Patents

Literature

114 results about "Diisopropyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diisopropyl ether is secondary ether that is used as a solvent. It is a colorless liquid that is slightly soluble in water, but miscible with organic solvents. It is used as an extractant and an oxygenate gasoline additive. It is obtained industrially as a byproduct in the production of isopropanol by hydration of propene. Diisopropyl ether is sometimes represented by the abbreviation "DIPE".

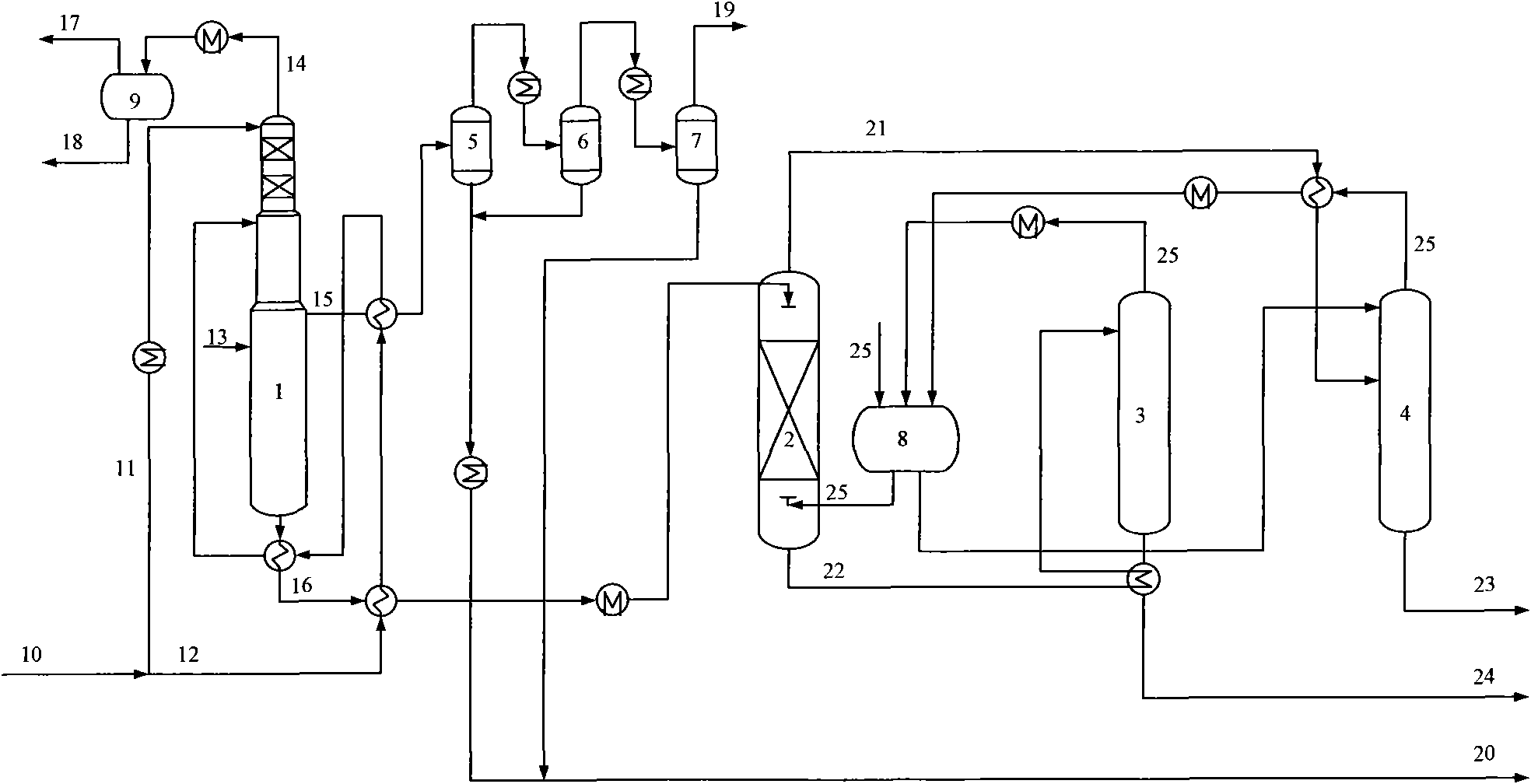

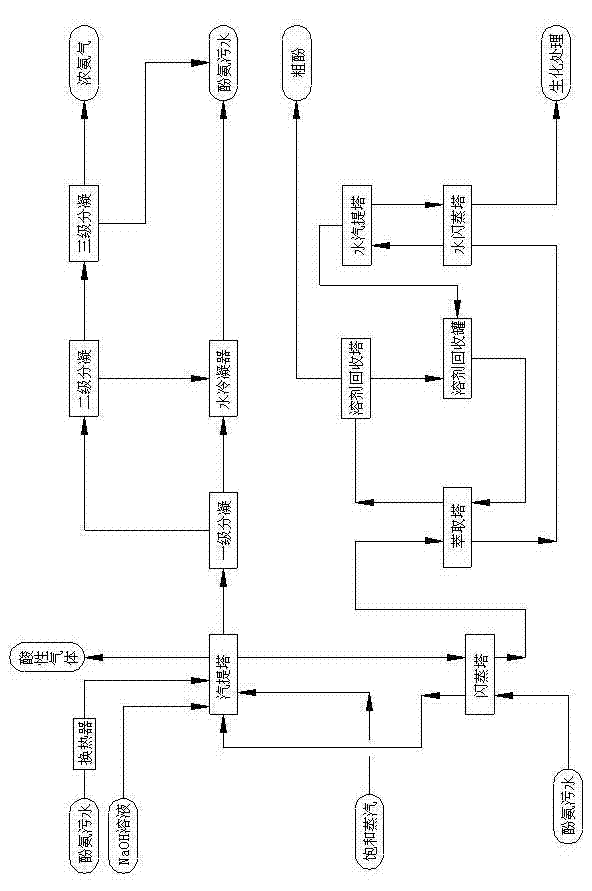

Method for treating coal gasification wastewater containing phenol and ammonia

InactiveCN101597124AEffective removal of fixed ammonia contentMeet the requirements of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by degassingCoal gasification wastewaterHigh concentration

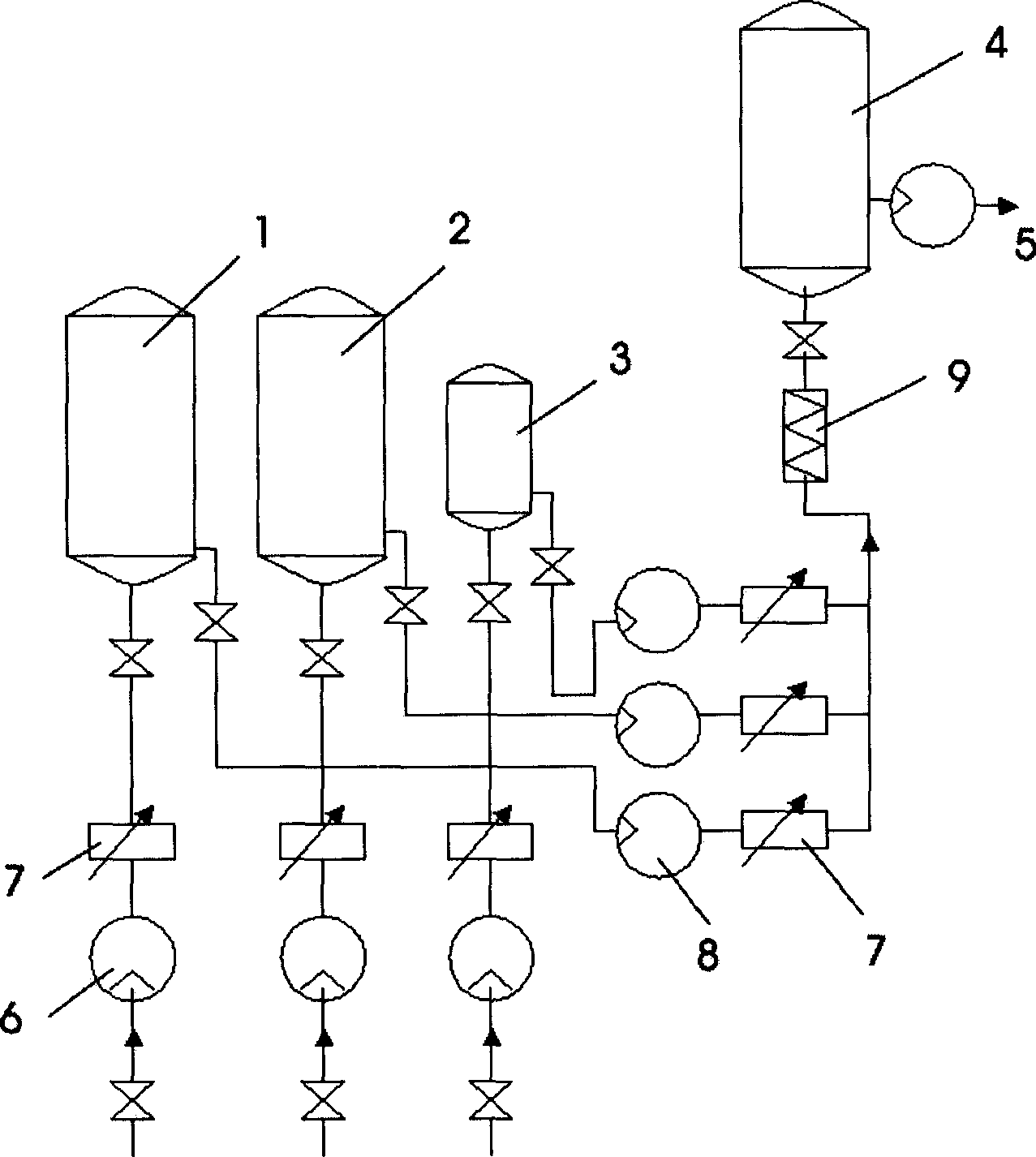

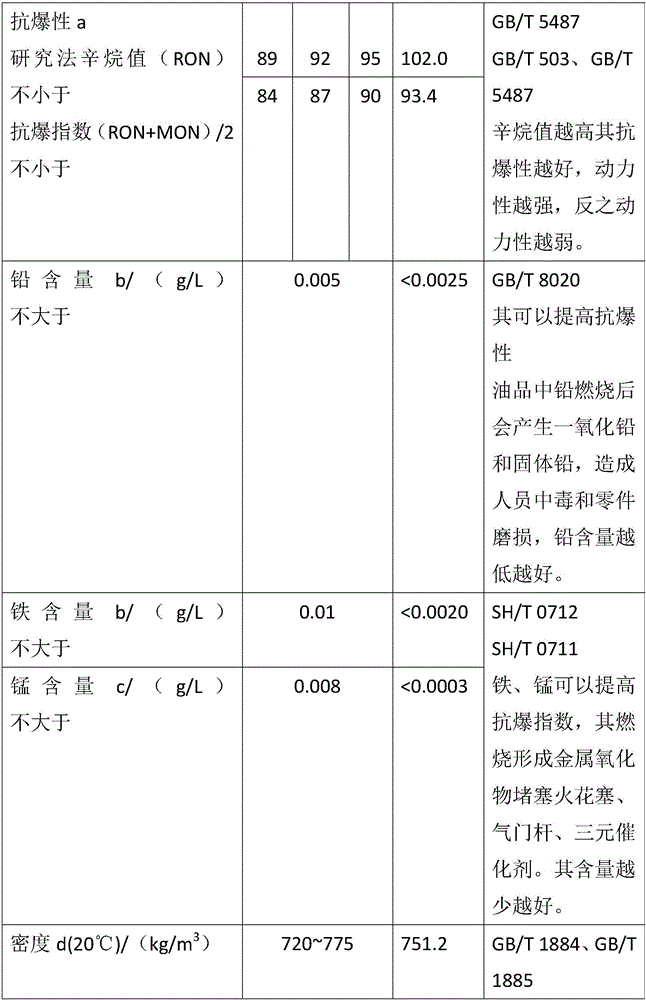

The invention relates to a method for treating coal gasification wastewater containing phenol and ammonia. The method comprises the following steps: single tower alkali injection and pressurization steam stripping removal of acidic gas and ammonia, three-level dephlegmation of lateral line tapped gas, extraction of phenol by diisopropyl ether and solvent recovery. The cold and hot coal gasification wastewater, according to a certain proportion, respectively enters a pressurization single tower from the upper part and middle upper part of a wastewater steam stripping tower, and acid gas is discharged from the tower top; the lateral line withdrawal mixed gas goes through three-level dephlegmation to obtain high-concentration ammonia, alkali is injected at the position below the lateral line to transform fixed ammonia into free ammonia which is to be removed; counter-current extraction is carried out on removed ammonia, residue of acid gas and diisopropyl ether to dephenolize; extraction solvent is recovered by a solvent recovery tower and a solvent steam stripping tower to obtain the byproduct, namely crude phenol. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, and the purified coal gasification wastewater meets the requirement of follow-up biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH +2

