Patents

Literature

428results about How to "Avoid removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

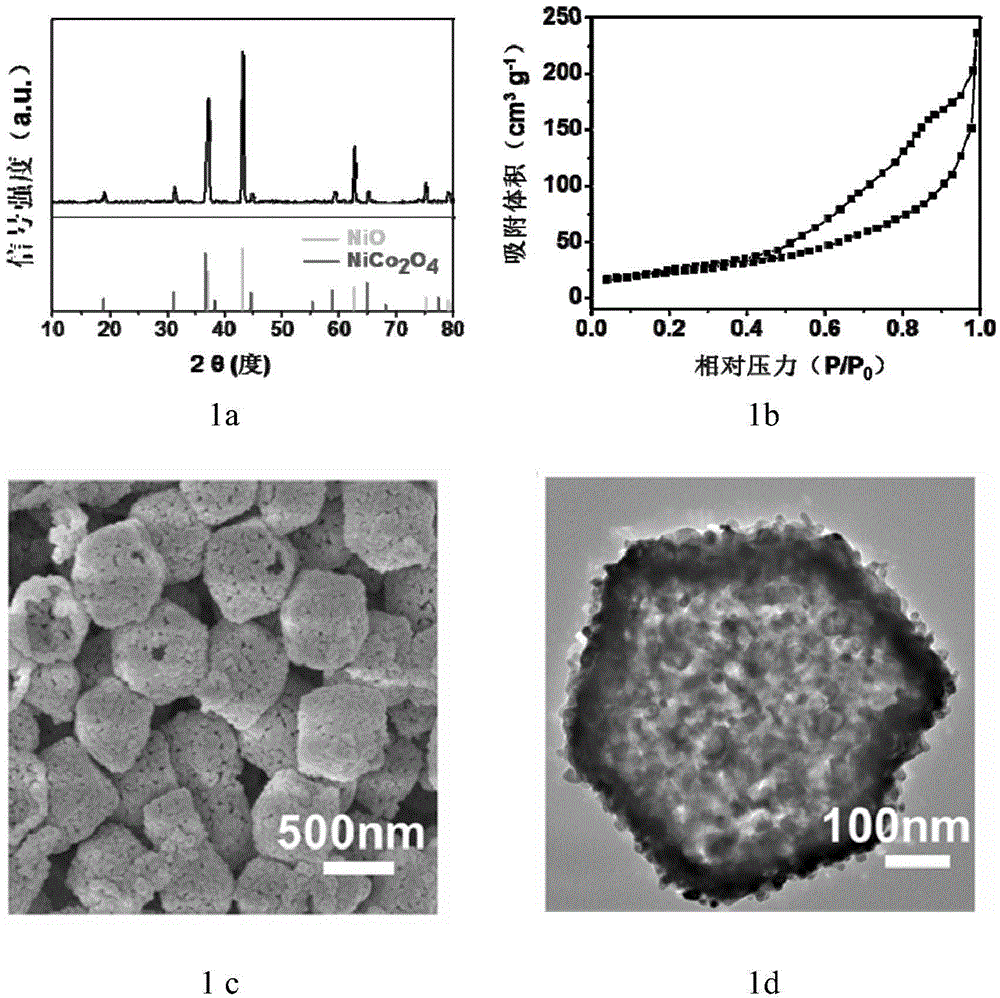

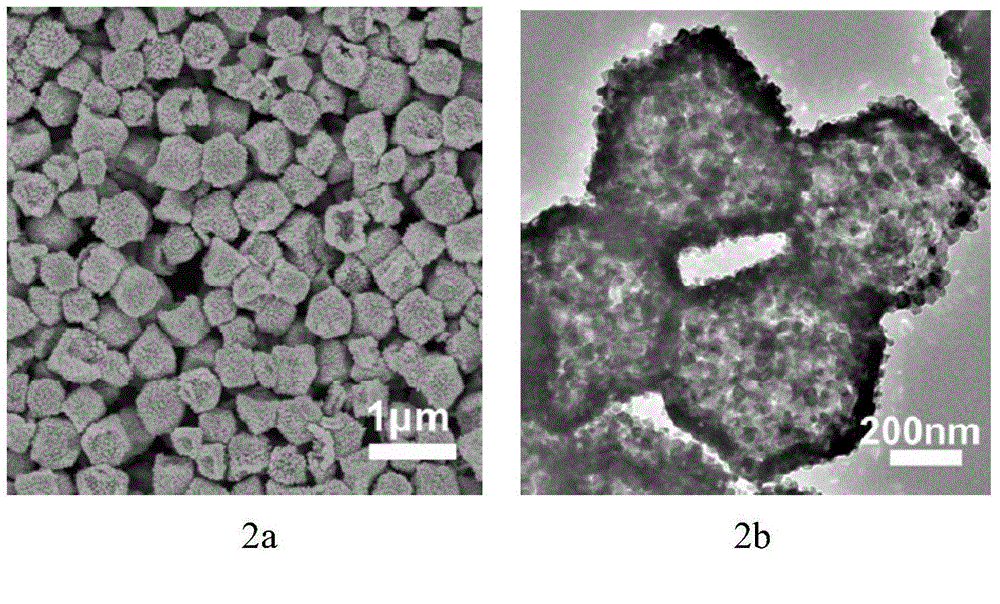

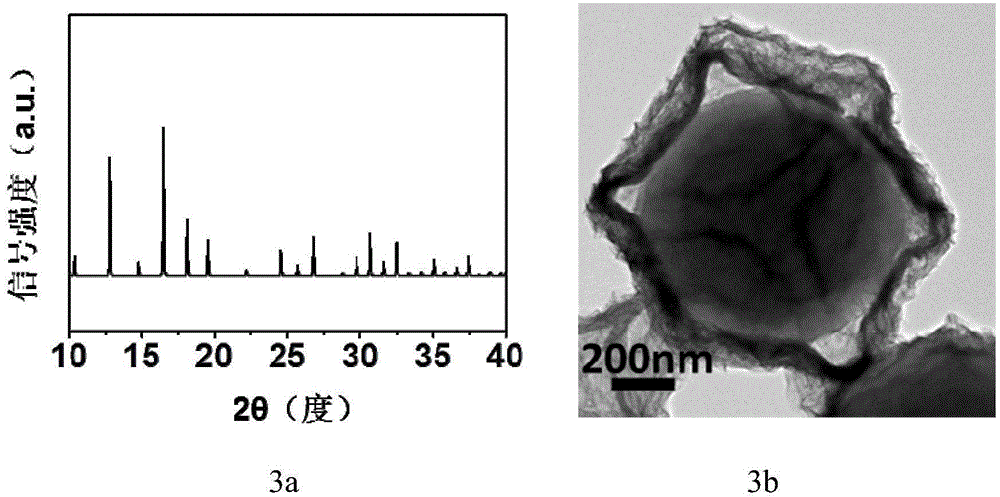

Preparation method of hollow nickel cobaltate nano polyhedron

The invention discloses a preparation method of a hollow nickel cobaltate nano polyhedron. The method comprises the following steps: (1) mixing an organic metal framework complex ZIF-67 and an alcoholic solution of nickel nitrate uniformly, and reacting at the temperature condition of 80-100 DEG C; (2) cooling to room temperature after reaction, collecting precipitate, cleaning by ethyl alcohol or other non-polar solvents, centrifuging, removing the solvents, and carrying out vacuum drying so as to obtain a hollow nickel cobalt hydroxide polyhedron; and (3) annealing the hollow nickel cobalt hydroxide polyhedron in air heating so as to obtain the porous nickel cobaltate nano hollow polyhedron. The method is simple to operate, and is environmentally friendly, and the mold plate removing process is omitted; the hollow obtained nickel cobaltate nano polyhedron has the relatively high specific surface area, relatively low mass transfer resistance and relatively excellent structure stability; as an electrode material of the lithium ion battery, the hollow nickel cobaltate nano polyhedron is superior to an existing transition metal oxide electrode material in cost and performance.

