Combined badam shell breaking and shell-kernel separating machine

A shell and kernel separation and combination technology, applied in the field of machinery, can solve the problems of low efficiency, restricting the development of the almond wood industry, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

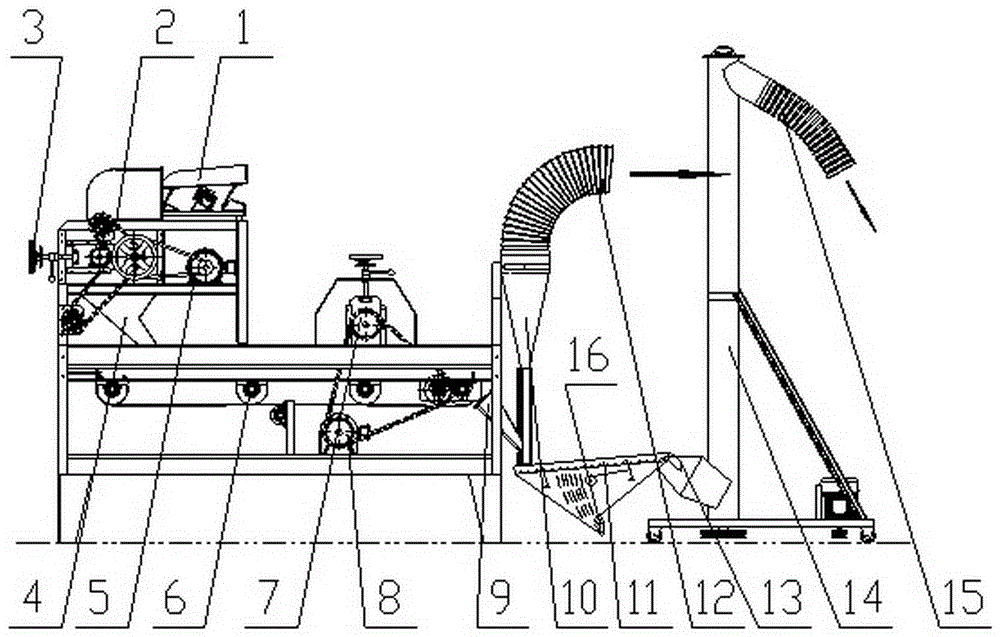

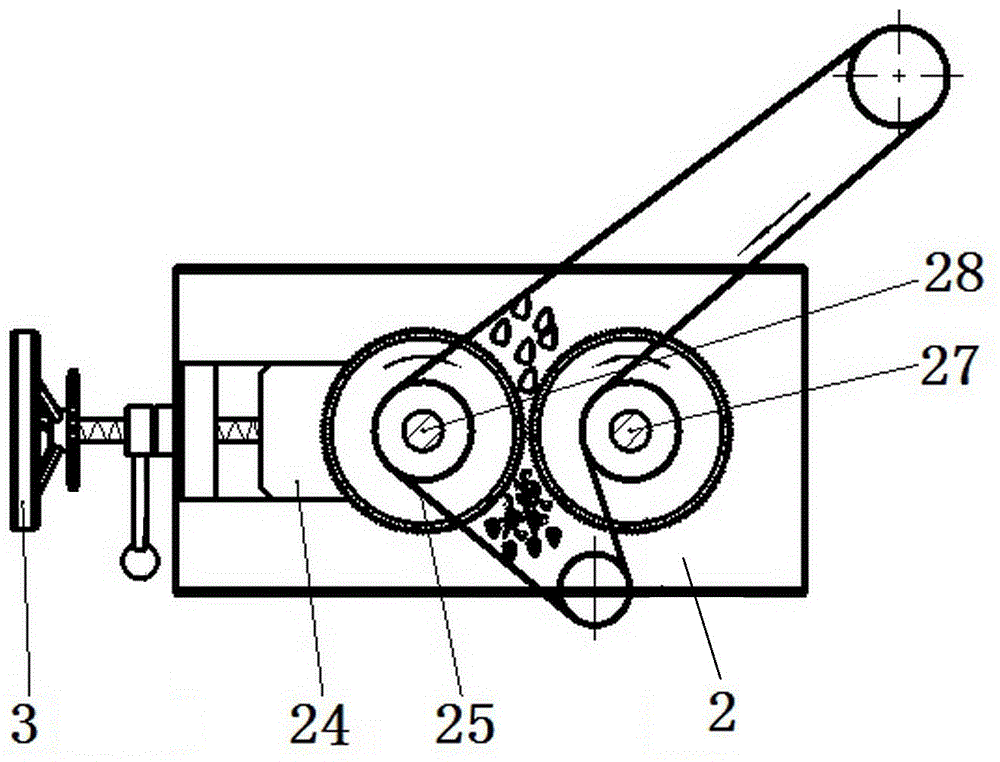

[0009] A combined almond shell breaking and shell kernel separator, such as figure 1 , figure 2 As shown, it includes frame, conveyor belt, driving motor, cycloidal reducer, vibration classifier, negative pressure fan and vertical hoist, and a primary shell breaker 2 with vibrating feeder 1 is arranged above the front of the frame , the main and driven shell breaking rollers 27, 28 are horizontally arranged side by side in the primary shell breaking device 2, and the roller shaft ends of the main and driven shell breaking rollers 27, 28 are equipped with sprockets. The shell rollers are driven by the drive motor 5 through the chain 25 to rotate in opposite directions, crushing the almond shells falling between the main and driven shell breaking rollers 27 and 28, and the discharge hopper 4 below the primary shell breaking device 2 is located on the conveyor belt 6, the discharge end of the conveyor belt 6 is connected with the feed hopper of the secondary shell breaking devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com