Patents

Literature

218results about How to "Improve the efficiency of breaking up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

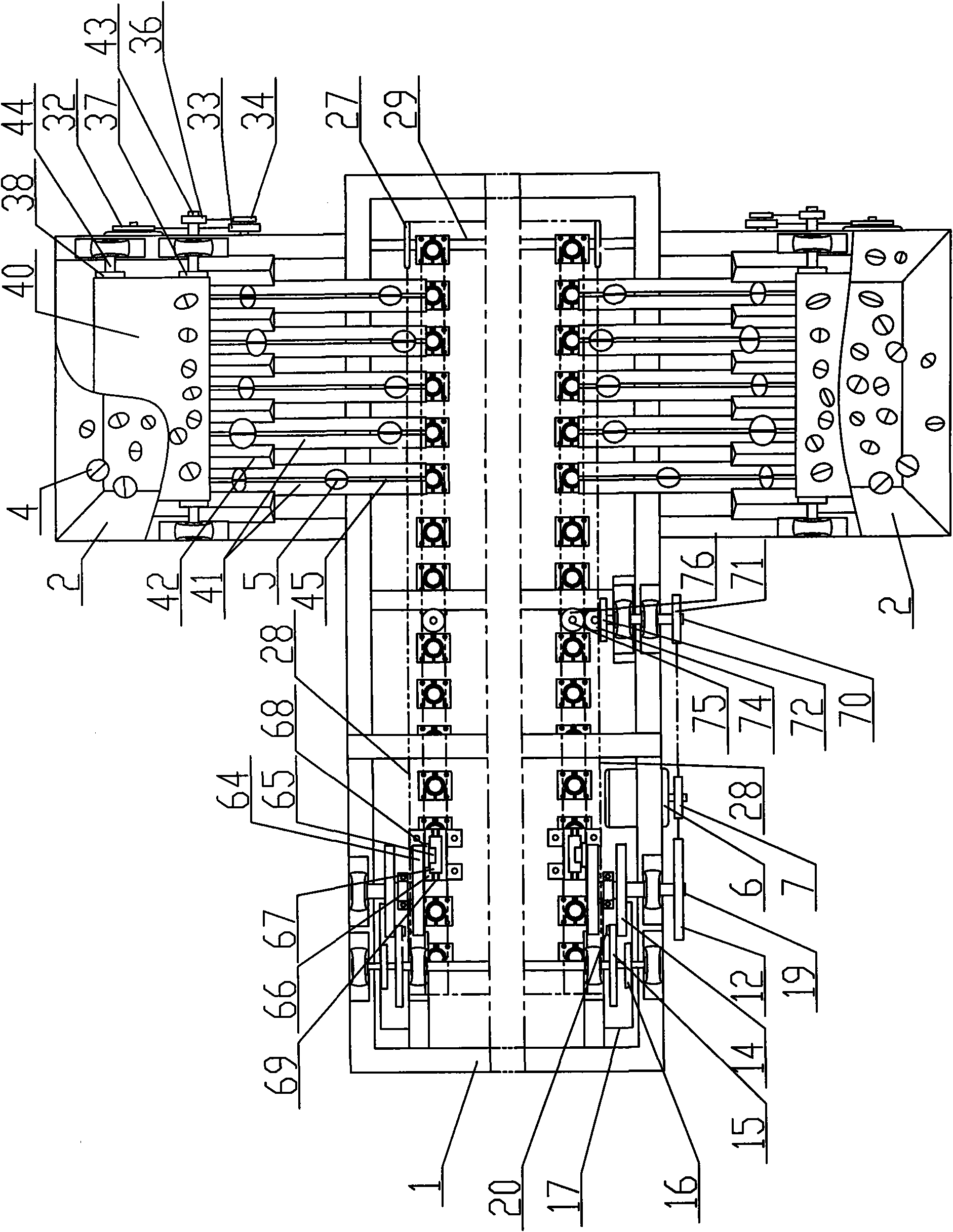

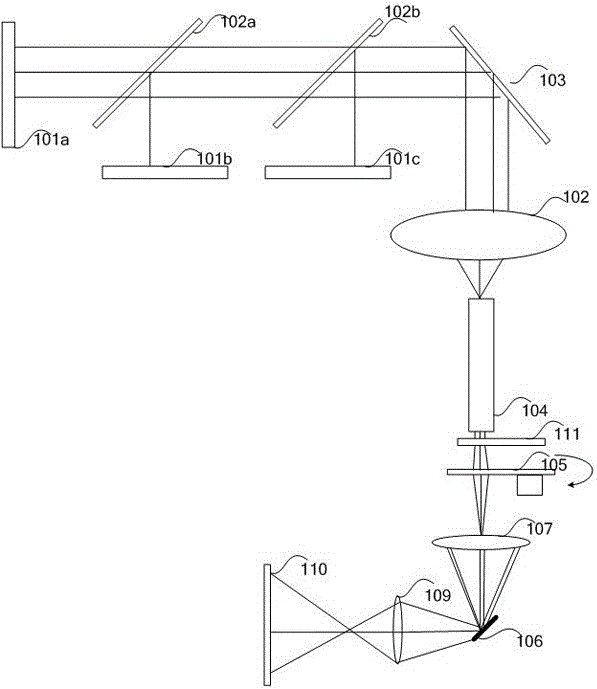

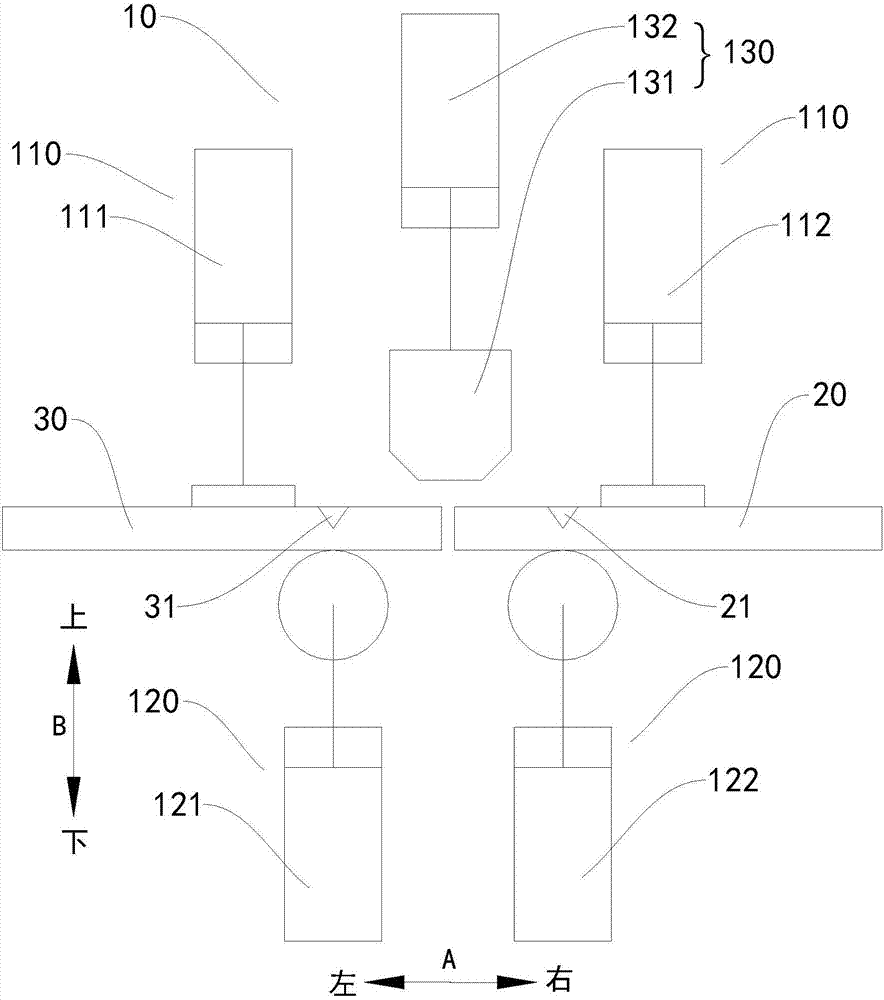

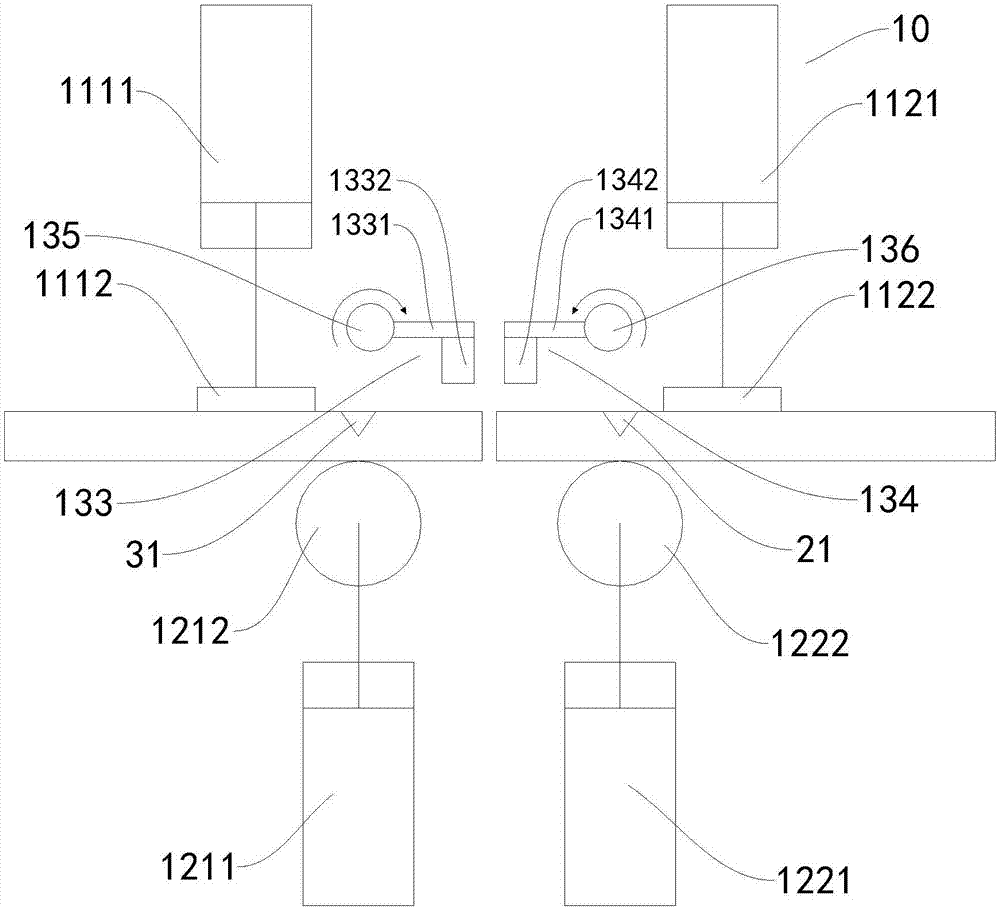

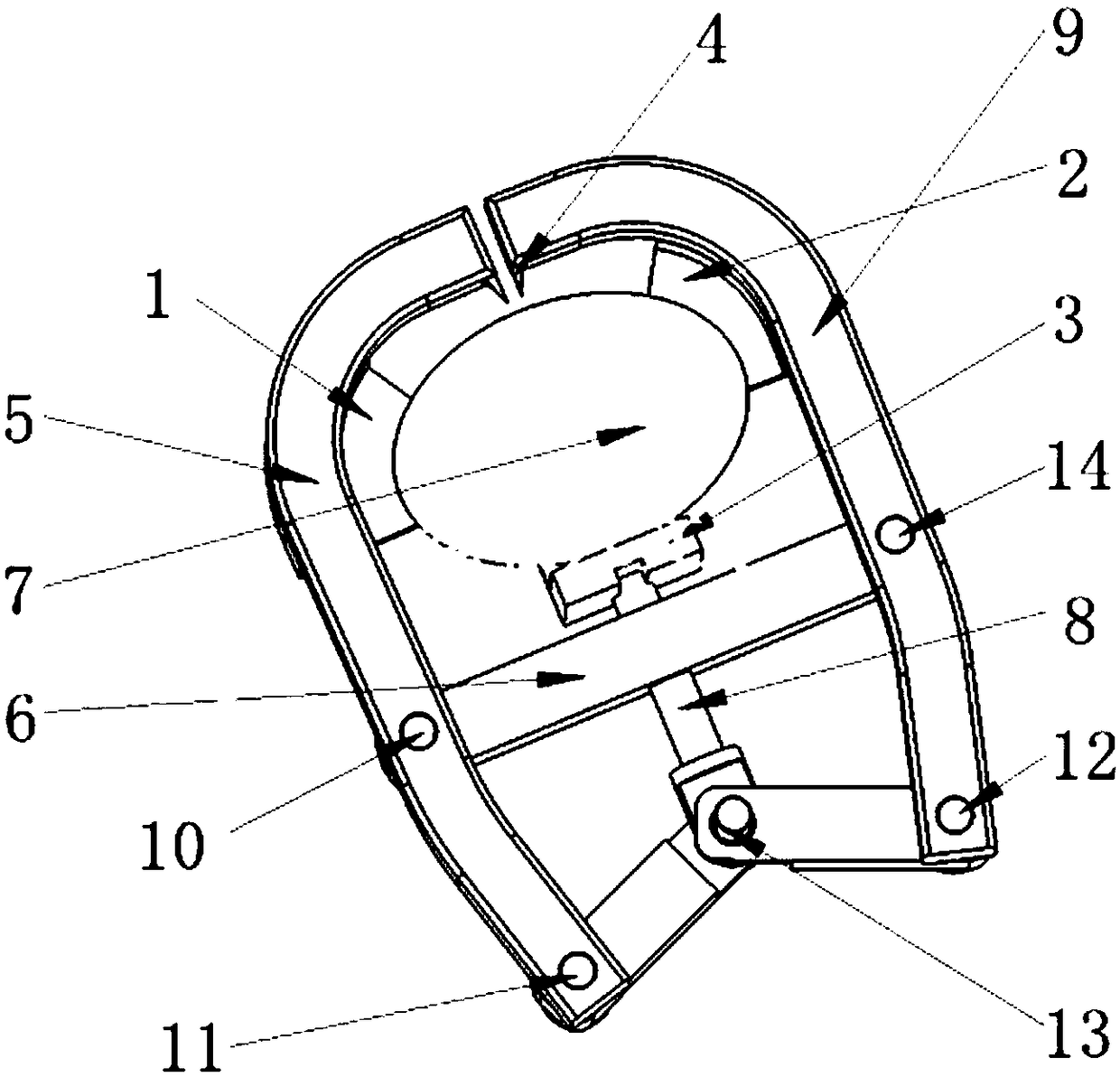

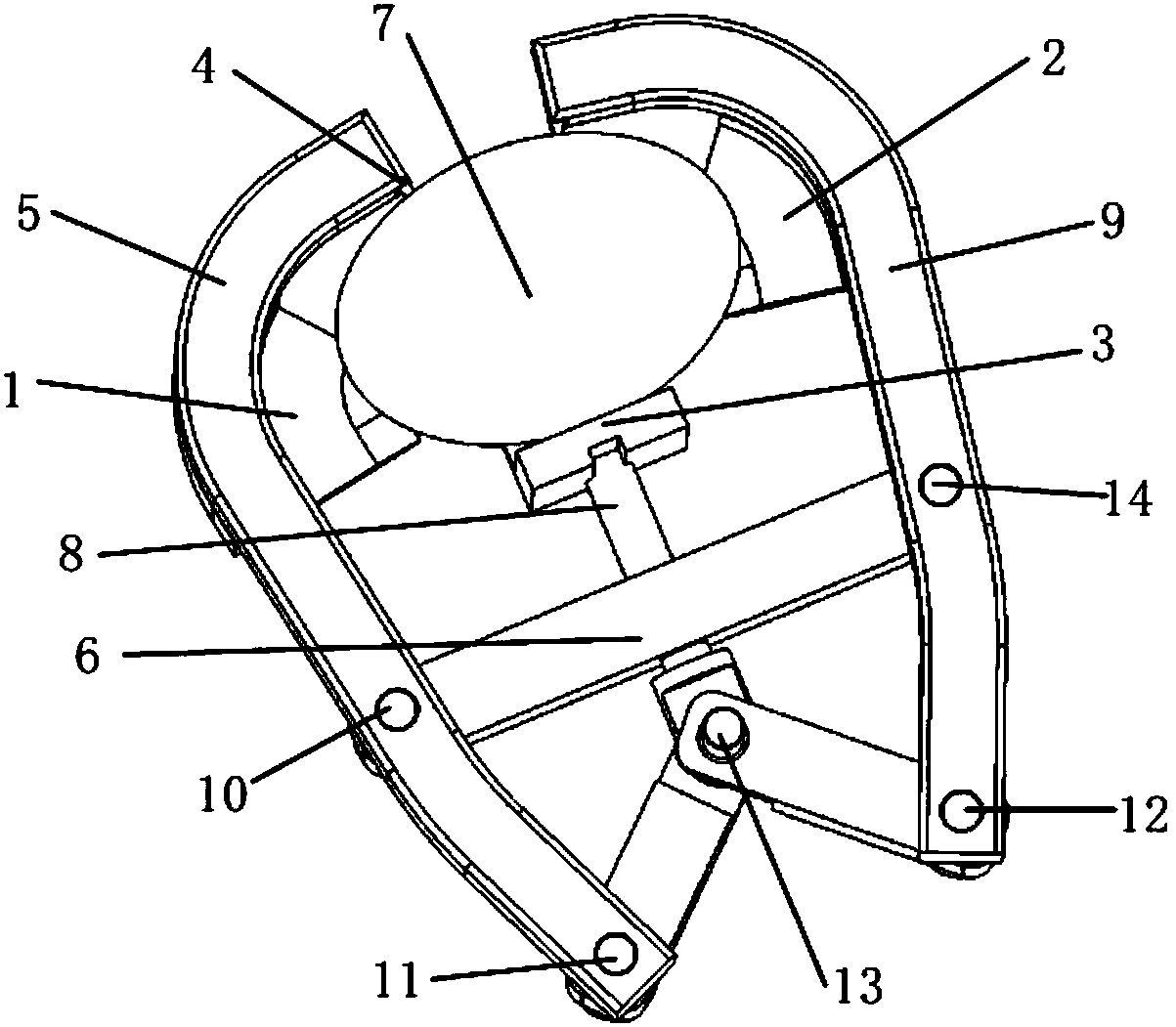

Device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion

ActiveCN106473167AReduce grading processPrecise pre-crackingHuskingHullingWalnut NutReciprocating motion