Owner:NANJING UNIV OF TECH

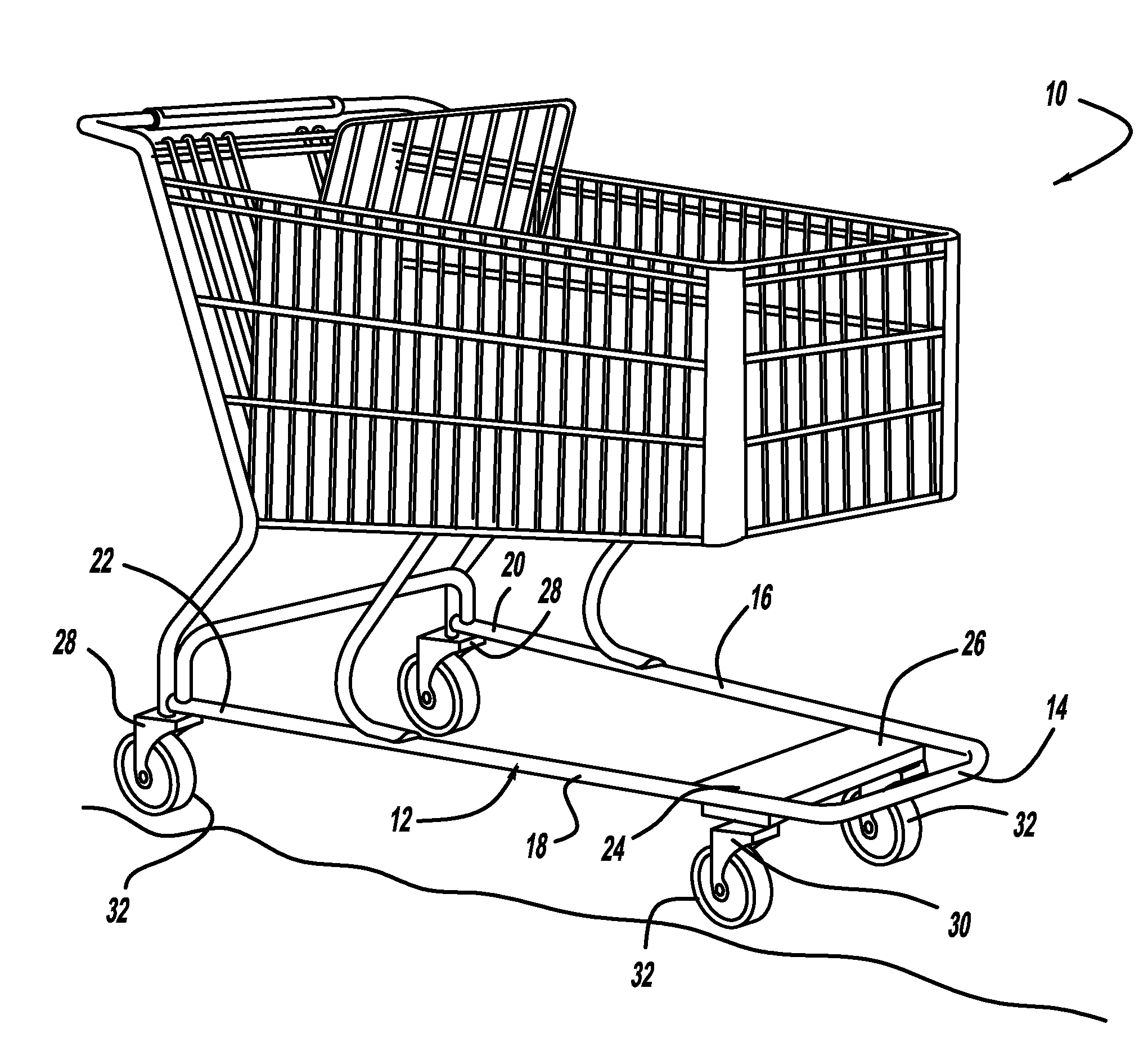

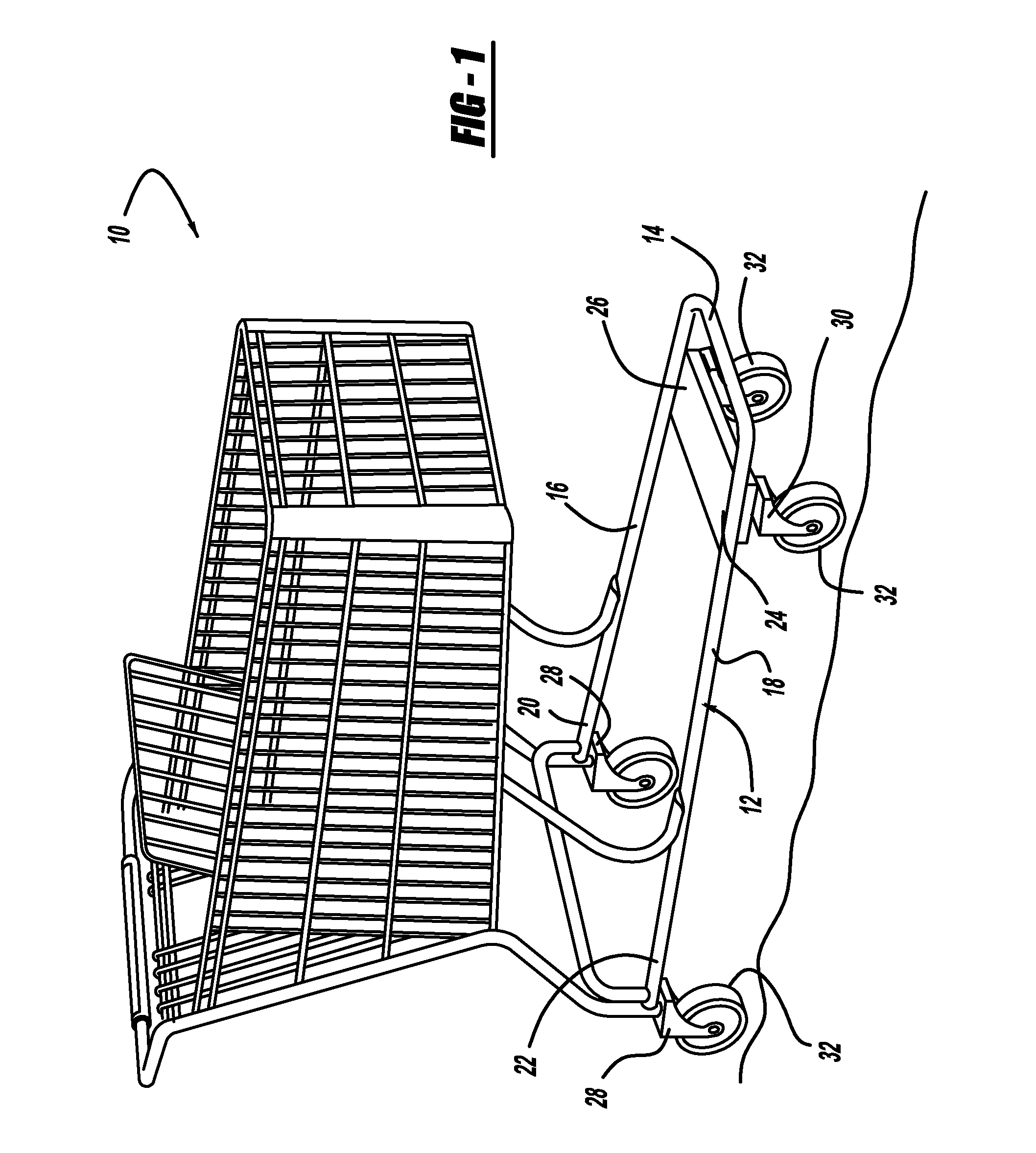

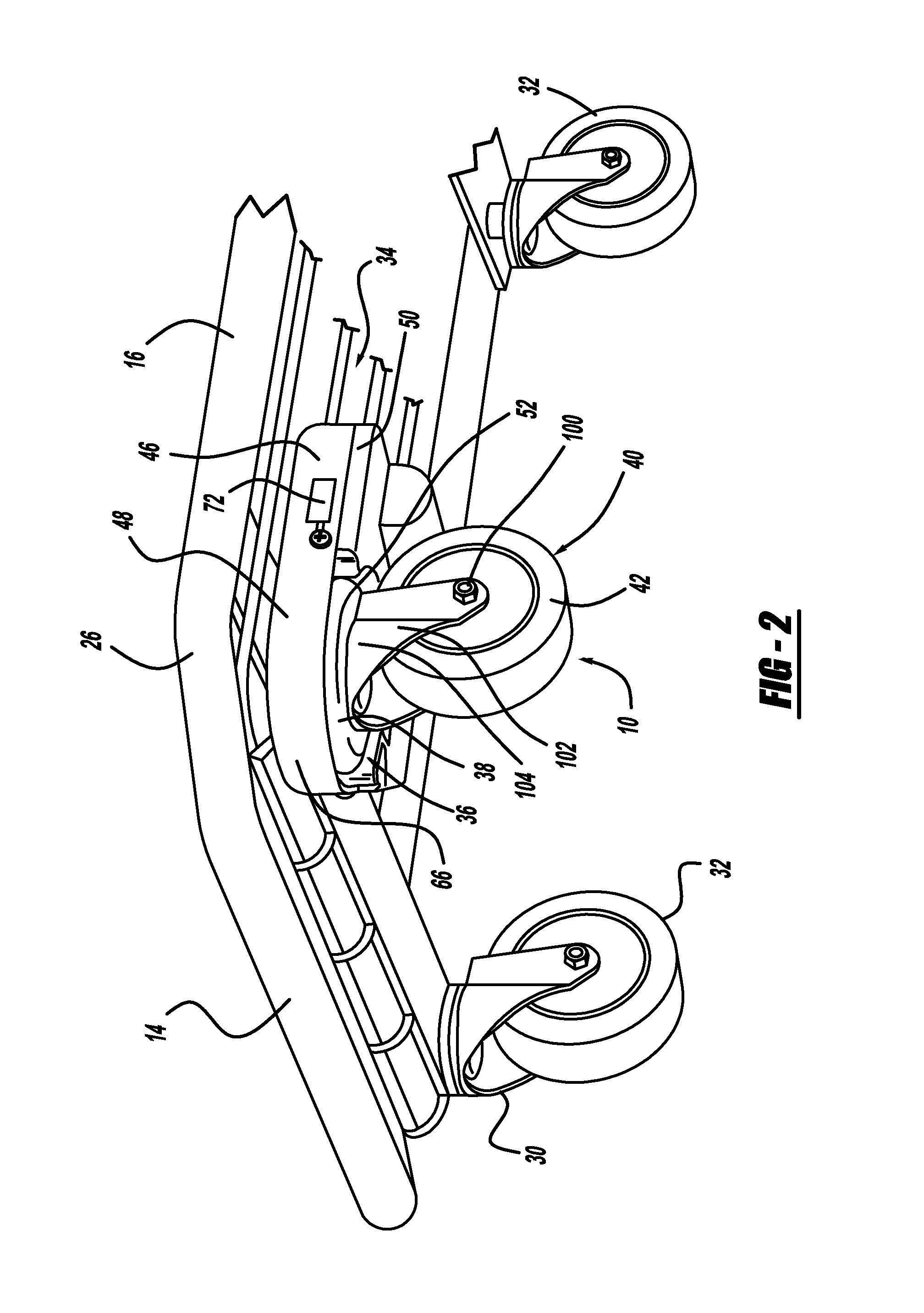

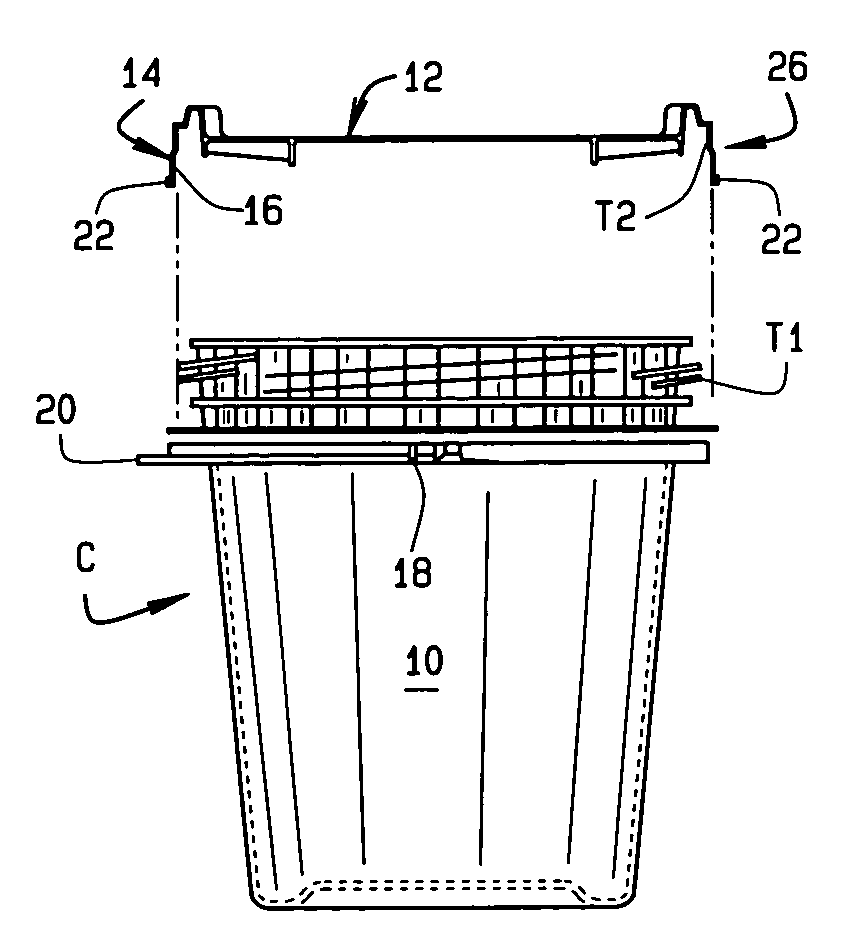

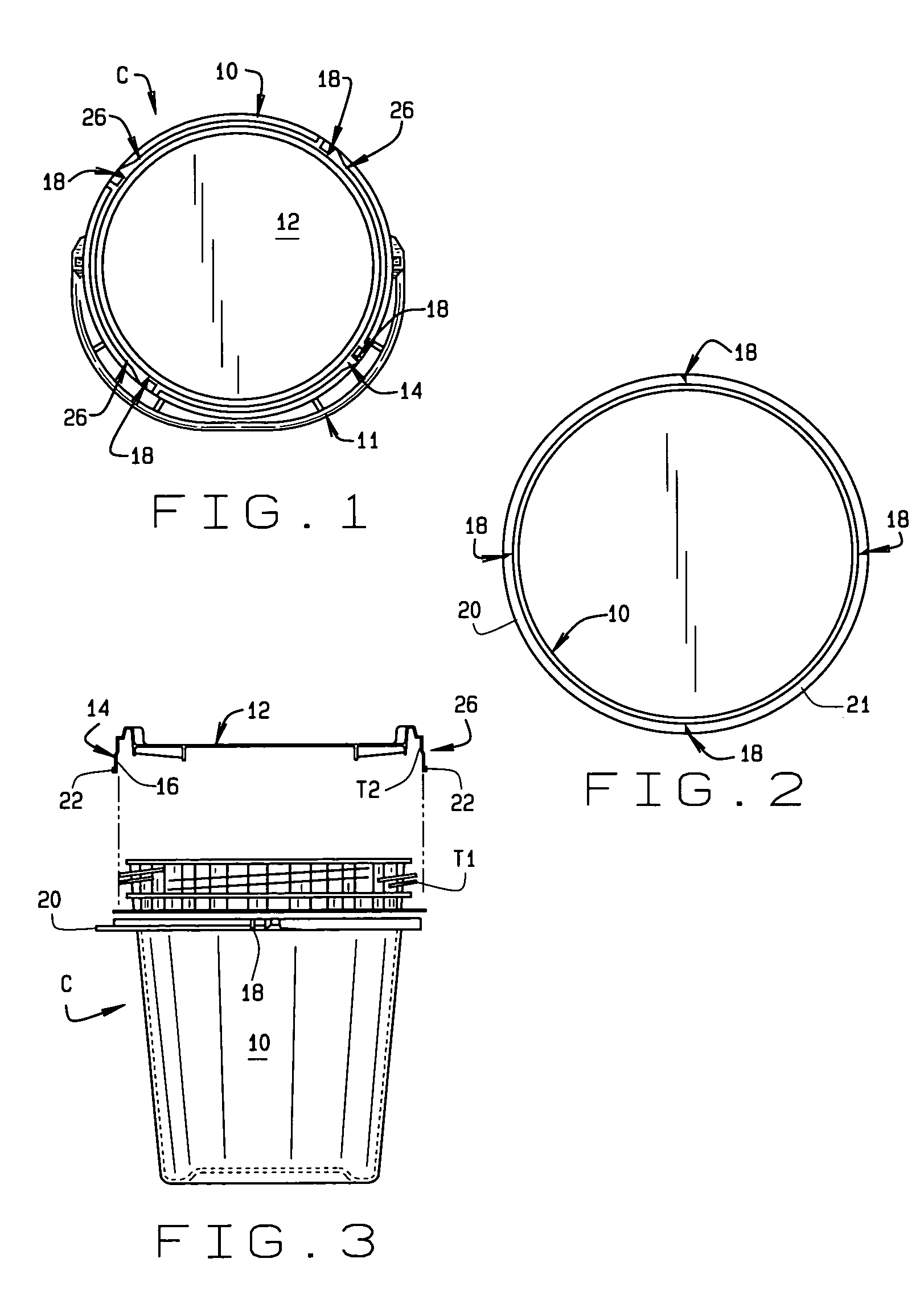

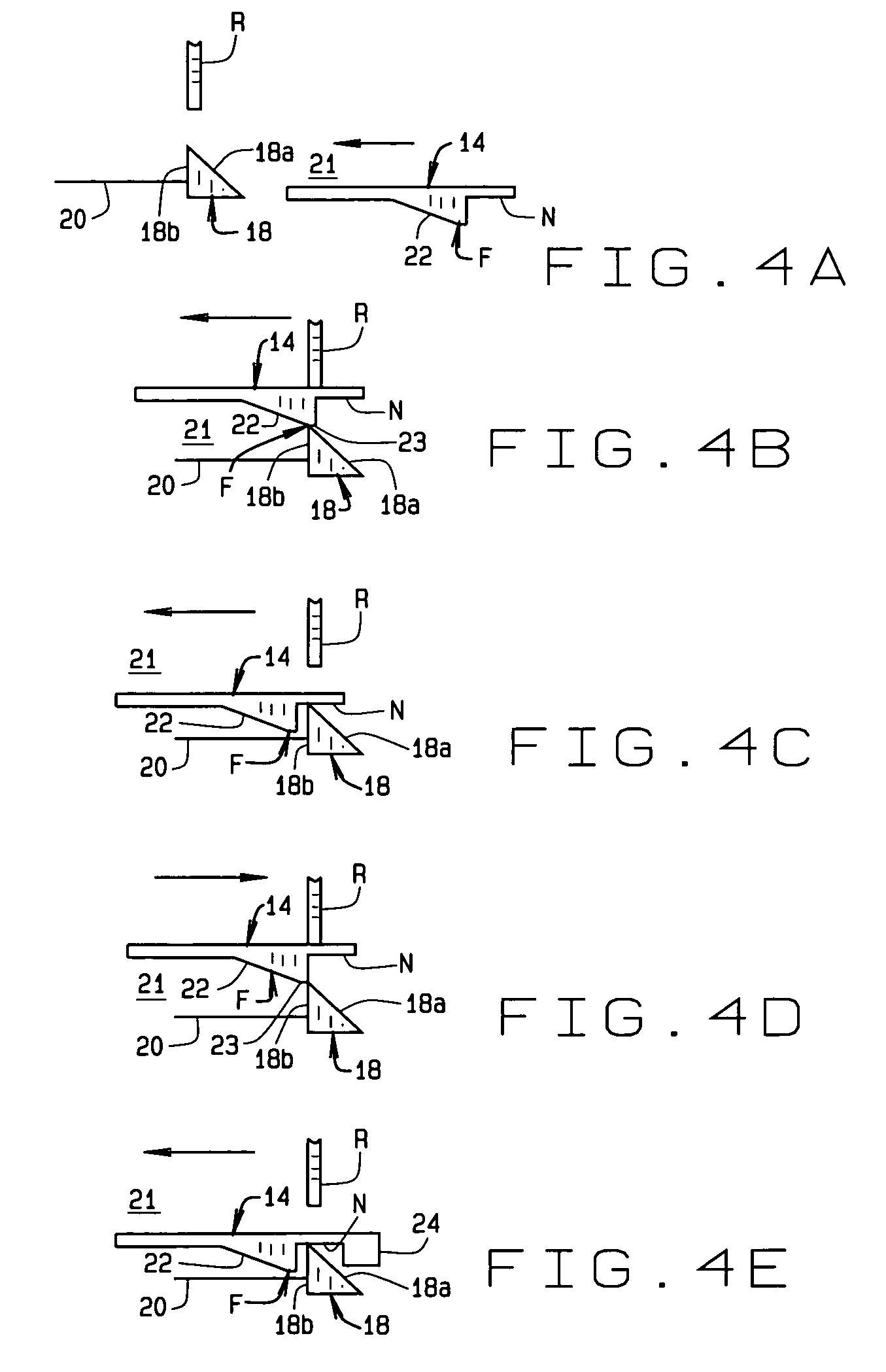

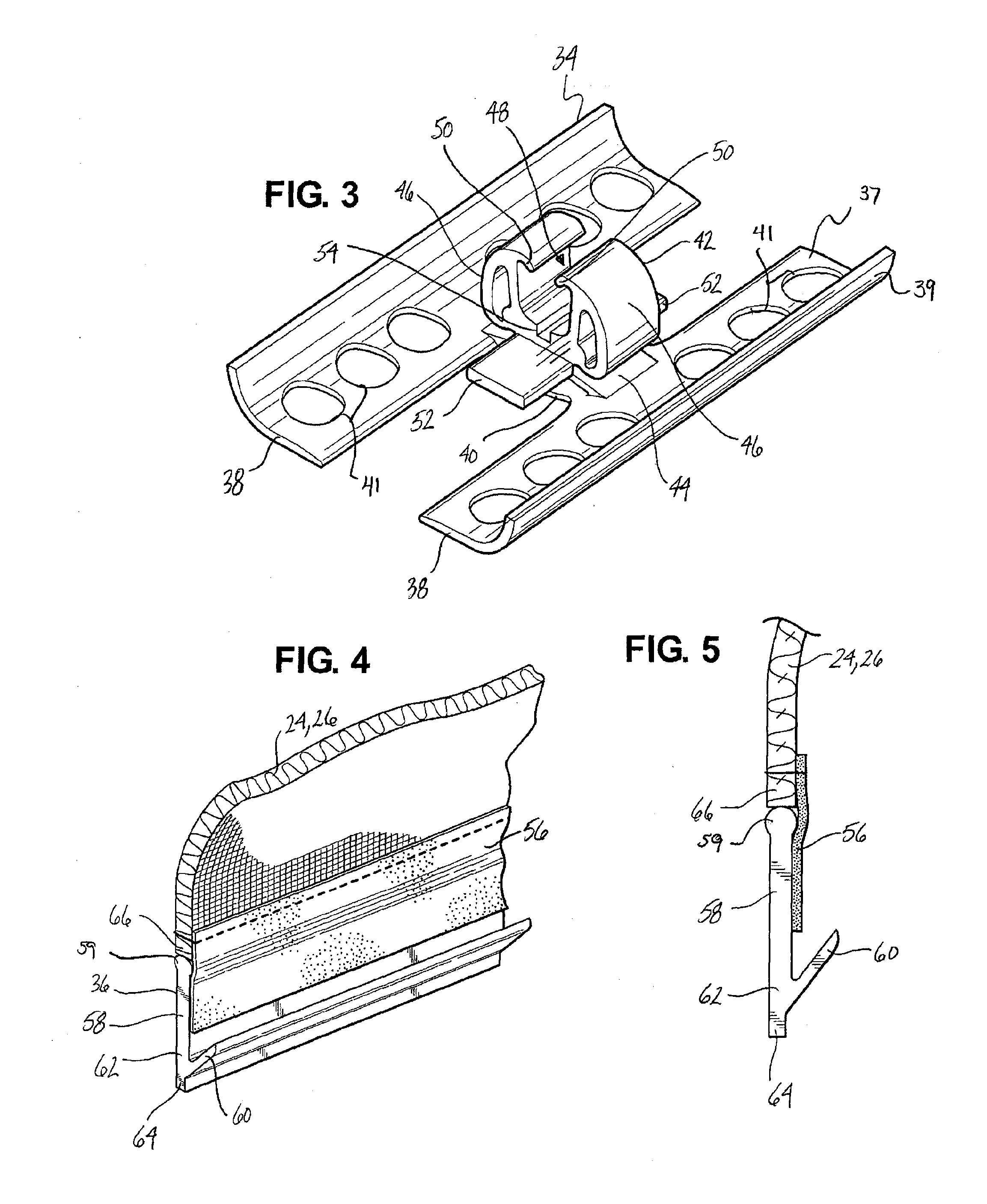

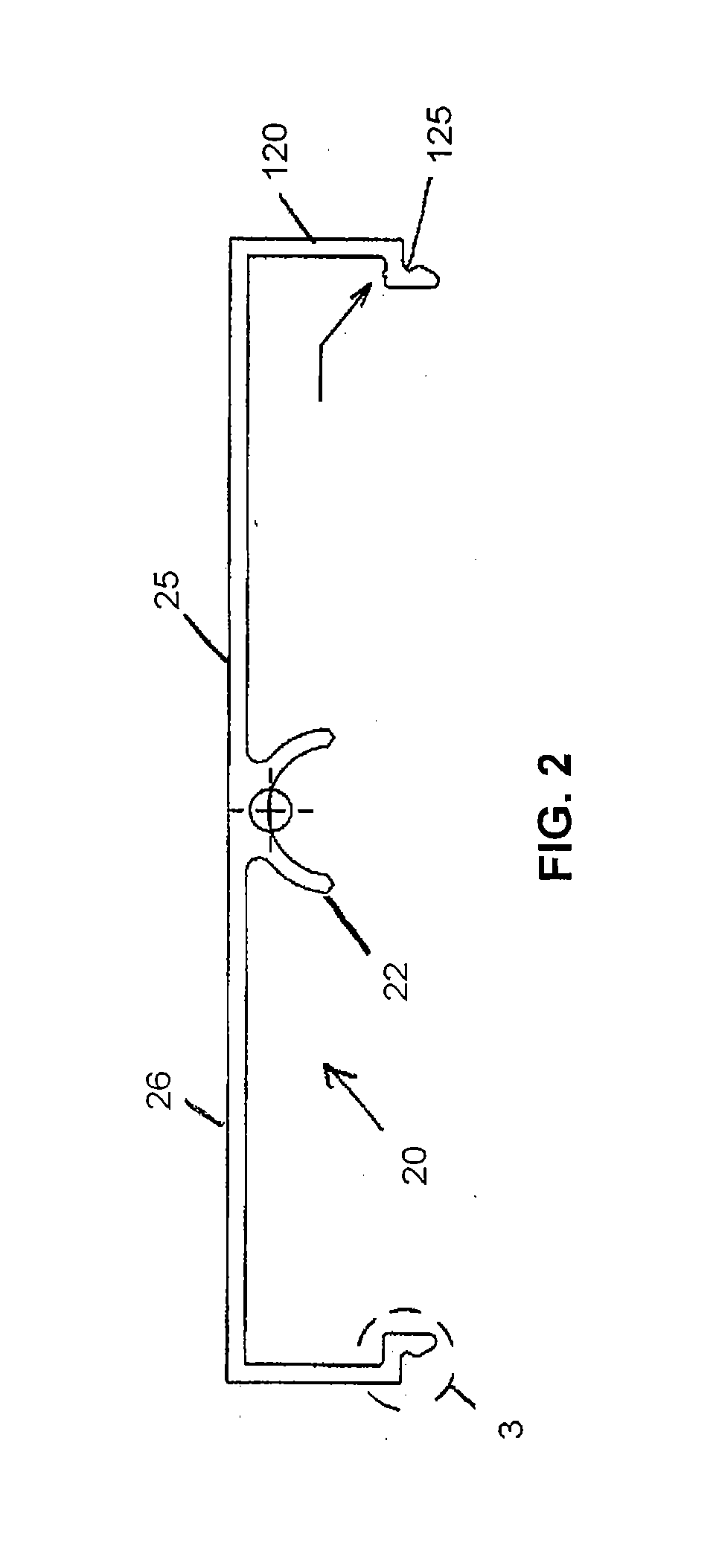

Security device and method for inhibiting the unauthorized removal of a transport vehicle from a designated use area

A security device for a transport vehicle for inhibiting the unauthorized removal of the vehicle from a designated use area comprises a mechanism for inhibiting forward movement of the vehicle, a sensor assembly for (a) detecting an attempted removal of the vehicle from the use area and generating a corresponding trigger signal, and (b) detecting a predetermined corrective action and generating a corresponding reset signal, and an actuator in communication with the sensor assembly for receiving the trigger signal and reset signal and activating and deactivating the mechanism respectively.

Owner:REINER ANDREW ERIC

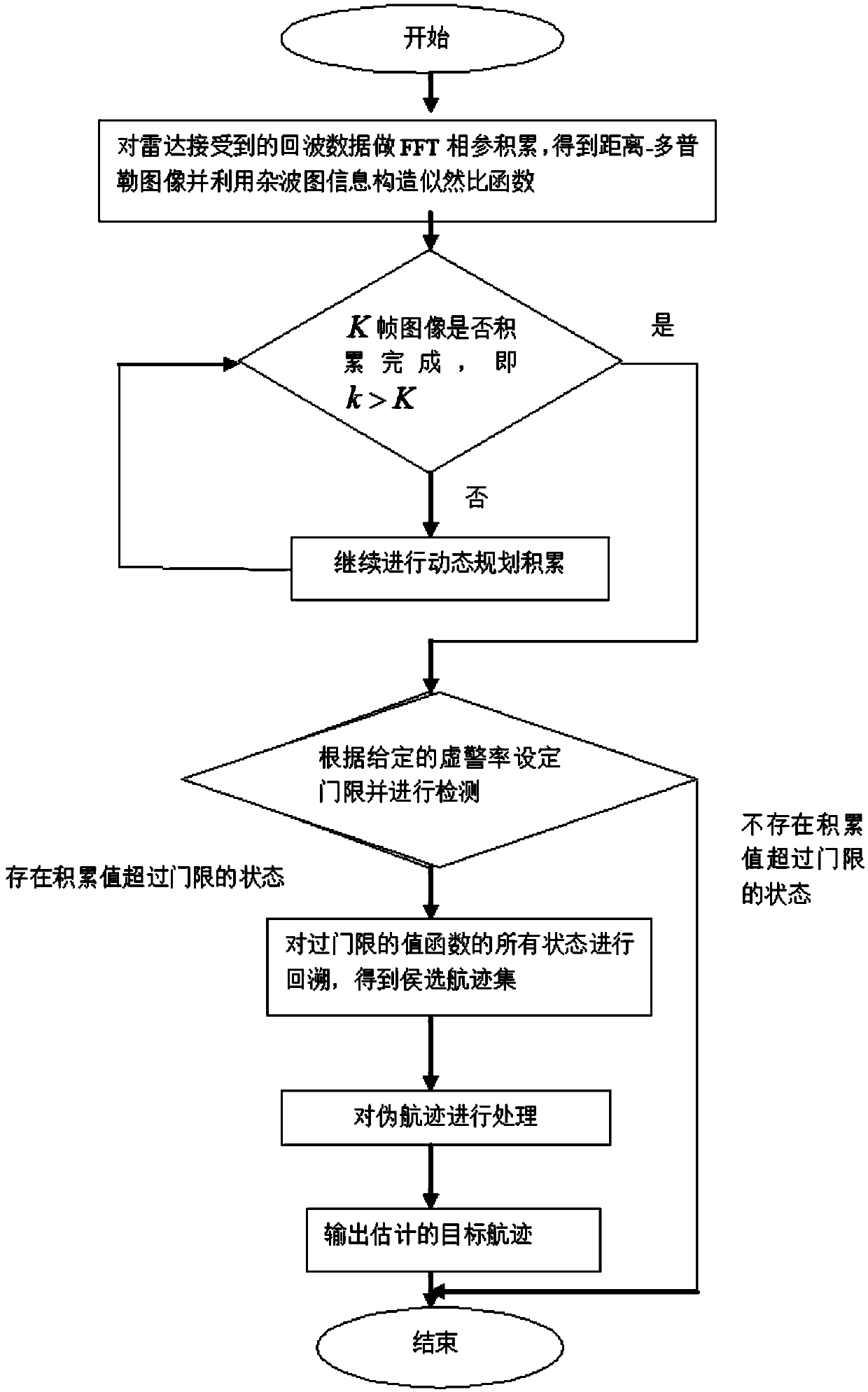

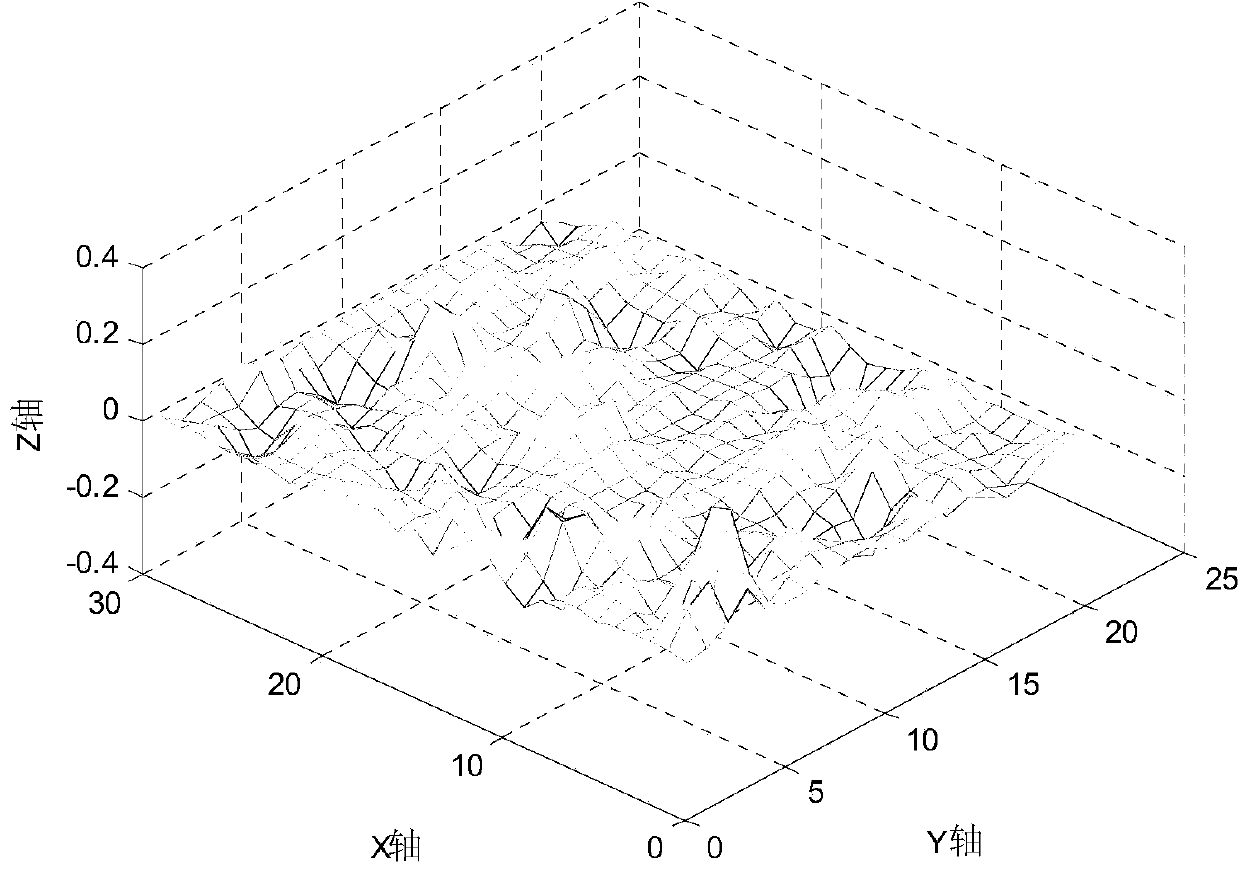

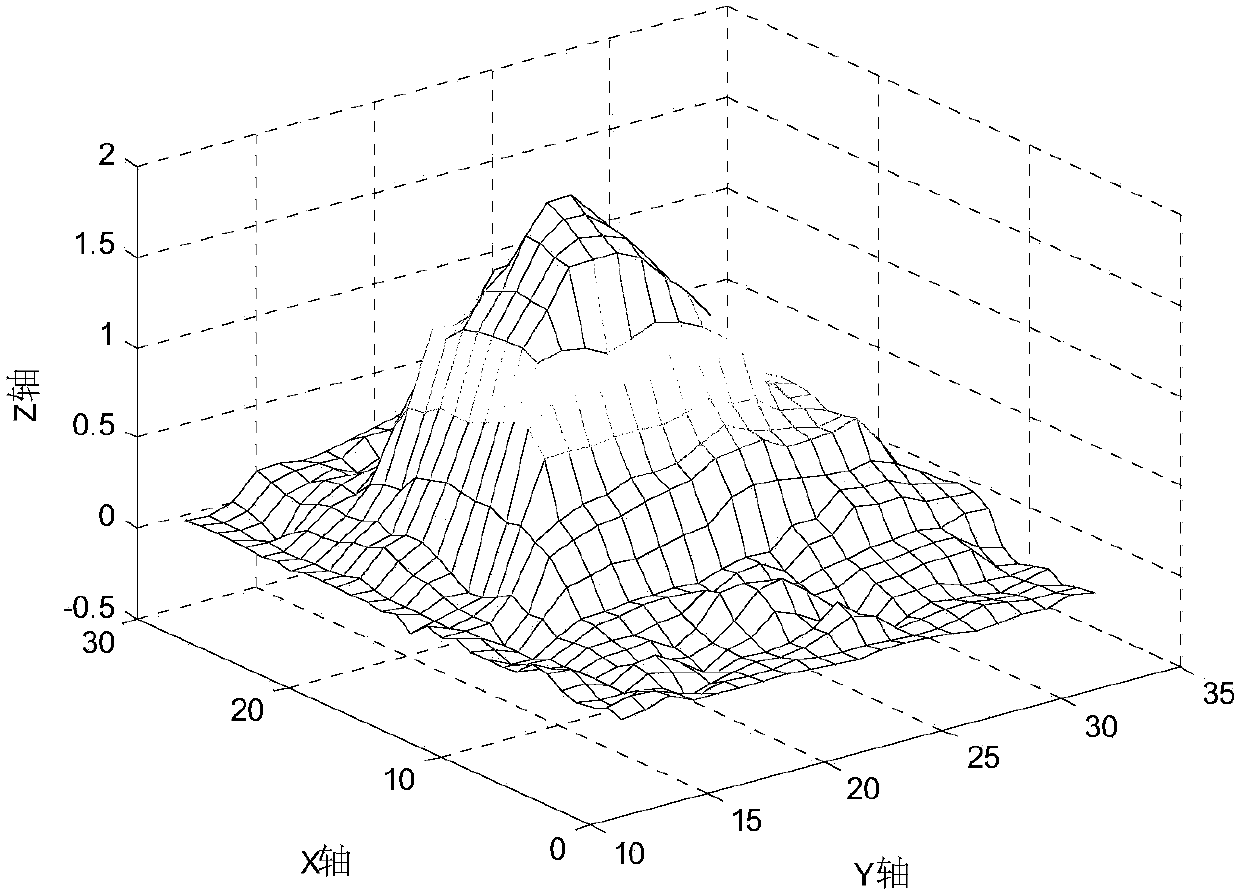

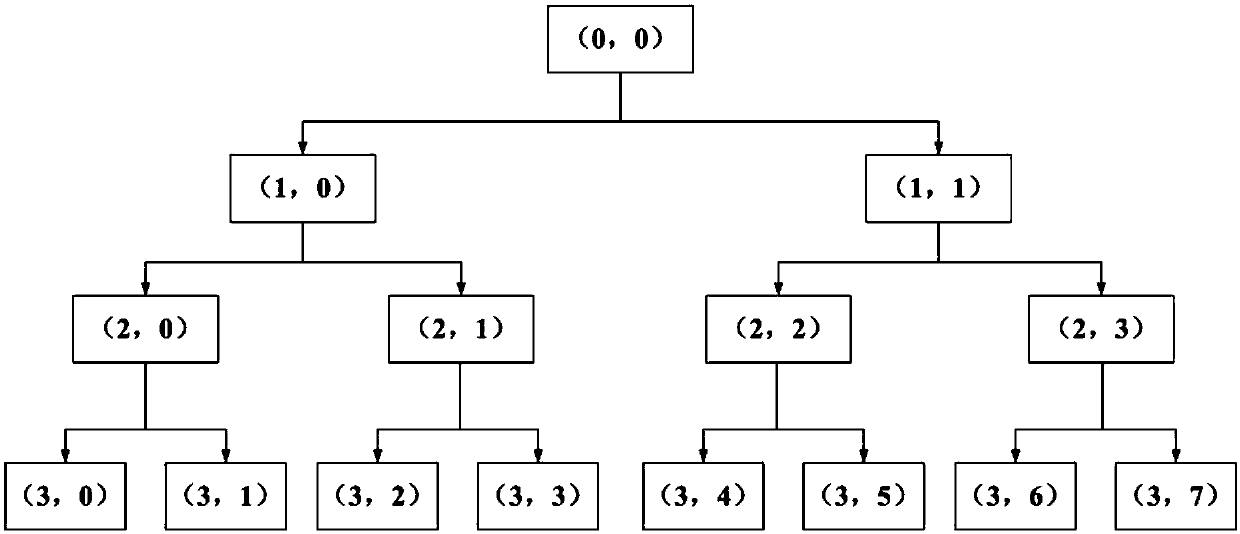

Method for conducting before-detection tracking on weak and small target in strong-clutter environment based on dynamic planning

ActiveCN104076355AAvoid removalReduce calculationRadio wave reradiation/reflectionDynamic planningGeomorphology

The invention belongs to the technical field of radar weak and small target detection and tracking, and particularly relates to a method for conducting before-detection tracking on a weak and small target in a strong-clutter environment based on dynamic planning. The method for conducting before-detection tracking on the weak and small target in the strong-clutter environment based on dynamic planning includes the first step of preprocessing echo data received by radar to obtain a processed distance-doppler two-dimensional image, and the second step of constructing a complex number likelihood ratio function according to the distance-doppler two-dimensional image, taking the complex number likelihood ratio function as a value function for dynamic planning, and conducting before-detection tracking on the target according to a dynamic planning method so as to obtain the target track.

Owner:XIDIAN UNIV

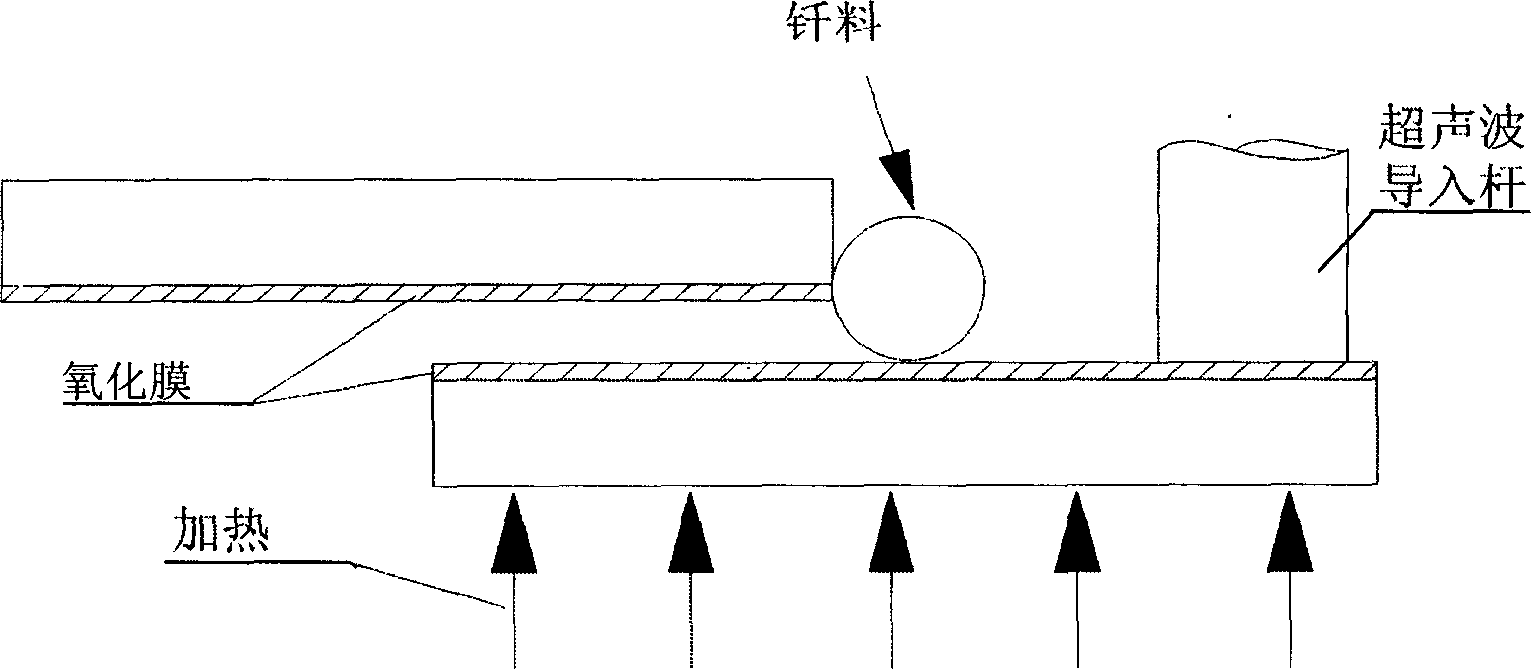

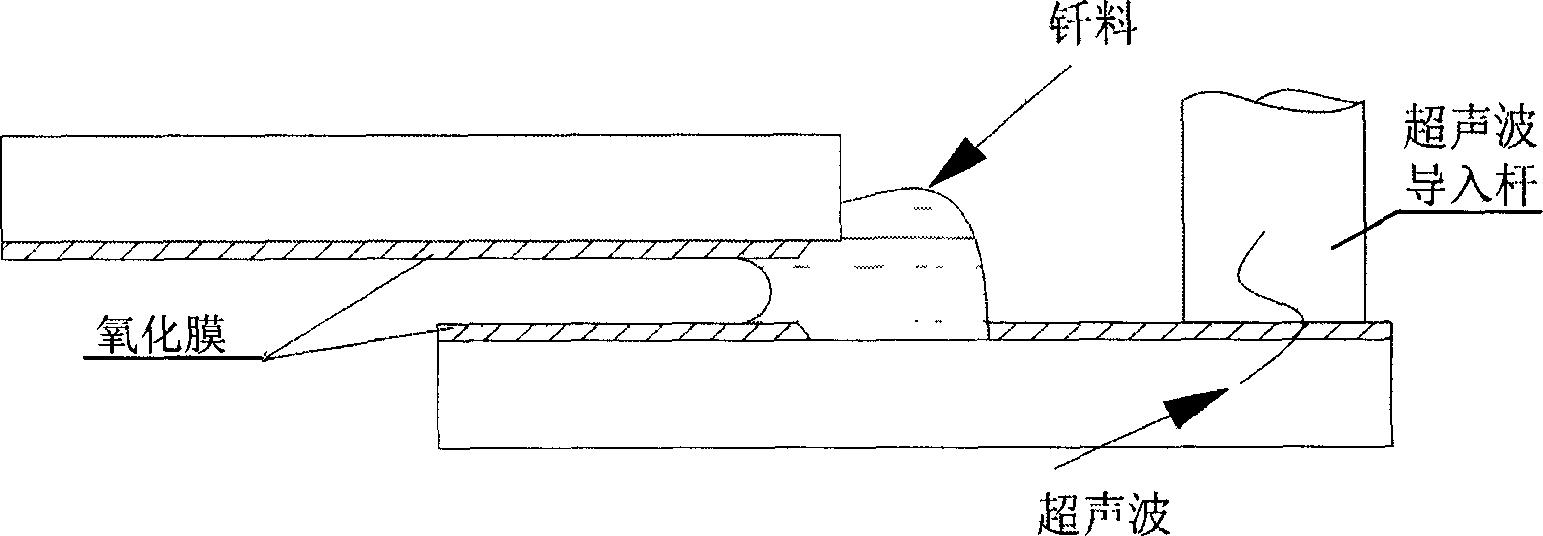

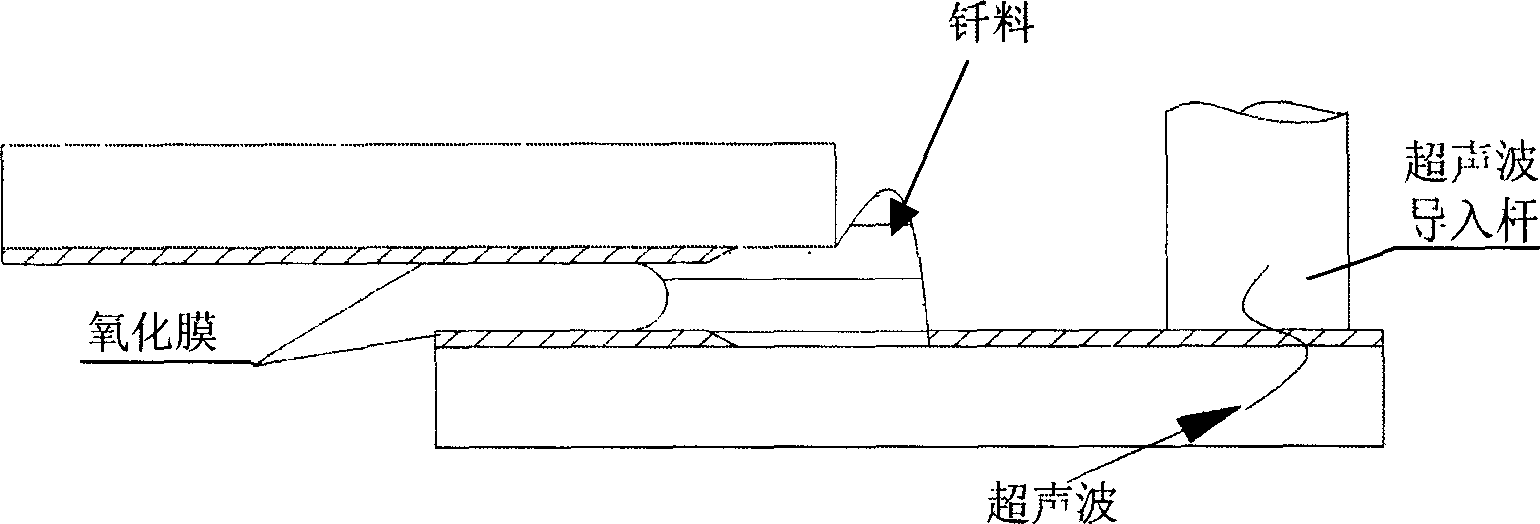

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1644291AAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

An ultrasonic capillary welding method for the Al-base composite material includes such steps as arranging upper and lower parts to be welded in such manner that the gap between them is 10-300 microns, putting the flux close to lap end, heating to smelt the flux, holding the temp, pressing the ultrasonic head onto surface of the part to be welded, and applying ultrasonic vibration for 0.5-15 S. Its advantages are high welding quality, low welding temp, and high speed.