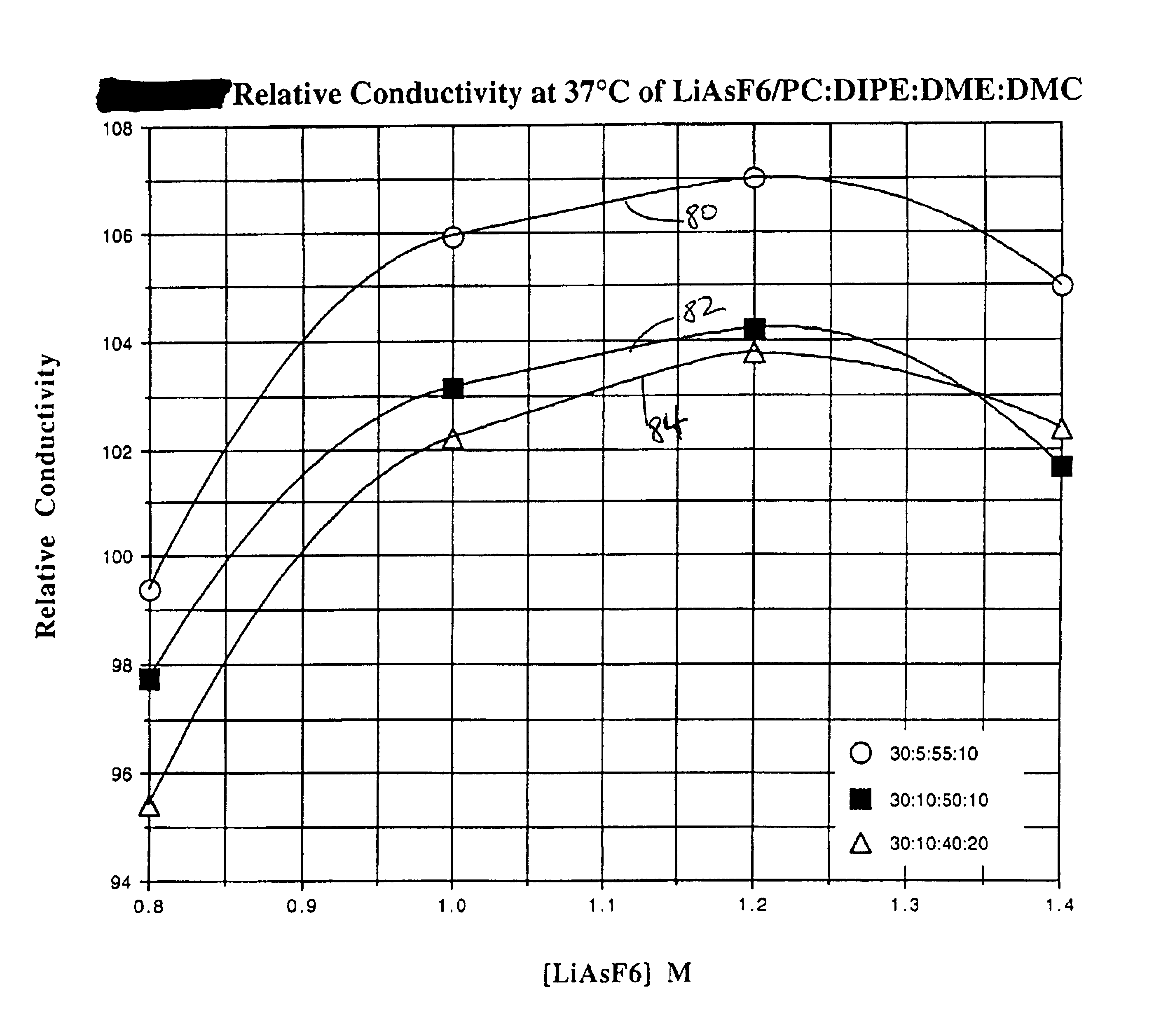

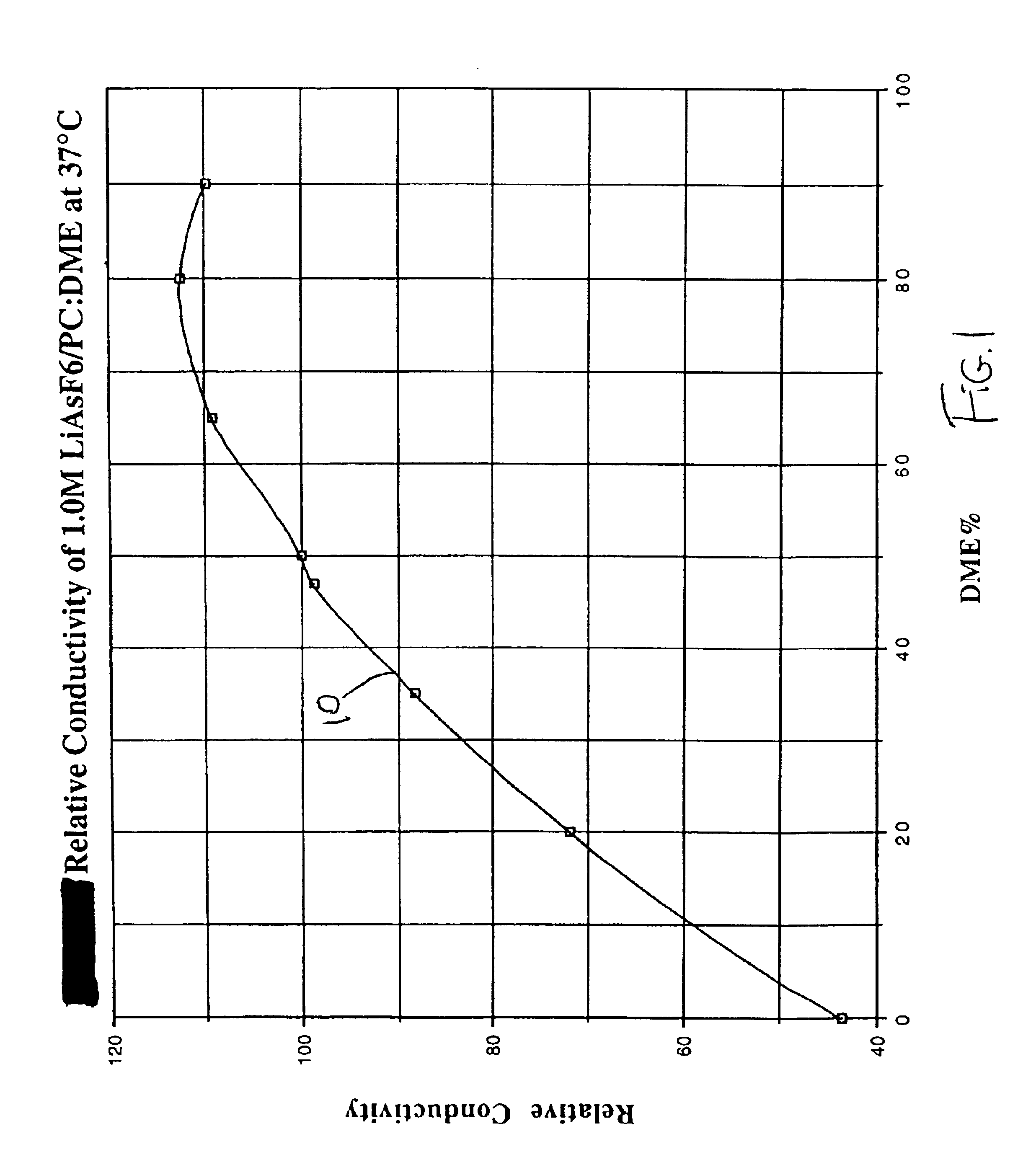

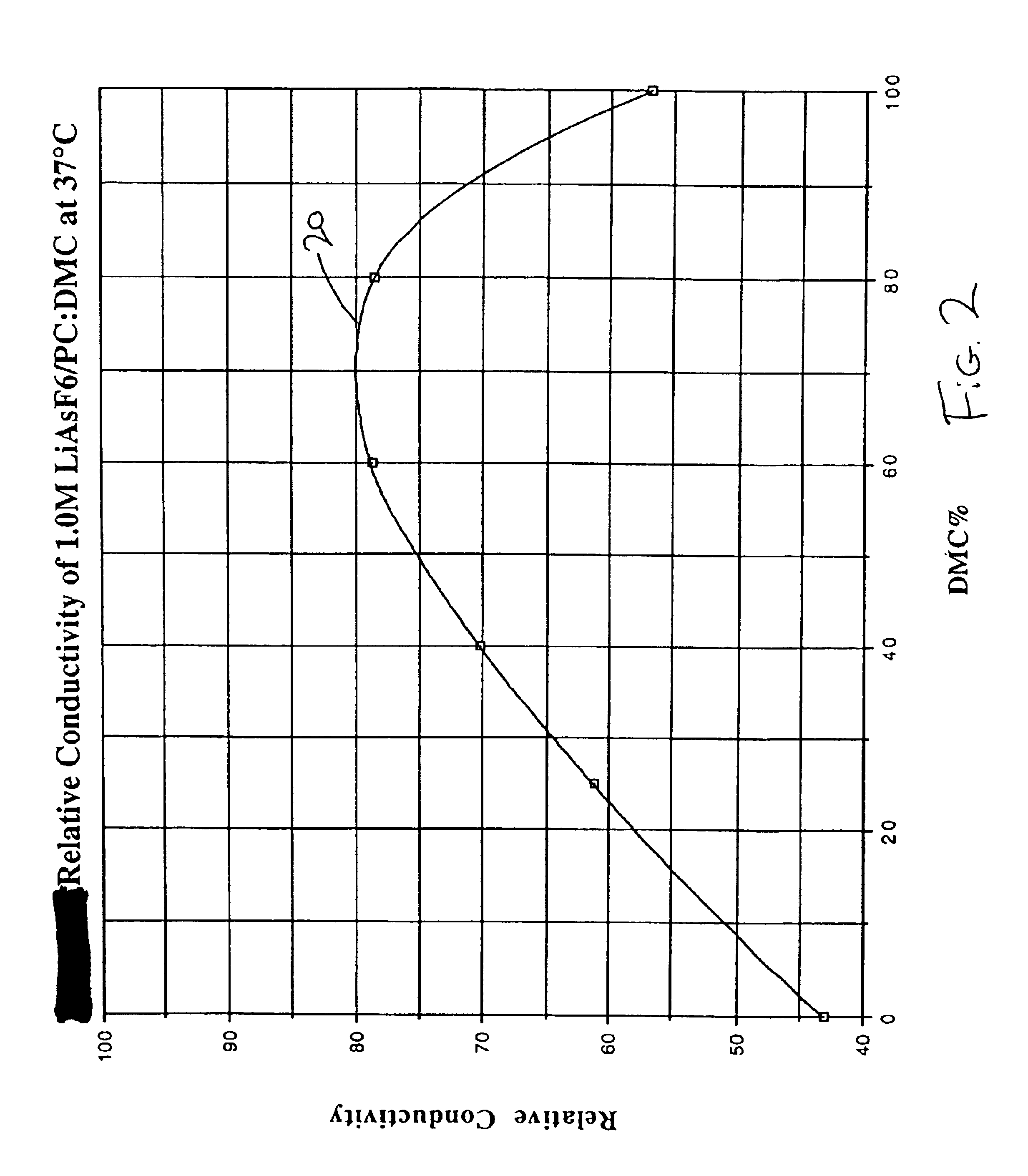

Highly conductive and stable nonaqueous electrolyte for lithium electrochemical cells

InactiveUS6844115B2Increase electrolyte conductivityImprove electrochemical stabilitySilver accumulatorsLead-acid accumulatorsPhysical chemistryPropylene carbonate

The present invention is directed to at least partially replacing PC and / or DME with a linear carbonate, preferably dimethyl carbonate, and a linear mono-ether, the most preferred being diisopropyl ether, in electrolytes useful for activating alkali metal-containing cells. This electrolyte has improved conductivity and provides electrochemical cells with enhanced discharge performance. A most preferred electrolyte comprises 1,2-dimethoxyethane, propylene carbonate, dimethyl carbonate and diisopropyl ether.

Owner:WILSON GREATBATCH LTD

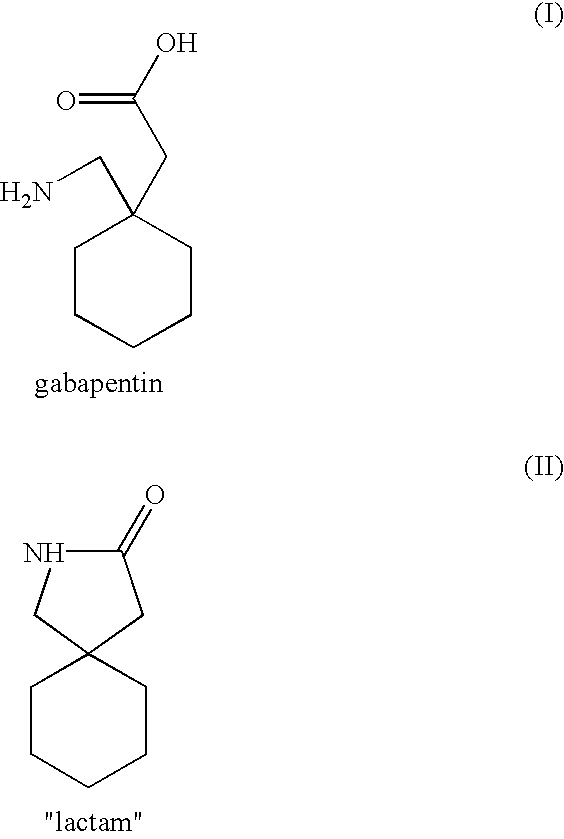

Process for the production of 1-(aminomethyl)-cyclohexyl-acetic acid in pure form

A process for the production and purification of gabapentin, i.e. 1-(aminomethyl)cyclohexyl-acetic acid, which comprises hydrolysis of 2-aza-spiro[4.5]decan-3-one with HCl, treatment of the resulting product and filtration with acetone, dissolution in water at isoelectric pH and crystallization or digestion in the hot in mixtures of diisopropyl ether with ethanol or methanol.

Owner:PROCOS

High content environment-friendly methanol gasoline

InactiveCN1884448ATo achieve a large proportion of accessionIncrease motivationLiquid carbonaceous fuelsKetoneTrimethylolpropane

The invention relates the methanol petrol, comprising 61-80 parts methanol, 10-29 parts base oil, 0.2-0.3 parts ethane, 0.2-0.3 parts skellysolve B, 3-5 parts methyl tert-butyl ether, 0.5-0.8 parts ethanol, 0.2-0.3 part 2, 2- dimethylbutane, 0.3-0.5 part tert-butanol, 0.2-0.3 part normal propyl alcohol, 0.1-0.3 part 2- ethyl (-1-) ethanol, 0.3-0.5 part ethylene glycol, 0.1-0.2 part 1, 3- dihydroxybutane, 0.2-0.5 part neopentyl glycol, 0.1-0.2 part 1, 6- dihydroxy hexane, 0.3-0.8 part trimethylolpropane, 0.2-0.8 part pentaerythrite, 0.6-0.8 part diisopropyl ether, 0.2-0.3 part ethyldioxy acetic acid ethyl ester, 0.2-0.4 part isoproyl nitrite, 0.2-0.5 part dimethyl ketone, 0.1-0.2 part diethyl malonate, 0.2-0.4 part diphenyl carbonate, 0.02-0.05 part 102TB corrosion inhibitor, and 0.02-0.05 part 107PT anti-swelling agent. The invention has the advantages of high methanol content, environment protection, and good earthquake resistance and dynamic.

Owner:顾杏泉

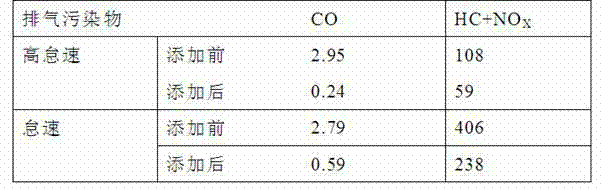

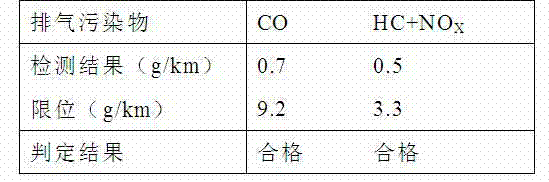

Automobile exhaust detergent and preparation method thereof

ActiveCN102408935AEffectively purify exhaust gasImprove protectionLiquid carbonaceous fuelsFuel additivesHigh carbonGlycerol

The invention relates to the technical field of automobile exhaust pollution control, especially an automobile exhaust detergent and a preparation method thereof. The automobile exhaust detergent is prepared by nitric acid propyl acetate, N, N-dimethylacetylamide, ethylene glycol monomethyl ether, diisopropyl ether, fatty alcohol, lauryl alcohol, high-carbon number fatty alcohol, multiple crude alcohol, glycerol palm kernel fatty acid ester and blackKwai acid glycerol according to a certain weight ratio. The invention has simple principle, easy preparation and low production cost, which can effectively purify exhaust gas discharged by vehicle and can help protect the environment; the pollution is reduced; the invention is suitable for wide promotion and application.

Owner:河北苏同兴盛新能源科技有限公司

Methanol gasoline cosolvent

InactiveCN102660336AImprove stabilityPrevent mutual separationLiquid carbonaceous fuelsIsobutanolGasoline

The invention discloses methanol gasoline cosolvent which is made of, by volume percent, 15%-30% of dimethylbenzene, 25%-35% of isobutanol, 2%-10% of dimethyl carbonate, 15%-30% of isopropanol, and 18%-25% of diisopropyl ether. A preparation method of the methanol gasoline cosolvent includes adding the materials into a preparing container, mixing well, and allowing for standing for more than 1 hour to obtain the clear methanol gasoline cosolvent. 0.2%-3% of the methanol gasoline cosolvent can be added into methanol to obtain modified methanol according to volume proportion, and the modified methanol can be made into methanol gasoline containing methanol which accounts for 10%-85% of total volume ratio. The preparation method and application of the methanol gasoline cosolvent are simple, safe and low in cost. Low-temperature phase separation resistance and water-gasoline phase separation resistance of the methanol gasoline can be improved effectively, the requirements of methanol gasoline on storage, transport and use are met, and the methanol gasoline cosolvent has the advantages that cold boot using methanol gasoline is achieved and explosion resistance of the methanol gasoline is improved.