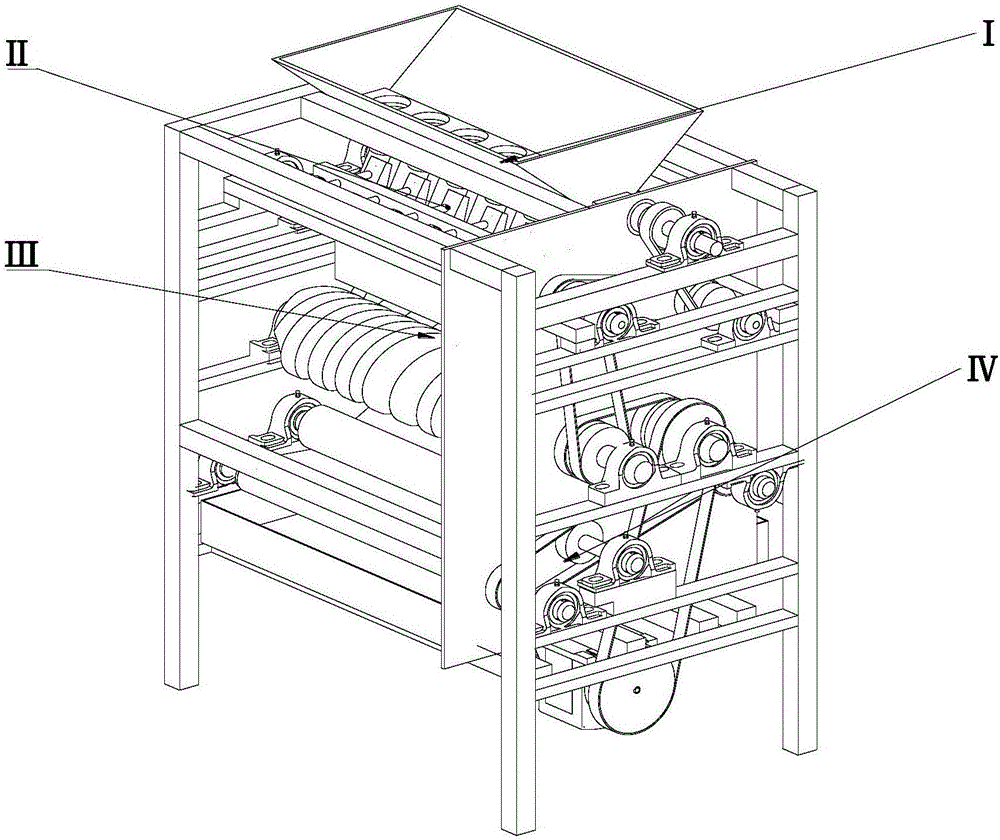

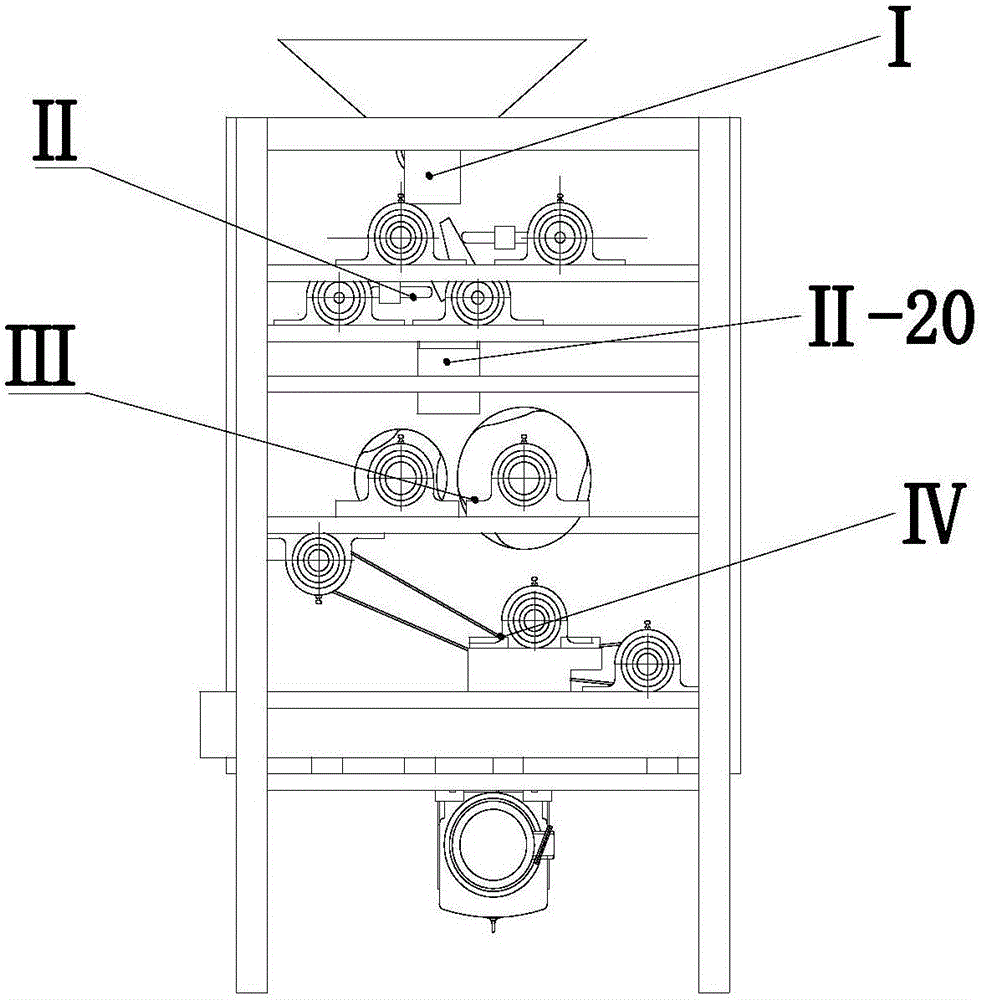

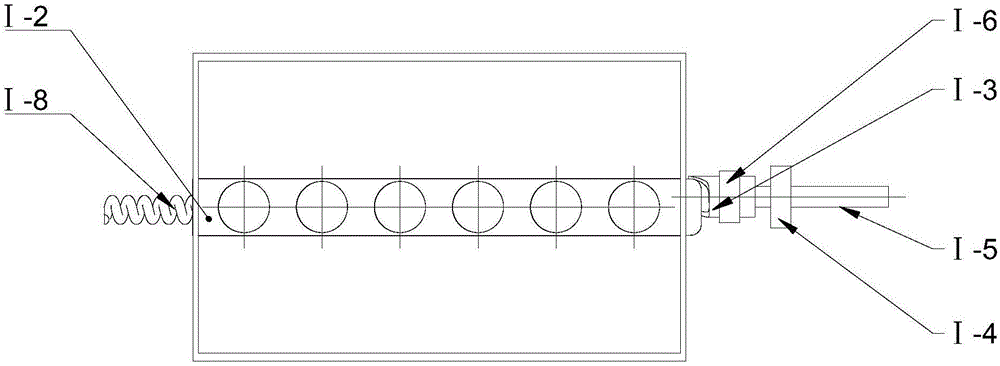

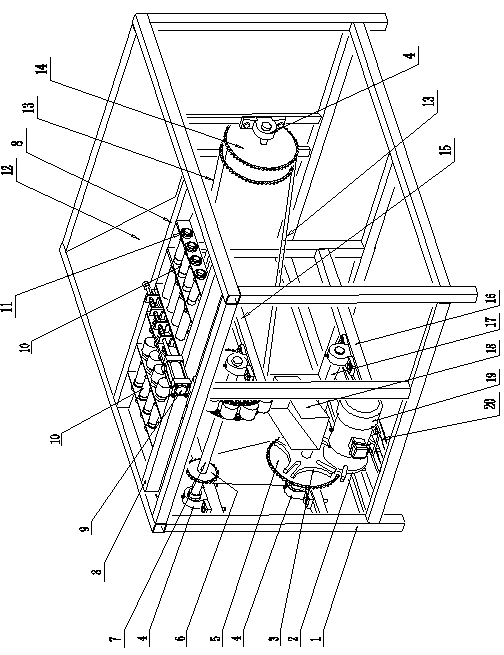

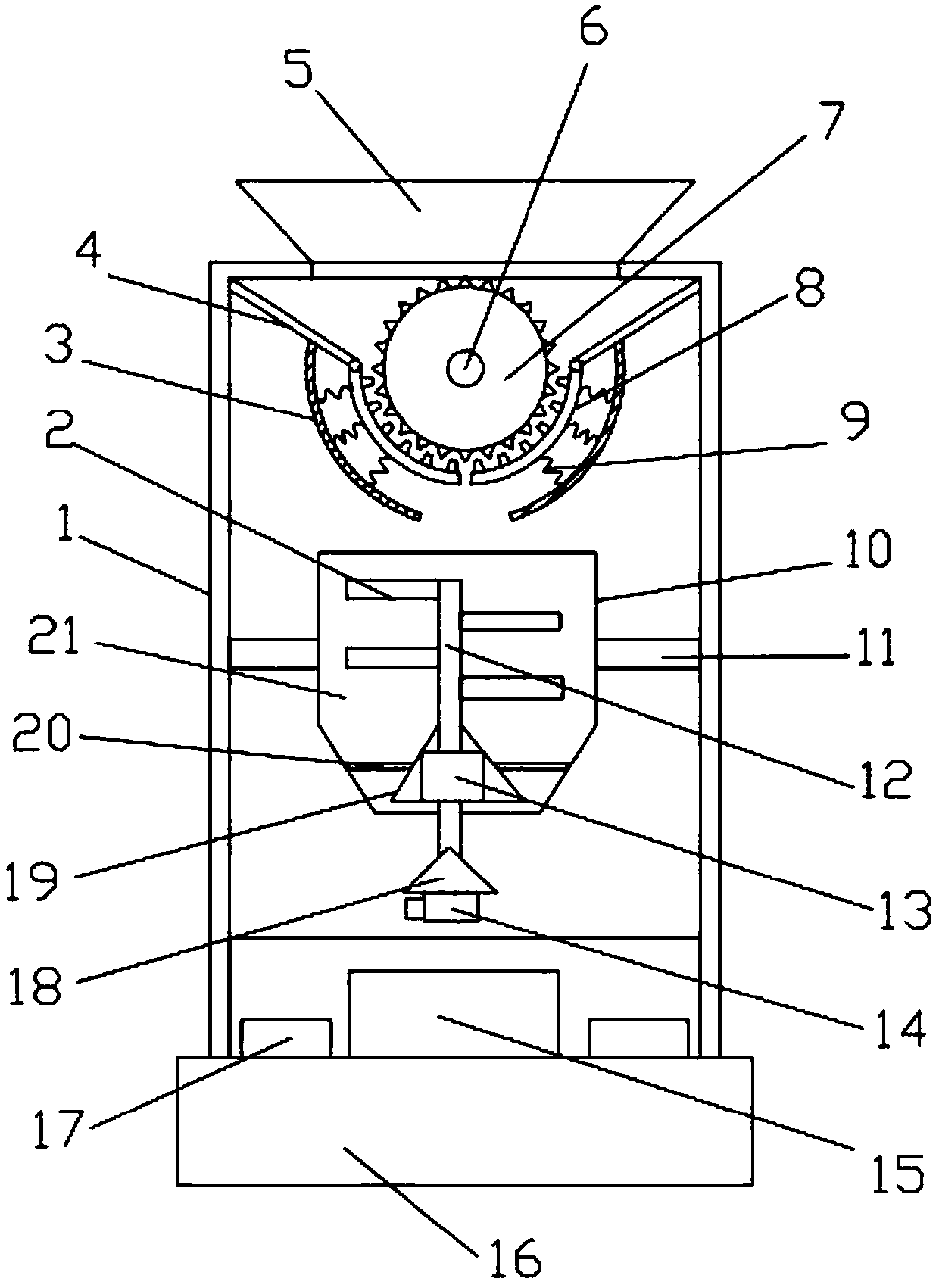

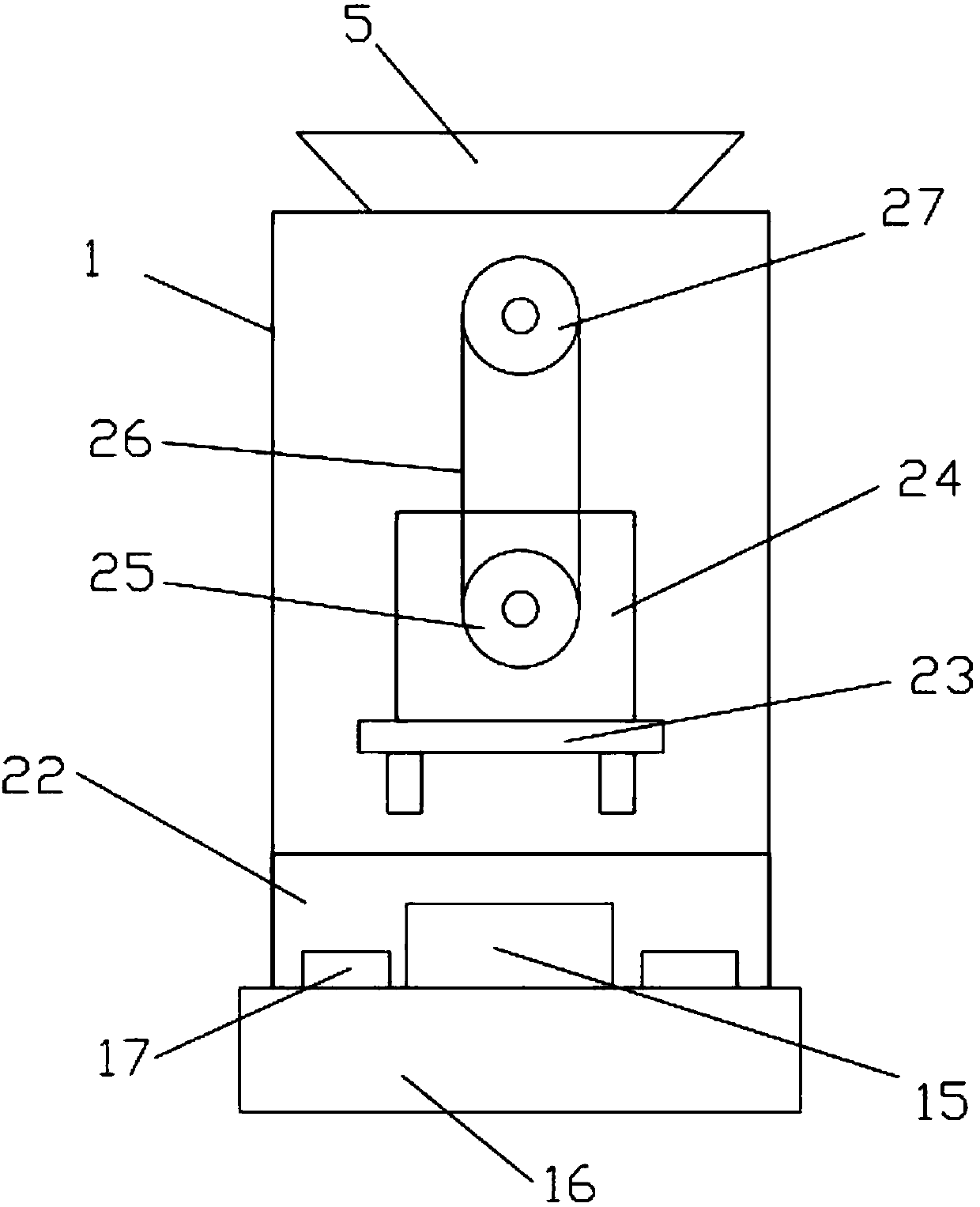

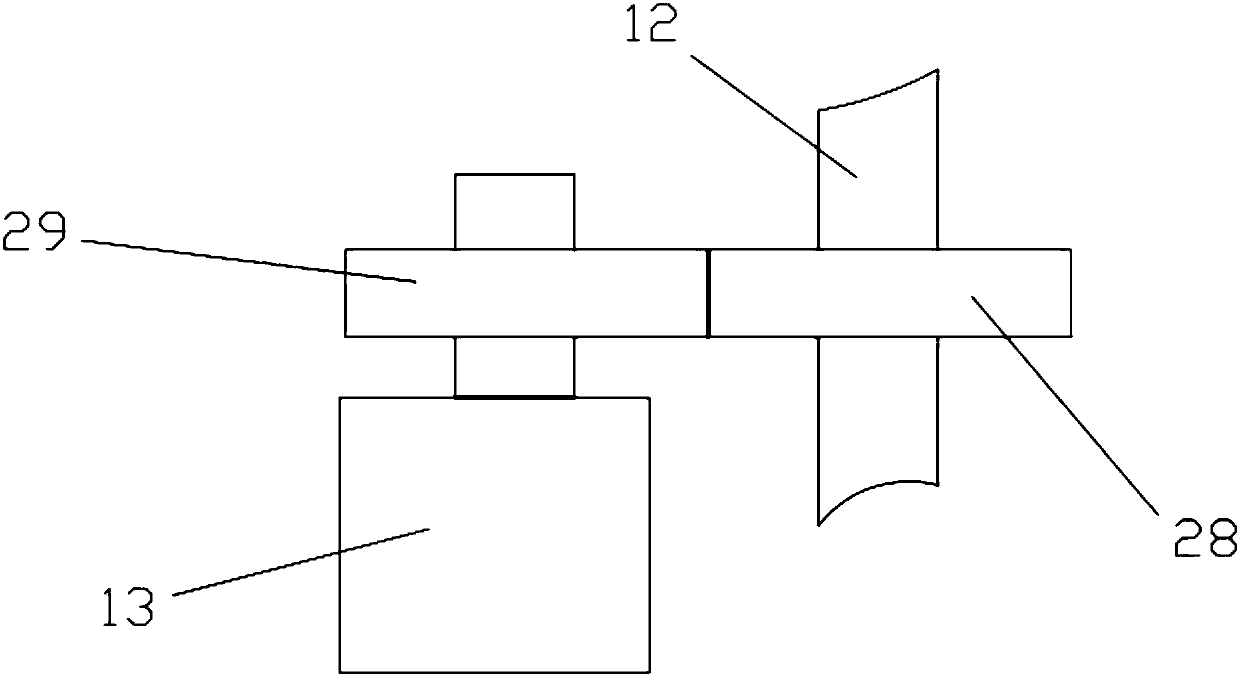

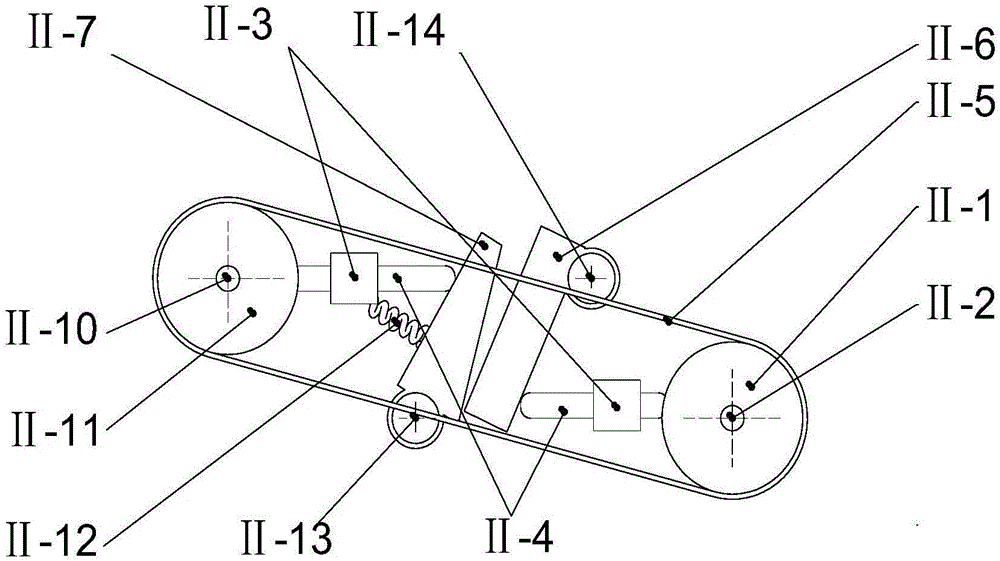

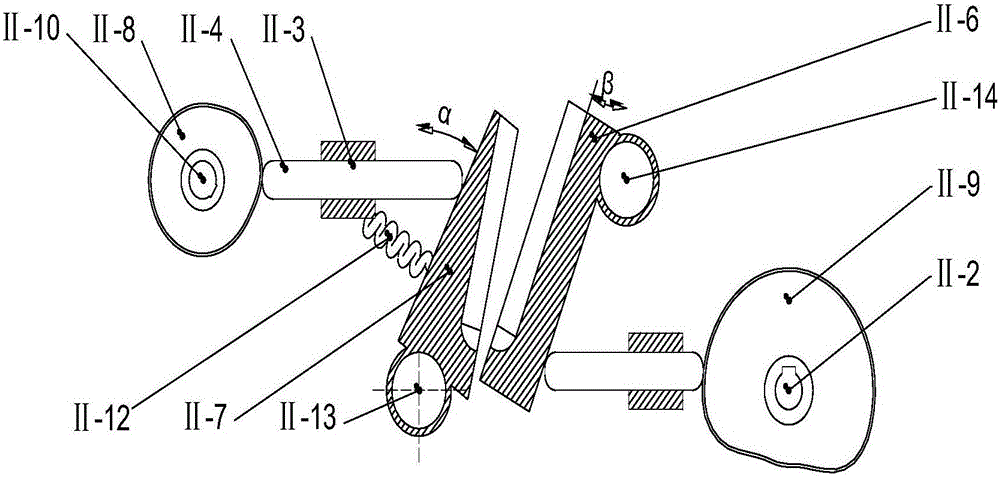

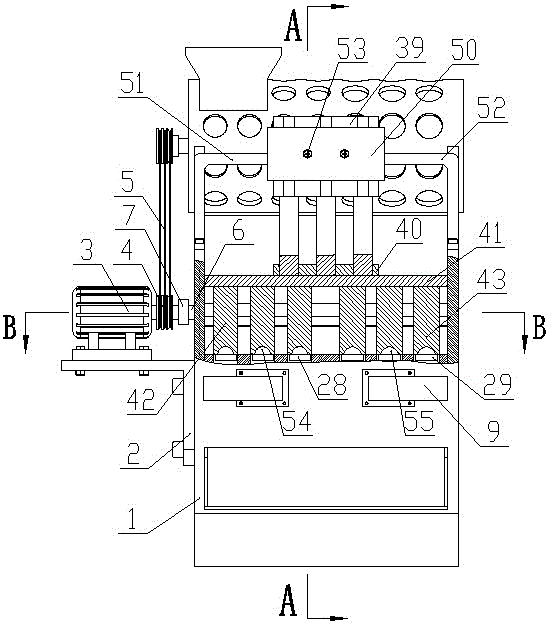

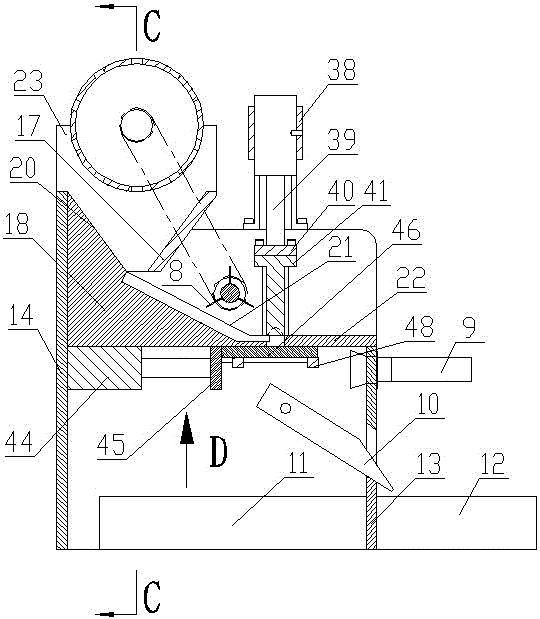

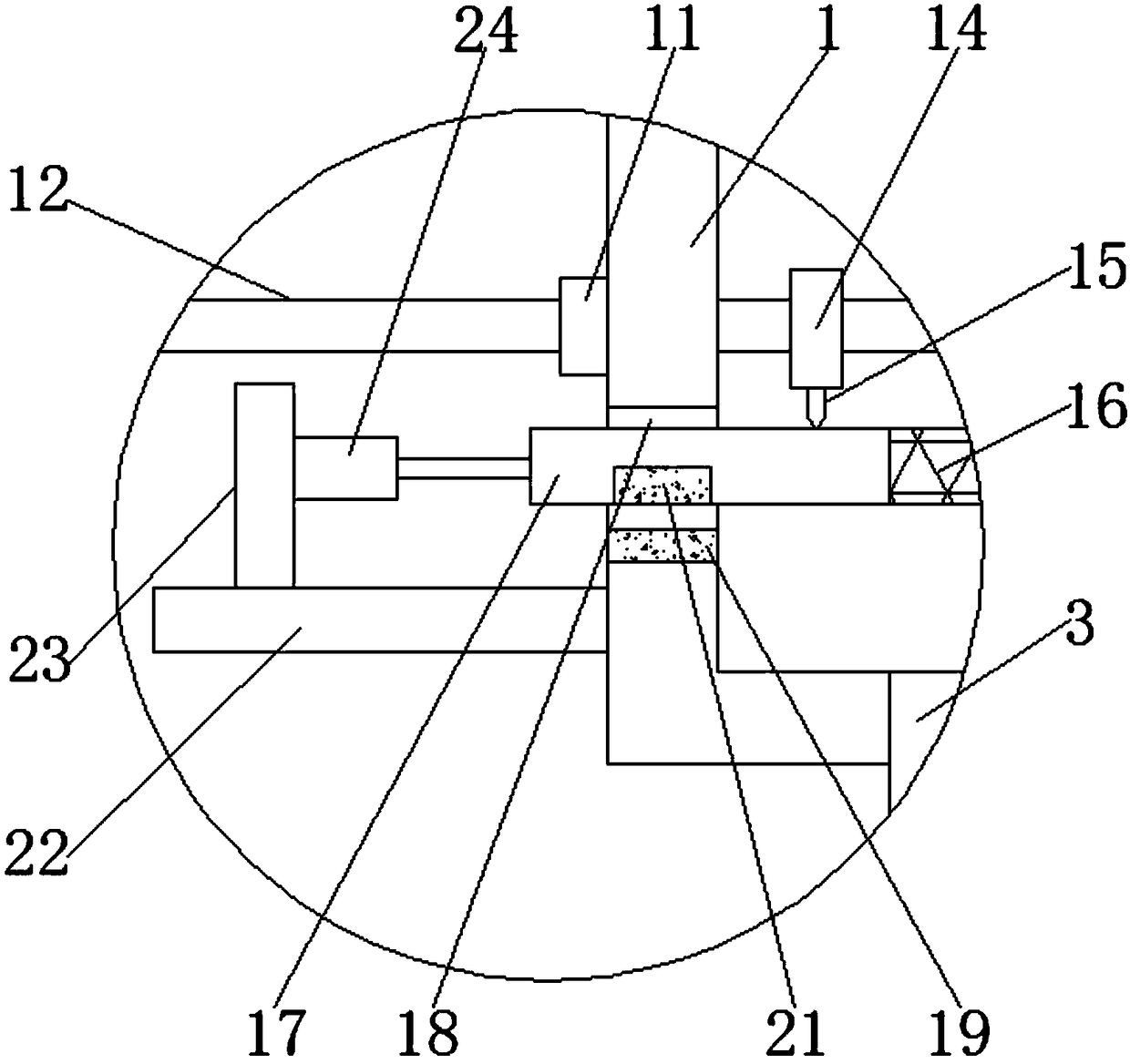

The invention discloses a device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion. The device comprises an intermittent feeding device, the a shell pre-breaking device, a flexible shell breaking device and a separating device, which are fixed on a machine frame, wherein the intermittent feeding device is used for performing intermittent batch feeding for the shell pre-breaking device; the shell pre-breaking device comprises an extruding part and a blanking part which are mutually matched; the extruding part is in reciprocating movement, and is matched with the blanking part for extruding walnuts, so that cracks are generated in the walnuts; the blanking part is in reciprocating movement, so that the extruded walnuts fall off to the flexible shell breaking device; the flexible shell breaking device is used for breaking walnut shells; and shells and kernels of the walnuts after shell breaking are separated for storage through the separating device. The device disclosed by the invention integrates a plurality of systems, and is compact in structure, the manufacturing cost of a machine is reduced, the occupied space for the operation of the machine is also reduced, and the miniaturization and the high efficiency of the machine are facilitated; in structure design, multiple connections including splicing, combining and the like for cooperating work can be realized; and the requirements of various production scales and the requirements of various production sites can be met, and the device is also suitable for families, and is widely applied.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

