Nickel-based welding rod used for ultralow-temperature steel and preparation method of nickel-based welding rod

A nickel-based electrode, ultra-low temperature technology, used in welding equipment, welding media, manufacturing tools, etc., can solve problems such as research description, and achieve the effects of reducing magnetic bias blowing, simple preparation method, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Get medicinal powder, take medicinal powder to account for the mass percentage of welding rod, each component of medicinal powder and its mass parts are as follows:

[0036] 8% marble, 0.5% sodium fluoride, 0.33% soda ash, 0.6% ferro-niobium, 1.4% ferro-molybdenum, 2.8% rutile, 2.2% quartz, 7% fluorite, 1.3% metal chromium, 0.5% CMC, 1.4 potassium carbonate %.

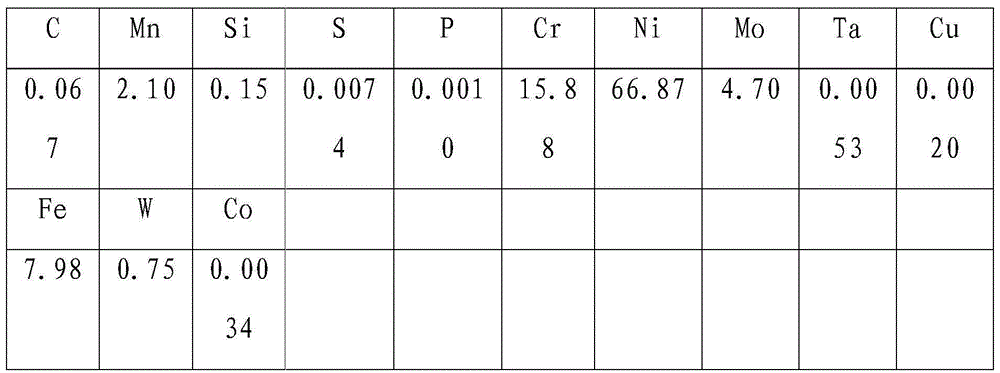

[0037] The mass of the welding core is 69.64%, and the composition meets the following requirements (wt%): the mass percentage of the welding core composition is C0.07-0.10%, Mn1.0-1.5, Si≤0.10, S:≤0.004, P≤0.005Cr15.0 -17.0, Mo3.5-4.0, Cu≤0.10, Fe4.0-5.0, Nb2.0-2.5, W0.8-1.2, the balance is nickel and trace impurities, the total weight of each component in the above welding core is 100 %.

[0038] The preparation method is as follows: mix the components of the above-mentioned medicinal powder evenly, add water glass with a mass ratio of 41-43Be' potassium silicate to sodium silicate at 20°C and a mass ratio o...

Embodiment 2

[0040] Get medicinal powder, take medicinal powder to account for the mass percentage of welding rod, each component of medicinal powder and its mass parts are as follows:

[0041] 9% marble, 0.4% sodium fluoride, 0.33% soda ash, 0.6% ferro-niobium, 1.5% ferro-molybdenum, 2.7% rutile, 2% quartz, 7% fluorite, 1.2% metal chromium, 0.5% CMC, 1.4 potassium carbonate %.

[0042] The binder accounts for 28% of the total mass content of the medicinal powder.

[0043] Welding core accounts for 73.42% of the total electrodes.

[0044] Then bake at a low temperature of 80-90°C for 1.5-2 hours, and at a high temperature of 300°C for 1-2 hours.

[0045] Other operation steps are as embodiment 1.

Embodiment 3

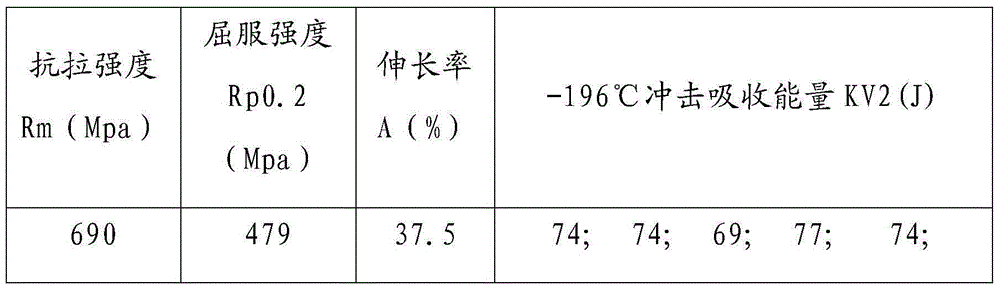

[0047] A special nickel-based electrode for ultra-low temperature steel of the present invention needs to strictly control the content of impurity elements in the deposited metal. The rod wire meeting the following composition requirements is used to produce the electrode, and the alkaline slag system is used to ensure that the deposited metal obtains good mechanical properties. performance.

[0048] Take the powder, the components of the powder and their mass parts are as follows: 7.5% marble, 0.47% sodium fluoride, 0.33% soda ash, 0.6% ferro-niobium, 1.4% ferro-molybdenum, 2.65% rutile, 2.8% quartz, 7 fluorite %, metal chromium 1.3%, CMC 0.5%, potassium carbonate 1.4%.

[0049] The mass of the welding core is 372.1g, and the composition meets the following requirements (wt%): the mass percentage of the welding core composition is C0.07-0.10%, Mn1.0-1.5, Si≤0.10, S:≤0.004, P≤0.005Cr15.0 -17.0, Mo3.5-4.0, Cu≤0.10, Fe4.0-5.0, Nb2.0-2.5, W0.8-1.2, the balance is nickel and trac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com