Owner:永州锦溁新能源开发有限公司

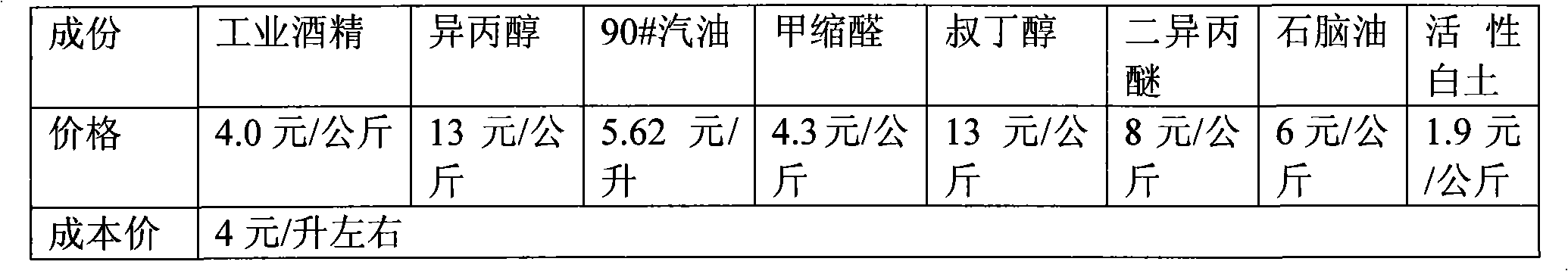

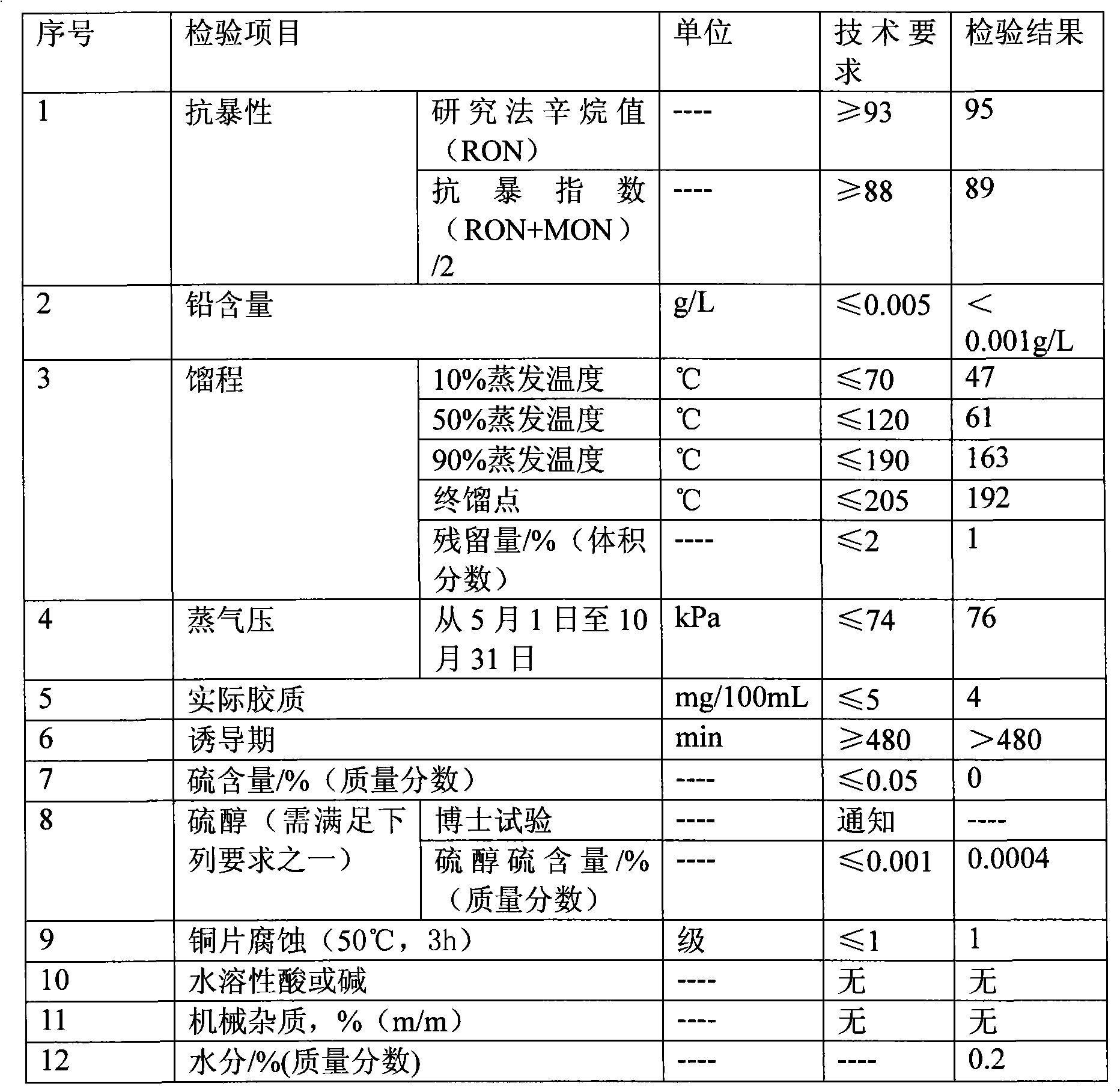

Ethanol gasoline for motor-vehicle and method of preparing the same

InactiveCN101358151AAchieve the effect of processingOctane reductionLiquid carbonaceous fuelsChemical reactionFiltration

The present invention relates to clean fuel, in particular to automotive ethanol gasoline and a preparation method thereof. The automotive ethanol gasoline is composed of the following ingredients in the weight percentage: 15.0 percent to 25.0 percent of industrial alcohol; 0.60 percent to 5.0 percent of isopropanol; 30.0 percent to 50.0 percent of gasoline; 29.0 percent to 45.0 percent of methylal; 4.0 percent to 15.0 percent of tertiary butyl alcohol; 2.0 percent to 10.0 percent of diisopropyl ether; and 1 percent to 5 percent of naphtha; after the ingredients are mixed, 1 percent to 6 percent of active floridin is added; and after stirring, physical and chemical reactions and filtration, the automotive ethanol gasoline is prepared. The automotive ethanol gasoline is characterized by high octane value and strong explosive force, the production cost is reduced, the emitted tail gas is smokeless and smellless, therefore the pollution of the automotive tail gas is reduced, and moreover, the automotive ethanol gasoline has no adverse effect on an automotive engine and can partially replace the prior gasoline.

Owner:郭国星

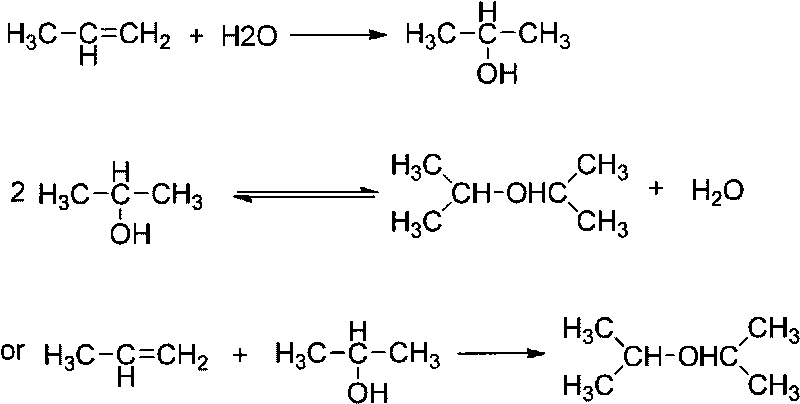

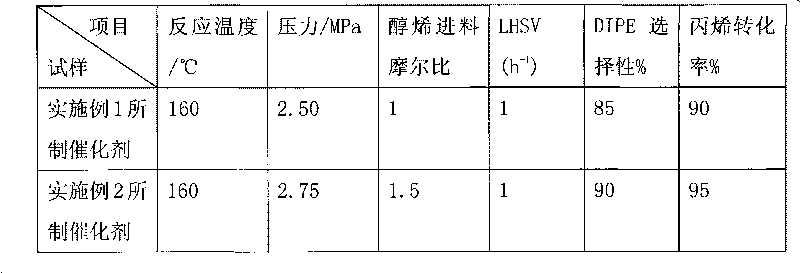

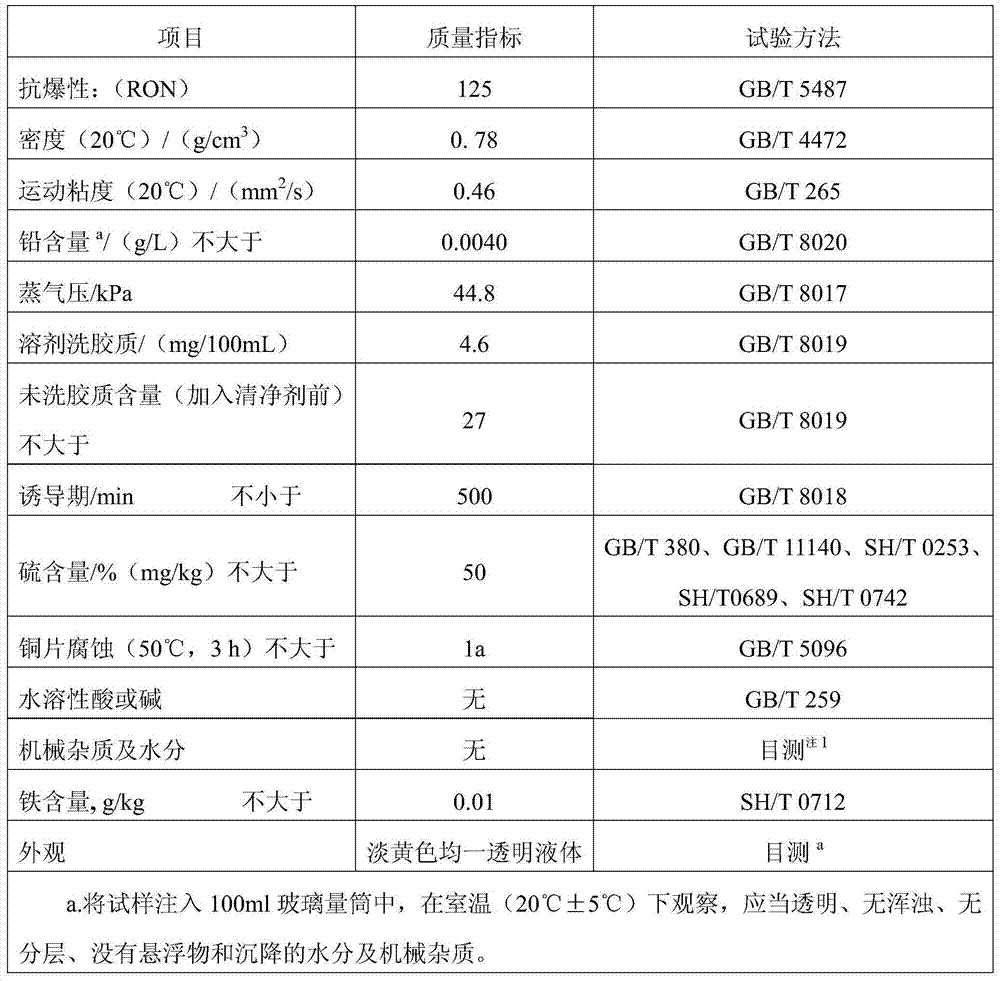

Catalyst for synthesizing propylene ether into DIPE (Diisopropyl Ether) and preparation method thereof

ActiveCN101757942ALow reaction temperatureLow reaction pressureMolecular sieve catalystsChemical industryDesorptionIon

The invention discloses a catalyst for synthesizing propylene ether into diisopropyl ether (DIPE), wherein the mol composition of the catalyst is SiO2: Al2O3: Cr2O3:MoO3 of 46:2:1:1. The invention also discloses a preparation method of the catalyst. In the catalyst for synthesizing the propylene ether into the diisopropyl ether, Cr ions and Mo ions which can be taken as active centers of non-protonic acid (L acid) are introduced into zeolite, play a role of the coordinated catalysis performance with the porous performance of the zeolite, which realizes an integrated process of adsorption-catalysis and etherification-desorption, thereby greatly improving the synthesis condition of the DIPE and effectively enhancing the propylene conversion ratio and the DIPE selectivity.

Owner:临沂星火知识产权服务有限公司

Composite gasoline additive and its prepn

InactiveCN101020848AImprove combustion qualityBoost octaneLiquid carbonaceous fuelsCombustionGasoline

The present invention relates to hydrocarbon containing fuel, and is especially one kind of composite gasoline additive and its preparation process. The composite gasoline additive consists of diisopropyl ether 60-70 wt% and ethanol 30-40 wt%. The composite gasoline additive has the functions of promoting combustion, eliminating carbon deposit, reducing tail gas and raising fuel oil utilizing rate greatly. The preparation process is simple and feasible.

Owner:JINAN UNIVERSITY

Automobile gasoline composite modifying agent

ActiveCN103194284ANot poisonedNo carbon depositionLiquid carbonaceous fuelsFuel additivesAntioxidantSolvent

The invention relates to an automobile gasoline composite modifying agent. The raw material of the modifying agent is prepared from the following components in percentage by weight: 25-50% of an octane value promoter, 30-50% of a combustion improver and 20-25% of a latent solvent, wherein the octane value promoter comprises the following components in percentage by weight: 20-45% of sec-butyl acetate, 30-40% of diisopropyl ether, 5-10% of absolute ethyl alcohol and 20-30% of methyl tert-butyl ether; the combustion improver comprises the following components in percentage by weight: 10-20% of cyclopentane, 47-50% of mixed light arene, 30-40% of alkylate and 3-6% of 1# jet fuel; and the latent solvent comprises the following components in percentage by weight: 10-30% of acetone, 25-30% of dimethoxy ethane, 20-25% of industrial isobutyl alcohol, 22.5-28% of industrial isopropyl alcohol, 1-4% of trinitromethane, 1-2% of glycol ethylene ether, 0.1-0.2% of a clearing agent polyisobutene succinimide, 0.2-0.4% of a metal deactivator T1201 and 0.2-0.4% of an antioxidant. By adopting the automobile gasoline composite modifying agent, a three-way catalyst of an organic ashless exhaust system cannot be poisoned, a fuel spray nozzle and a cylinder exhaust valve cannot be abraded, and carbon deposition and abrasive particles cannot be generated in a machine body.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