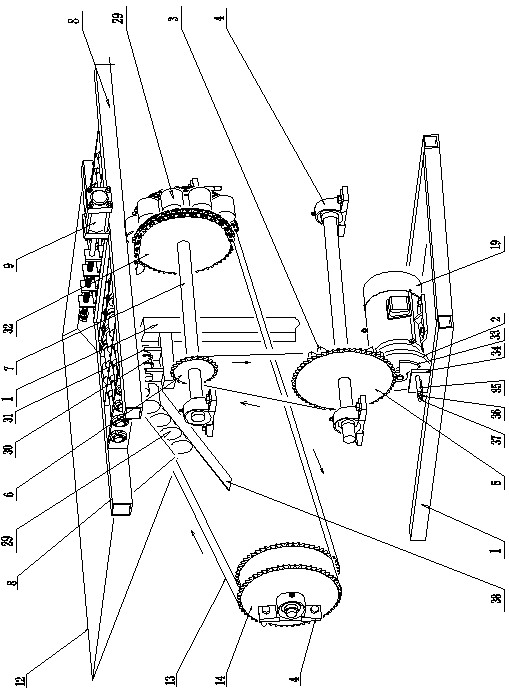

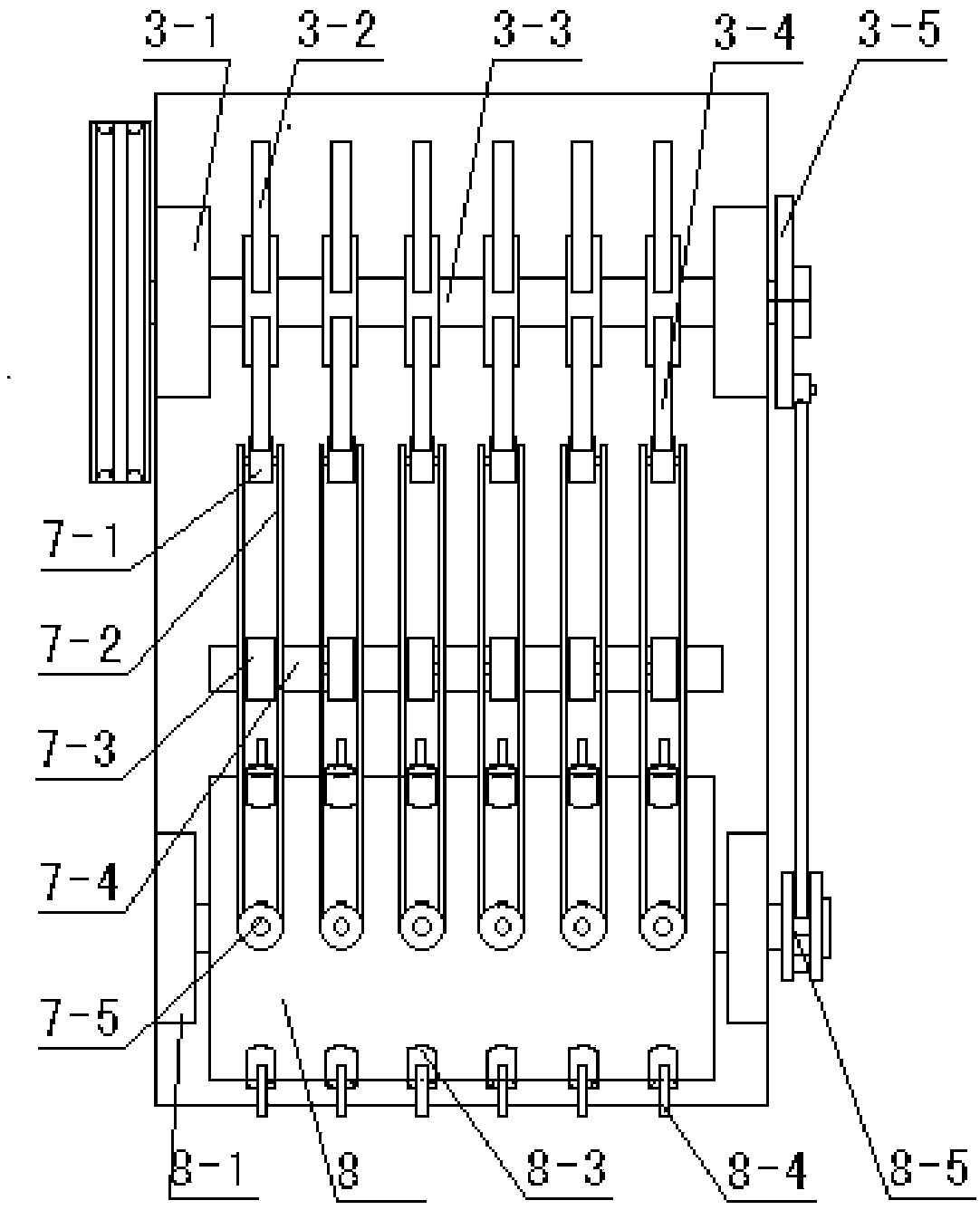

Pneumatic walnut hull breaking machine

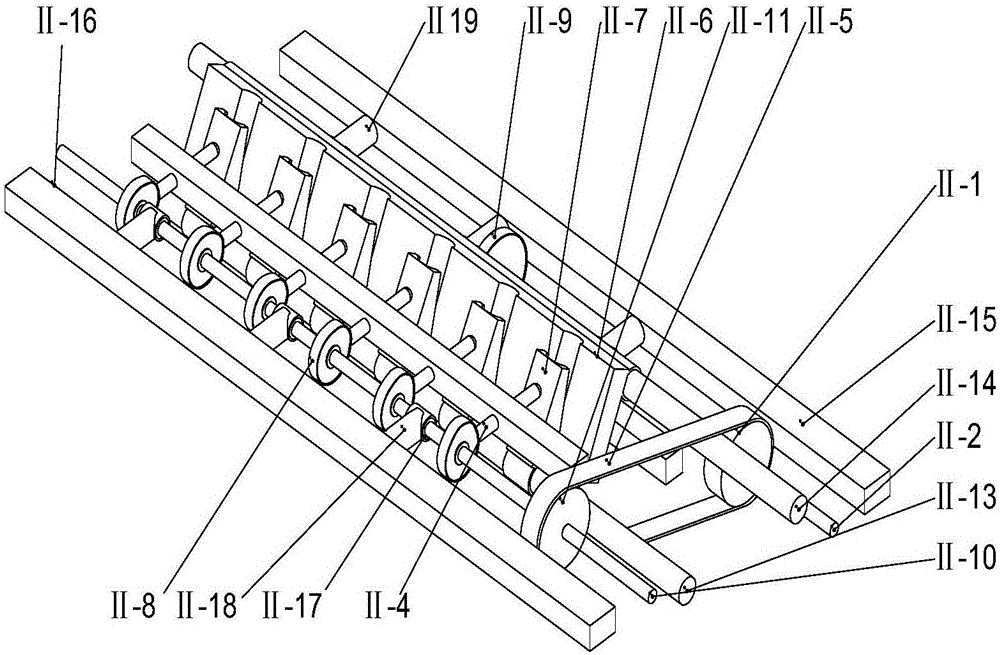

The invention provides a pneumatic walnut hull breaking machine and belongs to the field of forest fruits. The pneumatic walnut hull breaking machine consists of a machine frame, a transmission control device, a feeding mechanism and a hull breaking device. The hull breaking device is installed on the machine frame and consists of impact cylinders and holding cylinders which are installed among partition plates of a working rack in a connecting mode. The transmission control device is installed under the front portion of the machine frame and consists of an electric motor, a poking wheel, a control cam, a driving chain wheel, a grooved wheel, side-by-side front end chain wheels, a driven chain wheel, side-by-side back end chain wheels, a clamping switch, a holding switch and a strike switch, wherein the poking wheel, the control cam and the electric motor are sleeved coaxially, the driving chain wheel and the grooved wheel are sleeved on a lower shaft, the side-by-side front end chain wheels and the driven chain wheel are sleeved on an upper shaft, the side-by-side back end chain wheels are installed at the back portion of the machine frame, and the clamping switch, the holding switch and the strike switch are installed at the lower portion of the machine frame at intervals. The driving wheel, the driven wheel, the front end chain wheels and the back end chain wheels are respectively linked through chains, a material box is installed at the back portion of the working rack, a slot is arranged on one wall of the box, and the feeding mechanism is arranged under the position tightly close to the slot and consists of the side-by-side chains, rotary rollers installed on the chains at intervals in a connecting mode, rolling plate supporting the rotary rollers and tensioning chain wheels. The pneumatic walnut hull breaking machine is strong in adaptability on walnut types, complete in walnut hull separation, few in broken walnut nuts and high in hull breaking efficiency.