Owner:HARBIN INST OF TECH

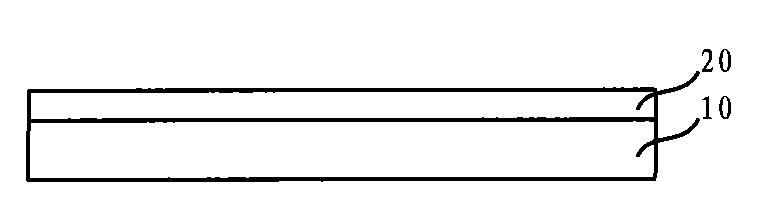

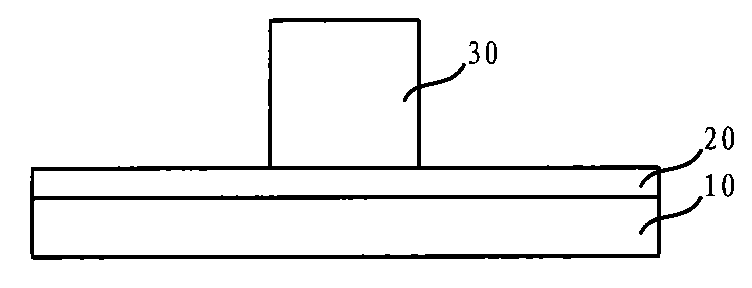

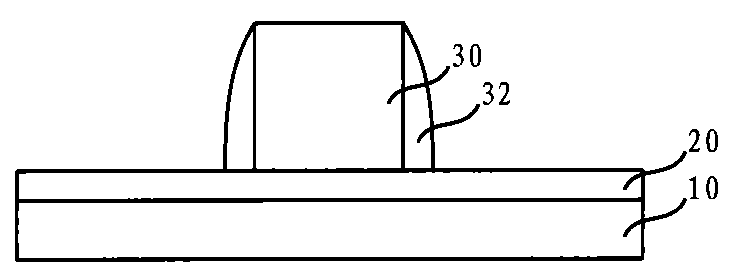

Metal grid forming method

InactiveCN101593686AAvoid damageAvoid removalSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricMetallurgy

The invention relates to a metal grid forming method, comprising the following steps: forming a gate dielectric layer on a substrate; forming an imaging amorphous carbon layer on the gate dielectric layer; forming a side wall surrounding the imaging amorphous carbon layer; forming a interlevel dielectric layer coating the imaging amorphous carbon layer and the side wall; flattening the interlevel dielectric layer and exposing the imaging amorphous carbon layer; removing the imaging amorphous carbon layer by oxygen ashing process to form grooves in the interlevel dielectric layer; forming metal layers to fill the grooves and coat the interlevel dielectric layer. The invention also provides another metal grid forming method. The surface damage of the substrate supporting the metal grid can be reduced by both of the methods.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

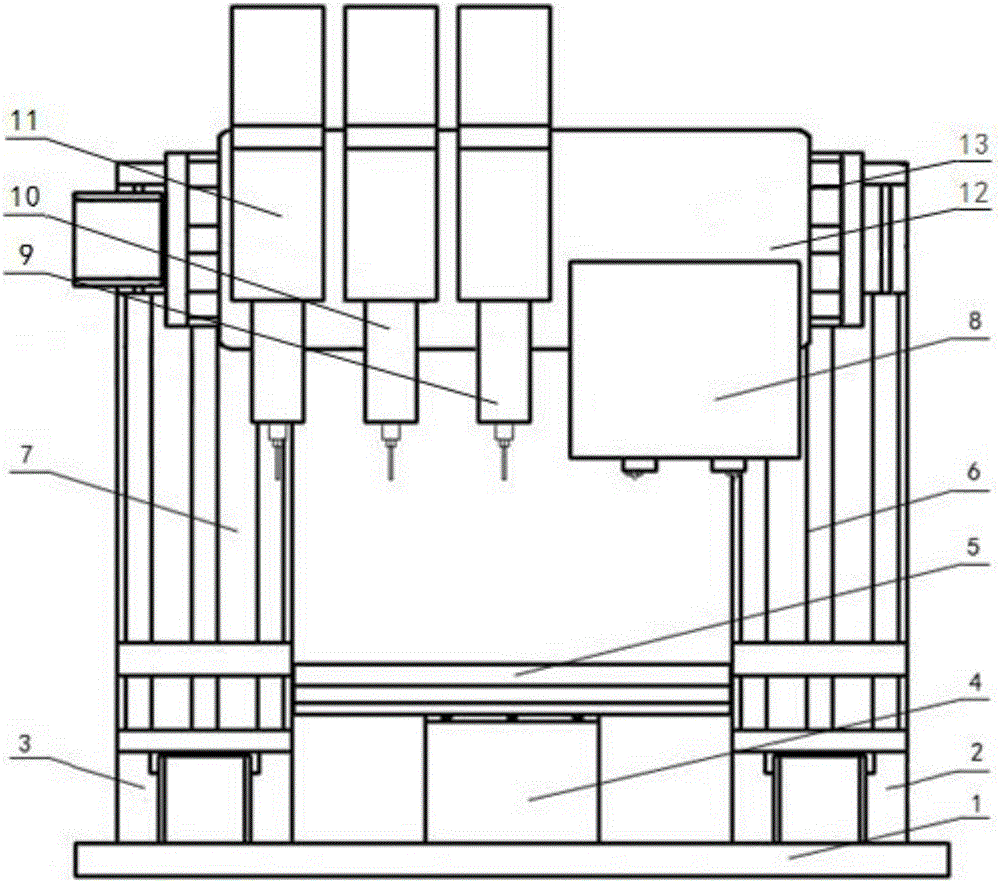

3D printing method for embedded electronic product and 3D printer

ActiveCN106493939AEfficient integrated manufacturingLow costAdditive manufacturing apparatus3D object support structuresComputer printingHemt circuits

The invention discloses a 3D printing method for an embedded electronic product and a 3D printer. After each layer of structure material is printed, a layer of release material is arranged around a support reserved position in a jet printing manner, support printing is conducted, and when the set of structure layers are printed, supports of reserved holes and grooves are removed, an electronic component is embedded, printing of the set of electric conduction layer structure, jet printing of electric conduction circuits and jet printing of dielectric materials between the electric conduction circuits are sequentially conducted, the process is repeatedly conducted till the last set of electric conduction layer structure is printed, and the electronic product is packaged through printing structure materials. The release material is introduced between the structure material and a support material, the support material is easy to remove, on one hand, removal of the supports through an ultrasonic alkaline solution is avoided (a traditional support removing technology is not allowed to be adopted in the embedded electronic product), and on the other hand, influences on a printed electric conduction circuit from support removal are avoided. The problem about support removal in the embedded electronic product manufacturing process is effectively solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

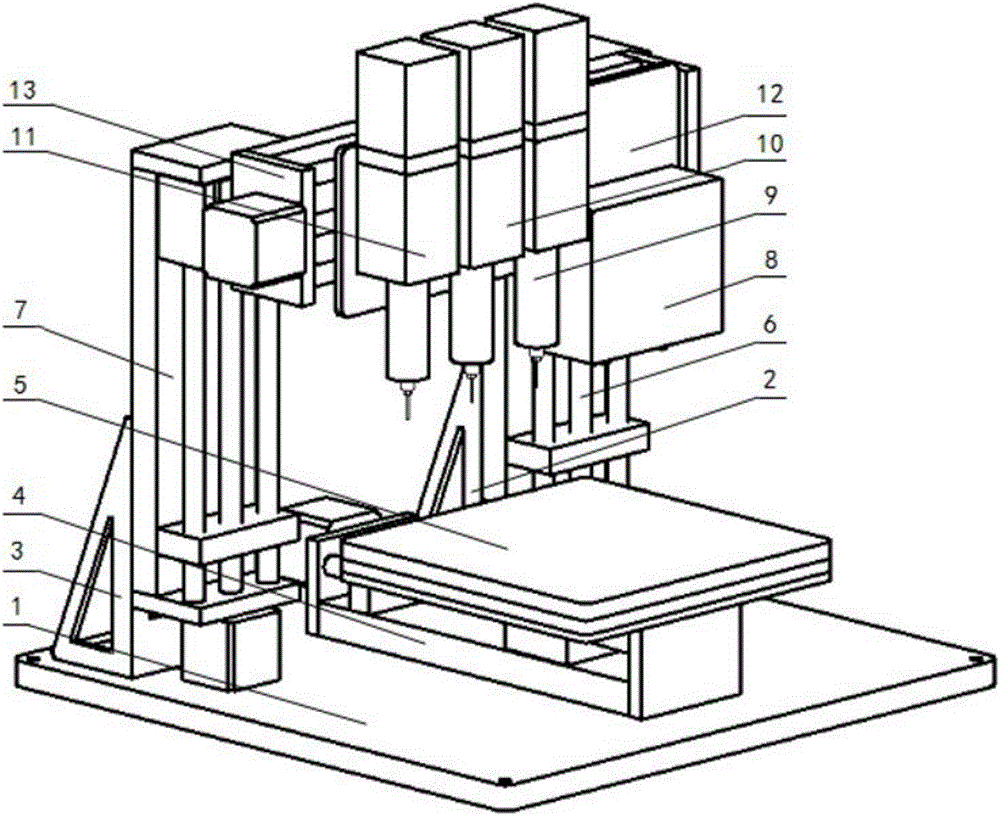

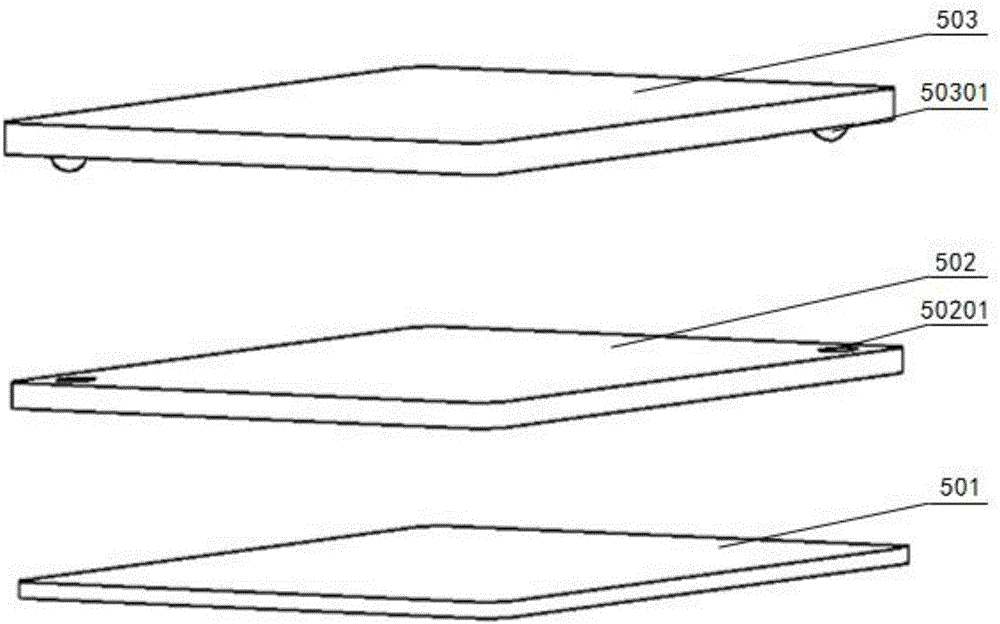

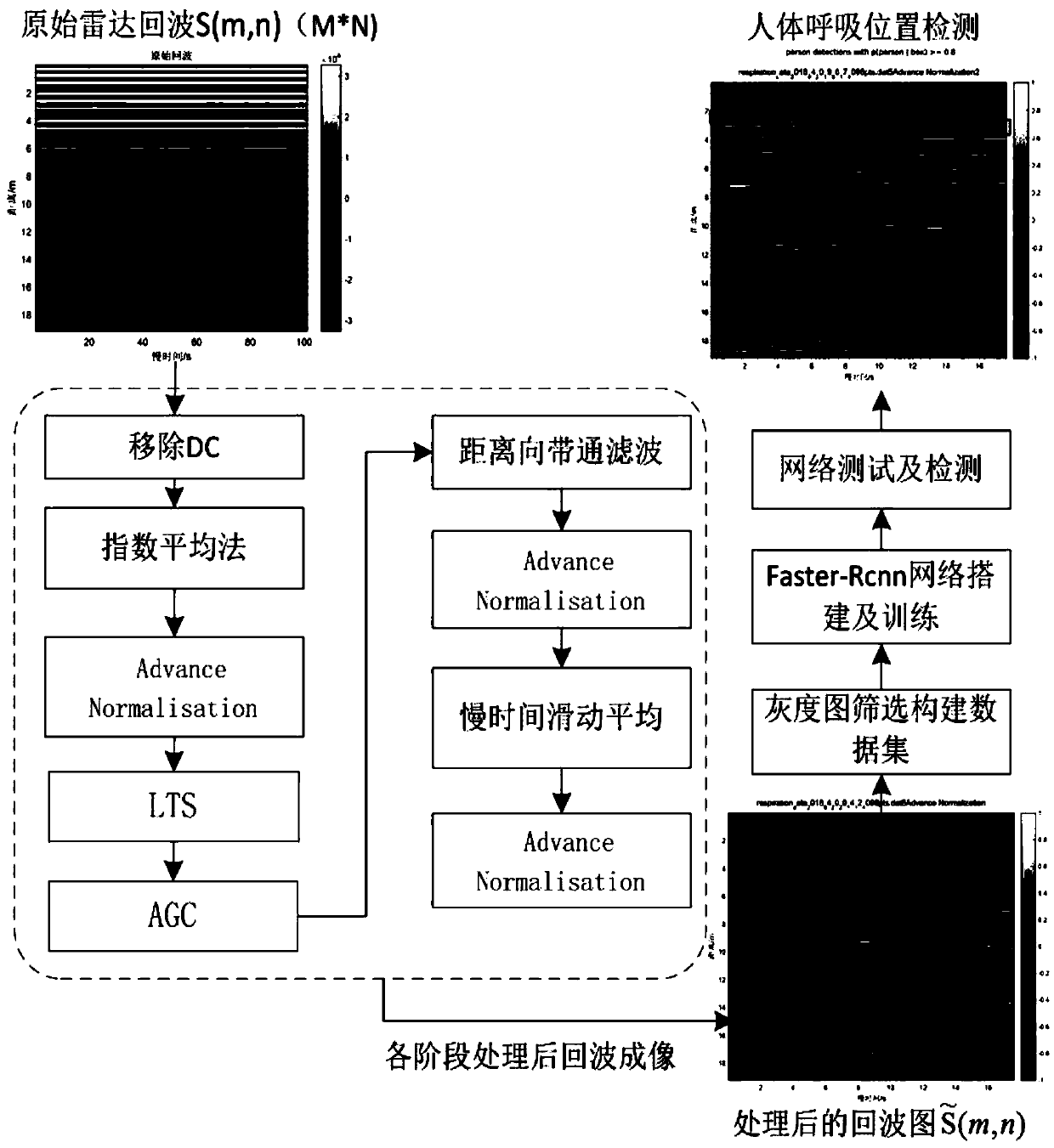

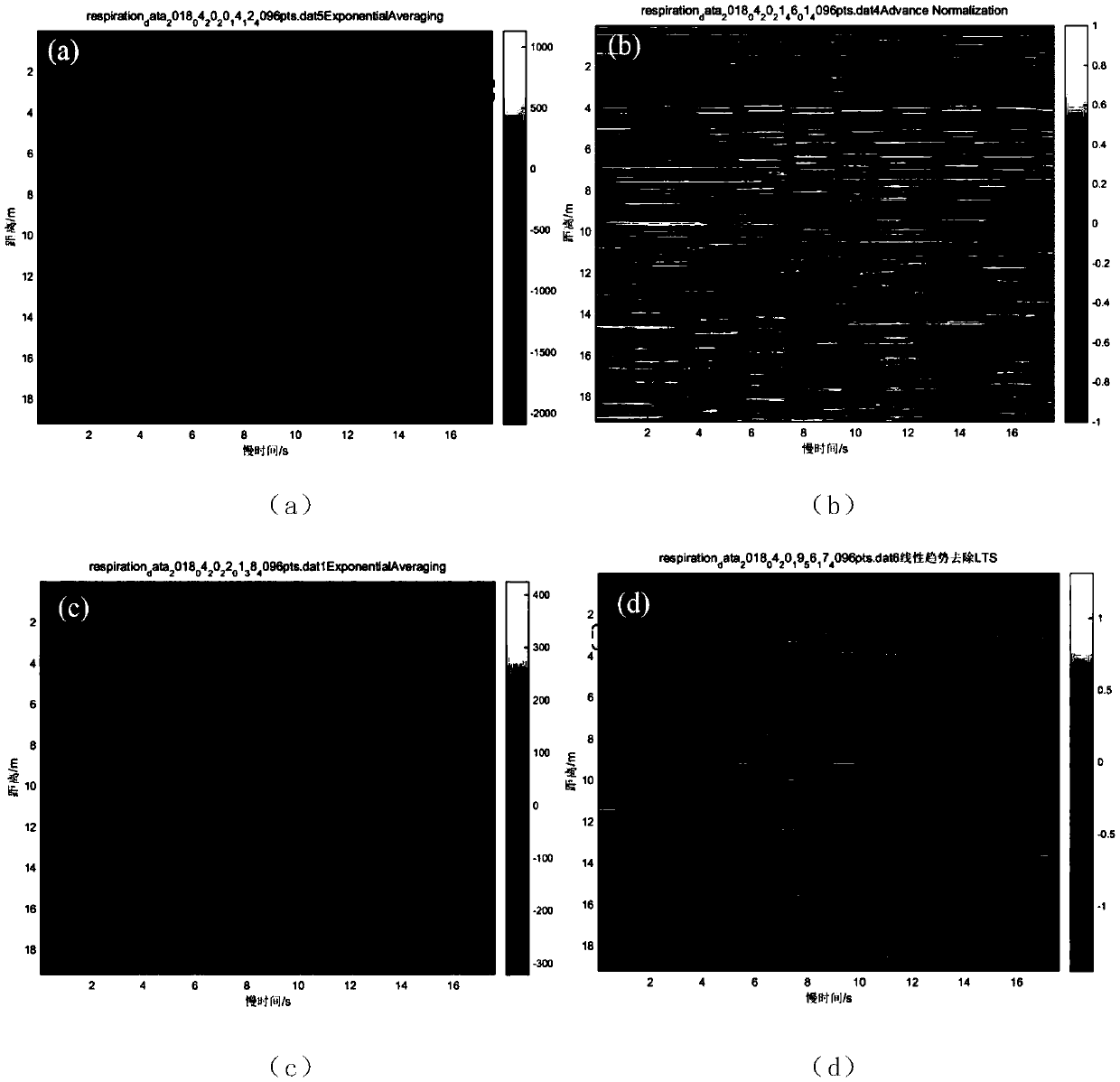

Through-wall ultra-wideband radar human body respiration signal detection method based on Faster-RCNN network

ActiveCN109031287AInsufficient avoidance of misjudgmentImprove signal-to-noise ratioRespiratory organ evaluationSensorsPattern recognitionData set

The invention discloses a through-wall ultra-wideband radar human body respiration signal detection method based on a Faster-RCNN network. The method comprises the following steps: performing denoising and weak signal enhancement preprocessing on an original slow time-distance two-dimension ultra-wideband radar echo signal; and then continuously performing signal enhancement and denoising on the processed echo by adopting an Advance Normalisation method; imaging the echo signal in the preprocessing process as a gray image by adopting MATLAB, wherein the image width is corresponding to the echoslow time direction, and the image height is corresponding to the echo distance direction; and screening the obtained gray image, annotating a data set, and training a Faster-RCNN network model to perform human body respiration weak signal identification. The method disclosed by the invention is high in identification accuracy rate, high in detection speed, and capable of providing better technical support for the radar echo target detection, the life detection and practical technologies in actual applications.