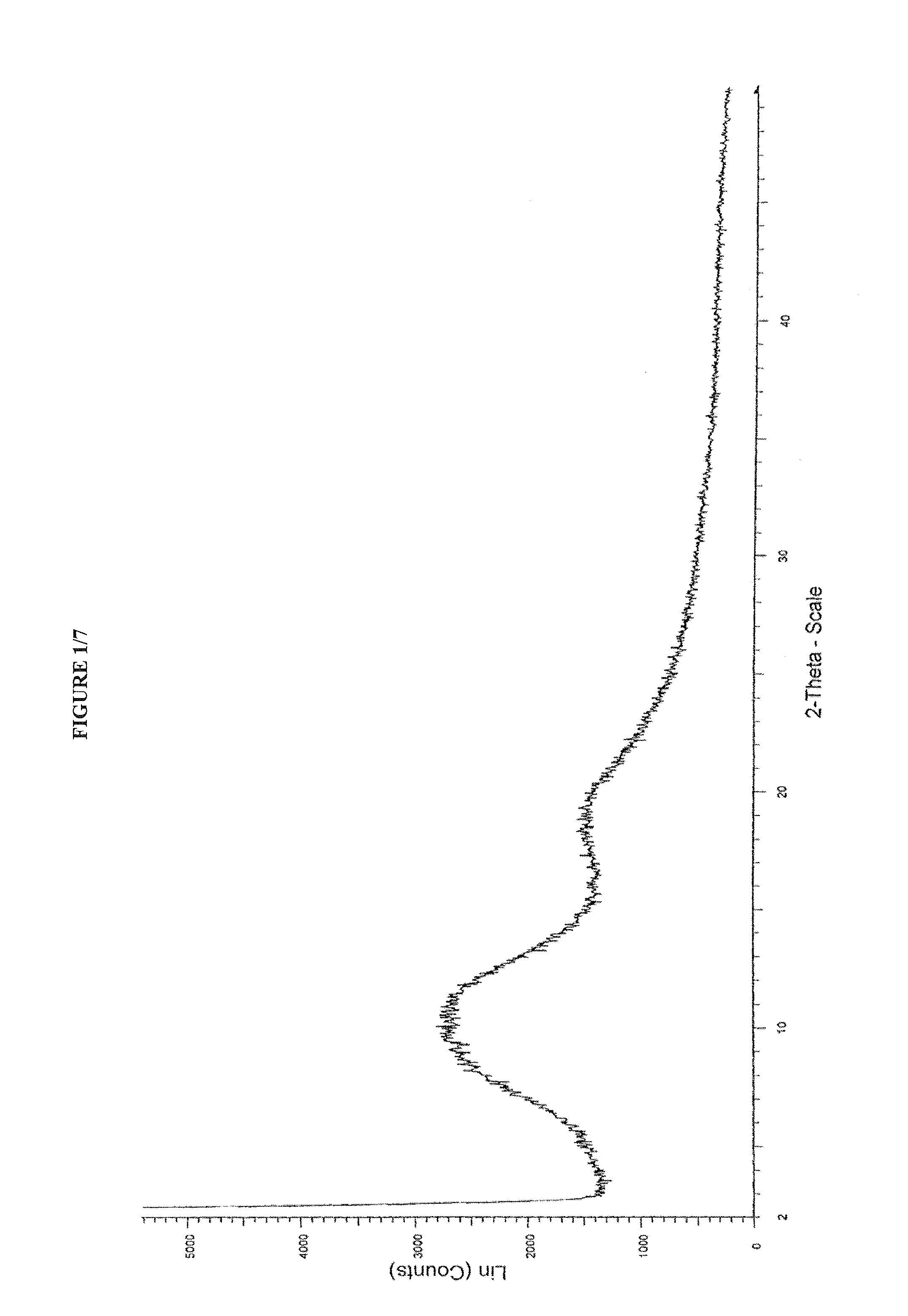

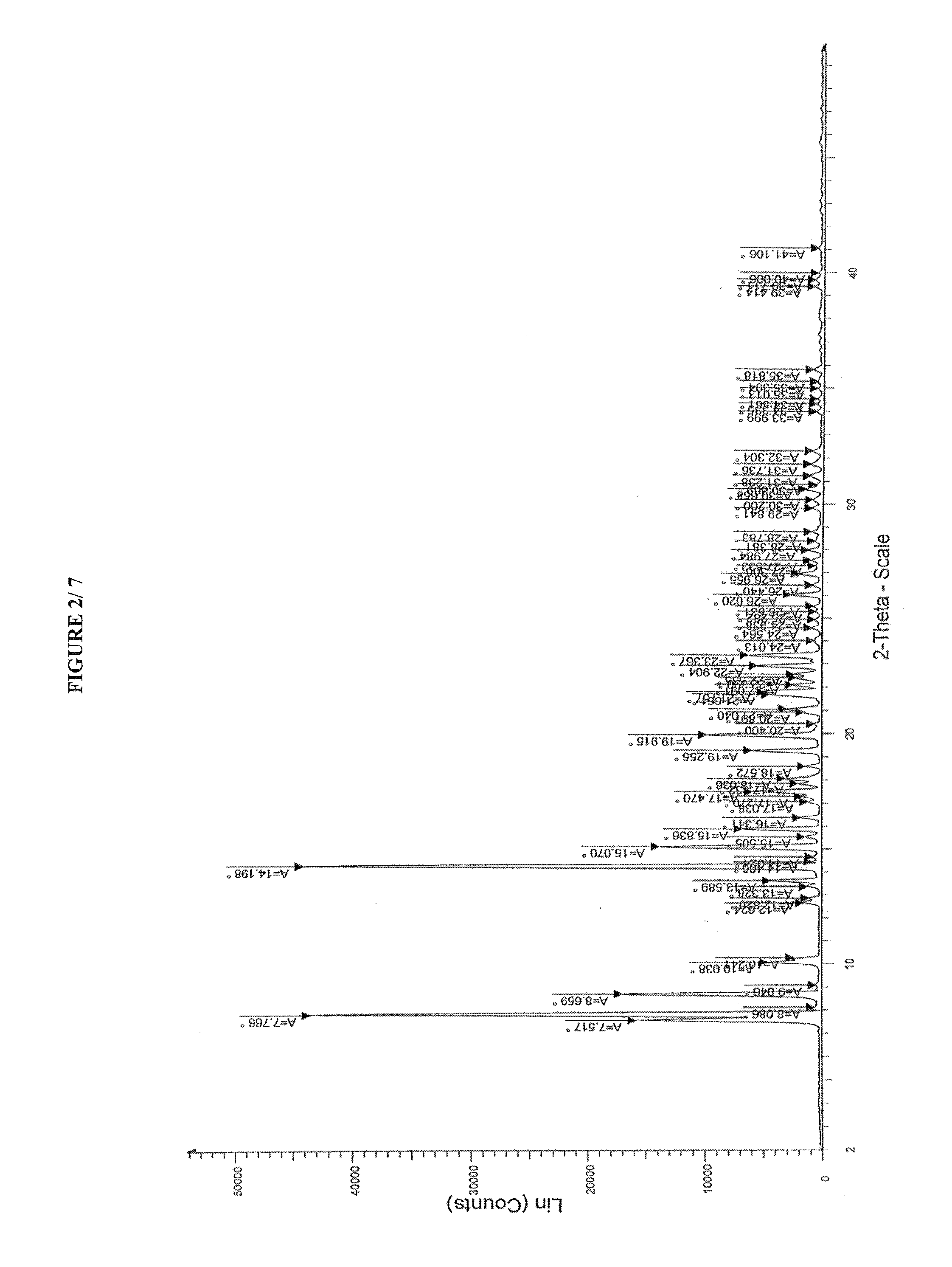

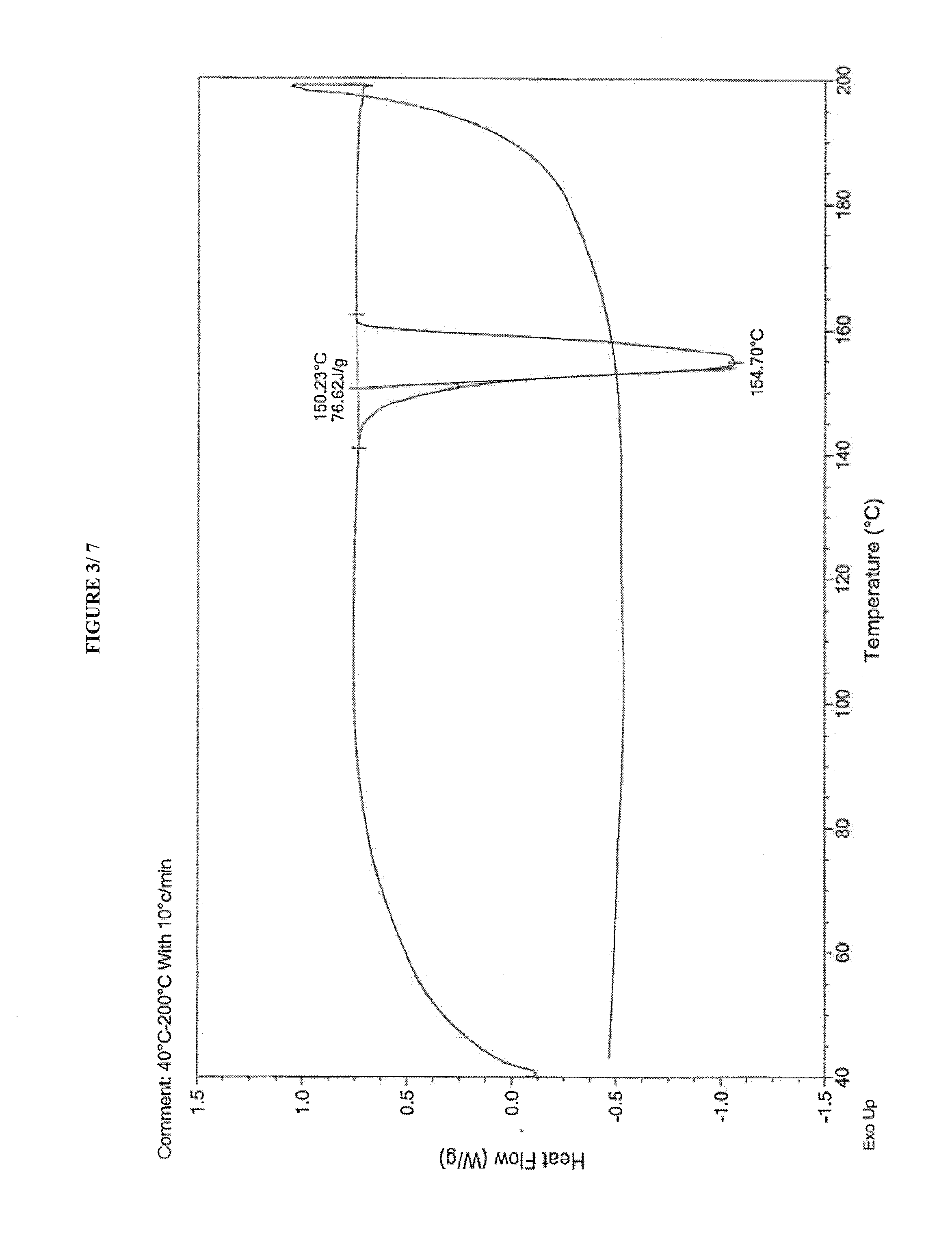

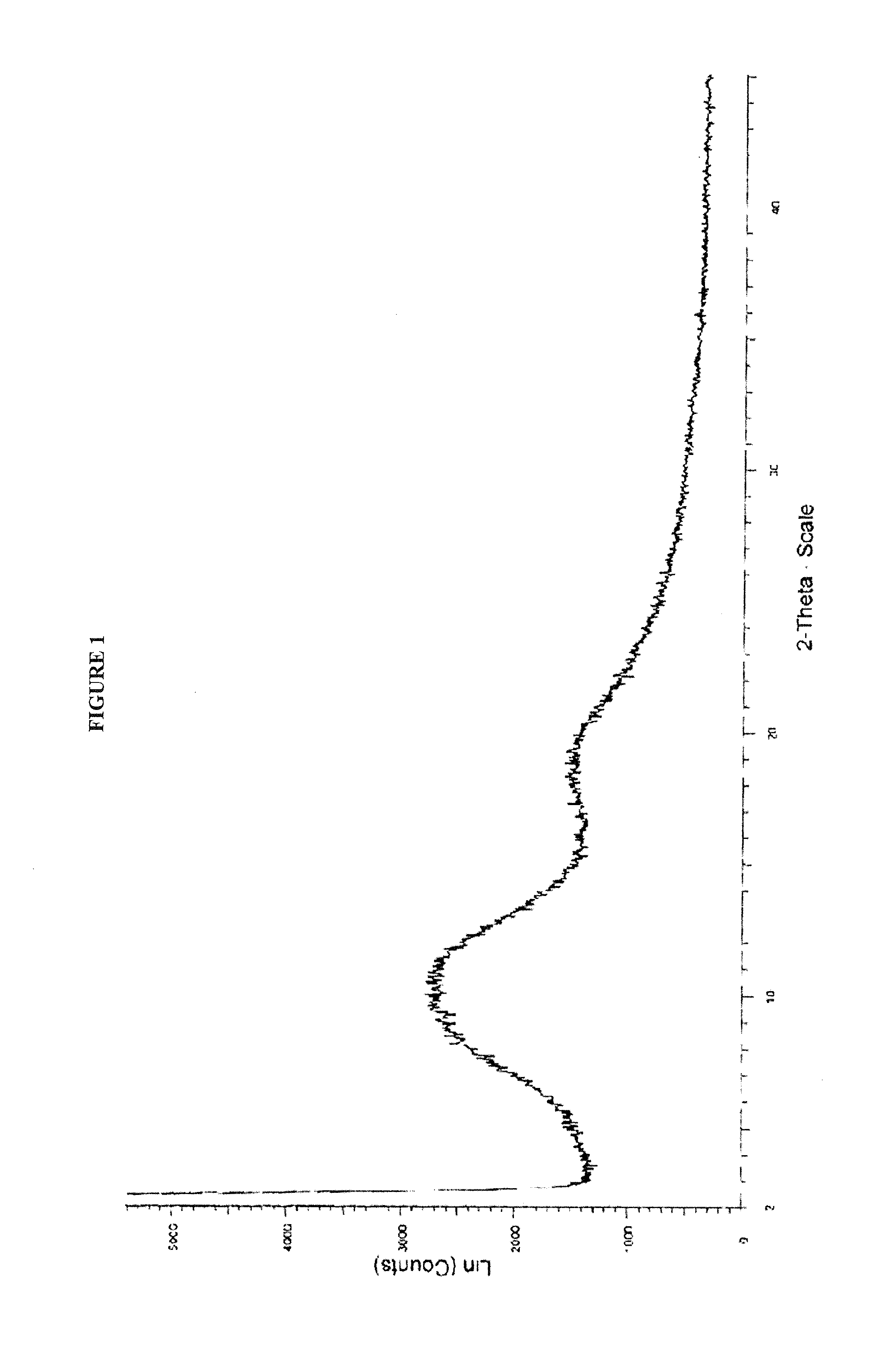

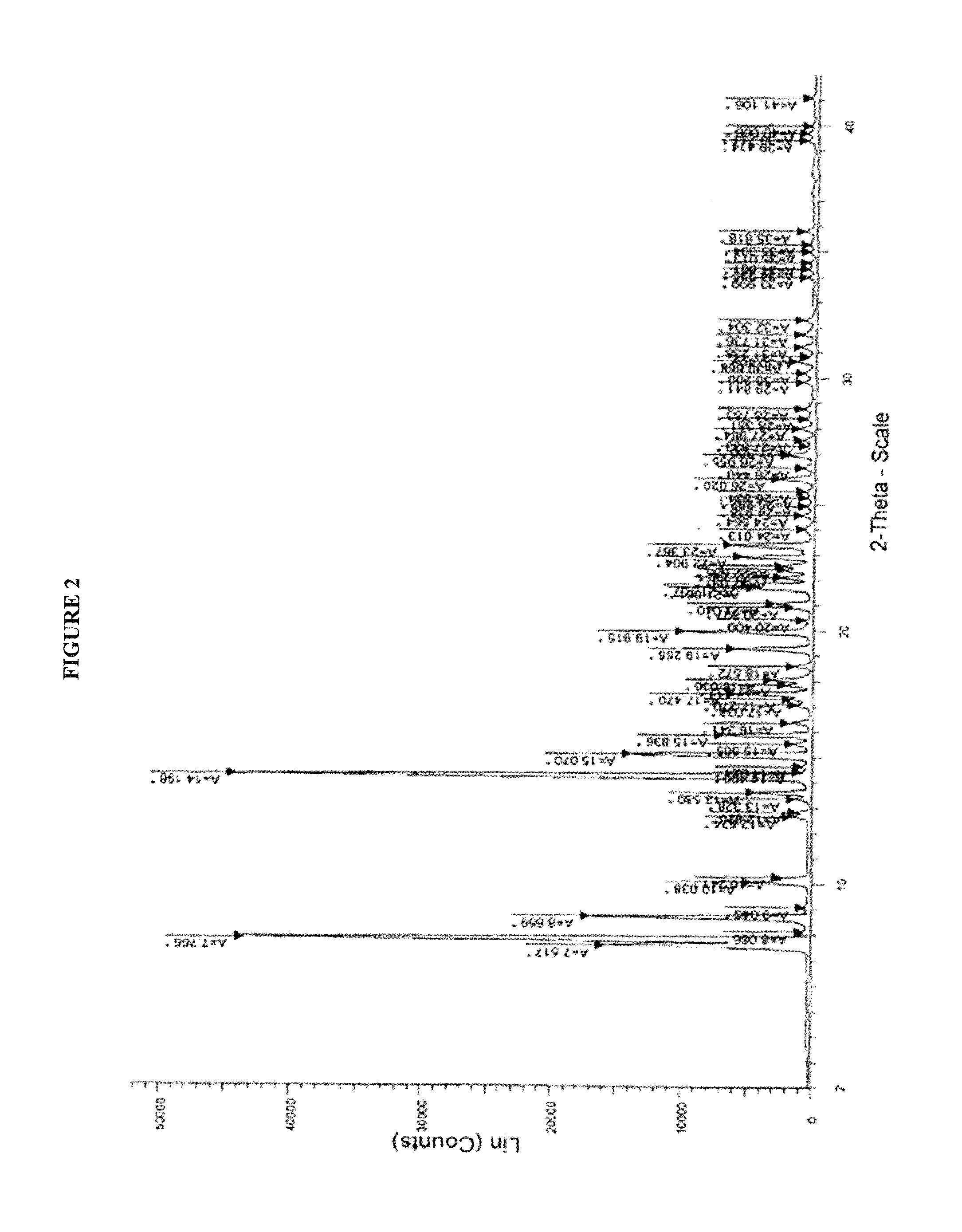

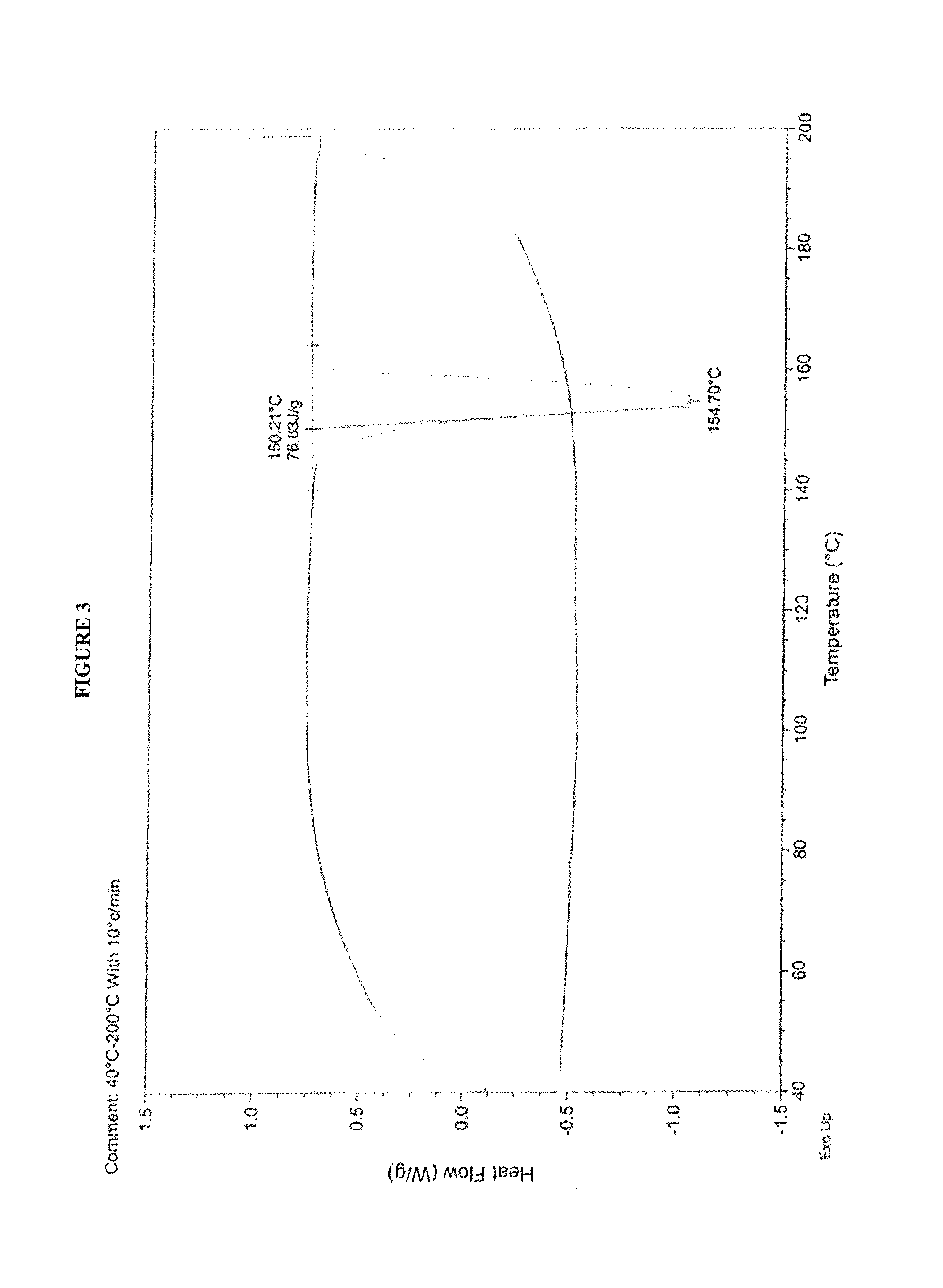

Process for preparing amorphous cabazitaxel

The present invention provides a process for preparing amorphous Cabazitaxel from the solvate form of Cabazitaxel.The present invention also provides novel diisopropyl ether solvate form of Cabazitaxel (I),and process for preparation thereof.Said amorphous Cabazitaxel and crystalline diisopropyl ether solvate of Cabazitaxel of the present invention can be utilized in preparing the pharmaceutical composition / s useful in the treatment of cancer.

Owner:SHILPA MEDICARE LTD

Process for preparing amorphous cabazitaxel

InactiveUS20150315164A1Therapeutic usefulnessOrganic active ingredientsBiocideCabazitaxelMedicinal chemistry

The present invention provides a process for preparing amorphous Cabazitaxel from the solvate form of Cabazitaxel.The present invention also provides novel diisopropyl ether solvate form of Cabazitaxel (I),and process for preparation thereof.Said amorphous Cabazitaxel and crystalline diisopropyl ether solvate of Cabazitaxel of the present invention can be utilized in preparing the pharmaceutical composition / s useful in the treatment of cancer.

Owner:SHILPA MEDICARE LTD

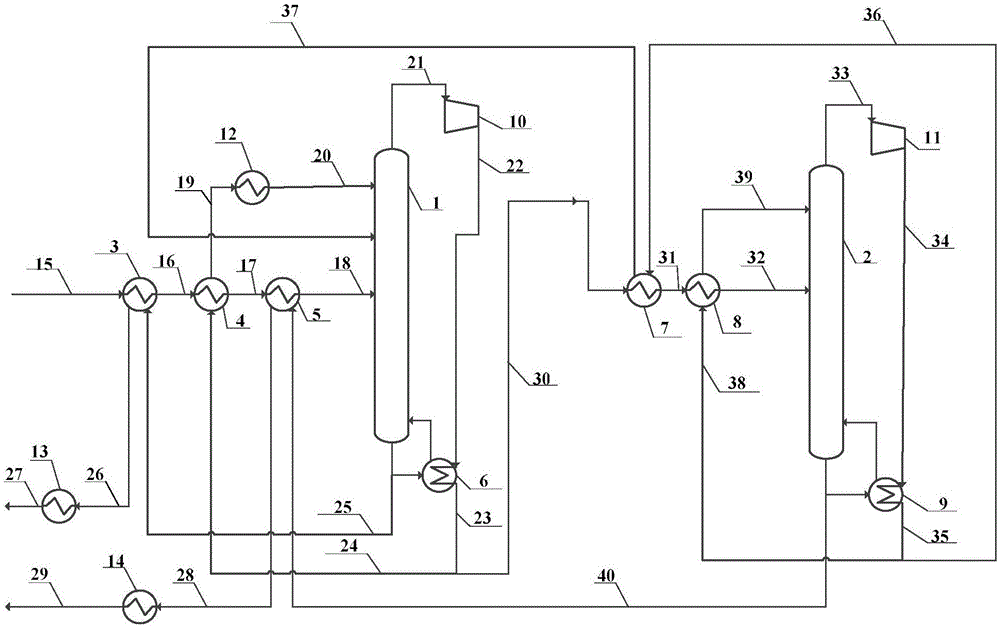

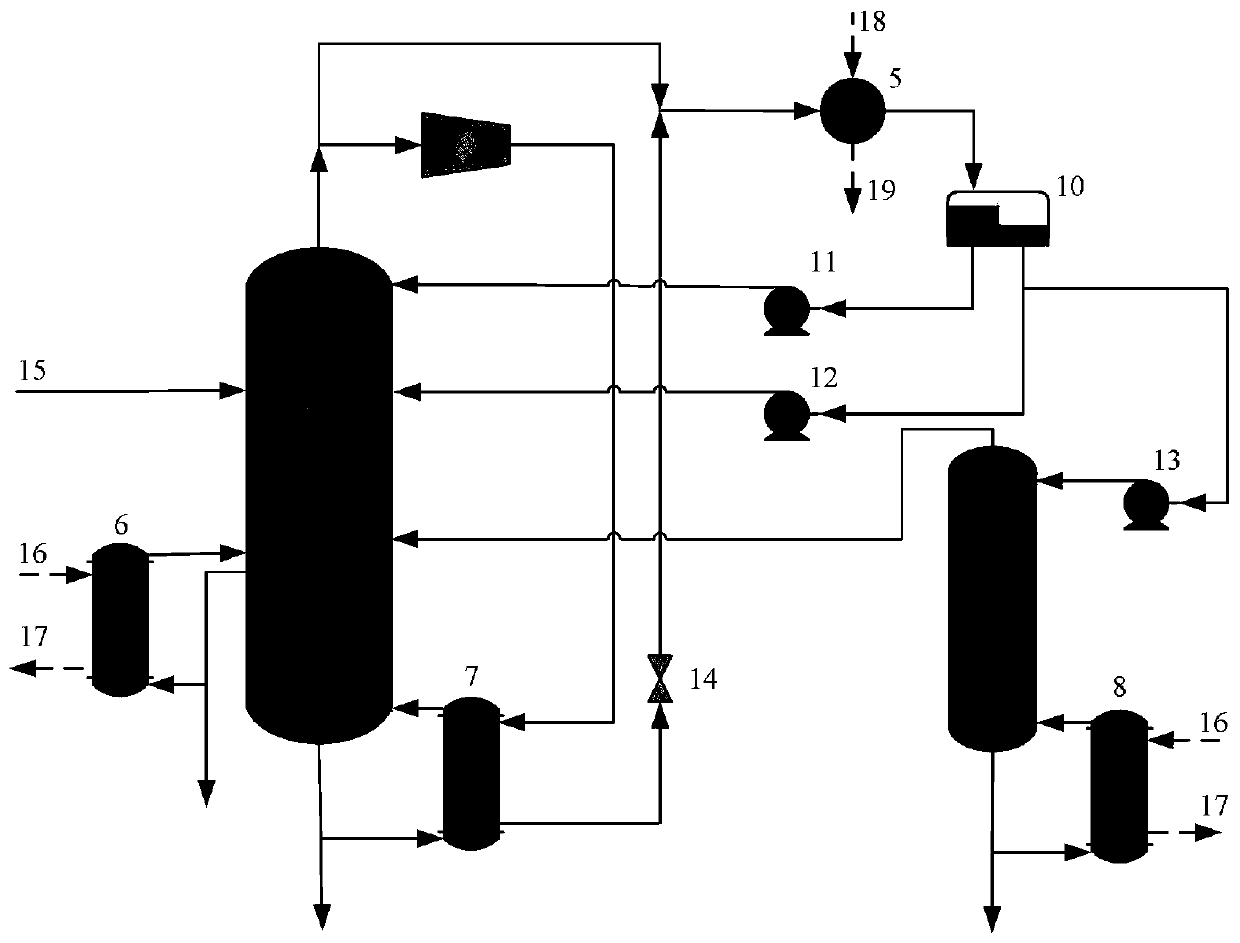

Device and method for separating isopropanol and diisopropyl ether mixture

