Low-resistance and high-efficiency powder concentrator

A low-resistance, high-efficiency, powder-separator technology, applied in mechanical equipment, engine components, engine sealing, etc., can solve the problem of increasing the number of powder-separating feed ports, affecting the stability of the classification flow field, and uneven distribution of powder by the powder-separator. problems, to achieve the effect of reducing equipment resistance, improving production environment, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

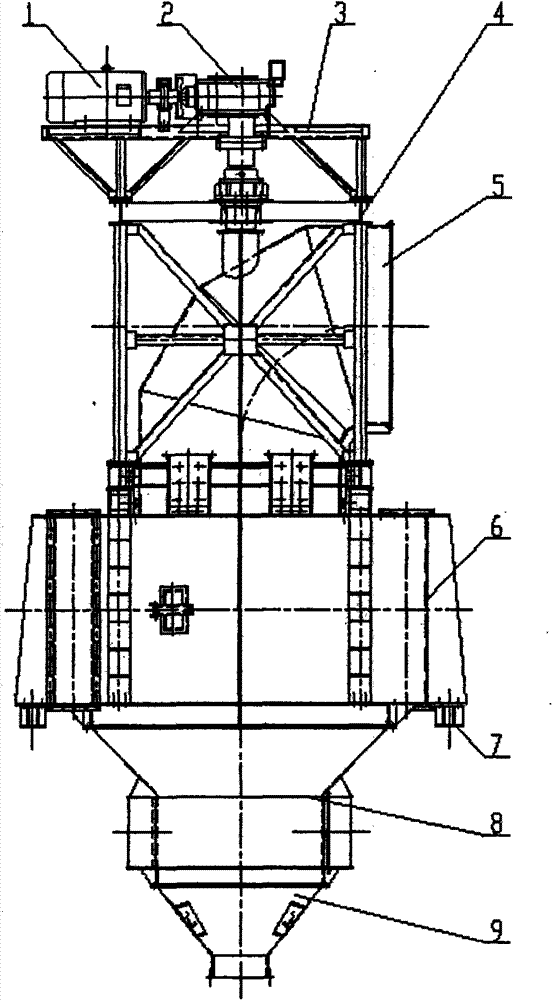

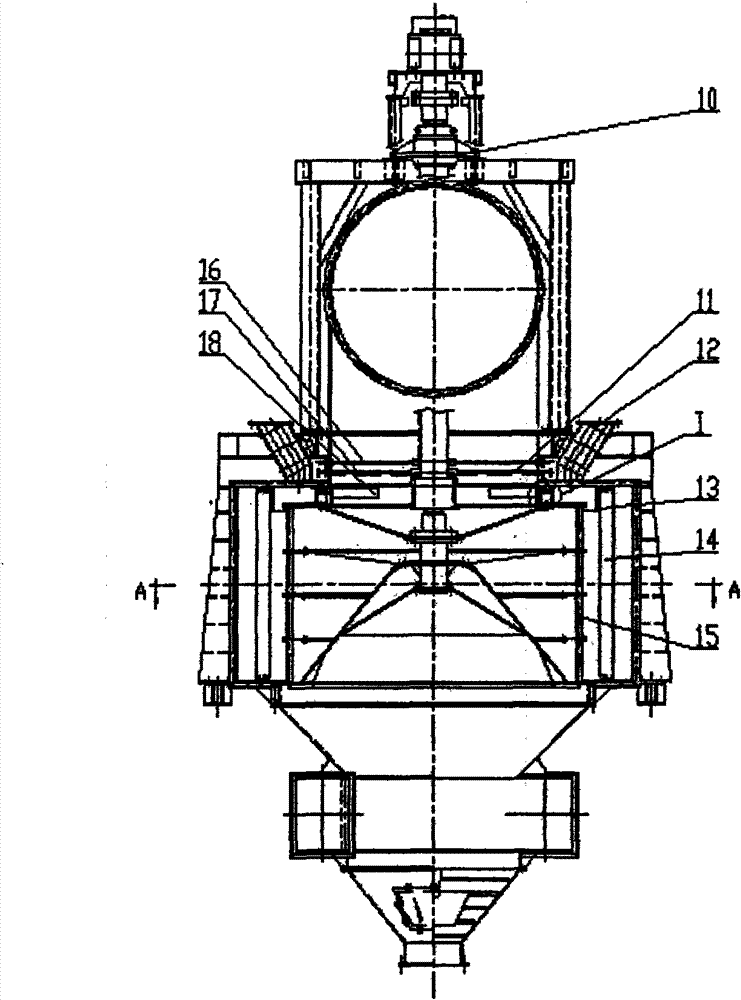

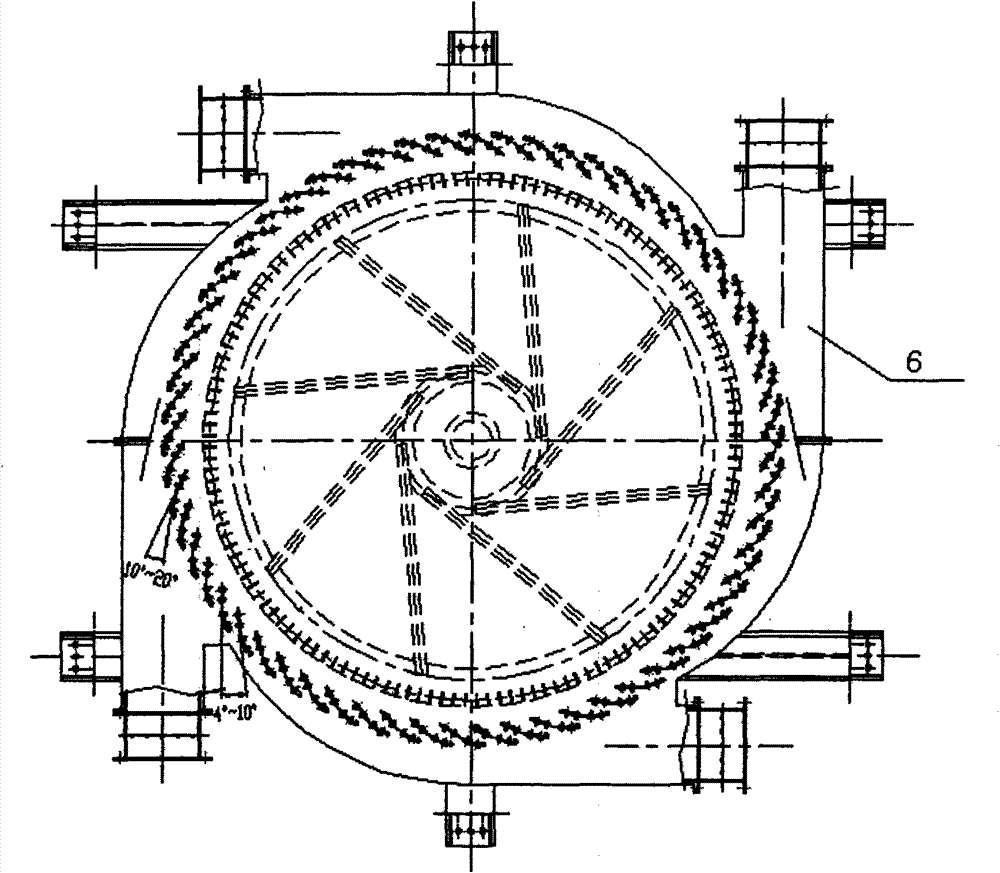

[0034] see Figure 1-4 .

[0035] A low-resistance and high-efficiency powder separator: it has a volute body 6, four air inlets are arranged on the outside of the volute body 6, the casing leg is installed at the lower end of the volute body, and the rotor assembly is installed inside the volute body, and the rotor assembly and There is a sealing structure between the volute shells, and a number of guide vanes are installed in the volute shell according to certain rules. The tertiary air inlet device is installed under the volute shell, and the air outlet pipe is connected above the volute shell. There is a beam bracket, and a motor reducer bracket is installed above the beam bracket. A motor and a reducer are installed on the motor reducer bracket. The output shaft of the reducer is connected to the main shaft, and the main shaft is connected to the rotor assembly through the air outlet pipe.

[0036] The sealing structure includes the rotor top plate, the inner edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com