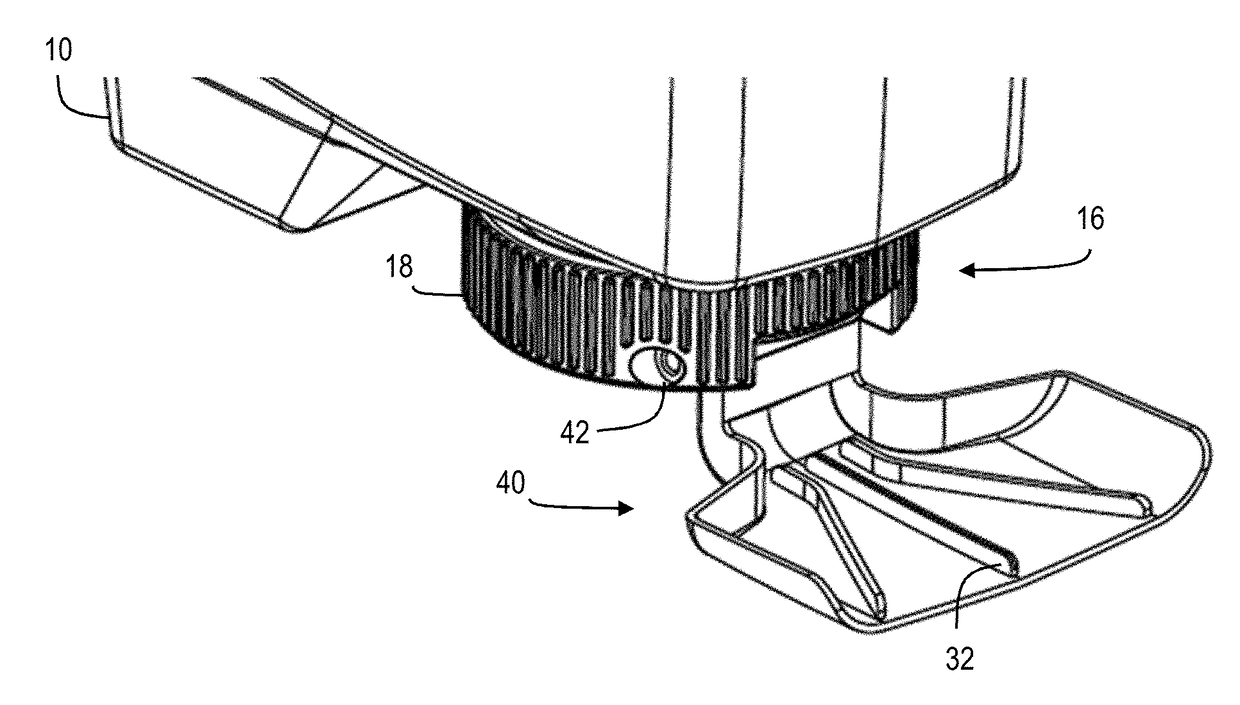

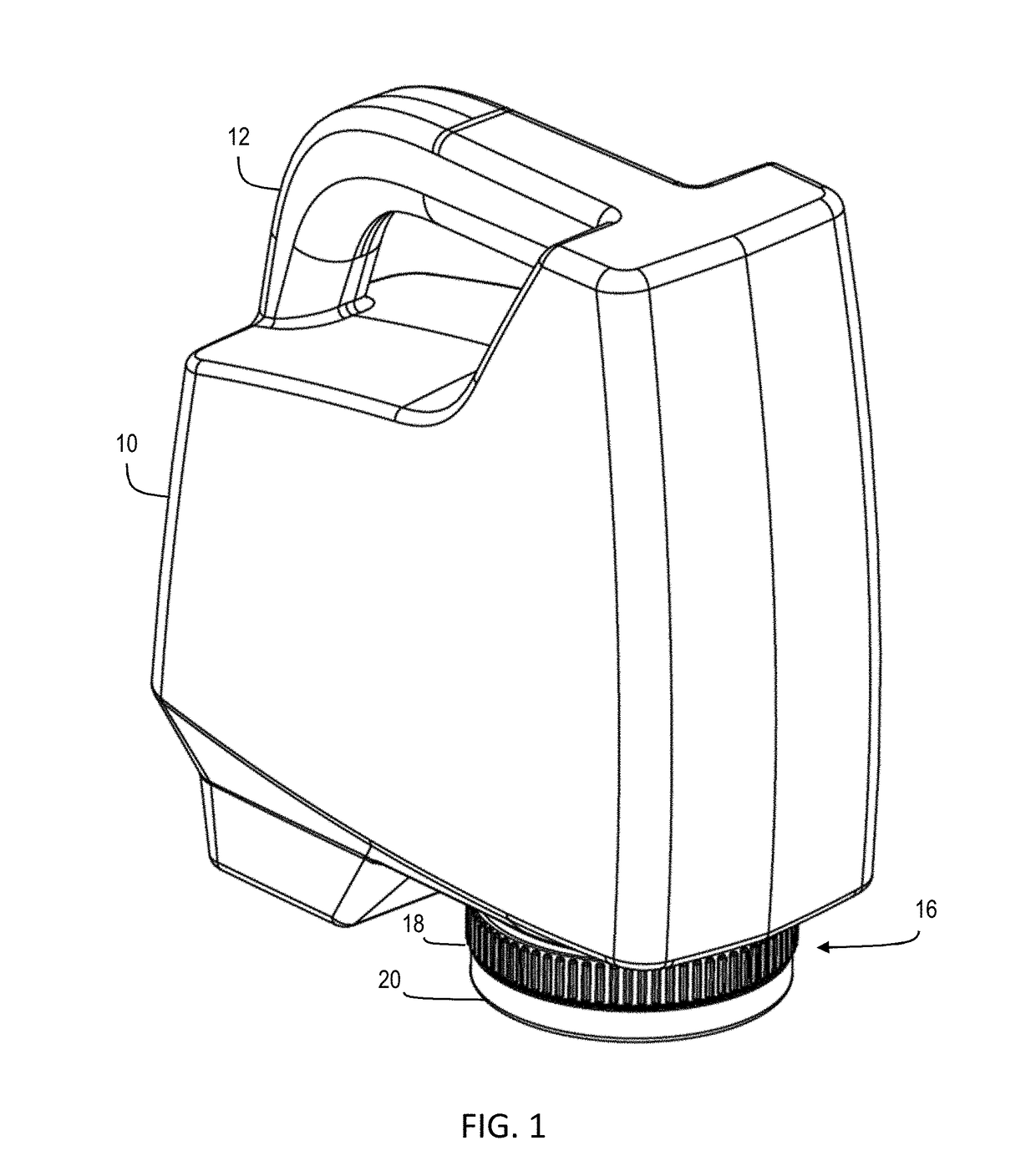

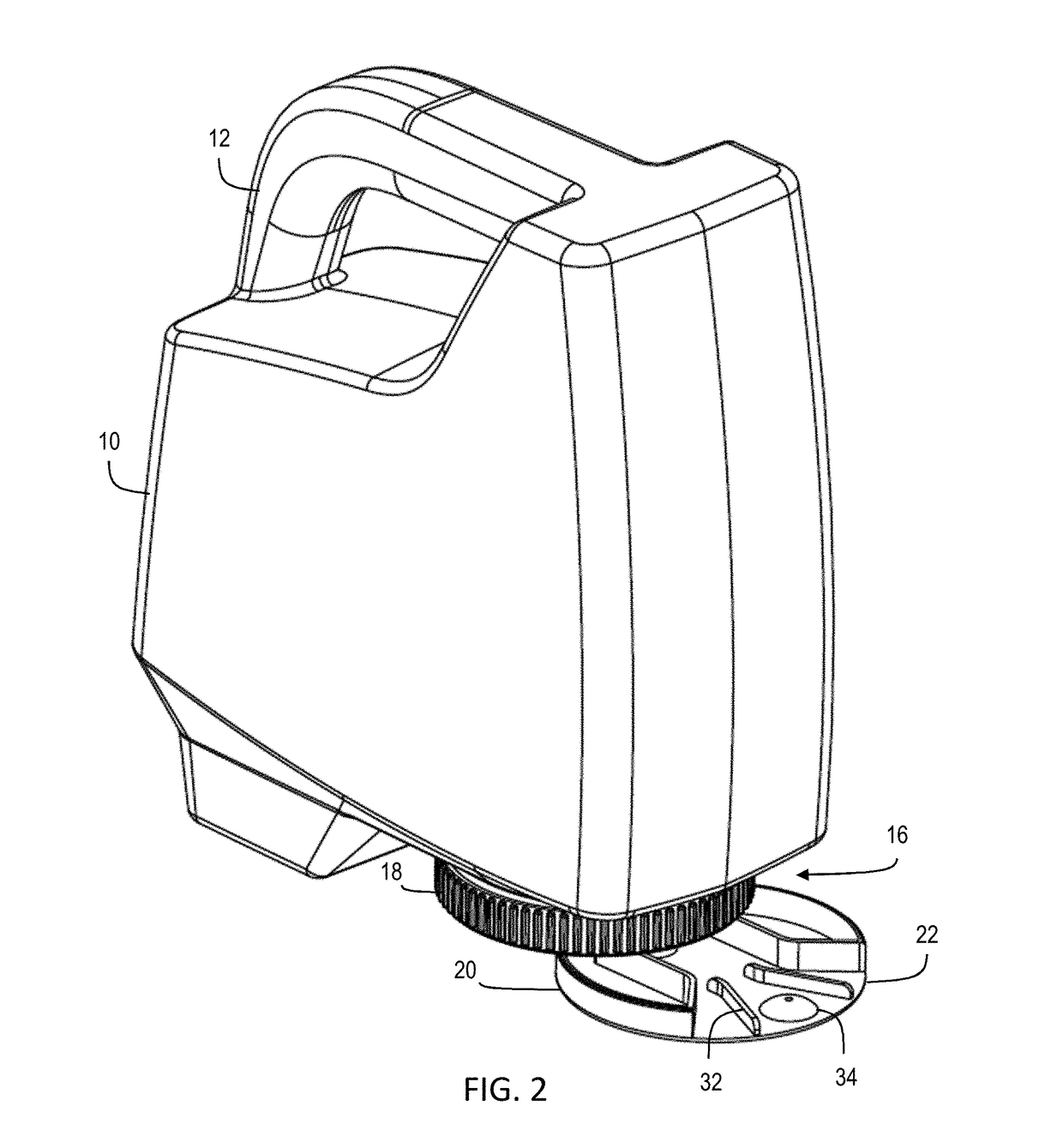

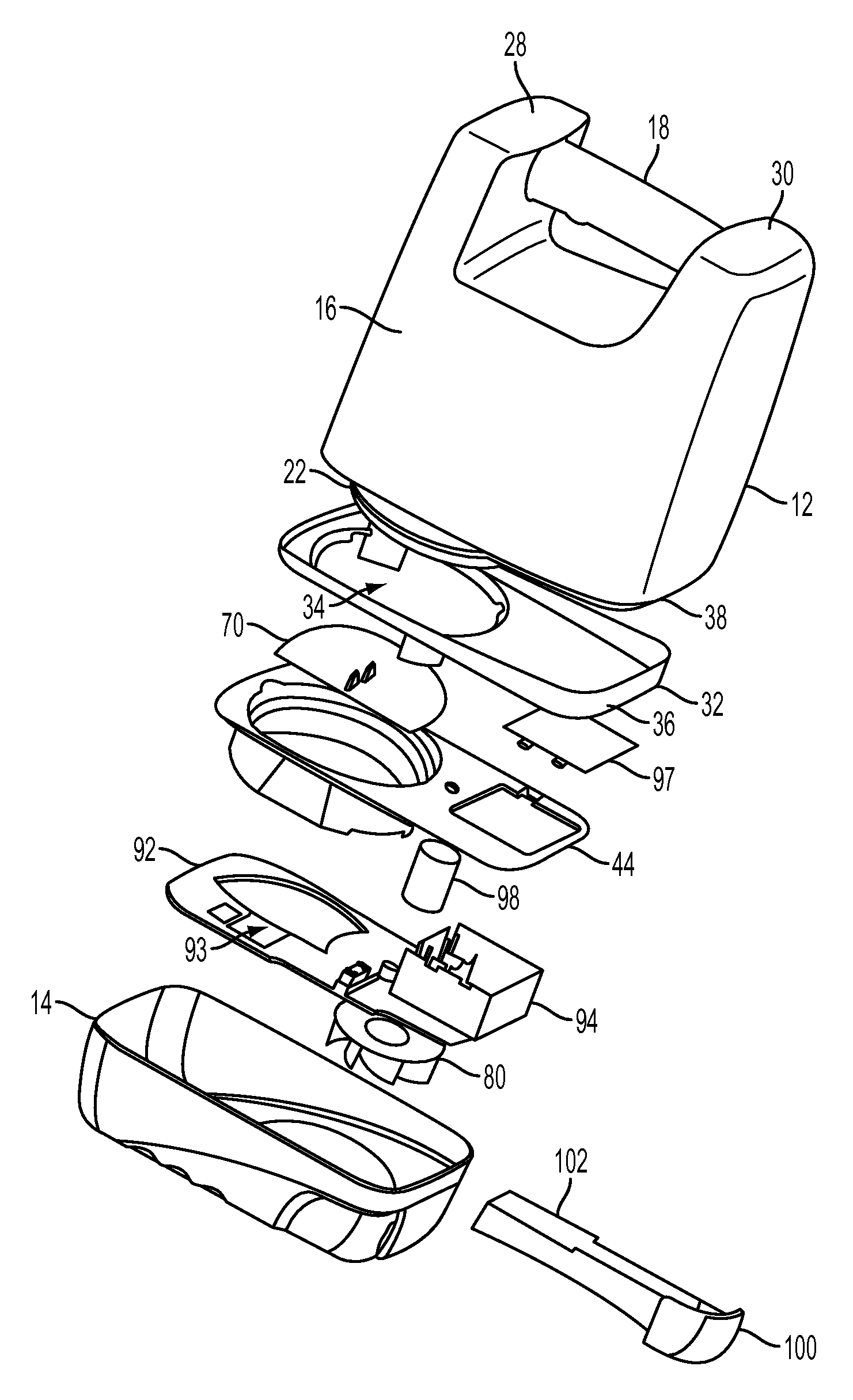

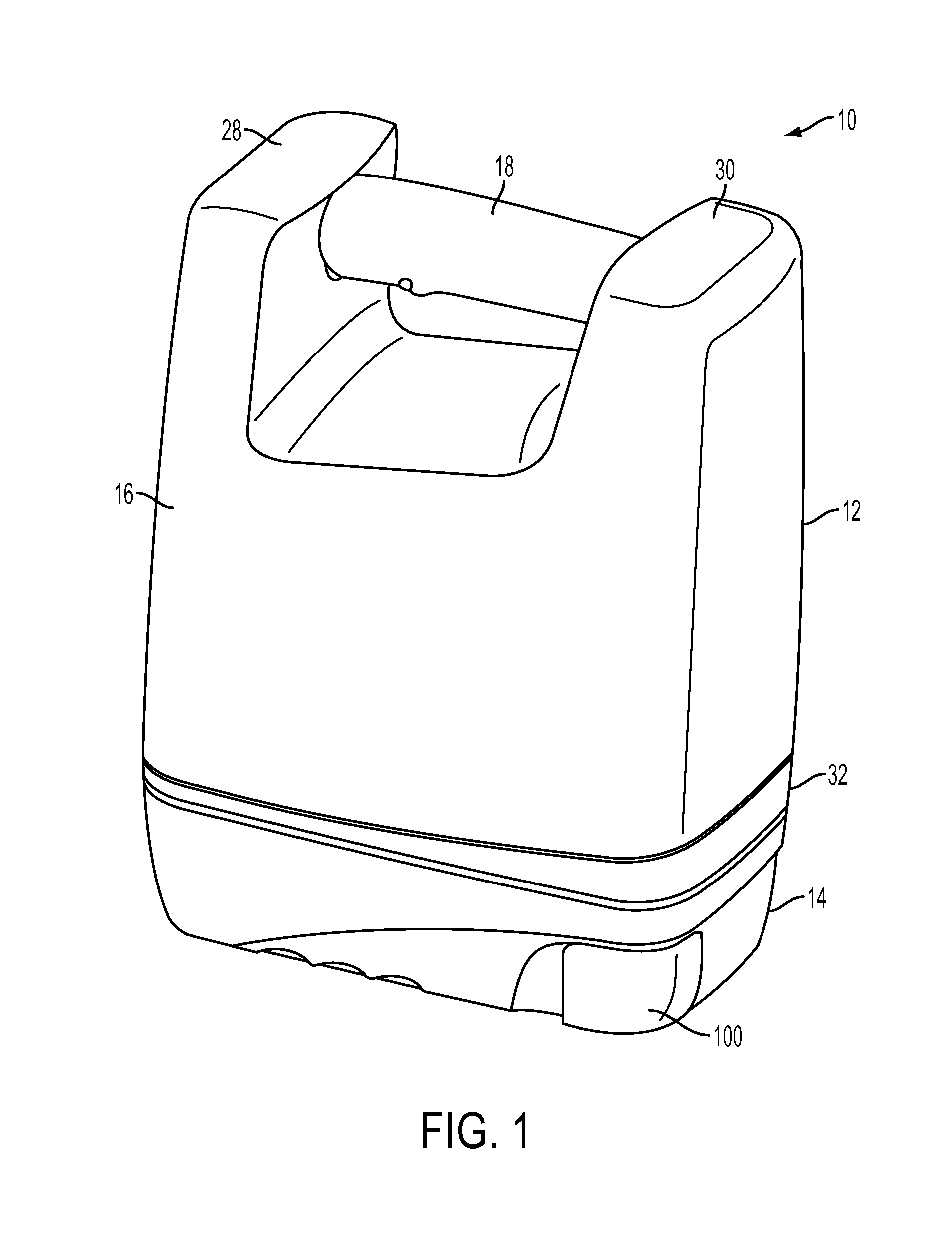

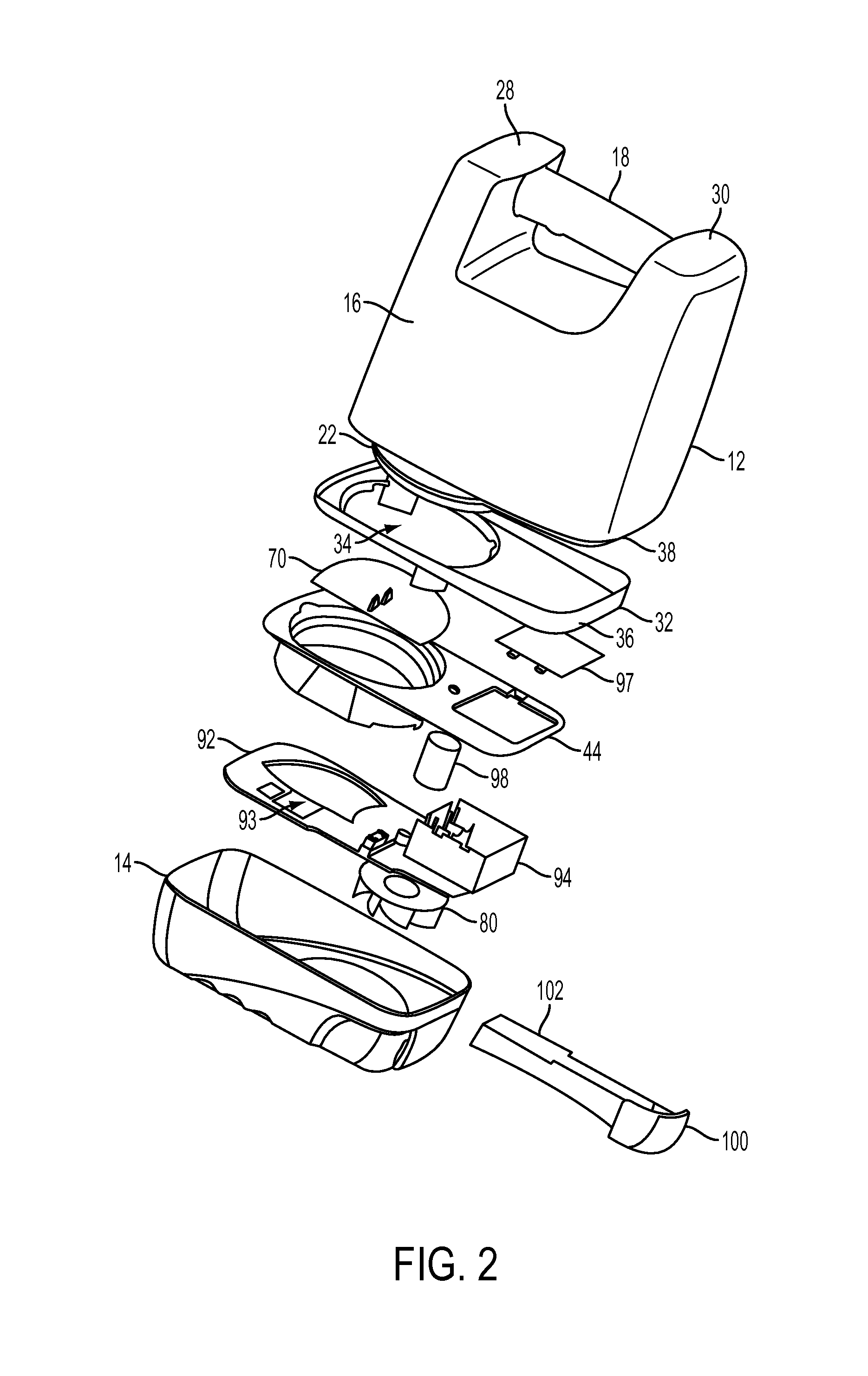

Electrically powered hand spreader

ActiveUS20140263484A1Minimize contactEasy to replenishFertiliser distributersLiquid spraying apparatusParticulatesHand held

A handheld spreader having a fillable container for dispensing particulate from an electrically powered blower assembly in a detachable base. The spreader includes a feed slide leading from the container to the air stream channel of the base that has a vibrating eccentric plate for guiding and improving the flow of particulate from container into the air stream. The container and base are frictionally engaged together, thereby allowing for easy assembly of spreader, including assembly after container has been filled with particulate, as well as easy reassembly if container is removed and refilled. The spreader includes a rotating slide that may be operated by a user to open and partially close the feed slide of the container to control the feed rate.