Owner:XINJIANG AGRI UNIV

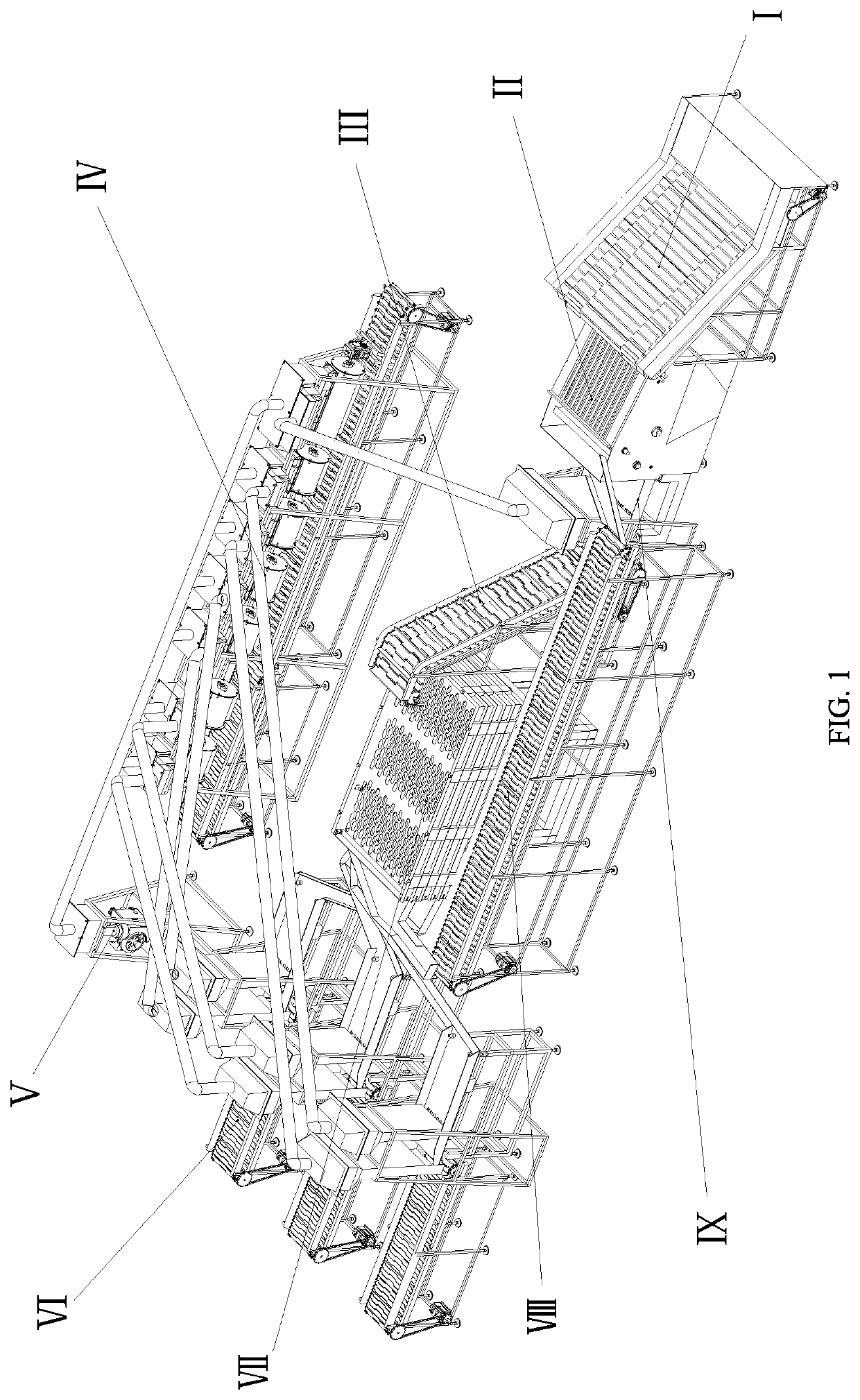

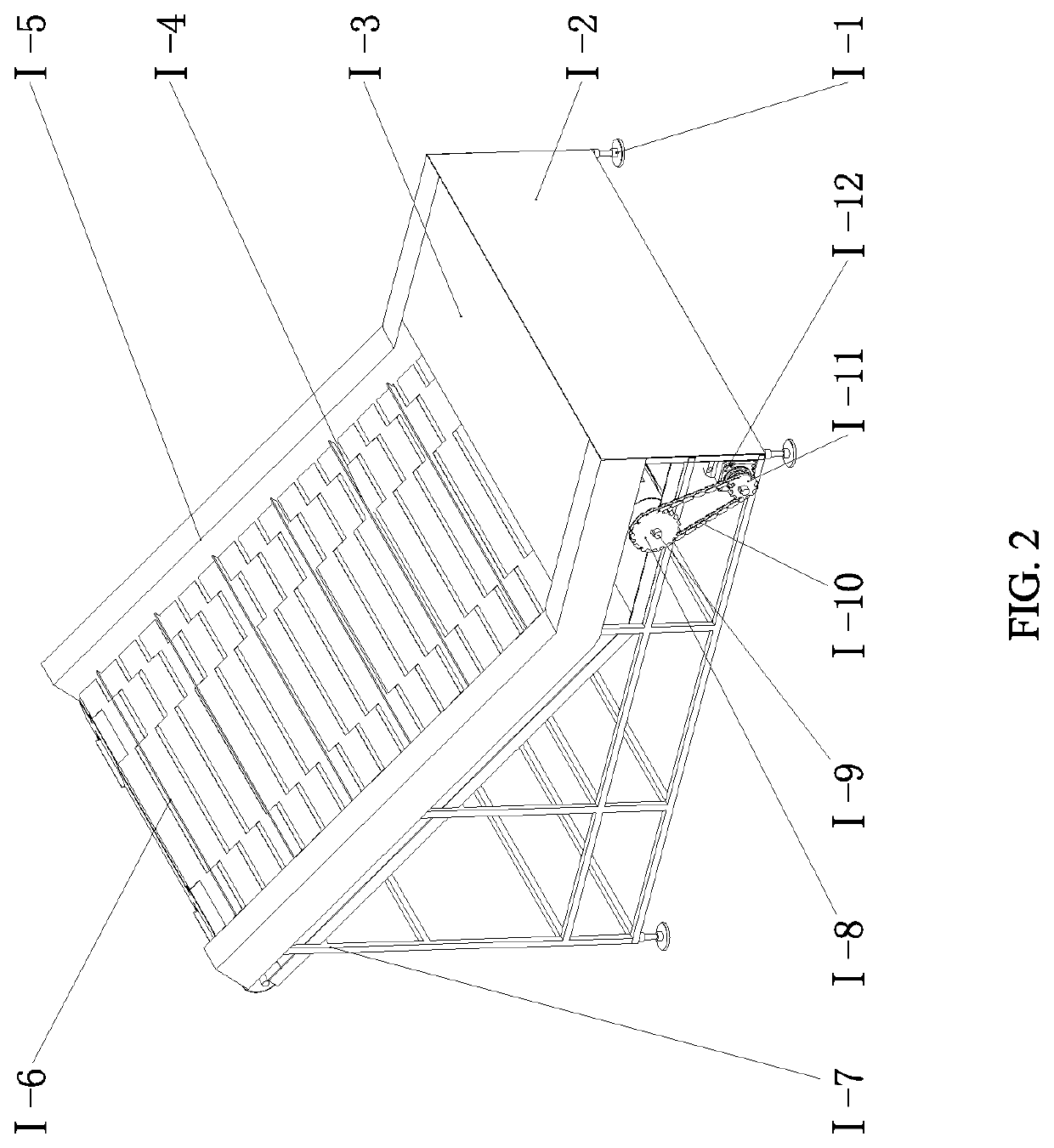

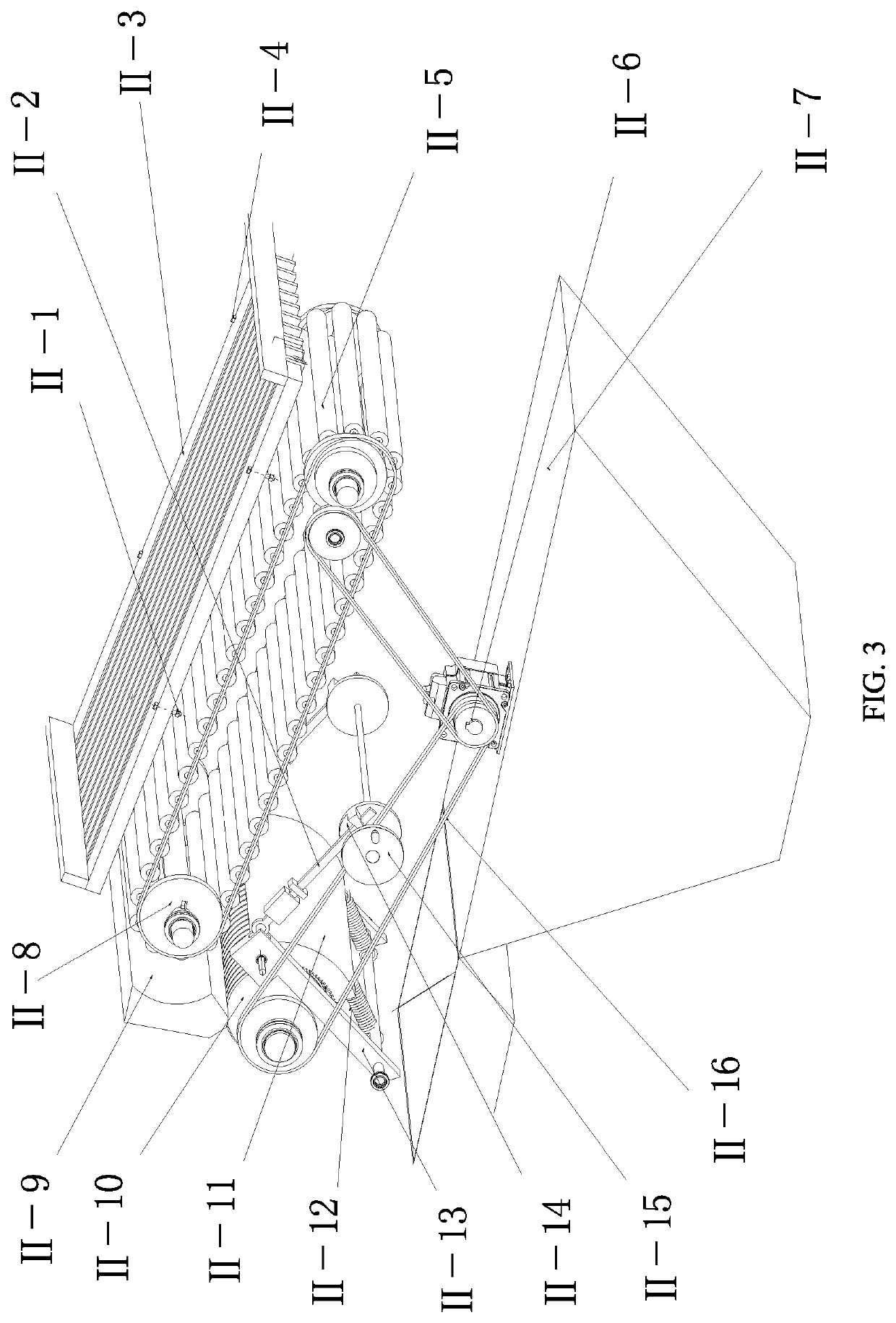

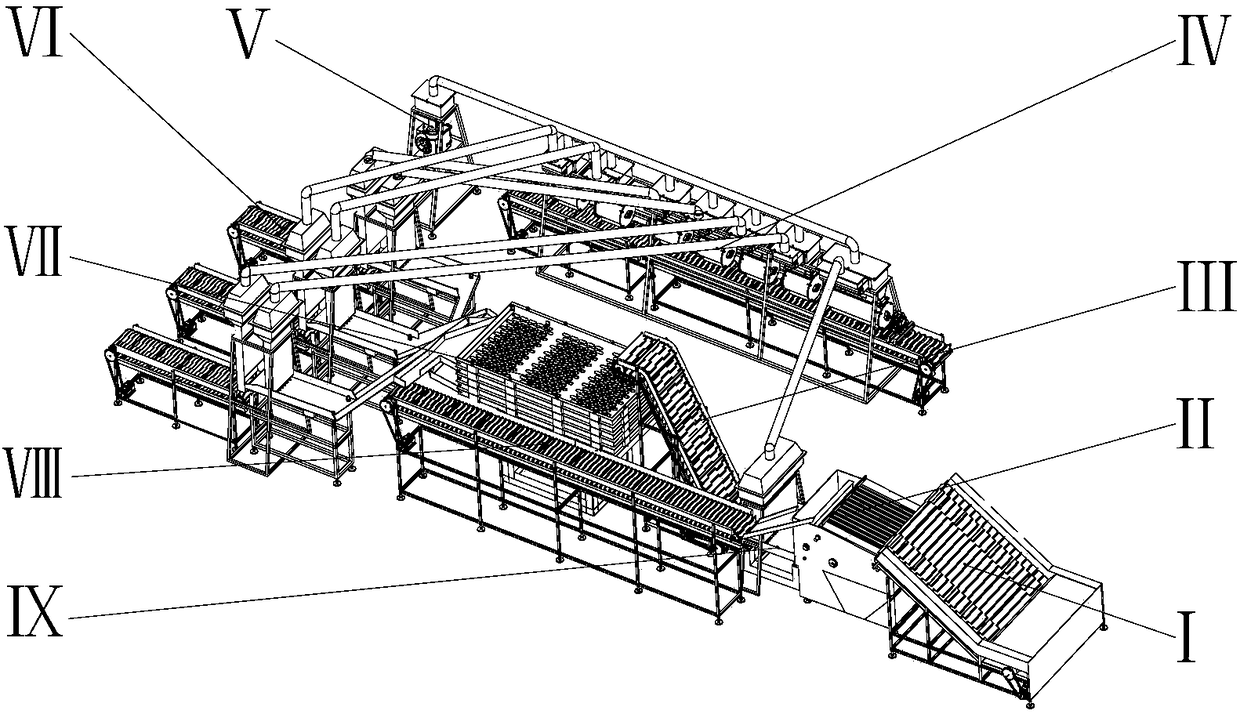

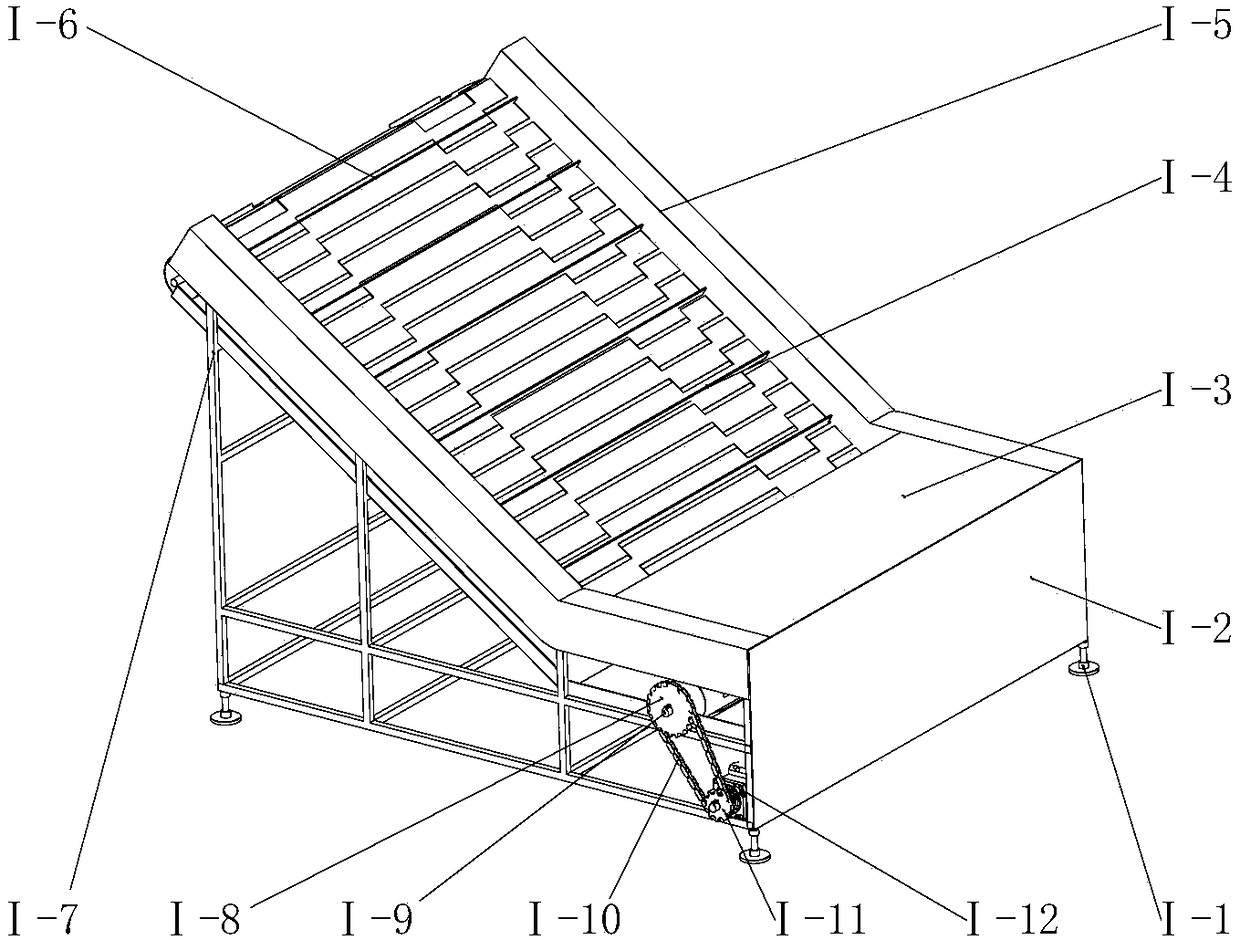

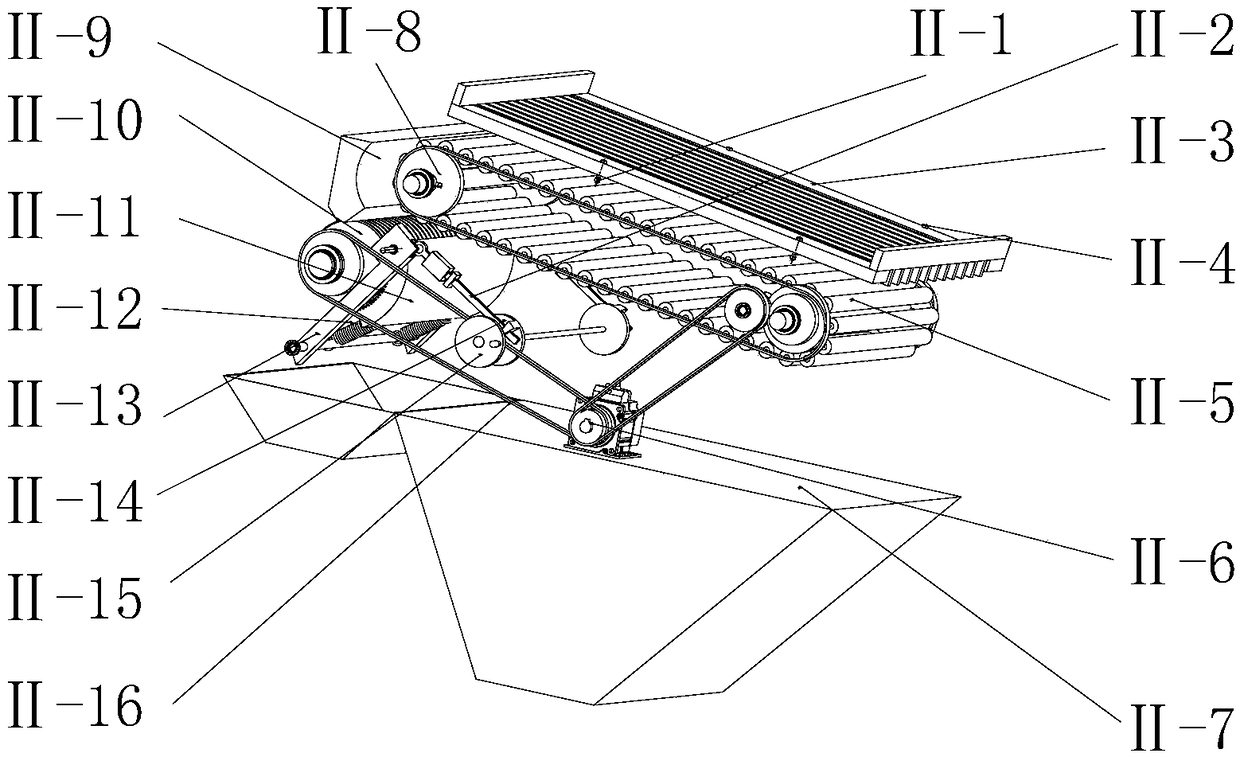

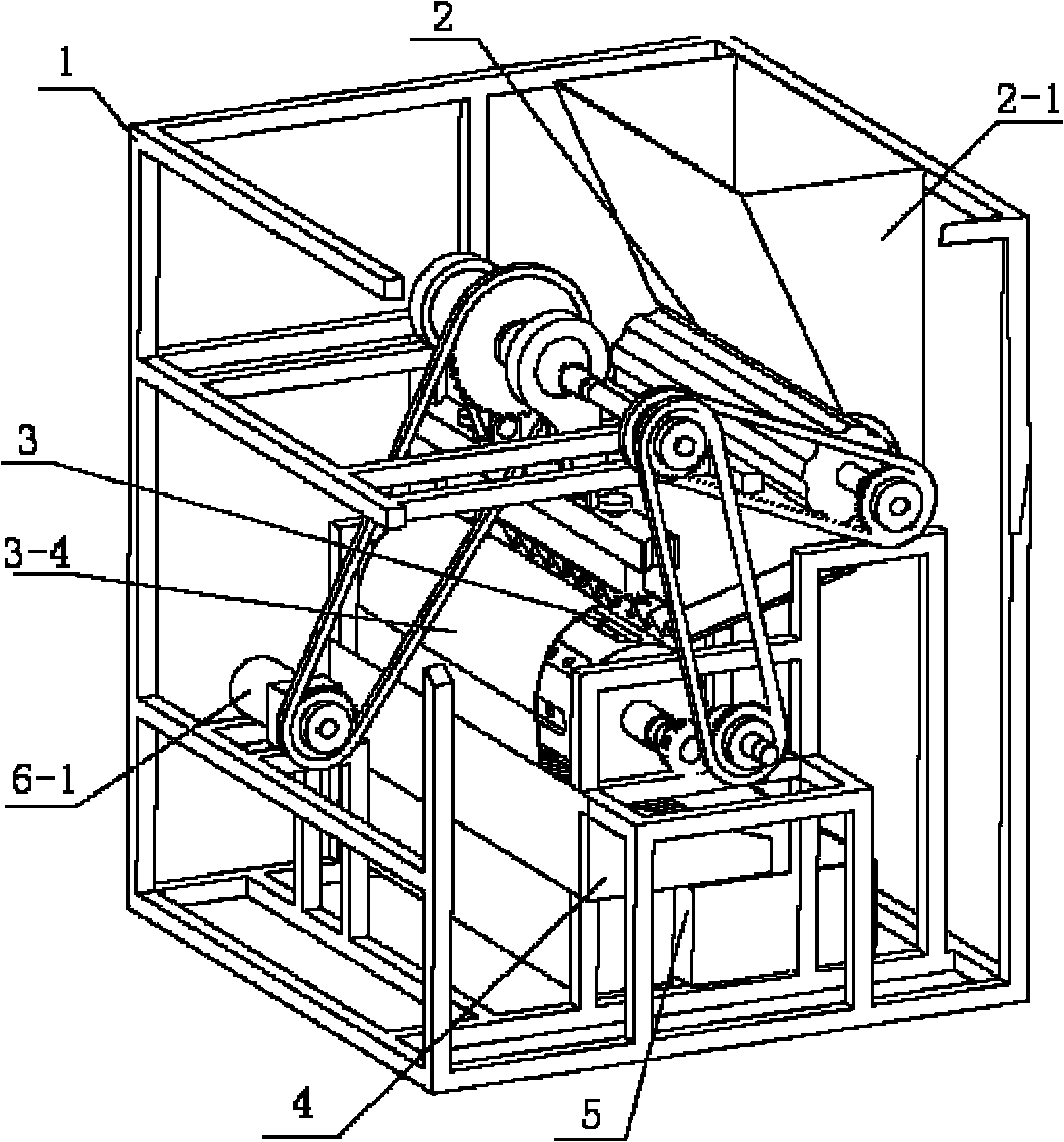

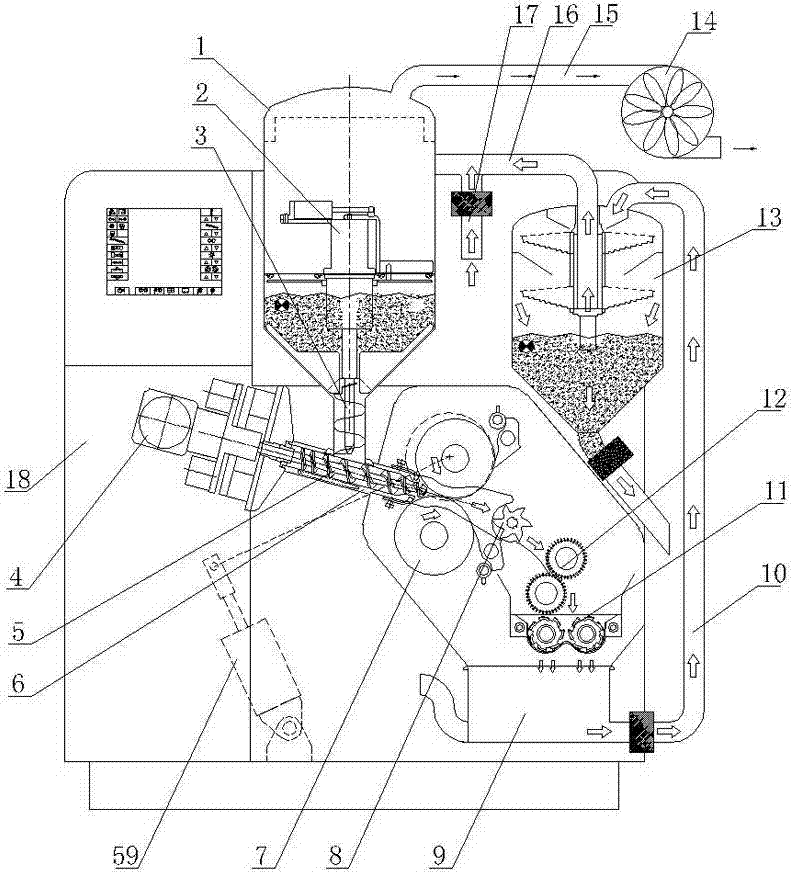

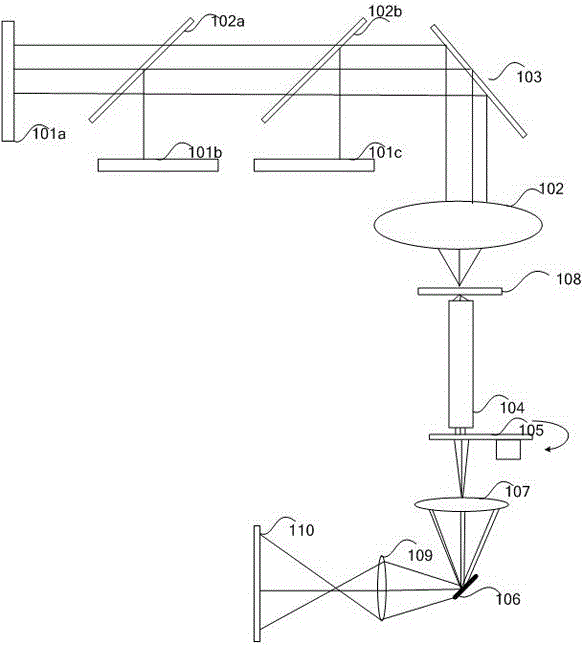

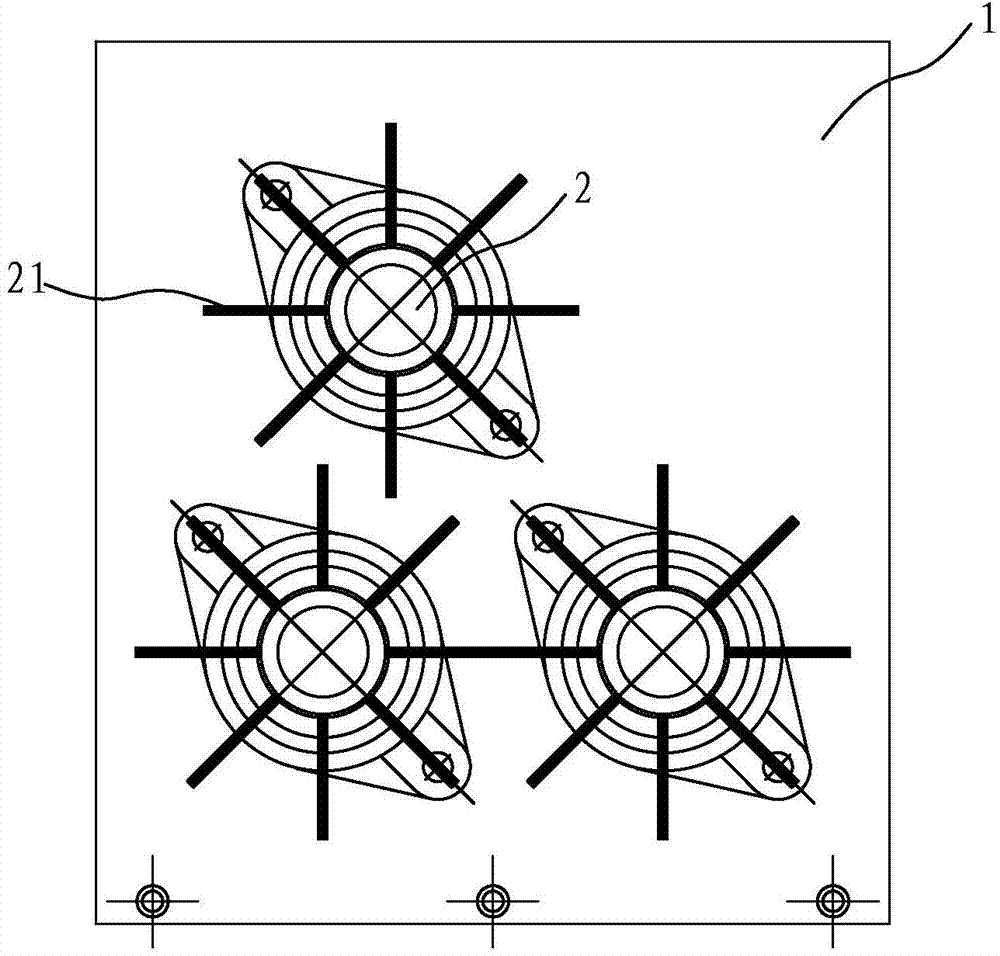

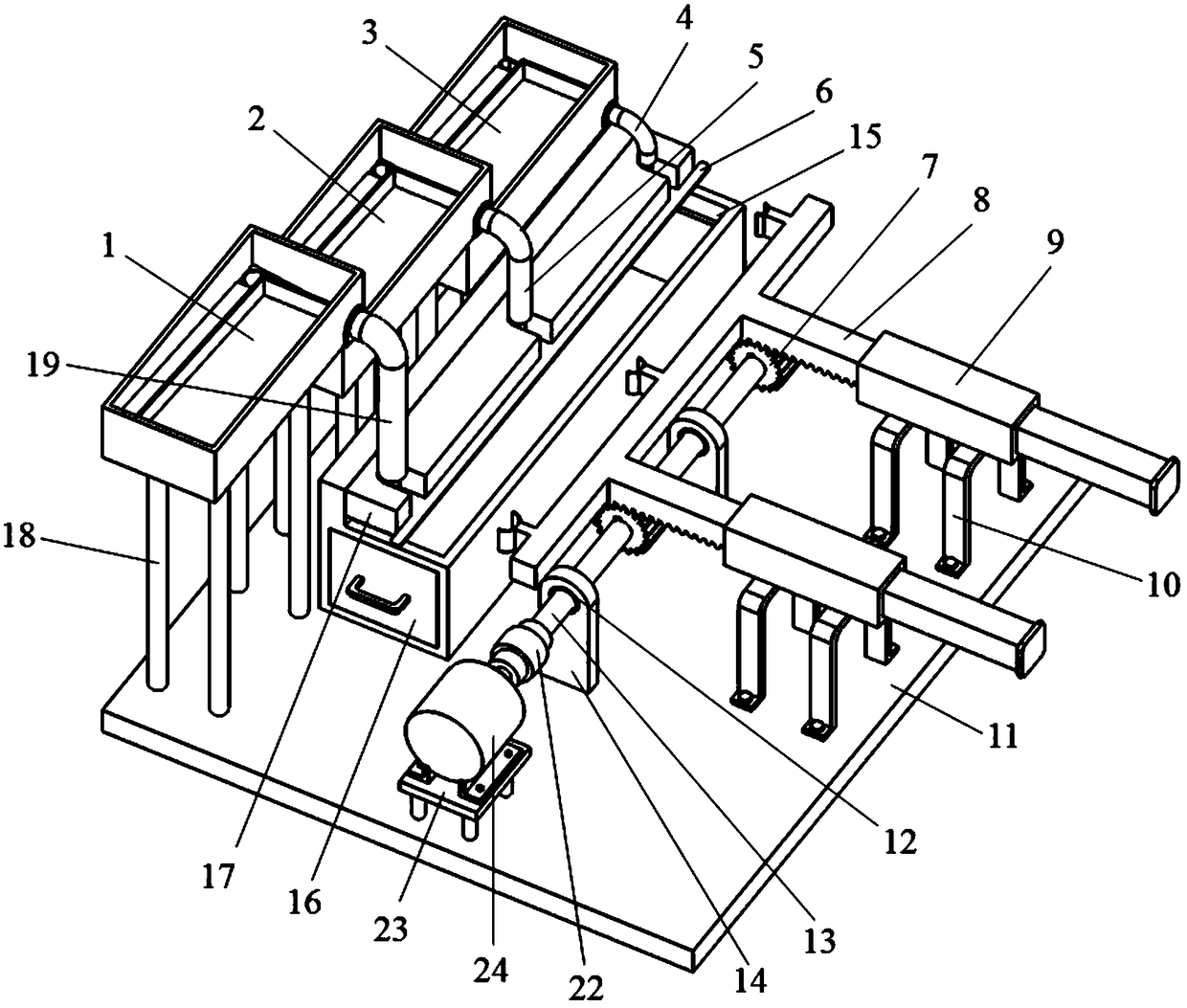

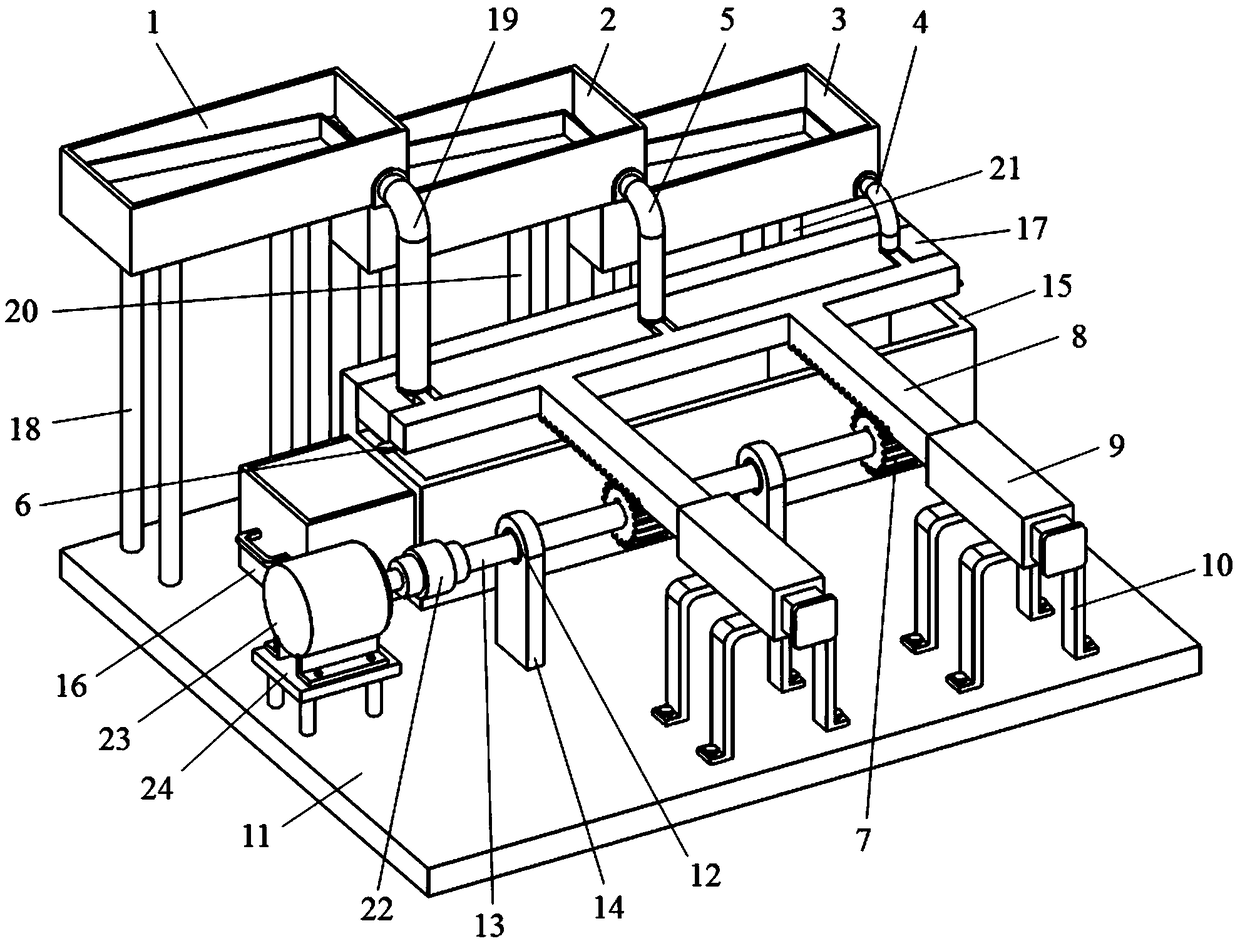

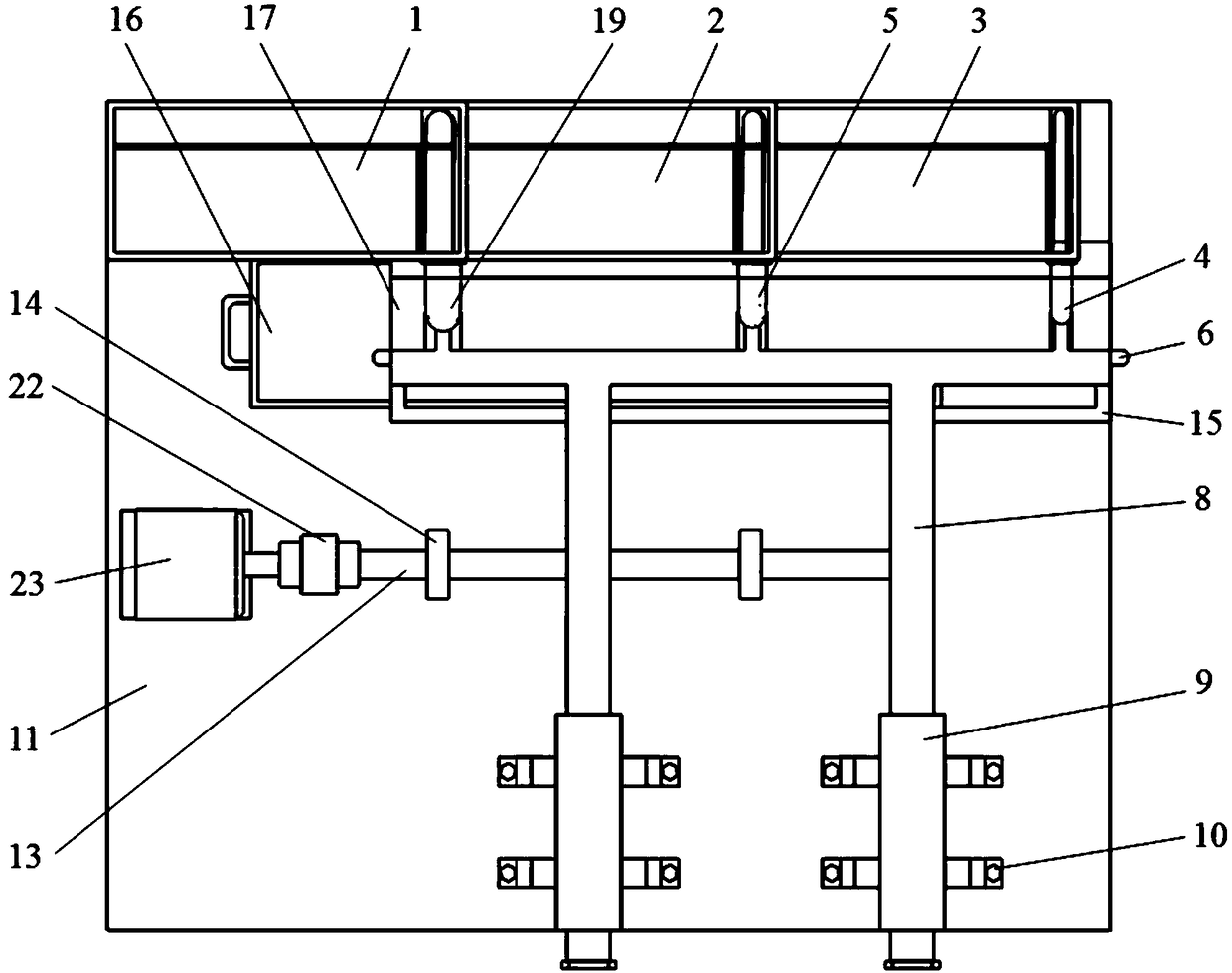

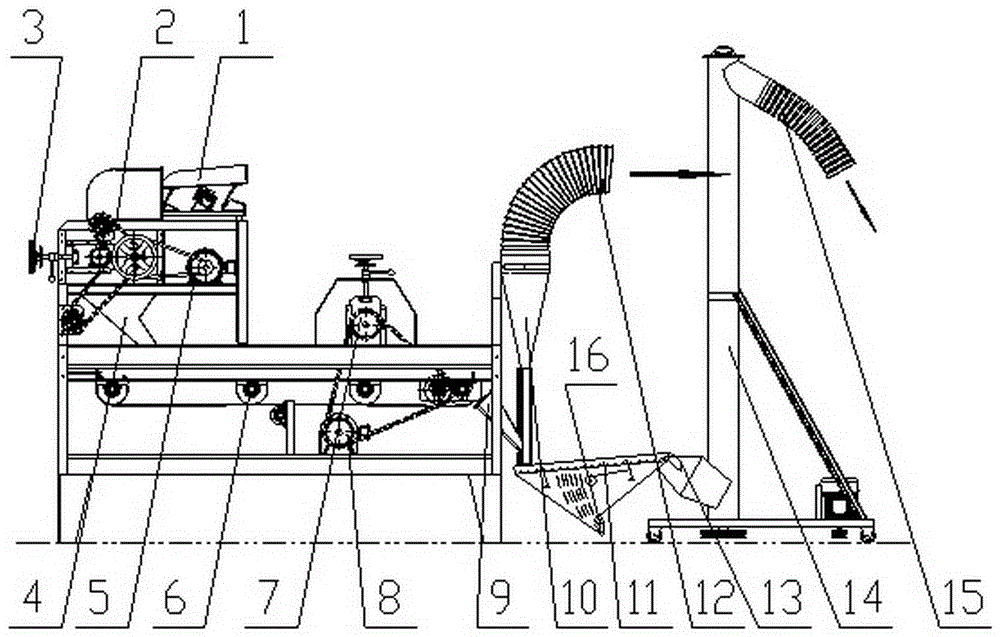

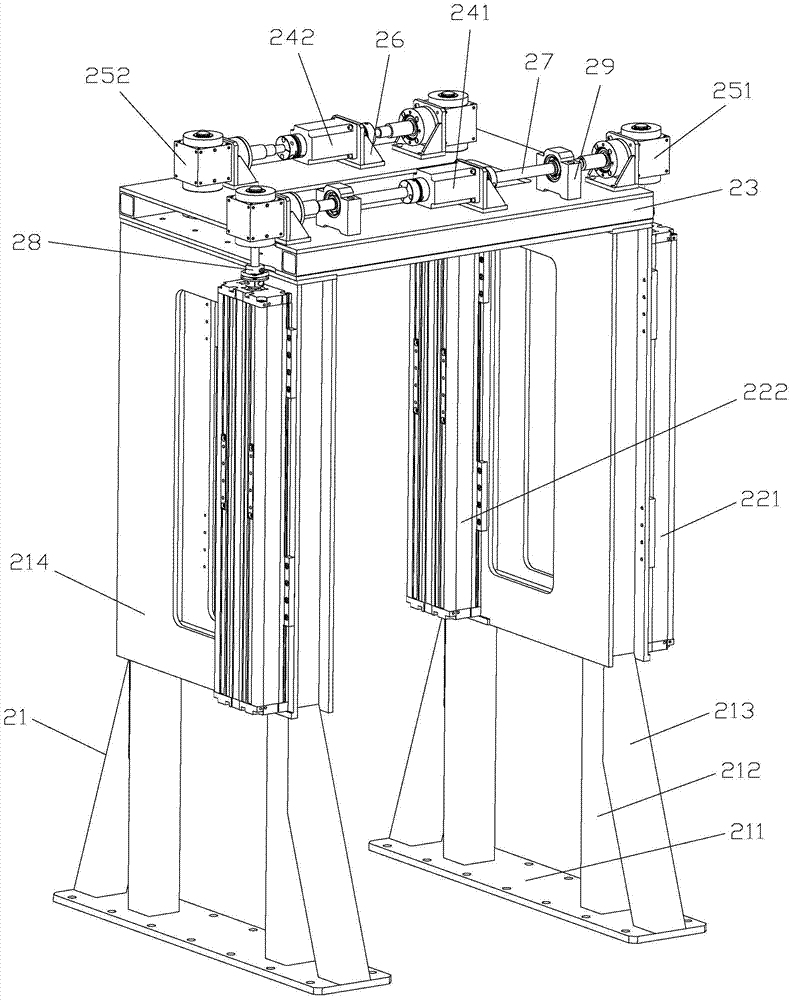

Automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation

PendingUS20200138083A1High speedHigh-efficiency walnut shell-breakingGas current separationHuskingWalnut NutProcess engineering

