Patents

Literature

455results about How to "No polluting emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure-reducing and injection-increasing agent for water injection well of low-permeability oilfield, and preparation method and application thereof

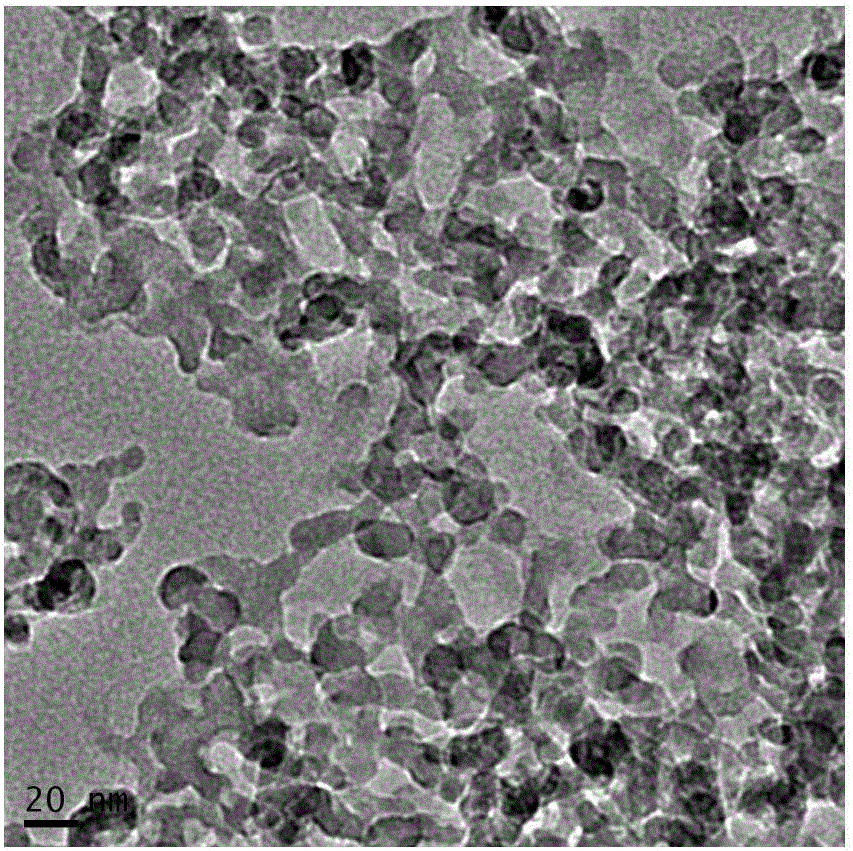

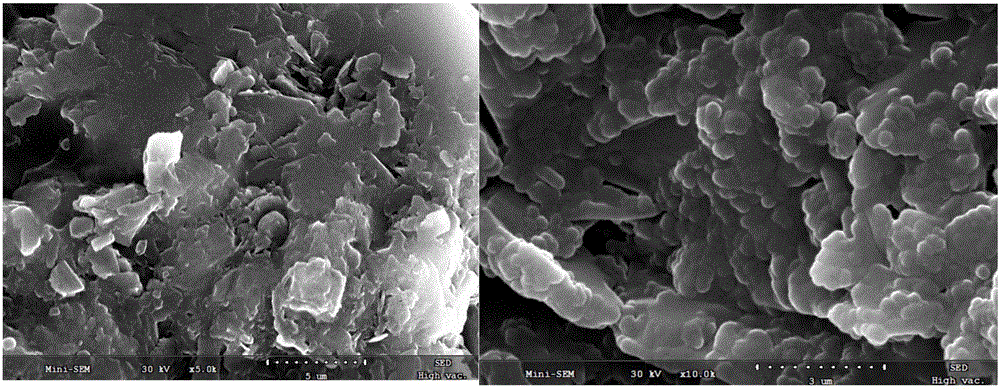

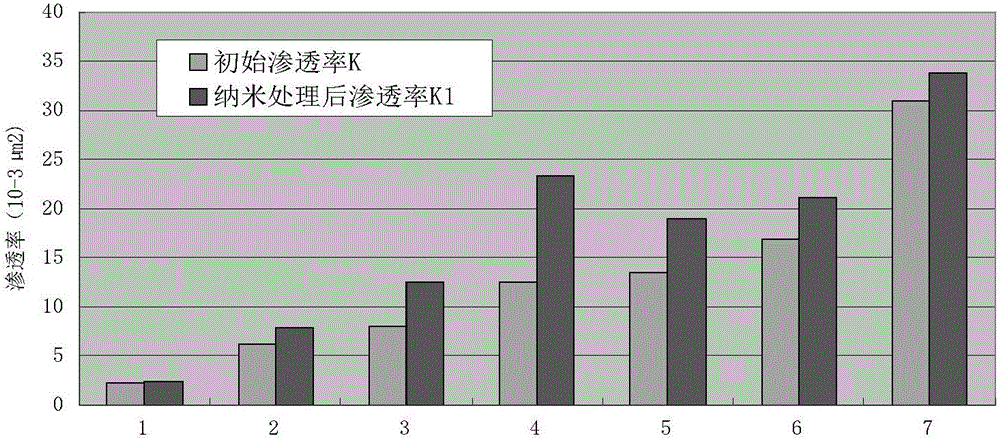

InactiveCN106085401ALarge specific surface areaReduce thicknessFluid removalDrilling compositionNanometreChemistry

The invention relates to a pressure-reducing and injection-increasing agent for a water injection well of a low-permeability oilfield, and a preparation method and application thereof. The pressure-reducing and injection-increasing agent is prepared from the following components by weight: 2.0 to 6.5% of a multifunctional surface treating agent, 0.75 to 3.15% of hydrophobic nanometer silica or nanometer poly-silicon and 2 to 8% of a pH conditioning agent, with the balance being deionized water, wherein the multifunctional surface treating agent comprises, by weight, 30 to 80% of a nonionic surfactant, 2 to 25% of an anionic surfactant and 10 to 50% of an ampholytic surfactant. The pressure-reducing and injection-increasing agent is free of pollution to strata and can overcome the problems of high water injection pressure, unqualified injection allocation of a water injection rate and a short action period of injection increase in the later stage of development. The preparation method is simple in process, free of emission of pollutants and easy for industrial large-scale production.

Owner:郑州东申石化科技有限公司

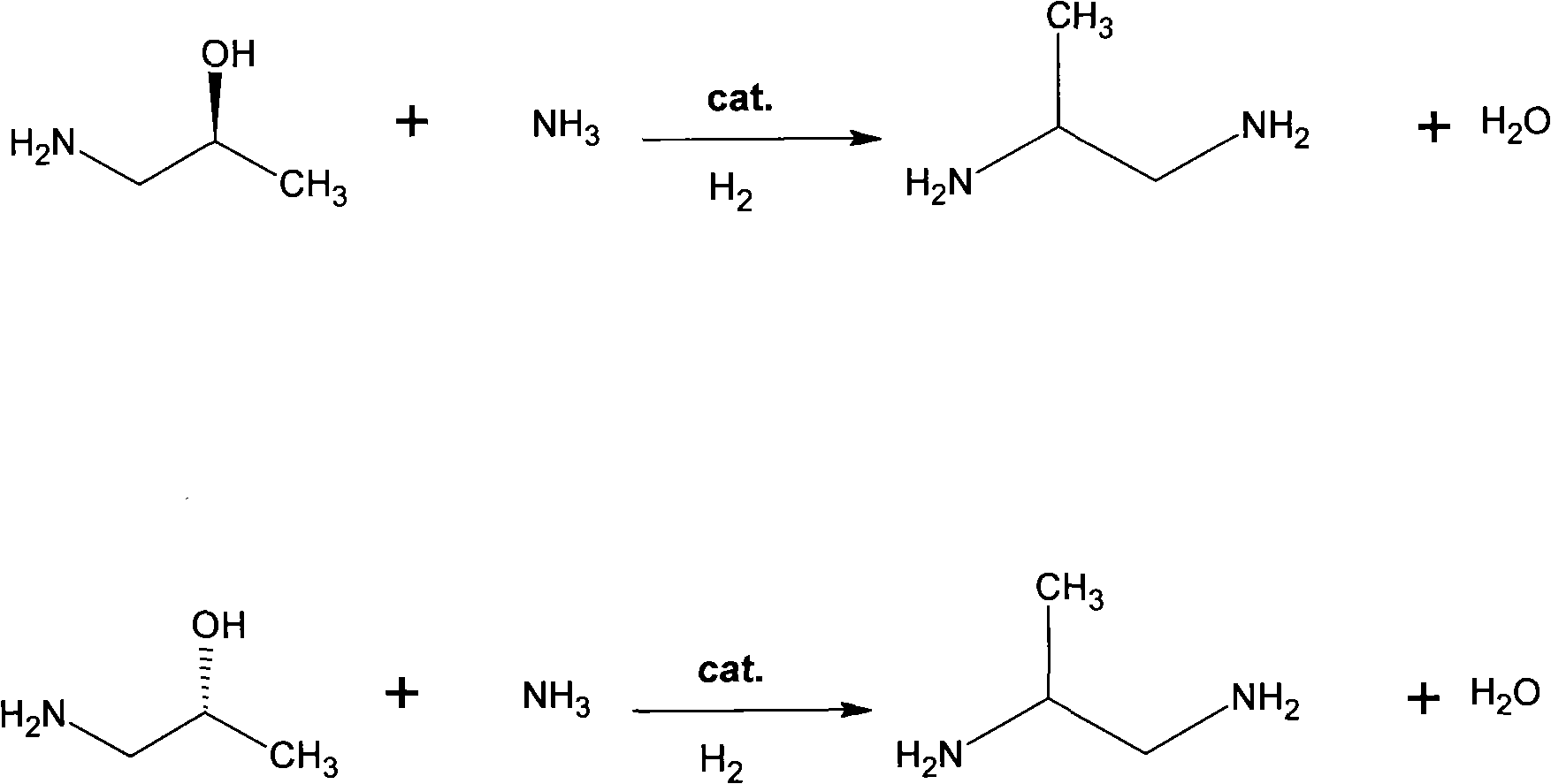

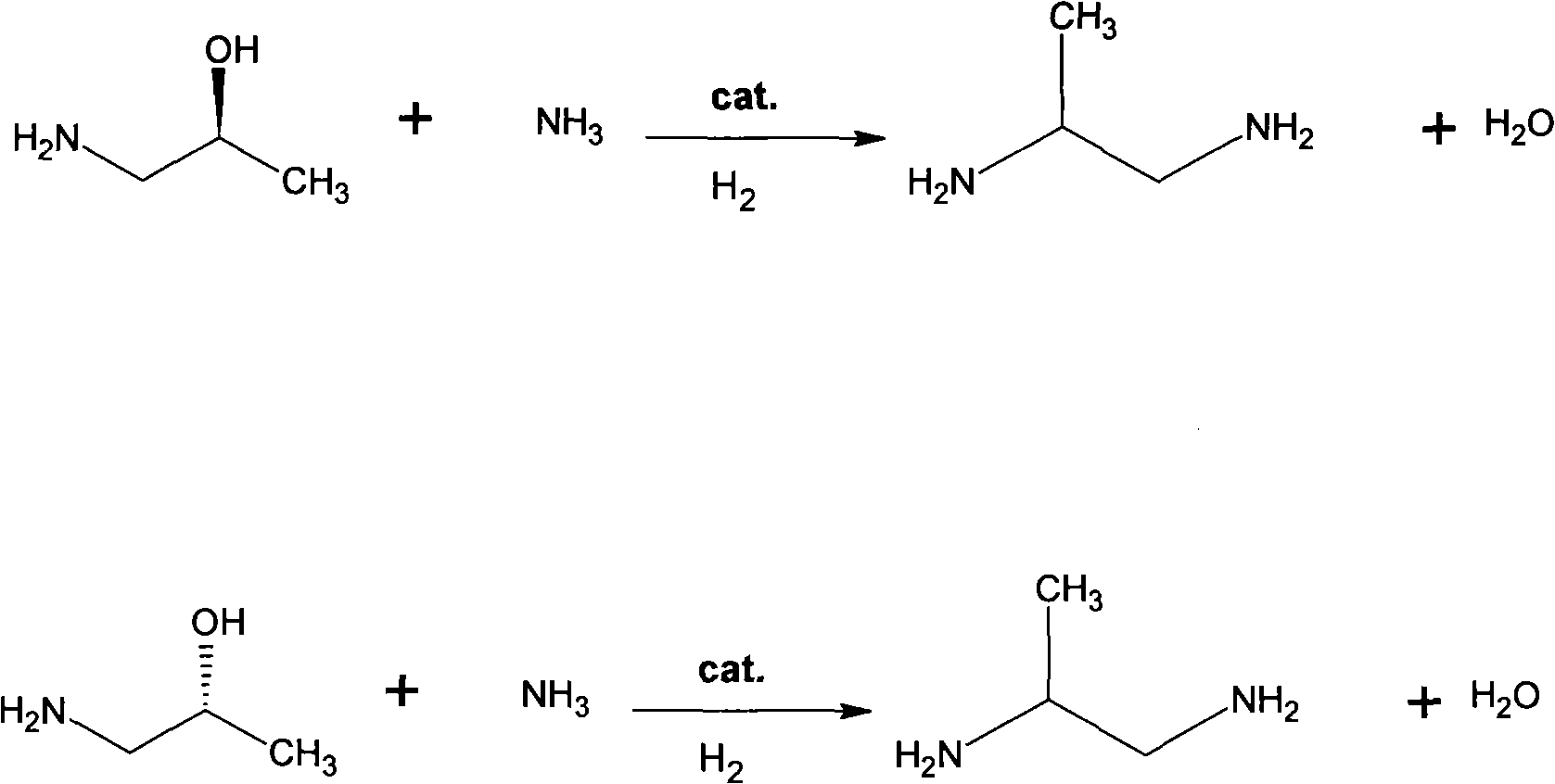

Preparation method of 1,2-propane diamine

InactiveCN101891628AThe process steps are simpleNo polluting emissionsOrganic compound preparationAmino compound preparationChemical synthesisHydrogen

The invention discloses a preparation method of 1,2-propane diamine, belonging to the technical field of chemical synthesis. The preparation method mainly comprises the following steps: adding monoisopropanolamine, water, ammonia, hydrogen and catalyst into a high-pressure reaction kettle, stirring at a high speed, performing the catalytic amination at 100-250 DEG C under a pressure of 5-15 MPa to obtain a mixture using 1,2-propane diamine as the main component, and finally rectifying to obtain 1,2-propane diamine, wherein the selectivity of the product is greater than 80%, and the purity of the product is greater than 99%. The method has the advantages of safety, environmental protection, simple operation, high conversion rate, low energy consumption, low raw material consumption and lowproduction cost.