Owner:XI AN JIAOTONG UNIV

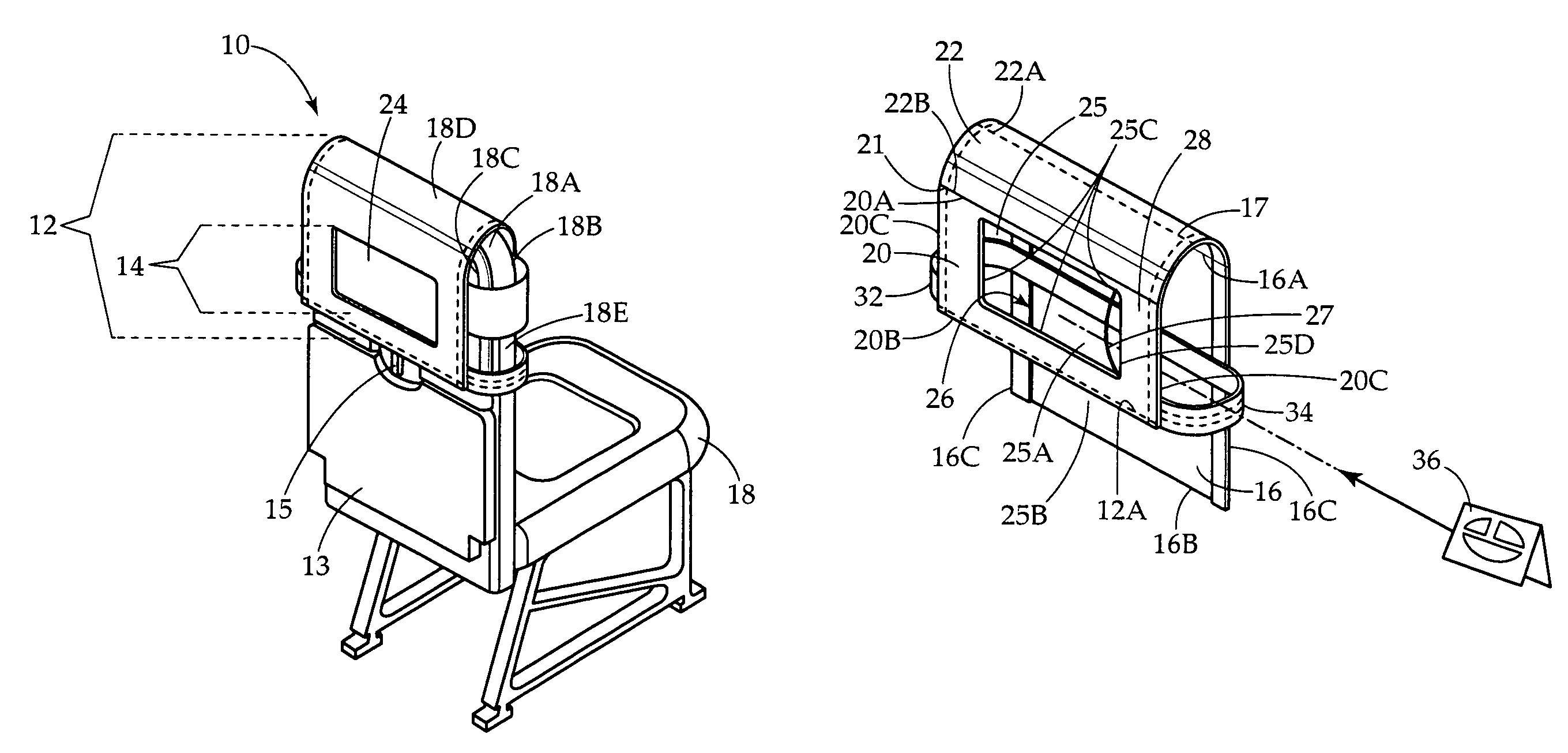

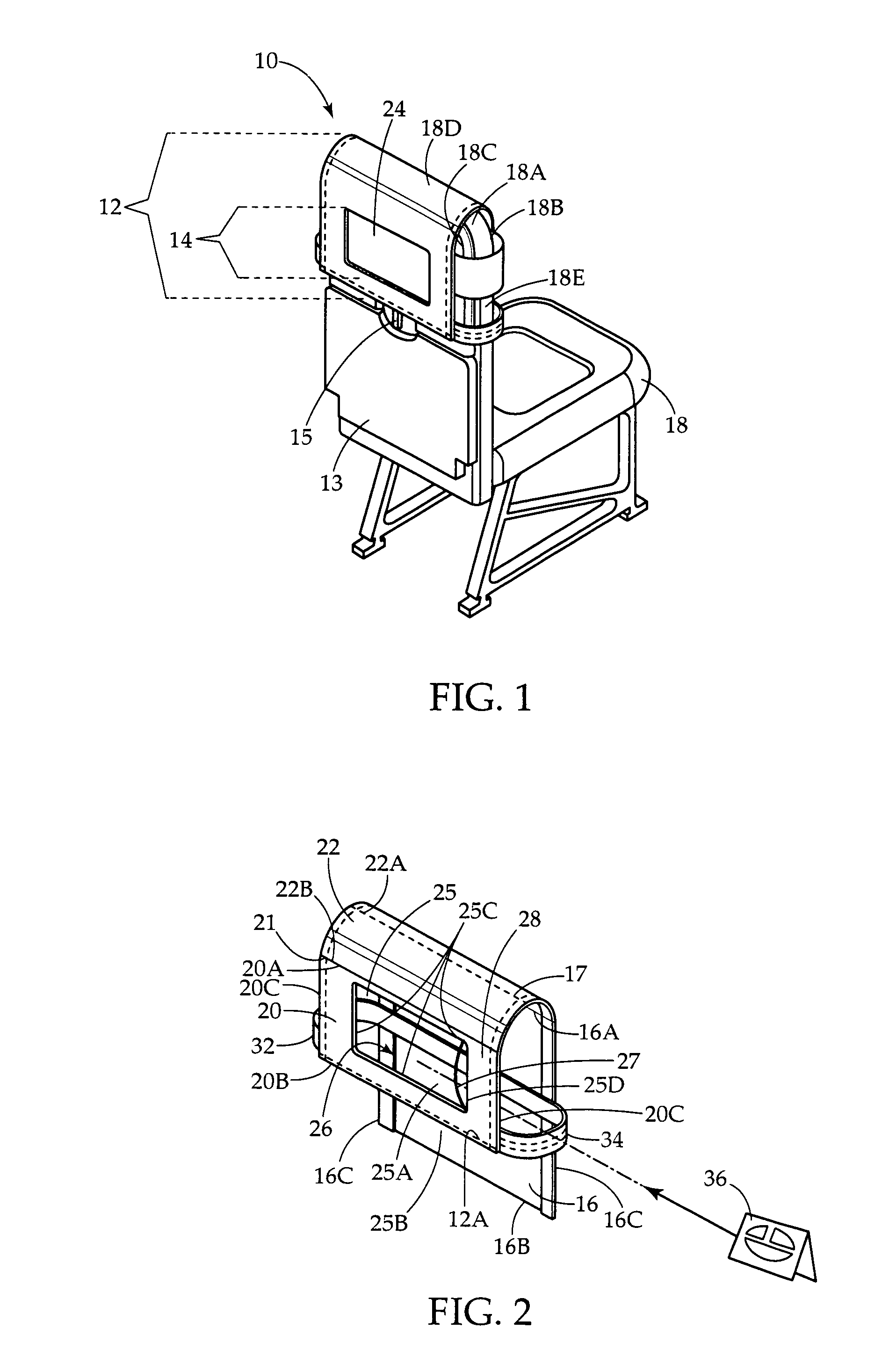

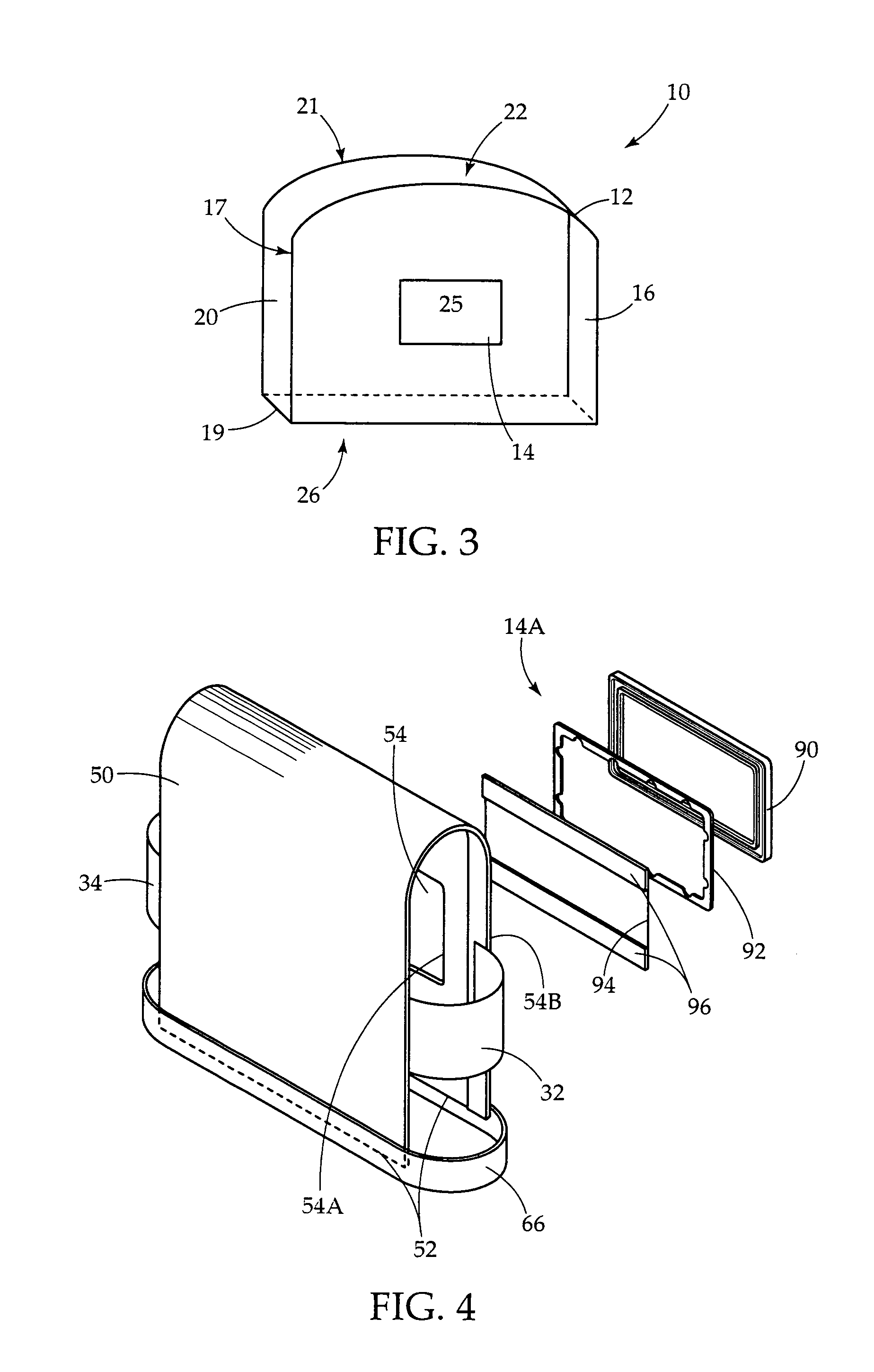

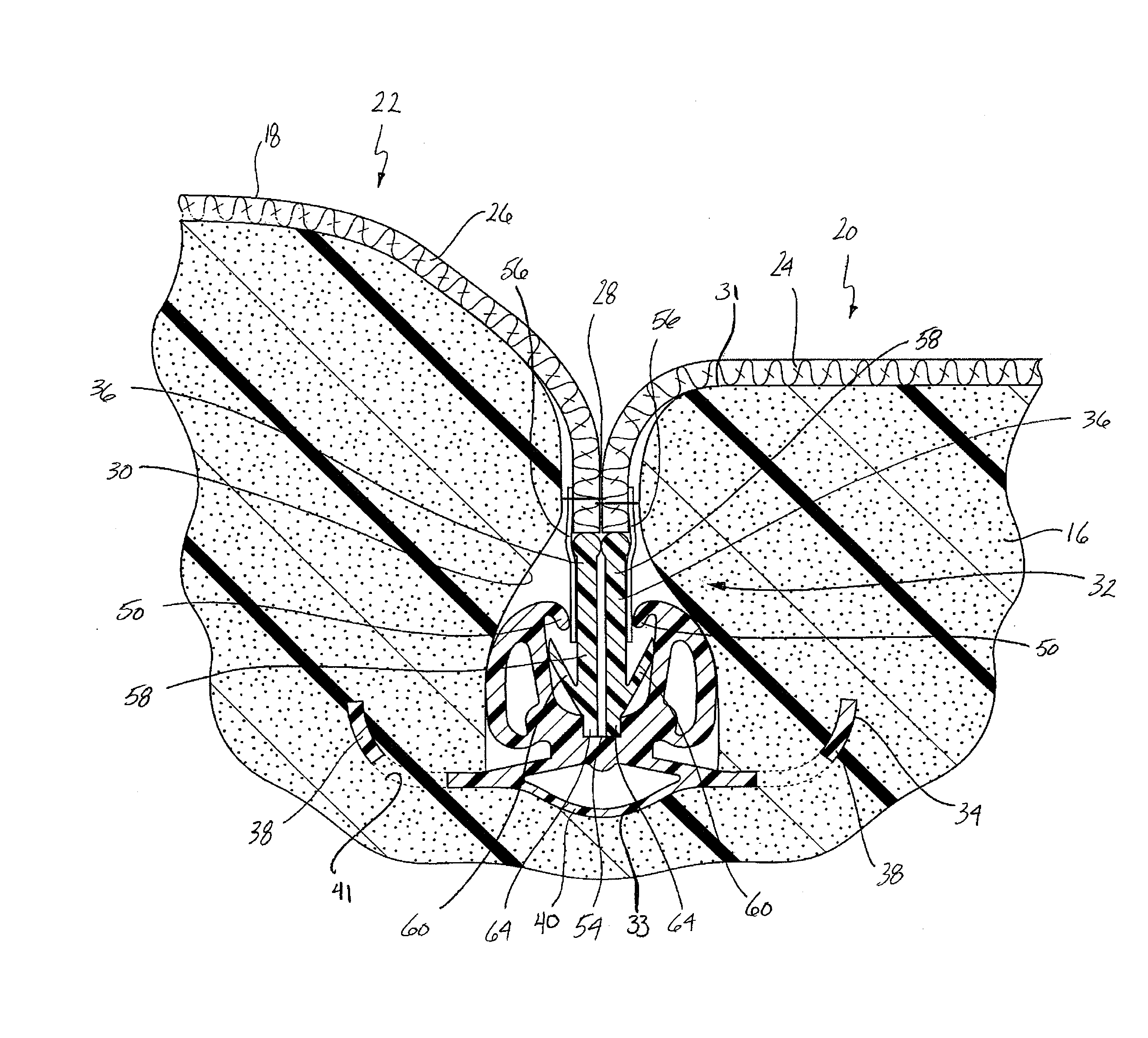

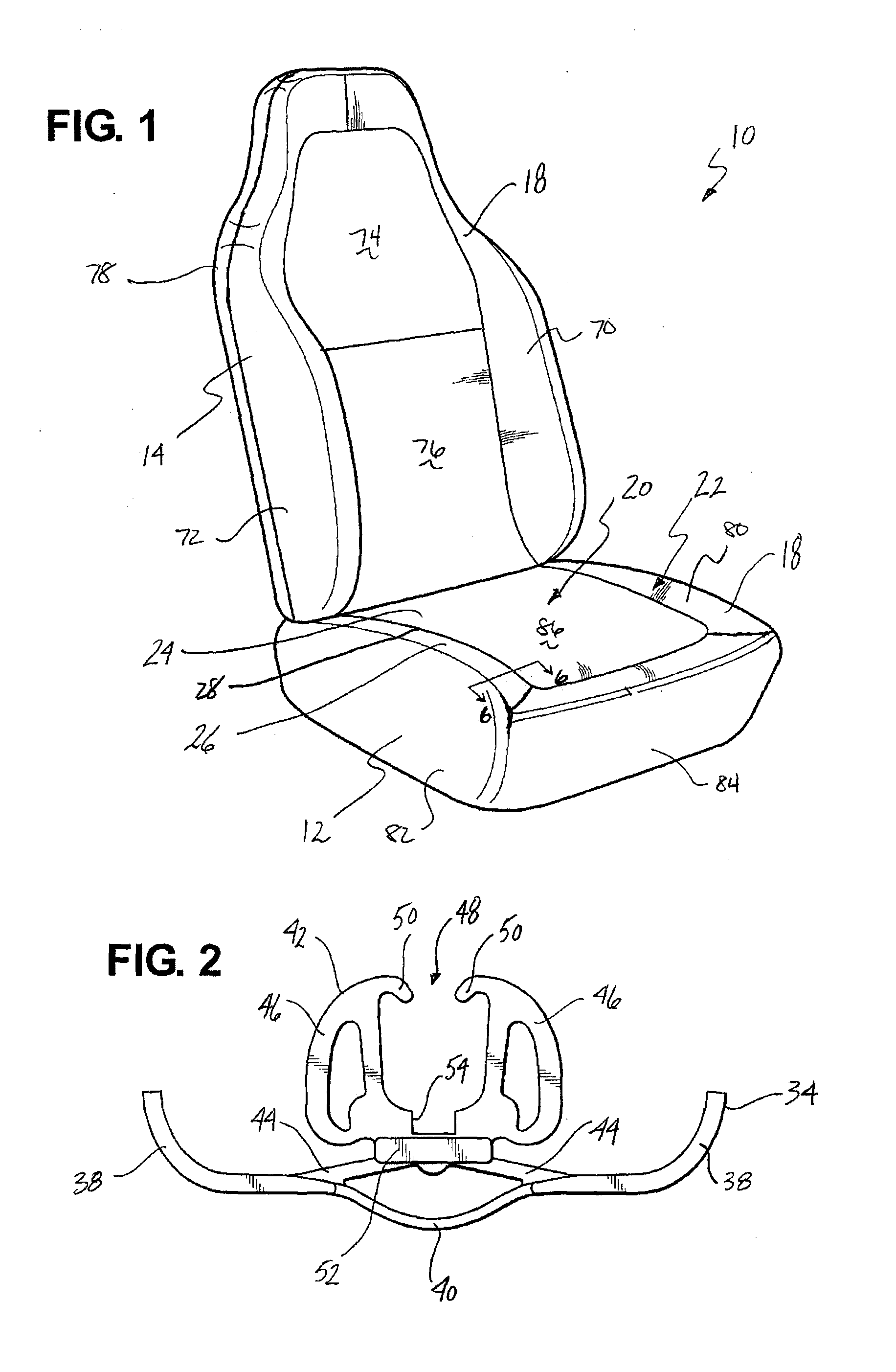

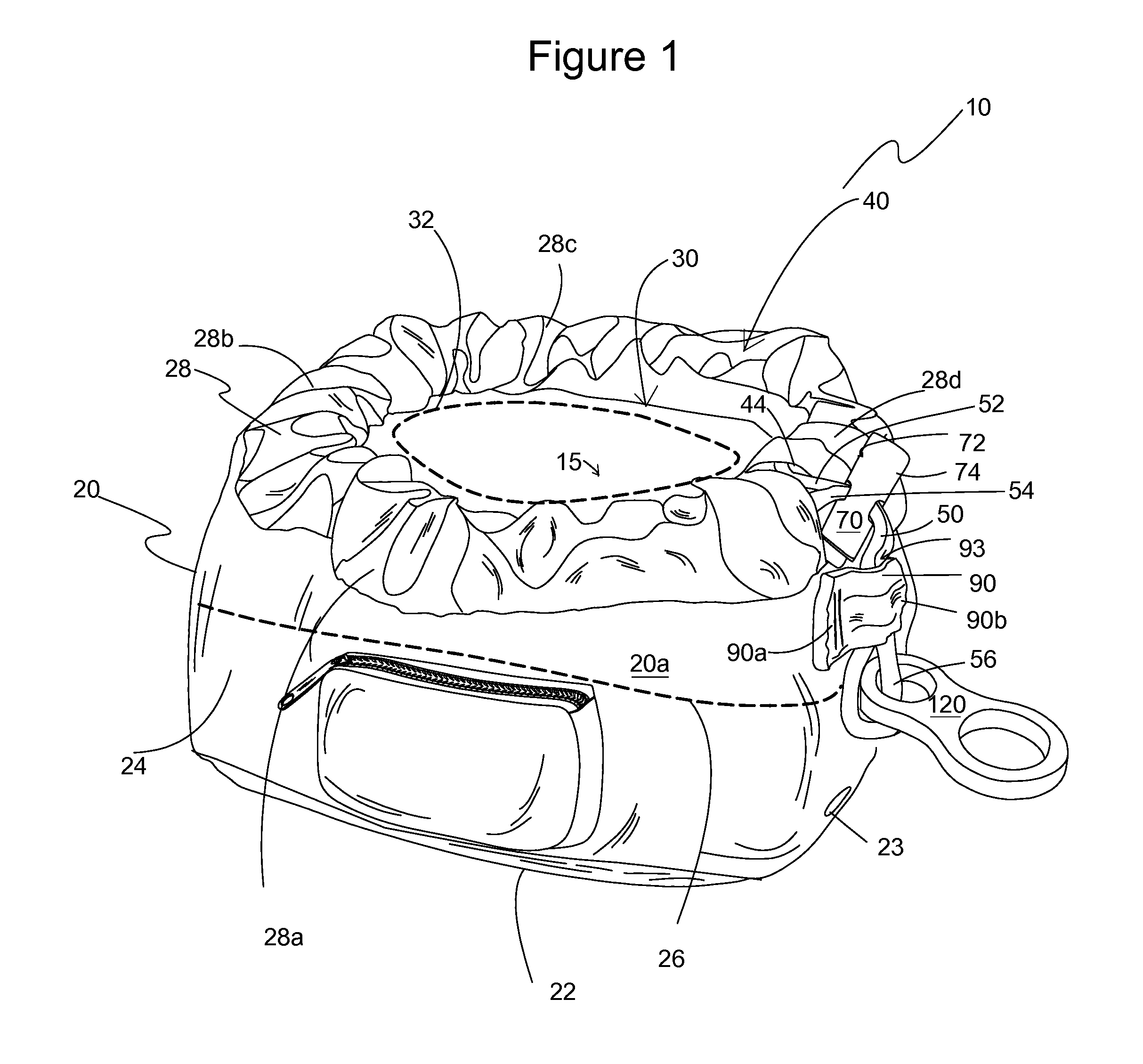

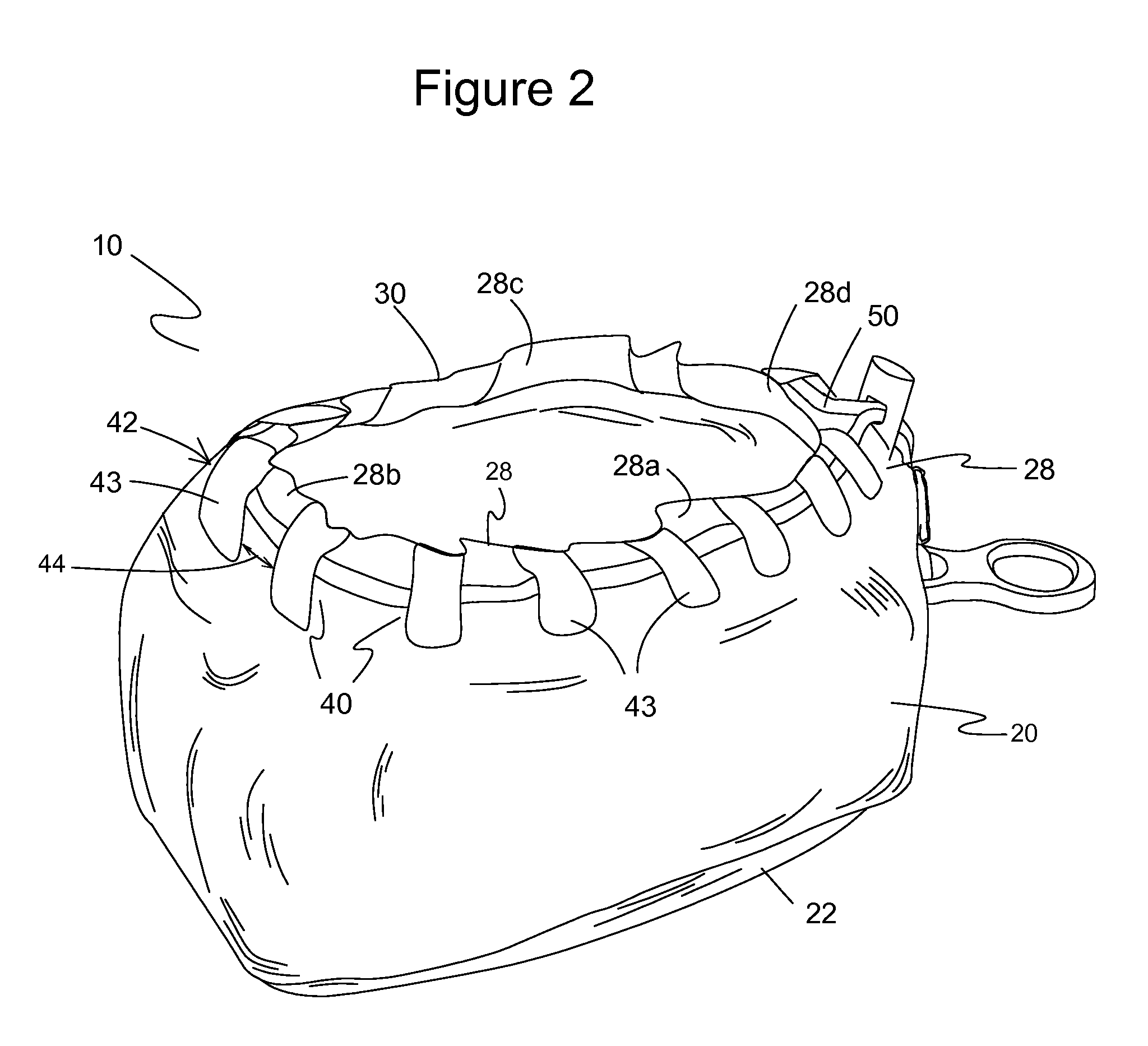

Seat headrest cover for use as a display device

InactiveUS7665804B1Avoid removalGood adhesionVehicle seatsStuffed mattressesHeadrest coverBiomedical engineering

A Federal Aviation Administration approved removable, reusable seat headrest apparatus for use as a display device on the seat headrest of a plane. The headrest apparatus includes a frame assembly and an advertising display. The frame assembly includes a first material portion, a second material portion and a median portion connected therebetween. The second material portion has a viewing window for accepting a viewing pocket or an interchangeable display. The interchangeable display includes a frame, molding and transparent insert. The viewing window receives and displays interchangeable advertising material therein, while allowing travelers to selectively review and retain the materials.

Owner:HEADREST DISPLAY

Child proof and tamper evident container

InactiveUS6983859B2Avoid removalPrevent removalCapsClosure using stoppersEngineeringMechanical engineering

Owner:BWAY COROPRATION

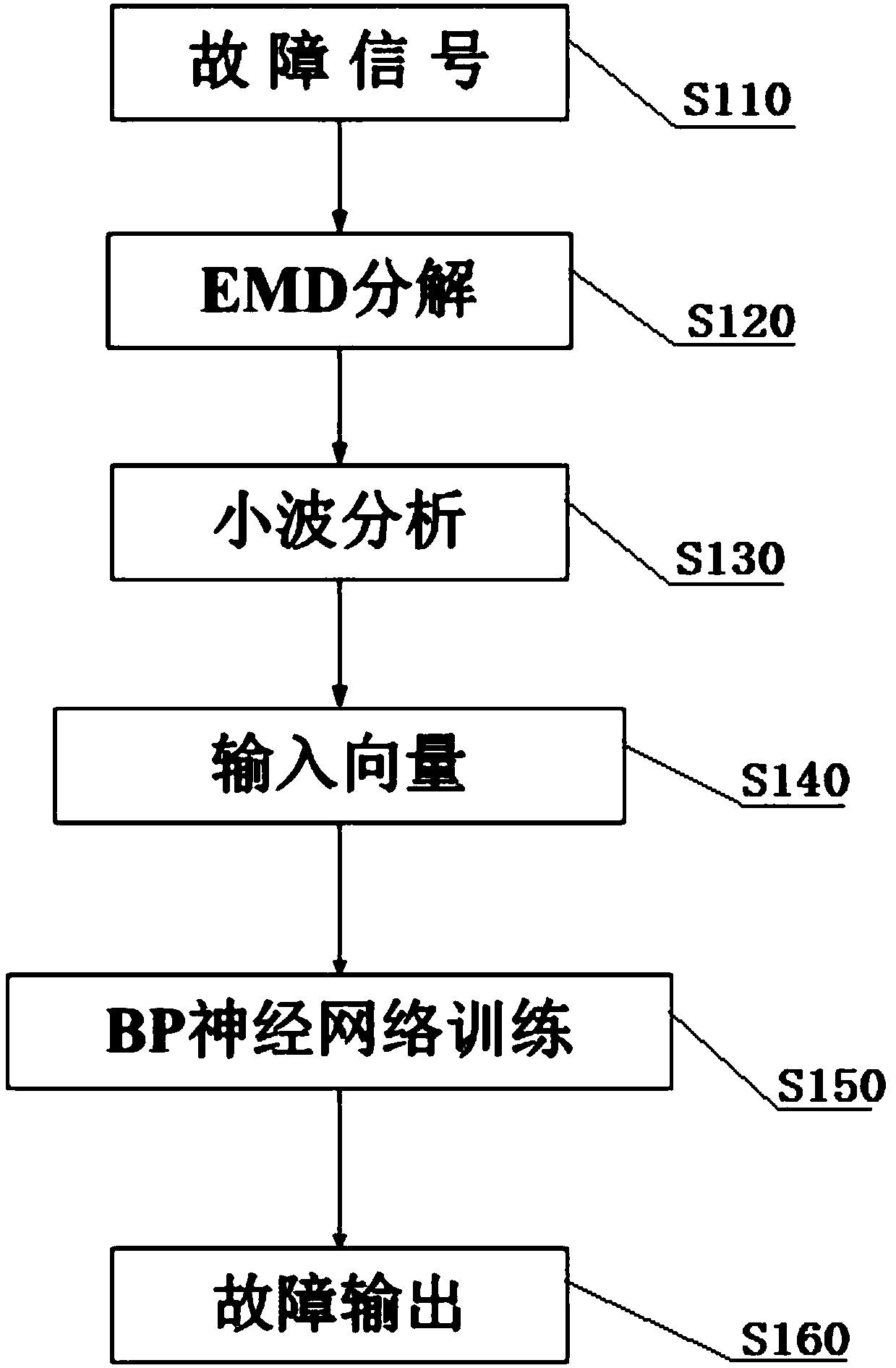

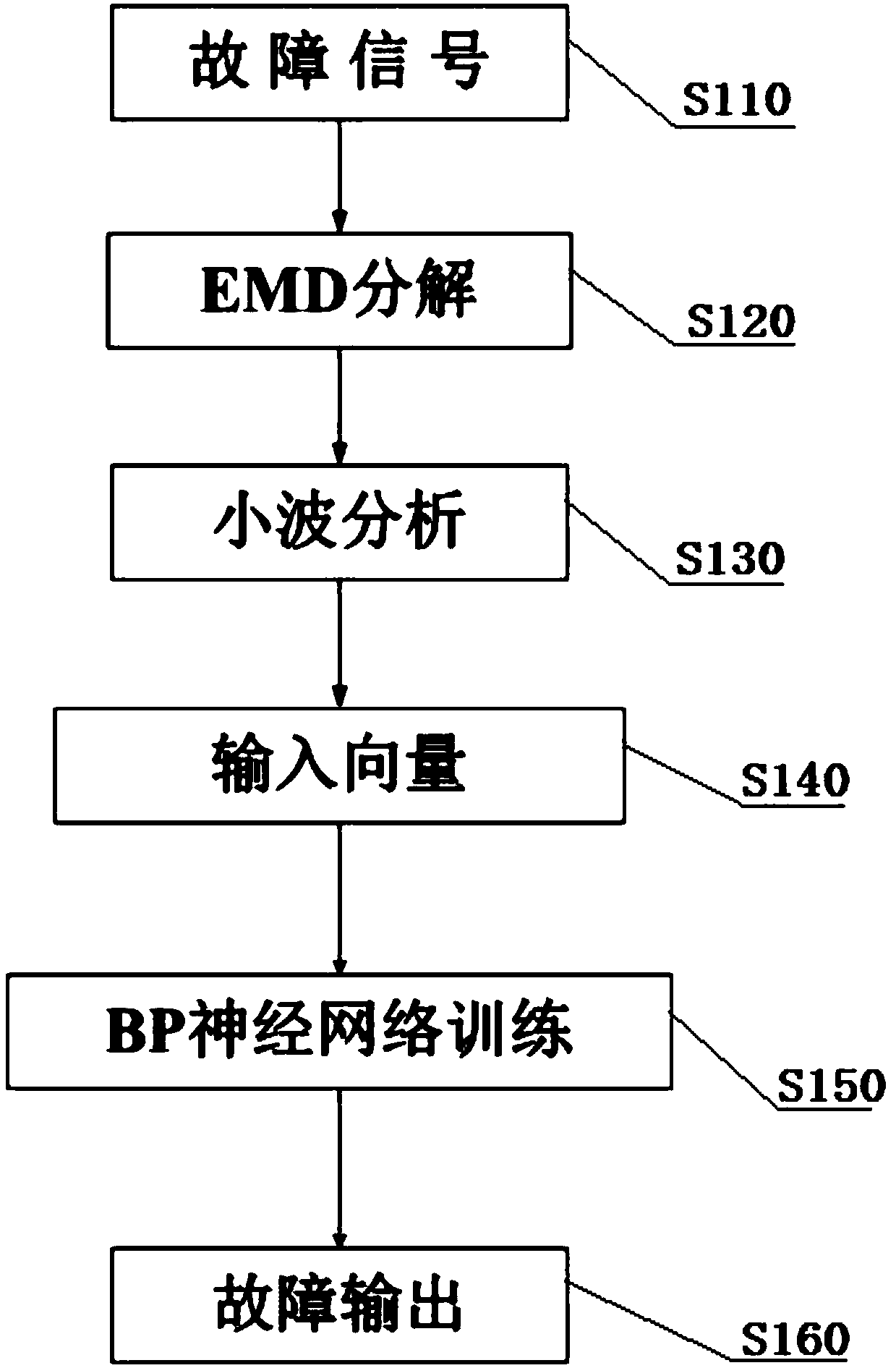

Transformer fault diagnosis method

The invention discloses a transformer fault diagnosis method, and the method comprises the steps: step1, a vibration signal of a transformer is acquired, and noise reduction preprocessing is performed on the vibration signal; step2, EMD decomposition is performed, obtained IMF components are selected according to set critical values, so that the IMF components with low amplitude are removed can be prevented; step3, wavelet analysis is performed, and feature vectors after de-noising are obtained; step4, a three layers BP neural system is constructed, feature vectors extracted from the wavelet analysis serves as input vectors of BP neural network training to train, and a fault signal is outputted. According to the invention, methods such as the wavelet analysis and the like are adopted to remove interference signal in the fault signal, transformer internal fault occurrence and development multi-process and multi-fault multiple modes are diagnosed through the neural network, the transformer fault can be quickly and accurately diagnosed, the fault diagnosis efficiency is improved, the service life of the transformer is prolonged, the unnecessary costs is reduced, and the cost is saved.