The disclosure discloses an automated production system for efficient walnut shell-breaking, kernel-taking and shell-kernel separation, solving the problem that the existing walnut shell breaking device cannot adapt to walnuts having different sizes and shell breaking rate and shell breaking efficiency cannot be ensured. The system can realize efficient shell-breaking, kernel-taking and shell-kernel separation on different varieties of walnuts, is quick in production speed and high in automation degree, and meanwhile is capable of improving entire kernel rate and kernel obtaining rate, reducing the damage rate of the walnut kernel and ensuring the high shell-breaking efficiency and thoroughness of shell and kernel separation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

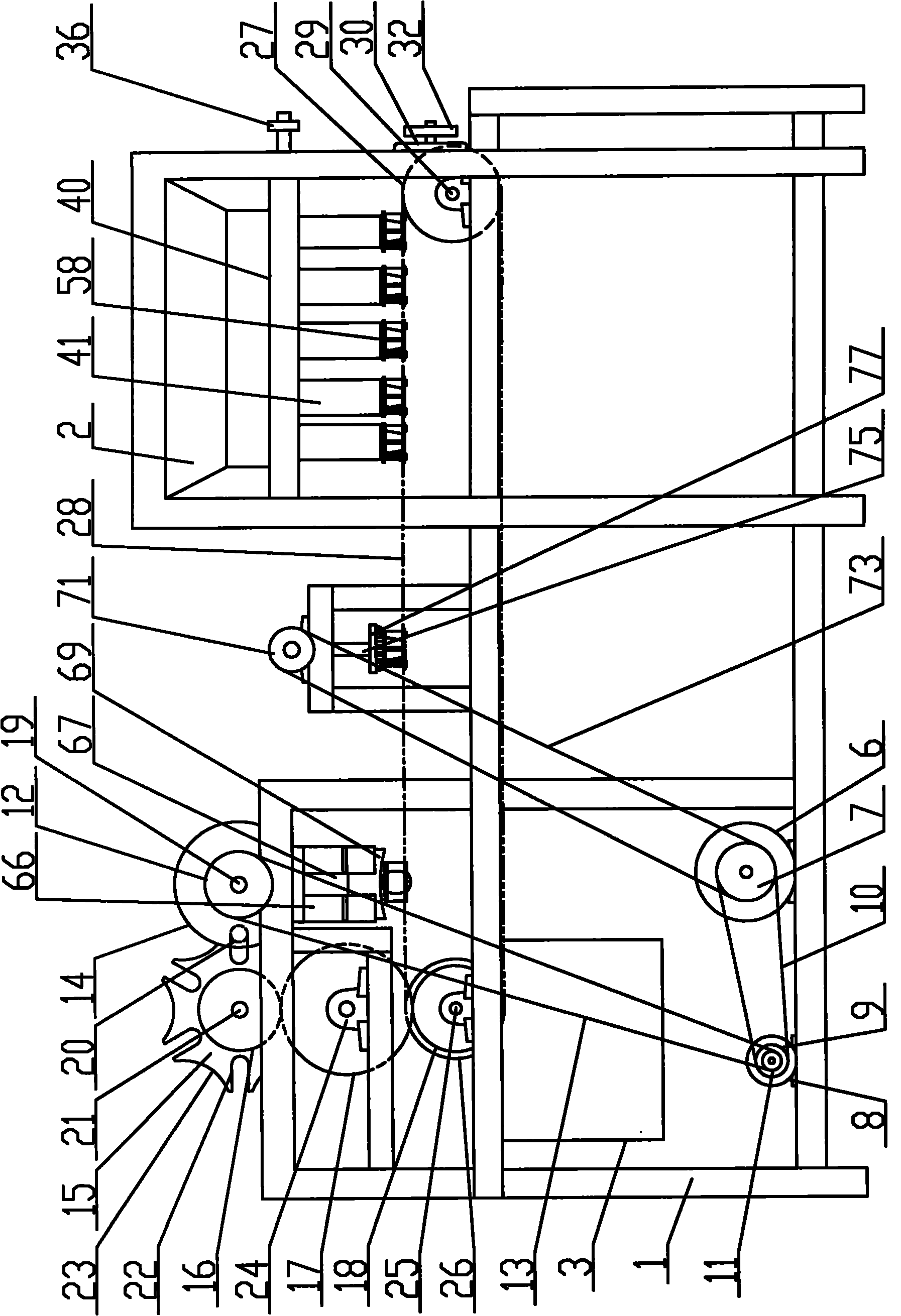

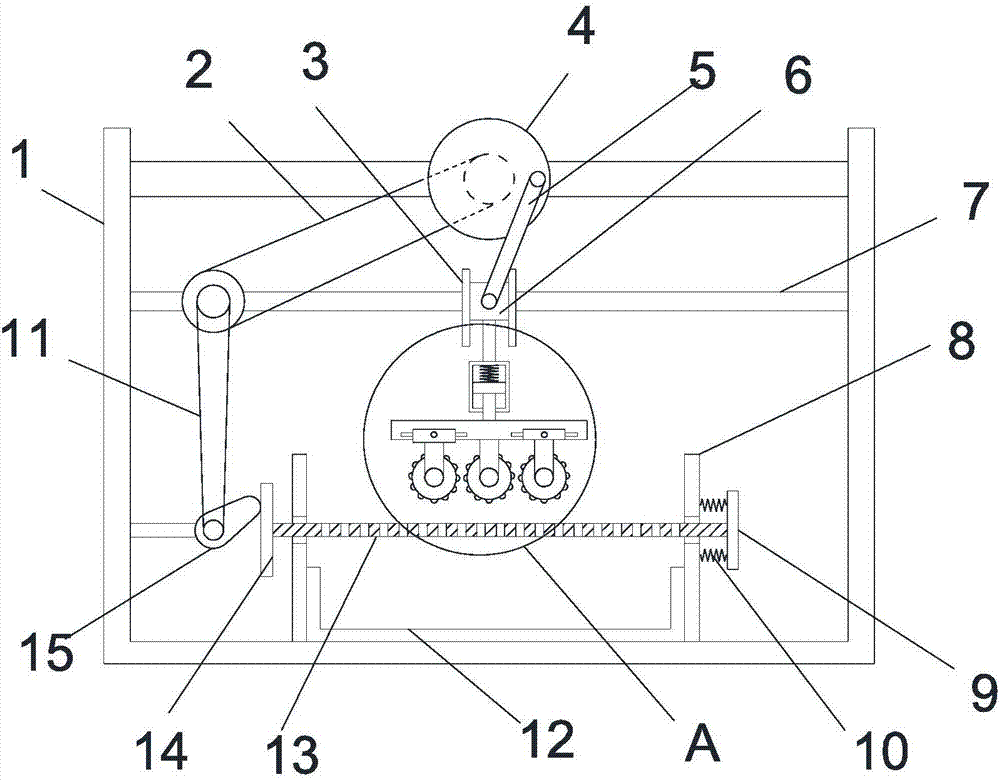

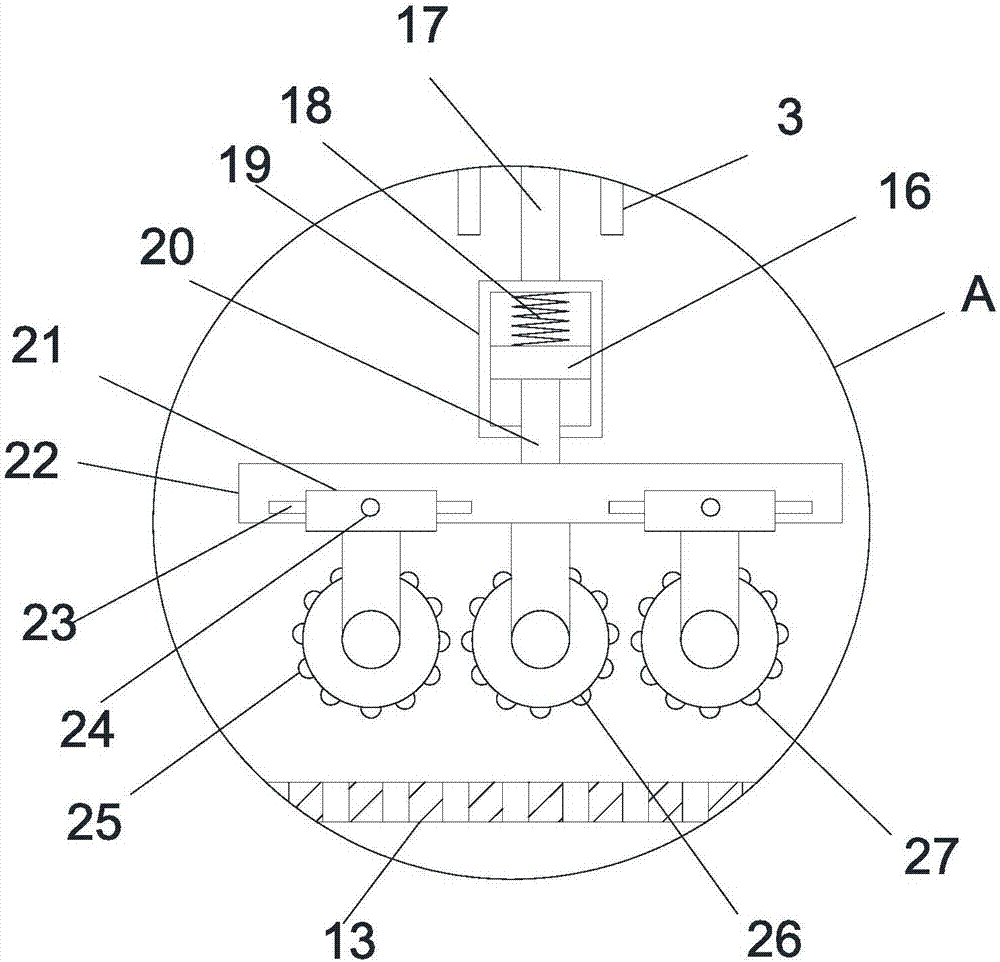

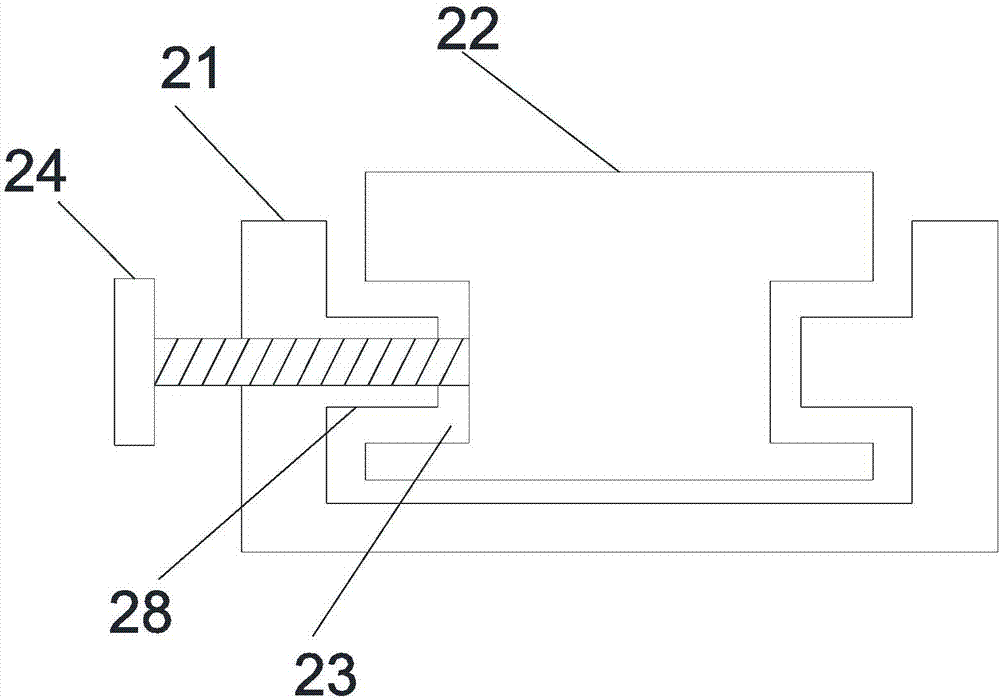

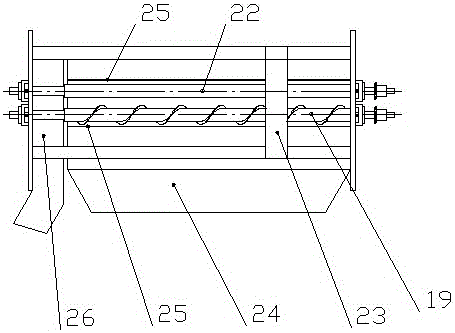

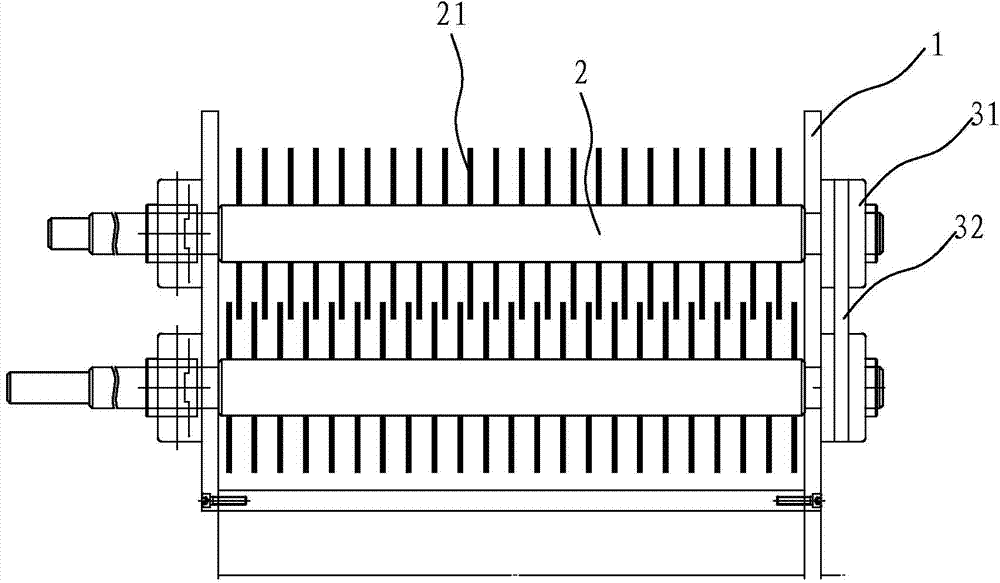

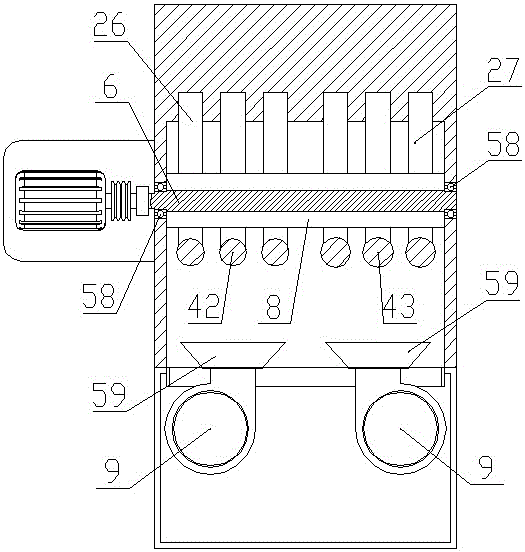

Automatic production system for highly-efficient walnut shell breaking and kernel obtaining and shell-kernel separation

PendingCN108576844AReduce manufacturing costSmall footprintGas current separationHuskingProduction rateSuction force

The invention discloses an automatic production system for highly-efficient walnut shell breaking and kernel obtaining and shell-kernel separation, and the automatic production system solves problemsthat the existing walnut shell breaking device can not adapt to walnuts in different sizes, and the shell breaking rate and the shell breaking efficiency can not be guaranteed. The automatic production system is capable of realizing highly-efficient shell breaking and kernel obtaining and shell-kernel separation for walnuts in different varieties, high in production rate and automation degree, improved in whole kernel rate and kernel obtaining rate, reduced in damage rate of walnut kernels and capable of ensuring high efficiency of shell breaking and thoroughness degree of shell-kernel separation. A technical scheme of the automatic production system is that: the automatic production system includes a shell breaking device: extruding components are arranged to extrude and break walnut shells; a walnut kernel vibrating and grading device: receiving shell-kernel mixture after shell breaking, subjecting the shell-kernel mixture to vibrating and grading, and conveying the graded shell-kernel mixture to each negative pressure shaking and sorting device, respectively; and the negative pressure shaking and sorting devices are connected to a negative pressure separation device, the negative pressure separation device sucks and stores the walnut shells through negative pressure suction force, and the walnut kernels are classified and stored through the negative pressure shaking and sorting devices.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Walnut splitting type shell-cracking kernel-taking machine

The invention relates to the technical field of shell-cracking devices for nut plant seed shells, in particular to a walnut splitting type shell-cracking kernel-taking machine which comprises a stand, feeding tanks, a material receiving tank, a transmission device, a delivery device, a feeding guide device and a splitting device. The feeding tanks are respectively fixed on the right side and the left side of the upper front part of the stand, the material receiving tank is fixed on the lower rear part of the stand, and the middle part of the stand is provided with the delivery device which can intermittently move. A walnut holding fixture which can fix each walnut and maintain the seam line to be vertical is installed on the delivery device. The invention has reasonable and compact structure, is convenient to use, can accurately position the walnut through the feeding guide device and the holding fixture on the delivery device, and crack the shell in the position perpendicular to the seam line of the walnut through the splitting device; and the mechanical shell cracking of a near-spherical walnut with a projecting seam line can be realized. The invention has the characteristics of high kernel integrity rate, high rate of shell cracking in one step, simple structure, convenient operation and high shell cracking efficiency.

Owner:XINJIANG AGRI UNIV

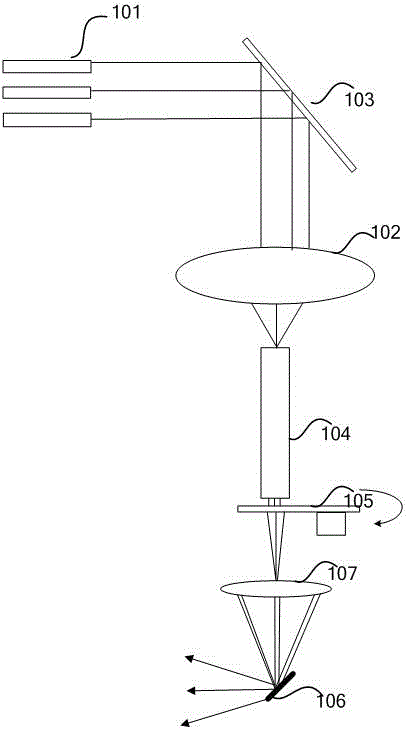

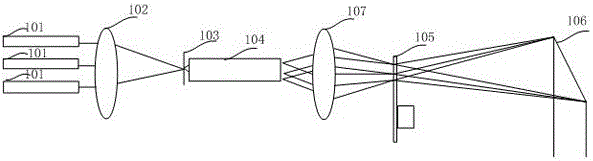

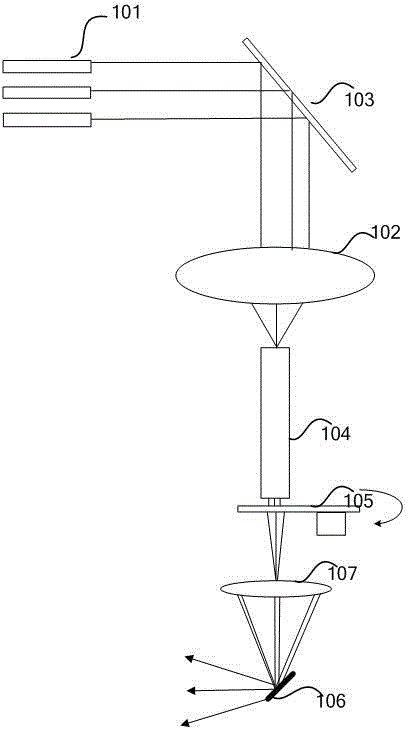

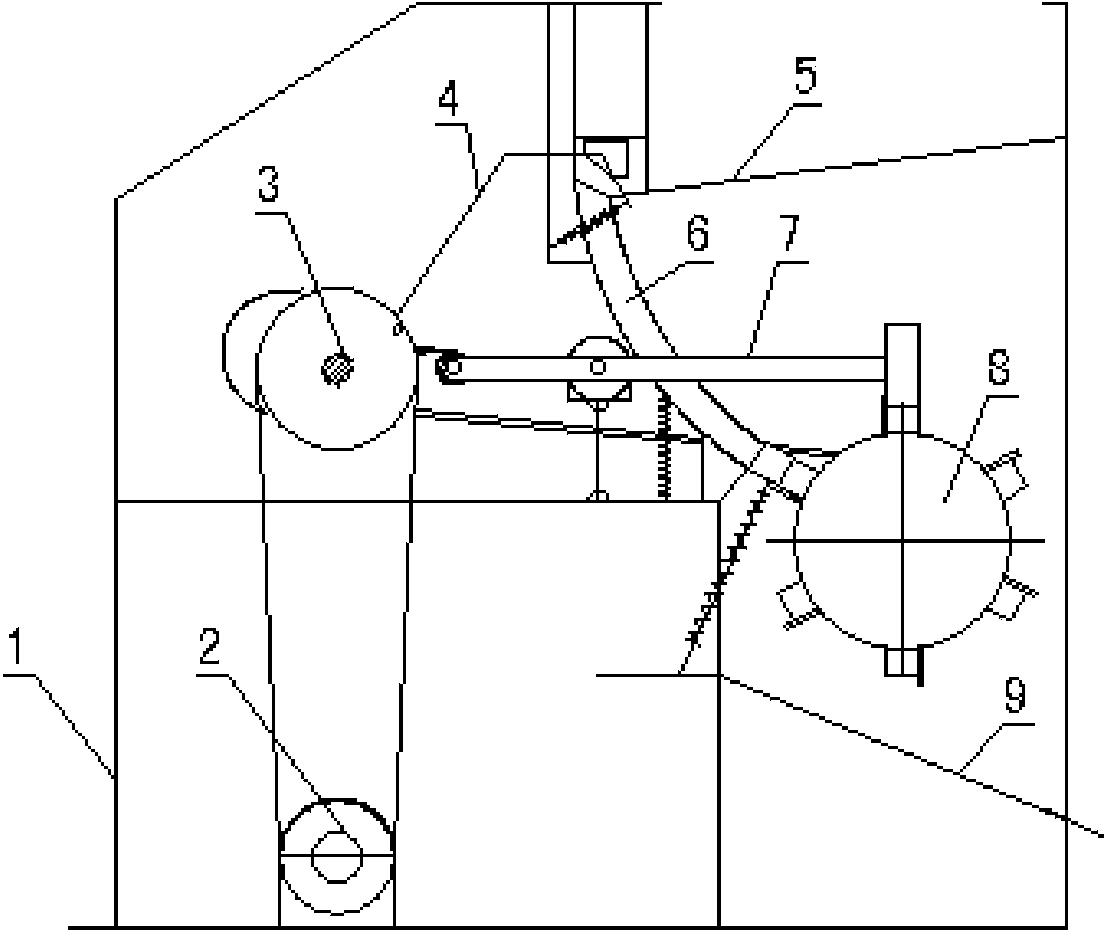

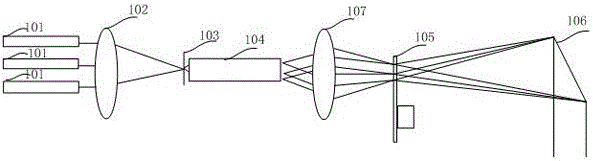

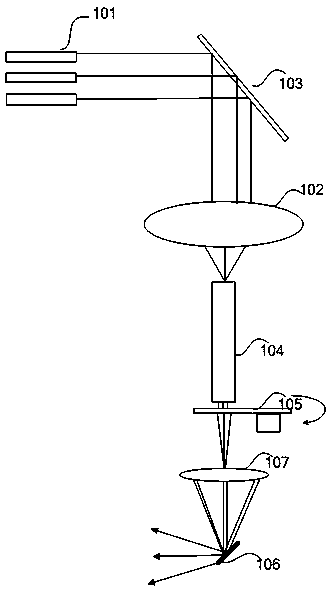

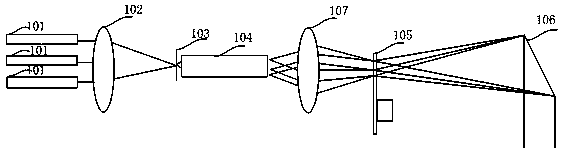

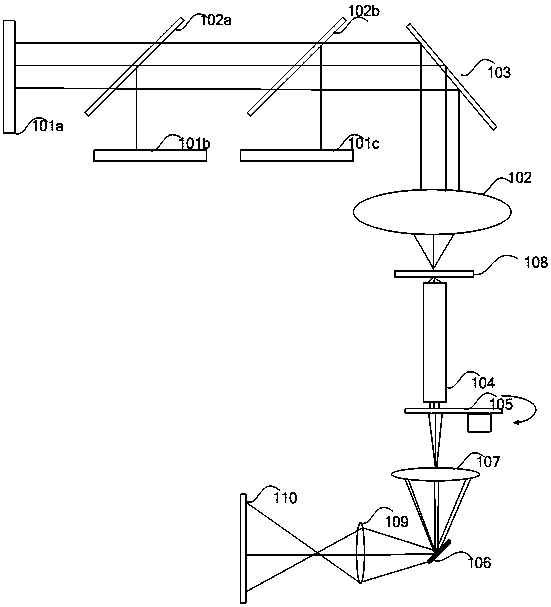

Laser projection system

InactiveCN106707671AVariety of divergence anglesImprove display qualityProjectorsOptical elementsDivergence angleLight beam

The invention discloses a laser projection system comprising a laser light source which emits laser beams of at least one color. The transmission light path of the laser beams includes a light homogenizing part which is used for receiving and homogenizing the laser beams; a light valve which is used for receiving the laser beams homogenized by the light homogenizing part and modulating the laser beams; a diffuse scattering phase plate which is arranged at the light incident surface side of the light homogenizing part and can increase the divergence angle of the beams; and a moving diffuser which is arranged at the light emergent surface side of the light homogenizing part and can greatly enhance the generation number of random phases, wherein the position of the moving diffuser is the object plane position of the light valve and the human eye integration effect is performed on the generated random phases so that the speckle effect of the projection frame can be weakened or eliminated to the greatest extent, and thus the speckle elimination effect and the display quality of the projection frame can be greatly enhanced.