Owner:张家港市大伟助剂有限公司

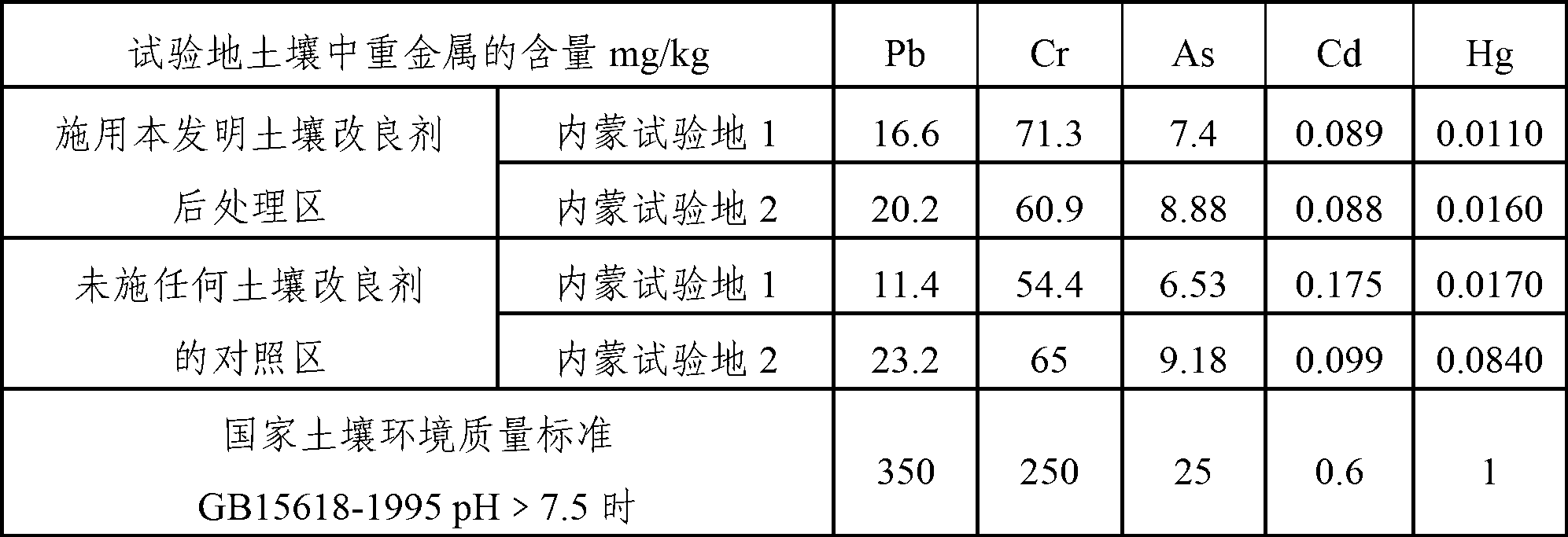

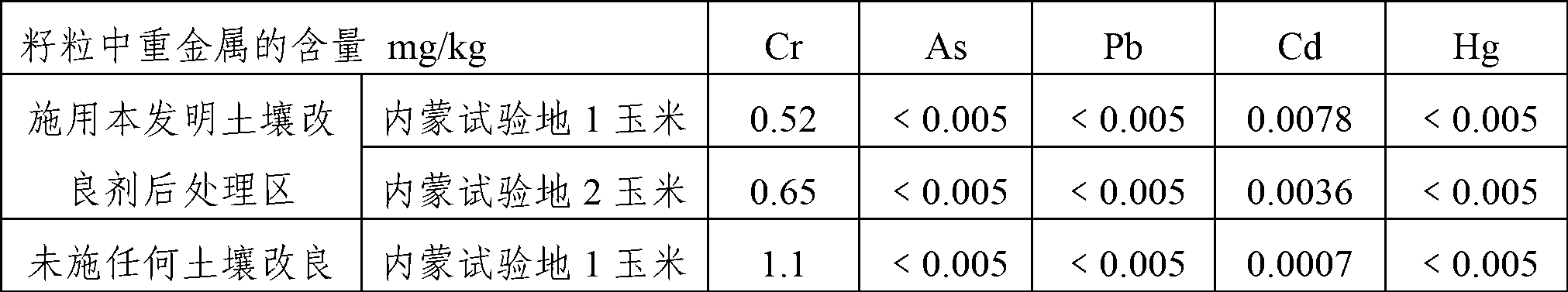

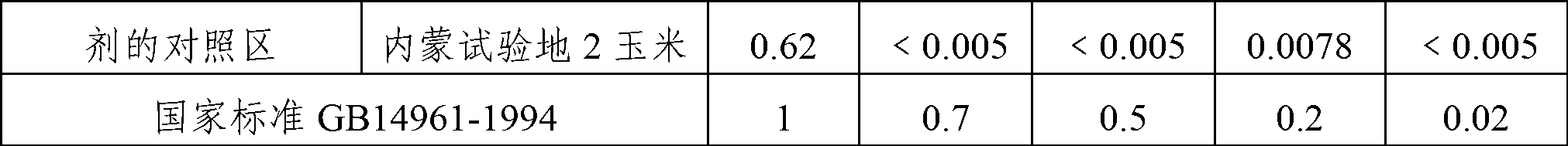

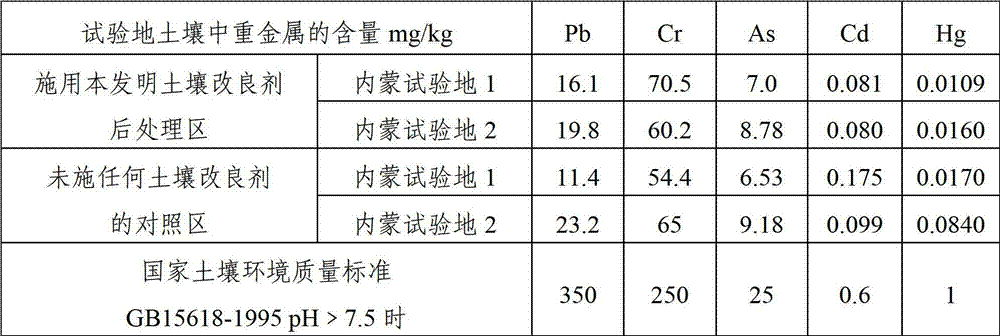

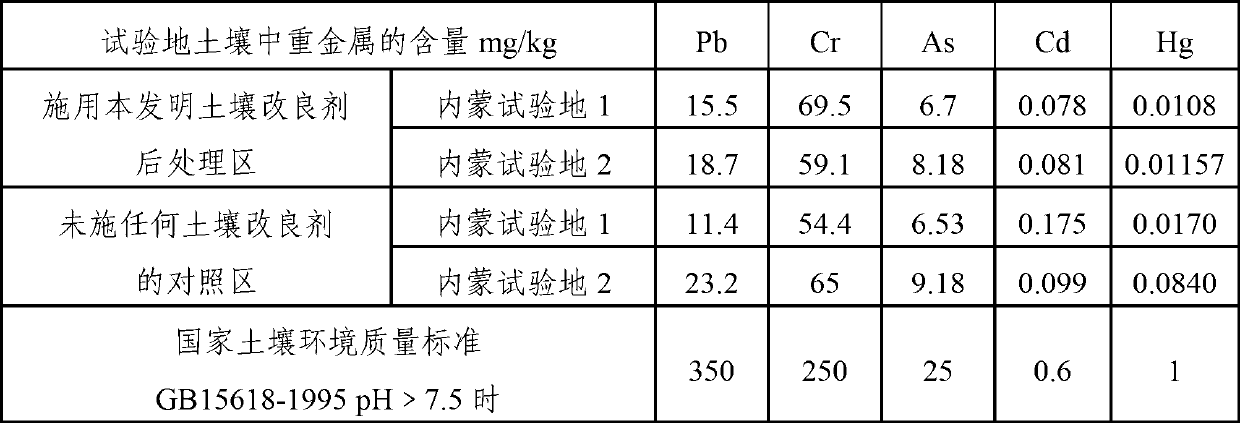

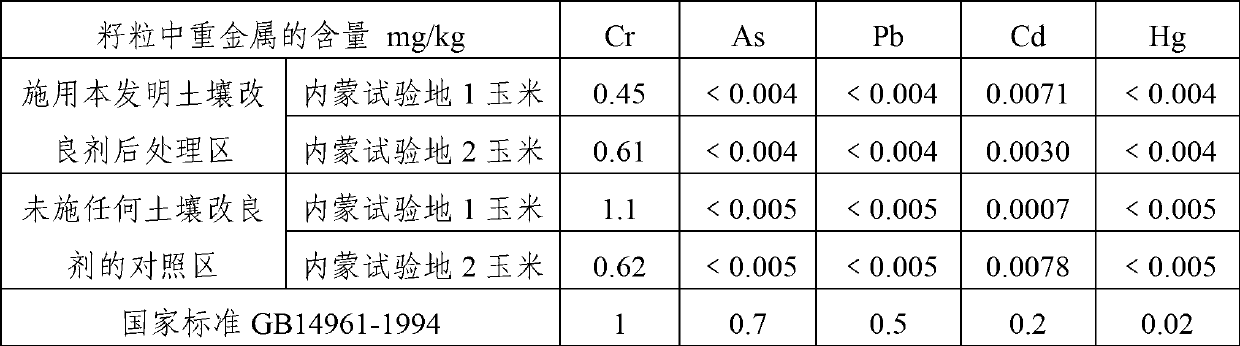

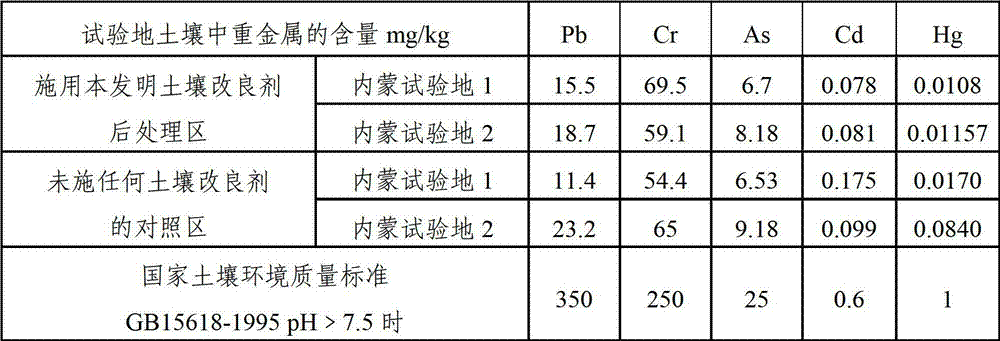

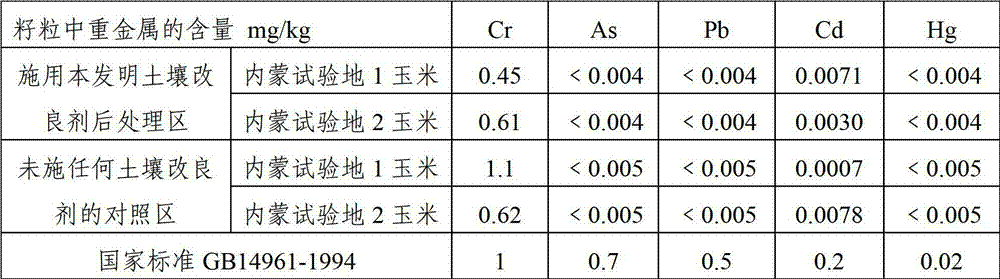

Soil improvement agent and processing method thereof

InactiveCN103013529AReduce alkalinityReduce physical propertiesAgriculture tools and machinesOther chemical processesPlant growthBiology

The invention relates to a soil improvement agent and a processing method thereof. The soil improvement agent comprises the following raw materials in parts by weight: 60-95 parts of desulfurized waste, 0.5-2.0 parts of inorganic accelerator, and 0.5-30 parts of organic accelerator. The soil improvement agent provided by the invention has the beneficial effects that calcium ions in the desulfurized waste are used to replace exchangeable sodium on the soil colloid, thus reducing the alkalization degree of the soil; at the same time, the excellent pore structure and physical property of the organic accelerator are used to improve the physical property of the soil and the granular structure of the soil, reduce the pH value of the soil, and improve the soil fertility; the inorganic accelerator can also improve the granular structure of the soil; in addition, with auxiliary inorganic fertilizer and organic fertilizer, the soil fertility of the soil can be further improved so as to provide nutrient contents for plant growth. To sum up, by adopting the scheme in the invention, unbalance of nutritive elements in the soil can be effectively overcome, the land capability is improved, the soil is loosened, and the fertilizer efficiency is increased, so that the soil salinization phenomenon is fundamentally harnessed step by step.

Owner:TSINGHUA UNIV

Biological compound fertilizer and production process thereof

InactiveCN101555173ASolve watering and irrigation problemsLow input costBio-organic fraction processingWaste based fuelContinuous croppingChemical reaction

The invention relates to a biological compound fertilizer and a production process thereof, which relates to the field of agricultural fertilizers and the production thereof. The prior biological bacterial fertilizer has the problems of not comprehensive enough nutrition, poorer water retention and drought-resistant degree and lower survival rate of biological bacteria. The invention provides a prescription that the biological compound fertilizer contains liquid-fertilizer sustained release agent with micropores, compound biological fertilizer, high-efficient organic matters, inorganic N P, K and micro elements in the lack of soil; and the production process adopts a method of roller- extrusion cold prilling and has no drying and air-cooling procedures and no any chemical actions. The invention has the advantages of more comprehensive nutrition, water retention, drought and continuous cropping resistance, the improvement of the survival rate and the reproduction rate of biological bacteria and balanced crop growth.

Owner:NANYANG BOLIDA FERTILIZER

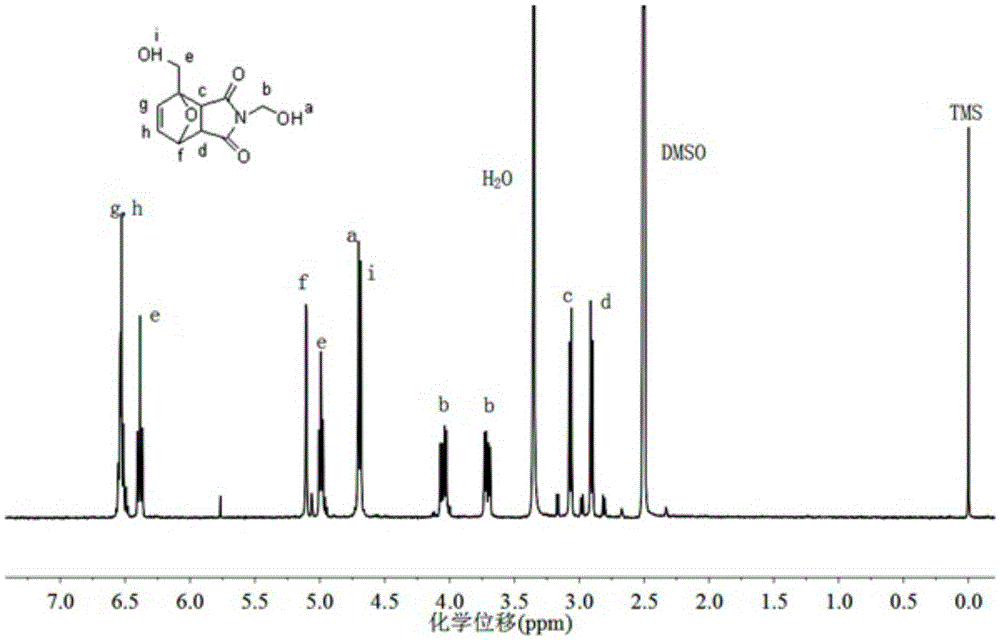

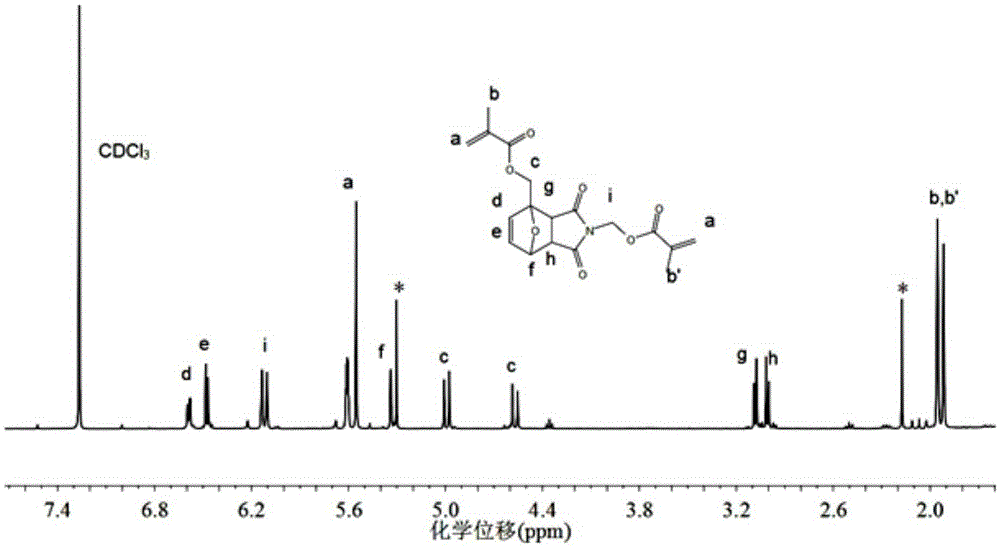

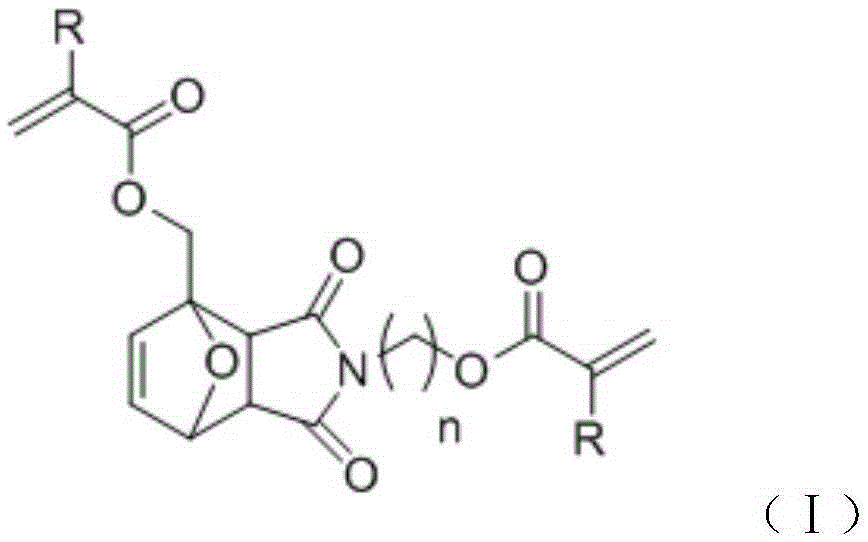

Bi-functionality-degree acrylic ester cross-linking agent and application thereof to 3D printing

The invention relates to the field of high molecular materials for photocuring 3D printing fast forming equipment and aims to provide a bi-functionality-degree acrylic ester cross-linking agent and application thereof to 3D printing. According to the preparation steps, under protection of nitrogen, furfuryl alcohol, N-hydroxyalkyl maleimide and solvent react, and suction filtration, washing and vacuum drying are carried out on the reaction product to obtain a dihydroxy-terminated Diels-Alder addition product; the addition product is dissolved into the solvent, a pyridine catalyst and acid anhydride are added, the mixture reacts, methyl alcohol is added, the mixture continues to react, methylene chloride is used for dissolving the product, and organic phases are collected to obtain a final product. The initial raw materials are wide in source, the preparation process and purification are simple, and the cross-linking agent is suitable for industrial production process; the product has universality, and the prepared vinyl polymer has excellent mechanical performance and solvent resistant performance of a thermosetting material at normal temperature, and has a recovery processing characteristic of thermoplastic at high temperature; use performance of the product is met, and the application is important breakthrough of the 3D printing material equipment technology.