Owner:MARCONI FRED

Full cone air assisted spray nozzle for continuous metal casting cooling

ActiveUS7611080B2Uniform particle distributionImprove particle distributionSpray nozzlesLiquid spraying apparatusEngineeringMixing chamber

A full cone liquid spray nozzle is provided. The spray nozzle includes a nozzle body having a discharge orifice at a downstream end and an inlet at an upstream end for connection to a liquid supply. A liquid flow passageway extends through the nozzle body communicating between the inlet and the discharge orifice. A vane is disposed in the liquid flow passageway upstream of the discharge orifice. The vane has a plurality of V-shaped passageways therein. Each V-shaped passageway extends inward at an angle with respect to a longitudinal axis of the vane between an upstream face and downstream face of the vane. A whirl and mixing chamber defined by the liquid flow passageway is arranged between the vane and the discharge orifice.

Owner:SPRAYING SYST

Adjustable division plate for classifier coal flow control

ActiveUS20150056024A1Optimize allocationPrevention of reverse air flowFuel feeding arrangementsSolid fuel pretreatmentEngineeringSolid particle

A solid particle distribution controller includes a plurality of division plates proximate a division between an upstream solid particle conveyance pipe and a plurality of downstream pipes. The solid particle distribution controller also includes a plurality of extension plates. Each of the extension plates is movably mounted proximate to a respective division plate for movement in an upstream and downstream direction with respect to the division plate. The plurality of extension plates are configured and adapted for motion in the upstream and downstream direction independent of one another to extend upstream of the division plates as needed to improve solid particle distribution among the downstream pipes.

Owner:BABCOCK POWER SERVICES

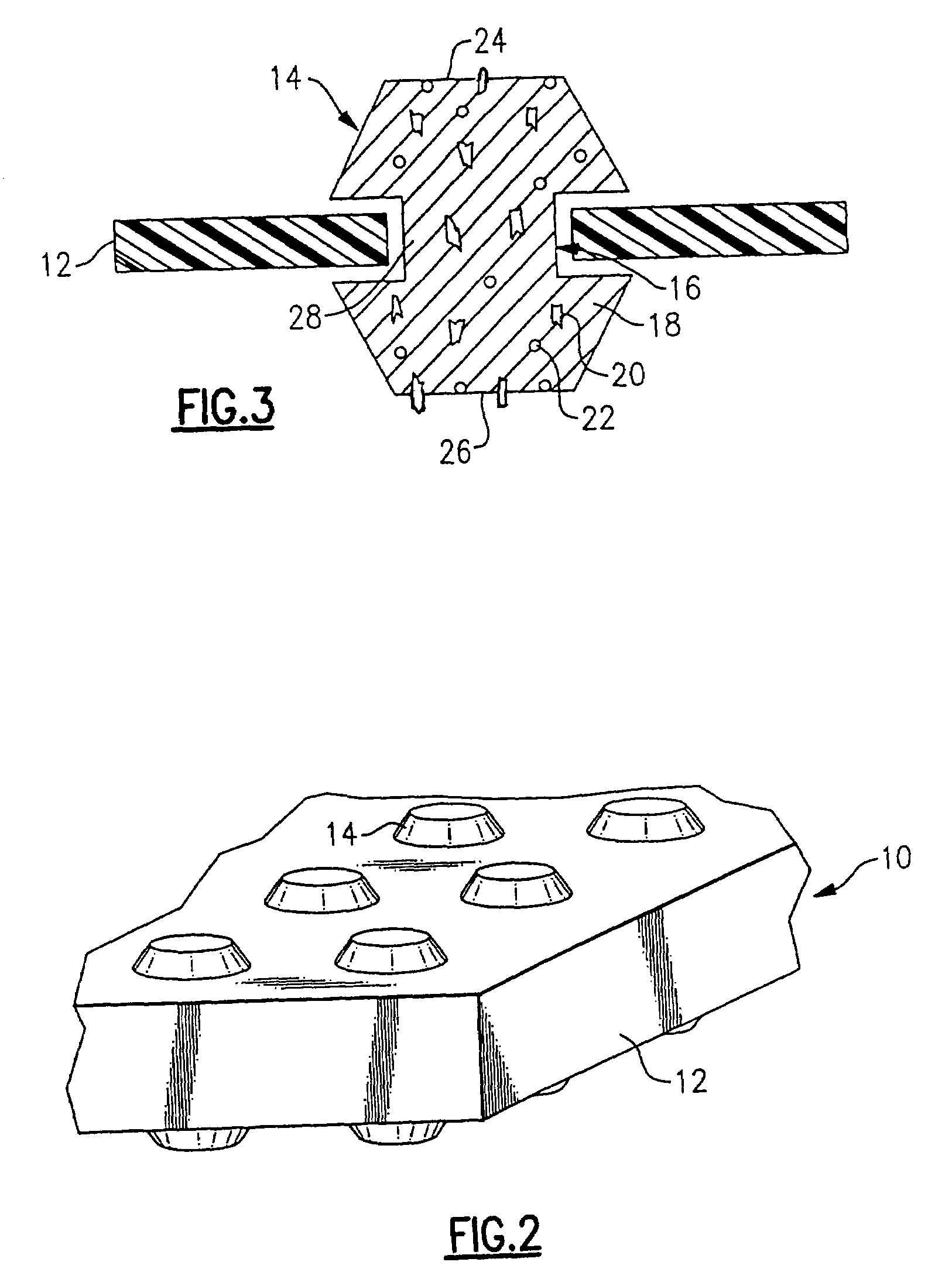

Particle distribution interposer and method of manufacture thereof

InactiveUS7083436B2Improved conductive particle distributionLess flashingSemiconductor/solid-state device detailsPrinted circuit aspectsElastomerThermoplastic

An interposer comprising a non-conductive carrier sheet with a pre-arranged pattern of conductive interconnect members positioned therethrough and formed from an elastomeric thermoplastic with suspended spherical and non-spherical conductive particles. The non-spherical conductive particles of the present invention are positioned substantially perpendicularly to and partially through the contact faces of the interconnect member, thereby resulting in higher conductivity and efficiency. The interposer is formed by a mold comprising two sections with first and second sets of vias formed in the first and second mold sections, respectively, which permit the injected elastomer mixture to flow completely through the mold cavity and thereby aligns the non-spherical conductive particles. The exit side of the mold is further contacted by support posts of a separable mold interface creating a network of vent passages for venting of air and the elastomer mixture, resulting in less pressure within the mold and less mold flash.

Owner:IBM CORP

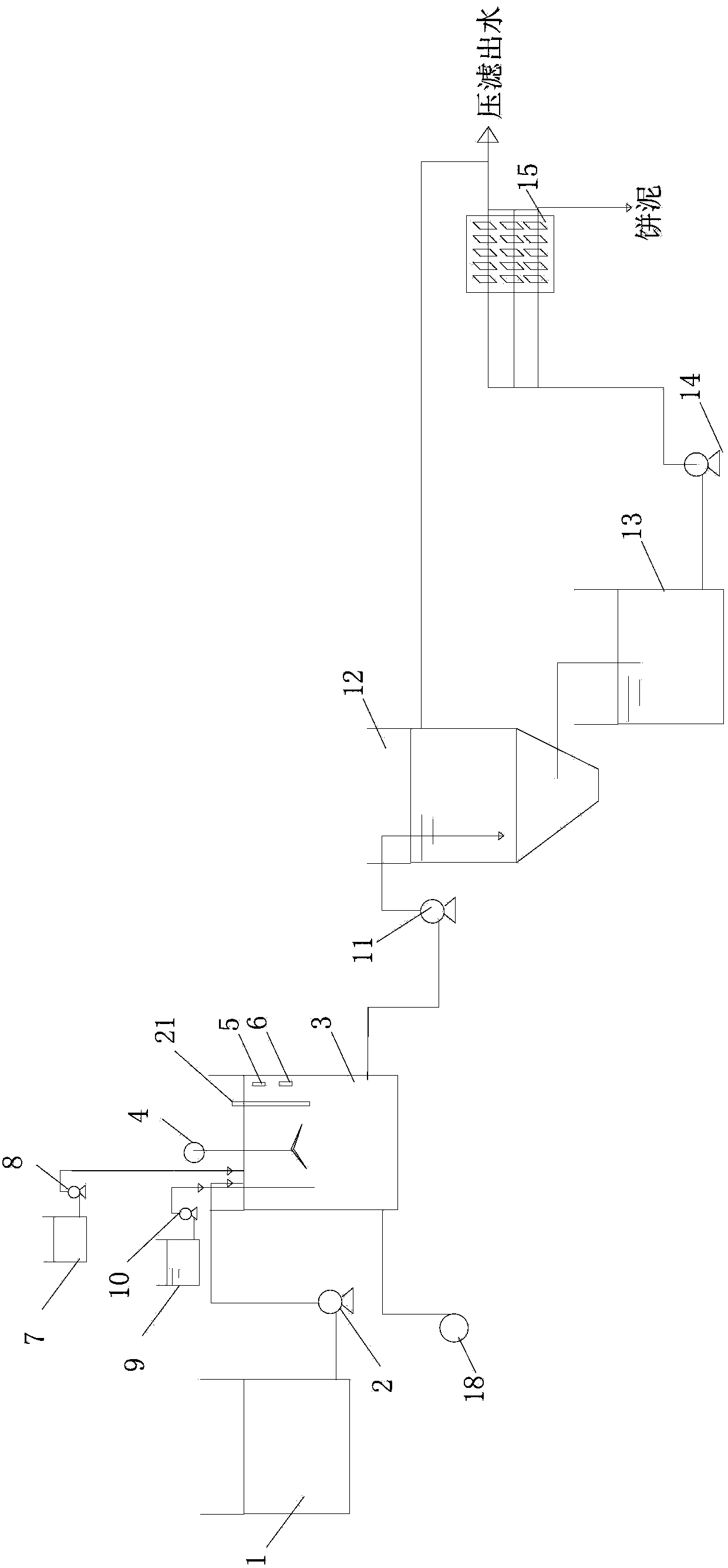

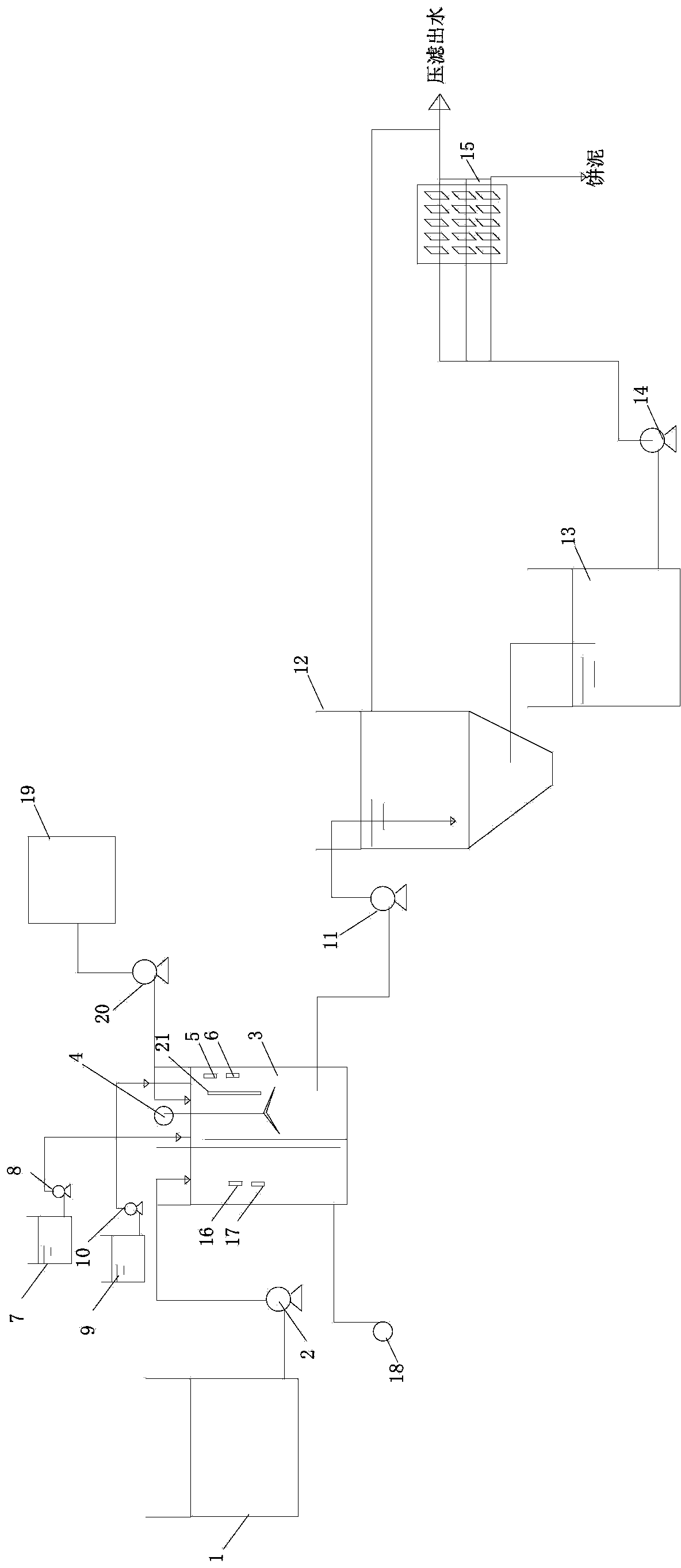

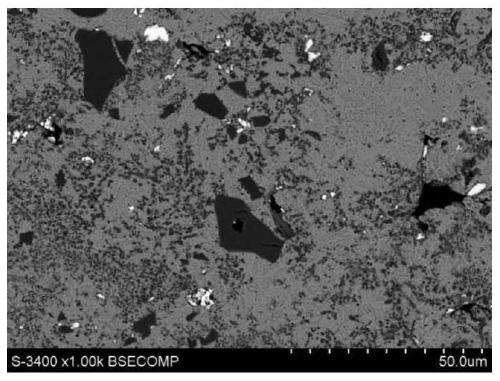

Acidic iron-containing wastewater recycling system and method for carrying out in situ modification by system

ActiveCN103408158AShort process reaction timeSmall footprintWaste water treatment from metallurgical processFerroso-ferric oxidesSludgeHigh pressure

The invention discloses an acidic iron-containing wastewater recycling system comprising a pickling wastewater storage pool, wherein the pickling wastewater storage pool is connected with a neutral oxidation reaction tank through a raw water acid proof pump, and a stirrer, a 1# online pH meter and a 1# online ORP (oxidation reduction potential) meter are fixed in the neutral oxidation reaction tank; an alkali liquor storage tank is connected with the neutral oxidation reaction tank through a 1# metering pump; a flocculant storage tank is connected with the neutral oxidation reaction tank through a 2# metering pump; the neutral oxidation reaction tank is connected with a settling tank through a slurry pump, the settling tank is connected with a sludge concentration tank, and a supernatant drain pipe is further connected to the settling tank; the sludge concentration tank is connected with a high pressure plate frame filter press through a high pressure slurry pump; and the neutral oxidation reaction tank is further connected with a blower. The invention further discloses an in situ modification method for treating wastewater by the acidic iron-containing wastewater recycling system. By adopting the acidic iron-containing wastewater recycling system disclosed by the invention, more than 55% of Fe3O4 can be stably prepared and recycled through in-situ reaction in an acidic wastewater neutralization tank under normal temperature and normal pressure conditions.

