Secondary cement and raw material selection process and fluid-bed conveyer and powder selection machine

A boiling type powder separator technology, applied in the direction of solid separation, separation of solids from solids with air flow, chemical instruments and methods, etc., can solve harmful and non-beneficial problems, and achieve the effect of improving the efficiency of powder selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

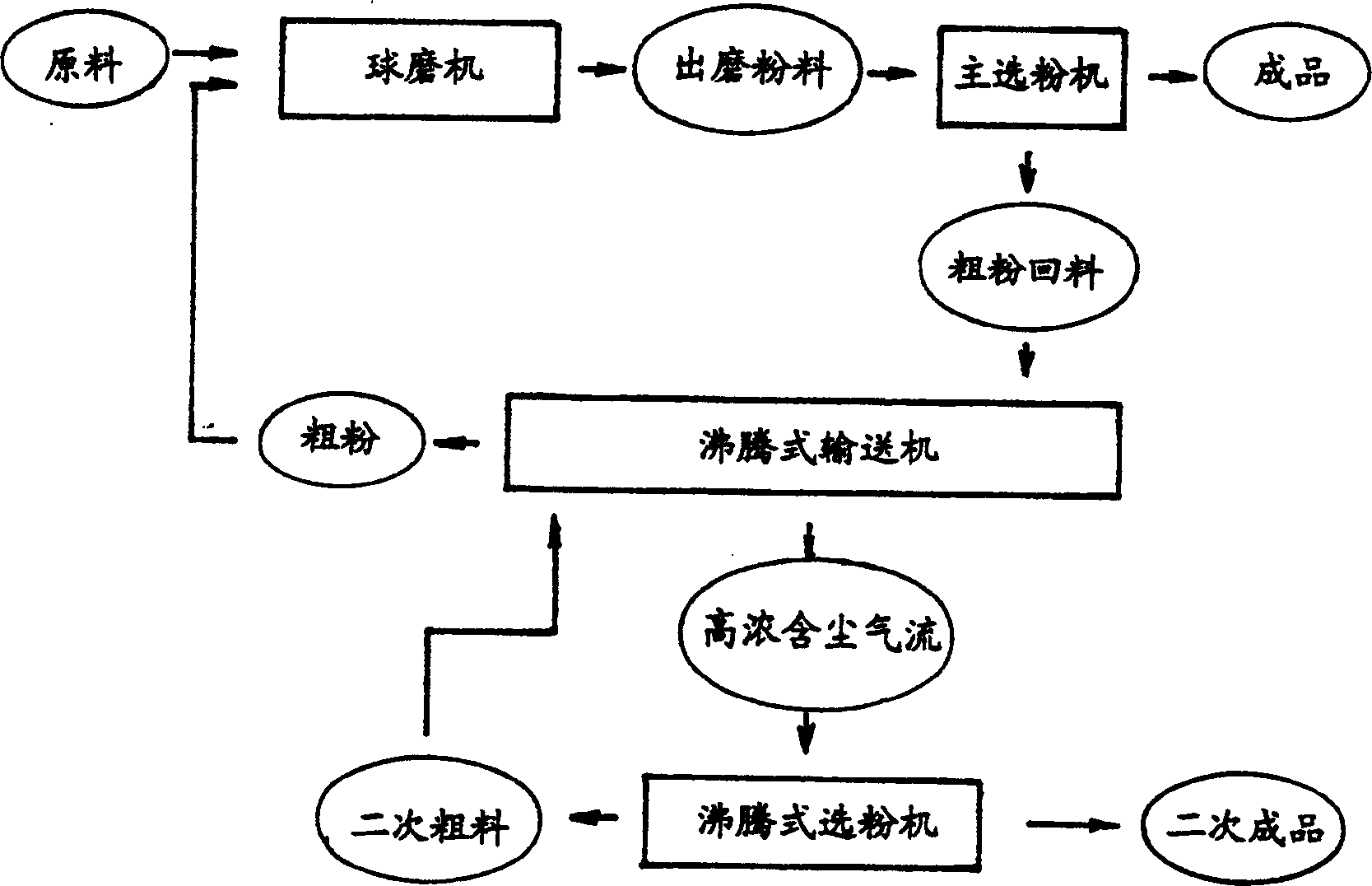

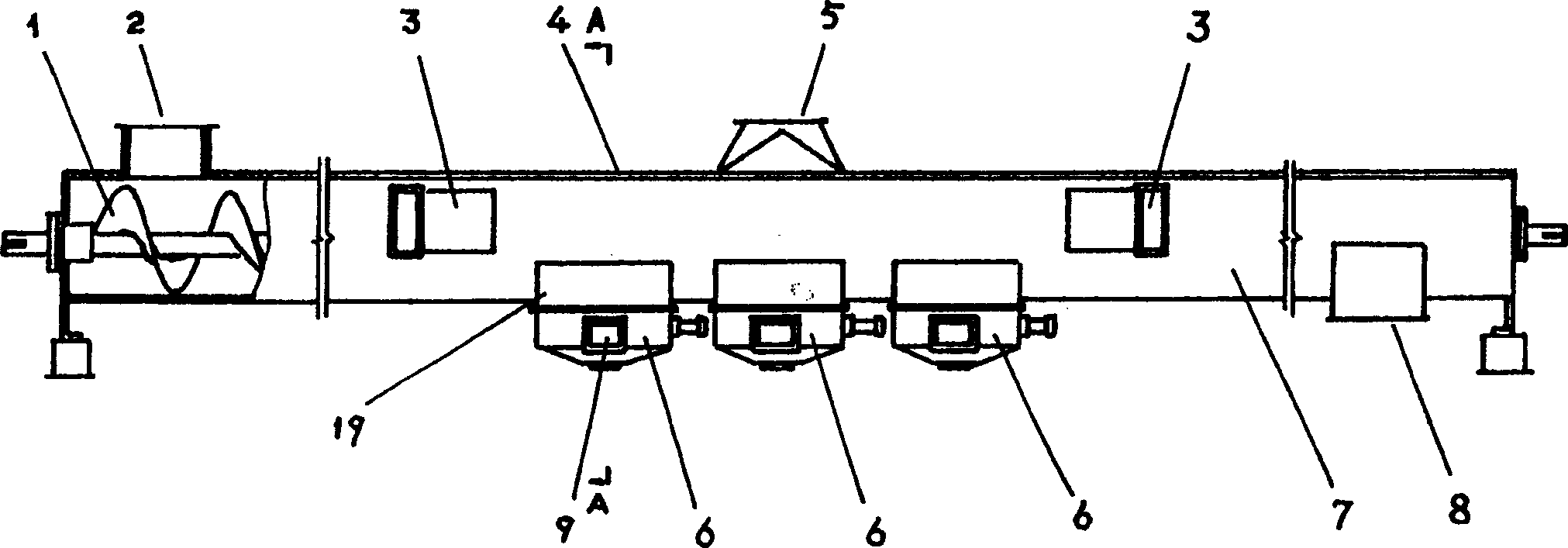

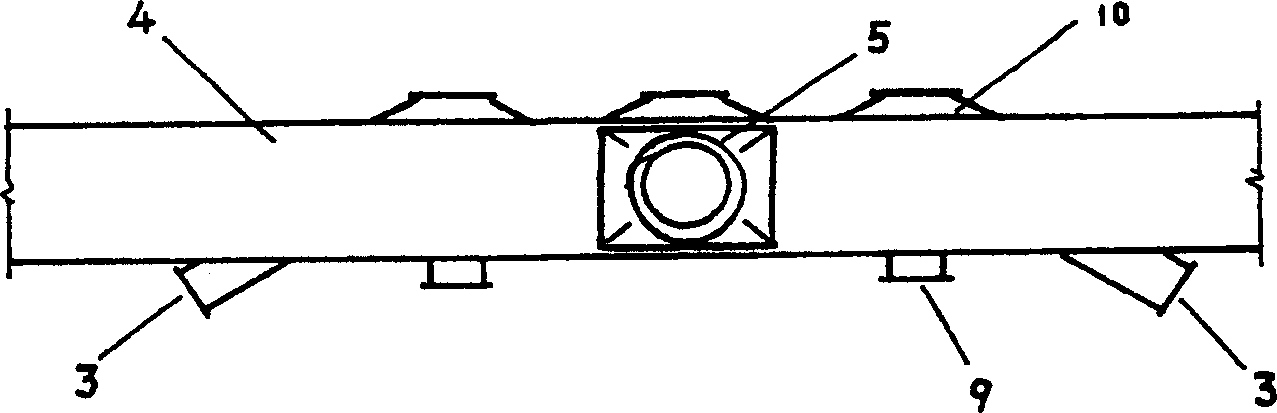

[0037] Such as figure 1 As shown, the secondary powder selection process includes sending the milled powder from the ball mill into the main powder separator for sorting to obtain qualified finished products and coarse powder returns, and the coarse powder returns are then processed by the secondary powder selection device. Secondary sorting, sorting out qualified secondary finished products and secondary coarse materials, and the secondary coarse materials are sent back to the ball mill for ball milling. The secondary powder selection device includes a boiling conveyor, a boiling powder separator, and a boiling conveyor The coarse powder returned by the main separator is transported to the ball mill head, and the high-concentration dust-containing airflow is separated from the coarse powder return during the conveying process, and the high-concentration dust-containing airflow enters the boiling type powder separator for further separation The qualified secondary finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com