Oil tea shell smashing and shell and seed sorting machine

A sorting machine and shell breaking technology, which is applied in the direction of shelling, solid separation, filtering, etc., can solve the problems of time-consuming, laborious, waste, and high impurity content in grains, so as to ensure continuous operation, reduce impurity content in sorting, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

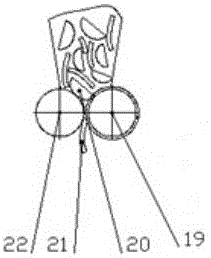

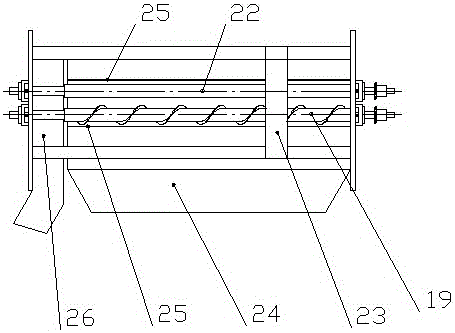

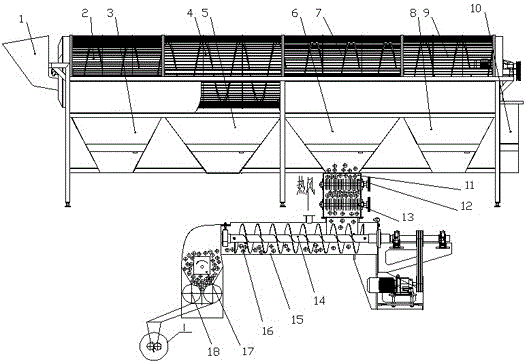

[0025] Example: such as Figure 1-3 as shown,

[0026] A camellia oleifera seed kernel sorting machine, which includes a frame, a grading mechanism and an independent processing unit corresponding to the sorting mechanism. The grading drum is formed by butting four grid cylinders, and the grid gaps of each grid cylinder are different. The clearance of the first-level grid cylinder 2 is 25mm, the clearance of the second-level grid cylinder 4 is 30mm, the clearance of the third-level grid cylinder 7 is 35mm, and the clearance of the fourth-level grid cylinder 9 is 40mm. Therefore, the tea fruit is divided into different grades at intervals of 5mm. The first grade is less than 25mm in diameter, the second grade is (25mm-30mm in diameter), the third grade is (30mm-35mm in diameter), and the fourth grade is in diameter. (35mm-40mm), the fifth level is greater than 40mm in diameter, and each grid cylinder corresponds to a sorting discharge trough (first-level sorting trough 3, seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com