Owner:殷若瑜

Process for hot immersion plating iron and steel with aluminium-zinc alloy

InactiveCN1392284ANo polluting emissionsImprove working conditionsHot-dipping/immersion processesRare earthZinc alloys

The present invention belongs to the field of hot immersion plating of iron and steel with aluminium-zinc alloy. The iron and steel after being pretreated with inactivation solution, compounded by using CrO3 0.2-5 wt%, K2MnO4 0.05-3 wt%, NaNO2 0.05-6 wt% and water, is hot immersion plated with aluminium-zinc alloy plating liquid with small amount of antioxidant alloy. The antioxidant alloy consists of Al 70-80 wt%, mixed RE 4-10 wt%, Si 8-10 wt%, Ni 3-5 wt%. The technological process can obtain high-quality smooth and bright coating without leakage, false plating, pinhole, color difference and other defects, and has low cost, simple operation and no drainage pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of phosphorus removal in high-phosphate-content industrial wastewater and phosphorus resource recovery of high-phosphate-content industrial wastewater

InactiveCN106477772ANo polluting emissionsRealize environmental protectionWater treatment compoundsTreatment involving filtrationHigh phosphatePhosphate ion

This invention provides a method of phosphorus removal in high-phosphate-content industrial wastewater and phosphorus resource recovery of high-phosphate-content industrial wastewater, solves the problems of phosphorus removal in industrial wastewater, domestic sewage and other types of sewage and phosphorus resource recovery, and is particularly applicable to the field of the high-phosphate-content industrial wastewater. The method comprises the following steps: uniformly mixing 0 to 0.5 part of inorganic electrolyte, 0 to 2.5 parts of a water-soluble high-molecular polymer, 5 to 10 parts of calcium hydroxide (or calcium oxide) and 87 to 95 parts of soluble calcium salt in percentage by weight to obtain an inorganic-organic composite phosphorus removal chemical reagent; and adjusting the PH value of the wastewater with acid and alkali, oxidizing non-orthophosphate ions in the wastewater with an oxidant to adjust the acidity of the wastewater, and adding the inorganic-organic composite phosphorus removal chemical reagent to precipitate the phosphorus in the wastewater. The total amount of phosphorus in the wastewater is reduced from about 15500 mg / L to 5 mg / L or below. The main component of a filter cake is hydroxyl calcium phosphate, and the phosphorus content reaches 15 percent or above; and the filter cake can be used for preparing phosphoric acid or phosphate fertilizer.

Owner:武汉青江化工黄冈有限公司

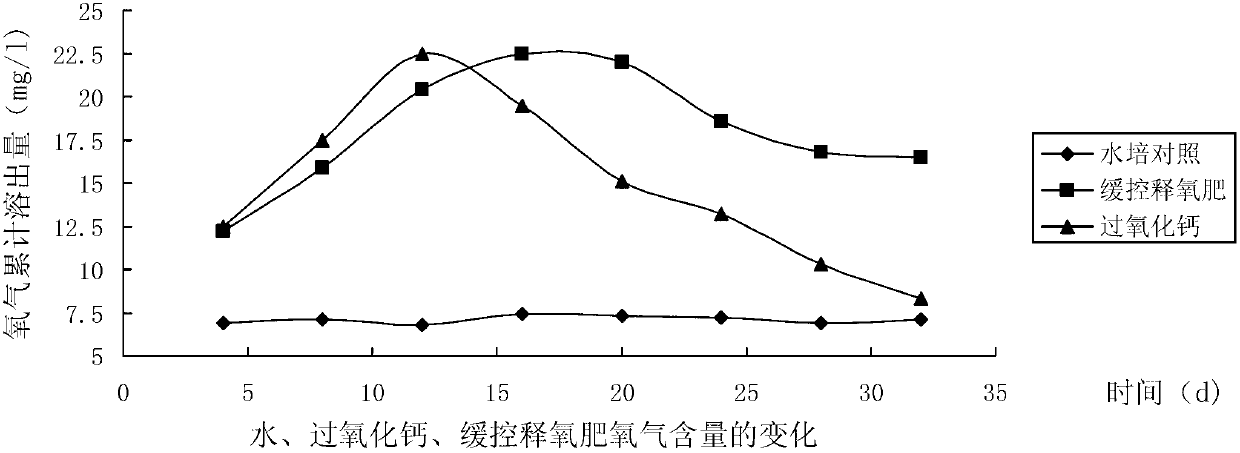

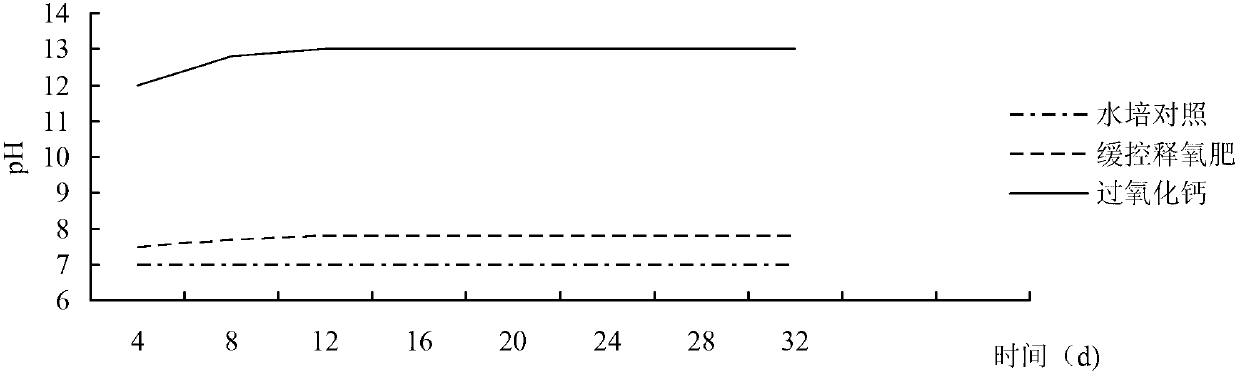

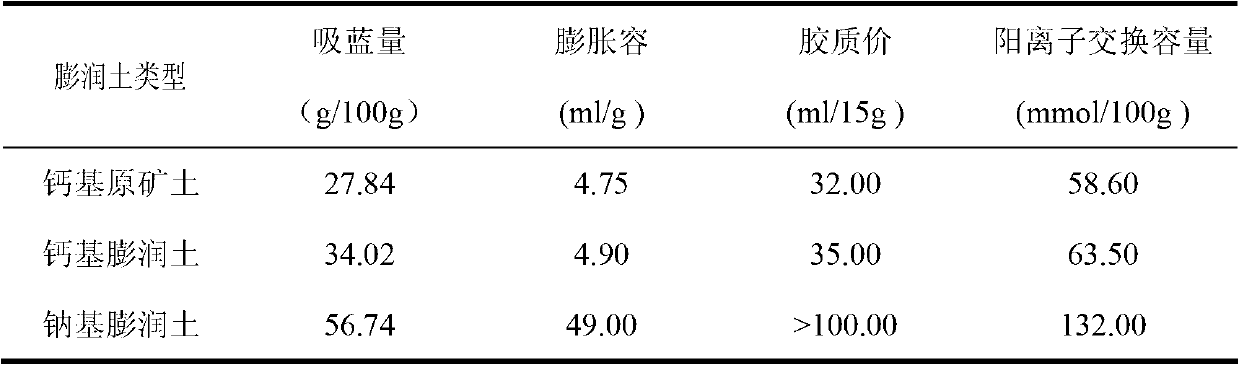

Sustained oxygen release fertilizer and preparation method thereof

InactiveCN102924176AMaintain physiological metabolismMaintain normal growth and developmentFertilizer mixturesPolyvinyl alcoholSuperoxide

The invention discloses a sustained oxygen release fertilizer which adopts a mixture comprising calcium superoxide, sodium bentonite and polyvinyl formal. The mass ratio of sodium bentonite to calcium superoxide is 12 to 5, and the mass of the polyvinyl formal is 15 percent of the gross mass of the sustained oxygen release. The sustained oxygen release fertilizer discusses the oxygen release feature and the pH value variation in the condition of aqueous medium. Experimental results show that compared with applying calcium superoxide powder only, the sustained oxygen release fertilizer has the characteristics that the fertilizer effect period is long, the applying method is simple, the production technology is simple, the source of material selected is wide, the material is environmentally friendly, and the sustained oxygen release fertilizer can be widely applied.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

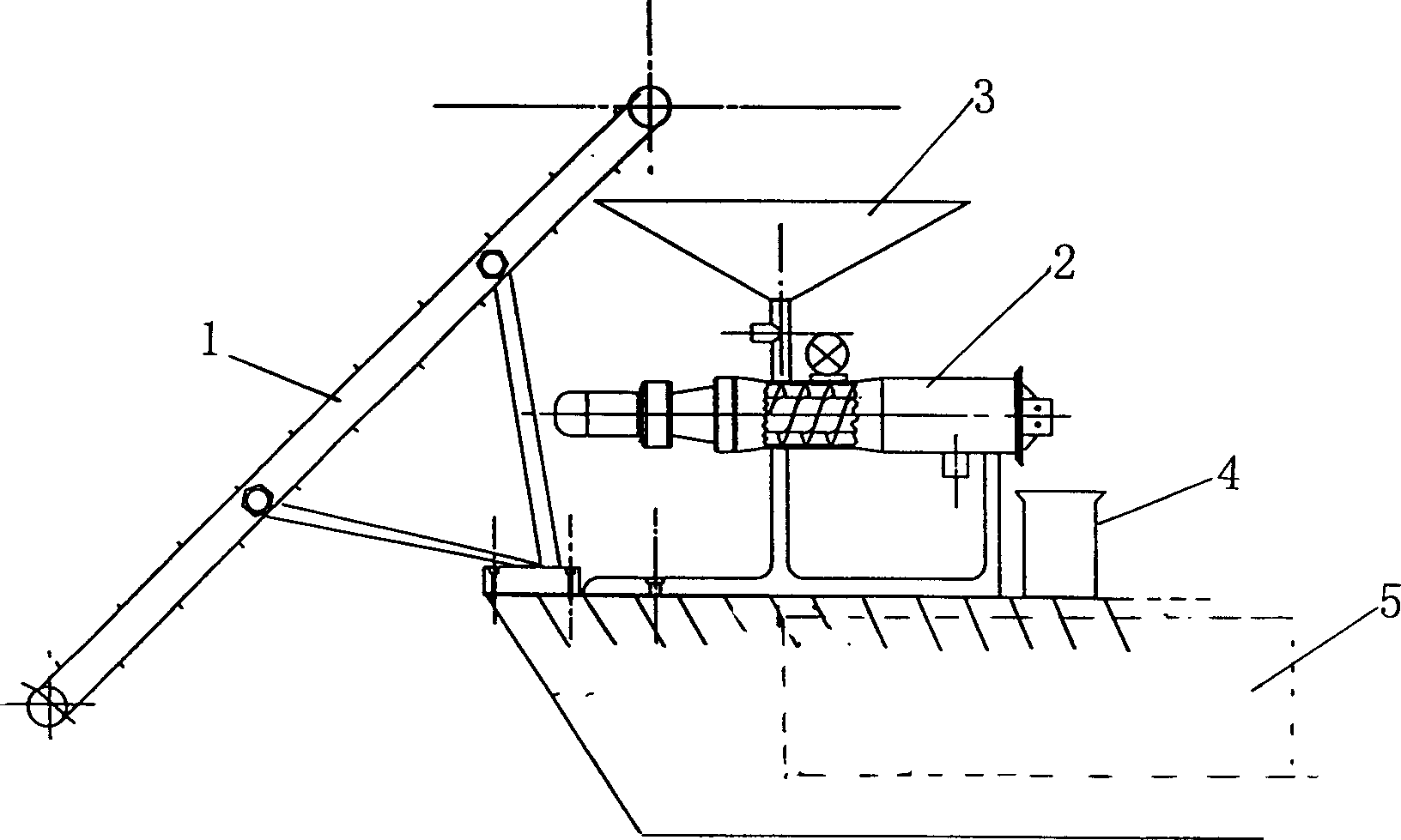

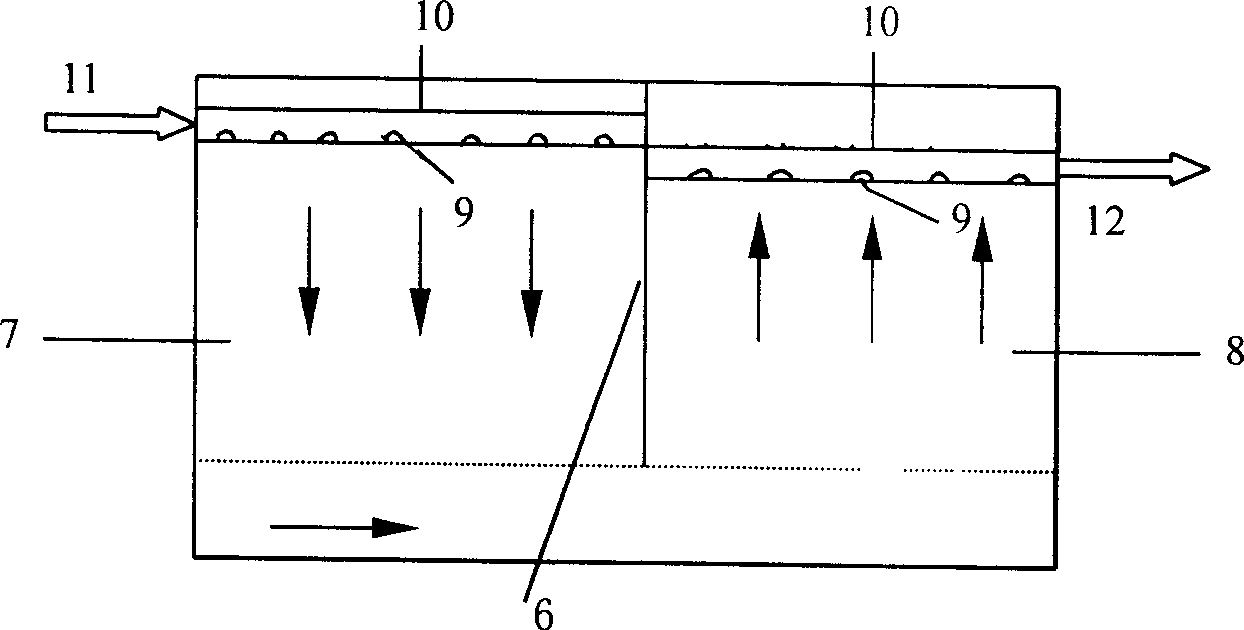

Movable water hyacinth treater on water surface

InactiveCN1439775ASimple structureEasy maintenanceWater cleaningWaterborne vesselsEnvironmental engineeringWater Hyacinths

A water hyacinth treating apparatus moving on water surface is composed of ship and the apparatus installed in ship, which consists of salvage mechanism, squeezing-dewatering unit, and water cleaning pool. Said water cleaning pool is divided into water inlet pool and water outlet pool. The sand, perforated water pipes and deep-root plants are arranged in both pools for cleaning the juice if water hyacinth. Its advantages are simple structure, saving labour, high effect and no pollution.

Owner:ZHEJIANG UNIV

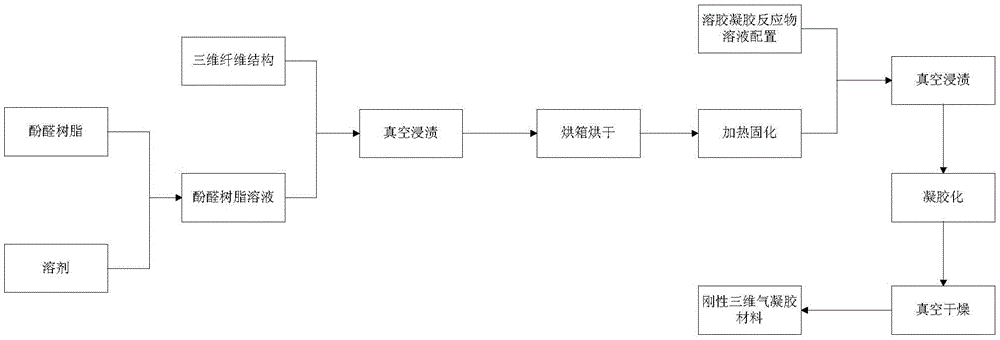

Preparation method of rigid structure reinforced phenolic aerogel heat shielding material

ActiveCN105601854ASolve problems that are difficult for large-scale engineering applicationsStrong dimensional stabilityEngineeringSolvent

The invention relates to a preparation method of a rigid structure reinforced phenolic aerogel heat shielding material. The method includes: firstly dissolving phenolic resin in a solvent in a vacuum impregnation container to form a phenolic solution, then pressing a three-dimensional fiber structure into the phenolic resin solution, and conducting vacuum pumping on the vacuum impregnation container, after a period of time, opening a seal cover to maintain smooth air pressure with the outside and conducting standing for a period of time, then taking out the three-dimensional fiber structure and putting it into an oven to perform drying, and conducting high temperature curing to form a rigid three-dimensional fiber structure, then mixing resorcinol, furfural, ethanol and sodium hydroxide uniformly in proportion in the vacuum impregnation container to form a reactant solution, then pressing the rigid three-dimensional fiber structure into the solution, conducting vacuum pumping on the vacuum impregnation container again, maintaining the state for a period of time, then placing the vacuum impregnation container into the oven to carry out sol-gel process, and finally taking out the gel-containing three-dimensional fiber structure and performing drying, thus obtaining the rigid structure reinforced phenolic aerogel product.