Owner:WUXI XINDU ENVIRONMENTAL PROTECTION EQUIP +1

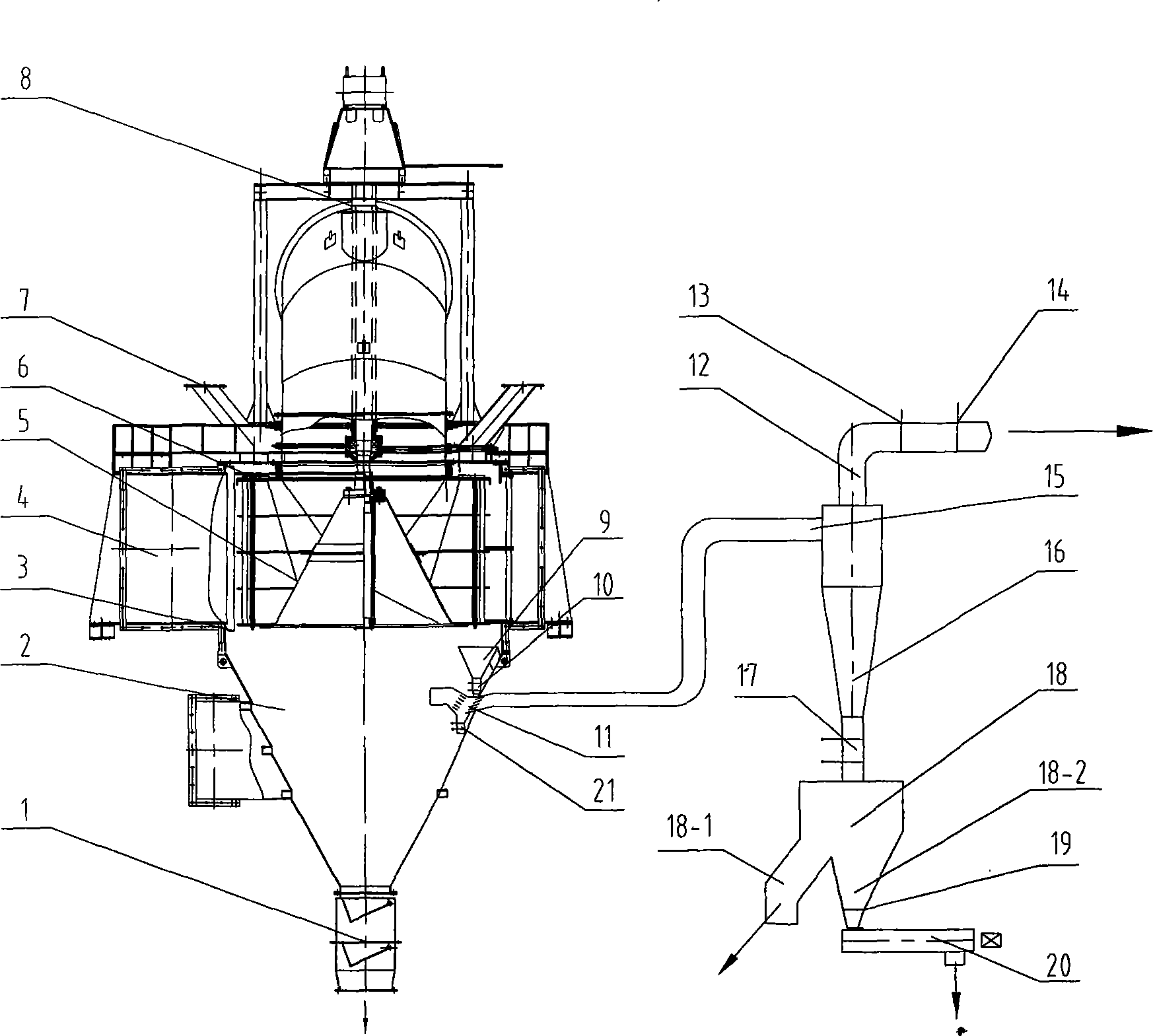

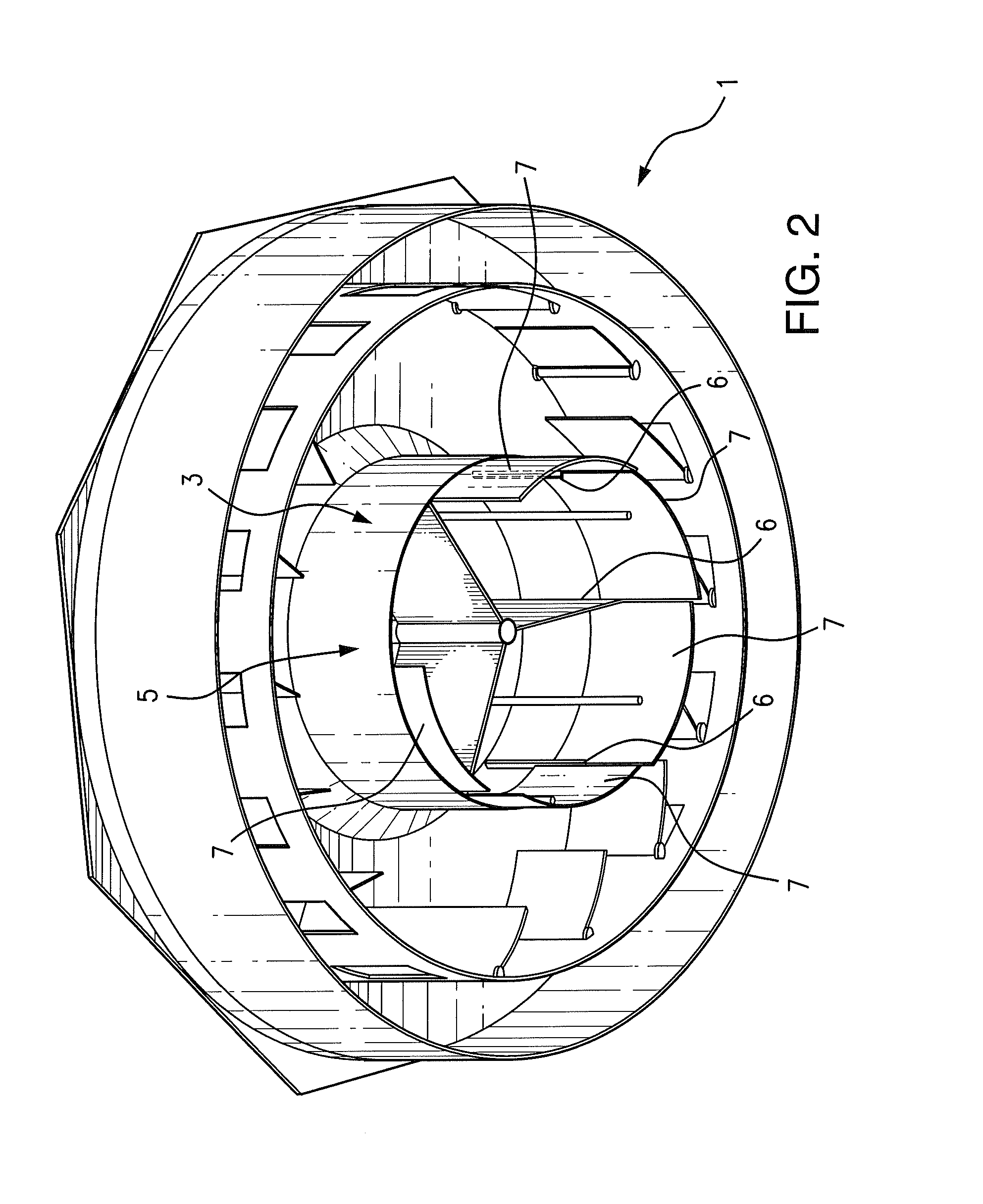

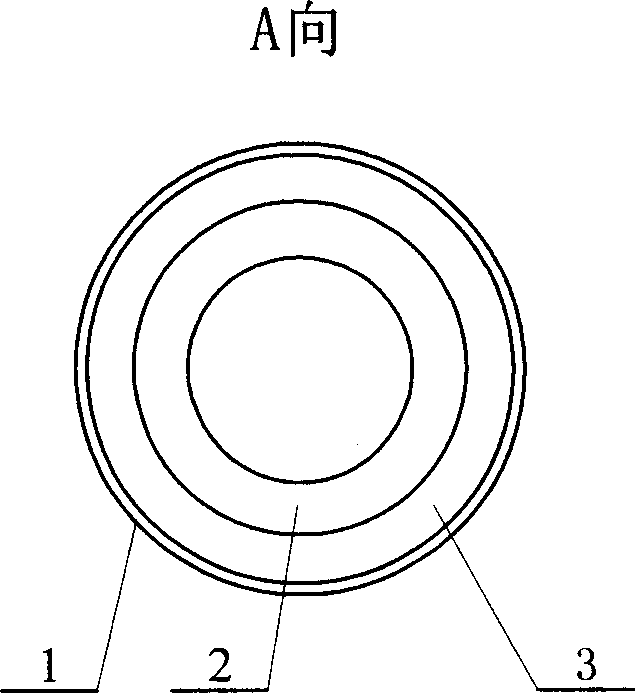

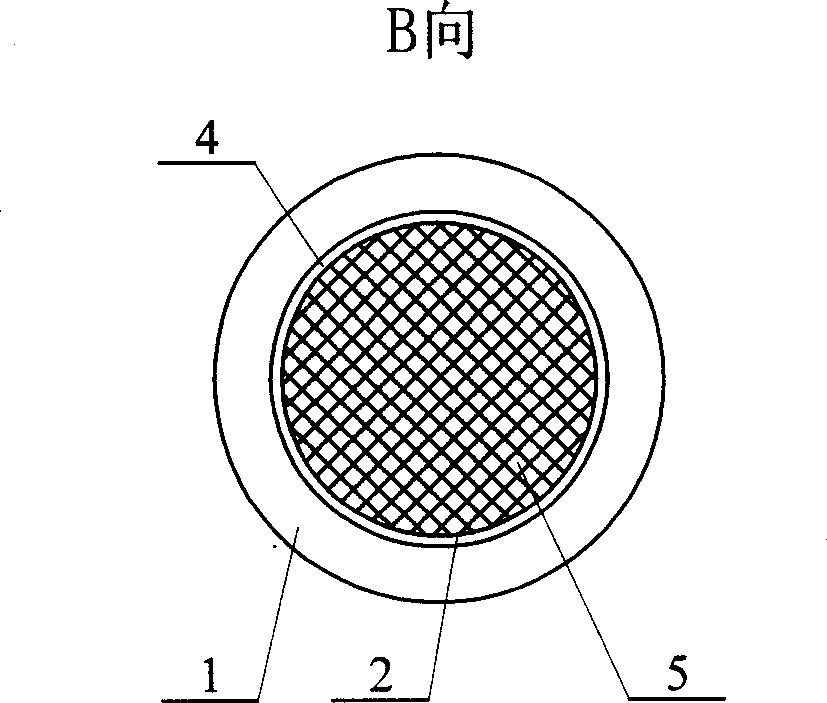

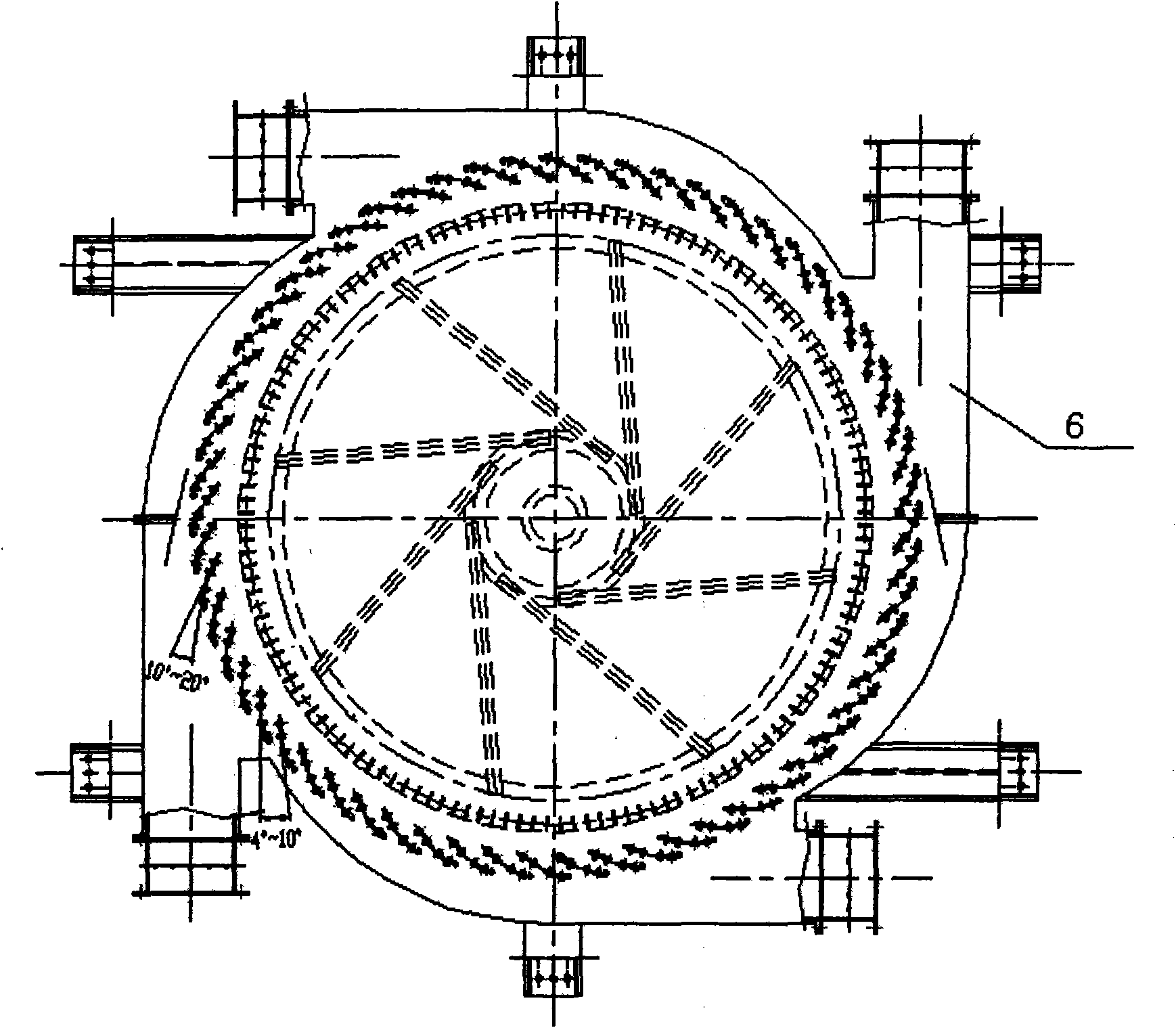

High-effective flour screening machine with wide size distribution of particles

ActiveCN101433897AImprove particle distributionGood compatibilityGas current separationGrain treatmentsWork performanceEngineering

The invention provides a high-efficiency powder-selecting machine with wide particle diameter distribution. The powder-selecting machine comprises a shell body, a cage-type rotor, a feed spreading tray, a central wind pipe and a coarse powder cone; the central wind pipe is arranged on the upper part of the shell body; the lower part of the shell body is provided with the feed spreading tray and the rotor; a wind inlet and a feed inlet are arranged on the shell body; the lower part of the rotor is provided with the coarse powder cone; a semiannular collecting hopper of a secondary sorting device is arranged on the upper part of the coarse powder cone; a lower mouth of the collecting hopper is communicated with an upper mouth of a four-way joint through a wind locking valve; two side mouths of the four-way joint are connected with a separator and secondary wind respectively; a lower mouth of the four-way joint is connected with the wind locking valve; an upper mouth of the separator is connected with a wind outlet pipe; and a lower mouth of the separator is communicated with an overflow valve through the wind locking valve. The high-efficiency powder-selecting machine can once sort out fine powder, finer powder and coarser powder needed by cement with wide particle diameter distribution, and improve the particle distribution of a sorted powder body so that water amount needed by the cement is reduced, improve the compatibility between the cement and an additive and the working performance of the cement and reduce energy consumption and production cost.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