Owner:STATE GRID CORP OF CHINA +1

Anti-Rotation Arrow Retainer And Clip

ActiveUS20110309667A1Avoid removalPrevent removalSnap fastenersUpholstery manufactureBiomedical engineering

Owner:MAGNA SEATING

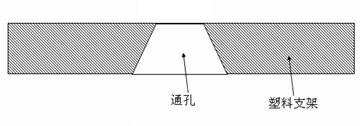

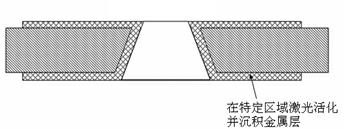

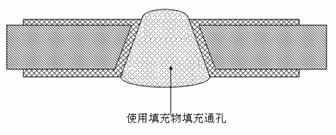

Method for achieving mutual conduction of inner and outer surfaces of plastic component

ActiveCN102665378AAvoid removalLow costCasings/cabinets/drawers detailsRadiating elements structural formsMechanical engineeringMetal

The invention discloses a method for achieving mutual conduction of inner and outer surfaces of a plastic component. The method comprises the following steps of: drilling a through hole at a preset position of the plastic component by using laser; and activating and depositing a metal layer in a specific area to achieve the electric conduction of the inner and outer surfaces of the plastic component. Because the aperture of the through hole is very small, a filler is not required to be filled in the through hole, and the outer surface of the plastic component can be directly coated with a coating layer. Due to the small aperture, the through hole can be directly covered by the coating layer. The through hole is applied to the field, and because the minimum aperture of the through hole can reach 0.02mm, the filler is not required to be filled in the through hole; and therefore, the cost is saved and traces left on the outer surface when the filler is not completely removed and the surface is not well leveled are avoided. The method can be also applied to a production technique for fabricating a mobile terminal antenna onto a shell.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

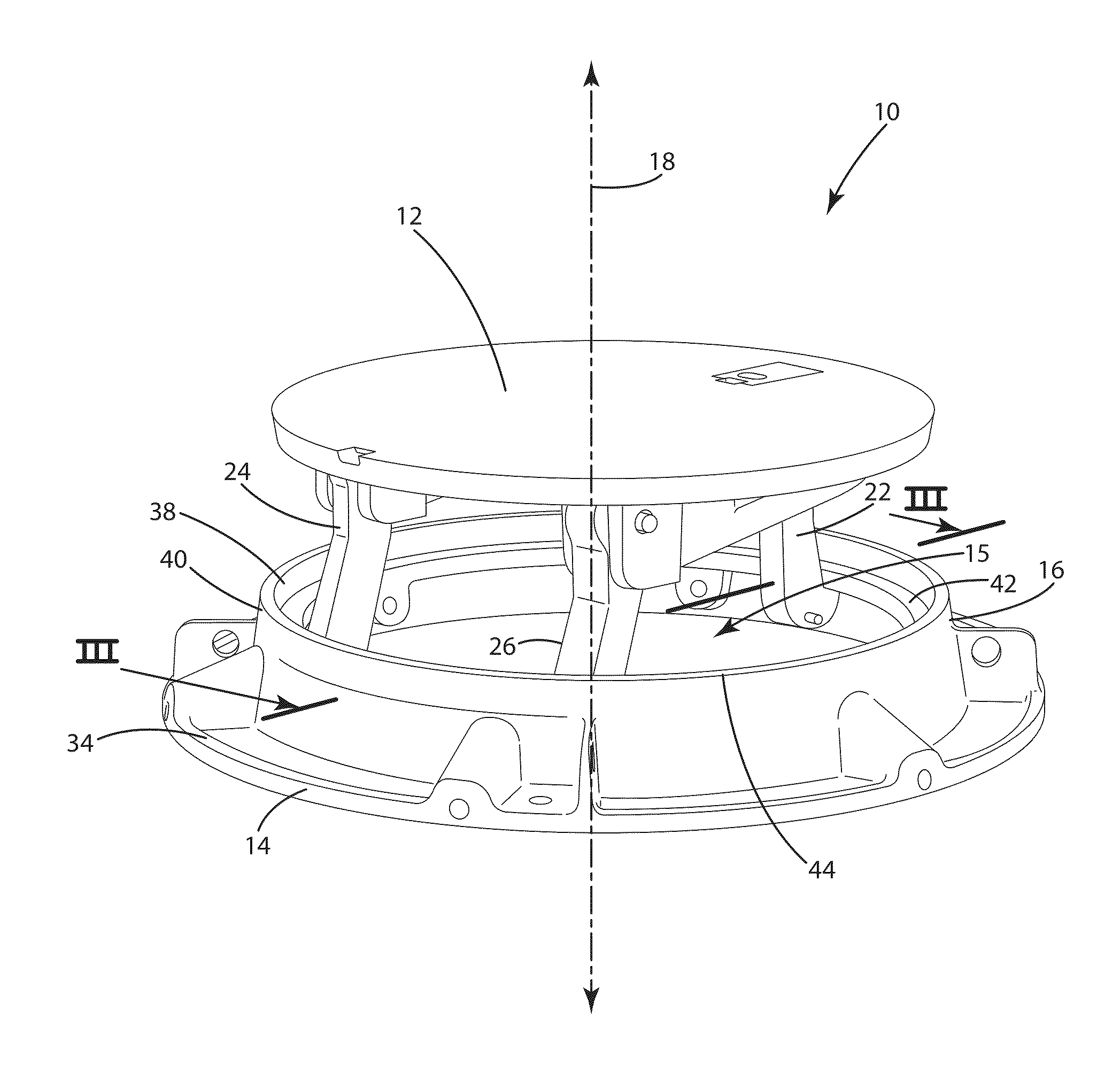

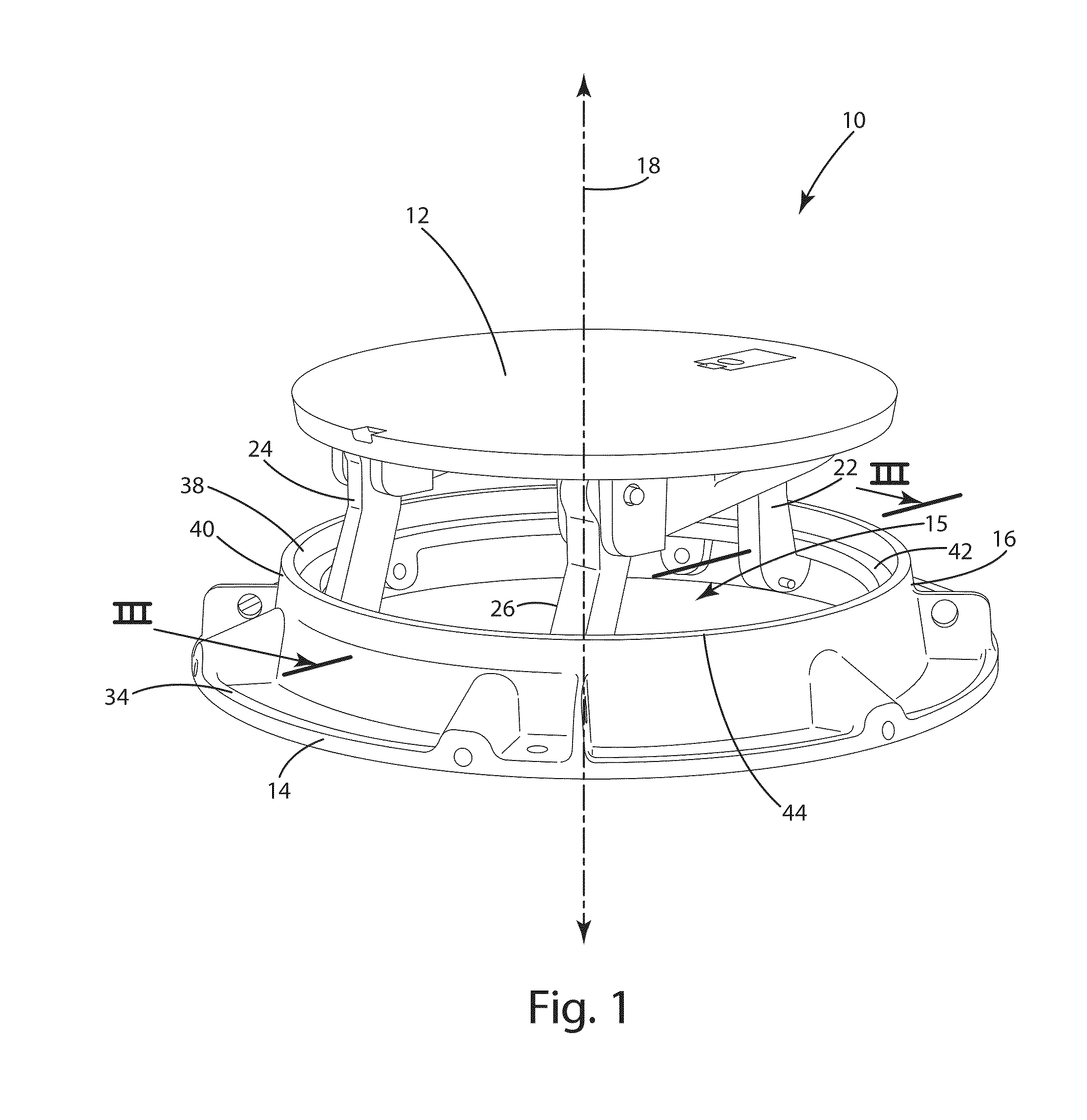

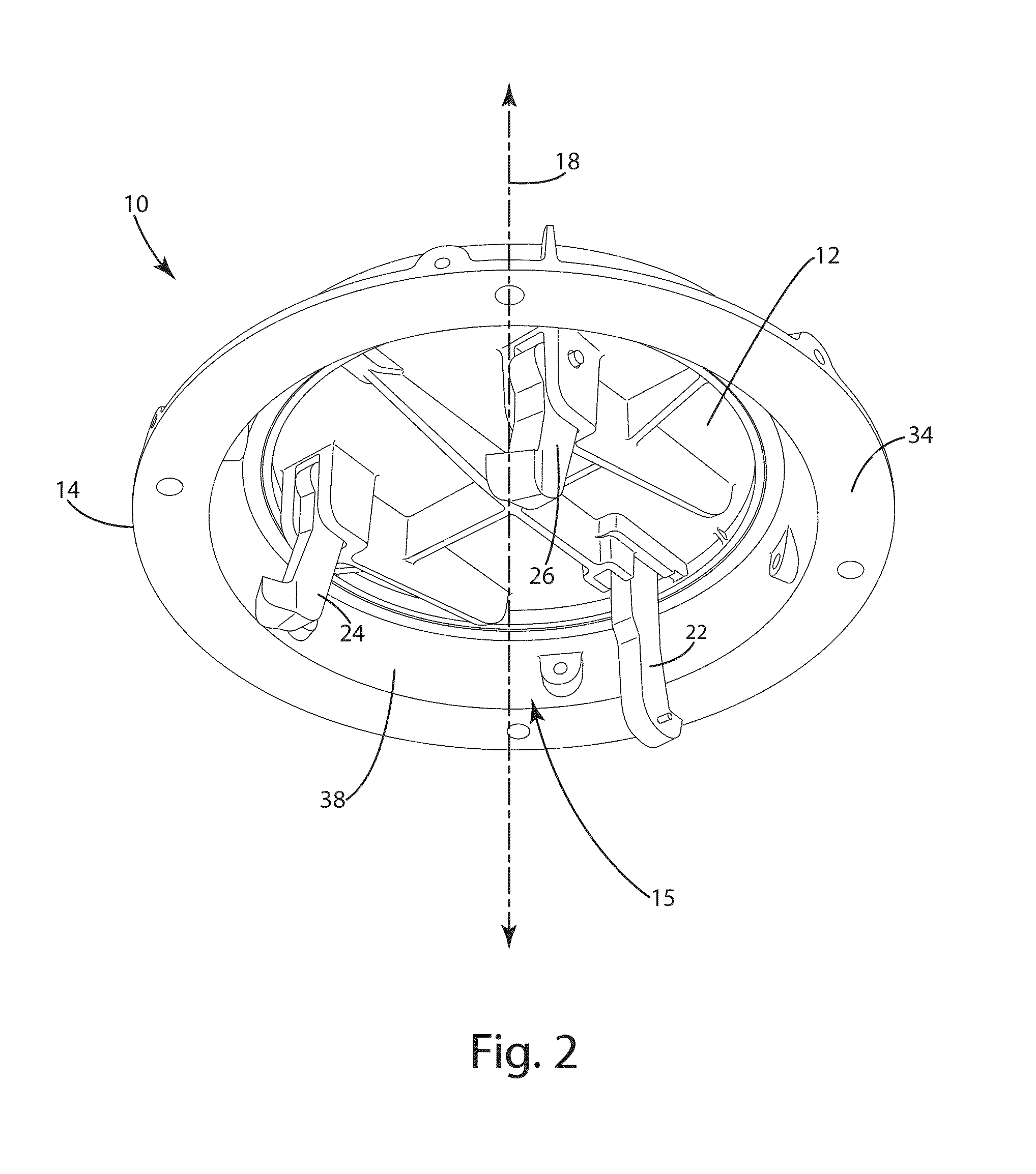

Explosion mitigating cover

ActiveUS20140169876A1Avoid removalPrevent decouplingArtificial islandsUnderwater structuresEngineeringSafety valve

A manhole cover assembly configured to behave as a relief valve in an explosion event, opening so that fluid, such as air or explosive gas, may vent from an underground area. The manhole cover assembly may include a manhole cover and a frame, and may be configured to limit movement of the manhole cover with respect to the frame in response to increased pressure on the manhole cover. In one embodiment, the manhole cover may include legs having angled surfaces adapted to substantially center or guide the manhole cover in the frame while the manhole cover displaces to release pressure. In another embodiment, one or more legs slidable within the manhole cover to enable configuring the manhole cover between a restraint mode and a removal mode.

Owner:EAST JORDAN IRON WORKS

Artificial leather effluent treating process

ActiveCN1810685ASolve the biggest problemsSolve the degradabilityWater contaminantsTreatment with aerobic and anaerobic processesOxygenAmmonia nitrogen

The artificial leather effluent treating process has different treating steps for different kinds of effluent with different COD and DMF concentrations. Effluent with high COD and DMF concentration is first treated in a DMF recovering system to recover DMF, then anaerobic treated and blown to eliminate generated ammonia nitrogen, and finally mixed with other low COD concentration effluent and further treated anaerobic / aerobic + coagulating precipitation process to reach the draining standard. The process has high treating effect, especially on high DMF content effluent.

Owner:江苏中宜金大环保产业技术研究院有限公司

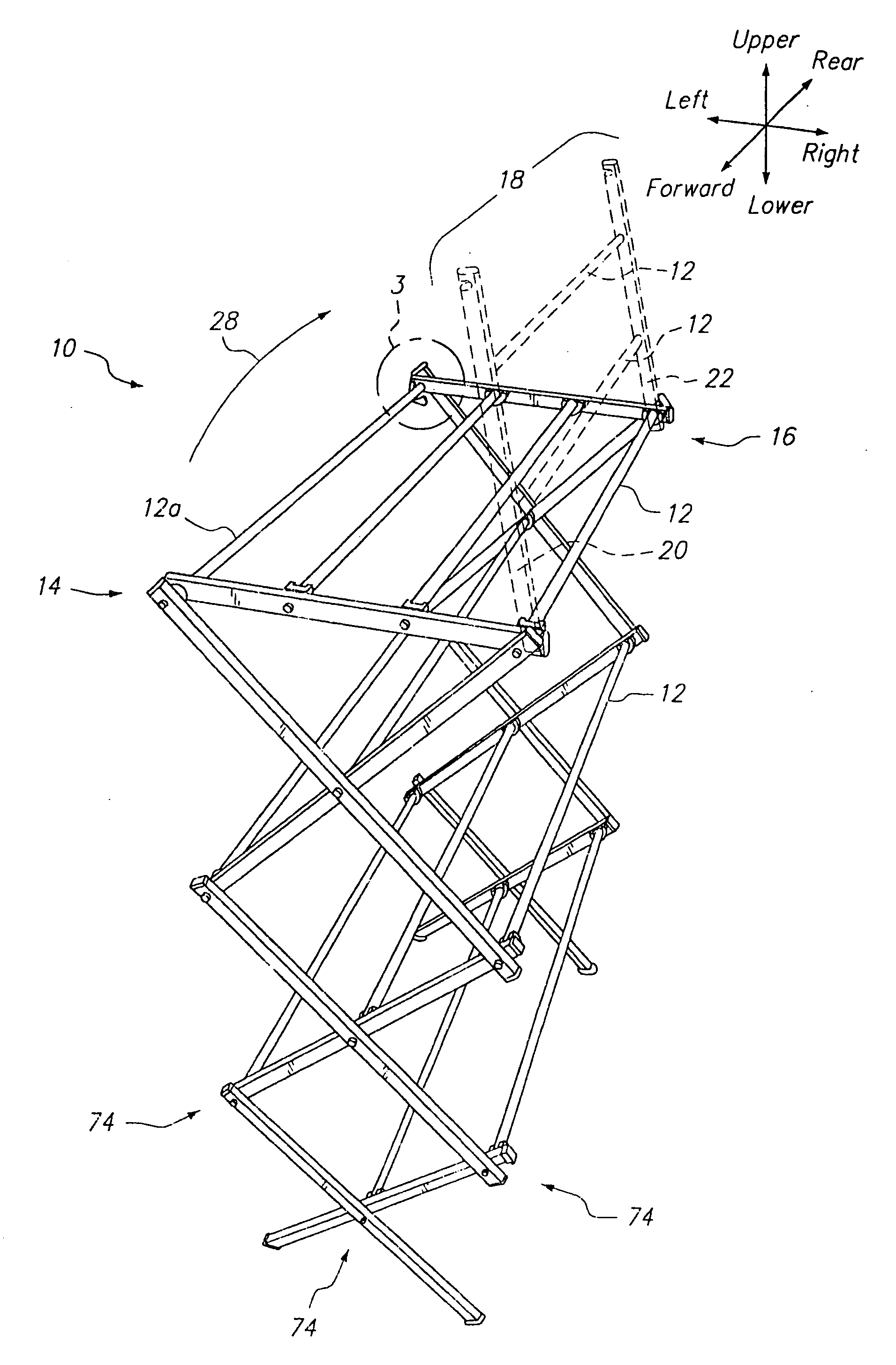

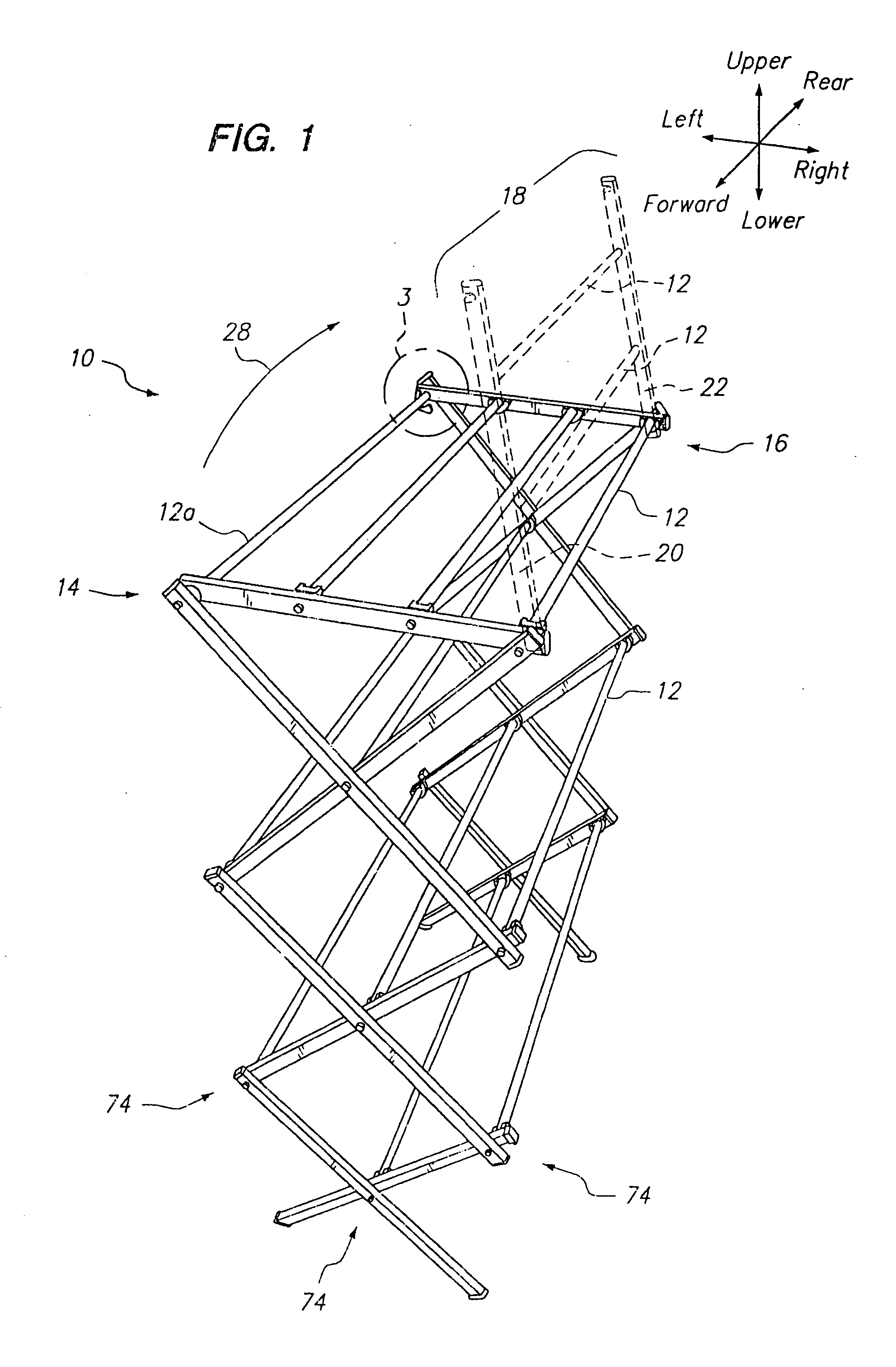

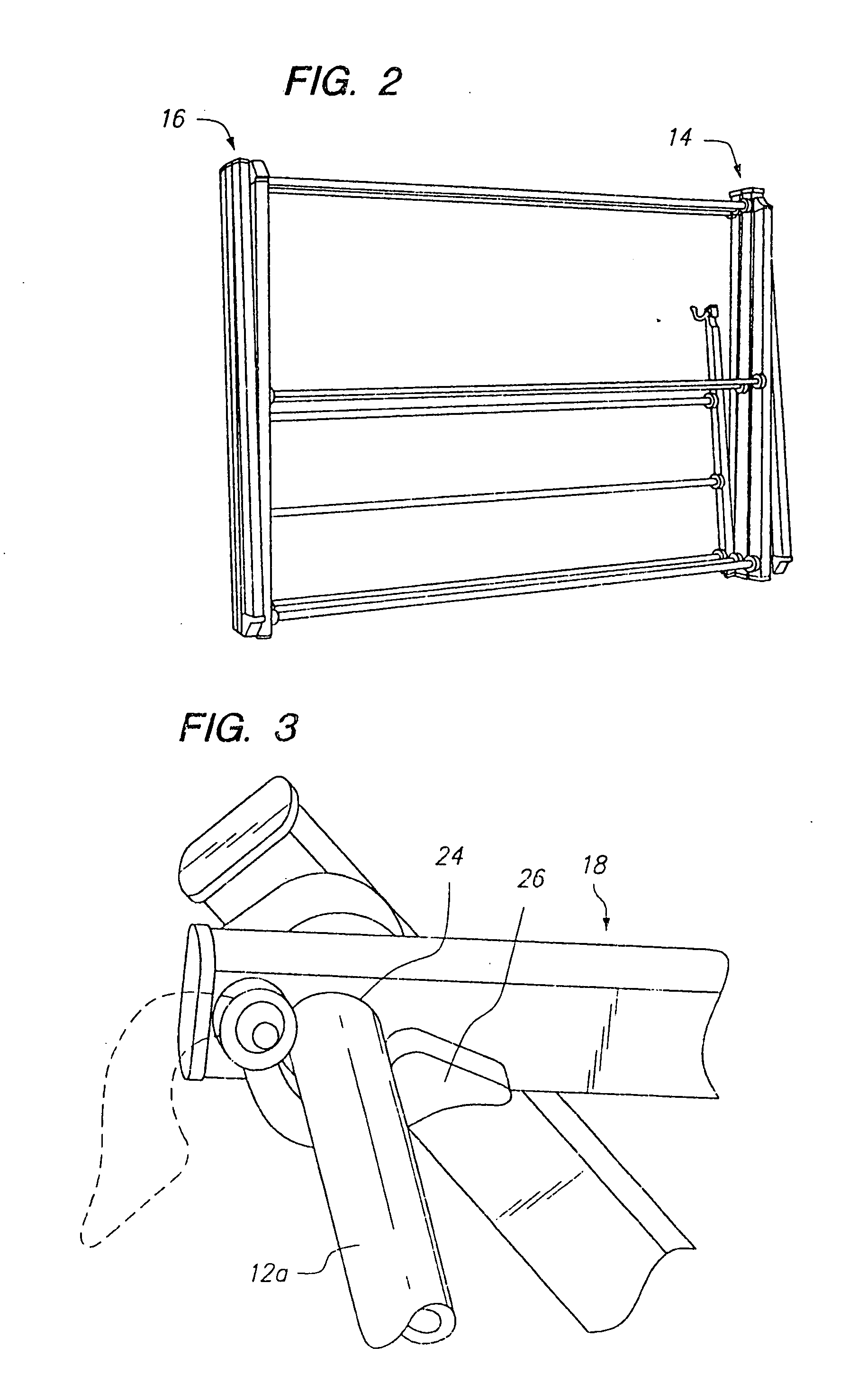

Connector for laundry rack

InactiveUS20070221598A1Avoid removalPrevent slippingOther drying apparatusFolding cabinetsLaundryEngineering

A collapsible laundry rack is provided wherein a plurality of cross members for hanging clothes may be attached to first and second scissor structures via a plurality of tab connectors and socket connectors. In particular, the distal ends of the cross members may be attached to the socket connector which is selectively removable from tab connectors attached to corresponding points of the first and second scissor structures. A socket portion of the socket connector may be aligned to a tab portion of the tab connector. Release levers formed on the tab portion may be inserted into the socket until retention members of the tab portion engage cam edges of the socket portion. To remove the tabs from the socket, the release levers may be inwardly deflected to deflect the retention members inwardly to release the retention members from the cam edges. Alternatively, the tab connectors may be attached to distal ends of the cross members. Also, the socket connectors may be attached to corresponding points of the first and second scissor structures.