Owner:HISENSE

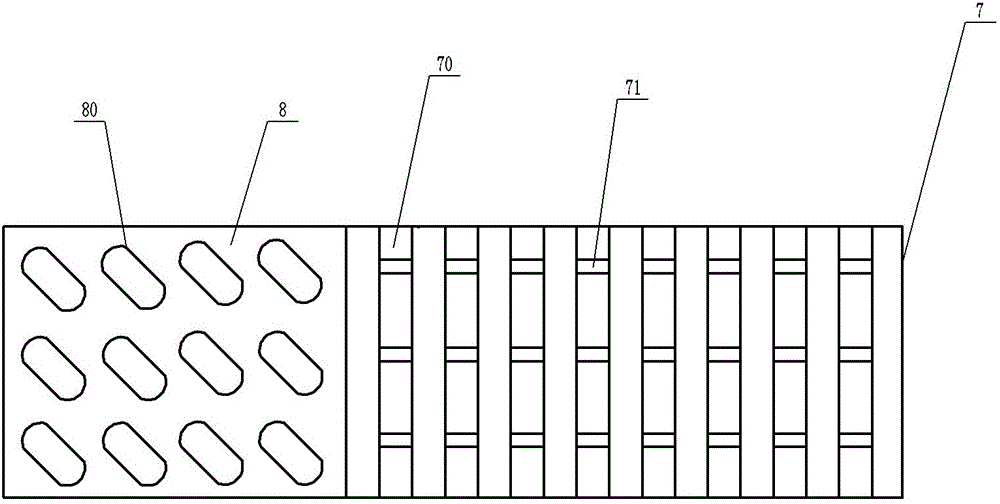

Hickory nut shell-crushing and sorting machine

The invention relates to a hickory nut shell-crushing and sorting machine. The hickory nut shell-crushing and sorting machine comprises a machine frame, a feeding module, an extruding module, a crushed shell separation sieve and a discharging module, wherein the feeding module comprises a feed hopper, a poking roller and a feeding guide slot; the extruding module comprises an extruding roller, an extruding heavy hammer, a lifting sliding rail and a cover board; the extruding roller is arranged on the machine frame through a bearing and a bearing pedestal; transverse slots are formed in the circumferential direction of the extruding roller uniformly; small round holes for accommodating the hickory nuts are formed in the transverse slot uniformly; an extruding blade is arranged in each small round hole; the lifting sliding rail is arranged on the machine frame; the cover board is arranged on the machine frame; the cover board is covered on the two sides and the top part of the extruding roller; a square hole of which the area is bigger than that of the lower end of the extruding heavy hammer is formed over the cover board; the crushed shell separation sieve is arranged under the extruding roller; and the discharging device is positioned under the crushed shell separation sieve. The hickory nut shell-crushing and sorting machine has the advantages of mechanized work, high production efficiency and stable work.

Owner:日照瑞达建设集团有限公司

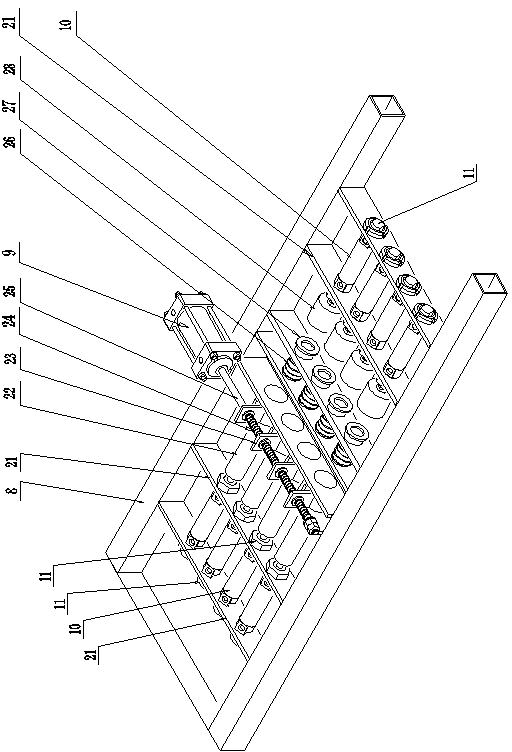

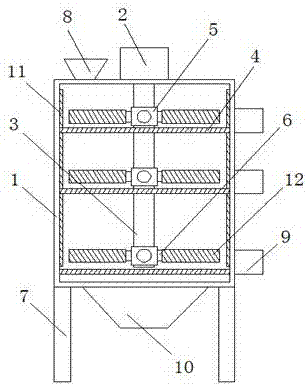

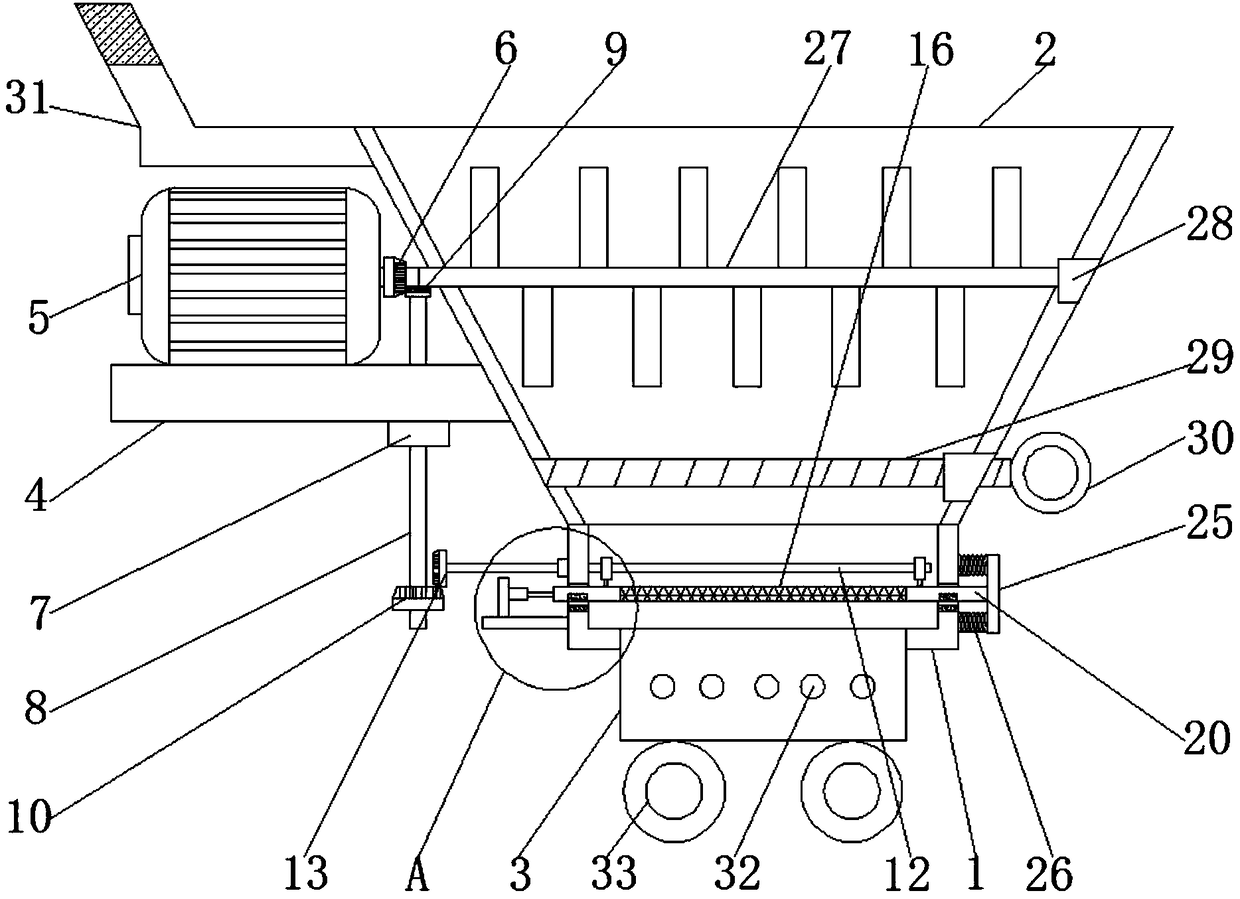

Rapid peanut deshelling device with screening function

InactiveCN107874279AImprove the efficiency of breaking upSpread evenlySievingScreeningEngineeringCam

The invention discloses a rapid peanut deshelling device with a screening function. The rapid peanut deshelling device comprises a frame, wherein a horizontal plate is fixedly mounted horizontally inside the frame; a deshelling tank is fixedly mounted at the bottom inside the frame; a collecting tank is arranged at the bottom inside the deshelling tank; a metal screening plate is arranged inside the frame in a horizontal sliding and penetration manner; a limiting push plate is fixedly mounted vertically art the left end of the metal screening plate; a rotating wheel is rotationally arranged onthe frame; a deshelling rotating roller I is vertically rotationally arranged on the lower surface of a sliding rack; a cam which is propped against the limiting push plate is rotationally arranged inside the frame; and a first belt pulley mechanism in transmission connection with the rotating wheel is arranged on the horizontal plate. Peanuts are subjected to deshelling operation through downward extrusion of the deshelling rotating roller I and a deshelling rotating roller II, the deshelling rotating roller I and the deshelling rotating roller II are moved relative to the metal screening plate, then the peanuts are subjected to rolling extrusion and deshelling of the deshelling rotating roller I and the deshelling rotating roller II, the peanut deshelling efficiency is greatly improved,and the peanuts can be deshelled relatively sufficiently and completely.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

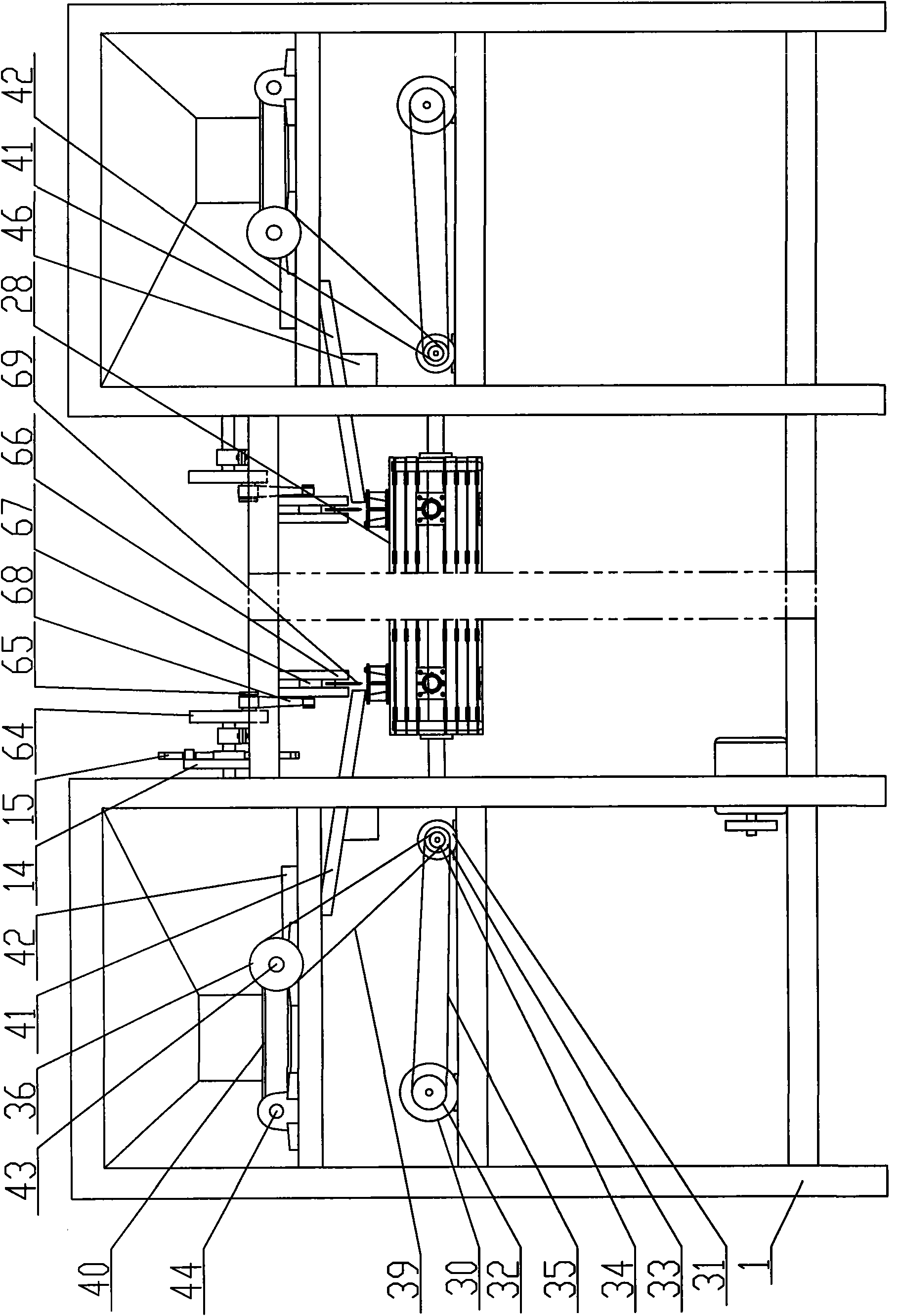

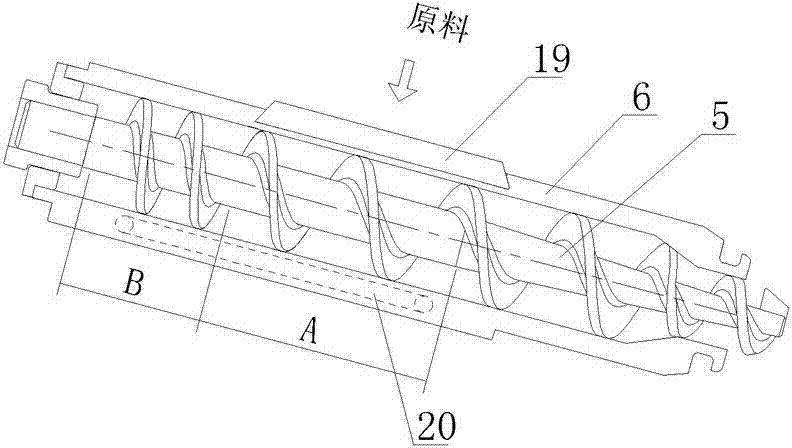

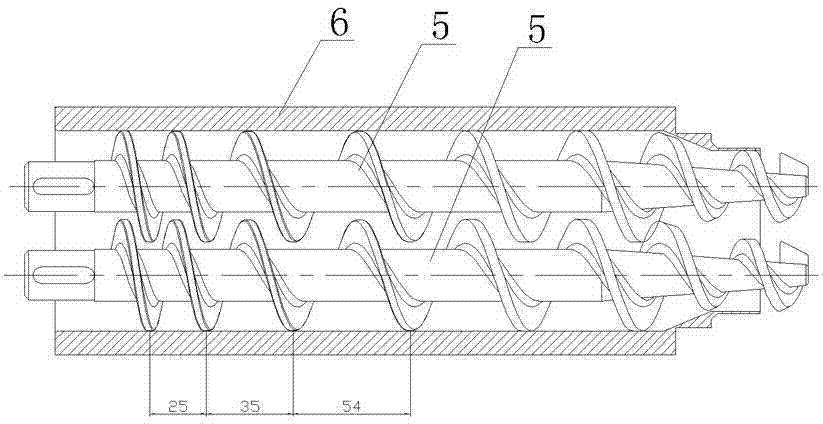

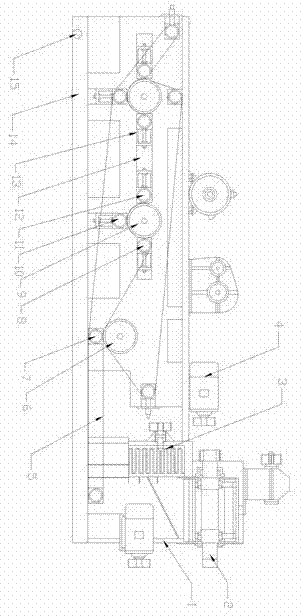

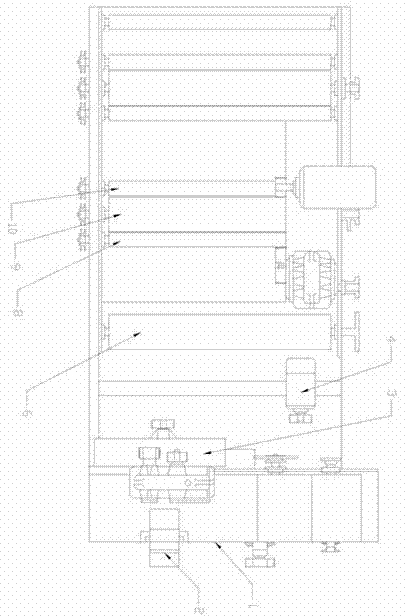

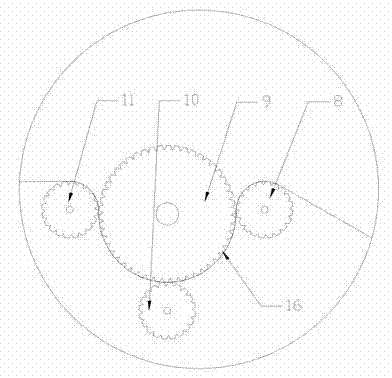

Dry method pelletizing machine

InactiveCN103861525ACompact structureFully automatedGranulation by material expressionEngineeringMechanical engineering

The invention discloses a dry method pelletizing machine. The dry method pelletizing machine is characterized by comprising a loading mechanism, a vertical feeding mechanism, an inclined feeding mechanism, a tabletting mechanism, a granulating mechanism, a straightening mechanism and a screening mechanism, wherein the loading mechanism comprises a charging basket which is communicated with a vacuum system, the vertical feeding mechanism comprises a vertical feeding motor and a vertical feeding screw rod, the inclined feeding mechanism comprises a feeding cylinder, a feeding screw rod and a feeding motor, the tabletting mechanism comprises an upper pinch roller and a lower pinch roller which rotate reversely, the granulating mechanism comprises a granulating wheel, the straightening mechanism comprises a straightening wheel, a straightening device and a screen straightening device, the screening mechanism comprises a screening barrel, a sieve tray and a powder receiving tray, and a feeding hole, a fine powder discharging hole and a finished product discharging hole are formed in the wall of the screening barrel. The dry method pelletizing machine is compact in structure, reliable in sealing and high in working efficiency, high quality finished product particles can be produced, fine powder ratio of finished product is controlled to be less than 4%, the dry method pelletizing machine can be applicable to various powders with different flowabilities, and automatic production can be completely realized.

Owner:ZHEJIANG FUTURE MACHINERY

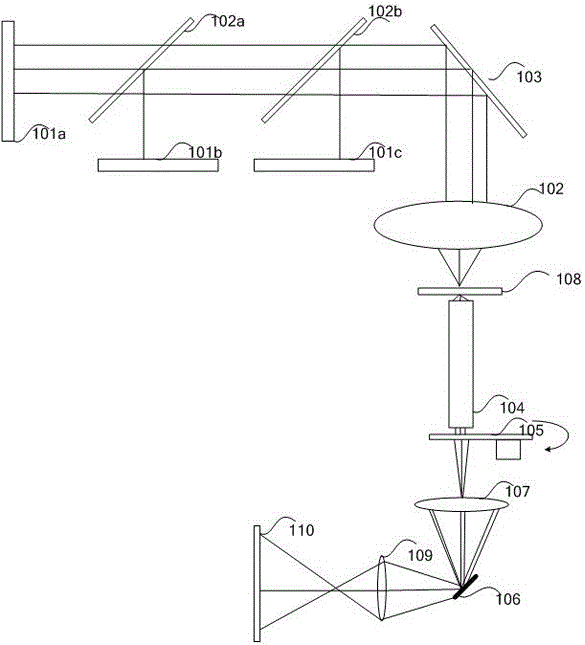

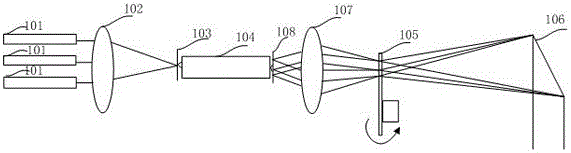

Laser projection system

InactiveCN106647127AVariety of divergence anglesImprove display qualityProjectorsOptical elementsIntegral actionProjection image

The invention discloses a laser projection system, comprising a laser light source which is used for emitting laser beams of at least one color; a light homogenization component which is used for receiving and homogenizing the laser beams; a light valve which is used for receiving the laser beams homogenized by the light homogenization component and modulating the laser beams; a vibrating reflection-type phase plate which is arranged on a light incident surface side of the light homogenization component; and a motion diffuser which is arranged on a light emergent surface side of the light homogenization component. A position at which the motion diffuser is located is an object plane position of the light valve. The number of produced random phases can be greatly increased, according to the random phases, through integral action of human eyes, the speckle effect of a projection image can be reduced or eliminated to the greatest extent, and the speckle eliminating effect and the display quality of the projection image can be greatly improved.

Owner:HISENSE

Pecan hulling machine

The invention discloses a pecan hulling machine. The pecan hulling machine comprises a machine frame, wherein the machine frame is provided with a feed device, a hulling device, a discharge device and a power transmission device, wherein the feed device comprises a feed hopper and a feed pipe; the hulling device comprises a feed cylinder and a beating rod assembly; a plurality of outwards convex hammer bases are evenly arranged on the circumference of the feed cylinder; a plurality of small concave pits are formed in the inwards concave surfaces of the hammer bases; the beating rod assembly comprises a beating rod idler wheel, a beating rod, a beating rod bearing base, a beating rod hammer and a beating rod spring; the front end and the rear end of the beating rod are provided with the beating rod hammer and the beating rod idler wheel respectively; the middle of the beating rod is hinged to the beating rod bearing base to form a lever fulcrum; the upper end of the beating rod spring is connected to the beating rod; the lower end of the beating rod spring is fixed to the machine frame; the beating rod is driven through a cam mechanism to vertically swing; the cam mechanism comprises a cam and a flat board; the flat board is arranged at the opposite end of the convex surface of the cam. The pecan hulling machine has the advantages that granules of hulled pecans are full and low in degree of breakage, the level of integration and degree of automation are high, the hulling efficiency is high, and cost is low.