Owner:BEIJING SATELLITE MFG FACTORY

Aquaculture water purifying agent

InactiveCN103508553AImprove biodegradation effectImprove securityWater/sewage treatment by flocculation/precipitationBiological water/sewage treatmentCelluloseWater quality

The invention relates to a water purifying agent, in particular to a water purifying agent for purifying an aquaculture water environment. The water purifying agent comprises the following components in parts by mass: 12 to 15 parts of poly dimethyl diallyl ammonium chloride, 25 to 40 parts of a microbial flocculant, 5 to 8 parts of an aquaculture oxygen supply agent, 9 to 12 parts of a biological enzyme and 7 to 10 parts of cellulose. After the formula is adopted, the microbial flocculant has the characteristics of biodegradability, safety, high efficiency, no toxicity and no secondary pollution, and overcomes the defects of inorganic polymer and synthetic organic polymer flocculants, and finally non-pollution discharge is realized. The poly dimethyl diallyl ammonium chloride is used as the organic water purifying agent and has the characteristics of small use amount, strong flocculation capacity, high efficiency and the like. The oxygen supply agent can rapidly and effectively increase dissolved oxygen in water, improves water quality, adsorbs and degrades organisms in the water and also can effectively sterilize the water.

Owner:丹阳市现代生态水产养殖场

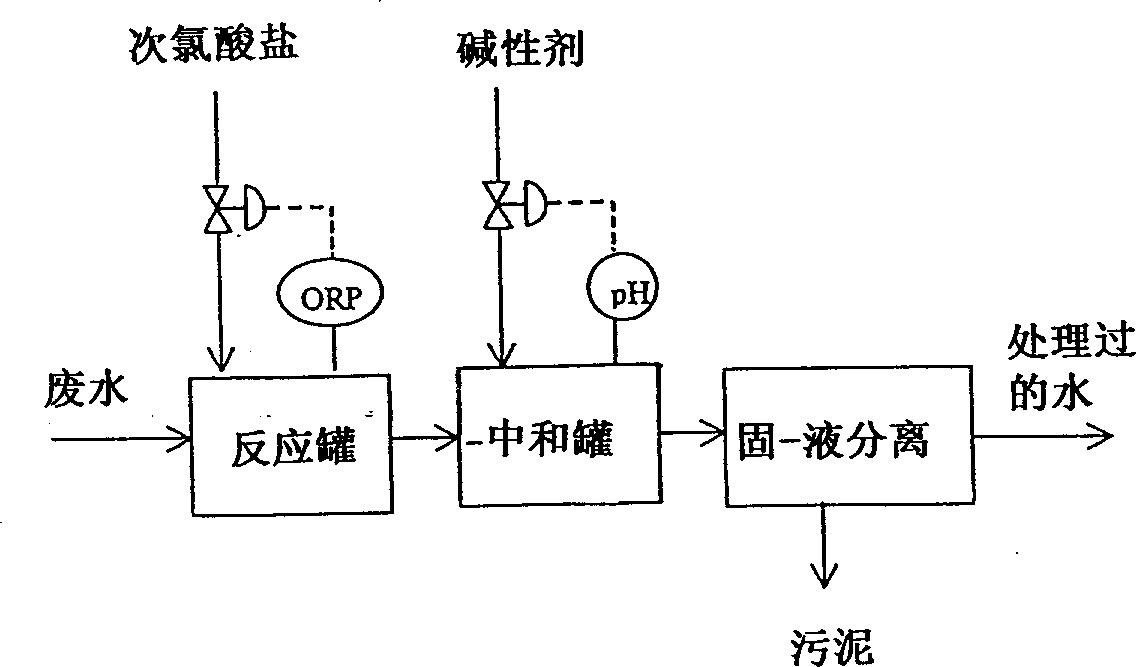

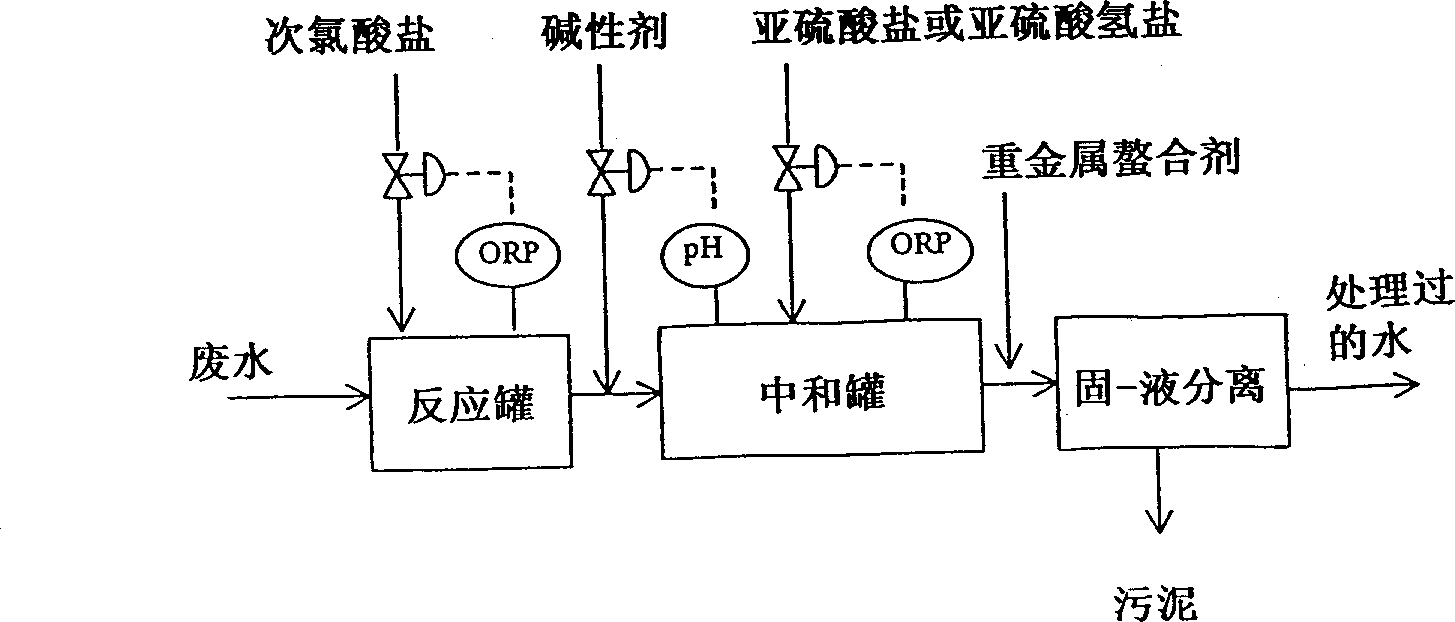

Method for flue gas desulfurization and flue gas desulfurization system

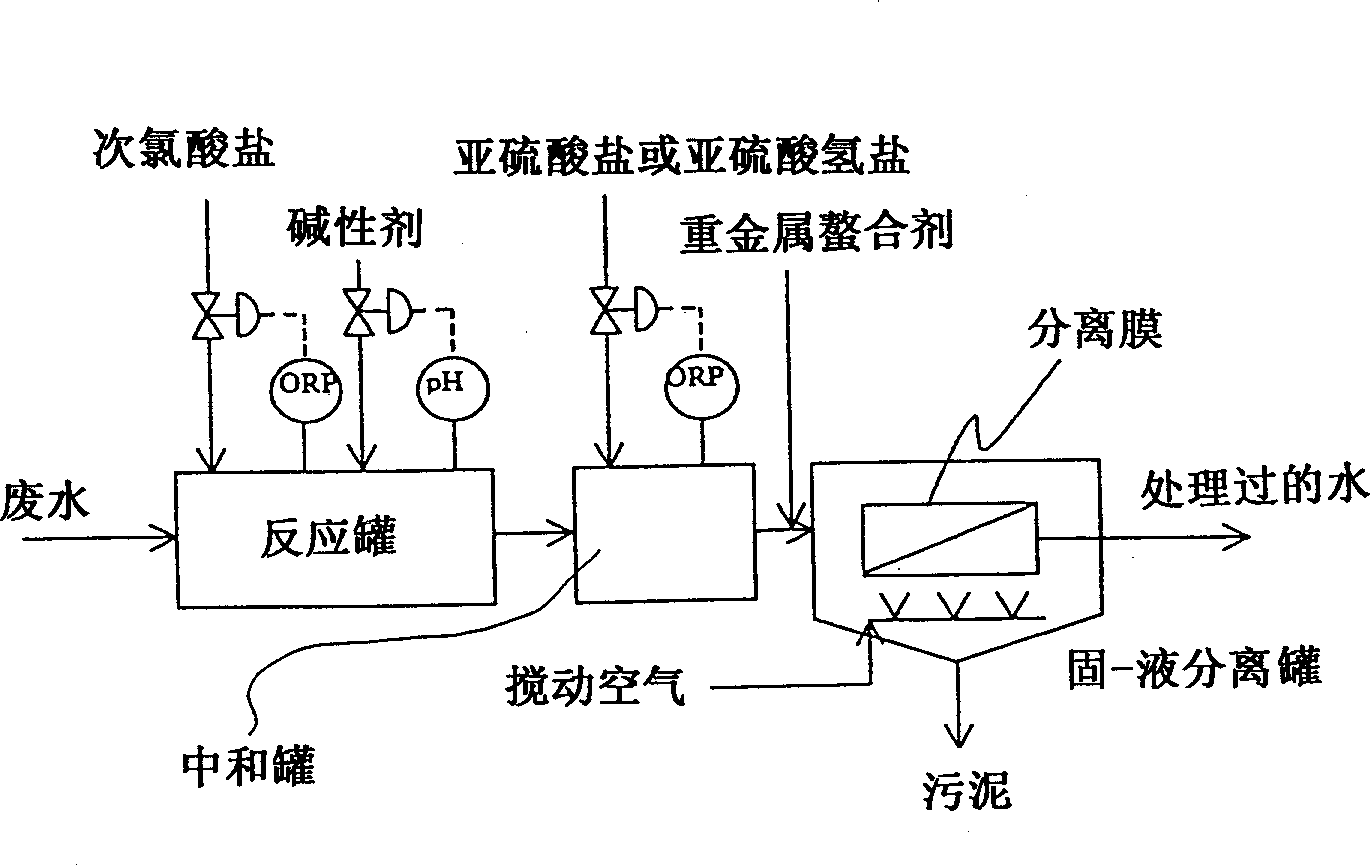

InactiveCN1304328ALow concentration and stableEfficient removalWaste water treatment from gaseous effluentsWater/sewage treatment by neutralisationChemistryHeavy metals

The invention provides a method for treating a drain water from a wet flue gas desulfurization apparatus for removing sulfur oxides in a flue gas by the wet lime-gypsum method, characterized as comprising adding a hypochlorite to the drain water, and then adjusting the pH of the resulting mixture to a value of 7 to 9.5, followed by separation between a solid and a liquid; and a method for desulfurizing a flue gas containing sulfur oxides and nitrogen oxides by the wet lime method, characterized as comprising an oxidizing step comprising drawing out a part of the slurry formed by absorption in a desulfurization step, followed by separation of gypsum, adjusting the pH of the resultant filtrate to a value of 3 to 4, and adding an oxidizing agent, a neutralizing step comprising adjusting the pH of the mixture resulting from the oxidizing step to a value of 7 to 9.5, and a solid-liquid separation step comprising separation between a solid and a liquid of the neutralized mixture. Accroding to the invention, these methods can be employed for removing NS compounds effectively, which affect adversely the desulfurization performance of the apparatus, and at the same time for removing heavy metals in the desulfurization drain water, particularly manganese, with economical advantage.

Owner:MITSUBISHI HEAVY IND LTD

Preparation method of humic acid-containing fertilizer and soil conditioner composition

The invention provides a preparation method of a humic acid-containing fertilizer and soil conditioner composition, wherein the preparation method includes treating a humic acid raw material and an activating agent through a coal grinding machine to obtain the humic acid-containing fertilizer and soil conditioner composition. The method avoids a high energy consuming problem of humic acid wet production comprising firstly adding water to carry out a reaction and then carrying out evaporation drying to remove moisture and a solid slag pollution problem after solid-liquid separation, the process is simple and convenient, the flow is shortened, and the obtained product has stable quality.

Owner:英卓科技有限公司

Conditioner for severely alkaline soil and processing method of conditioner

ActiveCN103031129AReduce alkalinityImprove aggregate structureOther chemical processesOrganic fertilisersAdditive ingredientPhysical property

The invention relates to a conditioner for severely alkaline soil and a processing method of the conditioner. The conditioner for the severely alkaline soil comprises the following raw materials in parts by weight: 88-92 parts of desulfuration waste, 1-3 parts of inorganic accelerator and 5-11 parts of organic accelerator. According to the conditioner for the severely alkaline soil, calcium ions in the desulfuration waste are used for replacing exchangeable sodium on a soil colloid, so that the alkalisation degree of the soil is reduced; an excellent pore structure and physical properties of the organic accelerator are used for improving physical characteristics and a granular structure of the soil; the pH value of the soil is decreased; the soil fertility is increased; the inorganic accelerator also can improve the granular structure of the soil; an inorganic fertilizer and an organic fertilizer are additionally adopted to further increase the soil fertility; and nutritional ingredients are provided for crop growth. In a word, the conditioner can effectively overcome nutritional element unbalance in the soil, increase the soil fertility, loosen the soil, improve the fertilizer efficiency and fundamentality control soil salinization gradually.