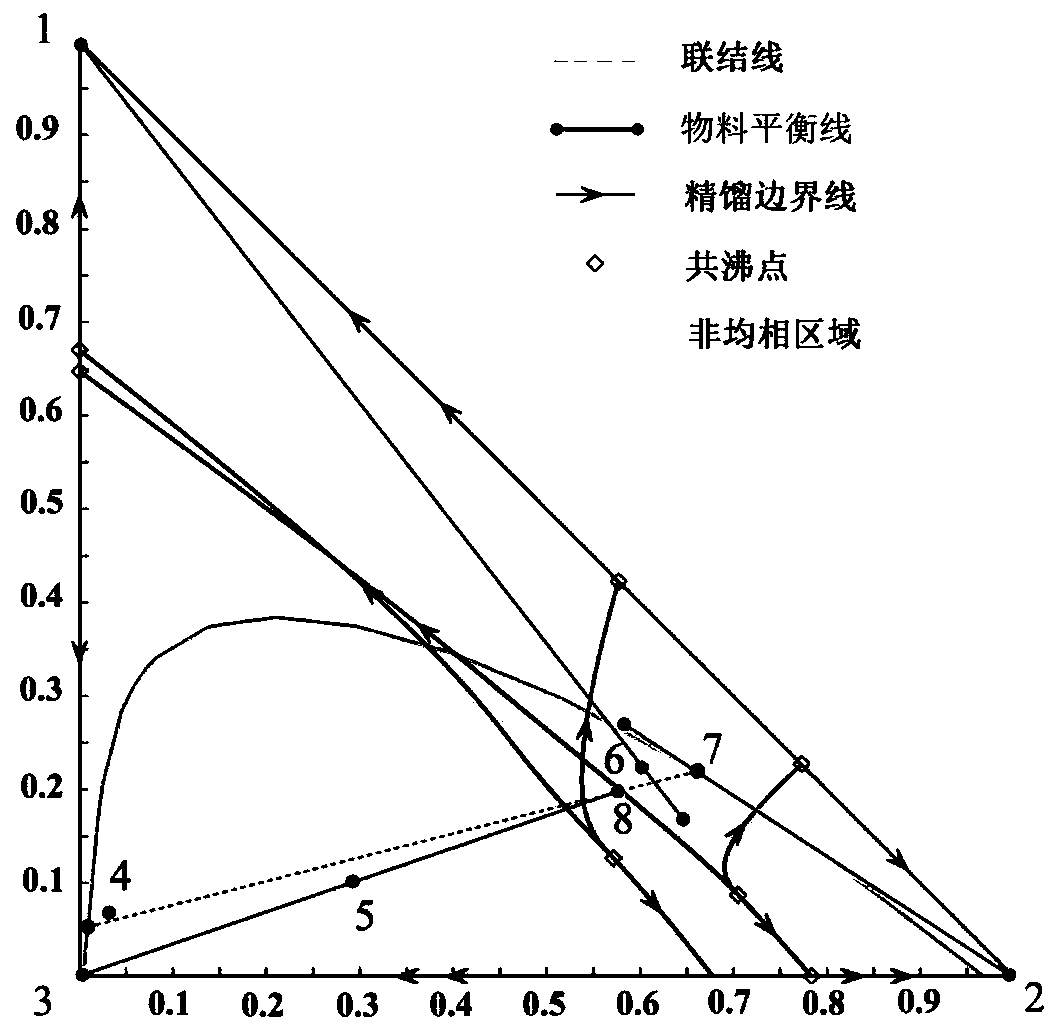

InactiveCN106748650AEfficient separationReduce energy consumptionEther separation/purificationOrganic compound preparationEconomic benefitsProcess engineering

The invention discloses a device and method for separating an isopropanol and diisopropyl ether mixture, and belongs to the technical field of rectification. An azeotropic steam material extracted from the top of a low-pressure tower is pressurized and heated by a compressor and then provides heat required by reboiling for a column kettle of the low-pressure tower, condensation of azeotropic steam of the low-pressure tower is completed, an azeotropic steam material extracted from the top of a high-pressure tower is pressurized and heated by the compressor and then provides heat required by reboiling for a column kettle of the high-pressure tower, and condensation of azeotropic steam of the high-pressure tower is completed. Compared with traditional schemes that cooling water is used for achieving tower-top material condensation and public heating projects are used for column kettle heating, waste heat of the materials at the bottoms of the high-pressure and low-pressure towers is used for pre-heating of materials and intermediate products, accordingly heat matching in a system is achieved, input of outside public heating projects is not needed, consumed energy and generated cost of the compressor are much lower than the traditional cooling water and the public heating projects, and good economic benefits are generated.

