Pneumatic walnut hull breaking machine

A shell breaking machine and walnut technology, which is applied in the field of forestry and fruit machinery, can solve the problems of poor adaptability of walnut varieties, difficult maintenance, and difficult separation of shells and kernels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

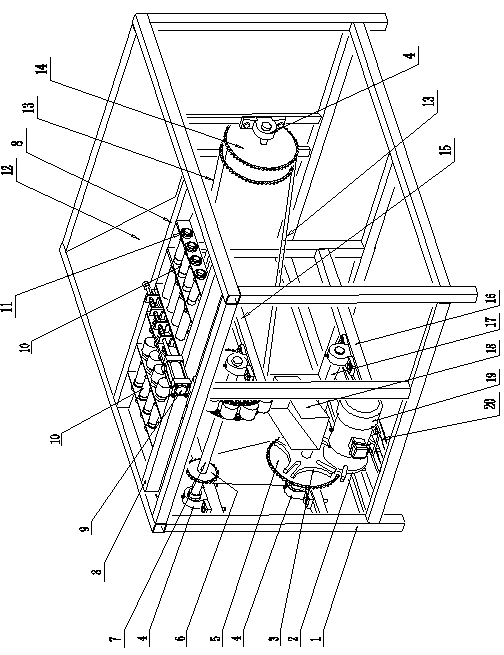

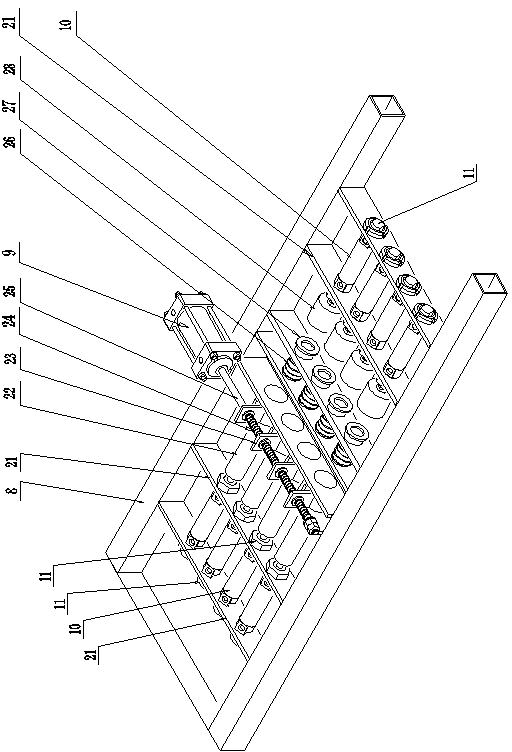

[0020] Example: such as figure 1 , 4 As shown, the pneumatic walnut shell breaking machine consists of a frame 1, a transmission control device, a feeding mechanism, and a shell breaking device. Frame 1 is a cuboid cavity frame, with a rectangular workbench 8 attached to the front of the upper end, upper and lower horizontal fixing frames 15, 16 are connected to the upper and lower parts of the cavity of the frame 1, and the bottom of the frame 1 is additionally connected There is a motor seat 20.

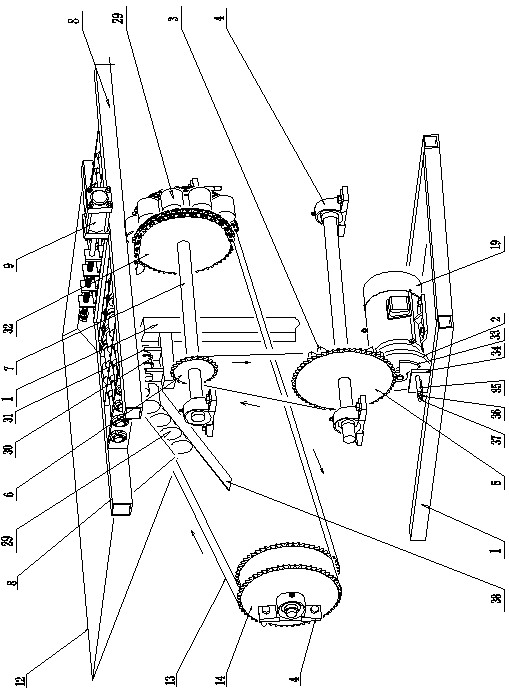

[0021] Transmission control device: such as figure 1 , 3 As shown in, 7, and 8, the output shaft of the Y series three-phase AC asynchronous motor 19 is coaxially installed with a dial wheel 2 and a control cam 33, and a Z-shaped lever 40 is attached to the disk surface of the dial wheel 2. A lower shaft 17 is installed on the lower fixing frame 16 through a bearing seat 4, and a driving sprocket 5 and a sheave 3 are sleeved on the shaft. The sheave 3 is cross-shaped as a whole, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com