Owner:华清农业开发有限公司

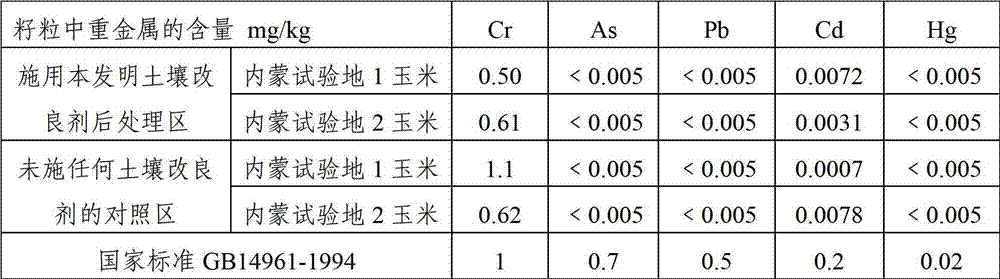

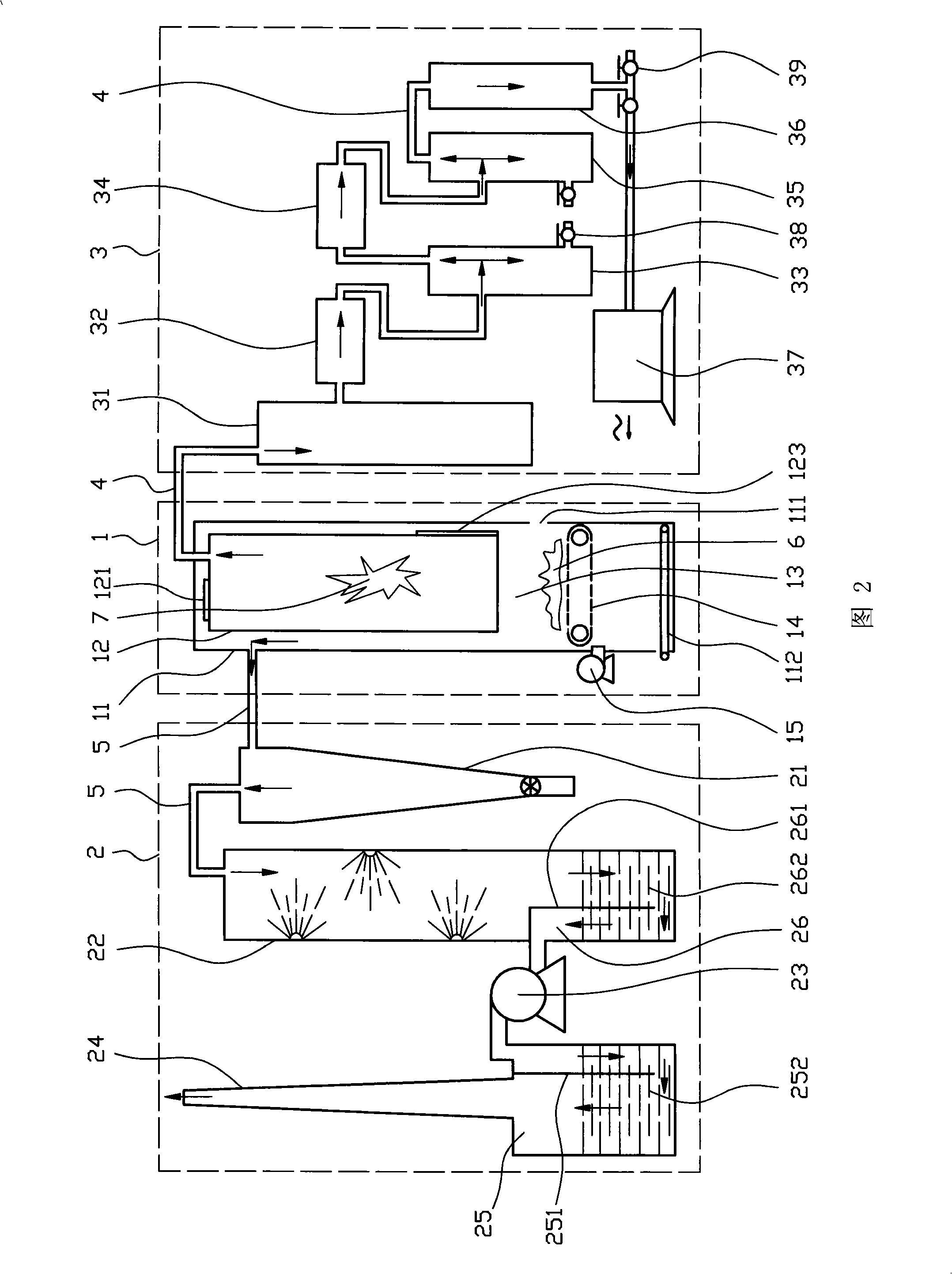

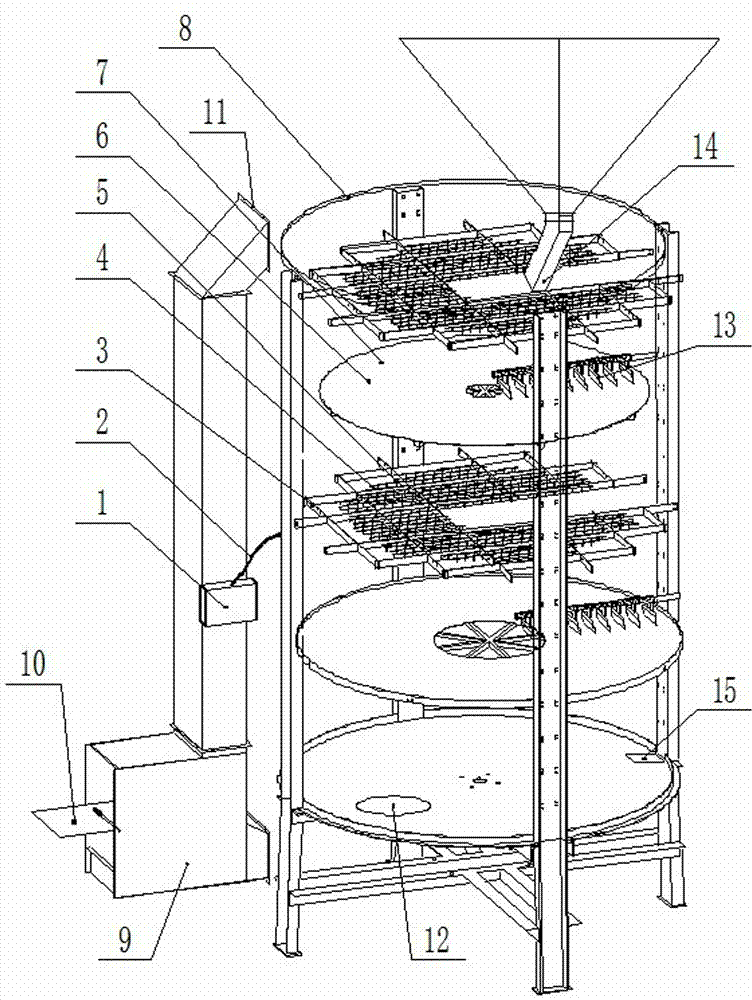

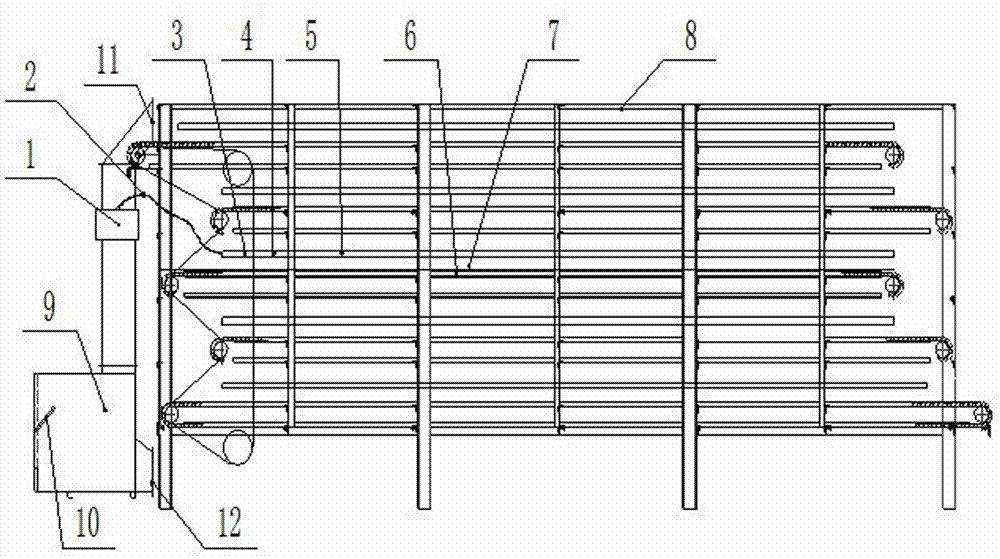

Industrialization reutilization device of environment protection type organic refuse and manufacturing technique thereof

InactiveCN101332463ARemove toxic and harmful componentsNo polluting emissionsPigmenting treatmentSolid waste disposalOxygen deficiencyCarbon black

The invention pertains to the technical field of garbage recycling, in particular to an environment-friendly industrialized recycling apparatus for organic wastes and a production process thereof; the apparatus consists of a normal pressure heating reaction device, a flue gas purification device and a gas recovery device; the flue gas purification device is communicated with a furnace cavity in the upper part of the inner cavity of a furnace body; the gas recovery device is communicated with an inner cavity of a reaction kettle in the upper part of the inner cavity of the furnace body; the production process are that: the wastes are classified and the high-molecular organic wastes are put in the reaction kettle and are cracked into micro-molecular gaseous-solid substances under the effects of high temperature, oxygen deficiency and a catalyst; the gaseous substances are formed into liquid oil by low temperature condensation and gas-liquid separation, and the liquid oil is stored in a gas-liquid separator; the uncondensed gas enters a gas tank and is made into a liquefied gas or used for supply power for a gas generator; the reaction residue is taken as raw material of industrial carbon black; the flue gas which reach standard after purification is discharged. The recycling device and the production process of the invention are especially suitable for the treatment and recycling of industrial solid wastes and organic domestic wastes.

Owner:陈弘毅

Application of moderate alkaline soil modifier

ActiveCN102994097AOvercome nutrient imbalancesImprove soilOther chemical processesOrganic fertilisersPhysical propertyExchangeable sodium

The invention relates to an application of a moderate alkaline soil modifier to soil improvement. The moderate alkaline soil modifier comprises, by weight, 80 to 90 parts of desulfation wastes, 3 to 5 parts of inorganic accelerators and 8 to 15 parts of organic accelerators. According to the moderate alkaline soil modifier, calcium ions in the desulfation wastes are utilized to replace exchangeable sodium on soil colloid, so that the alkalinity of the soil is reduced; simultaneously excellent pore structures and physical properties of the organic accelerators are utilized, so that the physical properties and the granular structure of the soil can be improved, the potential of hydrogen (pH) value of the soil can be reduced, and the soil fertility is increased; the granular structure of the soil can be improved as well by the aid of the inorganic accelerators; and the soil fertility can be further improved by the aid of inorganic fertilizers and organic fertilizers, and nutritional ingredients can be provided for crop growth. In a word, the moderate alkaline soil modifier has the advantages that the unbalanced nutrition elements in the soil can be effectively avoided, the soil fertility can be improved, the soil can be loosened, the fertilizer efficiency is increased, and the soil salinization and alkalization can be gradually and radically treated.

Owner:华清农业开发有限公司

Conditioner for moderately alkaline soil and processing method of conditioner

ActiveCN103031130AReduce alkalinityGood physical propertiesOther chemical processesOrganic fertilisersColloidSoil conditioner

The invention relates to a conditioner for moderately alkaline soil and a processing method of the conditioner. The conditioner for the moderately alkaline soil comprises the following raw materials in parts by weight: 80-90 parts of desulfuration waste, 3-5 parts of inorganic accelerator and 8-15 parts of organic accelerator. According to the conditioner for the moderately alkaline soil, calcium ions in the desulfuration waste are used for replacing exchangeable sodium on a soil colloid, so that the alkalisation degree of the soil is reduced; an excellent pore structure and physical properties of the organic accelerator are used for improving physical characteristics and a granular structure of the soil; the pH value of the soil is decreased; the soil fertility is increased; the inorganic accelerator also can improve the granular structure of the soil; an inorganic fertilizer and an organic fertilizer are additionally adopted to further increase the soil fertility; and nutritional ingredients are provided for crop growth. In a word, the conditioner can effectively overcome nutritional element unbalance in the soil, increase the soil fertility, loosen the soil, improve the fertilizer efficiency and fundamentality control soil salinization gradually.

