Combustion-supporting decoking coal saving agent

A coal-saving agent and descaling agent technology, which is applied in the field of coal-saving agents, can solve the problems of high coal cost and large coking, and achieve significant economic benefits, reduce the labor intensity of slag removal, and reduce the cost of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

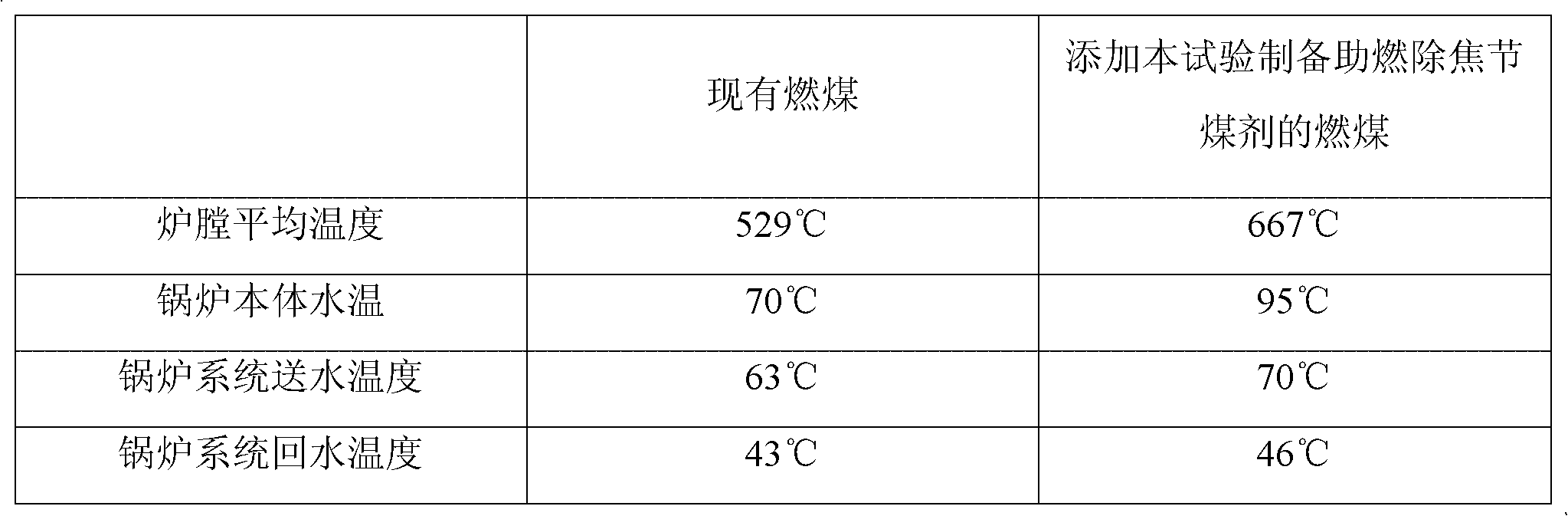

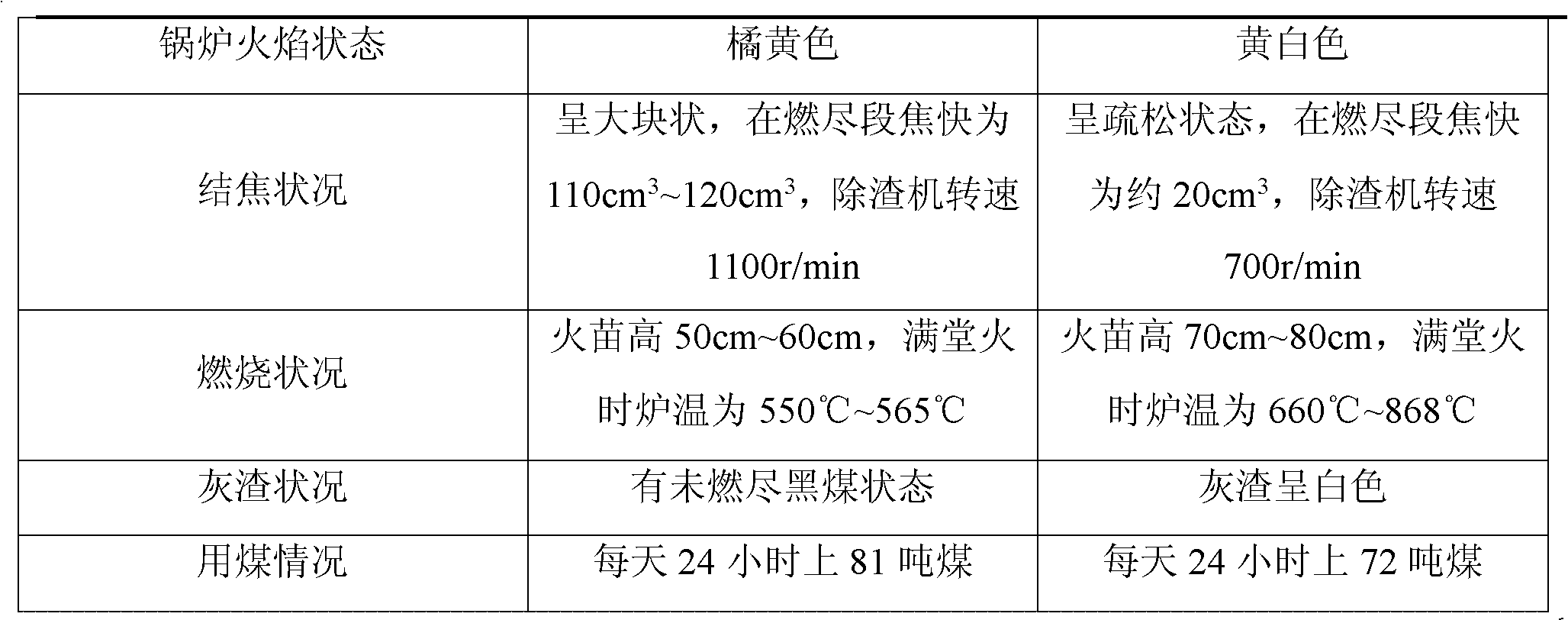

Examples

specific Embodiment approach 1

[0011] Specific embodiment one: this embodiment is a kind of combustion-supporting coke-removing coal-saving agent, by weight fraction by 4~10 parts of potassium permanganate, 2~6 parts of sodium chloride, 10~12 parts of dimethylmethanol-ethanol, 6 to 8 parts of rare earth lanthanum, 3 to 5 parts of dispersant, 4 to 6 parts of calcium chloride, 1 to 2 parts of high aluminum vanadium, 5 to 6 parts of alkene-xylene acrylic acid copolymer, 3 to 4 parts of methyl Isobutyl ketone, 5-8 parts of potassium peroxide, 6-8 parts of polyoxyethylene sorbitan monostearate, 4-6 parts of sulfur-fixing agent, 5-10 parts of Tween-60, 2-3 parts It is prepared by mixing tributyl phosphate, 8-15 parts of diisopropyl ether, 3-4 parts of descaling agent and 5-8 parts of penetrating agent.

[0012] The method of using the combustion-supporting coke-removing coal-saving agent prepared in this embodiment: add the combustion-supporting coke-removing coal-saving agent prepared in this embodiment to the c...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the dispersant is polyethylene glycol 400. The other specific embodiments are the same.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the sulfur-fixing agent is CaO. Other specific implementation modes 1 or 2 are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com