Owner:丁孝德

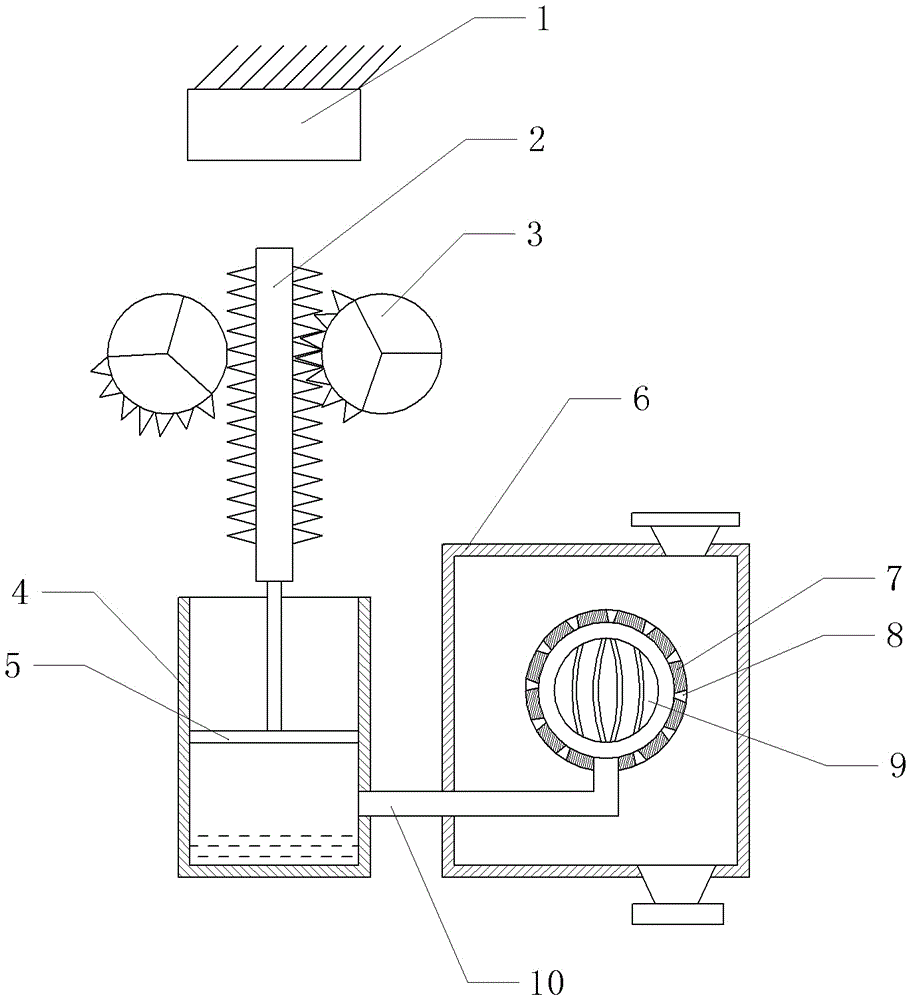

Feedstock scattering device for coir mattress

The invention belongs to the technical field of pretreatment of fiber materials and discloses a feedstock scattering device for a coir mattress. The feedstock scattering device comprises a scattering box and a power case, wherein a hollow scattering ball is arranged in the scattering box, a plurality of scattering holes are uniformly distributed in the sidewall of the scattering ball, the scattering ball communicates with a ventilating pipe, and the ventilating pipe penetrates through the scattering box and communicates with the power case; the power case contains water, a water surface is located below a communicating position of the ventilating pipe and the power case, a piston is arranged in the power case, and a piston rod is arranged at the upper end of the piston; a control device is arranged at the upper end of the piston rod and can drive the piston rod to slide up and down, and the piston rod can stay static during the switching of upward sliding and downward sliding. According to the feedstock scattering device for the coir mattress, the technical problem in the prior art that the feedstock scattering effect is poor during the manufacturing of the coir mattress is solved.

Owner:重庆市永川区植成家俱厂

Oil tea shell smashing and shell and seed sorting machine

The invention relates to the technical field of nut fruit crop classifying, shell smashing and shell and seed sorting equipment, in particular to an oil tea shell smashing and shell and seed sorting machine. Fresh tea fruits are classified at first by a tea fruit classifying mechanism, so that the tea fruits are processed after being classified according to the size, and the processing quality is greatly improved; shells of the tea fruits are cut by a shell cutting mechanism, therefore, surfaces of oil tea shells are fully distributed with tool marks, then the oil tea shells are dried by a hot air drying and shell cracking mechanism, and the tea fruits crack rapidly; and the shells of the oil tea are smashed by an extruding and shell smashing mechanism, in shell smashing, a roller coupler mechanism is used for extruding the shells of the oil tea, and finally, a shell and seed sorting mechanism is used for sorting so that tea shells and tea seeds are sorted from different channels. The oil tea shell smashing and shell and seed sorting machine is high in classifying speed, good in shell cracking effect, high in shell smashing efficiency, low in tea seed breakage rate, small in tea fruit damage and low in impurity content; and integration of classification, shell cutting, drying, shell breaking and sorting is realized by the whole system, continuous running of the machine is guaranteed, and work efficiency is greatly improved.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Glass breaking device, glass breaking method and glass cutting system

ActiveCN106977089AImprove the efficiency of breaking upSimple structureConveyorsGlass severing apparatusEngineeringElectrical and Electronics engineering

The invention discloses a glass breaking device, a glass breaking method and a glass cutting system with the glass breaking device. The glass breaking device comprises a support and a breaking part, wherein the support is provided with a first supporting part and a second supporting part for supporting a glass substrate; the first supporting part and the second supporting part are arranged alternately along the first direction; the breaking part is used for breaking the edge of the glass substrate, and is positioned between the first supporting part and the second supporting part in the first direction. The glass breaking device according to the implementation mode is high in breaking efficiency, simple in structure and low in manufacture cost, and can be assembled together with other devices conveniently.

Owner:北京远大信达科技有限公司

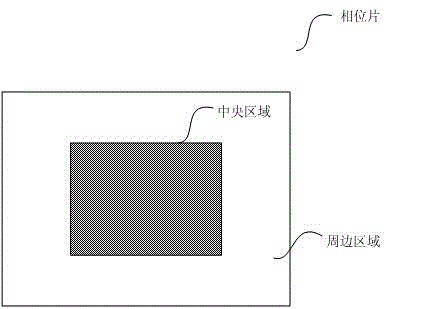

Laser projection system

InactiveCN106773485AVariety of divergence anglesAmplitude of small scatterProjectorsOptical elementsIntegral actionDivergence angle

The invention discloses a laser projection system which comprises a laser light source, a light homogenizing component, a light valve, a first phase plate and a motion diffuser, wherein the laser light source emits laser beams of at least one color; the light homogenizing component, the light valve and the first phase plate are included in a transmission light path of the laser beams; the light homogenizing component is used for receiving and homogenizing the laser beams; the light valve is used for receiving the laser beams homogenized by the light homogenizing component and modulating the laser beams; the first phase plate is arranged on the incident side of the light homogenizing component; the center area of the first phase plate is larger than a divergence angle of the laser beams in a surrounding area; the motion diffuser is arranged on the emergent side of the light homogenizing component and is capable of greatly improving the quantity of generated random phases; the position where the motion diffuser is positioned is conjugated to the light valve surface. Due to the human eye integral actions at the random phases, a spot dissipating effect of a projected picture can be weakened or eliminated to the greatest degree, so that the spot dissipating effect and projected picture display quality are greatly improved.

Owner:HISENSE

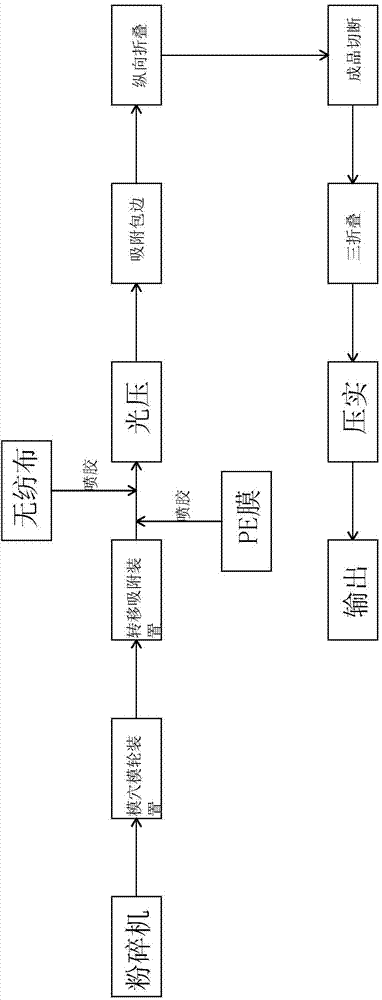

Absorption core production technology

The invention relates to an absorption core production technology which is high in production efficiency and low in production cost, and structures of produced absorption cores are simplified. The absorption core production technology includes the following steps that first, raw materials are conveyed into a pulverizer to be pulverized and then conveyed out; second, pile pulp is conveyed into a mold cavity and mold wheel device, high polymer material is added into the pile pulp, and forming is performed; third, formed cotton cores are adsorbed through a transfer and adsorption device and transferred onto a conveying belt to be conveyed; fourth, in the conveying process, the upper portion of the cotton cores are covered with a layer of non-woven cloth, the bottoms of the cotton cores are covered with a layer of PE film, and the cotton cores are made to adhere to the non-woven cloth and the PE film in an adhesive spraying mode; fifth, the cotton cores are conveyed into a smoothing and pressing device to be pressed and smoothed, and then the cotton cores are conveyed out; sixth, the edges of the cotton cores are coved, and then the cotton cores are longitudinally folded; seventh, the cotton cores are conveyed into a cutting device, and tailoring and edge removing are carried out to obtain finished products; eighth, the cotton cores are folded three times, and the folded cotton cores are compacted through a pressure device and then conveyed out.

Owner:福建培新机械制造实业有限公司

Laser projection system

InactiveCN109884851AVariety of divergence anglesEasily damagedProjectorsOptical elementsLight beamOptoelectronics

The invention discloses a laser projection system. The laser projection system comprises a laser light source, which respectively emits a first color laser, a second color laser, and a third color laser; before a laser beam emitted by the laser light source enters a light valve, the laser beam further passes through a light homogenizing part, which is used for receiving and homogenizing the laserbeam; the light valve used for receiving the laser beam homogenized by the light homogenizing part and modulating the laser beam; a fixed phase plate arranged on the light-entering surface side of thelight homogenizing part; and a rotary diffusion sheet arranged on the light-emitting surface side of the light homogenizing part, and the position of the rotary diffusion sheet is conjugated with thelight valve surface. The laser projection system provided by the invention can weaken or eliminate the speckle effect of a projected picture to the maximum extent, thereby greatly improving the speckle removing effect and the display quality of the projected picture.

Owner:HISENSE

Shell-breaking device for increasing germination rate of seeds

InactiveCN107046860AImprove the efficiency of breaking upQuality improvementGas current separationSeed and root treatmentEngineeringMultiple layer

The invention discloses a shell-breaking device for increasing the germination rate of seeds. The shell-breaking device comprises a shell-breaking chamber, a motor, a rotating shaft, sieve plates, a mounting block and a stirring rod, and is characterized in that the shell-breaking chamber is arranged on a bracket, a feeding opening, a discharging opening, a residual outlet are formed in the shell-breaking chamber, the inner wall of the shell-breaking chamber is provided with a scrubbing layer, the motor is arranged on the shell-breaking chamber, the rotating shaft is arranged in the shell-breaking chamber, one end of the rotating shaft is connected with the motor, the sieve plates are arranged in the shell-breaking chamber, the mounting block is arranged on the rotating shaft, the rotating shaft is provided with the stirring rod, and the stirring rod is provided with a scrubbing sleeve. According to the shell-breaking device for increasing the germination rate of the seeds, the inner wall of the shell-breaking chamber is provided with the scrubbing layer, the stirring rod is provided with the scrubbing sleeve, the stirring rod can drive the seeds in the shell-breaking chamber to rotate, the scrubbing layer and the scrubbing sleeve conduct scrubbing and shell-breaking on the surfaces of the seeds, the shell-breaking efficiency and quality of the seeds are improved, the multiple layers of sieve plates are arranged in the shell-breaking chamber, debris generated by seed shell-breaking can be separated from the seeds, screening of the seeds is achieved, and therefore the germination rate of the seeds after shell-breaking is increased.

Owner:芜湖市三山区绿色食品产业协会

Egg-breaking device

The invention discloses an egg-breaking device. Both the first and second bending bars are L-shaped, wherein the short side ends thereof are oppositely arranged to form a U-shaped structure as a whole. A blade is arrange perpendicular to the end face of each end, the blade edges are perpendicular to the inward direction, the bent portions of the two bent bars are fixedly connected with a first positioning block and a second positioning block for clamping and supporting an egg, the two ends of the straight bar are respectively articulated with the long sides of the first bending bar and the second bending bar. An ejector rod penetrate into that middle of the straight bar and is movably connected with the straight bar, the top end of which is fixedly connected with a third positioning blockfor clamping and supporting the egg. The space enclosed by the three positioning blocks is an egg placement area. The bottom end of the ejector rod is respectively articulated with one end of the first connecting arm and the second connecting arm, and the other end of the two connecting arms is respectively articulated with the bottom end of the long side of the two bent strips. The invention hasthe advantages of simple structure, convenient operation, automatic positioning of the egg, time-saving and labor-saving, high shell breaking efficiency, and the eggshell and the egg liquid do not splashes everywhere, and the invention is safe, sanitary and reliable.

Owner:SUZHOU INST OF TRADE & COMMERCE

High-efficiency hulling and separating device of camellia oleifera fruit device

ActiveCN107822153AIngenious structureReasonable arrangementHuskingHullingCamellia oleiferaEngineering

The invention discloses a high-efficiency hulling and separating device of a camellia oleifera fruit device. The high-efficiency hulling and separating device comprises a housing, wherein a base is arranged at the bottom of the housing; a feeding hopper is arranged at the top of the housing; flow-guiding plates are arranged at the inner top of the housing in a bilateral symmetry manner; arc-shapedtooth grooves which are in bilateral symmetry are respectively formed in the bottom end of each flow-guiding plate; a crushing roller is arranged between the two arc-shaped tooth grooves; crushing teeth which are meshed with the arc-shaped tooth grooves are arranged on the outer side of the crushing roller; and the crushing roller is mounted on a crushing shaft arranged in the housing in a sleeving manner. The high-efficiency hulling and separating device of a camellia oleifera fruit device provided by the invention is ingenious in structure and reasonable in arrangement; a hulling mechanismis ingeniously arranged, so that the hulling efficiency is high, and in addition, shell blocking can be effectively avoided; a kneading mechanism is ingeniously arranged, so that shells of crushed camellia oleifera fruits are thoroughly separated from kernels of the crushed camellia oleifera fruits through the centrifuging flexible extruding and kneading of a kneading belt; and a sorting mechanismis ingeniously arranged, so that the high-efficiency sorting of the shells and the kernels is realized.

Owner:ANHUI LONGMIANSHAN FOOD

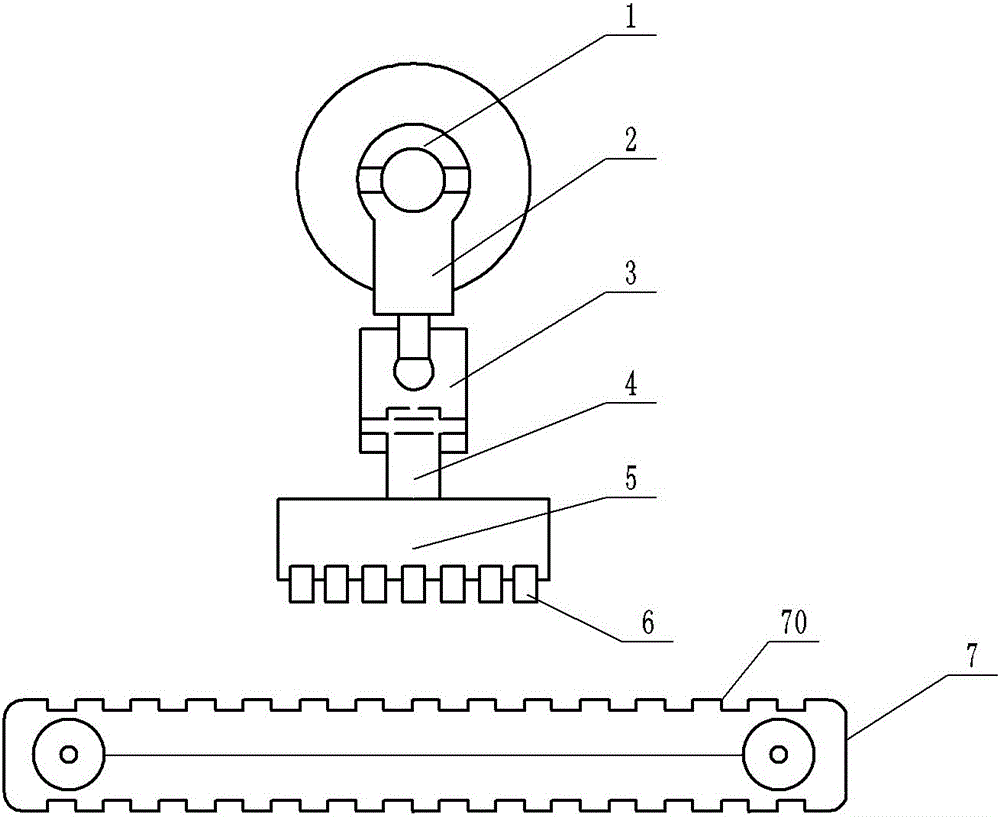

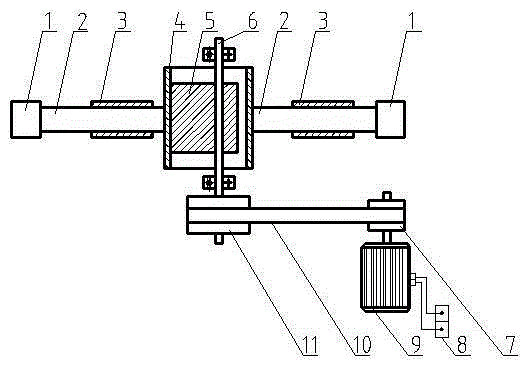

System and method for pressing walnuts into cracks based on precise self-positioning

InactiveCN106666763ASave energySave manpower and material resourcesHuskingHullingMaterial resourcesEngineering

The invention discloses a system and method for pressing walnuts into cracks based on precise self-positioning. The system comprises a driving mechanism, a transmission mechanism and a pressing mechanism. The driving mechanism generates driving force and pushes the transmission mechanism to reciprocate; the pressing mechanism comprises falling blocks and pressing blocks opposite to the falling blocks, gaps are formed between the falling blocks and the pressing blocks, and the gaps are gradually reduced so as to position falling walnuts; the transmission mechanism pushes the falling blocks and the pressing blocks, and the gaps between the pressing blocks and the falling blocks are changed so as to press walnuts falling into the gaps between the pressing blocks and the falling blocks so that cracks can be generated. By means of the system, the pre-shell-breaking process is added on the premise of effectively reducing the consumption of manpower and material resources and improving the production efficiency, and the completeness of kernels is fully guaranteed. Besides, through mechanism optimization, the working stability of the system is improved while mechanism simplification is achieved, the total cost of the system is reduced, and a significant production effect is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Walnut breaking machine

InactiveCN105996068ASize distinctionConvenient stamping and shell breakingHuskingHullingWalnut NutCoupling

The invention relates to a walnut breaking machine. The walnut breaking machine comprises a rack, wherein a spiral feeding device is arranged at the top of the rear end of the rack, a motor is fixed on the left side wall of the rack, the motor controls the spiral feeding device to feed through belt drive, a lower rotating shaft is rotatably arranged inside the rack, the motor controls the lower rotating shaft to rotate by virtue of a coupling, a material distribution board is arranged on a circular arc surface of the lower rotating shaft, a pneumatic stamping breaking device is arranged in front of the material distribution board, a pneumatic blanking device is arranged below the pneumatic stamping breaking device, a fan is fixedly arranged at a position, over against the pneumatic blanking device, on the front side wall of the rack, blanking plates are arranged below the pneumatic blanking device, the blanking plates are arranged in an inclined manner and are lower in the front and higher at the rear, the front ends of the blanking plates extend out of the rack, a waste hopper is arranged right below the blanking plates, the waste hopper is arranged inside the rack, a material collecting hopper is arranged below the front ends of the blanking plates, and the material collecting hopper is arranged in front of the rack. The walnut breaking machine operates in an electric and pneumatic combined manner, and walnuts are distinguished according to size specification, so that a breaking process is greatly simplified, and breaking efficiency is improved.

Owner:HUANGHE S & T COLLEGE

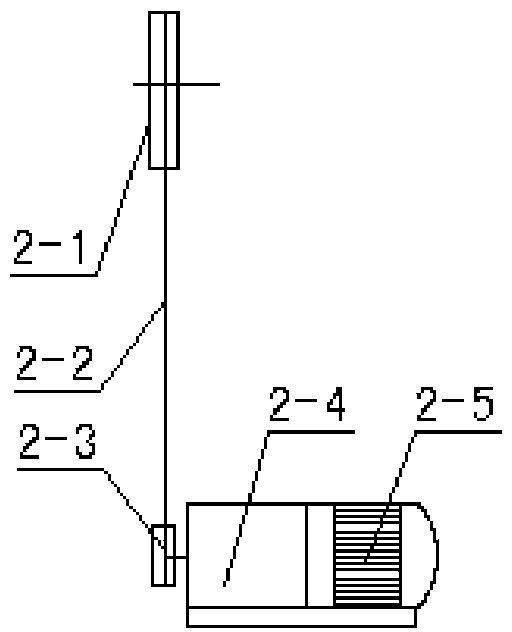

Automatic nut screening and cracking device

The invention relates to a nut cracking device, in particular to an automatic nut screening and cracking device which comprises a screening mechanism, a conveying mechanism, a collecting mechanism, apower mechanism and a bottom plate, wherein the screening mechanism, the conveying mechanism, the collecting mechanism and the power mechanism are mounted on the bottom plate. The screening mechanismcomprises a first screening box, a second screening box, a third screening box, a first supporting box, a second supporting box and a third supporting box, the conveying mechanism comprises a first bent pipe, a second bent pipe and a third bent pipe, the collecting mechanism comprises a baffle plate, a supporting box, a drawer and a base, and the power mechanism comprises a gear, a gear extrusionrod, a horizontal slide, a supporting frame, a bearing, a rotating shaft, a supporting seat, a coupler, a stepping motor and a motor support. The automatic nut screening and cracking device has the advantages that the stepping motor drives the rotating shaft to rotate, nut extrusion acting force can be controlled by setting a stepping angle, operation is simple, cracking effects are good, three different specifications of nuts can be simultaneously cracked, and cracking efficiency is high.