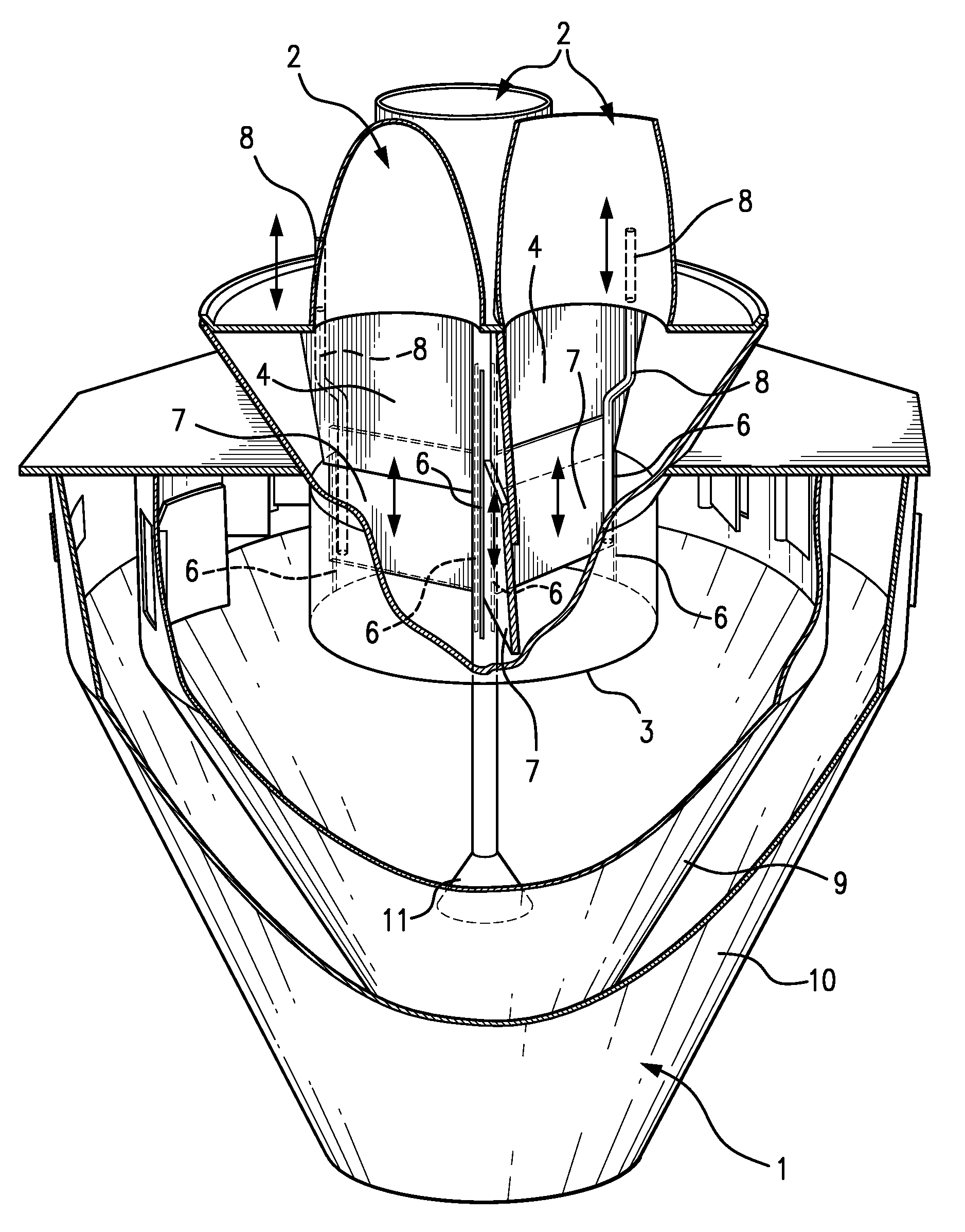

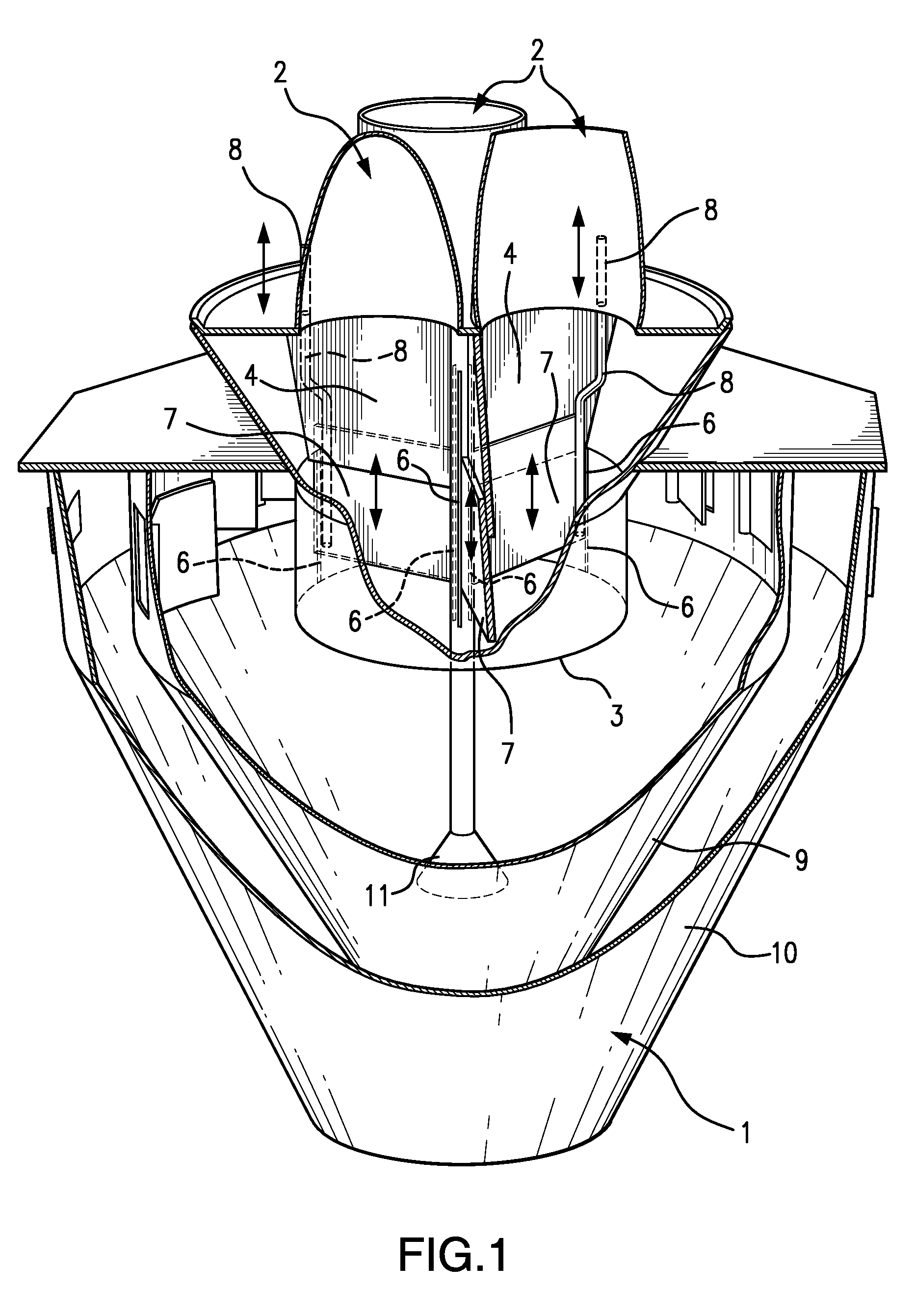

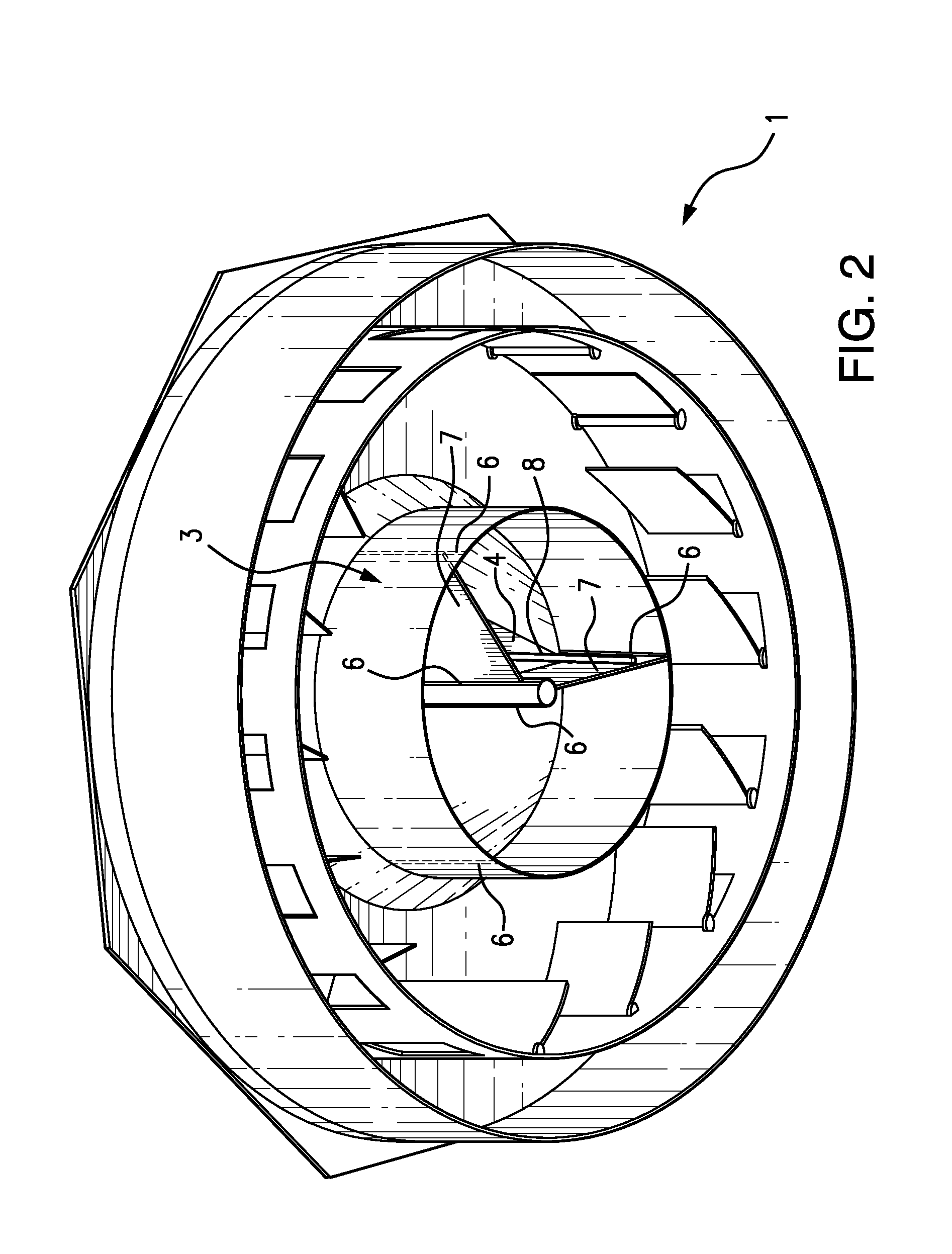

Coal flow distribution controllers for coal pulverizers

InactiveUS8915373B2Optimize allocationPrevention of reverse air flowFuel feeding arrangementsSolid fuel pretreatmentEngineeringSolid particle

A solid particle flow distribution controller includes an extension skirt configured to be mounted to a discharge skirt at a division between an upstream solid particle conveyance pipe and a plurality of downstream pipes. The extension skirt includes a plurality of circumferential segments. Each segment is movably mounted to the discharge skirt for movement in an upstream and downstream direction with respect to the discharge skirt. The segments of the extension skirt are configured and adapted for motion in the upstream and downstream direction independent of one another to extend upstream of the discharge skirt as needed to improve solid particle distribution among the downstream pipes.

Owner:BABCOCK POWER SERVICES

Dispersible dielectric particles and methods of forming the same

InactiveUS20030215606A1Reduce agglomerationInhibition formationLayered productsFixed capacitor dielectricSolventAgglomerate

Methods of forming dispersible dielectric particles, as well as articles and compositions that include the dispersible dielectric particles, are provided. The methods involve forming an aqueous mixture of dielectric (e.g., barium titanate-based) particles and replacing at least a portion of water in the mixture with a non-aqueous solvent (e.g., ethanol). According to one set of methods, the particles are then dried. The limited, or lack, of water present in the mixture during drying reduces capillary forces that otherwise may draw the particles together to cause formation of strong agglomerates. Thus, particle agglomeration during drying may be reduced which increases particle dispersibility. According to another set of methods of the invention, the particles are not dried after non-aqueous solvent replacement, thus, avoiding formation of agglomerates during drying and increasing dispersibility. In both sets of methods, particles (or mixtures thereof) may be further processed, for example, to form composite layers. As a result of the increased particle dispersibility, the particles are relatively uniformly distributed throughout the polymeric material. This uniform distribution improves properties of the composite layers which may be used as an embedded capacitor in electronic applications including printed circuit boards.

Owner:CABOT CORP

Coal flow distribution controllers for coal pulverizers

InactiveUS20120243969A1Optimize allocationPrevention of reverse air flowFluid heatersFuel feeding arrangementsSolid particleEngineering

A solid particle flow distribution controller includes an extension skirt configured to be mounted to a discharge skirt at a division between an upstream solid particle conveyance pipe and a plurality of downstream pipes. The extension skirt includes a plurality of circumferential segments. Each segment is movably mounted to the discharge skirt for movement in an upstream and downstream direction with respect to the discharge skirt. The segments of the extension skirt are configured and adapted for motion in the upstream and downstream direction independent of one another to extend upstream of the discharge skirt as needed to improve solid particle distribution among the downstream pipes.

Owner:BABCOCK POWER SERVICES

Mineral waste residue liquid composite grinding aid and preparation method thereof

The invention relates to a mineral waste residue liquid composite grinding aid and a preparation method thereof. The mineral waste residue liquid composite grinding aid is prepared from the following raw materials: 15-20 parts by weight of mixed alcohol, 5-10 parts by weight of ethyl acetate, 5-10 parts by weight of molasses, 1-10 parts by weight of lauryl sodium sulfate, 1-10 parts by weight of sodium hexametaphosphate and 800-100 parts by weight of water. The mineral waste residue liquid composite grinding aid has low toxicity, does not volatile and is stable in sources, sufficient in supplies, simple to process and prepare and low in cost; after granulated blast-furnace slag is doped in the mineral waste residue liquid composite grinding aid, the distribution and the morphology of separate particles can be improved, and the quality of mineral waste residue micro powder is not affected; the mineral waste residue liquid composite grinding aid has the advantages of increasing the yield and improving the quality of the mineral waste residue micro powder and meanwhile greatly reduces the energy consumption. The mineral waste residue liquid composite grinding aid has stable property, high cost performance and wide adaptability, is low in cost and mixing amount and can be used for improving the grinding effect and increasing the yield of a grinder by above 15%, the specific surface area of the mineral waste residue micro powder by 4.7%-6.2% under the condition of the same grinding time and the activity index of the mineral waste residue micro powder.

Owner:辽宁天宝华瑞建材有限公司

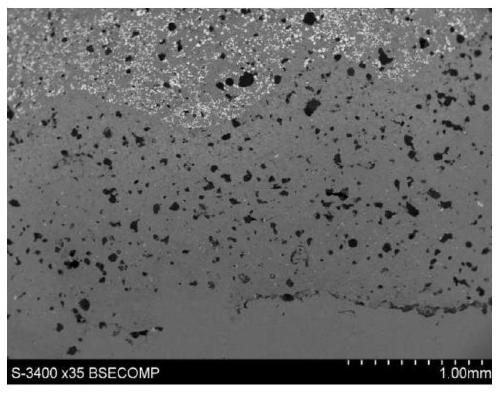

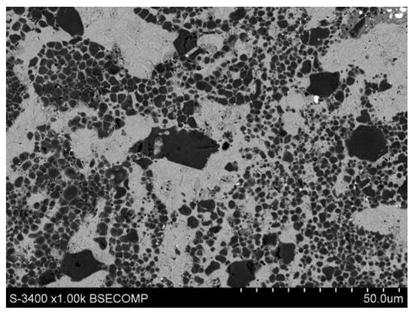

Wear-resistant steel-bonded hard alloy composite hammer head and manufacturing method thereof

ActiveCN111482579AHigh impact energy valueImprove toughnessFoundry mouldsFurnace typesTitanium metalDry sand

The invention provides a wear-resistant steel-bonded hard alloy composite hammer head and a manufacturing method thereof. The manufacturing method comprises the following steps of: step (1). blendingtitanium powder, graphite powder, additional hard particles and additives, adding a water-based binder, mixing uniformly, and making the mixture into alloy powder paste or stamping the mixture to forma preform; step (2). pasting the alloy powder paste or fixing the dried preform to the lost foam model of the hammer face of the hammer head, then coating anti-sticking sand fireproof paint, drying,burying in a box, and performing dry sand vibration modeling; and step (3). pouring high-toughness austenitic manganese steel or low-carbon alloy steel melt, using high-temperature molten steel to induce the combustion reaction between titanium and carbon in the alloy powder paste or preform, wherein TiC particles are generated in situ, and the high-temperature molten steel penetrates into an alloy particle layer, and interacts with additional TiC, WC, Al2O3 and other alloy powder particles; and performing cooling and cleaning, then performing heat treatment, and thus, the high-toughness and high-hardness wear-resistant steel-bonded hard alloy composite hammer head is manufactured.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

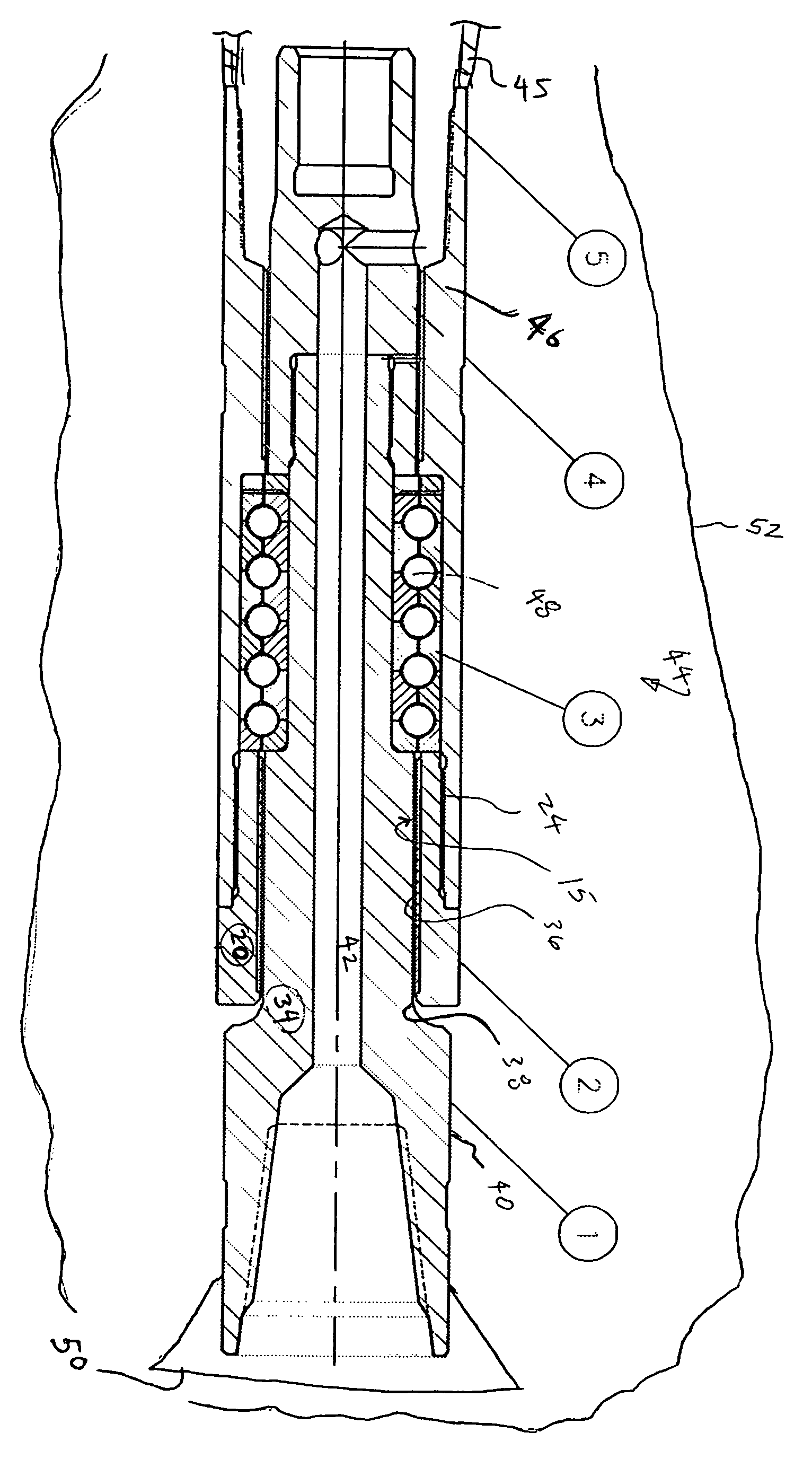

Process for manufacturing a bearing

InactiveUS7882638B2Strong and more ruggedEliminate needDrilling rodsShaftsEngineeringMechanical engineering

A process for manufacturing a bearing. The bearing may be used in a tool disposed within a bore hole. The process comprises providing a tubular sleeve and applying a hard facing material on the outer diameter of the tubular sleeve so that the hard facing material is fused onto the outer diameter, and thereafter applying a material layer on the outer diameter so that the material layer is fused onto the outer diameter. The method further includes machining the outer diameter so that a portion of the material layer is removed, and then machining the inner diameter so that only the hard facing material is left as an inner diameter. The method further includes machining the outer diameter and the inner diameter in order to form the bearing. In the most preferred embodiment, the method further includes placing the bearing into a housing, and inserting a mandrel into the bearing, and wherein a hard coating of the mandrel abuts the bearing. A mud motor for rotating a bit in a well bore is also disclosed.

Owner:RIVAL DOWNHOLE TOOLS LC

Liquid grinding aid for improving later strength of cement and preparation method of liquid grinding aid

The invention discloses a liquid grinding aid for improving the later strength of cement and a preparation method of the liquid grinding aid. The grinding aid is prepared from glycerol, modified diethanol amine, polycarboxylate alcohol amine ester, anhydrous sodium sulfate, ammonium acetate, paraffin oil, sodium lignin sulfonate, calcium lignosulphonate, sodium tripolyphosphate and deionized water. The grinding aid is simple in preparation process, low in cost, good in adaptability, capable of remarkably reducing the grinding energy consumption and improving the grinding efficiency and the later strength of cement, environmentally friendly, free of adverse effects on human health and good in application prospect.

Owner:山东天汇科技有限公司

Pipeline mud conveying device

InactiveCN107044146AReduce resistanceSpeed up the flowSoil-shifting machines/dredgersSteel ballHigh pressure

The invention discloses a pipeline mud conveying device. The pipeline mud conveying device comprises an outer pipeline, an inner pipeline concentric with the outer pipeline, and an air inlet formed in the outer pipeline, and a high-pressure air way is formed by a gap between the outer pipeline and the inner pipeline. A plurality of high-frequency vibrators are arranged in the high-pressure air way and located on the air inlet side. A high-pressure air hole communicating with the high-pressure air way is formed in the inner pipeline and located in the air inlet side. Each high-frequency vibrator comprises a pair of vibration supports, a vibrator shaft, a plurality of blades and a vibration steel ball arranged on the top of each blade through a vibration spring. The defects that during channel dredging work, the flowing resistance of mud in the pipelines is large, hydraulic power along the way is reduced rapidly, consequently, a dredger mud conveying system pipeline is abraded and blocked, the conveying distance is short and energy consumption is high are overcome, and therefore the flowing resistance of the mud in the pipelines is reduced, and hydraulic losses of mud along the way are reduced.

Owner:WUHAN UNIV OF TECH

Special type bone china material containing synthetic bone powder and preparation method thereof

ActiveCN104003364AStable particle distributionImproved particle size distributionPhosphorus compoundsThermal impactNatural bone

The invention relates to a special type bone china material containing synthetic bone powder. The special type bone china material comprises, by weight, 6-15 parts of quartz, 8-15 parts of potassium feldspar, 25-30 parts of kaolin, 5-10 parts of ball clay, 26-36 parts of natural bone powder, 10-20 parts of synthetic bone powder, and 0.1-0.15 part of CMC. The invention further provides a preparation method of the synthetic bone powder and a preparation method of the special type bone china material containing the synthetic bone powder. The transmittance of light of bone china products prepared through the method is remarkably increased, thermal impact resistance is substantially enhanced, particle distribution of the bone china pug is optimized, and the plasticity of the pug is obviously improved.

