A device for grading wood strength

A technology of wood and strength, applied in measuring devices, strength characteristics, analyzing materials, etc., can solve the problems of slow strength classification of workers, bottlenecks restricting processing capacity, and large discreteness of wood strength, so as to reduce labor costs and save labor. Cost, high level of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

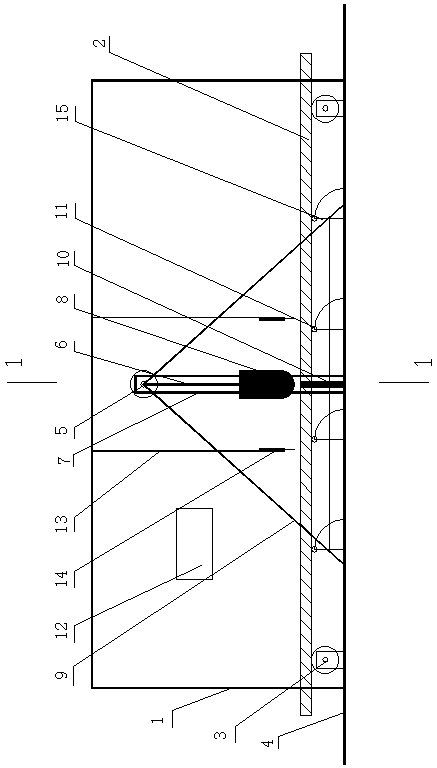

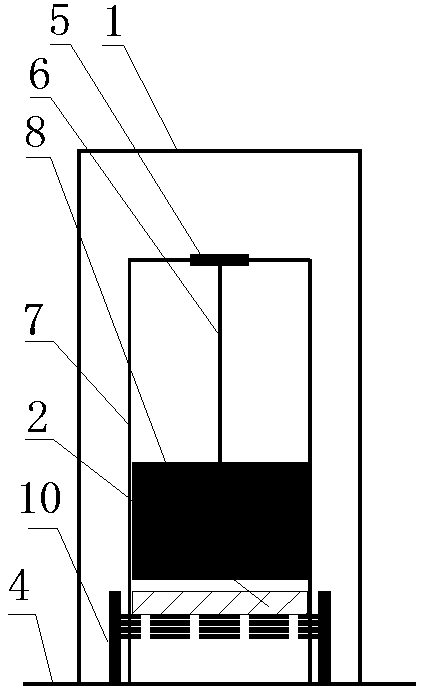

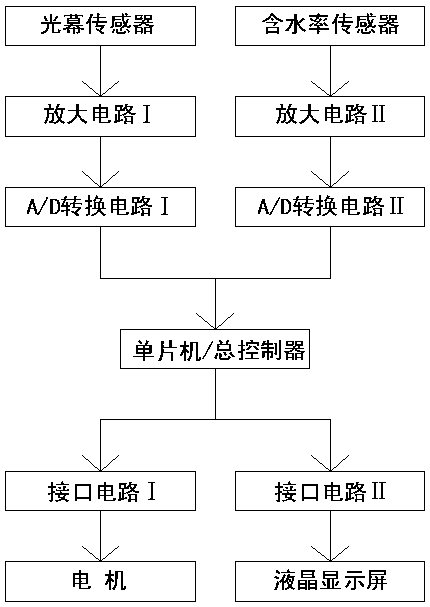

[0018] A device for grading wood strength, which consists of: rigid pedestal 4, fixed shaft support 3, protective cover 1, sling 6, standard load hammer 8, guide rail bracket 7, support member 9, light curtain sensor 10, At least one moisture content sensor bracket 13, at least one moisture content sensor 14, multiple transmission rollers 11 and multiple four-bar linkage mechanisms 15 (driven by a motor to achieve upright and down states),

[0019] The upper surface of the rigid pedestal 4 is fixedly provided with two fixed rotating shaft supports 3, and a plurality of four-bar linkages 15 are arranged between the two fixed rotating shaft supports 3, and the plurality of four-bar linkages 15 is connected with the rigid pedestal 4, and a transmission roller 11 is installed on one of the hinge shafts of each four-bar linkage mechanism 15, and the wheel centers of the plurality of transmission rollers 11 are connected on the same straight line, and the plurality of transmission ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com