Hydrate decomposition inhibitor suitable for natural gas hydrate formation drilling

A hydrate decomposition and hydrate technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of drilling fluid intrusion into the formation, well wall instability, and well wall collapse, so as to reduce the decomposition rate and ensure Applicability, the effect of prolonging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In order to further optimize the above technical scheme, the preparation method of poly-3-methylene 2-pyrrolidone specifically comprises the following steps:

[0026] (1) Add 1.0-1.5g of sodium hydride and 11.0-12.0g of diethyl oxalate into diisopropyl ether at a temperature of 30-40°C, and stir evenly;

[0027] (2) Dissolve 6.0-8.0g of 1-tert-butoxycarbonyl-2-pyrrolidone into 30-40mL of diisopropyl ether;

[0028] (3) Add the mixed solution obtained in step (2) dropwise to the mixed solution obtained in step (1) at a temperature of 30-40° C., and stir for 48 hours;

[0029] (4) washing the product obtained by the reaction in step (3) with diisopropyl ether; then dissolving it in dimethylformamide, adding paraformaldehyde and reacting at a temperature of 90-110° C. for 1.5-3 hours;

[0030] (5) The product obtained in step (4) was cooled, filtered, and purified by silica gel column chromatography to obtain 1-tert-butoxycarbonyl-3-methylene-2-pyrrolidone;

[0031] (6) ...