Owner:TSINGHUA UNIV

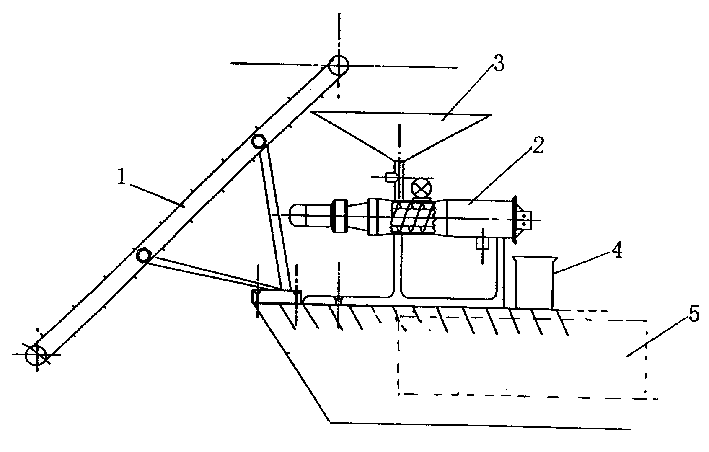

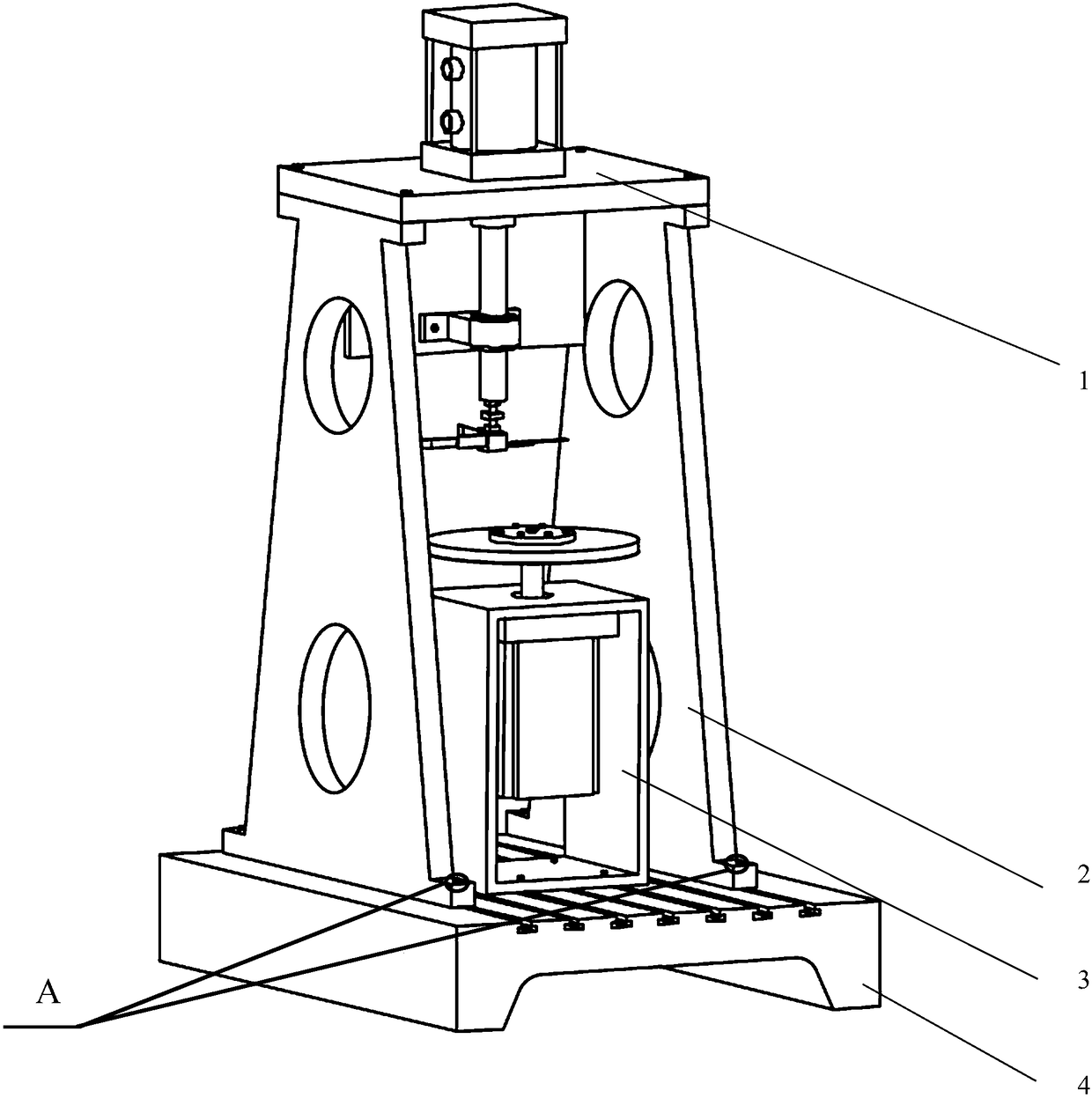

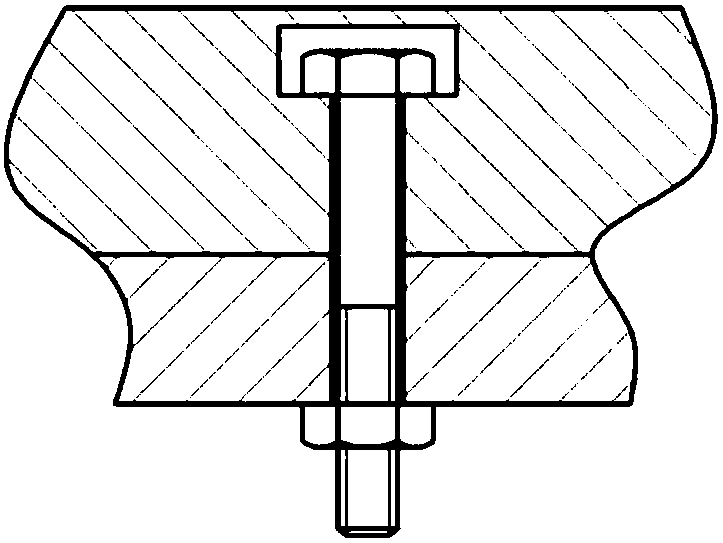

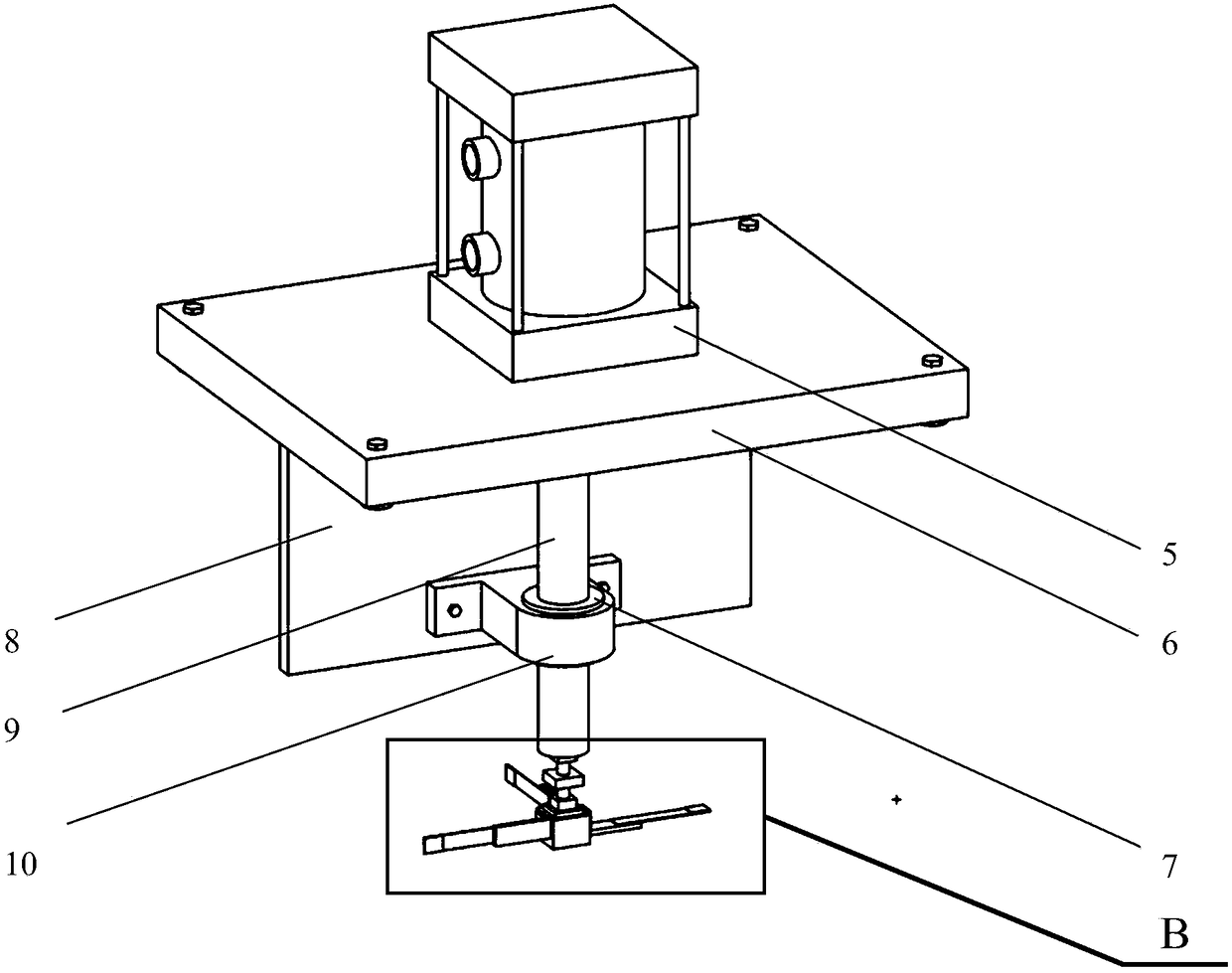

Test table used for studying friction vibration energy recycling efficiency

PendingCN108195538AReduce volumeHigh energy conversion rateVibration testingTangential forceEngineering

The invention provides a test table used for studying friction vibration energy recycling efficiency. In a motor module, a hollow support base is fixed on a machine base in a movable manner, a servo motor is mounted in the hollow support base and a brake disc is fixed on the upper portion of a motor output shaft. In a loading module, two support boards are fixed on the machine base in a movable manner; a hydraulic cylinder is mounted on a top board above the two support boards; a hydraulic cylinder guide rod protrudes from a linear bearing downwards; a normal force sensor, a tangential force sensor and a brake block are connected to the guide rod in sequence; piezoelectric elements are fixed on spring steel sheets on three side faces of the brake block while a three-dimensional acceleration sensor is fixed on the last side face. According to the invention, brake loading pressure, brake disc rotation speed, friction diameter and the like are changed according to practical working conditions and influence on friction vibration energy recycling efficiency by different working conditions is studied through verifying piezoelectric type friction vibration energy collection feasibility through electric signals collected in tests.

Owner:SOUTHWEST JIAOTONG UNIV

Nutritional type saline-alkali soil modifier

InactiveCN102051181AAct quicklyGood effectAgriculture tools and machinesOrganic fertilisersChemistryUrea

The invention discloses a nutritional type saline-alkali soil modifier which can be used for the improvement and fertilization of the new oasis and the secondary salinization soil, and belongs to the technical field of soil improvement. The modifier comprises the following raw materials in percentage by weight: 50%-70% of furfural residue, 20%-40% of matured sheep manure, 1%-2% of urea, 4%-6% of diammomium phosphate, 2%-4% of potassium chloride, 0.3%-0.5% of zinc sulfate and 0.3%-0.5% of manganese sulfate. The preparation method of the modifier comprises the following conventional steps: mixing the raw materials, grinding and sieving to prepare the nutritional type saline-alkali soil modifier provided by the invention. The modifier integrates the functions of improving saline-alkali soil,fertilizing soil and preserving moisture and fertility; and the production cost is low, the improvement effect is good, and the yield of the crop can be increased obviously.

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

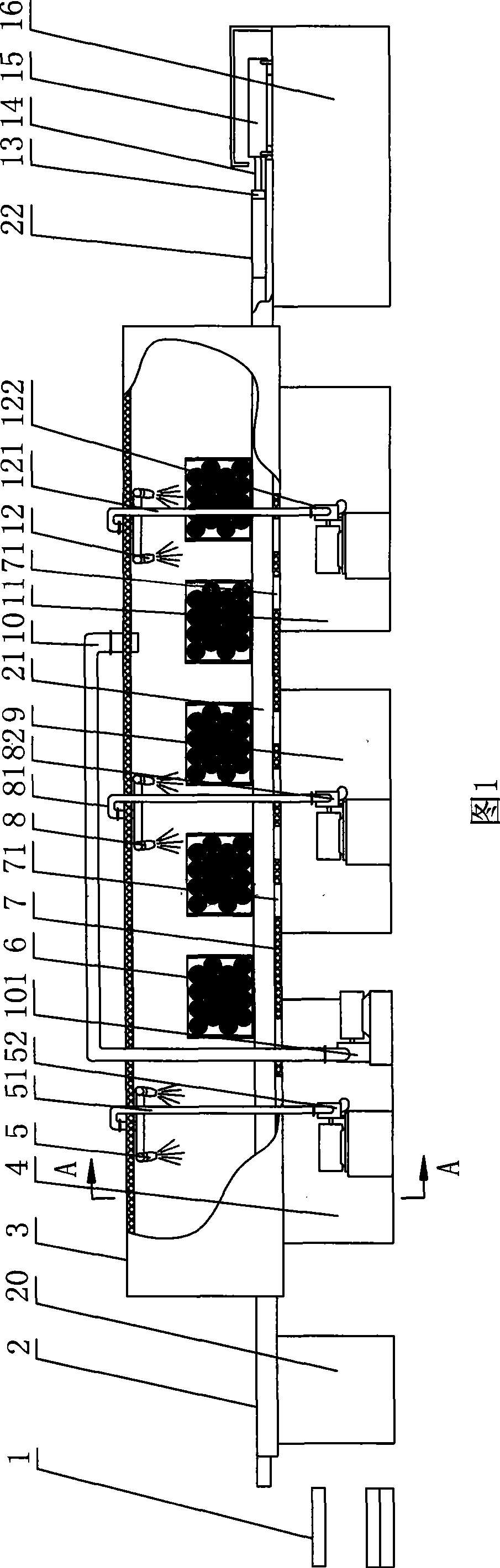

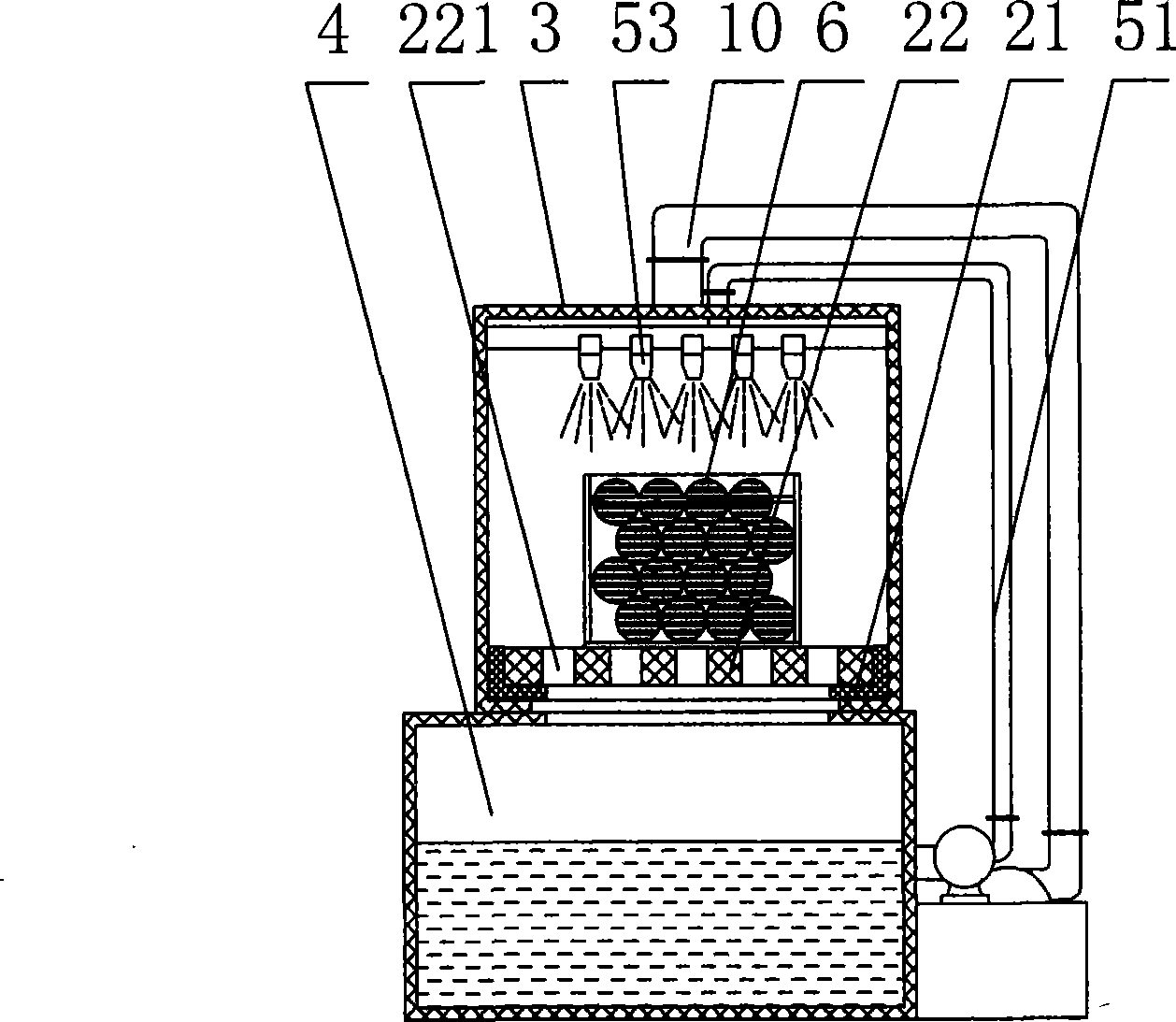

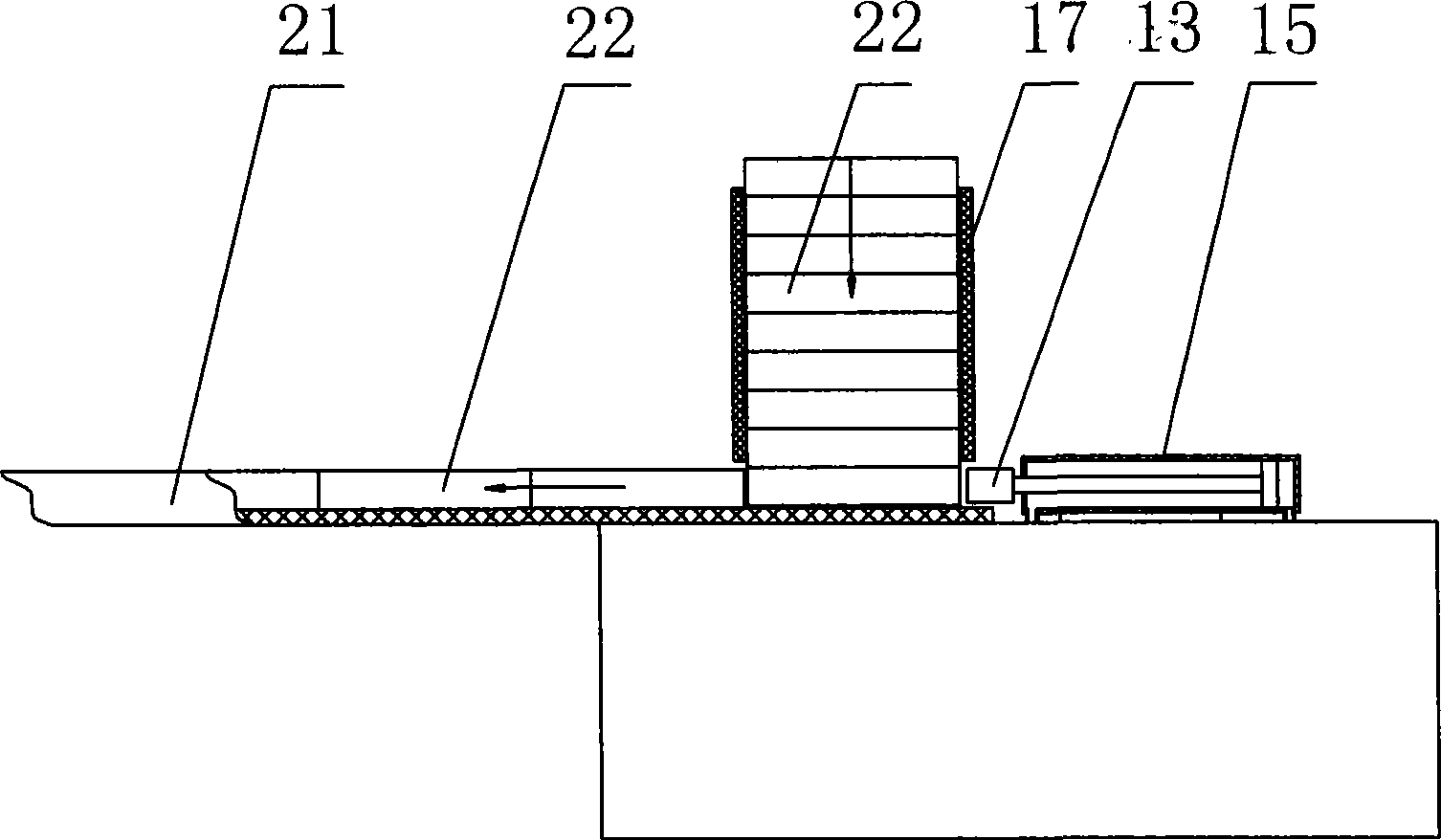

Device for cleaning vanadium-removing copper wire balls

ActiveCN101444781ANo effect on healthPhysical health effectsConveyorsCleaning using liquidsCopper wireSpray nozzle

A device for cleaning vanadium-removing copper wire balls comprises a tunnel, a copper wire ball conveying mechanism which is arranged at the bottom of the tunnel and passes through the entire tunnel, and a suction tube which is arranged at the top of the tunnel and connected with a vacuum pump. An acid cleaning spray nozzle set, a rough cleaning spray nozzle set and a fine cleaning spray nozzle set are sequentially arranged on the inner wall of the tunnel from the inlet of the tunnel, and an acid cleaning liquid storage tank, a rough cleaning liquid storage tank and a fine cleaning liquid storage tank are sequentially arranged below the copper wire ball conveying mechanism in the positions corresponding to the spray nozzle sets. The acid cleaning spray nozzle set, the rough cleaning spray nozzle set and the fine cleaning spray nozzle set are all connected with a high-pressure hydraulic pump via pipelines, and the high-pressure hydraulic pump is correspondingly connected with acid cleaning liquid storage tank, the rough cleaning liquid storage tank and the fine cleaning liquid storage tank. The entire cleaning process is enclosed and mechanized; and during the cleaning process, no irritant gases are discharged and an operator does not directly contact the copper wire balls, so as not to affect the health of the operator.