Owner:CHANGZHOU UNIV

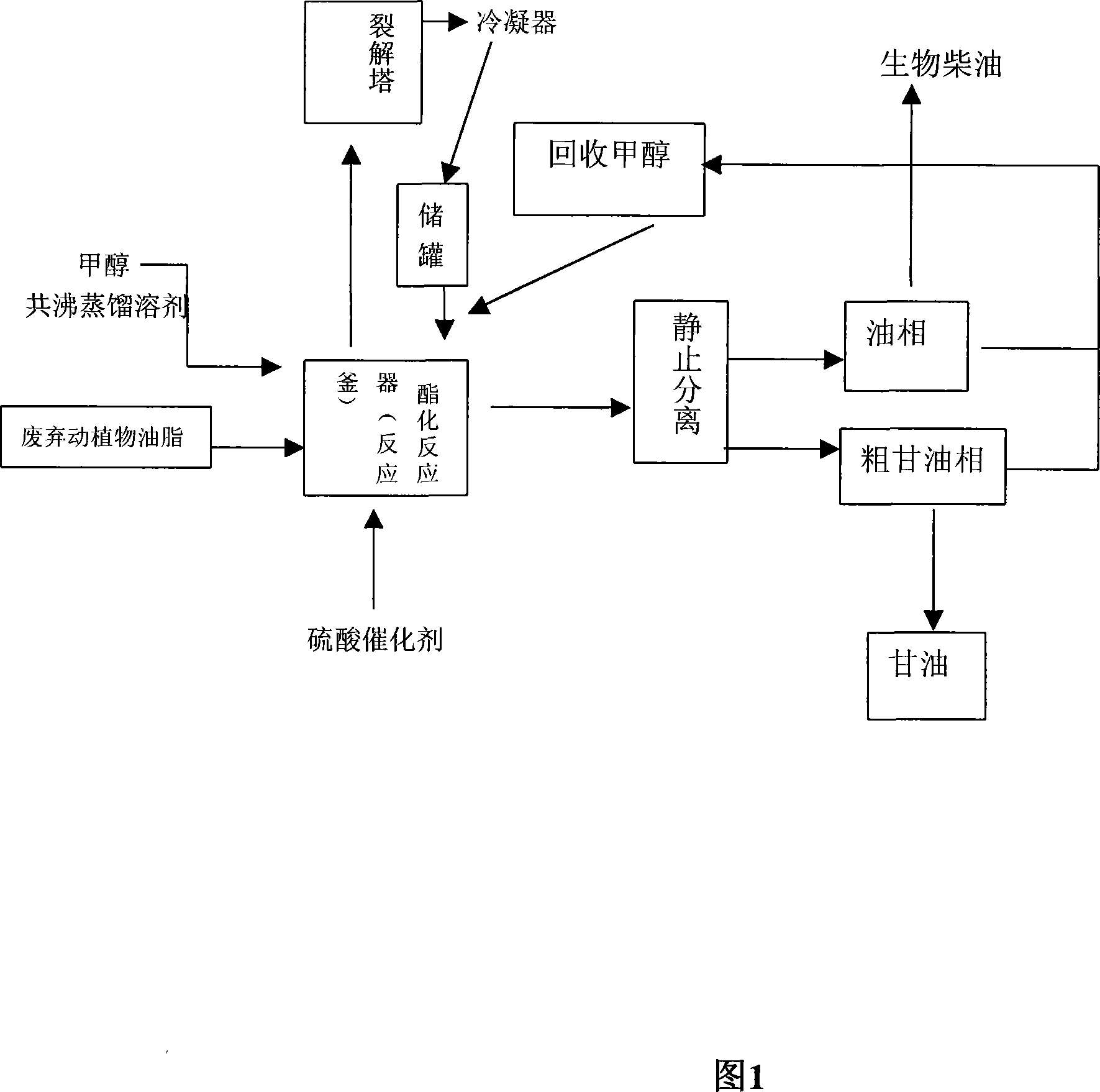

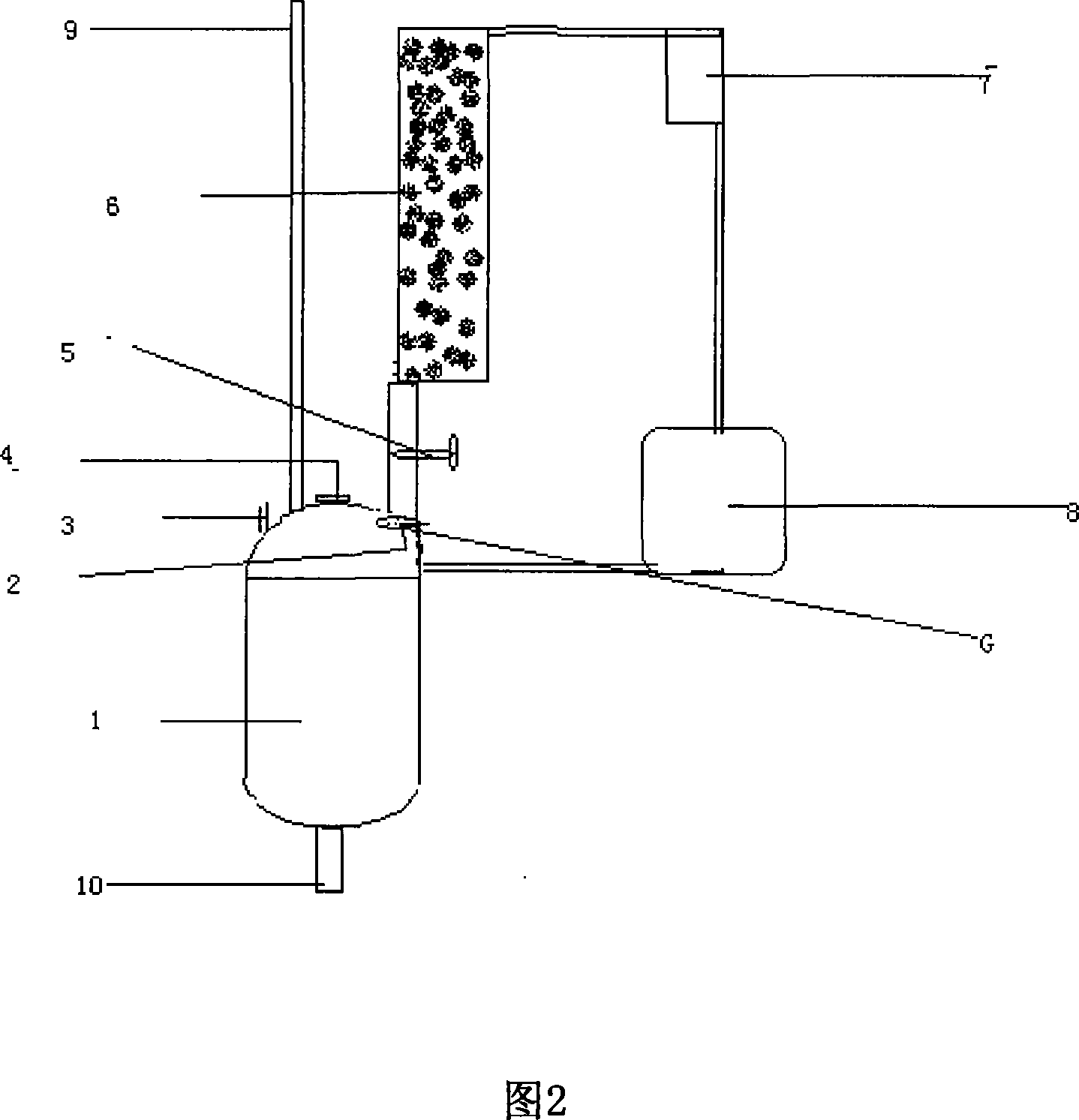

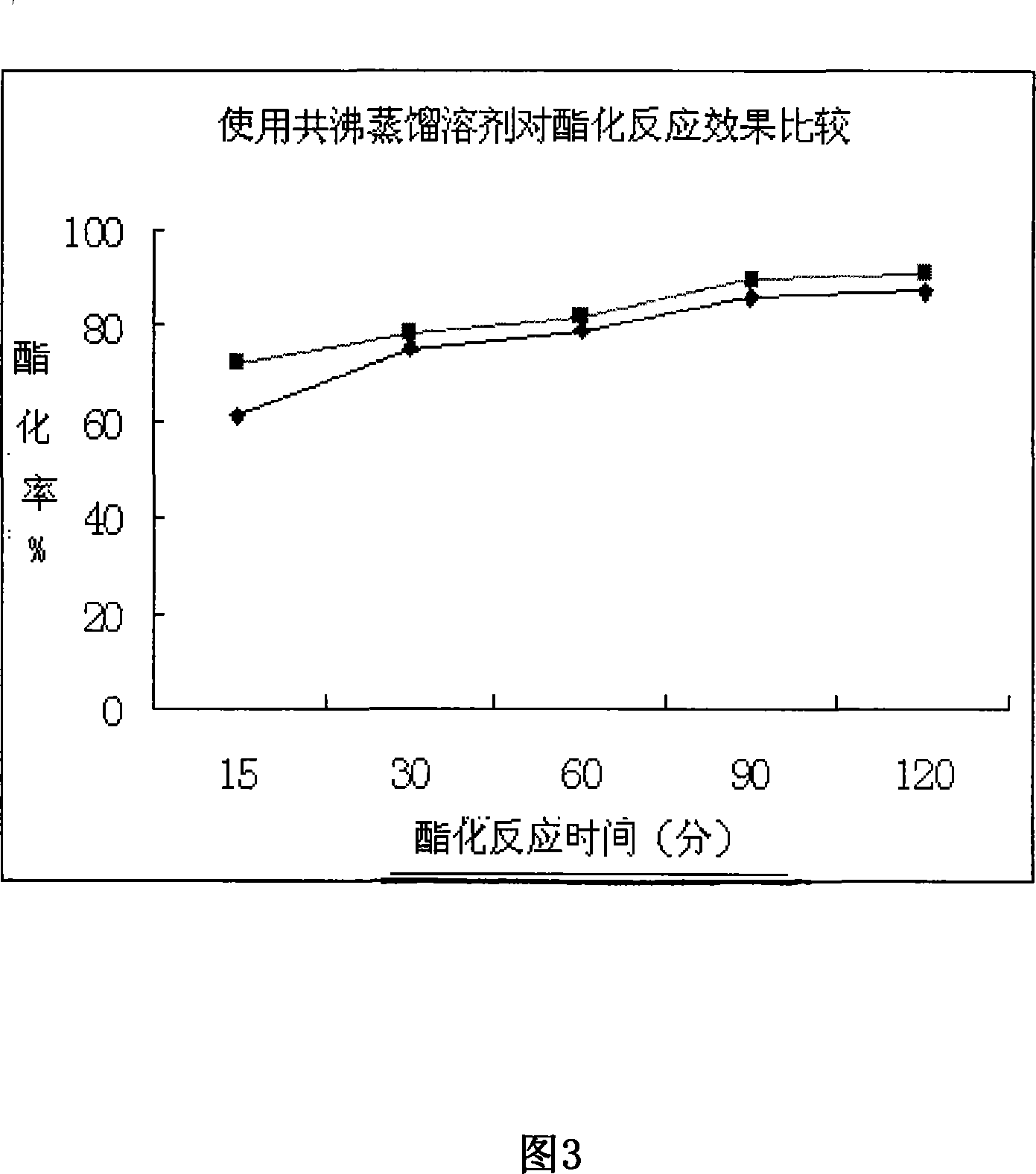

Method for producing low freezing point biodiesel by employing waste animal and vegetable oil coupling and special device

InactiveCN101157868ACatalytic crackingNo polluting emissionsBiofuelsLiquid hydrocarbon mixture productionAlkaneOil and grease

The invention pertains to the biological diesel preparation field, and in particular relates to a preparation method and a device for coupling production of low freezing point biological diesel by using waste animal and plant oil. The method is characterized in that: waste animal and plant oil with pH value of 6-192mgKOH / g is put into a reactor, heated and evaporated under 0.1 MPa to finish cracking reaction in the reactor; then alkane and fatty acid are obtained, which are put into a condenser to be added with methanol according to 6 to 10 mole ratio of alcohol / free fatty acid; 0.8 to 1.5 percent of concentrated sulfuric acid is added according to mass ratio of concentrated sulfate and oil; 10 to 20 percent of diisopropyl ether is added according to mass ratio of azeotropic distillation solvent and oil at 65 to 70 DEG C of the reaction temperature for 2 to 4 hours; after the reaction, the methanol is steamed out to be recycled; the separated upper oil phase is the biological diesel. Compared with the existing technique, the preparation method of the invention has low freezing point, low cost, and is in accordance with the technical direction of environment-friendly preparation.

Owner:HUAZHONG AGRI UNIV +1

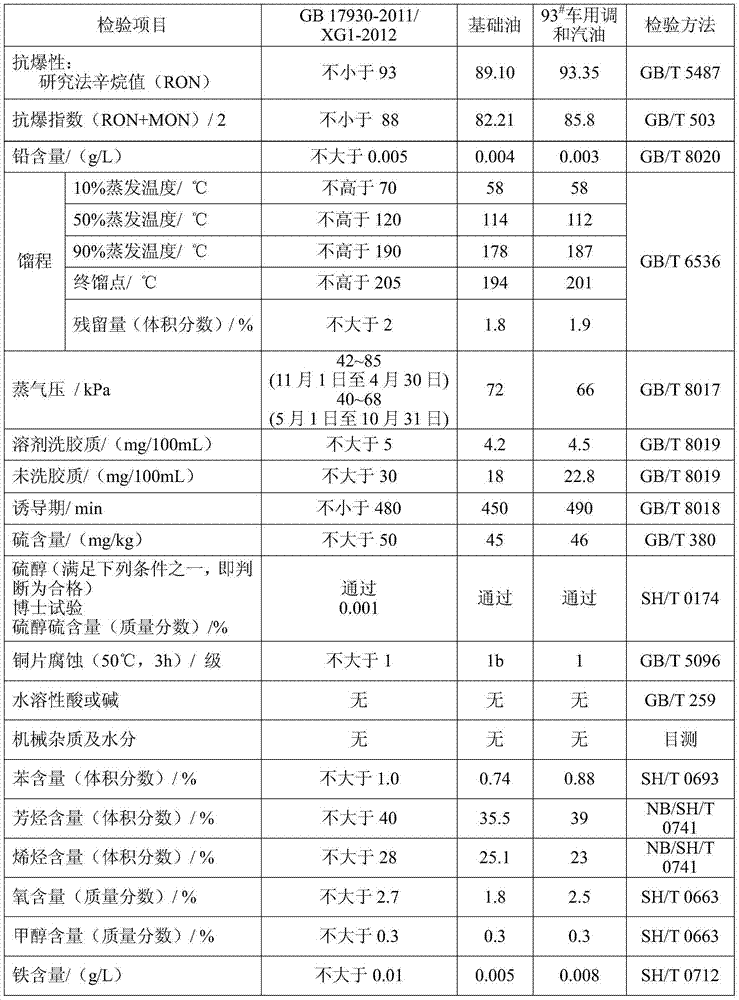

Composite additive for producing National Standard IV 93# gasoline from refinery base oil

InactiveCN104119967AIncrease powerIncrease torqueLiquid carbonaceous fuelsFuel additivesMass ratioMethyl carbonate

The invention provides a vehicle fuel oil composite additive which comprises the following components in percentage by mass: 35-80% of octane number enhancer, 15-38% of combustion improver and 5-27% of assistant. The octane number enhancer is composed of ethanol, tert-butyl acetate, methyl tert-butyl ether, cyclopentane and polymethoxy dimethyl ether in a mass ratio of 40:10:40:7:3; the combustion improver is composed of diisopropyl ether, dimethyl carbonate, nitromethane, acetone and glycol dimethyl ether in a mass ratio of 45:30:10:5:10; and the assistant is composed of isoamyl alcohol, isopropanol, 2-ethylhexanol, dipolylinoleic acid, metal passivator and antioxidant in a mass ratio of 20:60:8:10:0.4:1.6.When being applied to vehicle fuel oil, the composite additive can reduce or eliminate knocking, enable the fuel oil to have high octane number performance and ensure the fuel in the cylinder to be combusted completely, so that both the exhaust emission and fuel consumption are lowered, and the power and torsion of the engine are enhanced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Environment-friendly type methanol gasoline for vehicle

InactiveCN1923977ATo achieve a large proportion of accessionIncrease motivationLiquid carbonaceous fuelsKetoneTrimethylolpropane

The invention discloses a vehicle environmental-protective carbinol gasoline, which comprises the following parts: 1-40% carbinol, 50-89% basic oil, 0.1-0.3% ethane, 0.1-0.3% skellysolve B, 3-5% tertamyl methyl ether, 0.3-0.8% alcohol, 0.05-0.1% 2, 2-dimethylbutane, 0.1-0.3% tert-butanol, 0.1-0.3% normal propyl alcohol, 0.1-0.3% 2-ethyl(-1-) alcohol, 0.2-0.5% glycol, 0.1-0.15% 1, 3-dihydroxybutane, 0.3-0.8% neopentyl glycol, 0.1-0.15% 1, 6-hydroxylhexane, 0.2-0.5% trimethylolpropane, 0.3-0.5% pentaerythrite, 0.5-0.8% diisopropyl ether, 0.1-0.3% 2-ethyldioxy acetic ester, 0.1-0.3% isopropyl nitrate, 0.2-0.5% dimethyl ketone, 0.1-0.2% ethyl malonate, 0.05-0.2% diphenyl carbonate, 0.01-0.03% 102TB corrosion inhibitor and 0.01-0.03% 107PT anti-swelling agent.