Owner:GUANGDONG SONGFA CERAMICS

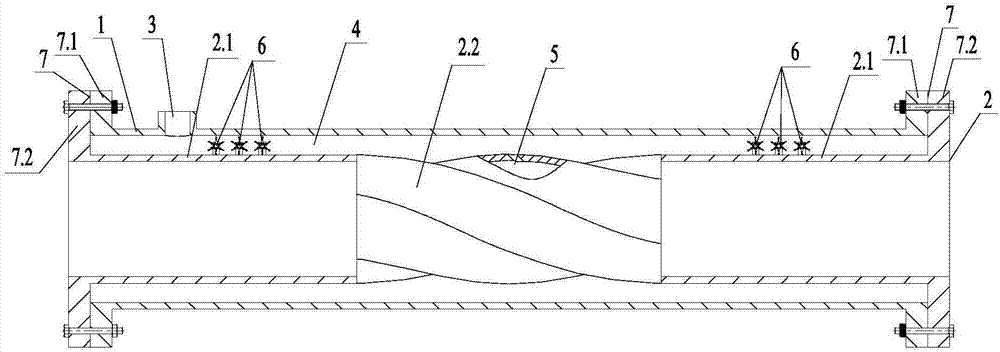

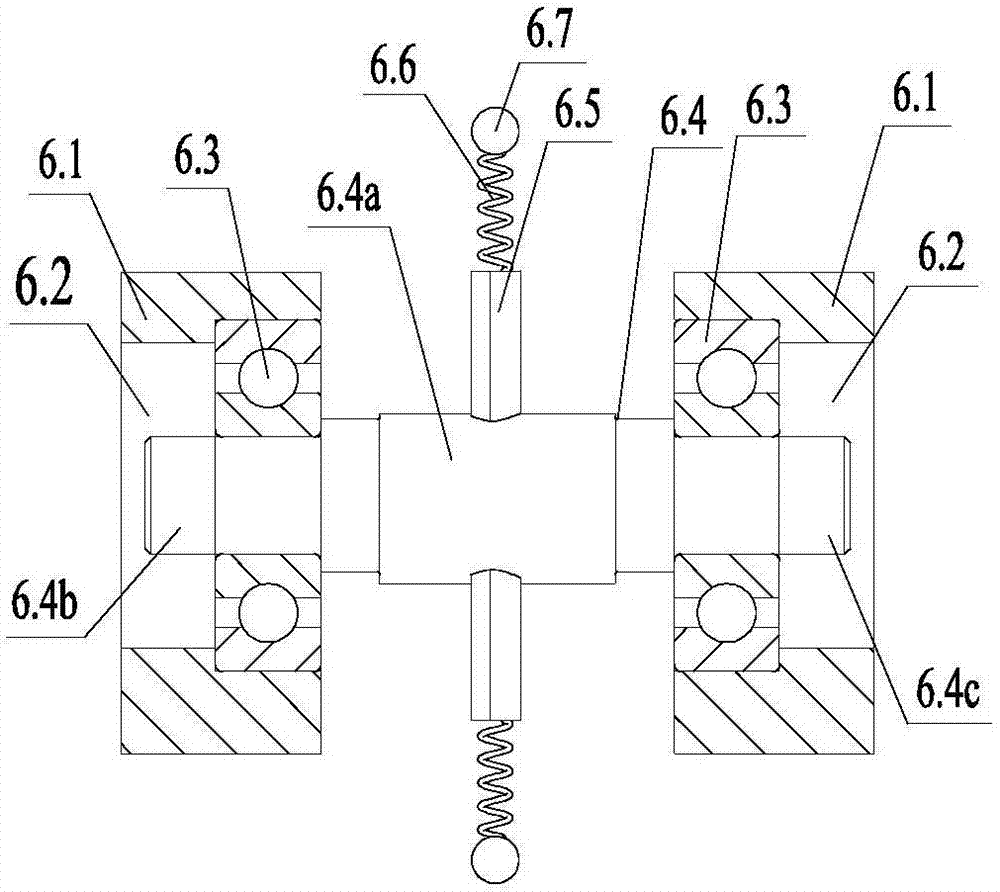

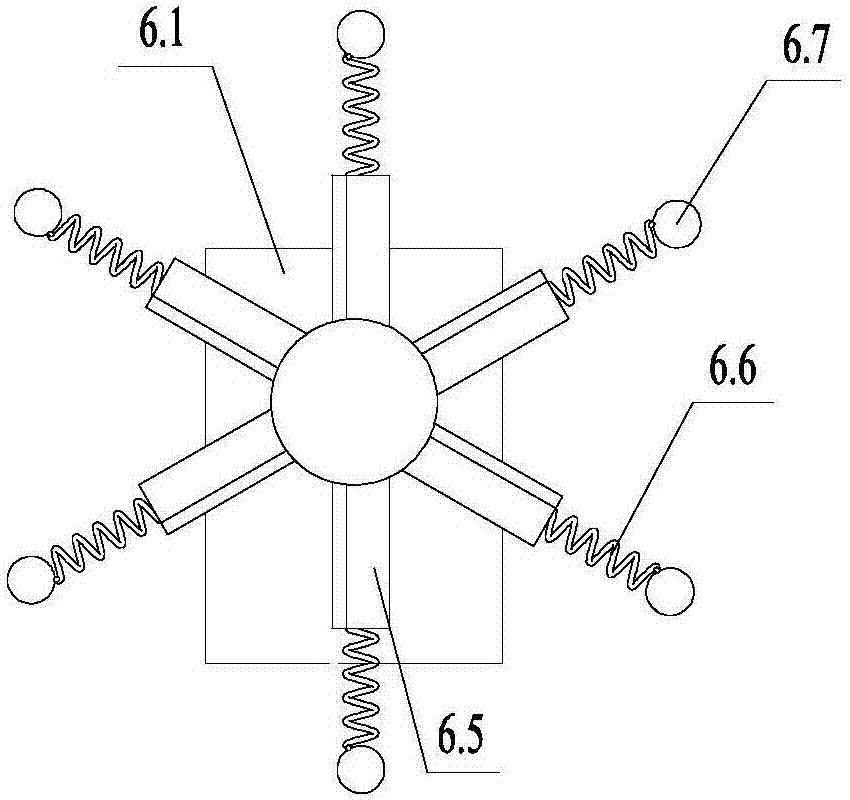

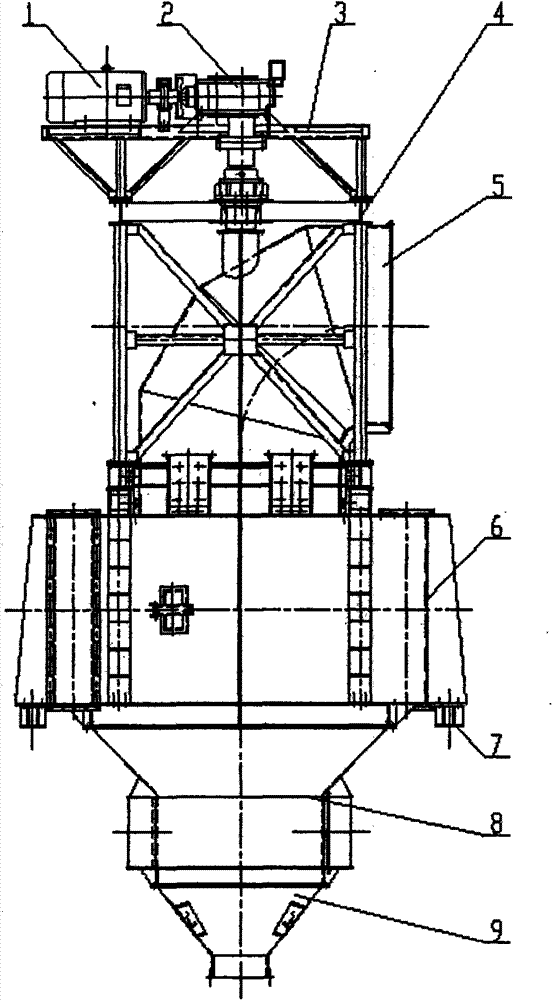

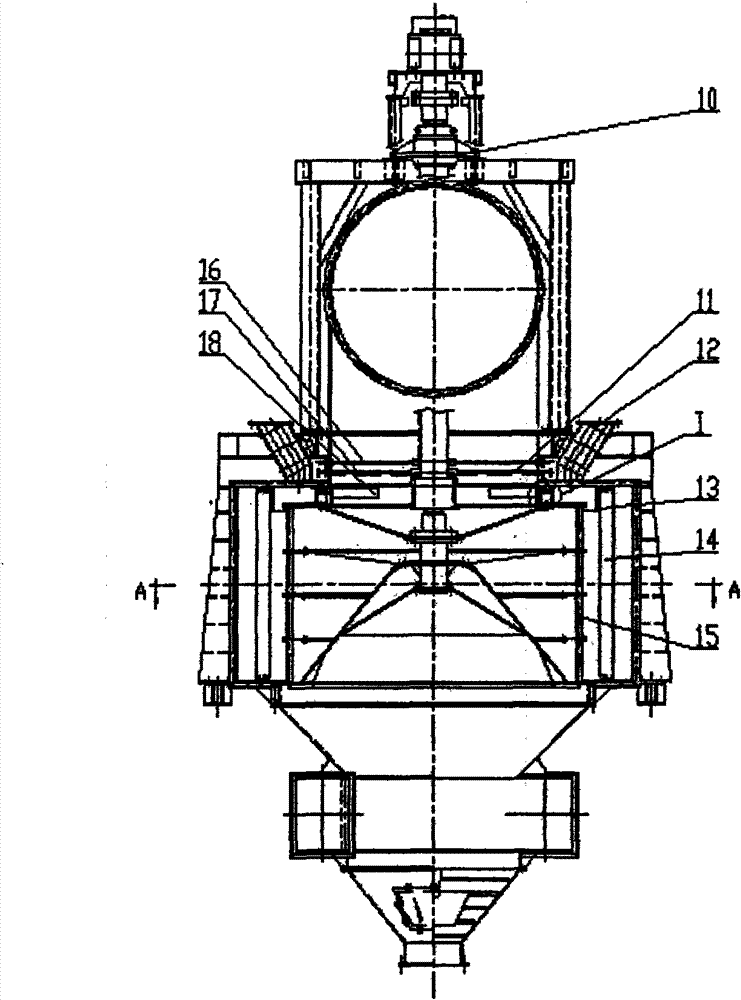

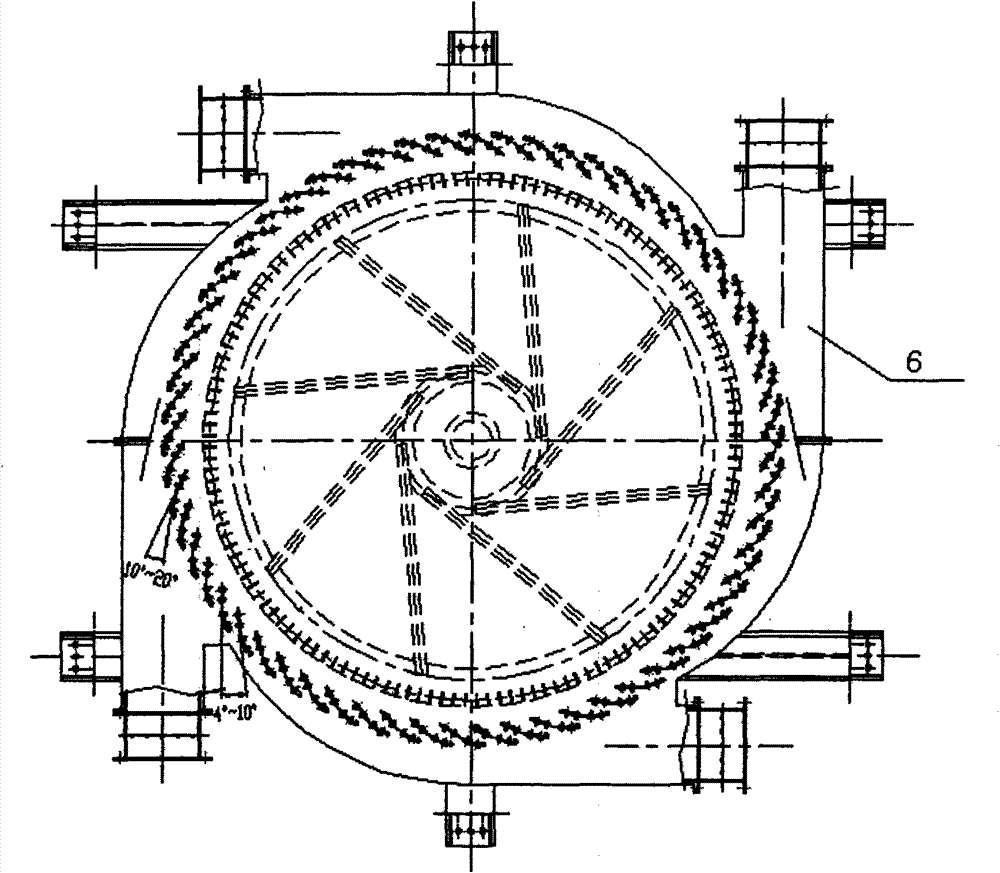

Horizontal inclined rotary fluidized bed desulfurizing reactor

InactiveCN1820827AUniform responseSolve the problem of low desulfurization reaction efficiencyDispersed particle separationChemical/physical processesInlet channelFluidized bed

The present invention provides one kind of horizontal inclined rotary fluidized bed desulfurizing reactor. The desulfurizing reactor is one double-layer structure including a truncated cone inner barrel with grid plate structure in the side wall, closed small caliber end and great caliber end as the gas outlet; and an outer barrel. There is a ring inlet channel formed between the small caliber end of the inner barrel and the outer barrel, the outer wall of great caliber end of the inner barrel is connected to the outer barrel, and the inclined reactor has outlet end higher than the inlet end. The present invention combines the fluidizing pneumatic force and the rotary centrifugal force well to realize the full reaction between SO2 and the desulfurizing agent grains, and has long reaction gas remaining period, high utilization rate one desulfurizing agent, and high desulfurizing efficiency up to 90-97 %.