Owner:仙桃市中星电子材料有限公司

Process for treating tar product wastewater

InactiveCN101607780ARaise the ratioReduce concentrationSludge treatment by de-watering/drying/thickeningTreatment with anaerobic digestion processesVolatile phenolsSlag

The invention discloses a process for treating tar product wastewater, which can improve the ratio of BOD / COD of the wastewater, reduce the concentration of ammonia thereof and the concentration of volatile phenol, and further lead the wastewater to be recycled or discharged without pollution. The process for treating the tar product wastewater is characterized in that: a. the wastewater which is generated by cleaning is conducted into a primary settling tank to be settled so as to remove the settled impurities; b. the wastewater is conducted into a wastewater circulating pool so as to remove big granular matters, partial suspended matters and partial oil, and reduce the content of COD; c. the wastewater is conducted into a coagulating air floating machine so as to remove the oil, slag, ammonia and nitrogen; d. the wastewater is conducted into an intermediate settling tank to settle the impurities of the coagulating air floating tank and simultaneously regulate the water quality; e. the wastewater is conducted into a hydrolytic acidification tank and the function of an anaerobe is utilized so as to degrade the refractory organic matters with big particles and molecules into biodegradable organic matters with small molecules; f. the wastewater is conducted into a contact oxidation tank, and under the contact oxidation action of aerobic bacteria, through aeration, the organic matters in the wastewater are absorbed and degraded by the aerobic bacteria; and g. the wastewater is recycled or discharged after reaching the standards after being settled by the inclined settling tank and treated by the post-treatment process.

Owner:JIANGSU TAIHU BOILER

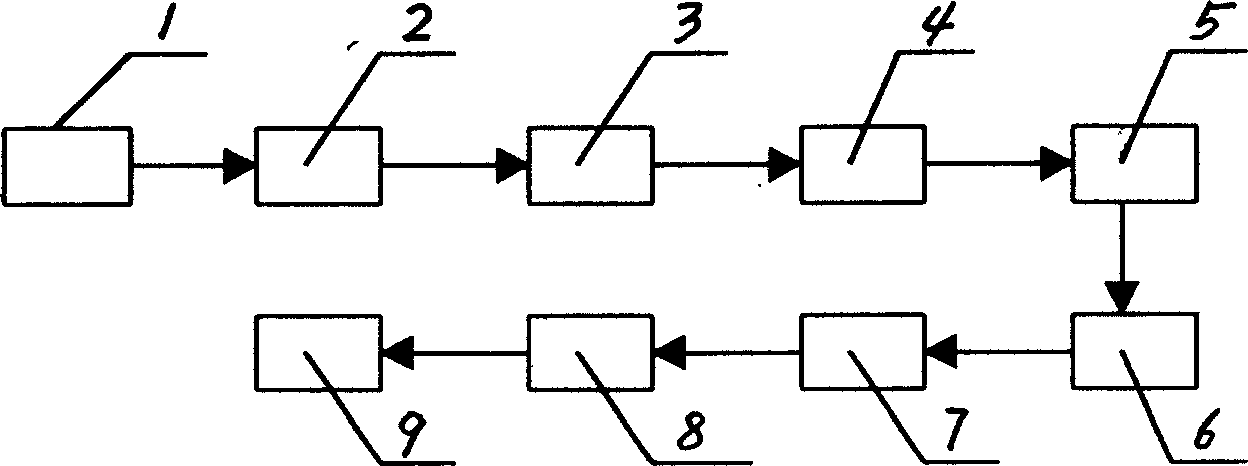

Waste paper regeneration environmental protection device and method

InactiveCN101798768AReasonable configurationHigh degree of automationFinely-divided cellulose conservationSludgeWater circulation

The invention relates to papermaking method and device, in particular relates to waste paper regeneration environmental protection device and method. The waste paper regeneration device is provided with a hydraulic pulper, a first stock tank, a first desander, an inclined sieve, a second stock tank, a pulping machine, a third stock tank, a header box, a fourth stock tank, a second desander, a pressure sieve, a paper machine, a boiler, a reaction tank and a wastewater filter tank. By adopting the waste paper regeneration method and device, a closed production and water circulation mode is formed. Compared with the prior art, the invention has reasonably configured device system composition, higher degree of automation, convenient operation and higher pulping efficiency, can recycle afterheat and wastewater after being processed into purified water, realizes the energy-saving and environmental-protection effect, obviously improves the product quality through detection and can regularly clean sludge and coal ash in the wastewater filter tank to be used as field fertilizers, thereby changing waste into valuable without pollutant emission.

Owner:侯俊民

Tobacco stalk fiber substance as well as preparation method and application thereof

InactiveCN102475353AReduce damageHigh proportion of long fibersFibreboardTobacco preparationFiber bundlePapermaking

The invention provides a tobacco stalk fiber substance as well as a preparation method and an application thereof. The tobacco stalk fiber substance is obtained by the way that tobacco stalk is taken as a main raw material and biological degumming and extraction are carried out, the tobacco stalk fiber substance mainly comprises a single tobacco stalk fiber and a tobacco stalk fiber bundle (containing 2-20 single tobacco stalk fibers), and the average length of the fibers is 3-30mm. Production steps comprise processes such as burdening, biological degumming, defibering, fiber extracting and the like. The preparation method provided by the invention has the advantages of low degree of disruption to the fiber, high defibering degree, high long fiber ratio, low requirement on strength of mechanical equipment, low energy consumption and water consumption and no pollution discharge. The prepared fiber can be widely applied to tobacco sheet processing, papermaking, preparation of substrate used for soilless culture and the like.

Owner:朱大恒

Treatment technology of automobile wheel assembly before painting primer

InactiveCN1569346AMeet the process requirementsNo polluting emissionsPretreated surfacesCoatingsImpellerEngineering

The invention provides a process before the car wheel assembly paint is coated. It includes following steps: a. the wheel assembly is impeller blasted in the impeller blasting machine with correspondent suspending machine; b. cleans the floating ash, steel pills and so on the surface of the piece with compressed air; c. the piece is suspended with swimming suspending machine; d. carries on degreasing process in the alkali washing groove; e. carries on one time of water clean; f. carries on the secondary water washing; g. carries on phosphorization process; h. carries on the third time of clean; i. it is cleaned with deioned water. After the process, the rust and oil can be eliminated.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

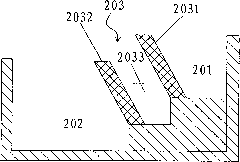

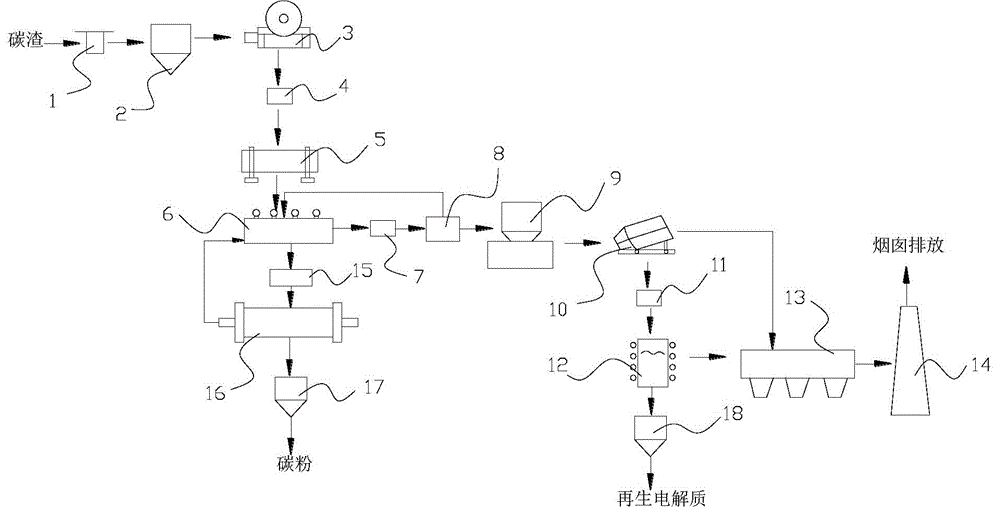

Device and method for producing regenerative electrolyte from aluminum-electrolysis carbon residues

InactiveCN103949460ANo dischargeSimple processSolid waste disposalIntermediate frequencyProcessing cost

The invention relates to a device and a method for producing regenerative electrolyte from aluminum-electrolysis carbon residues. The device comprises a sorting platform, a carbon residue stock bin, a crushing device, a first magnetic separation device, a ball milling device, a flotation tank, a second magnetic separation device, a sedimentation basin, a feeding device, a drying device, a third magnetic separation device, an intermediate frequency furnace, a dust-removal device and a chimney, which are sequentially connected with one another, wherein a carbon powder tank, a filter-press device and a carbon powder bin are further sequentially connected to the flotation tank, and a regenerative electrolyte bin is connected to the intermediate frequency furnace. The method comprises the following steps: (a) raw material sorting, (b) carbon residue crushing, (c) ball-milling, (d) flotation, (e) drying, (f) regenerative electrolyte refining, and (g) tail gas treatment. The method has the beneficial effects that the carbon residues are sorted to be a utilizable value resource, and basically no industrial waste residue is generated; the process is simple, the processing cost is low, the industrialized application is easily realized, the production water supply is completely recycled in the whole process, no polluted gas is discharged, and the method is a brand new method for processing and comprehensively utilizing the carbon residues and has a high promotional value.

Owner:JIANSHUI DEFU RENEWABLE RESOURCES

Method for extracting ginkgo seed bioactive polypeptides

ActiveCN106282287AThe active structure is not destroyedHigh extraction ratePeptide preparation methodsFermentationPectinaseCellulose breakdown

The invention discloses a method for extracting ginkgo seed bioactive polypeptides. The method comprises the following steps: pulverization: pulverizing to obtain ginkgo seed powder; enzymolysis: dissolving the ginkgo seed powder in water, uniformly stirring and mixing, regulating the pH value, adding a wall-breaking enzyme, pectinase, cellulase and proteinase while stirring, carrying out enzymolysis to obtain an enzymolysis solution, and carrying out enzyme inactivation by high temperature to obtain an enzyme inactivation solution; two-step extraction: regulating the temperature of the enzyme inactivation solution to 3-5 DEG C, keeping for 1-3 hours, hydrolyzing, separating to obtain a primary supernate and a primary residue, carrying out water extraction and separation on the primary residue, and collecting a secondary supernate; concentration: merging the primary and secondary supernates, and concentrating to obtain a concentrated solution; and drying: drying the concentrated solution to obtain the ginkgo seed bioactive polypeptides. The method disclosed by the invention prevents the active polypeptide structure from being damaged, and effectively enhances the extraction rate. The molecular weight of most small-molecule active polypeptides is less than 1000Da, so the bioactive polypeptides can be absorbed by the human body more easily.

Owner:徐州银杏源生物工程有限公司

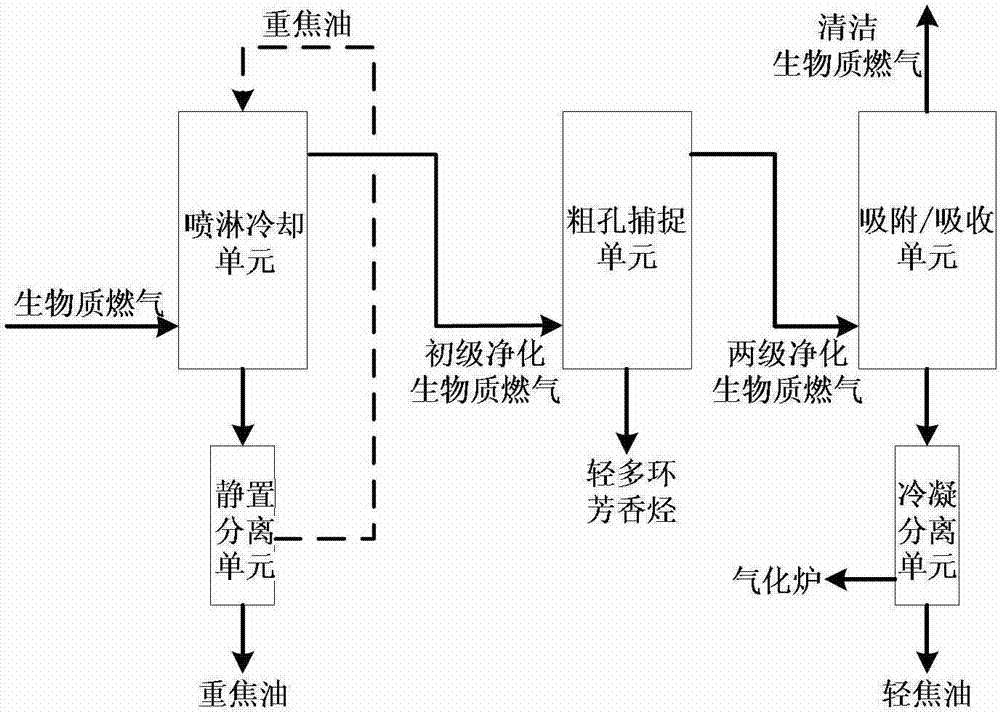

Multi-stage deep removing process of biomass gas tar

InactiveCN103087780AWide air adaptabilityGood spray cooling effectGas purification with selectively adsorptive solidsGas purification by liquid washingSorbentEngineering

The invention relates to a multi-stage deep removing process of biomass gas tar. The multi-stage deep removing process comprises the concrete steps of A, feeding high-temperature biomass gas containing tar generated by a biomass gasifier to a spray cooling unit after removing dust; spraying and cooling by heavy tar liquid to obtain primarily purified biomass gas; B, feeding the primarily purified biomass gas to a coarse capture unit, removing polycyclic aromatic hydrocarbon tar by capillary condensation and interception performance of a coarse material; and C, feeding the processed two-stage purified biomass gas to an adsorption or absorption unit; removing light tar to obtain clean gas by the adsorption effect of an adsorbent or an absorbent; and reducing the dew point of the biomass gas tar to -30 to 0 DEG C. By adopting the multi-stage deep removing process of the biomass gas tar provided by the invention, multiple multi-effect coupling deep removal of the tar can be achieved; the tar removal cost is low; and light and heavy tar products can be produced as byproducts.

Owner:NANJING TECH UNIV

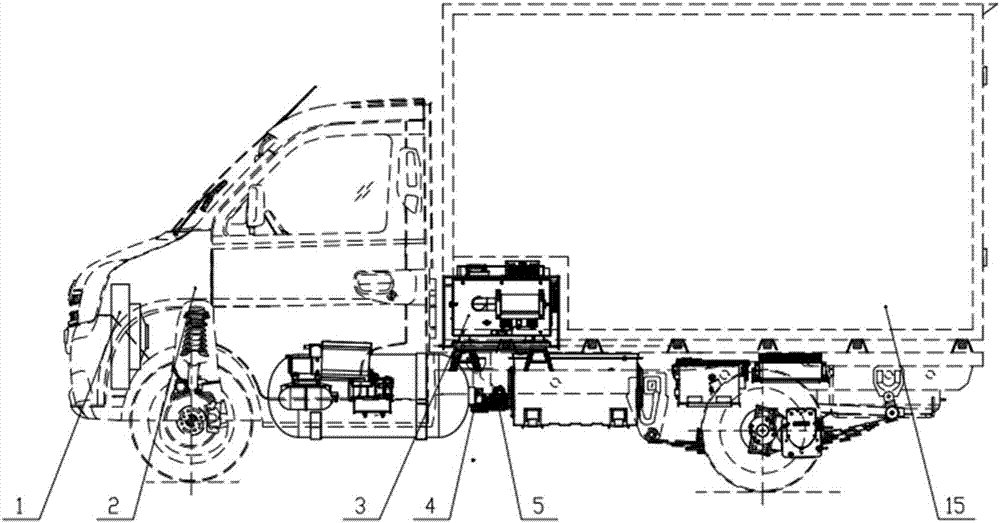

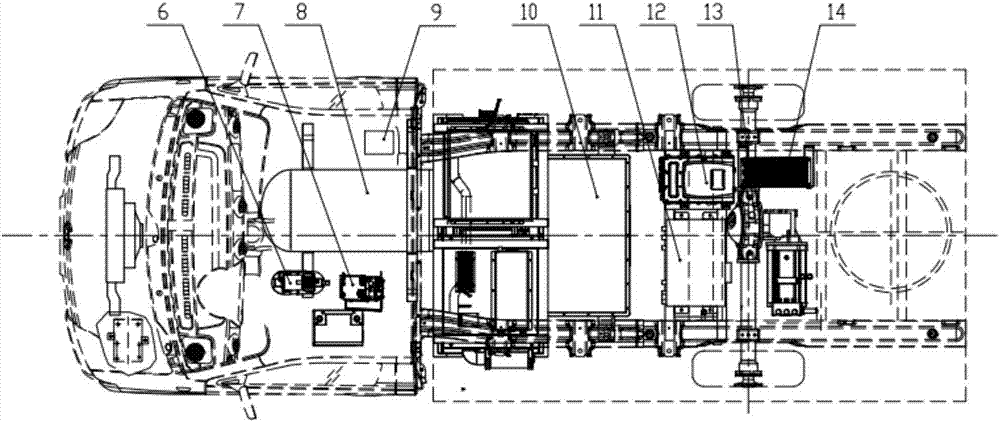

Vehicle structure arrangement of minisize fuel battery cargo van

PendingCN107161016AReduce noiseNo polluting emissionsElectric propulsion mountingPropulsion by batteries/cellsVehicle frameFuel type

The invention relates to a vehicle structure arrangement of a minisize fuel battery cargo van. Secondary development is performed on a 2.5T fuel type minisize truck. A 10kW fuel battery stack 3, a fuel battery controller, a hydrogen supply system, a hydrogen leakage alarming system 4, a hydrogen adding system 5, a hydrogen storing tank 8, a fuel battery cargo van special instrument, a central cooling system 1, a lithium battery and lithium battery management system 10, an electric drive axle system 13, a motor controller 12 matched with a fuel battery, and a vehicle controller 9 matched with the fuel battery are loaded on a cargo van frame 2, wherein the 10kW fuel battery stack 3 is arranged at the lower part of a cargo box 15; the central cooling system 1 is arranged at the front end of the cargo van frame 2; the vehicle controller 9 is arranged under a co-driver seat; the lithium battery and lithium battery management system 10 is arranged in a high-voltage box; and a high-voltage distributing box 11 and the motor controller 12 are arranged behind the lithium battery. According to the vehicle structure arrangement disclosed by the invention, a minisize cargo van of which the total weight is 2.2 T can achieve a loading capacity of 600 KG, is low in noise, and can realize non-pollution discharging; and the battery range between two loading processes is greater than 250Km, and time for loading fuel is 3-5 minutes.

