Microalgae biodiesel production device

A production device and technology of microalgae biology, applied in the direction of fat oil/fat production, biofuel, petroleum industry, etc., can solve the problems of undisclosed microalgae biodiesel, low yield of biodiesel, long reaction time, etc., and achieve energy saving Crisis problem, improvement of esterification efficiency, effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

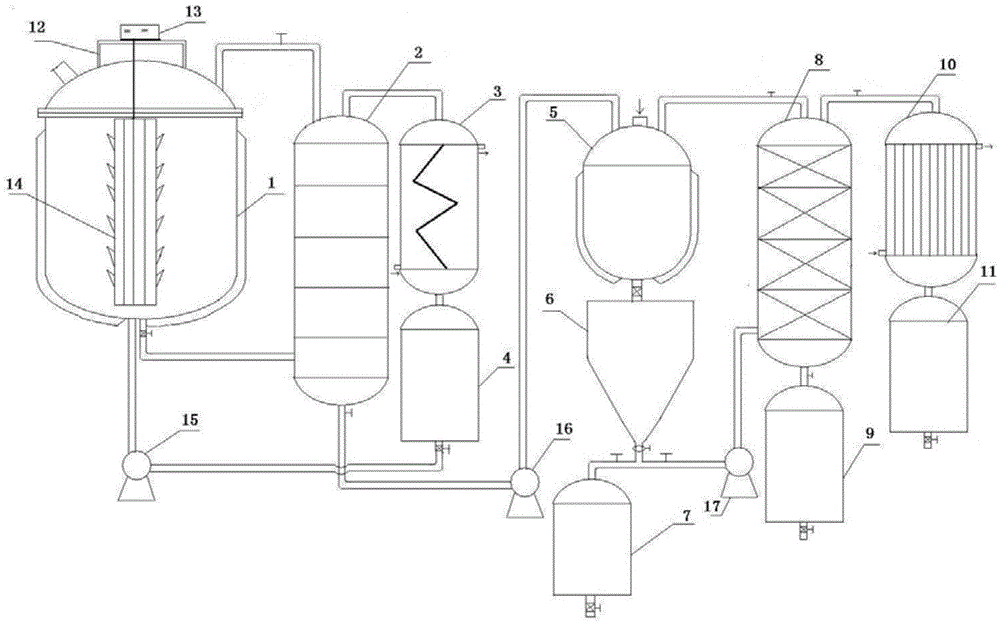

[0020] as attached figure 1 As shown, the microalgae biodiesel production device includes an oil extraction tank 1, a rectification tank A2, an esterification tank 5, and a separator 6; an ultrasonic generator 13 is arranged above the oil extraction tank 1, and the ultrasonic generator The bracket 12 is fixed on the oil extraction tank 1, and the ultrasonic vibrating rod 14 is connected below the ultrasonic generator. The lower end of A3 is connected to the solvent recovery tank 4, the bottom of the solvent recovery tank 4 is connected to the oil extraction tank 1 through the liquid pump A15, the top of the rectification tank A can also be connected to the oil extraction tank, and the bottom of the rectification tank A2 is connected to the esterification tank through the liquid pump B16 5 is connected, the bottom of the esterification tank 5 is connected to the separator 6, and the bottom end of the separator 6 is connected to the glycerin collector 10 and the rectifying tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com