Owner:HARBIN INST OF TECH

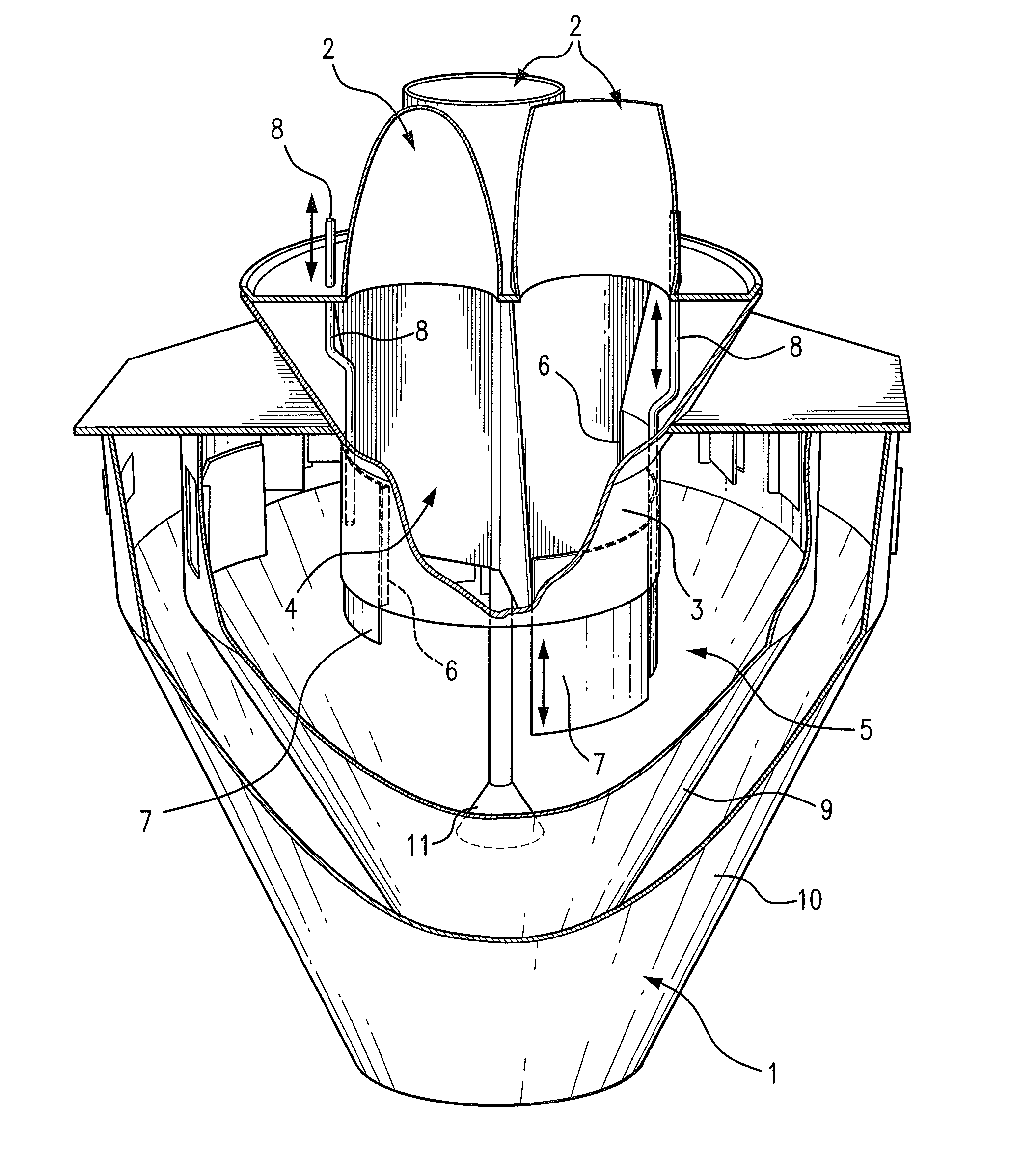

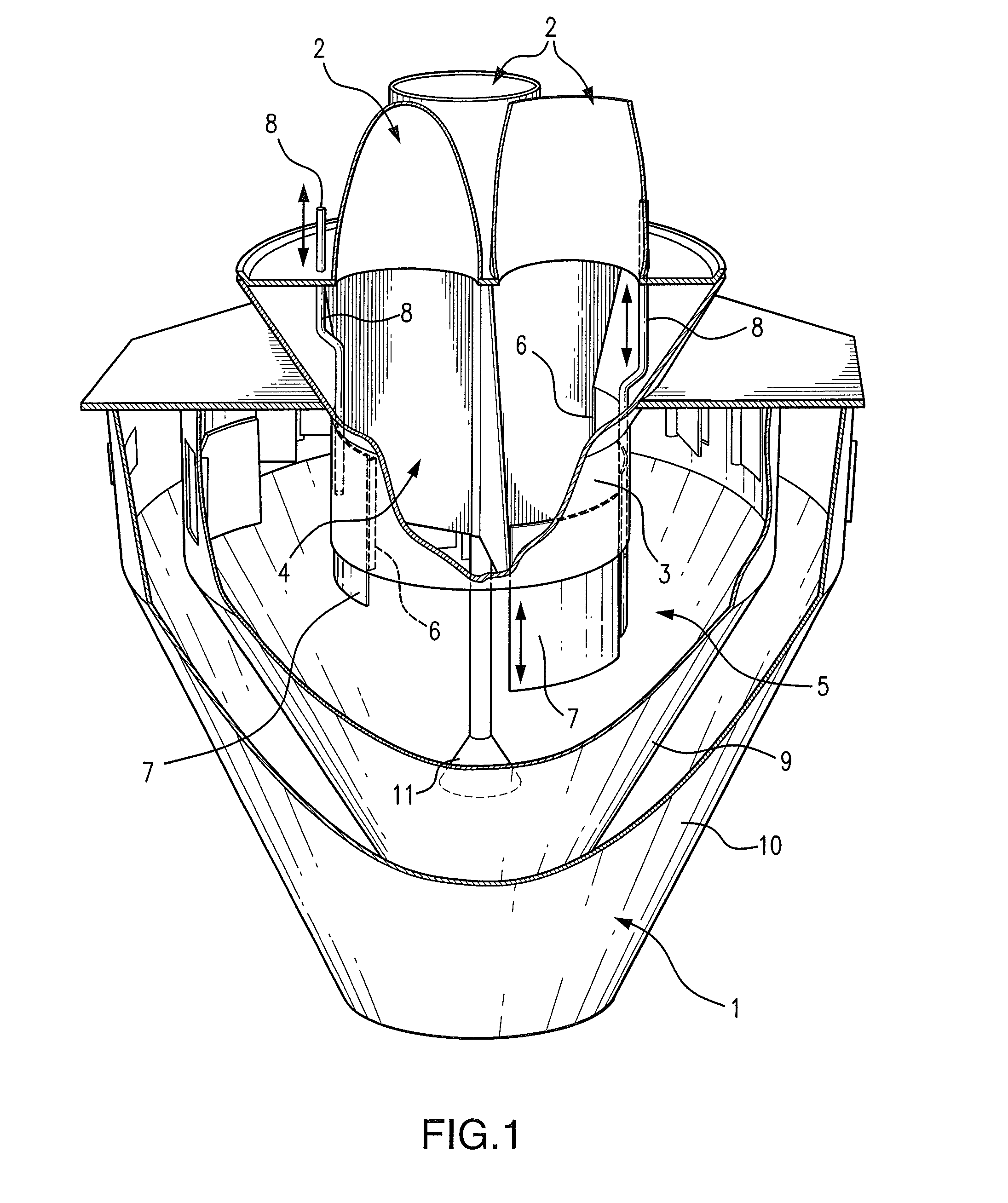

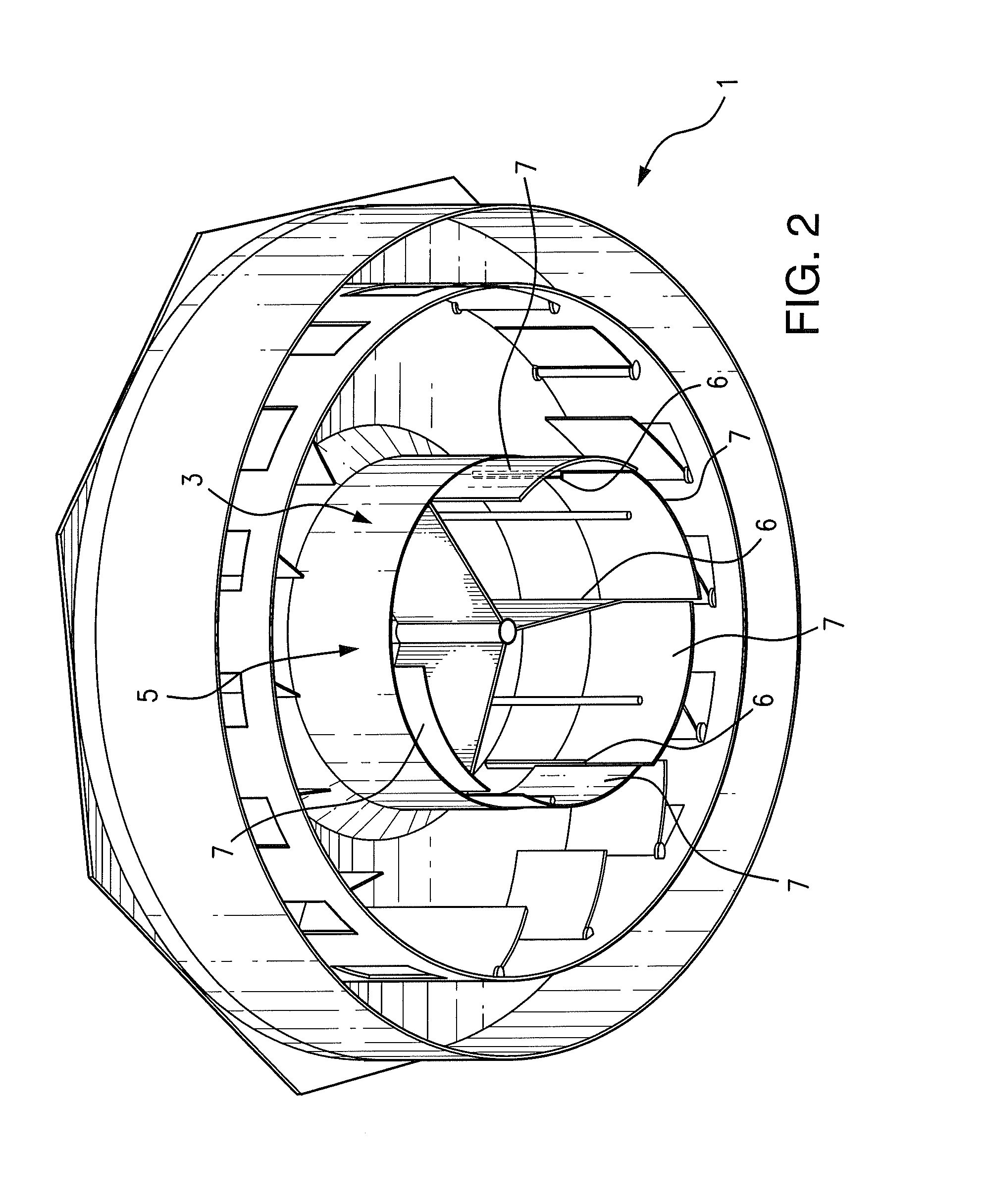

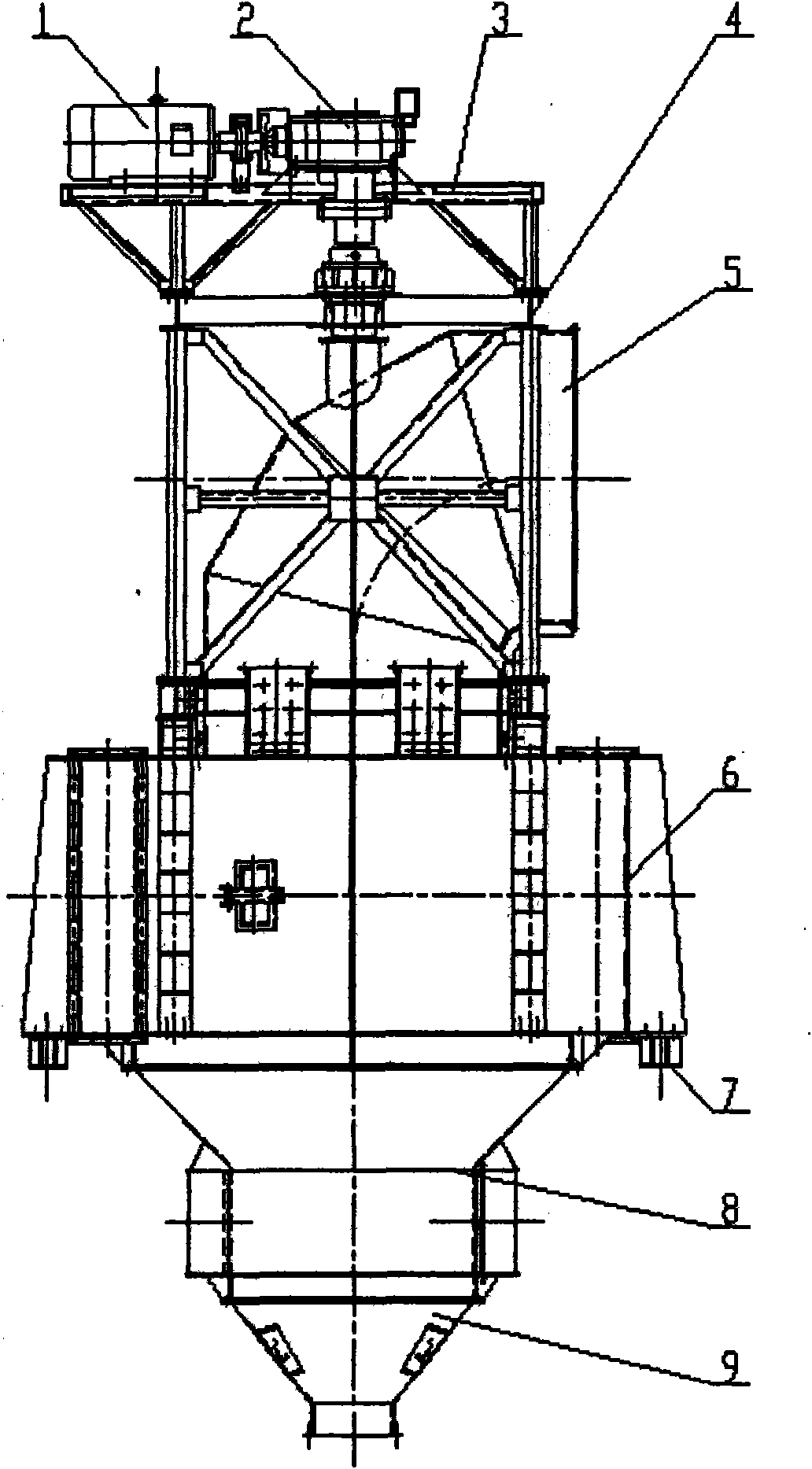

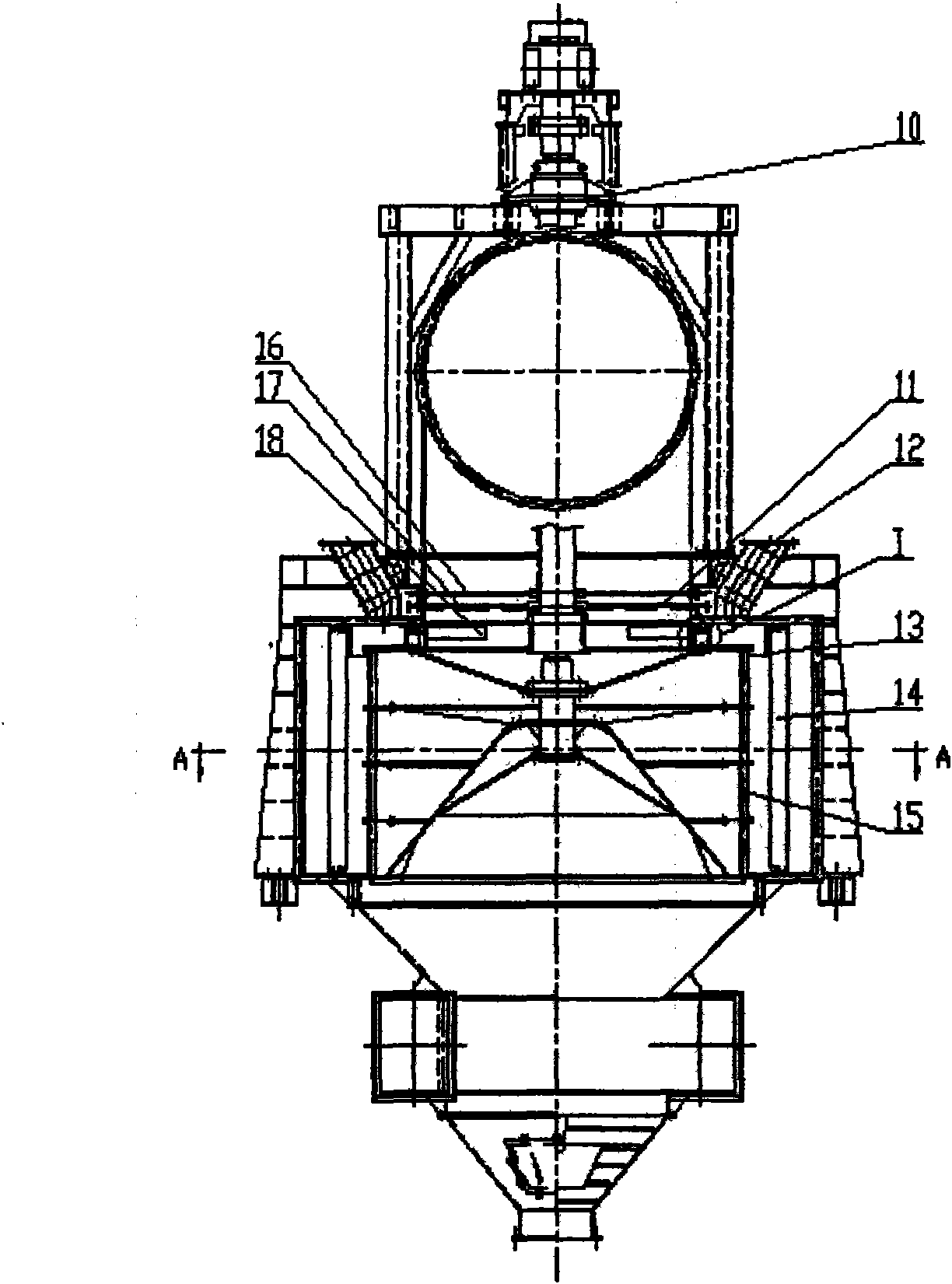

Low-resistance and high-efficiency powder concentrator

InactiveCN101653764AImprove powder selection efficiencyIncrease productionEngine sealsGas current separationLarge sizeMachining

The invention discloses a low-resistance and high-efficient powder concentrator which is a novel low-resistance and high-efficiency powder concentrator that is formed by scientifically combining two classification mechanisms together according to vortex classification and inertia centrifugal classification principles on the basis of comprehensively absorbing a classification principle of a third-generation high-efficient powder concentrator in the world and further carrying out improvement and development. The invention has high powder-concentration efficiency, reliable rotor seal, simple structure, small device size, light weight and flexible arrangement, can improve the yield of a mill by a large margin, does not need large-size castings or machining and is convenient for mounting and maintaining.