Owner:东风特汽(十堰)专用车有限公司

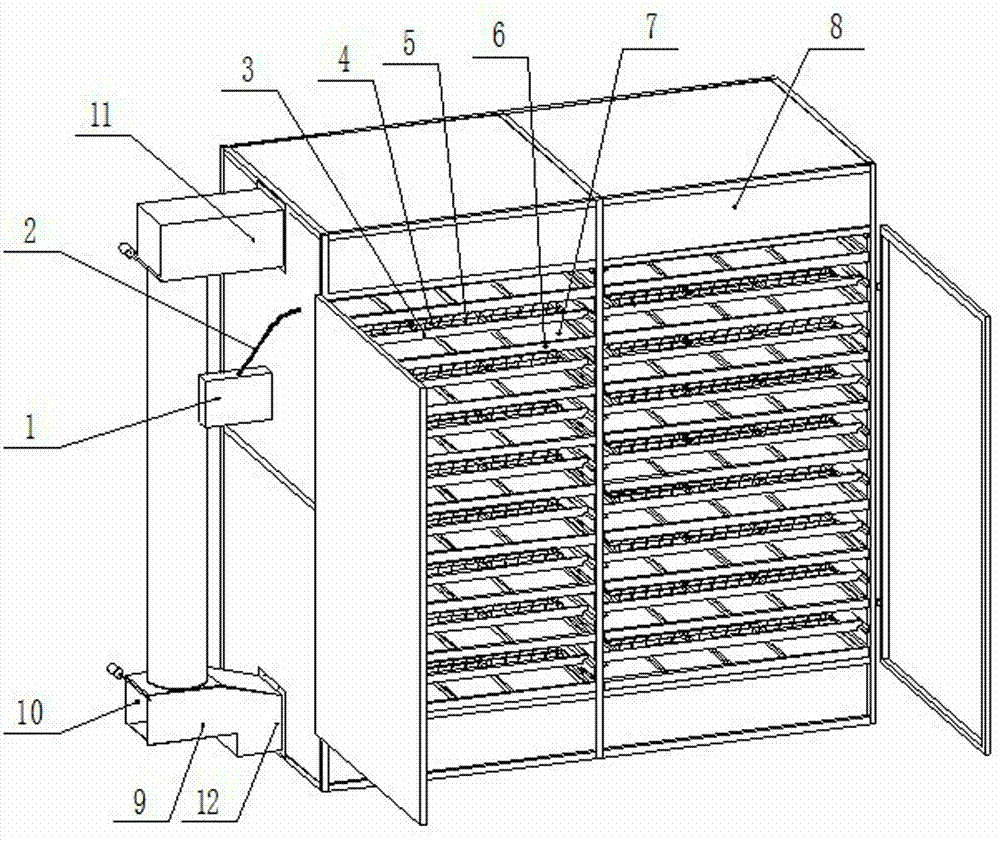

Crop dryer

InactiveCN102927793ANo lossNo polluting emissionsDrying chambers/containersDrying machines with local agitationFreeze-dryingEngineering

The invention discloses a crop dryer which consists of an enclosed case body, metal supporting plates, electrode racks on the metal supporting plates, and a dehumidifier arranged outside and connected with the case body. The metal supporting plates and the electrode racks are arranged in the case body. The electrode racks are connected with a cathode of a high voltage cable; the case body is connected with an anode of a high voltage power supply. The supporting plates and the electrode racks form an electrostatic field; an air inlet and an air outlet are formed on the case body; the air outlet of the case body is connected with a return air inlet of the dehumidifier; and the air inlet of the case body is connected with an air outlet of the dehumidifier. Compared with the present processes of thermal drying and vacuum freeze drying, the crop dryer discharges no pollution, produces no residue, and is low in energy consumption and dryness cost. The content of index components in a dried material is increased. The economic and social benefits are significant. In limited temperature regions, the drying speed of the drying process of the crop dryer is approximately twice as high as the thermal drying speed. If the drying process of the crop dryer is combined with the thermal drying, the drying effect can be doubled. The material is not required to be heated when the crop dryer works; the content of the index components in the dried material keeps high; and the crop dryer is low in operating cost.

Owner:桂林源林生态科技有限责任公司 +2

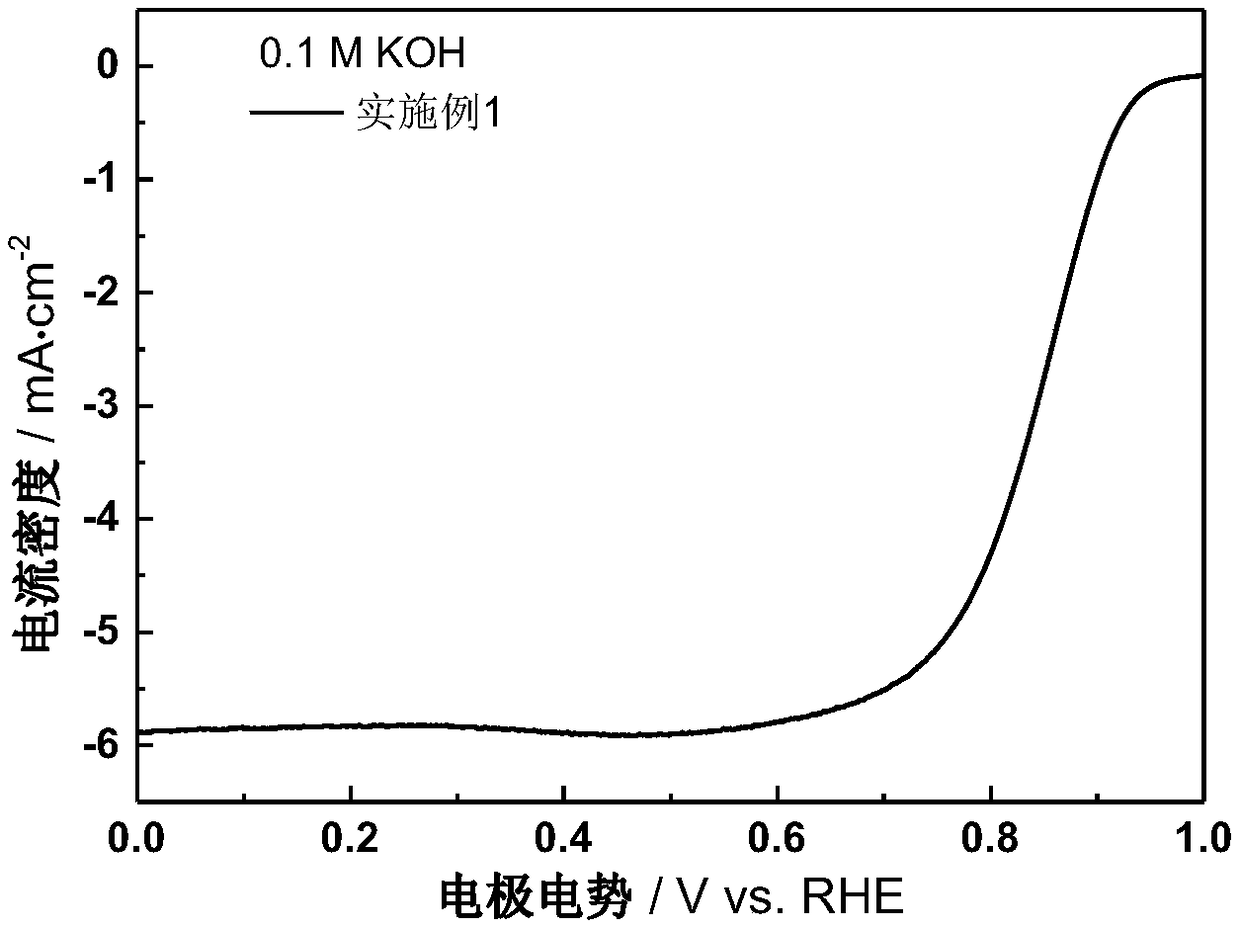

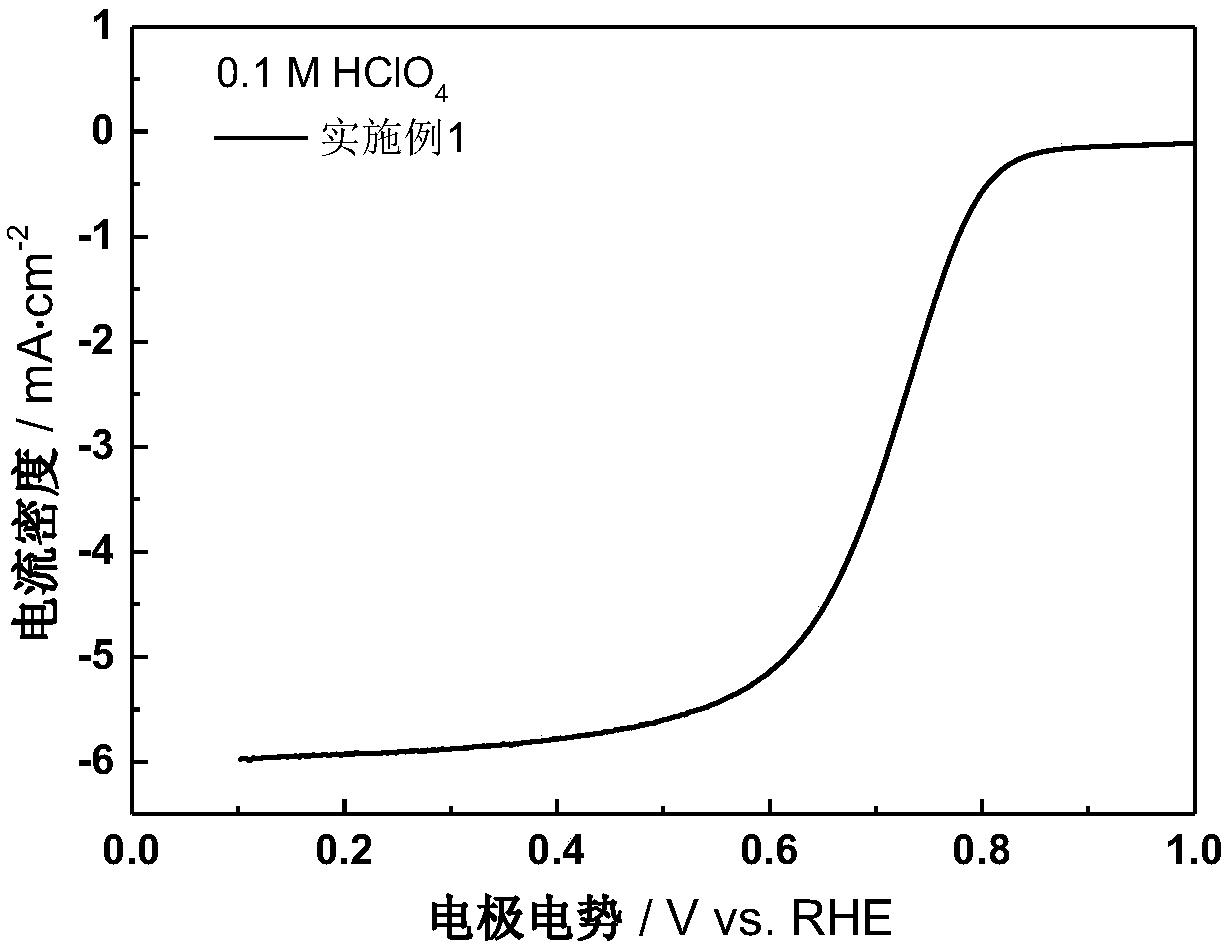

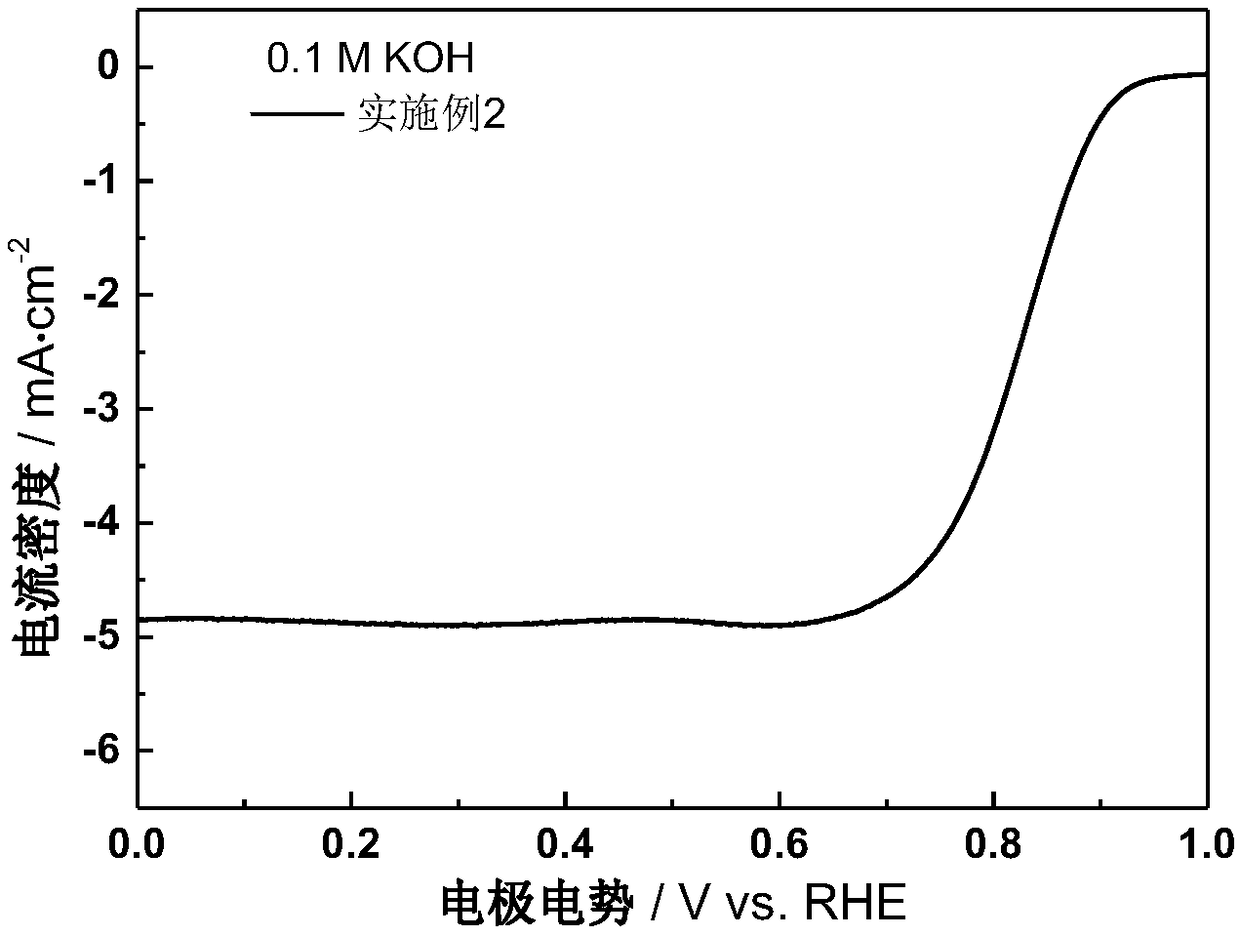

Iron-nitrogen doped oxygen reduction carbon catalyst with ordered hierarchical holes and preparation method of iron-nitrogen doped oxygen reduction carbon catalyst with ordered hierarchical holes

ActiveCN109433238AThe synthesis method is simpleCatalytic performance for efficient oxygen reduction reactionPhysical/chemical process catalystsMetal-organic frameworkPyrolysis

The invention belongs to the technical field of catalysts and discloses an iron-nitrogen doped oxygen reduction carbon catalyst with ordered hierarchical holes and a preparation method of the iron-nitrogen doped oxygen reduction carbon catalyst with the ordered hierarchical holes. A hierarchical-hole three-dimensional ordered iron doped metal organic framework is formed by a 3D skeleton template,then a high-temperature calcining pyrolysis method is adopted to obtain the iron-nitrogen doped carbon catalyst with ordered hierarchical holes and an oxygen reduction function, and a promising application prospect in the field of metal-air cells, regenerative fuel cells and the like is achieved.

Owner:宁波华储能源有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com