Owner:天津市蜜老头养蜂专业合作社

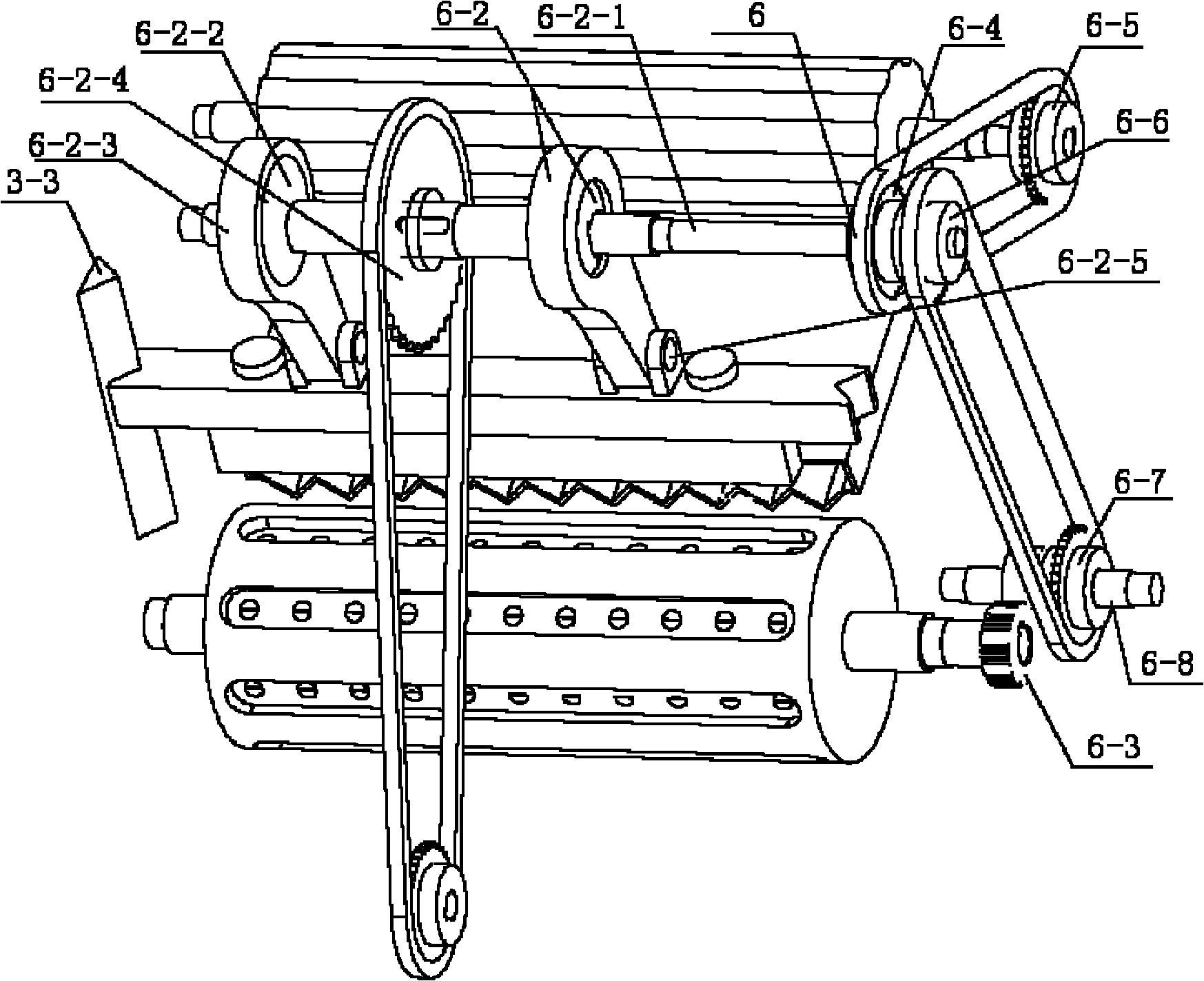

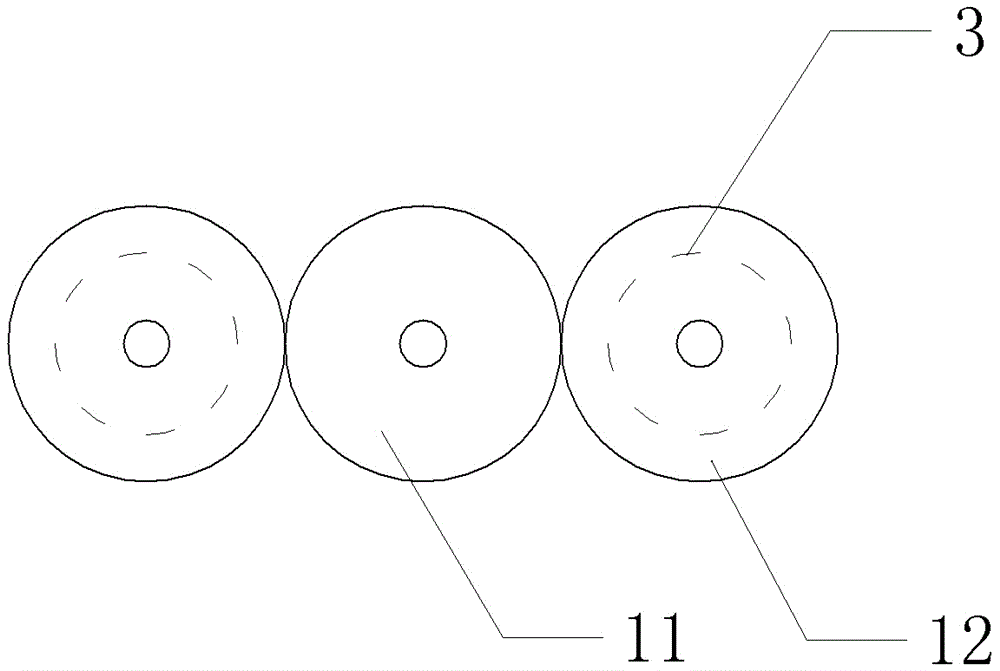

Silage processing equipment

InactiveCN104509956AControl moisture contentMoisture content is easy to controlFeeding-stuffEngineeringFodder

The invention provides silage processing equipment. The silage processing equipment comprises a rack, a conveyor belt, and a cutting device and a dispersing device which are connected in sequence, and further comprises a grinding device, wherein the grinding device comprises three compression roller wheel sets which are connected in sequence; the first compression roller wheel set is composed of an upper compression roller and a second compression roller; each of the second compression roller wheel set and the third compression roller wheel set is composed of one driving roller and three driven compression rollers, namely the driving roller driven by a motor, and the first driven compression roller, the second driven compression roller and the third driven compression roller which are located on the left and right sides and under the driving roller; the conveyor belt penetrates through a gap between the upper and lower compression rollers of the first compression roller wheel set and gaps among driving rollers of the second and third wheel sets and the driven compression rollers. The grinding device is reasonably designed and the moisture content of materials is controlled; the materials are prevented from going moldy and going bad due to bad weather; meanwhile, drying equipment is not used so that the energy consumption is reduced and the expenditure is saved. The silage processing equipment is suitable for crushing and machining silages including banana stems and leaves and the like.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Uniform-discharging fertilizing machine

InactiveCN108419495ABlanking evenlySolve the problem of uneven blankingFertiliser distributersMotor driveFertilizer

The invention provides a uniform-discharging fertilizing machine which comprises a first working bin, a second working bin, a third working bin and a screen. A first supporting plate is welded on theleft side of the second working bin, a motor is fixedly mounted at the top of the first supporting plate, a first bevel gear is fixedly mounted on the rotating shaft of the motor, a first rotating block is welded at the bottom of the first supporting plate, a transmission rod is rotatably connected inside the first rotating block, and the top of the transmission rod sequentially penetrates the topof the first rotating block and the bottom and the top of the first supporting plate and is fixedly mounted with a second bevel gear. Compared with the prior art, the uniform-discharging fertilizingmachine has the advantages that when the machine is in use, fertilizers are put into the second working bin first, then the motor is started, the rotating shaft of the motor drives a second connectionrod to rotate, the second connection rod stirs and mixes different fertilizers in the second working bin and breaks up some caked fertilizers, and a cylinder is started after mixing of the fertilizers in the second working bin is completed.

Owner:刘烨

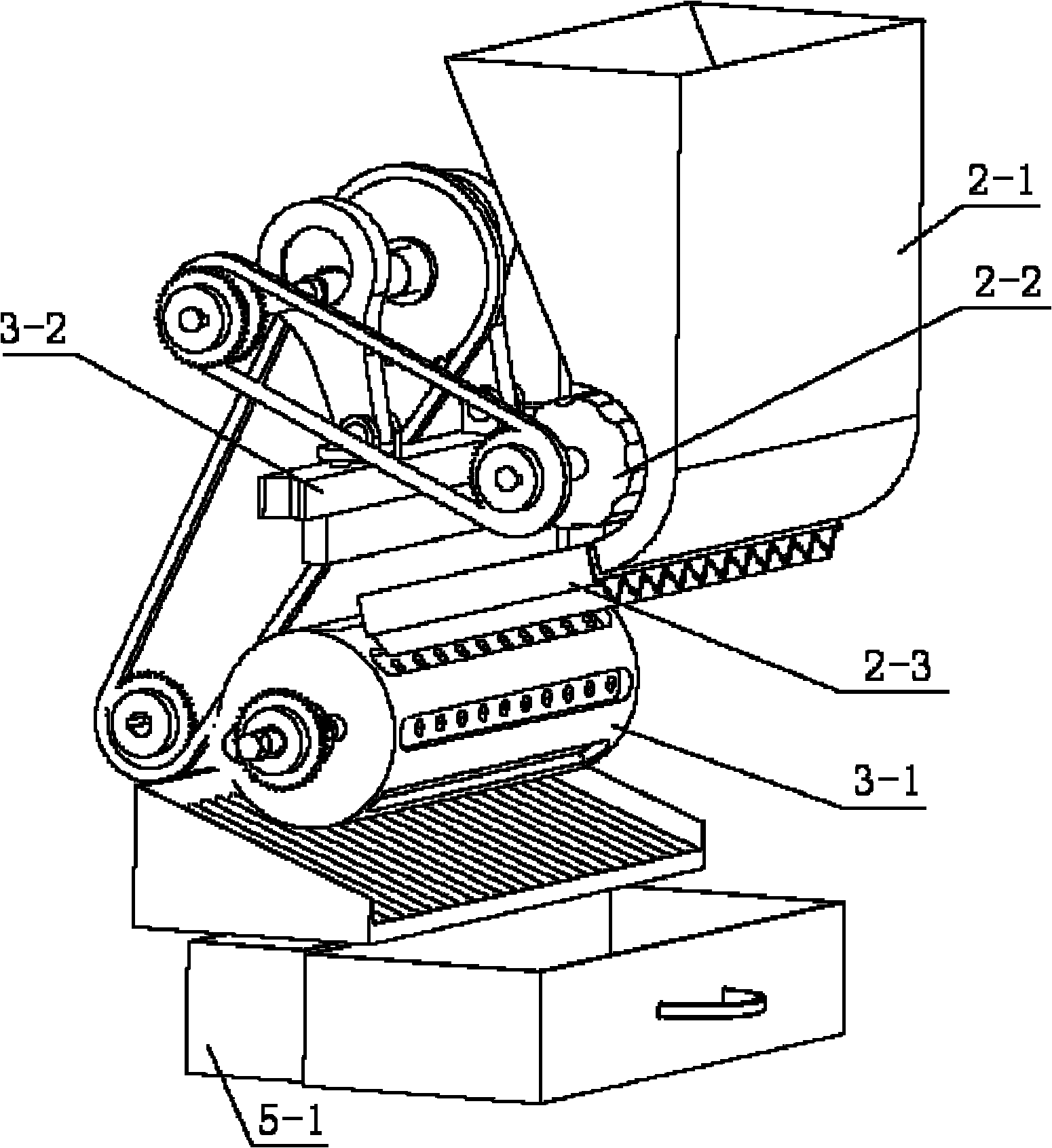

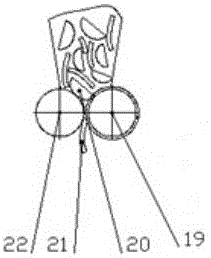

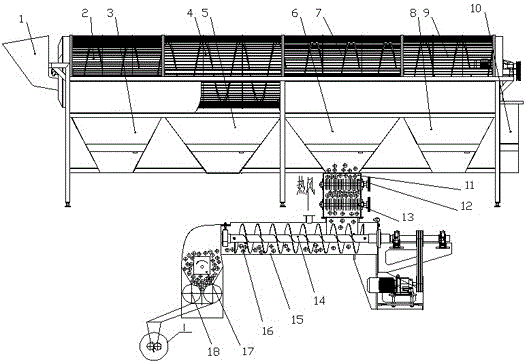

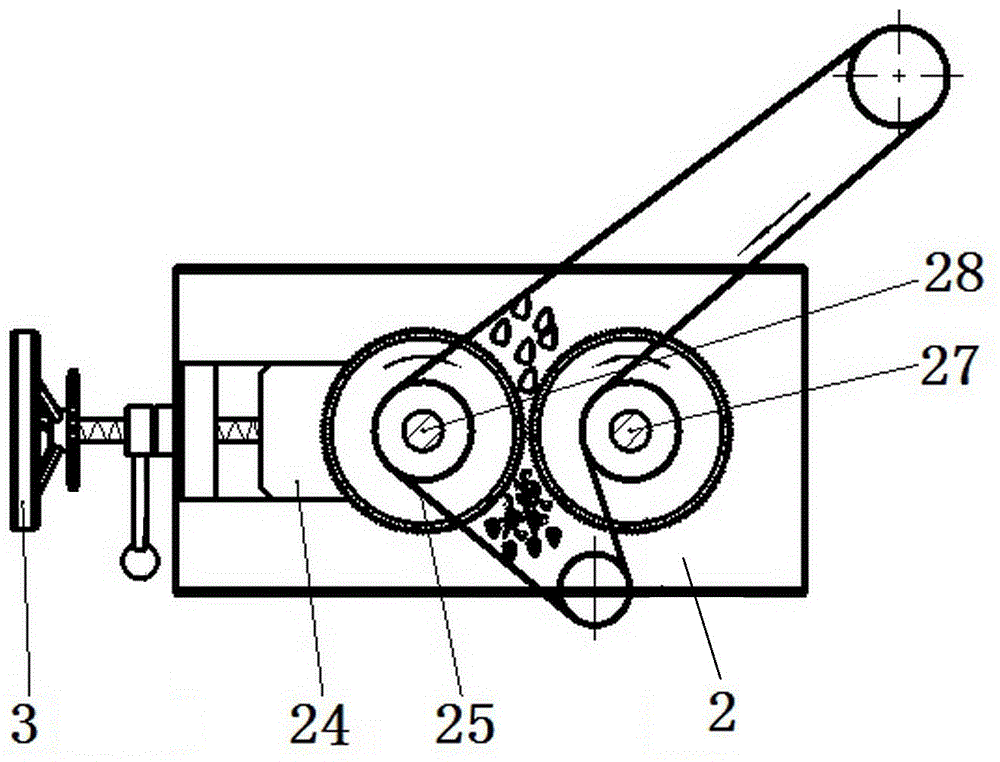

Combined badam shell breaking and shell-kernel separating machine

PendingCN106723119AImprove the efficiency of breaking upTo achieve the purpose of separationGas current separationHuskingDrive motorEngineering

The invention discloses a combined badam shell breaking and shell-kernel separating machine. A primary shell breaker with a vibratory feeder is arranged above the front portion of a rack, a driving shell breaking roller and a driven shell breaking roller are horizontally arranged in the primary shell breaker side by side at intervals, chain wheels are installed at the shaft ends of the driving shell breaking roller and the driven shell breaking roller, the driving shell breaking roller and the driven shell breaking roller are driven to perform opposite rotation by a driving motor through chains, a discharging hopper below the primary shell breaker is located above a conveying belt, the discharging end of the conveying belt is in linkage with a feeding hopper of a secondary shell breaker installed in the middle of the rack, concave pits or convex ribs are evenly distributed on the surfaces of the driving shell breaking roller and the driven shell breaking roller in the secondary shell breaker at intervals, a discharging port of the secondary shell breaker is connected with an air inlet pipe of a negative pressure fan, the lower end of the air inlet pipe of the negative pressure fan is located on a vibratory separation machine, a kernel discharging port is formed in the lower end of the vibratory separation machine, an outer-side-end separation discharging port of the vibratory separation machine is in linkage with a vertical lifter, and a discharging pipe of the vertical lifter is in linkage with the vibratory feeder.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

Walnut hull breaking device

The invention discloses a walnut shell cracking device, which comprises a punching part and a feeding structure. The punching part includes a crankshaft, a first connecting rod, a punch, a punching plate and a punching column. The punch and the punching plate pass through the first The two connecting rods are connected, and the stamping column is arranged at the bottom of the stamping plate; the feeding structure includes several chain plates, and the chain plates are arranged in a ring along the width direction, and the adjacent chain plates are connected by hinges. The inside of the chain plate is provided with a sprocket, and the sprocket drives the chain plate for transmission. This solution can significantly reduce the labor intensity of operators, without manually crushing walnuts, and greatly improves the efficiency of walnut shelling. The invention has the advantages of simple structure, convenience and practicality.

Owner:贵州天和农业发展有限公司

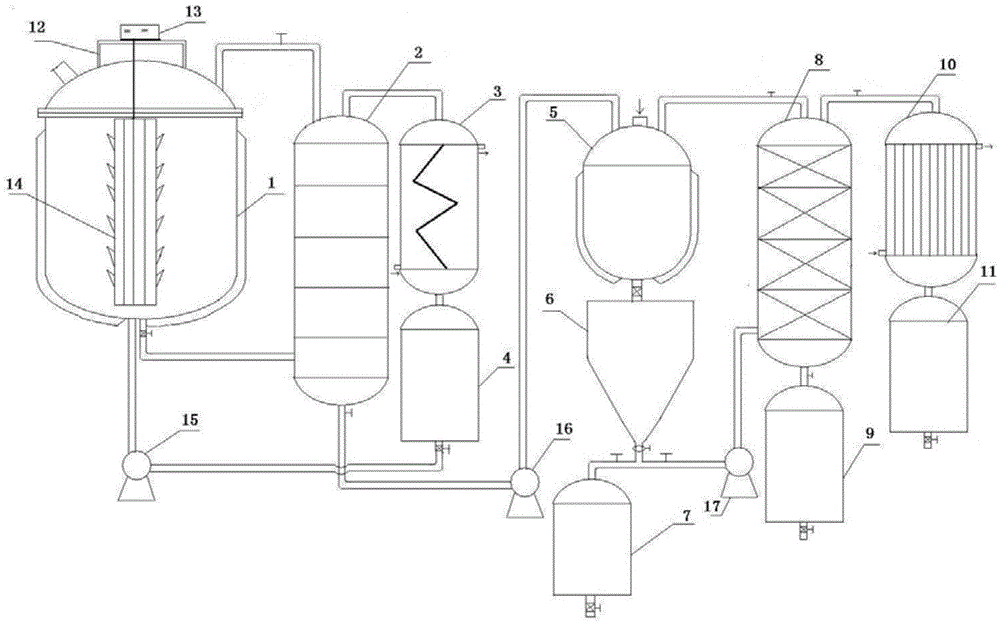

Microalgae biodiesel production device

InactiveCN105647652AHigh extraction rateIncrease productionFatty acid esterificationBiofuelsBiodieselSolvent

The invention discloses a microalgae biodiesel production device. The device comprises an oil extraction tank (1), a rectification tank A (2), an esterification tank (5) and a separator (6), wherein an ultrasonic generator (13) is arranged above the oil extraction tank (1), the lower side of the ultrasonic generator (13) is connected with an ultrasonic oscillation rod (14), the bottom end of the oil extraction tank (1) is connected with the middle-lower section of the rectification tank A (2), the top of the rectification tank A (2) is connected with a condenser A (3), the lower end of the condenser A (3) is connected with a solvent recovery tank (4), the bottom of the rectification tank A (2) is connected with the esterification tank (5) through a liquid pump B (16), the bottom of the esterification tank (5) is connected with the separator (6), the bottom end of the separator (6) is connected with a glycerin collector (10) and a feeding port of a rectification tank B (8), and the bottom end of the rectification tank B (8) is connected with a biodiesel collection tank (11). The device has the advantages that energy consumption is low, the structure is simple, reaction time is short, the microalgae oil extraction rate is high, the biodiesel yield is high, the purity is high, and the like.

Owner:薛晶

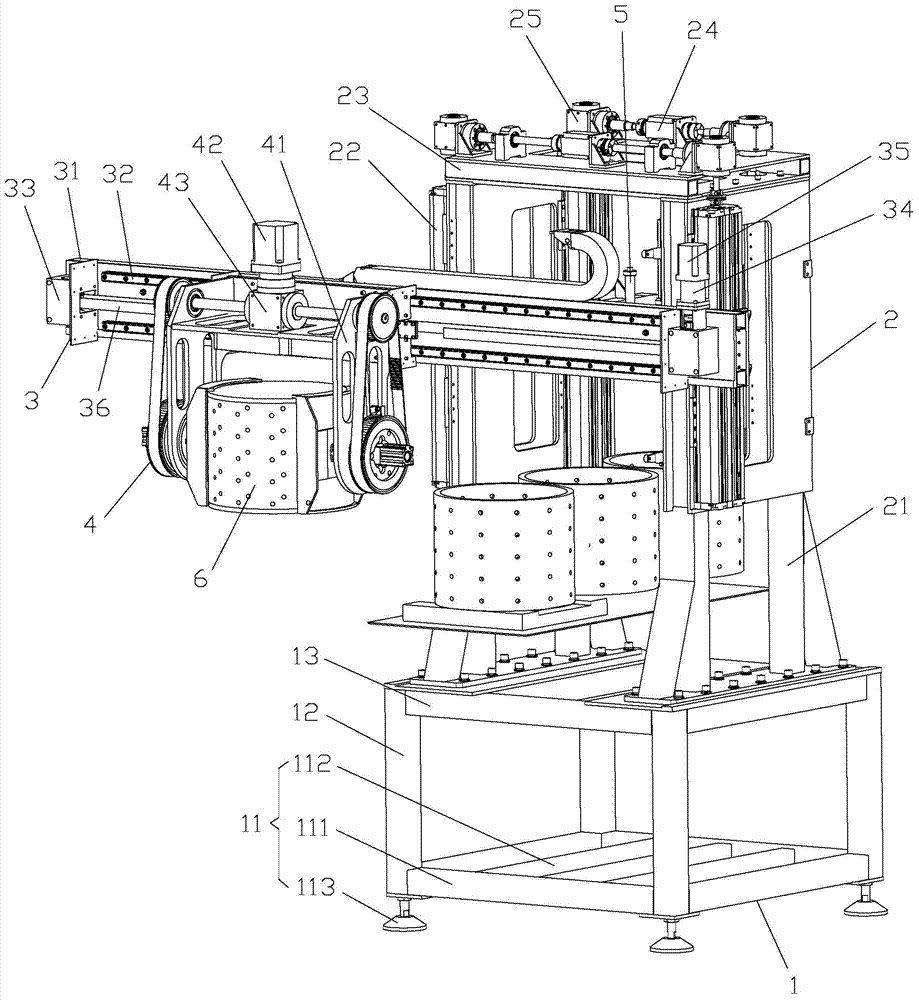

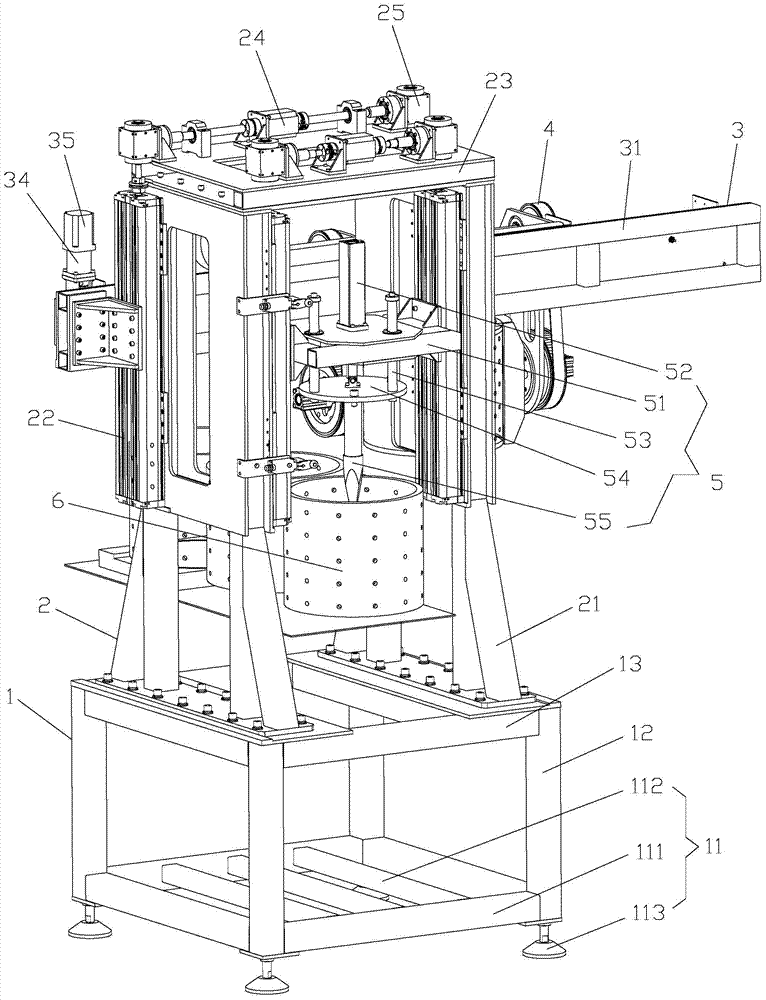

Full-automatic vanadium-nitrogen alloy discharging device

InactiveCN104326275AGuaranteed stabilityReduce noiseBottle emptyingLoading/unloadingElectricityDischarge efficiency

The invention relates to a full-automatic vanadium-nitrogen alloy discharging device. The device comprises a base, a Z-axis moving mechanism, a Y-axis moving mechanism, a turnover mechanism, a scattering mechanism and an electric control system, wherein the Z-axis moving mechanism, the Y-axis moving mechanism, the turnover mechanism and the scattering mechanism are electrically connected with the electric control system and are controlled to act by the electric control system; the Z-axis moving mechanism is arranged on the base, and comprises a Z-axis support, a Z-axis linear module, a Z-axis head piece, a Z-axis step motor and a Z-axis reducer; the Y-axis moving mechanism is arranged on the Z-axis linear module and comprises a Y-axis frame, a guide rail, a Y-axis bearing block, a Y-axis reducer, a Y-axis motor and a synchronous belt; the turnover mechanism is arranged on one side of the Y-axis moving mechanism; one end of the turnover mechanism is connected with the synchronous belt, and a graphite crucible is clamped to the other end of the turnover mechanism; the scattering mechanism is arranged on the Z-axis linear module. The full-automatic vanadium-nitrogen alloy discharging device is reasonable and compact in structural design, works stably and reliably, and is high in discharging efficiency, and the labor intensity of workers and dust harm on the workers can be effectively reduced.

Owner:CHENGDU UNIV OF INFORMATION TECH

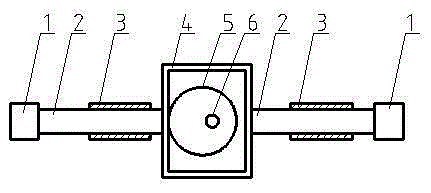

Walnut shell crushing machine

PendingCN105192853AImprove the efficiency of breaking upReduce labor intensityHuskingHullingWalnut NutUltimate tensile strength

The invention discloses a walnut shell crushing machine, and belongs to the technical field of an agricultural production device. The walnut shell crushing machine consists of an electric motor, a power transmission apparatus, an eccentric roller mechanism, a guide apparatus and a shell crushing apparatus. When a switch is switched on, the electric motor rotates, a driving belt wheel transfers the power to a driven belt wheel by virtue of a synchronizing belt, an eccentric roller is driven to rotate by virtue of a rotating shaft, when one side of a large end of the eccentric roller contacts a left side plate of a baffle plate box, a collision hammer is connected with the baffle plate box by virtue of a connecting rod and moves leftwards under the action of a guide sleeve so as to crush a walnut shell, and at the moment, feeding is carried out on the right part of the apparatus; when one side of the large end of the eccentric roller contacts a right side plate of the baffle plate box, the connecting rod and the collision hammer move rightwards under the action of the guide sleeve so as to crush the walnut shell, and at the moment, the feeding is carried out on the left part of the apparatus. By adopting the walnut shell crushing machine, the walnut shell can be automatically crushed, the walnut shell crushing efficiency is improved, and the labor intensity is alleviated; the walnut shell crushing machine is simple in structure, convenient to operate and maintain and convenient to popularize and use.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com