Owner:HEFEI CEMENT RES DESIGN INST

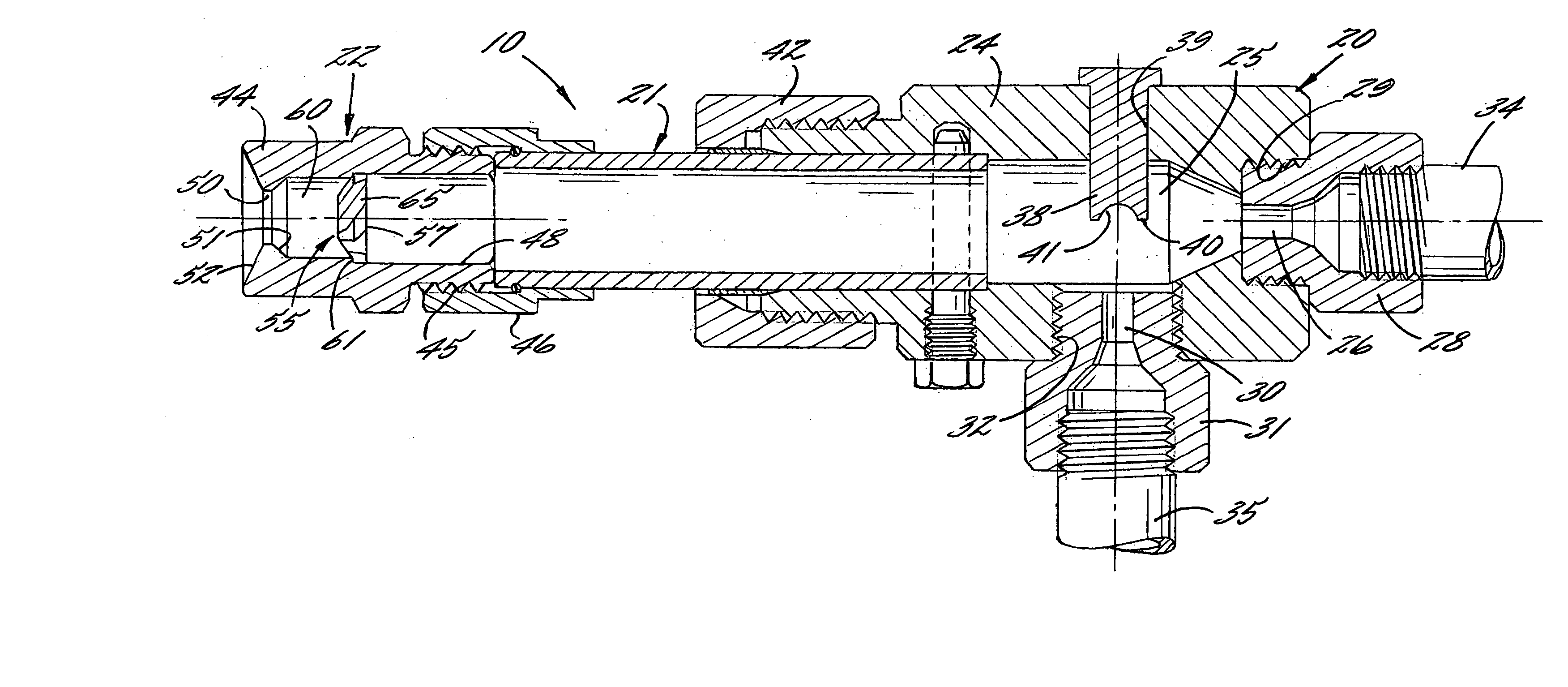

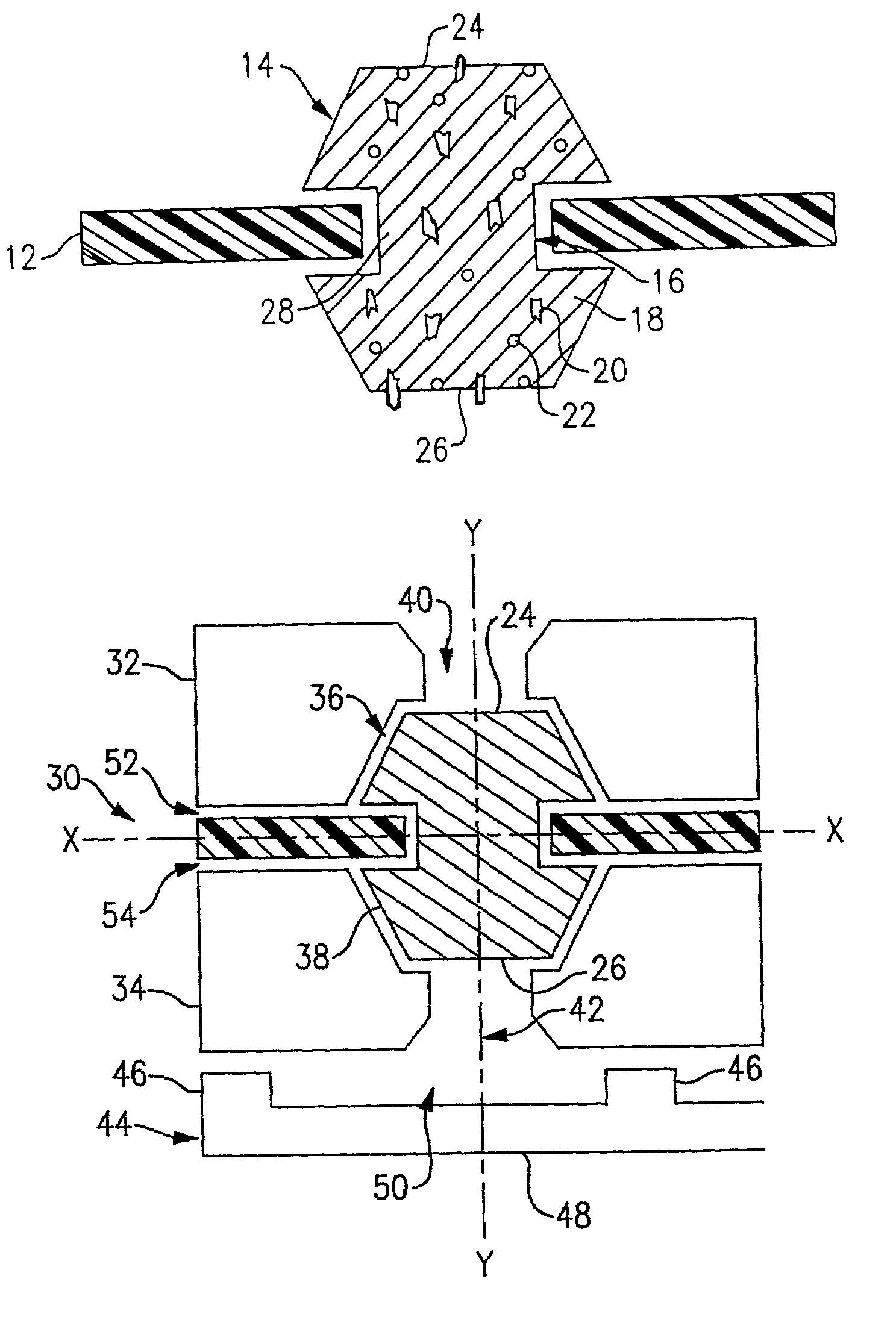

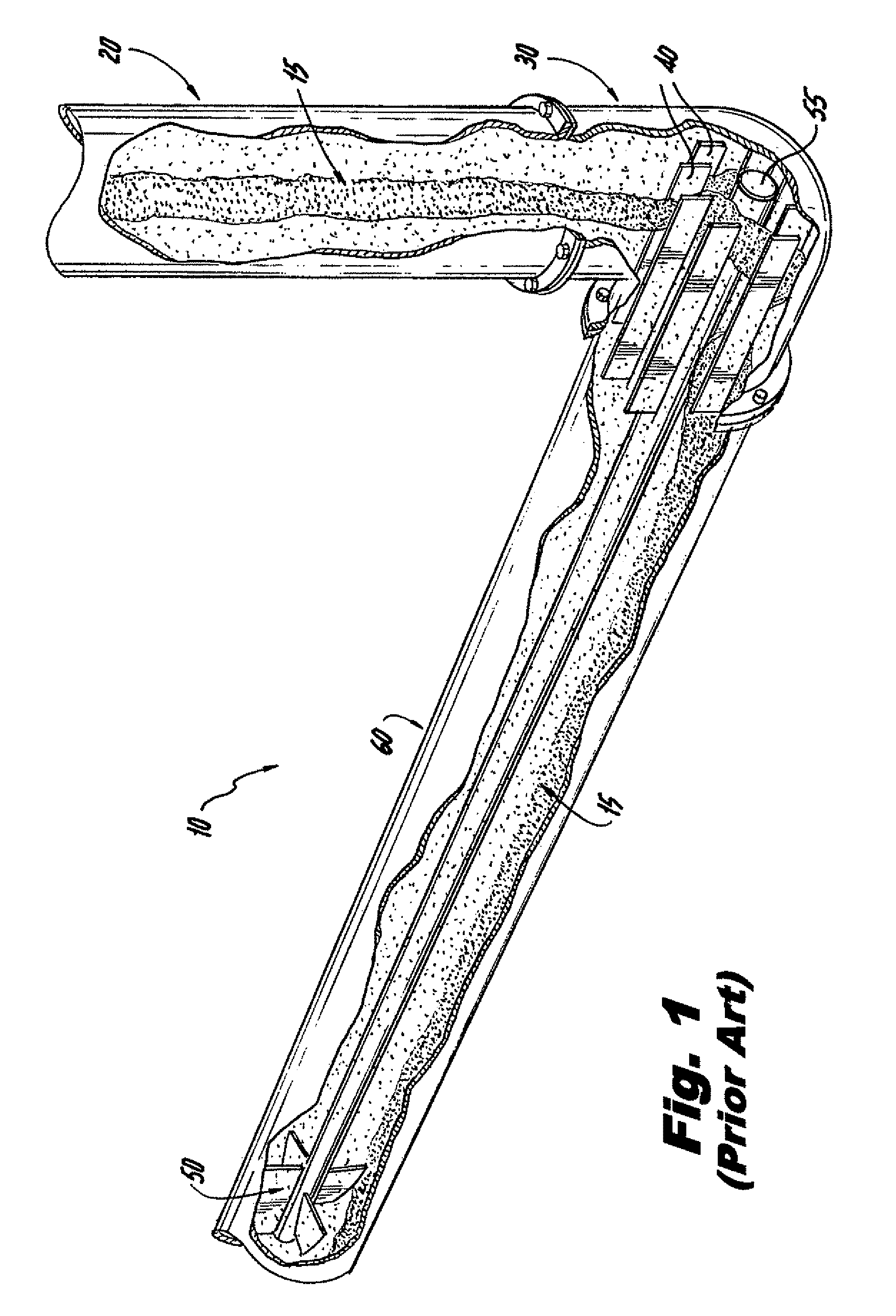

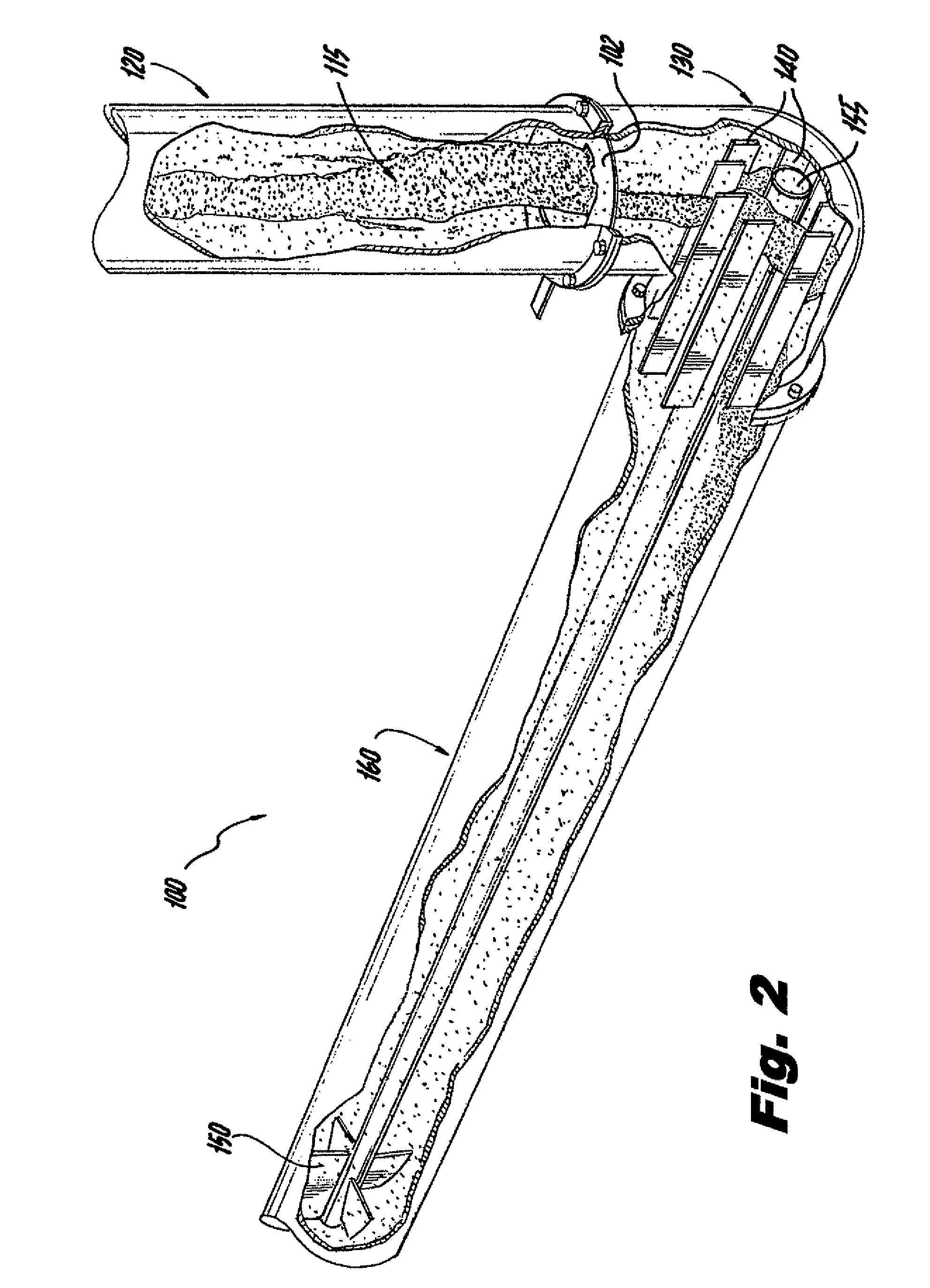

Anti-roping device for pulverized coal burners

ActiveUS8082860B2Improve particle distributionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelParticle flowVena contracta diameter

An orifice plate for improving particle distribution within a coal piping system includes a plate body defining a central orifice therethrough bounded by an inner periphery of the plate body. The plate body is configured and adapted to be affixed between end flanges of adjacent pipes in a coal piping system so as to generally align the central orifice with an internal flow passage through the coal piping system. Flow disruption features are defined in the inner periphery of the plate body. The flow disruption features are configured and adapted to disrupt a flow of air and particles flowing through the central orifice to provide a more uniform distribution of particles downstream of the plate body than upstream.