Owner:SABOUNJIAN AZAD

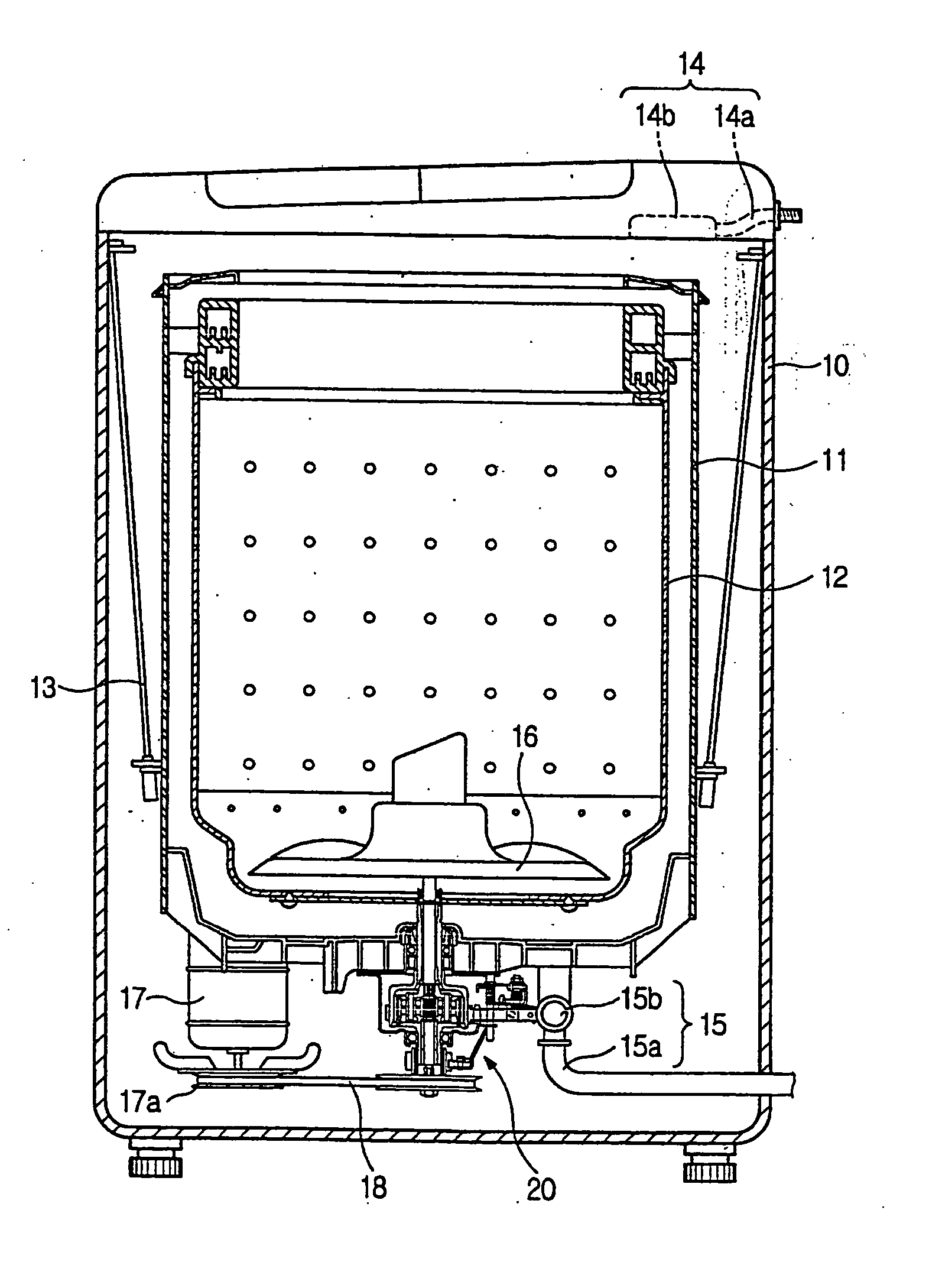

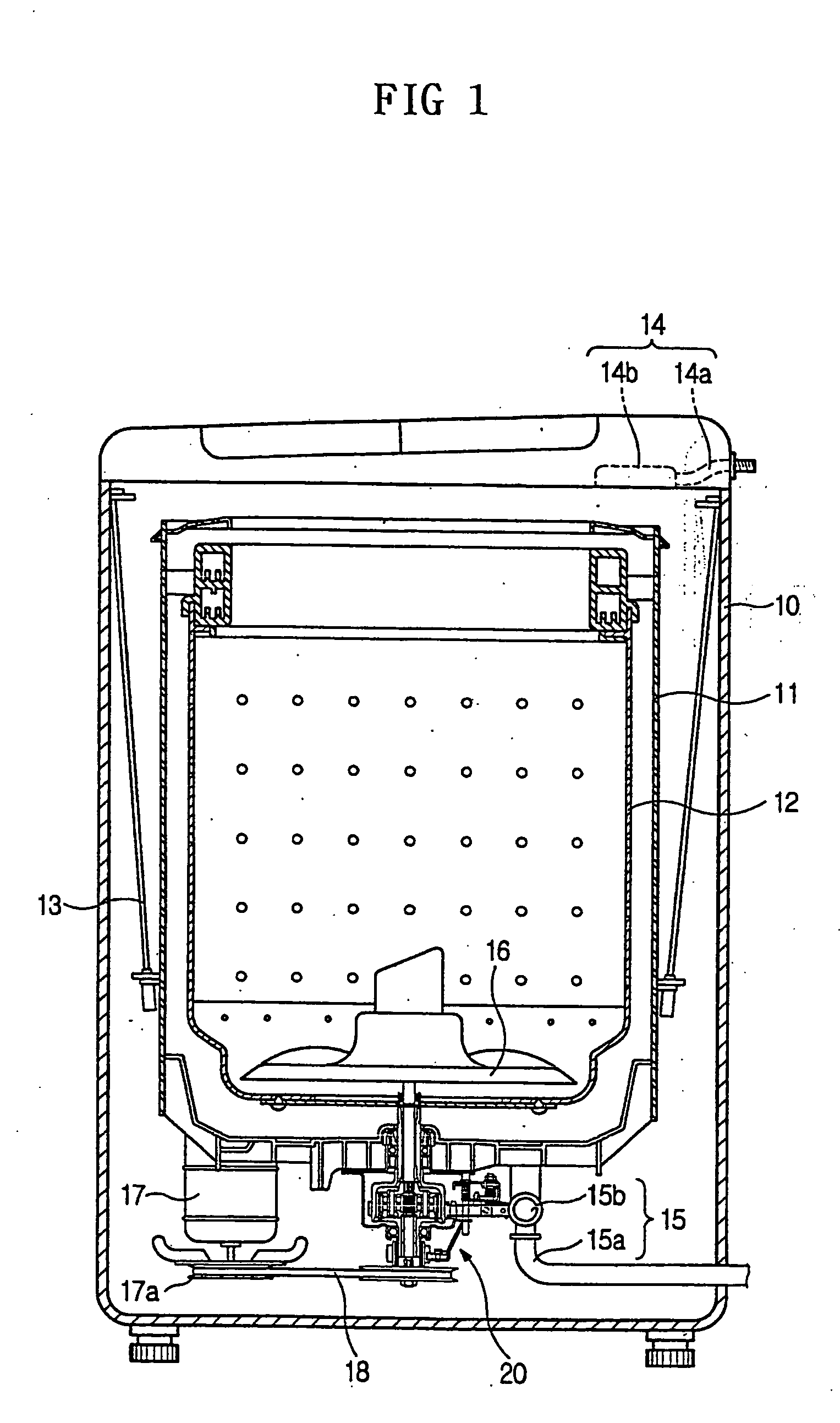

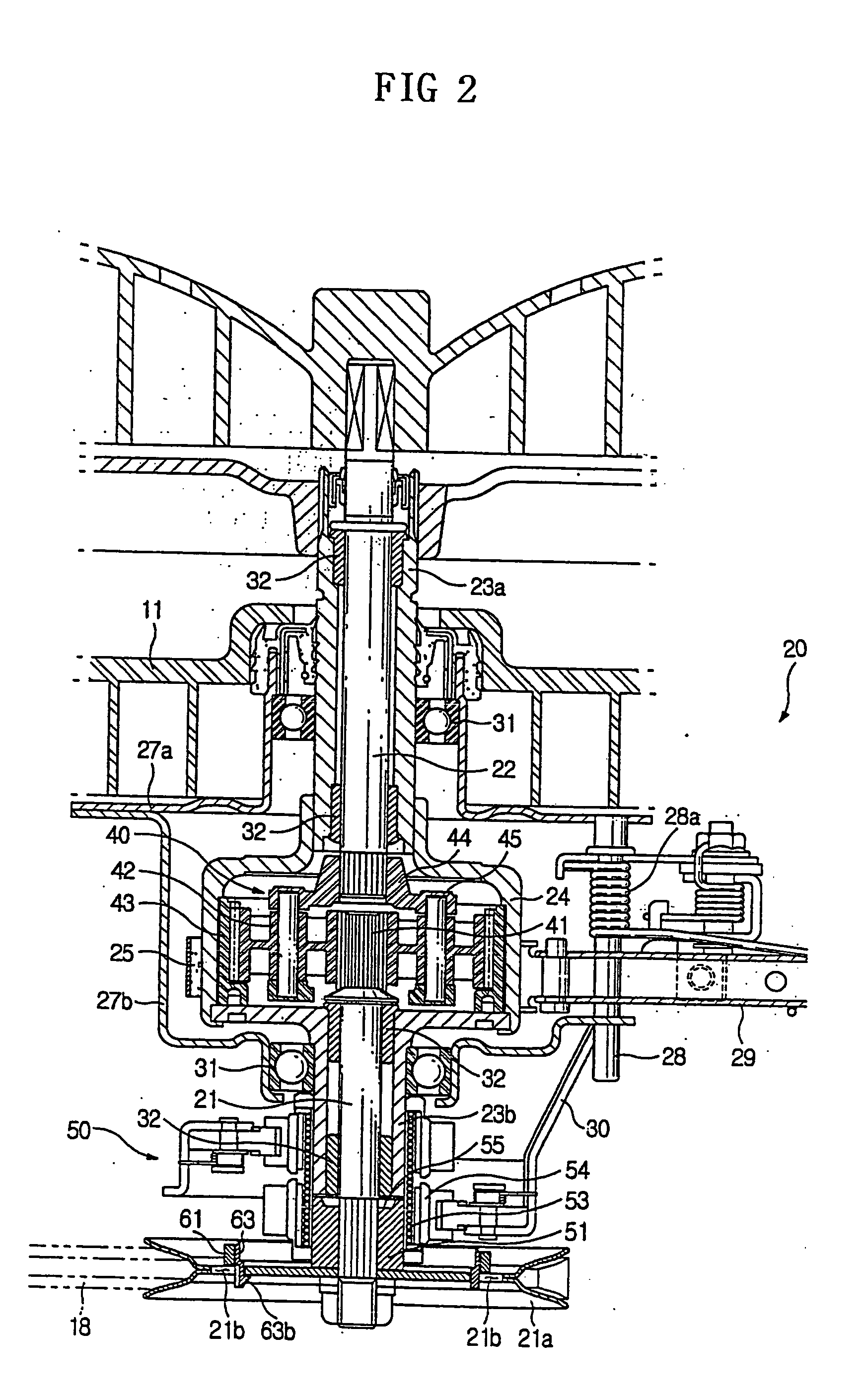

Washing machine

InactiveUS20050081573A1Avoid removalPrevent removalOther washing machinesControl devices for washing apparatusElectric machineryDrive motor

A washing machine capable of preventing a magnet, which detects a number of rotations of a washing shaft, from being removed from a predetermined position. The washing machine includes a drive motor to generate a rotating force. A washing shaft is rotated by the drive motor. A belt and a shaft pulley transmit the rotating force from the drive motor to the washing shaft. A magnet is mounted to the shaft pulley to rotate along with the shaft pulley. A magnetic sensor detects a number of rotations of the washing shaft, in response to a change in a magnetic field produced by the magnet. A locking unit is mounted at a first end thereof to the magnet, and at a second end thereof to the shaft pulley. Therefore, even when the vibrations caused by operations of the washing machine are transmitted to the magnet for a lengthy period of time, the magnet is connected to the shaft pulley by the locking unit without being removed from a predetermined position.

Owner:SAMSUNG ELECTRONICS CO LTD

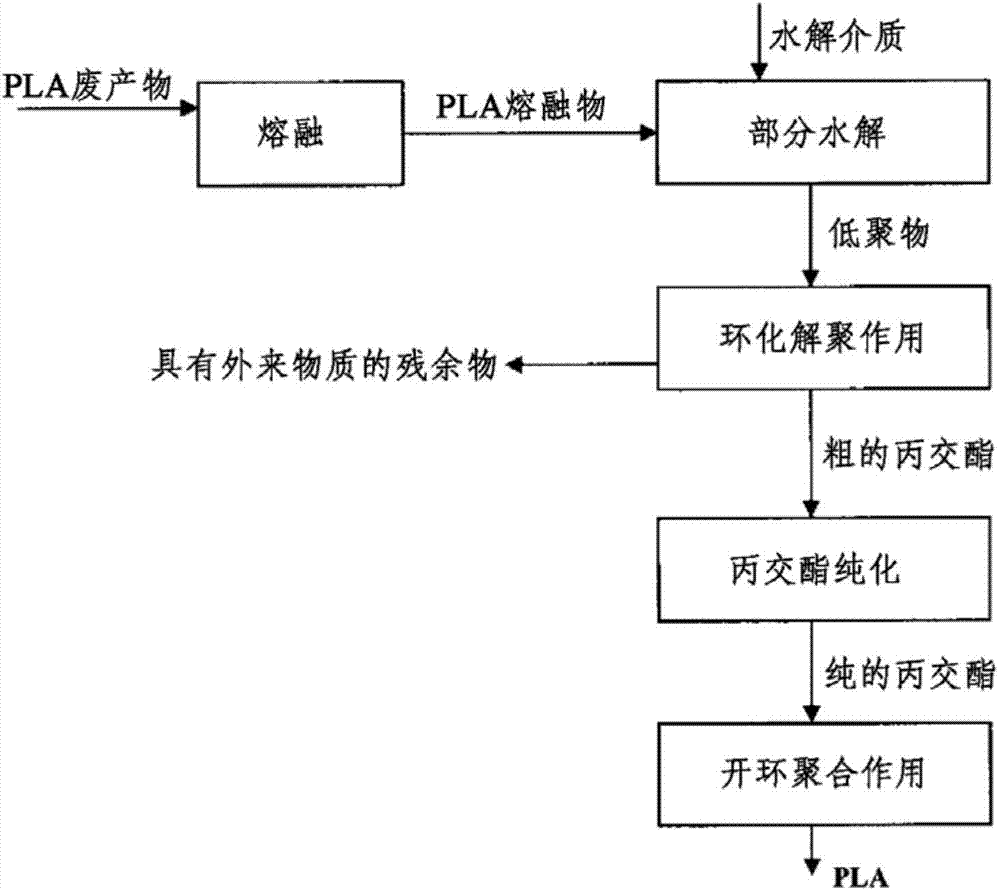

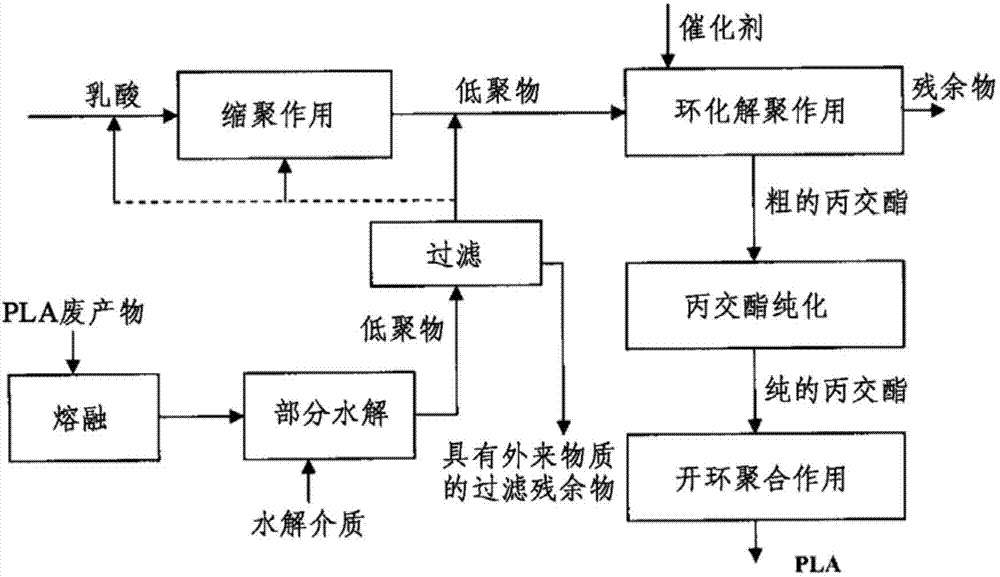

Process and apparatus for recovering lactide from polylactide or glycolide from polyglycolide

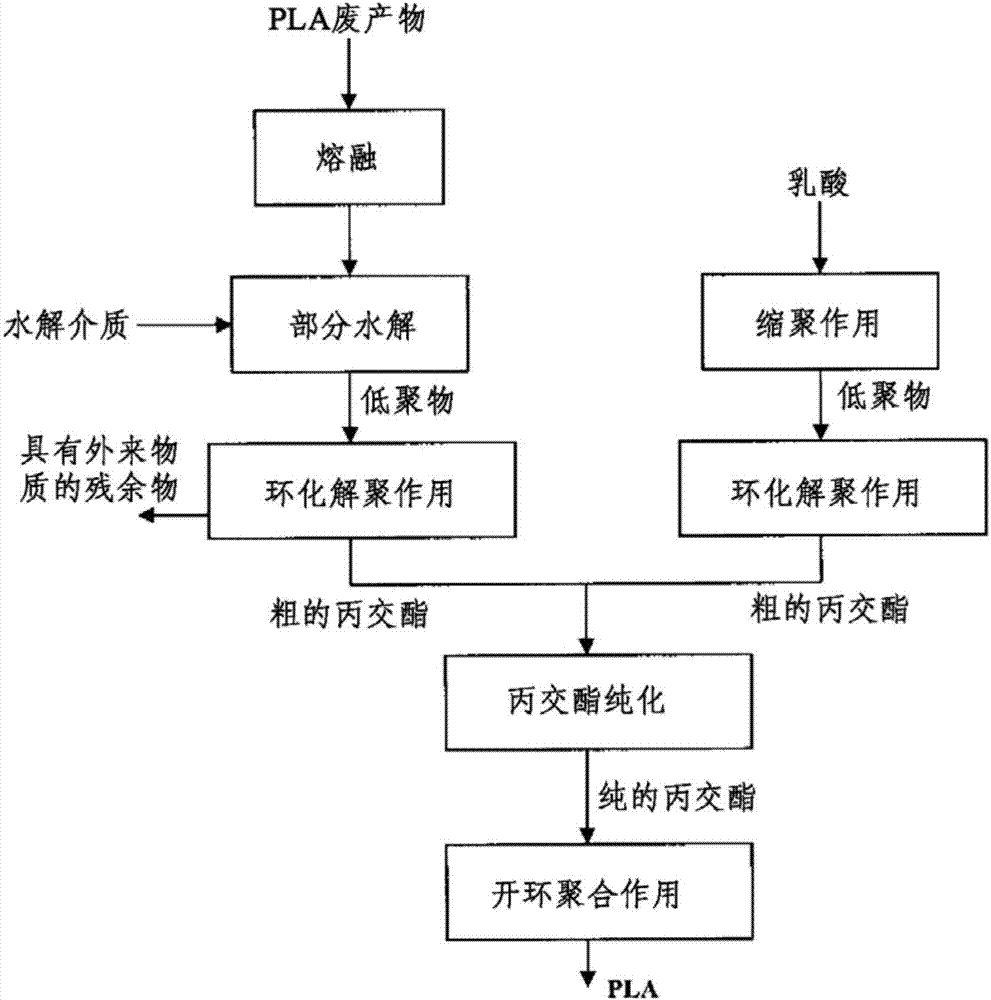

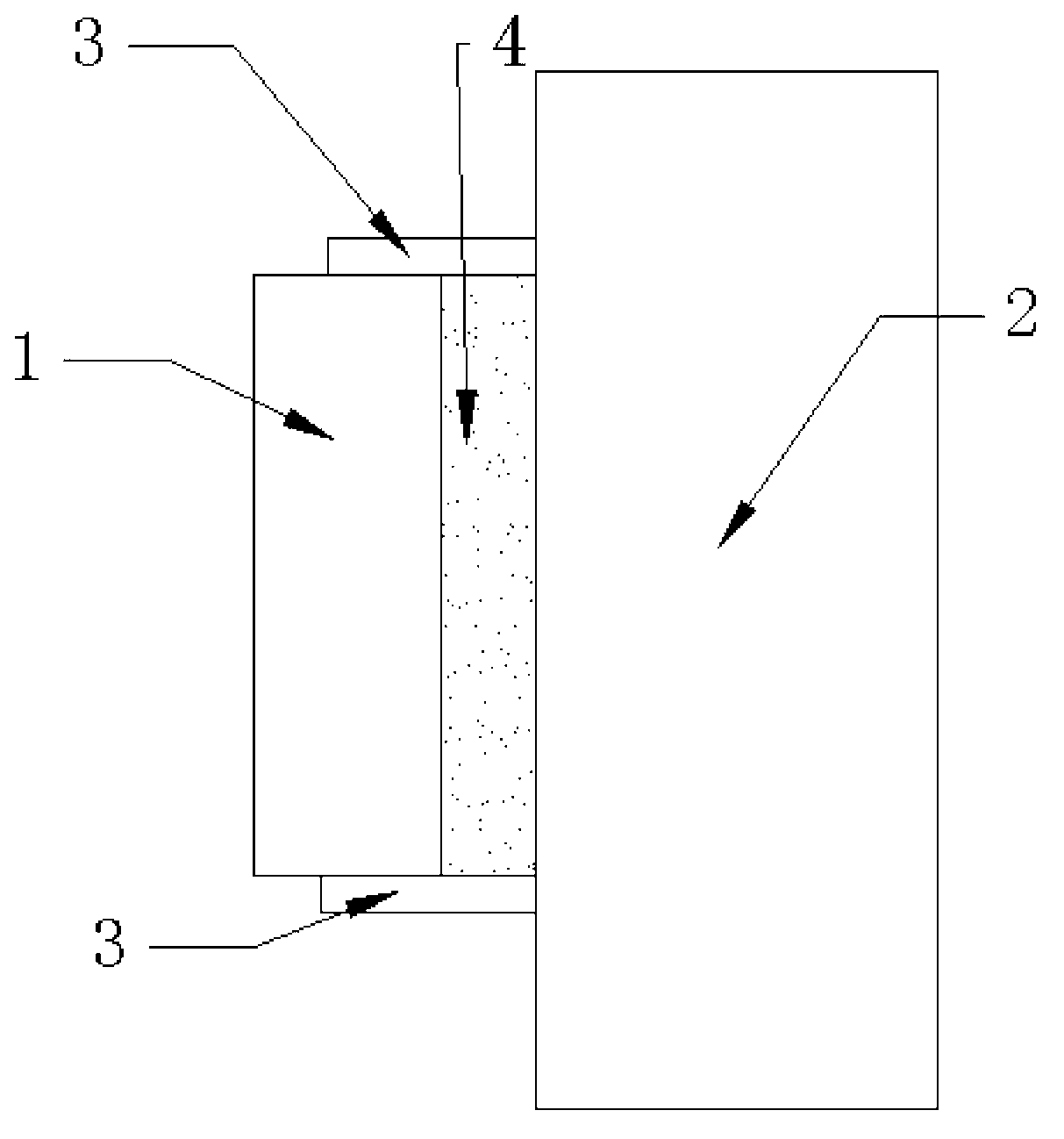

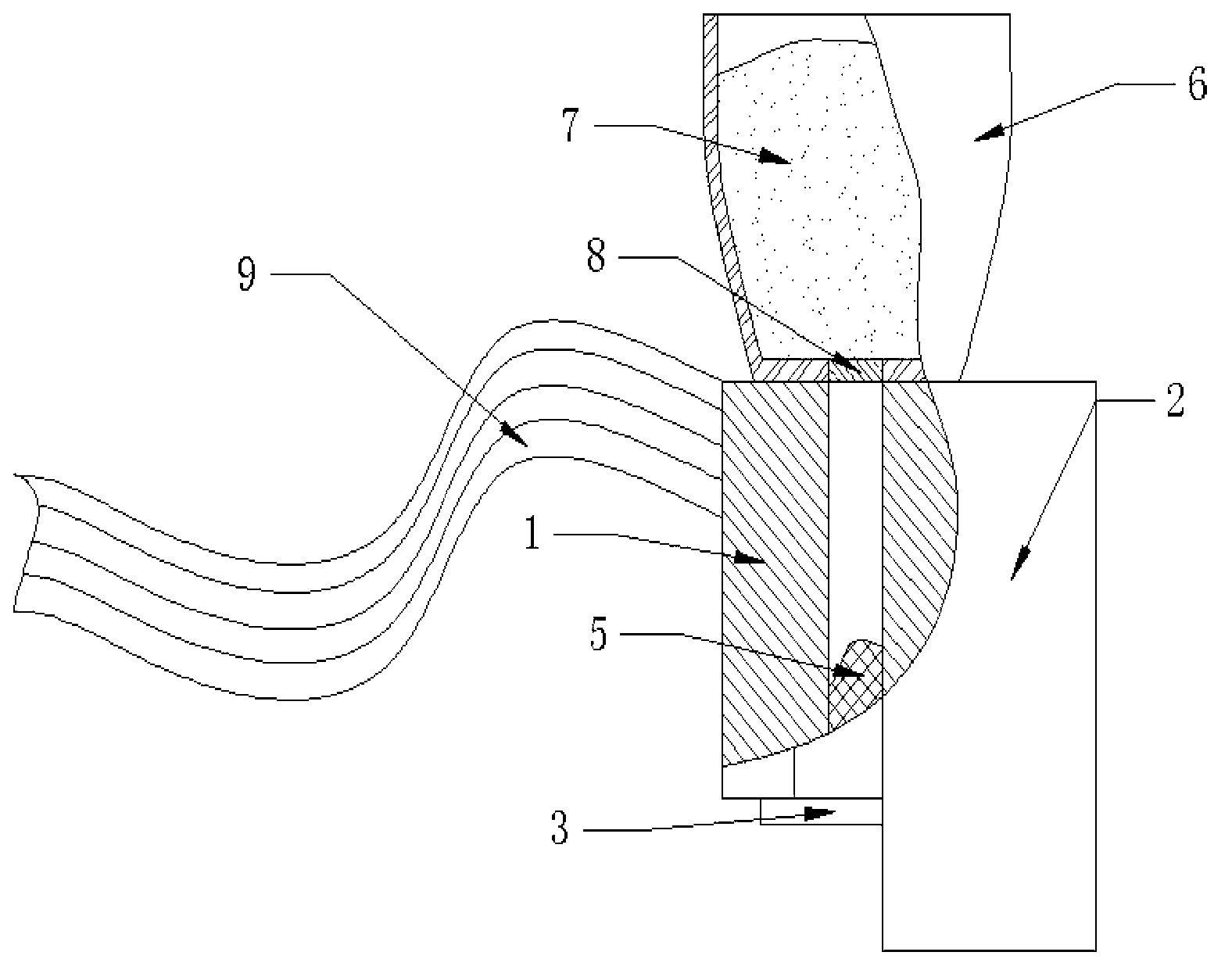

ActiveCN103781833ASave energySaverPlastic recyclingPreparation from carboxylic acid esters/lactonesPartial hydrolysisOligomer

The present invention relates to a process for recovering lactide from polylactide (PLA) or glycolide from polyglycolide (PGA), in which, in a first step, PLA or PGA is contacted with a hydrolysing medium and hydrolytically degraded to oligomers. In a further step, a cyclising depolymerisation of the oligomers obtained in the first step is effected to give lactide or glycolide. In addition, the present invention relates to an apparatus based on the combination of a hydrolysis apparatus with a depolymerisation reactor, with which the above-described process can be performed. The core of the process according to the invention is a partial hydrolysis of the polymeric materials originally used in combination with a cyclising depolymerisation.

