High-effective flour screening machine with wide size distribution of particles

A powder classifier and wide-grain technology, applied in solid separation, separation of solids from solids with air flow, grain treatment, etc., can solve the problems of increased investment, low proportion of mixed materials, and decreased cement performance, and achieve reduction Energy consumption and production cost, the effect of improving particle distribution and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

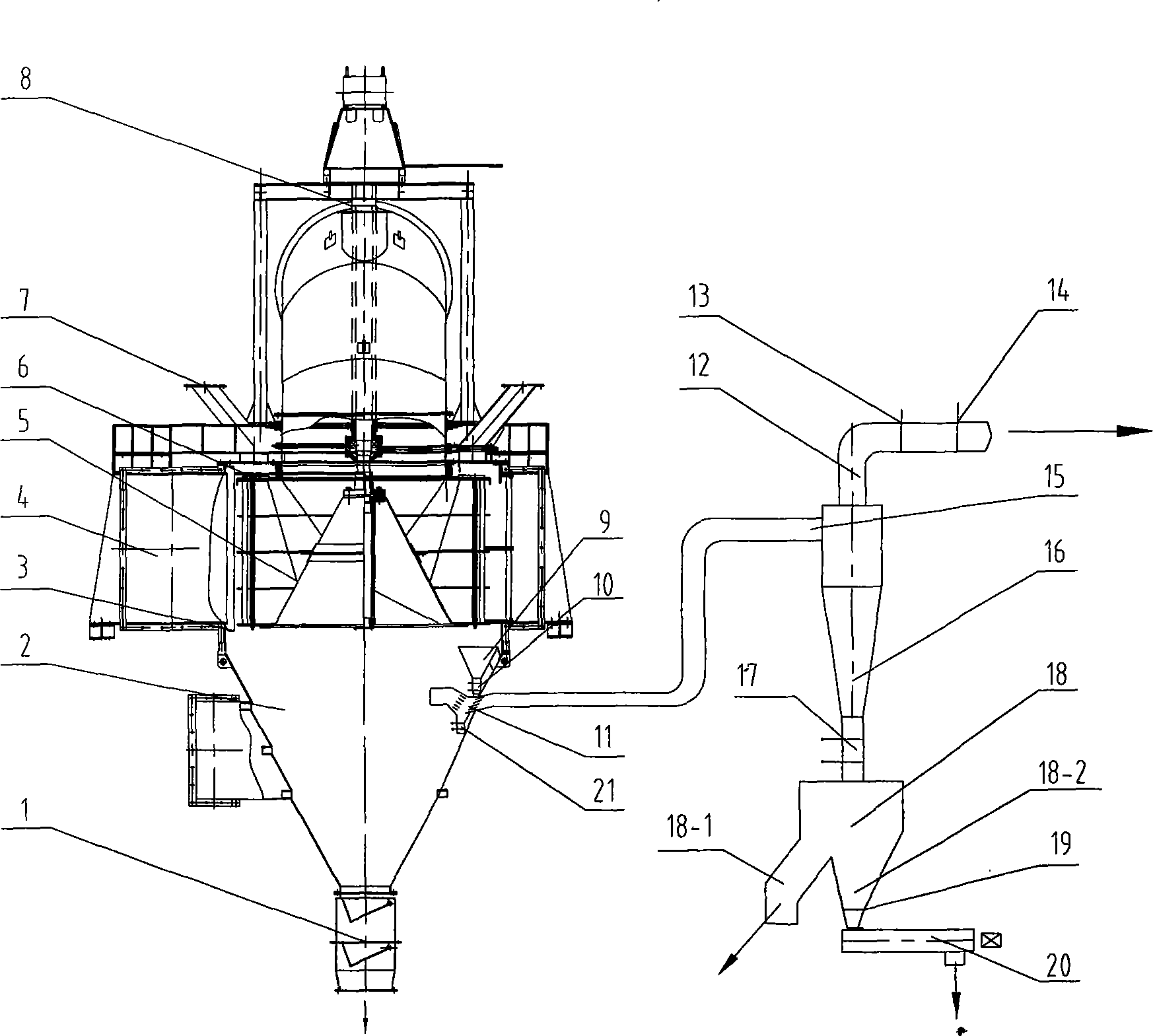

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] The present invention includes a housing 3, a cage rotor 5, a spreader 6, a central air duct 8, a coarse powder cone 2 and a secondary powder selection mechanism; the central air duct 8 is mounted on the upper part of the housing 3, and a Distributing disc 6 is provided with feeding port 7 on the housing 3 corresponding to distributing disc 6, and cage rotor 5 is provided under distributing disc 6, at the tangent line of housing 3 corresponding to cage rotor 5 An air inlet 4 is provided in the direction; a coarse powder cone 2 is provided below the cage rotor 5, and a discharge valve 1 is connected to the lower opening of the coarse powder cone 2. The secondary sorting device includes a collection hopper 9, a four-way joint 11, a separator 16 and an overflow bin 18. The annular collection hopper 9 is arranged on the top of the coarse powder cone 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com