Owner:BABCOCK POWER SERVICES

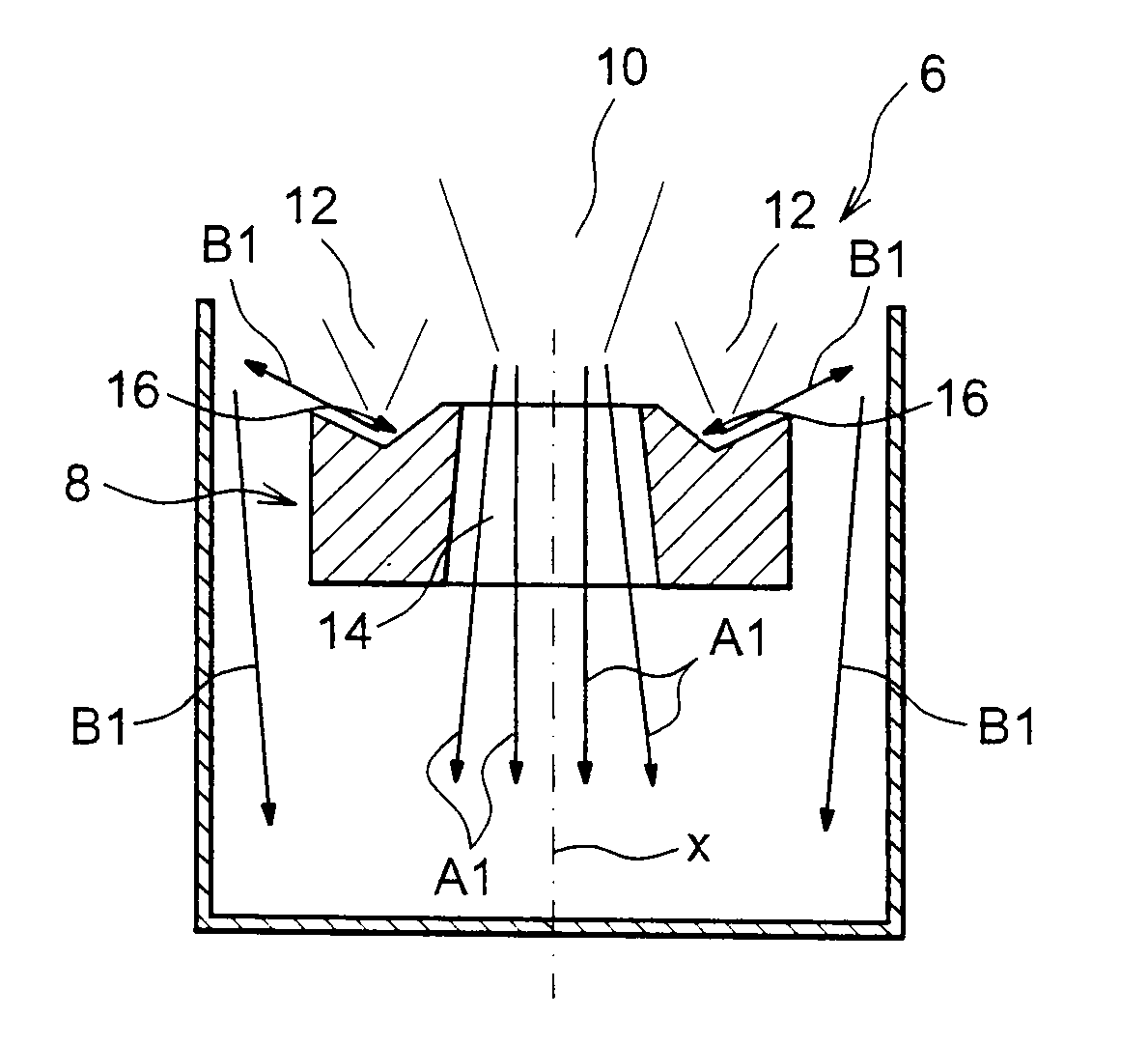

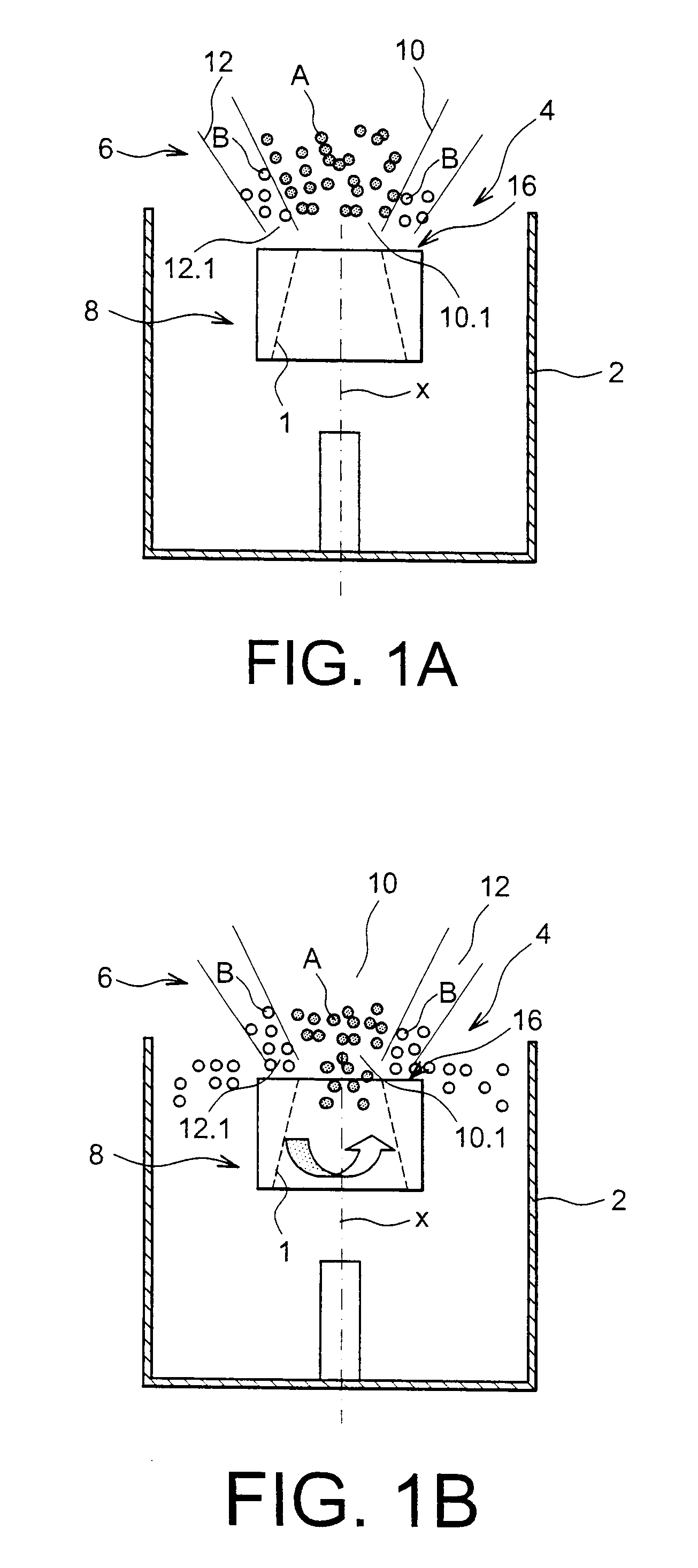

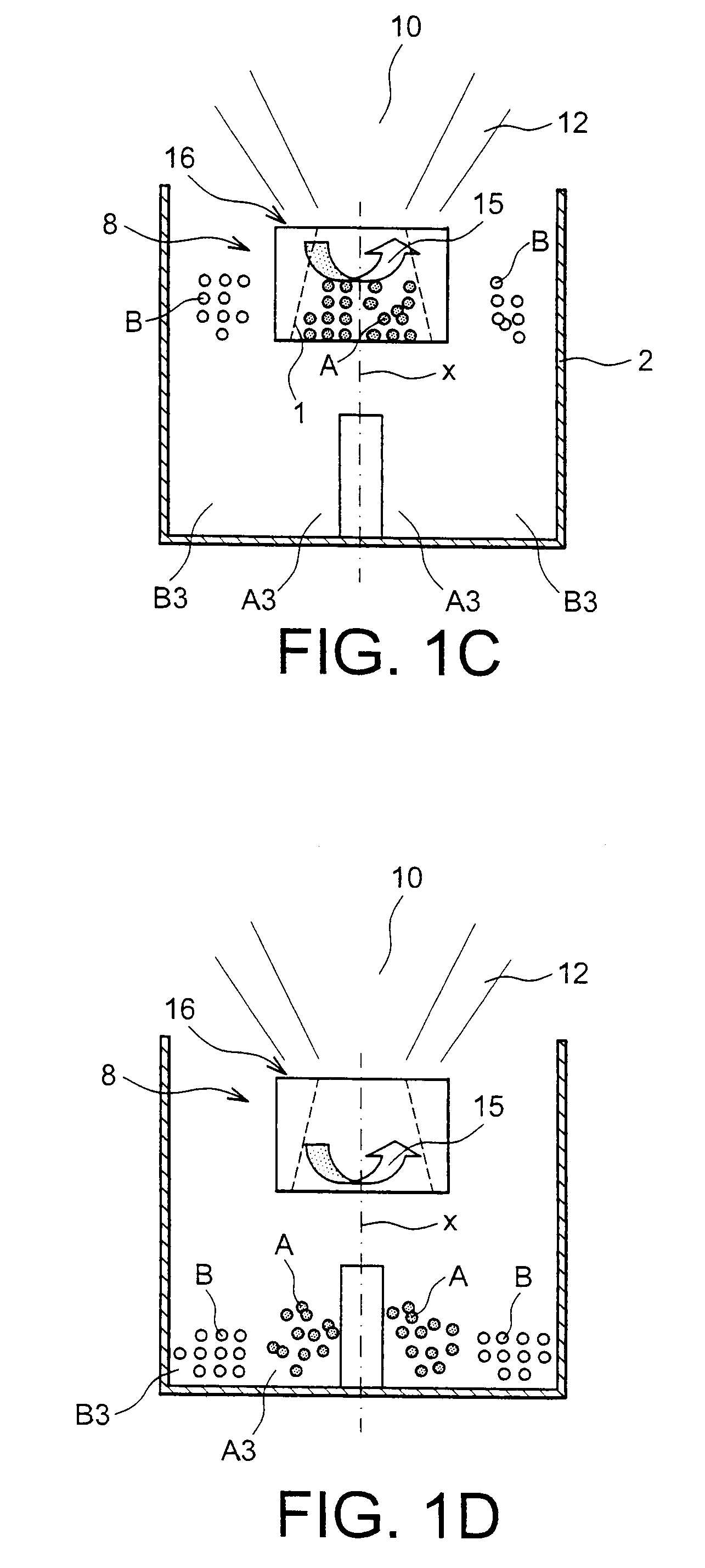

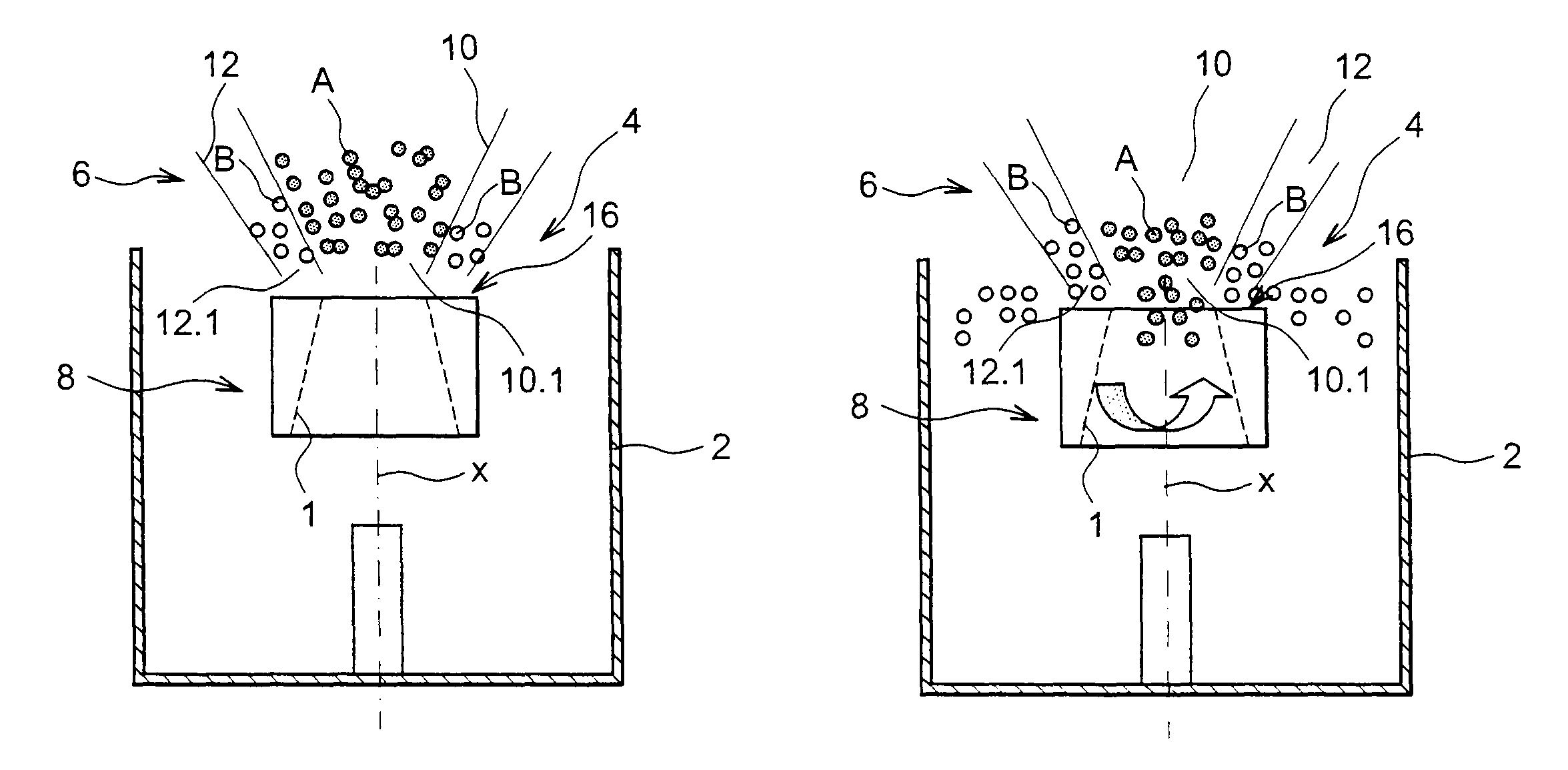

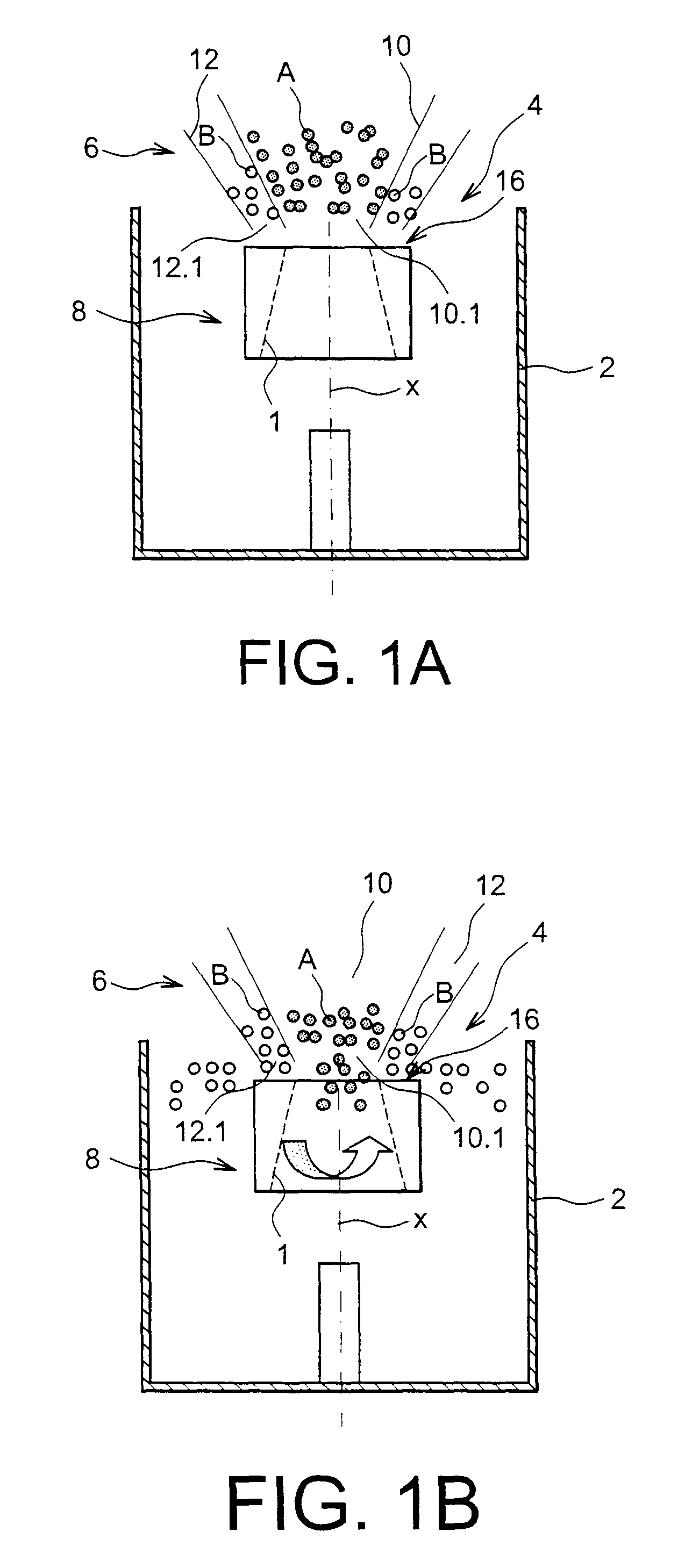

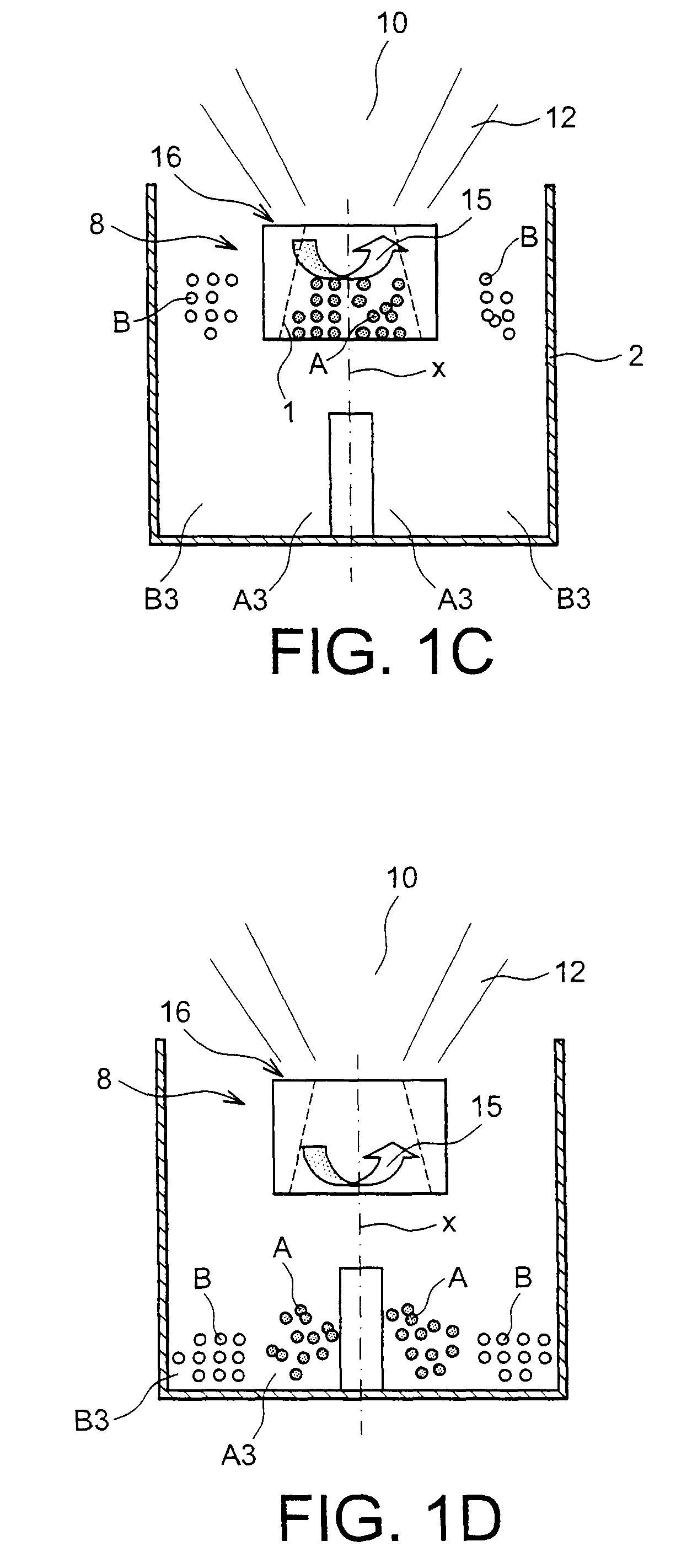

Filling device for at least two granular materials and filling method using such a device

InactiveUS20100320223A1Easily connectImprove particle distributionOpening closed containersBottle/container closureEngineeringMechanical engineering

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

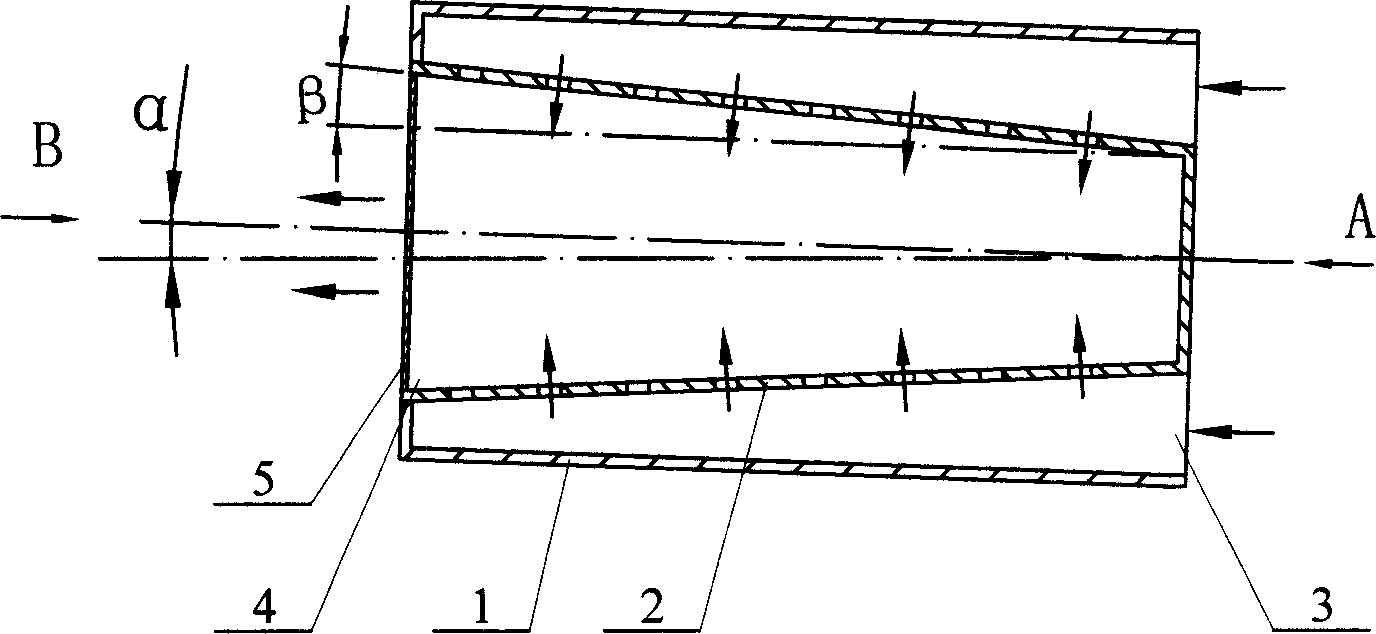

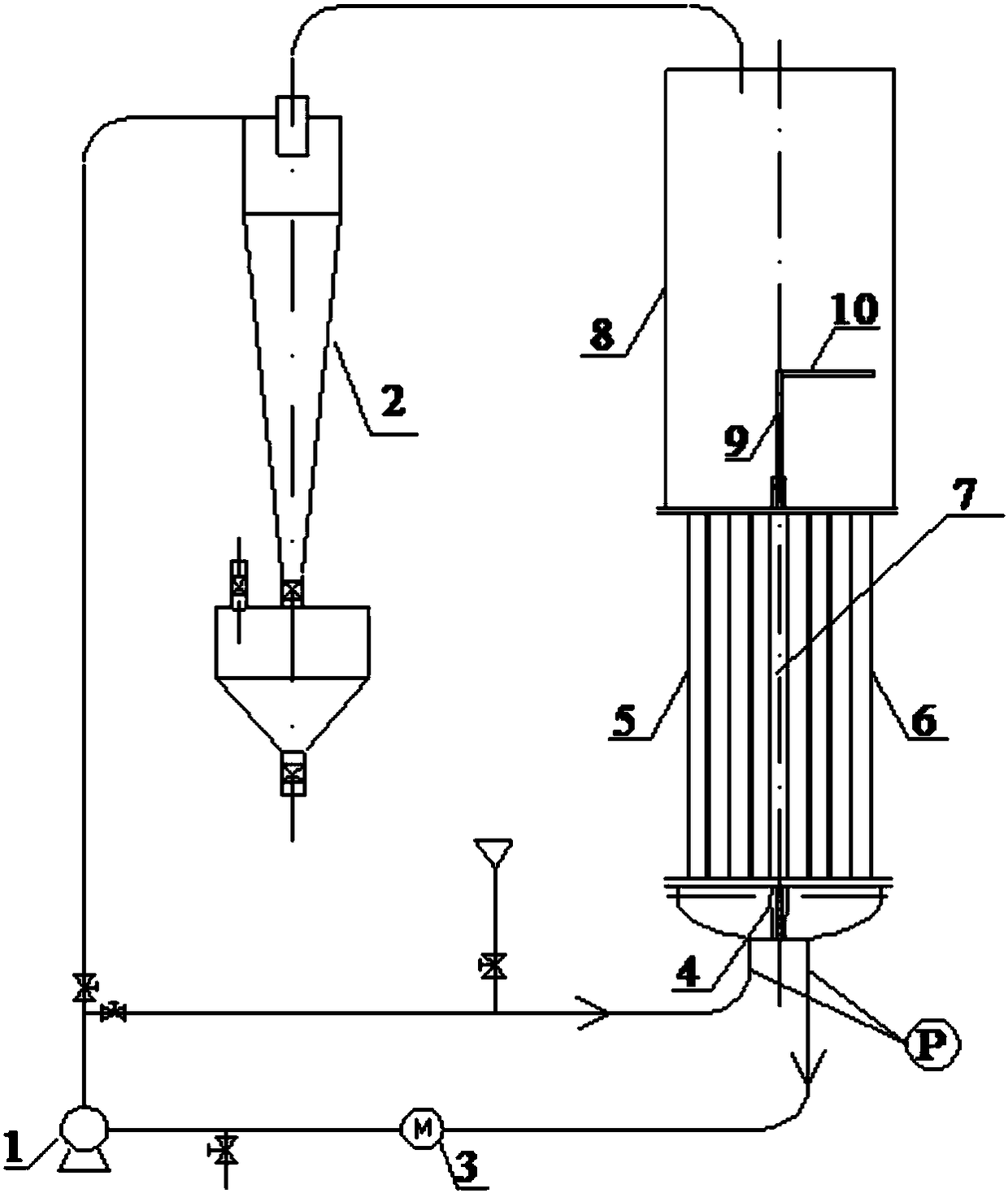

Vertical double-tube-pass circulation fluidized bed evaporator with separation plate

ActiveCN108187356AImprove particle distributionSimple structureEvaporator accessoriesEvaporators with forced circulationDouble tubeFluidized bed

The invention belongs to the technical field of evaporators, and discloses a vertical double-tube-pass circulation fluidized bed evaporator with a separation plate. The evaporator comprises a heatingchamber and an evaporation chamber, wherein the heating chamber comprises an ascending bed and a descending bed; the separation plate is arranged in the evaporation chamber; a mixed work medium prepared from solid particles and liquid phase work medium of pure water is added into the heating chamber and the evaporation chamber for forced circulation; a solid particle distribution plate is arrangedat the upper part of the separation plate; the solid particle distribution plate comprises a side plate fixedly connected to the separation plate and a main plate vertically connected onto the top ofthe side plate; the main plate is horizontally installed and is positioned above the descending bed; the main plate is provided with a plurality of rows of round holes which gradually become bigger from inside to outside and are used as solid particle passage openings. The evaporator has the advantages that the structure is simple; the processing is convenient; the online scale prevention and scale removal and reinforced heat transfer can be realized. The particle distribution device can effectively improve the particle distribution condition of the descending bed; solid particles can be uniformly distributed into a tube bundle of the descending bed; the heat transfer, scale prevention and scale removal effects can be further and favorably improved and reinforced.

Owner:TIANJIN UNIV

Filling device for at least two granular materials and filling method using such a device

InactiveUS8316896B2Good repeatabilityFirmly connectedLiquid fillingFeeding arrangmentsEngineeringGranular material

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Handheld shaker bottle with dispensing cap

InactiveUS20170217647A1Improve particle distributionControl flowOpening closed containersBottle/container closureHand heldBottle

Owner:ROSENBAUM NEIL +2

Electrically powered hand spreader

ActiveUS9222231B2Improve particle distributionMinimize contactFertiliser distributersWay cleaningParticulatesHand held

A handheld spreader having a fillable container for dispensing particulate from an electrically powered blower assembly in a detachable base. The spreader includes a feed slide leading from the container to the air stream channel of the base that has a vibrating eccentric plate for guiding and improving the flow of particulate from container into the air stream. The container and base are frictionally engaged together, thereby allowing for easy assembly of spreader, including assembly after container has been filled with particulate, as well as easy reassembly if container is removed and refilled. The spreader includes a rotating slide that may be operated by a user to open and partially close the feed slide of the container to control the feed rate.

Owner:MARCONI FRED

Low-resistance and high-efficiency powder concentrator

InactiveCN101653764BImprove powder selection efficiencyIncrease productionEngine sealsGas current separationLarge sizeMachining

The invention discloses a low-resistance and high-efficient powder concentrator which is a novel low-resistance and high-efficiency powder concentrator that is formed by scientifically combining two classification mechanisms together according to vortex classification and inertia centrifugal classification principles on the basis of comprehensively absorbing a classification principle of a third-generation high-efficient powder concentrator in the world and further carrying out improvement and development. The invention has high powder-concentration efficiency, reliable rotor seal, simple structure, small device size, light weight and flexible arrangement, can improve the yield of a mill by a large margin, does not need large-size castings or machining and is convenient for mounting and maintaining.

Owner:HEFEI CEMENT RES DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com