Owner:UHDE INVENTA FISCHER

Secondary self-propagating welding method for cathode soft belt and large bus for aluminum electrolysis cell

InactiveCN103317226AQuick Weld RepairUnique process methodWelding/cutting media/materialsAlumino-thermic welding apparatusCrucibleWeld seam

The invention relates to a secondary self-propagating welding method for a cathode soft belt and a large bus for an aluminum electrolysis cell. The method includes first taking down a waste cathode soft belt, welding an aluminum plate at one end of a new soft belt beam, welding a steel aluminum explosion block at the other end, coating aluminum welding flux on the groove face, arranging a crucible above a welding seam, arranging a self-fluxing plug in the crucible, preheating a bus material and the crucible, arranging welding powder into the welding seam and the crucible, evenly scattering pyrophoric powder on the surface of welding powder at the two positions, igniting the pyrophoric powder in the welding seam, erecting the crucible above the welding seam quickly after the welding powder finishes reaction and igniting the pyrophoric powder in the crucible at the moment to enable the welding powder in the crucible to react. When a metal solution enters the welding seam, welding of the aluminum plate at the end of the soft belt and the bus can be finished, and the steel aluminum explosion block at the other end of the soft belt is connected with a steel rod on a groove casing through arc welding. A workpiece with different sections has good conductivity and strength when the workpiece is welded through the method.

Owner:QINGTONGXIA ALUMINUM GRP +1

Fastener and process for using same

InactiveUS7524129B2Avoid removalPrevent removalRopes and cables for vehicles/pulleyNutsFastenerEngineering

A connector for securing first and second substrates together, comprising: an outer fastener and an inner fastener is disclosed and claimed. The outer fastener comprises a dowel shaped stud. The inner fastener comprises a flange and a pair of clips. The pair of clips includes a first portion and a second portion. The flange is lanced and includes a punched out portion. The stud interengages the flange and the second portion of the pair of clips urges the clips away from each other and away from the stud. The outer fastener is pressed into the first substrate and the second portion of the clips is pressed into the second substrate. The second portion of the clips include a turned back portion and the turned back portion of the clip grip the second substrate preventing removal of the inner fastener from the second substrate. The connector is tolerant of the misalignment of the inner and outer fasteners and the bores in which the fasteners reside.

Owner:STAFAST PROD

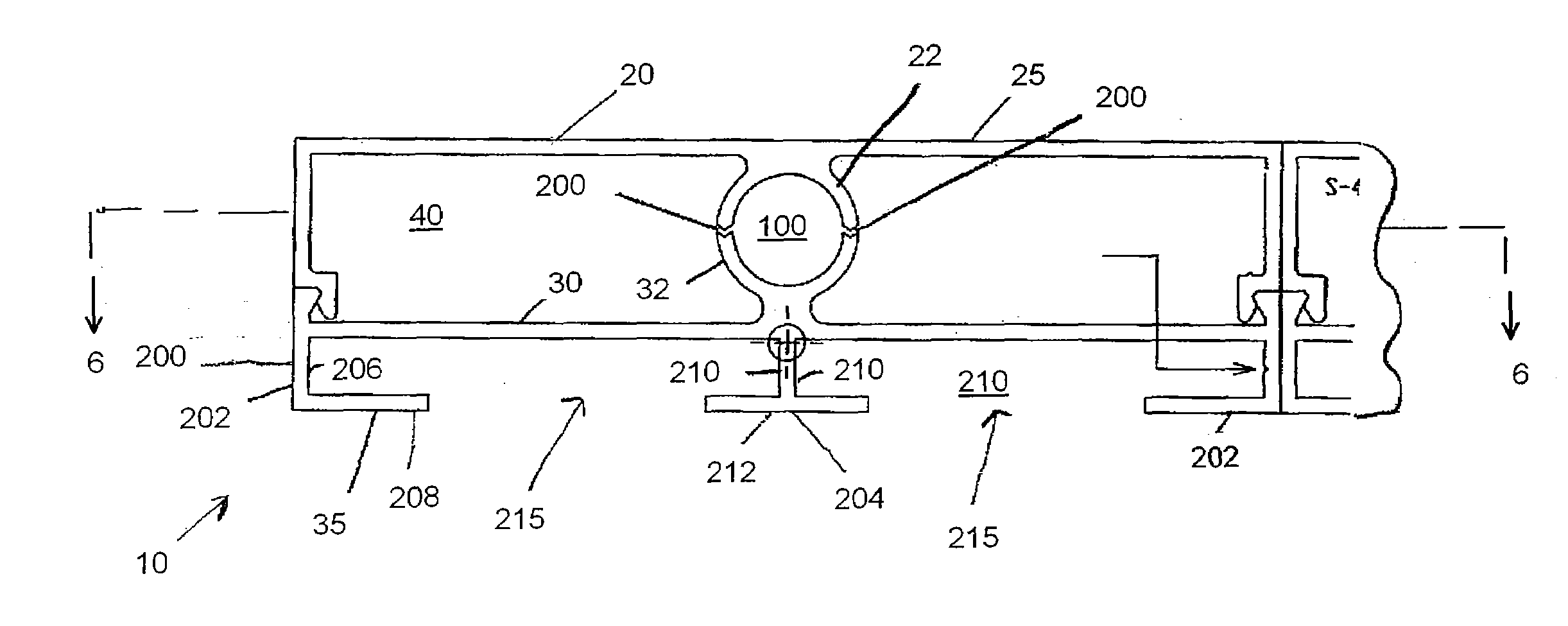

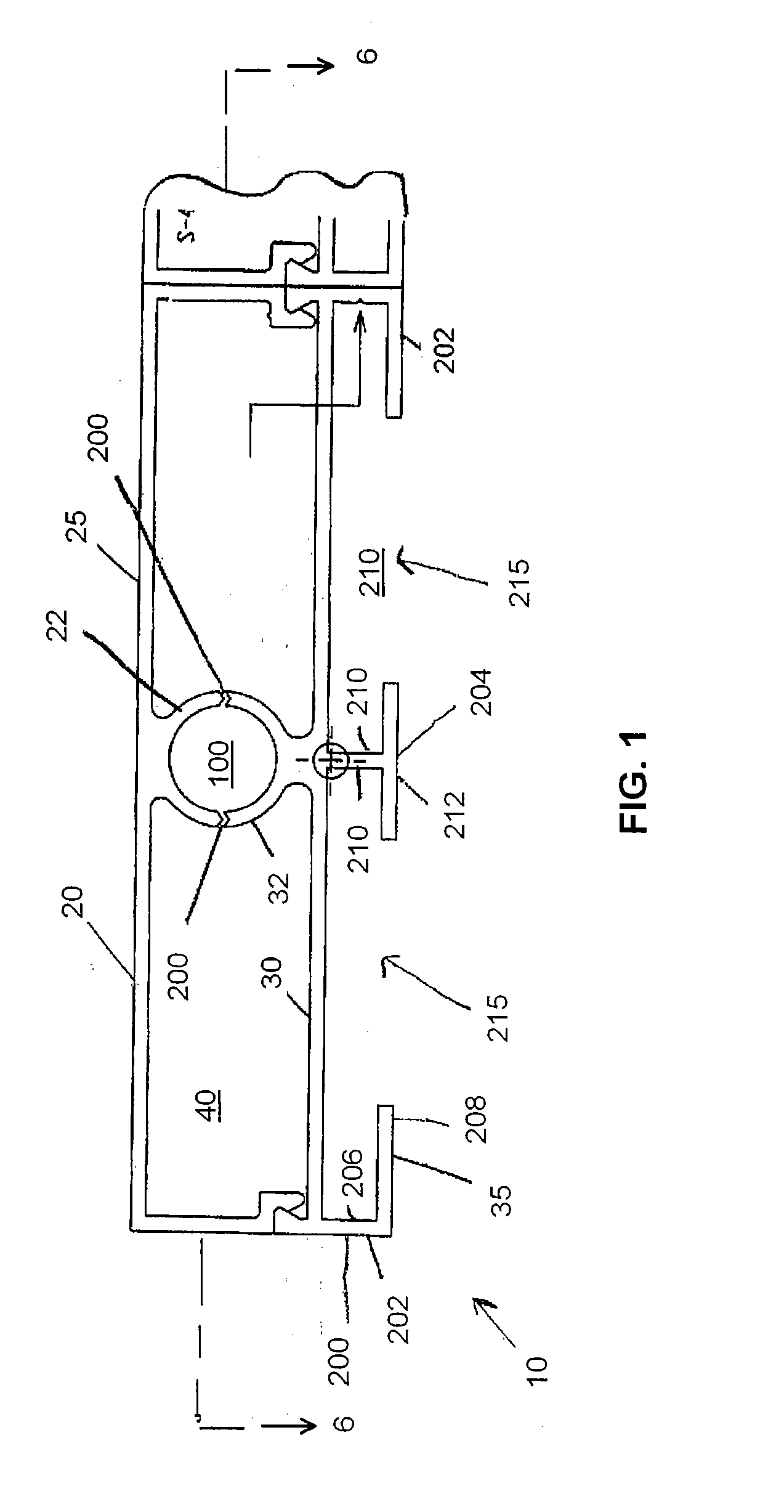

Drop-prevention pouch for cordless power tools

A drop-prevention pouch for a cordless power tool has a battery pack that defines a battery pack perimeter. The drop-prevention pouch includes a pouch floor and a sidewall extending transversely from the pouch floor and having a sidewall rim portion defining a pouch opening. The pouch floor and the pouch sidewall define a chamber sized to receive the battery pack when the battery pack is attached to the cordless power tool. A flexible conduit extends along the sidewall rim portion. A drawstring extends through the flexible conduit and is capable of restricting the pouch opening to be smaller than the battery pack perimeter, thereby preventing the drop-prevention pouch from being removed from the battery pack when the battery pack is attached to the cordless power tool.

Owner:PURE SAFETY GRP INC

Radiant heat wall covering system

ActiveUS20080164005A1Avoid removalPrevent removalFluid heatersHot-air central heatingRadiative heatingEngineering

A wall covering system for radiant heating includes a first wall covering portion and a second wall covering portion. The first portion is releasably connectable to the second portion in a direction substantially perpendicular to an outer surface of the first portion. The first portion includes a bottom side and top channel portion downwardly depending from the bottom side. The second portion includes a top side and a bottom channel portion extending upwardly from the top side. The top channel portion and the bottom channel portion bound a channel for receiving a heating conduit. The channel extends longitudinally relative to the first portion and the second portion.

Owner:KELLER JAMES P MR

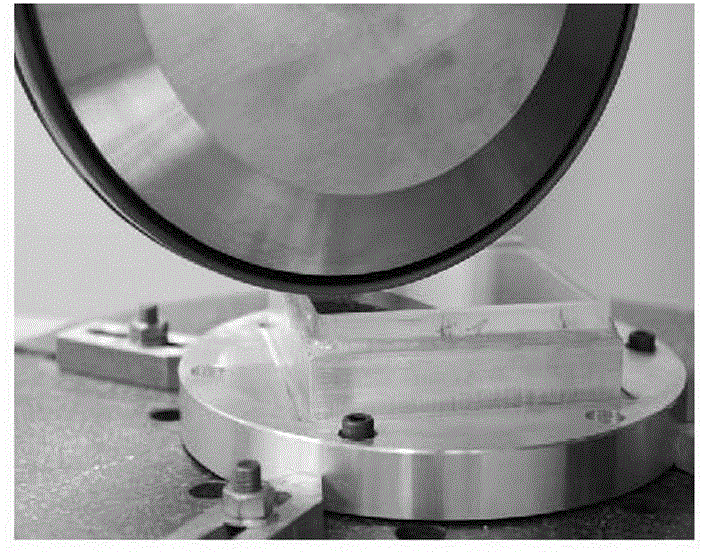

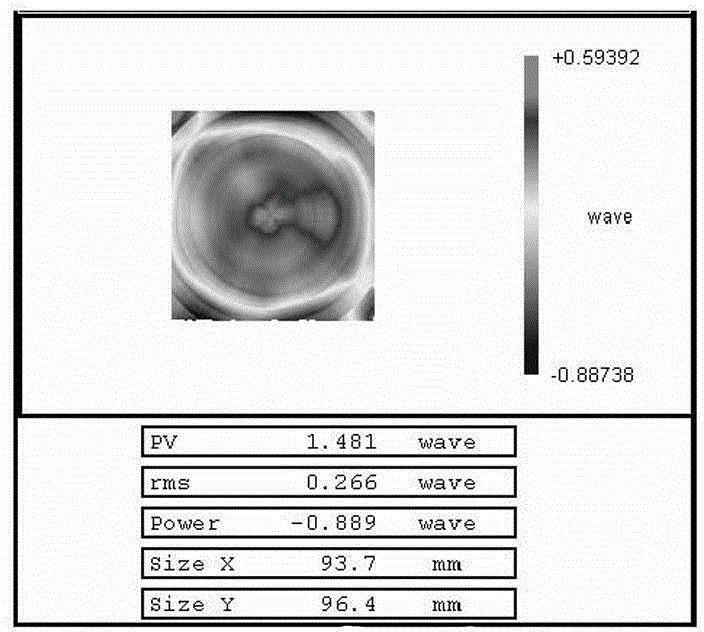

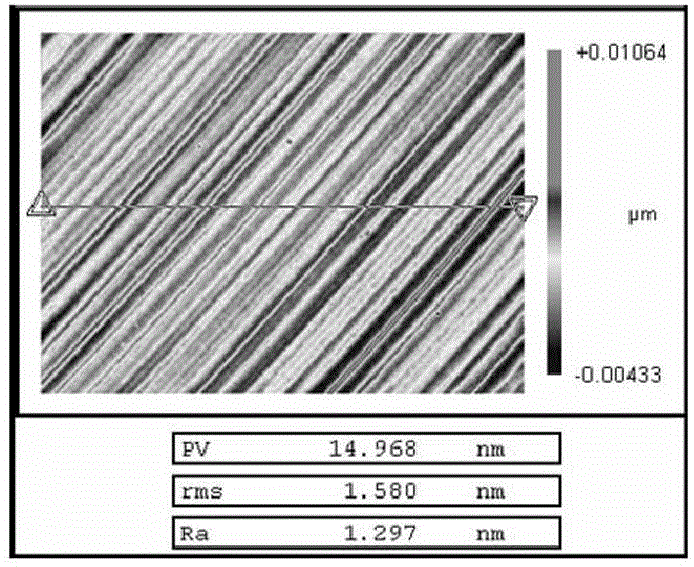

Magneto-rheological finishing method of easy-deliquescence crystals

ActiveCN104084849AImprove rheologyLow magnetic field viscosityPolishing compositions with abrasivesLow frequency bandEngineering

The invention discloses a magneto-rheological finishing method of easy-deliquescence crystals. The method includes the steps of firstly, preparing non-aqueous magneto-rheological finishing solution; secondly, adding the non-aqueous magneto-rheological finishing solution into a magneto-rheological machine tool circulating system for magneto-rheological finishing twice; thirdly, then using aromatic hydrocarbon to clean the easy-deliquescence crystals fast so as to complete the finishing. The method is simple in process flow and high in operability, and high-precision and ultra-smooth easy-deliquescence crystals which can satisfy the high, medium and low frequency band requirements of a strong-light optical system.

Owner:NAT UNIV OF DEFENSE TECH

Method for manufacturing semiconductor device and semiconductor device

InactiveCN1835196ASimple designSolve the removal problemSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device fabrication

A semiconductor device production method which includes steps of: preparing a wafer on which multiple integrated circuits are formed on a principal face; forming a rewiring which is electrically connected to the integrated circuits via a pad electrode; and dicing the wafer after forming an electrode terminal on the rewiring, including steps of: forming a first resin layer by sealing at least the rewiring and the electrode terminal formed on the principal face of the wafer with a first resin; processing a first dicing from a back face of the wafer to the principal face of the wafer or halfway to the first resin layer when the first resin layer is formed; forming a second resin layer by sealing a cut line outlined upon the first dicing and the back face of the wafer continuously with a first resin; and processing a second dicing while leaving the second resin layer which covers a side face outlined upon the first dicing.

Owner:YAMAHA CORP

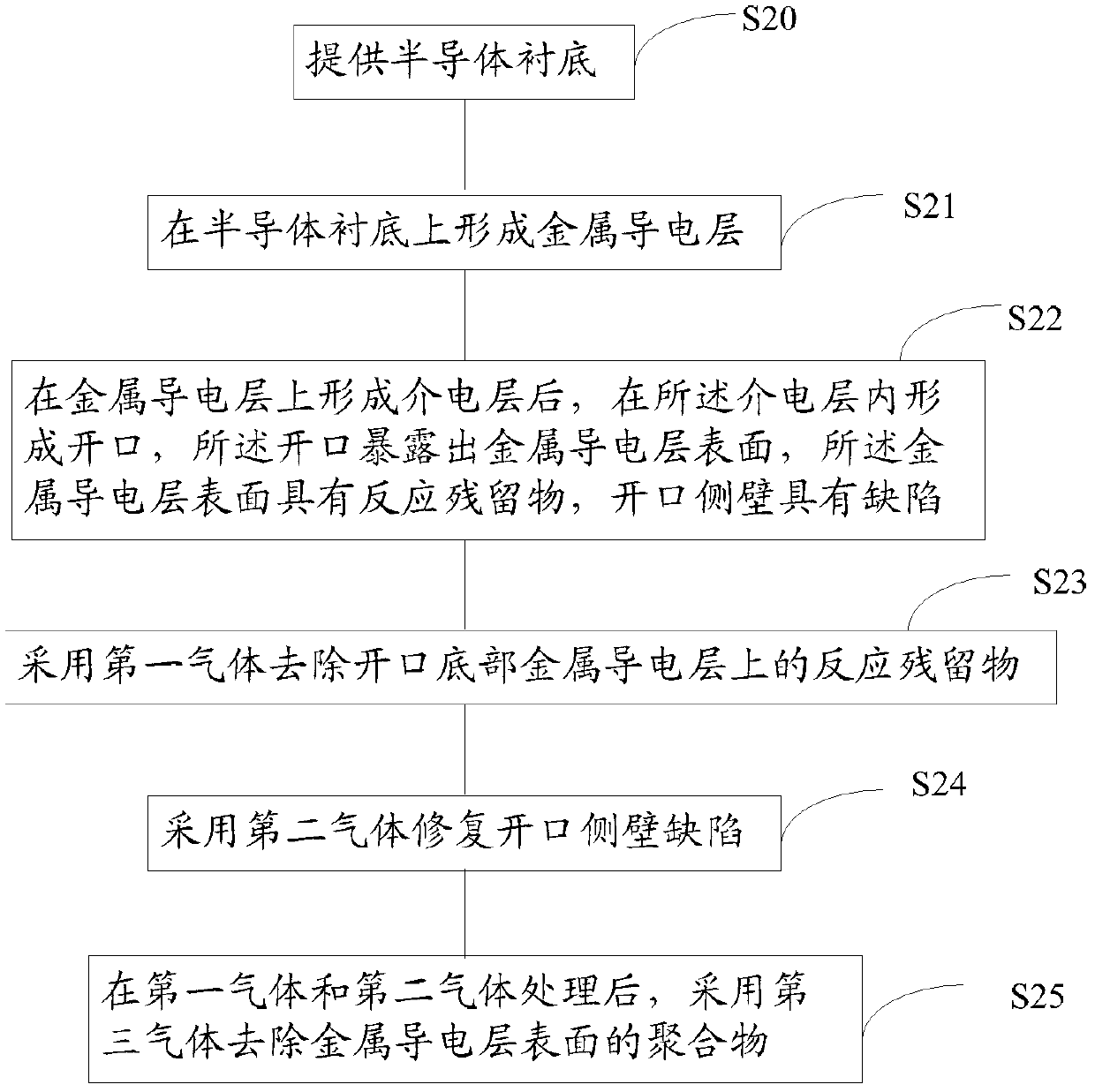

Method of forming opening

ActiveCN103377913AImprove yieldImprove reliabilitySemiconductor/solid-state device manufacturingAfter treatmentDielectric layer

Disclosed is a method of forming an opening. The method comprises the steps of providing a semiconductor substrate; forming a metal conductive layer on the semiconductor substrate; forming a dielectric layer on the metal conductive layer and forming an opening in the dielectric layer with the opening exposing a surface of the metal conductive layer, the surface of the metal conductive layer having a reaction residue and a side wall of the opening having a defect; removing the reaction residue on the metal conductive layer at the bottom of the opening by use of a first gas; repairing the defect on the side wall of the opening by use of a second gas; and removing, after treatment of the first gas and the second gas, a polymer on the surface of the metal conductive layer by use of a third gas. The method of forming the opening is used for improving electrical properties, stability and yield of an integrated circuit.

Owner:SEMICON MFG INT (SHANGHAI) CORP

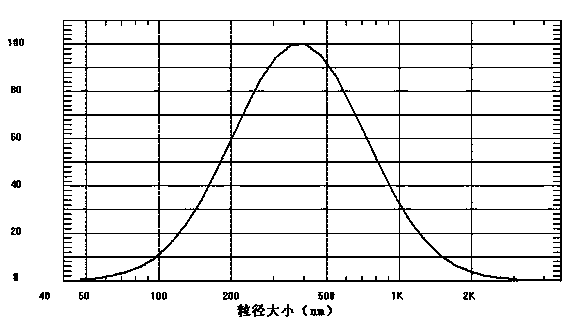

Oral proliposome containing atorvastatin calcium and preparation method of oral proliposome

InactiveCN103690485AHighlight substantive featuresSignificant progressMetabolism disorderPharmaceutical non-active ingredientsOral medicationPhospholipid

The invention relates to an oral proliposome containing atorvastatin calcium and a preparation method of the oral proliposome. The oral proliposome comprises the following components: 0.5%-10% of the atorvastatin calcium, 10%-30% of phospholipid, 2%-10% of poloxamer, 50%-87.3% of absolute ethanol and 0.2%-3% of a stabilizer. The preparation method comprises the following steps: adding the atorvastatin calcium, the phospholipid, the poloxamer and the stabilizer into the absolute ethanol solvent, mixing in the absence of water, and dissolving the mixture into a clear anhydrous solution so as to obtain an atorvastatin calcium proliposome preparation. The proliposome can be quickly self-assembled into the medicated proliposome preparation with a proper particle size and high encapsulation efficiency after being diluted by a proper hydration medium before use and is used for oral administration, the operation is easy and convenient, and the oral administration mode can be easily accepted by patients.