Owner:顾杏泉

Clean and environment-friendly methanol gasoline

InactiveCN1884449ATo achieve a large proportion of accessionIncrease motivationLiquid carbonaceous fuelsKetoneTrimethylolpropane

The invention relates the methanol petrol, comprising 41-60 parts methanol, 30-49 parts base oil, 0.2-0.3 parts ethane, 0.1-0.3 parts skellysolve B, 3-5 parts methyl tert-butyl ether, 0.5-0.8 parts ethanol, 0.2-0.3 part 2, 2- dimethylbutane, 0.3-0.5 part tert-butanol, 0.2-0.3 part normal propyl alcohol, 0.1-0.3 part 2- ethyl (-1-) ethanol, 0.2-0.5 part ethylene glycol, 0.1-0.2 part 1, 3- dihydroxybutane, 0.3-0.5 part neopentyl glycol, 0.1-0.2 part 1, 6- dihydroxy hexane, 0.3-0.8 part trimethylolpropane, 0.2-0.8 part pentaerythrite, 0.6-0.8 part diisopropyl ether, 0.2-0.3 part 2-ethyldioxy acetic acid ethyl ester, 0.2-0.35 part isoproyl nitrite, 0.2-0.6 part dimethyl ketone, 0.1-0.2 part diethyl malonate, 0.2-0.4 part diphenyl carbonate, 0.02-0.03 part 102TB corrosion inhibitor, and 0.02-0.03 part 107PT anti-swelling agent. The invention has the advantages of high methanol content, environment protection, and good earthquake resistance and dynamic.

Owner:顾杏泉

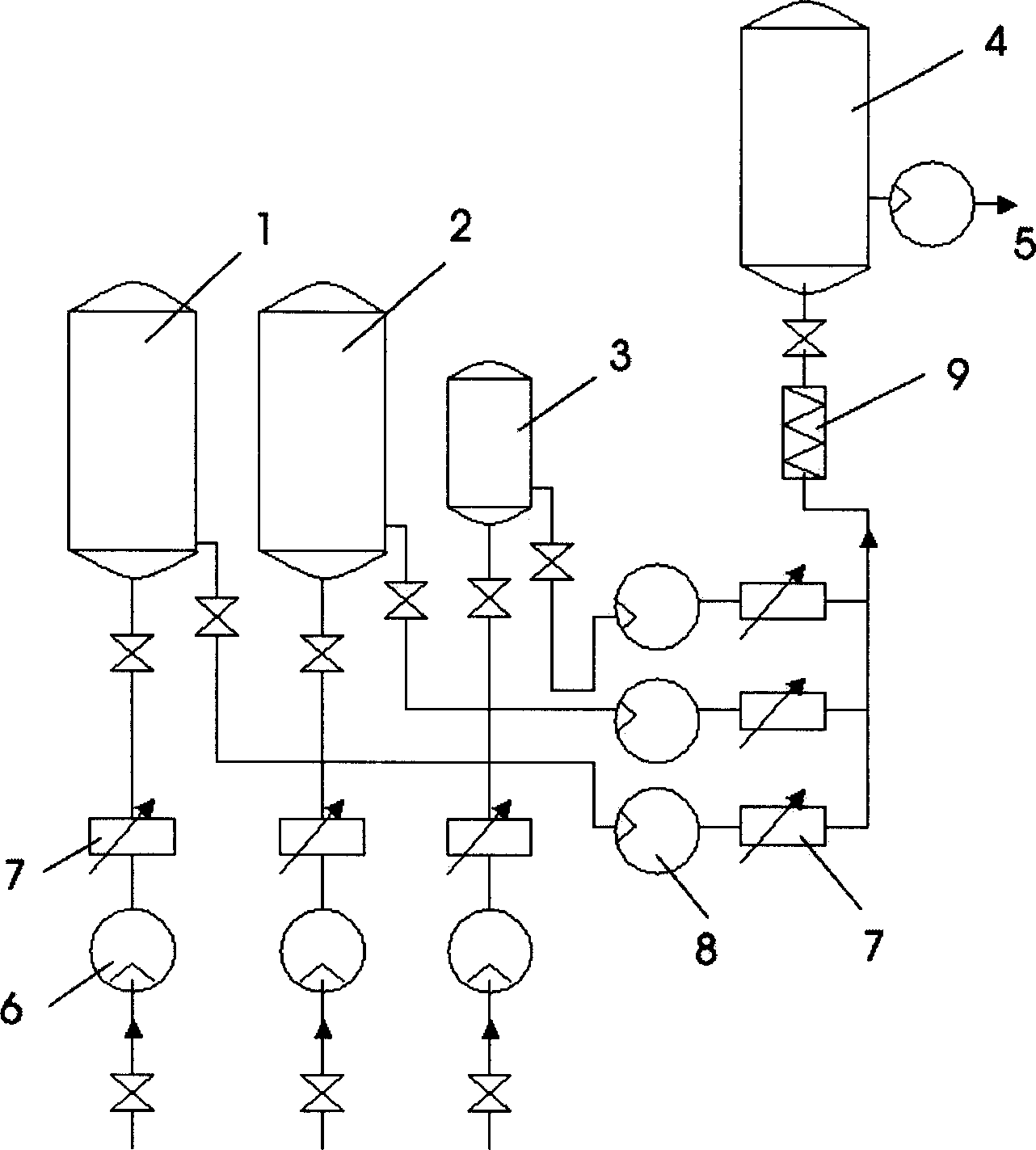

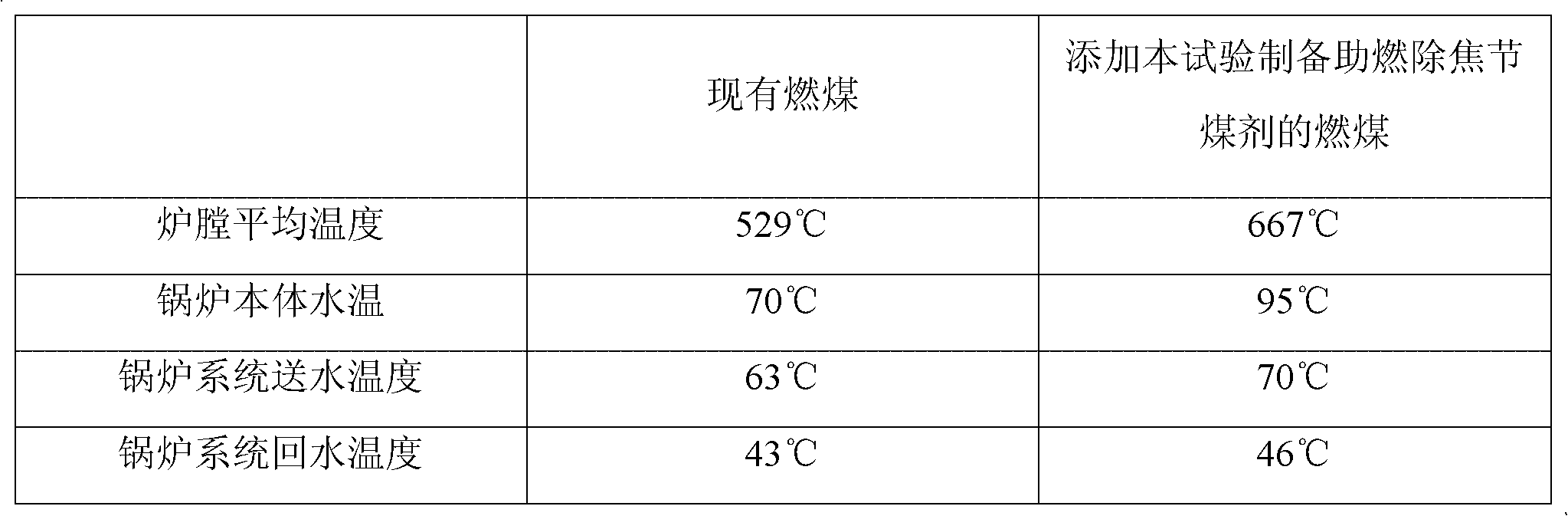

Combustion-supporting decoking coal saving agent

The invention provides a combustion-supporting decoking coal saving agent, relating to a coal saving agent. The invention aims at solving the problems that coal cost of an enterprise is high and a coked block is produced in a combustion process. The combustion-supporting decoking coal saving agent provided by the invention is formed by mixing potassium hypermanganate, sodium chloride, dimethylcarbinol-ethanol, rare earth lanthanum, dispersing agent, calcium chloride, high-alumina vanadine, olefine acid-dimethylbenzene acrylate copolymer, methylisobutylketone, potassium peroxide, polyoxyethylene sorbitan monostearate, sulphur-fixing agent, Tween-60, tributyl phosphate, diisopropyl ether, descaling agent and penetrant. The combustion-supporting decoking coal saving agent provided by the invention has the advantages that: firstly, after the combustion-supporting decoking coal saving agent is used, furnace box temperature is improved, slag carbon content is reduced, and dust and harmful gases such as carbon monoxide and sulphur dioxide are removed; and secondly, the combustion-supporting decoking coal saving agent provided by the invention also has decoking function, thus deslagging labour intensity is reduced, comprehensive fuel coal saving rate is 7-16%, and production cost is reduced. The combustion-supporting decoking coal saving agent provided by the invention is mainly used for preparing the coal saving agent.

Owner:哈尔滨巨龙节能设备经销有限责任公司

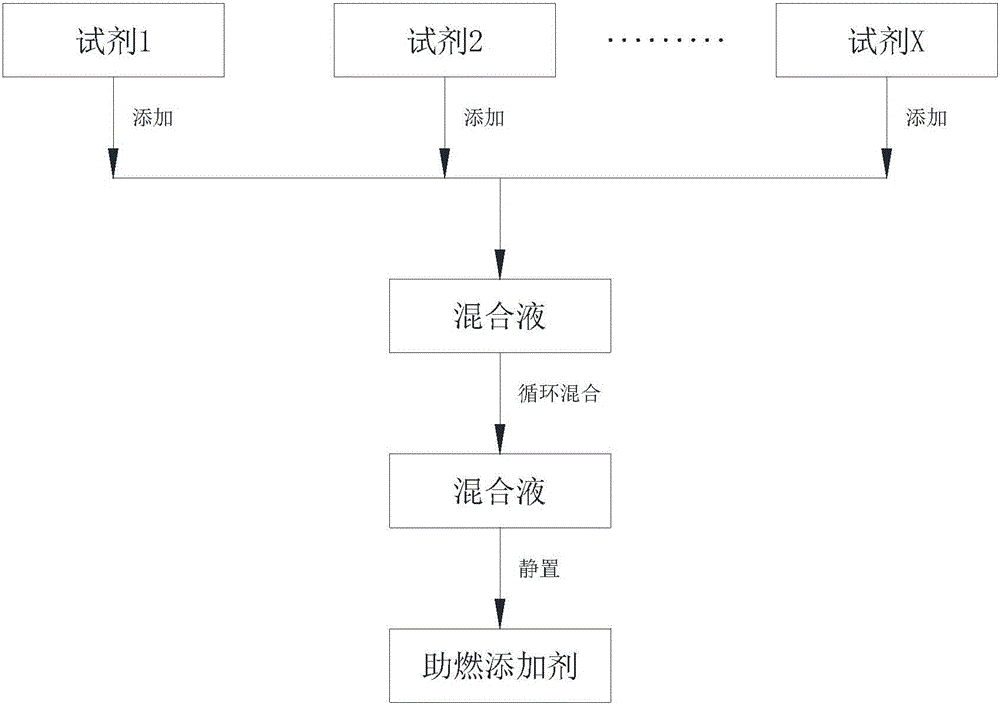

Fuel additive and preparation method thereof

The invention discloses a fuel additive. The fuel additive is prepared from the following raw materials in parts by weight: 50 to 80 parts of tourmaline nanometer powder, 2 to 5 parts of graphite nanometer powder, 5 to 10 parts of magnesium powder, 30 to 50 parts of diisopropyl ether, 10 to 20 parts of biological oil, 5 to 10 parts of dispersant, 5 to 30 parts of water and 0.1 to 0.2 part of ferrocene. The preparation method of the fuel additive comprises the step of uniformly mixing all of the raw materials at normal temperature and pressure. By using the fuel additive, the fuel quality can be improved, fuel is promoted to fully burn, the burning efficiency is improved, and the fuel is saved; the atomization quality of the fuel can be increased, so that the fuel fully burns, the emission of noxious gas is reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:丘濠玮 +2

Fuel additive and preparation method thereof

The invention discloses a fuel additive. The fuel additive is prepared from the following raw materials in parts by weight: 50 to 80 parts of tourmaline nanometer powder, 10 to 20 parts of alcohol, 30 to 50 parts of diisopropyl ether, 10 to 20 parts of biological oil, 5 to 10 parts of antioxidant, 5 to 10 parts of dispersant and 5 to 30 parts of water. The preparation method of the fuel additive comprises the step of uniformly mixing all of the raw materials at normal temperature and pressure. By using the fuel additive, the fuel quality can be improved, fuel is promoted to fully burn, the burning efficiency is improved, and the fuel is saved; the atomization quality of the fuel can be increased, so that the fuel fully burns, the emission of noxious gas is reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:丘濠玮

