Vehicle structure arrangement of minisize fuel battery cargo van

A micro fuel cell and structural arrangement technology, applied in battery/fuel cell control devices, electric vehicles, electric power devices, etc., can solve the problems of high emissions, high noise, limited installation of lithium batteries, etc., to achieve no pollution emissions, low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

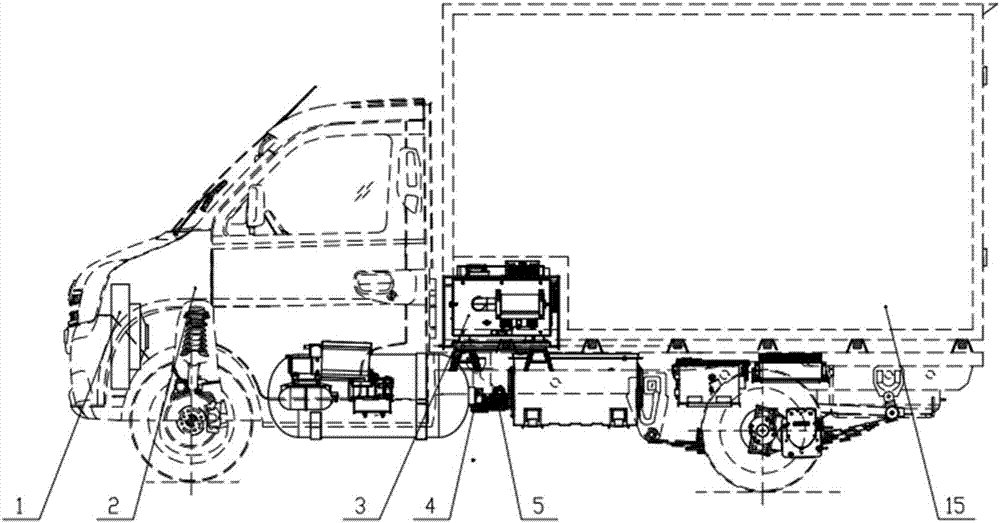

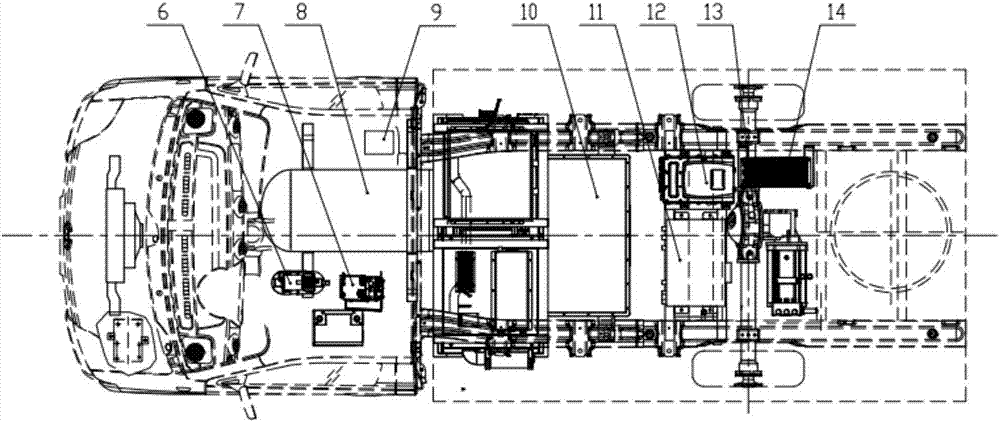

[0030] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0031] The design idea of the structure layout of the micro-fuel cell logistics vehicle in the embodiment of the present invention is as follows.

[0032] (1) The average power of the micro-logistics vehicle is 8KW to 10KW, equipped with a 10KW fuel cell stack to meet the operation requirements of the vehicle.

[0033] (2) Equipped with 10KW fuel cell stack required for working: FCU (fuel cell controller), hydrogen supply system, hydrogenation system 5, hydrogen storage tank 8, special instruments for fuel cell vehicles, and central cooling system 1 for fuel cell vehicles.

[0034] (3) Since hydrogen is an explosive gas, a hydrogen leakage alarm system is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com