Owner:RUNZE PHARMACEUTICAL (SUZHOU) CO LTD

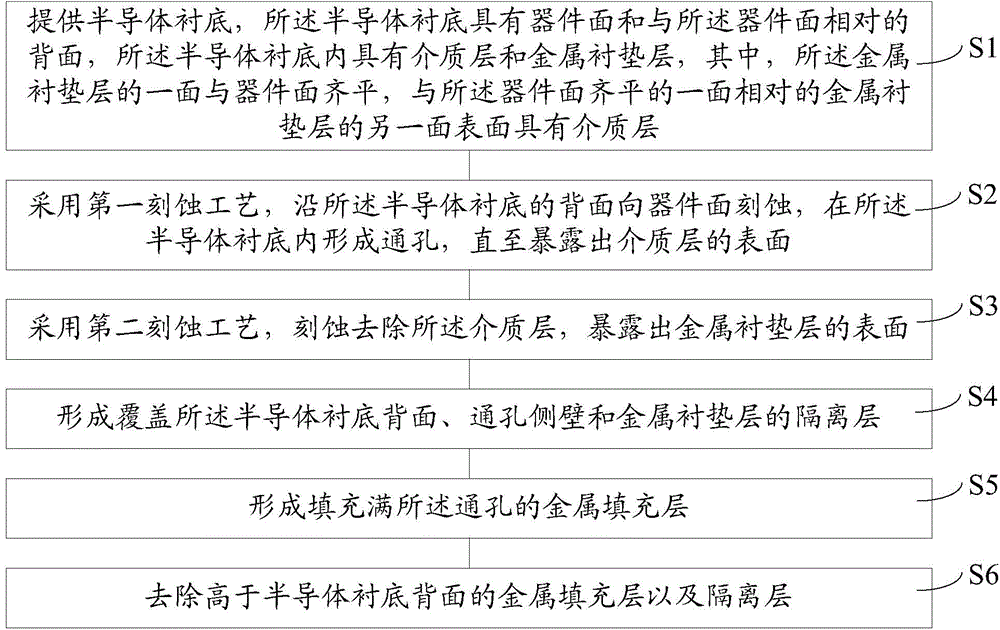

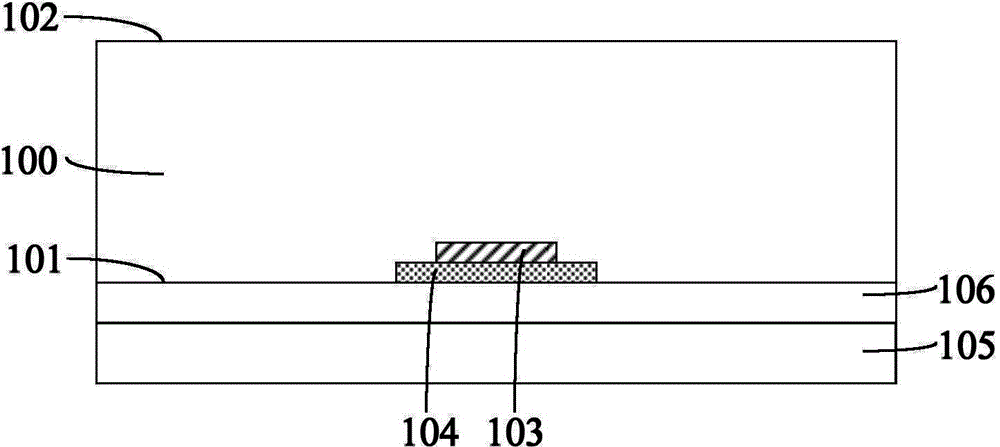

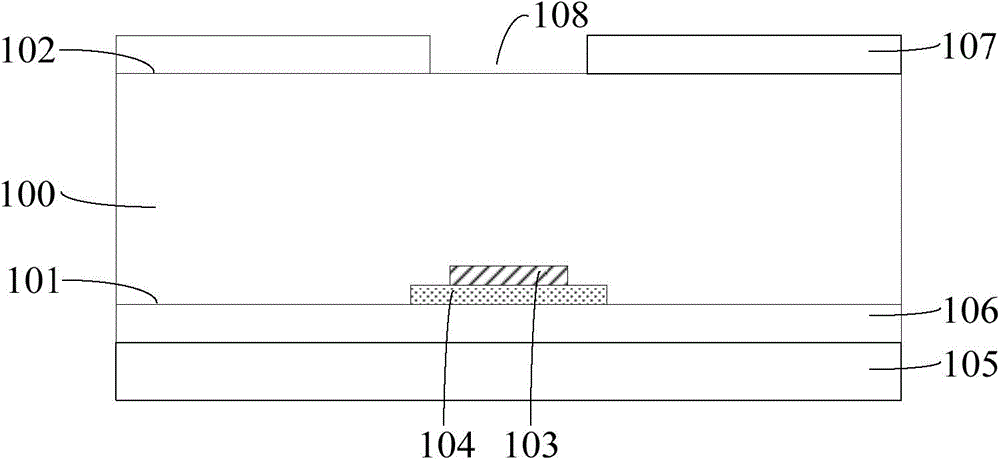

Forming method of semiconductor device

InactiveCN104617035AImprove reliabilityImprove electrical performanceSemiconductor/solid-state device manufacturingAnisotropic etchingDielectric layer

The invention provides a forming method of a semiconductor device. The forming method comprises the steps of providing a semiconductor substrate which is provided with a device surface and a back opposite to the device surface, etching the semiconductor substrate in a direction from the back of the semiconductor substrate to the device surface of the semiconductor substrate, forming a through hole in the semiconductor substrate to expose the surface of a dielectric layer, forming an insulating layer for covering the back of the semiconductor substrate, the sidewall of the through hole and the insulating layer of the dielectric layer, and etching off the insulating layer and the dielectric layer located at the bottom of the through hole by use of an anisotropic etching process to expose the surface of a metal liner layer, wherein the dielectric layer and the metal liner layer are formed in the semiconductor substrate; the insulating layer thinnest on the surface of the dielectric layer. The forming method has the advantages that the process of etching off the dielectric layer is prevented from damaging the sidewall of the through hole, the roughness of the sidewall of the through hole is improved, and therefore, the reliability of the semiconductor device can be improved, and the electric leakage problem can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

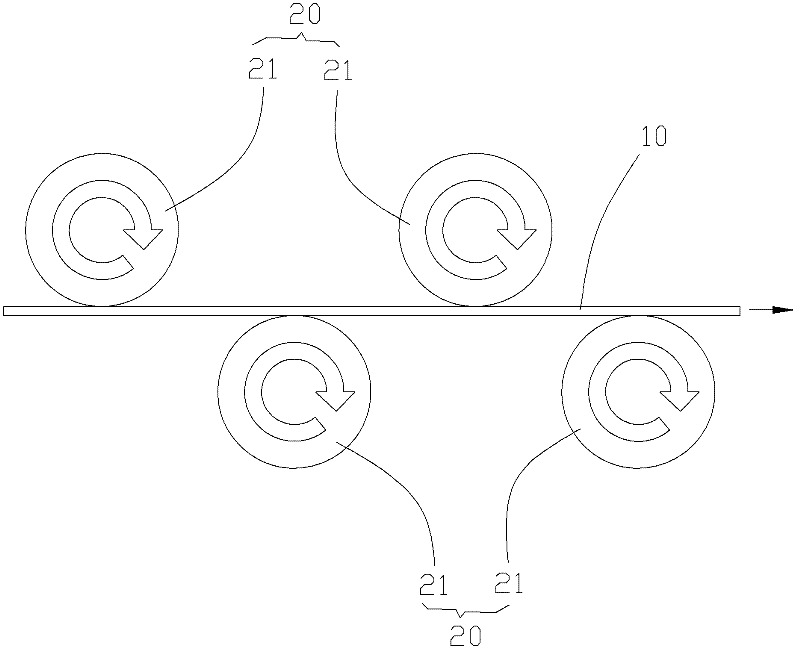

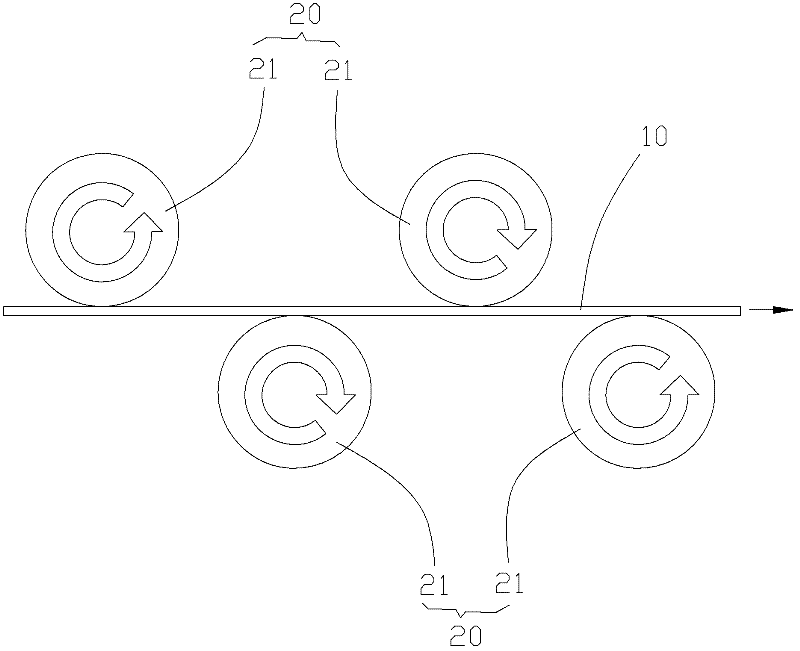

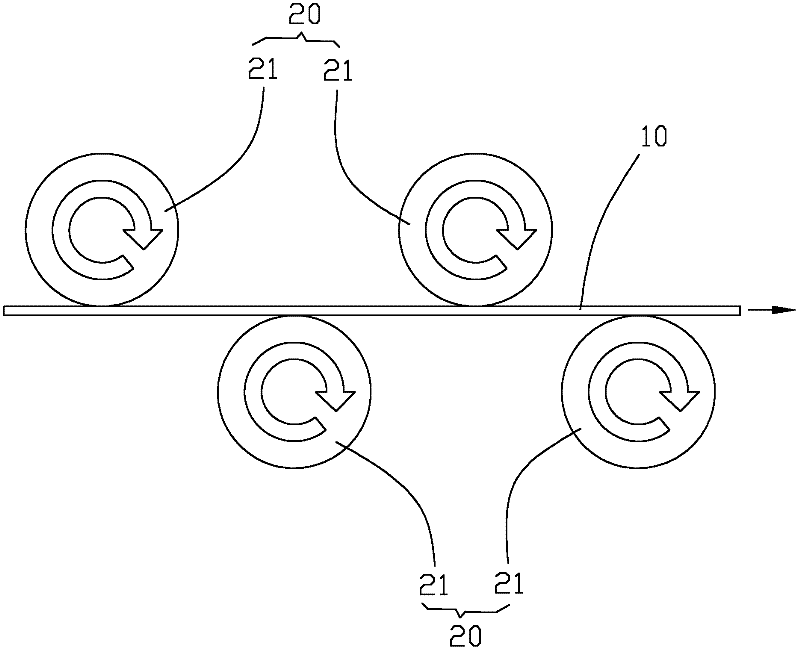

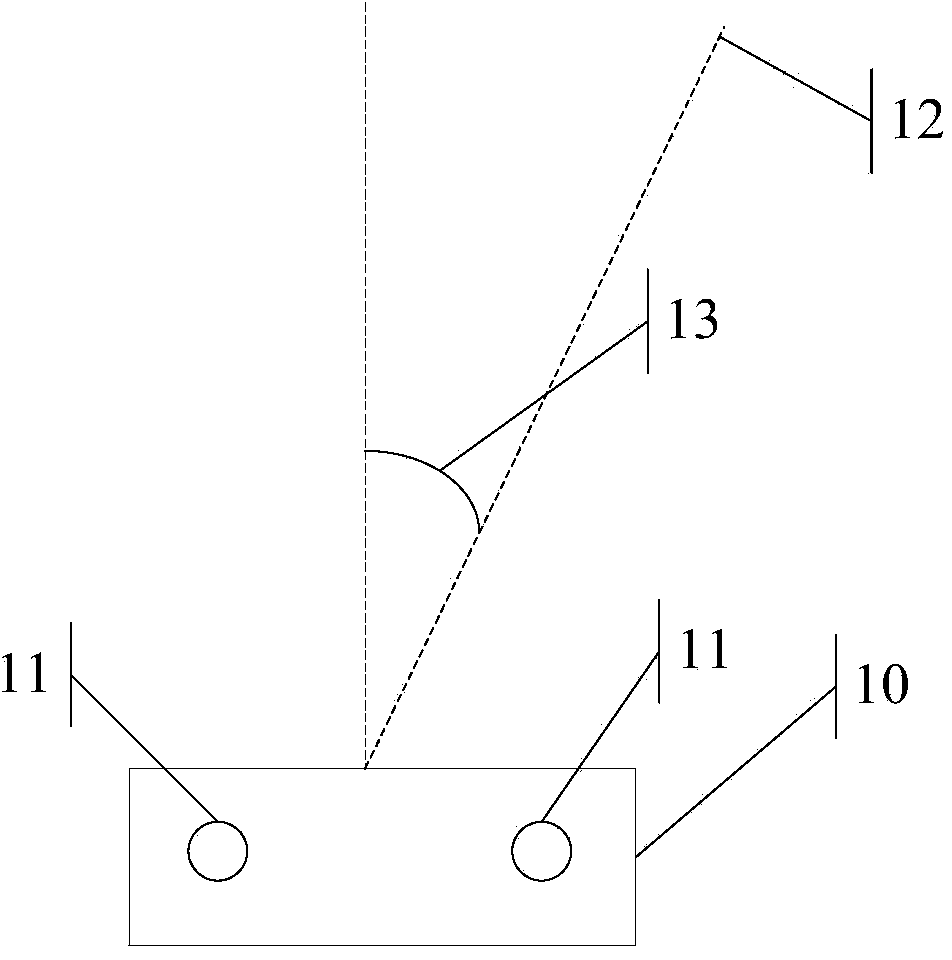

Board grinding method for removing orifice burrs of printed circuit board (PCB)

InactiveCN102416587AAvoid unidirectional removal of orifice bottom copper by grinding and brushingEfficient removalEdge grinding machinesPrinted circuit boardEngineering

The invention relates to a board grinding method for removing orifice burrs of a printed circuit board (PCB). The method comprises the following steps of: 1, providing a board grinding machine and a drilled PCB, wherein the board grinding machine comprises a pair of upper grinding wheels and a pair of lower grinding wheels, and two grinding wheels of each pair are respectively provided with grinding brushes; and 2, grinding the PCB which is positioned between the two pairs of upper and lower grinding wheels, and respectively grinding the upper and lower sides of the PCB by the grinding brushes of the two pairs of upper and lower grinding wheels to remove the drilled orifice burrs, wherein the rotating directions of the two grinding wheels of each pair are opposite when the board is ground. According to the board grinding method for removing the orifice burrs of the PCB, because the positive and negative grinding wheels are adopted for grinding the board, the drilled orifice burrs can be effectively removed, and the grinding brushes can be effectively prevented from removing the bottom copper of the orifice in a single direction.

Owner:DONGGUAN SHENGYI ELECTRONICS

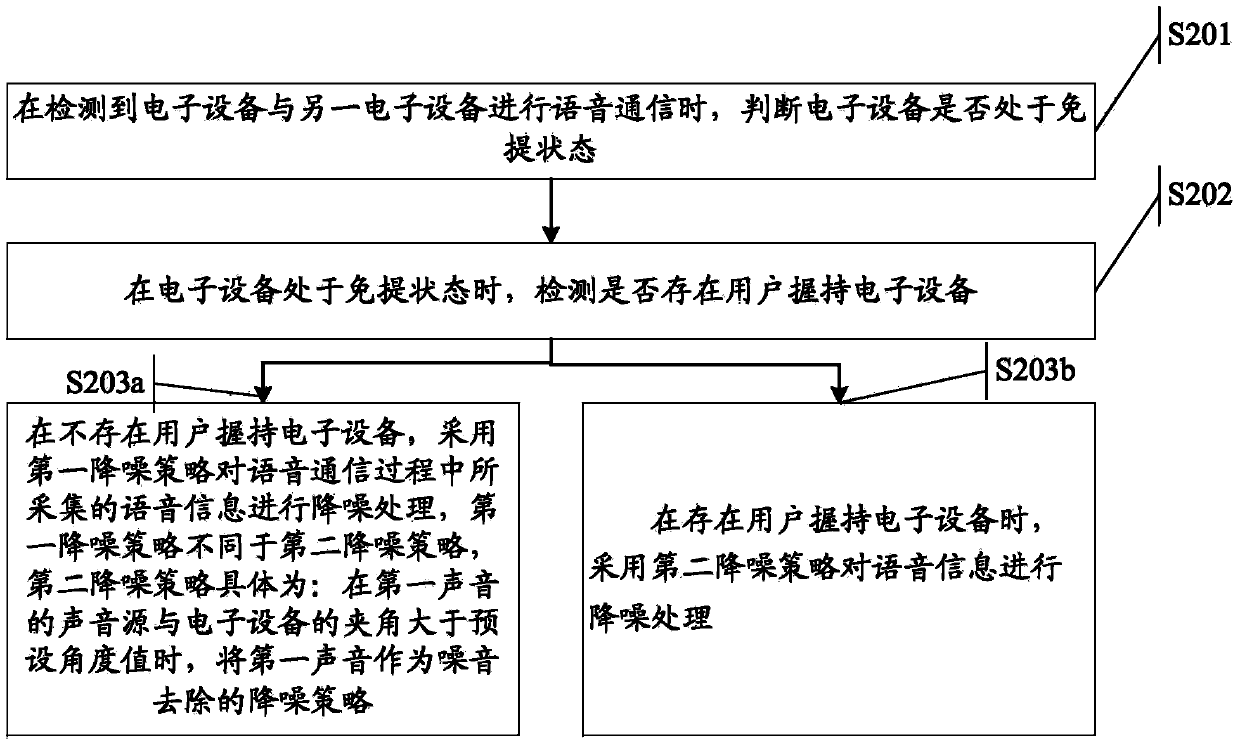

Information processing method and electronic device

ActiveCN104052886AGood removal effectAvoid removalTwo-way loud-speaking telephone systemsSpeech soundElectric equipment

The invention relates to the technical field of communication and discloses an information processing method and an electronic device in order to solve the problem that in the prior art, communication content is removed as noise easily because a selected noise reduction algorithm is not accurate enough. The method is applied to the electronic device. The method includes the steps that when it is detected that the electronic device and another electronic device are in voice communication, whether the electronic device is in a handfree state or not is judged; when the electronic device is in the handfree state, whether a user holds the electronic device or not is detected; when no user holds the electronic device, a first noise reduction strategy is adopted for performing noise reduction on voice information collected in the voice communication process, the first noise reduction strategy is different from a second noise reduction strategy, and according to the second noise reduction strategy, when an included angle between a sound source of first sound and the electronic device is larger than a preset angle, the first sound is removed as the noise.

Owner:LENOVO (BEIJING) CO LTD

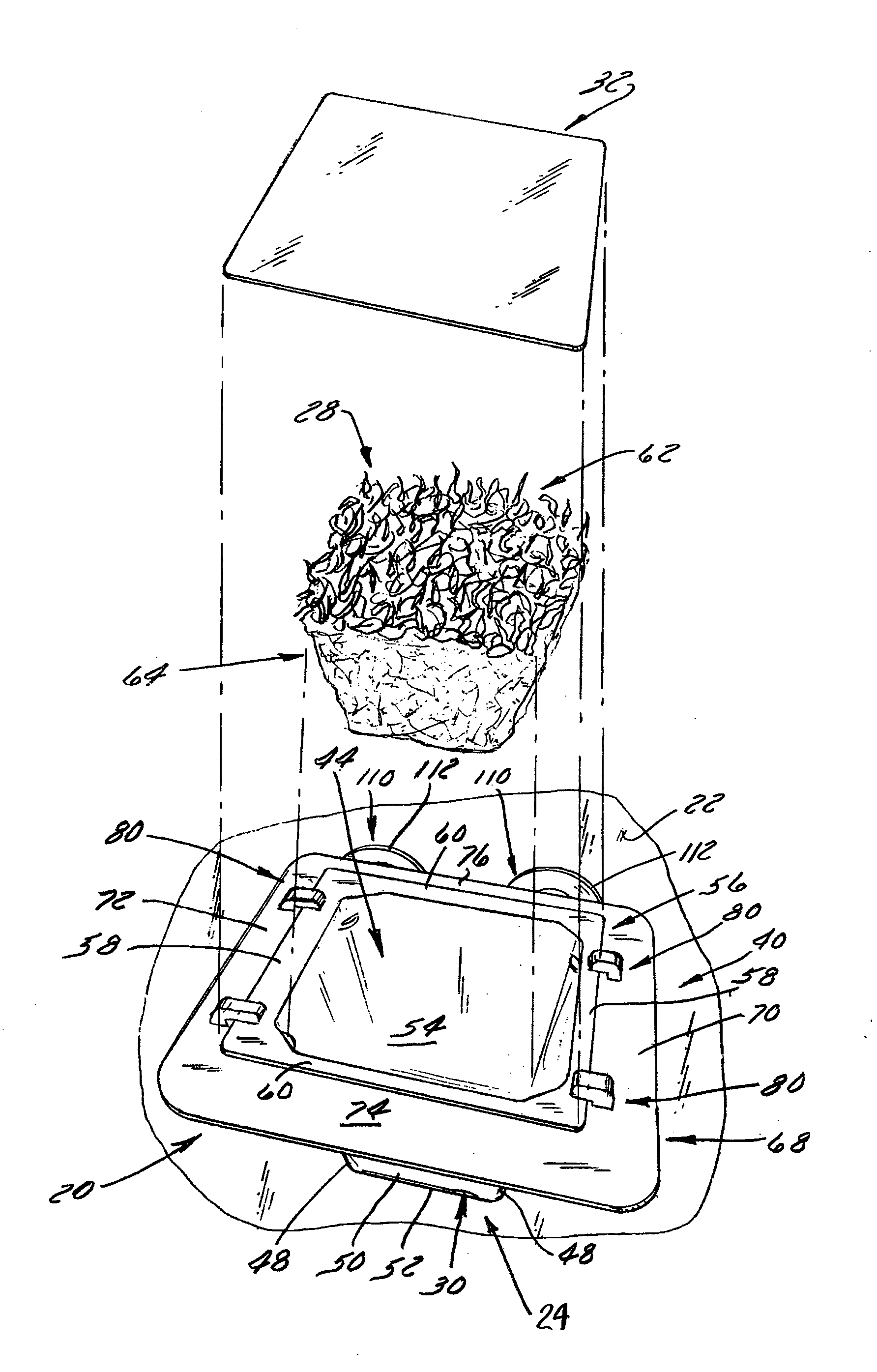

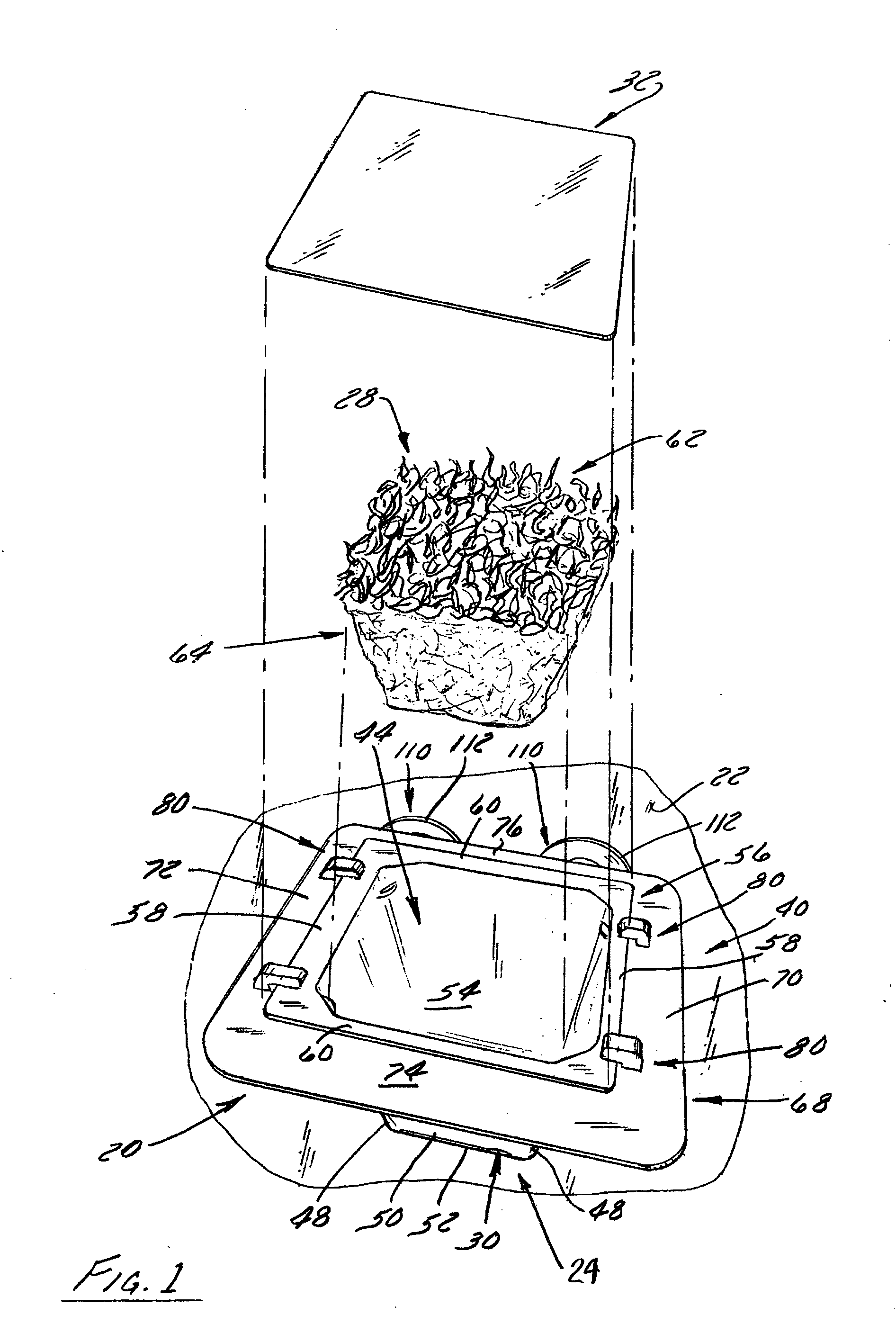

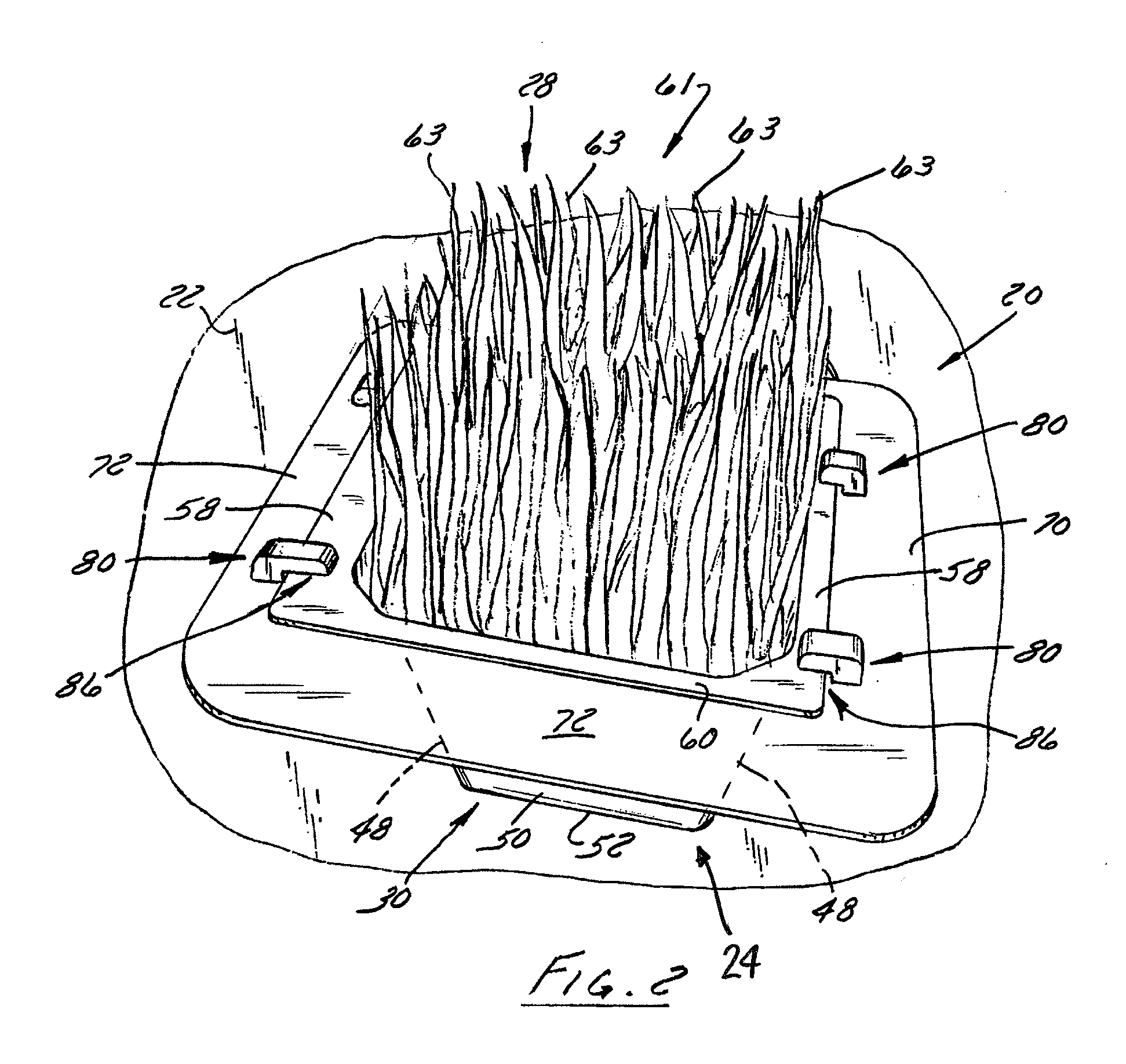

Pet Food Holder, Pet Food Containing Module & Method

A pet food holder and pet food containing module releasably carried by the holder that includes seeds or sprouts in a plug or pellet of food containing material in a cup of the module that germinate and grow into a plant that is edible by an animal. The holder includes a mounting arrangement used to releasably mount the holder to an object and a cradle that releasably receives the module. The mounting arrangement includes a mounting plate to which at least one mount is attached that can be a suction cup or hanger. The module includes a cover that is removed to enable germination of the seeds or sprouts. After germination, growth and being eaten by an animal, the module can be removed and replaced with a refill module.

Owner:PIONEER PET PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com