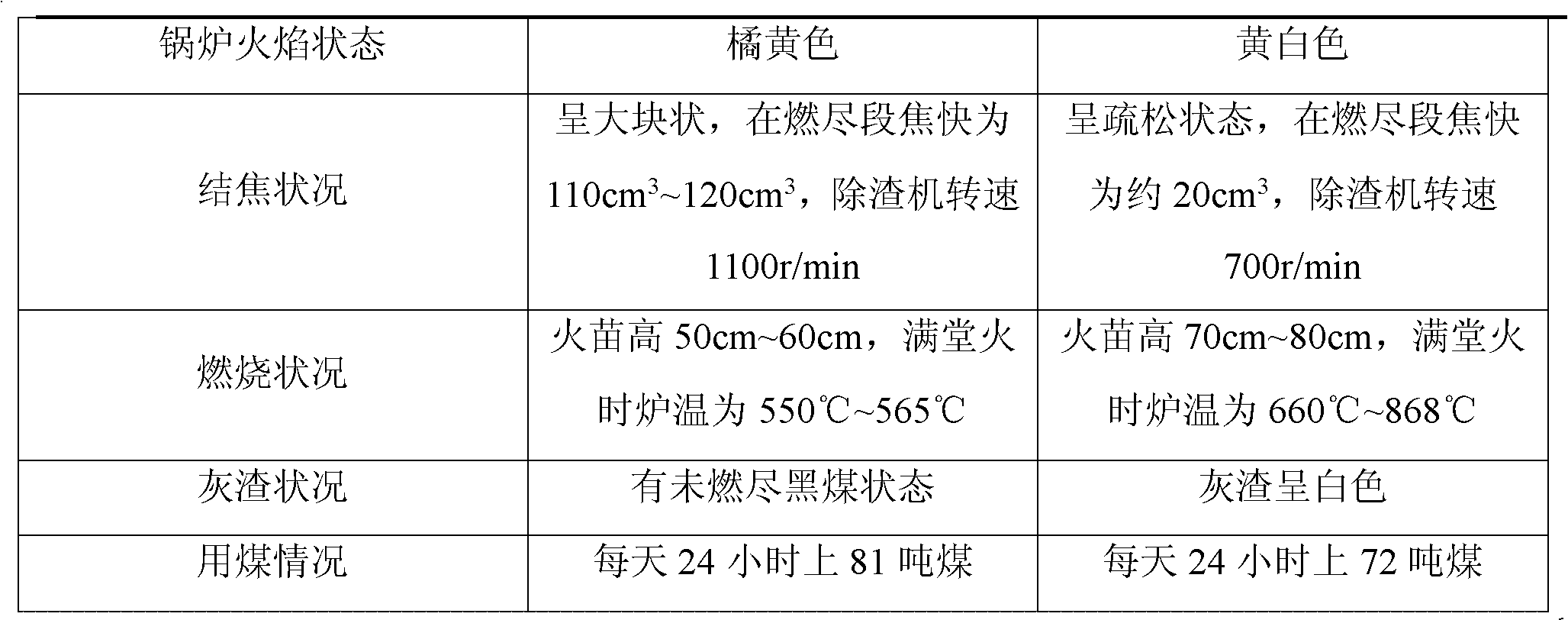

Phenol-ammonia coal gasification sewage treatment method

The invention relates to a phenol-ammonia coal gasification sewage treatment method, which comprises the four steps of single-tower alkali injection stripping deacidification and deamination, sedimentation filtration, extraction dephenolization and raffinate-phase solvent removal and flashing heat exchange. Phenol-ammonia coal gasification sewage is divided into cold flow and hot flow according to a proportion, the cold flow and the hot flow enter a stripping tower from the top and the middle upper part of the stripping tower respectively, and hot feedstock is the flow, directly heated by steam generated by flashing, of the sewage which is subjected to deamination and acidic gas removal and emitted from the bottom of the stripping tower; acidic gas is emitted from the top of the stripping tower, and a gas mixture is extracted from the side to obtain high-concentration ammonia by three-stage segregation; alkali is injected to a position blow the side to convert an ammonium salt into free ammonia for removal; stripping tower bottoms from which the ammonia and the acidic gas are removed are subjected to counter-current extraction with diisopropyl ether for dephenolization after being flashed and cooled, an extracting agent is recovered through a solvent recovery tower and a water stripping tower, and a crude phenol byproduct is also obtained. According to the method, the treated coal gasification sewage can reach a standard, and meanwhile, the sewage treatment energy consumption is lowered.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

Solvent type efficient compound cleaning detergent

InactiveCN105647695AImprove cleaning efficiencyWide range of cleaningNon-surface-active detergent solventsTetrachloroethyleneHalohydrocarbon

The invention discloses a solvent type efficient compound cleaning detergent. The solvent type efficient compound cleaning detergent comprises a halohydrocarbon solvent, alcohol solvents, ether solvents, ketone solvents, ester solvents, phenol solvents and water, wherein the halohydrocarbon solvent is tetrachloroethylene, the alcohol solvents are butanol, the ether solvents are diisopropyl ether, the ketone solvents are acetone, the ester solvents are methyl acetate, and the phenol solvents are phenol. The solvent type efficient compound cleaning detergent comprises the halohydrocarbon solvent, the alcohol solvents, the ether solvents, the ketone solvents, the ester solvents, the phenol solvents and the water and has the characteristics of high cleaning efficiency, wide cleaning range, low cost, good safety and good use effect.

Owner:SUZHOU LOTTE CHEM TECH

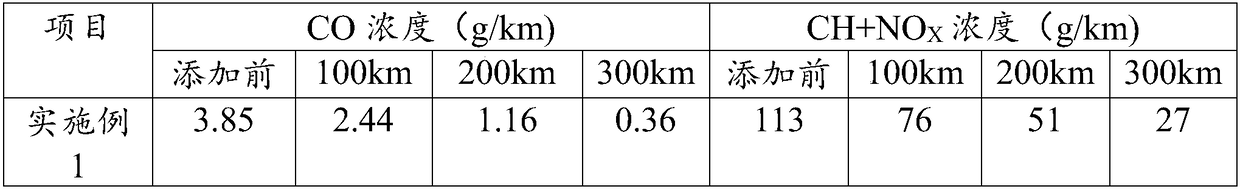

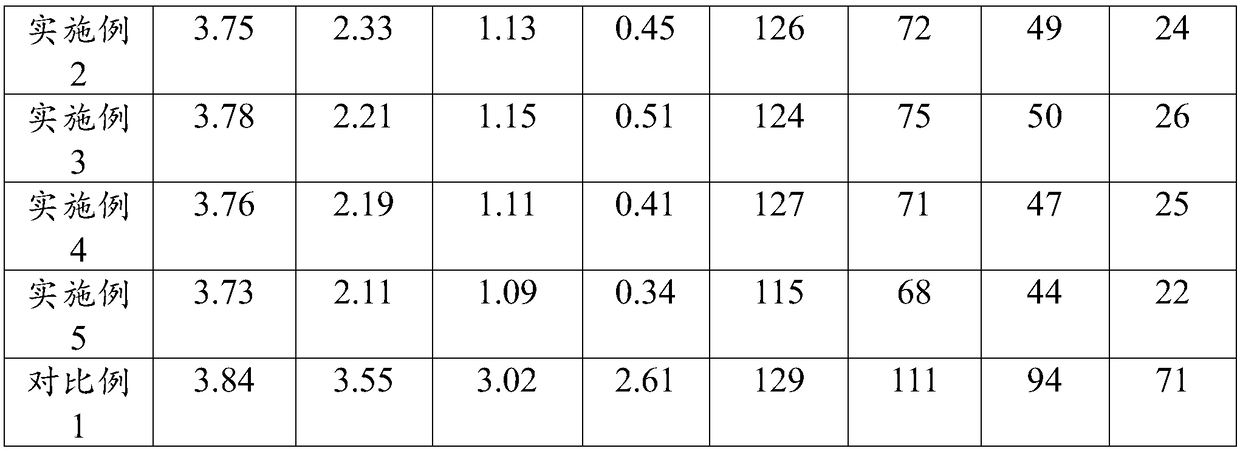

Energy-saving and combustion-supporting automotive tail gas gasoline detergent and preparation method thereof

InactiveCN108949260AGood miscibilityEasy to prepareLiquid carbonaceous fuelsFuel additivesLow speedCerium

The invention discloses an energy-saving and combustion-supporting automotive tail gas gasoline detergent and a preparation method thereof. The energy-saving and combustion-supporting automotive tailgas gasoline detergent is prepared from the following raw materials in parts by weight: 10 to 15 parts of methanol, 3 to 6 parts of ethyl acetate, 5 to 9 parts of cerium naphthenate, 2 to 10 parts ofpolyethylene polyamine, 8 to 15 parts of fatty alcohol, 6 to 16 parts of glycerol tristearate, 3 to 7 parts of isopropyl nitrate, 6 to 11 parts of diisopropyl ether, 2 to 5 parts of nano loaded type activated carbon, 7 to 23 parts of deionized water, 0.5 to 1 part of an antioxidant stabilizer, and 1 to 1.5 parts of N,N-dimethyl acetamide. The miscibility of the gasoline detergent and the gasolineis good, the preparation method is simple, stable combustion supporting can be achieved under the situation that a gasoline engine operates at low speed and low temperature or at high speed and high temperature, the power is improved, a baffled sense is avoided, the corrosivity is low, the loss is low for the engine, the adsorption degradation efficiency of sulfide, nitrogen oxide and inhalable particles produced by burning of gasoline is greatly improved, and the purity degree of the automotive tail gas is purified.

Owner:安徽绿色精灵新能源科技有限公司

Navigation alcohol fuel combustion-supporting additive for automobile and manufacturing method thereof

InactiveCN106701219AReduce accumulationExtend your lifeLiquid carbonaceous fuelsFuel additivesCerium nitrateAlcohol fuel

The invention discloses a navigation alcohol fuel combustion-supporting additive for an automobile, which solves the technical problems that an engine is hard to start, the oil consumption is great and exhaust gas emission is great as the existing methanol gasoline is hard to combust fully. The combustion-supporting additive comprises more than two reagents in the following components in parts by weight: 20-40 parts of mixed C4-C6 alcohol, 10-30 parts of ethyl formate, 10-30 parts of fatty acid, 0.5-2 parts of diisopropyl ether, 2-8 parts of tert-butyl methyl ether, 0.5-3 parts of cerium nitrate, 8-16 parts of a low-carbon solvent and 5-15 parts of mixed benzene. By adding the combustion-supporting additive disclosed by the invention, the defect in the prior art that methanol gasoline is hard to combust fully is overcome.

Owner:寇延华

Composite fuel oil additive

The invention relates to a composite fuel oil additive, which comprises the following raw materials according to weight part: 45 parts of diisopropyl ether, 30 parts of ethanol, 5 parts of naphthenic acid, 5 parts of arylamine and 15 parts of isobutene. According to the invention, the fuel oil additive is added in a fuel tank before oiling, then fuel oil is added, and the addition proportion is 2%. The composite fuel oil additive has the advantages of easily available raw materials, simple process and reasonable ratio, each physical and chemical index and usage performance of the gasoline can be greatly increased, lead free gasoline can be fully combusted, and environmental protection standard can be reached.

Owner:XIAN RUNDA CHEM TECH

Method and device for separating aqueous solution of isopropanol and diisopropyl ether

ActiveCN110028385AHigh purityReduce energy consumptionEther separation/purificationOrganic compound preparationReboilerHigh pressure

The invention discloses a method and device for separating an aqueous solution of isopropanol and diisopropyl ether. The separation method integrates heterogeneous azeotropic rectification technologyand variable-pressure rectification technology, partition tower technology and heat pump technology, and comprises the following steps: adding a raw water solution into an auxiliary tower T1, discharging water from the bottom of the secondary tower, condensing tower top steam and conducting layering, enabling all water phases and part of organic phases to be used for T1 backflow, and enabling remaining organic phases to enter T2, and enabling the tower top steam to be used for a heat pump process; and returning steam at the top of T2 to a main tower T1, and extracting isopropanol and diisopropyl ether products from the bottoms of T1 and T2. The device suitable for the method comprises a partition tower T1, a high-pressure stripping tower T2, a compressor C1, a decanter D1, a condenser E1 and reboilers E2, E3 and E4, wherein the E1, the E2, the E3 and the E4 are respectively connected to the top of the T1, the bottom of the auxiliary tower T1, the bottom of the T2 and the bottom of themain tower T1, the C1 is used for compressing part of steam at the top of the T1, and the D1 is connected behind the C1. The method and device solve the separation problem of a multi-azeotrope complexsystem, and have the advantages of high efficiency, energy saving, high product purity and high recovery rate.

Owner:SHANDONG UNIV OF SCI & TECH

Methanol gasoline and preparation method

The present invention relates to a kind of methanol gasoline and its preparation method. Isopropyl ether, benzene or toluene or xylene, iron naphthenate or iron pentacarbonyl, silicon aluminum phosphate or sodium dihydrogen phosphate, RP97 composite detergent and dispersant, carboxylate or sulfonate, silicon-type molecular sieve. The preparation must be carried out under normal temperature, normal pressure, non-spark, fireproof and explosion-proof environment. The steps are as follows: add isobutanol or isopropanol to benzene or toluene or xylene, and then add diisopropyl alcohol together Synthesize co-solution A in ether; add gasoline or light hydrocarbon or straight-run oil into methanol, and mix to form main solution B; mix and stir solution A and solution B to form solution C; then add other additives in turn, and stir evenly; Just filter. It has the advantages of low cost, high octane number, good stability, storage period of more than one year, and environmental protection. The preparation process is simple, and products of various labels can be prepared.

Owner:万清平

Mobile phone film with wear resistance

The invention provides a mobile phone film with wear resistance. The mobile phone film is prepared from the following raw materials by weight: 10 to 20 parts of unsaturated polyester resin, 0.4 to 0.7 part of a cross-linking agent, 5 to 8 parts of a filling material, 2 to 3 parts of a barium-zinc composite stabilizing agent, 0.4 to 0.8 part of an anti-oxidant CB, 5 to 8 parts of (tert-butylperoxyisopropyl)benzene, 4 to 10 parts of diisopropyl ether, 6 to 9 parts of micron-order SiO2 powder, 2 to 4 parts of an anti-ultraviolet agent, 5 to 9 parts of trimethylol propane, 7 to 12 parts of acrylic acid ester copolymer, 2 to 4 parts of an antifoaming agent, 5 to 7 parts of polyvinyl chloride, 2 to 3 parts of liquid paraffin, 4 to 8 parts of epoxy resin, 2 to 4 parts of a catalyst and 3 to 4 parts of a chain extender. The invention has the following beneficial effects: the mobile phone film with wear resistance can effectively prevent scratches, has good toughness and wear resistance, effectively protects a mobile phone and is low in manufacturing cost.

Owner:QINGDAO KELIKE INFORMATION TECH

Impact-resistant packaging film

InactiveCN104371164AImprove toughnessFlexible coversWrappersPolyethylene terephthalate glycolPolyvinyl chloride

The invention relates to an impact-resistant packaging film which is prepared from the following raw materials in parts by weight: 8-14 parts of calcium carbonate, 6-10 parts of tert-butyl peroxy cumene, 5-9 parts of polypropylene, 2-6 parts of PVC (polyvinyl chloride), 8-13 parts of dibutyl phthalate, 5-7 parts of ethylene-vinyl acetate resin, 6-11 parts of diisopropyl ether, 4-7 parts of polyethylene terephthalate, 1-5 parts of anti-ultraviolet agent, 5-8 parts of calcium nitrate, 3-6 parts of calcium chloride, 5-10 parts of micron-sized SiO2 powder, 3-5 parts of ethylene glycol and 14-20 parts of polyethylene resin. The impact-resistant packaging film has favorable toughness, can resist impact, and is simple and practical.

Owner:QINGDAO KELIKE INFORMATION TECH

Environmental protection energy-saving industrial fuel gas synergist and method for preparing same

InactiveCN1594511AHigh calorific valueIncrease profitGaseous fuelsLiquid carbonaceous fuelsAlkadieneFerrocene

The invention relates to a gas synergist, in particular an environmental protection energy-saving industrial fuel gas synergist and method for preparing same, wherein the synergist comprises (by weight proportion) diisopropyl ether 10-30 parts, ferrocene 1-5 parts, bicyclo ring alkadiene 1-7 parts.

Owner:SHENYANG JITAIER OLEFIN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com