Powder concentrator

A powder separator and cylinder technology, which is applied in the direction of solid separation, separation of solids from solids with airflow, grain processing, etc., can solve the problems of low efficiency of powder selection and poor dispersion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-6 The application is described in further detail.

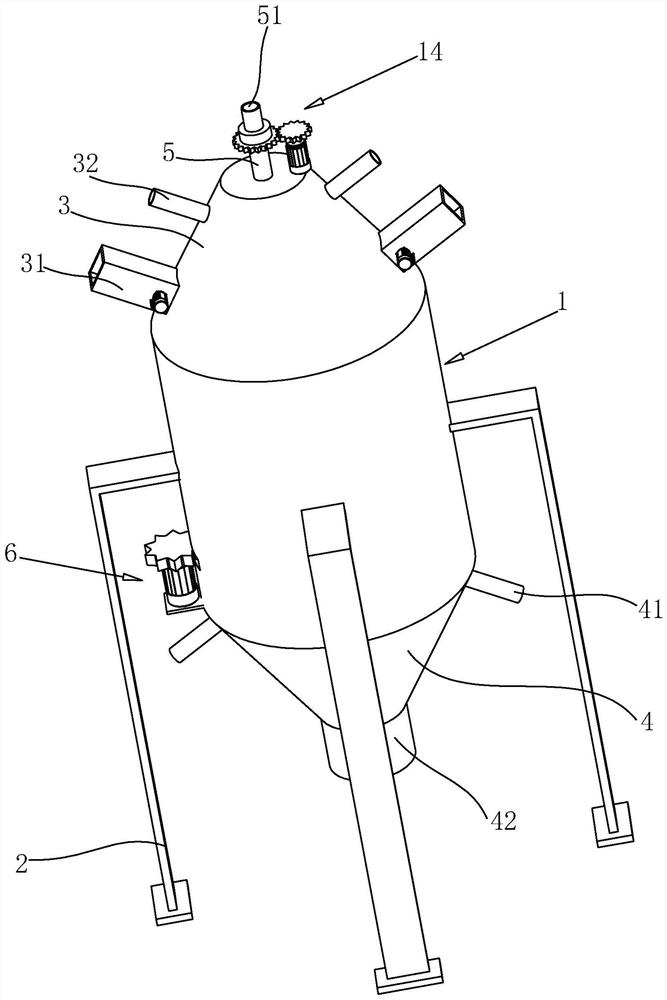

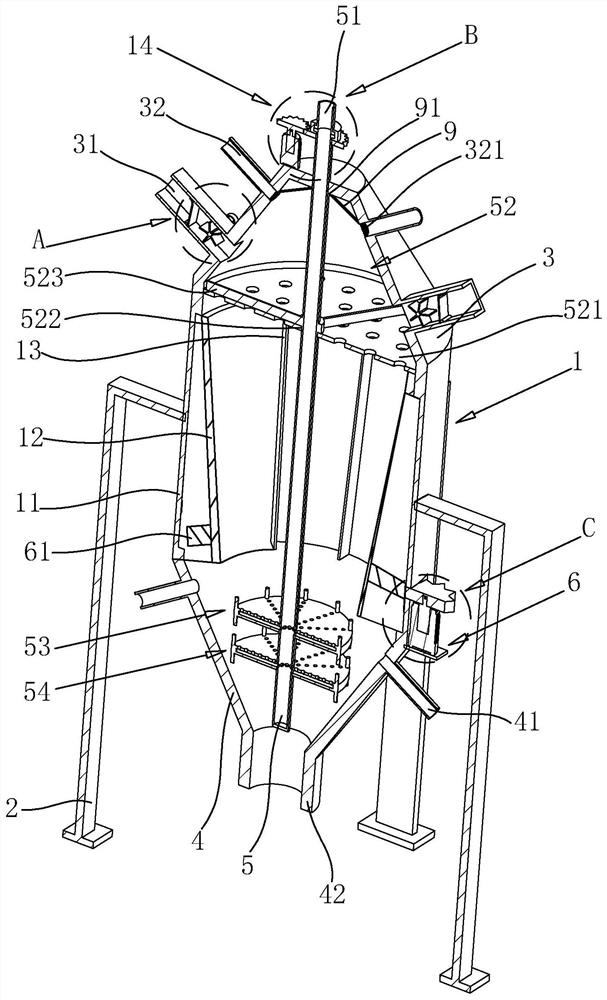

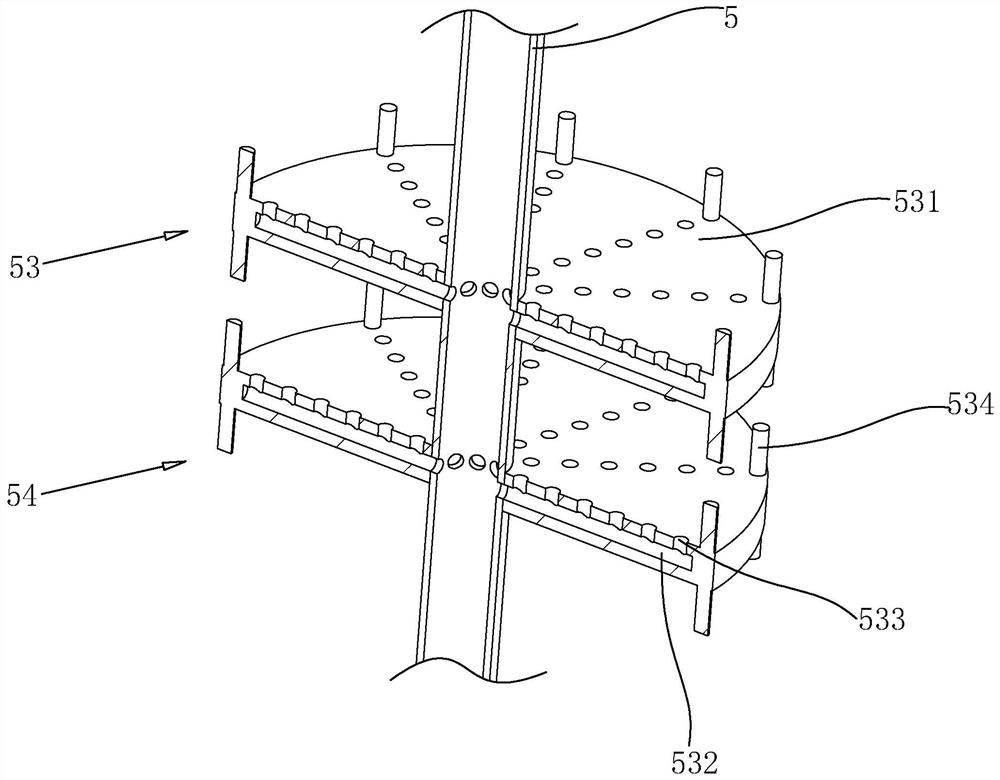

[0037] The embodiment of the present application discloses a powder separator. Such as figure 1 , figure 2 As shown, the powder classifier includes a cylinder body 1 and a bracket 2 fixed on the outside of the cylinder body 1. The top of the cylinder body 1 is fixed with a truncated upper shell 3, and the bottom of the cylinder body 1 is fixed with a funnel-shaped lower shell 4. The side wall of the shell 3 is provided with a feed pipe 31 near the side of the cylinder body 1, the side wall of the upper shell 3 is located above the feed pipe 31 and is provided with a discharge pipe 32, the side wall of the lower shell 4 is provided with an air inlet pipe 41, and the bottom of the lower shell 4 Coarse material outlet 42 is provided, the top center of upper shell 3 rotates vertically and is provided with a rotating tube 5 closed at the bottom, and the rotating tube 5 extends into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com