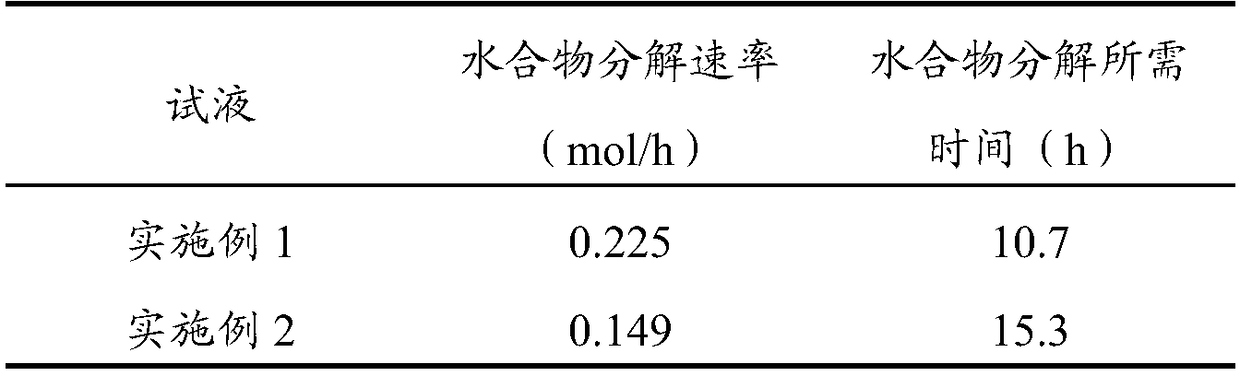

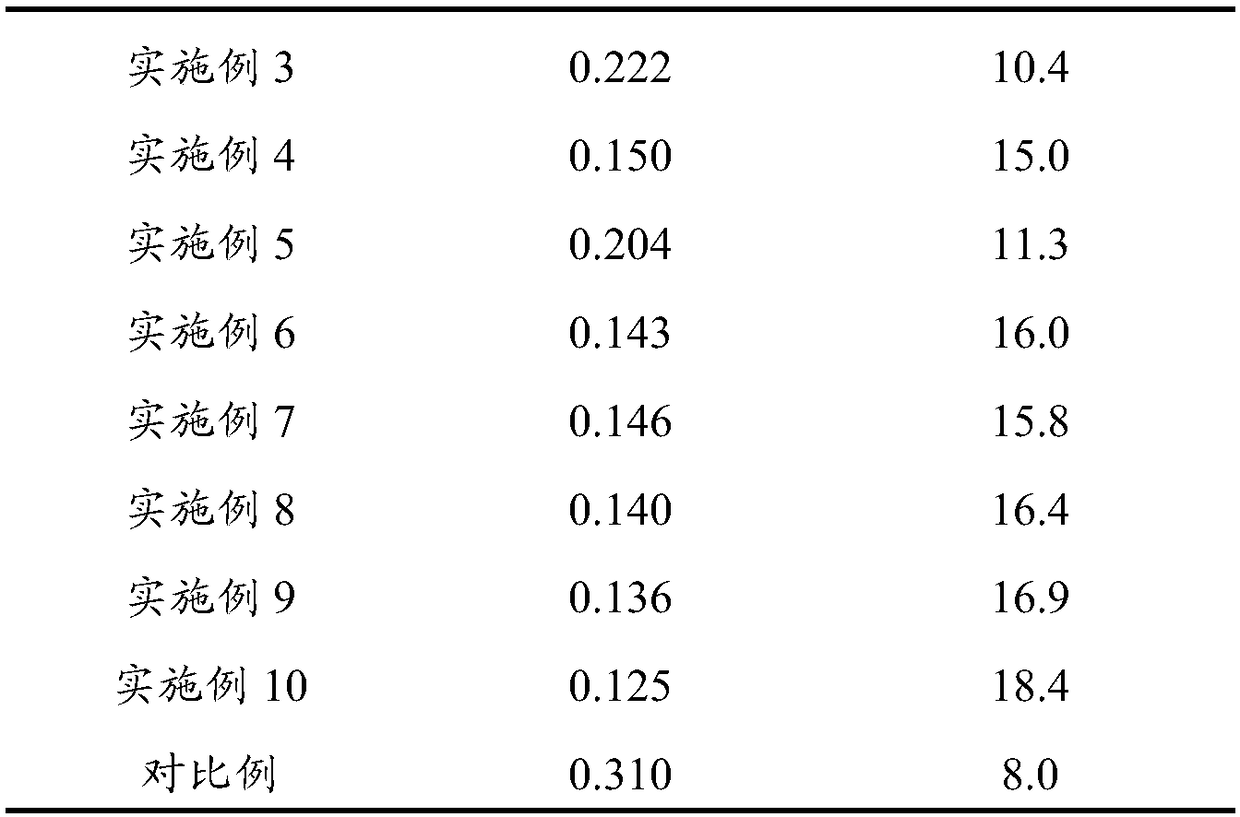

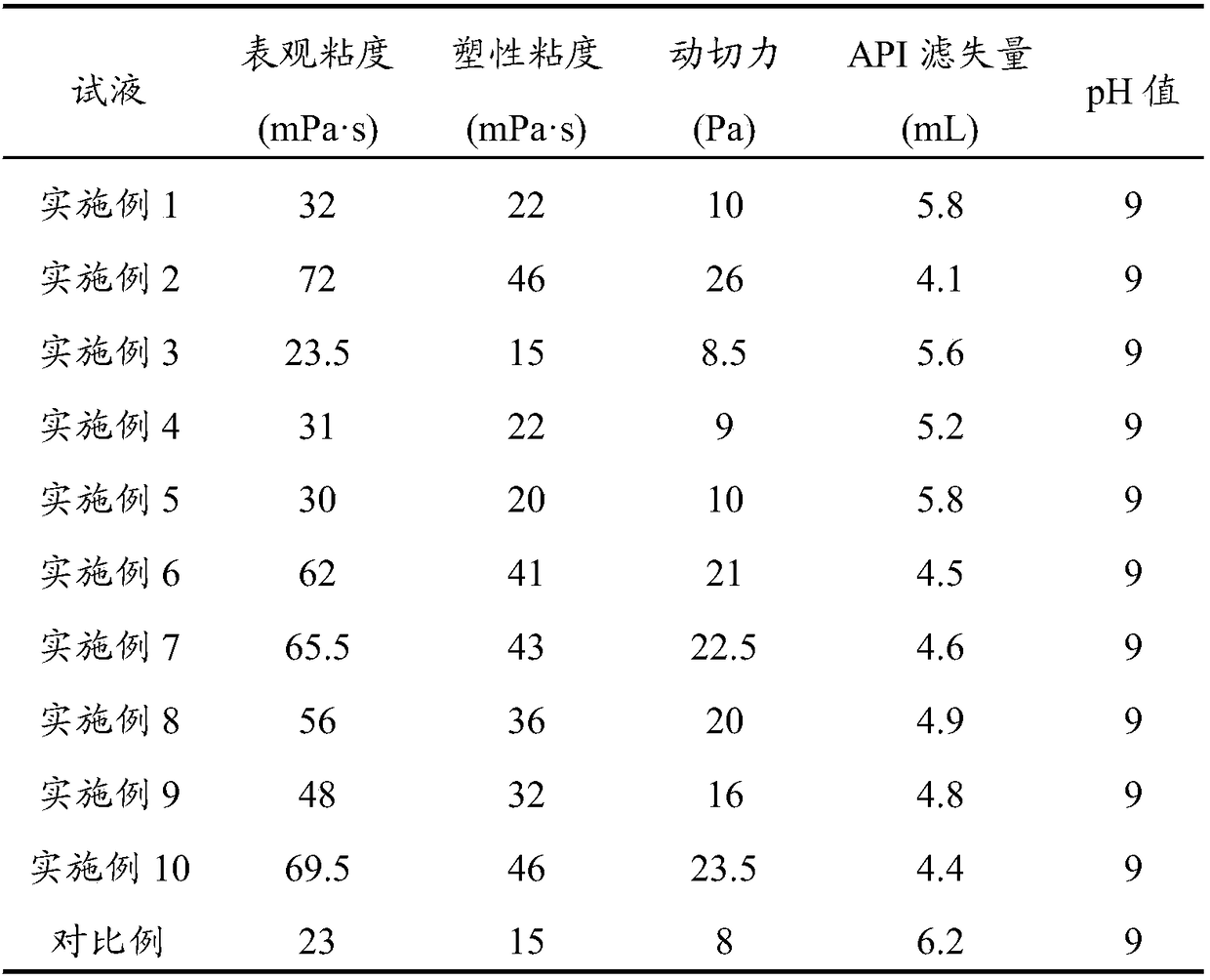

Embodiment 1

[0038] Embodiment 1: drilling fluid+0.1% poly N-vinylpyrrolidone;

Embodiment 2

[0039] Embodiment 2: drilling fluid+1.0% poly N-vinylpyrrolidone;

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com